Page 1

Output Holder for Controllers Instructions

Product Description, Installation and Wiring for

1750N Output Holder

Page 2

MicroMod Automation, Inc.

p

The Company

MicroMod Automation is dedicated to improving customer efficiency by providing the most cost-effective, application-specific process solutions

available. We are a highly responsive, application-focused company with years of expertise in control systems design and implementation.

We are committed to teamwork, high quality manufacturing, advanced technology and unrivaled service and support.

The quality, accuracy and performance of the Company's products result from over 100 years experience, combined with a continuous

program of innovative design and development to incorporate the latest technology.

Use of Instructions

Ì Warning. An instruction that draws attention to the risk of

injury or death.

Note. Clarification of an instruction or additional

information.

q Caution. An instruction that draws attention to the risk of

roduct, process or surroundings.

the

Although Warning hazards are related to personal injury, and Caution hazards are associated with equipment or property damage, it

must be understood that operation of damaged equipment could, under certain operational conditions, result in degraded process

system performance leading to personal injury or death. Therefore, comply fully with all Warning and Caution notices.

Information in this manual is intended only to assist our customers in the efficient operation of our equipment. Use of this manual for

any other purpose is specifically prohibited and its contents are not to be reproduced in full or part without prior approval of MicroMod

Automation, Inc.

Licensing, Trademarks and Copyrights

MOD 30 and MOD 30ML are trademarks of MicroMod Automation, Inc.

MODBUS is a trademark of Modicon Inc.

Health and Safety

To ensure that our products are safe and without risk to health, the following points must be noted:

The relevant sections of these instructions must be read carefully before proceeding.

1. Warning Labels on containers and packages must be observed.

2. Installation, operation, maintenance and servicing must only be carried out by suitably trained personnel and in accordance with the information

given or injury or death could result.

3. Normal safety procedures must be taken to avoid the possibility of an accident occurring when operating in conditions of high

4. pressure and/or temperature.

5. Chemicals must be stored away from heat, protected from temperature extremes and powders kept dry. Normal safe handling procedures must be

used.

6. When disposing of chemicals, ensure that no two chemicals are mixed.

Safety advice concerning the use of the equipment described in this manual may be obtained from the Company address on the back

cover, together with servicing and spares information.

i Information. Further reference for more detailed

information or technical details.

All software, including design, appearance, algorithms and source

codes, is copyrighted by MicroMod Automation, inc. and is owned

by MicroMod Automation or its suppliers.

Page 3

Output Holder Instructions

CONTENTS

CONTENTS

Page

SECTION 1 – PRODUCT DESCRIPTION

1.1 OVERVIEW ............................................................................................................................1-1

1.2 FEATURES .............................................................................................................................1-1

1.3 Related Information ................................................................................................................1-2

1.4 Explanation of Catalog Numbers ............................................................................................1-3

1.5 Ordering Information ...............................................................................................................1-3

1.6 Basic Hardware.......................................................................................................................1-4

1.7 Specifications ..........................................................................................................................1-5

SECTION 2 – MECHANICAL INSTALLATION

2.1 Overview ................................................................................................................................2-1

2.2 Displays and Cleaning ...........................................................................................................2-1

2.3 Unpacking ..............................................................................................................................2-1

2.4 Mounting .................................................................................................................................2-1

SECTION 3 – POWER, GROUNDING AND I/O CONNECTIONS

3.1 Overview ................................................................................................................................3-1

3.2 Connection Guidelines ...........................................................................................................3-1

3.3 Wiring and Connections .........................................................................................................3-1

3.4 Connecting other Controllers ..................................................................................................3-2

SECTION 4 - CONFIGURATION

4.1 Overview ................................................................................................................................4-1

4.2 Loading the Compound for MOD 30ML..................................................................................4-1

4.3 Loading the Compound for Modcell........................................................................................4-8

4.4 Connecting RUNINIT from the IF Block .................................................................................4-15

4.5 Theory of Operation ...............................................................................................................4-21

SECTION 5 – OPERATION AND MAINTAINANCE

5.1 Overview ................................................................................................................................5-1

5.2 Operation ...............................................................................................................................5-1

5.2.1 Front Panel .............................................................................................................................5-1

5.2.2 Control Keys ...........................................................................................................................5-2

5.3 Troubleshooting and Maintenance .........................................................................................5-3

ILLUSTRATIONS

Figure

1.1 1750N Output Holder .............................................................................................................1-1

1.2 Catalog Number ......................................................................................................................1-3

