Microcom Technologies GpLV, Gp User Manual

User Guide

Part Number: 0451-0024

Issue Number: 2

COMMANDERGGpp

model sizes 1 to 4

0.75kW to 110kW

(1HP to 150HP)

COMMANDERGGpp LVLV

model sizes 1 to 3

0.37kW to 22kW

(0.5HP to 30HP)

General Purpose Variable Speed Drive

for induction motors

General information

The manufacturer accepts no liability for any

consequences resulting from inappropriate ,

negligent or incorrect installation or adjustment of

the optional operating parameters of the equipment

or from mismatching the variable speed drive

(Drive) with the motor.

The contents of this User Guide are believed to be

correct at the time of printing. In the interests of a

commitment to a policy of continuous development

and improvement, the manufacturer reserves the

right to change the specification of the product or

its performance, or the contents of the User Guide,

without notice.

All rights reserved. No parts of this User Guide may

be reproduced or transmitted in any form or by any

means, electrical or mechanical including

photocopying, recording or by any informationstorage or retrieval system, without permission in

writing from the publisher.

Important...

Drive software version

This product is supplied with the latest version of

user-interface and machine-control software. If this

product is to be used with other Control Techniques

variable speed drives in an existing system, there

may be some differences between their software

and the software in this product. These differences

will cause a difference in functions. This may also

apply to variable speed drives returned from a

Control Techniques Service Centre.

If there is any doubt, contact a Control Techniques

Drive Centre.

Copyright © March 2000 Control Techniques Drives Ltd

Author: RFD

Issue Code: gpxu2

Issue Date: March 2000

S/W Version: V03.XX.07 onward

Contents

Chapter

1 Introduction 1-1

1.1 How this User Guide can help you 1-1

1.2 Model sizes 1-1

1.3 Configuration layers 1-2

1.4 Default configurations 1-2

1.5 Operating mode 1-2

1.6 User-interface modes 1-2

1.7 Macro configurations 1-3

1.8 Plug-in option modules 1-4

1.9 Serial communications 1-4

2 Getting Started 2-1

2.1 How to use this chapter 2-1

2.2 Making signal and power connections 2-1

2.3 Introduction to the display and keypad 2-6

Display and keypad 2-6

Resetting the Drive 2-7

2.4 Working with software parameters 2-7

Parameters 2-7

Types of parameter 2-7

Adjusting parameter values 2-7

Making new values effective, and saving

them 2-7

Parameter 0.00 2-8

2.8 Setting up operating limits 2-15

Minimum and maximum frequencies 2-15

Acceleration rate 2-15

Deceleration rate 2-15

Braking resistor 2-15

Torque producing current limit 2-16

Voltage-control modes 2-16

Boost voltage 2-17

Voltage/frequency characteristic 2-17

3 Setting Up the Drive

(Macro Configurations) 3-1

3.1 How to use this chapter 3-1

3.2 Enabling a different macro configuration3-1

3.3 Macro 0

(default configuration)

3.4 Macro 1

3.5 Macro 2

3.6 Macro 3

3.7 Macro 4

3.8 Macro 5

3.9 Macro 6

3.10 Macro 7

General purpose

Easy mode

Motorized potentiometer

Preset frequencies

Torque control

PID (set-point control)

Axis-limit control

Brake control

3-2

3-9

3-15

3-21

3-27

3-33

3-38

3-45

2.5 How macro configurations change the

arrangement of the Menu 0 parameters 2-8

2.6 Initial setting up 2-9

Restoring the Drive to a default

configuration 2-9

Enabling Macro 1 2-10

Configuring the Drive for the motor 2-10

Autotune 2-12

Changing the user interface mode 2-12

2.7 Operating instructions 2-13

Terminal mode 2-13

Keypad mode 2-14

Trip and enable 2-14

Commander GP User Guide

Issue code: gpxu2

d2

i

Appendix

A Programming Instructions A-1

A.1 Electrical connections A-1

A.2 Preparation A-1

A.3 Status mode A-2

A.4 Displaying the parameter

number in Status mode A-2

A.5 Entering Parameter mode

and returning to Status mode A-2

A.6 Selecting a parameter to access A-3

A.7 Changing the value of a parameter A-4

A.8 Saving new parameter values A-6

A.9 Flashing and non-flashing digits A-6

A.10 Negative values A-6

A.11 Changing the setting

of a bit parameter A-6

A.12 Selecting a different option A-7

A.13 Restoring the Drive to a default

configuration A-7

A.14 Summary of key operation A-7

B Security B-1

B.1 User-defined Security B-1

B.2 Setting-up User Security B-1

B.3 Unlocking User Security B-1

B.4 Locking User Security B-1

B.5 Summary B-1

C Signal Connections C-1

D Menu 0 Parameters D-1

D.1 Introduction D-1

D.2 Fixed-function parameters common

to all macro configurations D-2

D.3 Parameters specific to the macro

configurations D-8

E Diagnostics E-1

E.1 Status indications E-1

E.2 Alarm indications E-1

E.3 Trip codes E-2

ii

Commander GP User Guide

Issue code: gpxu2

d2

1 Introduction

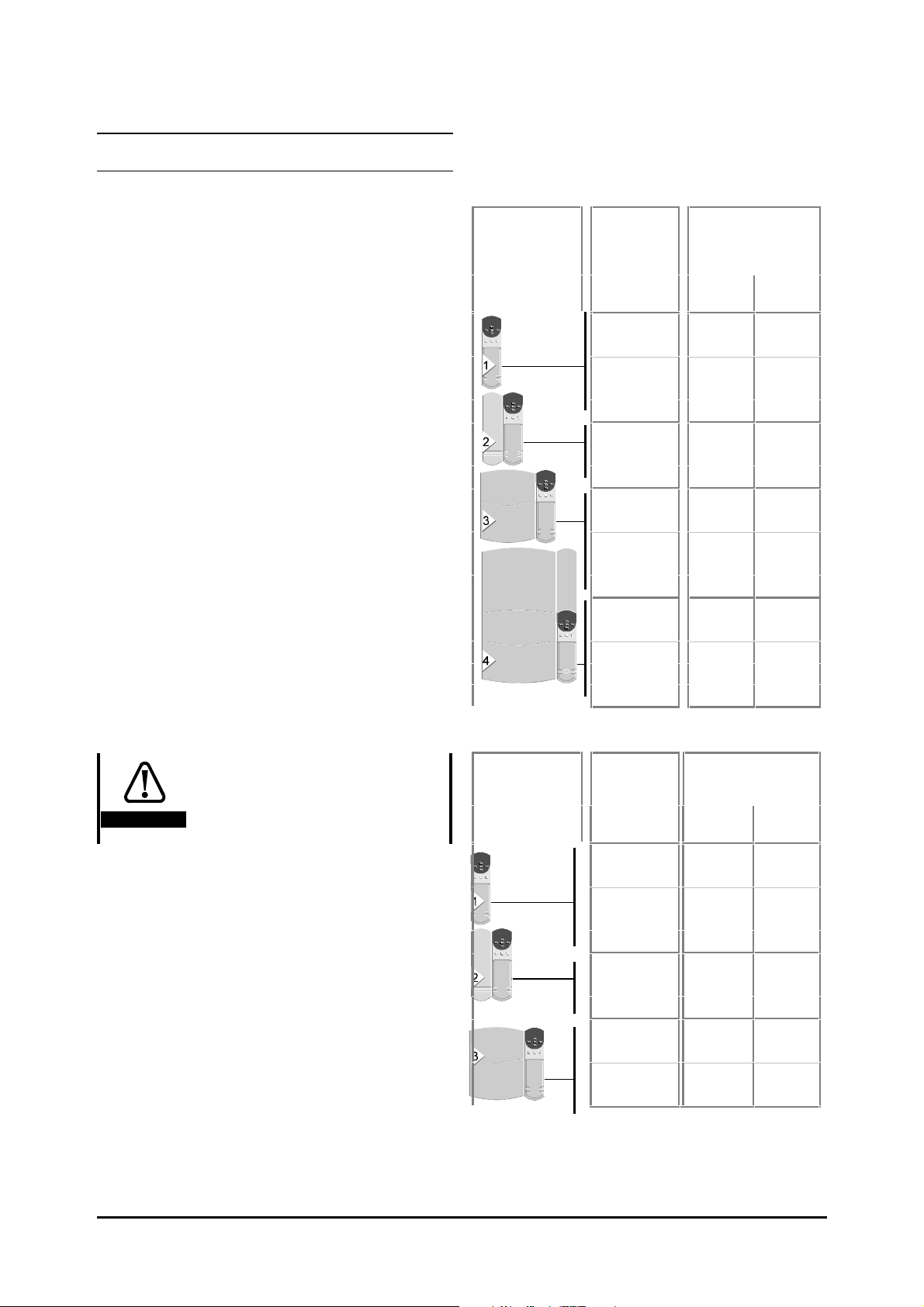

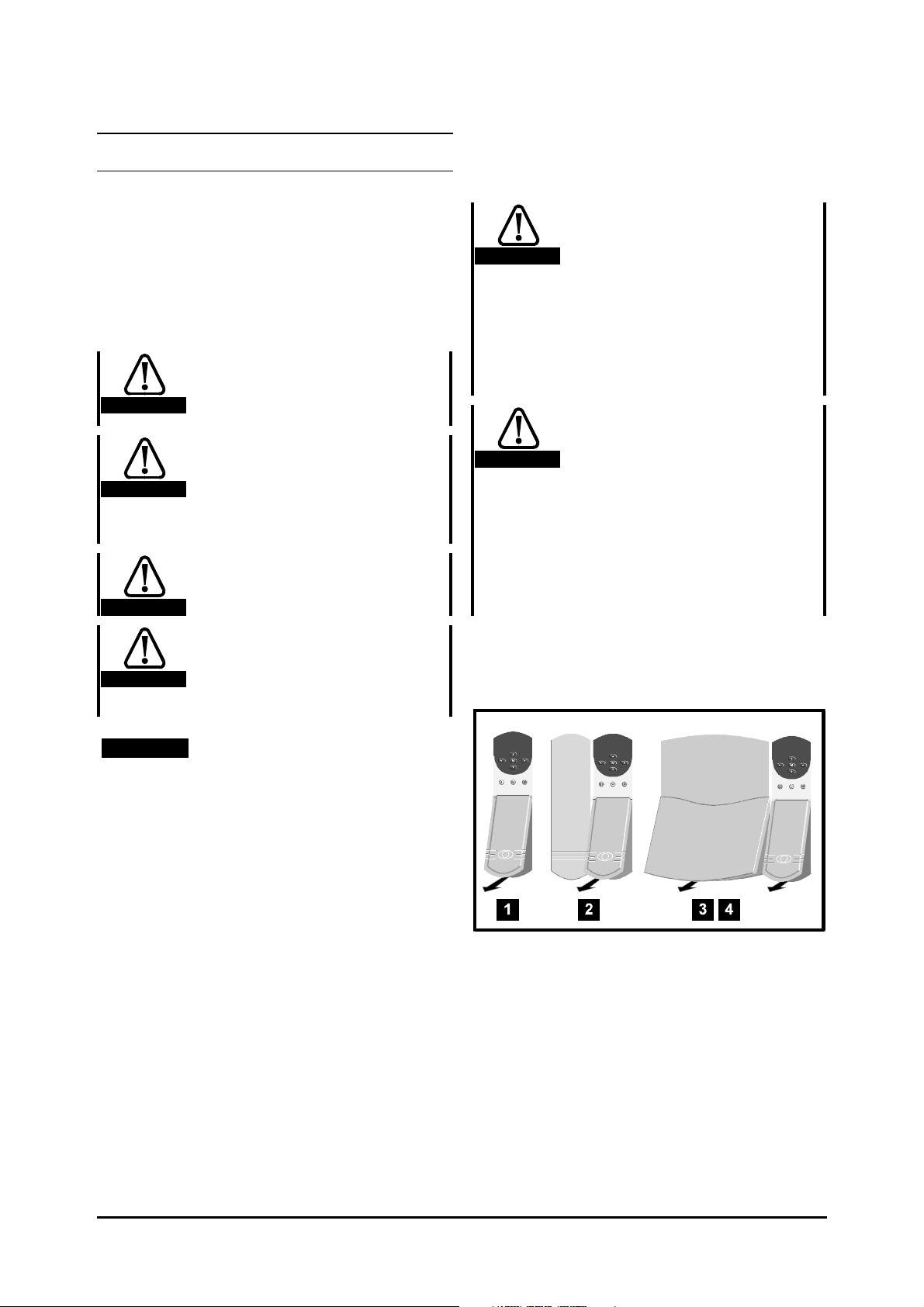

1.2 Model sizes

This User Guide refers to the models listed below.

1.1 How this User Guide

can help you

If this is your first encounter with a

Commander Gp Drive, read this User Guide

before referring to the accompanying

Installation Guide.

This User Guide is arranged on a step-by-step basis

to lead you through the following:

• Learning how to operate the Commander

Gp (Drive)

• When to refer to the Installation Guide

• Setting up the Commander Gp for basic

applications

Advanced programming of the

Commander Gp

For advanced programming of the Commander Gp,

refer to the Commander Gp Advanced User Guide. This

contains descriptions of all the advanced

parameters, as well as additional information, and

can be obtained from the Drive Centres and

distributors listed at the end of this User Guide.

The advanced parameters in software version

V03.01.07 onward can be accessed by use of the

UD71 Basic serial communications large option module

(see Serial communications later in this chapter).

