Page 1

PIC18F2XX0/2X21/2XX5/

4XX0/4X21/4XX5

Flash Microcontroller Programming Specification

1.0 DEVICE OVERVIEW

This document includes the programming specifications

for the following devices:

• PIC18F2221 • PIC18F4221

• PIC18F2321 • PIC18F4321

• PIC18F2410 • PIC18F4410

• PIC18F2420 • PIC18F4420

• PIC18F2455 • PIC18F4455

• PIC18F2480 • PIC18F4480

• PIC18F2510 • PIC18F4510

• PIC18F2515 • PIC18F4515

• PIC18F2520 • PIC18F4520

• PIC18F2525 • PIC18F4525

• PIC18F2550 • PIC18F4550

• PIC18F2580 • PIC18F4580

• PIC18F2585 • PIC18F4585

• PIC18F2610 • PIC18F4610

• PIC18F2620 • PIC18F4620

• PIC18F2680 • PIC18F4680

2.0 PROGRAMMING OVERVIEW

PIC18F2XX0/2X21/2XX5/4XX0/4X21/4XX5 devices

can be programmed using either the high-voltage

In-Circuit Serial Programming™ (ICSP™) method or

the low-voltage ICSP method. Both methods can be

done with the device in the users’ system. The

low-voltage ICSP method is slightly different than the

high-voltage method and these differences are noted

where applicable. This programming specification

applies to PIC18F2XX0/2X21/2XX5/4XX0/4X21/4XX5

devices in all package types.

2.1 Hardware Requirements

In High-Voltage ICSP mode, PIC18F2XX0/2X21/2XX5/

4XX0/4X21/4XX5 devices require two programmable

power supplies: one for VDD and one for MCLR/VPP/

RE3. Both supplies should have a minimum resolution

of 0.25V. Refer to Section 6.0 “AC/DC Characteris-

tics Timing Requirements for Program/Verify Test

Mode” for additional hardware parameters.

2.1.1 LOW-VOLTAGE ICSP PROGRAMMING

In Low-Voltage ICSP mode, PIC18F2XX0/2X21/2XX5/

4XX0/4X21/4XX5 devices can be programmed using a

VDD source in the operating range. The MCLR/VPP/

RE3 does not have to be brought to a different voltage,

but can instead be left at the normal operating voltage.

Refer to Section 6.0 “AC/DC Characteristics Timing

Requirements for Program/Verify Test Mode” for

additional hardware parameters.

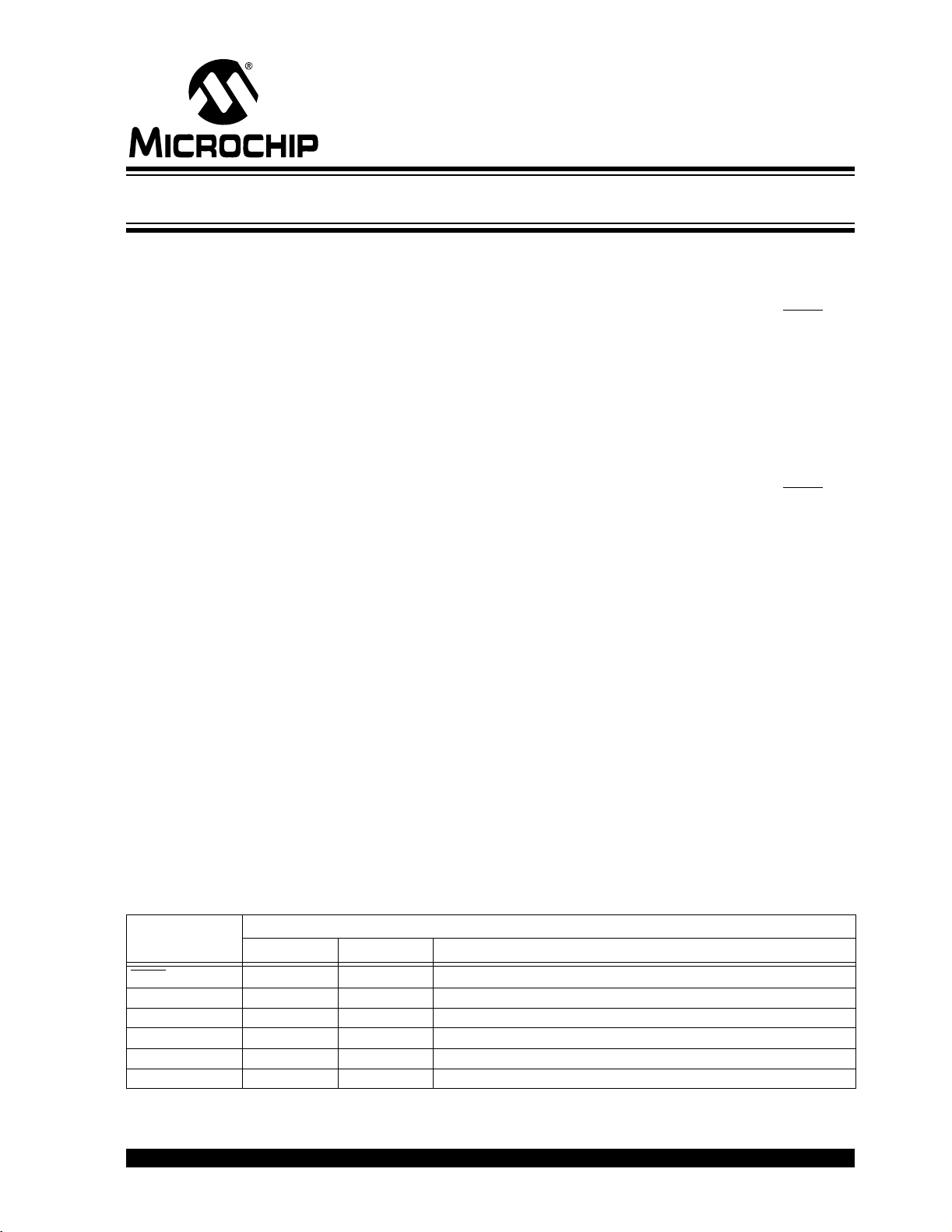

2.2 Pin Diagrams

The pin diagrams for the PIC18F2XX0/2X21/2XX5/

4XX0/4X21/4XX5 family are shown in Figure 2-1 and

Figure 2-2.

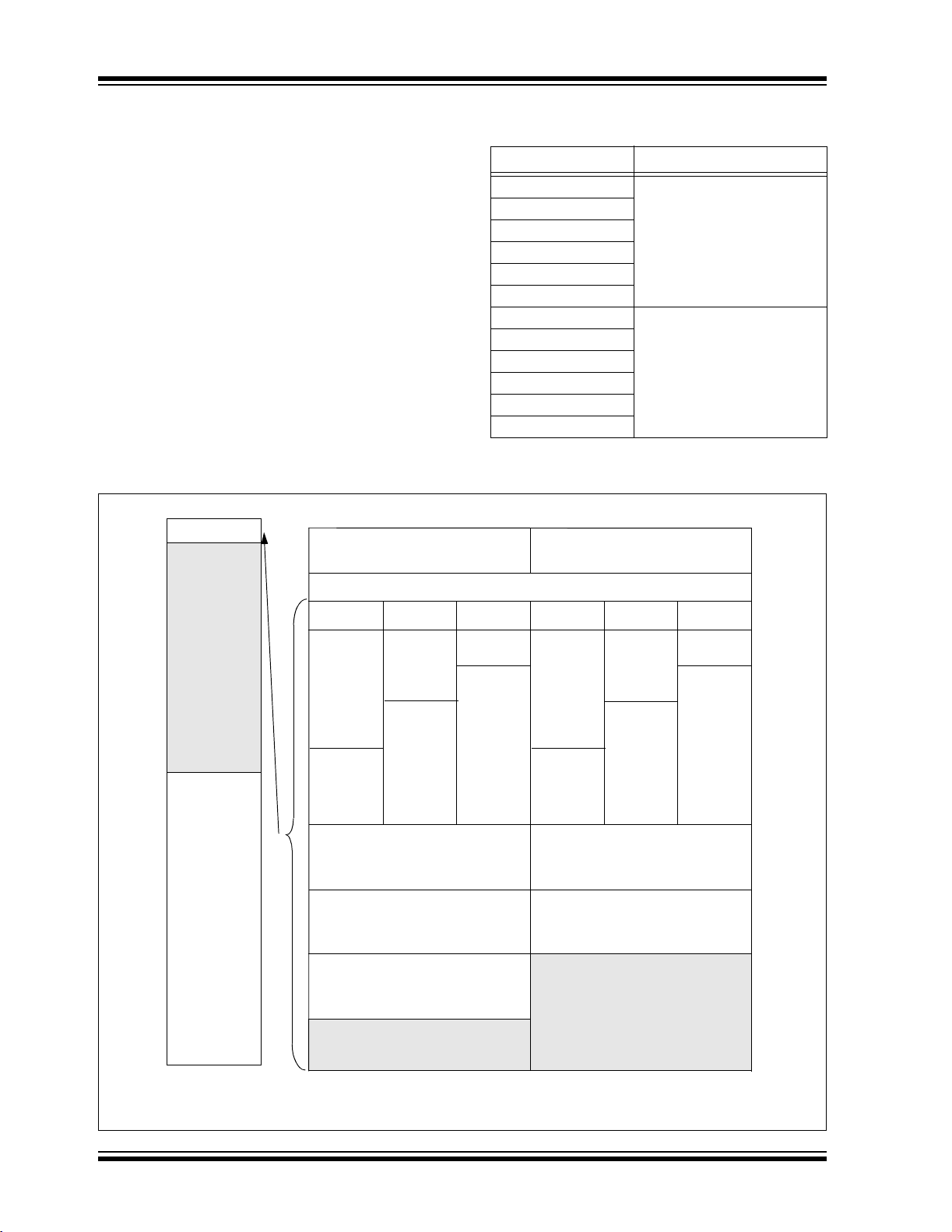

TABLE 2-1: PIN DESCRIPTIONS (DURING PROGRAMMING):

PIC18F2XX0/2X21/2XX5/4XX0/4X21/4XX5

Pin Name

MCLR

/VPP/RE3 VPP P Programming Enable

(2)

DD

V

(2)

V

SS

RB5 PGM I Low-Voltage ICSP™ Input when LVP

RB6 PGC I Serial Clock

RB7 PGD I/O Serial Data

Legend: I = Input, O = Output, P = Power

Note 1: See Figure 5-1

2: All power supply (V

© 2005 Microchip Technology Inc. DS39622E-page 1

Pin Name Pin Type Pin Description

VDD P Power Supply

VSS P Ground

for more information.

DD) and ground (VSS) pins must be connected.

During Programming

Configuration bit equals ‘1’

(1)

