1997 Microchip Technology Inc. DS40151C-page 1

M

HCS512

FEATURES

Security

• Secure storage of Manufacturer’s Code

• Secure storage of transmitter’s keys

• Up to four transmitters can be learned

•K

EE

L

OQ

code hopping technology

• Normal and secure learning mechanisms

Operating

• 3.0V – 6.0V operation

• 4 MHz RC oscillator

• Learning indication on LRNOUT

• Auto baud rate detection

• Power saving sleep mode

Other

• Stand alone decoder

• On-chip EEPROM for transmitter storage

• Four binary function outputs–15 functions

• 18-pin DIP/SOIC package

Typical Applications

• Automotive remote entry systems

• Automotive alarm systems

• Automotive immobilizers

• Gate and garage openers

• Electronic door locks

• Identity tokens

• Burglar alarm systems

Compatible Encoders

• HCS200, HCS300, HCS301, HCS360, HCS361

• NTQ106

DESCRIPTION

The Microchip Technology Inc. HCS512 is a code hopping decoder designed for secure Remote Keyless

Entry (RKE) systems. The HCS512 utilizes the patented K

EE

L

OQ

code hopping system and high security

learning mechanisms to make this a canned solution

when used with the HCS encoders to implement a unidirectional remote keyless entry system.

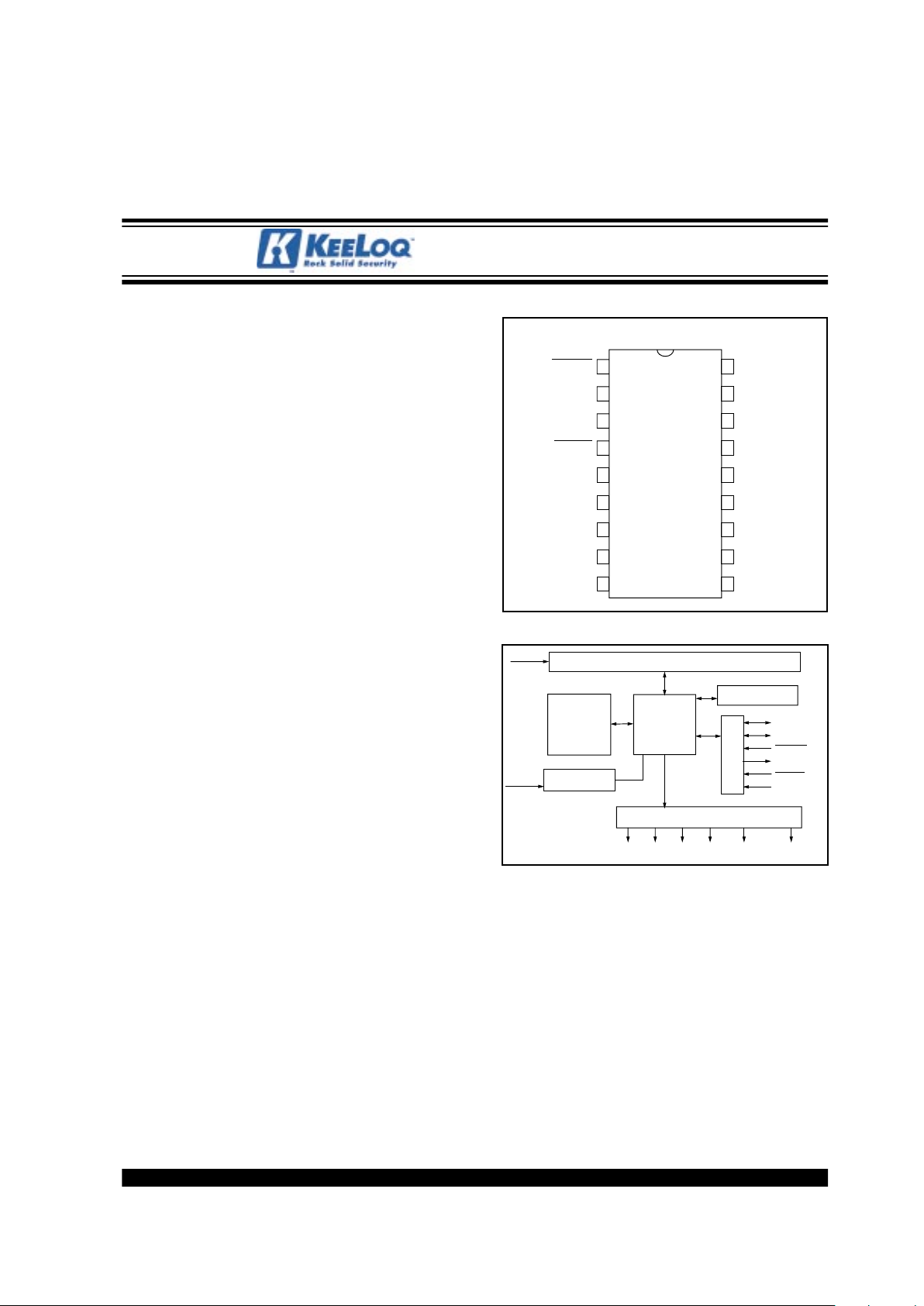

PACKA GE TYPE

BLOCK DIAGRAM

The Manufacturer’s Code, transmitter keys, and synchronization information are stored in protected on-chip

EEPROM. The HCS512 uses the D ATA and CLK inputs

to load the Manufacturer’s Code which cannot be read

out of the device.

The HCS512 operates over a wide voltage range of

3.0 volts to 6.0 volts. The decoder employs automatic

baud rate detection which allows it to compensate for

wide variations in transmitter data rate. The decoder

contains sophisticated error checking algorithms to

ensure only valid codes are accepted.

HCS512

PDIP, SOIC

1

2

3

4

5

6

7

8

9

LRNIN

LRNOUT

NC

MCLR

GND

S0

S1

S2

S3

18

17

16

15

14

13

12

11

10

RFIN

NC

OSCIN

OSCOUT

VDD

DATA

CLK

SLEEP

VLOW

S0 S1 S3S2VLOW

67-Bit Reception Register

EEPROM CONTROL

DECRYPTOR

OUTPUT

SEL

RFIN

OSCILLATOR

OSCIN

CONTROL

LRNOUT

DATA

CLK

LRNIN

MCLR

SLEEP

Code Hopping Decoder

HCS512

DS40151C-page 2

1997 Microchip Technology Inc.

1.0 K

EE

L

OQ

SYSTEM OVERVIEW

1.1 K

ey Terms

• Man

ufacturer’s Code – a 64-bit word, unique to

each manufacturer, used to produce a unique

encoder key in each transmitter (encoder).

• Encoder K

ey – a 64-bit key, unique for each transmitter. The encoder key controls the decryption

algorithm and is stored in EEPROM on the

decoder device.

• Lear

n – The receiver uses information that is

transmitted to derive the transmitter’s secret key,

decrypt the discrimination value and the synchronization counter in learning mode. The encoder

key is a function of the Manufacturer’s Code and

the device serial number and/or seed value.

The HCS encoders and decoders employ the K

EE

L

OQ

code hopping technology and an encryption algorithm

to achieve a high level of security. Code hopping is a

method by which the code transmitted from the transmitter to the receiver is different every time a button is

pushed. This method, coupled with a transmission

length of 66 bits, virtually eliminates the use of code

‘grabbing’ or code ‘scanning’.

1.2 HCS Encoder Over

view

The HCS encoders have a small EEPROM array which

must be loaded with several parameters before use.

The most important of these values are:

• A 28-bit serial number which is meant to be

unique for every encoder

• An encoder key that is generated at the time of

production

• A 16-bit synchronization value

The serial number for each encoder is programmed by

the manufacturer at the time of production. The

generation of the encoder key is done using a ke y generation algorithm (Figure 1-1). Typically, inputs to the

key generation algorithm are the serial number of the

encoder and a 64-bit manufacturer’s code. The manufacturer’s code is chosen by the system manufacturer

and must be carefully controlled. The manufacturer’s

code is a pivotal part of the overall system security.