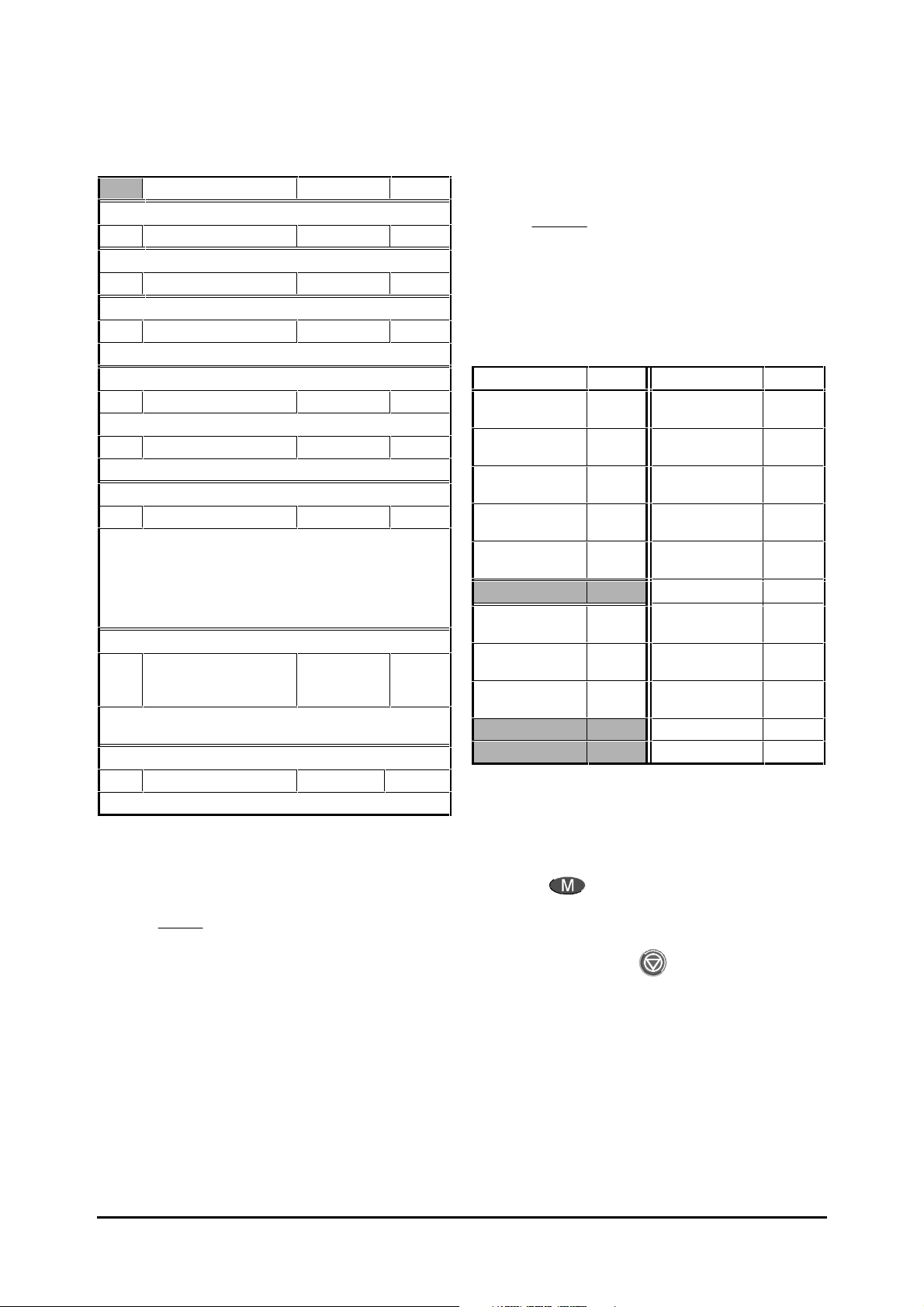

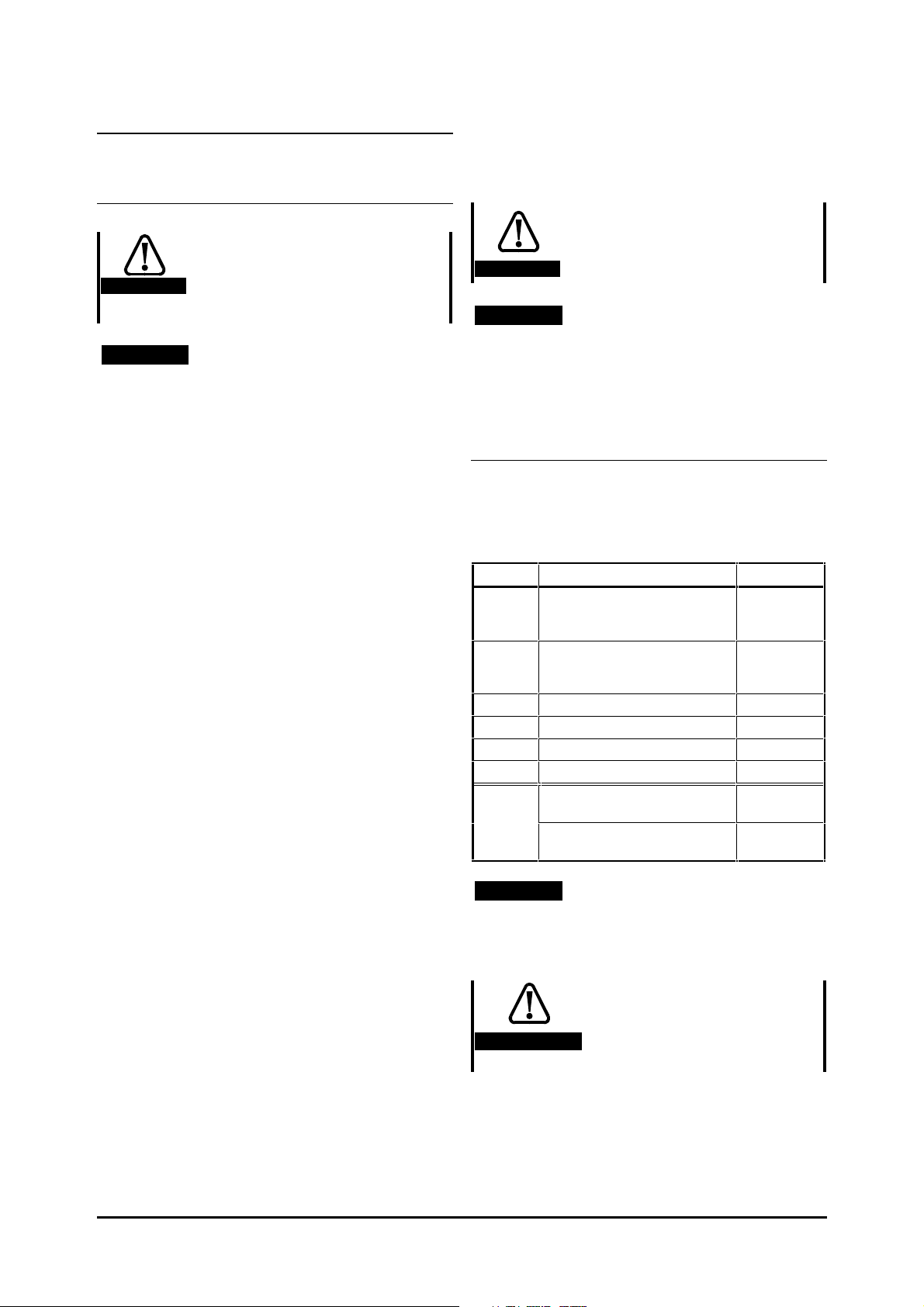

Model size Model code Nominal

rating for

standard AC

motors

kW

at 380VHPat 460V

GPD 1401 0.75 1.0

GPD 1402 1.1 1.5

GPD 1403 1.5 2.0

GPD 1404 2.2 3.0

GPD 1405 4.0 5.0

GPD 2401 5.5 7.5

GPD 2402 7.5 10

GPD 2403 11.0 15

GPD 3401 15.0 25

GPD 3402 18.5 30

GPD 3403 22.0 30

GPD 3404 30.0 40

GPD 3405 37.0 50

GPD 4401 45.0 75

GPD 4402 55.0 100

GPD 4403 75.0 125

GPD 4404 90.0 150

GPD 4405 110.0 150

Variable speed drives may be

hazardous if misused. Carefully

follow the instructions in this

Warning

User Guide and the Installation

Guide.

Commander GP User Guide

Issue code: gpxu2

Model size Model code Nominal rating

for standard

AC motors

KW

at 380VHPat 460V

GPD 1201 0.37 0.5

GPD 1202 0.55 0.75

GPD 1203 0.75 1.0

GPD 1204 1.1 1.5

GPD 1205 2.2 3.0

GPD 2201 3.0 4.0

GPD 2202 4.0 5.0

GPD 2203 5.5 7.5

GPD 3201 7.5 10

GPD 3202 11 15

GPD 3203 15 20

GPD 3204 22 30

Introduction 1-1

1.3 Configuration layers

1.5 Operating mode

The Drive has three layers of configuration, starting

from the base layer (1) as follows:

1. Default configuration

2. User-interface mode

3. Macro configuration

Each of the upper layers (2, 3) is superimposed on its

preceeding layer.

1.4 Default configurations

The Drive has a separate default configuration for the

AC supply conditions in Europe or in the USA. These

two default configurations are distinguished as

follows:

European

USA

The Drive is despatched from the factory in the

appropriate default configuration for the continent

in which it is to be sold. The default configuration

is Macro 0 (described in Macro configurations later in

this chapter).

The default configuration also defines the following

functions:

Europe

• Ability to select positive-logic for the digital

• Ability to adjust the current-loop PI gains

USA

• Ability to select digital control by two or

• Frequency demand indication

(These functions apply to Macro 0 only.)

Key used in this User Guide

AC supply voltage at 50Hz

AC supply voltage at 60Hz

control inputs

three wires

For use with standard AC induction motors.

The Drive applies power to the motor at frequencies

which are controlled by the user. The motor speed

is a result of the output frequency of the Drive and

slip due to the mechanical load.

The Drive can power a number of motors connected

in parallel (each motor must be protected against

overload; this is described in the Installation Guide).

The Drive can improve the performance of the

motor by applying the following:

• Slip compensation

• Fixed boost or Open-loop Vector operation

Fixed boost applies a fixed voltage boost at low

frequencies.

Open-loop Vector operation maintains almost

constant flux by dynamically adjusting the

motor voltage according to the load on the

motor.

1.6 User-interface modes

The motor can be started and stopped, the

direction of rotation reversed and the speed

changed by operation of the Drive in either of the

following user-interface modes:

Terminal mode

Applying signals from electrical contacts, a

system controller or PLC to digital and analog

inputs on the Drive.

For the USA default configuration, the Drive can

be configured for digital control by momentary

contacts.

Keypad mode

Manual operation of the keypad on the front

panel of the Drive. Minimal signal connections

are made to the Drive.

The following key denotes the default

configuration:

EUR> 50Hz AC supply (Europe)

USA> 60Hz

When no key is stated, the information applies to

both default configurations.

AC supply (USA)

1-2 Introduction

Commander GP User Guide

Issue code: gpxu2

1.7 Macro configurations

The Drive can be used to control the motor speed in

various ways for different types of application. To

reduce the number of adjustments to the Drive for

each type of application, eight macro configurations

(0 to 7) are available.

Macro 3

Preset frequencies

Four preset frequencies that are selected by external

contacts.

The macro configuration can be used in Terminal

mode only.

Each macro configuration requires specific signal

connections to be made to the Drive.

The macro configurations are as follows:

Macro 0

General purpose (default configuration)

Analog frequency control for general-purpose

applications.

The output frequency of the Drive is controlled by a

frequency reference. The motor speed will follow the

frequency reference so long as the maximum

permissible output current of the Drive is not

exceeded. These principles also apply to all other

macro configurations except Macro 4.

The macro configuration can be used in either

Keypad or Terminal mode.

The frequency can be controlled in either of the

following ways...

• Terminal mode: An analog frequency

reference signal applied to the Drive

• Keypad mode: By a user pressing keys on

the front panel of the Drive

Macro 1

Easy mode

Frequency control for basic applications. This is

similar to Macro 0, except, for simplicity, fewer

adjustments are required.

The macro configuration can be used in either

Keypad or Terminal mode.

The principles of controlling motor speed are the

same as for Macro 0.

The principles of controlling motor speed are the

same as for Macro 0.

Macro 4

Torque control

The motor torque is defined by a torque demand.

The motor speed will vary continuously as a result

of the difference between the load torque and the

torque demand up to a maximum speed which is

defined by a speed over-ride level.

The torque demand is supplied by an analog torque

reference signal that is applied to the Drive.

The macro configuration can be used in Terminal

mode only.

Macro 5

PID control

The Drive is operated with a frequency reference

and an analog feedback device in order to

dynamically maintain the speed to a user-defined

set-point under PID control.

The macro configuration can be used in Terminal

mode only.

The principles of controlling motor speed are the

same as for Macro 0.

Macro 6

Axis-limit control

Axis-limit control is used for applications which

require the process to be automatically stopped

when a position limit has been reached. A bipolar or

unipolar frequency reference can be used.

The macro configuration can be used in Terminal

mode only.

Macro 2

Motorized potentiometer

The frequency is controlled incrementally by

operation of up and down contacts.

The macro configuration can be used in Terminal

mode only.

The principles of controlling motor speed are the

same as for Macro 0.

Commander GP User Guide

Issue code: gpxu2

The principles of controlling motor speed are the

same as for Macro 0.

Macro 7

Brake control

Frequency control with brake control for crane or

hoist applications.

The macro configuration can be used in Terminal

mode or Keypad mode.

The principles of controlling motor speed are the

same as for Macro 0.

Introduction 1-3

1.8 Plug-in option modules

Operation of the Drive can be extended by the use

of plug-in option modules. The following modules

are available from the supplier of the Drive; an

appropriate User Guide is included with each

module:

Small option modules

UD50 Additional I/O

UD55 Cloning (parameter copying)

Large option modules

UD71 RS232/RS485 serial

communications

1.9 Serial communications

The Drive can be configured and fully controlled

from a system controller or PLC operating on a

RS232 or a 4-wire RS485 serial communications link.

A Basic serial communications large option module

must be fitted in the Drive. More information can

be obtained from a Drive Centre or distributor

listed at the end of this User Guide.

