Page 1

PIC18F2423/2523/4423/4523

Data Sheet

28/40/44-Pin, Enhanced Flash

Microcontrollers with 12-Bit A/D

and nanoWatt Technology

© 2006 Microchip Technology Inc. Preliminary DS39755A

Page 2

Note the following details of the code protection feature on Microchip devices:

• Microchip products meet the specification contained in their particular Microchip Data Sheet.

• Microchip believes that its family of products is one of the most secure families of its kind on the market today, when used in the

intended manner and under normal conditions.

• There are dishonest and possibly illegal methods used to breach the code protection feature. All of these methods, to our

knowledge, require using the Microchip products in a manner outside the operating specifications contained in Microchip’s Data

Sheets. Most likely, the person doing so is engaged in theft of intellectual property.

• Microchip is willing to work with the customer who is concerned about the integrity of their code.

• Neither Microchip nor any other semiconductor manufacturer can guarantee the security of their code. Code protection does not

mean that we are guaranteeing the product as “unbreakable.”

Code protection is constantly evolving. We at Microchip are committed to continuously improving the code protection features of our

products. Attempts to break Microchip’s code protection feature may be a violation of the Digital Millennium Copyright Act. If such acts

allow unauthorized access to your software or other copyrighted work, you may have a right to sue for relief under that Act.

Information contained in this publication regarding device

applications and the like is provided only for your convenience

and may be superseded by updates. It is your responsibility to

ensure that your application meets with your specifications.

MICROCHIP MAKES NO REPRESENTATIONS OR

WARRANTIES OF ANY KIND WHETHER EXPRESS OR

IMPLIED, WRITTEN OR ORAL, STATUTORY OR

OTHERWISE, RELATED TO THE INFORMATION,

INCLUDING BUT NOT LIMITED TO ITS CONDITION,

QUALITY, PERFORMANCE, MERCHANTABILITY OR

FITNESS FOR PURPOSE. Microchip disclaims all liability

arising from this information and its use. Use of Microchip

devices in life support and/or safety applications is entirely at

the buyer’s risk, and the buyer agrees to defend, indemnify and

hold harmless Microchip from any and all damages, claims,

suits, or expenses resulting from such use. No licenses are

conveyed, implicitly or otherwise, under any Microchip

intellectual property rights.

Trademarks

The Microchip name and logo, the Microchip logo, Accuron,

dsPIC, K

EELOQ, microID, MPLAB, PIC, PICmicro, PICSTART,

PRO MATE, PowerSmart, rfPIC and SmartShunt are

registered trademarks of Microchip Technology Incorporated

in the U.S.A. and other countries.

AmpLab, FilterLab, Migratable Memory, MXDEV, MXLAB,

SEEVAL, SmartSensor and The Embedded Control Solutions

Company are registered trademarks of Microchip Technology

Incorporated in the U.S.A.

Analog-for-the-Digital Age, Application Maestro, dsPICDEM,

dsPICDEM.net, dsPICworks, ECAN, ECONOMONITOR,

FanSense, FlexROM, fuzzyLAB, In-Circuit Serial

Programming, ICSP, ICEPIC, Linear Active Thermistor, Mindi,

MiWi, MPASM, MPLIB, MPLINK, PICkit, PICDEM,

PICDEM.net, PICLAB, PICtail, PowerCal, PowerInfo,

PowerMate, PowerTool, REAL ICE, rfLAB, rfPICDEM, Select

Mode, Smart Serial, SmartTel, Total Endurance, UNI/O,

WiperLock and ZENA are trademarks of Microchip

Technology Incorporated in the U.S.A. and other countries.

SQTP is a service mark of Microchip Technology Incorporated

in the U.S.A.

All other trademarks mentioned herein are property of their

respective companies.

© 2006, Microchip Technology Incorporated, Printed in the

U.S.A., All Rights Reserved.

Printed on recycled paper.

Microchip received ISO/TS-16949:2002 certification for its worldwide

headquarters, design and wafer fabrication facilities in Chandler and

Tempe, Arizona, Gresham, Oregon and Mountain View, California. The

Company’s quality system processes and procedures are for its

PICmicro

EEPROMs, microperipherals, nonvolatile memory and analog

products. In addition, Microchip’s quality system for the design and

manufacture of development systems is ISO 9001:2000 certified.

®

8-bit MCUs, KEEL

®

OQ

code hopping devices, Serial

DS39755A-page ii Preliminary © 2006 Microchip Technology Inc.

