Page 1

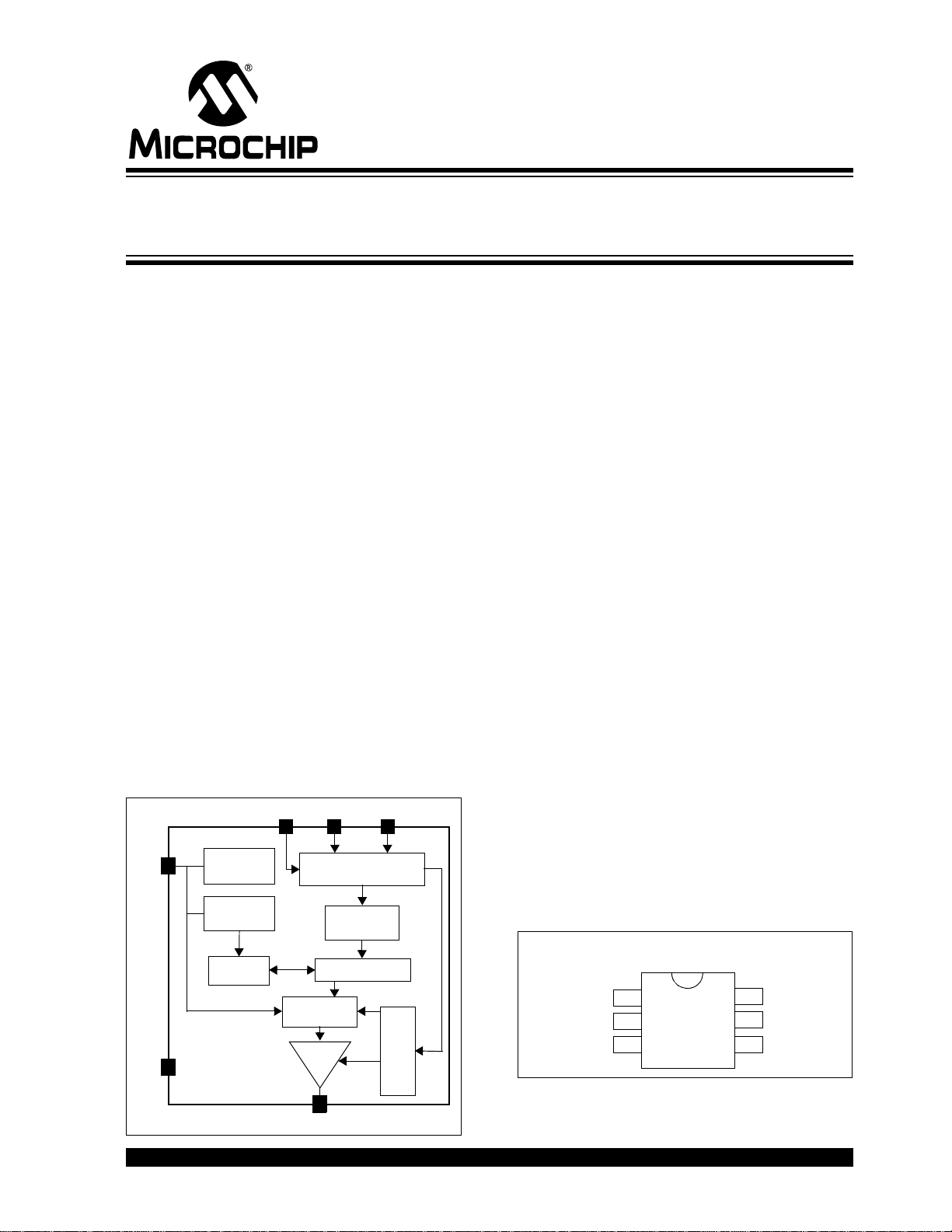

MCP4725

Resistive

Power-on

Reset

Charge

Pump

EEPROM

I2C Interface Logic

Input

Register

DAC Register

Op

Amp

Power-down

Control

V

DD

V

SS

SCL SDA

V

OUT

A0

String DAC

3

V

DD

SCL

SDA

V

SS

A0

SOT-23-6

V

OUT

2

1

4

5

6

12-Bit Digital-to-Analog Converter with EEPROM Memory

in SOT-23-6

Features

• 12-Bit Resolution

• On-Board Non-Volatile Memory (EEPROM)

• ±0.2 LSB DNL (typical)

• External A0 Address Pin

• Normal or Power-Down Mode

• Fast Settling Time of 6 µs (typical)

• External Voltage Reference (V

• Rail-to-Rail Output

• Low Power Consumption

• Single-Supply Operation: 2.7V to 5.5V

2CTM

•I

• Small 6-lead SOT-23 Package

• Extended Temperature Range: -40°C to +125°C

Interface:

- Eight Available Addresses

- Standard (100 kbps), Fast (400 kbps), and

High-Speed (3.4 Mbps) Modes

DD

)

Applications

• Set Point or Offset Trimming

• Sensor Calibration

• Closed-Loop Servo Control

• Low Power Portable Instrumentation

• PC Peripherals

• Data Acquisition Systems

Block Diagram

DESCRIPTION

The MCP4725 is a low-power, high accuracy, single

channel, 12-bit buffered voltage output Digital-to-Analog Convertor (DAC) with non-volatile memory

(EEPROM). Its on-board precision output amplifier

allows it to achieve rail-to-rail analog output swing.

The DAC input and configuration data can be

programmed to the non-volatile memory (EEPROM) by

the user using I

memory feature enables the DAC device to hold the

DAC input code during power-off time, and the DAC

output is available immediately after power-up. This

feature is very useful when the DAC device is used as

a supporting device for other devices in the network.

The device includes a Power-On-Reset (POR) circuit to

ensure reliable power-up and an on-board charge

pump for the EEPROM programming voltage. The

DAC reference is driven from V

power-down mode, the output amplifier can be configured to present a low, medium, or high resistance output load.

The MCP4725 has an external A0 address pin. This A0

pin can be tied to V

board.

The MCP4725 has a two-wire I

interface for standard (100 kHz), fast (400 kHz), or high

speed (3.4 MHz) mode.

The MCP4725 is an ideal DAC device where design

simplicity and small footprint is desired, and for applications requiring the DAC device settings to be saved

during power-off time.

The device is available in a small 6-pin SOT-23

package.

Package Type

2

C interface command. The non-volatile

DD directly. In

DD or VSS of the user’s application

2

C™ compatible serial

© 2007 Microchip Technology Inc. DS22039C-page 1

Page 2

MCP4725

1.0 ELECTRICAL CHARACTERISTICS

† Notice: Stresses above those listed under “Maximum ratings” may cause permanent damage to the device.

This is a stress rating only and functi onal operation of

the device at these or any other conditions above those

Absolute Maximum Ratings†

VDD...................................................................................6.5V

All inputs and outputs w.r.t V

Current at Input Pins ....................................................±2 mA

Current at Supply Pins ...............................................±50 mA

Current at Output Pins ...............................................±25 mA

Storage Temperature ....................................-65°C to +150°C

Ambient Temp. with Power Applied ..............-55°C to +125°C

ESD protection on all pins ................ ≥ 6kV HBM, ≥ 400V MM

Maximum Junction Temperature (T

.................–0.3V to VDD+0.3V

SS

) ......................... +150°C

J

indicated in the operation listings of this specification is

not implied. Exposure to maximum rating conditions for

extended periods may affect device reliability

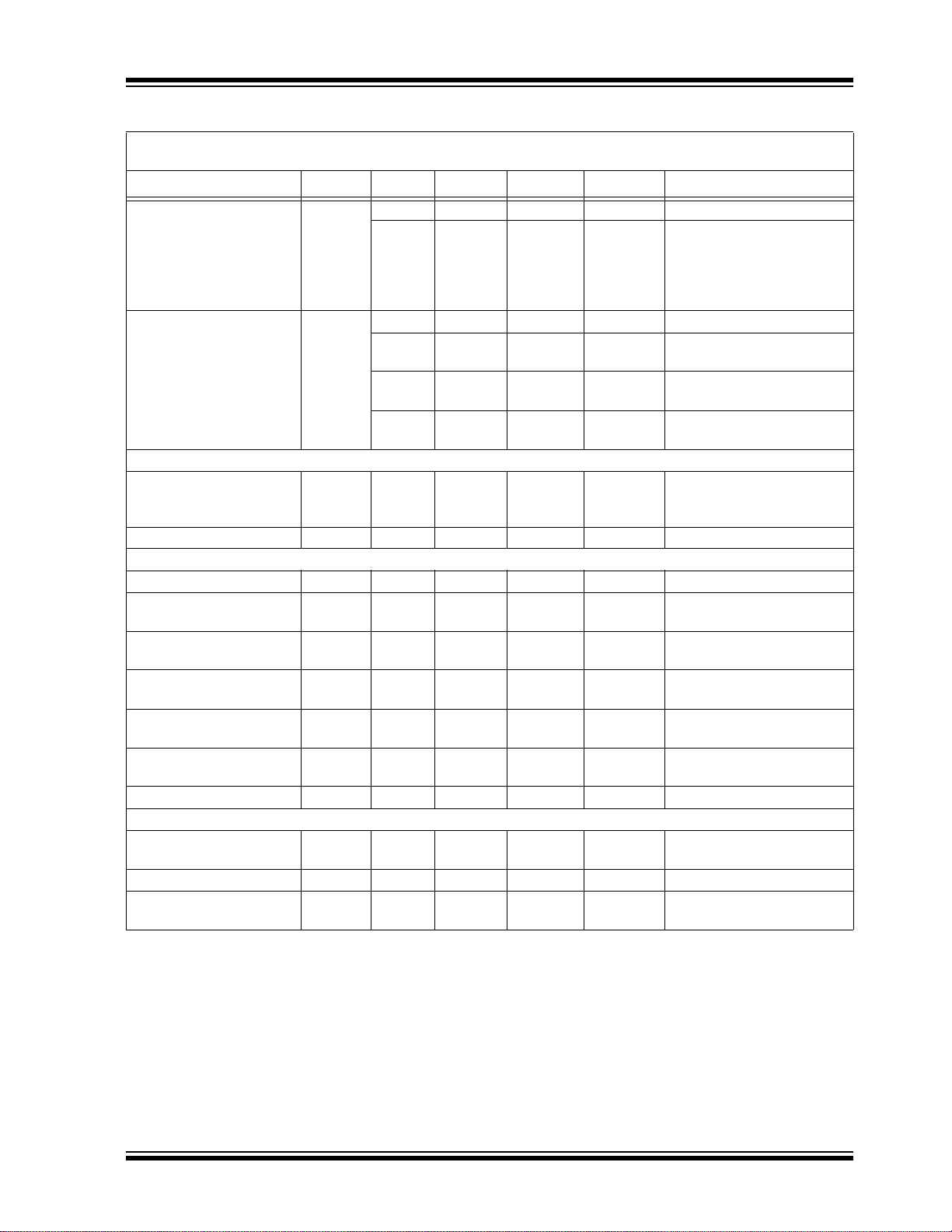

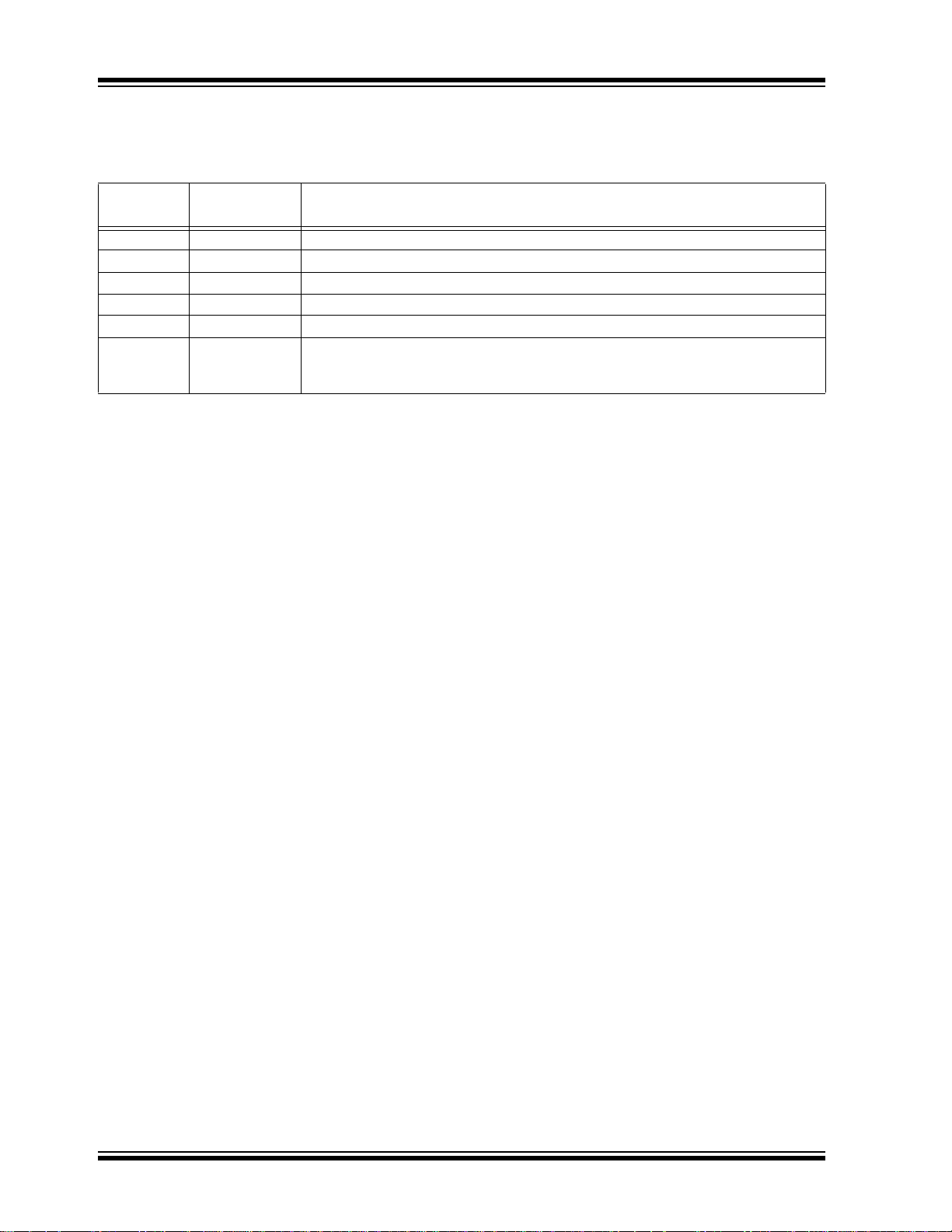

ELECTRICAL CHARACTERISTICS

Electrical Specifications: Unless otherwise indicated, all parameters apply at VDD = + 2.7V to 5.5V, VSS = 0V,

