HCS301

K

EE

L

OQ

Code Hopping Encoder*

FEATURES

Security

• Programmable 28-bit serial number

• Programmable 64-bit encryption key

• Each transmission is unique

• 66-bit transmission code length

• 32-bit hopping code

• 34-bit fixed code (28-bit serial number,

4-bit button code, 2-bit status)

• Encryption keys are read protected

Operating

• 3.5V - 13.0V operation

• Four button inputs

- 15 functions available

• Selectable baud rate

• Automatic code word completion

• Battery low signal transmitted to receiver

• Battery low indication on LED

• Non-volatile synchronization data

Other

• Functionally identical to HCS300

• Easy to use programming interface

• On-chip EEPROM

• On-chip oscillator and timing components

• Button inputs have internal pulldown resistors

• Current limiting on LED

• Low external component cost

output

Typical Applications

The HCS301 is ideal for Remote Keyless Entry (RKE)

applications. These applications include:

• Automotive RKE systems

• Automotive alarm systems

• Automotive immobilizers

• Gate and garage door openers

• Identity tokens

• Burglar alarm systems

DESCRIPTION

The HCS301, from Microchip Technology Inc., is a code

hopping encoder designed for secure Remote Keyless

Entry (RKE) systems. The HCS301 utilizes the K

code hopping technology , which incorporates high security, a small package outline, and low cost, to make this

device a perfect solution for unidirectional remote keyless entry systems and access control systems.

EE

OQ

L

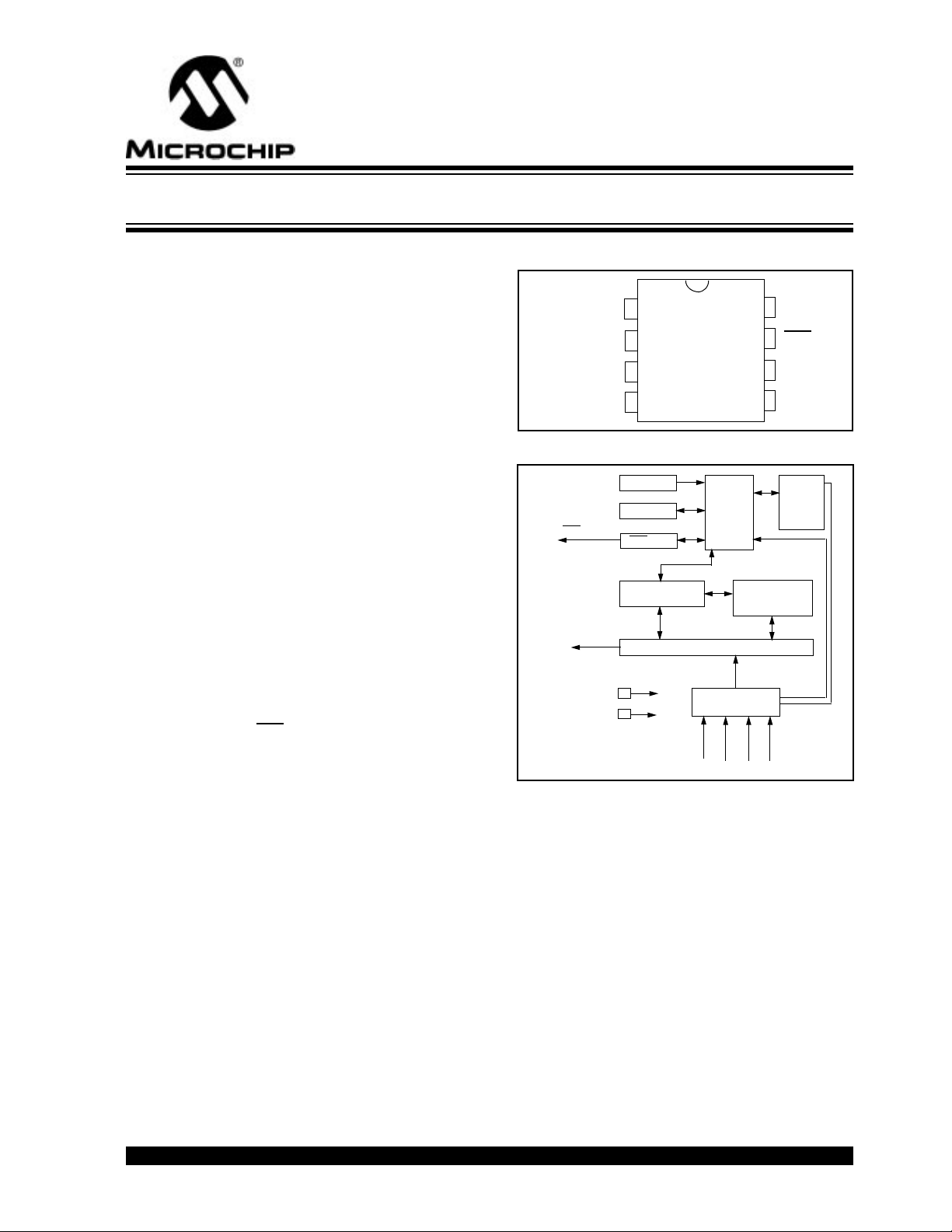

PACKA GE TYPES

PDIP, SOIC

8

DD

S0

S1

S2

S3

1

2

3

4

HCS301

V

LED

7

6

PWM

V

SS

5

HCS301 BLOCK DIAGRAM

Oscillator

Reset circuit

LED

PWM

The HCS301 combines a 32-bit hopping code

generated by a non-linear encryption algorithm, with a

28-bit serial number and six status bits to create a

66-bit transmission stream. The length of the

transmission eliminates the threat of code scanning

and the code hopping mechanism makes each

transmission unique, thus rendering code capture and

resend (code grabbing) schemes useless.

The encryption key, serial number, and configuration

data are stored in EEPROM which is not accessible via

any external connection. This makes the HCS301 a

very secure unit. The HCS301 provides an easy to use

serial interface for programming the necessary security

keys, system parameters, and configuration data.

The encryption keys and code combinations are programmable but read-protected. The keys can only be

verified after an automatic erase and programming

operation. This protects against attempts to gain

access to keys and manipulate synchronization values .

LED driver

EEPROM

VSS

VDD

Controller

32-bit shift register

Button input port

S

S

2

3

Encoder

S1S

0

Power

latching

and

switching

KeeLoq is a registered trademark of Microchip Technology Inc.

*Code hopping encoder patents issued for Europe, U. S. A., and R. S. A.

1996 Microchip Technology Inc.

Preliminary

DS21143A-page 1

HCS301

The HCS301 operates over a wide voltage range of

3.5 volts to 13.0 volts and has four button inputs in an

8-pin configuration. This allo ws the system designer the

freedom to utilize up to 15 functions. The only

components required for device operation are the buttons and RF circuitry, allowing a very low system cost.

1.0 SYSTEM OVERVIEW

ey Terms

K

ufacturer’s code – a 64-bit word, unique to

• Man

each manufacturer, used to produce a unique

encryption key in each transmitter (encoder).

• Encr

yption Key – a unique 64-bit key generated

and programmed into the encoder during the

manufacturing process. The encryption key

controls the encryption algorithm and is stored in

EEPROM on the encoder device.

1.1 Learn

The HCS product family facilitates several learn strategies to be implemented on the decoder. The following

are examples of what can be done. It must be pointed

out that there exists some third-party patents on learning strategies and implementation.

The HCS301 is a code hopping encoder device that is

designed specifically for keyless entry systems,

primarily for vehicles and home garage door openers. It

is meant to be a cost-effective, yet secure solution to

such systems. The encoder por tion of a keyless entry

system is meant to be held by the user and operated to

gain access to a vehicle or restricted area. The

HCS301 requires very few external components

(Figure 2-1).

1.1.1 NORMAL LEARN

The receiver uses the same information that is transmit-

ted during normal operation to derive the transmitter’s

secret key, decrypt the discrimination value and the

synchronization counter.

1.1.2 SECURE LEARN*

The transmitter is activated through a special button

combination to transmit a stored 48-bit value (random

seed) that can be used for key generation or be part of

the key. Transmission of the random seed can be disabled after learning is completed.

Most low-end keyless entry systems transmit the same

code from a transmitter every time a button is pushed.

