Page 1

Logic Functions

Data Base Reference

BOOK 2:

Algorithms, Tables and Sequential Logic Functions for

2001P - MODCELL™ Logic Control Identity Module (Version 6)

2004P - MODCELL™ Advanced Control Identity Module (Version 3)

1800P - MOD 30ML™ Identity Module (Version 2)

Page 2

MicroMod Automation, Inc.

The Company

MicroMod Automation is dedicated to improving customer efficiency by providing the most cost-effective, application-specific process

solutions available. We are a highly responsive, application-focused company with years of expertise in control systems design and

implementation.

We are committed to teamwork, high quality manufacturing, advanced technology and unrivaled service and support.

The quality, accuracy and performance of the Company's products result from over 100 years experience, combined with a continuous

program of innovative design and development to incorporate the latest technology.

Use of Instructions

Ì Warning. An instruction that draws attention to the risk of

injury or death.

Note. Clarification of an instruction or additional

information.

q Caution. An instruction that draws attention to the risk of

the product, process or surroundings.

Although Warning hazards are related to personal injury, and Caution hazards are associated with equipment or property damage, it

must be understood that operation of damaged equipment could, under certain operational conditions, result in degraded process

system performance leading to personal injury or death. Therefore, comply fully with all Warning and Caution notices.

Information in this manual is intended only to assist our customers in the efficient operation of our equipment. Use of this manual for

any other purpose is specifically prohibited and its contents are not to be reproduced in full or part without prior approval of MicroMod

Automation, Inc.

Licensing, Trademarks and Copyrights

MOD 30 and MOD 30ML are trademarks of MicroMod Automation, Inc.

MODBUS is a trademark of Modicon Inc.

Health and Safety

To ensure that our products are safe and without risk to health, the following points must be noted:

The relevant sections of these instructions must be read carefully before proceeding.

1. Warning Labels on containers and packages must be observed.

2. Installation, operation, maintenance and servicing must only be carried out by suitably trained personnel and in accordance with the information

given or injury or death could result.

3. Normal safety procedures must be taken to avoid the possibility of an accident occurring when operating in conditions of high

4. pressure and/or temperature.

5. Chemicals must be stored away from heat, protected from temperature extremes and powders kept dry. Normal safe handling procedures must be

used.

6. When disposing of chemicals, ensure that no two chemicals are mixed.

Safety advice concerning the use of the equipment described in this manual may be obtained from the Company address on the back

cover, together with servicing and spares information.

All software, including design, appearance, algorithms and source

codes, is copyrighted by MicroMod Automation, inc. and is owned by

MicroMod Automation or its suppliers.

i Information. Further reference for more detailed

information or technical details.

Page 3

PREFACE - BOOK 2

This document is the second of two books that includes database reference information to aid in

configuring an instrument with logic functionality. Information on database organization, database

memory block structures, I/O functions and communications is described in IB-23G600 Database

Reference for Logic Functions - Book 1.

Page 4

Page 5

Logic Functions - Book 2

CONTENTS

CONTENTS

Page

SECTION 8 - ALGORITHM FUNCTIONS DATABASE PARAMETERS

8.1 ALGORITHM BLOCKS......................................................................................................................8-1

8.2 EXPRESSION BLOCK (EX) .................................................................................................................3

8.2.1 Expression Block Operation........................................................................................................... 6

8.2.2 Expression Block Parameters........................................................................................................8

8.2.3 Typical Block Connections for Expression Block .........................................................................14

8.2.4 Expression Block Events..............................................................................................................15

8.2.5 Example 1: Using Expression Blocks to Store Trend Data..........................................................15

8.2.6 Example 2: Using IF-THEN-ELSE Statements in Expression Blocks..........................................16

8.3 INPUT COMMUNICATION BLOCK (IC).............................................................................................17

8.3.1 Input Communication Block Operation.........................................................................................19

8.3.2 Input Communication Block Parameters......................................................................................20

8.3.3 Typical Block Connections for Input Communication Block......................................................... 24

8.3.4 Input Communication Block Events ............................................................................................. 24

8.4 OUTPUT COMMUNICATION BLOCK (OC)....................................................................................... 25

8.4.1 Output Communication Block Operation...................................................................................... 27

8.4.2 Output Communication Block Parameters...................................................................................27

8.4.3 Typical Block Connections for Output Communication Block ......................................................29

8.4.4 Output Communication Block Events...........................................................................................29

8. 5 LINEARIZATION BLOCK (LN)............................................................................................................31

8.5.1 Linearization Block Capabilities ................................................................................................... 32

8.5.2 Linearization Block Parameters ................................................................................................... 37

8.5.3 Typical Softwiring Block Structures for Linearization Block .........................................................41

8.5.4 Using the Linearization Block.......................................................................................................42

8.5.5 Linearization Block Events...........................................................................................................42

8.6 PROCESS ALARM BLOCK (PA)........................................................................................................43

8.6.1 Process Alarm Block Capabilities ................................................................................................ 44

8.6.2 Process Alarm Block Parameters ................................................................................................46

8.6.3 Typical Softwiring Block Structures for Process Alarm Block ...................................................... 50

8.6.4 Using the Process Alarm Block.................................................................................................... 51

8.7 TIMER BLOCK (TM) ...........................................................................................................................53

8.7.1 Timer Block Operation .................................................................................................................54

8.7.2 Timer Block Parameters .............................................................................................................. 56

8.7.3 Time Values................................................................................................................................. 60

8.7.4 Typical Softwiring Block Structures for Timer Block.....................................................................60

8.7.5 Using the Timer Block..................................................................................................................61

8.7.6 Timer Block Events......................................................................................................................62

8.8 NOTIFICATION/REQUEST MESSAGE BLOCK (NM).......................................................................63

8.8.1 Notification/Request Message Block Operation...........................................................................66

8.8.2 Notification/Request Message Block Parameters........................................................................66

8.8.3 Typical Block Connections for Notification/Request Message Block ...........................................71

8.8.4 Notification/Request Message Block Events................................................................................ 72

8.8.5 Using the Notification/Request Message Block ........................................................................... 72

8.9 SUPERVISORY MESSAGE BLOCK (SM) .........................................................................................75

8.9.1 Supervisory Message Block Operation........................................................................................78

8.9.2 Supervisory Message Block Parameters..................................................................................... 78

8.9.3 Typical Block Connections for Supervisory Message Block.........................................................86

8.9.4 Supervisory Message Block Events.............................................................................................86

8.9.5 Using the Supervisory Message Block......................................................................................... 87

i

Page 6

Logic Functions - Book 2

CONTENTS

CONTENTS (Cont’d)

Page

8.10 TOTALIZER BLOCK (TOT).................................................................................................................89

8.10.1 Analog Input Examples.................................................................................................................91

8.10.2 Totalizer Block Timing Diagrams..................................................................................................92

8.10.3 Totalizer Block Parameters ..........................................................................................................97

8.10.4 Typical Block Connections for Totalizer Block............................................................................103

8.10.5 Totalizer Block Events................................................................................................................103

SECTION 9 - TABLE

9.1 TABLE LIBRARY BLOCKS ...................................................................................................................1

9.2 PIECEWISE TABLE BLOCK (PW)........................................................................................................3

9.2.1 Piecewise Table Block Operation...................................................................................................5

9.2.2 Piecewise Table Block Parameters................................................................................................7

9.2.3 Typical Block Connections for Piecewise Table Block ...................................................................8

SECTION 10 - SEQUENCE BLOCK DATABASE PARAMETERS

10.1 GENERAL..............................................................................................................................................1

10.2 BLOCK DESCRIPTION.........................................................................................................................1

10.3 SEQUENCE BLOCK OPERATION.......................................................................................................2

10.3.1 Input Processing.............................................................................................................................4

10.3.2 Transition Expression Evaluation...................................................................................................4

10.3.3 Step Determination.........................................................................................................................4

10.3.4 Output Management.......................................................................................................................6

10.3.5 Quality Checking ............................................................................................................................6

10.4 BLOCK PARAMETERS.........................................................................................................................6

10.4.1 Input Definitions..............................................................................................................................8

10.4.2 Output Definitions...........................................................................................................................9

10.4.3 Step Definitions ............................................................................................................................10

10.4.4 Transition Expressions.................................................................................................................12

10.4.5 Attribute Descriptions ...................................................................................................................13

10.5 BLOCK EVENTS.................................................................................................................................25

SECTION 11 - CONFIGURING THE SEQUENCE BLOCK

11.1 GENERAL..............................................................................................................................................1

11.2 APPLICATION EXAMPLE.....................................................................................................................1

11.2.1 Sequence Description ....................................................................................................................2

11.2.2 Configuration Procedure.................................................................................................................3

FUNCTIONS DATABASE PARAMETERS

ii

Page 7

Logic Functions - Book 2

CONTENTS

ILLUSTRATIONS

Figure Page

8-1. Functional Block Diagram, Expression Block.............................................................................................. 3

8-2. Expression (EX), General Menu..................................................................................................................4

8-3. Expression (EX), Expression Editing Display.............................................................................................. 4

8-4. Expression (EX), Inputs Definition Display..................................................................................................5

8-5. Expression (EX), Diagnostics Menu............................................................................................................ 5

8-6. Typical Block Connections for Expression Block.......................................................................................14

8-7. Functional Block Diagram, Input Communication Block............................................................................17

8-8. Input Communication Block (IC), General Menu....................................................................................... 18

8-9. Input Communication Block (IC), Data Source Menu................................................................................18

8-10. Input Communication Block (IC), Diagnostics Menu ...............................................................................19

8-11. Typical Block Connections for Input Communication Block..................................................................... 24

8-12. Functional Block Diagram, Output Communication Block....................................................................... 25

8-13. Output Communication Block (OC), General Menu ................................................................................ 26

8-14. Output Communication Block (OC), Data Destination Menu...................................................................26

8-15. Typical Block Connections for Output Communication Block..................................................................29

8-16. Functional Block Diagram, Linearization Block........................................................................................ 31

8-17. Linearization (LN), General Menu ........................................................................................................... 32

8-18. Modified Square Linearization Curve ...................................................................................................... 34

8-19. Modified Square Root Linearization Curve..............................................................................................35

8-20. Typical Softwiring Block Structures for Linearization Block..................................................................... 41

8-21. Softwiring Drawing for Linearization Block, Example .............................................................................. 42

8-22. Functional Block Diagram, Process Alarm Block..................................................................................... 43

8-23. Process Alarm Block (PA), General Menu ..............................................................................................44

8-24. Example of Process Alarm Tripping (Floating Point Data) ......................................................................45

8-25. Typical Softwiring Block Structures for Process Alarm Block..................................................................50

8-26. Example Softwiring Drawings for Process Alarm Blocks.........................................................................51

8-27. Functional Block Diagram, Timer Block................................................................................................... 53

8-28. Timer Block (TM), General Menu............................................................................................................54

8-29. Timing Diagram, Up Timer with WRAP = TRUE .....................................................................................55

8-30. Timing Diagram, Down Timer with WRAP = FALSE............................................................................... 56

8-31. Typical Softwiring Block Structures for Timer Block................................................................................60

8-32. Softwiring Drawing for Timer Block, Example 1 ...................................................................................... 61

8-33. Softwiring Drawing for Timer Block, Example 2 ...................................................................................... 61

8-34. Softwiring Drawing for Timer Block, Example 3 ...................................................................................... 62

8-35. Softwiring Drawing for Timer Block, Example 4 ...................................................................................... 62

8-36. Functional Block Diagram, Notification/Request Message Block............................................................64

8-37. Notification/Request Message Block (NM), General Menu ..................................................................... 65

8-38. Notification/Request Message Block (NM), Diagnostics Menu................................................................65

8-39. Typical Block Connections for Notification/Request Message Block.......................................................71

8-40. Example 1: Block Used for Notification Only...........................................................................................72

8-41. Example 2: Block Used for Notification/Request of Discrete Data ..........................................................73

8-42. Functional Block Diagram, Supervisory Message Block ......................................................................... 76

8-43. Supervisory Message (SM), General Menu ............................................................................................. 77

8-44. Supervisory Message (SM), Message Configuration Menu .....................................................................77

8-45. Typical Block Connections for Supervisory Message Block....................................................................86

8-46. Example 1: LSP Triggered Write Message .............................................................................................87