RL = 5 kΩ from V

Parameter Sym Min Typ Max Units Conditions

Power Requirements

Operating Voltage V

Supply Current I

Power-Down Current I

Power-On-Reset

Threshold

DC Accuracy

Resolution n 12 — — Bits Code Range = 000h to FFFh

INL Error INL — ±2 ±14.5 LSB Note 1

DNL DNL -0.75 ±0.2 ±0.75 LSB Note 1

Offset Error V

Offset Error Drift ΔV

Gain Error G

Gain Error Drift ΔGE/°C — -3 — ppm/°C

Output Amplifier

Phase Margin

Capacitive Load Stability CL — — 1000 pF RL = 5 kΩ, Note 2

Slew Rate SR — 0.55 — V/µs

Short Circuit Current I

Output Voltage Settling

Time

Note 1: Test Code Range: 100 to 4000.

2: This parameter is ensure by design and not 100% tested.

3: Within 1/2 LSB of the final value when code changes from 1/4 to 3/4 (400h to C00h) of full-scale.

4: Logic state of external address pin (A0 pin).

to VSS, CL = 100 pF, TA = -40°C to +125°C. Typical values are at +25°C.

OUT

DD

D

DDP

V

POR

OS

/°C — ±1 — ppm/°C -45°C to +25°C

OS

2.7 5.5 V

— 210 400 µA Digital input grounded, out-

— 0.06 2.0 µA VDD = 5.5V

—2 — V

0.02 0.75 % of FSR Code = 000h

— ±2 — ppm/°C +25°C to +85°C

-2 -0.1 2 % of FSR Code FFFh, not including

E

p

— 66 — Degree(°) CL = 400 pF, RL = ∞

M

—15 24 mA V

SC

TS —6 — µsNote 3

put unloaded, code = 000h

offset error

= 5V, V

DD

= Grounded

OUT

DS22039C-page 2 © 2007 Microchip Technology Inc.

Page 3

MCP4725

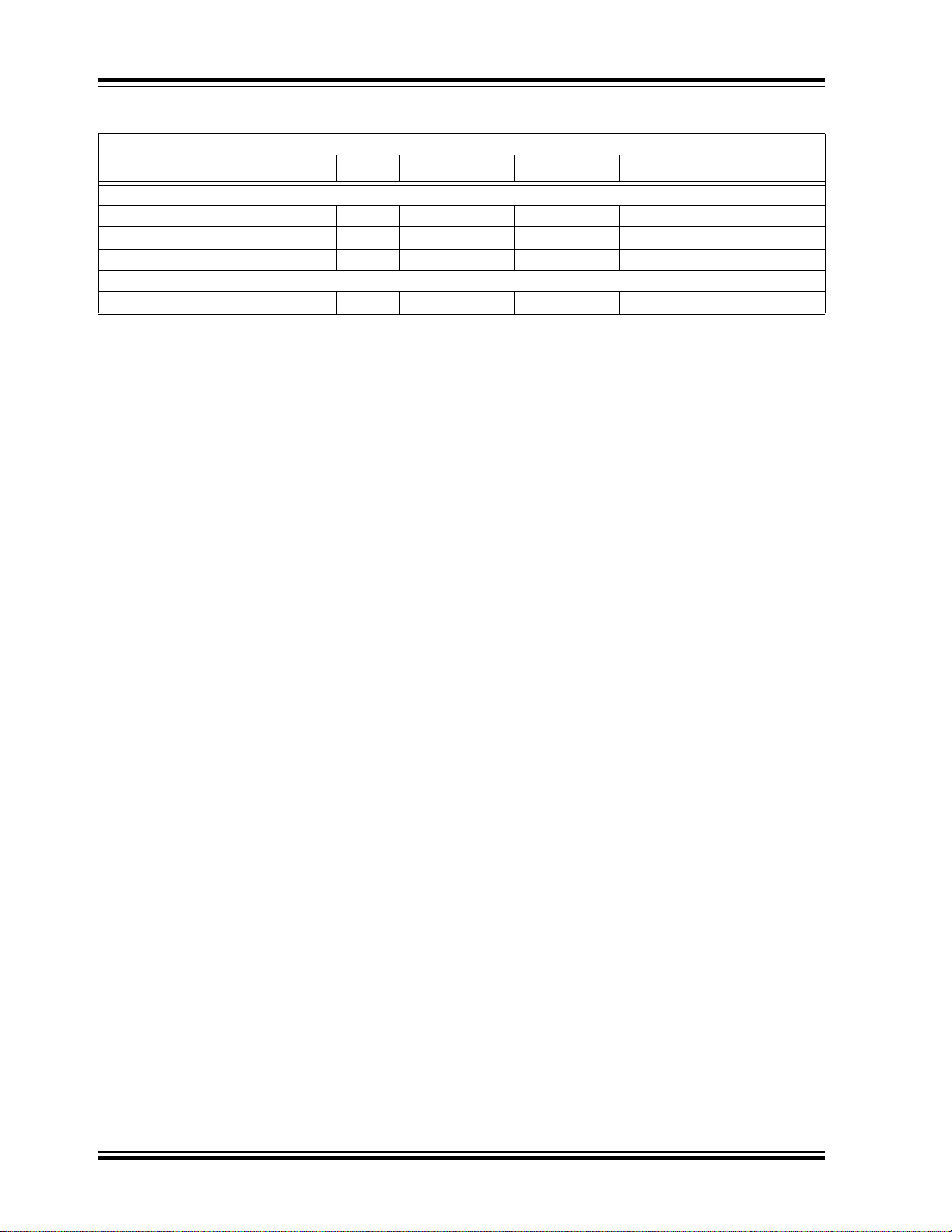

ELECTRICAL CHARACTERISTICS (CONTINUED)

Electrical Specifications: Unless otherwise indicated, all parameters apply at VDD = + 2.7V to 5.5V, VSS = 0V,

RL = 5 kΩ from V

Parameter Sym Min Typ Max Units Conditions

Power Up Time T

DC Output Impedance R

Dynamic Performance

Major Code Transition

Glitch

Digital Feedthrough — <10 — nV-s Note 2

Digital Interface

Output Low Voltage V

Input High Voltage

(SDA and SCL Pins)

Input Low Voltage

(SDA and SCL Pins)

Input High Voltage

(A0 Pin)

Input Low Voltage

(A0 Pin)

Input Leakage I

Pin Capacitance C

EEPROM

EEPROM Write Time T

Data Retention — 200 — Years At +25°C, (Note 2)

Endurance 1 — — Million

Note 1: Test Code Range: 100 to 4000.

2: This parameter is ensure by design and not 100% tested.

3: Within 1/2 LSB of the final value when code changes from 1/4 to 3/4 (400h to C00h) of full-scale.

4: Logic state of external address pin (A0 pin).

to VSS, CL = 100 pF, TA = -40°C to +125°C. Typical values are at +25°C.

OUT

PU

—2.5 — µsV

—5 — µsV

—1 — Ω Normal mode (V

OUT

—1 — kΩ Power-Down Mode 1

—100 — kΩ Power-Down Mode 2

—500 — kΩ Power-Down Mode 3

— 45 — nV-s 1 LSB change around major

— — 0.4 V IOL = 3 mA

OL

VIH 0.7V

V

— —0.3VDDV

IL

V

A0-Hi

V

— — 0.2V

A0-IL

— — ±1 µA SCL = SDA = A0 = V

LI

—— 3 pF Note 2

PIN

WRITE — 25 50 ms EEPROM Write time for 14

0.8V

DD

DD

—— V

—— Note 4

DD

Cycles

= 5V

DD

= 3V

DD

Coming out of Power-down

mode, started from falling

edge of ACK pulse in I

command.

OUT

(V

to VSS)

OUT

(V

to VSS)

OUT

(V

to VSS)

OUT

carry (800h to 7FFh)

(Note 2)

Note 4

SCL = SDA = A0 = V

bits

At +25°C, (Note 2)

2

C

to VSS)

or

SS

DD

© 2007 Microchip Technology Inc. DS22039C-page 3

Page 4

MCP4725

TEMPERATURE CHARACTERISTICS

Electrical Specifications: Unless otherwise indicated, VDD= +2.7V to +5.5V, VSS=GND.

Parameters Sym Min Typ Max Units Conditions

Temperature Ranges

Specified Temperature Range T

Operating Temperature Range T

Storage Temperature Range T

Thermal Package Resistances

Thermal Resistance, 6L-SOT-23 θ

A

A

A

JA

-40 — +125 °C

-40 — +125 °C

-65 — +150 °C

—190—°C/W

DS22039C-page 4 © 2007 Microchip Technology Inc.

Page 5

MCP4725

-0.04

0

0.04

0.08

0.12

0.16

0 1024 2048 3072 4096

Code

DNL (LSB)

-0.1

0

0.1

0.2

0.3

0 1024 2048 3072 4096

Code

DNL (LSB)

VDD = 5.5V

-0.1

0.0

0.1

0.2

0.3

0 1024 2048 3072 4096

Code

DNL (LSB)

-0.1

0.0

0.1

0.2

0.3

0.4

0 1024 2048 3072 4096

Code

DNL (LSB)

VDD = 2.7V

-4

-3

-2

-1

0

1

2

0 1024 2048 3072 4096

Code

INL(LSB)

2.7V

5.5V

-4

-3

-2

-1

0

1

2

0 1024 2048 3072 4096

Code

INL(LSB)

+25C

+125C

- 40C

+85C

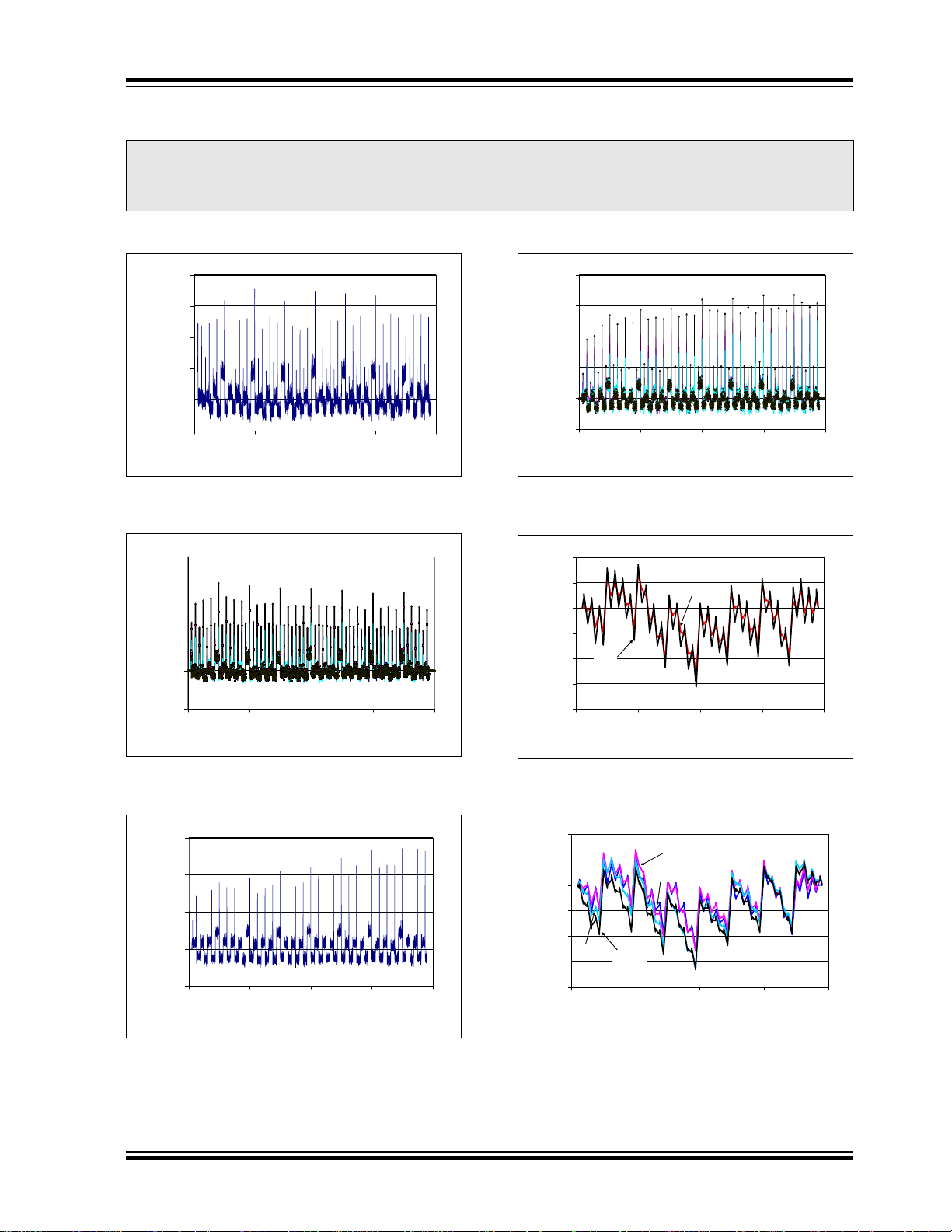

2.0 TYPICAL PERFORMANCE CURVES

Note: The graphs and tables provided following this note are a statistical summary based on a limited number of

samples and are provided for informational purposes only. The performance characteristics listed herein

are not tested or guaranteed. In some graphs or tables, the data presented may be outside the specified

operating range (e.g., outside specified power supply range) and therefore, outside the warranted range.