Serial communications can be used in conjunction

with Terminal mode or Keypad mode.

1-4 Introduction

Commander GP User Guide

Issue code: gpxu2

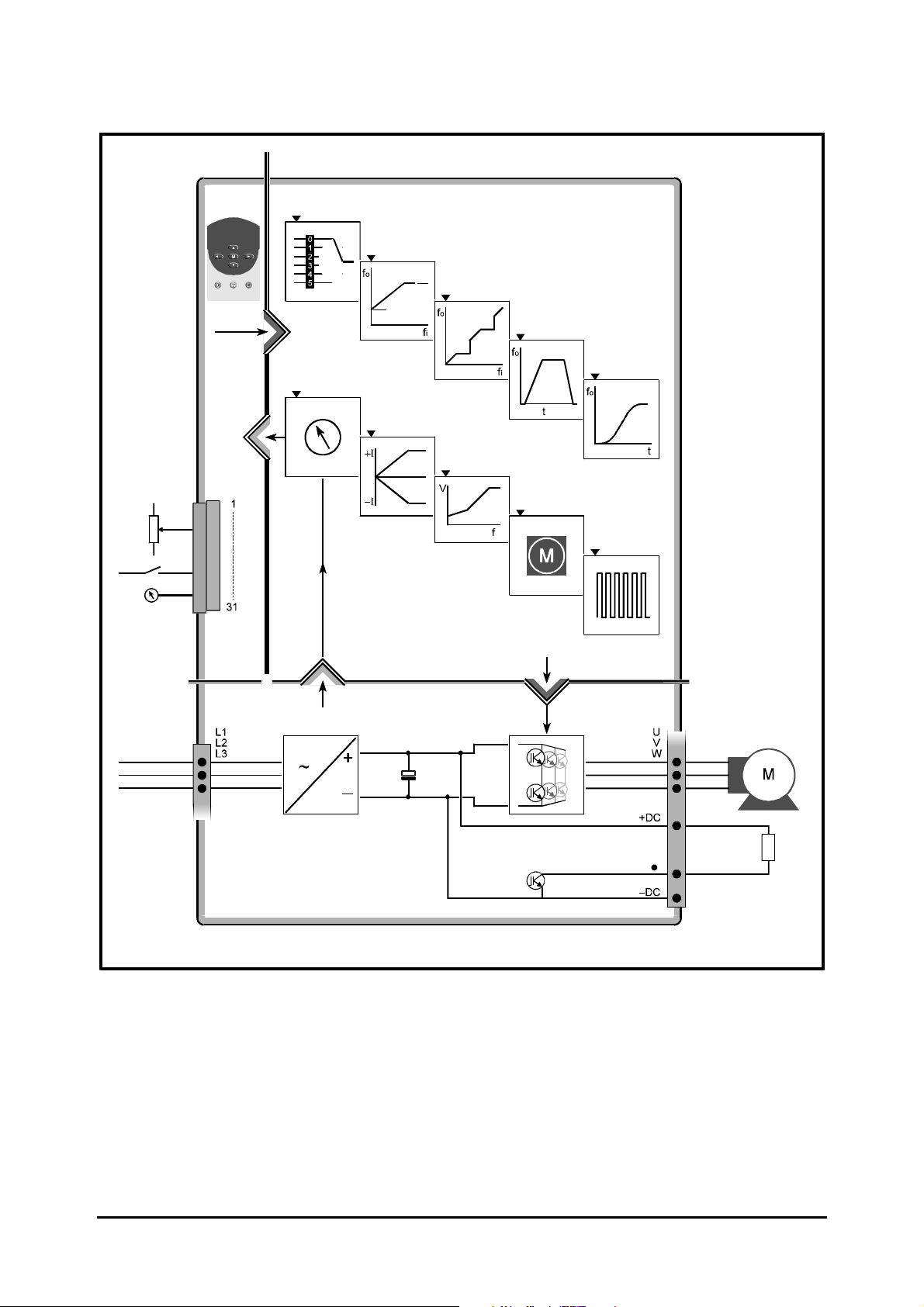

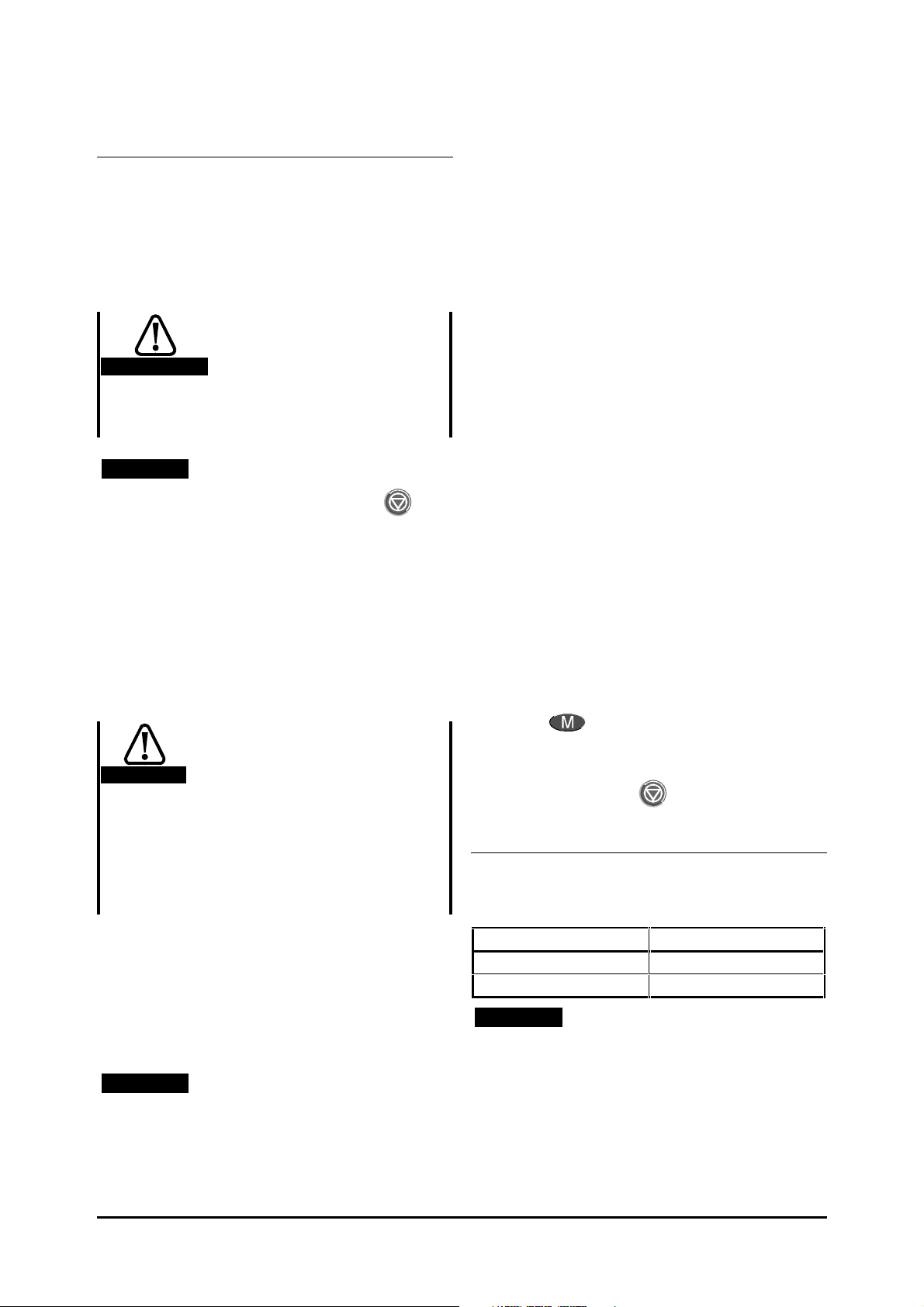

User interface

Display and

keypad

External

control and

monitoring

(analog and

digital)

User

control

Frequency reference

selection

Minimum and maximum

frequency limits

Monitoring

Current limit

Stop mode

Spinning motor sync.

Functions of the software

(controlled by the macro configurations)

Skip frequencies

Acceleration and

deceleration ramps

Voltage control

Motor parameters

S-ramp

PWM switching

frequency

Drive

Control

Monitoring

AC supply

DC bus

Power circuits

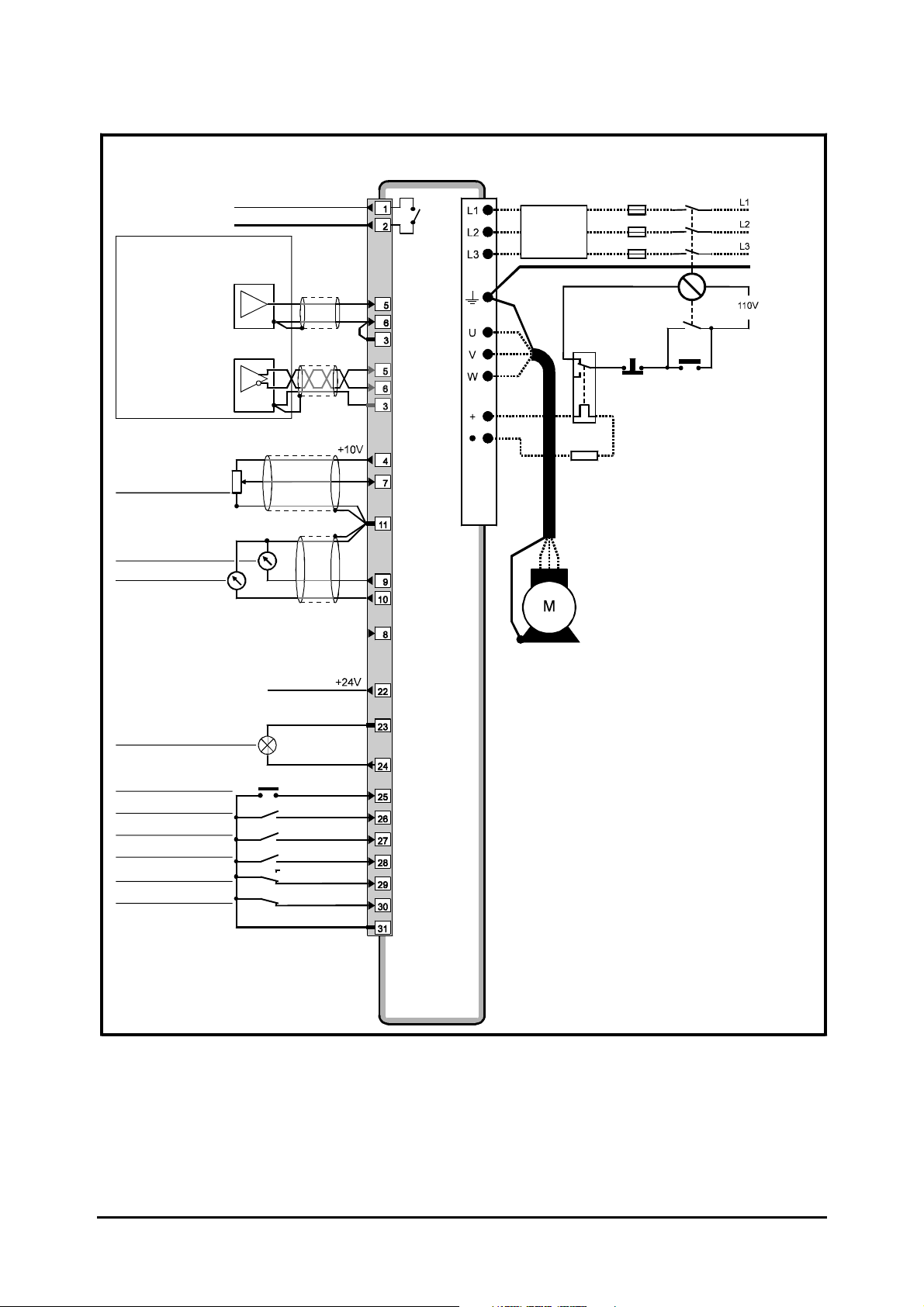

Figure 1–1 Block diagram of the Drive showing the main functions of the software,

and power connections (signal connections vary according to the

macro configuration)

Optional braking

resistor

Commander GP User Guide

Issue code: gpxu2

Introduction 1-5

1-6 Introduction

Commander GP User Guide

Issue code: gpxu2

2 Getting Started

2.2 Making signal and power

connections

2.1 How to use this chapter

It is recommended that you follow the instructions

in this chapter in the order that they appear. You

will be led through the initial stages of setting up

the Drive (in Macro 1 Easy mode) as well as being able

to familiarize yourself with operating the Drive.

The Drive must be operated

only by personnel having the

Warning

Warning

Warning

Warning

necessary training or

experience.

If this is the first time the

Drive has been operated,

ensure that no damage or

safety hazard could arise from

the motor starting

unexpectedly.

The motor must be fixed down

and the shaft guarded against

inadvertent contact.

Do not change parameter

values without careful

consideration; wrong values

may cause damage or a safety

hazard.

Stored charge

Warning

The Drive contains capacitors

that remain charged to a

potentially lethal voltage after

AC supply has been

the

disconnected. If the Drive has

been energized, the

must be isolated at least

ten minutes before work may

continue.

AC supply

Isolation

Warning

For instructions on removing the terminal covers,

see Mounting the Drive and RFI filter in Chapter 2

Installing the Drive in the Installation Guide.

The control circuits and

terminals are isolated from the

power circuits only by basic

insulation to IEC664–1. The

installer must ensure that all

external control circuits are

separated from human contact

by at least one layer of

insulation rated for use at the

AC supply voltage.

Notes

Keep a note of changes

When changing the values of parameters,

make a note of the new values in case they

need to be entered again.

Saving the changes

For new parameter-values to apply after

AC supply to the Drive is interrupted,

the

new values must be saved. This is described

in Saving new parameter-values in Appendix A

Programming Instructions.