Page 2

PIC18F2XX0/2X21/2XX5/4XX0/4X21/4XX5

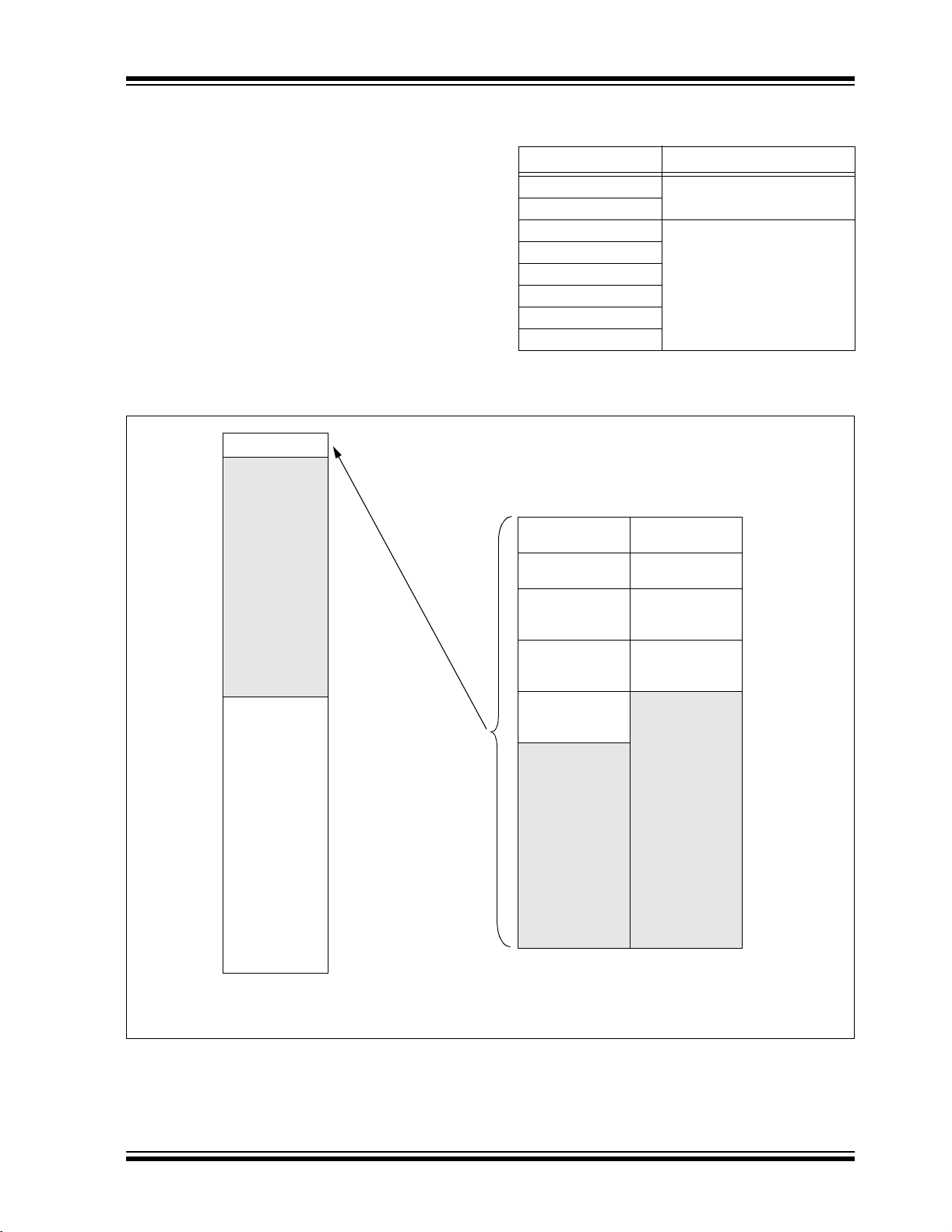

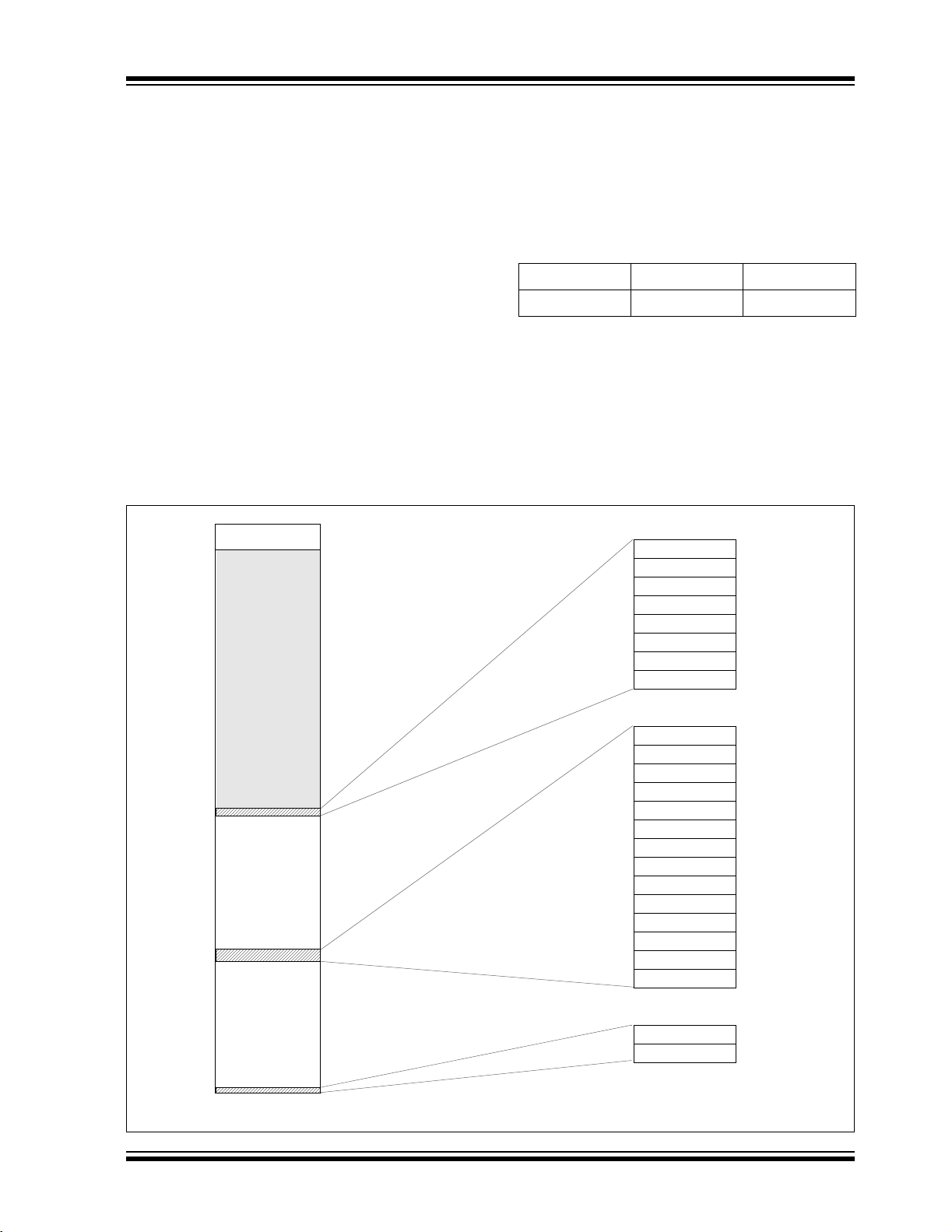

FIGURE 2-1: PIC18F2XX0/2X21/2XX5/4XX0/4X21/4XX5 FAMILY PIN DIAGRAMS

28-Pin SDIP, SOIC (300 MIL)

RB7/PGD

RB6/PGC

RB5/PGM

RB4

RB3

RB2

RB1

RB0

V

DD

VSS

RC7

RC6

RC5

RC4

The following devices are included in

28-pin SDIP and SOIC parts:

• PIC18F2221 • PIC18F2520

• PIC18F2321 • PIC18F2525

• PIC18F2410 • PIC18F2550

• PIC18F2420 • PIC18F2580

• PIC18F2455 • PIC18F2585

• PIC18F2480 • PIC18F2610

• PIC18F2510 • PIC18F2620

• PIC18F2515 • PIC18F2680

MCLR/VPP/RE3

RA0

RA1

RA2

RA3

RA4

RA5

V

OSC1

OSC2

RC0

RC1

RC2

RC3

PIC18F2XXX

28

27

26

25

24

23

22

21

20

19

18

17

16

15

1

2

3

4

5

6

SS

7

8

9

10

11

12

13

14

28-Pin QFN

The following devices are included in

28-pin QFN parts:

• PIC18F2221 • PIC18F2480

• PIC18F2321 • PIC18F2510

• PIC18F2410 • PIC18F2520

• PIC18F2420 • PIC18F2580

40-Pin PDIP (600 MIL)

The following devices are included in

40-pin PDIP parts:

• PIC18F4221 • PIC18F4520

• PIC18F4321 • PIC18F4525

• PIC18F4410 • PIC18F4550

• PIC18F4420 • PIC18F4580

• PIC18F4455 • PIC18F4585

• PIC18F4480 • PIC18F4610

• PIC18F4510 • PIC18F4620

• PIC18F4515 • PIC18F4680

RA2

RA3

RA4

RA5

V

OSC1

OSC2

MCLR/VPP/RE3

RA0

RA1

RA2

RA3

RA4

RA5

RE0

RE1

RE2

V

DD

VSS

OSC1

OSC2

RC0

RC1

RC2

RC3

RD0

RD1

/VPP/RE3

RB7/PGD

RB6/PGC

RB5/PGM

232425262728

12 13 14

RC4

RC3

PIC18F4XXX

22

RC5

RB4

21

20

19

18

17

16

15

RC6

40

39

38

37

36

35

34

33

32

31

30

29

28

27

26

25

24

23

22

21

RB3

RB2

RB1

RB0

V

DD

VSS

RC7

RB7/PGD

RB6/PGC

RB5/PGM

RB4

RB3

RB2

RB1

RB0

V

DD

VSS

RD7

RD6

RD5

RD4

RC7

RC6

RC5

RC4

RD3

RD2

RA0

RA1

MCLR

1

2

PIC18F2X21

3

PIC18F24X0

SS

4

5

PIC18F25X0

6

7

10 11

8

9

RC0

RC1

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

RC2

DS39622E-page 2 © 2005 Microchip Technology Inc.

Page 3

PIC18F2XX0/2X21/2XX5/4XX0/4X21/4XX5

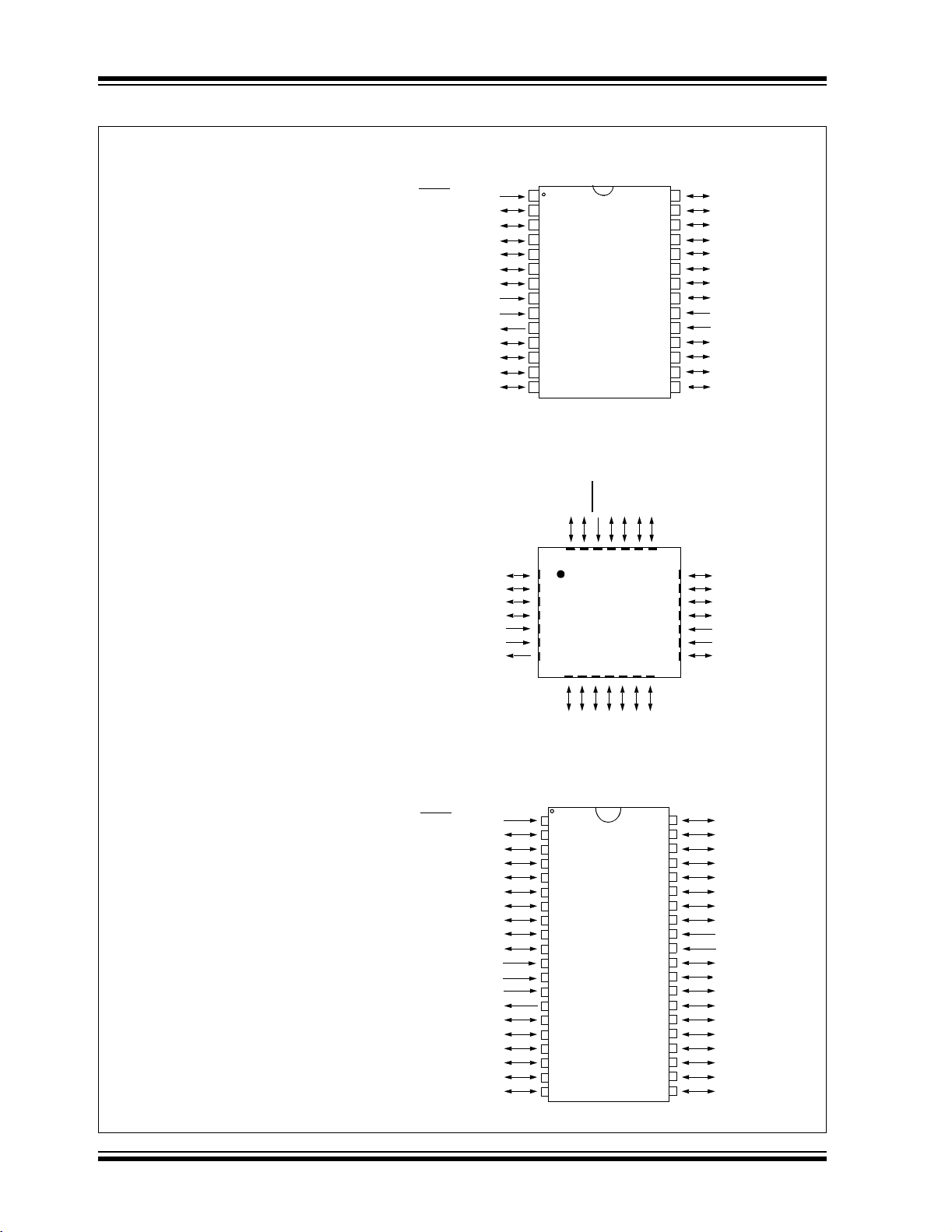

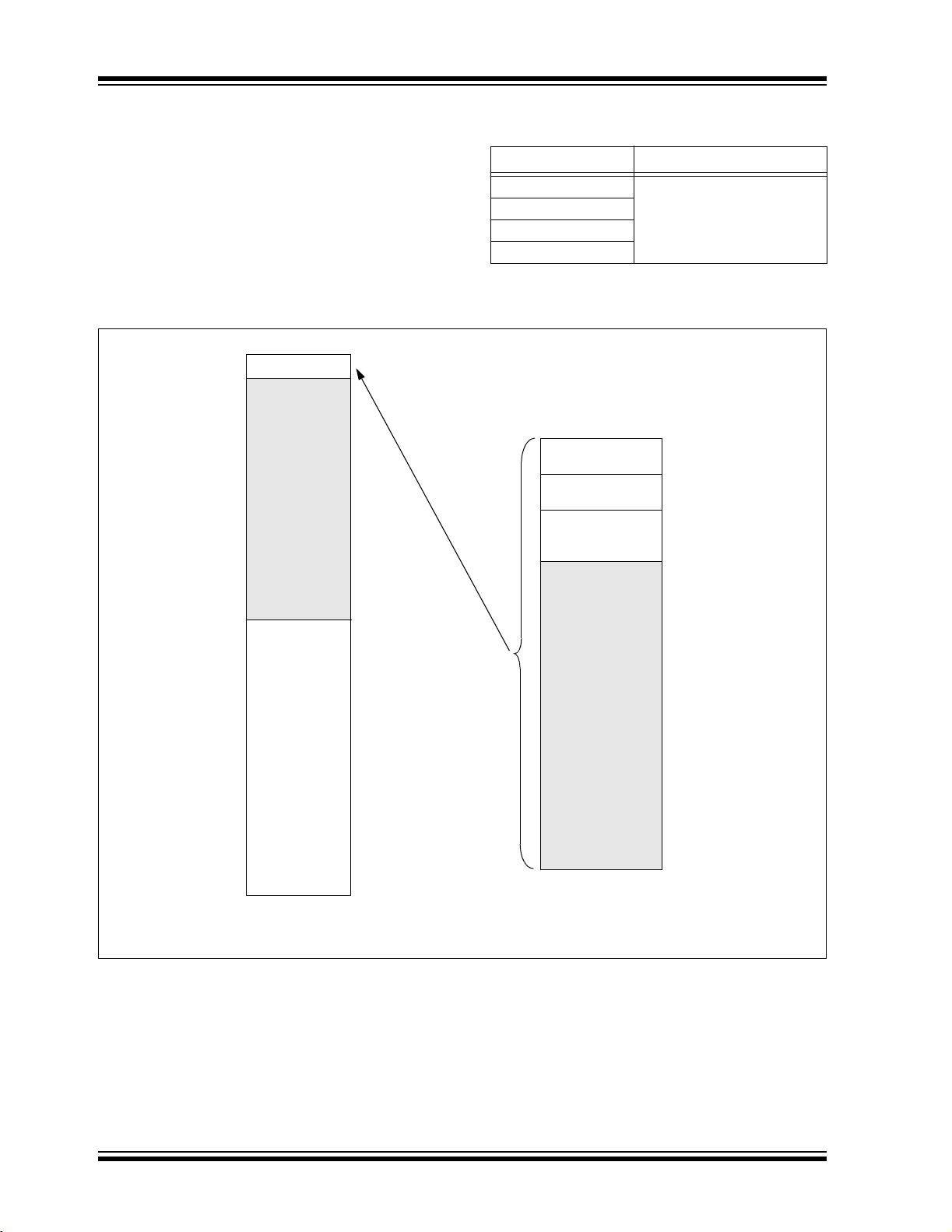

FIGURE 2-2: PIC18F2XX0/2X21/2XX5/4XX0/4X21/4XX5 FAMILY PIN DIAGRAMS

/ICPORTS

44-Pin TQFP

The following devices are included in

40-pin TQFP parts:

• PIC18F4221 • PIC18F4515

• PIC18F4321 • PIC18F4525

• PIC18F4410 • PIC18F4550

• PIC18F4420 • PIC18F4580

• PIC18F4455 • PIC18F4585

• PIC18F4480 • PIC18F4610

• PIC18F4510 • PIC18F4620

• PIC18F4520 • PIC18F4680

RC7

RD4

RD5

RD6

RD7

V

SS

VDD

RB0

RB1

RB2

RB3

1

2

3

4

5

6

7

8

9

10

11

RC6

RC5

44

43

121314

RC4

RD3

RD2

RD1

414039

42

PIC18F4XXX

15

16

17

(1)

RD0

RC3

RC2

RC1

363435

37

38

1819202122

NC

33

32

31

30

29

28

27

26

25

24

23

(1)

NC

RC0

OSC2

OSC1

V

SS

VDD

RE2

RE1

RE0

RA5

RA4

/ICVPP

Note 1: These pins are NC (No Connect) for all devices listed

above with the exception of the PIC18F4221,

PIC18F4321, PIC18F4455 and the PIC18F4550

devices (see Section 2.8 “Dedicated ICSP/ICD

Port (44-Pin TQFP Only)” for more information on

programming these pins in these devices).