Note: Unless otherwise indicated, TA = +25°C, VDD = +5.0V, VSS = 0V, RL = 5 kΩ to VSS, CL = 100 pF.

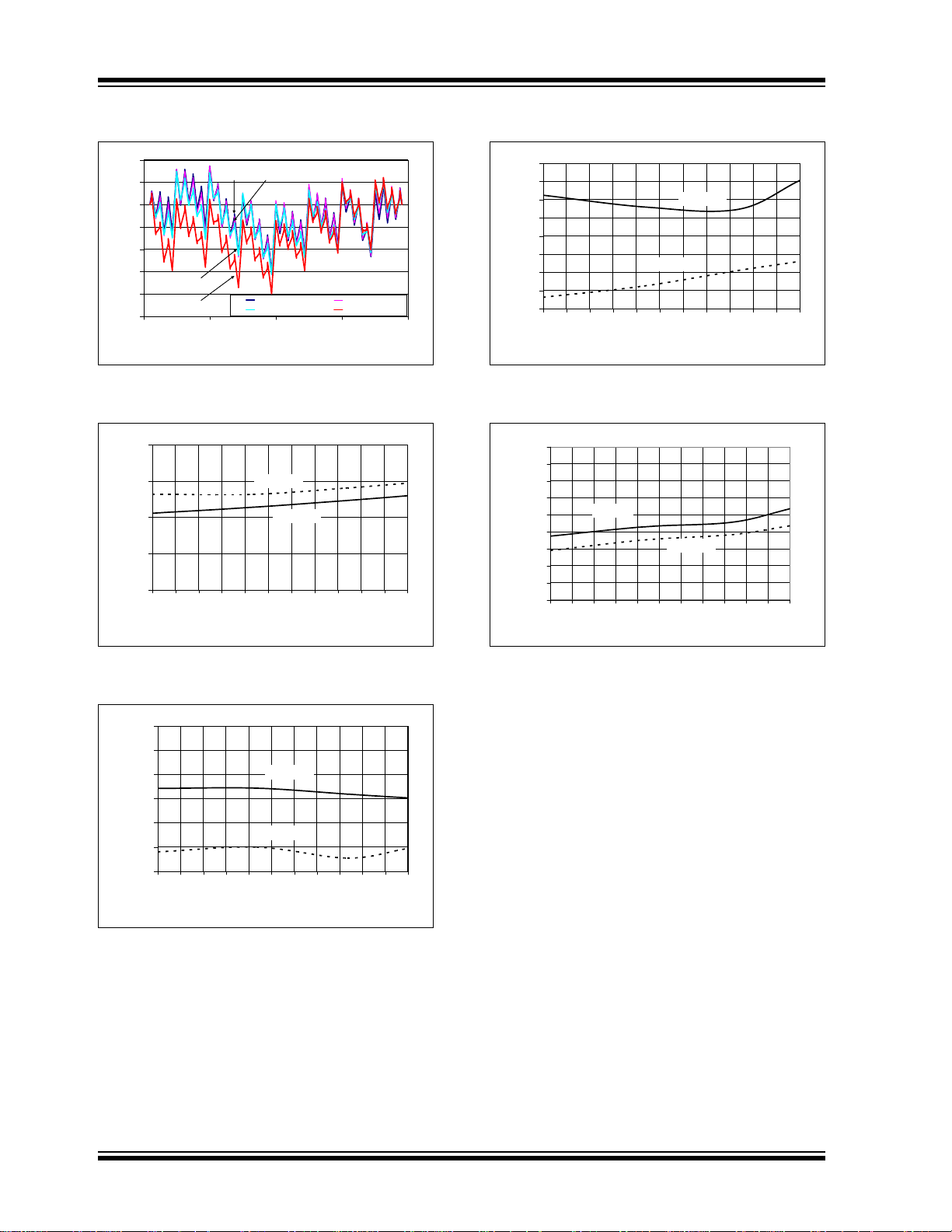

FIGURE 2-1: DNL vs. Code (VDD = 5.5V).

FIGURE 2-2: DNL vs. Code and

Temperature (TA = -40°C to +125°C).

FIGURE 2-4: DNL vs. Code and

Temperature (T

= -40°C to +125°C).

A

FIGURE 2-5: INL vs. Code.

FIGURE 2-3: DNL vs. Code (V

© 2007 Microchip Technology Inc. DS22039C-page 5

= 2.7V).

DD

FIGURE 2-6: INL vs. Code and

Temperature (V

= 5.5V).

DD

Page 6

MCP4725

-5

-4

-3

-2

-1

0

1

2

0 1024 2048 3072 4096

Code

INL(LSB)

TA = -40 C TA = 25 C

TA = 85 C TA = 125 C

+125 C

- 40 C

+85 C

+25 C

-1

0

1

2

3

-40 -25 -10 5 20 35 50 65 80 95 110 125

Temperature (°C)

Zero Scale Error (mV)

VDD = 5.5V

VDD = 2.7V

-60

-50

-40

-30

-20

-10

0

-40 -25 -10 5 20 35 50 65 80 95 110 125

Temperature (°C)

Full-Scale Error (mV)

VDD = 2.7V

VDD = 5.5V

-5

-4

-3

-2

-1

0

1

2

3

-40 -25 -10 5 20 35 50 65 80 95 110 125

Temperature (°C)

Output Error (mV)

VDD = 2.7V

VDD = 5.5V

0

50

100

150

200

250

300

350

400

450

-40 -25 -10 5 20 35 50 65 80 95 110 125

Temperature(°C)

I

DD

(uA)

VDD = 2.7V

VDD = 5V

Note: Unless otherwise indicated, TA = +25°C, VDD = +5.0V, VSS = 0V, RL = 5 kΩ to VSS, CL = 100 pF.

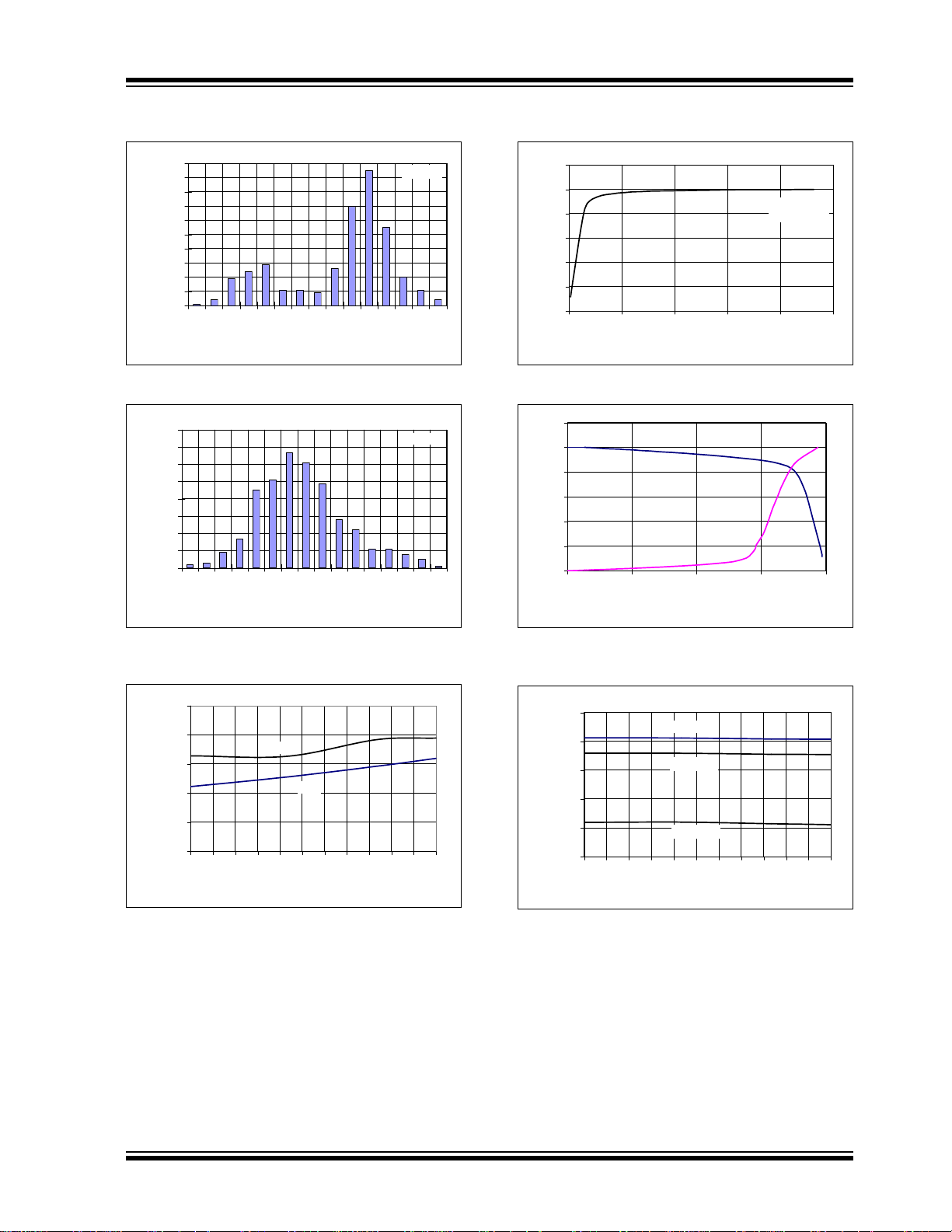

FIGURE 2-7: INL vs. Code and

Temperature (V

= 2.7V).

DD

FIGURE 2-8: Zero Scale Error vs. Temperature (Code = 000d).

FIGURE 2-10: Output Error vs. Temperature (Code = 4000d).

FIGURE 2-11: I

vs. Temperature.

DD

FIGURE 2-9: Full-Scale Error vs. Temperature (Code = 4095d).

DS22039C-page 6 © 2007 Microchip Technology Inc.

Page 7

MCP4725

0

10

20

30

40

50

60

70

80

90

100

180

184

188

192

196

200

204

208

212

216

220

224

228

232

236

Current (µA)

Occurance

VDD = 5V

VDD = 2.7V

0

10

20

30

40

50

60

70

80

163

165

167

169

171

173

175

177

179

181

183

185

187

189

191

193

Current (µA)

Occurance

0.00

0.50

1.00

1.50

2.00

2.50

-40 -25 -10 5 20 35 50 65 80 95 110 125

Temperature (°C)

Offset Error (mV)

2.7V

5.5V

0

1

2

3

4

5

6

012345

Load Resistance (kΩ)

V

OUT

(V)

VDD = 5V

Code = FFFh

0

1

2

3

4

5

6

0481216

I

SOURCE/SINK

(mA)

V

OUT

(V)

Code = FFFh

Code = 000h

VDD = 5V

1.00

1.50

2.00

2.50

3.00

3.50

-40 -25 -10 5 20 35 50 65 80 95 110 125

Temperature (°C)

V

IH

Threshold (V)

VDD = 5.5V

VDD = 5.0V

VDD = 2.7V

Note: Unless otherwise indicated, TA = +25°C, VDD = +5.0V, VSS = 0V, RL = 5 kΩ to VSS, CL = 100 pF.

FIGURE 2-12: IDD Histogram .

FIGURE 2-13: I

Histogram.

DD

FIGURE 2-15: V

vs. Resistive Load.

OUT

FIGURE 2-16: Source and Sink Current Capability.

FIGURE 2-14: Offset Error vs. Temperature

and V

© 2007 Microchip Technology Inc. DS22039C-page 7

.

DD

FIGURE 2-17: V

Temperature and V

High Threshold vs.

IN

.