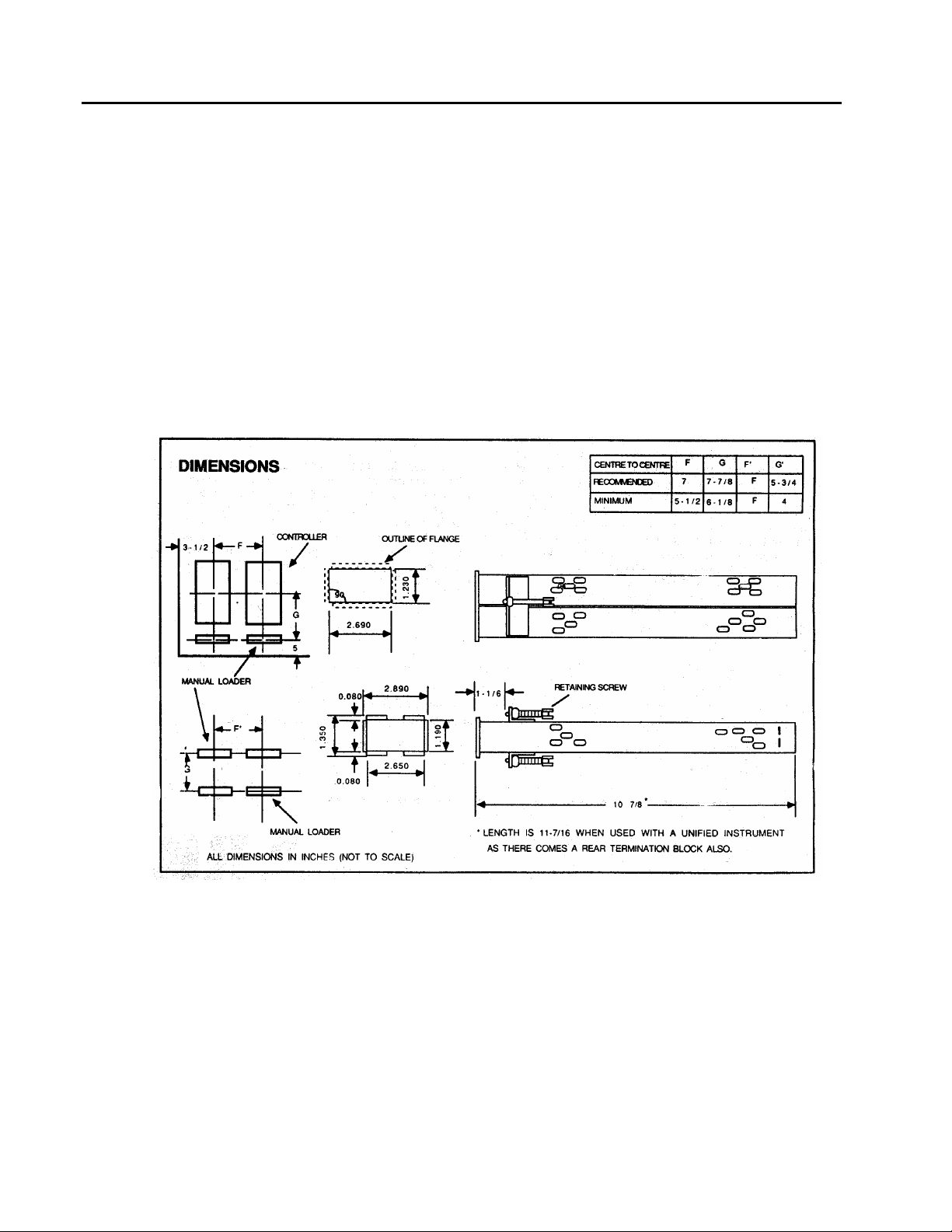

2.1 Output Holder Mounting Dimensions......................................................................................2-2

3.1 Generic Output Holder Connection Diagram..........................................................................3-1

3.2 Wiring Diagram ......................................................................................................................3-2

4.1 Opening the Component Gallery ............................................................................................4-1

4.2 Component Gallery ................................................................................................................4-2

4.3 Un-compounding the Compound............................................................................................4-3

4.4 PID_OH Compound ................................................................................................................4-4

4.5 AOUT / AOM block Configuration ........................................................................................... 4-5

4.6 Execution Order ......................................................................................................................4-7

1

Page 4

Output Holder Instructions

CONTENTS

4.7 Opening Component Gallery.................................................................................................. 4-8

4.8 Component Gallery................................................................................................................. 4-9

4.9 Un-compounding the Compound ........................................................................................... 4-10

4.10 PID_OH_MCELL Compound ................................................................................................. 4-11

4.11 AOM block Configuration........................................................................................................ 4-12

4.12 Execution Order...................................................................................................................... 4-14

4.13 Connection Menu ................................................................................................................... 4-15

4.14 Connection Menu ................................................................................................................... 4-15

4.15 IF Block attributes................................................................................................................... 4-16

4.16 Connection to EX block .......................................................................................................... 4-16

4.17 EX Block Connection Input..................................................................................................... 4-17

4.18 EX Block Connection.............................................................................................................. 4-17

4.19 Connection Menu ................................................................................................................... 4-18

4.20 Connection Menu ................................................................................................................... 4-18

4.21 IF Block attributes................................................................................................................... 4-19

4.16 Connection to PID block ......................................................................................................... 4-19

4.23 Connection to PID block ......................................................................................................... 4-20

4.24 PID Block Connection............................................................................................................. 4-20

5.1 Output Holder Front panel ...................................................................................................... 5-1

TABLES

Table

4.1 PID_OH Compound ............................................................................................................... 4-4

4.2 PID_OH_MCELL Compound ................................................................................................ 4-11

5.1 Troubleshooting...................................................................................................................... 5-3

2

Page 5

1.1 OVERVIEW

For safe operation some processes require that valve position be maintained above a

closed position even when a controller might be removed for service or replacement. The

1750N Output Holder is capable of identifying a controller’s output fault and to maintain the

last good value to the field control device for safe operation. When the controllers output

signal to the output holder is restored and again valid the output holder returns control of the

field device to the controller. Under normal operation i.e.; the controllers output is good,

the controllers output is passed through the output holder to the field control device

unaffected.

The 1750N functions as an output holder and a manual loader when connected to a MOD

30ML Controller or Modcell Multiloop Processor.

Output Holder Instructions

PRODUCT DESCRIPTION

SECTION 1

PRODUCT DESCRIPTION

1.2 FEATURES

Output held at last value

Manual control & output display

Feedback circuit for bumpless transfer

Compatible with standard MOD

Figure 1 .1. 1750N Output Holder

1 -1

Page 6

Output Holder Instructions

PRODUCT DESCRIPTION

1.3 RELATED INFORMATION

A general description of the MODCELL and MOD 30ML instruments, mechanical installation

instructions, electrical connection instructions, and communication connection instructions

can be found in the following documents.

• IB-23C600 - Installation for MODCELL Multiloop Processor

• IB-23C601 - Installation for Remote I/O modules (Extended I/O)

• IB-1800R-INS - Installation for MOD 30ML Multiloop Controller

• IB-1800R-M30 - Installation for the MOD 30ML Replacement for MOD 30 Instruments

• IB-23A160 - Instructions for Instrument Communications Network (ICN) Planning

Installation and setup information for the communications link can be found in the following

documents:

• IB-23C001 - Instructions for 1720N Communications Link

• IB-23C003 - Users guide for 17321N ICN Mini Link

• IB-23C004 - Users Guise for 1733N Mini Link/External

Reference information on the data base structure and configuration parameters applicable to

both MODCELL and MOD 30ML instruments can be found in the following documents.

• IB-23G600 - Data Base Reference for Logic I/O and Communication Functions

• IB-23G601 - Data Base Reference for Advanced Control Functions

• IB-23G602 - Data Base Reference for Algorithm, Table and Sequencer Functions

• IB-23H141 - User’s Guide for MODCELL Application Builder Software

General operation and setup information, and reference information on the data base

structures and configuration parameters, which apply only to the MOD 30ML Multiloop

Controller can be found in the following documents.