Commander GP User Guide

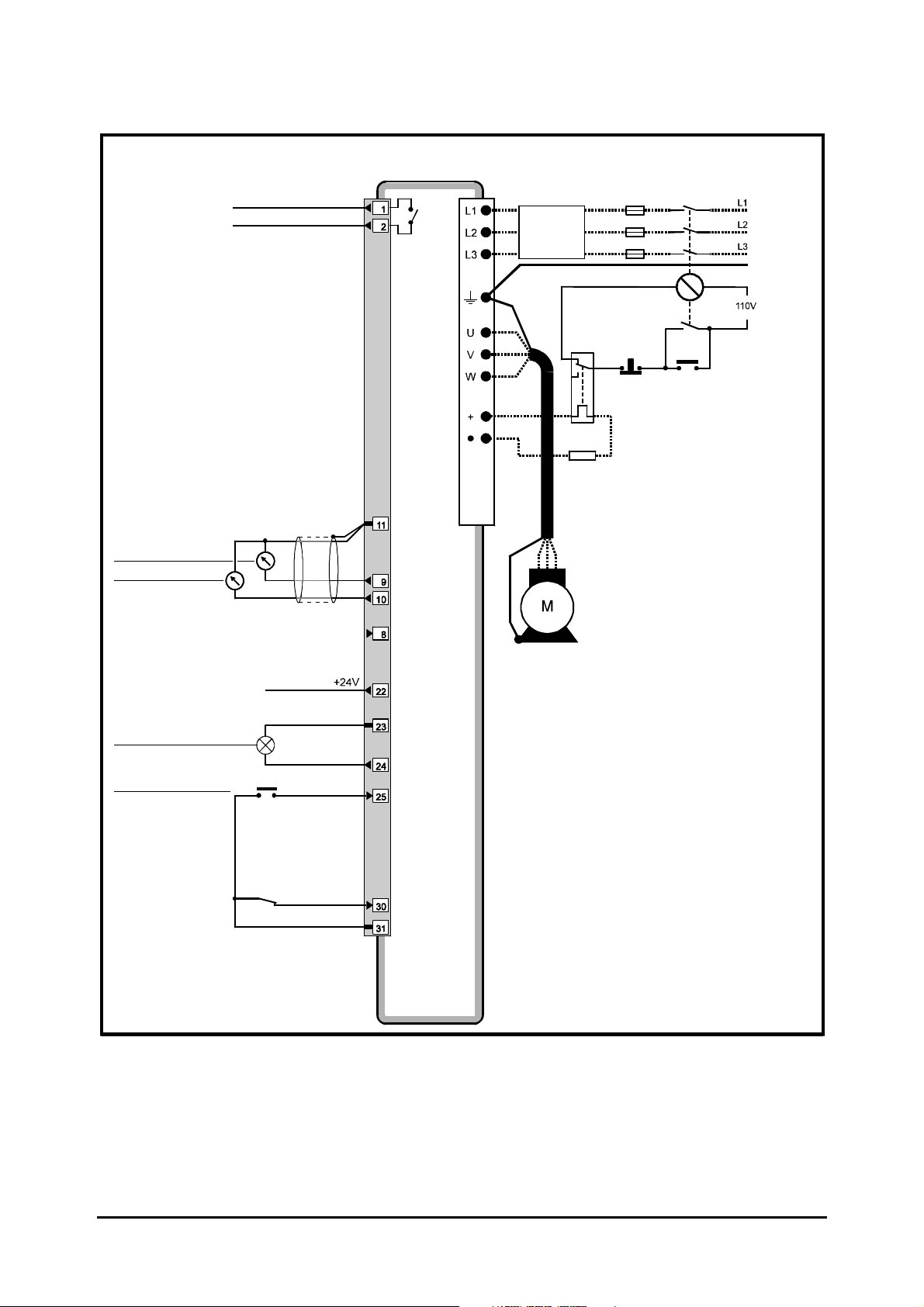

Issue code: gpxu2

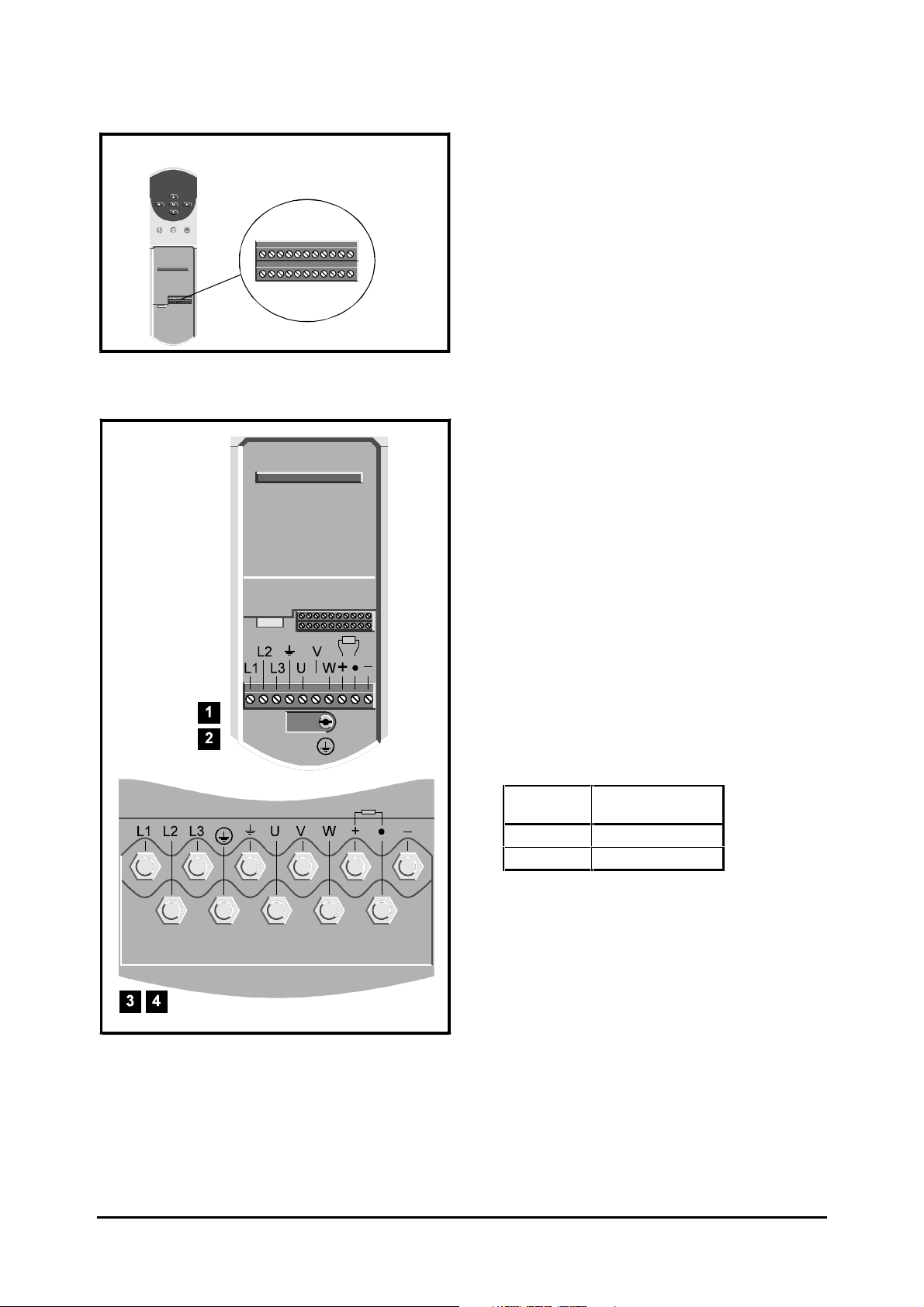

Figure 2–1 Removing the terminal covers for

access to the connectors

Getting Started 2-1

111

21 31

Figure 2–2 Location of the signal connector

1. Observe the safety warnings and cautions given

in Chapter 1 Safety information of the Installation

Guide and in this chapter.

2. Refer to the following:

• Chapter 2 of the Installation Guide in order

to install the Drive

• Figure 2–2 for the location of the

signal connector

• Figure 2–3 for the locations of the

power connections

• Figure 2–5 or 2–6 in this chapter in order to

make the signal and power connections for

operation in Terminal or Keypad mode.

Note that Macros 2, 3, 4, 5, 6 operate only in

Terminal mode. If one of these macro

configurations is to be enabled after the

initial setting up covered in this chapter, you

may wish to set up the Drive now in

Terminal mode in order to learn how to

operate it in this mode.

Signal connector for all models The two

terminal blocks of the signal connector can be

unplugged from the Drive by pulling them

downward.

Figure 2–3 Locations of the power connectors

Power connector for model sizes 1

and 2 The power connector can be unplugged

from the Drive by pulling it downward.

Power connections to model sizes 3

and 4 The power connections are made to

M10 studs located in the power section of the

Drive.

3. Note that the default user-interface mode is

as follows:

Continent User-interface

mode

EUR Terminal

USA Keypad

(Instructions for changing the user-interface

mode are given later.)

2-2 Getting Started

Commander GP User Guide

Issue code: gpxu2

4. When connecting a motor to the Drive, observe

the following:

• Preferably the motor should be identical to

the motor that is to be used in the

application, but this is not essential.

• The motor shaft must not be attached to

any equipment, or exposed.

5. No motor thermistor connection is required at

this stage, but a thermistor will be required

later if the Drive is to be operated in any macro

configuration except Macros 1 and 5. When

Macro 1 or Macro 5 is enabled, the thermistor is

ignored by the Drive. (Instructions for

connecting a motor thermistor to the signal

connector are given for each macro

configuration in Chapter 3 Setting Up the Drive.)

After having made control

connections, carefully check

Warning

that terminal 30 is open-circuit

to ensure the Drive is in the

Stop state when the

AC supply

is first connected.

6. After re-fitting the terminal cover, connect the

Drive to the

AC supply.

Commander GP User Guide

Issue code: gpxu2

Getting Started 2-3

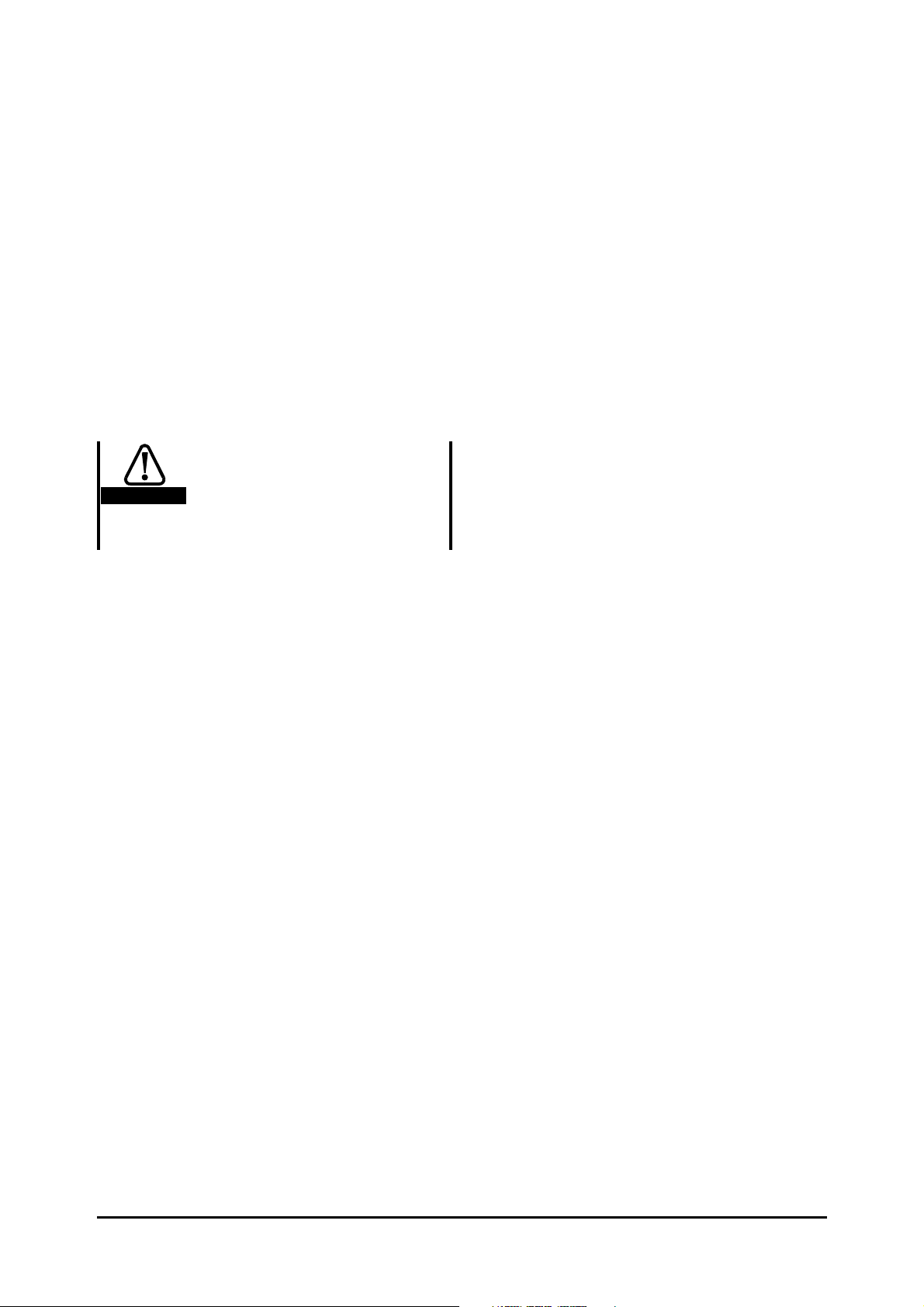

Refer to the Installation Guide for

cable sizes and fuse ratings

Status relay

Drive healthy

Analog frequency reference 1

(remote)

Connections for

single-ended input

Connections for

differential input signal

Analog frequency

reference 2

(local)

