Page 1

MODBUS Communications for User’s Guide

MODCELL 2050R Supplement

Indicating Process Controller

2050R Model B Version 2.8

2051R Model B Version 2.8

Page 2

MicroMod Automation, Inc.

Further reference for more detailed

des, is copyrighted by

The Company

MicroMod Automation is dedicated to improving customer efficiency by providing the most cost-effective, applicationspecific process solutions available. We are a highly responsive, application-focused company with years of expertise in

control systems design and implementation.

We are committed to teamwork, high quality manufacturing, advanced technology and unrivaled service and support.

The quality, accuracy and performance of the Company's products result from over 100 years experience, combined with

a continuous program of innovative design and development to incorporate the latest technology.

Use of Instructions

Ì Warning. An instruction that draws attention to the

risk of injury or death.

q Caution. An instruction that draws attention to the risk

of the product, process or surroundings.

Although Warning hazards are related to personal injury, and Caution hazards are associated with equipment or property

damage, it

must be understood that operation of damaged equipment could, under certain operational conditions, result in degraded

process

system performance leading to personal injury or death. Therefore, comply fully with all Warning and Caution notices.

Information in this manual is intended only to assist our customers in the efficient operation of our equipment. Use of this

manual for

any other purpose is specifically prohibited and its contents are not to be reproduced in full or part without prior approval

of MicroMod Automation, Inc.

Licensing, Trademarks and Copyrights

MOD 30 and MOD 30ML are trademarks of MicroMod Automation, Inc.

MODBUS is a trademark of Modicon Inc.

Health and Safety

To ensure that our products are safe and without risk to health, the following points must be noted:

The relevant sections of these instructions must be read carefully before proceeding.

1. Warning Labels on containers and packages must be observed.

2. Installation, operation, maintenance and servicing must only be carried out by suitably trained personnel and in

accordance with the information given or injury or death could result.

3. Normal safety procedures must be taken to avoid the possibility of an accident occurring when operating in

conditions of high

4. pressure and/or temperature.

5. Chemicals must be stored away from heat, protected from temperature extremes and powders kept dry. Normal

safe handling procedures must be used.

6. When disposing of chemicals, ensure that no two chemicals are mixed.

Safety advice concerning the use of the equipment described in this manual may be obtained from the Company address

on the back

cover, together with servicing and spares information.

All software, including design, appearance, algorithms and source co

MicroMod Automation, inc. and is owned by MicroMod Automation or its suppliers.

Note. Clarification of an instruction or additional

information.

i Information.

information or technical details.

Page 3

IB-23C650M

CONTENTS

CONTENTS

Page

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

About This Supplement . . . . . . . . . . . . . . . . . . . . . . 1

About Modbus Communications . . . . . . . . . . . . . . . . 1

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Controller Option Requirements . . . . . . . . . . . . . . . . 3

2-Wire Modbus Network Connections . . . . . . . . . . . . 3

4-Wire Modbus Network Connections . . . . . . . . . . . . 5

Communication Applications . . . . . . . . . . . . . . . . . . . . . . 9

Standard Control with Modbus Communications . . . . 9

Supervisory Control . . . . . . . . . . . . . . . . . . . . . . . . 9

Computer Control . . . . . . . . . . . . . . . . . . . . . . . . . . 10

RS-485 Communications Setup . . . . . . . . . . . . . . . . . . . 11

Basic Operation With a Host Device . . . . . . . . . . . . . . . . 27

Enabling Write Communication With a Host . . . . . . . 27

Standard Communication With a Host . . . . . . . . . . . . 27

Supervisory Station . . . . . . . . . . . . . . . . . . . . . . . . . 29

Computer Auto/Manual Station . . . . . . . . . . . . . . . . . 30

Diagnostic Messages . . . . . . . . . . . . . . . . . . . . . . . 31

Modbus Protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Communications Speed . . . . . . . . . . . . . . . . . . . . . . 33

Message Response Time . . . . . . . . . . . . . . . . . . . . 33

Messages Supported . . . . . . . . . . . . . . . . . . . . . . . 34

Message Formats . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Controller Attribute Listing - Register Data . . . . . . . . . . . . 39

Common Data (registers) . . . . . . . . . . . . . . . . . . . . 39

Ramp/Soak Profile and Totalizer Data (registers) . . . . 42

Tuning Parameter Data (registers) . . . . . . . . . . . . . . 44

Alarm Data (registers) . . . . . . . . . . . . . . . . . . . . . . . 46

Computer Activity Data (registers) . . . . . . . . . . . . . . 47

Ramp/Soak Profile Configuration Data (registers) . . . . 49

More Computer Activity Data (registers) . . . . . . . . . . 51

Controller Attribute Listing - Coil Data . . . . . . . . . . . . . . . 55

Computer Activity Data (coils) . . . . . . . . . . . . . . . . . 55

Digital Input and Output Data (coils) . . . . . . . . . . . . . 56

Ramp/Soak Data (coils) . . . . . . . . . . . . . . . . . . . . . . 57

i

Page 4

IB-23C650M

CONTENTS

CONTENTS (Cont’d)