• IB-1800R-OPR - Operation for MOD 30ML Multiloop Controller

• IB-1800R-APP - Data Base Reference for Display, Alarm, and Built-in I/O Functions

Training labs and tutorial can be found in the following documents:

• IB-VIZAPP-TUT – Training labs for configuring MOD 30ML using ViZapp Software.

• IB-1800R-SCR – Display Guide – Scripting hints, help and examples formed 30ML using

ViZapp Software

• IB-MLOPR-TUT – MOD 30ML Operation Training manual.

1 -2

Page 7

1.4 EXPLANATION OF CATALOG NUMBERS

The products described in this book have catalog numbers that help identify specific features.

In addition, some products are assigned a serial number which can be used to track

manufacturing data.

The catalog number stamped on the product data contains a series of single and multiplecharacter codes. These codes provide specific information concerning various electrical

and/or structural options. Certain code combinations are not allowed, and options and

combinations are subject to change. An example of a typical catalog number is as follows:

Sample Catalog No.

Base Number

Unused

Electrical Code

Power

Options

Unused

Model/Design Level

1750N Z 21 1 0 0 A

Figure 1 .2. Catalog Number

Output Holder Instructions

PRODUCT DESCRIPTION

1.5 ORDERING INFORMATION

NOTE: One analog input is required on the MOD 30ML Controller to accommodate the

feedback circuit for bumpless transfer.

Code No. Description

1750NZ10001A Manual Loader/Output Holder

1 -3

Page 8

Output Holder Instructions

PRODUCT DESCRIPTION

1.6 BASIC HARDWARE

The 1750N, Figure 1-1, is designed for mounting in a panel with a 11.5 inch depth. The

instrument housing contains a 6-point termination facility which accepts all instrument I/O and

power connections.

The 4-20mA output from the MOD 30ML controller is wired in series with the 1750N, and

then to the field. As long as the output from the controller is within the specific limits, the

output holder output is identical to the input (controller output signal). In case of controller

failure resulting in loss of output, the Output Holder retains the last output, thereby enabling

the defective instrument to be replaced without interruption to the process.

A separate output return signal is fed back to the controller, so that when the defective

instrument is replaced the output will automatically match that of the Manual Loader for

bumpless transfer of control. The output holder also provides a discrete output that can be

connected to the controller. This input is the status of the output holder’s presence and can

be used in the controller’s configuration logic.

Use of the Return / Feedback signal (1-5 mA Monitor to controller) and the Output Holder

Sense Discrete signal are optional.

When the 1750N is installed, the output may still be viewed and manipulated when the

controller is removed from the panel for service. Up/Down pushbuttons are provided on the

front panel, allowing direct manipulation of the output by the operator in the event of

controller failure. Output indication is provided by a 10-segment LED bar graph. Screwed

terminal connections are provided for interconnection with the MOD 30ML terminal block.

One Analog Input is required on the MOD 30ML / Modcell for the feedback circuit. Either a

built-in analog input or a plug-in analog input module may be used. A standard configuration

strategy for the MOD 30ML with the feedback circuit is provided in the library of the Visual

Application Designer configuration tool for MOD 30ML / Modcell.

1 -4

Page 9

1.7 SPECIFICATIONS

ANALOG INPUT INPUT/OUTPUT CHARACTERISTICS

Span (0 to 100%)

Lower Limit

Upper Limit

ANALOG OUTPUT (I out)

Span (0 to 100%)

Lower Limit

Upper Limit

CURRENT RETURN (I Return)

Span (0 to 100%)

Lower Limit

Upper Limit

CALIBRATED ACCURACY (% of span)

I out, Run mode

(with respect to analog input)

I out, Hold mode

(with respect to run mode analog

input)

I return, Run mode

(with respect to analog input

span)

I return, Hold mode

(with respect to run mode analog

input span)

INDICATION ACCURACY

1 bar

4 to 20 mA

2.72 mA

21.28 mA

4 to 20 mA

2.72 mA

21.28 mA

1 to 5 mA

0.68 mA

5.32 mA

± 0.5% max

± 1.0% max

± 0.8% max

± 1.2% max

10% ± 2% of

output span

Output Holder Instructions

PRODUCT DESCRIPTION

Analog input resistance

Analog output (I out)

Resistance

Open circuit output voltage

ANALOG OUTPUT LOAD CAPABILITY

Resistance

Capacitance

Inductance

POWER SUPPLY REQUIREMENTS

Normal Operating Range

Allowable Operating range

Allowable Ripple Maximum

Current

ENVIRONMENTAL CHARACTERISTICS

Humidity effect

Static discharge

RFI

Operating temperature

Storage temperature

PHYSICAL CHARACTERISTICS

Width

Depth

Height

Weight.

250 ohms typical

50 kohms min

24V dc max

800 ohms max

10 micro F max

10 H max

23V to 28V dc

20V dc to 28 V dc

1.0 V peak to peak

200 mA max

±0.1% from 25 to

95% relative humidity

at 9°F (32 °C)

<= 10 kV

SAMA standard PMC

33.1.1978 class 1,

Bands A,B, and C

+41°F (+5°C) to

122°F (50°C)

-40°F (-40°C) to

167°F (75°C)

69mm

292mm

35mm

600 GMS

1 -5

Page 10

Output Holder Instructions

PRODUCT DESCRIPTION

1 -6

Page 11

MECHANICAL INSTALLATION

2.1 OVERVIEW

Read these instructions thoroughly before starting installation. Installation personnel should

be qualified technicians..

2.2 Displays and Cleaning

The display is protected by an overlay that can be removed after installation. The face of the

display, while made of scratch-resistant plastic, can be abraded by harsh materials such as

paper towels and industrial wipes. Lens cleaning tissues and soft cloths are suitable for

cleaning displays. Remove dust from the rear of the instrument by removing it from the

instrument housing and spraying exposed surfaces with non-corrosive, non-toxic,

nonflammable inert dusting gas.

2.3 UNPACKING

Unpack and visually inspect the instrument housing and the output holder for

any damage. Save packing materials for any reshipment, or to support any claim of shipment

damage. All damage claims are made against the carrier and are the responsibility of the

customer.

