Micro Fence Circle Jig User guide

MICRO FENCE

The Micro Fence Circle Jig

13160 Saticoy St. N. Hollywood, CA 91605 Phone 1-800-480-6427

Email: microfence@microfence.com Website: www.microfence.com

Circle Jig

The

a separate complete tool, (the

INSTRUCTIONS FOR OPERATION:

Circle Jig

The

curves and circles. It will provide telescoping adjustability and measuring capability for circles with

diameters from approximately 6" to 48". It will also function as the adjustable portion of your own

shop-made jig for larger work requirements. We hope it will serve as a catalyst for your thinking as

you dream up and plan your woodworking projects.

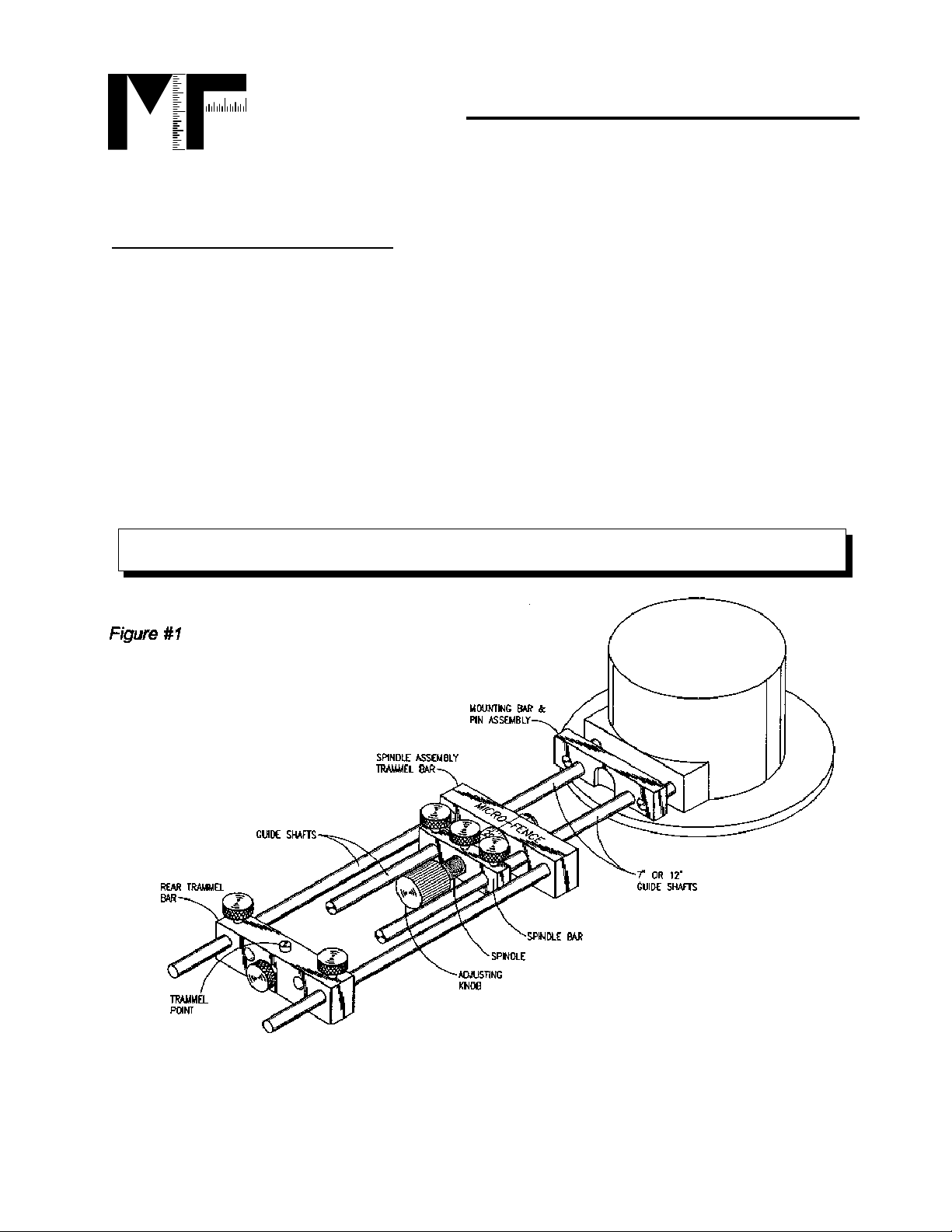

If you already own a Micro Fence Edge Guide, you have the appropriate mounting bar, pins and

guide shafts for the installation of the

body/spindle assembly and replace it with the

the unit will appear as shown in Fig.1.) If you have purchased the

own the entire Micro Fence System, the proper mounting bar, pins and screws will be supplied with

the tool.