SPEED

TORQUE

signal

0V common

0V common

0V common

Signal

connector

Power

terminals

Optional

RFI filter

Thermal

protection

device

Stop

Optional braking resistor

Refer to the Installation Guide for sizing

of the optional braking resistor

Start /

Reset

0V common

AT SPEED

RESET

JOG SELECT

RUN FORWARD

RUN REVERSE

LOCAL / REMOTE

External trip

REMOTE

LOCAL

0V common

Figure 2–5 Power connections, and signal connections for Terminal mode (Macro 1 only)

2-4 Getting Started

Commander GP User Guide

Issue code: gpxu2

Refer to the Installation Guide for

cable sizes and fuse ratings

Status relay

Drive healthy

SPEED

TORQUE

0V common

Signal

connector

Encoder

Power

Optional

RFI filter

Thermal

protection

device

Stop Start /

Optional braking resistor

Refer to the Installation Guide for sizing

of the optional braking resistor

Reset

0V common

AT SPEED

RESET

External trip

0V common

Figure 2–6 Power connections, and signal connections for Keypad mode (Macro 1 only)

Commander GP User Guide

Issue code: gpxu2

Getting Started 2-5

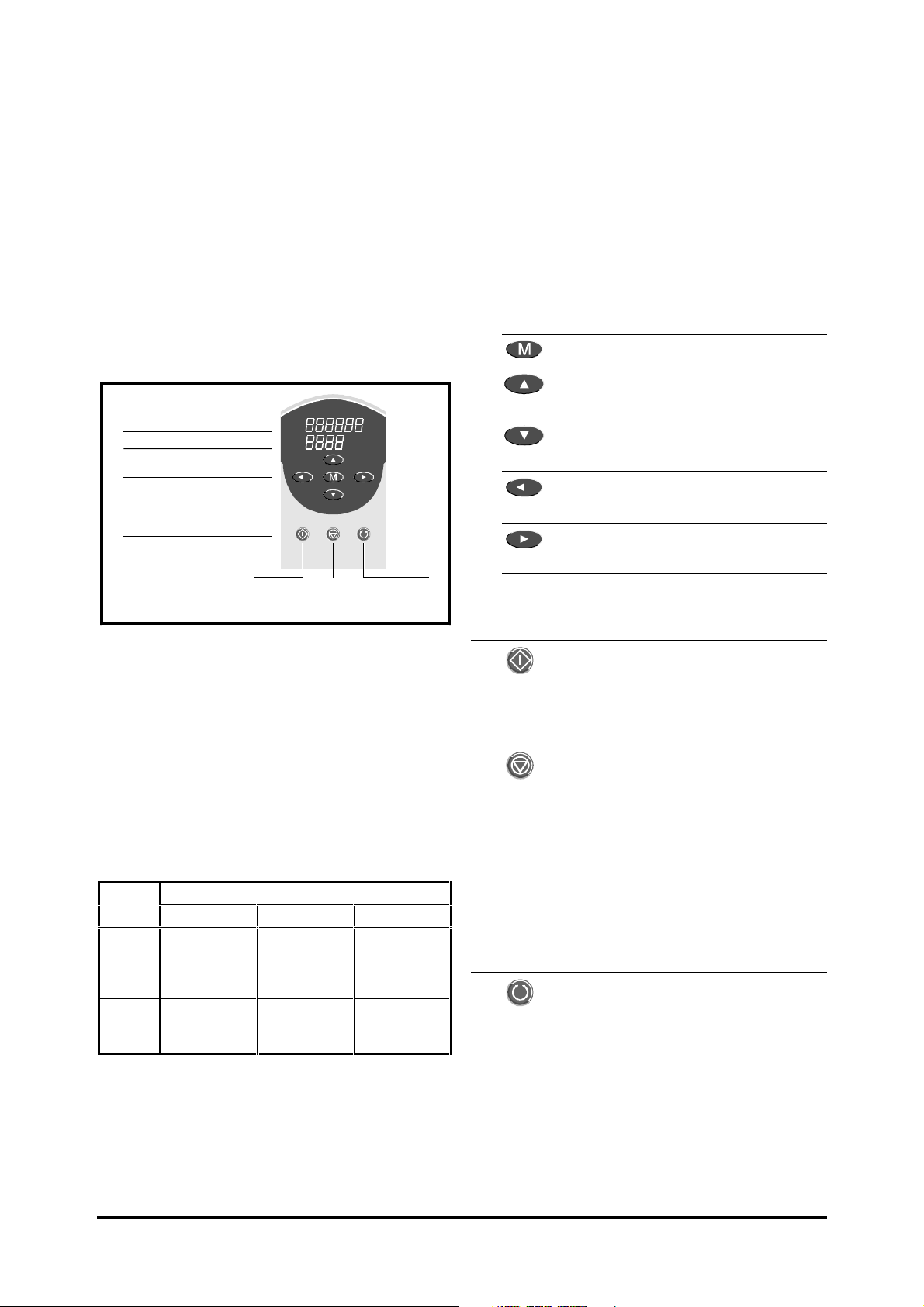

2.3 Introduction to the

display and keypad

Display and keypad

The display and keypad are used for the following:

• Reading and changing the values of software

parameters that are used to configure,

control and monitor the Drive

• Displaying the operating status of the Drive

• Displaying fault and trip codes

Upper display

Lower display

Programming keys

Control keys

Run Stop

Reset

Figure 2–7 Display and keypad

Forward /

Reverse

Programming keys

These are used for the following:

• Changing the mode of operation of the

display

• Selecting a parameter to edit

• Editing the selected parameter

• Saving new values given to parameters

The functions of the programming keys are as

follows:

Change the display mode

Select a parameter

Increase the value of a digit

Select a parameter

Decrease the value of a digit

Display the parameter number

Select the next left display digit

Display the parameter number

Select the next right display digit

Control keys

The functions of the control keys are as follows:

Display

The display has three display modes as follows...

• Status mode

Used to indicate the status of the Drive

• Parameter mode

Used for selecting a parameter to edit

• Edit mode

Used for editing the selected parameter

... and shows the following:

Display Display mode

Status Parameter Edit

Upper Value of

parameter (

Lower Status of the

Drive

Value of

0)

parameter (0)

Parameter

number (0.10)

rdY

Operating instructions for the display and keypad

are given in Appendix A Programming Instructions.

Value of

parameter (0)

(selected digit

flashes)

Parameter

number (0.10)

(RUN) Start the Drive running.

The RUN key is active only when the Drive is

operating in Keypad mode (parameter 0.05

Reference select set at 4).

(STOP–RESET) The three functions of

this key are as follows:

• Stop the Drive

• Reset the Drive after it has tripped

• Make new parameter-values take effect

The STOP-RESET key is active when the Drive

is operating in Keypad mode. This key acts only

as RESET when the Drive is operating in

Terminal mode (parameter 0.05 Reference select

set at 0, 1, 2, 3 or 5).

(FWD/REV) Change the direction of

rotation of the motor. (This is not enabled by

default, and is described later in this chapter in

Enabling reverse direction in Keypad mode.)

2-6 Getting Started

Commander GP User Guide

Issue code: gpxu2

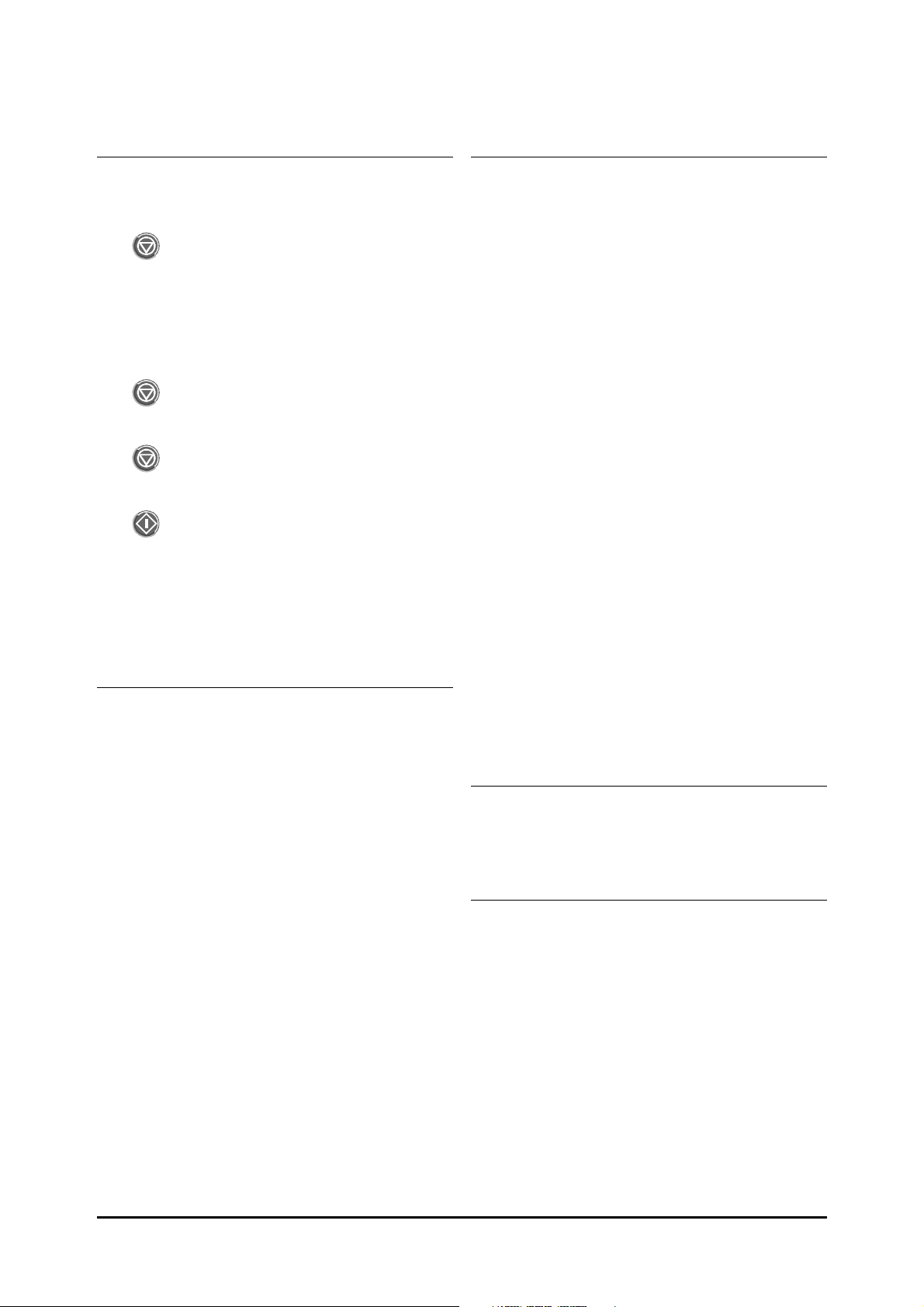

Resetting the Drive

Types of parameter

Terminal mode

When the Drive is stopped, press:

Alternatively, close the RESET contact (see

Figure 2–5).

Keypad mode

When the Drive is stopped, press:

When the Drive is running, press and hold...

... then press:

Release both keys at the same time.

2.4 Working with

software parameters

Parameters

The software parameters are contained in a menu

named Menu 0. Each parameter has a number as

well as a name. These are represented in this User

Guide as (for example, parameter 03 in Menu 0):

0.03 Acceleration rate

When the value of a parameter is referred to, it is

indicated as [0.03].

Variable and bit parameters

There are two types of parameter, as follows:

• Bit parameters

• Variable parameters

Bit parameters can be set at 0 or 1 to carry out the

following:

• Enable and disable functions

• Select from two options

Variable parameters can be set at any value within

the specified range to carry out the following:

• Enter values

• Select from more than two options

No distinction is made in the parameter numbering

system between variable and bit parameters. When

a bit parameter is selected on the Drive display, the

word bit appears.

Read–write and read-only

Both types of parameter can be as follows:

• Read–write (

• Read-only (

Read–write parameters are programmable by the

user. Read-only parameters are for information

purposes; they cannot be programmed.

The settings of read–write and read-only

parameters can be read on the display or remotely

using serial communications.

RW)

RO)

Adjusting parameter values

Instructions on adjusting parameter values are given

in Appendix A Programming Instructions.

Commander GP User Guide

Issue code: gpxu2

Making new values effective,

and saving them

The new value of most parameters takes effect as

soon as it is entered. Some parameters (such as the

destination-selection parameters for the analog

inputs) require the Drive to be reset before their

new values take effect.

Unless a save procedure is carried out, the new value

will be lost when the

the Drive (described in Saving new parameter-values

in Appendix A Programming Instructions).