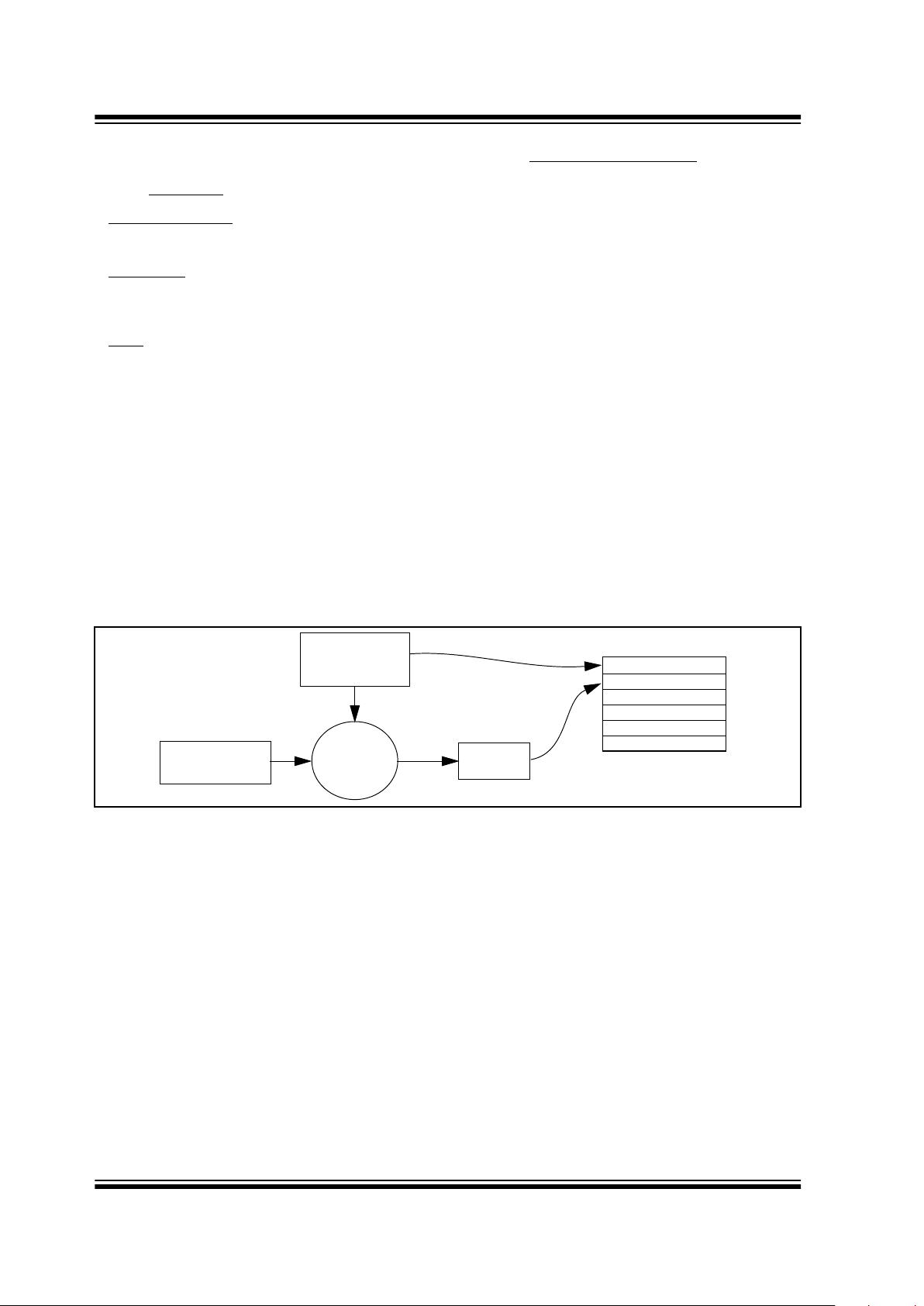

FIGURE 1-1: CREATION AND STORAGE OF ENCODER KEY DURING PRODUCTION

Transmitter

Manufacturer’s

Serial Number or

Code

Encoder

Key

Key

Generation

Algorithm

Serial Number

Encoder Key

Sync Counter

.

.

.

HCSXXX EEPROM Array

Seed

HCS512

1997 Microchip Technology Inc. DS40151C-page 3

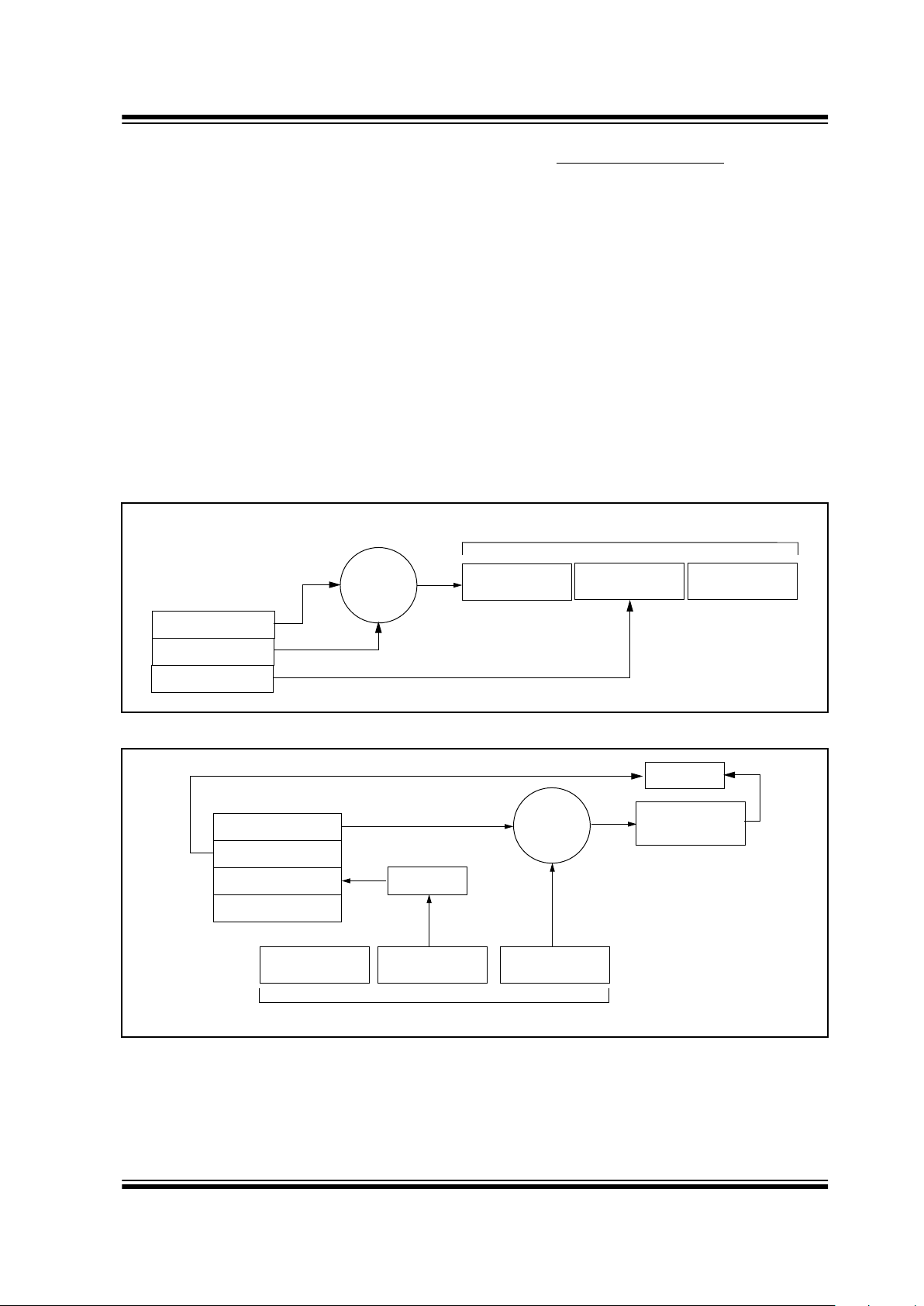

The 16-bit synchronization value is the basis for the

transmitted code changing for each transmission and is

updated each time a button is pressed. Because of the

complexity of the code hopping encryption algorithm, a

change in one bit of the synchronization value will result

in a large change in the actual transmitted code. There

is a relationship (Figure 1-3) between the key values in

EEPROM and how they are used in the encoder . Once

the encoder detects that a button has been pressed,

the encoder reads the button and updates the synchronization counter. The synchronization value is then

combined with the encoder key in the encryption algorithm, and the output is 32 bits of encrypted information.

This data will change with every button press, hence , it

is referred to as the hopping portion of the code word.

The 32-bit hopping code is combined with the button

information and the serial number to form the code

word transmitted to the receiver.