Be sure your router is unplugged and switched off before installing this accessory.

is available as an accessory to the Edge-Guide, (the

Circle Jig Complete

was designed to maximize your router's versatility and efficiency in the making of

Circle Jig Attachment

).

. Simply slide off the Micro Fence

Circle Jig Attachment

Circle Jig Attachment),

. (When properly assembled,

Circle Jig Complete

and do not

or as

There are several ways in which your

certain advantages when addressing specific types of work requirements. Your first decision will be

to select the assembly that best serves your needs. Some of the most common tasks are listed in

the following pages.

Circle Jig

Revised 01/30/2002 1

can be assembled. Each configuration offers

MICRO FENCE

The Micro Fence Circle Jig

13160 Saticoy St. N. Hollywood, CA 91605 Phone 1-800-480-6427

Email: microfence@microfence.com Website: www.microfence.com

Circles Between 12" and 48" Diameter:

for circle cutting. We recommend your circles be initially "blanked out" slightly oversized with either

band or sabre saw, and then trued to perfection with our Circle Jig and your router fitted with a

spiral-fluted straight bit. We realize that this approach may not be the most efficient production

technique, but it will reduce the cutting load for your router and make the entire process a safer and

more manageable experience.

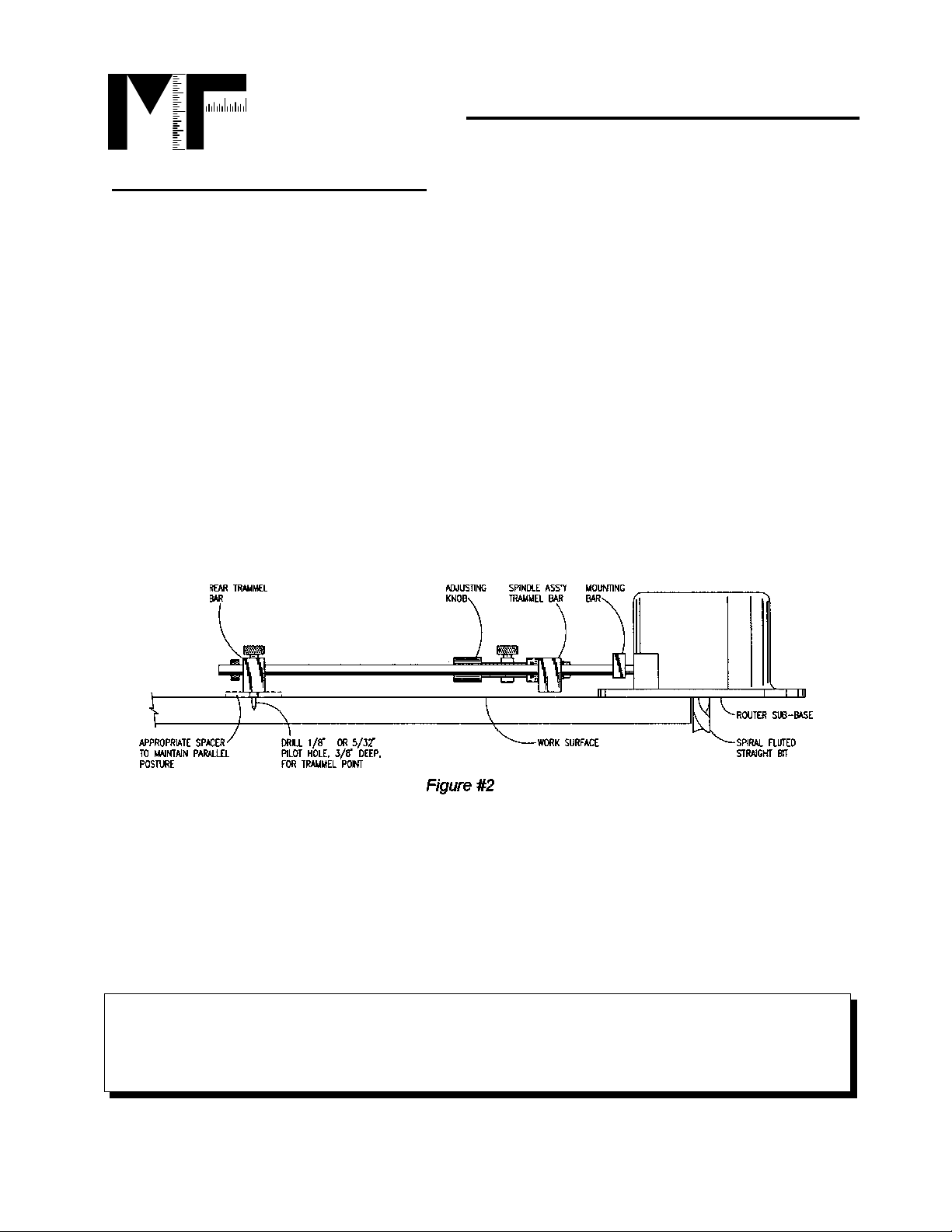

Use a compass or trammel beam for your original layout and then drill a 1/8" or 5/32" pilot hole, Drill

approximately 3/8" deep at the center position to receive the spiked end of the trammel point.

Unless you're working with material less than 1/2' thick, you won't have to drill all the way through

your workpiece.

unmarked)

locking screw slightly loosened. Place the trammel bar, over the pilot hole and gently tap the 5/32"

spike on the end of the trammel point into it. The trammel bar should be adjusted up or down on the

pin to insure that the entire jig is parallel to the work surface. (See Fig. 2). If you wish you may

insert a spacer of appropriate thickness between the work surface and the bottom of the trammel

bar. Be sure, then, to tighten the locking thumbscrew.