44-Pin QFN

The following devices are included in

44-pin QFN parts:

• PIC18F4221 • PIC18F4515

• PIC18F4321 • PIC18F4525

• PIC18F4410 • PIC18F4550

• PIC18F4420 • PIC18F4580

• PIC18F4455 • PIC18F4585

• PIC18F4480 • PIC18F4610

• PIC18F4510 • PIC18F4620

• PIC18F4520 • PIC18F4680

RC7

RD4

RD5

RD6

RD7

V

AVDD

VDD

RB0

RB1

RB2

SS

/ICPGC

/ICPGD

(1)

(1)

NC

NC

RC6

D+/VP

44

43

1

2

3

4

5

PIC18F4XXX

6

7

8

9

10

11

121314

RB4

RB5/PGM

D-/VM

RD3

414039

42

RB6/PGC

RD2

16

15

RA0

/VPP/RE3

RB7/PGD

MCLR

USB

RD1

RD0

V

37

38

17

1819202122

RA1

RC2

363435

RA2

RC1

RA3

RC0

33

32

31

30

29

28

27

26

25

24

23

OSC2

OSC1

V

SS

AVSS

VDD

AVDD

RE2

RE1

RE0

RA5

RA4

NC

RB3

RB4

RB5/PGM

RB6/PGC

RB7/PGD

RA0

RA3

RA2

RA1

/VPP/RE3

MCLR

© 2005 Microchip Technology Inc. DS39622E-page 3

Page 4

PIC18F2XX0/2X21/2XX5/4XX0/4X21/4XX5

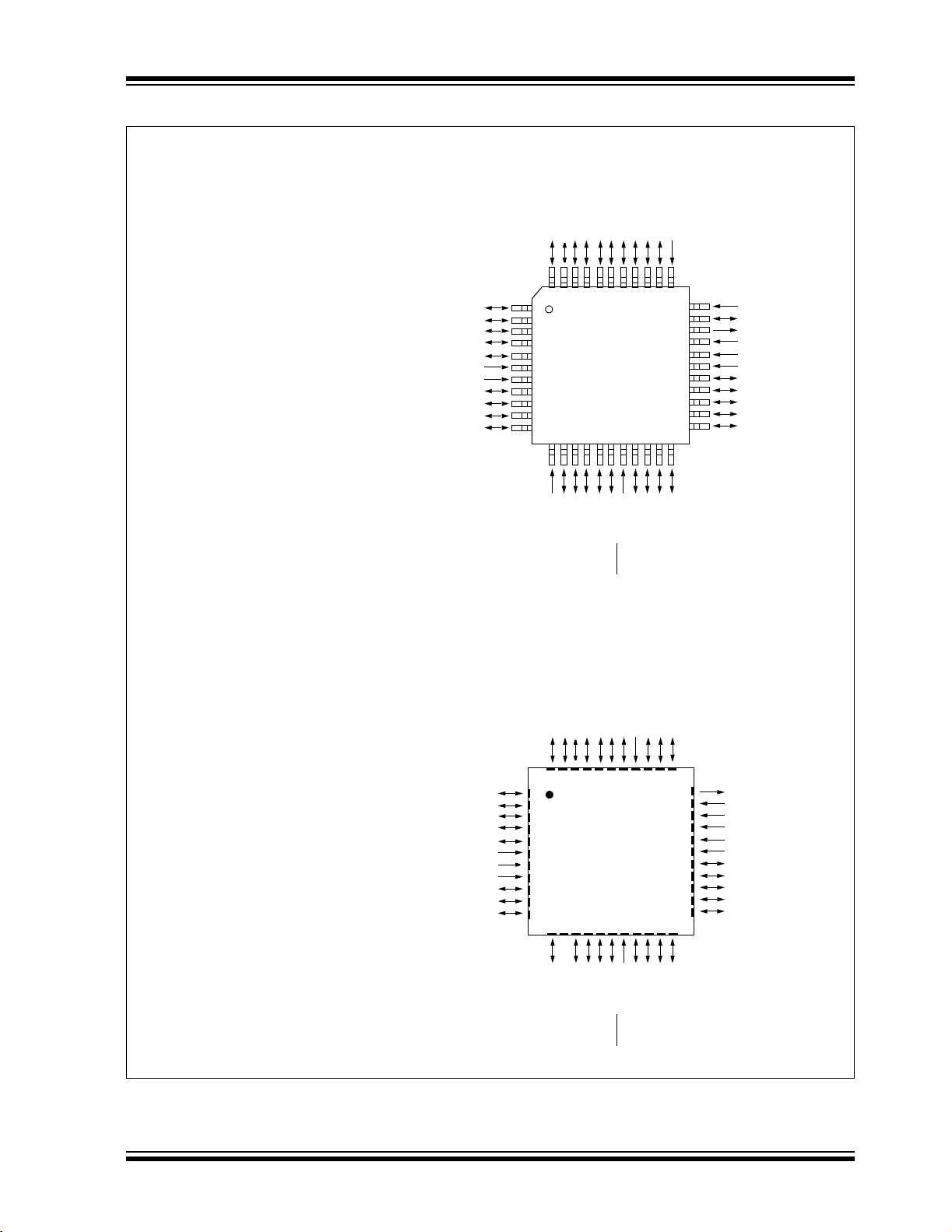

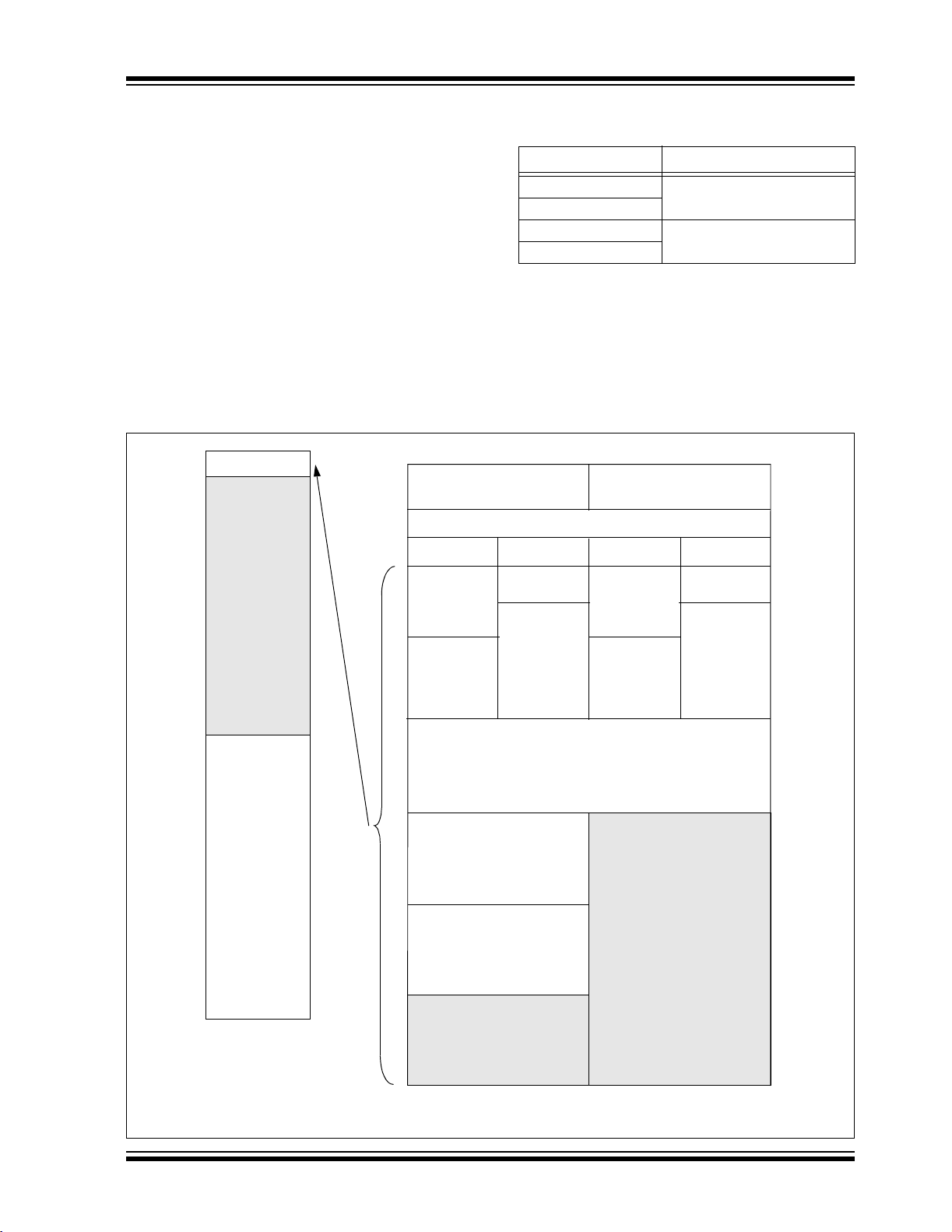

2.3 Memory Maps

TABLE 2-2: IMPLEMENTATION OF CODE

For PIC18FX6X0 devices, the code memory space

extends from 0000h to 0FFFFh (64 Kbytes) in four

16-Kbyte blocks. For PIC18FX5X5 devices, the code

memory space extends from 0000h to 0BFFFFh

(48 Kbytes) in three 16-Kbyte blocks. Addresses

0000h through 07FFh, however, define a “Boot Block”

region that is treated separately from Block 0. All of

these blocks define code protection boundaries within

the code memory space.

The size of the Boot Block in PIC18F2585/2680/4585/

4680 devices can be configured as 1, 2 or 4K words

(see Table 5-1). This is done through the BBSIZ<1:0>

bits in the Configuration register, CONFIG4L. It is

important to note that increasing the size of the Boot

Block decreases the size of Block 0.

Device Code Memory Size (Bytes)

PIC18F2515

PIC18F2525

PIC18F2585

PIC18F4515

PIC18F4525

PIC18F4585

PIC18F2610

PIC18F2620

PIC18F2680

PIC18F4610

PIC18F4620

PIC18F4680

FIGURE 2-3: MEMORY MAP AND THE CODE MEMORY SPACE

FOR PIC18FX5X5/X6X0 DEVICES

000000h

01FFFFh

Code Memory

64 Kbytes

(PIC18FX6X0)

MEMORY SIZE/DEVICE

MEMORY

000000h-00BFFFh (48K)

000000h-00FFFFh (64K)

48 Kbytes

(PIC18FX5X5)

Address

Range

200000h

3FFFFFh

Unimplemented

Read as ‘0’

Configuration

and ID

Space

11/10 01 00

Boot

Block*

Block 0

Boot

Block*

Block 0

Boot

Block*

Block 0

Block 1

Block 1

Block 2

Block 3

Unimplemented

Reads all ‘0’s

BBSIZ<1:0>

11/10 01 00

Boot

Block*

Block 0

Unimplemented

Reads all ‘0’s

Boot

Block*

Block 0

Block 1

Block 2

Boot

Block*

Block 0

000000h

0007FFh

000800h

000FFFh

001000h

001FFFh

002000h

003FFFh

004000h

007FFFh

008000h

00BFFFh

00C000h

00FFFFh

01FFFFh

Note: Sizes of memory areas are not to scale.

* Boot Block size is determined by the BBSIZ1:BBSIZ0 bits in CONFIG4L.

DS39622E-page 4 © 2005 Microchip Technology Inc.

Page 5

PIC18F2XX0/2X21/2XX5/4XX0/4X21/4XX5

For PIC18FX5X0 devices, the code memory space

TABLE 2-3: IMPLEMENTATION OF CODE

extends from 000000h to 007FFFh (32 Kbytes) in four

8-Kbyte blocks. For PIC18FX4X5 devices, the code

memory space extends from 000000h to 005FFFh

(24 Kbytes) in three 8-Kbyte blocks. Addresses

000000h through 0007FFh, however, define a “Boot

Block” region that is treated separately from Block 0. All

of these blocks define code protection boundaries

within the code memory space.

Device Code Memory Size (Bytes)

PIC18F2455

PIC18F4455

PIC18F2510

PIC18F2520

PIC18F2550

PIC18F4510

PIC18F4520

PIC18F4550

FIGURE 2-4: MEMORY MAP AND THE CODE MEMORY SPACE

FOR PIC18FX4X5/X5X0 DEVICES

000000h

1FFFFFh

200000h

Code Memory

Unimplemented

Read as ‘0’

MEMORY SIZE/DEVICE

32 Kbytes

(PIC18FX5X0)

Boot Block Boot Block

Block 0 Block 0

Block 1 Block 1

Block 2 Block 2

Block 3

008000h

MEMORY

000000h-005FFFh (24K)

000000h-007FFFh (32K)

24 Kbytes

(PIC18FX4X5)

Address

Range

000000h

0007FFh

000800h

001FFFh

002000h

003FFFh

004000h

005FFFh

006000h

007FFFh

Configuration

and ID

Space

3FFFFFh

Note: Sizes of memory areas are not to scale.

© 2005 Microchip Technology Inc. DS39622E-page 5

Unimplemented

Reads all ‘0’s

Unimplemented

Reads all ‘0’s

1FFFFFh

Page 6

PIC18F2XX0/2X21/2XX5/4XX0/4X21/4XX5

For PIC18FX4X0 devices, the code memory space

TABLE 2-4: IMPLEMENTATION OF CODE

extends from 000000h to 003FFFh (16 Kbytes) in two

8-Kbyte blocks. Addresses 000000h through 0003FFh,

however, define a “Boot Block” region that is treated

separately from Block 0. All of these blocks define code

protection boundaries within the code memory space.

Device Code Memory Size (Bytes)

PIC18F2410

PIC18F2420

PIC18F4410

PIC18F4420

FIGURE 2-5: MEMORY MAP AND THE CODE MEMORY SPACE

FOR PIC18FX4X0 DEVICES

000000h

1FFFFFh

Code Memory

Unimplemented

Read as ‘0’

MEMORY SIZE/DEVICE

16 Kbytes

(PIC18FX4X0)

Boot Block

Block 0

Block 1

MEMORY

000000h-003FFFh (16K)

Address

Range

000000h

0007FFh

000800h

001FFFh

002000h

003FFFh

004000h

200000h

Configuration

and ID

Space

3FFFFFh

Note: Sizes of memory areas are not to scale.

005FFFh

006000h

007FFFh

008000h

Unimplemented

Reads all ‘0’s

1FFFFFh

DS39622E-page 6 © 2005 Microchip Technology Inc.

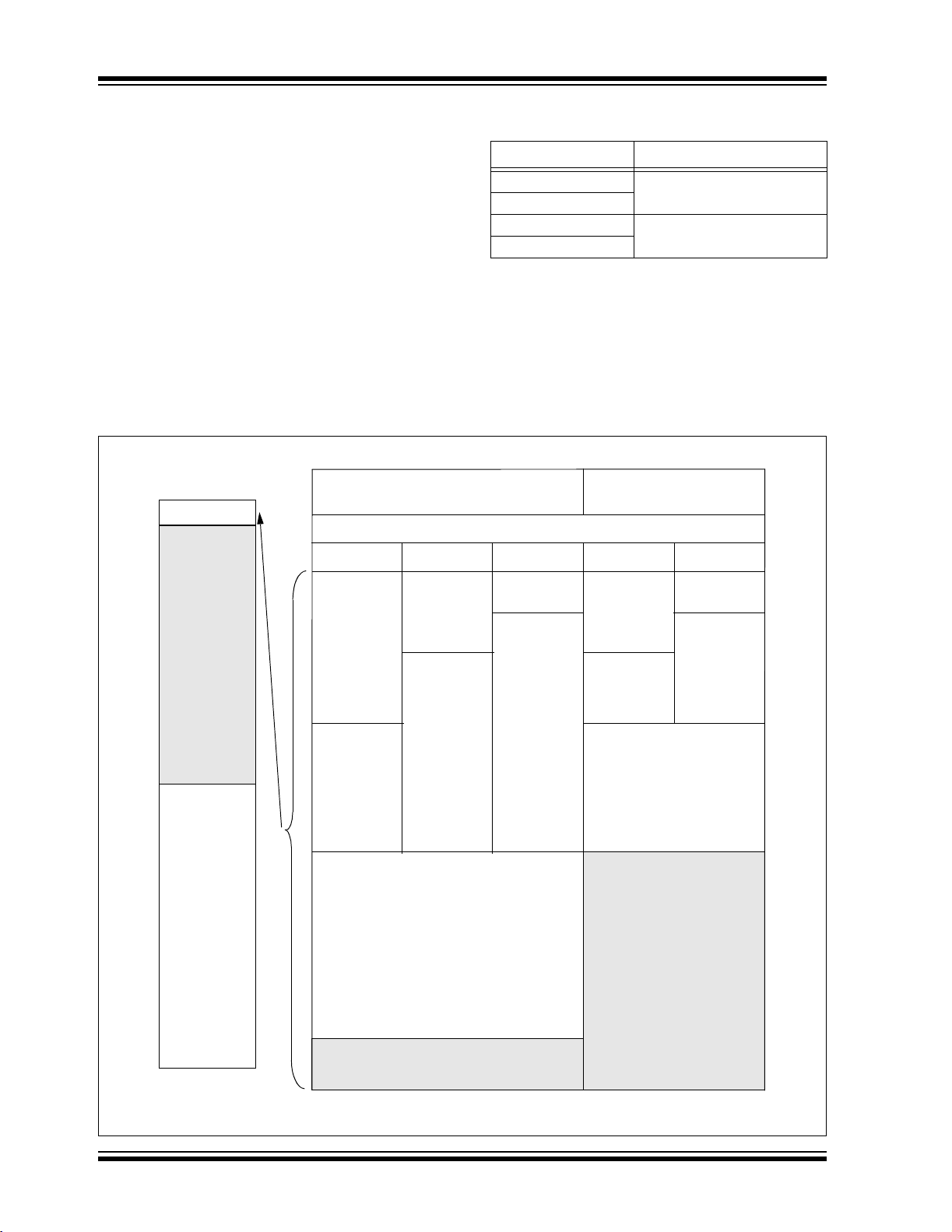

Page 7

PIC18F2XX0/2X21/2XX5/4XX0/4X21/4XX5

For PIC18F2480/4480 devices, the code memory

TABLE 2-5: IMPLEMENTATION OF CODE

space extends from 0000h to 03FFFh (16 Kbytes) in

one 16-Kbyte block. For PIC18F2580/4580 devices,

the code memory space extends from 0000h to

07FFFh (32 Kbytes) in two 16-Kbyte blocks.