Page

Totalizer Data (coils) . . . . . . . . . . . . . . . . . . . . . . . . 57

Autotune Data (coils) . . . . . . . . . . . . . . . . . . . . . . . . 57

Process Alarm Data (coils) . . . . . . . . . . . . . . . . . . . . 58

Diagnostic Data (coils) . . . . . . . . . . . . . . . . . . . . . . . 59

Ramp/Soak Profile Data (coils) . . . . . . . . . . . . . . . . . 60

Record of Database . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

ILLUSTRATIONS

Figure Page

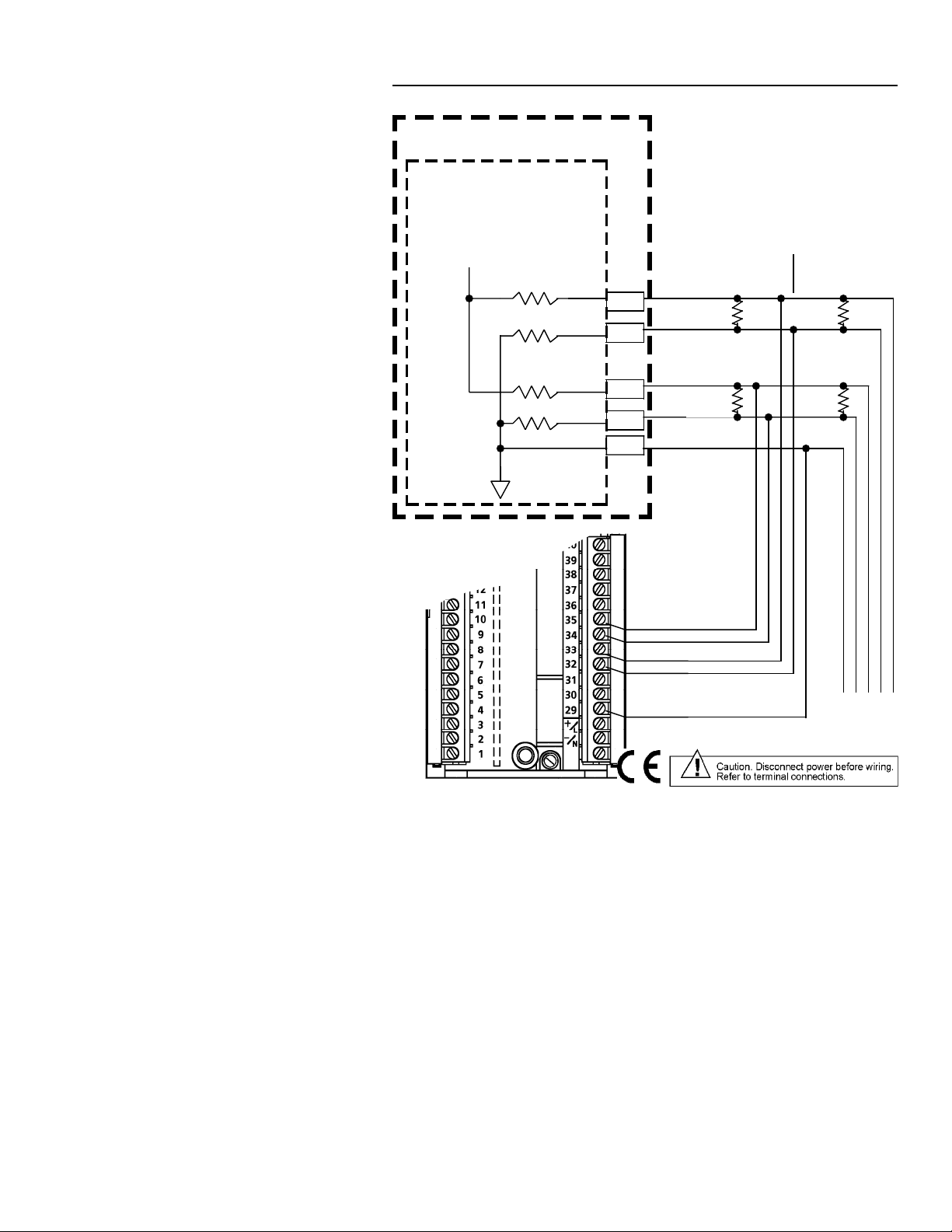

1 Typical 2-Wire Modbus Network Connections . . . . . . 4

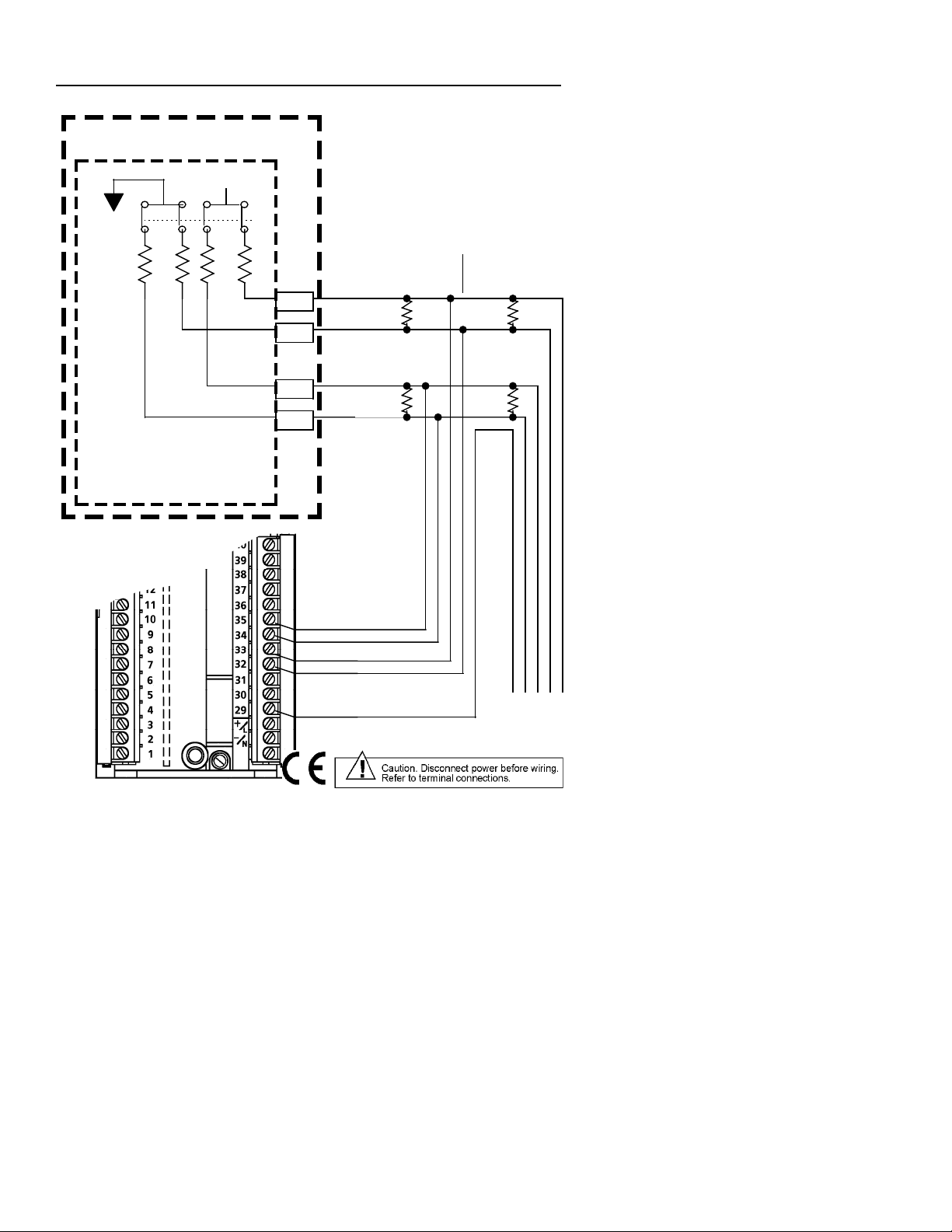

2 Typical 4-Wire Modbus Network Connections with . . . 6

a Host Device as Master

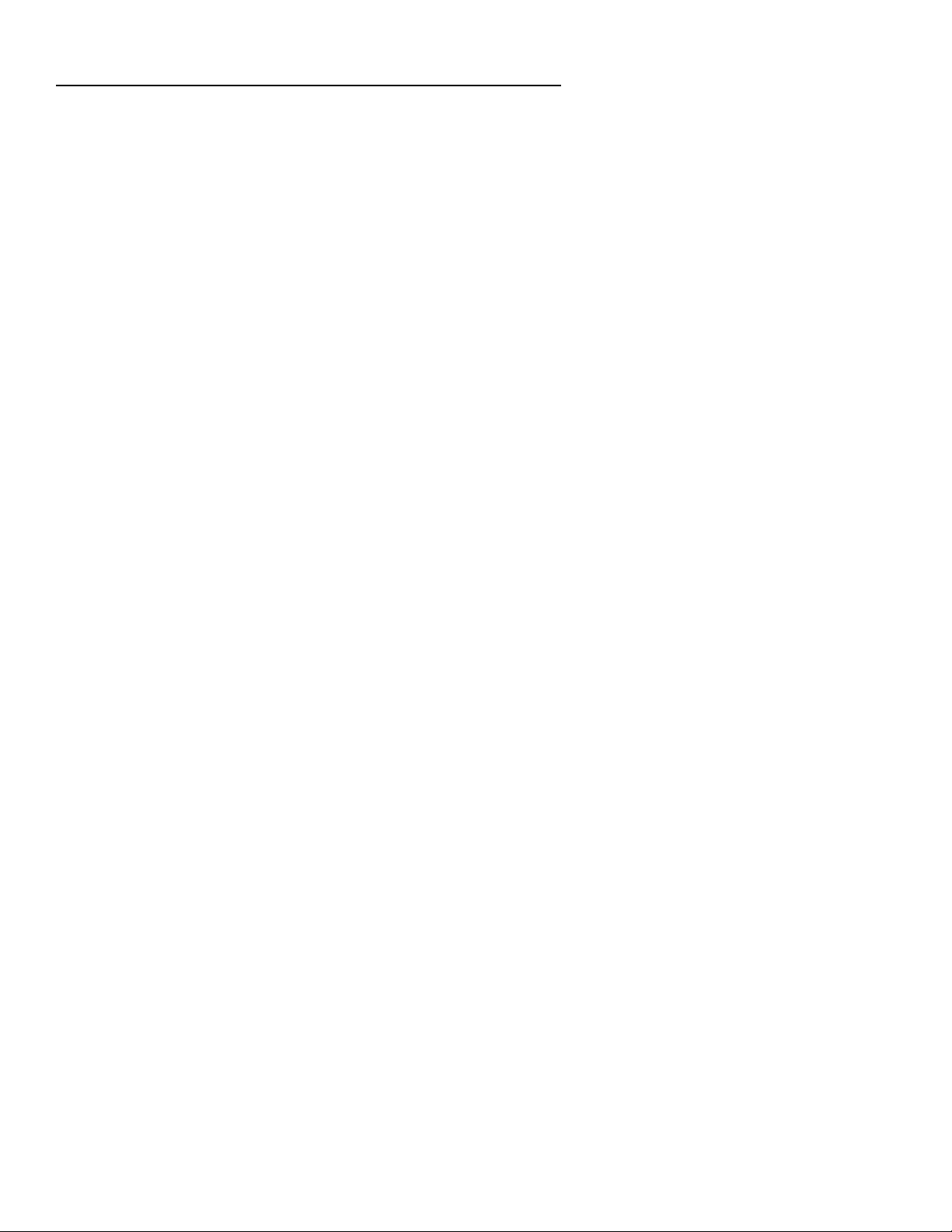

3 Typical 4-Wire Modbus Network Connections with . . . 7

a MODCELL Multiloop Processor as Master

TABLES

Table Page

1 RS-485 Setup Menu . . . . . . . . . . . . . . . . . . . . . . . . 12

2 Modbus Messages Supported by MODCELL 2050 . . . 35

ii

Page 5

IB-23C650M

INTRODUCTION

INTRODUCTION

About This Supplement

This supplement provides instructions for installation, setup, and use of

the Modbus RS-485 serial communications option available in the

MODCELL 2050 Single Loop Controller. Comprehensive instructions

covering all aspects of the controller not related to Modbus

communication are included in the

IB-23C650 User’s Guide.

Specific information provided in this supplement is as follows:

• Instructions for connecting the controller to a Modbus network using

either a 2-Wire or 4-wire configuration.

• Application information including controller operation as a supervisory

station or computer auto/manual station using Modbus

communications.

• Step-by-step instructions for setup of the communications function

using the RS-485 MENU in the controller data base.

• Operating instructions for the controller when Modbus

communication with a host device is enabled.

• A description of the Modbus messages supported and the message

formats.

• Controller attribute reference data. The listing includes register data

for numeric attributes and coil data for boolean (discrete) attributes.

About Modbus Communications

A 2050R controller and a host device connected to a Modbus network

communicate via a master/slave relationship. The host device functions

as the Modbus master and the controller functions as the slave. The

master is in command of the communications transaction and talks to

one slave (controller) at a time. The master sends a message to a

slave and waits to receive an answer back from that slave before it

talks to the another slave. Each slave has a unique address which

1

Page 6

IB-23C650M

INTRODUCTION

allows it to be identified by the master. This permits multiple slaves

(controllers) to reside on a single Modbus network.

The controller can be assigned any address between 1 and 247.

Addresses are set in the RS-485 MENU as part of the setup for

modbus communication. Address 0 is the “broadcast” address. Only

write messages can use it. All controllers process the message, but

there is no response back to the host.

Other types of slaves may reside on a network with the controllers.

Modbus does not support peer-to-peer communications where two

controllers can talk directly with each other.

2

Page 7

IB-23C650M

INSTALLATION

INSTALLATION

This section provides instructions for making Modbus network connections

using either a 2-wire or 4-wire configuration. This information assumes that

physical installation and all other electrical connections are being made in

accordance with the instructions in IB-23C650.

Before making any connections, be sure the controller can support Modbus

communications; see the option requirements below.

Controller Option Requirements

The controller must be equipped with an option card and firmware Version 2 to

run MODBUS RS-485 serial communications. The option card (Catalog No.

2050NZ10100A) and Version 2 firmware may have already been installed in

the controller during manufacture. If necessary these items can be installed in

the field. Instruments manufactured with the option card and Version 2

firmware are identified by digits in the instrument catalog number as shown

below:

