Page 1

ICN Mini Link User’s Guide

1731N Model A – Mini Link Board for PC AT (Version 1)

1732N Model A – ICN Interface Board (Version 1)

Page 2

MicroMod Automation, Inc.

The Company

MicroMod Automation is dedicated to improving customer efficiency by providing the most cost-effective, application-specific process solutions

available. We are a highly responsive, application-focused company with years of expertise in control systems design and implementation.

We are committed to teamwork, high quality manufacturing, advanced technology and unrivaled service and support.

The quality, accuracy and performance of the Company's products result from over 100 years experience, combined with a continuous

program of innovative design and development to incorporate the latest technology.

Use of Instructions

Ì Warning. An instruction that draws attention to the risk of

injury or death.

Note. Clarification of an instruction or additional

information.

q Caution. An instruction that draws attention to the risk of

the product, process or surroundings.

Although Warning hazards are related to personal injury, and Caution hazards are associated with equipment or property damage, it

must be understood that operation of damaged equipment could, under certain operational conditions, result in degraded process

system performance leading to personal injury or death. Therefore, comply fully with all Warning and Caution notices.

Information in this manual is intended only to assist our customers in the efficient operation of our equipment. Use of this manual for

any other purpose is specifically prohibited and its contents are not to be reproduced in full or part without prior approval of MicroMod

Automation, Inc.

Licensing, Trademarks and Copyrights

MOD 30 and MOD 30ML are trademarks of MicroMod Automation, Inc.

MODBUS is a trademark of Modicon Inc.

Health and Safety

To ensure that our products are safe and without risk to health, the following points must be noted:

The relevant sections of these instructions must be read carefully before proceeding.

1. Warning Labels on containers and packages must be observed.

2. Installation, operation, maintenance and servicing must only be carried out by suitably trained personnel and in accordance with the information

given or injury or death could result.

3. Normal safety procedures must be taken to avoid the possibility of an accident occurring when operating in conditions of high

4. pressure and/or temperature.

5. Chemicals must be stored away from heat, protected from temperature extremes and powders kept dry. Normal safe handling procedures must be

used.

6. When disposing of chemicals, ensure that no two chemicals are mixed.

Safety advice concerning the use of the equipment described in this manual may be obtained from the Company address on the back

cover, together with servicing and spares information.

i Information. Further reference for more detailed

information or technical details.

All software, including design, appearance, algorithms and source

codes, is copyrighted by MicroMod Automation, inc. and is owned by

MicroMod Automation or its suppliers.

Page 3

IB-23C003

CONTENTS

––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––

CONTENTS

Page

SECTION 1 - INTRODUCTION

1.1 DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.2 EXPLANATION OF SERIAL AND CATALOG NUMBER . . . . . . . . . . . . . . . . . . 1-2

1.3 PRODUCT DESCRIPTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1.3.1 1731N Mini Link Board for AT Style PC . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1.3.2 1732N ICN Interface Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

1.4 TECHNICAL SUMMARY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

1.5 RELATED DOCUMENTATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

SECTION 2 - INSTALLATION

2.1 PREPARING THE PERSONAL COMPUTER . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.2 DETERMINING MINI LINK BASE ADDRESS/INTERRUPT LEVEL . . . . . . . . . . 2-2

2.3 INSTALLING THE MINI LINK BOARD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

2.4 SWITCH AND JUMPER SETTINGS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2.4.1 Serial Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2.4.2 ICN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

SECTION 3 - PROGRAMMING MINI LINK INTERRUPTS

3.1 GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.2 COMMUNICATIONS POLLING (NO INTERRUPTS) . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.3 COMMUNICATIONS USING INTERRUPT SERVICE ROUTINES . . . . . . . . . . . . . . . 3-1

SECTION 4 - TROUBLESHOOTING THE MINI LINK

4.1 NO RESPONSE FROM LINK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.2 PARITY, FRAMING OR OVERRUN ERROR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.3 FROZEN DISPLAY/NO RESPONSE FROM PC KEYBOARD . . . . . . . . . . . . . . . . . . 4-2

4.3 NO RESPONSE FROM THE FIELD INSTRUMENTS . . . . . . . . . . . . . . . . . . . . . . . 4-2

APPENDIX A - ALPHANUMERIC LISTING OF JUMPERS AND SWITCHES

APPENDIX B - CONNECTOR DESCRIPTIONS

ILLUSTRATIONS

Figure Page

1-1 Mini Link Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

A-1 Switch and Jumper Locations for 1731N Mini Link . . . . . . . . . . . . . . . . . . . . . . A-1

A-2 Switch and Jumper Locations for 1732N ICN Interface Board . . . . . . . . . . . . . . . A-2

i

Page 4

IB-23C003

CONTENTS

–––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––

TABLES

Table Page

2-1 Personal Computer Device Inventory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2-2 DIP Switch SW2, PC/AT Serial Port Base Address . . . . . . . . . . . . . . . . . . . . . . 2-3

2-3 Mini Link Hardware Interrupts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

2-4 Mini Link Interrupt Polarity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

2-5 Mini Link PC/AT Serial Port Baud Rates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

2-6 Mini Link External Serial Port Baud Rates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

3-1 Interrupt Service Vector Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

A-1 Alphanumeric Listing of Jumpers and Switches for 1731N Mini Link . . . . . . . . . . A-1