The relative number of code combinations for a lo w end

system is also a relatively small number. These

shortcomings provide the means for a sophisticated

thief to create a device that ‘grabs’ a transmission and

re-transmits it later, or a device that scans all possible

combinations until the correct one is found.

The HCS301 employs the K

encryption algorithm to achieve a high level of security.

Code hopping is a method by which the code

transmitted from the transmitter to the receiver is

different every time a button is pushed. This method,

coupled with a transmission length of 66 bits, virtually

eliminates the use of code ‘grabbing’ or code

‘scanning’.

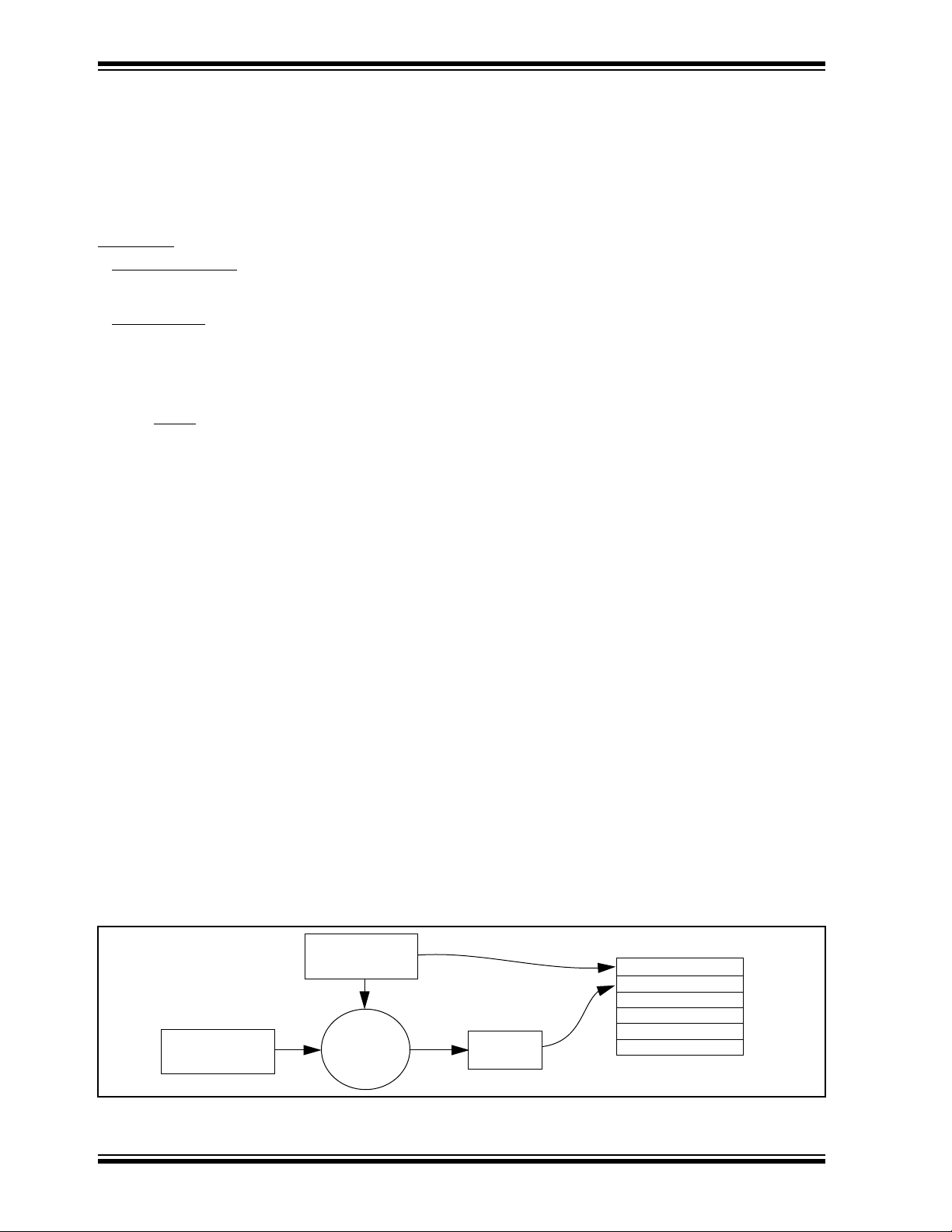

As indicated in the block diagram on page one, the

HCS301 has a small EEPROM array which must be

loaded with several parameters before use. The most

important of these values are:

• A 28-bit serial number which is meant to be

unique for every encoder

• An encryption key that is generated at the time of

production

• A 16-bit synchronization value

The serial number for each transmitter is programmed

by the manufacturer at the time of production. The

generation of the encryption key is done using a key

generation algorithm (Figure 1-1). Typically, inputs to

the key generation algorithm are the serial number of

the transmitter and a 64-bit manufacturer’s code. The

manufacturer’s code is chosen by the system

manufacturer and must be carefully controlled. The

manufacturer’s code is a pivotal part of the overall

system security.

EE

L

OQ

code hopping

FIGURE 1-1: CREATION AND STORAGE OF ENCRYPTION KEY DURING PRODUCTION

HCS301 EEPROM Array

Serial Number

Encryption Key

Sync Counter

.

.

.

1996 Microchip Technology Inc.

Manufacturer’s

EE

OQ

*K

L

learning patents pending.

DS21143A-page 2

Code

Transmitter

Serial Number

Key

Generation

Algorithm

Encryption

Key

Preliminary

HCS301

The 16-bit synchronization value is the basis for the

transmitted code changing for each transmission, and

is updated each time a button is pressed. Because of

the complexity of the code hopping algorithm, a change

in one bit of the synchronization value will result in a

large change in the actual transmitted code. There is a

relationship (Figure 1-2) between the key values in

EEPROM and how they are used in the encoder . Once

the encoder detects that a button has been pressed,

the encoder reads the button and updates the synchronization counter. The synchronization value is then

combined with the encryption key in the encryption

algorithm and the output is 32 bits of encrypted information. This data will change with every button press,

hence, it is referred to as the hopping portion of the

code word. The 32-bit hopping code is combined with

the button information and the serial number to form the

code word transmitted to the receiver. The code word

format is explained in detail in Section 4.3.

Any type of controller may be used as a receiver, but it

is typically a microcontroller with compatible firmware

that allows the receiver to operate in conjunction with a

transmitter, based on the HCS301. Section 7.0

provides more detail on integrating the HCS301 into a

total system.

Before a transmitter can be used with a particular

receiver, the transmitter must be ‘learned’ by the

receiver. Upon learning a transmitter, information is

stored by the receiver so that it may track the

transmitter, including the serial number of the

transmitter, the current synchronization value for that

transmitter and the same encryption key that is used on

the transmitter. If a receiv er receives a message of v alid

format, the serial number is checked and, if it is from a

learned transmitter, the message is decrypted and the

decrypted synchronization counter is checked against

what is stored. If the synchronization value is verified,

then the button status is checked to see what operation

is needed. Figure 1-3 shows the relationship between

some of the values stored by the receiver and the values received from the transmitter.

FIGURE 1-2: BASIC OPERATION OF TRANSMITTER (ENCODER)

Transmitted Information

EEPROM Array

Encryption Key

Sync Counter

Serial Number

KEELOQ

Encryption

Algorithm

32 Bits of

Encrypted Data

Serial Number

FIGURE 1-3: BASIC OPERATION OF RECEIVER (DECODER)