Sample Catalog Number: 2050RZ10 1 02 A

RS-485 Communications Option Card

RS-485 Firmware Version

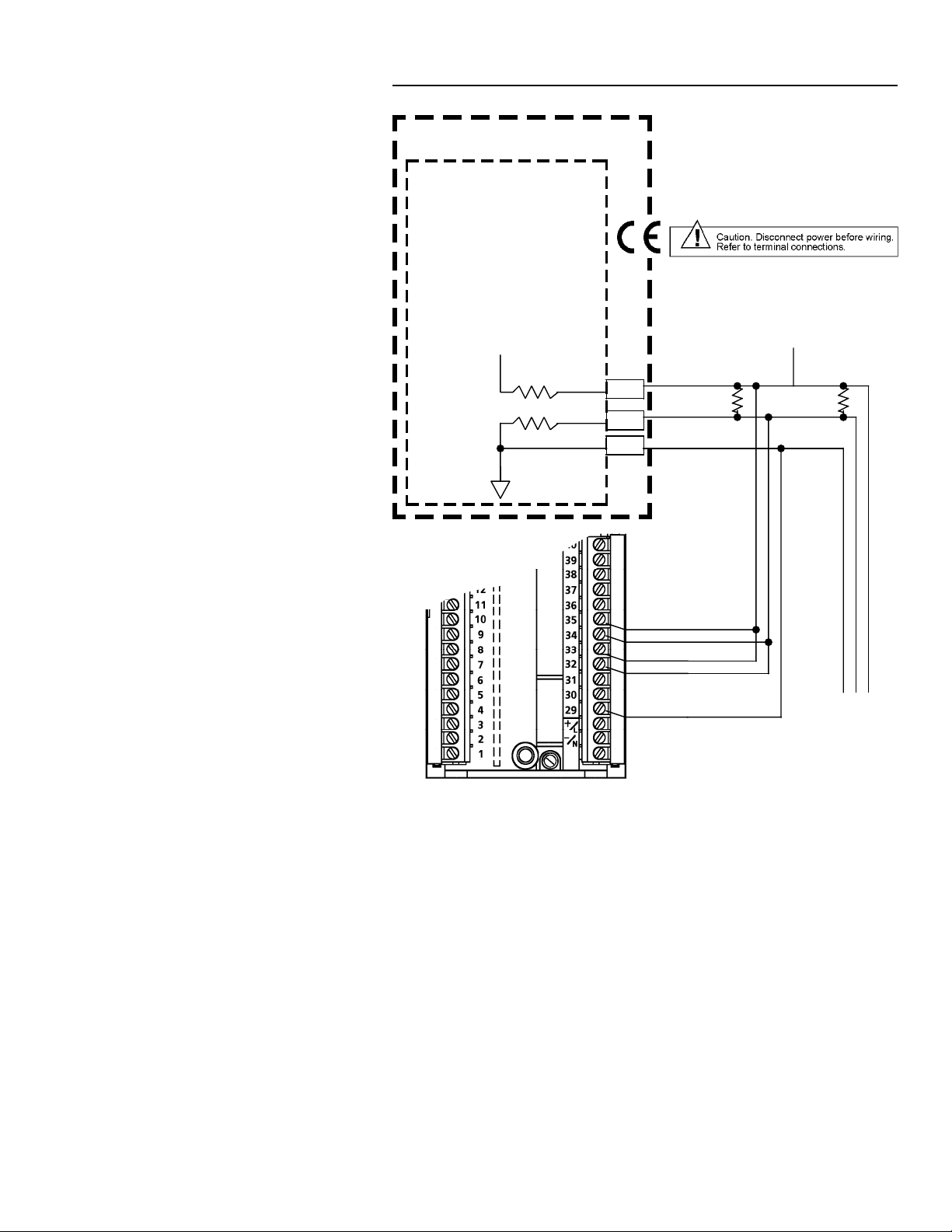

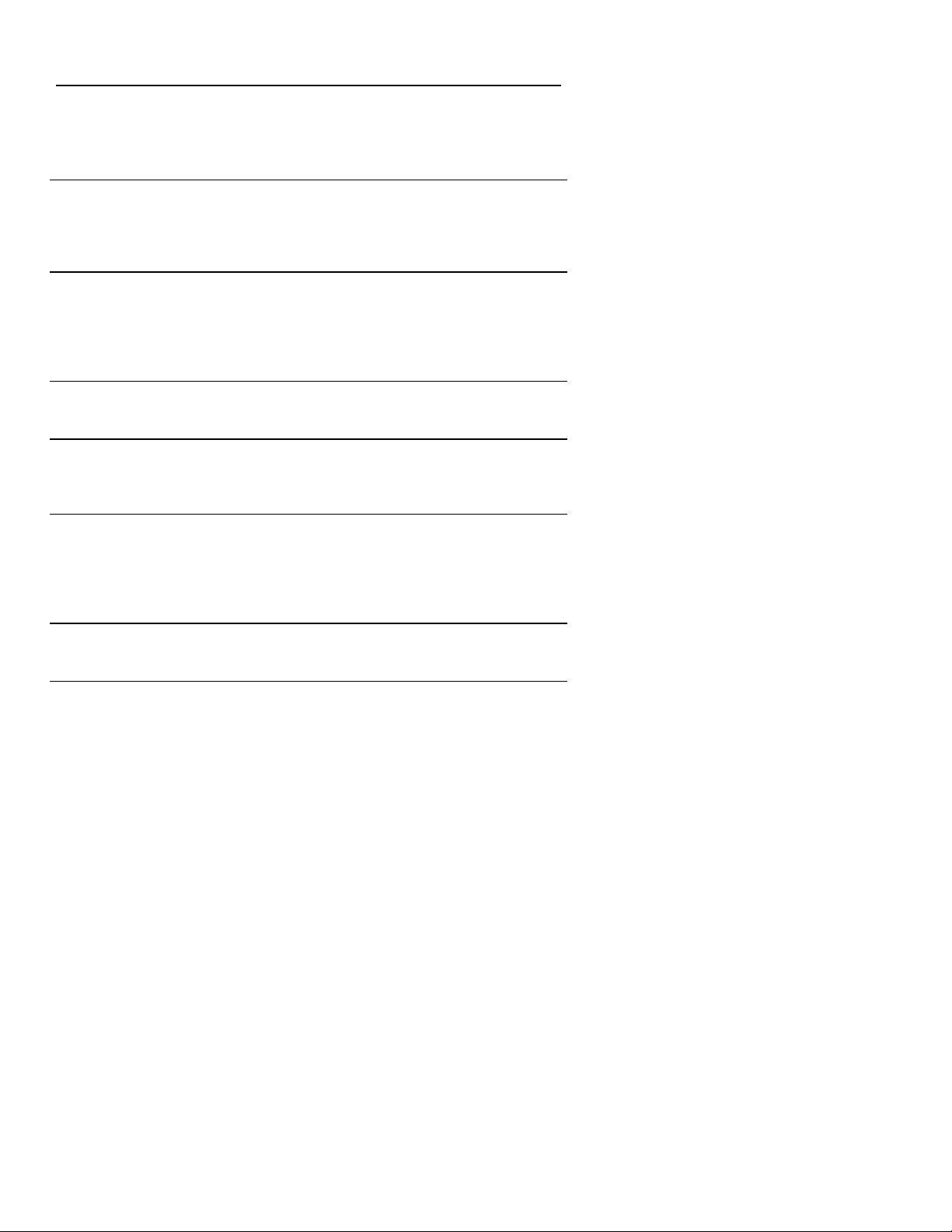

2-Wire Modbus Network Connections

Connections for a typical Modbus network using a 2-wire configuration are

shown in Figure 1. The host device functions as the master and the

controllers function as slaves. It is recommended that no more than 32 devices

be connected on a single network. The devices and host must have a

common ground.

The master is responsible for providing the 560 ohm pull-up and pull-down

bus stabilizing resistors. Connect 120 ohm termination resistors across the

transmission line at both ends as shown. The number of devices can be

increased by the use of repeaters. The termination resistors may not be

required if the line length is very short.

Cable requirements depend on the length of the run. For short runs of 10 to

25 ft (3 to 6m) virtually any 2-wire shielded or twisted pair is suitable. For runs

up to 4000 ft (1219m) Belden 9841 cable or equivalent is recommended. This

cable is a 24 AWG twisted pair with a foil shield. The insulation is low

dissipation (polypropylene). A drain wire is provided for grounding the shield.

3

Page 8

IB-23C650M

INSTALLATION

Personal Computer Modbus Master

RS485 Interface

+5V dc

560

All resistors are 0.25W.

Other 2050R's

wired same way

without resistors.

RX/TX+

120

RX/TX-560

COM

120

RX+

RX -

TX+

TX -

COM

Last

2050R

Figure 1. Typical 2-Wire Modbus Network Connections

.

4

Page 9

IB-23C650M

INSTALLATION

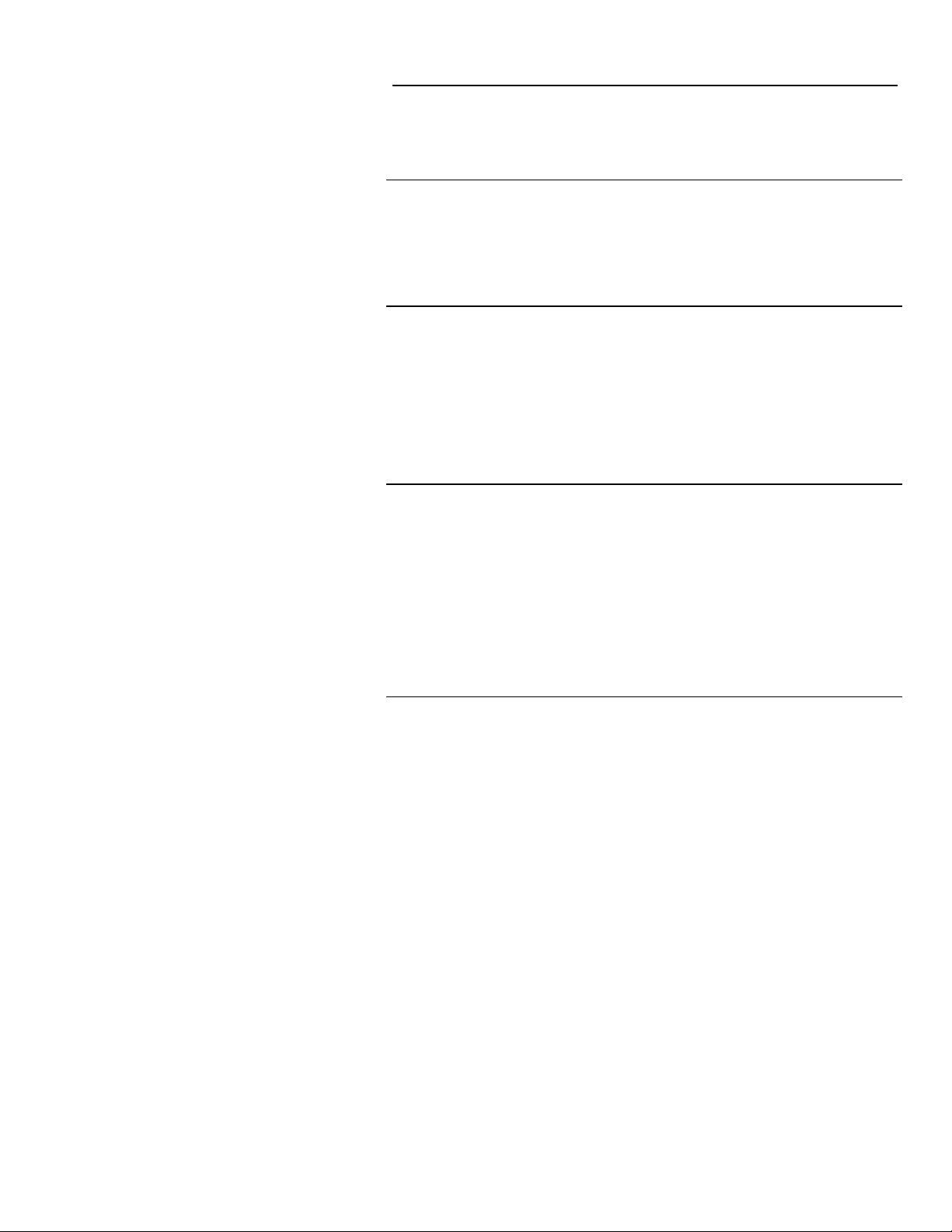

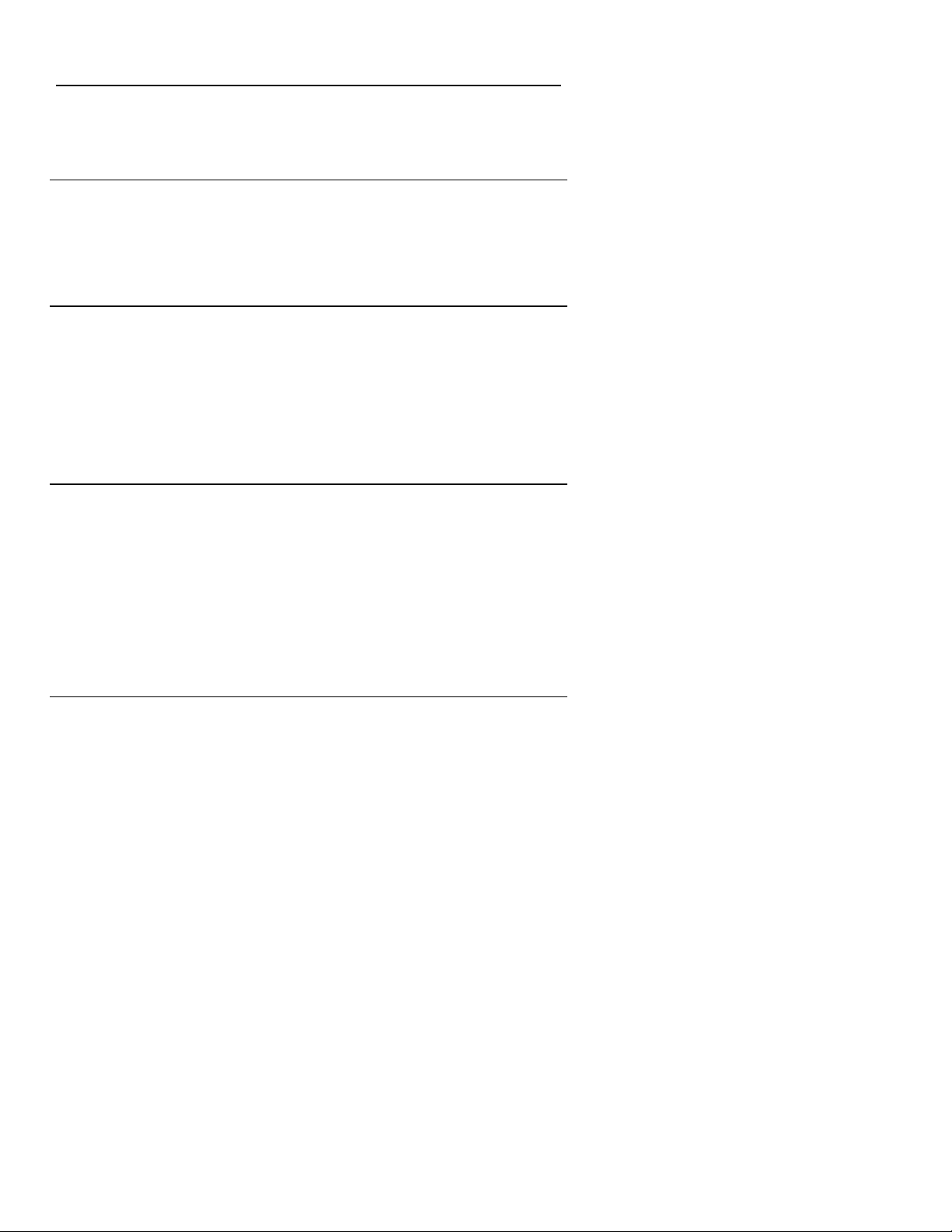

4-Wire Modbus Network Connections

Connections for typical Modbus networks using a 4-wire configuration are

shown in Figures 2 and 3. The host device functions as the master and the

controllers function as slaves. It is recommended that no more than 32 devices

be connected on a single network. The number of devices can be increased

by the use of repeaters.