Page 3

PIC18F2423/2523/4423/4523

28/40/44-Pin, Enhanced Flash Microcontrollers with

12-Bit A/D and nanoWatt Technology

Peripheral Highlights:

• 12-bit, up to 13-channel Analog-to-Digital

Converter module (A/D):

- Auto-acquisition capability

- Conversion available during Sleep

• Dual analog comparators with input multiplexing

• High-current sink/source 25 mA/25 mA

• Three programmable external interrupts

• Four input change interrupts

• Up to 2 Capture/Compare/PWM (CCP) modules,

one with Auto-Shutdown (28-pin devices)

• Enhanced Capture/Compare/PWM (ECCP)

module (40/44-pin devices only):

- One, two or four PWM outputs

- Selectable polarity

- Programmable dead time

- Auto-shutdown and auto-restart

• Master Synchronous Serial Port (MSSP) module

supporting 3-wire SPI (all 4 modes) and I

Master and Slave modes

• Enhanced USART module:

- Supports RS-485, RS-232 and LIN 1.2

- RS-232 operation using internal oscillator

block (no external crystal required)

- Auto-wake-up on Start bit

- Auto-Baud Detect

2

C™

Power-Managed Modes:

• Run: CPU on, peripherals on

• Idle: CPU off, peripherals on

• Sleep: CPU off, peripherals off

• Idle mode currents down to 5.8 μA, typical

• Sleep mode current down to 0.1 μA, typical

• Timer1 Oscillator: 1.8 μA, 32 kHz, 2V

• Watchdog Timer: 2.1 μA

• Two-Speed Oscillator Start-up

Flexible Oscillator Structure:

• Four Crystal modes, up to 25 MHz

• 4x Phase Lock Loop (available for crystal and

internal oscillators)

• Two External RC modes, up to 4 MHz

• Two External Clock modes, up to 25 MHz

• Internal oscillator block:

- 8 user-selectable frequencies, from 31 kHz to 8 MHz

- Provides a complete range of clock speeds

from 31 kHz to 32 MHz when used with PLL

- User-tunable to compensate for frequency drift

• Secondary oscillator using Timer1 @ 32 kHz

• Fail-Safe Clock Monitor:

- Allows for safe shutdown if external clock stops

Special Microcontroller Features:

• C compiler optimized architecture:

- Optional extended instruction set designed to

optimize re-entrant code

• 100,000 erase/write cycle Enhanced Flash

program memory typical

• 1,000,000 erase/write cycle Data EEPROM

memory typical

• Flash/Data EEPROM Retention: 100 years typical

• Self-programmable under software control

• Priority levels for interrupts

• 8 x 8 Single-Cycle Hardware Multiplier

• Extended Watchdog Timer (WDT):

- Programmable period from 4 ms to 131s

• Single-Supply In-Circuit Serial

Programming™ (ICSP™) via two pins

• In-Circuit Debug (ICD) via two pins

• Operating voltage range: 2.0V to 5.5V

• Programmable 16-level High/Low-Voltage

Detection (HLVD) module:

- Supports interrupt on High/Low-Voltage Detection

• Programmable Brown-out Reset (BOR):