AC supply is disconnected from

Getting Started 2-7

Parameter 0.00

Parameter 0.00 is a special read–write parameter

that is used for the following:

• Saving new values given to parameters

• Controlling security

• Enabling macro configurations

These functions are controlled by the user entering

specific values, as shown below:

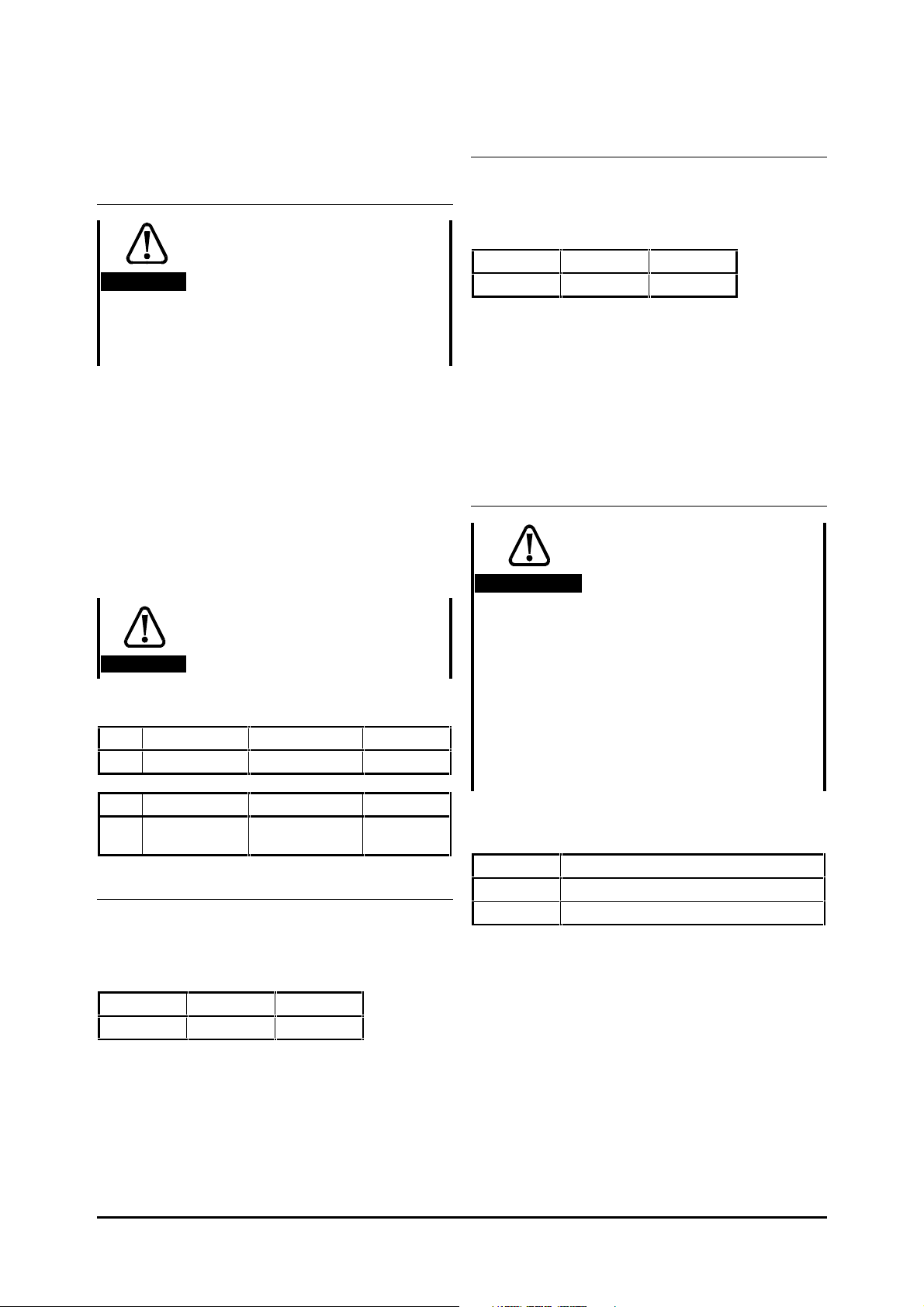

Value Function

Saving new parameter-values

The Drive can be running or stopped

(described in Appendix A Operating Instructions)

1000

Controlling security

The Drive can be running or stopped

(described in Appendix B Security and Accessing the

Advanced Parameters)

0 ~ 255 User security code

2000 Lock security

Restoring the Drive to a default configuration

The Drive must be stopped

(described later in this chapter)

1233 Restore default values to all parameters for

1244 Restore default values to all parameters for

Selecting Macros 0 to 7

The Drive must be stopped

(described in Chapter 3 Setting Up the Drive)

2001 Macro 1 Easy mode

2002 Macro 2 Motorized potentiometer

2003 Macro 3 Preset speeds

2004 Macro 4 Torque control

2005 Macro 5 PID (set-point) control

2006 Macro 6

2007 Macro 7

2009 Macro 0 General purpose

2010 Macro 0 General purpose

The Drive must be reset to make a newly selected

function or configuration take effect.

50Hz

AC supply frequency (Europe)

60Hz

AC supply frequency (USA)

Axis-limit control

Brake control

(USA default configuration)

(EUR default configuration)

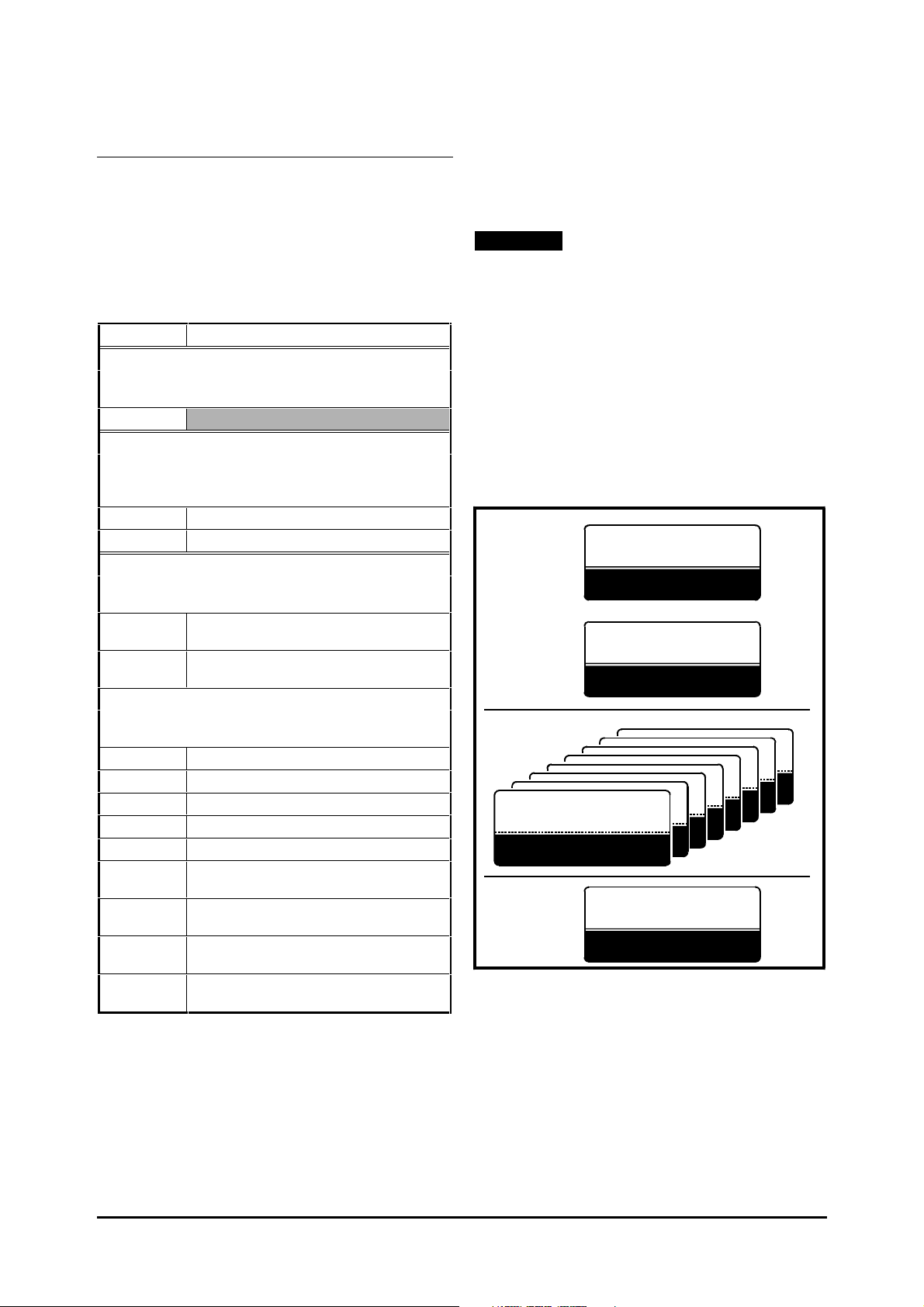

2.5 How macro configurations

change the arrangement of

the Menu 0 parameters

Note

Do not confuse the term Macro with the

term Menu. Menu 0 contains parameters;

macro configurations re-define some of

these parameters to perform specific

functions. Menu 0 always exists, but is

affected by the macro configuration that is

enabled.

Only one macro configuration can be

enabled at a time.

Menu 0 contains 51 parameters which are arranged

in four groups, as shown in Figure 2–8.

Common to

all macros

Configuration and saving

parameter

Fixed-function parameters

Specific to

each macro

0.11 ~ 0.30

Re-programmable parameters

Common

to all

macros

Fixed-function parameters

Figure 2–8 How the Menu 0 parameters are

grouped and the relationship with

the macro configurations

0.00

0.01 ~ 0.10

Macro 0

1

0.31 ~ 0.50

7

6

5

4

3

2

Instructions for using parameter 0.00 are given at

the appropriate places in this User Guide

2-8 Getting Started

Commander GP User Guide

Issue code: gpxu2

Macro 0

2.6 Initial setting up

When Macro 0 is enabled, the re-programmable

parameters have their default functions.

Macro 1

When Macro 1 Easy Mode is enabled, none of the

re-programmable parameters are available.

Macros 2 to 7

When one of these macro configurations is enabled,

the functions of some re-programmable parameters

are specific to the macro configuration.

Other factors that affect the

re-programmable parameters

In addition to the changes caused by the macro

configurations, the functions of some

re-programmable parameters are changed by the

default configuration of the Drive (EUR or USA)

These are are shown in Appendix D Menu 0

Parameters.

Where to find information on

parameters

The functions of the parameters are listed for each

macro configuration in Chapter 3 Setting Up the Drive.

The functions of the parameters for each macro

configuration are described in detail in Appendix D

Menu 0 Parameters.

Noting the user values

A parameter table for each macro configuration in

Chapter 3 Setting Up the Drive has a column for you

to note the values entered in the parameters.

Restoring the Drive

to a default configuration

Do not attempt to restore the

Drive to a default

configuration when the Drive is

Warning

Restoring the Drive to a default configuration is not

essential for initial setting up, but should be used

for achieving the following:

• When one of the macros 2 to 7 is currently

• Intentionally restoring all parameters to

• Changing (or re-applying) the default

1. Enter either of the following values in

parameter 0.00:

EUR> (Europe, 50Hz

USA> (USA, 60Hz

running.

Restoring the Drive to a

default configuration enables

Macro 0 and returns all

parameters to their default

values including the motor

parameters. (If any one of the

macros 1 to 7 has been enabled,

the Drive still reverts to

Macro 0.)

After restoring the Drive to a

default configuration, it will be

necessary for the required

parameter values to be

re-entered before the Drive is

next run.

enabled, and a different macro

configuration is required

their default values (this includes the motor

parameters)

configuration for the continent in which the

Drive is to be used

AC supply): 1233

AC supply): 1244

Commander GP User Guide

Issue code: gpxu2

2. Press

3. Set 0.00 at 1000.

4. Press

(RESET key).

(RESET key).

Getting Started 2-9

The following conditions now apply:

• All the default values (including those of the

motor parameters) take effect

• Macro 0 is enabled

If required, any other macro configuration can be

enabled.

Enabling Macro 1

Do not attempt to enable any

macro configuration when the

Drive is running.

Warning

Note

If the Drive is to be operated in Macro 1 or

5 and a braking resistor is to be used, now

set parameter 0.15 at FASt. Then follow

the instructions below.

The setting of parameter 0.15 must be

changed now because the function of this

parameter is changed when one of these

macro configurations is enabled.

1. Set parameter 0.00 at 2001.

2. Reset the Drive.

The configuration layers (see Chapter 1 Introduction)

are now as follows:

1. Appropriate default configuration for the

continent (EUR or USA)

2. Macro 1 Easy mode

Configuring the Drive for the motor

The values of the motor

parameters affect the

Warning

Caution

protection of the motor and

the safety of the system.

When entering values, make

sure they are relevant to the

motor that is to be used. The

default values in the Drive

should not be relied upon.

The motor parameters should

be set to within 10% of the

required values for the motor.

Failure to do this may result in

poor response.

It is essential that the correct

value is entered in parameter

0.46 Motor – rated current. This

affects the thermal protection

of the motor.