When the host is a device such as a personal computer, the instruments and

host must have a common ground as shown in Figure 2. When the host is a

MODCELL Multiloop Processor, Figure 3, connection of the processor to the

instrument common line is not required because the processor connections

are optically isolated.

The master is responsible for providing the 560 ohm pull-up and pull-down

bus stabilizing resistors. In the MODCELL processor, these resistors are

provided in the RS-485 communications module, and the TERM switch on the

module must be set at YES to connect the resistors to the network (see

IB-23C600 MODCELL Multiloop Processor Installation Instructions for

more information). Connect 120 ohm termination resistors across the

transmission line at both ends as shown. The termination resistors may not be

required if the line length is very short.

Cable requirements depend on the length of the run. For short runs of 10 to

25 ft (3 to 6m) virtually any 2-wire shielded or twisted pair is suitable. For runs

up to 1000 ft (305m), Belden 9502 cable or equivalent is recommended. This

cable is a dual 24 AWG twisted pair with an overall foil shield. A drain wire is

provided for grounding the shield. For runs up to 4000 ft (1219m) Belden

9729 or equivalent is recommended. This cable is a dual 24 AWG twisted pair

with a foil shield for each pair. The cable insulation is low dissipation

(polypropylene). Two separate drain wires are provided for grounding the

shields.

5

Page 10

IB-23C650M

INSTALLATION

Personal Computer Modbus Master

RS485 Interface

+5V dc

560

560

560

560

2050R Controller

(Modbus Slave)

All resistors are 0.25W.

Other 2050R's

wired same way

without resistors.

RX+

120

RX-

TX+

120

TX-

COM

120

120

RX+

RX -

TX+

TX -

COM

Figure 2. Typical 4-Wire Modbus Network Connections with a Host

Device as Master

6

Last

2050R

Page 11

IB-23C650M

INSTALLATION

Modcell Processor

Isolated +5Vdc

560

TERM

Switch

YES

Modbus Master

2034N RS-485 MODULE

(Module Locations 31 & 32)

2050R Controller

(Modbus Slave)

S31

1

2

S32

1

2

All resistors are 0.25W.

Other 2050R's

wired same way

without resistors.

RX+

120

RX-

TX+

120

TX-

120

120

RX+

RX -

TX+

TX -

COM

2050R

Figure 3. Typical 4-Wire Modbus Network Connections with a

MODCELL Multiloop Processor as Master

Last

7

Page 12

IB-23C650M

INSTALLATION

Blank Page

8

Page 13

IB-23C650M

COMMUNICATION APPLICATIONS

COMMUNICATION APPLICATIONS

The following are sample applications available with the controller through the

use of Modbus communications. The RS-485 MENU is used to set up the

controller for these applications. The setup requirements are described in

detail in Table 1.

Standard Control With Modbus Communications

For this application, the instrument acts as a stand alone single loop controller

which can receive read/write commands from a host Modbus device such as a

personal computer, MODCELL Multiloop Processor, PLC, etc. Multiple

instruments and other devices can be on a single Modbus network. Each

device on a network must have a unique address. The instrument address is

assigned using the Bus Address attribute in the RS-485 MENU.

During runtime operation, the last attribute entry to the controller becomes the

active entry. For example, if the operator sets an active set-point value via the

instrument display and moments later the host sends a new active set-point

value, the controller uses the operators value until it receives the host value.

At that time the host value becomes the new active set-point value.

A prompt in the DISPLAYS MENU permits the operator to disable the host

from writing to the controller. The host can still receive data from the

instrument, but can not write to it. This is useful if the operator must maintain

manual control of the process and does not want the host to write to the

instrument. The operator can reinitiate the host write capacity via the

DISPLAYS MENU when required.

The Computer Timeout attribute is not active in this application. When

necessary, this attribute is initialized by the host as a means of notifying the

instrument of a communication failure. In this application, failure of the host or

the communications has no effect on instrument operation. The controller

continues to operate with its current attribute values as if nothing happened.

Supervisory Control

The controller receives its set-point from the host device in a supervisory

control application. All other aspects of controller operation are similar to

standard control as described above. The PID control function is provided by

the controller.

9

Page 14

IB-23C650M

COMMUNICATION APPPLICATIONS

Attributes in the RS-485 MENU permit the supervisory control mode to be

indicated via the set-point status display on the front of the instrument. Each

of the three characters in the status display is configurable so that the user

can choose an appropriate mnemonic to represent the supervisory control

mode.

A timeout value can be defined for communications traffic to the instrument via

the Computer Timeout attribute. An activity timer in the instrument is

initialized by the host when operation starts. This action also enables the

configured set-point status display.

The timer monitors the communications bus for activity to the instrument

within the specified timeout period. If there is no communications activity to

the instrument during the specified time, a "computer failure" is declared.

During a computer failure the controller assumes local control with I/O and

mode states as defined under "Computer Failure Setup" in the RS-485

MENU.

When the controller is receiving a set-point from the host, the set-point status

display can be configured to indicate that the host is the set-point source. The

R/L key still performs its normal function. The set-point status display

indicates changes in the set-point source ( LOC, LO1, etc. ).

Computer Control

In a computer control application, the instrument functions as a computer

auto/manual station. The host performs the PID control function with the

results communicated to the controller and then to the field.

Attributes in the RS-485 MENU permit the computer control mode to be

indicated via the control and set-point status displays on the front of the

instrument. Each of the three characters in each status display is configurable

so that the user can choose appropriate mnemonics to represent the computer

control mode and set-point status.

A computer timeout value is defined and a timer monitors communications in

the same manner as for supervisory control. When the computer is active, the

function of the AUTO, R/L and Maunal keys can be configured to provide a

signal to the computer upon which it can take some programmed action.

10

Page 15

IB-23C650M

RS-485 COMMUNICATIONS SETUP

RS-485 COMMUNICATIONS SETUP

Before starting the communications setup, refer to the Setup Section in

IB-23C650 for information about the setup preparation, method, and controls.

Perform the communications setup using the RS-485 MENU as described in

Table 1.

Note: In order to access the RS-485 MENU, the RS-485 Communications

Enable attribute in the BASE CONFIGURATION MENU must be set at

YES. Refer to Table 1, Base Configuration in IB-23C650.

11

Page 16

IB-23C650M

RS-485 COMMUNICATIONS SETUP

Table 1. RS-485 Setup Menu

Step Step Description

1

2

3

4

5

RS-485 Menu. (requires option board)

UP

moves to RELAYS **MENU**.

DN

moves to RAT BIAS **MENU** if A/M ratio bias

is enabled, or to SETPTS **MENU** otherwise.

SCRL

advances to Step 2 (read only in auto).

Bus Enable

UP

or

DN

selects ON or OFF.

SCRL

to advance to Step 3.

Instrument Address

UP

or

DN

sets instrument address.

SCRL

to advance to Step 4.

Baud Rate

UP

or

DN

sets instrument baud rate.

SCRL

to advance to Step 5.

Parity Selection

UP

or

DN

sets instrument parity.

SCRL

to advance to Step 6.

Top

Display

RS-485

BUS

BUS

BAUD

PARITY

6

7

12

Stop Bit Selection

UP

or

DN

sets number of stop bits.

SCRL

to advance to Step 7.

Allowed Access Type

UP

or

DN

sets communications access type.

SCRL

to advance to Step 8.

STOP

ACCESS

Page 17

RS-485 COMMUNICATIONS SETUP

Table 1. RS-485 Setup Menu

IB-23C650M

Middle

Display

**MENU**

ENABLE ON

Bottom

Display

Entry Description

None.

= enables the bus for communications with a

host device.

= disables the communications bus from

OFF

receiving or writing with a host device.

The bus must be disabled in order to make

changes in the following steps.

ADDRESS XXX Where X is any address between 1 and 247.

Each instrument on a bus must have a unique

address.

RATE XXXX Where X is one of the following baud rates;

150, 300, 1200, 2400, 4800, 9600, 19200,

38400. All devices on the same bus must have

the same baud rate.

SELECT

ODD

EVEN

BITS 1

= Parity calculation is odd.

= Parity calculation is even.

Note: Total word length equals start bit (1) +

data (8 bits) + parity (1) + stop bits (1/2).

Total word length can be 11 or 12 bits.

= One stop bit appended to character.

2

= Two stop bits appended to character.

TYPE RD_ONLY

RD/WRITE

= Allows the host device to read only from the

controller.

= Allows the host device to read data from and

write data to the controller.

13

Page 18

IB-23C650M

RS-485 COMMUNICATIONS SETUP

Table 1. RS-485 Setup Menu

Step Step Description

8

8.1

8.2

Computer Activity Setup.

UP

begins setup at Step 8.1.

SCRL

to advance to Step 9 (Enable Bus).

Computer Activity Timeout.

UP

or

DN

sets value.

SCRL

to advance to Step 8.2.

Computer Activity Mnemonic (Auto )

UP

or

DN

sets value (press

press

UP

to start at A or press

Press

SCRL

to access the next character.

Repeat through the third character. Press

after the third character to continue with step 8.3.

UP

to begin then

DN

to start at 9 ).

Top

Display

COMPUTER

COMPUTER

CMP AUTO

SCRL

8.3

14

Computer Activity Mnemonic (Manual)

UP

or

DN

set values and

characters as described in Step 8.2. Press

after the third character to continue with step 8.4.

SCRL

accesses

SCRL

CMP MAN

Page 19

RS-485 COMMUNICATIONS SETUP

Table 1. RS-485 Setup Menu

IB-23C650M

Middle

Display

SETUP

Bottom

Display

Entry Description

Steps 8.1 through 8.12.6.1.1allow setup for the

controller to be used as a computer

auto/manual (CAM) or supervisory station when

connected to a host device. No entries are

required if the instrument is to be used as a

stand alone controller which can receive

read/write commands from a host device.

TIMEOUT XXXXX X represents a time between 1 and 16383

seconds. The computer activity timeout

function is initialized and maintained by the

computer (host). If the time between sessions

of bus activity is greater than this value, a

Computer Fail is declared. This causes the

activity timer to be disabled, and the computer

status reverts to LOCKED. The controller

returns to local with parameters as defined in

Step 8.12.