- With software enable option

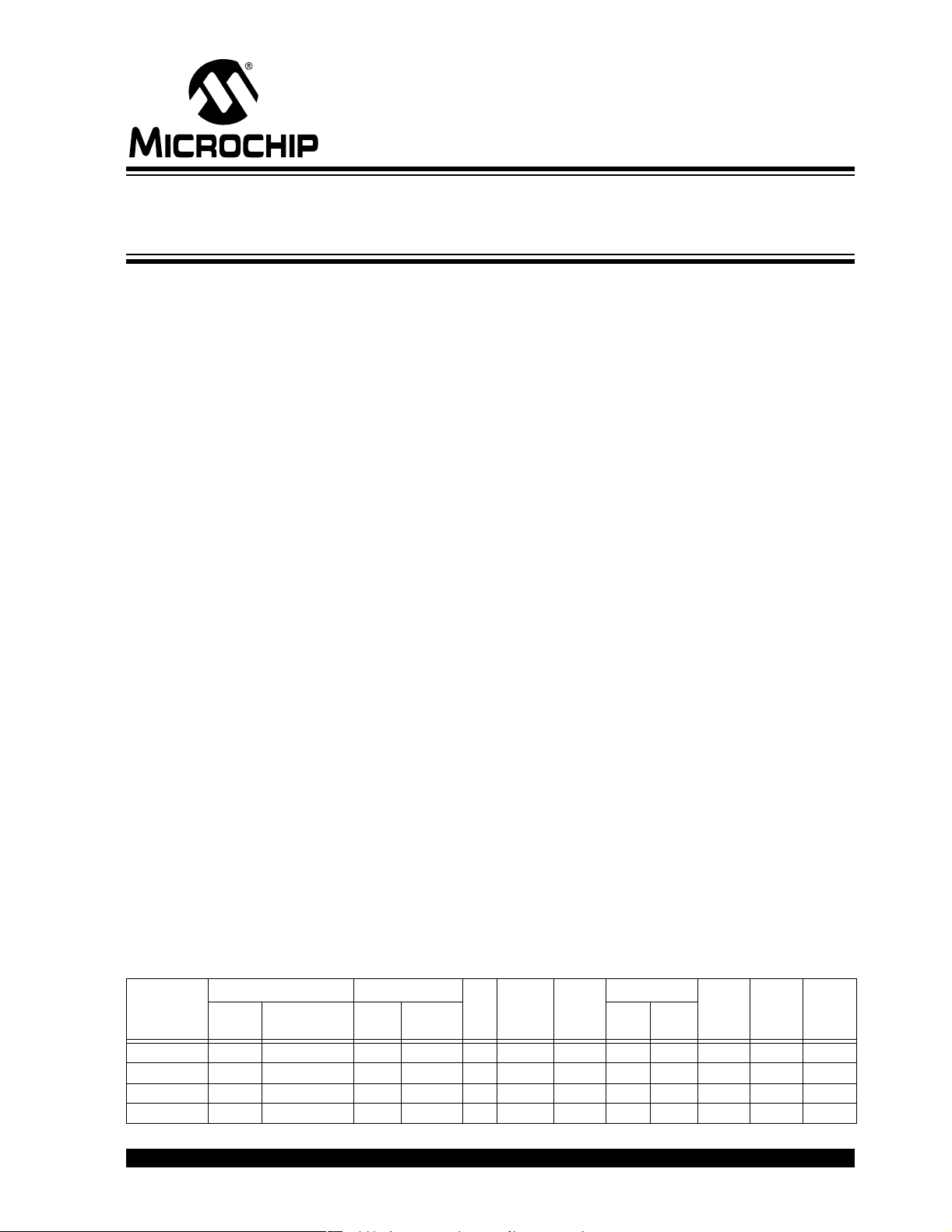

Program Memory Data Memory

Device

PIC18F2423 16K 8192 768 256 25 10 2/0 Y Y 1 2 1/3

PIC18F2523 32K 16384 1536 256 25 10 2/0 Y Y 1 2 1/3

PIC18F4423 16K 8192 768 256 36 13 1/1 Y Y 1 2 1/3

PIC18F4523 32K 16384 1536 256 36 13 1/1 Y Y 1 2 1/3

© 2006 Microchip Technology Inc. Preliminary DS39755A-page 1

Flash

(bytes)

# Single-Word

Instructions

SRAM

(bytes)

EEPROM

(bytes)

I/O

12-Bit

A/D (ch)

CCP/

ECCP

(PWM)

SPI

MSSP

Master

2

I

C™

Comp.