1.3 HCS Decoder Over

view

Before a transmitter can be used with a particular

receiver, the transmitter must be ‘learned’ by the

receiver. Upon learning a transmitter, information is

stored by the receiver so that it may track the

transmitter, including the serial number of the

transmitter, the current synchronization value for that

transmitter, and the same encoder key that is used on

the transmitter. If a receiv er receives a message of v alid

format, the serial number is checked and, if it is from a

learned transmitter, the message is decrypted and the

decrypted synchronization counter is checked against

what is stored. If the synchronization value is verified,

then the button status is checked to see what operation

is needed. Figure 1-3 shows the relationship between

some of the values stored by the receiver and the values received from the transmitter.

FIGURE 1-2: BASIC OPERATION OF TRANSMITTER (ENCODER)

FIGURE 1-3: BASIC OPERATION OF RECEIVER (DECODER)

KEELOQ

Algorithm

Button Press

Information

Encryption

EEPROM Array

32 Bits of

Encrypted Data

Serial Number

Transmitted Information

Encoder Key

Sync Counter

Serial Number

Button Press

Information

EEPROM Array

Encoder Key

32-Bits of

Encrypted Data

Serial Number

Received Information

Decrypted

Synchronization

Counter

Check for

Match

Check for

Match

KEELOQ

Algorithm

Decryption

Sync Counter

Serial Number

Manufacturer’s Code

HCS512

DS40151C-page 4

1997 Microchip Technology Inc.

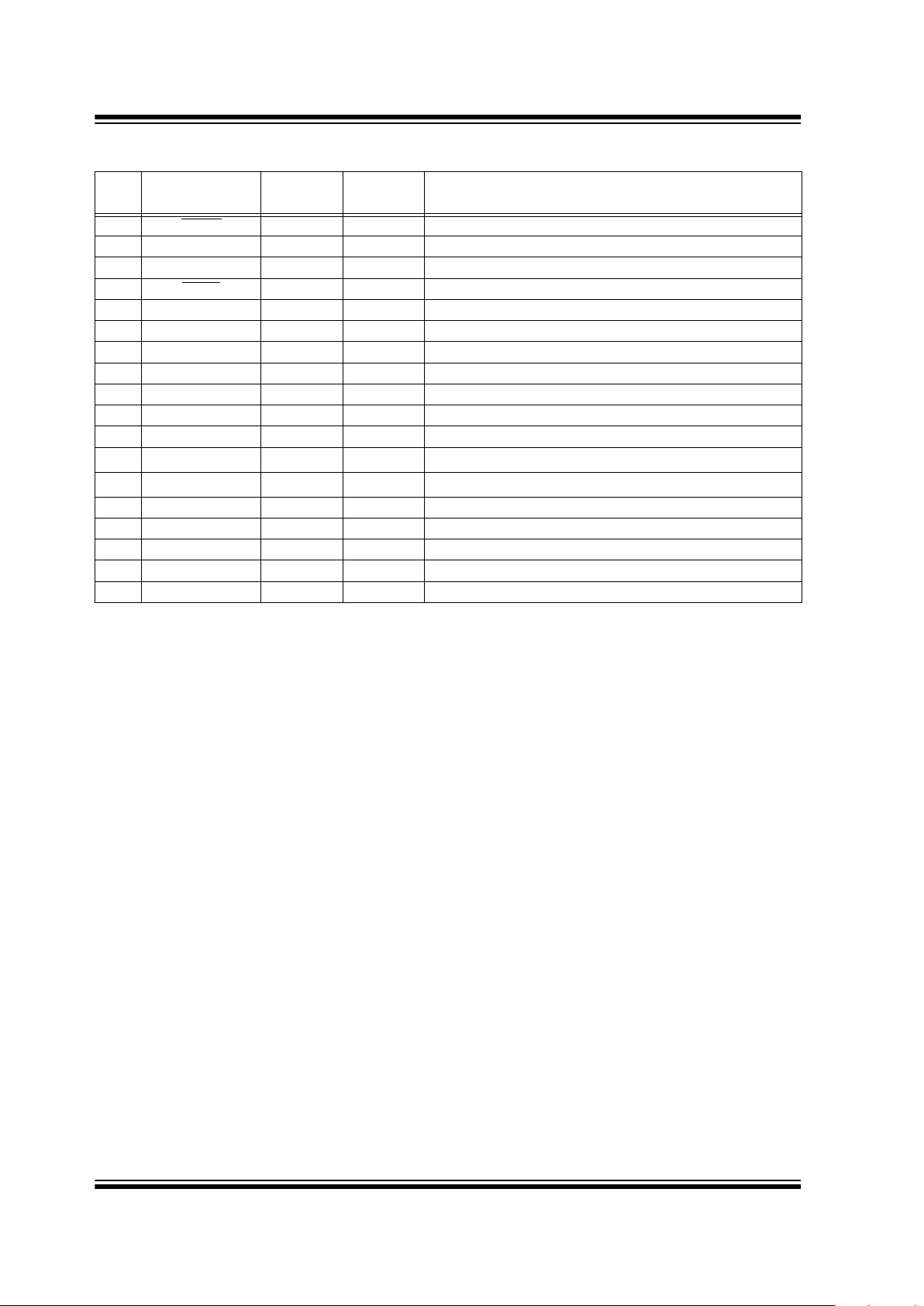

2.0 PIN ASSIGNMENT

PIN

Decoder

Function

I/O

(1)

Buffer

Type

(1)

Description

1 LRNIN

I TTL Learn input - initiates learning, 10K pull-up required on input

2 LRNOUT O TTL Learn output - indicates learning

3 NC — TTL Do not connect

4 MCLR

I ST Master clear input

5 Ground P — Ground connection

6 S0 O TTL Switch 0

7 S1 O TTL Switch 1

8 S2 O TTL Switch 2

9 S3 O TTL Switch 3

10 Vlow O TTL Battery low indication output

11 SLEEP I TTL Connect to RFIN to allow wake-up from sleep

12 CLK I/O

TTL/ST

(2)

Clock in programming mode and synchronous mode

13 DATA I/O

TTL/ST

(2)

Data in programming mode and synchronous mode

14 V

DD

P — Power connection

15 OSC

OUT

— — Oscillator out – no connection

16 OSC

IN

(4 MHz) I ST Oscillator in – recommended values 10 k Ω and 10pF

17 NC — —

18 RFIN I TTL RF input from receiver

Note 1: P = power, I = in, O = out, and ST = Schmitt Trigger input.

2:

Pin 12 and Pin 13 have a dual purpose. After reset, these pins are used to determine if programming mode

is selected in which case they are the clock and data lines. In normal operation, they are the clock and data

lines of the synchronous data output stream.

HCS512

1997 Microchip Technology Inc. DS40151C-page 5

3.0 DESCRIPTION OF FUNCTIONS

3.1 P

arallel Interface

The HCS512 activates the S3, S2, S1 & S0 outputs

according to Table 3-1 when a new valid code is

received. The outputs will be activated for approximately 500 ms. If a repeated code is received during

this time, the output extends f or approximately 500 ms.