MNEMONIC XXX Where X = any of the following characters:

Letters A through Z,

Any of the special characters:

b, c, super c, d, h, sub L, super L,

super m, super n, o, r, super T, u,

super V, w, <, >, =, +, –, *, #, /, %,

degrees (super o), or space,

Numbers 0 through 9.

Mnemonic appears in the control mode status

display when the activity timer is initialized by

the host and control mode is automatic.

Default mnemonic is CMP.

MNEMONIC XXX Where X = any of the characters listed in

Step 8.2

Mnemonic appears in the control mode status

display when the activity timer is initialized by

the host and control mode is manual.

Default mnemonic is MAN.

15

Page 20

IB-23C650M

RS-485 COMMUNICATIONS SETUP

Table 1. RS-485 Setup Menu

Step Step Description

8.4.

8.5

8.6

Computer Control Mode Value

UP

or

DN

sets value.

SCRL

to advance to Step 8.5

Computer Set-point Mnemonic (Local)

UP

or

DN

sets value (press

press

UP

to start at A or press

Press

SCRL

to access the next character.

Repeat through the third character. Press

after the third character to continue with Step 8.6.

Computer Set-point Mnemonic (Local 2)

UP

or

DN

set values and

characters as described in Step 8.5. Press

after the third character to continue with Step 8.7.

UP

SCRL

to begin then

DN

to start at 9.

accesses

Top

Display

COMPUTER

CMP LOC

SCRL

CMP LO2

SCRL

8.7

16

Computer Set-point Mnemonic (Local 3)

UP

or

DN

set values and

characters as described in Step 8.5. Press

after the third character to continue with Step 8.8.

SCRL

accesses

SCRL

CMP LO3

Page 21

RS-485 COMMUNICATIONS SETUP

Table 1. RS-485 Setup Menu

IB-23C650M

Middle

Display

MODE VAL XXX

Bottom

Display

Entry Description

Where X = any value between 0 and 255.

This value is OR'd into bits 9-12 of the Control

Mode register (#14) when the activity timer is

enabled. Default value is 1.

MNEMONIC XXX Where X = any of the following characters:

Letters A through Z,

Any of the special characters:

b, c, super c, d, h, sub L, super L,

super m, super n, o, r, super T, u,

super V, w, <, >, =, +, –, *, #, /, %,

degrees (super o), or space,

Numbers 0 through

Mnemonic appears in the set-point status

display when the activity timer is initialized by

the host and set-point source is local, or when

coil #8 is True and the computer set-point

mode is Local. Default is LOC.

MNEMONIC XXX Where X = any of the characters listed in

Step 8.5.

Mnemonic appears in the set-point status

display when the activity timer is initialized by

the host and set-point source is Local 2.

Default is LO2.

MNEMONIC XXX Where X = any of the characters listed in

Step 8.5.

Mnemonic appears in the set-point status

display when the activity timer is initialized by

the host and set-point source is Local 3.

Default is LO3.

17

Page 22

IB-23C650M

RS-485 COMMUNICATIONS SETUP

Table 1. RS-485 Setup Menu

Step Step Description

8.8

8.9

8.10

8.11

Computer Set-point Mnemonic (Local 4)

UP

or

DN

set values and

characters as described in Step 8.5. Press

after the third character to continue with Step 8.9.

Computer Set-point Mnemonic (Remote)

UP

or

DN

set values and

characters as described in Step 8.5. Press

after the third character to continue with Step 8.10.

Computer Set-point Mode Value.

UP

or

DN

sets value

SCRL

to advance to Step 8.11

Use Computer Active Tag

UP

or

DN

selects yes or no.

SCRL

to advance to Step 8.11.1 from yes or

Step 8.12 (Computer Failure Setup) from no.

SCRL

SCRL

Top

Display

CMP LO4

accesses

SCRL

CMP REM

accesses

SCRL

COMPUTER

USE CMP

8.11.1

8.12

18

Computer Active Tag

UP

or

DN

sets value (press

press

UP

to start at letter A or press

9.

Press

SCRL

to access the next character.

Repeat through the last character. Press

after the last character to advance to Step 8.12

Computer Failure Setup.

UP

begins setup at step 8.12.1.

SCRL

to advance to Step 9 (bus enable).

UP

to begin then

DN

to start at

SCRL

COMPUTER

CMP FAIL

Page 23

RS-485 COMMUNICATIONS SETUP

Table 1. RS-485 Setup Menu

IB-23C650M

Middle

Display

MNEMONIC XXX

Bottom

Display

Entry Description

Where X = any of the characters listed in

Step 8.5.

Mnemonic appears in the set-point status

display when the activity timer is initialized by

the host and set-point source is Local 4.

Default is LO4.

MNEMONIC XXX Where X = any of the characters listed in

Step 8.5.

Mnemonic appears in the set-point status

display when the activity timer is initialized by

the host and set-point source is remote.

Default is REM.

SPMD VAL XXX Where X = any value between 5 and 255.

This value is OR'd into bits 13-6 of the the setpoint mode register (#15) when the activity

timer is enabled. Default value is 1.

ACT TAG YES

= Display the computer active tag configured

in Step 8.11.1 instead of the Tag Name

configured in the Tune Menu when the activity

timer is initialized by the host, This display

appears in the top location in the Displays

Menu.

=Don’t display computer active tag.

NO

ACT TAG XXXXXXXX Where X = any of the characters listed in

Step 8.5.

This is the tag name displayed when Step 8.11

is set at yes. Default tag is COMPUTER.

SETUP This menu provides setup for the control mode,

output values, set-point value and relays status

following a computer failure. A failure is

defined as a loss of communications from teh

computer for a time greater than the timeout

period configured in step 8.1.

19

Page 24

IB-23C650M

RS-485 COMMUNICATIONS SETUP

Table 1. RS-485 Setup Menu

Step Step Description

8.12.1

8.12.1.1 Computer Fail Output.

8.12.1.1.1 Computer Fail Output Value.

8.12.2

Computer Fail Control Mode.

UP

or

DN

sets desired mode.

SCRL

to advance to

Step 8.12.2 from AUTO if output 2 is available

Step 8.12.3 from AUTO if Relay A is available

Step 8.12.4 from AUTO if Relay B is available

Step 8.12.5 from AUTO if Relay C is available

or to Step 8.12.1.1 otherwise.

UP

or

DN

sets control output value.

SCRL

to advance to Step 8.12.1.1.1 (Computer

Failed Output Value) from "NEW VALU" or to any

step between 8.12.2 and 8.12.5 for outputs

enabled as manual or computer only. If no

outputs are assigned to manual or computer only,

continue with Step 8.12.6 (Computer Fail Set-point

Mode).

UP

or

DN

sets output value.

SCRL

to advance to any step between 8.12.2 and

8.12.5 for outputs enabled as manual or computer

only. If no outputs are assigned to manual or

computer only, continue with Step 8.12.6

(Computer Fail Set-point Mode).

Computer Fail Output 2.

UP

or

DN

sets value

SCRL

to advance to Step 8.12.2.1 (Computer Fail

Output 2 Value) from "NEW VALU" or to any step

between 8.12.3 and 8.12.5 for outputs enabled as

manual or computer only. If no additional outputs

are assigned to manual or computer only, continue

with Step 8.12.6 (Computer Fail Set-point Mode).

Top

Display

CMP FAIL

CMP FAIL

CMP FAIL

CMP FAIL

20

Page 25

RS-485 COMMUNICATIONS SETUP

Table 1. RS-485 Setup Menu

IB-23C650M

Middle

Display

CTL MODE LAST

OUTPUT LAST

Bottom

Display

MANUAL

AUTO

NEW VALU

Entry Description

=controller maintains the same control mode

after a communications failure has been

detected.

=controller operates in manual following a

computer failure with the output as defined in

Step 8.12.1.1.

=controller operates in automatic following a

computer failure with the set-point as defined in

Step 8.12.6.1.1.

=control output holds at the output value prior

to the computer failure.

=control output set to value set in Step

8.12.1.1.1.

Note: This new value is used only if the

controller mode in Step 8.12.1 is manual (MAN)

and a computer failure is detected.

OUT VAL XXX Where X = any value between 0 and 100%.

This is the output of the controller if a computer

failure is detected and the controller is in

manual.

OUTPUT 2 LAST

NEW VALU

=output 2 holds at the same value prior to the

computer failure.

=output set to value set in Step 8.12.2.1.

Note: This new value is used only if the

retransmission variable in the "MA OUTP

MENU" has been selected as manual or

computer only, and if a computer failure is

detected (see Table 4 in IB-23C650 for more

information).

21

Page 26

IB-23C650M

RS-485 COMMUNICATIONS SETUP

Table 1. RS-485 Setup Menu

Step Step Description

8.12.2.1 Computer Fail Output 2 Value.

UP

or

DN

sets output 2 value.

SCRL

to advance to any step between 8.12.3 and

8.12.5 for additional outputs enabled as manual or

computer only. If no outputs are assigned to

manual or computer only, continue with Step

8.12.6 (Computer Fail Set-point Mode).

8.12.3

8.12.4

8.12.5

8.12.6

Computer Fail Relay A.

UP

or

DN

sets relay condition.

SCRL

to advance to Step 8.12.4 for relay B or

Step 8.12.5 for relay C if they have been selected

for manual or computer only or to Step 8.12.6

(Computer Fail Set-point Mode) if relays B or C

have not been selected.

Computer Fail Relay B.

UP

or

DN

sets relay condition.

SCRL

to advance to step 8.12.5 for relay C if it

has been selected for manual or computer only or

to Step 8.12.6 (Computer Fail Set-point Mode) if it

has not been selected.

Computer Fail Relay C.

UP

or

DN

sets relay condition.

SCRL

to advance to Step 8.12.6 (Computer Fail

Set-point Mode).

Computer Fail Set-point Mode.

UP

or

DN

sets the set-point mode.

SCRL

to advance to Step 9 (Bus Enable) from

LAST, REMOTE, or a local set-point configured as

fixed in the set-points menu, or to Step 8.12.6.1

(Computer Fail Set-point) otherwise.

Top

Display

CMP FAIL

CMP FAIL

CMP FAIL

CMP FAIL

CMP FAIL

22

Page 27

RS-485 COMMUNICATIONS SETUP

Table 1. RS-485 Setup Menu

IB-23C650M

Middle

Display

Bottom

Display

OUT2 VAL XXX

RELAY A LAST

OFF

ON

RELAY B LAST

OFF

ON

RELAY C LAST

OFF

ON

SPT MODE LAST

LOCAL

LOCAL-2

LOCAL-3

LOCAL-4

REMOTE

Entry Description

Where X = any value between 0 and 100%.

This is the output 2 value the controller will

have if the retransmission variable in the "MA

OUTP MENU" has been selected as manual or

computer only and a computer failure has been

detected.

=relay state remains as it was prior to the

detection of a computer fail.

=relay goes to off state after a computer fail.

=relay goes to on state after a computer fail.

=relay state remains as it was prior to the

detection of a computer fail.

=relay goes to off state after a computer fail.

=relay goes to on state after a computer fail.

=relay state remains as it was prior to the

detection of a computer fail.

=relay goes to off state after a computer fail.

=relay goes to on state after a computer fail.

= controller uses the same set-point source

after a computer fail has been detected.

=Selecting any other set-point source causes

the controller to use the selected set-point after

a computer fail has been detected.