EUSART

Timers

8/16-Bit

Page 4

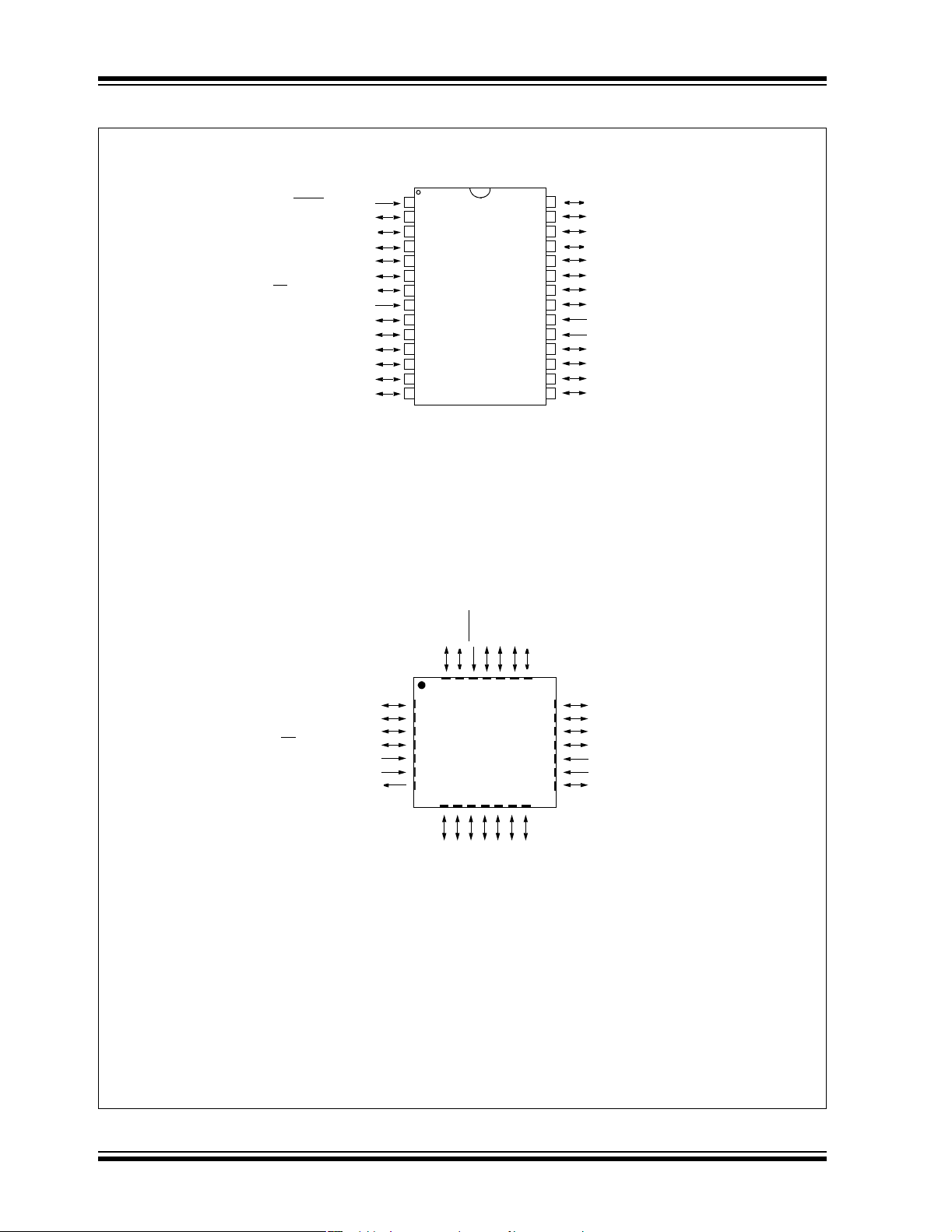

PIC18F2423/2523/4423/4523

Pin Diagrams

28-Pin PDIP, SOIC

28-Pin QFN

RA5/AN4/SS

(1)

MCLR/VPP/RE3

RA0/AN0

RA2/AN2/V

RA4/T0CKI/C1OUT

OSC2/CLKO

RC0/T1OSO/T13CKI

RC1/T1OSI/CCP2

RA1/AN1

REF-/CVREF

RA3/AN3/VREF+

/HLVDIN/C2OUT

OSC1/CLKI

(3)

(3)

RC2/CCP1

RC3/SCK/SCL

V

/RA7

/RA6

1

2

3

4

5

6

7

SS

(2)

8

9

10

11

12

13

14

PIC18F2423

/VPP/RE3

MCLR

RA0/AN0

RA1/AN1

28

27

26

25

24

23

22

21

20

PIC18F2523

19

18

17

16

15

RB7/KBI3/PGD

RB6/KBI2/PGC

RB5/KBI1/PGM

RB4KBI0/AN11

RB7/KBI3/PGD

RB6//KBI2/PGC

RB5/KBI1/PGM

RB4/KBI0/AN11

RB3/AN9/CCP2

RB2/INT2/AN8

RB1/INT1/AN10

RB0/INT0/FLT0/AN12

DD

V

VSS

RC7/RX/DT

RC6/TX/CK

RC5/SDO

RC4/SDI/SDA

(2)

RA2/AN2/VREF-/CVREF

RA3/AN3/VREF+

RA5/AN4/SS

RA4/T0CKI/C1OUT

/HLVDIN/C2OUT

OSC1/CLKI

OSC2/CLKO

(3)

(3)

V

/RA7

/RA6

232425262728

1

2

3

PIC18F2423

4

SS

PIC18F2523

5

6

7

8

9

(2)

RC1/T1OSI/CCP2

RC0/T1OSO/T13CKI

10 11

RC2/CCP1

12 13 14

RC3/SCK/SCL

RC5/SDO

RC4/SDI/SDA

RC6/TX/CK

21

20

19

18

17

16

15

RB3/AN9/CCP2

RB2/INT2/AN8

RB1/INT1/AN10

RB0/INT0/FLT0/AN12

V

DD

VSS

RC7/RX/DT

(2)

22

Note 1: It is recommended to connect the bottom pad of QFN package parts to VSS.