Addresses 0000h through 07FFh, however, define a

“Boot Block” region that is treated separately from

Block 0. All of these blocks define code protection

boundaries within the code memory space.

Device Code Memory Size (Bytes)

PIC18F2480

PIC18F4480

PIC18F2580

PIC18F4580

The size of the Boot Block in PIC18F2480/2580/4480/

4580 devices can be configured as 1 or 2K words (see

Table 5-1). This is done through the BBSIZ bit in the

Configuration register, CONFIG4L. It is important to

note that increasing the size of the Boot Block

decreases the size of Block 0.

FIGURE 2-6: MEMORY MAP AND THE CODE MEMORY SPACE

FOR PIC18F2480/2580/4480/4580 DEVICES

000000h

01FFFFh

Code Memory

Unimplemented

Read as ‘0’

32 Kbytes

(PIC18FX580)

10 1 0

Boot Block*

MEMORY SIZE/DEVICE

BBSIZ<0>

Boot Block*

Boot Block*

MEMORY

000000h-003FFFh (16K)

000000h-007FFFh (32K)

16 Kbytes

(PIC18FX480)

Boot Block*

Address

Range

000000h

0007FFh

000800h

000FFFh

001000h

Block 0 Block 0

200000h

Configuration

and ID

Space

3FFFFFh

Unimplemented

Reads all ‘0’s

Note: Sizes of memory areas are not to scale.

* Boot Block size is determined by the BBSIZ bit in CONFIG4L.

Block 2

Block 3

Block 0 Block 0

001FFFh

002000h

Block 1

003FFFh

004000h

005FFFh

006000h

Unimplemented

Reads all ‘0’s

007FFFh

01FFFFh

© 2005 Microchip Technology Inc. DS39622E-page 7

Page 8

PIC18F2XX0/2X21/2XX5/4XX0/4X21/4XX5

For PIC18F2221/4221 devices, the code memory

TABLE 2-6: IMPLEMENTATION OF CODE

space extends from 0000h to 00FFFh (4 Kbytes) in one

4-Kbyte block. For PIC18F2321/4321 devices, the

code memory space extends from 0000h to 01FFFh

(8 Kbytes) in two 4-Kbyte blocks. Addresses 0000h

through 07FFh, however, define a variable “Boot Block”

region that is treated separately from Block 0. All of

these blocks define code protection boundaries within

the code memory space.

Device Code Memory Size (Bytes)

PIC18F2221

PIC18F4221

PIC18F2321

PIC18F4321

The size of the Boot Block in PIC18F2221/2321/4221/

4321 devices can be configured as 256, 512 or

1024 words (see Figure 2-7). This is done through the

BBSIZ<1:0> bits in the Configuration register,

CONFIG4L (see Table 5-1). It is important to note that

increasing the size of the Boot Block decreases the

size of Block 0.

FIGURE 2-7: MEMORY MAP AND THE CODE MEMORY SPACE

FOR PIC18F2221/2321/4221/4321 DEVICES

MEMORY SIZE/DEVICE

000000h

01FFFFh

200000h

Code Memory

Unimplemented

Read as ‘0’

11/10 01 00 11/10/01 00

Boot Block*

1K word

Block 0

1K word

8Kbytes

(PIC18FX321)

Boot Block*

512 words

Block 0

1.5K words

BBSIZ<1:0>

Boot Block*

256 words

Block 0

1.75K words

MEMORY

4Kbytes

(PIC18FX221)

Boot Block*

512 words

Block 0

0.5K words

000000h-000FFFh (4K)

000000h-001FFFh (8K)

Address

Range

Boot Block*

256 words

Block 0

0.75K words

Block 1

1K word

000000h

0001FFh

000200h

0003FFh

000400h

0007FFh

000800h

000FFFh

001000h

Configuration

and ID

Space

3FFFFFh

Note: Sizes of memory areas are not to scale.

* Boot Block size is determined by the BBSIZ<1:0> bits in CONFIG4L.

DS39622E-page 8 © 2005 Microchip Technology Inc.

Block 1

2K words

Unimplemented

Reads all ‘0’s

Unimplemented

Reads all ‘0’s

001FFFh

002000h

1FFFFFh

Page 9

PIC18F2XX0/2X21/2XX5/4XX0/4X21/4XX5

In addition to the code memory space, there are three

blocks that are accessible to the user through table

reads and table writes. Their locations in the memory

map are shown in Figure 2-8.

Users may store identification information (ID) in eight

ID registers. These ID registers are mapped in

addresses 200000h through 200007h. The ID locations

read out normally, even after code protection is applied.

2.3.1 MEMORY ADDRESS POINTER

Memory in the address space, 0000000h to 3FFFFFh,

is addressed via the Table Pointer register, which is

comprised of three Pointer registers:

• TBLPTRU, at RAM address 0FF8h

• TBLPTRH, at RAM address 0FF7h

• TBLPTRL, at RAM address 0FF6h

Locations 300000h through 30000Dh are reserved for

the configuration bits. These bits select various device

options and are described in Section 5.0 “Configura-

TBLPTRU TBLPTRH TBLPTRL

Addr[21:16] Addr[15:8] Addr[7:0]

tion Word”. These configuration bits read out normally,

even after code protection.

Locations 3FFFFEh and 3FFFFFh are reserved for the

device ID bits. These bits may be used by the program-

The 4-bit command, ‘0000’ (core instruction), is used to

load the Table Pointer prior to using many read or write

operations.

mer to identify what device type is being programmed

and are described in Section 5.0 “Configuration

Word”. These device ID bits read out normally, even

after code protection.

FIGURE 2-8: CONFIGURATION AND ID LOCATIONS FOR PIC18F2XX0/2X21/2XX5/4XX0/4X21/4XX5

DEVICES

000000h

01FFFFh

Code Memory

Unimplemented

Read as ‘0’

ID Location 1 200000h

ID Location 2 200001h

ID Location 3 200002h

ID Location 4 200003h

ID Location 5 200004h

ID Location 6 200005h

ID Location 7 200006h

ID Location 8 200007h

CONFIG1L 300000h

CONFIG1H 300001h

CONFIG2L 300002h

1FFFFFh

Configuration

and ID

Space

2FFFFFh

3FFFFFh

Note: Sizes of memory areas are not to scale.

© 2005 Microchip Technology Inc. DS39622E-page 9

CONFIG2H 300003h

CONFIG3L 300004h

CONFIG3H 300005h

CONFIG4L 300006h

CONFIG4H 300007h

CONFIG5L 300008h

CONFIG5H 300009h

CONFIG6L 30000Ah

CONFIG6H 30000Bh

CONFIG7L 30000Ch

CONFIG7H 30000Dh

Device ID1 3FFFFEh

Device ID2 3FFFFFh

Page 10

PIC18F2XX0/2X21/2XX5/4XX0/4X21/4XX5

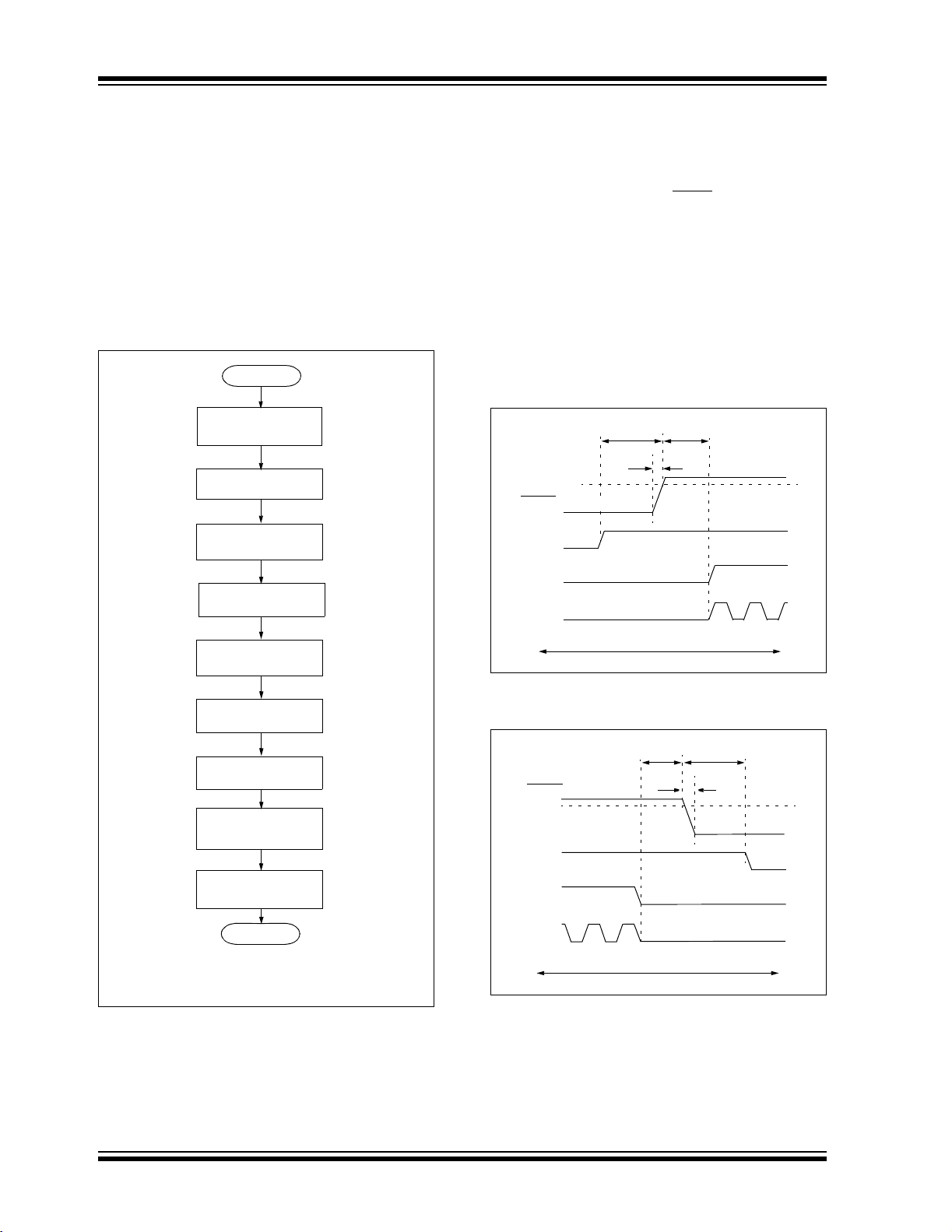

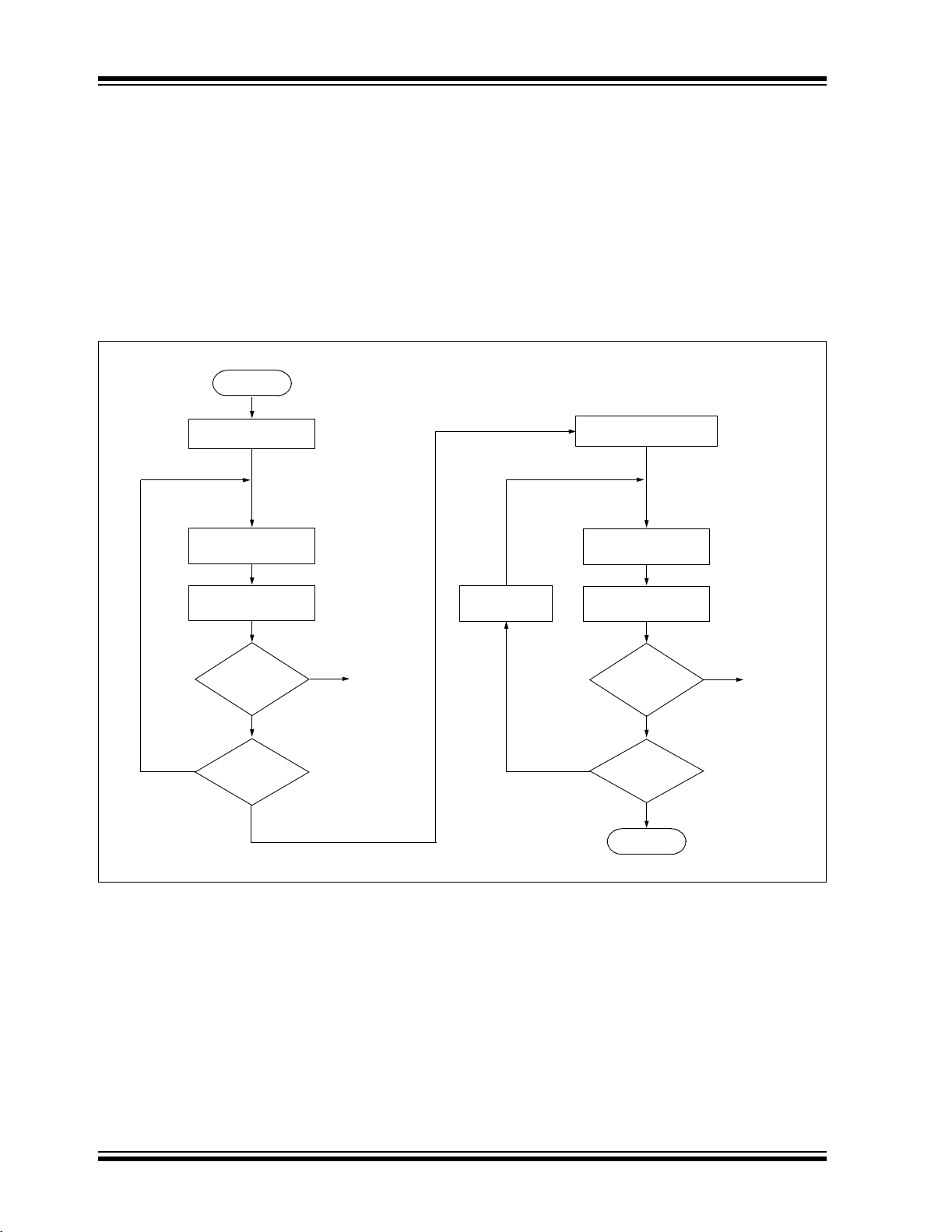

2.4 High-Level Overview of the Programming Process

Figure 2-9 shows the high-level overview of the

programming process. First, a Bulk Erase is performed.

Next, the code memory, ID locations and data EEPROM

are programmed (selected devices only, see Section 3.3

“Data EEPROM Programming”). These memories are

then verified to ensure that programming was successful.

If no errors are detected, the configuration bits are then

programmed and verified.

FIGURE 2-9: HIGH-LEVEL

PROGRAMMING FLOW

Start

Perform Bulk

Erase

Program Memory

Program IDs

2.5 Entering and Exiting High-Voltage ICSP Program/Verify Mode

As shown in Figure 2-10, the High-Voltage ICSP

Program/Verify mode is entered by holding PGC and

PGD low and then raising MCLR/VPP/RE3 to VIHH

(high voltage). Once in this mode, the code memory,

data EEPROM (selected devices only, see Section 3.3

“Data EEPROM Programming”), ID locations and

configuration bits can be accessed and programmed in

serial fashion. Figure 2-11 shows the exit sequence.

The sequence that enters the device into the Program/

Verify mode places all unused I/Os in the high-impedance

state.