8-47. Example 2: Operator Triggered Read Message......................................................................................88

8-48. Functional Block Diagram, Totalizer........................................................................................................89

8-49. Totalizer Block (TOT), General Menu...................................................................................................... 90

8-50. Totalizer Block (TOT), Control Inputs Menu............................................................................................ 90

8-51. Totalizer Block (TOT), Initialization / Restart Menu................................................................................. 91

iii

Page 8

Logic Functions - Book 2

CONTENTS

ILLUSTRATIONS

Figure Page

8-52. Totalizer Block Timing Diagram, DIRECTION = UP, AUTO WRAP = NO...............................................92

8-53. Totalizer Block Timing Diagram, DIRECTION = UP, AUTO WRAP = YES.............................................94

8-54. Totalizer Block Timing Diagram, DIRECTION = DOWN, AUTO WRAP = NO ........................................95

8-55. Totalizer Block Timing Diagram, DIRECTION = DOWN, AUTO WRAP = YES.......................................96

8-56. Typical Block Connections for Totalizer Block ........................................................................................103

9-1. Functional Block Diagram, Piecewise Table Block ......................................................................................3

9-2. Piecewise Table Block (PW), Table Configuration Menu.............................................................................4

9-3. Piecewise and Inverse Piecewise Linearization...........................................................................................6

9-4. Typical Block Connections for Piecewise Table Block.................................................................................8

10-1. Functional Block Diagram, Sequence Block ..............................................................................................3

10-2. Step Determination Logic Diagram............................................................................................................5

10-3. Sequence Block, General Menu ................................................................................................................6

10-4. Sequence Block, Additional Attributes Menu .............................................................................................7

10-4. Sequence Block, Diagnostics Menu...........................................................................................................7

10-5. Sequence Block, Inputs Definition Menu ...................................................................................................8

10-6. Sequence Block, Outputs Definition Menu.................................................................................................9

10-7. Sequence Block Step Display..................................................................................................................11

10-8. Sequence Block Step Definition Menu.....................................................................................................11

11-1. Piping and Instrument Diagram for the Application Example.....................................................................1

11-2. Sequence Flow Chart ................................................................................................................................2

TABLES

Table Page

8-1. Expression Block Attributes, Valid Values, Mnemonics, and Data Types...................................................8

8-2. Input Communication Block Attributes, Valid Values, Mnemonics, and Data Types..................................21

8-3. Output Communication Block Attributes, Valid Values, Mnemonics, and Data Types...............................27

8-4. Linearizer Block Variable Fields, Mnemonics, Byte Counts, and Data Types............................................37

8-5. Process Alarm Block Attributes, Valid Values, Mnemonics, and Data Types............................................46

8-6. Timer Block Attributes, Valid Values, Mnemonics, and Data Types ..........................................................57

8-7. Notification/Request Message Block Attributes, Valid Values, Mnemonics, and Data Types....................66

8-8. Supervisory Message Block Attributes, Valid Values, Mnemonics, and Data Types..................................78

8-9. Totalizer Block Attributes, Valid Values, Mnemonics, and Data Types.......................................................97

9-1. Piecewise Table Block Attributes, Valid Values, Mnemonics, and Data Types ...........................................7

10-1. Sequence Block Attributes, Valid Values, Mnemonics, and Data Types ..................................................13

11-1. Starting the Configuration ..........................................................................................................................3

11-2. Loop Compound and Sequence Block Placement Procedure...................................................................4

11-3. Input Definition Procedure..........................................................................................................................5

11-4. Output Definition Procedure.......................................................................................................................6

11-5. Output Requirements for Each Step..........................................................................................................7

11-6. Step, Output and Transition Logic Definition Procedure............................................................................8

11-7. I/O Module Definition Procedure................................................................................................................9

11-8. I/O Module Connection Procedure............................................................................................................10

11-9. Database Compilation Procedure.............................................................................................................11

iv

Page 9

ALGORITHM FUNCTIONS DATABASE PARAMETERS

8.1 ALGORITHM BLOCKS

Function blocks (algorithm blocks that execute the logic) cannot operate independently in the

instrument database. Groups of related function blocks must be organized into loops.

Algorithm blocks are placed in a loop compound. The algorithm block types are:

EX Expression Block. Reference IB-23G602 Section 8.2. This block

IC Input Communications Block. Reference IB-23G602 Section 8.3.

Logic Functions - Book 2

ALGORITHM BLOCK

SECTION 8

evaluates a user specified expression each time it executes. The

result is discrete or floating point depending on the final operation.

An auxiliary result can be used to convert to other data types.

This block receives data from an Output Communications Block in

another instrument.

OC Output Communications Block. Reference IB-23G602 Section 8.4.

This block transmits data to an Input Communications Block in

another instrument.

LN Linearization Block. Reference IB-23G602 Section 8.5. This block

produces a linearized value of a floating point input.

PA Process Alarm Block. Reference IB-23G602 Section 8.6. This block

produces a discrete signal to advise of an irregular process condition.

TM Timer Block. Reference IB-23G602 Section 8.7. This block is used

to perform timing functions such as delayed start/stop or periodic

reset.

NM Notification Message Block. Reference IB-23G602 Section 8.8. This

block sends a message over the ICN and can request a response.

8-1

Page 10

Logic Functions - Book 2

ALGORITHM BLOCK

The actual number of function blocks in a database depends upon configuration memory and

the mix of block types.

SM Supervisory Message Block. Reference IB-23G602 Section 8.9.

This block reads, writes, sets, tunes or configures an attribute over

the ICN or internally. When SET is selected, all message destination

fields are disabled except for the Attribute field. To make a

connection with SET enabled, start from the target block and connect

to this blocks SETENTRY (signal flow is actually from this block to the

selected attribute). Like configured list connections, the target

attribute can be assigned an alias; however, it is not used with PC-30.

A connection to SETENTRY is ignored for all message types other

than SET.

TOT Totalizer Block. This block is used to count an analog input signal.

Features include: Threshold, Up, Down, Wrap, Scale Factor,

Predetermined Count 1 & 2 and Limit Status.

NOTE Normally, occurrence numbers are compiled in consecutive order (e.g.,

TM1, then TM2, then TM3 etc.). Forcing higher occurrence numbers out

of order uses up memory space.

8-2

Page 11

8.2 EXPRESSION BLOCK (EX)

The expression block evaluates a user-specified expression each time it executes. Logical,

arithmetic, and conditional operators can be mixed at will in the expression, with the final

result being scaled to a configured data type. An auxiliary output can provide the result scaled

to another data type. Expressions are entered by the user in algebraic format using ‘C’

symbology for operators and functions and assuming ‘C’ like operator precedence. An

expression can be as simple as a single operand (result data type must be configured in this

case) or as complex as can be fit on the configurator screen.

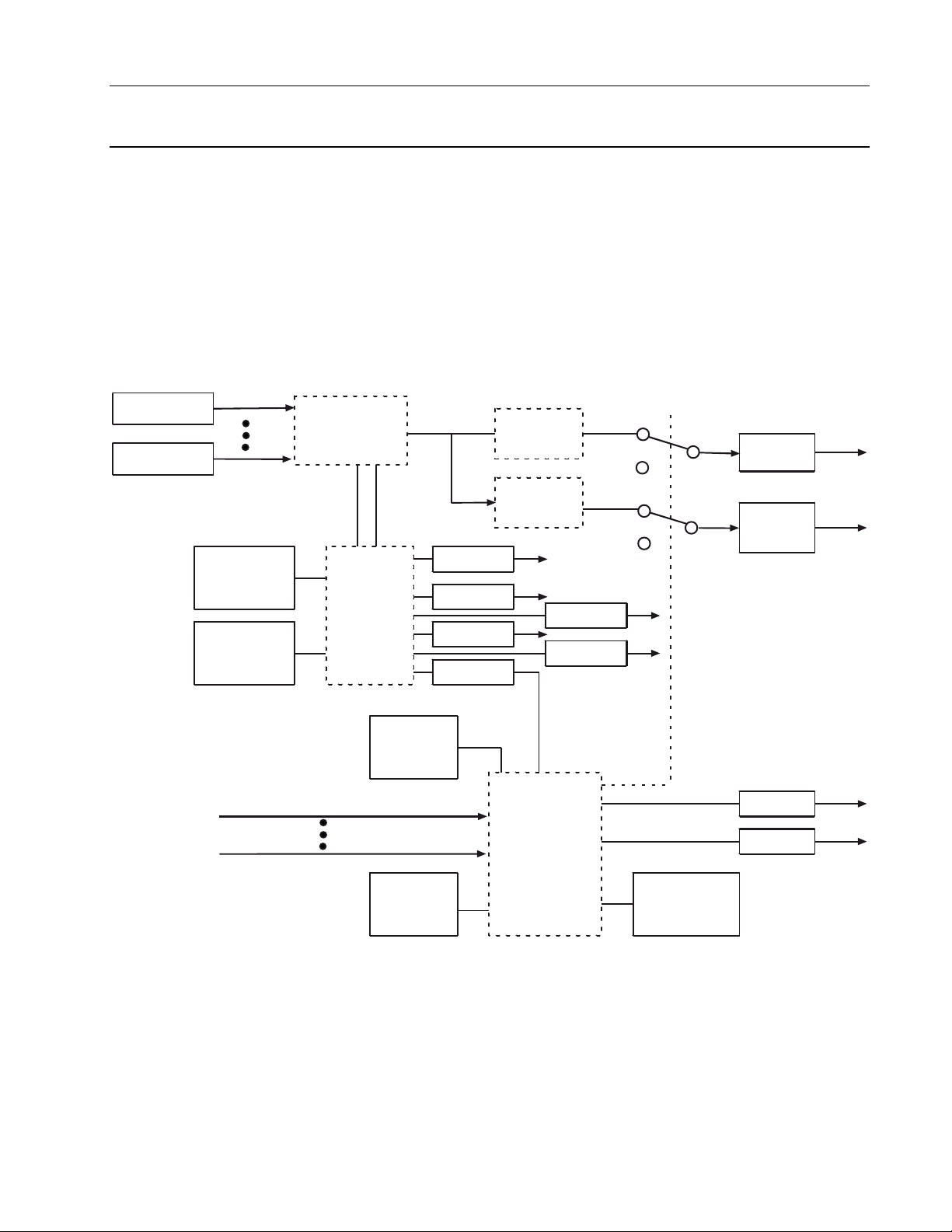

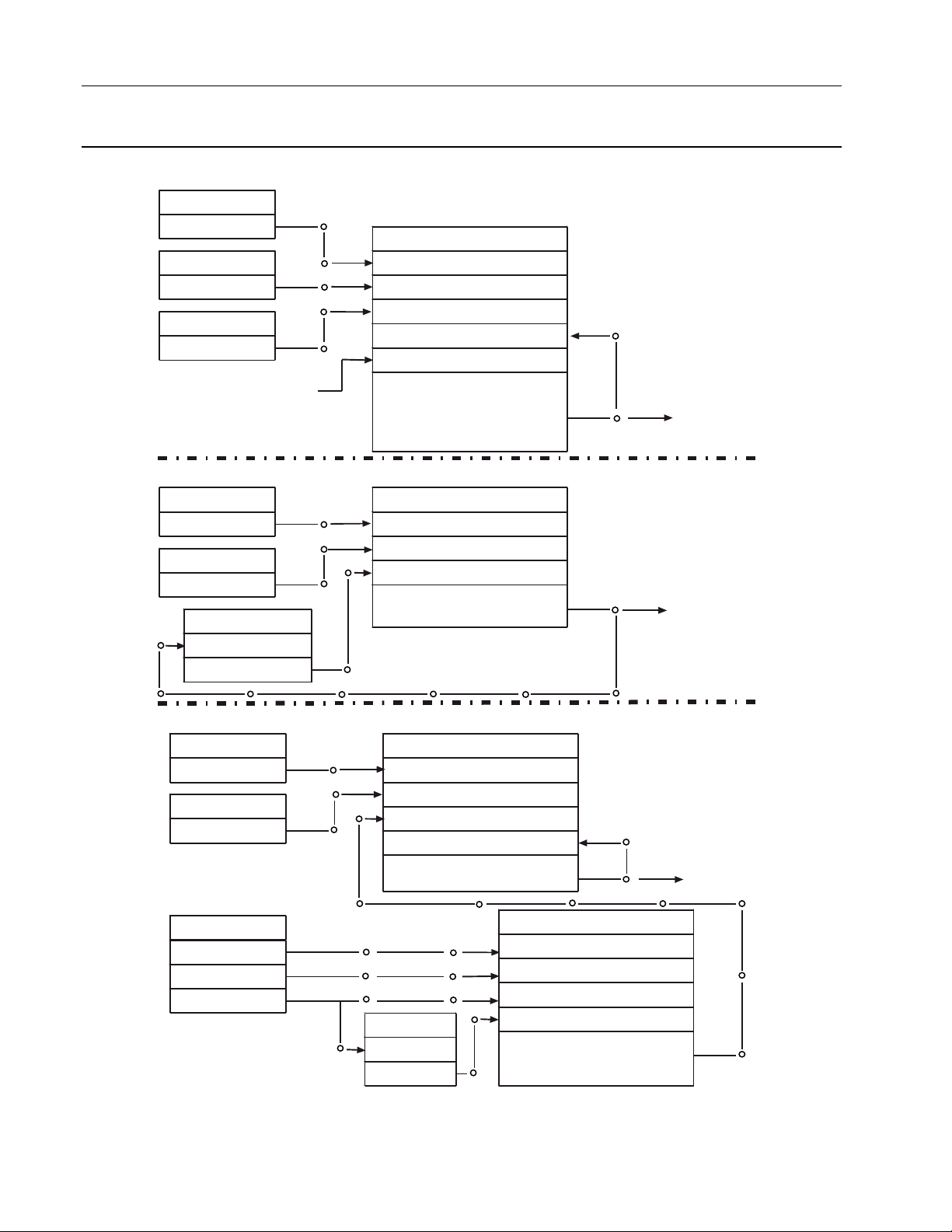

Block outputs are the result, auxiliary result, and their qualities. A functional block diagram of