DD

Page 8

MCP4725

0.50

0.70

0.90

1.10

1.30

1.50

1.70

1.90

2.10

2.30

2.50

-40 -25 -10 5 20 35 50 65 80 95 110 125

Temperature (C)

V

IL

Threshold (V)

VDD = 5.5V

VDD = 5.0V

VDD = 2.7V

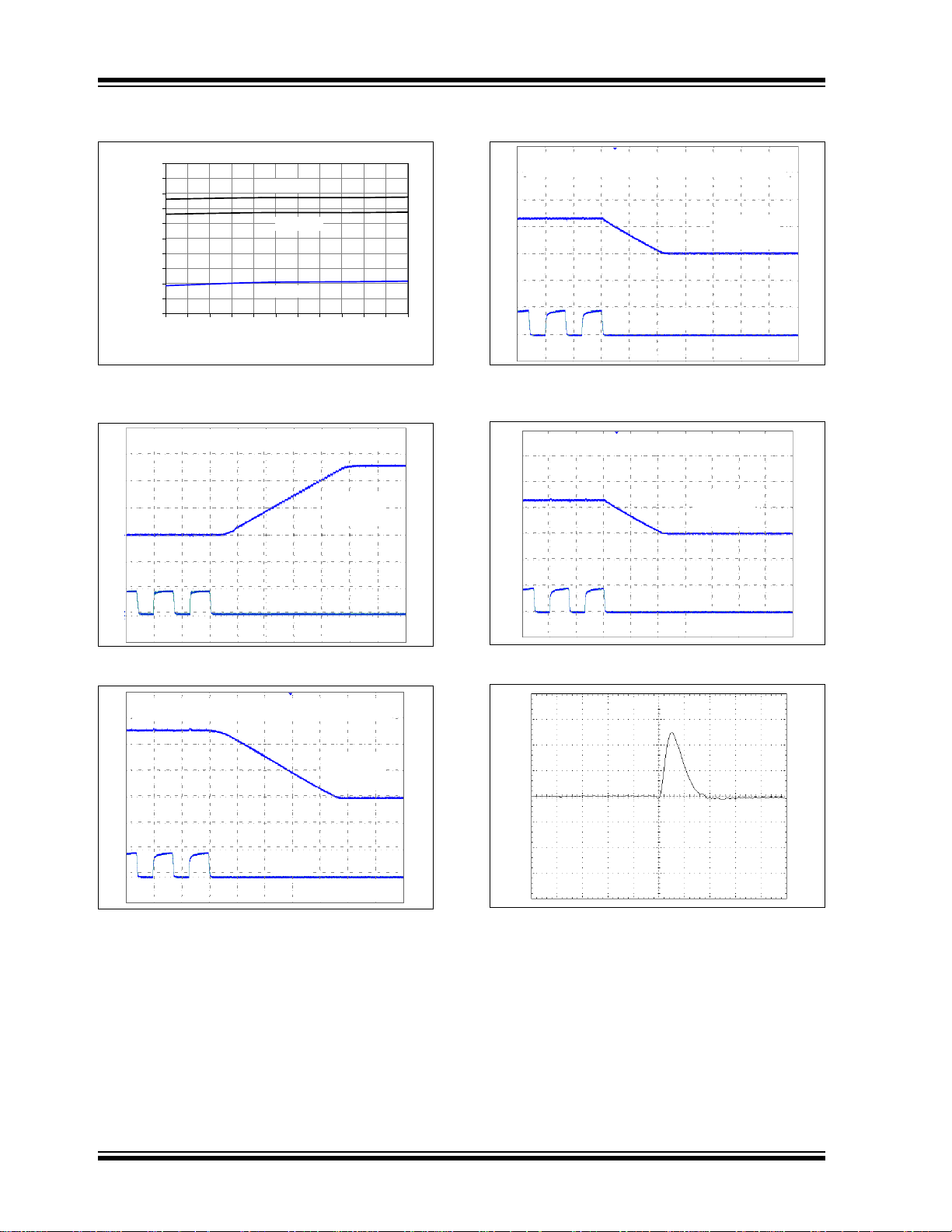

Full-Scale Code Change: 000h to FFFh

V

OUT

(2V/Div)

CLK

Time (2µs/Div)

Full-Scale Code Change: FFFh to 000h

V

OUT

(2V/Div)

CLK

Time (2µs/Div)

Half-Scale Code Change: 000h to 7FFh

V

OUT

(2V/Div)

CLK

Time (2µs/Div)

V

OUT

(2V/Div)

CLK

Time (2µs/Div)

Half-Scale Code Change: 7FFh to 000h

Code Change: 800h to 7FFh

V

OUT

(20 mV/Div)

Time (1µs/Div)

Note: Unless otherwise indicated, TA = +25°C, VDD = +5.0V, VSS = 0V, RL = 5 kΩ to VSS, CL = 100 pF.

FIGURE 2-18: VIN Low Threshold vs.

Temperature and V

DD

.

FIGURE 2-19: Full-Scale Settling Time.

FIGURE 2-21: Half-Scale Settling Time.

FIGURE 2-22: Half-Scale Settling Time.

FIGURE 2-20: Full-Scale Settling Time.

DS22039C-page 8 © 2007 Microchip Technology Inc.

FIGURE 2-23: Code Change Glitch.

Page 9

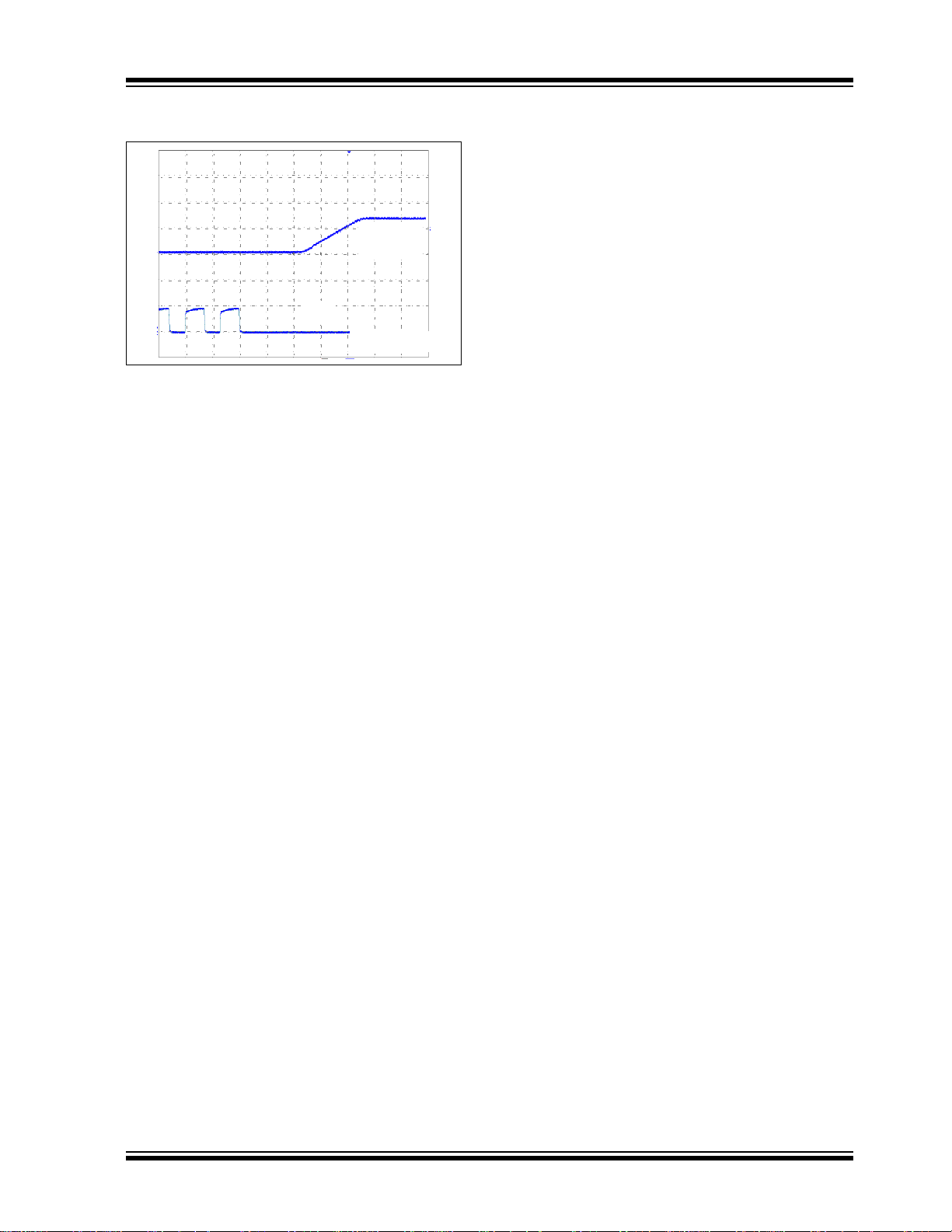

MCP4725

V

OUT

(2V/Div)

CLK

Time (2µs/Div)

Note: Unless otherwise indicated, TA = +25°C, VDD = +5.0V, VSS = 0V, RL = 5 kΩ to VSS, CL = 100 pF.

FIGURE 2-24: Exiting Power Down Mode.

© 2007 Microchip Technology Inc. DS22039C-page 9

Page 10

MCP4725

3.0 PIN DESCRIPTIONS

The descriptions of the pins are listed in Table 3-1.

TABLE 3-1: PIN FUNCTION TABLE

Pin No.

SOT-23

1V

2V

3V

4SDAI

5SCLI

6 A0 Device Address Selection pin. This pin can be tied to V

Name Function

OUT

SS

DD

Analog Output Voltage

Ground Reference

Supply Voltage

2

C Serial Data

2

C Serial Clock Input

driven by the digital logic levels. The logic state of this pin determines what the A0

bit of the I

2

C address bits should be.

or VDD, or can be actively

SS

3.1 Analog Output Voltage (V

V

is an analog output voltage from the DAC device.

OUT

OUT

)

DAC output amplifier drives this pin with a range of V

to VDD.

3.2 Supply Voltage (VDD, VSS)

VDD is the power supply pin for the device. The voltage

at the V

DAC reference input. The power supply at the VDD pin

should be clean as possible for a good DAC

performance.

This pin requires an appropriate bypass capacitor of

about 0.1 µF (ceramic) to ground. An addi tional 10 µF

capacitor (tantalum) in parallel is also recommended to

further attenuate high frequency noise present in

application boards. The supply voltage (V

maintained in the 2.7V to 5.5V range for specified

operation.

V

SS

device. The user must connect the V

plane through a low impedance connection. If an

analog ground path is available in the application PCB

(printed circuit board), it is highly recommended that

the V

within an analog ground plane of the circuit board.

pin is used as the supply input as well as the

DD

) must be

DD

is the ground pin and the current return path of the

pin to a ground

SS

pin be tied to the analog ground path or isolated

SS

SS

3.4 Serial Clock Pin (SCL)

SCL is the serial clock pin of the I2C interface. The

MCP4725 acts only as a slave and the SCL pin accepts

only external serial clocks. The input data from the

Master device is shifted into the SDA pin on the rising

edges of the SCL clock and output from the MCP4725

occurs at the falling edges of the SCL clock. The SCL

pin is an open-drain N-channel driver. Therefore, it

needs a pull-up resistor from the V

pin. Refer to Section 7.0 “I

2

C Serial Interface Com-

munication” for more details of I

line to the SCL

DD

2

C Serial Interface

communication.

3.5 Device Address Selection Pin (A0)

This pin is used to select the A0 address bit by the user.

The user can tie this pin to VSS (logic ‘0’), or VDD (logic

‘1’), or can be actively driven by the digital logic levels,

such as the I

“Device Addressing” for more details of the address

bits.

2

C Master Output. See Section 7.2

3.3 Serial Data Pin (SDA)

SDA is the serial data pin of the I2C interface. The SDA

pin is used to write or read the DAC register and

EEPROM data. The SDA pin is an open-drain N-chan

nel driver. Therefore, it needs a pull-up resistor from the

line to the SDA pin. Except for start and stop

V

DD

conditions, the data on the SDA pin must be stable

during the high period of the clock. The high or low

state of the SDA pin can only change when the clock

signal on the SCL pin is low. Refer to Section 7.0 “I

Serial Interface Communication” for more details of

I2C Serial Interface communication.

DS22039C-page 10 © 2007 Microchip Technology Inc.

2

C

Page 11

MCP4725

LSB

Ideal

V

REF

2

n

------------ -

V

Full Scale–

V

Zero Scale–

–()

2

n

1–

---------------------------------------------------------------------

==

Where:

V

REF

= The reference voltage = VDD in the

MCP4725. This V

REF

is the ideal

full-scale voltage range

n = The number of digital input bits.

(n = 12 for MCP4725)

INL

V

OUTVIdeal

–()

LSB

---------------------------------------

=

Where:

V

Ideal

= Code*LSB

V

OUT

= The output voltage measured at

the given input code

010001000

Analog

Output

(LSB)

DAC Input Code

011 111100 101

1

2

3

4

5

6

0

7

110

Ideal Transfer Function

Actual Transfer Function

INL = < -1 LSB

INL = 0.5 LSB

INL = - 1 LSB

DNL

ΔV

OUT

LSB–

LSB

----------------------------------=

Where:

Δ

V

OUT

= The measured DAC output

voltage difference between two

adjacent input codes.