2: RB3 is the alternate pin for CCP2 multiplexing.

3: OSC1/CLKI and OSC2/CLKO are only available in select oscillator modes and when these pins are not

being used as digital I/O. Refer to Section 2.0 “Oscillator Configurations” for additional information.

DS39755A-page 2 Preliminary © 2006 Microchip Technology Inc.

Page 5

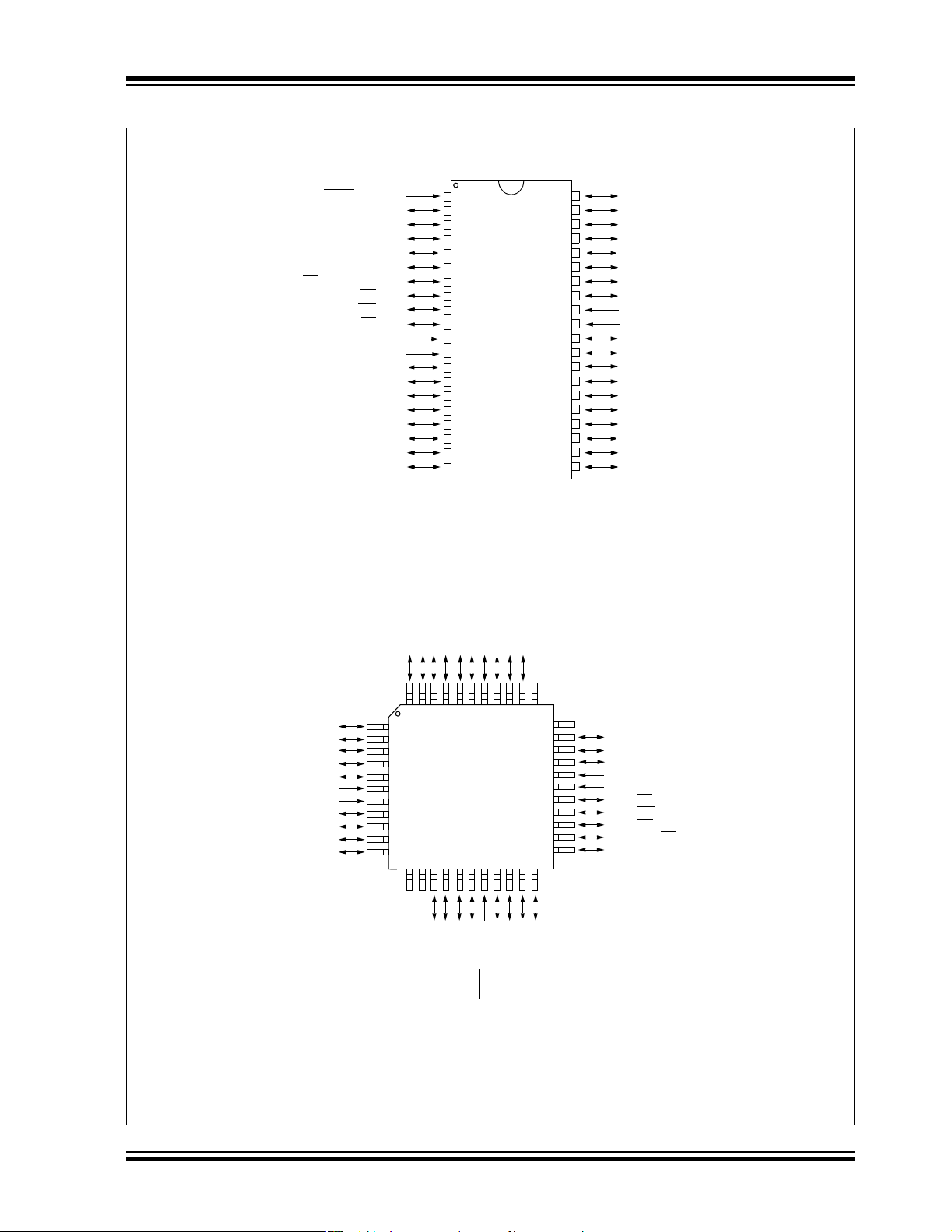

Pin Diagrams (Cont.’d)