an expression block is shown in Figure 8-1. The displays, which are used to configure the

Expression block, are shown in Figure 8-2 (page 1), Figure 8-3 (page 2) and Figure 8-4 (page

4).

Input No. 1

Expression

Evaluation

Input No. 46

Data Type

Conversion

Logic Functions - Book 2

EXPRESSION BLOCK

GOOD

Result

BAD

Calculation Error

Calculation Error

(ENABLE/

SUPPRESS)

Diagnostic

Group

(NONE, 1 - 7)

Syntax Error

Expression

Error

Bad Inputs

Accepted

(YES/NO)

Input (1) Status

Input (46) S tatus

State

(RUN, HOLD,

OFF, DEBUG)

CERRU

CERRUQ

CERRA

CERRAQ

Data Type

Conversion

ETYPE

EPOS

Quality Check

GOOD

BAD

Set Qual ity BAD

on Calculation

Auxili a ry

Result

RQ

AUXQ

Error?

(YES/NO)

Figure 8-1. Functional Block Diagram, Expression Block

8-3

Page 12

Logic Functions - Book 2

EXPRESSION BLOCK

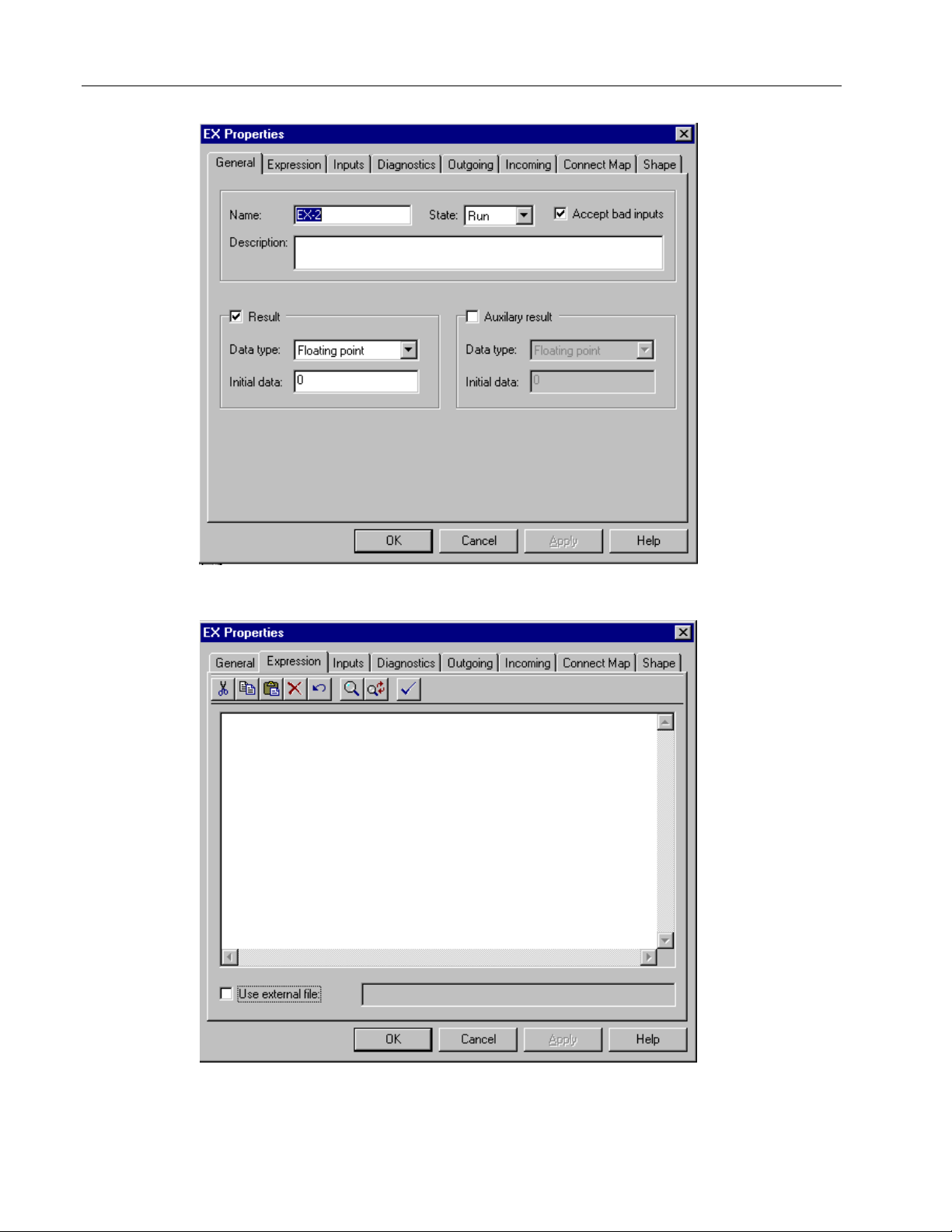

Figure 8-2. Expression (EX), General Menu

8-4

Figure 8-3. Expression (EX), Expression Editing Display

Page 13

Logic Functions - Book 2

EXPRESSION BLOCK

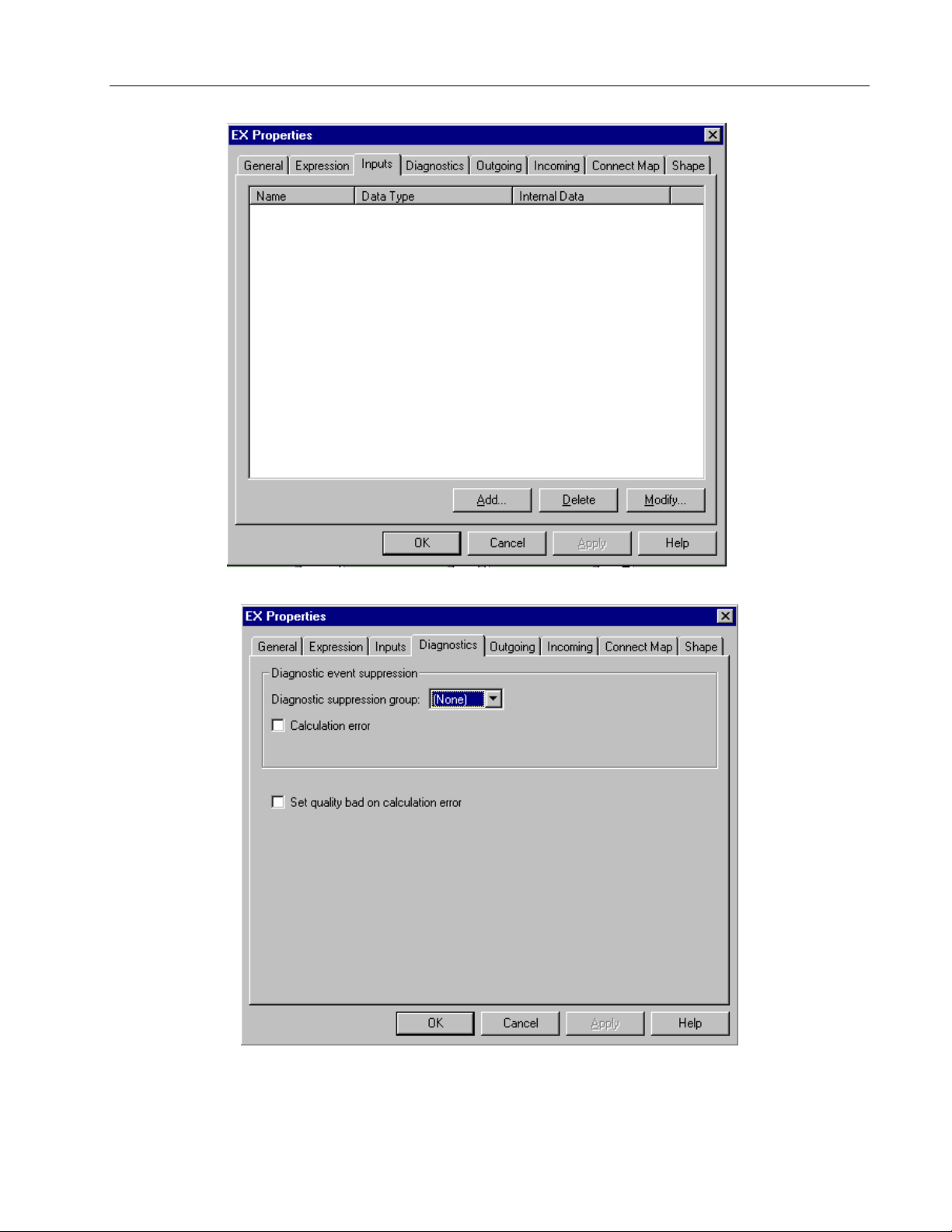

Figure 8-4. Expression (EX), Inputs Definition Display

Figure 8-5. Expression (EX), Diagnostics Menu

8-5

Page 14

8.2.1 Expression Block Operation

Operator precedence in an expression starts with the unary (single operand) operators and

continues with the binary (double operand) operators. The order of evaluation can be

changed using parentheses or the conditional operators. The order of precedence is:

1. ** (RAISED_TO_THE_POWER)

2. SQRT (SQUARE_ROOT),

MOM (MOMENTARY),

! (Logical NOT),

ABS (ABSOLUTE),

EXP (EXPONENTIAL),

NLOG (NATURAL_LOG),

LOG (LOG_10),

INT (INTEGER)

3. * (TIMES),

/ (DIVIDE),

4. + (PLUS),

– (MINUS)

NOTE: May be interpreted as a sign if immediately befor e mnemonic

(I1+I2). Use I1++I2 or I1+ I2 to be sure.

5. < (LESS_THAN),

> (GREATER_THAN),

<= (LESS_THAN_OR_EQUAL),

>= (GREATER_THAN_OR_EQUAL),

6. == (EQUALS),

!= (UNEQUAL)

7. && (Logical AND)

8. | | (Logical OR)

Logic Functions - Book 2

EXPRESSION BLOCK

8-6

Data Considerations During Evaluation

For Boolean operators, data of any type is considered TRUE if non-zero. For logical

operations, all operands are scaled to DISCRETE during evaluation.