A-2 Alphanumeric Listing of Jumpers and Switches for 1732N ICN Interface Board . . A-2

B-1 IBM PC/AT Mini Link Board Connector Pinout . . . . . . . . . . . . . . . . . . . . . . . . . B-1

B-2 Mini Link RS-232 Connector Pinout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-2

B-3 Mini Link ICN0 and ICN1 Connector Pinout . . . . . . . . . . . . . . . . . . . . . . . . . . . B-2

ii

Page 5

1.1 DESCRIPTION

The 1731N Mini Link with 1732N ICN Interface Board, Figure 1-1, provides a general

purpose serial interface to MOD 30 and MODCELL instruments via the Instrument

Communications Network (ICN). The 1731N Mini Link supports one ICN and the 1732N

ICN Interface Board supports a second ICN. The Mini Link provides intelligent buffers that

enable the operation of higher level devices (such as personal or other computers) by:

• Assembling display and tuning information for a number of instruments and storing the

data in block format. This relieves the host from executing individual requests and

improves the efficiency of the communications.

• Permitting the host device to download and upload instrument configuration

information. This enables instrument configuration to be performed at a central

location using a personal computer that can easily display, manipulate and document

data.

IB-23C003

INTRODUCTION

SECTION 1

INTRODUCTION

• Permitting limited peer-to-peer communications between ICNs.

• Providing diagnostic checks for message validity resulting in secure general purpose

serial interfaces to the ICN.

• Off-loading trend functions when supported by the host application software.

S-3002-134

Figure 1-1. Mini Link Module

1-1

Page 6

IB-23C003

INTRODUCTION

Physically the Mini Link is a PC/AT plug-in module which completely emulates the 1720N

Communications Link (refer to IB-23C001) for up to two Instrument Communications

Networks. The base configuration consists of:

• An Integral PC/AT Serial Port (dedicated to the Mini Link)

This serial port is DIP switch and jumper configurable to perform as an I/O-mapped

memory device at I/O base addresses 000

through 3F8h. These addresses include

h

the memory maps for the standard serial ports COM1, COM2, COM3 and COM4 (see

Section 2.4, Switch and Jumper Settings).

• One Instrument Communications Network Controller

The base ICN Controller is accessed via a two-wire or three-wire connection at the

rear of the personal computer using the three screw terminal block at the connection

marked "ICN0". Communication can be maintained between the personal computer

and up to 15 field instruments.

• Optical Isolation Between Instruments and Personal Computer

The optical isolation feature is jumper-selectable (see Section 2.4, Switch and

Jumper Settings) and provides a minimum of 3000 Vdc electrical insulation between

the Instrument Communications Network and the personal computer. THIS FEATURE

IS NOT FACTORY SET.

• External Pushbutton Reset

A 750ms reset pulse can be issued to the Mini Link by pressing the reset button

located at the rear of the personal computer. The button is prominently labeled

"RESET".

• A Second Serial Port for An External Controlling Device

The Mini Link includes a nine-pin D-Shell connector for an external RS-232 serial port.

This serial port could be used to provide redundant control of the instrument system

with a local or remote external computer.

The 1731N Mini Link Board can be enhanced with a 1732N ICN Interface Board to provide

communications access to an additional 15 field instruments. This daughter board is

mounted to the Mini Link board and is accessed via a two- or three-wire connection at the

rear of the personal computer using the three-screw terminal block at the connection

marked "ICN1".

1.2 EXPLANATION OF SERIAL AND CATALOG NUMBER

The products described in this book have numbers that help identify specific features.

The general format of these numbers is described below. Specific product descriptions

follow in Section 1.3.

The serial number stamped on the product data plate consists of the catalog number and,

in some cases, a sequential identification number. The serial number, which is described

below, contains a series of single and multiple-character codes. These codes provide

specific information concerning various electrical and/or structural options. Certain

combinations are not allowed. Options and combinations are subject to change.

1-2

Page 7

Sample Serial No. 1731N Z 10 1 01 A – 555

Base Number

Unused

Catalog

Number

Electrical Code

ICN Interface

Firmware

Model/Design Level

Sequential Identification Number

1.3 PRODUCT DESCRIPTIONS

The following product is maintained at the serial and catalog number level. The

descriptions included in this section give a brief overview of its functions and features.

IB-23C003

INTRODUCTION

1.3.1 1731N Mini Link Board for AT Style PC

The 1731N Mini Link Board is a full length card with dimensions and bus connections for

use in the IBM PC/AT style personal computer. The central processor for the Mini Link is

the 63B09E using an 8-bit bus and a 2 mHz dual phase clock. The processor board

checks message protocol and handles all data transfers between the ICN interface boards

and intelligent devices connected to the serial I/O board. Each ICN interface board

services direct communication with one ICN (up to 15 instruments).

The processor board keeps track of all message requests and responses. A request to

the processor board for foreground (display) data from a host device results in the data

being retrieved from the instrument ICN interface board which is automatically updated

every 250 msec. This permits the data to be sent immediately to the host. A request

from a host device for the background (tuning) data of an instrument is acknowledged with

a "wait and acknowledge" response. The instrument ICN interface board retrieves the

requested background data from the instrument and passes it to the processor board.

When all of the data for the deferred request is received by the processor board, it is

immediately transmitted to the host.