40-Pin PDIP

PIC18F2423/2523/4423/4523

44-Pin TQFP

RA2/AN2/V

RA5/AN4/SS

OSC2/CLKO

RC0/T1OSO/T13CKI

RC1/T1OSI/CCP2

MCLR/VPP/RE3

RA0/AN0

RA1/AN1

REF-/CVREF

RA3/AN3/VREF+

RA4/T0CKI/C1OUT

/HLVDIN/C2OUT

RE0/RD

/AN5

RE1/WR

/AN6

RE2/CS

/AN7

V

DD

VSS

OSC1/CLKI

(2)

/RA7

(2)

/RA6

RC2/CCP1/P1A

RC3/SCK/SCL

RD0/PSP0

RD1/PSP1

1

2

3

4

5

6

7

8

9

10

11

12

13

14

RC6/TX/CK

RC5/SDO

RC4/SDI/SDA

15

16

17

18

19

20

RD3/PSP3

RD2/PSP2

RD1/PSP1

RD0/PSP0

RC3/SCK/SCL

(1)

40

39

38

37

36

35

34

33

32

31

30

29

PIC18F4523

PIC18F4423

28

27

26

25

24

23

22

21

(1)

RC2/CCP1/P1A

RC1/T1OSI/CCP2

NC

RB7/KBI3/PGD

RB6/KBI2/PGC

RB5/KBI1/PGM

RB4/KBI0/AN11

RB3/AN9/CCP2

RB2/INT2/AN8

RB1/INT1/AN10

RB0/INT0/FLT0/AN12

V

DD

VSS

RD7/PSP7/P1D

RD6/PSP6/P1C

RD5/PSP5/P1B

RD4/PSP4

RC7/RX/DT

RC6/TX/CK

RC5/SDO

RC4/SDI/SDA

RD3/PSP3

RD2/PSP2

(1)

15

RB5/KBI1/PGM

38

39

1819202122

16

17

/VPP/RE3

RB7/KBI3/PGD

RB6/KBI2/PGC

MCLR

37

RA0/AN0

363435

RA1/AN1

33

32

31

30

29

28

27

26

25

24

23

REF-/CVREF

RA3/AN3/VREF+

RA2/AN2/V

NC

RC0/T1OSO/T13CKI

OSC2/CLKO

OSC1/CLKI

SS

V

VDD

RE2/CS/AN7

RE1/WR

RE0/RD

RA5/AN4/SS

RA4/T0CKI/C1OUT

(2)

/RA6

(2)

/RA7

/AN6

/AN5

/HLVDIN/C2OUT

RC7/RX/DT

RD4/PSP4

RD5/PSP5/P1B

RD6/PSP6/P1C

RD7/PSP7/P1D

RB0/INT0/FLT0/AN12

RB1/INT1/AN10

RB2/INT2/AN8

RB3/AN9/CCP2

V

VDD

4443424140

1

2

3

4

PIC18F4423

SS

(1)

5

6

7

8

9

10

11

121314

NC

PIC18F4523

NC

RB4/KBI0/AN11

Note 1: RB3 is the alternate pin for CCP2 multiplexing.

2: OSC1/CLKI and OSC2/CLKO are only available in select oscillator modes and when these pins are not

being used as digital I/O. Refer to Section 2.0 “Oscillator Configurations” for additional information.