For comparison or arithmetic operations, all operands are scaled to floating point during

evaluation. DATE operands are expanded to include the century and treated as 4 byte

unsigned integers. Prior to applying the operator(s), if the year is in the range 0–89, 100 is

added to make comparisons work properly across the calendar year 2000 (valid for 1990 to

2089). Thus 3/18/95 (stored internally as $5F0312) is treated as $005F0312, or decimal

6226706, while 7/25/2012, (stored internally as $0C0719) is treated as $00700719, or decimal

7341849. HEX and ASCII operands are not allowed.

Evaluation Results

The result of an expression evaluation is DISCRETE if the last operator processed was

logical, or FLOATING POINT if it was arithmetic. This result is then scaled to the configured

data types for the result and auxiliary result outputs of the expression block.

The MOMENTARY Operator

The MOMENTARY operator allows a user to embed an ‘edge detection’ in an expression.

The result of the MOMENTARY operation is TRUE only if its operand was FALSE in the most

recent evaluation and is now TRUE. Note that the MOMENTARY operator is distinct from the

MOMENTARY DISCRETE input data type.

The INTEGER Operator

Page 15

Logic Functions - Book 2

EXPRESSION BLOCK

The INTEGER operator removes the decimal portion of a number, leaving only the integer

portion. It does not round the number. For example, INT(12.678) = 12 and INT(_746.21) =

_746.

The Conditional Operators

The conditional operators (IF, THEN, and ELSE) let you specify when operations are

evaluated. The IF expression (between the IF and THEN conditionals) is evaluated first.

This expression may be enclosed in parentheses. When the calculated value of the IF

expression is TRUE (non-zero), the THEN expression is evaluated. When it is FALSE (zero),

the ELSE expression is evaluated. The ELSE expression is optional. When the IF

expression evaluates to FALSE and there is no ELSE, the result is not updated. Brackets ({})

should be used for nesting conditionals. If brackets are not present, an ELSE expression is

paired with the last unpaired IF. Notice how the brackets change the pairing of the IF and

ELSE expressions in the following example.

Using Expression Blocks as Recipes

Expression block inputs can be used as a recipe. Any number of local or remote

inputs to the block can be configured without using them in the expression, and for

this purpose only, HEX and ASCII inputs are allowed.

Syntax Errors

When there is a syntax error in the expression or a stack overflow during evaluation (can only

happen with a very deeply nested expression), the expression error diagnostic will be

reported, the results will not be updated and output qualities will be set bad.

Momentary Discrete Local Input

The value of a MOMENTARY DISCRETE local input is changed back to FALSE whenever a

TRUE is found so that it is detected in only one evaluation of an expression. The momentary

discrete feature allows a user to embed a ‘push-button’ in an expression. MOMENTARY

DISCRETE is a unique data type which can only be used as a local input to an expression

block. Another block pointed at this input will see a DISCRETE data type. Setting the local

data to HIGH or LOW configures a local input of this type.

8-7

Page 16

8.2.2 Expression Block Parameters

The mnemonics, valid values, and data types for all fields that may be selected for display

and/or be used in making softwiring connections are listed in Table 8-1. The following further

defines the expression block configuration parameters.

Block Type

EX This is the expression block type. The expression block type code is 15.

Occurrence

1 to 4096 There may be up to 4096 ‘instances’ allowed of the EX block type (subject to

configuration and database size limitations).

Expression

Algebraic expression written in terms of user names for inputs, values (use usual convention

for data types) for constants, ‘C’ symbology for operators and functions. The order of

evaluation of an expression is determined by operator precedence, and parentheses may be

used to change the order of evaluation. An entry is required (there is no default). See

Section 8.2.1 for a description of the expression evaluation operation and valid operators.

Logic Functions - Book 2

EXPRESSION BLOCK

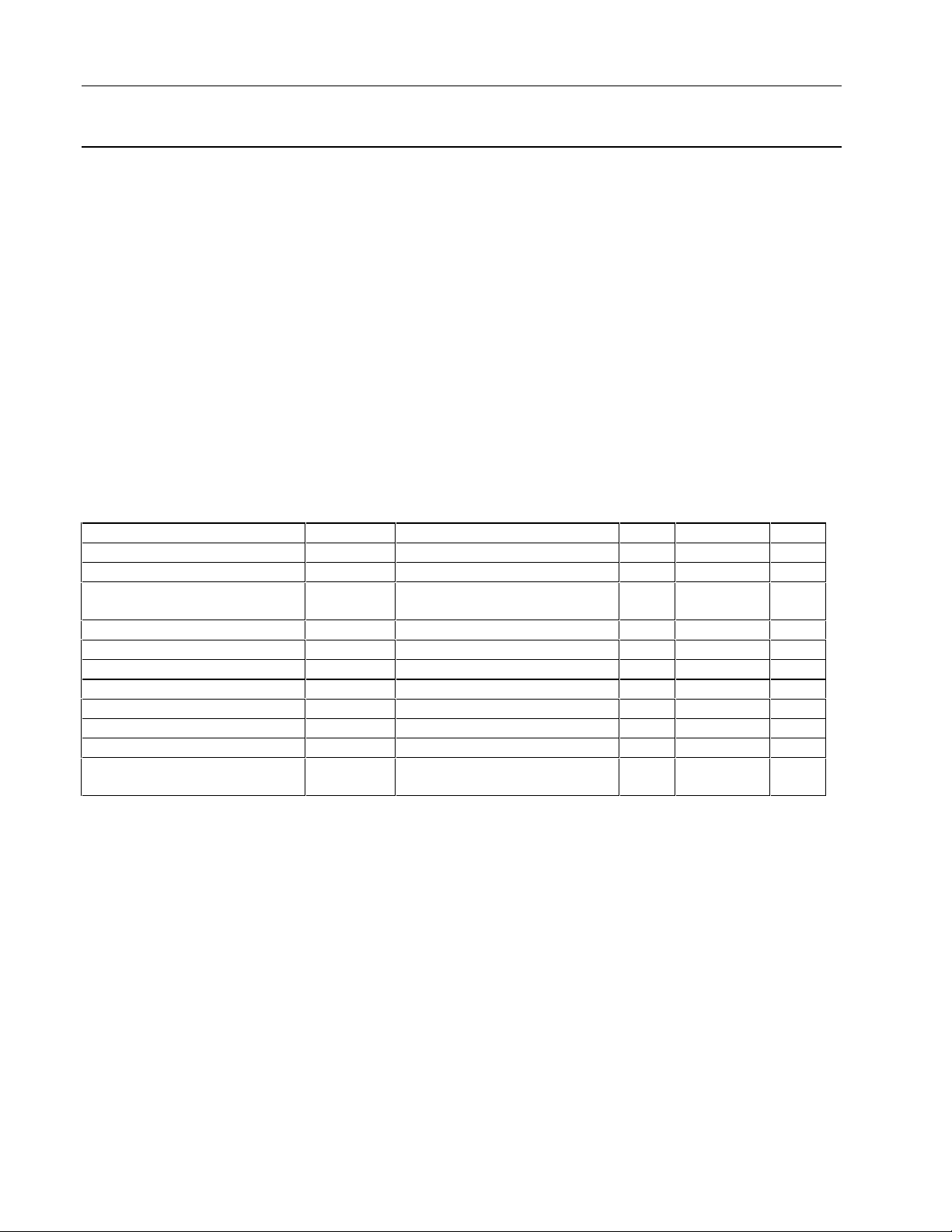

Table 8-1. Expression Block Attributes, Valid Values, Mnemonics, and Data Types

Field Name /

Version VERSION 1, 2, 3 – – R Long State 00

Block Length BLKLEN Number of bytes of database – – R Count 01

Block State

Bad Inputs

Diagnostic Group

Calculation error

Calc. Error Unacked CERRU NO (0), YES (1) – WR Discrete 06

Calc. Error Unacked Quality CERRUQ GOOD (0), BAD (1) – WR Discrete 07

Calc. Error Active CERRA NO (0), YES (1) – WR Discrete 08

Calc. Error Active Quality CERRAQ GOOD (0), BAD (1) – WR Discrete 09

Set quality bad on calculation

error?

Attribute

Mnemonic Valid Values CWR Data Type Attr

STATE RUN(0), HOLD(1), OFF(2),

DEBUG(3)

BADINP Rejected (0), Accepted (1) CWR Discrete 03

SUPPGRP NONE, 1, 2, 3, 4, 5, 6, 7 CWR Long State 04

CERRS ENABLE (0), SUPPRESS (1) CWR Discrete 05

SETQBAD NO (0), YES (1) CWR Discrete 10

CWR Short State 02

8-8

Page 17

Logic Functions - Book 2

EXPRESSION BLOCK

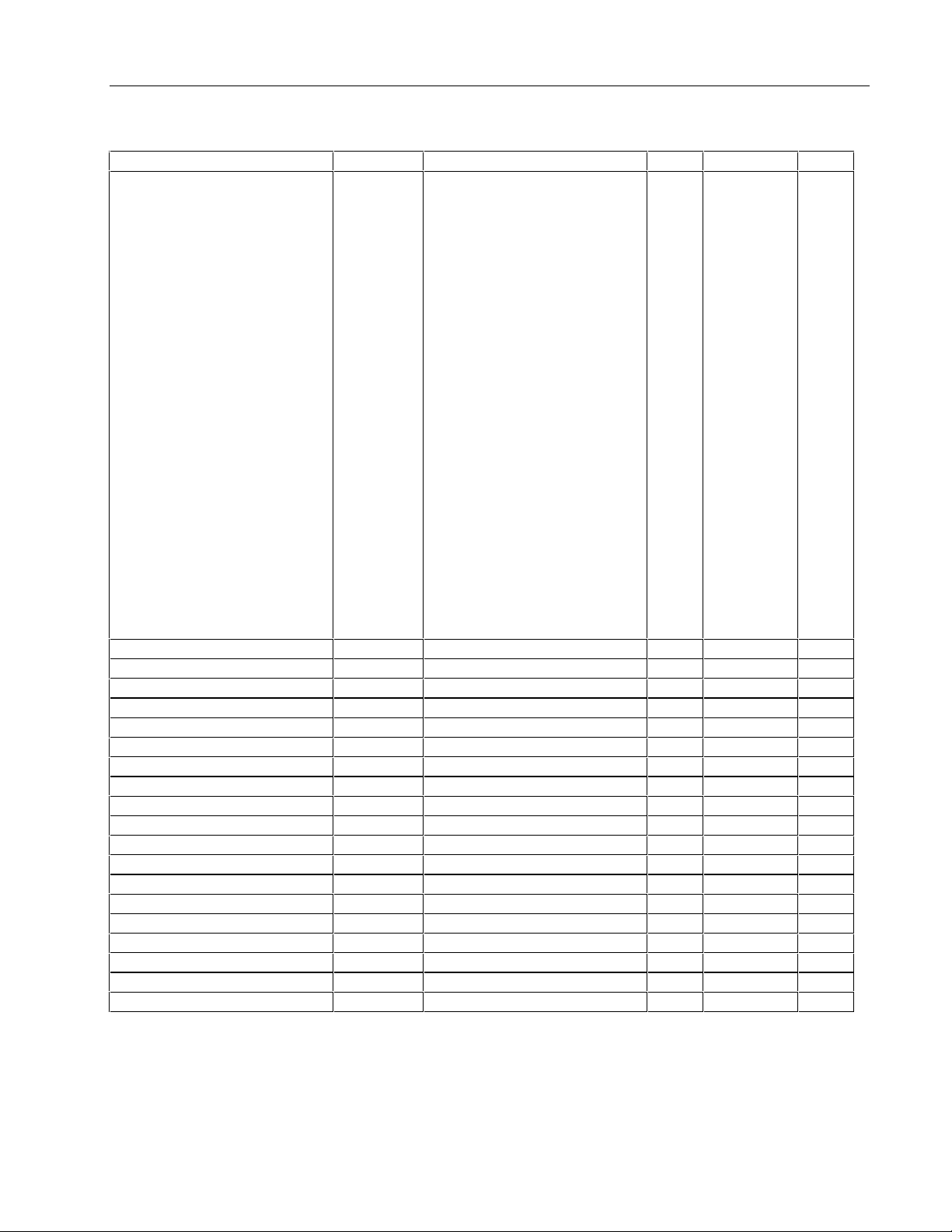

Table 8-1. Expression Block Attributes, Valid Values, Mnemonics, and Data Types (Cont’d)

Field Name /

Error Type ETYPE 0 No Error

Error Position EPOS – – R Count 12

Aux Result

Aux Result Quality AUXQ GOOD (0), BAD (1) – WR Discrete 47

Result

Result Quality

Input 1 I1 CWR 50

Input 2 I2 CWR 51

Input 3 I3 CWR 52

Input 4 I4 CWR 53

Input 5 I5 CWR 54

Input 6 I6 CWR 55

Input 7 I7 CWR 56

Input 8 I8 CWR 57

Input 9 I9 CWR 58

Input 10 I10 CWR 59

…… CWR…

Input 100 I100 CWR 149

…… CWR…

Input 800 I800 CWR 849

Attribute

Mnemonic Valid Values CWR Data Type Attr

– – R Long State 11

Calculation Errors

1 Calc Out of Range

2 SQRT of Negative Num

3 Result Overflow

4 Aux Result Overflow

5 NLog of Non-Pos Num

6 Log of Non-Pos Num

7 Zero Raised to Non-Pos

Num

8 Neg Raised to Noninteger

Syntax Errors

20 Estack Overflow

21 Input Not Found

22 Misaligned Operand

23 Unknown Operand

Type

24 Unknown Constant

Type

25 Misaligned Constant

26 Read from Empty Stack

27 Unknown Operator

AUX CWR 46

RCWR48

RQ GOOD (0), BAD (1) – WR Discrete 49

8-9

Page 18

Logic Functions - Book 2

EXPRESSION BLOCK

00

02 State (STATE) ....................................................................................................................CWR

03 Bad Inputs (BADINP).........................................................................................................CWR

Block Version

The expression block is at version 3. The functional changes are:

All block state changes are reported as events. See Section 2.4.1, State Changes for

additional information.