FIGURE 2-10: ENTERING HIGH-VOLTAGE

PROGRAM/VERIFY MODE

P13

P1

D110

MCLR/VPP/RE3

VDD

P12

Program Data EE

Verify Program

Verify IDs

Verify Data

Program

Configuration Bits

Verify

Configuration Bits

Done

Note 1: Selected devices only, see Section 3.3

“Data EEPROM Programming”.

(1)

PGD

PGC

PGD = Input

FIGURE 2-11: EXITING HIGH-VOLTAGE

PROGRAM/VERIFY MODE

P16

MCLR/VPP/RE3

D110

VDD

PGD

PGC

PGD = Input

P17

P1

DS39622E-page 10 © 2005 Microchip Technology Inc.

Page 11

PIC18F2XX0/2X21/2XX5/4XX0/4X21/4XX5

2.6 Entering and Exiting Low-Voltage ICSP Program/Verify Mode

When the LVP configuration bit is ‘1’ (see Section 5.3

“Single-Supply ICSP Programming”), the

Low-Voltage ICSP mode is enabled. As shown in

Figure 2-12, Low-Voltage ICSP Program/Verify mode

is entered by holding PGC and PGD low, placing a logic

high on PGM and then raising MCLR

In this mode, the RB5/PGM pin is dedicated to the

programming function and ceases to be a general

purpose I/O pin. Figure 2-13 shows the exit sequence.

The sequence that enters the device into the Program/

Verify mode places all unused I/Os in the high-impedance

state.

FIGURE 2-12: ENTERING LOW-VOLTAGE

PROGRAM/VERIFY MODE

P15

MCLR/VPP/RE3

VDD

VIH

PGM

PGD

PGC

VIH

PGD = Input

FIGURE 2-13: EXITING LOW-VOLTAGE

PROGRAM/VERIFY MODE

P16

MCLR/VPP/RE3

VDD

PGM

PGD

PGC

VIH

PGD = Input

/VPP/RE3 to VIH.

P12

P18

VIH

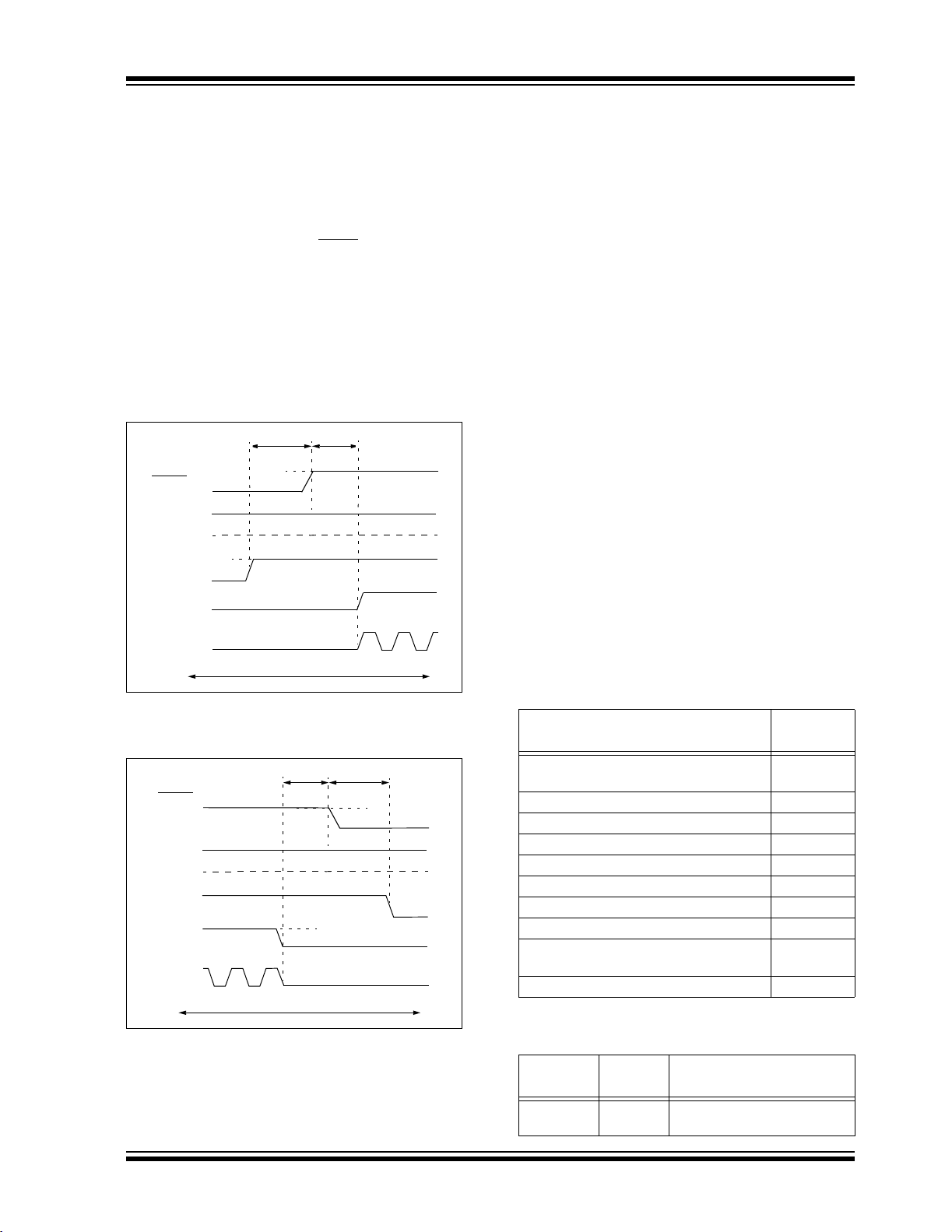

2.7 Serial Program/Verify Operation

The PGC pin is used as a clock input pin and the PGD

pin is used for entering command bits and data input/

output during serial operation. Commands and data are

transmitted on the rising edge of PGC, latched on the

falling edge of PGC and are Least Significant bit (LSb)

first.

2.7.1 4-BIT COMMANDS

All instructions are 20 bits, consisting of a leading 4-bit

command followed by a 16-bit operand, which depends

on the type of command being executed. To input a

command, PGC is cycled four times. The commands

needed for programming and verification are shown in

Ta bl e 2 -7 .

Depending on the 4-bit command, the 16-bit operand

represents 16 bits of input data or 8 bits of input data

and 8 bits of output data.

Throughout this specification, commands and data are

presented as illustrated in Table 2-8. The 4-bit

command is shown Most Significant bit (MSb) first. The

command operand, or “Data Payload”, is shown

<MSB><LSB>. Figure 2-14 demonstrates how to

serially present a 20-bit command/operand to the

device.

2.7.2 CORE INSTRUCTION

The core instruction passes a 16-bit instruction to the

CPU core for execution. This is needed to set up

registers as appropriate for use with other commands.

TABLE 2-7: COMMANDS FOR

PROGRAMMING

Description

Core Instruction

(Shift in16-bit instruction)

Shift out TABLAT register 0010

Table Read 1000

Table Read, post-increment 1001

Table Read, post-decrement 1010

Table Read, pre-increment 1011

Table Write 1100

Table Write, post-increment by 2 1101

Table Write, start programming,

post-increment by 2

Table Write, start programming 1111

TABLE 2-8: SAMPLE COMMAND

SEQUENCE

4-Bit

Command

1101 3C 40 Table Write,

Data

Payload

Core Instruction

post-increment by 2

4-Bit

Command

0000

1110

© 2005 Microchip Technology Inc. DS39622E-page 11

Page 12

PIC18F2XX0/2X21/2XX5/4XX0/4X21/4XX5

FIGURE 2-14: TABLE WRITE, POST-INCREMENT TIMING (1101)

PGC

PGD

P2

1234

P4

P3

1011

4-Bit Command 16-Bit Data Payload

P2A

P2B

1234

P5

000 000 01000111 1 0

04C3

5678

PGD = Input

2.8 Dedicated ICSP/ICD Port (44-Pin TQFP Only)

The PIC18F4221/4321 and PIC18F4455/4550 44-pin

TQFP devices are designed to support an alternate

programming input, the dedicated ICSP/ICD port. The

primary purpose of this port is to provide an alternate

In-Circuit Debugging (ICD) option and free the pins

(RB6, RB7 and MCLR

debugging the application. In conjunction with ICD

capability, however, the dedicated ICSP/ICD port also

provides an alternate port for ICSP.

Setting the ICPORT configuration bit enables the

dedicated ICSP/ICD port. The dedicated ICSP/ICD

port functions the same as the default ICSP/ICD port;

however, alternate pins are used instead of the default

pins. Table 2-9 identifies the functionally equivalent

pins for ICSP purposes:

The dedicated ICSP/ICD port is an alternate port. Thus,

ICSP is still available through the default port even

though the ICPORT configuration bit is set. When the

) that would normally be used for

10 11 13 15 161412

9

P5A

IH is seen on the MCLR/VPP/RE3 pin prior to applying

V

IH to the ICRST/ICVPP pin, then the state of the

V

ICRST/ICV

seen on ICRST/ICV

PP/RE3, then the state of the MCLR/VPP/RE3 pin is

V

PP pin is ignored. Likewise, when the VIH is

PP prior to applying VIH to MCLR/

234

1

nnnn

Fetch Next 4-Bit Command

ignored.

Note: The ICPORT configuration bit can only be

programmed through the default ICSP

port. Chip Erase functions through the

dedicated ICSP/ICD port do not affect this

bit.

When the ICPORT configuration bit is set

(dedicated ICSP/ICD port enabled), the

NC/ICPORTS pin must be tied to either

DD or VSS.

V

The ICPORT configuration bit must be

maintained clear for all 28-pin and 40-pin

devices; otherwise, unexpected operation

may occur.

TABLE 2-9: ICSP™ EQUIVALENT PINS

Pin Name

Pin Name Pin Type Dedicated Pin Pin Description

MCLR/VPP/RE3 VPP P NC/ICRST/ICVPP Programming Enable

RB6 PGC I NC/ICCK/ICPGC Serial Clock

RB7 PGD I/O NC/ICDT/ICPGD Serial Data

Legend: I = Input, O = Output, P = Power

DS39622E-page 12 © 2005 Microchip Technology Inc.

During Programming

Page 13

PIC18F2XX0/2X21/2XX5/4XX0/4X21/4XX5

3.0 DEVICE PROGRAMMING

Programming includes the ability to erase or write the

various memory regions within the device.

In all cases except high-voltage ICSP Bulk Erase, the

EECON1 register must be configured in order to

operate on a particular memory region.

When using the EECON1 register to act on code

memory, the EEPGD bit must be set (EECON1<7> = 1)

and the CFGS bit must be cleared (EECON1<6> = 0).

The WREN bit must be set (EECON1<2> = 1) to

enable writes of any sort (e.g., erases) and this must be

done prior to initiating a write sequence. The FREE bit

must be set (EECON1<4> = 1) in order to erase the

program space being pointed to by the Table Pointer.

The erase or write sequence is initiated by setting the

WR bit (EECON1<1> = 1). It is strongly recommended

that the WREN bit only be set immediately prior to a

program erase.

3.1 ICSP Erase

3.1.1 HIGH-VOLTAGE ICSP BULK ERASE

Erasing code or data EEPROM is accomplished by

configuring two Bulk Erase Control registers located at

3C0004h and 3C0005h. Code memory may be erased

portions at a time, or the user may erase the entire

device in one action. Bulk Erase operations will also

clear any code-protect settings associated with the

memory block erased. Erase options are detailed in

Table 3-1. If data EEPROM is code-protected

(CPD = 0), the user must request an erase of data

EEPROM (e.g., 0084h as shown in Table 3-1).

The code sequence to erase the entire device is shown

in Table 3-2 and the flowchart is shown in Figure 3-1.

Note: A Bulk Erase is the only way to reprogram

code-protect bits from an ON state to an

OFF state.

TABLE 3-2: BULK ERASE COMMAND

SEQUENCE

4-Bit

Command

0000

0000

0000

0000

0000

0000

1100

0000

0000

0000

0000

0000

0000

1100

0000

0000

Data

Payload

0E 3C

6E F8

0E 00

6E F7

0E 05

6E F6

0F 0F

0E 3C

6E F8

0E 00

6E F7

0E 04

6E F6

87 87

00 00

00 00

Core Instruction

MOVLW 3Ch

MOVWF TBLPTRU

MOVLW 00h

MOVWF TBLPTRH

MOVLW 05h

MOVWF TBLPTRL

Write 0Fh to 3C0005h

MOVLW 3Ch

MOVWF TBLPTRU

MOVLW 00h

MOVWF TBLPTRH

MOVLW 04h

MOVWF TBLPTRL

Write 8787h TO 3C0004h

to erase entire

device.

NOP

Hold PGD low until

erase completes.

FIGURE 3-1: BULK ERASE FLOW

TABLE 3-1: BULK ERASE OPTIONS

Description

Chip Erase 0F87h

Erase Data EEPROM

Erase Boot Block 0081h

Erase Config Bits 0082h

Erase Code EEPROM Block 0 0180h

Erase Code EEPROM Block 1 0280h

Erase Code EEPROM Block 2 0480h

Erase Code EEPROM Block 3 0880h

Note 1: Selected devices only, see Section 3.3

“Data EEPROM Programming”.

The actual Bulk Erase function is a self-timed

operation. Once the erase has started (falling edge of

the 4th PGC after the NOP command), serial execution

will cease until the erase completes (parameter P11).

During this time, PGC may continue to toggle but PGD

must be held low.

(1)

(3C0005h:3C0004h)

Data

0084h

Start

Write 0F0Fh

to 3C0005h

Write 8787h to

3C0004h to Erase

Entire Device

Delay P11 + P10

Time

Done

© 2005 Microchip Technology Inc. DS39622E-page 13

Page 14

PIC18F2XX0/2X21/2XX5/4XX0/4X21/4XX5

FIGURE 3-2: BULK ERASE TIMING

12 34

PGC

1

P5

21516

P5A

123

4

1 2 15 16P5123

P5A

4

P11

P10

12

PGD

4-Bit Command

11

Data Payload

000000

16-Bit

00011

0

4-Bit Command 4-Bit Command

PGD = Input

3.1.2 LOW-VOLTAGE ICSP BULK ERASE

When using low-voltage ICSP, the part must be

supplied by the voltage specified in parameter D111

Bulk Erase is to be executed. All other Bulk Erase

details as described above apply.

If it is determined that a program memory erase must

be performed at a supply voltage below the Bulk Erase

limit, refer to the erase methodology described in

Section 3.1.3 “ICSP Row Erase” and Section 3.2.1

“Modifying Code Memory”.

If it is determined that a data EEPROM erase

(selected devices only, see Section 3.3 “Data

EEPROM Programming”) must be performed at a

supply voltage below the Bulk Erase limit, follow the

methodology described in Section 3.3 “Data

EEPROM Programming” and write ‘1’s to the array.

if a

00

16-Bit

Data Payload

0000

Erase Time

Data Payload

3.1.3 ICSP ROW ERASE

Regardless of whether high or low-voltage ICSP is

used, it is possible to erase one row (64 bytes of data),

provided the block is not code or write-protected. Rows

are located at static boundaries, beginning at program

memory address 000000h, extending to the internal

program memory limit (see Section 2.3 “Memory

Maps”).

The Row Erase duration is externally timed and is

controlled by PGC. After the WR bit in EECON1 is set,

a NOP is issued, where the 4th PGC is held high for the

duration of the programming time, P9.

After PGC is brought low, the programming sequence

is terminated. PGC must be held low for the time

specified by parameter P10 to allow high-voltage

discharge of the memory array.

The code sequence to Row Erase a PIC18F2XX0/2X21/

2XX5/4XX0/4X21/4XX5 device is shown in Table 3-3.