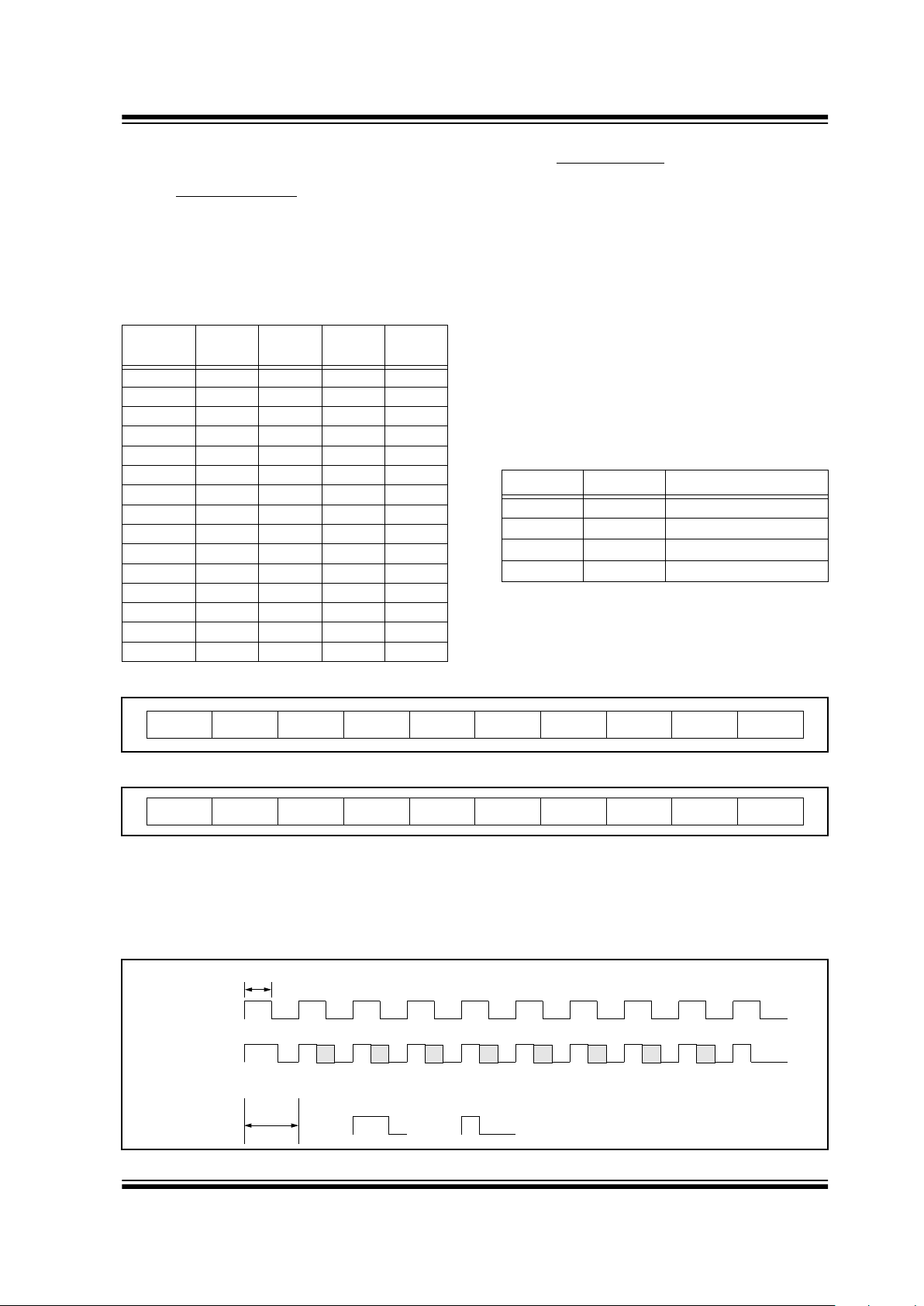

TABLE 3-1: FUNCTION OUTPUT TABLE

3.2 Serial Interface

The decoder has a PWM/Synchronous interface connection to microcontrollers with limited I/O. An output

data stream is generated when a valid transmission is

received. The data stream consists of one start bit, four

function bits, one bit for battery status, one bit to indicate a repeated transmission, two status bits, and one

stop bit. (Table 3-1). The DATA and CLK lines are used

to send a synchronous event message.

A special status message is transmitted on the second

pass of learn. This allows the controlling microcontroller

to determine if the learn was successful (Result = 1)

and if a previous transmitter was ov erwritten (Overwrite

= 1). The status message is shown in Figure 3-2.

Table 3-2 show the values for TX1:0 and the n umber of

transmitters learned.

TABLE 3-2: STATUS BITS

FIGURE 3-1: DATA OUTPUT FORMAT

FIGURE 3-2: STATUS MESSAGE FORMAT

A 1-wire PWM or 2-wire synchronous interface can be used.

In 1-wire mode, the data is transmitted as a PWM signal with a basic pulse width of 400 µ s.

In 2-wire mode, synchronous mode PWM bits start on the rising edge of the clock, and the bits must be sampled on the

falling edge. The start and stop bits are ‘1’.

FIGURE 3-3: PWM TRANSMISSION FORMAT

Function

Code

S3 S2 S1 S0

0001 0 0 0 1

0010 0 0 1 0

0011 0 0 1 1

0100 0 1 0 0

0101 0 1 0 1

0110 0 1 1 0

0111 0 1 1 1

1000 1 0 0 0

1001 1 0 0 1

1010 1 0 1 0

1011 1 0 1 1

1100 1 1 0 0

1101 1 1 0 1

1110 1 1 1 0

1111 1 1 1 1

TX1 TX0 Number of Transmitters

0 0 One

0 1 Two

1 0 Three

1 1 Four

START S3 S2 S1 S0

V

LOW

TX1 TX0 STOPREPEAT

START 0 0 0 0

RESULT

TX1 TX0 STOPOVRWR

S3Start S2 S1 S0 VLOW RPT ReservedReserved Stop

1200µs

CLK

DATA

“1” “0”

600µs

HCS512

DS40151C-page 6

1997 Microchip Technology Inc.

4.0 DECODER OPERATION

4.1 Learning a

Transmitter to a Receiver

Either the serial number-based learning method or the

seed-based learning method can be selected. The

learning method is selected in the configuration byte. In

order for a transmitter to be used with a decoder, the

transmitter must first be ‘learned’. When a transmitter is

learned to a decoder, the decoder stores the encoder

key, a check value of the serial number and current synchronization value in EEPROM. The decoder must

keep track of these values for every transmitter that is

learned. The maximum number of transmitters that can

be learned is four. The decoder must also contain the

Manufacturer’s Code in order to learn a transmitter. The

Manufacturer’ s Code will typically be the same for all

decoders in a system.

The HCS512 has f our memory slots. After an “erase all”

procedure, all the memory slots will be cleared. Erase

all is activated by taking LRNIN

low for approximately

10 seconds. When a new transmitter is learned, the

decoder searches for an empty memory slot and stores

the transmitter’s information in that memory slot. When

all memory slots are full, the decoder randomly overwrites existing transmitters.

4.1.1 LEARNING PROCEDURE

Learning is activated by taking the LRNIN

input low for

longer than 64 ms. This input requires an external pullup resistor.

To learn a new transmitter to the HCS512 decoder, the

following sequence is required:

1. Enter learning mode by pulling LRNIN low for

longer than 64 ms. The LRNOUT output will go

high.

2. Activate the transmitter until the LRNOUT output

goes low indicating reception of a valid code

(hopping message).

3. Activate the transmitter a second time until the

LRNOUT toggles for 4 seconds (in secure learning mode, the seed transmission must be transmitted during the second stage of learn by

activating the appropriate buttons on the transmitter).

If LRNIN

is taken low momentarily during the

learn status indication, the indication will be terminated. Once a successful learning sequence

is detected, the indication can be terminated

allowing quick learning in a manufacturing setup.

4. The transmitter is now learned into the decoder.

5. Repeat steps 1-4 to learn up to four transmitters.

6. Learning will be terminated if two non-sequential

codes were received or if two acceptable codes

were not decoded within 30 seconds.

The following checks are performed on the decoder to

determine if the transmission is valid during learn:

• The first code word is checked for bit integrity.

• The second code word is checked for bit integrity.

• The hopping code is decrypted.

• If all the checks pass, the serial number and synchronization counters are stored in EEPROM

memory.