RUN 0 Normal Operation. Block is executed.

HOLD 1 Block is not executed. Qualities retain previous values.

OFF 2 Block is not executed. Qualities will be BAD.

DEBUG 3 Block is not executed. No fields are updated. All attributes are

See Section 2.3.2, Data Quality for additional information.

Rejected 0 Block checks data quality on its inputs and will only run its algorithm if

Accepted 1 Block runs its algorithm without a check on input quality and output

(VERSION)................................................................................................. – – R

1 Initial Release

2 Added operators for **, ABS, EXP, NLOG, LOG, INT, and the

conditional operators IF, THEN, and ELSE.

3 Added Inputs 21 through 46.

writeable.

its input is good (no action will be taken on the value). T he result will

be held at the previous value and the result quality will be set bad.

quality is set to good.

04 Diagnostic Group (SUPPGRP).........................................................................................CWR

The diagnostic error reported by this block can be grouped for System Event block control of

its reporting. The selections are:

NONE No group assigned.

1 to 7 Defines the diagnostic group number for the diagnostic suppression group

controlled by the System Event block.

05 Calculation Error (CERRS)...............................................................................................CWR

When a calculation error (calculation overflow, divide by zero, square root of negative number

etc.) is detected, the block completes the calculation using some reasonable value (+ or maximum value for overflows, zero for square root of negative number, etc.), reports the

diagnostic error as “CALCULATION ERROR”, and sets the output quality bad if “Set quality

bad on calculation error?” is YES. The diagnostic error will clear and the quality will be set

back to good when a subsequent execution of the block performs a successful calculation. A

calculation error is also reported when improper syntax is found in the expression or when a

stack overflow occurs due to too many nested operations.

ENABLED 0 Calculation error is enabled.

SUPPRESSED 1 Calculation error is suppressed.

06 Calc. Error Unacked (CERRU)..........................................................................................– WR

If the calculation error diagnostic is enabled, the unacknowledged status indicates if the

diagnostic is or is not acknowledged. Only writeable in DEBUG.

8-10

NO 0 Diagnostic error is acknowledged.

YES 1 Diagnostic error is unacknowledged.

Page 19

Logic Functions - Book 2

EXPRESSION BLOCK

07 Calc. Error Unacked Quality (CERRUQ)......................................................................... – WR

If the calculation error diagnostic is enabled, this status indicates if the quality of the

unacknowledged diagnostic is GOOD or BAD. Only writeable in DEBUG.

GOOD 0 Quality when the loop block is RUN or HOLD.

BAD 1 Quality when the loop block is OFF.

08 Calc. Error Active (CERRA) ............................................................................................. – WR

If the calculation error diagnostic is enabled, the active status indicates if the diagnostic is

active even after acknowledgement. Only writeable in DEBUG.

NO 0 Diagnostic error is not active.

YES 1 Diagnostic error is active.

09 Calc. Error Active Quality (CERRAQ)............................................................................. – WR

If the calculation error diagnostic is enabled, this status indicates if the quality of the active

diagnostic is GOOD or BAD. Only writeable in DEBUG.

GOOD 0 Quality when the loop block is RUN or HOLD.

BAD 1 Quality when the loop block is OFF.

10 Set quality bad on calculation error? (SETQBAD) .........................................................CWR

The result quality can be affected by a calculation error as follows. Note that result quality is

always set bad on a syntax error.

NO 0 Result quality is not affected by a calculation error.

YES 1 Quality is set BAD when a calculation error occurs.

11

Error Type

When an error occurs, a code indicating the type of error detected is stored in the block for

user reference. In the case of a configuration error, the location of the error is also stored

(EPOS).

NO ERROR 0

Calculation Errors:

CALC OUT OF RANGE 1 There was an overflow or underflow somewhere

SQRT OF NEGATIVE NUM 2 Calculation was completed using 0 for the square

RESULT OVERFLOW 3 Result is error free, but its value is too large to fit

(ETYPE) ...........................................................................................................– – R

in the calculation. Calculation was completed

using max or min value for that intermediate

result.

root.

the configured data type. The result is set to the

maximum or minimum value for the configured

data type.

AUX RESULT OVERFLOW 4 Same as result overflow.

NLOG OF NON POS NUM 5 Attempt to calculate the natural log of a number

less than or equal to zero. Calculation was

completed using 0 for the natural log

intermediate result.

8-11

Page 20

Logic Functions - Book 2

EXPRESSION BLOCK

LOG OF NON POS NUM 6 Same as NLog of non-positive number.

ZERO RAISED TO NON POS 7 Attempt to calculate zero to a non-positive

power.

NUM Calculation was completed using 0 for the inter-

mediate result.

NEG RAISED TO NON 8 Attempt to calculate a negative number to a

INTEGER non-integer power. Calculation was completed

using 0 for the intermediate result.

Syntax Errors:

ESTACK OVERFLOW 20 There was not sufficient evaluation stack to

complete the calculation.

INPUT NOT FOUND 21 One of the input operands was not found.

MISALIGNED OPERAND 22 Input operand token at odd address.

UNKNOWN OPERAND TYPE 23 Unknown data type found for input operand.

UNKNOWN CONSTANT TYPE 24 Unknown data type found for constant operand.

MISALIGNED CONSTANT 25 Multiple byte constant at odd address.

READ FROM EMPTY STACK 26 An operator was found with no operand(s)

remaining on the evaluation stack.

UNKNOWN OPERATOR 27 An unknown operator was found.

12

46 Aux Result (AUX)............................................................................................................... CWR

47 Aux Result Quality (AUXQ)..............................................................................................– WR

Error Position

This is the offset into the expression where the error was detected.

This is the block auxiliary result after the expression is evaluated. During startup, this is the

auxiliary result initial data value. The initial data value must match the auxiliary result data

type. If NONE is selected, no initial data is placed in the auxiliary result.

The auxiliary result can be enabled (box checked) or disabled (box not checked) by

configuration. When enabled, the auxiliary result and auxiliary result quality attributes are

made part of the database. When disabled, the auxiliary result and auxiliary result quality

attributes are removed from the database.

The auxiliary result can be any of the following data types: Floating Point, Count, Discrete,

Short State, Long State, Msec Time.

This data quality field will go BAD if any of the blocks quality checks become active.

(EPOS).......................................................................................................– – R

8-12

Page 21

Logic Functions - Book 2

EXPRESSION BLOCK

48 Result Initial Value (R).......................................................................................................CWR

This is the block result after the expression is evaluated. During startup, this is the result initial

data value. The initial data value must match the result data type. If NONE is selected, a zero

is placed in the result.

The result can be enabled (box checked) or disabled (box not checked) by configuration.

When enabled, the result and result quality attributes are made part of the database. When

disabled, the result and result quality attributes are removed from the database.

The result can be any of the following data types: Floating Point, Count, Discrete, Short State,

Long State, Msec Time. The selection of AUTO in the configurator allows the configurator to

determine if the result is either discrete or floating point (Expression Block Version 1 only).

The selection depends on the final operation performed in evaluating the expression. If you

upgrade your database from version 1, AUTO will change to Floating Point and a warning will

appear in the configurator.

49 Result Quality (RQ)...........................................................................................................– WR

This data quality field will go BAD if any of the blocks quality checks become active.

50 Input 1 (I1) ..........................................................................................................................CWR

through

95 Input 46 (I46) ......................................................................................................................CWR

The input values are writeable only if the data is local. The user name for an input is an eight

(8) character alphanumeric used to identify the input in the expression. The default names

are I1 through I46. Invalid characters are: operators, space, comma, period.

NONE Indicates an unused input. Inputs used in the expression cannot be

NONE.

LSP Any external variable, any data type.

Local Data Any local data, any data type. Local data can use a unique data type,

Momentary Discrete, as a local input to an expression block. Another

block pointed at this input will see a DISCRETE data type. Setting

the local data to HIGH or LOW configures a local input of this type.

HEX and ASCII inputs can be specified for recipe or data storage

applications, but cannot be referenced in the expression. See

Section 8.2.1, Expression Block Operation.

8-13

Page 22

8.2.3 Typical Block Connections for Expression Block

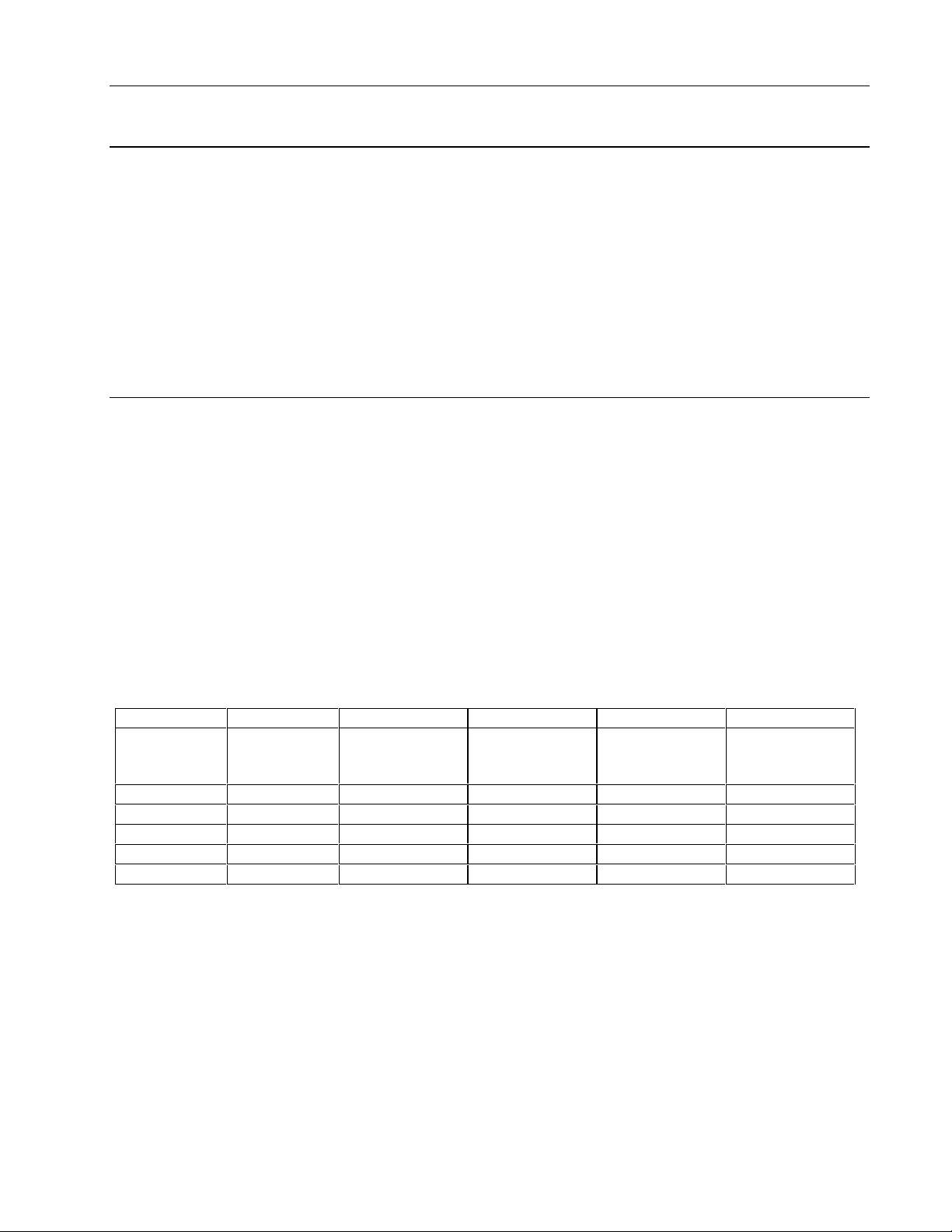

Typical softwiring block structures used on softwiring diagrams are shown in Figure 8-6.