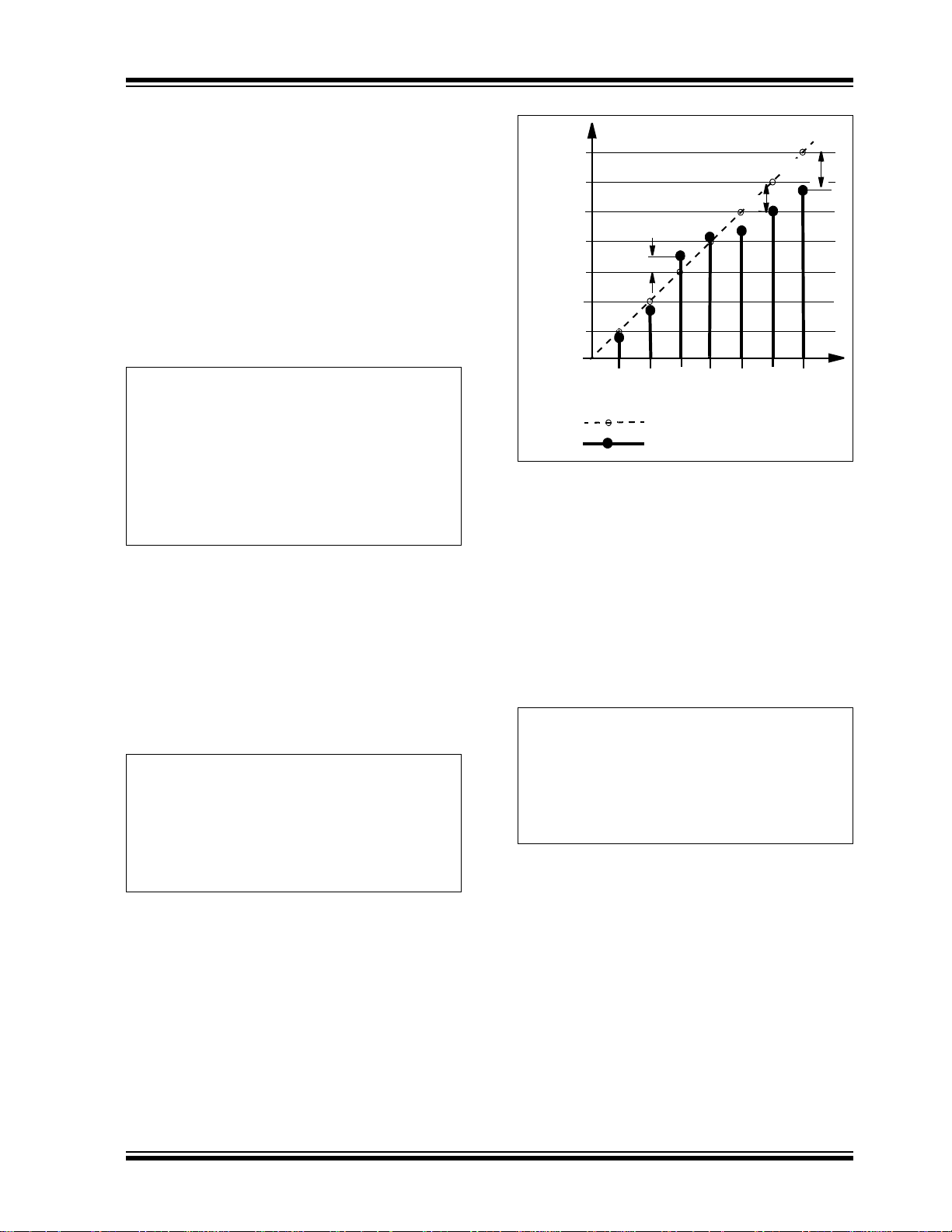

4.0 TERMINOLOGY

4.1 Resolution

The resolution is the number of DAC output states that

divide the full-scale range. For the 12-bit DAC, the

resolution is 212 or the DAC code ranges from 0 to

4095.

4.2 LSB

The least significant bit or the ideal voltage difference

between two successive codes.

EQUATION 4-1:

4.3 Integral Nonlinearity (INL) or Relative Accuracy

INL error is the maximum deviation between an actual

code transition point and its corresponding ideal

transition point (straight line). Figure 2-5 shows the INL

curve of the MCP4725. The end-point method is used

for the calculation. The INL error at a given input DAC

code is calculated as:

FIGURE 4-1: INL Accuracy.

4.4 Differential Nonlinearity (DNL)

Differential nonlinearity error (Figure 4-2) is the

measure of step size between codes in actual transfer

function. The ideal step size between codes is 1 LSB.

A DNL error of zero would imply that every code is

exactly 1 LSB wide. If the DNL error is less than 1 LSB,

the DAC guarantees monotonic output and no missing

codes. The DNL error between any two adjacent codes

is calculated as follows:

EQUATION 4-3:

EQUATION 4-2:

© 2007 Microchip Technology Inc. DS22039C-page 11

Page 12

MCP4725

010

001

000

Analog

Output

(LSB)

DAC Input Code

011

111

100

101

1

2

3

4

5

6

0

7

DNL = 2LSB

DNL = 0.5 LSB

110

Ideal Transfer Function

Actual Transfer Function

Analog

Output

Ideal Transfer Function

Actual Transfer Function

DAC Input Code

0

Offset

Error

FSE

V

OUTVIdeal

–()

LSB

---------------------------------------=

Where:

V

Ideal

=(V

REF

) (1 - 2-n) - V

OFFSET

V

REF

= The reference voltage.

V

REF

= VDD in the MCP4725

Analog

Output

Actual Transfer Function

Actual Transfer Function

DAC Input Code

0

Gain Error

Ideal Transfer Function

after Offset Error Removed

Full-Scale

Error

FIGURE 4-2: DNL Accuracy.

In the MCP4725, the gain error is not calibrated at the

factory and most of the gain error is contributed by the

output op amp saturation near the code range beyond

4000. For the applications which need the gain error

specification less than 1% maximum, the user may

consider using the DAC code range between 100 and

4000 instead of using full code range (code 0 to 4095).

The DAC output of the code range between 100 and

4000 is much linear than full-scale range (0 to 4095).

The gain error can be calibrated by software in applications.

4.7 Full-Scale Error (FSE)

Full-scale error (Figure 4-4) is the sum of offset error

plus gain error. It is the difference between the ideal

and measured DAC output voltage with all bits set to

one (DAC input code = FFFh).

EQUATION 4-4:

4.5 Offset Error

Offset error (Figure 4-3) is the deviation from zero voltage output when the digital input code is zero. This

error affects all codes by the same amount. In the

MCP4725, the offset error is not trimmed at the factory.

However, it can be calibrated by software in application

circuits.

FIGURE 4-3: Offset Error.

4.6 Gain Error

Gain error (see Figure 4-4) is the difference between

the actual full-scale output voltage from the ideal output

voltage on the transfer curve. The gain error is

calculated after nullifying the offset error, or full scale

error minus the offset error.

The gain error indicates how well the slope of the actual

transfer function matche s the slope of th e ideal transfe r

function. The gain error is usually expressed as percent

of full-scale range (% of FSR) or in LSB.

DS22039C-page 12 © 2007 Microchip Technology Inc.

FIGURE 4-4: Gain Error and Full-Scale Error.

4.8 Gain Error Drift

Gain error drift is the variation in gain error due to a

change in ambient temperature. The gain error drift is

typically expressed in ppm/oC.

Page 13

4.9 Offset Error Drift

Offset error drift is the variation in offset error due to a

change in ambient temperature. The offset error drift is

typically expressed in ppm/

o

C.

4.10 Settling Time

The Settling time is the time delay required for the DAC

output to settle to its new output value from the start of

code transition, within specified accuracy. In the

MCP4725, the settling time is a measure of the time

delay until the DAC output reaches its final value

(within 0.5 LSB) when the DAC code changes from

400h to C00h.

4.11 Major-Code Transition Glitch

Major-code transition glitch is the impulse energy

injected into the DAC analog output when the code in

the DAC register changes state. It is normally specified

as the area of the glitch in nV-Sec. and is measured

when the digital code is changed by 1 LSB at the major

carry transition (Example: 011...111 to 100... 000, or

100... 000 to 011 ... 111).

MCP4725

4.12 Digital Feedthrough

Digital feedthrough is the glitch that appears at the

analog output caused by coupling from the digital input

pins of the device. It is specified in nV-Sec. and is

measured with a full scale change on the digital input

pins (Example: 000... 000 to 111... 111, or 111... 111 to

000... 000). The digital feedthrough is measured when

the DAC is not being written to the register.

© 2007 Microchip Technology Inc. DS22039C-page 13

Page 14

MCP4725

V

OUT

V

REFDn

×

()

4096

------------------------------ -

=

Where:

V

REF

=V

DD

Dn= Input code

5.0 GENERAL DESCRIPTION

The MCP4725 is a single channel buffered voltage

output 12-bit DAC with non-volatile memory

(EEPROM). The user can store configuration register

bits (2 bits) and DAC input data (12 bits) in non-volatile

EEPROM (14 bits) memory.

When the device is powered on first, it loads the DAC

code from the EEPROM and outputs the analog output

accordingly with the programmed settings. The user

can reprogram the EEPROM or DAC register any time.

The device uses a resistor string architecture. DAC’s

output is buffered with a low power precision amplifier.

This output amplifier provides low offset voltage and

low noise, as well as rail-to-rail output. The amplifier

can also provide high source currents (V

VSS).

The DAC can be configured to normal or power saving

power-down mode by setting the configuration register

bits.

2

The device uses a two-wire I

C compatible serial

interface and operates from a single power supply

ranging from 2.7V to 5.5V.

5.1 Output Voltage

The input coding to the MCP4725 device i s unsigned

binary. The output volt age range is from 0V to VDD. The

output voltage is given in Equation 5-1:

OUT

pin to

5.1.2 DRIVING RESISTIVE AND

CAPACITIVE LOADS

The MCP4725 output stage is capable of driving loads

up to 1000 pF in parallel with 5 kΩ load resistance.

Figure 2-15 shows the V

vs. Resistive Load. V

OUT

OUT

drops slowly as the load resistance decreases after

about 3.5 kΩ.

5.2 LSB SIZE

One LSB is defined as the ideal voltage difference

between two successive codes. (see Equation 4-1).

Table 5-1 shows an example of the LSB size over

full-scale range (V

DD

).

TABLE 5-1: LSB SIZES FOR MCP4725

(EXAMPLE)

Full-Scale

Range

)

(V

DD

3.0V 0.73 mV 3 / 4096

5.0V 1.22 mV 5 / 4096

LSB

Size

Condition

5.3 Voltage Reference

The MCP4725 device uses the VDD as its voltage

reference. Any variation or noises on the VDD line can

affect directly on the DAC output. The V

as clean as possible for accurate DAC performance.

needs to be

DD

EQUATION 5-1:

5.1.1 OUTPUT AMPLIFIER

The DAC output is buffered with a low-power, precision

CMOS amplifier. This amplifier provides low offset

voltage and low noise. The output stage enables the

device to operate with output voltages close to the

power supply rails. Refer to Section 1.0 “Electrical

Characteristics” for range and load conditions.

The output amplifier can drive the resistive and high

capacitive loads without oscillation. The amplifier can

provide maximum load current as high as 25 mA which

is enough for most of a programmable voltage

reference applications.

5.4 Reset Conditions

In the Reset conditions, the device uploads the

EEPROM data into the DAC register. The devi ce can

be reset by two independent events: (a) by POR or (b)

2

C General Call Reset Command.

by I

The factory default settings for the EEPROM prior to

shipment are shown in Table 4-3 (set for a middle scale

output). The user can rewrite or read the DAC register

or EEPROM anytime after the Power-On-Reset event.

5.4.1 POWER-ON-RESET

The device’s internal Power-On-Reset (POR) circuit

ensures that the device powers up in a defined state.

If the power supply voltage is less than the POR threshold (V

there will be no DAC output. When the V

above the V

the reset period, the device uploads all configurati on

and DAC input codes from EEPROM. The DAC output

will be the same as for the value last stored in the

EEPROM. This enables the device returns to the same

state that it was at the last write to the EEPROM before

it was powered off.

= 2V, typical), all circuits are disabled and

POR

, the device takes a reset state. During

POR

increases

DD

DS22039C-page 14 © 2007 Microchip Technology Inc.

Page 15

5.5 Normal and Power-Down Modes

1kΩ

100 kΩ 500 kΩ

Power-Down

Control Circuit

Resistive

Load

V

OUT

OP

Amp

Resistive String DAC

The device has two modes of operation: Normal mod e

and power-down mode. The mode is selected by

programming the power-down bits (PD1 and PD0) in

the Configuration register. The user can also program

the two power-down bits in non-volatile EEPROM

memory.

When the normal mode is selected, the device

operates a normal digital-to-analog conversion. If the

power-down mode is selected, the device enters a

power saving condition by shutting down most of the

internal circuits. During the power-down mode, all

internal circuits except the I

and there is no data conversion event, and no V

available. The device also switches the output stage

from the output of the amplifier to a known resistive

load. The value of the resistive load is determined by

the state of the power-down bits (PD1 and PD0).

Table 5-2 shows the outcome of the power-down bit

and the resistive load.

During the power-down mode, the device draws about

60 nA (typical). Although most of i nternal circuits are

shutdown, the serial interface remains active in o rder

to receive the I

2

C command.

The device exits the power-down mode immediately

when (a) it receives a new write command for normal

mode or (b) it receives an I

Command.