Included in the shipping container is a bag containing mounting brackets and screws, and an

information package. A card containing several copies of a writeable instrument identification

tag is included in the information package. Write required data on the tag and insert it under

the translucent strip at the bottom of the front panel after the controller is installed.

2.4 MOUNTING

The output holder must be installed in an approved enclosure or installed in a means

acceptable to the authority having jurisdiction for electrical installations.

∆WARNING Do not install a MOD 30ML controller in a residential, commercial or light

industrial environment in the European Union.

Select a mounting location where:

Output Holder Instructions

MECHANICAL INSTALLATION

SECTION 2

• There is minimum vibration.

• The ambient temperature is between 32 and 122°F (0 and 50°C) with a relative humidity

of 5-95% RH (noncondensing). The ambient temperature and humidity requirements

apply to the air directly below the output holder.

• The installation allows for free air flow above and below the unit.

• If it is necessary to mount two or more output holders or controllers above each other,

and the room ambient temperature is above 70°F, heat generated by the lower

instruments may raise the ambient of the upper instruments above the 122°F limit. To

assure that operating temperatures are within specified limits, it is recommended that a

fan be installed below the instruments to force air circulation over the instruments in an

upward direction. Air velocity should be at least 100 to 200 feet per minute.

2 -1

Page 12

Output Holder Instructions

MECHANICAL INSTALLATION

• The panel provides rigid support for a fully loaded 5.5-pound (2.5 kg) controller and any

other panel devices.

• Electrical wiring routing and support are planned.

Mount the output holder as follows:

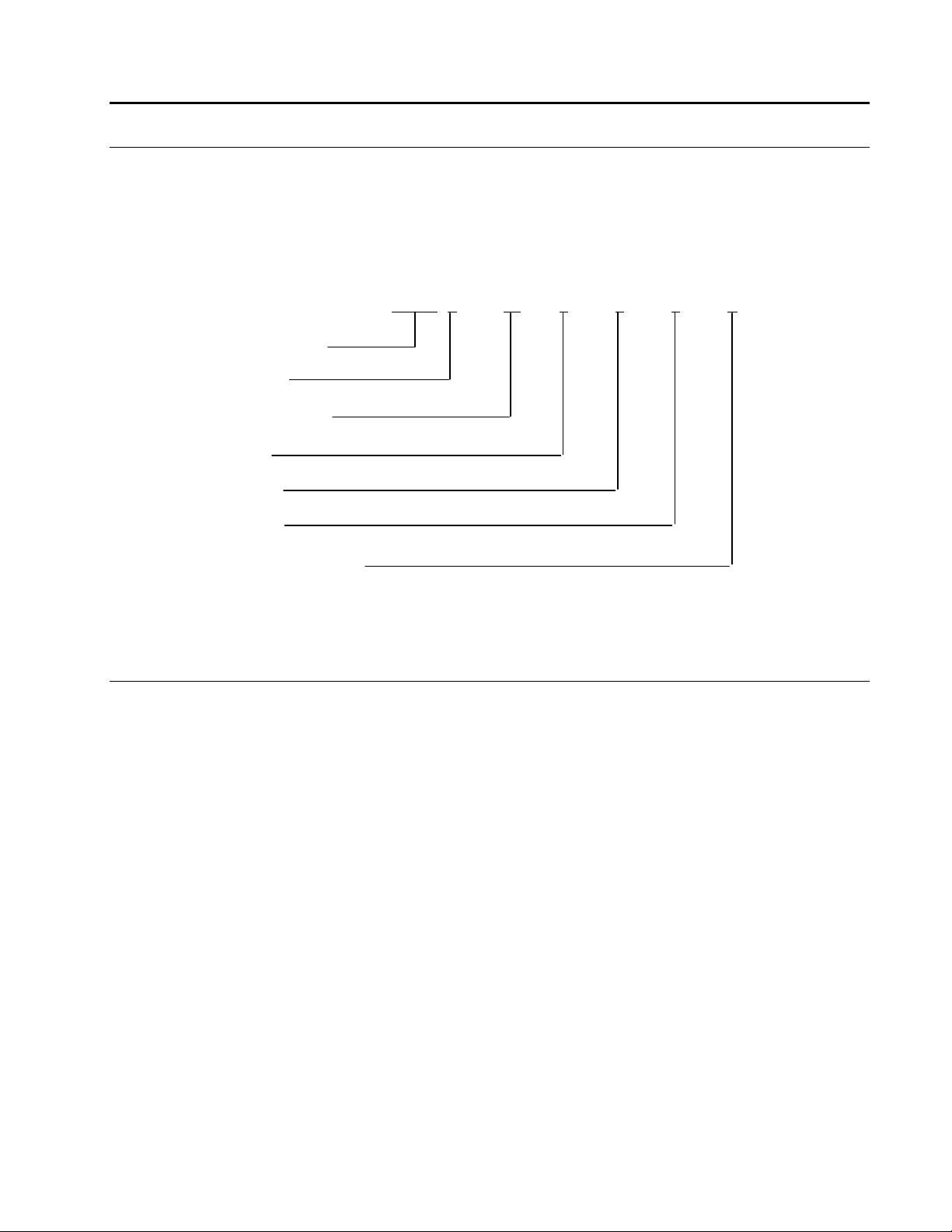

1. Prepare the panel as indicated in Figure 2-1.

2. Slide instrument into panel cutout.

3. Insert brackets into slots in top and bottom of instrument housing.

4. Tighten retaining screws to a torque of 5 inch-pounds (0.6 Nm) or 1-1/2 turns after

contact is made with the back of the panel.

MOUNTING DIMENSIONS

2 -2

Figure 2 .1. Output Holder Mounting Dimensions

Page 13

POWER, GROUNDING, AND I/O CONNECTIONS

3.1 OVERVIEW

Read this section thoroughly before making any connections. Installation personnel should

be qualified technicians. Observe all electrical code requirements and safety standards

applicable to these wiring procedures.

Specific instructions and connection diagrams for the various built-in inputs and outputs are

provided in the following sections. A listing of the applicable electrical specifications is

included in each section.

3.2 CONNECTION GUIDELINES

The wiring connections described in this section are made with the output holder installed in

its operating location and with the power off.