Logic Functions - Book 2

EXPRESSION BLOCK

VCI1

Result

VCI2

Result

VCI3

Result

Logic to select value

(other expression block)

DI1

Result

DI2

Result

EX2 (BADINP=YES)

COUNT (Input_1)

COUNT

R

R

R

R

R

Input Selector Example

EX1

Input_1

Input_2

Input_3

Input_4

SELECT (Input_5)

(SELECT==1)*Input_1+

(SELECT==2)*Input_2+

(SELECT==3)*Input_3+

(SELECT>1

Input_4

R

SELECT>3) *

Counter Example

EX1 (BADINP=NO)

Input_1

RESET (Input_2)

COUNT (Input_3)

!RESET * (COUNT +

MOM(Input_1))

R

R

Selector Example Notes

This example selects

between three inputs b y

using another expression

block that produces a

select value . If none of the

three are selected, then

the previous input (input

4) is selected.

Selected Signal

Counter Example Notes

This example counts a

digital input with reset

provided by another digital

input. The seco nd

expression block is set up

to keep the first

expression from latching

quality BAD.

Count

8-14

VCI1

Result

DI2

Result

TM1*

High Limit Status

High Limit

Time

Tota lize r Example Notes

This example totalizes an

input (i.e. gpm) with reset

provided by a digital input.

The second expression

block is set up to keep the

first expression from

latching quality BAD.

R

R

R

HLSTAT

HILIM

TIME

Totalizer Example

EX1 (BADINP= N O)

GPM (Input 1)

RESET (Input 2)

MIN (Input 3)

TOTAL (Input 4)

!RESET * (TOTAL + GPM * MIN)

EX2 (BADINP= YES)

HLST AT (Input 1)

HILIM (Input 2)

TIME (Input 3)

EX3

TIME (Input 1)

TIME

LAST (Input 4)

(HLSTAT * (HILIM - LAST +

TIME) + !HLSTAT * (TIME LAST)) / 60000.0

Figure 8-6. Typical Block Connections for Expression Block

Totalized Value

R

Page 23

8.2.4 Expression Block Events

The event codes (and their suggested text messages) for the expression block are given

below. See the referenced database attributes (in brackets) for additional information. See

System Event Block, Logic Functions - Book 1, IB-23G600 for a description of event

transitions.

0 BLOCK STATE SET TO RUN

1 BLOCK STATE SET TO HOLD

2 BLOCK STATE SET TO OFF

3 BLOCK STATE SET TO DEBUG

4 CALCULATION ERROR (5)

8.2.5 Example 1: Using Expression Blocks to Store Trend Data

Expression blocks can be used for local data storage. You may want to do this for two

reasons: either to allow trend storage without tying up communication links to the host, or to

allow the MODCELL to accumulate data locally for later upload even if the communication line

(for example a modem) is disconnected for a period. For remote installations, another benefit

of trending using the expression block is portability. The data is stored in main memory, and

is therefore backed up onto the Memory Module. The trend data can therefore, be removed in

the Memory Module and taken elsewhere for analysis with a blank Memory Module left on the

MODCELL for another weeks or months data collection.

Logic Functions - Book 2

EXPRESSION BLOCK

For analog variables, data is typically stored as period averages for a configured number of

periods (trend cycles). The application engineer must pick the number of variables to be

stored and the number of instantaneous values to store for the "fastest" trend period and

finally, the application engineer needs to specify how many averages to store for the slower

time periods. This is best done in table form as shown below.

Setup for Storing Trend Data Using Expression Blocks

Variable Scan Rate

(seconds)

FC-101 5

FC-102 5

FC-103 5

TC-100 5

TC-101 5

Trend Cycle 1 Trend Cycle 2 Trend Cycle 3 Trend Cycle 4

(20)

Five Second

Samples

√

√

√√

√√√√

√√√√

(30)

One Minute

Averages

(24)

Fifteen Minute

Averages

(24)

One Hour

Averages

8-15

Page 24

Logic Functions - Book 2

EXPRESSION BLOCK

In this example, all variables are on the same scan rate. If the variables have different scan

rates, the historian loop can include some expression blocks to average or sample the faster

variables so all variables are trended at the same resolution and time base. Alternately, the

entire historian can be run at the fastest frequency. The number of samples in each trend

cycle in this example is kept less than 30 to fit conveniently on the LCP screen for display of a

trend. More or fewer averages can be included in a given trend cycle as required, and the

number and size of the trend cycles can be adjusted. Trends can be based on sample

averages, maximums or minimums, based on the expression block.

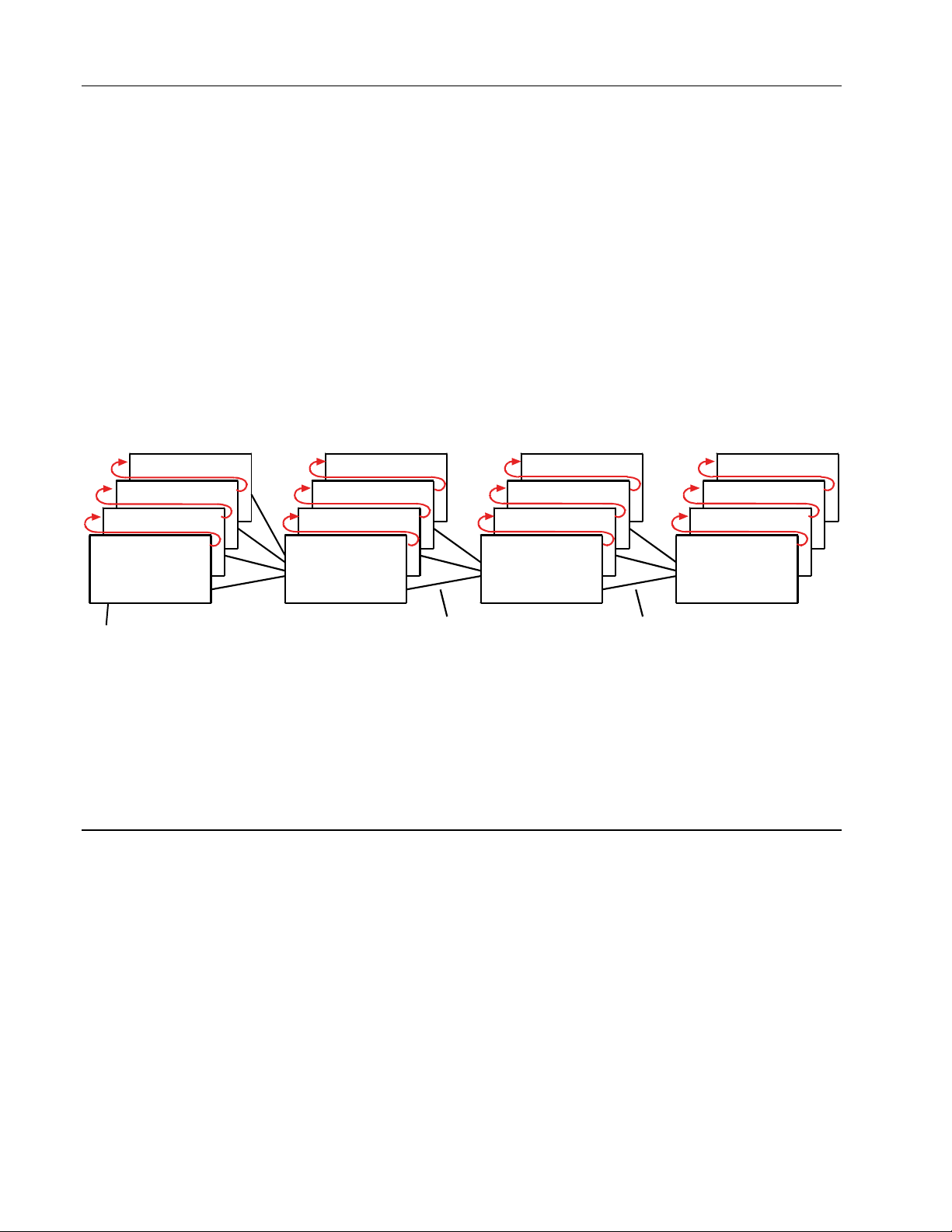

A typical Analog Historian/Trending Loop is shown below. The instantaneous value is passed

back in the "bucket Brigade" of Trend Cycle 1. The application engineer specifies how many

buckets to put in the brigade (note the execution order). The last block (that is the block

holding the oldest variable) is the first block in the loop to run.

AI

TREND CYCLE 1

Loop Execution

Every 5 sec.

EX-1

EX-18-2

EX-19

EX-20

Out=In

TREND CYCLE 2

Loop Execution

Every Minute

EX-1

EX-28-2

EX-29

EX-30

Out= Σ In/20

First

15 Blocks

Only

TREND CYCLE 3

Loop Execution

Every 15 Minutes

EX-1

EX-22-2

EX-23

EX-24

Out= Σ In/15

TREND CYCLE 4

Loop Execution

EX-22-2

EX-23

EX-24

Out= Σ In/4

First

4 Blocks

Only

Trend Cycle 2 is constructed the same way, except the first block (the one holding the most

current value) is an averaging block that takes the average of several blocks in the Trend

Cycle 1 "bucket brigade." This block can include logic to correct its output if one or more of

the input variables from the prior trend cycle contain "bad Quality" data flags. The process

repeats for Trend Cycle 3 and for as many trend cycles as are needed.

8.2.6 Example 2: Using IF-THEN-ELSE Statements in Expression Blocks

IF-THEN-ELSE statements make it much easier to write readable expressions for sequence

logic. For example, if you want an expression block to identify which of three tanks is the

lowest to determine which will be filled next, you could use the following formula in an

expression block:

Every Hour

EX-1

8-16

If (L1<L2) && (L1<L3) then 1 else

If (L2<L1) && (L2<L3) then 2 else

If (L3<L2) && (L3<L1) then 3

Page 25

8.3 INPUT COMMUNICATION BLOCK (IC)

The input communication block is used to receive data from the output communication block,

or output communication block channel for MOD 30 controllers and recorders, or another

instrument on the ICN via communication messages. The block specifies the source, data

type, and whether quality is to be received with the data. It also has the capability of receiving

other MOD 30 data types and storing the data as a MODCELL data type; for example,

continuous may be received and floating point stored. A mode switch is available so that the

data being received can be ignored, and allow an operator to manually change the data.

Finally, two diagnostics are provided. One diagnostic (source diagnostic) is provided to detect

a configuration error within either the block or within an Output Communication block in

another instrument. The other (timeout diagnostic) is provided to detect a break in the

communications that has halted the continual flow of data from the source.