Catalog Number Description for 1731N

BASE NUMBER 1731N Mini Link Board for AT Style PC

UNUSED Z Unused Character

ELECTRICAL CODE 10 General Purpose

ICN INTERFACE 1 One ICN

2 Two ICNs

VERSION 01 Version 1

MODEL A 1st design level

Sample Number 1731NZ10101A (Product is serialized)

1-3

Page 8

IB-23C003

INTRODUCTION

1.3.2 1732N ICN Interface Board

The ICN Interface Board is an ICN controller card only and is used to add a second ICN to

the 1731N when the option board was not originally specified. The central processor is

the 63B09E using an 8-bit bus and a 2 mHz dual phase clock.

Catalog Number Description for 1732N

BASE NUMBER 1732N ICN Interface Board

UNUSED Z Unused Character

ELECTRICAL CODE 10 General Purpose

UNUSED 0 Unused Character

FIRMWARE VERSION 01 Version 1

MODEL A 1st design level

Sample Number 1732NZ10001A

1-4

Page 9

1.4 TECHNICAL SUMMARY

POWER REQUIREMENTS

1731N Mini Link Board for AT Style PC

+5VDC at 0.8 Amp provided by personal computer

+24VDC at 0.2 Amp generated on Mini Link board

PHYSICAL CHARACTERISTICS

Card Dimensions (Including Card Edge Connector)

1731NZ10101A Length: 13.26 inches (336.80 mm)

I/O Ports

Serial Port 1: Internal AT I/O Channel compatible card edge

Serial Port 2: J2, DB9 female

ICN0: J3, 2-wire communications, ground

ICN1: J4, 2-wire communications, ground

IB-23C003

INTRODUCTION

Width: 4.75 inches (120.65 mm)

Height: 0.70 inches (17.78 mm)

ICN Connections: 18 AWG (1mm), twisted pair wire (an additional 18 AWG wire is

required to use the isolation feature as described in Section 2.4.2.).

Switches and Jumpers: See Appendix A

Microprocessor

Link Processor: 63B09E, 8 bit, 2 mHz dual phase clock

ICN Processor: 63B09E, 8 bit, 2 mHz dual phase clock

COMMUNICATIONS

PC/AT Serial Port 1: Configurable as COM1, COM2, COM3, or COM4 as well as

non-standard I/O addresses

External Serial Port 2: Configurable as IRQ3 through IRQ7

Serial Port Transmission Standard: RS-232

Serial Port Parity: None (not configurable)

Serial Port Baud Rates: 76800*, 38400*, 19200, 9600

ICN Baud Rates: 62500*, 31250

* Software and firmware support for these baud rates is currently unavailable.

1-5

Page 10

IB-23C003

INTRODUCTION

PERFORMANCE CHARACTERISTICS

Absolute Maximum Ratings*

Temperature Under Bias: 0°C to +60°C ( 32°F to 140°F)

Storage Temperature: –40°C to +85°C (–40°F to 185°F)

Power Dissipation: 10W

Ambient Temperature Specifications

Operating: +4°C to +49°C +(40°F to +120°F)

Storage: -40°C to +74°C (–40°F to +165°F)

Relative Humidity

5 to 90% RH at 32°C

I/O Mapping: Supports I/O mapping on any 8-byte boundary between 000h and 3F8h

(cannot be installed as a memory mapped device).

Message Queue

Active: 4

Waiting Processing: 4

ICN Interface Memory Size

RAM: 16K bytes

PROM: 32K bytes

Trend

Variables Accumulated: 100 maximum; 16-bit words

Types per Variable: Minimum, maximum, average

Resolution: 1 minute

* Maximum ratings indicate limits beyond which permanent damage may occur. Continuous operation at these

limits is not intended and should be limited to those conditions specified under DC ELECTRICAL

CHARACTERISTICS.

DC ELECTRICAL CHARACTERISTICS

Symbol Parameter

One ICN

Min Max

Two ICNs

Min Max

Units

ICC Supply Current (Vcc=5V) 0.6 0.9 1.25 1.75 A

VILAT Input Low Voltage (PC to Mini Link) -0.5 0.8 -0.50 0.80 V

VIHAT Input High Voltage (PC to Mini Link) 2.0 Vcc 2.00 Vcc V

VOLAT Output Low Voltage (Mini Link to PC) --- 0.4 --- 0.40 V

VOHAT Output High Voltage (Mini Link to PC) 2.4 --- 2.40 --- V

AC ELECTRICAL CHARACTERISTICS

Symbol Parameter

One ICN

Min Max

Two ICNs

Min Max

Units

tADS Address Strobe Width 60 --- 60 --- ns

tAH Address Hold Time 0 --- 0 --- ns

tMR Master Reset Pulse Width 100 --- 100 --- us

tRC Read Cycle Delay 175 --- 175 --- ns

tAR Read Delay from Address 60 --- 60 --- ns

tRD IOR Read Strobe Width 125 --- 125 --- ns

RC Read Cycle = tRC + tAR + tRD 360 --- 360 --- ns

tWC IOW Write Strobe Width 100 --- 100 --- ns

tAW Write Delay from Address 60 --- 60 --- ns

tWR IOW Write Strobe Width 100 --- 100 --- ns

WC Write Cycle = tWC + tAW + tWR 360 --- 360 --- ns

1-6

Page 11

1.5 RELATED DOCUMENTATION

Additional reference information on ICN/Link communications can be found in the following

documents.