1. The power wire size must be from 14 AWG (1.6 mm) to 18 AWG (1.0 mm) with a 600V, -

20°C +105°C UL, CSA approved rating.

2. The signal wire size can be as small as 22 AWG (0.65 mm). All analog input wiring must

be shielded twisted pairs.

3.3 WIRING AND CONNECTIONS

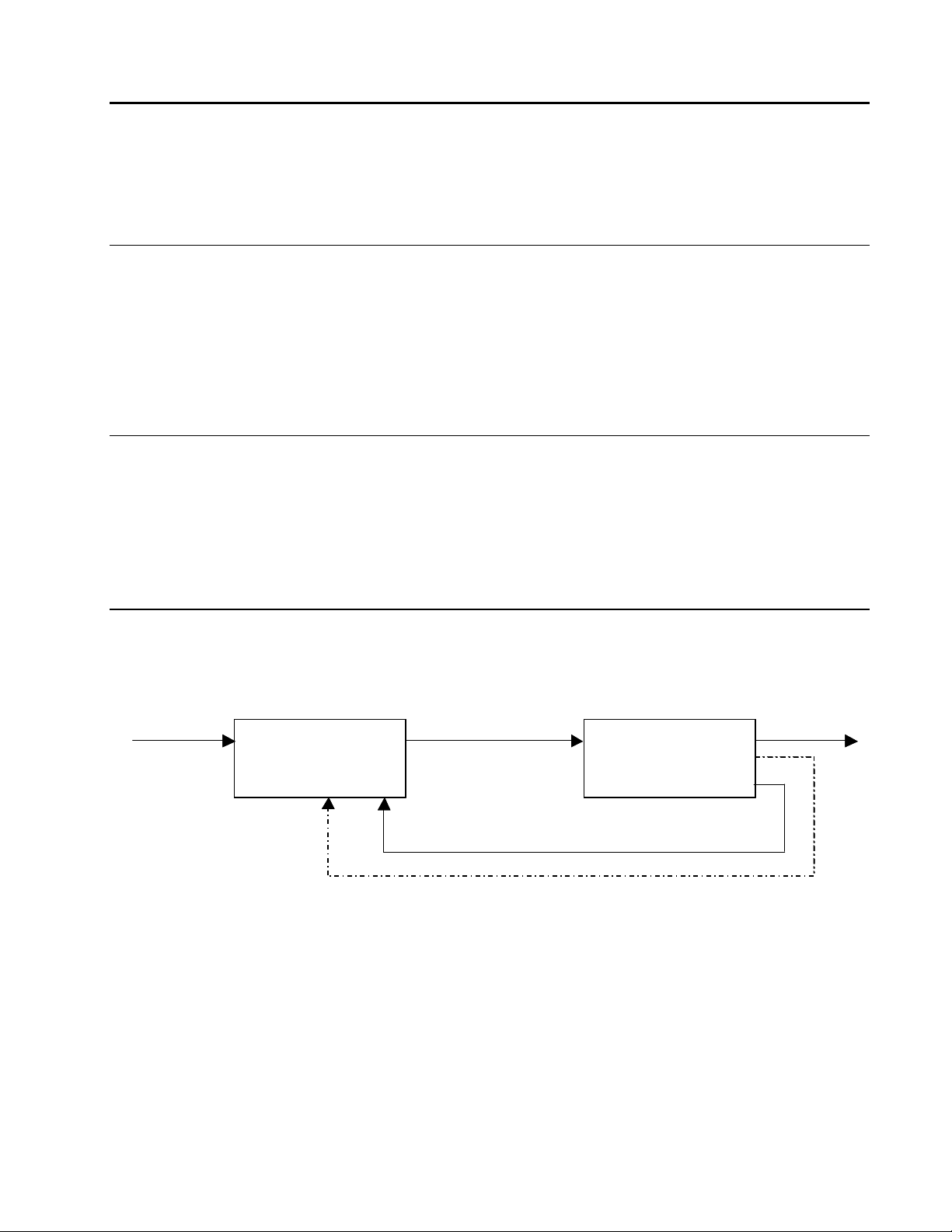

The following figure provides a generic reference as to the signal paths between the

controller and the 1750N Output Holder.

Output Holder Instructions

POWER, GROUNDING, AND I/O CONNECTIONS

SECTION 3

Process Input Controller Output

Process Input Controller Output

Controller

ControllerController

OH Sense to Controller

OH Sense to Controller

Figure 3 .1. Catalog Number

The 1-5 mA monitor to Controller and the OH Sense to Controller connections in the above

scheme are optional. For these connections, two additional inputs are required: The input

types are:

1. 1-5 mA monitor to controller (Return) – one non-two wire input (2002A)

2. OH Sense to the controller – one digital input (2006AZ)

The wiring diagram is shown in the next figure:

1750N

1750N

4-20 mA

4-20 mA

1-5 mA monitor to Controller

1-5 mA monitor to Controller

1750N

Output Holder

Output Holder

Output Holder

4-20 mA to Process

4-20 mA to Process

3 -1

Page 14

Output Holder Instructions

POWER, GROUNDING, AND I/O CONNECTIONS

+

24 VDC

24 VDC

Power

Power

Controller

Controller

+

–

–

1750N Output Holder

1750N Output Holder

+24 VDC from Power Supply1

+24 VDC from Power Supply1

2

Power Supply and Signal Commons

2

Power Supply and Signal Commons

Output

Output

AOUT or 2003A

AOUT or 2003A

4-20mA

4-20mA

O.H. Sense Input

O.H. Sense Input

2006A

2006A

Contact Closure to TCI

Contact Closure to TCI

Output Track Input

Output Track Input

AIN or 2002A

AIN or 2002A

1-5mA to OPTI

1-5mA to OPTI

+

+

–

–

+

+

–

–

+

+

–

–

3

4-20mA Output from Controller

3

4-20mA Output from Controller

4

1-5mA Monitor to Controller

4

1-5mA Monitor to Controller

5

O.H. Sense to Controller (internally tied to Common)

5

O.H. Sense to Controller (internally tied to Common)

6

4-20mA Output to Field Device

6

4-20mA Output to Field Device

Figure 3 .2. Wiring diagram

The exact wire connections for a particular MOD 30ML Controller or Modcell depends on how

many outputs are being held and where the Sense and Return I/O points for each loop are

located on the controller. For example, if you are using the MOD 30ML controller and if you

are not using the built-in input 2, it may be set up for 1-5 mA non-two wire and used to bring

in the Return signal.