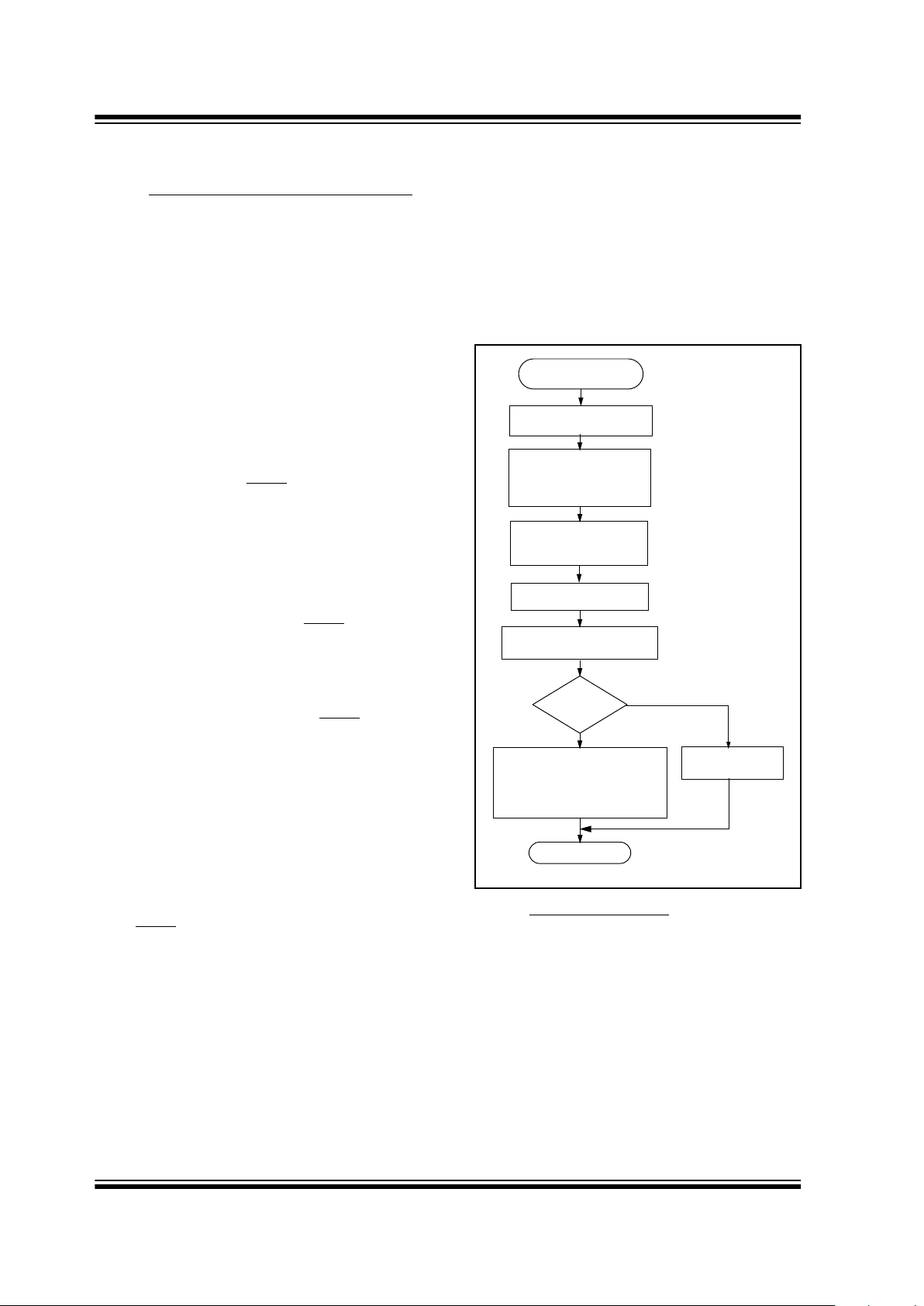

Figure 4-1 shows a flow chart of the learn sequence.

FIGURE 4-1: LEARN SEQUENCE

4.2 V

alidation of Codes

The decoder waits for a transmission and checks the

serial number to determine if the transmitter has been

learned. If learned, the decoder decrypts the encrypted

portion of the transmission using the encoder key. It

uses the discrimination bits to determine if the decryption was valid. If everything up to this point is valid, the

synchronization value is evaluated.

Enter Learn

Mode

Wait for Reception

of Second

Compare Discrimination

Value with Serial Number

Use Generated Key

to Decrypt

Equal

Serial number check value

Synchronization counter

?

Exit

Learn successful. Store:

Learn

Unsuccessful

No

Yes

Wait for Reception

of a Valid Code

Non-Repeated

Valid Code

Generate Key

from Serial Number

or Seed Value

Encoder Key

HCS512

1997 Microchip Technology Inc. DS40151C-page 7

4.3 V

alidation Steps

Validation consists of the following steps:

• Search EEPROM to find the Serial Number Check

Value Match

• Decrypt the Hopping Code

• Compare the 10 bits of discrimination value with

the lower 10 bits of serial number

• Check if the synchronization counter falls within

the first synchronization window.

• Check if the synchronization counter falls within

the second synchronization window.

• If a valid transmission is found, update the synchronization counter, else use the ne xt transmitter

block and repeat the tests.

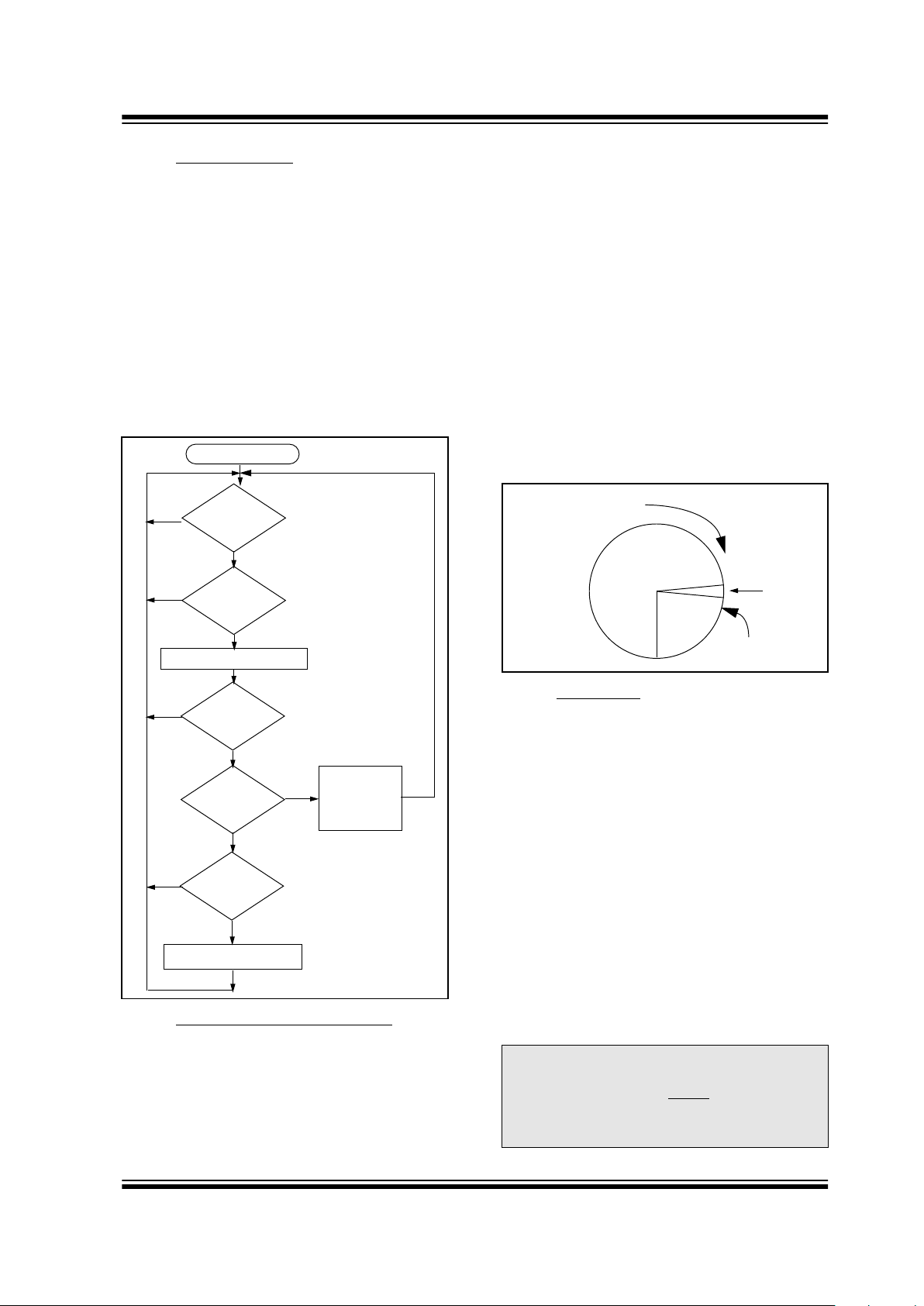

FIGURE 4-2: DECODER OPERATION

4.4 Synchronization with Decoder

The K

EE

L

OQ

technology features a sophisticated

synchronization technique (Figure 4-3) which does not

require the calculation and storage of future codes. If

the stored counter value for that particular transmitter

and the counter value that was just decrypted are within

a formatted window of 16, the counter is stored and the

command is executed. If the counter value was not

within the single operation window, but is within the

double operation window of 16K, the transmitted synchronization value is stored in a temporary location,

and it goes back to waiting for another transmission.

When the next valid transmission is received, it will

check the new value with the one in temporary storage.

If the two values are sequential, it is assumed that the

counter was outside of the single operation ‘window’,

but is now back in sync, so the new synchronization

value is stored and the command executed. If a transmitter has somehow gotten out of the double operation

window, the transmitter will not work and must be

relearned. Since the entire window rotates after each

valid transmission, codes that hav e been used become

part of the ‘blocked’ (48K) codes and are no longer

valid. This eliminates the possibility of grabbing a previous code and retransmitting it to gain entry.