The flowchart shown in Figure 3-3 depicts the logic

necessary to completely erase a PIC18F2XX0/2X21/

2XX5/4XX0/4X21/4XX5 device. The timing diagram that

details the Start Programming command and

parameters P9 and P10 is shown in Figure 3-5.

n

16-Bit

n

Note: The TBLPTR register can point at any byte

within the row intended for erase.

DS39622E-page 14 © 2005 Microchip Technology Inc.

Page 15

PIC18F2XX0/2X21/2XX5/4XX0/4X21/4XX5

TABLE 3-3: ERASE CODE MEMORY CODE SEQUENCE

4-Bit

Command

Step 1: Direct access to code memory and enable writes.

0000

0000

0000

Step 2: Point to first row in code memory.

0000

0000

0000

Step 3: Enable erase and erase single row.

0000

0000

0000

Step 4: Repeat step 3, with address pointer incremented by 64 until all rows are erased.

FIGURE 3-3: SINGLE ROW ERASE CODE MEMORY FLOW

Data Payload Core Instruction

8E A6

9C A6

84 A6

6A F8

6A F7

6A F6

88 A6

82 A6

00 00

BSF EECON1, EEPGD

BCF EECON1, CFGS

BSF EECON1, WREN

CLRF TBLPTRU

CLRF TBLPTRH

CLRF TBLPTRL

BSF EECON1, FREE

BSF EECON1, WR

NOP – hold PGC high for time P9 and low for time P10.

Addr = Addr + 64

Start

Configure

Device for

Row Erases

Start Erase Sequence

and Hold PGC High

for Time P9

Hold PGC Low

for Time P10

No

All

rows

done?

Done

Addr = 0

Yes

© 2005 Microchip Technology Inc. DS39622E-page 15

Page 16

PIC18F2XX0/2X21/2XX5/4XX0/4X21/4XX5

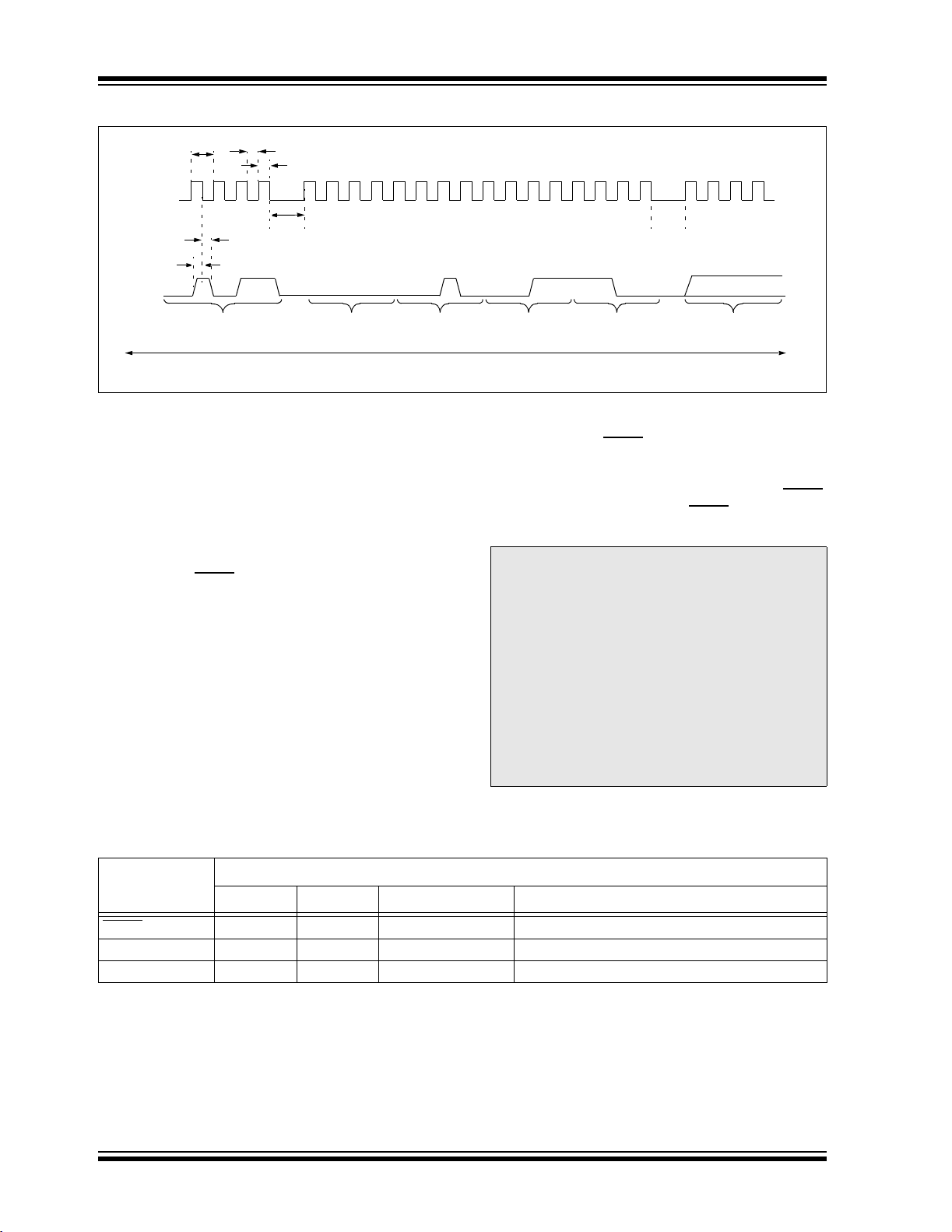

3.2 Code Memory Programming

Programming code memory is accomplished by first

loading data into the write buffer and then initiating a

programming sequence. The write and erase buffer

sizes, shown in Table 3-4, can be mapped to any

location of the same size beginning at 000000h. The

actual memory write sequence takes the contents of

this buffer and programs the proper amount of code

memory that contains the Table Pointer.

The programming duration is externally timed and is

controlled by PGC. After a Start Programming

command is issued (4-bit command, ‘1111’), a NOP is

issued, where the 4th PGC is held high for the duration

of the programming time, P9.

TABLE 3-4: WRITE AND ERASE BUFFER SIZES

Devices (Arranged by Family)

PIC18F2221, PIC18F2321, PIC18F4221, PIC18F4321 8 64

PIC18F2410, PIC18F2510, PIC18F4410, PIC18F4510

PIC18F2420, PIC18F2520, PIC18F4420, PIC18F4520

PIC18F2480, PIC18F2580, PIC18F4480, PIC18F4580

PIC18F2455, PIC18F2550, PIC18F4455, PIC18F4550

PIC18F2515, PIC18F2610, PIC18F4515, PIC18F4610

PIC18F2585, PIC18F2680, PIC18F4585, PIC18F4680

After PGC is brought low, the programming sequence

is terminated. PGC must be held low for the time

specified by parameter P10 to allow high-voltage

discharge of the memory array.

The code sequence to program a PIC18F2XX0/2X21/

2XX5/4XX0/4X21/4XX5 device is shown in Table 3-5.

The flowchart, shown in Figure 3-4, depicts the logic

necessary to completely write a PIC18F2XX0/2X21/

2XX5/4XX0/4X21/4XX5 device. The timing diagram

that details the Start Programming command and

parameters P9 and P10 is shown in Figure 3-5.

Note: The TBLPTR register must point to the

same region when initiating the programming sequence as it did when the write

buffers were loaded.

Write Buffer Size

(bytes)

Erase Buffer Size

(bytes)

32 64

64 64PIC18F2525, PIC18F2620, PIC18F4525, PIC18F4620

TABLE 3-5: WRITE CODE MEMORY CODE SEQUENCE

4-Bit

Command

Step 1: Direct access to code memory and enable writes.

0000

0000

Step 2: Load write buffer.

0000

0000

0000

0000

0000

0000

Step 3: Repeat for all but the last two bytes.

1101 <MSB><LSB> Write 2 bytes and post-increment address by 2.

Step 4: Load write buffer for last two bytes.

1111

0000

To continue writing data, repeat steps 2 through 4, where the address pointer is incremented by 2 at each iteration of the loop.

Data Payload Core Instruction

8E A6

9C A6

0E <Addr[21:16]>

6E F8

0E <Addr[15:8]>

6E F7

0E <Addr[7:0]>

6E F6

<MSB><LSB>

00 00

BSF EECON1, EEPGD

BCF EECON1, CFGS

MOVLW <Addr[21:16]>

MOVWF TBLPTRU

MOVLW <Addr[15:8]>

MOVWF TBLPTRH

MOVLW <Addr[7:0]>

MOVWF TBLPTRL

Write 2 bytes and start programming.

NOP - hold PGC high for time P9 and low for time P10.

DS39622E-page 16 © 2005 Microchip Technology Inc.

Page 17

PIC18F2XX0/2X21/2XX5/4XX0/4X21/4XX5

FIGURE 3-4: PROGRAM CODE MEMORY FLOW

N = N + 1

Start

N = 1

LoopCount = 0

Configure

Device for

Writes

Load 2 Bytes

to Write

Buffer at <Addr>

No

All

bytes

written?

N = 1

LoopCount =

LoopCount + 1

Start Write Sequence

Yes

and Hold PGC

High until Done

and Wait P9

Hold PGC Low

for Time P10

No

All

locations

done?

Yes

Done

FIGURE 3-5: TABLE WRITE AND START PROGRAMMING INSTRUCTION TIMING (1111)

P10

PGC

1234

34 65

1 2 15 16

P5

123 4

P9

P5A

12

PGD

1

11

4-Bit Command 16-Bit Data Payload

nnn

n

nn n n

00

00

4-Bit Command

Programming Time

0

030

16-Bit

Data Payload

1

PGD = Input

© 2005 Microchip Technology Inc. DS39622E-page 17

Page 18

PIC18F2XX0/2X21/2XX5/4XX0/4X21/4XX5

3.2.1 MODIFYING CODE MEMORY

The previous programming example assumed that the

device had been Bulk Erased prior to programming

(see Section 3.1.1 “High-Voltage ICSP Bulk Erase”).

It may be the case, however, that the user wishes to

modify only a section of an already programmed

device.

The appropriate number of bytes required for the erase

buffer must be read out of code memory (as described

in Section 4.2 “Verify Code Memory and ID

Locations”) and buffered. Modifications can be made

on this buffer. Then, the block of code memory that was

read out must be erased and rewritten with the

modified data.

The WREN bit must be set if the WR bit in EECON1 is

used to initiate a write sequence.

TABLE 3-6: MODIFYING CODE MEMORY

4-Bit

Command

Step 1: Direct access to code memory.

Step 2: Read and modify code memory (see Section 4.1 “Read Code Memory, ID Locations and Configuration Bits”).

0000

0000

Step 3: Set the Table Pointer for the block to be erased.

0000

0000

0000

0000

0000

0000

Step 4: Enable memory writes and setup an erase.

0000

0000

Step 5: Initiate erase.

0000

0000

Step 6: Load write buffer. The correct bytes will be selected based on the Table Pointer.

0000

0000

0000

0000

0000

0000

1101

.

.

.

1111

0000

To continue modifying data, repeat Steps 2 through 6, where the address pointer is incremented by the appropriate number of bytes

(see Table 3-4) at each iteration of the loop. The write cycle must be repeated enough times to completely rewrite the contents of

the erase buffer.

Step 7: Disable writes.

0000 94 A6 BCF EECON1, WREN

Data Payload Core Instruction

8E A6

9C A6

0E <Addr[21:16]>

6E F8

0E <Addr[8:15]>

6E F7

0E <Addr[7:0]>

6E F6

84 A6

88 A6

82 A6

00 00

0E <Addr[21:16]>

6E F8

0E <Addr[8:15]>

6E F7

0E <Addr[7:0]>

6E F6

<MSB><LSB>

.

.

.

<MSB><LSB>

00 00

BSF EECON1, EEPGD

BCF EECON1, CFGS

MOVLW <Addr[21:16]>

MOVWF TBLPTRU

MOVLW <Addr[8:15]>

MOVWF TBLPTRH

MOVLW <Addr[7:0]>

MOVWF TBLPTRL

BSF EECON1, WREN

BSF EECON1, FREE

BSF EECON1, WR

NOP - hold PGC high for time P9 and low for time P10.

MOVLW <Addr[21:16]>

MOVWF TBLPTRU

MOVLW <Addr[8:15]>

MOVWF TBLPTRH

MOVLW <Addr[7:0]>

MOVWF TBLPTRL

Write 2 bytes and post-increment address by 2.

Repeat as many times as necessary to fill the write buffer

Write 2 bytes and start programming.

NOP - hold PGC high for time P9 and low for time P10.

DS39622E-page 18 © 2005 Microchip Technology Inc.

Page 19

PIC18F2XX0/2X21/2XX5/4XX0/4X21/4XX5

3.3 Data EEPROM Programming

Note: Data EEPROM programming is not

available on the the following devices:

• PIC18F2410 •PIC18F4410

• PIC18F2510 •PIC18F4510

• PIC18F2515 •PIC18F4515

• PIC18F2610 •PIC18F4610

Data EEPROM is accessed one byte at a time via an

address pointer (register pair EEADRH:EEADR) and a

data latch (EEDATA). Data EEPROM is written by

loading EEADRH:EEADR with the desired memory

location, EEDATA with the data to be written and initiating a memory write by appropriately configuring the

EECON1 register. A byte write automatically erases the

location and writes the new data (erase-before-write).

When using the EECON1 register to perform a data

EEPROM write, both the EEPGD and CFGS bits must

be cleared (EECON1<7:6> = 00). The WREN bit must

be set (EECON1<2> = 1) to enable writes of any sort

and this must be done prior to initiating a write

sequence. The write sequence is initiated by setting the

WR bit (EECON1<1> = 1).

The write begins on the falling edge of the 4th PGC

after the WR bit is set. It ends when the WR bit is

cleared by hardware.

After the programming sequence terminates, PGC must

still be held low for the time specified by parameter P10

to allow high-voltage discharge of the memory array.

FIGURE 3-6: PROGRAM DATA FLOW

Start

Set Address

Set Data

Enable Write

Start W ri te

Sequence

No

No

WR bit

clear?

Yes

Done?

Yes

Done

FIGURE 3-7: DATA EEPROM WRITE TIMING

1234

PGC

PGD

Poll WR bit

0000

PGC

PGD

1

P5

BSF EECON1, WR4-Bit Command

21516

P5A

12 34

P5

0000

PGD = Input

21516 123

1

P5A

MOVF EECON1, W, 04-Bit Command

PGD = Input PGD = Output

P11A

Poll WR bit, Repeat until Clear

(see below)

4

1 2 15 16

P5 P5A

0000

4-Bit Command

MOVWF TABLAT

P10

Shift Out Data

(see Figure 4-4)

12

n

n

16-Bit Data

Payload

© 2005 Microchip Technology Inc. DS39622E-page 19

Page 20

PIC18F2XX0/2X21/2XX5/4XX0/4X21/4XX5

TABLE 3-7: PROGRAMMING DATA MEMORY

4-Bit

Command

Step 1: Direct access to data EEPROM.

0000

0000

Step 2: Set the data EEPROM address pointer.

0000

0000

0000

0000

Step 3: Load the data to be written.

0000

0000

Step 4: Enable memory writes.

0000 84 A6 BSF EECON1, WREN

Step 5: Initiate write.

0000 82 A6 BSF EECON1, WR

Step 6: Poll WR bit, repeat until the bit is clear.

0000

0000

0000

0010

Step 7: Hold PGC low for time P10.

Step 8: Disable writes.

0000 94 A6 BCF EECON1, WREN

Repeat steps 2 through 8 to write more data.

Note 1: See Figure 4-4 for details on shift out data timing.

Data Payload Core Instruction

9E A6

9C A6

0E <Addr>

6E A9

OE <AddrH>

6E AA

0E <Data>

6E A8

50 A6

6E F5

00 00

<MSB><LSB>

BCF EECON1, EEPGD

BCF EECON1, CFGS

MOVLW <Addr>

MOVWF EEADR

MOVLW <AddrH>

MOVWF EEADRH

MOVLW <Data>

MOVWF EEDATA

MOVF EECON1, W, 0

MOVWF TABLAT

NOP

Shift out data

(1)

DS39622E-page 20 © 2005 Microchip Technology Inc.