When the DAC operation mode is changed from

power-down to normal mode, the output settling time

takes less than 10 µs, but greater than the standard

Active mode settling time (6 µs, typ ical).

2

C interface are disabled

OUT

2

C General Call Wake-Up

is

MCP4725

FIGURE 5-1: Output Stage for Power-Down Mode.

TABLE 5-2: POWER-DOWN BITS

PD1 PD0 Function

00Normal Mode

011kΩ resistor to ground

10100 kΩ resistor to ground

11500 kΩ resistor to ground

Note 1: In the power-down mode: V

most of internal circuits are disabled.

© 2007 Microchip Technology Inc. DS22039C-page 15

is off and

OUT

(1)

(1)

(1)

Page 16

MCP4725

5.6 Non-Volatile EEPROM Memory

The MCP4725 device has a 14-bit wide EEPROM

memory to store configuration bit (2 bits) and DAC

input data (12 bits). These bits are readable and re-writable with I

on-chip charge pump circuit to write the EEPROM

memory bits without using an external program voltage.

The EEPROM writing operation is initiated when the

device receives an EEPROM write command (C2 = 0,

C1 = 1, C0 = 1). The configuration and writing data bits

2

C interface commands. The device has an

are transferred to the EEPROM memory block. A

status bit, RDY/BSY

writing and goes high as the write operation is

completed. While the RDY/BSY

EEPROM writing), any new write command is ignored

(for EEPROM or DAC register). Table 5-3 shows the

EEPROM bits and factory default settings. Table 5-4

shows the DAC input register bits of the MCP4725.

TABLE 5-3: EEPROM MEMORY AND FACTORY DEFAULT SETTINGS

(TOTAL NUMBER OF BITS: 14 BITS)

Bit

Name

Bit

Function

Factory

Default

Value

Note 1: See Table 5-2 for details.

PD1 PD0 D11 D10 D9 D8 D7 D6 D5 D4 D3 D2 D1 D0

Power-Down

Select

(2 bits)

00

2: Bit D11 = ‘1’ (while all other bits are “0”) enables the device to output 0.5 * V

(1)

(2)

1

00000000000

DAC Input Data (12 bits)

, stays low during the EEPROM

bit is low (during the

(= middle scale output).

DD

TABLE 5-4: DAC REGISTER

Bit

Name

Bit

Function

Note 1: Write EEPROM status indication bit (0:EEPROM write is not completed. 1:EEPROM write is complete.)

C2 C1 C0

Command

Type

RDY/

PORPD1PD0D11D10D9D8D7D6D5D4D3D2D1D0

BSY

(1) Power-

Down

Select

Data (12 bits)

DS22039C-page 16 © 2007 Microchip Technology Inc.

Page 17

MCP4725

6.0 THEORY OF OPERATION

When the device is connected to the I2C bus line, the

device is working as a slave device. The Master (MCU)

can write/read the DAC input register or EEPROM

using the I

device address contains four fixed bits ( 1100 = device

code) and three address bits (A2, A1, A0). The A2 and

A1 bits are hard-wired during manufacturing, and A0 bit

is determined by the logic state of A0 pin. The A0 pi n

can be connected to V

digital logic levels.

The following sections describe the communication

protocol to send or read the data code and write/read

the EEPROM using the I

2

“I

C Serial Interface Communication”.

6.1 Write Commands

The write commands are used to load the configuration

bits and DAC input code to the DAC register, or to write

to the EEPROM of the device. The write command

types are defined by using three write command type

bits (C2, C1, C0). Table 6-2 shows the write comman d

types and their functions. There are three command

types for the MCP4725. The four “reserved” commands

in Table 6-2 are for future use. The MCP4725 ignores

the “reserved” commands. Write command protocol

examples are shown in Figure 6-1 and Figure 6-2.

The input data code is coded as shown in Table 6-1.

The MSB of the data is always transmitted first and the

format is unipolar binary.

TABLE 6-1: INPUT DATA CODING

111111111111 (FFFh) V

111111111110 (FFEh) V

000000000010 (002h) 2 LSB

000000000001 (001h) 1 LSB

000000000000 (000h) 0

2

C interface command. The MCP4725

or VSS, or actively driven by

DD

2

C interface. See Section 7.0

Input Code

Nominal Output Voltage

(V)

- 1 LSB

DD

- 2 LSB

DD

6.1.1 WRITE COMMAND FOR FAST

MODE (C2 = 0, C1 = 0, C0 = X,

X = DON’T CARE)

The fast write command is used to update the DAC

register. The data in the EEPROM of the device is not

affected by this command. This command updates

Power-Down mode selection bits (PD1 and PD0) and

12 bits of the DAC input code in the DAC register.

Figure 6-1 shows an example of the fast write

command for the MCP4725 device.

6.1.2 WRITE COMMAND FOR DAC INPUT

REGISTER (C2 = 0, C1 = 1, C0 = 0)

In MCP4725, this command performs the same

function as the Fast Mode command in Section 6.1.1

“Write Command for Fast mode (C2 = 0, C1 = 0,

C0 = X, X = Don’t Care)”. Figure 6-2 shows the write

command protocol for the MCP4725.

As shown in Figure 6-2, the D11 - D0 bits in the third

and fourth bytes are DAC input data. The last 4 bits (X,

X, X, X) in the fourth byte are don’t care bits.

The device executes the Master’s write command after

receiving the last byte (4th byte). The Master can send

a STOP bit to terminate the current sequence, or send

a Repeated START bit followed by an address byte. If

the device receives three data bytes continuously after

the 4th byte, it updates from the 2nd to the 4th data

bytes with the last three input data bytes.

The contents of the register are updated at the end of

the 4th byte. The device ignores any partially received

data bytes if the I

ends before completing the 4th byte.

2

C communication with the Master

6.1.3 WRITE COMMAND FOR DAC INPUT

REGISTER AND EEPROM

(C2 = 0, C1 = 1, C0 = 1)

When the device receives this command, it (a) loads

the configuration and data bits to the DAC register, and

(b) also writes the EEPROM. When the device is

writing the EEPROM, the RDY/BSY

stays low until the EEPROM write operation is

completed. The state of the RDY/BSY

monitored by a read command. Figure 6-2 shows the

details of the this write command protocol and

Figure 6-3 shows the details of the read command.

bit goes low and

bit can be

© 2007 Microchip Technology Inc. DS22039C-page 17

Page 18

MCP4725

1st byte (Device Addressing)

Device Code

Address

R/W

ACK (MCP4725)

2nd byte

3rd byte

DAC Register Data (12 bits)

ACK (MCP4725)

Repeat bytes of 2nd and 3rd bytes

Change DAC Code in Fast Mode: (C2,C1) = (0,0)

Fast Mode Command (C2, C1 = 0, 0)

ACK (MCP4725)

Power Down Select

Start Bit

2nd byte

3rd byte

Read/Write Command

Stop Bit

Stop Bit

see Note 1

see Note 2

ACK (MCP4725)

see Note 2

Note 1: A2 and A1 bits are programmed at the factory by hard-wired, and A0 bit is determined by the logic state

of A0 pin.

2: The device updates V

OUT

at the falling edge of the ACK pulse of the 3rd byte.

1100A2 0A1 A0 00PD1PD0D11 D8D10 D9 D7 D6 D5 D4 D3 D0D2 D1

00PD1PD0D11 D8D10 D9 D7 D6 D5 D4 D3 D0D2 D1

Bits

ACK (MCP4725)

TABLE 6-2: WRITE COMMAND TYPE

C2 C1 C0 Command Name

0 0 X Fast Mode This command is used to change the DAC register. EEPROM is not affected

00X “ “

0 1 0 Write DAC Register Load configuration bits and data code to the DAC Register

0 1 1 Write DAC Register

and

EEPROM

1 0 0 Reserved Reserved for future use

1 0 1 Reserved Reserved for future use

1 1 0 Reserved Reserved for future use

1 1 1 Reserved Reserved for future use

Note 1: X = Dont’ Care. Fast Mode does not use C0 bit.

2: The MCP4725 ignores the “Reserved” commands.

Function

(a) Load configuration bits and data code to the DAC Register

and

(b) also write the EEPROM

FIGURE 6-1: Write Command for Fast Mode.

DS22039C-page 18 © 2007 Microchip Technology Inc.

Page 19

MCP4725

(A) Write DAC Register: (C2, C1, C0) = (0,1,0) or

(B) Write DAC Register and EEPROM: (C2, C1, C0) = (0,1,1)

1st byte (Device Addressing)

ACK (MCP4725)

2nd byte 3rd byte

ACK (MCP4725)

4th byte

D3 D2 D0D1

1 1 0 0 A2 A1 A0 0

C2 C1 C0 X X PD1 PD0 X X X X XD11D10 D9 D8 D7 D6 D5 D4

Start Bit

DAC Register Data (12 bits)

Stop

Power Down Selection

Unused

Unused

Unused

Device Code

Address Bits R/W

Bit

Write Command Type:

Write DAC Register: (C2 = 0, C1 = 1, C0 = 0)

Write DAC Register and EEPROM: (C2 = 0, C1 = 1, C0 = 1). See Note 1

• The device updates the V

OUT

after this ACK pulse is issued.

• For EEPROM Write:

- The Charge Pump initiates the EEPROM writing sequence at the falling edge of this ACK pulse.

- The RDY/BSY

bit (pin) goes “low” at the falling edge of this ACK pulse and back to “high” immediately after

the EEPROM write is completed.

ACK (MCP4725)

2nd byte 3rd byte

ACK (MCP4725)

4th byte

D3 D2 D0D1C2C1 C0 X X PD1PD0 X X X X XD11D10 D9 D8D7 D6 D5D4

Stop

Bit

Repeat Bytes of 2nd - 4th bytes

Note 1: RDY/BSY bit stays “low” during the EEPROM write. Any new write command including repeat bytes during the

EEPROM write mode is ignored.

The RDY/BSY

bit sets to “high” after the EEPROM write is completed.

FIGURE 6-2: Write Commands for DAC Input Register and EEPROM.

© 2007 Microchip Technology Inc. DS22039C-page 19

Page 20

MCP4725

1st byte

ACK (MCP4725)

2nd byte 3rd byte

ACK (Master)

4th byte

D3 D2 D0D1

1 1 0 0 A2 A1 A0 1

RDY/

XXXPD1PD0X

XXXX

D11 D10 D9 D8 D7 D6 D5 D4

Start Bit

Device Code Address Bits

R/W

5th byte 6th byte

D7 D6 D4D5 D3 D2 D1 D0

X PD1 PD0 X D11 D10 D9 D 8

Stop

Bit

Note 1: Bytes 2 - 6 are repeated in repeat bytes after byte 6.

2: X is don’t care bit.

Read Command

DAC register Data (12 bits)

in DAC Register

Current Settings

See Note 2

EEPROM Write Status Indicate Bit

(1: Completed, 0: Incomplete)

BSY

EEPROM Data

POR

ACK (Master)

ACK (Master)

6.2 READ COMMAND

If the R/W bit is set to a logic “high”, then the device

outputs on SDA pin, the DAC register and EEPROM

data. Figure 6-3 shows an example of reading the

register and EEPROM data. The 2nd byte in Figure 6-3

indicates the current condition of the device operation.

The RDY/BSY

The RDY/BSY bit stays low during EEPROM writng

and high when the writing is completed..

bit indicates EEPROM writing status.

FIGURE 6-3: Read Command and Output Dat a Format.

DS22039C-page 20 © 2007 Microchip Technology Inc.

Page 21

MCP4725

Star t bit

Read/Write bit

Address Byte

R/W ACK

Acknowledge bit

Slave Address

1

1

0

0

Slave Address for MCP4725

A2

A1

A0

Note: A2 and A1: Programmed (hard-wired) at the factory.

Please Contact Microchip T echnology Inc. for A2 and

A1 programming options.

A0: Use the logic level state of A0 pin.

Device Code Address Bits

7.0 I2C SERIAL INTERFACE COMMUNICATION

7.1 OVERVIEW

The MCP4725 device uses a two-wire I2C serial

interface that can operate on a standard, fast or high

speed mode. A device that sends data onto the bus is

defined as transmitter, and a device receiving data as

receiver. The bus has to be controlled by a master

device which generates the serial clock (SCL), controls

the bus access and generates the START and STOP

conditions. The MCP4725 device works as slave. Both

master and slave can operate as transmitter or

receiver , but the master device determine s which mode

is activated. An example of hardware connection

diagram is shown in Figure 8-1. Communication is

initiated by the master (microcontroller) which sends

the STAR T bit, followed by the slave address byte. The

first byte transmitted is always the slave address byte,

which contains the device code, the address bits, and

the R/W

is 1100.

When the device receives a read command (R/W = 1),

it transmits the contents of the DAC input register and

EEPROM. A non-acknowledge (NAK) or repeated start

bit can be transmitted at any time. See Figure 6-3 for

the read operation example. If writing to the device (R/

W = 0), the device will expect write command type bits

in the following byte. See Figure 6-1 and Figure 6-2 for

the write operation examples.