EEPROM Array

Encryption Key

Sync Counter

Serial Number

Manufacturer Code

Button Press

Information

Check for

Match

Serial Number

KEELOQ

Encryption

Algorithm

32 Bits of

Encrypted Data

Button Press

Information

Check for

Match

Decrypted

Synchronization

Counter

1996 Microchip Technology Inc.

Received Information

Preliminary

DS21143A-page 3

HCS301

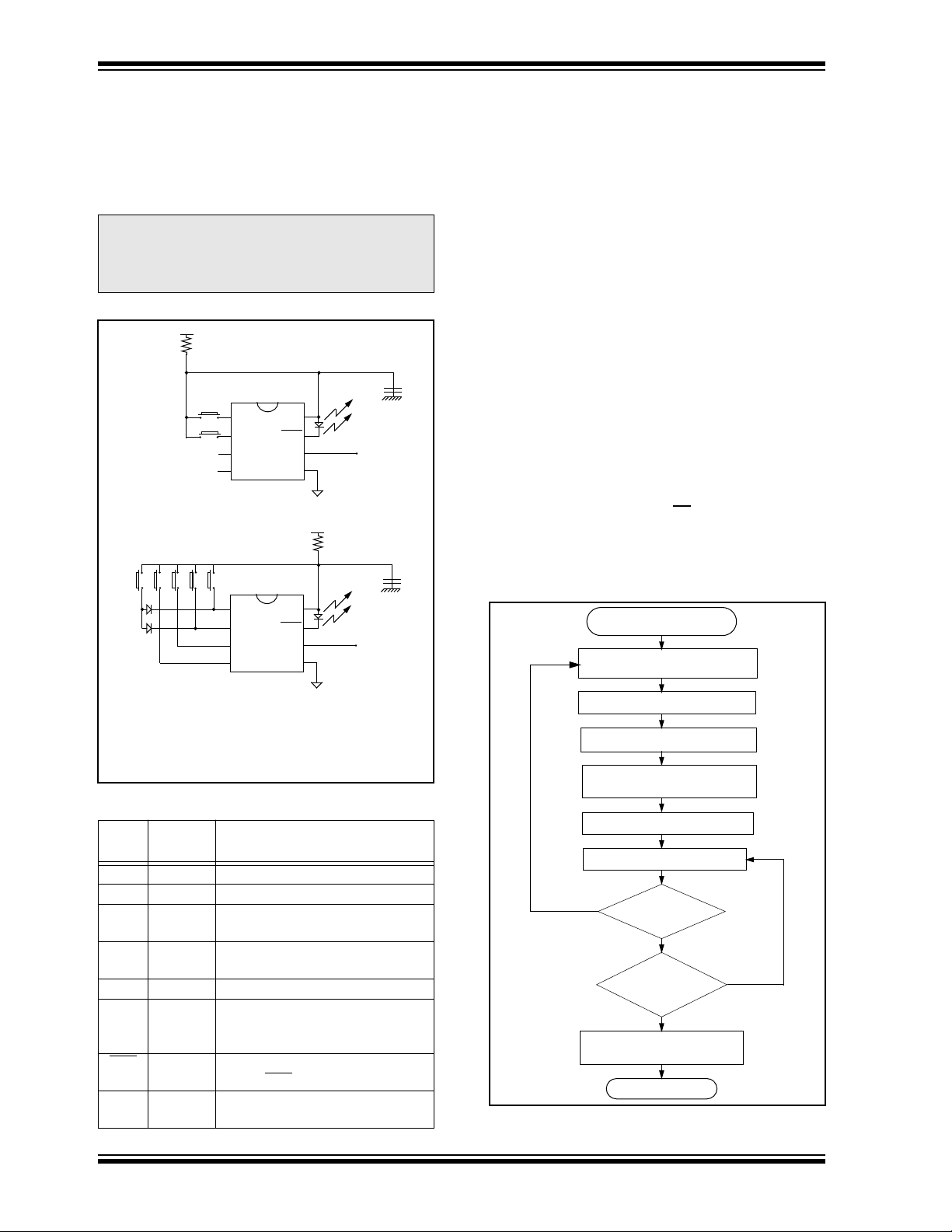

2.0 DEVICE OPERATION

As shown in the typical application circuits (Figure 2-1),

the HCS301 is a simple device to use. It requires only

the addition of buttons and RF circuitry for use as the

transmitter in your security application. A description of

each pin is described in Table 2-1.

Note: When V

loads, a resistor with a minimum value of 50 Ω

should be used in line with V

clamping of PWM at 9.0V in the event of PWM

overshoot.

FIGURE 2-1: TYPICAL CIRCUITS

(Note 2)

B0

B1

B4 B3 B2 B1 B0

DD

> 9.0V and driving low capacitive

DD

. This prevents

+12V

R

VDD

S0

VDD

S1

S2

S3

2 button remote control

LED

PWM

V

SS

(Note 2)

VDD

Tx out

+12V

R

The high security level of the HCS301 is based on the patented K

EE

L

OQ

technology . A b lock cipher based on a b lock

length of 32 bits and a key length of 64 bits is used. The

algorithm obscures the information in such a way that ev en

if the transmission information (before coding) differs by

only 1 bit from the information in the previous transmission, the next coded transmission will be totally different.

Statistically, if only 1 bit in the 32-bit string of information

changes, approximately 50 percent of the coded transmission will change. The HCS301 will wake up upon detecting

a switch closure and then delay approximately 10 ms for

switch debounce (Figure 2-2). The synchronization information, fixed information, and switch information will be

encrypted to form the hopping code. The encrypted or

hopping code portion of the transmission will change every

time, even if the same b utton is pushed again. A code that

has been transmitted will not occur again for more than

64K transmissions. This will provide more than 18 years of

typical use before a code is repeated, based on 10 operations per day. Overflow information sent from the encoder

can be used by the decoder to extend the number of

unique transmissions to more than 192K.

If, in the transmit process, it is detected that a new button(s) has been pressed, a reset will immediately be

forced and the code word will not

be completed. Please

note that buttons removed will not have any effect on the

code word unless no buttons remain pressed. In this case ,

the code word will be completed and the power down will

occur.

S0

VDD

LED

S1

PWM

S2

S3

V

SS

5 button remote control (Note1)

Note 1: Up to 15 functions can be implemented by pressing

more than one button simultaneously or by using a

suitable diode array.

Tx out

2: Resistor (R) is recommended for current limiting.

TABLE 2-1: PIN DESCRIPTIONS

Name

S0 1 Switch input 0

S1 2 Switch input 1

S2 3 Switch input 2/Can also be clock

S3 4 Switch input 3/Clock pin when in

V

SS

PWM 6 Pulse width modulation (PWM)

LED

V

DD

Pin

Number

Description

pin when in programming mode

programming mode

5 Ground reference connection

output pin/Data pin for

programming mode

7 Cathode connection for directly

driving LED

during transmission

8 Positive supply voltage

connection

FIGURE 2-2: ENCODER OPERATION

Power Up

(A button has been pressed)

Reset and Debounce Delay

Load T r ansmit Register

Yes

Word Transmission

(10 ms)

Sample Inputs

Update Sync Info

Encrypt With

Encryption Key

T r ansmit

Buttons

Added?

No

All

Buttons

Released?

Yes

Complete Code

Stop

No

DS21143A-page 4

Preliminary

1996 Microchip Technology Inc.

HCS301

3.0 EEPROM MEMORY ORGANIZATION

The HCS301 contains 192 bits (12 x 16-bit words) of

EEPROM memory (Table 3-1). This EEPROM array is

used to store the encryption key information,

synchronization value, etc. Further descriptions of the

memory array is given in the following sections.