• IB-23G001 ICN Communication Link Programmers Reference Manual

• IB-23C001 ICN Communication Link Instruction Book for 1720N

IB-23C003

INTRODUCTION

1-7

Page 12

IB-23C003

INTRODUCTION

1-8

Page 13

SECTION 2

INSTALLATION

2.1 PREPARING THE PERSONAL COMPUTER

Prepare your PC/AT as follows:

1. Turn off the system unit.

2. Turn off all external options (printer, display, etc.).

3. Unplug the system unit power cord from the electrical outlet.

4. Unplug any external options from the electrical outlet.

5. Remove the system unit cover mounting screws.

6. Remove the system unit cover.

7. Use Table 2-1 as a worksheet to record the types of devices already installed in your

system unit. Keep this worksheet filed in a safe place for reference purposes when

troubleshooting.

IB-23C003

INSTALLATION

NOTE

To determine the base address and/or Interrupts used by previously

installed devices you may have to refer to the device documentation.

Table 2-1. Personal Computer Device Inventory

Expansion Installed Device Base Address Interrupts

Slot

1 _______________ ___________ ______

2 _______________ ___________ ______

3 _______________ ___________ ______

4 _______________ ___________ ______

5 _______________ ___________ ______

6 _______________ ___________ ______

7 _______________ ___________ ______

8 _______________ ___________ ______

2-1

Page 14

IB-23C003

INSTALLATION

2.2 DETERMINING MINI LINK BASE ADDRESS/INTERRUPT LEVEL

The total I/O address space required by the Mini Link is eight bytes in length. To

guarantee operation, the selected base address must be at least eight bytes below any

base address listed in Table 2-1.

Generally, if there are no serial devices (mouse, modem, or RS-232 serial card) any of the

standard COMx locations can be selected. These addresses have been reproduced in

this document. See the Section 2.4, Switch and Jumper Settings.

If your system is configured with a mouse, modem, RS-232 card or other serial devices,

more care will need to be taken.

1. If you have previously determined that there exists an open COMx address area

(including the associated Interrupt Line) use Table 2-2 to set the correct I/O address

on switch SW2. Select the corresponding Interrupt Line as shown in Table 2-3.

2. If you already have serial devices installed in your system, you must select a new

address for the Mini Link. Any selected base address will be a multiple of 8 (i.e.,

2E8

, 300h, 3F0h, 3F8h, etc.). Base addresses below 100h are not recommended!

h

Additionally, the highest address decoded by the Mini Link is 3FF

set the base address.

. Use Table 2-2 to

h

Address lines A0, A1 and A2 are not switch selectable. These lines

are used as Register Select Lines for the Mini Link UART.

3. Once the base address has been selected, you must select an interrupt level. Use

Table 2-3 to set ONE of the jumpers W15, W16, W17, W18 or W19 to select IRQ3,

IRQ4, IRQ5, IRQ6, or IRQ7, respectively.

2.3 INSTALLING THE MINI LINK BOARD

1. Remove the screw from the rear plate of an empty expansion slot. Save the screw

and discard the expansion slot cover.

2. Hold the Mini Link by the top and firmly press it into the expansion slot. If your

system's chassis has an expansion card guide, make sure the Mini Link card fits

snugly without interference to any card components.

3. Install the screw you removed in Step 1.

4. Install the system unit cover.

5. Install the cover mounting screws.

NOTE

2-2

6. Install the external options and power cords.

Page 15

2.4 SWITCH AND JUMPER SETTINGS

This section contains a brief description of the Mini Link switches and jumpers with an

application table for each. A quick reference table of all switches, jumpers, and their

functions is in Appendix A.

2.4.1 Serial Ports

The Mini Link has two serial ports. Each serial port can be configured with an

independent baud rate and CTS signal for access by two controlling consoles. The first

serial port is dedicated to the PC/AT I/O Channel and requires base address and interrupt

configuration. The second (optional) serial port can be accessed via a nine pin D-type

connector at the rear of the PC/AT by any RS-232 device.

Base Address of PC/AT Serial Port

The serial port dedicated to the PC/AT I/O Channel is factory configured to occupy the

standard I/O address of COM2 (02F8

of the PC/AT Serial Port is switch selectable using DIP switch SW2. Table 2-2 identifies

the possible DIP switch configurations for SW2.

IB-23C003

INSTALLATION

) with an interrupt level of IRQ3. The base address

h

Table 2-2. DIP Switch SW2, PC/AT Serial Port Base Address

Switch Setting for Port / Interrupt / Address

Switch

Assign-

ment

COM1,

IRQ4, 3F8

h

COM2,

IRQ3, 2F8

h

COM3,

IRQ4, 3E8

h

COM4,

IRQ3, 2E8

h

SW2-1 A3 OPEN OPEN OPEN OPEN

SW2-2 A4 OPEN OPEN CLOSED CLOSED

SW2-3 A5 OPEN OPEN OPEN OPEN

SW2-4 A6 OPEN OPEN OPEN OPEN

SW2-5 A7 OPEN OPEN OPEN OPEN

SW2-6 A8 OPEN CLOSED OPEN CLOSED

SW2-7 A9 OPEN OPEN OPEN OPEN

SW2-8 CommPort

OPEN OPEN OPEN OPEN

Enable*

* Set SW2-8 to the CLOSED position to disable the Mini Link entirely without removing the board from the personal

computer.