(This will allow you to work upside-down and leave the top side of your work

. Position the trammel point in the center hole of the rear trammel bar, leaving the brass

Figure 1 illustrates the assembly used most frequently

Set the initial jig position so that the router bit is slightly clear of the material to be cut. Make a

"power-off" revolution to check all settings and to see that a smooth, uninterrupted motion will be

achieved. The use of a dry lubricant spray on the sub-base of the router may provide improved

motion. Once you are satisfied that all systems are "go", you're ready to make a circle.

Turning the spindle clockwise draws the bit toward the fence; counter-clockwise pushes

it away. Remember that routers rotate clockwise, (when viewed from above). Your feed

should be counter-clockwise to avoid “climb-cutting.” Take it easy. NEVER force your

router beyond it’s load capability.

Revised 01/30/20022

MICRO FENCE

g

q

The Micro Fence Circle Jig

13160 Saticoy St. N. Hollywood, CA 91605 Phone 1-800-480-6427

Email: microfence@microfence.com Website: www.microfence.com

Be sure to tighten all mounting and adjusting screws firmly. Failure to do so can result in

spoiled work or injury. We encourage you to develop the habit of rechecking tightness

uently during use to insure that the router’s vibration has not caused loosening.

fre

Start the router and gently "dial" into the cut. Turn the Circle Jig's adjusting knob clockwise until you

hear the bit touch the workpiece. When contact has occurred, dial approximately .010" further and

make an initial pass around the work. "Dead" spots or heavier cutting sounds will indicate the

trueness of your circle. We recommend subsequent cuts in roughly .010" increments until you

become familiar with the characteristics of both material and machine. Your circle will be true when

even cutting occurs all the way around the work. Check your diameter with tape measure or

calipers and continue "dialing in" until you achieve the dimension you require.

Note

: Micro Fence's Vacuum Center will allow you to secure your jig to the work surface without

any need for a pilot hole. Call for additional information.