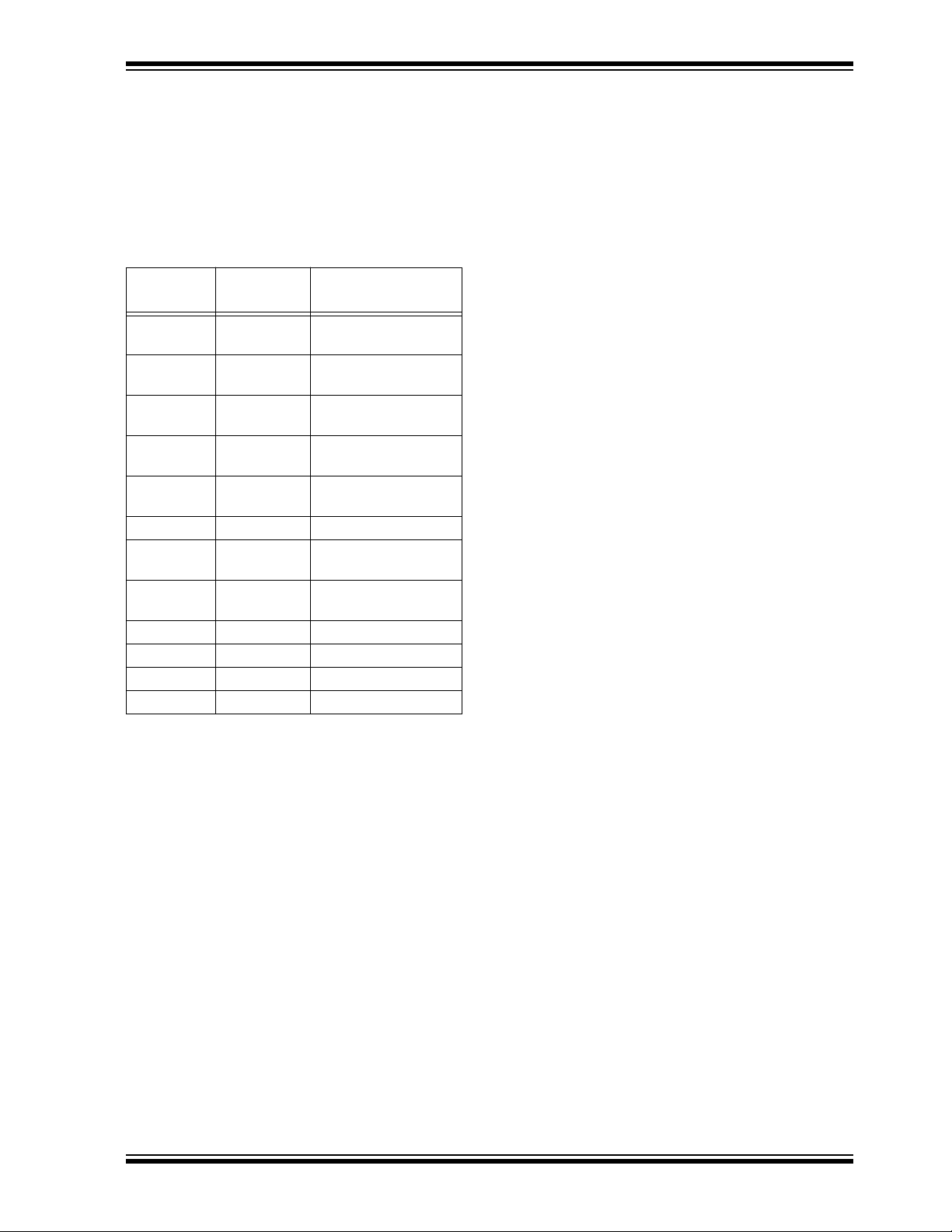

TABLE 3-1: EEPROM MEMORY MAP

WORD

ADDRESS

0 KEY_0 64-bit encryption key

1 KEY_1 64-bit encryption key

2 KEY_2 64-bit encryption key

3 KEY_3 64-bit encryption key

4 SYNC 16-bit synchronization

5 RESERVED Set to 0000H

6 SER_0 Device Serial Number

7 SER_1(Note) Device Serial Number

8 SEED_0 Seed Value (word 0)

9 SEED_1 Seed Value (word 1)

10 EN_KEY 16-bit Envelope Key

11 CONFIG Configuration Word

Note: The MSB of the serial number contains a bit

3.1 Key_0 - Key_3 (64-Bit Encryption Key)

The 64-bit encryption key is used by the transmitter to

create the encrypted message transmitted to the

receiver. This key is created and programmed at the

time of production using a key generation algorithm.

The key generation algorithm is different from the

K

encryption method. Inputs to the key generation

algorithm are the serial number for the particular

transmitter being used and the 64-bit manufacturer’s

code. While the key generation algorithm supplied from

Microchip is the typical method used, a user may elect

to create their own method of key generation. This may

be done providing that the decoder is programmed with

the same means of creating the key for

decryption purposes.

EE

L

OQ

MNEMONIC DESCRIPTION

(word 0)

(word 1)

(word 2)

(word 3)

value

(word 0)

(word 1)

used to select the auto shutoff timer.

algorithm, although it too is a proprietary

3.2 SYNC (Synchronization Counter)

This is the 16-bit synchronization value that is used to

create the hopping code for transmission. This value

will be changed after every transmission.

3.3 SER_0, SER_1 (Encoder Serial Number)

SER_0 and SER_1 are the lower and upper words of

the device serial number, respectively. Although there

are 32 bits allocated for the serial number, only the

lower order 28 bits are transmitted. The serial number

is meant to be unique for every transmitter. The most

significant bit of the serial number (Bit 31) is used to

turn the auto shutoff timer on or off.

3.3.1 AUTO-SHUTOFF TIMER SELECT

The most significant bit of the serial number (Bit 31) is

used to turn the Auto-shutoff timer on or off. This timer

prevents the transmitter from draining the battery

should a button get stuck in the on position for a long

period of time. The time period is approximately

25 seconds, after which the device will go to the

Time-out mode. When in the Time-out mode , the device

will stop transmitting, although since some circuits

within the device are still active, the current dr a w within

the Shutoff mode will be more than Standby mode. If

the most significant bit in the serial number is a one,

then the Auto-shutoff timer is enabled, and a zero in the

most significant bit will disable the timer. The length of

the timer is not selectable.

3.4 SEED_0, SEED_1 (Seed Word)

This is the two-word (32 bits) seed code that will be

transmitted when all four buttons are pressed at the same

time. This allows the system designer to implement the

secure learn feature or use this fixed code word as part of

a different key gener ation/tr ac king process .

3.5 EN_Key (Envelope Encryption Key)

Envelope encryption is a selectable option that

encrypts the portion of the transmission that contains

the transmitter serial number and function code. Selecting this option is done by setting the appropriate bit in

the configuration word (Table 3-2). Normally, the serial

number and function code are transmitted in the clear

(unencrypted), but for an added level of security, the

system designer may elect to implement this option.

The envelope encryption key is used to encrypt the

serial number and function code portion of the transmission, if the envelope encryption option has been

selected. The envelope encryption algorithm is a different algorithm than the key generation or transmit

encryption algorithm. The EN_k e y is typically a random

number and the same for all transmitters in a system.

1996 Microchip Technology Inc.

Preliminary

DS21143A-page 5

HCS301

3.6 Configuration Wor d

The configuration word is a 16-bit word stored in

EEPROM array that is used by the device to store

information used during the encryption process, as well

as the status of option configurations. Further

explanations of each of the bits are described in the

following sections.