Page 21

PIC18F2XX0/2X21/2XX5/4XX0/4X21/4XX5

3.4 ID Location Programming

The ID locations are programmed much like the code

memory. The ID registers are mapped in addresses

200000h through 200007h. These locations read out

normally even after code protection.

Note: The user only needs to fill the first 8 bytes

of the write buffer in order to write the ID

locations.

TABLE 3-8: WRITE ID SEQUENCE

4-Bit

Command

Step 1: Direct access to code memory and enable writes.

0000

0000

Step 2: Load write buffer with 8 bytes and write.

0000

0000

0000

0000

0000

0000

1101

1101

1101

1111

0000

Data Payload Core Instruction

8E A6

9C A6

0E 20

6E F8

0E 00

6E F7

0E 00

6E F6

<MSB><LSB>

<MSB><LSB>

<MSB><LSB>

<MSB><LSB>

00 00

BSF EECON1, EEPGD

BCF EECON1, CFGS

MOVLW 20h

MOVWF TBLPTRU

MOVLW 00h

MOVWF TBLPTRH

MOVLW 00h

MOVWF TBLPTRL

Write 2 bytes and post-increment address by 2.

Write 2 bytes and post-increment address by 2.

Write 2 bytes and post-increment address by 2.

Write 2 bytes and start programming.

NOP - hold PGC high for time P9 and low for time P10.

Table 3-8 demonstrates the code sequence required to

write the ID locations.

In order to modify the ID locations, refer to the methodology described in Section 3.2.1 “Modifying Code

Memory”. As with code memory, the ID locations must

be erased before being modified.

© 2005 Microchip Technology Inc. DS39622E-page 21

Page 22

PIC18F2XX0/2X21/2XX5/4XX0/4X21/4XX5

3.5 Boot Block Programming

The code sequence detailed in Table 3-5 should be

used, except that the address used in “Step 2” will be in

the range of 000000h to 0007FFh.

3.6 Configuration Bits Programming

Unlike code memory, the configuration bits are

programmed a byte at a time. The Table Write, Begin

Programming 4-bit command (‘1111’) is used, but only

8 bits of the following 16-bit payload will be written. The

LSB of the payload will be written to even addresses and

the MSB will be written to odd addresses. The code

sequence to program two consecutive configuration

locations is shown in Table 3-9.

Note: The address must be explicitly written for

each byte programmed. The addresses

can not be incremented in this mode.

TABLE 3-9: SET ADDRESS POINTER TO CONFIGURATION LOCATION

4-Bit

Command

Step 1: Enable writes and direct access to config memory.

0000

0000

(1)

Step 2

Note 1: Enabling the write protection of configuration bits (WRTC = 0 in CONFIG6H) will prevent further writing of configuration

: Set Table Pointer for config byte to be written. Write even/odd addresses.

0000

0000

0000

0000

0000

0000

1111

0000

0000

0000

1111

0000

bits. Always write all the configuration bits before enabling the write protection for configuration bits.

Data Payload Core Instruction

8E A6

8C A6

0E 30

6E F8

0E 00

6E F7

0E 00

6E F6

<MSB ignored><LSB>

00 00

0E 01

6E F6

<MSB><LSB ignored>

00 00

BSF EECON1, EEPGD

BSF EECON1, CFGS

MOVLW 30h

MOVWF TBLPTRU

MOVLW 00h

MOVWF TBLPRTH

MOVLW 00h

MOVWF TBLPTRL

Load 2 bytes and start programming.

NOP - hold PGC high for time P9 and low for time P10.

MOVLW 01h

MOVWF TBLPTRL

Load 2 bytes and start programming.

NOP - hold PGC high for time P9 and low for time P10.

FIGURE 3-8: CONFIGURATION PROGRAMMING FLOW

Start

Load Even

Configuration

Address

Program Program

LSB

Delay P9 and P10

Time for Write

Done

DS39622E-page 22 © 2005 Microchip Technology Inc.

Start

Load Odd

Configuration

Address

MSB

Delay P9 and P10

Time for Write

Done

Page 23

PIC18F2XX0/2X21/2XX5/4XX0/4X21/4XX5

4.0 READING THE DEVICE

4.1 Read Code Memory, ID Locations and Configuration Bits

Code memory is accessed one byte at a time via the

4-bit command, ‘1001’ (table read, post-increment).

The contents of memory pointed to by the Table Pointer

(TBLPTRU:TBLPTRH:TBLPTRL) are serially output on

PGD.

TABLE 4-1: READ CODE MEMORY SEQUENCE

4-Bit

Command

Step 1: Set Table Pointer.

0000

0000

0000

0000

0000

0000

Step 2: Read memory and then shift out on PGD, LSb to MSb.

1001 00 00 TBLRD *+

Data Payload Core Instruction

0E <Addr[21:16]>

6E F8

0E <Addr[15:8]>

6E F7

0E <Addr[7:0]>

6E F6

MOVLW Addr[21:16]

MOVWF TBLPTRU

MOVLW <Addr[15:8]>

MOVWF TBLPTRH

MOVLW <Addr[7:0]>

MOVWF TBLPTRL

The 4-bit command is shifted in LSb first. The read is

executed during the next 8 clocks, then shifted out on

PGD during the last 8 clocks, LSb to MSb. A delay of

P6 must be introduced after the falling edge of the 8th

PGC of the operand to allow PGD to transition from an

input to an output. During this time, PGC must be held

low (see Figure 4-1). This operation also increments

the Table Pointer by one, pointing to the next byte in

code memory for the next read.

This technique will work to read any memory in the

000000h to 3FFFFFh address space, so it also applies

to the reading of the ID and Configuration registers.

FIGURE 4-1: TABLE READ POST-INCREMENT INSTRUCTION TIMING (1001)

9

P6

10 11 13 15 161412

P14

LSb

12

Shift Data Out

PGD = Output

34

56

P5A

MSb

Fetch Next 4-Bit Command

PGC

PGD

1234

1001

1234

P5

PGD = Input

5678

1234

nnnn

PGD = Input

© 2005 Microchip Technology Inc. DS39622E-page 23

Page 24

PIC18F2XX0/2X21/2XX5/4XX0/4X21/4XX5

4.2 Verify Code Memory and ID Locations

The verify step involves reading back the code memory

space and comparing it against the copy held in the

programmer’s buffer. Memory reads occur a single byte

at a time, so two bytes must be read to compare

against the word in the programmer’s buffer. Refer to

Section 4.1 “Read Code Memory, ID Locations and

Configuration Bits” for implementation details of

reading code memory.

FIGURE 4-2: VERIFY CODE MEMORY FLOW

Start

Set TBLPTR = 0

Read Low Byte

with Post-increment

The Table Pointer must be manually set to 200000h

(base address of the ID locations) once the code

memory has been verified. The post-increment feature

of the table read 4-bit command may not be used to

increment the Table Pointer beyond the code memory

space. In a 64-Kbyte device, for example, a

post-increment read of address FFFFh will wrap the

Table Pointer back to 000000h, rather than point to

unimplemented address 010000h.

Set TBLPTR = 200000h

Read Low Byte

with Post-Increment

Read High Byte

with Post-increment

Word = Expect

No

code memory

verified?

Does

data?

All

Yes

Yes

No

Failure,

Report

Error

Increment

Pointer

Read High Byte

with Post-Increment

Word = Expect

No

Does

data?

Yes

All

ID locations

verified?

Yes

Done

No

Failure,

Report

Error

DS39622E-page 24 © 2005 Microchip Technology Inc.

Page 25

PIC18F2XX0/2X21/2XX5/4XX0/4X21/4XX5

4.3 Verify Configuration Bits

A configuration address may be read and output on

PGD via the 4-bit command, ‘1001’. Configuration data

is read and written in a byte-wise fashion, so it is not

necessary to merge two bytes into a word prior to a

compare. The result may then be immediately

compared to the appropriate configuration data in the

programmer’s memory for verification. Refer to

Section 4.1 “Read Code Memory, ID Locations and

Configuration Bits” for implementation details of

reading configuration data.

4.4 Read Data EEPROM Memory

Data EEPROM is accessed one byte at a time via an

address pointer (register pair EEADRH:EEADR) and a

data latch (EEDATA). Data EEPROM is read by loading

EEADRH:EEADR with the desired memory location

and initiating a memory read by appropriately configuring the EECON1 register. The data will be loaded into

EEDATA, where it may be serially output on PGD via

the 4-bit command, ‘0010’ (Shift Out Data Holding

register). A delay of P6 must be introduced after the

falling edge of the 8th PGC of the operand to allow

PGD to transition from an input to an output. During this

time, PGC must be held low (see Figure 4-4).

The command sequence to read a single byte of data

is shown in Table 4-2.

FIGURE 4-3: READ DATA EEPROM

FLOW

Start

Set

Address

Read

Byte

Move to TABLAT

Shift Out Data

No

Done?

Yes

Done

TABLE 4-2: READ DATA EEPROM MEMORY

4-Bit

Command

Step 1: Direct access to data EEPROM.

0000

0000

Step 2: Set the data EEPROM address pointer.

0000

0000

0000

0000

Step 3: Initiate a memory read.

0000 80 A6 BSF EECON1, RD

Step 4: Load data into the Serial Data Holding register.

0000

0000

0000

0010

Note 1: The <LSB> is undefined. The <MSB> is the data.

Data Payload Core Instruction

9E A6

9C A6

0E <Addr>

6E A9

OE <AddrH>

6E AA

50 A8

6E F5

00 00

<MSB><LSB>

BCF EECON1, EEPGD

BCF EECON1, CFGS

MOVLW <Addr>

MOVWF EEADR

MOVLW <AddrH>

MOVWF EEADRH

MOVF EEDATA, W, 0

MOVWF TABLAT

NOP

Shift Out Data

(1)

© 2005 Microchip Technology Inc. DS39622E-page 25

Page 26

PIC18F2XX0/2X21/2XX5/4XX0/4X21/4XX5

FIGURE 4-4: SHIFT OUT DATA HOLDING REGISTER TIMING (0010)

PGC

PGD

1234

0100

1234

P5

PGD = Input

5678

4.5 Verify Data EEPROM

A data EEPROM address may be read via a sequence

of core instructions (4-bit command, ‘0000’) and then

output on PGD via the 4-bit command, ‘0010’ (TABLAT

register). The result may then be immediately

compared to the appropriate data in the programmer’s

memory for verification. Refer to Section 4.4 “Read

Data EEPROM Memory” for implementation details of

reading data EEPROM.

4.6 Blank Check

The term “Blank Check” means to verify that the device

has no programmed memory cells. All memories must

be verified: code memory, data EEPROM, ID locations

and configuration bits. The device ID registers

(3FFFFEh:3FFFFFh) should be ignored.

A “blank” or “erased” memory cell will read as a ‘1’.

Therefore, Blank Checking a device merely means to

verify that all bytes read as FFh except the configuration bits. Unused (reserved) configuration bits will

read ‘0’ (programmed). Refer to Table 5-1 for blank

configuration expect data for the various PIC18F2XX0/

2X21/2XX5/4XX0/4X21/4XX5 devices.

Given that Blank Checking is merely code and data

EEPROM verification with FFh expect data, refer to

Section 4.4 “Read Data EEPROM Memory” and

Section 4.2 “Verify Code Memory and ID Locations”

for implementation details.

91011 13 15161412

P6

P14

LSb

12

PGD = Output

34

56

Shift Data Out

1234

P5A

nnnn

MSb

Fetch Next 4-Bit Command

PGD = Input

FIGURE 4-5: BLANK CHECK FLOW

Start

Blank Check Device

Is

device

blank?

No

Abort

Yes

Continue

DS39622E-page 26 © 2005 Microchip Technology Inc.

Page 27

PIC18F2XX0/2X21/2XX5/4XX0/4X21/4XX5

5.0 CONFIGURATION WORD

The PIC18F2XX0/2X21/2XX5/4XX0/4X21/4XX5

devices have several Configuration Words. These bits

can be set or cleared to select various device

configurations. All other memory areas should be

programmed and verified prior to setting Configuration

Words. These bits may be read out normally, even after

read or code protection. See Table 5-1 for a list of

5.2 Device ID Word

The device ID word for the PIC18F2XX0/2X21/2XX5/

4XX0/4X21/4XX5 devices is located at

3FFFFEh:3FFFFFh. These bits may be used by the

programmer to identify what device type is being

programmed and read out normally, even after code or

read protection. See Table 5-2 for a complete list of

device ID values.

configuration bits and device IDs and Table 5-3 for the

configuration bit descriptions.

5.1 ID Locations

A user may store identification information (ID) in eight

FIGURE 5-1: READ DEVICE ID WORD FLOW

Start

Set TBLPTR = 3FFFFE

ID locations mapped in 200000h:200007h. It is recommended that the Most Significant nibble of each ID be

Fh. In doing so, if the user code inadvertently tries to

Read Low Byte

with Post-Increment

execute from the ID space, the ID data will execute as

a NOP.

Read High Byte

with Post-Increment

Done

TABLE 5-1: CONFIGURATION BITS AND DEVICE IDs

File Name Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

(1)

300000h

300001h CONFIG1H IESO FCMEN

300002h CONFIG2L — —

300003h CONFIG2H — — — WDTPS3 WDTPS2 WDTPS1 WDTPS0 WDTEN ---1 1111

300005h CONFIG3H MCLRE

300006h CONFIG4L DEBUG XINST

300008h CONFIG5L — — — —CP3

300009h CONFIG5H CPD CPB

30000Ah CONFIG6L

30000Bh CONFIG6H WRTD WRTB WRTC

30000Ch CONFIG7L

30000Dh CONFIG7H

3FFFFEh DEVID1

3FFFFFh DEVID2

Legend: x = unknown, u = unchanged, - = unimplemented.Shaded cells are unimplemented, read as ‘0’.

Note 1: Implemented in PIC18F2455/2550/4455/4550 devices only.

CONFIG1L — — USBDIV CPUDIV1 CPUDIV0 CLKDIV2 CLKDIV1 CLKDIV0 --00 0000

— — FOSC3 FOSC2 FOSC1 FOSC0

—

VREGEN

— — — — LPT1OSC PBADEN

— —

ICPORT

BBSIZ1

— BBSIZ

BBSIZ1

— — — — — — 11-- ----

— — — —WRT3

— — — — EBTR3

— EBTRB — — — — — — -1-- ----

(7)

DEV2 DEV1 DEV0 REV4 REV3 REV2 REV1 REV0 See Table 5-2

(7)

DEV10 DEV9 DEV8 DEV7 DEV6 DEV5 DEV4 DEV3 See Table 5-2

2: Implemented in PIC18F2221/2321/4221/4321 and PIC18F2585/2680/4585/4680 devices only.

3: Implemented in PIC18F2221/2321/4221/4321 and PIC18F2480/2580/4480/4580 devices only.

4: Implemented in PIC18F4221/4321 devices only.

5: These bits are only implemented on specific devices. Refer to Section 2.3 “Memory Maps” to determine which bits apply based on

available memory.

6: In PIC18F2480/2580/4480/4580 devices, this bit is read-only in normal execution mode; it can be written only in Program mode.

7: DEVID registers are read-only and cannot be programmed by the user.

8: Implemented in all devices with the exception of the PIC18F2480/2580/4480/4580 and PIC18F2585/2680/4585/4680 devices.