2-3

Page 16

IB-23C003

INSTALLATION

Hardware Interrupts and Polarity for PC/AT Serial Port

The Mini Link hardware interrupt levels may be set as shown in Table 2-3. Interrupt

polarity is set as shown in Table 2-4.

Table 2-3. Mini Link Hardware Interrupts

Interrupt

Level

W15 W16 W17 W18 W19

Jumper IN

IRQ3 Y NNNN

IRQ4 N Y N N N

IRQ5 N N Y N N

IRQ6 N N N Y N

IRQ7 NNNNY

Table 2-4. Mini Link Interrupt Polarity

Interrupt

Polarity

Jumper IN

W20 W21

Logic 1* Y N

Logic 0 N Y

* In most applications, the personal computer requires the factory set Interrupt Polarity of Logic 1.

BAUD Rates for Serial Ports 1 and 2

The Mini Link BAUD rates may be set as shown in Table 2-5 for serial port 1 and inTable

2-6 for serial port 2.

Table 2-5. Mini Link PC/AT Serial Port Baud Rates

Jumper IN

BAUD

W3 W4 W5 W6 W7

76800* Y NNNN

38400* N Y N N N

19200 N N Y N N

9600 N N N Y N

* Not recommended for use with currently available software.

2-4

Page 17

IB-23C003

INSTALLATION

Table 2-6. Mini Link External Serial Port Baud Rates

Jumper IN

BAUD

W12 W11 W10 W9 W8

76800* Y NNNN

38400* N Y N N N

19200 N N Y N N

9600 N N N Y N

* Not recommended for use with currently available software.

Clear-To-Send (CTS) for Serial Ports 1 and 2

Both the PC/AT and the External Serial Ports are outfitted with a CTS connection. In most

cases, the CTS signal will not be needed. In the event that your configuration requires a

CTS signal, install jumpers W1 and W2 as follows:

W1 Enables Clear To Send on External Serial Port 2

W2 Enables Clear To Send on PC/AT Serial Port 1

RS-232 Test Signal Jumper

Jumper W22 provides access to the 5V power plane of the Mini Link. If Jumper W22 is

connected, the 5V signal will appear on pin 9 of the RS-232 connector. This jumper will

normally be used for test purposes only.

2-5

Page 18

IB-23C003

INSTALLATION

2.4.2 ICN

ICN Isolation

The Mini Link is fitted with Opto-isolation components capable of providing a minimum of

3000 VDC electrical insulation between the Instrument Communication Network and the

PC/AT digital circuitry. This option is jumper-selectable by disabling the connection on

W23 (remove this jumper to enable optical isolation). If optical isolation is enabled, the

ICN connector must be fitted with a ground wire. This third wire should be secured to a

GROUND TERMINAL on the termination panel.

Mini Link ICN Device Address

Each device on a given Instrument Communication Network must be assigned a unique

address between 0 and 15. Normally, the Mini Link will be assigned an address of 0

(Factory Set) with the instruments starting at 1, 2, 3, etc. In the case where the factoryset device address is not suitable, use SW1 to change the address for ICN0 and use

switch U1 .to change the address for ICN1.

ICN Baud Rate

The factory-set baud rate for instrument communication over the ICN is 31,250 bps. This

baud rate can be increased to 62,500 bps as follows:

ICN0

W13 Installed – Selects ICN0 Baud Rate of 62,500 bps

W14 Installed – Selects ICN0 Baud Rate of 31,250 bps

ICN1

J2 Installed – Selects ICN1 Baud Rate of 31,250 bps

J3 Installed – Selects ICN1 Baud Rate of 62,500 bps

2-6

Page 19

PROGRAMMING MINI LINK INTERRUPTS

SECTION 3

PROGRAMMING MINI LINK INTERRUPTS

3.1 GENERAL

The IBM PC/AT has reserved hardware interrupts for common devices (printers, disk

drives, etc.) within the interrupt level range (IRQ3-IRQ7) of the Mini Link. The Mini Link

does not support the high order (8-15) interrupt request lines available on the IBM PC/AT.

To operate the Mini Link on COM1, COM2, COM3 or COM4, the jumper settings from

Tables 2-2, 2-3 and 2-4 must be employed exactly as they appear. MicroMod Auto-

mation assumes no liability for improperly installed hardware or damage caused by

improperly installing the Mini Link card in your personal computer.

3.2 COMMUNICATIONS POLLING (NO INTERRUPTS)

IB-23C003

Not all serial communications routines require the use of hardware interrupts. If your

controlling software polls the Transmit Data Register Empty (TDRE) and Receive Data

Register Full (RDRF) status bits of the PC/AT Serial Port, you probably will not need to

enable ANY of the interrupt lines. The Mini Link will continue to function properly without

an enabled Interrupt Request Line.

3.3 COMMUNICATIONS USING INTERRUPT SERVICE ROUTINES

To enable a particular Mini Link Interrupt line (IRQ3-IRQ7), Interrupt Service Routine

commands must be issued to the 8259 Programmable Interrupt Controller (PIC) by the

controlling software. In most cases, these commands are issued by the controlling

software package (PC30, etc.). In those cases where the user is programming the Mini

Link, the software protocol described below is observed.