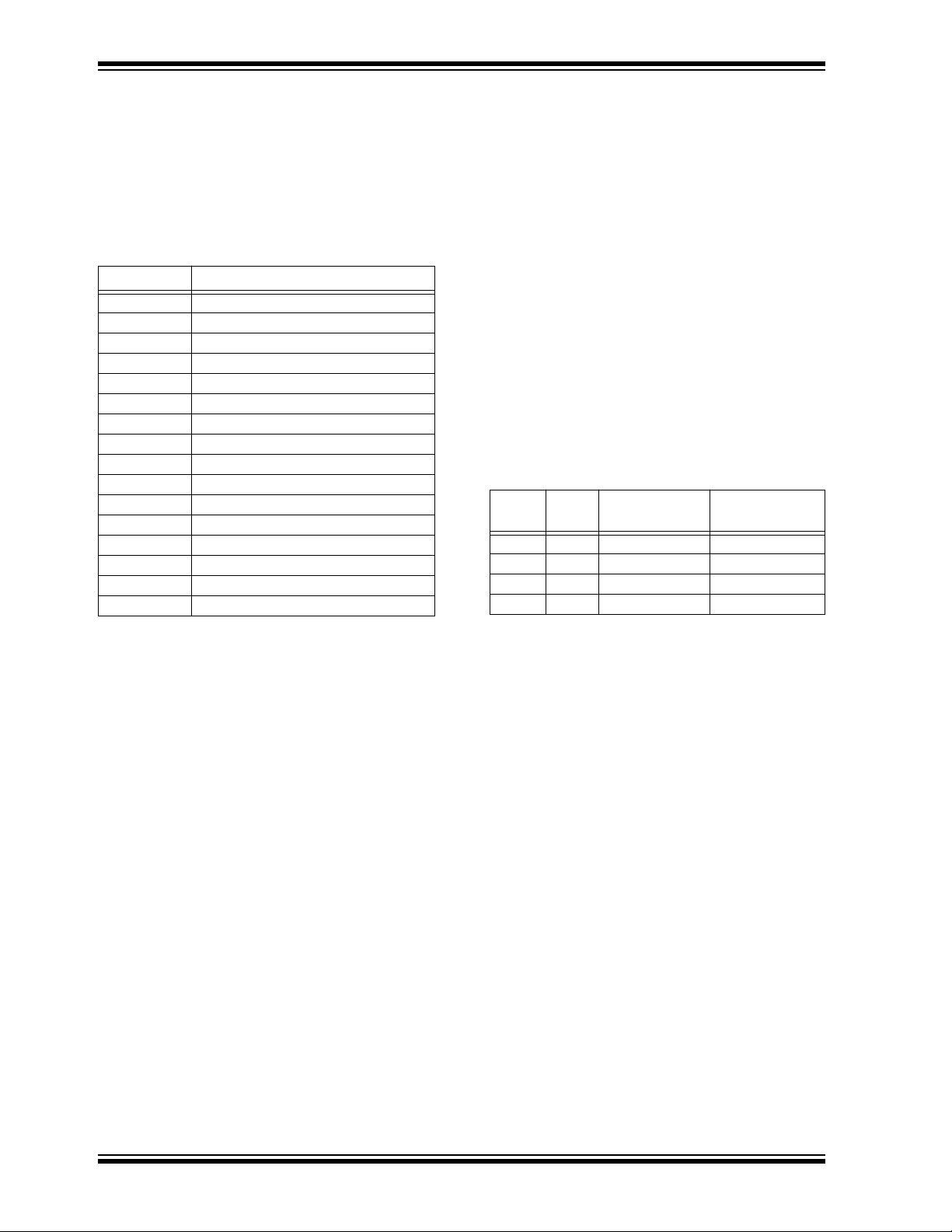

TABLE 3-2: CONFIGURATION WORD

Bit Number Bit Description

0 Discrimination Bit 0

1 Discrimination Bit 1

2 Discrimination Bit 2

3 Discrimination Bit 3

4 Discrimination Bit 4

5 Discrimination Bit 5

6 Discrimination Bit 6

7 Discrimination Bit 7

8 Discrimination Bit 8

9 Discrimination Bit 9

10 Overflow Bit 0 (OVR0)

11 Overflow Bit 1 (OVR1)

12 Low V oltage Trip Point Select

13 Baudrate Select Bit 0 (BSL0)

14 Baudrate Select Bit 1 (BSL1)

15 Envelope Encryption Select (EENC)

0x0000 and clear OVR1 the second time the counter

wraps. Once cleared, OVR0 and OVR1 cannot be set

again, thereby creating a permanent record of the

counter overflow. This prevents fast cycling of 64K

counter. If the decoder system is programmed to track

the overflow bits, then the effective number of unique

synchronization values can be extended to 196,608.

3.6.3 ENVELOPE ENCRYPTION (EENC)

If the EENC bit is set to a 1, the serial number and func-

tion code will also be encrypted so that it will appear to

be random. The 16-bit en velope k ey and env elope algorithm will be used for encryption.

3.6.4 BAUDRATE SELECT BITS (BSL0, BSL1)

BSL0 and BSL1 select the speed of transmission and

the code word blanking. Table 3-3 shows how the bits

are used to select the different baud rates and

Section 5.2 provides detailed explanation in code word

blanking.

TABLE 3-3: BAUDRATE SELECT

BSL1 BSL0

0 0 400 µ s All

0 1 200 µ s 1 out of 2

1 0 100 µ s 1 out of 2

1 1 100 µ s 1 out of 4

Basic Pulse

Element

Code Wor ds

T ransmitted

3.6.1 DISCRIMINATION VALUE (DISC0 TO DISC9)

The discrimination value can be programmed with any

value to serve as a post decryption check on the

decoder end. In a typical system, this will be

programmed with the 10 least significant bits of the

serial number or a constant value, which will also be

stored by the receiver system after a transmitter has

been learned. The discrimination bits are part of the

information that is to form the encrypted portion of the

transmission. After the receiver has decrypted a transmission, the discrimination bits can be checked against

the stored value to verify that the decryption process

was valid.

3.6.2 OVERFLOW BITS (OVR0 AND OVR1)

The overflow bits are used to e xtend the number of possible synchronization values. The synchronization

counter is 16 bits in length, yielding 65,536 values

before the cycle repeats. Under typical use of

10 operations a day, this will provide nearly 18 years of

use before a repeated value will be used. Should the

system designer conclude that is not adequate, then

the overflow bits can be utilized to e xtend the number of

unique values. This can be done by programming

OVR0 and OVR1 to 1s at the time of production. The

encoder will automatically clear OVR0 the first time that

the synchronization value wraps from 0xFFFF to

DS21143A-page 6

Preliminary

1996 Microchip Technology Inc.

HCS301

3.6.5 LOW VOLTAGE TRIP POINT SELECT

The low voltage trip point select bit is used to tell the

HCS301 what V

level is being used. This information

DD

will be used by the device to determine when to send

the voltage low signal to the receiver. When this bit is

set to a one, the V

from a 9.0 volt or 12.0 volt V

then the V

DD

level is assumed to be 6.0 volts. Refer to

level is assumed to be operating

DD

level. If the bit is set low,

DD

Figure 3-1 for voltage trip point.

The LED current limiting resistor value also affects the

LED current:

•V

LOW

•V

LOW

is tested at 3.5V and 13.0V.

LOW

V

1 (high limiting).

=

0 (low limiting).

=

FIGURE 3-1: TYPICAL VOLTAGE TRIP

POINTS (BY

CHARACTERIZATION)

Volts (V)

5.5

5.0

4.5

4.0

3.5

3.0

2.5

9.0

8.5

8.0

7.5

7.0

-40 20 40 100

-20 0 60 80

VLOW sel = 0

VLOW sel = 1

Temp (C)

V

LOW

Max

Min

Max

Min

4.0 T RANSMITTED W ORD

4.1 Transmission Format

The HCS301 transmission is made up of several parts

(Figure 4-1). Each transmission is begun with a

preamble and a header, followed by the encrypted and

then the fixed data. The actual data is 66 bits which

consists of 32 bits of encrypted data and 34 bits of fixed

data. Each transmission is followed by a guard period

before another transmission can begin. Refer to

Table 8-4 for transmission timing requirements. The

encrypted portion provides up to four billion changing

code combinations and includes the button status bits

(based on which buttons were activated) along with the

synchronization counter value and some discrimination

bits. The fixed portion is compr ised of the status bits,

the function bits and the 28-bit serial number. The fixed

and encrypted sections combined increase the number

of combinations to 7.38 x 10

4.2 Synchronous T ransmission Mode

Synchronous transmission mode can be used to clock

the code word out using an external clock.

T o enter synchronous transmission mode , the programming mode start-up sequence must be executed as

shown in Figure 4-3. If either S1 or S0 is set on the f alling edge of S2 (or S3), the device enters synchronous

transmission mode. In this mode, it functions as a normal transmitter, with the e xception that the timing of the

PWM data string is controlled externally and that 16

extra bits are transmitted at the end with he code word.

The button code will be the S0, S1 value at the falling

edge S2 or S3. The timing of the PWM data str ing is

controlled by supplying a clock on S2 or S3 and should

not exceed 20 KHz. The code word is the same as in

PWM mode with 16 reserved bits at the end of the

word. The reser ved bits can be ignored. When in synchronous transmission mode S2 or S3 should not be

toggled until all internal processing has been completed as shown in Figure 4-4.

19

.

1996 Microchip Technology Inc.

4.3 Code Wor d Organization

The HCS301 transmits a 66-bit code word when a

button is pressed. The 66-bit word is constructed from

a Fixed Code portion and an Encrypted Code por tion

(Figure 4-2).

The Encrypted Data is generated from 4 button bits, 2

overflow counter bits, 10 discrimination bits and the

16-bit sync value (Figure 8-5).

The Fixed Code Data is made up from two status bits,

four button bits and the 28-bit serial number. The four

button bits and the 28-bit serial number may be

encrypted with the Envelope Key if the envelope

encryption is enabled by the user.