Note: The local set-points need not be enabled

in the "SETPTS MENU" for this use. If

ramp/soak is running at the time of a computer

fail, and a mode other than LAST has been

selected, ramp/soak will discontinue.

23

Page 28

IB-23C650M

RS-485 COMMUNICATIONS SETUP

Table 1. RS-485 Setup Menu

Step Step Description

8.12.6.1 Computer Fail Set-point

UP

or

DN

sets the set-point value.

SCRL

to advance to step 9 (Bus Enable) from

LAST or Step 8.12.6.1.1 (Computer Fail Set-point

Value) from NEW VALU.

8.12.6.1.1 Computer Fail Set-point Value.

UP

or

DN

sets the set-point value.

SCRL

to advance to Step 9 (Bus Enable)

9

Bus Enable.

UP

or

DN

SCRL

to advance to Step 1

selects ON or OFF.

Top

Display

CMP FAIL

CMP FAIL

BUS

24

Page 29

RS-485 COMMUNICATIONS SETUP

Table 1. RS-485 Setup Menu

IB-23C650M

Middle

Display

SETPOINT LAST

Bottom

Display

NEW VALU

Entry Description

If any of the LOCAL set-point sources were

selected in the previous step, "LAST" will

cause the controller to use the current set-point

value in that location. Selecting "NEW VALU"

allows a new value (defined in Step 8.12.6.1.1)

to be written into the set-point source register.

Note: The set-point value entered into that setpoint source in the "SETPTS MENU" will be

overwritten by the new value.

Ex.; LOC3 is selected as the computer fail setpoint mode (step 8.4.6) and has been set at

58.3 in the "SETPTS MENU". The computer

fail set-point value (set in Step 8.12.6.1.1) is set

at 38.6. When a computer fail is detected, 38.6

will be written into LOC3.

SPT VALU XXXX Where X = -3000 to 30000. This value is

limited by the specific set-point limits.

ENABLE ON

= enables the bus for communications with a

host device.

= disables the communications bus from

OFF

receiving or writing with a host device.

This duplicate entry is provided for

convenience since the bus must be re-enabled

following any parameter change.

NOTE: IF this attribute setting is changed

from OFF to ON, communication with

the host device must be initiated by

switching from LOCKED to

REQUESTED at the computer (CMP)

prompt in the DISPLAYS MENU. See

Basic Operation With a Host

Device for more information.

25

Page 30

IB-23C650M

RS-485 COMMUNICATIONS SETUP

Blank Page

26

Page 31

IB-23C650M

BASIC OPERATION WITH A HOST DEVICE

BASIC OPERATION WITH A HOST DEVICE

This section supplements the Basic Operation Section in IB-23C650.

It covers the operational activities related to Modbus communication

which are performed in the DISPLAYS MENU.

Enabling Write Communication With a Host

After completing the RS-485 communications setup, the host can read

instrument data when the bus is enabled (see Table 1, Step 9). If write

communication is required and the communication mode is LOCKED,

the write function can be enabled as follows:

1. Go to the DISPLAYS MENU.

2. Press scroll. This allows the

computer activity status to be

displayed in the DISPLAYS

MENU.

3 Press scroll until CMP appears

in the bottom status display

location.

4. Press

Standard Communication With a Host

In the standard communications mode the instrument functions as a

stand alone controller which can receive read and write commands from

the host. In this mode the last attribute entry becomes the active entry.

For example, if the operator sets an active set-point value via the

instrument display, and moments later the host sends a new set-point

value, the controller uses the operators value until it receives the host

value. At that time the host value becomes the new active set-point.

DN

or UP key to initiate

communication with the host.

When the key is pressed, the

engineering display reads

REQUESTD for a few seconds,

then changes to ENABLED.

27

Page 32

IB-23C650M

BASIC OPERATION WITH A HOST DEVICE

If necessary, the operator can disable the host from writing to the

controller. This gives the operator total control of the instrument

operation. The host can still read data from the instrument but cannot

write to it.

To disable the host, access the CMP status display as described in the

previous section. When CMP appears, press the

change the status from ENABLED to LOCKED.

DN

or UP key to

28

Page 33

IB-23C650M

BASIC OPERATION WITH A HOST DEVICE

Supervisory Station

When the controller and host device are configured to provide a

supervisory function, the controller receives its set-point from the host

device. The controller executes its PID algorithm in the normal manner,

and in general functions the same as a standard controller. This activity

is initiated by the host.

The displays and control key operation for a supervisory station are as

follows:

Tag display can be configured to

indicate that the host has initiated

activity. Default indication is

COMPUTER.

The auto and manual keys perform

their normal function.

This status display shows a

configured mnemonic when the

host initializes activity. The default

is CMP. For supervisory operation,

the display can be configured to

show AUT to indicate that the PID

function still resides in the

controller.

The R/L key can be disconnected

by a coil when the host initializes

activity. This allows the key to be

read by the host to select multiple

set-points stored in the host.

The status display shows a

configurable mnemonic indicating

which host set-point is being

written to the controller. Defaults

are: LOC, LO2, LO3, LO4 and

REM.

To check the Modbus

communication status, press the

scroll key to access CMP. Status

is indicated as ENABLED or

LOCKED.

29

Page 34

IB-23C650M

BASIC OPERATION WITH A HOST DEVICE

Computer Auto/Manual Station

When the controller and host device are configured to provide a

computer auto/manual function, the host performs the PID control

function. The results are communicated to the instrument and then to

the field. This activity is initiated by the host.

The displays and control key operation for a computer auto/manual

station are as follows:

Tag display can be configured to

indicate that the host has initiated

activity. Default indication is

COMPUTER.

The auto and manual keys can be

disconnected by a coil when the

host initiates activity. This allows

the keys to be read by the host

which then initiates programmed

action.

This status display shows a

configured mnemonic indicating the

programmed action. Defaults are

CMP for automatic and MAN for

manual.

30

The R/L key permits selection of

any set-point enabled in the setpoints menu. This may be

disconnected by a coil so the R/L

key can be read by the host to

select set-points stored in the host.

The status display shows a

configurable mnemonic indicating

the set-point source. Defaults are:

LOC, LO2, LO3, LO4 and REM.

To check Modbus communication

status, press the scroll key to

access CMP. Status is indicated

as ENABLED or LOCKED. The

locked status is displayed after the

controller is switched to manual.

Page 35

IB-23C650M

BASIC OPERATION WITH A HOST DEVICE

Diagnostic Messages

The controller provides diagnostic messages which alert the user to

communication problems . The Diagnostic messages are displayed on

the TAG line. When one or more unacknowledged messages exist, the

red LED on the ALARM key flashes, the message alternates with the

TAG on the top display, and the beeper sounds if configured to do so.

This activity continues until all diagnostic conditions are either

acknowledged or no longer active. When only acknowledged diagnostic

messages exist, the red LED is steady and the tag display shows only

the tag.

Press the alarm key to view messages and acknowledge any

unacknowledged conditions using the UP key.

Communication problems are indicated by the following diagnostic

messages:

• [CMP INHB]

RS-485 bus write messages have been locked out by the operator.

• [CMP ERR]

One or more framing, parity, crc, etc. errors has occurred on RS485 bus.

• [OVERCFGD]

Instrument is unable to complete all configured tasks in less than

250 msec. (operation will continue, but time based activities will be

in error).

31

Page 36

IB-23C650M

BASIC OPERATION WITH A HOST DEVICE

32

Page 37

IB-23C650M

MODBUS PROTOCOL

MODBUS PROTOCOL

Communications Speed

The controller supports baud rates of 150, 300, 1200, 2400, 4800, 9600, 19.2K,

and 38.4K baud. Messages are not buffered. A new message (including

broadcast type) will not be accepted until an existing message has been

processed and responded to if necessary.

Message Response Time

The controller typically takes between 10 and 30 milliseconds to respond to a

message requesting 10 registers. This time is from the end of the request

message to the start of the response message.

The total amount of time a message takes to get back and forth between the

host and the slave depends on the message size, baud rate and the slave's

time to process the message. The following information is for a request

message to read 10 registers:

• request message size is 8 characters + 3.5 idle time characters (11.5).

• response message size is 25 characters + 3.5 idle time characters (28.5).

• for this example, a character is 11 bits (1 start, 8 data, 1 parity, 1 stop).

• Therefore, the total typical time using a controller response time of 30

milliseconds is shown below for the various baud rates:

Baud Rate

150 623 2090 2743

300 312 1045 1387

1200 78 261 369

2400 39 131 190

4800 19 65 114

9600 10 33 73

19200 5 16 51

38400 2 8 40

Request Time

(mSec)

Response

Time (mSec)

Total Typical

Time (mSec)

33

Page 38

IB-23C650M

MODBUS PROTOCOL

Messages Supported

The controller utilizes registers and coils to access information. The following

MODBUS messages are supported by the controller. See the Gould

MODBUS Protocol Reference Guide dated Jan. 1985 for further detail.

Note: In cases where the controller processor is already heavily loaded, it

may be necessary to limit the number of registers or coils addressed

by any single message. Limiting the number of coils and registers in

a single message will avoid pushing the instrument into the "over

configured" condition (>250 milliseconds scan time). Only repetitive

messages are a concern in this regard.

34

Page 39

IB-23C650M

MODBUS PROTOCOL

Table 2.

MODBUS

Function

Code

MODBUS messages supported by the 2050R Controller

MODBUS

Message Name

01 Read Coil

Status

02 Read Input

Status

03 Read Holding

Registers

04 Read Input

Registers

05 Force Single

Coil

06 Preset Single

Register

08 Loopback

Diagnostic Test

15 Force Multiple

Coils

16 Preset Multiple

Registers

2050R Definition

Read "n" consecutive discrete (boolean) points

from a specified starting point. The controller

returns zeros for points which do not contain

defined data and will nak any request for point

numbers greater than 9999. See Note, page 34.

Same as Read Coil Status.

Read "n" consecutive registers from specified

starting register. The controller returns zeros for

registers which do not contain defined data and

will nak any request for register numbers greater

than 9999. See Note, page 34.

Same as Read Holding Registers

Write one discrete (boolean) point. The controller

will nak this if the point is not currently writeable.

Write one register. The controller will nak this if

the register is not currently writeable. It will also

apply any currently applicable limits to the value

before storage in the database.

Echo the message. Only "Return of Query" is

supported.

Write "n" consecutive coils from a specified

starting coil. The controller will nak if any of the

coils are not currently writeable, but will still do all

the writes which are valid. See Note, page 34.

Write "n" consecutive registers from a specified

starting register. The controller will nak if any of

the registers are not currently writeable, but will

still do all the writes which are valid, applying any

currently applicable limits to the values before

storage in the database. See Note, page 34.

35

Page 40

IB-23C650M

MODBUS PROTOCOL

Message Formats

The following message formats are used to transfer information between the

controller and a host. Refer to the message format example for format details.

Read Coil Status, Read Input Status

Master Message Format Bytes

0 1 2 & 3 4 & 5 6 & 7

Device Address Function Code Starting Coil Number Number of Coils CRC

Slave Response Bytes

0123

Device

Address

Function

Code

Number of

Data Bytes

Data byte #1 ... Data Byte #n CRC

...

x

Read Holding Registers, Read Input Registers

Master Message Format Bytes

0 1 2 & 3 4 & 5 6 & 7

Device Address Function Code Starting Register Number Number of Registers CRC

x+1 &

x+2

Slave Response Bytes

0 1 2 3 & 4

Device

Address

Function

Code

Force Single Coil

Number of

Data Bytes

Register #1

data

...