CPU Response to Programmed Interrupt

When an interrupt is generated by a device on the personal computer I/O channel, the

CPU responds by:

1. Completing the current CPU instruction

2. Saving the contents of volatile registers

3. Fetching the interrupt ID from the PIC

4. Fetching the interrupt service routine vector associated with interrupt ID

5. Executing the interrupt service routine at the memory location pointed to by the

interrupt service routine vector

6. Restoring the contents of volatile registers

7. Continuing execution of the current program

3-1

Page 20

IB-23C003

PROGRAMMING MINI LINK INTERRUPTS

Interrupt Service Routine Location

It is the user's responsibility to install an Interrupt Service Routine at an appropriate

memory location (according to the configured hardware interrupt) which does not interfere

with concurrently operated software or hardware.

In most cases, these interrupt service routines will be simple Transmit/Receive operations

with user conditions determining success or failure of the routines. Table 3-1 lists the

interrupt service vector locations. These are valid for most default system memory maps.

Table 3-1. Interrupt Service Vector Locations

Interrupt Low Memory Location Of Service Vector *

IRQ3 0000:000C

IRQ4 0000:0010

IRQ5 0000:0014

IRQ6 0000:0018

IRQ7 0000:001C

* These addresses are assigned by software only. Because they are not hardwired into

the system, they could be changed by resident or normally terminated routines.

h

h

h

h

h

3-2

Page 21

TROUBLESHOOTING THE MINI LINK

4.1 NO RESPONSE FROM LINK

For software that polls Transmit Data Register Empty (TDRE) and Receive Data Register

Full (RDRF), a "No Response From Link" error indicates that:

• The hardware-configured base address (see Table 2-2 settings for switch SW2) does

not match the address used by the controlling software for serial communications

or,

• There exists installed hardware whose I/O address space conflicts with the Mini Link

base address as configured by SW2.

In addition, if the controlling software uses Interrupt Service Routines for serial

communications, the configured Interrupt Request Line for the PC/AT Serial Port (see

Table 2-3 jumper settings for W15 - W19) must match the Interrupt Request line expected

by the controlling software. There must be no conflict with any other installed interruptdriven hardware. Use Table 2-1 to determine an appropriate Interrupt Request Line.

IB-23C003

TROUBLESHOOTING THE MINI LINK

SECTION 4

If the Mini Link is configured for an address location other than COM1 or COM2 and the

controlling software is interrupt-driven, it is the user's responsibility to make sure that

proper Interrupt Service Routine Vectors and Interrupt Service Routines are in place at the

time of operation.

Be wary of serial ports that are integrated on the personal computer system board. Some

manufacturers have included a serial port (usually COM1, IRQ4) as part of the system

board, eliminating that address and interrupt space for use by user-installed hardware.

See the User's Manual for your system for more information.

4.2 PARITY, FRAMING OR OVERRUN ERROR

Check the configured baud rate for the PC/AT Serial Port of the Mini Link. Confirm that

the configured baud rate is the same as that expected by the controlling software (see

Table 2-5 jumper settings for W3 - W7).

If this error occurs on the External Serial Port, check the configured baud rate for the

External Serial Port (see Table 2-6 jumper settings for W8 - W12).

4-1

Page 22

IB-23C003

TROUBLESHOOTING THE MINI LINK

4.3 FROZEN DISPLAY/NO RESPONSE FROM PC KEYBOARD

This type of problem is usually indicative of address or interrupt conflict on the personal

computer I/O channel. You must establish a clear range of eight bytes I/O address space

(in the range 000

no other installed devices using the same interrupt request line as the Mini Link.

Use Table 2-1 as a guide to determine unused address space on your system's I/O

channel and Interrupt Request Bus. If you cannot determine the base addresses of the

installed hardware, contact the technical support representative of the hardware in

question.

If you continue to have difficulties in making the Mini Link work, contact your sales

representative.

to 3FFh) to successfully operate the Mini Link. In addition, there can be

h

4.3 NO RESPONSE FROM THE FIELD INSTRUMENTS

If communication has been established between the Mini Link and the Personal Computer,

but the instruments on the ICN do not respond, compare your configuration to the

checklist below:

1. The ICN (+) lead of the two-wire interface is connected to the terminal block (+)

screw on the rear of the Mini Link.

2. The ICN (–) lead of the two-wire interface is connected to the terminal block (–) screw

on the rear of the Mini Link.

3. If using the Isolation Feature (see jumper setting for W23), there is a third wire

connected between the Mini Link terminal block GND screw and ICN ground on the

instrument termination panel.

4. The length of the ICN (including the total length of the physical two-wire bus between

each node on the ICN and the length of the instrument cables between the nodes and

the instruments) does not exceed 2000 feet or 609.6m.

5. The ICN is appropriately terminated as described in the instructions for MOD 30 or

MODCELL.

6. If using a base configuration of the Mini Link (supporting 1 ICN) the two- wire interface

is connected to the Mini Link terminal block labeled ICN0.

7. If using a fully-configured Mini Link (supporting 2 ICNs) the two-wire interface for the

first ICN is connected to the Mini Link terminal block labeled ICN0 while the two-wire

interface for the second ICN is connected to the Mini Link terminal block labeled ICN1.