Preliminary

DS21143A-page 7

HCS301

FIGURE 4-1: CODE WORD TRANSMISSION FORMAT

LOGIC ‘0’

LOGIC ‘1’

Bit

Period

Preamble

TP

Header

TH

Encrypted Portion

of Transmission

THOP

FIGURE 4-2: CODE WORD ORGANIZATION

Fixed Code Data Encrypted Code Data

Repeat

(1 bit)

VLOW

(1 bit)

1 bit of Status

1 bit Fixed

Button

Status

(4 bits)

28-bit

Serial Number

+

Serial Number and

Button Status (32 bits)

Button

Status

(4 bits)

FIGURE 4-3: SYNCHRONOUS TRANSMISSION MODE

t = 50 ms

PWM

Fixed Portion of

Transmission

+

TFIX

Discrimina-

tion bits

(12 bits)

32 bits of Encrypted Data

Guard

Time

TG

16-bit

Sync Value

66 bits

of Data

Transmitted

S2(S3)

S[1:0]

“01,10,11”

FIGURE 4-4: TRANSMISSION WORD FORMAT DURING SYNCHRONOUS TRANSMISSION MODE

Reserved Padding

Button

Code

Serial Number Data Word Sync Counter

16 2 4 28 16 16

Transmission Direction

DS21143A-page 8

Preliminary

1996 Microchip Technology Inc.

HCS301

5.0 SPECIAL FEATURES

5.1 Code Wor d Completion

Code word completion is an automatic feature that

makes sure that the entire code word is transmitted,

even if the button is released before the transmission is

complete. The HCS301 encoder powers itself up when

a button is pushed and powers itself down after the

command is finished, if the user has already released

the button. If the button is held down beyond the time

for one transmission, then multiple transmissions will

result. If another button is activated during a

transmission, the active transmission will be aborted

and the new code will be generated using the new

button information.

5.2 Blank Alternate Code Word

Federal Communications Commission (FCC) part 15

rules specify the limits on fundamental power and

harmonics that can be transmitted. Power is calculated

on the worst case average power transmitted in a

100ms window. It is therefore advantageous to

minimize the duty cycle of the transmitted word. This

can be achieved by minimizing the duty cycle of the

individual bits and by blanking out consecutive words.

Blank Alternate Code Word (BACW) is used for

reducing the average power of a transmission

(Figure 5-1). This is a selectable feature that is

determined in conjunction with the baudrate selection

bits BSL0 and BSL1. Using the BACW allows the user

to transmit a higher amplitude transmission if the

transmission length is shorter. The FCC puts

constraints on the average power that can be

transmitted by a device, and BA CW eff ectively pre v ents

continuous transmission by only allowing the transmission of every second or every fourth code word. This

reduces the average power transmitted and hence,

assists in FCC approval of a transmitter device.

5.3 Envelope Encryption Option

Envelope Encryption is a user selectable option which

is meant to offer a higher level of security for a code

hopping system. During a normal transmission with the

envelope encryption turned off, the 28-bit serial number

and function code are transmitted in the clear (unencrypted). If envelope encryption is selected, then the

serial number and function code are also encrypted

before transmission. The encryption for the serial number is done using a different algorithm than the transmission algorithm. The envelope encryption scheme is

not nearly as complex as the K

hence, not as secure. When the env elope encryption is

used, the serial number must be decrypted using the

envelope key and envelope decryption. After the serial

number is obtained, the normal decryption method can

be used to decrypt the hopping code.

EELOQ algorithm and,

FIGURE 5-1: BLANK ALTERNATE CODE WORD (BACW)

Amplitude

100ms

Time

BACW Disabled

(All words transmitted)

BACW Enabled

(1 out of 2 transmitted)

BACW Enabled

(1 out of 4 transmitted)

100ms

A

2A

4A

One Code Word

100ms

100ms

1996 Microchip Technology Inc. Preliminary DS21143A-page 9

HCS301

5.4 Secure Learn

In order to increase the level of security in a system, it is

possible for the receiver to implement what is known as

a secure learn function. This can be done b y utilizing the

seed value on the HCS301 which is stored in EEPROM

and can only be transmitted when all four button inputs

are pressed at the same time (Table 5-1). Instead of the

normal key generation method being used to create the

encryption key, this seed value is used.

TABLE 5-1: PIN ACTIVATION TABLE

S3 S2 S1 S0 Notes

10001 1

20010 1

30011 1

40100 1

50101 1

60110 1

70111 1

81000 1

91001 1

10 1 0 1 0 1

11 1 0 1 1 1

12 1 1 0 0 1

13 1 1 0 1 1

14 1 1 1 0 1

15 1 1 1 1 2

Note 1: Transmit generated 32-bit code hopping

word.

2: Transmit 32-bit seed value.

5.6 VLOW: Voltage LOW indicator

The VLOW bit is transmitted with every transmission

(Figure 8-5) and will be transmitted as a one if the

operating voltage has dropped below the low voltage

trip point. The trip point is selectable between two

values, based on the battery voltage being used. See

Section 3.6.5 for a description of how the low voltage

select option is set. This VLOW signal is transmitted so

the receiver can alert the user that the transmitter battery is low.

5.7 RPT: Repeat indicator

This bit will be low for the first transmitted word. If a

button is held down for more than one transmitted code

word, this bit will be set to indicate a repeated code

word and remain set until the button is released.

5.8 LED Output Operation

During normal transmission the LED output is LOW. If

the supply voltage drops below the low voltage trip

point, the LED

5 Hz during the transmission (Section 3.6.5). The limiting resistor is selectable between two nominal values

(Section 3.6.5).

output will be toggled at approximately

5.5 Auto-shutoff

The Auto-shutoff function automatically stops the

device from transmitting if a button inadvertently gets

pressed for a long period of time. This will prevent the

device from draining the battery if a button gets pressed

while the transmitter is in a pocket or purse. This function can be enabled or disabled and is selected by setting or clearing the Auto-shutoff bit (Section 3.3.1).

Setting this bit high will enable the function (turn

Auto-shutoff function on) and setting the bit low will disable the function. Time-out period is approximately 25

seconds.

DS21143A-page 10 Preliminary 1996 Microchip Technology Inc.

HCS301

6.0 PROGRAMMING THE HCS301

When using the HCS301 in a system, the user will have

to program some parameters into the device including

the serial number and the secret key before it can be

used. The programming cycle allows the user to input

all 192 bits in a serial data stream, which are then

stored internally in EEPROM. Programming will be

initiated by forcing the PWM line high, after the S3 line

has been held high for the appropriate length of time

line (Table 6-1 and Figure 6-1). After the program mode

is entered, a delay must be provided to the device for

the automatic bulk write cycle to complete. This will

write all locations in the EEPROM to an all zeros pattern. The device can then be programmed by clocking

in 16 bits at a time, using S3 as the clock line and PWM

FIGURE 6-1: PROGRAMMING WAVEFORMS

S3

(Clock)

PWM

(Data)

Enter Program

Mode

TPS

TPH1

T

PBW

TCLKH

TDS

TCLKL

Bit 0 Bit 1 Bit 2 Bit 3 Bit 14 Bit 15 Bit 16 Bit 17

as the data in line. After each 16-bit word is loaded, a

programming delay is required for the internal program

cycle to complete. This delay can take up to Twc. At the

end of the programming cycle, the device can be verified (Figure 6-2) by reading back the EEPROM. Reading is done by clocking the S3 line and reading the data

bits on PWM. For security reasons, it is not possible to

execute a verify function without first programming the

EEPROM. A verify operation can only be done

immediately following the program cycle.

Note: To ensure that the device does not acci-

dentally enter programming mode (resulting in a bulk erase), PWM should never be

pulled high by the circuit connected to it.

Special care should be taken when driving

PNP RF transistors.

TWC

TDH

TPH2

Data for Word 0 (KEY_0)

Repeat 12 times for each word

Note 1: Unused button inputs to be held ground during the entire programming sequence.

2: The V

DD pin must be taken to ground after a programming/verify cycle.

FIGURE 6-2: VERIFY WAVEFORMS

End of

Programming Cycle

PWM

(Data)

S3

(Clock)

Note: If a verify operation is to be done, then it must immediately follow the program cycle.

Begin Verify Cycle Here

Bit 0Bit191Bit190

TWC

Data in Word 0

Bit 1 Bit 2 Bit 3 Bit 15Bit 14 Bit 16 Bit 17 Bit190 Bit191

TDV

TABLE 6-1: PROGRAMMING/VERIFY TIMING REQUIREMENTS

VDD = 5.0V ± 10%

25° C ± 5 °C

Parameter Symbol Min. Max. Units

Program mode setup time T

Hold time 1 T

Hold time 2 T

Bulk Write time T

Program delay time T

Program cycle time T

Clock low time T

Clock high time T

Data setup time T

Data hold time T

Data out valid time T

PS 3.5 4.5 ms

PH1 3.5 — ms

PH250 — µs

PBW — 2.2 ms

PROG — 2.2 ms

WC —36ms

CLKL 25 — µs

CLKH 25 — µs

DS 0—µs

DH 18 — µs

DV 10 24 µs

Data for Word 1

1996 Microchip Technology Inc. Preliminary DS21143A-page 11

HCS301

7.0 INTEGRATING THE HCS301 INTO A SYSTEM

Use of the HCS301 in a system requires a compatible

decoder. This decoder is typically a microcontroller with

compatible firmware. Microchip will provide (via a

license agreement) firmware routines that accept

transmissions from the HCS301 and decrypt the

hopping code portion of the data stream. These

routines provide system designers the means to

develop their own decoding system.