FIGURE 4-3: SYNCHRONIZATION WINDOW

4.5 Sleep Mode

The sleep mode of the HCS512 is used to reduce current consumption when no RF input signal is present.

Sleep mode will only be effective in systems where the

RF receiver is relatively quiet when no signal is present.

During sleep, the clock stops, thereby significantly

reducing the operating current. Sleep mode is enabled

by the SLEEP bit in the configuration byte.

The HCS512 will enter sleep mode when:

• The RF line is low

• After a function output is switched off

• Learn mode is terminated (time-out reached)

The device will not enter sleep mode when:

• A function output is active

• Learn sequence active

• Device is in programming mode

The device will wake up from sleep when:

• The SLEEP input pin changes state

• The CLOCK line changes state

?

Transmission

Received

Does

Ser # Check Val

Match

?

Decrypt Transmission

Is

Decryption

Valid

?

Is

Counter

Within 16

?

Is

Counter

Within 32K

?

Update

Counter

Execute

Command

Save Counter

in Temp Location

Start

No

No

No

No

Yes

Yes

Yes

Yes

Yes

No

and

Note: During sleep mode the CLK line will

change from an output line to an input line

that can be used to wake up the device.

Connect CLK to LRNIN

via a 100K resistor

to reliably enter the learn mode whenever

sleep mode is active.

Blocked

Entire Window

rotates to eliminate

previously

used codes

Current

Position

(48K Codes)

Double

Operation

(16K

Single Operation

Window (16 Codes)

Codes)

HCS512

DS40151C-page 8

1997 Microchip Technology Inc.

5.0 INTEGRATING THE HCS512

INTO A SYSTEM

The HCS512 can act as a stand alone decoder or be

interfaced to a microcontroller. Typical stand alone

applications include garage door openers and electronic door locks. In stand alone applications, the

HCS512 will handle learning, reception, decryption,

and validation of the received code; and generate the

appropriate output. For a garage door opener, the

HCS512 input will be connected to an RF receiver, and

the output, to a relay driver to connect a motor controller.

Typical systems where the HCS512 will be connected

to a microcontroller include vehicle and home security

systems. The HCS512 input will be connected to an RF

receiver and the function outputs to the microcontroller.

The HCS512 will handle all the decoding functions and

the microcontroller, all the system functions. The serial

output mode with a 1- or 2-wire interface can be used if

the microcontroller is I/O limited.

6.0 DECODER PROGRAMMING

The PG306001 production programmer will allow easy

setup and programming of the configuration byte and

the manufacturer’s code.

6.1 Confi

guration Byte

The configuration byte is used to set system configuration for the decoder. The LRN bits determine which

algorithm (Decrypt or XOR) is used for the key generation. SC_LRN determines whether normal learn (key

derived from serial number) or secure learn (key

derived from seed value) is used.

TABLE 6-1: CONFIGURATION BYTE

TABLE 6-2: LEARN METHOD LRN0, LRN1

DEFINITIONS

Bit Name Description

0 LRN0 Learn algorithm select

1 LRN1 Not used

2 SC_LRN Secure Learn enable (1 = enabled)

3 SLEEP Sleep enable (1 = enabled)

4 RES1 Not used

5 RES2 Not used

6 RES3 Not used

7 RES4 Not used

LRN0 Description

0 Decrypt algorithm

1 XOR algorithm

HCS512

1997 Microchip Technology Inc. DS40151C-page 9

6.2 Pr

ogramming the Manufacturer’s

Code

The manufacturer’s code must be programmed into

EEPROM memory through the synchronous programming interface using the DATA and CLK lines. Provision

must be made for connections to these pins if the

decoder is going to be programmed in circuit.

Programming mode is activated if the CLK is low for at

least 1ms and then goes high within 64 ms after powerup, stays high for longer than 8ms but not longer than

128 ms. After entering programming mode the 64-bit

manufacturer’s code, 8-bit configuration byte, and 8-bit

checksum is sent to the device using the synchronous

interface. After receiving the 80-bit message the checksum is verified and the information is written to

EEPROM. If the programming operation was successful, the HCS512 will respond with an acknowledge

pulse.

After programming the manufacturer’s code, the

HCS512 decoder will automatically activate an

Erase All function, removing all transmitters from the

system.

6.3 Do

wnload Format

The manufacturer’s code and configuration byte must

be downloaded least significant byte, least significant

bit first as shown in Table 6-3.

6.4 Chec

ksum

The checksum is used by the HCS512 to check that the

data downloaded was correctly received before programming the data. The checksum is calculated so that

the 10 bytes added together (discarding the overflow

bits) is zero. The checksum can be calculated b y adding

the first 9 bytes of data together and subtracting the

result from zero. Throughout the calculation the overflow is discarded.

Given a manufacturer’s code of 0123456789ABCDEF

16

and a configuration word of 1

16

, the

checksum is calculated as shown in Figure 6-1. The

checksum is 3F

16

.

6.5 T

est Transmitter

The HCS512 decoder will automatically add a test

transmitter each time an Erase All Function is done. A

test transmitter is defined as a transmitter with a serial

number of zero. After an Erase All, the test transmitter

will always work without learning and will not check the

synchronization counter of the transmitter. Lear ning of

any new transmitters will erase the test transmitter.

TABLE 6-3: DOWNLOAD DATA

FIGURE 6-1: CHECKSUM CALCULATION

Note 1: A transmitter with a serial number of zero

cannot be learned. Learn will fail after the

first transmission.

2:

Always learn at least one transmitter after

an Erase All sequence. This ensures that

the test transmitter is erased.

Byte 9 Byte 8 Byte 7 Byte 6 Byte 5 Byte 4 Byte 3 Byte 2 Byte 1 Byte 0

Check-

sum

Config

Man

Key_7

Man

Key_6

Man

Key_5

Man

Key_4

Man

Key_3

Man

Key_2

Man

Key_1

Man

Key_0

Byte 0, right-most bit downloaded first.

0116 + 2316 = 24

6

2416 + 4516 = 69

16

6916 + 6716 = D0

16

D016 + 8916 = 159

16

5916 + AB16 = 10416 (Carry is discarded)

04

16

+ CD16 = D116 (Carry is discarded)

D1

16

+ EF16 = 1C0

16

C016 + 116 = C116 (Carry is discarded)

(FF

16

- C116) + 116 = 3F

16

HCS512

DS40151C-page 10 1997 Microchip Technology Inc.

FIGURE 6-2: PROGRAMMING WAVEFORMS

TABLE 6-4: PROGRAMMING TIMING

REQUIREMENTS

Bit1Bit0 Bit78 Bit79

Ack

MCLR

CLK

(Clock)

DAT

(Data)

Enter Program Mode

Acknowledge

pulse

T

PS

T

PH1

T

CKL

T

CKH

T

ACK

T

PH2

80-bit Data Package

Parameter Symbol Min. Max. Units

Program mode setup time TPS 1 64 ms

Hold time 1 TPH1 8 128 ms

Hold time 2 TPH2 0.05 320 ms

Clock High Time TCKH 0.05 320 ms

Clock Low Time TCKL 0.050 320 ms

Acknowledge Time TACK — 80 ms

Note: FOSC equals 4 MHz.

HCS512

1997 Microchip Technology Inc. DS40151C-page 11

7.0 KEY GENERATION SCHEMES

The HCS512 decoder has two key generation schemes. Normal learning uses the transmitter’s serial number to derive

two input seeds which aµ re used as inputs to the ke y gener ation algorithm. Secure learning uses the seed transmission

to derive the two input seeds. Two key generation algorithms are available to convert the inputs seeds to secret keys.

The appropriate scheme is selected in the configuration word.

FIGURE 7-1:

7.1 Normal Learning (Serial Number Derived)

The two input seeds are composed from the serial number in two ways, depending on the encoder type. The encoder

type is determined from the number of bits in the incoming transmission. SourceH is used to calculate the upper 32 bits

of the encoder key, and SourceL, for the lower 32 bits.

For 24-bit serial number encoders (56-bit transmissions):

SourceH = 65H + 24 bit Serial Number

SourceL = 2BH + 24 bit Serial Number

For 28-bit serial number encoders (66 / 67-bit transmissions):

SourceH = 6H + 28 bit Serial Number

SourceL = 2H + 28 bit Serial Number

7.2 Secure Learning (Seed Derived)

The two input seeds are composed from the seed value that is transmitted during secure learning. The lower 32 bits of

the seed transmission is used to compose the lower seed, and the upper 32 bits, for the upper seed. The upper 4 bits

(function code) are set to zero.