In all cases, the Sense signal will require the installation of a 2006AZ digital input module. It

is also your preference to use or not use the SENSE signal from the output holder. Refer to

chapter 4 for different configuration options with respect to the Sense signal.

3.4 CONNECTING OTHER CONTROLLERS

The output holder can also be used with controllers other than MOD 30ML and Modcell.

Follow the same scheme as given in Figure 3.2.

Use of the Return / Feedback signal (1-5 mA Monitor to controller) and the Output Holder

Sense Discrete signal are optional.

Field Device

Field Device

3 -2

Page 15

SECTION 4

CONFIGURATION

4.1 OVERVIEW

The Compound Gallery in the ViZApp (Visual Application Builder) software includes a

compound called PID_OH. This section explains how to configure MOD 30ML or Modcell

using this compound for use with the Output Holder. The purpose of this compound is to

cause the control loop to synchronize its output holder before turning its field output on. This

will in turn cause a bump less transfer. This happens only when the controller first initializes

at power up.

4.2 LOADING THE COMPOUND FOR MOD 30ML

The PID_OH compound has a fully functional PID, with I/O, Display, Tuning List and also the

logic for bumpless transfer of output.

Output Holder Instructions

CONFIGURATION

If you already have your PID configured, you can delete the blocks that are not required from

this compound after loading.

1. Launch the ViZapp Software and open your workspace, project and the instrument

database.

2. The PID_OH compound can only be loaded inside a loop compound. Open the loop

compound where you want to load the PID_OH compound.

3. Select Project – Gallery – Component Gallery from the menu bar as shown in the

figure below:

Figure

4 .1. Opening the Component Gallery

4 -1

Page 16

Output Holder Instructions

CONFIGURATION

4. The Component Gallery dialog will be displayed as shown in the next figure. Select

the Compounds tab and click on the PID_OH compound from the list of compounds

as shown and then click on the Export button.

Figure 4 .2. Component Gallery

The Compound will be placed in your database. The function blocks are located

inside this compound. You can un-compound the loaded PID_OH compound. With

the loaded compound selected, select Objects – Uncompound from the menu bar.

Refer to the next figure:

4 -2

Page 17

Output Holder Instructions

CONFIGURATION

Figure 4 .3. Un-compounding the compound

After you un-compounded the PID_OH compound, it will be displayed as shown in

the next figure.

4 -3

Page 18

Output Holder Instructions

CONFIGURATION

Figure 4 .4. PID_OH Compound

The compound has the following function blocks:

Block Name Type Description

pid PID The PID control block

disp DISP Display for the PID

TuningList TL Tuning list for the PID

PV AIN Built-in input used for PV

Pv_i VCI Signal conditioning for the AIN

op_ao AOUT Built-in analog output block

RETURN AIN Built-in input used to get the feedback from the output

holder. Configured as 1-5 mA

RETURNF1 VCI Signal conditioning for the AIN. Configured as 0 – 100

%

SENSE DIM Digital input to sense the presence of the output holder

SENSEF DI Signal Conditioning for the DIM block

OP_T_LGC EX Logic for bumpless transfer

Table 4-1. PID_OH Compound

There is also a Notes block that has text that explains how to use this compound as

shown in the Figure 4-4. This compound can be used as it is.

You may need to make the following changes depending on your process

application:

4 -4

Page 19

Output Holder Instructions

CONFIGURATION

1. The compound uses an AIN (Built-in Analog Input) block configured as current input (420mA) and a VCI block for ranging it to 0-100 engineering units linear. It also has a builtin AOUT block. You can substitute different type of input or module, conditioning and

analog output blocks

2. The compound also has preconfigured PID, Display and Tuning List blocks, which you

can substitute with your existing blocks in your database.

3. The compound uses a built-in input (RETURN) and a VCI conditioning (RETURNF1)

blocks for reading the feedback from the output holder. This is the feedback of the output

value from the output holder sent to the field. This value is tied to the output track input

(OPTI) of the PID block so that the PID block tracks this value upon start up. This is how

a bump less transfer of output value is achieved. If you do not need bumpless transfer of

output, you can optionally remove these two blocks.

4. The AOUT block is configured as shown below for Restart/Failsafe conditions:

Figure 4 .5. AOUT / AOM block configuration

The Restart output is configured as Preset with a value of –25. The reason for this is

when a faulty controller is replaced with a new or a repaired one, a momentary zero

output from the controller at startup will be seen as a valid input by the output holder and

it will switch to zero values. To avoid this a momentary faulty value (negative 25) is

introduced at the startup and then the PID block’s output will override this value.

5. The compound uses a Digital input block (DIM - SENSE) and a digital conditioning block

(DI – SENSEF) to sense the presence of the output holder. This discrete signal along

4 -5

Page 20

Output Holder Instructions

CONFIGURATION

with the RUNINIT signal from the Interface (IF) block is used in the EX block to enable

output tracking in the PID block. The logic configured in the EX block OP_T_LGC is as

shown below:

In the above expression && is the logical AND function. The RUNINIT signal from the IF

block goes high momentarily upon controller startup. If the output holder is not present,

the PID block does not have to switch its output to track mode upon start up.

If bumpless transfer of output is not an issue (refer to step 3 above) in your application,

then you can remove these blocks also.

6. Connect the RUNINIT attribute from the IF block to the RUNINIT User Input of the EX

(OP_T_LGC ) block. Refer to the section 2-3-1 for the procedure.

7. The following relative EXECUTION ORDER MUST BE MAINTAINED!

If using other I/O for Sense and Return be sure to maintain same relative execution

order. To set the execution order, select Objects – Set Execution Order – List Mode from

the ViZapp menu bar to display the Execution order table as shown in the next figure:

SENSE && RUNINIT

PV

pv_I

RETURN

RETURNF1

SENSE

SENSF

OP_T_LGC

Pid

op_ao

Disp

TuneList

4 -6

Page 21

Output Holder Instructions

CONFIGURATION

Figure 4 .6. Execution Order

If you are using the MOD30 Conversion Style Instrument, change Input Signal Range

of PV to 1 to 5 Volts and RETURN to 0.25 to 1.25 Volts.