The MCP4725 supports all three I

• Standard Mode: bit rates up to 100 kbit/s

• Fast Mode: bit rates up to 400 kbit/s

• High Speed Mode (HS mode): bit rates up to

Refer to the Phillips I

the I2C specifications.

bit. The device code for the MCP4725 device

2

C operating modes:

3.4 Mbit/s

2

C document for more details of

7.2 Device Addressing

The address byte is the first byte received following the

ST ART condition from the master device. The first part

of the address byte consists of a 4-bit device code

which is set to 1100 for the MCP4725. The device code

is followed by three address bits (A2, A1, A0) which are

programmed as follows:

• The choice of A2 and A1 bits are provided by the

customer as part of the ordering process. These

bits are then programmed (hard-wired) during

manufacturing

• The A2 and A1 are programmed to ‘00’ (default),

if not requested by customer

• A0 bit is determined by the logic state of A0 pin.

The A0 pin can be tied to V

actively driven by digital logic levels. The advantage of using the A0 pin is that the users can control the A0 bit on their application PCB circuit and

also two identical MCP4725 devices can be used

on the same bus line.

When the device receives an address byte, it compares

the logic state of the A0 pin with the A0 address bit

received before responding with the acknowledge bit.

The logic state of the A0 pin needs to be set prior to the

interface communication.

or VSS, or can be

DD

© 2007 Microchip Technology Inc. DS22039C-page 21

FIGURE 7-1: Device Addressing

Page 22

MCP4725

LSB

First Byte

ACK

x

0

0 0 0 0 0 0 0 A A

xxx

xxx

x

(General Call Address)

Second Byte

ACK

7.3 General Call

The MCP4725 device acknowledges the general call

address (0x00 in the first byte). The meaning of the

general call address is always specified in the second

byte (see Figure 7-2). The I

allow to use “00000000” (00h) in the second byte.

Please refer to the Phillips I

details of the General Call specifications. The

MCP4725 supports the following general calls:

7.3.1 GENERAL CALL RESET

The general reset occurs if the second byte is

“00000110” (06h). At the acknowledgement of this

byte, the device will abort current conversion and

perform an internal reset similar to a power-on-reset

(POR). Immediately after this reset event, the device

uploads the contents of the EEPROM into the DAC

register.

7.3.2 GENERAL CALL WAKE-UP

If the second byte is “00001001” (09h), the device will

reset the power-down bits. After receiving this command, the power-down bits of the DAC register are set

to a normal operation (PD1, PD2 = 0,0). The

power-down bit settings in EEPROM are not affected.

2

C specification does not

2

C document for more

7.5 I2C BUS CHARACTERISTICS

The I2C specification defines the following bus

protocol:

• Data transfer may be initiated only when the bus

is not busy.

• During data transfer, the data line must remain

stable whenever the clock line is HIGH. Changes

in the data line while the clock line is HIGH will be

interpreted as a START or STOP condition.

Accordingly, the following bus conditions have been

defined using Figure 7-3.

7.5.1 BUS NOT BUSY (A)

Both data and clock lines remain HIGH.

7.5.2 START DATA TRANSFER (B)

A HIGH to LOW transition of the SDA line while the

clock (SCL) is HIGH determines a START condition.

All commands must be preceded by a START

condition.

7.5.3 STOP DATA TRANSFER (C)

A LOW to HIGH transition of the SDA line while the

clock (SCL) is HIGH determines a STOP condition. All

operations must be ended with a STOP condition.

FIGURE 7-2: General Call Address Format.

7.4 High-Speed (HS) Mode

The I2C specification requires that a high-speed mode

device must be ‘activated’ to operate in high-speed

(3.4 Mbit/s) mode. This is done by sending a special

address byte of 00001XXX following the START bit.

The XXX bits are unique to the h igh-speed (HS) mode

Master. This byte is referred to as the high-speed (HS)

Master Mode Code (HSMMC). The MCP4725 device

does not acknowledge this byte. However, upon

receiving this command, the device switches to HS

mode and can communicate at up to 3.4 Mbit/s on SDA

and SCL lines. The device will switch out of the HS

mode on the next STOP condition.

For more information on the HS mode, or other I

modes, please refer to the Phillips I

2

C specification.

2

7.5.4 DATA VALID (D)

The state of the data line represents valid data when,

after a START condition, the data line is stable for the

duration of the HIGH period of the clock signal.

The data on the line must be changed during the LOW

period of the clock signal. There is one clock pulse per

bit of data.

Each data transfer is initiated with a START condition

and terminated with a STOP condition.

C

DS22039C-page 22 © 2007 Microchip Technology Inc.

Page 23

MCP4725

SCL

SDA

(A) (B) (D) (D) (A)(C)

START

CONDITION

ADDRESS OR

ACKNOWLEDGE

VALID

DATA

ALLOWED

TO CHANGE

STOP

CONDITION

7.5.5 ACKNOWLEDGE

Each receiving device, when addressed, is obliged to

generate an acknowledge after the reception of each

byte. The master device must generate an extra clock

pulse which is associated with this acknowledge bit.

The device that acknowledges, has to pull down the

SDA line during the acknowledge clock pulse in such a

way that the SDA line is stable LOW during the HIGH

period of the acknowledge related clock pulse. Of

course, setup and hold times must be taken into

account. During reads, a master must send an end of

data to the slave by not generating an acknowledge bit

on the last byte that has been clocked out of the slave.

In this case, the slave (MCP4725) will leave the data

line HIGH to enable the master to generate the STOP

condition.

FIGURE 7-3: Data Transfer Sequence On The Serial Bus.

© 2007 Microchip Technology Inc. DS22039C-page 23

Page 24

MCP4725

TABLE 7-1: I2C SERIAL TIMING SPECIFICATIONS

Electrical Specifications: Unless otherwise specified, all limits are specified for TA = -40 to +85°C, VDD = +2.7V to +5.0V, VSS = 0V .

Parameters Sym Min Typ Max Units Conditions

Standard Mode

Clock frequency f

Clock high time

Clock low time

SDA and SCL rise time (Note 1)

SDA and SCL fall time (Note 1) T

START condition hold time T

Repeated START condition

setup time

Data hold time (Note 3)

Data input setup time

STOP condition setup time

STOP condition hold time

Output valid from clock

(Notes 2 and 3)

Bus free time

SCL

T

HIGH

T

LOW

T

HD:STA

T

SU:STA

T

HD:DAT

T

SU:DAT

T

SU:STO

T

HD:STD

T

T

BUF

R

F

AA

Fast Mode

Clock frequency

Clock high time

Clock low time

SDA and SCL rise time (Note 1)

SDA and SCL fall time (Note 1) T

START condition hold time T

Repeated START condition

setup time

Data hold time (Note 4) T

Data input setup time

STOP condition setup time

STOP condition hold time

Output valid from clock

(Notes 2 and 3)

Bus free time

T

SCL

T

HIGH

T

LOW

T

HD:STA

T

SU:STA

HD:DAT

T

SU:DAT

T

SU:STO

T

HD:STD

T

T

BUF

R

F

AA

Note 1: This parameter is ensured by characterization and not 100% tested.

2: This specification is not a part of the I2C specification. This specification is equivalent to the Data Hold Time (

plus SDA Fall (or rise) time:

T

AA

3: If this parameter is too short, it can create an unintended Start or Stop condition to other devices on the bus line. If this

parameter is too long, Clock Low time (T

4: For Data Input: This parameter must be longer than t

Clock Low time (T

For Data Output: This parameter is characterized, and tested indirectly by testing T

) can be affected.

LOW

5: All timing parameters in high-speed modes are tested at V

0 — 100 kHz

4000 — — ns

4700 — — ns

— — 1000 ns From VIL to V

— — 300 ns From VIH to V

IH

IL

4000 — — ns After this period, the first clock

pulse is generated.

4700 — — ns Only relevant for repeated Start

condition

0 — 3450 ns

250 — — ns

4000 — — ns

4000 — — ns

0 — 3750 ns

4700 — — ns Time between START and STOP

conditions.

0 — 400 kHz

600 — — ns

1300 — — ns

20 + 0.1Cb — 300 ns From VIL to V

20 + 0.1Cb — 300 ns From VIH to V

IH

IL

600 — — ns After this period, the first clock

pulse is generated

600 — — ns Only relevant for repeated Start

condition

0 — 900 ns

100 — — ns

600 — — ns

600 — — ns

0 — 1200 ns

1300 — — ns Time between START and STOP

conditions.

= T

HD:DAT

+ TF (OR TR).

) can be affected.

LOW

. If this parameter is too long, the Data Input Setup (T

SP

parameter.

AA

DD

= 5V.

T

HD:DAT

SU:DAT

)

) or

DS22039C-page 24 © 2007 Microchip Technology Inc.

Page 25

MCP4725

TABLE 7-1: I2C SERIAL TIMING SPECIFICATIONS (CONTINUED)

Electrical Specifications: Unless otherwise specified, all limits are specified for TA = -40 to +85°C, VDD = +2.7V to +5.0V, VSS = 0V .

Parameters Sym Min Typ Max Units Conditions

High Speed Mode (Note 5)

Clock frequency f

Clock high time

SCL

T

HIGH

0—3.4

1.7

60

——ns

120

Clock low time

SCL rise time (Note 1)

SCL fall time (Note 1)

SDA rise time (Note 1)

SDA fall time (Note 1)

START condition hold time

Repeated START condition

setup time

Data hold time (Note 4)

Data input setup time

STOP condition setup time

STOP condition hold time

Output valid from clock

(Notes 2 and 3)

Bus free time

T

LOW

T

T

T

R: DAT

T

F: DATA

T

HD:STA

T

SU:STA

T

HD:DAT

T

SU:DAT

T

SU:STO

T

HD:STD

T

AA

T

BUF

R

F

160

——nsC

320

——4080ns From VIL to VIH,Cb = 100 pF

——4080ns From VIH to VIL,Cb = 100 pF

——80

160

——80

160

160 — — ns After this period, the first clock

160 — — ns Only relevant for repeated Start

0

0

—70

150

10 — — ns

160 — — ns

160 — — ns

— — 150

310

160 — — ns Time between STAR T and STOP

Note 1: This parameter is ensured by characterization and not 100% tested.

2: This specification is not a part of the I2C specification. This specification is equivalent to the Data Hold Time (

plus SDA Fall (or rise) time:

T

AA

= T

HD:DAT

+ TF (OR TR).

3: If this parameter is too short, it can create an unintended Start or Stop condition to other devices on the bus line. If this

parameter is too long, Clock Low time (T

4: For Data Input: This parameter must be longer than t

Clock Low time (T

) can be affected.

LOW

) can be affected.

LOW

. If this parameter is too long, the Data Input Setup (T

SP

For Data Output: This parameter is characterized, and tested indirectly by testing T

5: All timing parameters in high-speed modes are tested at V

DD

= 5V.

MHz

Cb = 100 pF

MHz

C

= 400 pF

b

Cb = 100 pF

ns

C

= 400 pF

b

= 100 pF

b

C

= 400 pF

b

C

= 400 pF

b

C

= 400 pF

b

ns From VIL to VIH,Cb = 100 pF

C

= 400 pF

b

ns From VIH to VIL,Cb = 100 pF

C

= 400 pF

b

pulse is generated

condition

ns Cb = 100 pF

C

= 400 pF

b

ns Cb = 100 pF

C

= 400 pF

b

conditions.

T

SU:DAT

parameter.

AA

HD:DAT

) or

)

© 2007 Microchip Technology Inc. DS22039C-page 25

Page 26

MCP4725

T

F

SCL

SDA

T

SU:STA

T

SP

T

HD:STA

T

LOW

T

HIGH

T

HD:DAT

T

AA

T

SU:DAT

T

R

T

SU:STO

T

BUF

0.3V

DD

0.7V

DD

FIGURE 7-4: I2C Bus Timing Data.

DS22039C-page 26 © 2007 Microchip Technology Inc.

Page 27

MCP4725

MCP4725

V

OUT

A0

SCL

V

SS

1

2

3

4

5

6

V

DD

SDA

10 µF0.1 µF

R

R

Analog

V

DD

V

DD

To MCU

(MASTER)

Output

Note 1: R is the pull-up resistor. Typically

1 ~ 10 kΩ

2: A0 can be tied to V

SS

, V

DD

or driven by

MCU

123456789

SCL

SDA

11

0

0A2A1A0

1

Start

Bit

Address Byte

Address bits

Device bits

R/W

Start

Bit

MCP4725

ACK

Response

8.0 TYPICAL APPLICATIONS

The MCP4725 device is one of Microchip’s latest DAC

device family with non-volatile EEPROM memory. The

device is a general purpose resistive string DAC

intended to be used in applications where a preci sion,

and low power DAC with moderate bandwidth is

required.

Since the device includes non-volatile EEPROM

memory, the user can use this device for applications

that require the output to return to the previous set-up

value on subsequent power-ups.

Applications generally suited for the MCP4725 device

family include:

• Set Point or Offset Trimming

• Sensor Calibration

• Portable Instrumentation (Battery Powered)

• Motor Speed Control

8.1 Connecting to I2C BUS using Pull-Up Resistors

The SCL and SDA pins of the MCP4725 are open-drain

configurations. These pins require a pull-up resistor as

shown in Figure 8-1. The value of these pull-up

resistors depends on the operating speed (standard,

fast, and high speed) and loading capacitance of the

2

C bus line. Higher value of pull-up resistor consumes

I

less power, but increases the signal transition time

(higher RC time constant) on the bus. Therefore, it can

limit the bus operating speed. The lower resistor value,

on the other hand, consumes higher power, but allows

higher operating speed. If the bus line has higher

capacitance due to long bus line or high number of

devices connected to the bus, a smaller pull-up resistor

is needed to compensate the long RC time constant.