For 32-bit seed encoders:

SourceH = Serial Number

Lower 28 bits

with upper 4 bits always zero

SourceL = Seed

32 bits

For 48-bit seed encoders:

SourceH = Seed

Upper 16 bits

+ Serial Number

Upper 16 bits

with upper 4 bits always zero

SourceL = Seed

Lower 32 bits

For 64-bit seed encoders:

Note: 64-bit seeds are handled as 48-bit seeds

SourceH = Seed

Upper 16 bits

+ Serial Number

Upper 16 bits

with upper 4 bits always zero

SourceL = Seed

Lower 32 bits

Seed

Patched

Serial

Number

Key Generation

Algorithms

------------------Decrypt

XOR

Encoder

Key

Manufacturer’s

Key

HCS512

DS40151C-page 12 1997 Microchip Technology Inc.

7.3 Key Generation Algorithms

There are two key generation algorithms implemented in the HCS512 decoder. The KEELOQ decryption algorithm pro-

vides a higher level of security than the XOR algorithm. Section 6.1 describes the selection of the algorithms in the configuration byte.

7.3.1 K

EELOQ DECRYPT ALGORITHM

This algorithm uses the K

EELOQ decryption algorithm and the manufacturer’s code to derive the encoder k ey as f ollows:

Key

Upper 32 bits

= F

KEELOQ Decrypt

(SourceH) |

64 Bit Manufacturers Code

Key

Lower 32 bits

= F

KEELOQ Decrypt

(SourceL) |

64 Bit Manufacturers Code

7.3.2 XOR WITH THE MANUFACTURER’S CODE

The two 32-bits seeds are XOR with the manufacturer’s code to form the 64 bit encoder key.

Key

Upper 32 bits

= SourceH ⊗ Manufacturers Code |

Upper 32 bits

Key

Lower 32 bits

= SourceL ⊗ Manufacturers Code |

Lower 32 bits

After programming the manufacturer’s code, the HCS512 decoder will automatically activate an Erase All function,

removing all transmitters from the system.

If LRNIN

is taken low momentarily during the learn status indication, the indication will be terminated. Once a successful

learning sequence is detected, the indication can be terminated, allowing quick learning in a manufacturing set up.

FIGURE 7-2: HCS512 KEY GENERATION

KEELOQ

Decryption

Algorithm

Padding

6/65

28/24-bit Serial Number

Padding

2/2B

28/24-bit Serial Number

MS 32 bits of Encoder Key

LS 32 bits of Encoder Key

SC_LRN = 0

LRN0 = 0

KEELOQ

Decryption

Algorithm

Padding

0000b

MS 28 bits of Seed Transmission

LS 32 bits of Seed Transmission

MS 32 bits of Encoder Key

LS 32 bits of Encoder Key

SC_LRN = 1

XOR

Padding

0000b

MS 28 bits of Seed Transmission

LS 32 bits of Seed Transmission

MS 32 bits of Encoder Key

LS 32 bits of Encoder Key

LRN0 = 1

HCS512

1997 Microchip Technology Inc. DS40151C-page 13

8.0 KEELOQ ENCODERS

8.1 Transmission Format (PWM)

The KEELOQ encoder transmission is made up of several parts (Figure 8-1). Each transmission begins with

a preamble and a header, followed by the encrypted

and then the fixed data. The actual data is 56/66/67 bits

which consists of 32 bits of encrypted data and 24/34/

35 bits of non-encrypted data. Each transmission is

followed by a guard period bef ore another transmission

can begin. The encr ypted portion provides up to four

billion changing code combinations and includes the

button status bits (based on which buttons were activated) along with the synchronization counter value

and some discrimination bits. The non-encr ypted portion is comprised of the status bits, the function bits,

and the 24/28-bit serial number. The encrypted and

non-encrypted combined sections increase the number

of combinations to 7.38 x 10

19

.

8.2 Code Word Organization

The HCSXXX encoder transmits a 66/67-bit code word

when a button is pressed. The 66/67-bit word is constructed from an encryption portion and a nonencrypted code portion (Figure 8-2).

The Encrypted Data is generated from f our button bits ,

two overflow counter bits, ten discrimination bits, and

the 16-bit synchronization value.

The Non-encrypted Data is made up from 2 status

bits, 4 function bits, and the 28/32-bit serial number.

FIGURE 8-1: CODE WORD TRANSMISSION FORMAT

FIGURE 8-2: CODE WORD ORGANIZATION

LOGIC ‘0’

LOGIC ‘1’

Bit

Period

Preamble

Header

Encrypted Portion

of Transmission

Fixed Portion of

Transmission

Guard

Time

TP

TH

THOP

TFIX

TG

Repeat

Vlow

(1 bit)

Button Sta-

tus (4 bits)

28-bit

Serial Number

Button

Status

(4 bits)

Discrimina-

tion bits

(12 bits)

16-bit

Sync Value

CRC1* CRC0*

3/2 bits +

Serial Number and But-

ton Status (32 bits)

+ 32 bits of Encrypted Data

Encrypted DataNon-encrypted Data

*HCS360/361

66/67 bits

of Data

Transmitted

HCS512

DS40151C-page 14 1997 Microchip Technology Inc.

9.0 ELECTRICAL CHARACTERISTICS FOR HCS512

Absolute Maximum Ratings †

Ambient temperature under bias.............................................................................................................-55°C to +125°C

Storage temperature...............................................................................................................................-65°C to +150°C

Voltage on any pin with respect to V

SS (except VDD)......................................................................... -0.6V to VDD +0.6V

Voltage on V

DD with respect to Vss...................................................................................................................0 to +7.5V

Total power dissipation (Note 1)........................................................................................................................... 800 mW

Maximum current out of V

SS pin ........................................................................................................................... 150 mA

Maximum current into V

DD pin .............................................................................................................................. 100 mA

Input clamp current, Iik (V

I < 0 or VI > VDD).........................................................................................................± 20 mA

Output clamp current, IOK (V

O < 0 or VO >VDD)..................................................................................................± 20 mA

Maximum output current sunk by any I/O pin.......................................................................................................... 25 mA

Maximum output current sourced by any I/O pin.....................................................................................................20 mA

Note: Power dissipation is calculated as follows: Pdis = V

DD x {IDD - ∑ IOH} + ∑ {(VDD–VOH) x IOH} + ∑(VOl x IOL)

† NOTICE: Stresses above those listed under “Absolute Maximum Ratings” may cause permanent damage to the

device. This is a stress rating only and functional operation of the device at those or any other conditions above those

indicated in the operation listings of this specification is not implied. Exposure to maximum rating conditions for

extended periods may affect device reliability.

HCS512

1997 Microchip Technology Inc. DS40151C-page 15

TABLE 9-1: DC CHARACTERISTICS

TABLE 9-2: AC CHARACTERISTICS

FIGURE 9-1: RESET WATCHDOG TIMER, OSCILLATOR START-UP TIMER AND POWER-UP

TIMER TIMING

Standard Operating Conditions (unless otherwise stated)

Operating temperature

Commercial (C): 0°C ≤ T

A ≤ +70°C for commercial

Industrial (I): -40°C ≤ T

A ≤ +85°C for industrial and

Symbol Characteristic Min Typ

(†)

Max Units Conditions

V

DD Supply Voltage 3.0 — 6.0 V

V

POR VDD start voltage to

ensure Reset

— VSS — V

S

VDD VDD rise rate to

ensure Reset

0.05* — — V/ms

I

DD Supply Current —

—

1.8

7.3

15

4.5

10

32

mA

mA

µA

FOSC = 4 MHz, VDD = 5.5V

(During EEPROM programming)

In SLEEP mode

VIL Input Low Voltage VSS — 0.16 VDD V except MCLR = 0.2 VDD

VIH Input High Voltage 0.48 VDD — VDD V except MCLR = 0.85 VDD

VOL Output Low Voltage — — 0.6 V IOL = 8.5 mA, VDD = 4.5V

V

OH Output High Voltage VDD-0.7 — — V IOH = -3.0 mA, VDD = 4.5V

†Data in “Typ” column is at 5.0V, 25°C unless otherwise stated. These parameters are for design guidance

only and are not tested.

*These parameters are characterized but not tested.

Note: Negative current is defined as coming out of the pin.

Symbol Characteristic Min Typ Max Units Conditions

F

OSC Oscillator frequency 2.7 4 6.21 MHz Rext = 10K, Cext = 10pF

T

E

PWM elemental

pulse width

65 — 1080 µs 4.5V < V

DD < 5.5V

Oscillator components tolerance < 6%.