BORV1 BORV0 BOREN1 BOREN0 PWRTEN

(1)

(1)

(2)

(2)

(6)

— 100- -1-1

BBSIZ0

(3)

BBSIZ0

— — — — — 111- ----

(2)

(2)

—

ICPORT

LVP

(4)

(5)

(5)

(5)

CP2

WRT2

EBTR2

(5)

CP1 CP0 ---- 1111

(5)

WRT1 WRT0 ---- 1111

(5)

EBTR1 EBTR0 ---- 1111

CCP2MX

— 1--- -01-

—STVREN

Default/

Unprogrammed

00-- 0111

00-- 0101

---1 1111

--01 1111

(8)

1--- -011

10-- -1-1

1000 -1-1

10-0 -1-1

1000 01-1

Valu e

(1)

(1)

(8)

(1)

(2)

(3)

(4)

© 2005 Microchip Technology Inc. DS39622E-page 27

Page 28

PIC18F2XX0/2X21/2XX5/4XX0/4X21/4XX5

TABLE 5-2: DEVICE ID VALUE

Device

DEVID2 DEVID1

PIC18F2221 21h 011x xxxx

PIC18F2321 21h 001x xxxx

PIC18F2410 11h 011x xxxx

PIC18F2420 11h 010x xxxx

PIC18F2455 12h 011x xxxx

PIC18F2480 1Ah 111x xxxx

PIC18F2510 11h 001x xxxx

PIC18F2515 0Ch 111x xxxx

PIC18F2520 11h 000x xxxx

PIC18F2525 0Ch 110x xxxx

PIC18F2550 12h 010x xxxx

PIC18F2580 1Ah 110x xxxx

PIC18F2585 0Eh 111x xxxx

PIC18F2610 0Ch 101x xxxx

PIC18F2620 0Ch 100x xxxx

PIC18F2680 0Eh 110x xxxx

PIC18F4221 21h 010x xxxx

PIC18F4321 21h 000x xxxx

PIC18F4410 10h 111x xxxx

PIC18F4420 10h 110x xxxx

PIC18F4455 12h 001x xxxx

PIC18F4480 1Ah 101x xxxx

PIC18F4510 10h 101x xxxx

PIC18F4515 0Ch 011x xxxx

PIC18F4520 10h 100x xxxx

PIC18F4525 0Ch 010x xxxx

PIC18F4550 12h 000x xxxx

PIC18F4580 1Ah 100x xxxx

PIC18F4585 0Eh 101x xxxx

PIC18F4610 0Ch 001x xxxx

PIC18F4620 0Ch 000x xxxx

PIC18F4680 0Eh 100x xxxx

Note: The ‘x’s in DEVID1 contain the device revision code.

Device ID Value

DS39622E-page 28 © 2005 Microchip Technology Inc.

Page 29

PIC18F2XX0/2X21/2XX5/4XX0/4X21/4XX5

TABLE 5-3: PIC18F2XX0/2X21/2XX5/4XX0/4X21/4XX5 BIT DESCRIPTIONS

Bit Name

IESO CONFIG1H Internal External Switchover bit

FCMEN CONFIG1H Fail-Safe Clock Monitor Enable bit

FOSC3:FOSC0 CONFIG1H Oscillator Selection bits

FOSC3:FOSC0 CONFIG1H Oscillator Selection bits (PIC18F2455/2550/4455/4550 devices only)

USBPLL CONFIG1L USB Clock Selection bit (PIC18F2455/2550/4455/4550 devices only)

CPUDIV1:

CPUDIV0

PLLDIV2:

PLLDIV0

Note 1: The BBSIZ bit and BBSIZ1:BBSIZ0 bits cannot be changed once any of the following code-protect bits are

enabled: CPB or CP0, WRTB or WRT0, EBTRB or EBTR0.

2: Not available in PIC18FXX8X devices.

Configuration

Words

1 = Internal External Switchover mode enabled

0 = Internal External Switchover mode disabled

1 = Fail-Safe Clock Monitor enabled

0 = Fail-Safe Clock Monitor disabled

11xx = External RC oscillator, CLKO function on RA6

101x = External RC oscillator, CLKO function on RA6

1001 = Internal RC oscillator, CLKO function on RA6, port function on RA7

1000 = Internal RC oscillator, port function on RA6, port function on RA7

0111 = External RC oscillator, port function on RA6

0110 = HS oscillator, PLL enabled (clock frequency = 4 x FOSC1)

0101 = EC oscillator, port function on RA6

0100 = EC oscillator, CLKO function on RA6

0011 = External RC oscillator, CLKO function on RA6

0010 = HS oscillator

0001 = XT oscillator

0000 = LP oscillator

111X = HS oscillator, PLL enabled , HS used by USB

110X = HS oscillator, HS used by USB

1011 = Internal oscillator, HS used by USB

1010 = Internal oscillator, XT used by USB

1001 = Internal oscillator, CLKO function on RA6, EC used by USB

1000 = Internal oscillator, port function on RA6, EC used by USB

0111 = EC oscillator, PLL enabled, CLKO function on RA6, EC used by USB

0110 = EC oscillator, PLL enabled, port function on RA6, EC used by USB

0101 = EC oscillator, CLKO function on RA6, EC used by USB

0100 = EC oscillator, port function on RA6, EC used by USB

001X = XT oscillator, PLL enabled, XT used by USB

000X = XT oscillator, XT used by USB

Selects the clock source for full speed USB operation:

1 = USB clock source comes from the 96 MHz PLL divided by 2

0 = USB clock source comes directly from the OSC1/OSC2 oscillator block;

no divide

CONFIG1L CPU System Clock Selection bits (PIC18F2455/2550/4455/4550 devices only)

11 = CPU system clock divided by 4

10 = CPU system clock divided by 3

01 = CPU system clock divided by 2

00 = No CPU system clock divide

CONFIG1L Oscillator Selection bits (PIC18F2455/2550/4455/4550 devices only)

Divider must be selected to provide a 4 MHz input into the 96 MHz PLL:

111 = Oscillator divided by 12 (48 MHz input)

110 = Oscillator divided by 10 (40 MHz input)

101 = Oscillator divided by 6 (24 MHz input)

100 = Oscillator divided by 5 (20 MHz input)

011 = Oscillator divided by 4 (16 MHz input)

010

= Oscillator divided by 3 (12 MHz input)

001 = Oscillator divided by 2 (8 MHz input)

000 = No divide – oscillator used directly (4 MHz input)

Description

© 2005 Microchip Technology Inc. DS39622E-page 29

Page 30

PIC18F2XX0/2X21/2XX5/4XX0/4X21/4XX5

TABLE 5-3: PIC18F2XX0/2X21/2XX5/4XX0/4X21/4XX5 BIT DESCRIPTIONS (CONTINUED)

Bit Name

VREGEN CONFIG2L USB Voltage Regulator Enable bit (PIC18F2455/2550/4455/4550 devices only)

BORV1:BORV0 CONFIG2L Brown-out Reset Voltage bits

BOREN1:BOREN0 CONFIG2L Brown-out Reset Enable bits

PWRTEN CONFIG2L Power-up Timer Enable bit

WDPS3:WDPS0 CONFIG2H Watchdog Timer Postscaler Select bits

WDTEN CONFIG2H Watchdog Timer Enable bit

MCLRE CONFIG3H MCLR

LPT1OSC CONFIG3H Low-Power Timer1 Oscillator Enable bit

PBADEN CONFIG3H PORTB A/D Enable bit

Note 1: The BBSIZ bit and BBSIZ1:BBSIZ0 bits cannot be changed once any of the following code-protect bits are

enabled: CPB or CP0, WRTB or WRT0, EBTRB or EBTR0.

2: Not available in PIC18FXX8X devices.

Configuration

Words

Description

1 = USB voltage regulator enabled

0 = USB voltage regulator disabled

11 =V

BOR set to 2.0V

BOR set to 2.7V

10 =V

BOR set to 4.2V

01 =V

00 =V

BOR set to 4.5V

11 = Brown-out Reset enabled in hardware only (SBOREN is disabled)

10 = Brown-out Reset enabled in hardware only and disabled in Sleep mode

(SBOREN is disabled)

01 = Brown-out Reset enabled and controlled by software (SBOREN is enabled)

00 = Brown-out Reset disabled in hardware and software

1 = PWRT disabled

0 = PWRT enabled

1111 = 1:32,768

1110 = 1:16,384

1101 = 1:8,192

1100 = 1:4,096

1011 = 1:2,048

1010 = 1:1,024

1001 = 1:512

1000 = 1:256

0111 = 1:128

0110 = 1:64

0101 = 1:32

0100 = 1:16

0011 = 1:8

0010 = 1:4

0001 = 1:2

0000 = 1:1

1 = WDT enabled

0 = WDT disabled (control is placed on SWDTEN bit)

Pin Enable bit

1 =MCLR

0 = RE3 input pin enabled, MCLR

1 = Timer1 configured for low-power operation

0 = Timer1 configured for higher power operation

1 = PORTB A/D<4:0> pins are configured as analog input channels on Reset

0 = PORTB A/D<4:0> pins are configured as digital I/O on Reset

pin enabled, RE3 input pin disabled

pin disabled

DS39622E-page 30 © 2005 Microchip Technology Inc.

Page 31

PIC18F2XX0/2X21/2XX5/4XX0/4X21/4XX5

TABLE 5-3: PIC18F2XX0/2X21/2XX5/4XX0/4X21/4XX5 BIT DESCRIPTIONS (CONTINUED)

Bit Name

PBADEN CONFIG3H PORTB A/D Enable bit (PIC18FXX8X devices only)

CCP2MX CONFIG3H CCP2 MUX bit

DEBUG CONFIG4L Background Debugger Enable bit

XINST CONFIG4L Extended Instruction Set Enable bit

ICPORT CONFIG4L Dedicated In-Circuit (ICD/ICSP™) Port Enable bit

BBSIZ1:BBSIZ0

BBSIZ1:BBSIZ0

Configuration

Words

1 = PORTB A/D<4:0> and PORTB A/D<1:0> pins are configured as analog input

channels on Reset

0 = PORTB A/D<4:0> pins are configured as digital I/O on Reset

1 = CCP2 input/output is multiplexed with RC1

0 = CCP2 input/output is multiplexed with RB3

1 = Background debugger disabled, RB6 and RB7 configured as general

purpose I/O pins

0 = Background debugger enabled, RB6 and RB7 are dedicated to In-Circuit

Debug

1 = Instruction set extension and Indexed Addressing mode enabled

0 = Instruction set extension and Indexed Addressing mode disabled

(Legacy mode)

(PIC18F2455/2550/4455/4550 and PIC18F2221/2321/4221/4321

devices only)

1 = ICPORT enabled

0 = ICPORT disabled

(1)

CONFIG4L Boot Block Size Select bits (PIC18F2585/2680/4585/4680 devices only)

11 = 4K words (8 Kbytes) Boot Block

10 = 4K words (8 Kbytes) Boot Block

01 = 2K words (4 Kbytes) Boot Block

00 = 1K words (2 Kbytes) Boot Block

(1)

CONFIG4L Boot Block Size Select bits (PIC18F2321/4321 devices only)

11 = 1K words (2 Kbytes) Boot Block

10 = 1K words (2 Kbytes) Boot Block

01 = 512 words (1 Kbyte) Boot Block

00 = 256 words (512 bytes) Boot Block

Description

(2)

Boot Block Size Select bits (PIC18F2221/4221 devices only)

11 = 512 words (1 Kbyte) Boot Block

10 = 512 words (1 Kbyte) Boot Block

01 = 512 words (1 Kbyte) Boot Block

00 = 256 words (512 bytes) Boot Block

(1)

BBSIZ

LVP CONFIG4L Low-Voltage Programming Enable bit

STVREN CONFIG4L Stack Overflow/Underflow Reset Enable bit

Note 1: The BBSIZ bit and BBSIZ1:BBSIZ0 bits cannot be changed once any of the following code-protect bits are

enabled: CPB or CP0, WRTB or WRT0, EBTRB or EBTR0.

2: Not available in PIC18FXX8X devices.

© 2005 Microchip Technology Inc. DS39622E-page 31

CONFIG4L Boot Block Size Select bits (PIC18F2480/2580/4480/4580 devices only)

1 = 2K words (4 Kbytes) Boot Block

0 = 1K words (2 Kbytes) Boot Block

1 = Low-Voltage Programming enabled, RB5 is the PGM pin

0 = Low-Voltage Programming disabled, RB5 is an I/O pin

1 = Reset on stack overflow/underflow enabled

0 = Reset on stack overflow/underflow disabled

Page 32

PIC18F2XX0/2X21/2XX5/4XX0/4X21/4XX5

TABLE 5-3: PIC18F2XX0/2X21/2XX5/4XX0/4X21/4XX5 BIT DESCRIPTIONS (CONTINUED)

Bit Name

CP3 CONFIG5L Code Protection bits (Block 3 code memory area)

CP2 CONFIG5L Code Protection bits (Block 2 code memory area)

CP1 CONFIG5L Code Protection bits (Block 1 code memory area)

CP0 CONFIG5L Code Protection bits (Block 0 code memory area)

CPD CONFIG5H Code Protection bits (Data EEPROM)

CPB CONFIG5H Code Protection bits (Boot Block memory area)

WRT3 CONFIG6L Write Protection bits (Block 3 code memory area)

WRT2 CONFIG6L Write Protection bits (Block 2 code memory area)

WRT1 CONFIG6L Write Protection bits (Block 1 code memory area)

WRT0 CONFIG6L Write Protection bits (Block 0 code memory area)

WRTD CONFIG6H Write Protection bit (Data EEPROM)

WRTB CONFIG6H Write Protection bit (Boot Block memory area)

WRTC CONFIG6H Write Protection bit (Configuration registers)

Note 1: The BBSIZ bit and BBSIZ1:BBSIZ0 bits cannot be changed once any of the following code-protect bits are

enabled: CPB or CP0, WRTB or WRT0, EBTRB or EBTR0.

2: Not available in PIC18FXX8X devices.

Configuration

Words

Description

1 = Block 3 is not code-protected

0 = Block 3 is code-protected

1 = Block 2 is not code-protected

0 = Block 2 is code-protected

1 = Block 1 is not code-protected

0 = Block 1 is code-protected

1 = Block 0 is not code-protected

0 = Block 0 is code-protected

1 = Data EEPROM is not code-protected

0 = Data EEPROM is code-protected

1 = Boot Block is not code-protected

0 = Boot Block is code-protected

1 = Block 3 is not write-protected

0 = Block 3 is write-protected

1 = Block 2 is not write-protected

0 = Block 2 is write-protected

1 = Block 1 is not write-protected

0 = Block 1 is write-protected

1 = Block 0 is not write-protected

0 = Block 0 is write-protected

1 = Data EEPROM is not write-protected

0 = Data EEPROM is write-protected

1 = Boot Block is not write-protected

0 = Boot Block is write-protected

1 = Configuration registers are not write-protected

0 = Configuration registers are write-protected

DS39622E-page 32 © 2005 Microchip Technology Inc.

Page 33

PIC18F2XX0/2X21/2XX5/4XX0/4X21/4XX5

TABLE 5-3: PIC18F2XX0/2X21/2XX5/4XX0/4X21/4XX5 BIT DESCRIPTIONS (CONTINUED)

Bit Name

EBTR3 CONFIG7L Table Read Protection bit (Block 3 code memory area)

EBTR2 CONFIG7L Table Read Protection bit (Block 2 code memory area)

EBTR1 CONFIG7L Table Read Protection bit (Block 1 code memory area)

EBTR0 CONFIG7L Table Read Protection bit (Block 0 code memory area)

EBTRB CONFIG7H Table Read Protection bit (Boot Block memory area)

DEV10:DEV3 DEVID2 Device ID bits

DEV2:DEV0 DEVID1 Device ID bits

REV4:REV0 DEVID1 Revision ID bits

Note 1: The BBSIZ bit and BBSIZ1:BBSIZ0 bits cannot be changed once any of the following code-protect bits are

enabled: CPB or CP0, WRTB or WRT0, EBTRB or EBTR0.

2: Not available in PIC18FXX8X devices.

Configuration

Words

Description

1 = Block 3 is not protected from table reads executed in other blocks

0 = Block 3 is protected from table reads executed in other blocks