© 2006 Microchip Technology Inc. Preliminary DS39755A-page 3

Page 6

PIC18F2423/2523/4423/4523

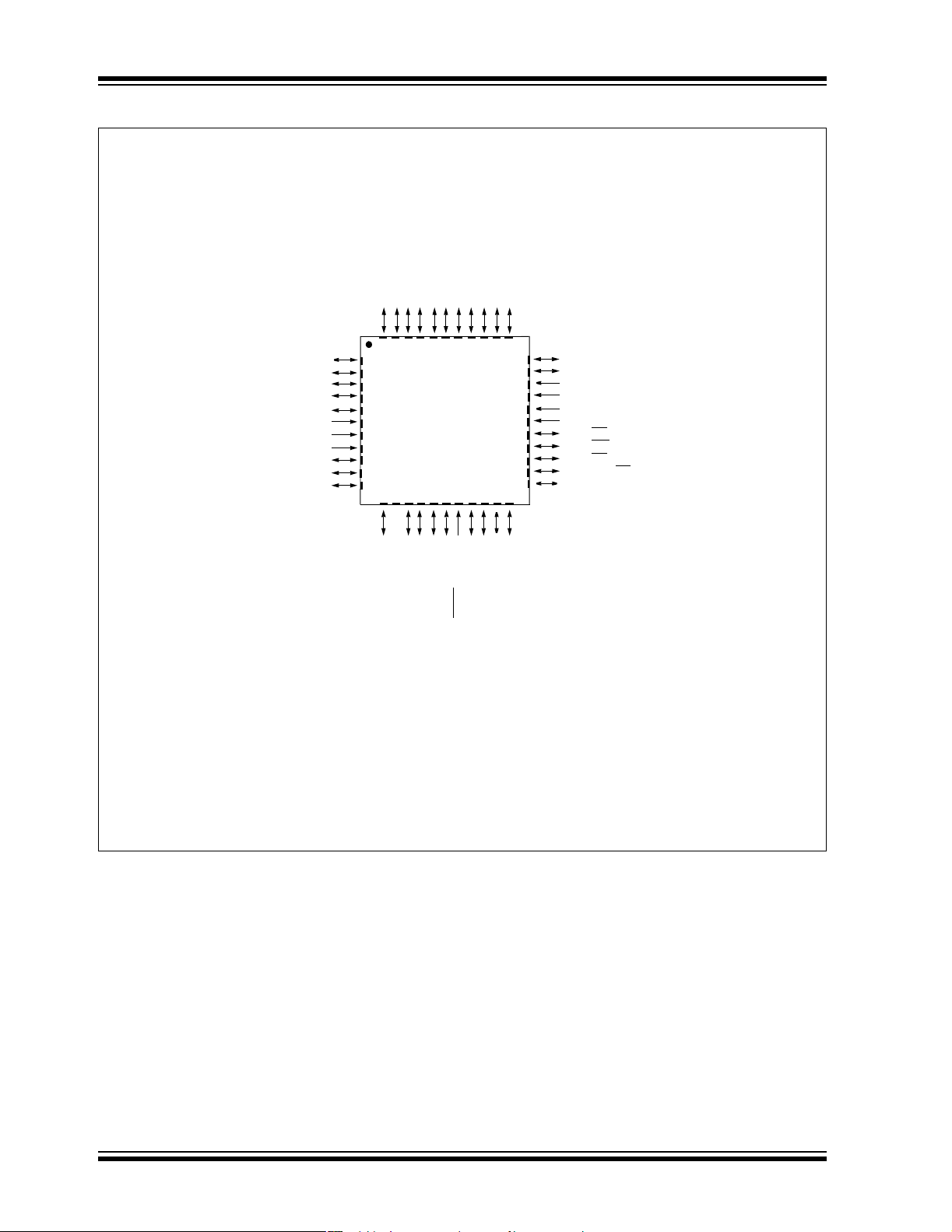

Pin Diagrams (Cont.’d)

44-Pin QFN

(1)

RC7/RX/DT

RD4/PSP4

RD5/PSP5/P1B

RD6/PSP6/P1C

RD7/PSP7/P1D

RB0/INT0/FLT0/AN12

RB1/INT1/AN10

RB2/INT2/AN8

V

VDD

VDD

(2)

RC6/TX/CK

RC5/SDO

RC4/SDI/SDA

RD3/PSP3

RD2/PSP2

RD1/PSP1

RD0/PSP0

15

16

RB6/KBI2/PGC

RB5/KBI1/PGM

38

39

1819202122

17

/VPP/RE3

RB7/KBI3/PGD

MCLR

4443424140

1

2

3

4

5

SS

6

7

8

9

10

11

121314

(2)

RB3/AN9/CCP2

PIC18F4423

PIC18F4523

NC

RB4/KBI0/AN11

RC3/SCK/SCL

RC2/CCP1/P1A

RC1/T1OSI/CCP2

363435

37

RA1/AN1

RA0/AN0

REF-/CVREF

RA2/AN2/V

RC0/T1OSO/T13CKI

33

32

31

30

29

28

27

26

25

24

23

REF+

RA3/AN3/V

OSC2/CLKO

OSC1/CLKI

SS

V

VSS

VDD

VDD

RE2/CS/AN7

RE1/WR

RE0/RD

RA5/AN4/SS

RA4/T0CKI/C1OUT

(3)

/RA6

(3)

/RA7

/AN6

/AN5

/HLVDIN/C2OUT

Note 1: It is recommended to connect the bottom pad of QFN package parts to VSS.

2: RB3 is the alternate pin for CCP2 multiplexing.

3: OSC1/CLKI and OSC2/CLKO are only available in select oscillator modes and when these pins are not

being used as digital I/O. Refer to Section 2.0 “Oscillator Configurations” for additional information.