Keep a note of the values given

to the motor parameters, since

motor parameters are restored

to their default values when

the Drive is restored to a

default configuration (this

must be done if the Drive has

been used with Macro 2 to 7

enabled and a different macro

configuration is to be enabled)

2-10 Getting Started

Commander GP User Guide

Issue code: gpxu2

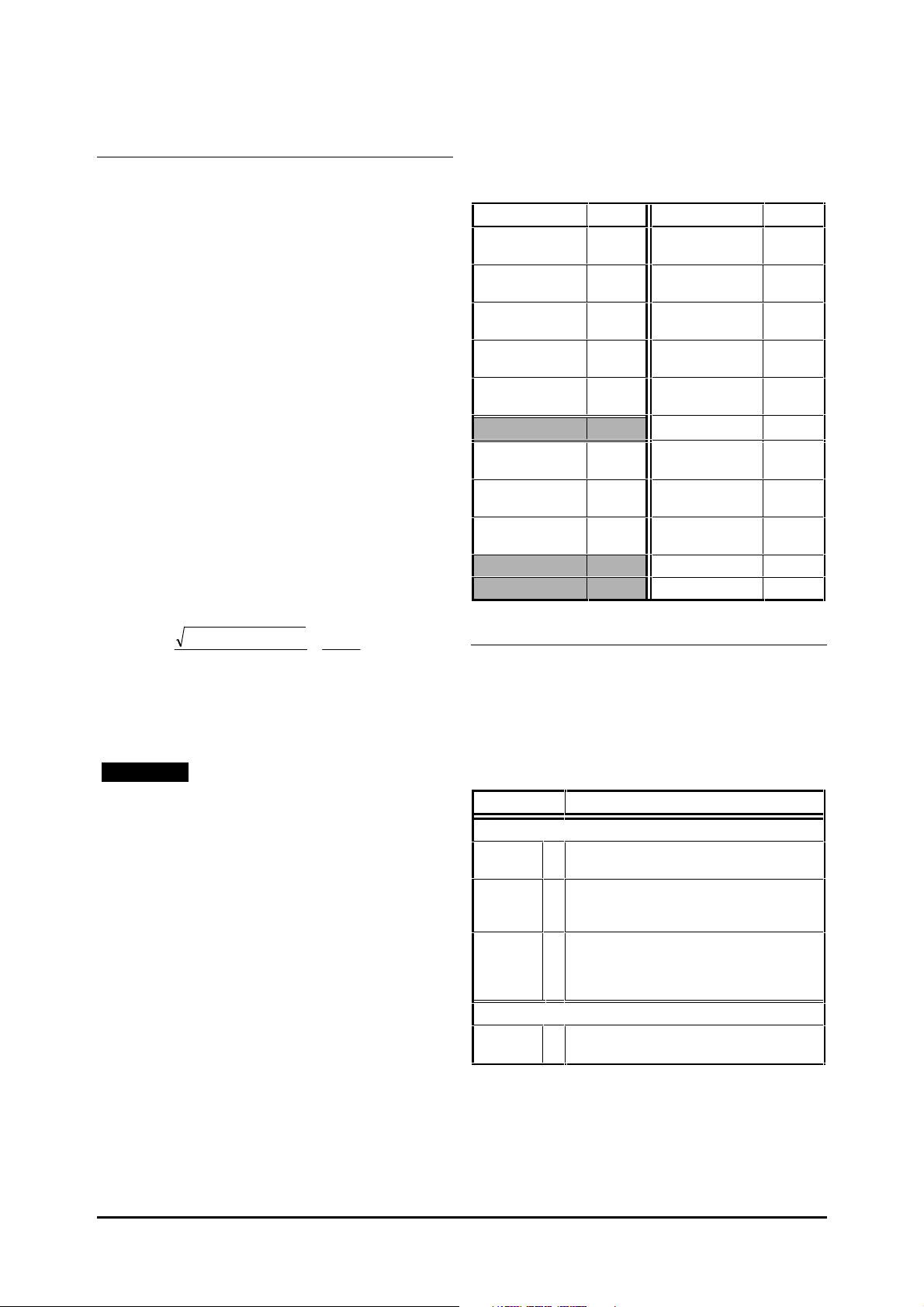

Enter the motor ratings in the motor parameters of

Model

GPD 3201

GPD 3401

GPD 3402

GPD 3202

GPD 3403

GPD 3203

GPD 3404

GPD 3405

GPD 3204

GPD 4401

GPD 4402

GPD 4403

GPD 4404

GPD 4405

the Drive, as follows:

Default value Range Unit

0.41 PWM switching frequency

3 3, 4.5, 6, 9, 12 kHz

0.42 Motor – number of poles

4 2 ~ 32 poles

0.43 Motor – power factor

0.92 0 ~ 1.0

(See Autotune later in this chapter)

0.44 Motor – rated voltage (Standard models)

400 (EUR)460 (USA) 0 ~ 480 V

0.44 Motor – rated voltage (LV models)

220 0 ~ 240 V

Enter the rated value.

0.45 Motor – rated speed

0 0 ~ 6000 RPM

When 0.45 is set at 0, no slip compensation is applied by

the Drive. When a value greater than zero is entered, slip

compensation is applied but instability can occur with

motor loads that have predominant inertia. To avoid this

instability, set 0.45 at 0. The value can be changed at a

later time.

0.46 Motor – rated current

FLC

(see the following Values

of FLC table)

Ensure that the motor current-rating applies to the

winding configuration used.

0.47 Motor – rated frequency

50 (EUR) 60 (USA) 0 ~ 1000.0 Hz

Enter the rated value.

0 ~ FLC A

When the number of motor poles

is not known

Example

Rated motor speed: 1450 RPM

AC

supply frequency: 50Hz

P ==

××==50 120

1450

414.

Therefore, the number of poles = 4

(The inaccuracy of the calculation is caused by slip,

in this case 50

RPM.)

Values of FLC

Model FLC (A)

GPD 1201

GPD 1401

GPD 1202

GPD 1402

GPD 1203

GPD 1403

GPD 1204

GPD 1404

GPD 1205

GPD 1405

GPD 2201

GPD 2401

GPD 2202

GPD 2402

GPD 2203

GPD 2403

2.1

2.8

3.8

5.6

9.5

12

16

25

FLC (A)

34

40

46

60

70

74

96

124

156

180

202

Saving the values

Use the following procedure:

1. Set parameter 0.00 at 1000.

Calculate the number of poles from the following:

f

120

××

P

==

N

Where:

AC supply frequency

f

N Rated full-load speed of the motor

The number of poles will be the whole number

immediately below the value of P. Enter this whole

number in 0.42.

Commander GP User Guide

Issue code: gpxu2

2. Press

. The display returns to Parameter

mode. Do not press any keys within eight

seconds; the display then enters Status mode.

3. Momentarily press

to reset the Drive.

Getting Started 2-11

Autotune

Autotune is a sequence of tests performed by the

Drive. The results of the tests are subsequently

used by the Drive for controlling the motor.

Autotune should be used after the motor

parameters have been entered, but before the Drive

is used. Normally (and if the motor is not changed),

Autotune needs performing only once.

During the following

procedures, the Drive will

Warning

Note

To stop the test at any time, press .

The motor will then coast to a stand-still

and the test will not be completed.

If the Drive trips

If the Drive trips during the test, note the trip code

that appears on the upper display and refer to

Appendix E Diagnostics. The test will not be

completed.

Direction of rotation

power the motor and cause

the shaft to rotate at up to

2

/3 full speed. Before

starting, make sure it will be

safe for the motor to be run.

1. Ensure the motor is unloaded and at a stand-still.

2. Ensure the EXTERNAL TRIP contact is closed.

3. Follow this step only if the Drive has previously

been set up and both of the following have

occurred...

• The setting of parameter 0.07 Voltage mode

selector has been changed to Ur

• A different motor is now connected to the

Drive

... change the setting of parameter 0.07 to

Ur_I. (See Open-loop voltage control modes later

in this chapter.)

4. Disconnect, then after at least 10 seconds,

re-connect the

to measure the stator resistance of the motor

— it is essential for the Drive to be aware of the

actual value of stator resistance for Autotune

to be performed correctly).

5. Set parameter 0.40 Autotune enable at 1. The

following tests are performed:

• The motor is accelerated up to two-thirds

rated frequency in the forward direction

while the magnetizing current is measured

• The motor is decelerated to a stand-still

6. Parameter 0.43 Motor – power factor is

automatically updated.

7. Parameter 0.40 is automatically returned to zero.

AC supply (this causes the Drive

Saving the values

1. Set parameter 0.00 at 1000.

Stored charge

Warning

The motor shaft should rotate clockwise as viewed

from the free end of the shaft during Autotune. If

the shaft rotates in the reverse direction, stop the

test, remove the

connections. If required, change the motor phase

connections and repeat Autotune.

Procedure

The Drive contains capacitors

that remain charged to a

potentially lethal voltage after

AC supply has been

the

disconnected. If the Drive has

been energized, the

must be isolated at least

ten minutes before work may

continue.

AC supply and check the motor

AC supply

Note

If the settings of parameters 0.41 to 0.47

are changed by a user after Autotune has

been performed, it is essential that

Autotune is repeated.

2-12 Getting Started

2. Press

mode. Do not press any keys within eight

seconds; the display then enters Status mode.

3. Momentarily press

. The display returns to Parameter

to reset the Drive.

Changing the user-interface mode

Change the user-interface mode, as required. If jog

is required, select Terminal mode (jog is available

only in Macros 0, 1, 4).

User-interface mode Set parameter 0.05 at...

Terminal 0

Keypad 4

Note

The main function of parameter 0.05 is a

reference selector which has other settings

that operate the Drive in Terminal mode.

At this stage, do not use any of these other

settings.

Use of parameter 0.05 is described for

Macros 0 and 1 in Chapter 3 Setting Up the

Drive.

Commander GP User Guide

Issue code: gpxu2

2.7 Operating instructions

Before completing the initial setting up of the Drive,

you will need to learn how to operate it. Refer to

the following instructions for Terminal mode or

Keypad mode, as appropriate.

Terminal mode

Variable frequency

In Terminal mode (with Macro 1), the Drive can

control the motor as follows:

• Run (forward and reverse)

• Jog/Preset frequency (forward and reverse)

1. Ensure the control signal connections shown in

Figure 2–5 are made.

2. Check that the FREQUENCY potentiometer is

set at minimum.

3. Ensure that the EXTERNAL TRIP contact is

open.

4. Connect the Drive to the

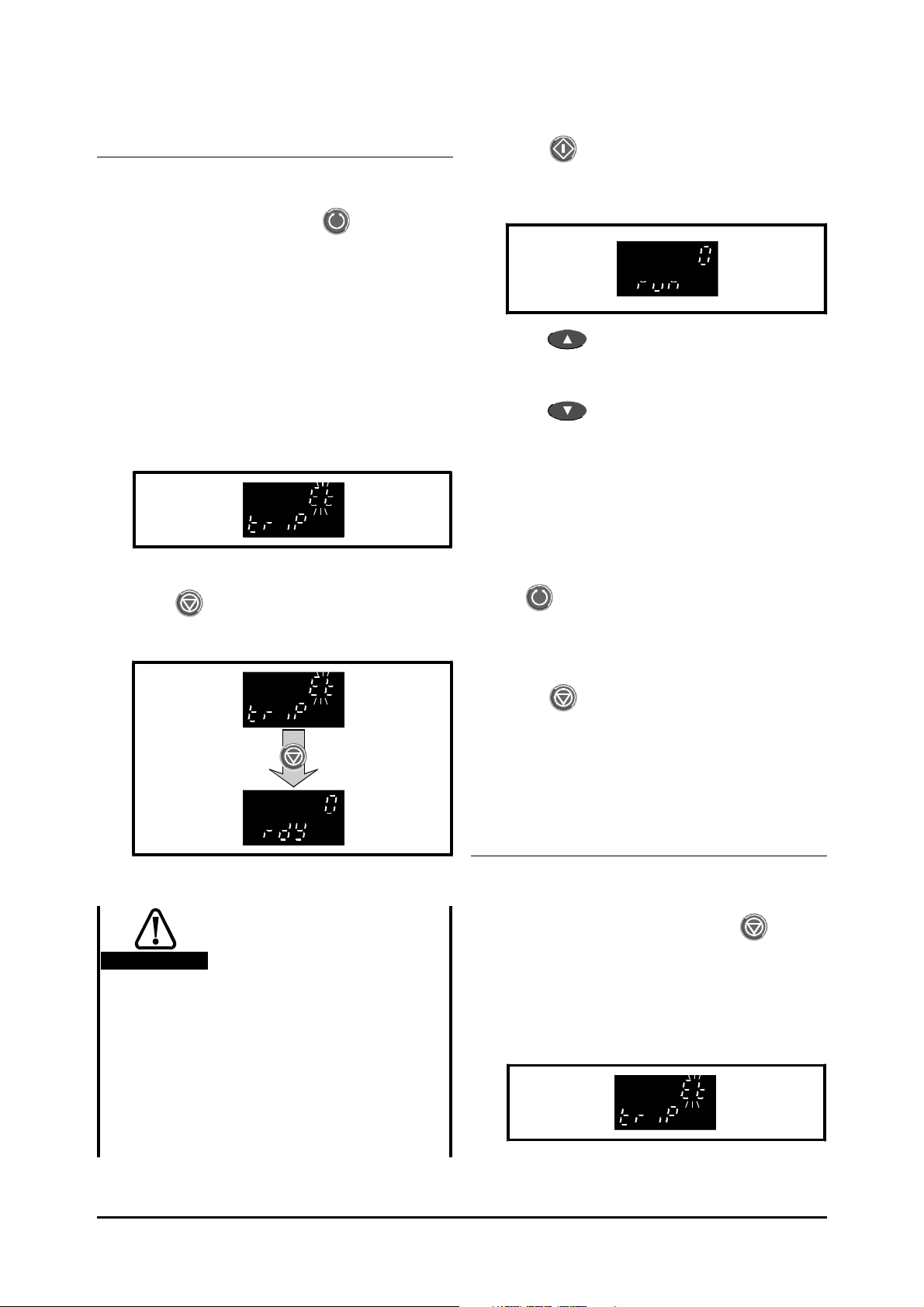

5. The display indicates as follows:

6. Close the EXTERNAL TRIP contact.

7. Press

contact.

8. The display indication changes as follows:

or momentarily close the RESET

AC supply.

11. Advance the FREQUENCY potentiometer.

12. The value shown by the upper display increases

accordingly, and the motor speed increases.

13. Open the RUN FORWARD contact. The

following occur:

• The value of the upper display reduces

to zero

• The lower display shows dEC, then rdY

• The motor speed reduces to zero

14. If required, repeat steps 10 to 13 using the

RUN REVERSE contact.

If you do not require the use of jog / preset

frequency, go to Trip and Enable later in this

chapter

Jog/Preset frequency

The jog function can be used alternatively as a

preset frequency. The default value is 1.5Hz.

1. Close the JOG/PRESET SELECT contact. Then

close the RUN FORWARD contact. It is

essential that the contacts are closed in this

order, otherwise the Drive will run forward (or

reverse) normally at variable speed.

The display indicates a fixed low speed that

cannot be changed by the FREQUENCY

potentiometer. The motor runs at this low

speed.

2. Open the RUN FORWARD contact to stop

the Drive.

9. Ensure parameter 0.10 Motor speed is displayed

(default).

10. Close the RUN FORWARD contact. The display

indicates as follows:

Commander GP User Guide

Issue code: gpxu2

3. If required, repeat steps 1 and 2 using the

RUN REVERSE contact.

4. If the JOG/PRESET SELECT contact is opened

before the RUN FORWARD or RUN REVERSE

contact, the motor speed will become

controlled by the FREQUENCY potentiometer.

Go to Trip and Enable later in this chapter

Getting Started 2-13

Keypad mode

Motor direction in Keypad mode

In Keypad mode (with Macro 1), (FWD/REV) is

disabled by default; the Drive can control the motor

in the forward direction only. For reverse

operation, see the Commander Gp Advanced User Guide.