7.1 Learning a transmitter to a receiver

In order for a transmitter to be used with a decoder , the

transmitter must first be ‘learned’. Several learning

strategies can be followed in the decoder implementation. When a transmitter is lear ned to a decoder, it is

suggested that the decoder stores the serial number

and current synchronization value in EEPROM. The

decoder must keep track of these values for every

transmitter that is learned (Figure 7-1). The maximum

number of transmitters that can be learned is only a

function of how much EEPROM memory storage is

available. The decoder must also store the manufacturer’s code in order to learn a transmission transmitter ,

although this value will not change in a typical system

so it is usually stored as part of the microcontroller

ROM code. Storing the manufacturer’s code as part of

the ROM code is also better for security reasons.

It must be stated that some learning strategies have

been patented and care must be taken not to infringe.

FIGURE 7-1: TYPICAL LEARN SEQUENCE

Enter Learn

Mode

Wait for Reception

of a Valid Code

Generate Key

from Serial Number

Use Generated Key

to Decrypt

Compare Discrimination

Value with Fixed Value

Equal

?

Yes

Wait for Reception

of Second Valid Code

Use Generated Key

to Decrypt

Compare Discrimination

Value with Fixed Value

Equal

?

Yes

No

No

Counters

Sequential

?

Yes

Learn successful Store:

Serial number

Encryption key

Synchronization counter

Exit

No

Learn

Unsuccessful

DS21143A-page 12 Preliminary 1996 Microchip Technology Inc.

HCS301

7.2 Decoder operation

In a typical decoder operation (Figure 7-2), the key generation on the decoder side is done by taking the serial

number from a transmission and combining that with

the manufacturer’s code to create the same secret key

that was used by the transmitter . Once the secret key is

obtained, the rest of the transmission can be decrypted.

The decoder waits for a transmission and immediately

can check the serial number to determine if it is a

learned transmitter. If it is, it tak es the encrypted portion

of the transmission and decrypts it using the stored key .

It uses the discrimination bits to determine if the

decryption was valid. If everything up to this point is

valid, the synchronization value is evaluated.

FIGURE 7-2: TYPICAL DECODER

OPERATION

Start

No

Transmission

Received

?

Yes

No

Decrypt T ransmission

Does

Serial Number

Match

?

Yes

7.3 Synchronization with Decoder

The KEELOQ technology features a sophisticated

synchronization technique (Figure 7-3) which does not

require the calculation and storage of future codes. If

the stored counter value for that particular transmitter

and the counter value that was just decrypted are within

a formatted window of say 16, the counter is stored and

the command is executed. If the counter value was not

within the single operation window, but is within the

double operation window of say 32K window, the transmitted synchronization value is stored in temporary

location and it goes back to waiting for another transmission. When the next valid transmission is received,

it will check the new value with the one in temporary

storage. If the two values are sequential, it is assumed

that the counter had just gotten out of the single operation ‘window’, but is now back in sync, so the new synchronization value is stored and the command

executed. If a transmitter has somehow gotten out of

the double operation window, the transmitter will not

work and must be re-learned. Since the entire window

rotates after each valid transmission, codes that have

been used are part of the ‘block ed’ (32K) codes and are

no longer valid. This eliminates the possibility of grabbing a previous code and re-transmitting to gain entry.

Note: The synchronization method described in

this section is only a typical implementation

and because it is usually implemented in

firmware, it can be altered to fit the needs

of a particular system

FIGURE 7-3: SYNCHRONIZATION WINDOW

No

Decryption

Valid

No

No

Counter

Within 16

Counter

Within 32K

Save Counter

in T emp Location

Is

?

Yes

Is

?

No

Is

?

Yes

Yes

Execute

Command

and

Update

Counter

Entire Window

rotates to eliminate

use of previously

used codes

Blocked 32K

Codes

Open 32K

Codes

Current

Position

Current window

of 16 codes

1996 Microchip Technology Inc. Preliminary DS21143A-page 13

HCS301

8.0 ELECTRICAL CHARACTERISTICS

TABLE 8-1: ABSOLUTE MAXIMUM RATINGS

Symbol Item Rating Units

DD Supply voltage -0.3 to 13.3 V

V

IN Input voltage -0.3 to 13.3 V

V

OUT Output voltage -0.3 to VDD + 0.3 V

V

OUT Max output current 25 mA

I

STG Storage temperature -55 to +125 °C (Note)

T

LSOL Lead soldering temp 300 °C (Note)

T

ESD ESD rating 4000 V

V

Note: Stresses above those listed under “ABSOLUTE MAXIMUM RATINGS” ma y cause permanent damage to the

device.

TABLE 8-2: DC CHARACTERISTICS

Commercial (C): Tamb = 0°C to +70°C

Industrial (I): Tamb = -40°C to +85°C

3.5V < V

DD < 13.0V

Parameter Sym. Min Typ* Max Unit Conditions

Operating current (avg) I

Standby current I

High level Input voltage V

Low level input voltage V

High level output voltage V

Low level output voltage V

sink current ILED 3.5

LED

Resistance; S0-S3 R

Resistance; PWM R

* Typical values are at 25°C.

CC 0.6

CCS 110µA

IH 0.4 VDD VDD+

IL -0.3 0.15 VDD V

OH 0.5VDD VIOH = -2 mA

OL 0.08 VDD VIOL = 2 mA

S0-3 40 60 80 KΩ VIN = 4.0V

PWM 80 120 160 KΩ VIN = 4.0V

2.7

1.5

8.0

4.7

3.7

1.0

3.0

12.0

0.3

5.9

4.6

VDD = 3.5V

mA

V

DD = 6.6V

V

DD = 13.0V

(Figure 8-1)

V

mA VDD = 6.6V, Vlow source = 0

V

DD = 13.0V, Vlow source = 1

DS21143A-page 14 Preliminary 1996 Microchip Technology Inc.

FIGURE 8-1: TYPICAL ICC CURVE OF HCS301 WITH EXTERNAL RESISTORS

50Ω External

12.0

10.0

8.0

6.0

mA

4.0

2.0

0.0

23456789 1112

VBAT [V]

1K External

12.0

10

HCS301

13

mA

mA

10.0

8.0

6.0

4.0

2.0

0.0

2 3 4 5 6 7 8 9 11121310

VBAT [V]

2K External

12.0

10.0

8.0

6.0

4.0

2.0

0.0

2 3 4 5 6 7 8 9 11121310

VBAT [V]

LEGEND

Typical

Maximum

Minimum

1996 Microchip Technology Inc. Preliminary DS21143A-page 15

HCS301

FIGURE 8-2: POWER UP AND TRANSMIT TIMING

Button Press

PWM

Sn

Detect

DB

T

TTD

T

BP

Code

Word

1

TABLE 8-3: POWER UP AND TRANSMIT TIMING REQUIREMENTS

VDD = +3.5 to13.0V

Commercial (C): Tamb = 0°C to +70°C

Industrial (I): Tamb = -40°C to +85°C

Code Word Transmission

Code

Word

2

TTO

Code

Word

3

Code

Word

n

Parameter Symbol Min Max Unit Remarks

Time to second button press T

Transmit delay from button detect T

Debounce delay T

Auto-shutoff time-out period T

Note 1: TBP is the time in which a second button can be pressed without completion of the first code word and the

intention was to press the combination of buttons.

2: The auto shutoff timeout period is not tested.

BP 10 + Code

Word Time

TD 10 25 ms

DB 615ms

TO 20 40 s

25 + Code

Word Time

ms

(Note 1)

(Note 2)

FIGURE 8-3: PWM FORMAT

TE

TE

TE

LOGIC ‘0’

LOGIC ‘1’

TBP

Preamble

TP

Header

TH

Encrypted Portion

of Transmission

THOP

Fixed portion of

Transmission

TFIX

Guard

Time

TG

FIGURE 8-4: PREAMBLE/HEADER FORMAT

Data Word

P0

DS21143A-page 16 Preliminary 1996 Microchip Technology Inc.