8. Optionally you can include the output holder feedback (RETURN) only in the

configuration and not the presence of the output holder (SENSE). In this case you do not

need the discrete input module in the controller. The configuration will not have the

SENSE (DIM), SENSEF (DI) and the OP_T_LGC (EX) blocks. You can delete these

blocks from the loaded compound. You would still need to connect a track command

input to the PID block. This will again be the RUNINIT signal from the IF block connected

to the TCI attribute of the PID block ensuring bumpless transfer of the output value. Refer

to the section 4.4 Connection RUNINIT from the IF block, Option 2 for the procedure.

9. Compile and download your database to the controller.

4 -7

Page 22

Output Holder Instructions

CONFIGURATION

4.3 LOADING THE COMPOUND FOR MODCELL

The PID_OH compound has a fully functional PID, with I/O and also the logic for bumpless

transfer of output.

If you already have your PID configured, you can delete the blocks that are not required from

this compound after loading.

1. Launch the ViZapp Software and open your workspace, project and the instrument

database.

2. The PID_OH1 compound can only be loaded inside a loop compound. Open the loop

compound where you want to load the PID_OH compound.

3. Select Project – Gallery – Component Gallery from the menu bar as shown in the

figure below:

4 -8

Figure 4 .7. Opening the Component Gallery

4. The Component Gallery dialog will be displayed as shown in the next figure. Select the

Compounds tab and click on the PID_OH_MCELL compound from the list of compounds

as shown and then click on the Export button.

Page 23

Output Holder Instructions

CONFIGURATION

Figure 4 .8. Component Gallery

The Compound will be placed in your database. The function blocks are located inside

this compound. You can un-compound the loaded PID_OH compound. With the loaded

compound selected, select Objects – Uncompound from the menu bar. Refer to the

next figure:

4 -9

Page 24

Output Holder Instructions

CONFIGURATION

4 -10

Figure 4 .9. Un-compounding the compound

After you un-compounded the PID_OH compound, it will be displayed as shown in the

next figure.

Page 25

Output Holder Instructions

CONFIGURATION

Figure 4 .10. PID_OH1 Compound

The compound has the following function blocks:

Block Name Type Description

pid PID The PID control block

PV VCIM Voltage/Current Input block used for PV

Pv_i VCI Voltage/Current Signal conditioning for the AIN

op_ao AOM Analog output block

RETURN VCIM Voltage/Current input used to get the feedback from

the output holder. Configured as 1-5 mA

RETURNF1 VCI Signal conditioning for the AIN. Configured as 0 – 100

%

SENSE DIM Digital input to sense the presence of the output holder

SENSEF DI Signal Conditioning for the DIM block

OP_T_LGC EX Logic for bumpless transfer

Table 4-1. PID_OH Compound

There is also a Notes block that has text that explains how to use this compound as

shown in the Figure 4-4. This compound can be used as it is.

You may need to make the following changes depending on your process application:

1. The compound uses a Voltage/Current Input module (VCIM) block configured as current

input (4-20mA) and a VCI block for ranging it to 0-100 engineering units linear. It also has

an analog output module (AOM) block. You can substitute different type of input or

module, conditioning and analog output blocks

2. The compound also has preconfigured PID block, which you can substitute with your

existing PID block in your database.

4 -11

Page 26

Output Holder Instructions

CONFIGURATION

3. The compound uses a VCIM (RETURN) and a VCI conditioning (RETURNF1) blocks for

reading the feedback from the output holder. This is the feedback of the output value

from the output holder sent to the field. This value is tied to the output track input (OPTI)

of the PID block so that the PID block tracks this value upon start up. This is how a bump

less transfer of output value is achieved. If you do not need bumpless transfer of output,

you can optionally remove these two blocks.

4. The AOM block is configured as shown below for Restart/Failsafe conditions:

4 -12

Figure 4 .11. PID_OH1 Compound

The Restart output is configured as Preset with a value of –25. The reason for this is

when a faulty controller is replaced with a new or a repaired one, a momentary zero

output from the controller at startup will be seen as a valid input by the output holder and

Page 27

Output Holder Instructions

CONFIGURATION

it will switch to zero values. To avoid this a momentary faulty value (negative 25) is

introduced at the startup and then the PID block’s output will override this value.

5. The compound uses a Digital input block (DIM - SENSE) and a digital conditioning block

(DI – SENSEF) to sense the presence of the output holder. This discrete signal along

with the RUNINIT signal from the Interface (IF) block is used in the EX block to enable

output tracking in the PID block. The logic configured in the EX block OP_T_LGC is as

shown below:

SENSE && RUNINIT

In the above expression && is the logical AND function. The RUNINIT signal from the IF

block goes high momentarily upon controller startup. If the output holder is not present,

the PID block does not have to switch its output to track mode upon start up.

If bumpless transfer of output is not an issue (refer to step 3 above) in your application,

then you can remove these blocks also.

6. Connect the RUNINIT attribute from the IF block to the RUNINIT User Input of the EX

(OP_T_LGC ) block. Refer to the section 2-3-1 for the procedure.

7. The following relative EXECUTION ORDER MUST BE MAINTAINED!

PV

pv_I

RETURN

RETURNF1

SENSE

SENSF

OP_T_LGC

Pid

op_ao

If using other I/O for Sense and Return be sure to maintain same relative execution

order. To set the execution order, select Objects – Set Execution Order – List Mode from

the ViZapp menu bar to display the Execution order table as shown in the next figure:

4 -13

Page 28

Output Holder Instructions

CONFIGURATION

Figure 4 .12. Execution Order

8. Optionally you can also include the feedback (RETURN) only in the configuration and not

the presence of the output holder (SENSE). In this case you do not need the discrete

input module in the controller. The configuration will not have the SENSE (DIM),

SENSEF (DI) and the OP_T_LGC (EX) blocks. You can delete these blocks from the

loaded compound. You would still need to connect a track command input to the PID

block. This will again be the RUNINIT signal from the IF block connected to the TCI

attribute of the PID block ensuring bumpless transfer of the output value. Refer to the

section 4.4 Connection RUNINIT from the IF block, Option 2 for the procedure.