... Register #n

Master Message Format Bytes

0 1 2 & 3 4 & 5 6 & 7

Device Address Function Code Coil Number Coil Data

ON = FF00

OFF =0000

Slave Response (simple echo) Bytes

0 1 2 & 3 4 & 5 6 & 7

Device Address Function Code Coil Number Coil Data

ON = FF00

OFF =0000

36

x & x+1

data

x+2 &

x+3

CRC

CRC

CRC

Page 41

IB-23C650M

MODBUS PROTOCOL

Preset Single Register

Master Message Format Bytes

0 1 2 & 3 4 & 5 6 & 7

Device Address Function Code Register Number Register Data CRC

Slave Response (simple echo) Bytes

0 1 2 & 3 4 & 5 6 & 7

Device Address Function Code Register Number Register Data CRC

Loopback Diagnostic Test

Master Message Format Bytes

0 1 2 & 3 4 & 5 6 & 7

Device Address Function Code Diagnostic Code

(0000 only)

Data (ignored) CRC

Slave Response (simple echo) Bytes

0 1 2 & 3 4 & 5 6 & 7

Device Address Function Code Diagnostic Code

(0000 only)

Data (ignored) CRC

Force Multiple Coils

Master Message Format Bytes

0 1 2 & 3 4 & 5 6 7

Device

Address

Function

Code

Starting

Coil

Number

Number

of Coils

Number

of Data

Bytes

Data Byte1... Data

...

x

Byte n

Slave Response Bytes

0 1 2 & 3 4 & 5 6 & 7

Device Address Function Code Starting Coil Number Number of Coils CRC

x+1 &

x+2

CRC

37

Page 42

IB-23C650M

MODBUS PROTOCOL

Preset Multiple Registers

Master Message Format Bytes

x &

0 1 2 & 3 4 & 5 6 7 & 8

Device

Address

Function

Code

Starting

Register

Number

Number

of

Registers

Number

of Data

Bytes

Register

Data 1

...

x+1

... Register

Data n

& x+3

CRC

Slave Response Bytes

0 1 2 & 3 4 & 5 6 & 7

Device Address Function Code Starting Register Number Number of Registers CRC

Coil Data Example

Coil data is packed 1 bit per coil. The low order bit of the first data byte

contains the addressed coil and unused bits are zero filled. For instance, if

coils 22 through 33 are requested, two data bytes will be returned with the coil

data located as follows; (coils 22,24,25,26,29,30,32 and 33 are on).

coil # 29 26 25 24 22 33 32 30

data bytes 1 & 2 10011101 00001101

x +2

38

Page 43

IB-23C650M

CONTROLLER ATTRIBUTE LISTING - REGISTER DATA

CONTROLLER ATTRIBUTE LISTING - REGISTER DATA

The tables in this section provide a listing of the controller’s numeric attributes

which are addressed as registers. The tables divide the attributes into related

groups such as tuning, alarms, etc. A group of numeric attributes may have

associated boolean (discrete) attributes which are addressed as coils. The

boolean attributes are listed in the next section.

The following tables list the attributes in order by Modbus register number.

The letters below each number indicate whether the attribute is readable and

writeable or read only:

• R W Readable and Writeable

• R _ Read only

Common Data (registers)

Reg.

#

4

Maximum milliseconds used in any

R W

one cycle. This value is updated by

the controller and can be reset to zero

with a write by the host.

5

Average milliseconds used per cycle.

R _

This should not exceed 250

milliseconds.

6

Bits 15 - 4 indicate unacknowledged

R _

process alarms (PA) and diagnostics

(DIAG).

Refer to coil numbers 41-48 for

alarms and 49-64 for diagnostics.

Description Register Value

Bit 15 = PA1

Bit 14 = PA2

Bit 13 = PA3

Bit 12 = PA4

Bit 11 = DIAG1

Bit 10 = DIAG2

Bit 9 = DIAG3

Bit 8 = DIAG4

Bit 7 = DIAG5

Bit 6 = DIAG6

Bit 6 = DIAG7

Bit 6 = DIAG8

Bits 0-3 Not Used

Typically written from

host as 0.

Number of

milliseconds

2050R

Displayed Value

not displayed

not displayed

39

Page 44

IB-23C650M

CONTROLLER ATTRIBUTE LISTING - REGISTER DATA

Common Data (registers) Cont’d

Reg.

#

7

Field Input 1

R _

Note: This register permits reading of

actual process input to 2050R when

Coil #14 is TRUE. Data is copied to

Reg. #10 when Coil #14 is FALSE.

8

Field Input 2

R _

Note: This register permits reading of

actual input 2 to 2050R when Coil

#15 is TRUE. Data is copied to Reg.

#11 when Coil #15 is FALSE.

9

Bits

Bits 15 - 4 indicate active process

15 - 4

alarms (PA) and diagnostics (DIAG).

R _

See Register #6 for bit descriptions.

Bits

Process decimal point. Positions the

1 & 0

decimal point in the process and set-

R _

points engineering displays.

10

Process Variable for Display

R W

• Coil #14 is FALSE:

Description Register Value

Register #9, Bits 1 & 0 = 0

Register #9, Bits 1 & 0= 1

Register #9, Bits 1 & 0= 2

Register.#9, Bits 1 & 0 = 3

Same as Reg. #7 Same as Reg. #7

Actual 2050R Process variable

(field input 1) is displayed

-32000 to +32000

-32000 to +32000

-32000 to +32000

-32000 to +32000

0

1

2

3

Same as Reg. #7

values

Displayed Value

-32000 to +32000

-3200.0 to +3200.0

-320.00 to +320.00

-32.000 to +32.000

displayed when Coil

#14 is TRUE. See

values

displayed when Coil

#15 is TRUE. See

Same as Reg. #7

2050R

Values are not

Reg. #10

Values are not

Reg. #11.

n

n.n

n.nn

n.nnn

values

• Coil #14 is TRUE:

Display value is written from host

11

Active set-point variable

R W

12

R W

13

R W

Register No. 9, Bits 1 & 0 = 0

Register No. 9, Bits 1 & 0 = 1

Register No. 9, Bits 1 & 0 = 2

Register No. 9, Bits 1 & 0 = 3

Control analog output value. -80 to 1100 -8.0 to 110.0

Input No. 2

• Coil # 15 is FALSE:

Input No. 2 value is obtained

from Field Input 2

• Coil #15 is TRUE:

Input No. 2 value is written from

host

Same as Reg. #7

values

-3000 to 30000

-3000 to 30000

-3000 to 30000

-3000 to 30000

Same as Reg. #7

values

Same as Reg. #7

values

40

Same as Reg. #7

values

-3000 to 30000

-300.0 to 3000.0

-30.00 to 300.00

-3.000 to 30.000

Same as Reg. #7

values

Same as Reg. #7

values

Page 45

CONTROLLER ATTRIBUTE LISTING - REGISTER DATA

Common Data (registers) Cont’d

Reg.

#

14

Computer active control mode value

Bits

(this is a copy of register #77).

9 - 2

This part present only when activity

R W

timer is enabled.

Bit 10

Output Tracking 1

R W

Bit 1

Computer Auto/Manual status.

R W

When Coil #10 is TRUE, the A and M

keys change this status instead of the

controller mode.

This part present only when activity

timer is enabled.

Bit 0

Control mode of 2050R 1

R W

15

Computer (host) Set-point mode value

Bits

This part present only when activity

13 - 6

timer is enabled.

R W

Bits

Computer Remote/Local status.

5 - 0

When Coil #8 is TRUE, the R/L key

R W

changes this status instead of the setpoint status.

This part present only when activity

timer is enabled.

Bits

2050R Set-point source 0

2 - 0

R W

16

Analog output #2 value -100 to 1100 -10.0 to 110.0

R W

17

Local set-point 1 value Same as Reg.#11 Same as Reg.#11

R W

18

Local set-point 2 value Same as Reg.#11 Same as Reg.#11

R W

19

Local set-point 3 value Same as Reg.#11 Same as Reg.#11

R W

20

Local set-point 4 value Same as Reg.#11 Same as Reg.#11

R W

Description Register Value

0 to 255 Not Displayed

0

1

0

0

5 to 255 Not Displayed

0

1

2

3

4

•

•

•

to value in register

#123

1

2

3

4

See RS-485 Setup;

Displayed Mnemonic

See RS-485 Setup;

Displayed Mnemonic

IB-23C650M

2050R

Displayed Value

Table 1, Step 8.4.

TRK

AUT

MAN

is configurable,

defaults are shown.

See Reg. #75, 76,

113 & 114

AUT

MAN

Table 1, Step 8.10.

LOC

LO2

LO3

LO4

REM

is configurable for

values 0-5, defaults

are shown.

See Reg #78 &

#115 thru #122

LOC

LO2

LO3

LO4

REM

41

Page 46

IB-23C650M

CONTROLLER ATTRIBUTE LISTING - REGISTER DATA

Ramp/Soak Profile and Totalizer Data (registers)

Reg.

#

30

Ramp/soak segment time remaining.

R _

Time remaining in the currently active

ramp/soak segment.

31

Current ramp/soak cycle. 0 to 65535 0 to 65535

R _

32

Current ramp/soak segment 1 to 10 1 to 10

R _

33

Floating point totalized count hi bytes.

R _

Upper 2 bytes of totalized count in

IEEE floating point format.

Description Register Value

0 to 32000 0.0 to 3200

Displayed Value

2050R

Register #9, bits 1 & 0 = 0

Register #9, bits 1 & 0 = 1

Register #9, bits 1 & 0 = 2

Register #9, bits 1 & 0 = 3

34

Floating point totalized count low

R _

bytes. Lower 2 bytes of totalized

count in IEEE floating point format.

35

Integer totalized count. Permits

R _

transfer of totalized count in integer

format. Tops out at 65K

Register # 9, Bits 1&0 = 0

Register # 9, Bits 1&0 = 1

Register # 9, Bits 1&0 = 2

Register # 9, Bits 1&0 = 3

36

Floating point totalizer preset hi bytes.

R W

Upper 2 bytes of totalizer preset

number in IEEE floating point format.

37

Floating point totalizer preset low

R W

bytes. Lower 2 bytes of totalizer

preset number in IEEE floating point

format.

38

Integer totalizer preset count. Permits

R W

transfer of totalizer preset number in

integer format.

IEEE Single

precision floating

point value

Same as above

Same as above

Same as above

Same as Reg #33 Same as Reg #33

0 to 65535

0 to 65535

0 to 65535

0 to 65535

Same as Reg #33 Same as Reg #33

Same as Reg #33 Same as Reg #33

Same as Reg #35 Same as Reg #35

0000000 to

9999999

000000.0 to

999999.9

00000.00 to

99999.99

0000.000 to

9999.999

0 to 65535

0 to 6553.5

0 to 655.35

0 to 65.535

42

Page 47

CONTROLLER ATTRIBUTE LISTING - REGISTER DATA

Ramp/Soak Profile and Totalizer Data (registers) Cont’d

Reg.

#

39

Floating point totalizer predetermined

R W

count hi bytes. Upper 2 bytes of

totalizer predetermined count in IEEE

floating point format.

40

Floating point totalizer predetermined

R W

count low bytes. Lower 2 bytes of

predetermined count in IEEE floating

point format

41

Integer totalizer predetermined count.

R W

Permits transfer of totalizer

predetermined count in integer format.

42

Totalizer scale decimal point. Sets the

R _

decimal point position in the totalizer

scale factor (Reg. # 43).

43

Totalizer scale factor. Permits

R W

fractional scaling of an input signal.