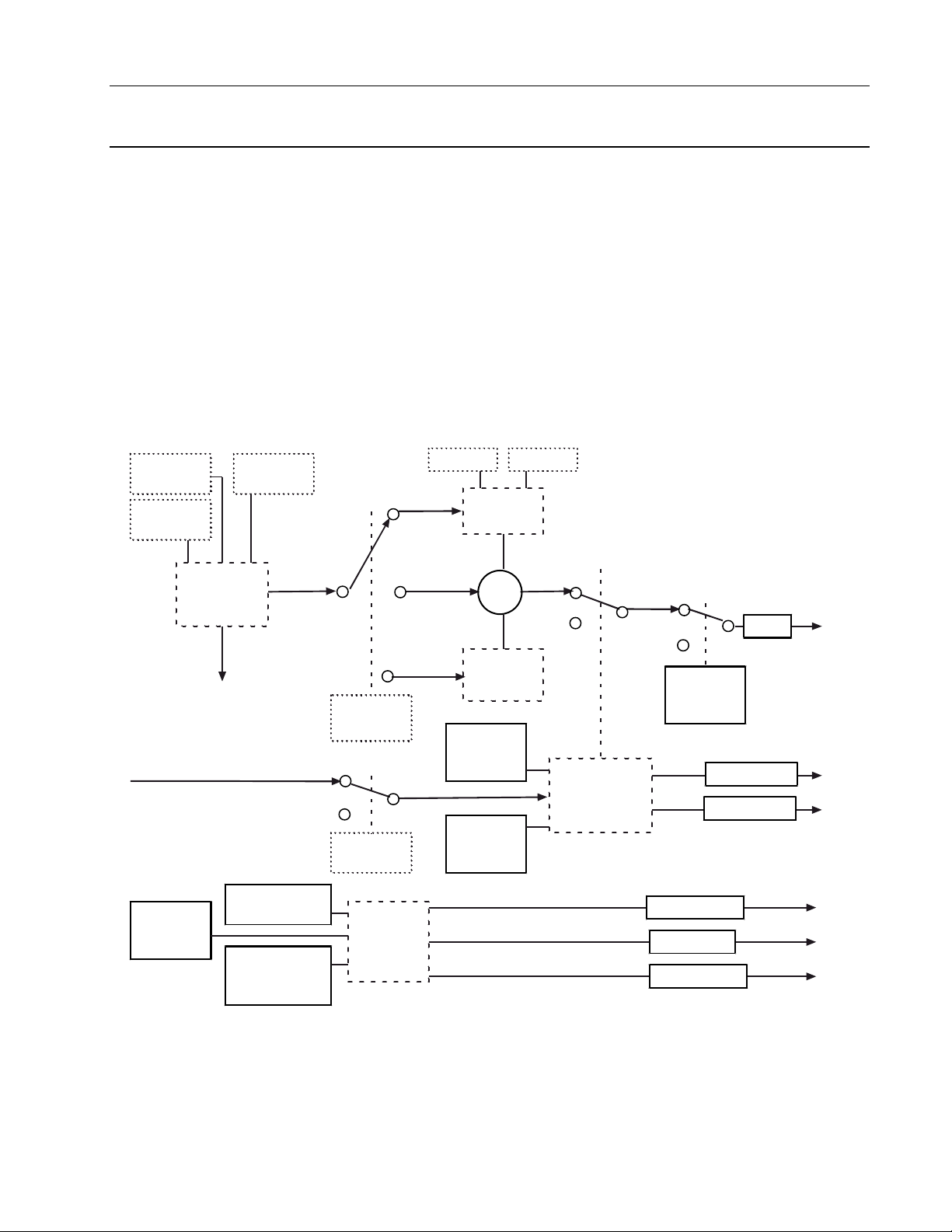

Block outputs are the data and data quality and diagnostic errors and error quality. A

functional block diagram of a input communication block is shown in Figure 8-7. Displays used

to configure the Input Communication block are shown in Figures 8-8 through Figure 8-10.

Logic Functions - Book 2

INPUT COMMUNICATION BLOCK

Instrument

Number

Port

Number

Input Data

Quality

Diagnostic

Group

(None, 1 - 7)

Occurrence

Data

Source

TO:

Diagnostic

Errors

Not Receivin g

Data (Enab/Supp)

Unexpected Data

(Enab/Supp)

Number

Receiving

YES

NO

Data

Type

Receive

Quality

Diagnostic

Errors

Top Bottom

Continuous

All others

ASCII or

HEX

Range

OR

Maximum

Field Size

(1-126)

Bad Inputs

Accepted

(YES)

State (RUN,

HOLD, OFF,

DEBUG)

GOOD

BAD

Quality Check

AUTO

Result

MANUAL

Mode

Result Qual ity

Error Quality

Error Count

Active Errors

Unacked Errors

Figure 8-7. Functional Block Diagram, Input Communication Block

8-17

Page 26

Logic Functions - Book 2

INPUT COMMUNICATION BLOCK

Figure 8-8. Input Communication Block (IC), General Menu

8-18

Figure 8-9. Input Communication Block (IC), Data Source Menu

Page 27

Logic Functions - Book 2

INPUT COMMUNICATION BLOCK

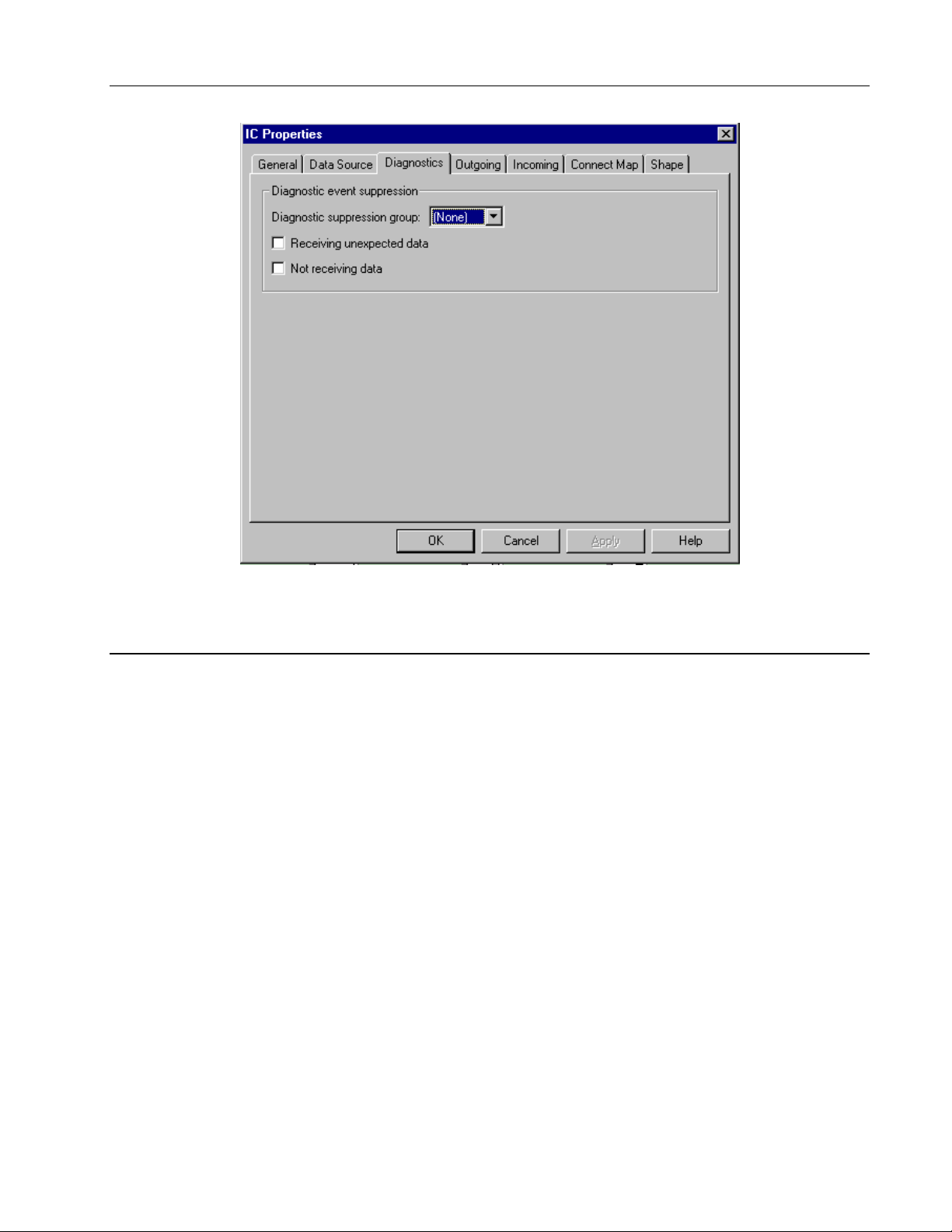

Figure 8-10. Input Communication Block (IC), Diagnostics Menu

8.3.1 Input Communication Block Operation

The Input Communication block is a loop function block that checks the ICN receive buffer to

determine if new information has been received, and also whether any source or time-out

diagnostic errors have been detected. If no new data has been received for 2 seconds, then

the timeout diagnostic is detected. When in auto and this diagnostic is detected, the result

quality is set bad. The current status of both diagnostics is passed to the System Event block

for processing. If new data has been received and the mode is auto, then the result field is

updated. If quality is being received with the data, then the result quality field is updated with

that value. If only the data is being received, the quality is set good.

On a warm or cold start, if the block mode is auto and the block/loop state is not debug, data

quality is set to bad and the receive buffer is cleared. Additionally, on a cold start, the status

of diagnostics are cleared and their qualities set BAD.

8-19

Page 28

Logic Functions - Book 2

INPUT COMMUNICATION BLOCK

8.3.2 Input Communication Block Parameters

The mnemonics, valid values, and data types for all fields that may be selected for display

and/or be used in making softwiring connections are listed in Table 8-2. The following further

defines the input communication block configuration parameters.

Block Type

IC This is the input communication block type.

Occurrence

1 to 32 There may be up to 32 ‘instances’ allowed of the IC block type.

Data Source....................................................................................................................... C – –

The data source information is configured in this block and is used to define the

source of the incoming data.

Instrument Number Instrument Numbers are: 0 to 15. This number represents the

ICN address of the instrument sending the data.

Port Number Port Numbers are: 1 to 3. This number represents which ICN

block should receive the data.

Occurrence Number Occur rence Numbers are: 1 to 16 for MOD 30 XL and Recorder

or 1 to 32 for MOD 30 SLU and MODCELL instruments. This

number represents the output communication point in the

instrument sending the data.

Receive Quality? NO - Data quality is not sent and not expected from MOD 30

instruments

YES - Data quality is sent and is with the data expected from

MODCELL instruments.

Data Type Format of the data to be received may be: CONTINUOUS,

DISCRETE, SHORT STATE, DATE, TIME, CTRL MODE,

LONG STATE, FLOAT PT, ASCII, or MSEC TIME, HEX,

COUNT.

Range Range applies to continuous data only. Enter range in floating

point. The range is applied to the continuous data before it is

stored.

Bottom Indicates the 0% value(low). Default is 0.00000.

8-20

Top Indicates the 100% value (high). Default is

100.00000

Maximum Field Size Indicates the maximum number of bytes or characters the data

field can take. Valid values are 1 to 126. This parameter

applies only when receiving hex bytes or ASCII characters.

Page 29

Logic Functions - Book 2

INPUT COMMUNICATION BLOCK

02

State

(STATE).....................................................................................................................CWR

All block state changes are reported as informational events. See Section 2.4.1,

State Changes for additional information.

RUN 0 Normal Operation. Block is executed.

HOLD 1 Block is not executed. Qualities retain previous values.

OFF 2 Block is not executed. Qualities will be BAD.

DEBUG 3 Block is not executed. No fields are updated. All attributes are

writeable.