130 — 1080 µs 3V < Vdd < 6V

Oscillator components tolerance <10%

T

OD Output delay 70 90 115 ms

T

A Output activation time 322 500 740 ms

T

RPT REPEAT activation time 32 50 74 ms

T

LRN LRNIN activation time 21 32 — ms

T

MCLR MCLR low time 150 — — ns

T

OV Time output valid — 150 222 ms

VDD

MCLR

I/O Pins

TOV

TMCLR

HCS512

DS40151C-page 16 1997 Microchip Technology Inc.

FIGURE 9-2: OUTPUT ACTIVATION

RFIN

S[3,2,1,0]

LRNOUT

0s 1s 2s 3s 4s 5s

1 Code Word 50ms

TOD

TA

TA

VLOW

Note 1: Output is activated as long as code is received.

2: Output is activated if battery low (V

LOW) is detected.

Note 2

Note 1

HCS512

1997 Microchip Technology Inc. DS40151C-page 17

FIGURE 9-3: TYPICAL DECODER APPLICATION CIRCUIT

S1

S2

S3

LRNOUT

S0

V

D

D

G

N

D

G

N

D

V

DD

LOW VOLTAGE DETECTOR—DO NOT OMIT

VI

VO

10K

V

DD

10K

10 pF

14

P2

5

V

DD

10K

1

RECEIVE DATA INPUT

1

2

3

12V

GND

1N4004/7

100 µF

POWER SUPPLY

G

N

D

LM7805

VI

VO

VDD

NC

RFIN

LRNIN

LRNOUT

S0

S1

S2

S3

VLOW

SLEEP

CLK

DAT

MCLR

NC

OSCIN

OSCOUT

4

3

16

15

LEARN

BUTTON

Vlow

P3

1K

1K

1K

1K

1K

1K

100µF

P4

P3

P2

In Circuit

17

18

1

2

6

7

8

9

10

11

12

13

HCS512

P4

100K

Programming Pads

DATA

CLOCK

RESET

GND P1

HCS512

DS40151C-page 18 1997 Microchip Technology Inc.

NOTES:

HCS512

1997 Microchip Technology Inc. DS40151C-page 19

HCS512 PRODUCT IDENTIFICATION SYSTEM

To order or obtain information, e.g., on pricing or delivery, refer to the factory or the listed sales office.

Sales and Support

Package:

P = Plastic DIP (300 mil Body), 8-lead

SN = Plastic SOIC (300 mil Body), 18-lead

Temperature

Range:

Blank = 0˚C to +70˚C

I = -40˚C to +85˚C

Device:

HCS512 Code Hopping Decoder

HCS512T Code Hopping Decoder (Tape and Reel)

HCS512 — /P

Data Sheets

Products supported by a preliminary Data Sheet may have an errata sheet describing minor operational differences and recommended workarounds. To determine if an errata sheet exists for a particular device, please contact one of the following:

1. Your local Microchip sales office.

2. The Microchip Corporate Literature Center U.S. FAX: (602) 786-7277.

3. The Microchip’s Bulletin Board, via your local CompuServe number (CompuServe membership NOT required).

Please specify which device, revision of silicon and Data Sheet (include Literature #) you are using.

Information contained in this publication regarding device applications and the like is intended for suggestion only and may be superseded by updates. No representation or

warranty is given and no liability is assumed by Microchip Technology Incorporated with respect to the accuracy or use of such information, or infringement of patents or other

intellectual property rights arising from such use or otherwise. Use of Microchip’s products as critical components in life support systems is not authorized except with express

written approval by Microchip. No licenses are conv eyed, implicitly or otherwise, under any intellectual property rights. The Microchip logo and name are registered trademarks

of Microchip Technology Inc. in the U.S.A. and other countries. All rights reserved. All other trademarks mentioned herein are the property of their respective companies.

DS40151C-page 20

1997 Microchip Technology Inc.

AMERICAS

Corporate Office

Microchip T echnology Inc.

2355 West Chandler Blvd.

Chandler, AZ 85224-6199

Tel: 602-786-7200 Fax: 602-786-7277

Technical Support:

602 786-7627

Web:

http://www.microchip.com

Atlanta

Microchip T echnology Inc.

500 Sugar Mill Road, Suite 200B

Atlanta, GA 30350

Tel: 770-640-0034 Fax: 770-640-0307

Boston

Microchip T echnology Inc.

5 Mount Royal Avenue

Marlborough, MA 01752

Tel: 508-480-9990 Fax: 508-480-8575

Chicago

Microchip T echnology Inc.

333 Pierce Road, Suite 180

Itasca, IL 60143

Tel: 630-285-0071 Fax: 630-285-0075

Dallas

Microchip T echnology Inc.

14651 Dallas Parkway, Suite 816

Dallas, TX 75240-8809

Tel: 972-991-7177 Fax: 972-991-8588

Dayton

Microchip T echnology Inc.

Two Prestige Place, Suite 150

Miamisburg, OH 45342

Tel: 937-291-1654 Fax: 937-291-9175

Los Angeles

Microchip T echnology Inc.

18201 Von Karman, Suite 1090

Irvine, CA 92612

Tel: 714-263-1888 Fax: 714-263-1338

New Y ork

Microchip T echnology Inc.

150 Motor Parkway, Suite 416

Hauppauge, NY 11788

Tel: 516-273-5305 Fax: 516-273-5335

San Jose

Microchip T echnology Inc.

2107 North First Street, Suite 590

San Jose, CA 95131

Tel: 408-436-7950 Fax: 408-436-7955

Toronto

Microchip T echnology Inc.

5925 Airport Road, Suite 200

Mississauga, Ontario L4V 1W1, Canada

Tel: 905-405-6279 Fax: 905-405-6253

ASIA/PACIFIC

Hong Kong

Microchip Asia Pacific

RM 3801B, Tower Two

Metroplaza

223 Hing Fong Road

Kwai Fong, N.T., Hong Kong

Tel: 852-2-401-1200 Fax: 852-2-401-3431

India

Microchip T echnology Inc.

India Liaison Office

No. 6, Legacy, Convent Road

Bangalore 560 025, India

Tel: 91-80-229-4036 Fax: 91-80-559-9840

Korea

Microchip T echnology Korea

168-1, Youngbo Bldg. 3 Floor

Samsung-Dong, Kangnam-Ku

Seoul, Korea

Tel: 82-2-554-7200 Fax: 82-2-558-5934

Shanghai

Microchip T echnology

RM 406 Shanghai Golden Bridge Bldg.

2077 Yan’an Road West, Hong Qiao District

Shanghai, PRC 200335

Tel: 86-21-6275-5700

Fax: 86 21-6275-5060

Singapore

Microchip T echnology Taiwan

Singapore Branch

200 Middle Road

#10-03 Prime Centre

Singapore 188980

Tel: 65-334-8870 Fax: 65-334-8850

Taiwan, R.O.C

Microchip T echnology Taiwan

10F-1C 207

Tung Hua North Road

T aipei, Taiwan, ROC

Tel: 886 2-717-7175 Fax: 886-2-545-0139

EUROPE

United Kingdom

Arizona Microchip Technology Ltd.

Unit 6, The Courtyard

Meadow Bank, Furlong Road

Bourne End, Buckinghamshire SL8 5AJ

Tel: 44-1628-851077 Fax: 44-1628-850259

France

Arizona Microchip Technology SARL

Zone Industrielle de la Bonde

2 Rue du Buisson aux Fraises

91300 Massy, France

Tel: 33-1-69-53-63-20 Fax: 33-1-69-30-90-79

Germany

Arizona Microchip Technology GmbH

Gustav-Heinemann-Ring 125

D-81739 Müchen, Germany

Tel: 49-89-627-144 0 Fax: 49-89-627-144-44

Italy

Arizona Microchip Technology SRL

Centro Direzionale Colleoni

Palazzo Taurus 1 V. Le Colleoni 1

20041 Agrate Brianza

Milan, Italy

Tel: 39-39-6899939 Fax: 39-39-6899883

JAPAN

Microchip Technology Intl. Inc.

Benex S-1 6F

3-18-20, Shinyokohama

Kohoku-Ku, Yokohama-shi

Kanagawa 222 Japan

Tel: 81-45-471- 6166 Fax: 81-45-471-6122

7/29/97

Printed on recycled paper.

All rights reserved. ©1997, Microchip Technology Incorporated, USA. 6/97

M

W

ORLDWIDE

S

ALES

& S

ERVICE

Loading...

Loading...