Description Register Value

Register No. 42 =0

Register No. 42 =1

Register No. 42 =2

Register No. 42 =3

Displayed Value

Same as Reg #33 Same as Reg #33

Same as Reg #33 Same as Reg #33

Same as Reg #35 Same as Reg #35

0

1

2

3

1 to 30000

1 to 30000

1 to 30000

1 to 30000

0.001 to 30.000

IB-23C650M

2050R

0

0.0

0.00

0.000

1 to 30000

0.1 to 3000.0

0.01 to 300.00

43

Page 48

IB-23C650M

CONTROLLER ATTRIBUTE LISTING - REGISTER DATA

Tuning Parameter Data (registers)

Reg.

#

50

Autotune output step size

R W

51

Autotune hysteresis value

R W

52

Autotune process variable maximum

R W

(high trip point)

Description Register Value

Register No. 9 = 0

Register No. 9 = 1

Register No. 9 = 2

Register No. 9 = 3

Register #9, bits 1 & 0 = 0

-29970 or Reg. #53

value +30 to

300000.

Displayed Value

1 TO 500 0.1 to 50.0

1 to 30000

1 to 30000

1 to 30000

1 to 30000

-2997 or Low Trip

Point +3 to 30000.

2050R

0.1 to 3000.0

0.01 to 300.00

0.001 to 30.000

0.001 to 30.000

Register #9, bits 1 & 0 = 1

Register #9, bits 1 & 0 = 2

Register #9, bits 1 & 0 = 3

53

Autotune process variable minimum

R W

(low trip point)

Register #9, bits 1 & 0 = 0

Register #9, bits 1 & 0 = 1

Register #9, bits 1 & 0 = 2

Register #9, bits 1 & 0 = 3

54R_Autotune error number 0

Same as above

Same as above

Same as above

-30000 to 299970 or

Reg. #52 value - 30

Same as above

Same as above

Same as above

-299.7 or Low Trip

Point +0.3 to

3000.0

-29.97 or Low Trip

Point +0.03 to

300.00

-2.997 or Low Trip

Point +0.003 to

30.000

-3000 to 29997 or

High Trip Point - 3.

-300.0 to 2999.7 or

High Trip Point

- 0.3.

-30.00 to 299.97 or

High Trip Point

- 0.03.

-3.000 to 29.997 or

High Trip Point

- 0.003.

2

3

5

6

No error

Increase step

Process slow

Decrease step

Response limited

44

Page 49

CONTROLLER ATTRIBUTE LISTING - REGISTER DATA

Tuning Parameter Data (registers) Cont’d

Reg.

#

55

Gain or heat gain value 1 to 30000 0.1 to 3000.0

R W

56

Reset or heat reset 10 to 12000 0.01 to 120.00

R W

57

Preact value 0 to 30000 0.0 to 3000.0

R W

58

Manual reset value 0 to 1000 0.0 to 100.0%

R W

59

Remote set-point ratio or AMRB ratio -30000 to 30000 -300.00to 300.00

R W

60

Remote set-point bias or AMRB bias

R W

61

Time proportioning cycle time or heat

R W

cycle time

62

On/off differential gap

R W

63

Heat/cool output crossover 1 to 3000 0.1 to 300.0%

R W

64

Crossover output off hysteresis 0 to 250 0.0 to 25.0 in %

R W

65

Cool gain value 1 to 30000 0.1 to 3000.0

R W

66

Cool reset value 10 to 1200 0.1 to 120.0

R W

67

Cool cycle time value 10 to 3000 1.0 to 300.0 sec.

R W

68

Position proportioning deadband value 0 to 500 0.0 to 50.0%

R W

69

Position proportioning preact value 0 to 500 0.0 to 50.0%

R W

Description Register Value

Register #9, bits 1 & 0 = 0

Register #9, bits 1 & 0 = 1

Register #9, bits 1 & 0 = 2

Register #9, bits 1 & 0 = 3

Register #9, bits 1 & 0 = 0

Register #9, bits 1 & 0 = 1

Register #9, bits 1 & 0 = 2

Register #9, bits 1 & 0 = 3

repeats/minute

seconds derivative

response

-30000 to 300000

-30000 to 300000

-30000 to 300000

-30000 to 300000

10 to 3000 1.0 to 300.0 sec.

0 to 1000

0 to 1000

0 to 1000

0 to 1000

output centered on

IB-23C650M

2050R

Displayed Value

-3000 to 30000

-300.0 to 3000.0

-30.00 to 300.00

-3.000 to 30.000

0 to 100

0.0 to 10.0

0.00 to 1.00

0.000 to 0.100

crossover value

(±25%)

repeats/minute

45

Page 50

IB-23C650M

CONTROLLER ATTRIBUTE LISTING - REGISTER DATA

Alarm Data (registers)

Reg.

#

70

Alarm 1 trip point

R W

• Process High or Low

Description Register Value

Register #9, bits 1 & 0 = 0

Register #9, bits 1 & 0 = 1

Register #9, bits 1 & 0 = 2

Register #9, bits 1 & 0 = 3

-2995 to 30000

-2995 to 30000

-2995 to 30000

-2995 to 30000

Displayed Value

-299.5 to 3000.0

-29.95 to 300.00

-2.995 to 30.000

2050R

-2995 to 30000

• Deviation High or Low

• Output High or Low

• Input 2 High or low

71

Alarm 2 trip point Same as Reg. # 70 Same as Reg. #70

R W

72

Alarm 3 trip point Same as Reg. # 70 Same as Reg. #70

R W

73

Alarm 4 trip point Same as Reg. # 70 Same as Reg. #70

R W

Register #9, bits 1 & 0 = 0

Register #9, bits 1 & 0 = 1

Register #9, bits 1 & 0 = 2

Register #9, bits 1 & 0 = 3

1 to 30000

1 to 30000

1 to 30000

1 to 30000

0 to 1000

Same as Process

high or low

0.01 to 300.00

0.001 to 30.000

Same as Process

high or low

1 to 30000

0.1 to 3000.0

0.0 to 100.0

46

Page 51

CONTROLLER ATTRIBUTE LISTING - REGISTER DATA

Computer Activity Data (registers)

Reg.

#

74

Computer active: timeout value 1 to 16383 1 to 16383 sec.

R W

75

Automatic control mode status display

R W

mnemonic with computer active.

Default display is CMP. Each

character is configurable; this register

defines the first character (C in the

default CMP).

76

Same as display described in Reg.

R W

#75. This register defines the second

and third characters (M and P in the

default CMP).

77

Computer active: control mode value

R W

Default is 1.

78

Local Set-point status display

R W

mnemonic with computer active.

Default display is LOC. Each

character is configurable; this register

defines the first character (L in the

default LOC)

79

Same as display described in Reg.

R W

#78. This register defines the second

and third characters (O and C in the

default LOC).

Description Register Value

ASCII code for first

character in status

display

ASCII code for

second and third

characters in status

display

0 to 255 0 to 255

Same as Reg. #75 Letter L (default) or

.

Same as Reg. #76

Letter C (default) or

letters A-Z,

numbers 0-9 plus

other special

characters per

configuration. See

RS-485 Setup

Menu.

Letters M and P

(default) or letters

A-Z, numbers 0-9

plus other special

characters per

configuration. See

RS-485 Setup

Menu.

letters A-Z,

numbers 0-9 plus

other special

characters per

configuration. See

RS-485 Setup Menu

Letters O and C

(default) or letters

A-Z, numbers 0-9

plus other special

characters per

configuration. See

RS-485 Setup

Menu

IB-23C650M

2050R

Displayed Value

.

Note: The "computer active" references in this section mean "when the

computer activity timer is enabled".

47

Page 52

IB-23C650M

CONTROLLER ATTRIBUTE LISTING - REGISTER DATA

Computer Activity Data (registers) Cont’d

Reg.

#

80

Computer active: set-point mode value 0 to 255 0 to 255

R W

81

Computer fail: control mode 0

R W

82

Computer fail: output value 0 to 1000 0.0 to 100.0%

R W

83

Computer fail: output 2 value 0 to 1000 0.0 to 100.0%

R W

84

Computer fail: relay A 0

R W

85

Computer fail, relay B Same as Reg. #84 Same as Reg. #84

R W

86

Computer fail: relay C Same as Reg. #84 Same as Reg. #84

R W

87

Computer fail: set-point mode 0

R W

88

Computer fail: set-point value

R W

Description Register Value

Register #9, bits 1 & 0 = 0

Register #9, bits 1 & 0 = 1

Register #9, bits 1 & 0 = 2

Register #9, bits 1 & 0 = 3

-3000 to 30000

-3000 to 30000

-3000 to 30000

-3000 to 30000

Displayed Value

1

2

1

2

1

2

3

4

5

-3000 to 30000

-300.0 to 3000.0

-30.00 to 300.00

-3.000 to 30.000

2050R

Last

Manual

Auto

Last

Off

On

Last

LOC

LO2

LO3

LO4

REM

48

See register #113 through #131 for

more computer activity data

Page 53

CONTROLLER ATTRIBUTE LISTING - REGISTER DATA

Ramp/Soak Profile Configuration Data (registers)

Reg.

#

89

Ramp/soak soak hysteresis

R W

90

Ramp/soak ramp hysteresis Same as Reg. #89 Same as Reg. #89

R W

91

Ramp/soak number of segments 0 to 10 0 to 10

R W

92

Ramp/soak segment 1 starting set-

R W

point

93

Ramp/soak segment 1 ending set-

R W

point

94

Ramp/soak segment 1 ramp-rate

R W

- OR Ramp/soak segment 1 soak-time

Description Register Value

Register #9, bits 1 & 0 = 0

Register #9, bits 1 & 0 = 1

Register #9, bits 1 & 0 = 2

Register #9, bits 1 & 0 = 3

Register #9, bits 1 & 0 = 0

Register #9, bits 1 & 0 = 1

Register #9, bits 1 & 0 = 2

Register #9, bits 1 & 0 = 3

Register #9, bits 1 & 0 = 0

Register #9, bits 1 & 0 = 1

Register #9, bits 1 & 0 = 2

Register #9, bits 1 & 0 = 3

Register #9, bits 1 & 0 = 0

Register #9, bits 1 & 0 = 1

Register #9, bits 1 & 0 = 2

Register #9, bits 1 & 0 = 3

Displayed Value

1 to 30000

1 to 30000

1 to 30000

1 to 30000

-3000 to 30000

-3000 to 30000

-3000 to 30000

-3000 to 30000

-3000 to 30000

-3000 to 30000

-3000 to 30000

-3000 to 30000

1 to 30000

1 to 30000

1 to 30000

1 to 30000

0 to 30000

IB-23C650M

2050R

1 to 30000

0.1 to 3000.0

0.01 to 300.00

0.001 to 30.000

-3000 to 30000

-300.0 to 3000.0

-30.00 to 300.00

-3.000 to 30.000

-3000 to 30000

-300.0 to 3000.0

-30.00 to 300.00

-3.000 to 30.000

1 to 30000

0.1 to 3000.0

0.01 to 300.00

0.001 to 30.000

0.0 to 3000.0

95

Ramp/soak segment 2 ending set-

R W

point

96

Ramp/soak segment 2 ramp-rate or

R W

soak-time

97

Ramp/soak segment 3 ending set-

R W

point

98

Ramp/soak segment 3 ramp-rate or

R W

soak-time

Units are hours or

minutes as defined

in Time Units.

Same as Reg. #93 Same as Reg. #93

Same as Reg. #94 Same as Reg. #94

Same as Reg. #93 Same as Reg. #93