8. Instrument address is properly configured in hardware and software.

4-2

9. Mini Link ICN device address (as set by BCD switch SW1) does not conflict with any

instrument ICN device address.

Page 23

APPENDIX A - JUMPERS AND SWITCHES

APPENDIX A

JUMPERS AND SWITCHES

IB-23C003

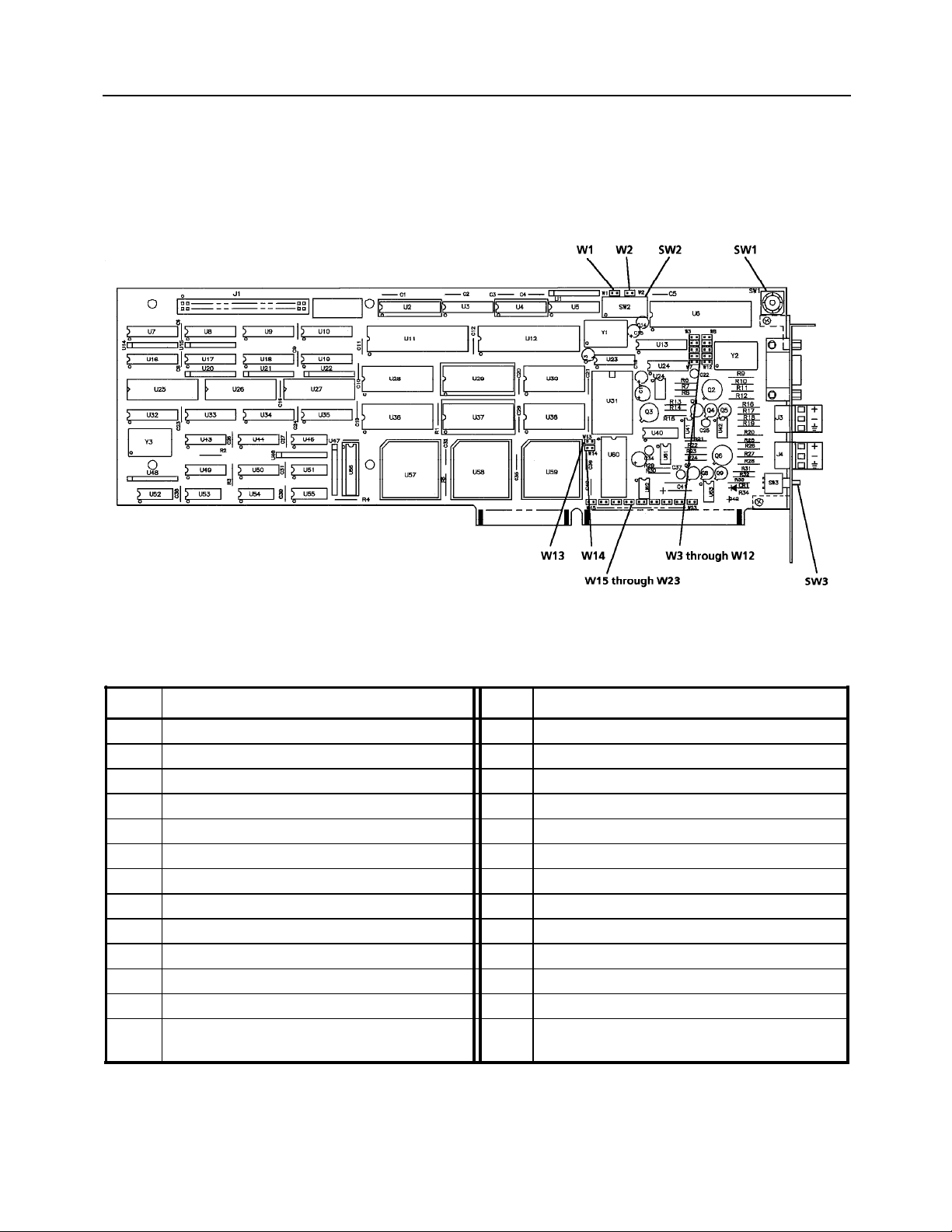

S-3002-134A

Figure A-1. Switch and Jumper Locations for 1731N Mini Link

Table A-1. Alphanumeric Listing of Jumpers and Switches for 1731N Mini Link

Ref. Function Ref. Function

SW1 Mini Link ICN Device Address W11* Select 38400 Baud on External Serial Port

SW2 Base Address of Integral Serial Port W12* Select 76800 Baud on External Serial Port

SW3 Mini Link Reset Switch W13 Select ICN Baud Rate of 62500 bps

W1 Enable CTS on External Serial Port W14 Select ICN Baud Rate of 31250 bps

W2 Enable CTS on PC/AT Serial Port W15 Select IRQ3 for Integral Serial Port

W3* Select 76800 Baud on Integral Serial Port W16 Select IRQ4 for Integral Serial Port

W4* Select 38400 Baud on Integral Serial Port W17 Select IRQ5 for Integral Serial Port

W5 Select 19200 Baud on Integral Serial Port W18 Select IRQ6 for Integral Serial Port

W6 Select 9600 Baud on Integral Serial Port W19 Select IRQ7 for Integral Serial Port

W7 RESERVED W20 Select Interrupt Polarity Logic 1

W8 RESERVED W21 Select Interrupt Polarity Logic 0

W9 Select 9600 Baud on External Serial Port W22 Enable 5V Test Signal on 9-pin RS-232

W10 Select 19200 Baud on External Serial Port W23 De-Select Isolation Feature on ICN / PC

Interface

* Software and firmware support for these baud rates is currently unavailable.