9. Compile and download your database to the controller.

4 -14

Page 29

4.4 CONNECTING RUNINIT FROM THE IF BLOCK

Option1: When using both RETURN and SENSE signals from the output holder:

To connect the RUNNIT attribute from the IF block, refer to the section select the

connector (multi segment or right angle) from the Algorithms Window and then click on a

blank area of the instrument document near the EX block.

Output Holder Instructions

CONFIGURATION

Figure 4 .13. Connection Menu

Select Compound External from the menu as shown above.

Figure 4 .14. Connection Menu

Select the IF block from the menu and then click on the OK button.

4 -15

Page 30

Output Holder Instructions

CONFIGURATION

Figure 4 .15. IF block attributes

Select the RUNINIT attribute from the list and click on the OK button. Drag the

connection line to the EX block and click on it.

Figure 4 .16. Connection to EX block

4 -16

Page 31

Output Holder Instructions

CONFIGURATION

Figure 4 .17. EX block Connection Input

Select the user Input RUNINIT and click on OK. The connection is complete now. See

the next figure:

Figure 4 .18. EX block connection

4 -17

Page 32

Output Holder Instructions

CONFIGURATION

Option2: When using only the RETURN signal from the output holder:

To connect the RUNNIT attribute from the IF block, refer to the section select the

connector (multi segment or right angle) from the Algorithms Window and then click on a

blank area of the instrument document near the EX block.

Select Compound External from the menu as shown above.

Figure 4 .19. Connection Menu

4 -18

Figure 4 .20. Connection Menu

Select the IF block from the menu and then click on the OK button.

Page 33

Output Holder Instructions

CONFIGURATION

Figure 4 .21. IF block attributes

Select the RUNINIT attribute from the list and click on the OK button. Drag the

connection line to the PID block and click on it.

Figure 4 .22. Connection to PID block

4 -19

Page 34

Output Holder Instructions

CONFIGURATION

Figure 4 .23. Connection to PID block

Select the user Input TCI and click on OK. The connection is complete now. See the next

figure:

Figure 4 .24. PID block connection

4 -20

Page 35

4.5 THEORY OF OPERATION

When the instrument powers up the process value is read first followed by the RETURN and

SENSE inputs. The expression block OP_T_LGC is executed next with a result that becomes

true when both the SENSE and RUNINIT inputs are true. The SENSE input will always be

true when an output holder is present. The RUNINIT input is true only for a moment when the

instrument powers up. The output of the EX block is connected t the track command input

(TCI) of the PID block. For this brief moment that the EX block’s output is true, the PID

block’s output will track the RETURN input connected to its track source (OPTI). This is the

feedback from the output holder of what it sends to the field. The PID block uses this value

until told to change based on automatic or manual manipulation. This PID output value is

sent to the output block causing the output block’s output current to be equal to that of the

output holder output.

The return input block is set to receive 1 to 5 mA. Its input conditioning block converts this

into 0 to 100 as engineering units that correspond to the PID block output.

The initial value of the SENSE input block and its corresponding input conditioning block are

set to false. As well the output block’s initial value is also set to zero. This permits the output

holder card to maintain the control of the device until the controller’s output is synchronized to

the output holder’s output.

Output Holder Instructions

CONFIGURATION

4 -21

Page 36

5.1 OVERVIEW

This chapter provides operating instruction and maintenance information for the output holder

instrument.

5.2 OPERATION

The output holder can display the controller’s output in a 10 segment horizontal bar graph. It

has 2 keys (UP and DOWN) that enable manual output adjustment in the absence of the

main controller.

Operator activity available during runtime:

Monitor the output only as long as the main controller whose output is sending a valid

output to the output holder

Monitor and manipulate the output using the UP and the DOWN keys when the output

holder is not receiving a healthy value from the controller.

5.2.1 FRONT PANEL

The front panel has the UP and DOWN keys and a 10 segment bar graph as shown below::

Output Holder Instructions

OPERATION AND MAINTAINANCE

SECTION 5

OPERATION AND MAINTAINANCE

Figure 5 .1. Output Holder front panel

5 -1

Page 37

Output Holder Instructions

OPERATION AND MAINTAINANCE

5.2.2 CONTROL KEYS

The operator control keys are:

5.2.3 BAR DISPLAY

The 10 segment horizontal bar graph provides visual indication of the output holder’s output.

Each segment represents up to 10 % of the output. The segment’s light intensity varies as

the value changes from minimum to maximum of the value it represents.

Used to ramp up the output holder’s output when the controller

output is not valid.

Used to ramp down the output holder’s output when the

controller is not valid.

5.2.2 UP /DOWN KEY OPERATION

Press the UP key or DOWN key to manipulate the output. Pressing and holding the key will

make the rate of ramping faster.

5 -2

Page 38

5.3 TROUBLESHOOTING AND MAINTAINANCE

Indication

The bar graph does not

show any indication

The bar graph does not

show any indication and

pressing the UP key does

not change the value

Possible Cause Solution

The output is zero percent.

This is because each

segment in the bar graph

represents 10 % of the value.

Each segment has varying

light intensity to represent

any intermediate value.

This could be because there

is no load at the output of the

output holder or the wires are

cut or there is loose

connection at the terminals.

Faulty instrument

Output Holder Instructions

OPERATION AND MAINTAINANCE

Check the wiring at the

terminals 6 and 2 at the

back or the load (Current

to pressure converter or

the final control element).

Call customer service.

5 -3

Page 39

Output Holder Instructions

OPERATION AND MAINTAINANCE

Notes:

5 -4

Page 40

Page 41

The Company’s policy is one of continuous product improvement and the right

is reserved to modify the information contained herein without notice, or to

make engineering refinements that may not be reflected in this bulletin.

Micromod Automation assumes no responsibility for errors that may appear in

this manual.

© 2004 MicroMod Automation, Inc. Printed in USA

IB-1750N-INS, Issue 2 12/2004

MicroMod Automation, Inc.

75 Town Centre Drive

Rochester, NY USA 14623

Tel. 585-321 9200

Fax 585-321 9291

www.micromodautomation.com

Loading...

Loading...