The pull-up resistor is typically chosen between 1 k Ω

and 10 kΩ ranges for standard and fast modes, and

less than 1 kΩ for high speed mode.

Two devices with the same A2 and A1 address bits can

be connected to the same I2C bus by utilizing the A0

address pin (Example: A0 pin of device A is tied to VDD,

and the other device’s pin is tie d to V

SS.)

8.1.1 DEVICE CONNECTION TEST

The user can test the presence of the MCP4725 on the

2

I

C bus line without performing the data conversion.

This test can be achieved by checking an acknowledge

response from the MCP4725 after sending a read or

write command. Here is an example using Figure 8-2:

(a) Set the R/W

(b) If the MCP4725 is connected to the I

bit “HIGH” in the address byte.

2

C bus line, it

will then acknowledge by pulling SDA bus LOW

during the ACK clock and then release the bus

back to the I

(c) A STOP or repeated START bit can then be issued

from the Master and I

2

C Master.

2

C communication can con-

tinue.

FIGURE 8-2: I2C Bus Connection Test.

FIGURE 8-1: I2C Bus Interface

Connection with A0 pin tied to V

© 2007 Microchip Technology Inc. DS22039C-page 27

.

SS

Page 28

MCP4725

8.2 Using Non-Volatile EEPROM Memory

The user can store the DAC input code (12 bits) and

power-down configuration bits (2 bits) in the internal

non-volatile EEPROM memory using the I

command. The user can also read the EEPROM data

using the I

powered after power is shut down, the device uploads

the EEPROM contents to the DAC register automatically and provides the DAC output immediately. This

feature is very useful in applications where the DAC

device is used to provide set point or calibration data for

other devices in the application system. The DAC will

not lose the important system operational parameters

due to the system power failure incidents. See

Section 5.6 “Non-Volatile EEPROM Memory” for

more details of the non-volatile EEPROM memory.

2

C read command. When the device is first

2

C write

8.3 Power Supply Considerations

The power supply to the device is used for both V

and DAC reference voltage. Any noise induced on the

line can affect on the DAC performance. Typical

V

DD

application will require a bypass capacitor in order to

filter out high frequency noise on the VDD line. The

noise can be induced onto the power supply’s traces or

as a result of changes on the DAC output. The bypass

capacitor helps to minimize the effect of these noise

sources on signal integrity. Figure 8-1 shows an

example of using two bypass capacitors (a 10 µF

tantalum capacitor and a 0.1 µF ceramic capacitor) in

parallel on the V

placed as close to the VDD pin as possible (within

4mm).

The power source should be as clean as possible. If the

application circuit has separate digital and analog

power supplies, the V

should reside on the analog plane.

line. These capacitors should be

DD

and VSS pins of the MCP4725

DD

DD

8.4 Layout Considerations

Inductively-coupled AC transients and digital switching

noise from other devices can affect on DAC

performance and DAC output signal integrity. Careful

board layout will minimize these effects. Bench testing

has shown that a multi-layer board utilizing a low-inductance ground plane, isolated inputs, isolated outputs

and proper decoupling are critical to achieving the

performance that the MCP4725 is capable of providing.

Particularly harsh environments may require shielding

of critical signals. Separate digital and analog ground

planes are recommended. In this case, the V

the ground pins of the VDD capacitors of the MCP4725

should be terminated to the analog ground plane.

pin and

SS

8.5 Application Examples

The MCP4725 is a rail-to-rail output DAC designed to

operate with a VDD range of 2.7V to 5.5V. Its output

amplifier is robust enough to drive common, small-signal loads directly, thus eliminating the cost and size of

an external buffer for most applications.

8.5.1 DC SET POINT OR CALIBRATION

A common application for the MCP4725 is a

digitally-controlled set point or a calibration of variable

parameters such as sensor offset or bias point.

Example 8-1 shows an example of the set point setting.

Since the MCP4725 is a 12-bit DAC and uses the V

supply as a reference source, it provides a VDD/4096 of

resolution per step.

DD

DS22039C-page 28 © 2007 Microchip Technology Inc.

Page 29

MCP4725

To MCU

(MASTER)

R

R

V

DD

Comparator

R

1

R

2

0.1 µF

V

TRIP

R

SENSE

MCP4725

V

DD

V

OUT

A0

SCL

V

SS

1

2

3

4

5

6

V

DD

SDA

10 µF0.1 µF

V

DD

D Input Code (0 to 4095)=

V

OUT

V

DD

D

4096

----------- -

×

=

V

TRIP

V

OUT

R

2

R1R2+

-------------------

⎝⎠

⎛⎞

=

Light

(Ceramic) (Tantalum)

8.5.2 DECREASING THE OUTPUT STEP

SIZE

Calibrating the threshold of a diode, transistor or

resistor may require a very small step size in the DAC

output voltage. These applications may require about

200 µV of step resolution within 0.8V of range.

One method of achieving this small step resolution is

using a voltage divider at the DAC output. An example

is shown in Example 8-1. The step size of the DAC out-

put is scaled down by the factor of the ratio of the voltage divider. Note that the bypass capacitor on the

output of the voltage divider plays a critical function in

attenuating the output noise of the DAC and the

induced noise from the environment.

EXAMPLE 8-1: Set Point Or Threshold Calibration.

© 2007 Microchip Technology Inc. DS22039C-page 29

Page 30

MCP4725

V

TRIP

R

1

R

2

0.1 µF

Comparator

R

3

V

CC-

where D = DAC Input Code (0 – 4095)

V

CC+

V

CC+

V

CC-

V

OUT

V

OUT

V

DD

D

2

12

-------

=

R

23

R2R

3

R2R3+

------------------=

V

23

V

CC+R2

()V

CC-R3

()+

R

2R3

+

-----------------------------------------------------=

V

trip

V

OUTR23V23R1

+

R

2R23

+

------------------------------------------- -=

R

1

R

23

V

23

V

OUT

V

O

Thevenin

Equivalent

R

sense

To MCU

(MASTER)

R

R

MCP4725

V

DD

V

OUT

A0

SCL

V

SS

1

2

3

4

5

6

V

DD

SDA

10 µF0.1 µF

V

DD

8.5.3 BUILDING A “WINDOW” DAC

Some sensor applications require very high resolution

around the set point or threshold voltage.

Example 8-2 shows an example of creating a “window”

around the threshold using a voltage divider network

with a pull-up and pull-down resistor. In the circuit, the

output voltage range is scaled down, but its step resolution is increased greatly.

EXAMPLE 8-2: Single-Supply “Window” DAC.

DS22039C-page 30 © 2007 Microchip Technology Inc.

Page 31

MCP4725

V

DD

V

OUT

R

3

R

4

R

2

R

1

VIN+

0.1 µF

V

CC

+

V

CC

–

V

IN+

V

OUTR4

R3R4+

--------------------=

V

O

VOV

IN+

1

R

2

R

1

----- -+

⎝⎠

⎛⎞

V

DD

R

2

R

1

----- -

⎝⎠

⎛⎞

–=

To MCU

(MASTER)

R

R

MCP4725

V

DD

V

OUT

A0

SCL

V

SS

1

2

3

4

5

6

V

DD

SDA

10 µF0.1 µF

V

DD

where D = DAC Input Code (0 – 4095)

V

OUTVDD

D

2

12

-------

=

8.5.4 BIPOLAR OPERATION

Bipolar operation is achievable using the MCP4725 by

using an external operational amplifier (op amp). This

allows a general purpose DAC, with its cost and

availability advantages, to meet almost any desired

output voltage range, power and noise performance.

Example 8-3 illustrates a simple bipolar voltage source

configuration. R

and R2 allow the gain to be selected,

1

while R3 and R4 shift the DAC's output to a selected

offset. Note that R4 can be tied to V

DD

(= V

REF

) instead

of VSS, if a higher offset is desired. Note that a pull-up

to VDD could be used, instead of R4, if a higher offset is

desired.

EXAMPLE 8-3: Digitally-Controlled Bipolar Voltage Source.

© 2007 Microchip Technology Inc. DS22039C-page 31

Page 32

MCP4725

R2–

R

1

-------- -

2.05–

V

DD

-------------

2.05–

4.1

-------------==

R

2

R

1

----- -

1

2

-- -=

→

If R1 = 20 kΩ and R2 = 10 kΩ, the gain will be 0.5.

R

4

R3R4+()

-----------------------

2.05V 0.5 V

DD

⋅()+

1.5 V

DD

⋅

------------------------------------------------

2

3

-- -==

If R4 = 20 kΩ, then R3 = 10 kΩ

8.5.4.1 Design a Bipolar DAC using

Example 8-3

Some applications desires an output step magnitude of

1 mV with an output range of ±2.05V. The following

steps explain the design solution:

1. Calculate the range: +2.05V – (-2.05V) = 4.1V.

2. Calculate the resolution needed:

4.1V/1 mV = 4100

12

Since 2

3. The amplifier gain (R

must be equal to the desired minimum output to

achieve bipolar operation. Since any gain can

be realized by choosing resistor values (R

the V

4.1V is used, solve for the amplifier’s gain by

setting the DAC to 0, knowing that the output

needs to be -2.05V. The equation can be

simplified to:

= 4096 for 12-bit resolution.

), multiplied by VDD,

2/R1

value must be selected first. If a VDD of

DD

1+R2

),

4. Next, solve for R

and R4 by setting the DAC to

3

4096, knowing that the output needs to be

+2.05V .

DS22039C-page 32 © 2007 Microchip Technology Inc.

Page 33

8.5.5 PROGRAMMABLE CURRENT

LOAD

V

DD

I

L

I

B

R

SENSE

R

R

MCP4725

V

DD

V

OUT

A0

SCL

V

SS

1

2

3

4

5

6

V

DD

SDA

10 µF0.1 µF

V

DD

D Input Code (0 to 4095)=

I

L

V

OUT

R

SENSE

------------------

β

β 1+

------------

=

V

OUT

V

DD

D

4096

----------- -

×

=

I

B

I

L

β

----

=

V

OUT

To MCU

(MASTER)

SOURCE

Example 8-3 illustrates an example how to convert the

DAC voltage output to a digitally selectable current

source by adding a voltage follower and a sensor

register.

MCP4725

FIGURE 8-3: Digitally Controllable Current Source.

© 2007 Microchip Technology Inc. DS22039C-page 33

Page 34

MCP4725

USB Cable to PC

PICkit Serial

MCP4725 SOT-23-6 EV Board

DAC Analog Output

1st Write Byte

2nd Write Byte

3rd Write Byte

4th Write Byte

9.0 DEVELOPMENT SUPPORT

9.1 Evaluation & Demonstration

Boards

The MCP4725 SOT-23-6 Evaluation Board is available

from Microchip Technology Inc. This board works with

Microchip’s PICkit™ Serial Analyzer. The user can

program the DAC input codes and EEPROM data, or

read the programmed data using the easy to use PICkit

Serial Analyzer with the Graphic User Interface software. Refer to www.microchip.com for further information on this product’s capabilities and availability.

FIGURE 9-2: Setup for the MCP4725 SOT-23-6 Evaluation Board with PICkit™ Serial Analyzer.

FIGURE 9-1: MCP4725 SOT-23-6 Evaluation Board.

FIGURE 9-3: Example of PICkit™ Serial User Interface.

DS22039C-page 34 © 2007 Microchip Technology Inc.

Page 35

10.0 PACKAGING INFORMATION

1

6-Lead SOT-23

XXNN

Example

1

AJ25

Part Number

Address

Option

Code

MCP4725A0T-E/CH A0 (00) AJNN

MCP4725A1T-E/CH A1 (01) APNN

MCP4725A2T-E/CH A2 (10) AQNN

MCP4725A3T-E/CH A3 (11) ARNN

Legend: XX...X Customer-specific information

Y Year code (last digit of calendar year)

YY Year code (last 2 digits of calendar year)

WW Week code (week of January 1 is week ‘01’)

NNN Alphanumeric traceability code

Pb-free JEDEC designator for Matte Tin (Sn)

* This package is Pb-free. The Pb-free JEDEC designator ( )

can be found on the outer packaging for this package.

Note: In the event the full Microchip part number cannot be marked on one line, it will

be carried over to the next line, thus limiting the number of available

characters for customer-specific information.

3

e

10.1 Package Marking Information

MCP4725

3

e

© 2007 Microchip Technology Inc. DS22039C-page 35

Page 36

MCP4725

6-Lead Plastic Small Outline Transistor (CH) [SOT-23]

Notes:

1. Dimens ions D and E1 do not include mold flash or protrusions. Mold flash or protrusions shall not exceed 0.127 mm per side.

2. Dimens ioning and tolerancing per ASME Y14.5M.

BSC: Basic Dimension. Theoretically exact value shown without tolerances.

Note: For the most current package drawings, please see the Microchip Packaging Specification located at

http://www.microchip.com/packaging

Units MILLIMETERS

Dimension Limits MIN NOM MAX

Number of Pins N 6

Pitch e 0.95 BSC

Outside Lead Pitch e1 1.90 BSC

Overall Height A 0.90 – 1.45

Molded Package Thickness A2 0.89 – 1.30

Standoff A1 0.00 – 0.15

Overall Width E 2.20 – 3.20

Molded Package Width E1 1.30 – 1.80

Overall Length D 2.70 – 3.10