A-1

Page 24

IB-23C003

APPENDIX A - JUMPERS AND SWITCHES

Figure A-2. Switch and Jumper Locations for 1732N ICN Interface Board

Table A-2. Alphanumeric Listing of Jumpers and Switches for 1732N ICN Interface Board

Ref. Function

J2 Select ICN1 Baud Rate of 31,250 bps

J3* Select ICN1 Baud Rate of 62,500 bps

U1 Mini Link ICN1 Device Address

* Firmware support for this baud rates is currently unavailable.

A-2

Page 25

APPENDIX B - CONNECTOR DESCRIPTIONS

APPENDIX B

CONNECTOR DESCRIPTIONS

Table B-1. IBM PC/AT Mini Link Board Connector Pinout

IB-23C003

Component Side

("A" side w/A1 near rear panel)

I/O Pin Signal I/O

("B" side w/B1 near rear panel)

I/O Pin Signal I/O

Circuit Side

A1 –I/OCHCK I B1 GND GND

A2* SD7 I/O B2* RESET D O

A3* SD6 I/O B3* +5V Power

A4* SD5 I/O B4 IRQ9 I

A5* SD4 I/O B5 –5V Power

A6* SD3 I/O B6 DRQ2 I

A7* SD2 I/O B7 –12V Power

A8* SD1 I/O B8 0WS I

A9* SD0 I/O B9 +12V Power

A10 –IOCHRDY I B10* GND GND

A11* AEN O B11 –SMEMW O

A12 SA19 I/O B12 –SMEMR O

A13 SA18 I/O B13* –IOW I/O

A14 SA17 I/O B14* –IOR I/O

A15 SA16 I/O B15 –DACK3 O

A16 SA15 I/O B16 DRQ3 I

A17 SA14 I/O B17 –DACK1 O

A18 SA13 I/O B18 DRQ1 I

A19 SA12 I/O B19 –Refresh I/O

A20 SA11 I/O B20 CLK O

A21 SA10 I/O B21* IRQ7 I

A22* SA9 I/O B22* IRQ6 I

A23* SA8 I/O B23* IRQ5 I

A24* SA7 I/O B24* IRQ4 I

A25* SA6 I/O B25* IRQ3 I

A26* SA5 I/O B26 –DACK2 O

A27* SA4 I/O B27 T/C O

A28* SA3 I/O B28 BALE O

A29* SA2 I/O B29* +5V Power

A30* SA1 I/O B30 OSC O

A31* SA0 I/O B31* GND GND

C1 SBHE I/O D1 –MEMCS16 I

C2 LA23 I/O D2 –I/OCS16 I

C3 LA22 I/O D3** IRQ10 I

C4 LA21 I/O D4** IRQ11 I

C5 LA20 I/O D5** IRQ12 I

C6 LA19 I/O D6** IRQ15 I

C7 LA18 I/O D7** IRQ14 I

C8 LA17 I/O D8 –DACK0 O

C9 –MEMR I/O D9 DRQ0 I

C10 –MEMW I/O D10 –DACK5 O

C11 SD08 I/O D11 DRQ5 I

C12 SD09 I/O D12 –DACK6 O

C13 SD10 I/O D13 DRQ6 I

C14 SD11 I/O D14 –DACK7 O

C15 SD12 I/O D15 DRQ7 I

C16 SD13 I/O D16 +5V Power

C17 SD14 I/O D17 –MASTER I

C18 SD15 I/O D18 GND GND

* Currently in use by the Mini Link ** Usable by the Mini Link with minor

modification

B-1

Page 26

IB-23C003

APPENDIX B - CONNECTOR DESCRIPTIONS

Table B-2. Mini Link RS-232 Connector Pinout

I/O Pin Signal Name I/O

1 GND GND

2 RXDATA I

3 TXDATA O

4 NC -

5 GND GND

6 NC -

7 RTS I

8 CTS O

9* NC -

* Pin 9 can be configured to present Mini Link's 5VDC (for test purposes only) by using jumper W22.

Table B-3. Mini Link ICN0 and ICN1 Connector Pinout

Terminal Signal Name*

1 IBUS(+)

2 IBUS(–)

GND GND

* Two- or Three-Wire Connection for ICN0 and ICN1. The (+) and (-) terminals accept signals from the ICN. The third terminal,

labeled "GND" is used when the Isolation Feature is employed (see jumper setting for W23).

B-2

Page 27

Page 28

The Company’s policy is one of continuous product improvement and the right

is reserved to modify the information contained herein without notice, or to

make engineering refinements that may not be reflected in this bulletin.

Micromod Automation assumes no responsibility for errors that may appear in

this manual.

© 2004 MicroMod Automation, Inc. Printed in USA

IB-23C003, Issue 2 04/2005

MicroMod Automation, Inc.

75 Town Centre Drive

Rochester, NY USA 14623

Tel. 585-321 9200

Fax 585-321 9291

Loading...

Loading...