9. Press

10. The upper display should indicate zero; the

lower display will indicate as follows:

to start the Drive running.

Variable frequency

1. Ensure the control signal connections shown in

Figure 2–6 are made.

2. Ensure that the EXTERNAL TRIP contact is open.

3. Connect the Drive to the

4. The display indicates as follows:

5. Close the EXTERNAL TRIP contact.

6. Press

7. The display indication changes as follows:

AC supply.

11. Press to increase the speed. The value

of the upper display increases and the motor

speed increases.

12. Press

of the upper display decreases and the motor

speed decreases.

When the Drive is configured to accept a

bipolar speed reference, continuing to press

this key after the motor has stopped will cause

the speed to increase in the reverse direction.

(For operation with a bipolar speed reference,

see the Commander Gp Advanced User Guide.)

13. If

speed at a convenient value and then press this

key. The speed reduces to zero then increases

to the set value in the opposite direction.

14. Press

occur:

• The value of the upper display reduces

to zero

• The lower display shows dEC, then rdY

• The motor speed reduces to zero

to decrease the speed. The value

(FWD/REV) has been enabled, set the

to stop the Drive. The following

Ensure parameter 0.10 Motor speed is displayed

(default).

If the Drive has been used

previously in keypad mode,

Warning

check that the value of

parameter 0.35 is zero

before proceeding with the

next step. If it is not zero,

use the speed control keys as

appropriate to set

parameter 0.35 at zero.

If parameter 0.35 is not

zero, when the Drive is

started it will immediately

accelerate to the speed set

in this parameter.

2-14 Getting Started

Trip and enable

1. If the Drive trips, and a motor is connected, the

motor will coast. See Appendix E Diagnostics.

To clear a trip, momentarily press

Terminal mode only, momentarily close the

RESET contact.

2. If the EXTERNAL TRIP contact is opened while

the Drive is stopped or running, the Drive trips

(and the motor will coast). The display will

indicate as follows:

Commander GP User Guide

or, for

Issue code: gpxu2

2.8 Setting up operating limits

Unit

s/100Hz

Deceleration rate

Minimum and maximum frequencies

Do not set the maximum

frequency at a value that is

excessive for the motor.

Warning

If the intended maximum

frequency affects the safety of

the machinery, additional

independent over-speed

protection must be used.

Set parameter 0.02 Maximum frequency at the

required value. When initially setting up the Drive,

leave 0.01 Minimum frequency at the default value of

zero so that the motor shaft does not rotate as

soon as a

RUN command is received. When it is

known to be safe to do so, set 0.01 at the required

value.

Note the following:

• Slip compensation can cause the output

frequency of the Drive to exceed [0.02].

For operation at motor speeds

greater than twice base speed,

contact the supplier of the

Caution

motor.

Default values and range

0.01 Default value Range Unit

0 0 ~ [0.02] Hz

0.02 Default value Range Unit

50 Hz (EUR)

60 Hz (USA)

0 ~ 1000 Hz

Acceleration rate

To adjust the acceleration rate, adjust parameter

0.03 Acceleration rate. Increase the value to

increase the time taken for acceleration (ie. reduce

the acceleration rate).

Range Default Unit

0 ~ 3200 5 s/100Hz

To adjust the deceleration rate, adjust parameter

0.04 Deceleration rate. Increase the value to

increase the time taken for deceleration (ie. reduce

the deceleration rate).

Range Default

0 ~ 3200 10

If the Drive trips when decelerating the motor and

the display indicates OU, this indicates that the

maximum permissible

DC-bus voltage has been

exceeded during braking. Increase the value of

0.04 Deceleration rate or, if a braking resistor is not

currently connected, return to Planning the

installation in Chapter 2 Installing the Drive in the

Installation Guide for instructions on connecting a

braking resistor.

Braking resistor

The Drive does not contain a

braking resistor; when

Warning

If a braking resistor is being used, set the following

parameter at FASt in order to prevent instability:

Macro Parameter

0 2 3 4

1 5 6 7 See the Commander Gp Advanced User Guide

For Macros 1 and 5, the Note at the beginning of

Enabling Macro 1 earlier in this chapter gave

instructions for changing the setting of this

parameter. When Macro 6 or 7 is enabled, the

setting is made automatically. See 0.15 Ramp mode

selector in Appendix D Menu 0 Parameters.

required, an external

braking resistor must be

used (see the Installation

Guide).

Depending on the setting of

parameter 0.15, failure to

connect a braking resistor

when one is required may

result in deceleration times

being extended or the Drive

tripping during braking

which would leave the

motor free to coast.

0.15 Ramp mode selector

If the required acceleration cannnot be achieved, it

may be necessary to increase the value of

0.06 Current limit.

Commander GP User Guide

Issue code: gpxu2

Getting Started 2-15

Torque-producing current limit

Model

GPD 3201

GPD 3401

GPD 3402

GPD 3202

GPD 3403

GPD 3203

GPD 3404

GPD 3405

GPD 3204

GPD 4401

GPD 4402

GPD 4403

GPD 4404

GPD 4405

The value of FLC is given in the following table.

Set parameter 0.06 Current limit at the required

percentage of rated motor torque (or rated active

torque-producing current).

The current limit is used to protect the motor and

Drive from excessive current and applies under

motoring and regenerating conditions. When the

Drive is operating in torque control, the current

limit limits the value of torque demand.

The total motor current comprises a magnetizing

current and an active (torque-producing) current.

Since the maximum torque produced by the motor

is proportional to the value of parameter 0.06

Current limit, this current limit is a torque-producing

current limit.

When 0.06 is set at its maximum value, the

maximum total motor current is as follows:

150% x FLC

Where FLC is the rated (full-load) current of the

Drive.

The maximum value of 0.06 is given by the

following (but cannot exceed 400 (%)):

Values of FLC

Model FLC (A)

GPD 1201

GPD 1401

GPD 1202

GPD 1402

GPD 1203

GPD 1403

GPD 1204

GPD 1404

GPD 1205

GPD 1405

GPD 2201

GPD 2401

GPD 2202

GPD 2402

GPD 2203

GPD 2403

25

12

16

2.1

2.8

3.8

5.6

9.5

FLC (A)

34

40

46

60

70

74

96

124

156

180

202

22

( . ) ( cos )

15 1

[. ]

MAX

==

−−−−

cos [ . ]

φφ

φφ

FLC

××××

046

100

(%)006

Where:

[0.46] = Value of Motor – rated current

cosφ is the power factor of the motor.

Note

The results from these equations may not

correspond exactly with the maximum

output current from the Drive, since the

Drive may round up the calculated figure.

Voltage-control modes

The default setting is as follows:

Macro 1: Fd

Macros 0, 2, 3, 4, 5, 6, 7: Ur_I

To change the voltage control mode, select the

required setting in parameter 0.07 Voltage mode

selector, as follows:

Setting Function

Vector modes

Ur_S

Ur_I

Ur

Fd

0 Motor stator resistance is measured each

time the Drive is started.

1 Motor stator resistance is measured at

power-up if the

closed and no other trip condition exists.

2 Motor stator resistance is not measured

(use this mode only after having used

Ur_S or Ur_I to measure the stator

resistance).

Fixed boost mode

3 Fixed voltage boost that can be manually

adjusted by parameter 0.08 Boost voltage.

EXTERNAL TRIPEXTERNAL TRIP contact is

2-16 Getting Started

The Vector modes give better performance at low

speed than the fixed-boost mode, but require the

stator resistance to be accurately measured by the

Drive.

Commander GP User Guide

Issue code: gpxu2

Note

If parameter 0.39 Synchronize to a spinning

motor is to be set at 1, for reliable

operation of the Drive, set parameter 0.07

at Fd.

When Ur_I is selected, the

AC

Warning

motor might kick when the

supply is connected to the

Drive (with the

contact already closed).

EXTERNAL TRIP

Boost voltage

Use this procedure only when 0.07 Voltage mode

selector has been set at Fd.

Where actions apply to a particular control mode,

the following key is used:

K> Keypad mode

T> Terminal mode

1. Connect the load to the motor.

2. Close the EXTERNAL TRIP contact.

3. Ensure the frequency reference is zero.

4. K> Press

T> Close the RUN FORWARD or RUN

REVERSE contact.

Increase the frequency reference to a value

slightly above zero. If the motor shaft does

not rotate, increase the value of parameter

0.08 Boost voltage sufficiently to cause the

shaft to rotate.

Default value: 3%

Range: 0 ~ 25%

5. If the motor is noisy and becomes unnecessarily

heated, reduce the value of 0.08.

6. Stop the Drive.

Save the new parameter-value.

Voltage/frequency characteristic

If the motor is to drive a pump or fan where the load

can vary, set parameter 0.09 Dynamic V/f select at 1.

This selects an automatic voltage/frequency

characteristic which reduces power consumption

and acoustic noise in the motor when lightly loaded.

For an explanation of the effects of the

voltage/frequency characteristic, see parameter 0.09

Dynamic V/f select in Appendix D Menu 0 Parameters.

Commander GP User Guide

Issue code: gpxu2

Getting Started 2-17

2-18 Getting Started

Commander GP User Guide

Issue code: gpxu2

3 Setting Up the Drive

(Macro Configurations)

Do not change parameter

values without careful

Warning

consideration; wrong values

may cause damage or a safety

hazard.

3.2 Enabling a different

macro configuration

Do not attempt to enable any

macro configuration when the

Drive is running.

Warning

Note

Notes

Keep a note of changes

When changing the values of parameters,

make a note of the new values in case they

need to be entered again.

Saving the changes

For new parameter-values to apply after

AC supply to the Drive is interrupted,

the

new values must be saved. Refer to

Saving new parameter-values in Appendix A

Programming Instructions.

3.1 How to use this chapter

When setting up the Drive for the first time, you

must first have followed Chapter 2 Getting Started;

Macro 1 Easy mode will then be enabled. Whether

you keep Macro 1 or enable a different macro

configuration, the settings you made in Chapter 2

will remain unchanged. During the course of setting

up the Drive, you may need to change some of these

settings. If so, refer again to Chapter 2.

It is recommended that you follow the instructions

in this chapter in the order that they appear. You

will be led through the following:

• • Enabling the required macro

configuration (if a macro other than

Macro 1 is required)

• • Changing the signal connections

accordingly

• • Adjusting parameters that are

specific to the macro configuration

• • A list of subsidiary functions that

can be set up

Only one macro configuration can be

enabled at a time.

Enabling a different macro

configuration after getting started

with Macro 1

If Macro 1 is to remain enabled, ignore this section

and go to Macro 1 later in this chapter.

1. To enable a different macro configuration, set

parameter 0.00 as follows:

Macro Function Setting

2 Motorized potentiometer

(frequency control by up and

down contacts)

3 Four preset frequencies

(selected by digital control

signals)

4 Torque control 2004

5 PID (set-point) control 2005

6 Axis-limit control 2006

7 Brake control 2007

0 General purpose

(USA default configuration)

General purpose

(EUR default configuration)

Note

The values of the fixed parameters are not

changed when any one of these macro

configurations is enabled.

When Macro 0 is enabled, the

functions of parameters

Caution

0.27 to 0.29 differ between

the EUR and USA default

configurations.

2002

2003

2009

2010

Commander GP User Guide

Issue code: gpxu2

2. Reset the Drive.

3. Go to the relevant section in this chapter for

the macro configuration that has been enabled.

Setting Up the Drive 3-1

Enabling a different macro

configuration after using Macros 2 to 7

If any one of the macros from 2 to 7 has been

enabled (after the instructions in this chapter have

previously been followed), proceed as follows...

1. Go to Initial setting up in Chapter 2 Getting

Started. Start proceeding through that section

by referring to Restoring the Drive to a default

configuration.

2. Follow the remainder of Initial setting up.

3. Return to this chapter and follow Enabling a

different macro configurationafter getting started

with Macro 1 earlier in this chapter.

3.3 Macro 0

General purpose

(

default configuration

Features

Specific features

Macro 0 places the Drive in a default configuration

for general-purpose use.

When a UD50 small option module is fitted in the

Drive, the following additional functions become

automatically available for Macro 0 only:

• Volt-free relay contact which closes when

the Drive is AT OR BELOW MINIMUM SPEED

• Volt-free relay contact which closes when

the Drive is AT SPEED

• DRIVE RUNNING digital output

• MOTOR CURRENT OVERLOAD ALARM

digital output

• (EXCESSIVE) HEATSINK TEMPERATURE

ALARM digital output

• MOTOR CURRENT MAGNITUDE

analog output

• Frequency offset can be selected and

applied

• Operation in torque mode can be selected

• A bipolar or unipolar frequency reference

can be applied

To change the functions of the UD50 or to enable

the UD50 to be used with other macro

configurations, see the Commander Gp Advanced User

Guide. With Drive software versions V03.01.05, a

UD50 cannot be used with any of the other macro

configurations.

)

Standard features

• Macro 0 operates in Terminal or Keypad

mode

• In Terminal mode, digital control by

RUN FORWARD, RUN REVERSE and

JOG SELECT contacts

• Local and remote analog frequency inputs,

or setting of frequency by use of the keypad

• Keypad control of speed can be

uni-directional or bi-directional

• Selection of analog input modes

• Adjustable Jog/Preset frequency

• Adjustment of minimum and maximum

frequencies

• Adjustment of acceleration and deceleration

ramps

• S-ramp

• Skip frequencies

• Selection of stopping modes

• Selection of braking mode

• Motor thermistor input

• Negative logic for the digital inputs

(EUR> positive logic can be selected)

• EUR> Adjustment of current-loop PI gains

• USA> Indication of frequency demand

• USA> Digital control by three-wire

momentary contacts can be selected

• SPEED and TORQUE analog outputs

• AT SPEED digital output

• External trip digital input

• Drive RESET digital input

3-2 Setting Up the Drive

Commander GP User Guide

Issue code: gpxu2

Loading...

Loading...