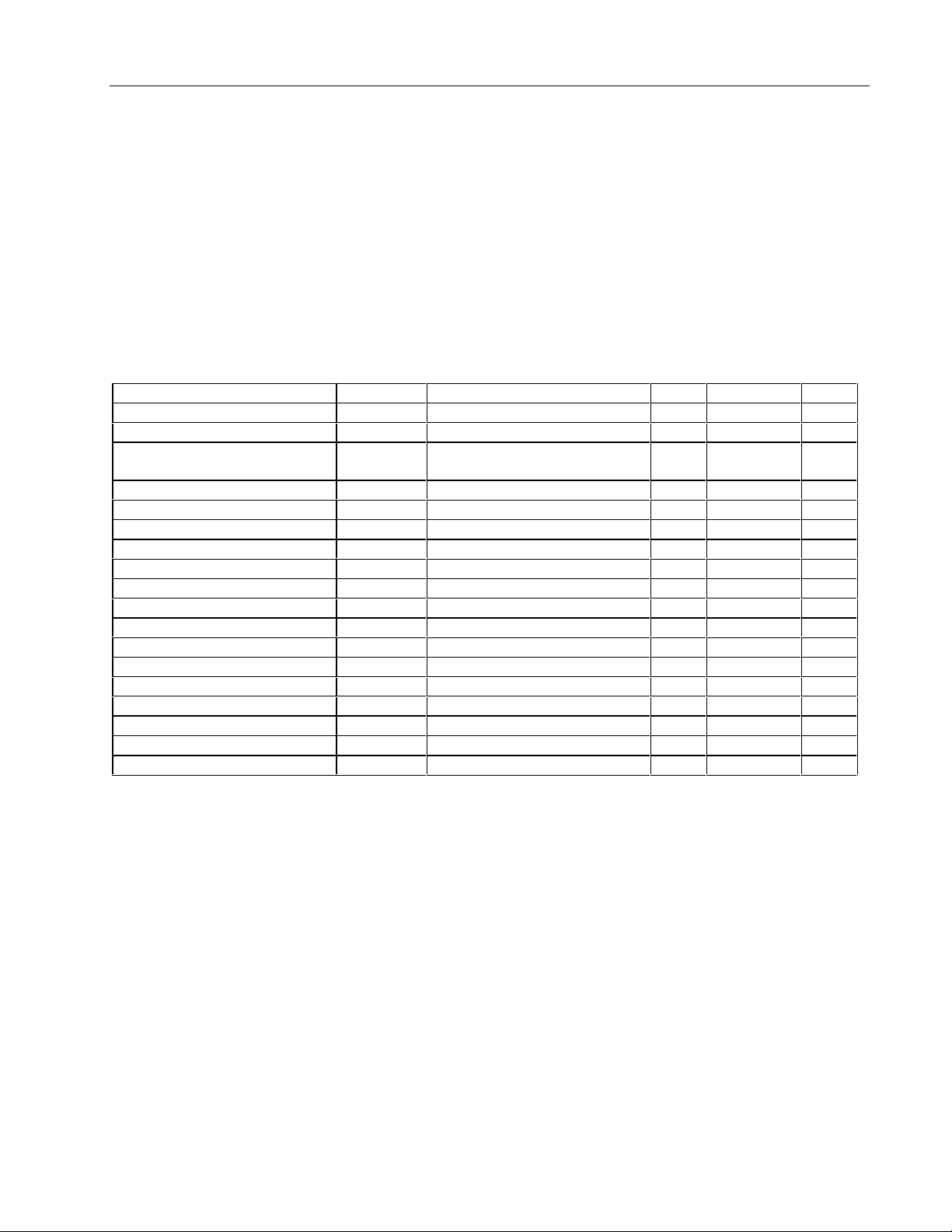

Table 8-2. Input Communication Block Attributes, Valid Values, Mnemonics, and Data Types

Field Name /

Version VERSION 1 – – R Long State 00

Block Length BLKLEN – – R Count 01

Block State

Bad Inputs Accepted

Diagnostic Group

Receiving unexpected data

Unacked Source Diag SRCUNACK FALSE, TRUE – WR Discrete 06

Unacked Source Diag Quality SRCUNQ GOOD (0), BAD – WR Discrete 07

Not receiving data

Unacked Timeout Diag TOUNACK FALSE, TRUE – WR Discrete 09

Unacked Timeout Diag Qual TOUNACKQGOOD (0), BAD – WR Discrete 10

Timeout Diag Active TOACT CLEAR (0), ACTIVE (1) – WR Discrete 11

Timeout Diag Active Quality TOACTQ GOOD (0), BAD – WR Di screte 12

Source Diag Counter SRCCNT 0-65535 – WR Count 13

Source Diag Counter Quality SRCCNTQ GOOD (0), BAD – WR Discrete 14

Data Update Mode

Initial Data (Result)

Result Quality

Attribute

Mnemonic Valid Values CWR Data Type Attr

STATE RUN(0), HOLD(1), OFF(2),

DEBUG(3)

BADINP Accepted (1) – – R Discrete 03

SUPPGRP NONE, or 1 to 7 CWR Long State 04

SRCSUPP ENABLE, SUPPRESS CWR Discrete 05

TOSUPP ENABLE, SUPPRESS CWR Discrete 08

MODE MANUAL, AUTO CWR Discrete 15

R CWR any 16

RQ GOOD (0), BAD – WR Discrete 17

CWR Short State 02

03

04

Bad Inputs

This block runs with bad inputs accepted. There is no check on input quality. Result quality

depends on how receive quality was configured. See result quality attribute for possible

conditions. See Section 2.3.2, Data Quality for additional information.

Diagnostic Group

The diagnostic errors reported by this block can be grouped for System Event block control of

their reporting. The selections are:

NONE No group assigned.

1 to 7 The number of the diagnostic suppression group as controlled by the System

(BADINP).........................................................................................................– – R

(SUPPGRP) .........................................................................................CWR

Event block.

8-21

Page 30

Logic Functions - Book 2

INPUT COMMUNICATION BLOCK

05

06

07

Receiving unexpected data

Indicates whether the source diagnostic error is enabled or suppressed. This diagnostic is

provided to detect a configuration error (source or data type incorr ect) within either this block

or within an Output Communication block in another instrument.

ENABLE 0 The receiving unexpected data (source) diagnostic error is enabled.

SUPPRESS 1 The receiving unexpected data (source) diagnostic error is

Unacked Source Diagnostic

If the receiving unexpected data diagnostic is enabled, the unacknowledged status indicates if

the diagnostic error is or is not acknowledged.

NO 0 Diagnostic error is acknowledged.

YES 1 Diagnostic error is unacknowledged.

Unacked Source Diagnostic Quality

If the receiving unexpected data diagnostic is enabled, this status indicates if the quality of the

unacknowledged diagnostic is GOOD or BAD. Only writeable in DEBUG.

GOOD 0 Quality when the block (or its controlling loop) is RUN or HOLD.

BAD 1 Quality when the block (or its controlling loop) is OFF.

(SRCSUPP).........................................................................CWR

When this diagnostic is detected, the diagnostic message

RECEIVING UNEXPECTED MESSAGE is reported.

suppressed. Acknowledgement status remains clear.

(SRCUNACK).....................................................................– WR

(SRCUNQ)............................................................– WR

08

09

10

Not receiving data

Indicates whether the timed-out diagnostic error is enabled or suppressed. This diagnostic is

provided to detect a break in the communications that has halted the continual flow of data

from the source. If no new data has been received for 2 seconds, then the timeout diagnostic

is detected.

ENABLE 0 The timed-out diagnostic error is enabled. When this diagnostic is

SUPPRESS 1 The timed-out diagnostic error is suppressed. Acknowledgement

Unacked Timeout Diagnostic

If the not receiving data diagnostic is enabled, the unacknowledged status indicates if the

diagnostic error is or is not acknowledged.

NO 0 Diagnostic error is acknowledged.

YES 1 Diagnostic error is unacknowledged.

Unacked Timeout Diagnostic Quality

If the not receiving data diagnostic is enabled, this status indicates if the quality of the

unacknowledged diagnostic is GOOD or BAD. Only writeable in DEBUG.

GOOD 0 Quality when the block (or its controlling loop) is RUN or HOLD.

BAD 1 Quality when the block (or its controlling loop) is OFF.

(TOSUPP)........................................................................................... CWR

detected, the result quality is set BAD and the diagnostic message

NOT RECEIVING DATA is reported.

status remains clear.

(TOUNACK)......................................................................– WR

(TOUNACKQ) .....................................................– WR

8-22

Page 31

Logic Functions - Book 2

INPUT COMMUNICATION BLOCK

11

12

13

14

15

Timeout Diagnostic Active

If the not receiving data diagnostic is enabled, the active status indicates if the diagnostic error

is active even after acknowledgement.

CLEAR 0 Diagnostic error is not active.

ACTIVE 1 Diagnostic error is active.

Timeout Diagnostic Active Quality

If the not receiving data diagnostic is enabled, this status indicates if the quality of the active

diagnostic is GOOD or BAD. Only writeable in DEBUG.

GOOD 0 Quality when the block (or its controlling loop) is RUN or HOLD.

BAD 1 Quality when the block (or its controlling loop) is OFF.

Source Diagnostic Counter

0-65535. This is a free running count of the source diagnostic errors detected.

Source Diagnostic Counter Quality

BAD, GOOD. Indicates the quality of the source diagnostic error counter. Quality is set to

BAD when the block (or its controlling loop) is OFF.

Data Update Mode

Indicates how the data being received is updated. Switching mode is an informational event.

MANUAL 0 In manual the result data and quality are not updated by the source.

(MODE)...............................................................................................CWR

(TOACT)............................................................................... – WR

(TOACTQ)............................................................... – WR

(SRCCNT)........................................................................... – WR

(SRCCNTQ)........................................................... – WR

The result data is operator writeable in manual. When the block

mode is set to manual from auto, the event message BLOCK MODE

SET TO MANUAL is reported.

16

17

AUTO 1 In auto the result data and quality are updated by the source. When

the block mode is set to auto from manual, the event message

BLOCK MODE SET TO AUTO is reported.

Initial Data Result

This is the block output value after ranging and mode is applied. During startup, this is the

initial data value.

Result Quality

The result quality field depends on how receive quality was configured. The possible

conditions are:

Result quality is GOOD when receiving just data.

•

Result quality is the received quality when receive quality is configured as YES.

•

Result quality is BAD when no data is received for two or more seconds.

•

(R) ........................................................................................................CWR

(RQ)........................................................................................................... – WR

8-23

Page 32

Logic Functions - Book 2

INPUT COMMUNICATION BLOCK

8.3.3 Typical Block Connections for Input Communication Block

Typical softwiring block structures used on softwiring diagrams are shown in Figure 8-11. For

input communications, data quality may or may not be received (see result quality attribute).

Continuous

Data

Data Source (ICN1,

Instrument 2, OC3)

IC1

Result

Result Quality

Mode

Figure 8-11. Typical Block Connections for Input Communication Block

8.3.4 Input Communication Block Events

The event codes (and their suggested text messages) for the input communication block are

given below. See the referenced data base attributes (in brackets) for additional information.

See System Event Block, Logic Functions - Book 1, IB-23G600 for a description of event

transitions.

0 BLOCK STATE SET TO RUN

1 BLOCK STATE SET TO HOLD

2 BLOCK STATE SET TO OFF

3 BLOCK STATE SET TO DEBUG

4 RECEIVING UNEXPECTED MESSAGE (5)

5 NOT RECEIVING DATA (8)

6 BLOCK MODE SET TO MANUAL

7 BLOCK MODE SET TO AUTO

R

RQ

MODE

Softwiring connection to

another block with quality

logically attached.

Operator indication

of Mode

8-24

Page 33

8.4 OUTPUT COMMUNICATION BLOCK (OC)

The output communication block is used to transmit data to an input communication block, or

input communication block channel for MOD 30 controllers and recorders, of other

instruments on the ICN via communication messages. The block specifies the data

destination, data type, and whether quality is to be sent with the data. It also has the

capability of sending MOD30 data types by converting the data from a MODCELL data type;

for example, floating point may be input and continuous sent.

Block outputs are result and result quality. A functional block diagram of an output

communication block is shown in Figure 8-12. The displays used to configure the Output

Communication block is shown in Figures 8-13 and 8-14.

Logic Functions - Book 2

OUTPUT COMMUNICATION BLOCK

Local Value

LSP

Input

Bad Inputs

Accepted

(YES)

State (RUN,

HOLD, OFF,

DEBUG)

Input Data Quality

NONE

GOOD

BAD

Quality Check

GOOD

AUTO

MANUAL

AUTO

MANUAL

Mode

Result

Lock

Comm Lock

(IF Block)

Result

Quality

Unlock

Unlock

Lock

ASCII or HEX

Data

Type

Top Bottom

Floating Pt

All Others

Send

Quality

YES

NO

Range

OR

Maximum

Field Size

(1-126)

Destination

Instrument

Number

Port

Number

Occurrence

Number

Data

Figure 8-12. Functional Block Diagram, Output Communication Block

8-25

Page 34

Logic Functions - Book 2

OUTPUT COMMUNICATION BLOCK

Figure 8-13. Output Communication Block (OC), General Menu

8-26

Figure 8-14. Output Communication Block (OC), Data Destination Menu

Page 35

8.4.1 Output Communication Block Operation

The Output Communication block is a loop function block that writes the ICN send buffer every