Preamble Header

P12

23 TE

10 TE

Transmission

Bit 0 Bit 1

FIGURE 8-5: DATA WORD FORMAT

LSB

LSB

MSB MSB S3 S0 S1 S2 VLOW RPT

HCS301

Serial Number Button Code Status

Header

Bit 0 Bit 1

Hopping Code Word

Bit 30

Bit 31 Bit 32 Bit 33 Bit 58 Bit 59

Bit 60

Bit 61

Fixed Code Word

Bit 62 Bit 63 Bit 64 Bit 65

TABLE 8-4: CODE WORD TRANSMISSION TIMING REQUIREMENTS

VDD = +3.5 to 13.0

Commercial (C): Tamb = 0°C to +70°C

Industrial (I): Tamb = -40°C to +85°C

Symbol Characteristic

Number

of T

Min. Typ. Max. Min. Typ. Max. Min. Typ. Max. Units

E

All 1 out of 2 1 out of 4

TE Basic pulse element 1 280 400 620 140 200 310 70 100 155 µs

BP PWM bit pulse width 3 840 1200 1860 420 600 930 210 300 465 µs

T

P Preamble duration 23 6.4 9.2 14.3 3.2 4.6 7.1 1.6 2.3 3.6 ms

T

H Header duration 10 2.8 4.0 6.2 1.4 2.0 3.1 0.7 1.0 1.6 ms

T

HOP Hopping code duration 96 26.9 38.4 59.5 13.4 19.2 29.8 6.7 9.6 14.9 ms

T

FIX Fixed code duration 102 28.6 40.8 63.2 14.3 20.4 31.6 7.1 10.2 15.8 ms

T

G Guard Time 39 10.9 15.6 24.2 5.5 7.8 12.1 2.7 3.9 6.0 ms

T

— T otal Transmit Time 270 75.6 108.0 167.4 37.8 54.0 83.7 18.9 27.0 41.9 ms

— PWM data rate — 1190 833 538 2381 1667 1075 4762 3333 2151 bps

Note: The timing parameters are not tested but derived from the oscillator clock.

Code Wor ds T ransmitted

Guard

Time

FIGURE 8-6: HCS301 TE VS. TEMP (BY CHARACTERIZATION ONLY)

1.7

1.6

1.5

1.4

1.3

1.2

TE

1.1

1.0

0.9

0.8

0.7

0.6

-50 -40 -30 -20 -10 0 10 20 30 40 50 60 70 80 90

TE Max.

VDD = 3.5V

VDD ≥ 5.0V

TE Max.

VDD = 5.0V

Typical

VDD ≥ 5.0V

TE Min.

TEMPERATURE

1996 Microchip Technology Inc. Preliminary DS21143A-page 17

HCS301

NOTES:

DS21143A-page 18 Preliminary 1996 Microchip Technology Inc.

NOTES:

HCS301

1996 Microchip Technology Inc. Preliminary DS21143A-page 19

HCS301

HCS301 Product Identification System

To order or to obtain information (e.g., on pricing or delivery), please use the listed part numbers, and refer to the factory or the listed

sales offices.

HCS301 - /P

Package: P = Plastic DIP (300 mil Body), 8-lead

SN = Plastic SOIC (150 mil Body), 8-lead

Temperature Blank = 0°C to +70°C

Range: I = -40°C to +85°C

AMERICAS

Corporate Office

Microchip T echnology Inc.

2355 West Chandler Blvd.

Chandler, AZ 85224-6199

Tel: 602 786-7200 Fax: 602 786-7277

Technical Support:

Web:

http://www.microchip.com

Atlanta

Microchip T echnology Inc.

500 Sugar Mill Road, Suite 200B

Atlanta, GA 30350

Tel: 770 640-0034 Fax: 770 640-0307

Boston

Microchip T echnology Inc.

5 Mount Royal Avenue

Marlborough, MA 01752

Tel: 508 480-9990 Fax: 508 480-8575

Chicago

Microchip T echnology Inc.

333 Pierce Road, Suite 180

Itasca, IL 60143

Tel: 708 285-0071 Fax: 708 285-0075

Dallas

Microchip T echnology Inc.

14651 Dallas Parkway, Suite 816

Dallas, TX 75240-8809

Tel: 214 991-7177 Fax: 214 991-8588

Dayton

Microchip T echnology Inc.

Suite 150

Two Prestige Place

Miamisburg, OH 45342

Tel: 513 291-1654 Fax: 513 291-9175

Los Angeles

Microchip T echnology Inc.

18201 Von Karman, Suite 1090

Irvine, CA 92715

Tel: 714 263-1888 Fax: 714 263-1338

New Y ork

Microchip T echnology Inc.

150 Motor Parkway, Suite 416

Hauppauge, NY 11788

Tel: 516 273-5305 Fax: 516 273-5335

602 786-7627

Device:

HCS301

HCS301T

AMERICAS (CON’T)

San Jose

Microchip T echnology Inc.

2107 North First Street, Suite 590

San Jose, CA 95131

Tel: 408 436-7950 Fax: 408 436-7955

Toronto

Microchip T echnology Inc.

5925 Airport Road, Suite 200

Mississauga, Ontario L4V 1W1, Canada

Tel: 905 405-6279Fax: 905 405-6253

ASIA/PACIFIC

Hong Kong

Microchip T echnology

RM 3801B, Tower Two

Metroplaza

223 Hing Fong Road

Kwai Fong, N.T. Hong Kong

Tel: 852 2 401 1200 Fax: 852 2 401 3431

Korea

Microchip T echnology

168-1, Youngbo Bldg. 3 Floor

Samsung-Dong, Kangnam-Ku,

Seoul, Korea

Tel: 82 2 554 7200 Fax: 82 2 558 5934

Singapore

Microchip T echnology

200 Middle Road

#10-03 Prime Centre

Singapore 188980

Tel: 65 334 8870 Fax: 65 334 8850

Taiwan

Microchip T echnology

10F-1C 207

Tung Hua North Road

T aipei, Taiwan, ROC

Tel: 886 2 717 7175 Fax: 886 2 545 0139

Code Hopping Encoder

Code Hopping Encoder (Tape and Reel)

EUROPE

United Kingdom

Arizona Microchip Technology Ltd.

Unit 6, The Courtyard

Meadow Bank, Furlong Road

Bourne End, Buckinghamshire SL8 5AJ

Tel: 44 1628 851077 Fax: 44 1628 850259

France

Arizona Microchip Technology SARL

Zone Industrielle de la Bonde

2 Rue du Buisson aux Fraises

91300 Massy - France

Tel: 33 1 69 53 63 20 Fax: 33 1 69 30 90 79

Germany

Arizona Microchip Technology GmbH

Gustav-Heinemann-Ring 125

D-81739 Muenchen, Germany

Tel: 49 89 627 144 0 Fax: 49 89 627 144 44

Italy

Arizona Microchip Technology SRL

Centro Direzionale Colleoni

Palazzo Pegaso Ingresso No. 2

Via Paracelso 23, 20041

Agrate Brianza (MI) Italy

Tel: 39 39 689 9939 Fax: 39 39 689 9883

JAPAN

Microchip Technology Intl. Inc.

Benex S-1 6F

3-18-20, Shin Yokohama

Kohoku-Ku, Yokohama

Kanagawa 222 Japan

Tel: 81 45 471 6166 Fax: 81 45 471 6122

6/14/96

All rights reserved.

1996, Microchip Technology Inc.,USA., 6/96

Information contained in this publication regarding device applications and the like is intended through suggestion only and may be superseded by updates. No representation or warranty is given and no liability is assumed by Microchip Technology Incorporated with respect to the accuracy or use of such information, or infringement

of patents or other intellectual property rights arising from such use or otherwise. Use of Microchip’s products as critical components in life support systems is not authorized except with express written approval by Microchip . No licenses are conveyed, implicitly or otherwise, under any intellectual property rights. The Microchip logo and

name are registered trademarks of Microchip Technology Inc. All rights reserved. All other trademarks mentioned herein are the property of their respective companies.

DS21143A-page 20 Preliminary 1996 Microchip Technology Inc.

Loading...

Loading...