Circles Smaller than 12":

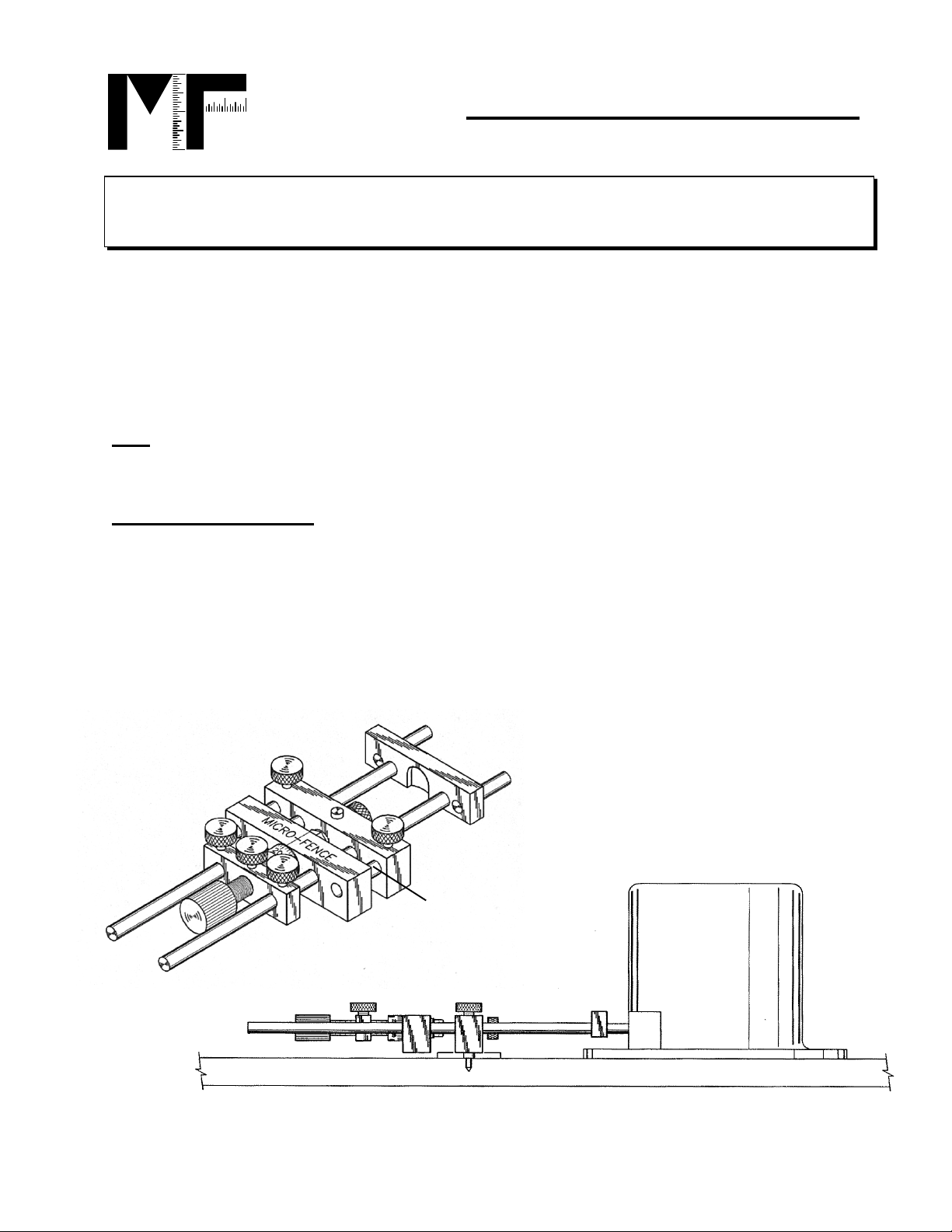

The Micro Fence Circle Jig system offers an assembly option for smaller circles. Figures 3 & 4 show

the rear trammel bar mounted in front of the spindle assembly using the two 5/16” X 1 1/2" pins that

are included in your parts bag. After removing the two 12" guide shafts from the spindle assembly

trammel bar, these pins may be installed in a position pointing toward your router. They will provide

a place to mount the rear trammel bar, and thus utilize the 1/4" trammel pin as your center.

pay particular attention to keep the Circle Jig parallel to your workpiece.

can be adjusted vertically so that its shoulder supports the jig. Optionally, a spacer, (or washer) of

appropriate thickness can be placed between the work and the bottom of the spindle bar.

(See Figure 4).

Figure #3

5/16” x 1½” Pins

The trammel point

ure #4

Fi

Always

Revised 01/30/2002 3

Loading...

Loading...