DS39755A-page 4 Preliminary © 2006 Microchip Technology Inc.

Page 7

PIC18F2423/2523/4423/4523

Table of Contents

1.0 Device Overview .......................................................................................................................................................................... 7

2.0 Oscillator Configurations ............................................................................................................................................................ 23

3.0 Power-Managed Modes ............................................................................................................................................................. 33

4.0 Reset .......................................................................................................................................................................................... 41

5.0 Memory Organization................................................................................................................................................................. 53

6.0 Flash Program Memory.............................................................................................................................................................. 73

7.0 Data EEPROM Memory ............................................................................................................................................................. 83

8.0 8 x 8 Hardware Multiplier............................................................................................................................................................ 89

9.0 Interrupts .................................................................................................................................................................................... 91

10.0 I/O Ports ................................................................................................................................................................................... 105

11.0 Timer0 Module ......................................................................................................................................................................... 123

12.0 Timer1 Module ......................................................................................................................................................................... 127

13.0 Timer2 Module ......................................................................................................................................................................... 133

14.0 Timer3 Module ......................................................................................................................................................................... 135

15.0 Capture/Compare/PWM (CCP) Modules ................................................................................................................................. 139

16.0 Enhanced Capture/Compare/PWM (ECCP) Module................................................................................................................ 147

17.0 Master Synchronous Serial Port (MSSP) Module .................................................................................................................... 161

18.0 Enhanced Universal Synchronous Asynchronous Receiver Transmitter (EUSART) ............................................................... 205

19.0 12-Bit Analog-to-Digital Converter (A/D) Module ..................................................................................................................... 227

20.0 Comparator Module.................................................................................................................................................................. 237

21.0 Comparator Voltage Reference Module ................................................................................................................................... 243

22.0 High/Low-Voltage Detect (HLVD)............................................................................................................................................. 247

23.0 Special Features of the CPU.................................................................................................................................................... 253

24.0 Instruction Set Summary.......................................................................................................................................................... 271

25.0 Development Support............................................................................................................................................................... 321

26.0 Electrical Characteristics.......................................................................................................................................................... 325

27.0 DC and AC Characteristics Graphs and Tables....................................................................................................................... 363

28.0 Packaging Information.............................................................................................................................................................. 365

Appendix A: Revision History............................................................................................................................................................. 373

Appendix B: Device Differences ........................................................................................................................................................ 373

Appendix C: Conversion Considerations ........................................................................................................................................... 374

Appendix D: Migration from Baseline to Enhanced Devices.............................................................................................................. 374

Appendix E: Migration from Mid-Range to Enhanced Devices .......................................................................................................... 375

Appendix F: Migration from High-End to Enhanced Devices ............................................................................................................. 375

Index ................................................................................................................................................................................................. 377

The Microchip Web Site..................................................................................................................................................................... 387

Customer Change Notification Service .............................................................................................................................................. 387

Customer Support .............................................................................................................................................................................. 387

Reader Response .............................................................................................................................................................................. 388

PIC18F2423/2523/4423/4523 Product Identification System ............................................................................................................ 389

© 2006 Microchip Technology Inc. Preliminary DS39755A-page 5

Page 8

PIC18F2423/2523/4423/4523

TO OUR VALUED CUSTOMERS

It is our intention to provide our valued customers with the best documentation possible to ensure successful use of your Microchip

products. To this end, we will continue to improve our publications to better suit your needs. Our publications will be refined and

enhanced as new volumes and updates are introduced.

If you have any questions or comments regarding this publication, please contact the Marketing Communications Department via

E-mail at docerrors@microchip.com or fax the Reader Response Form in the back of this data sheet to (480) 792-4150. We

welcome your feedback.

Most Current Data Sheet

To obtain the most up-to-date version of this data sheet, please register at our Worldwide Web site at:

http://www.microchip.com

You can determine the version of a data sheet by examining its literature number found on the bottom outside corner of any page.

The last character of the literature number is the version number, (e.g., DS30000A is version A of document DS30000).

Errata

An errata sheet, describing minor operational differences from the data sheet and recommended workarounds, may exist for current

devices. As device/documentation issues become known to us, we will publish an errata sheet. The errata will specify the revision

of silicon and revision of document to which it applies.

To determine if an errata sheet exists for a particular device, please check with one of the following:

• Microchip’s Worldwide Web site; http://www.microchip.com

• Your local Microchip sales office (see last page)

When contacting a sales office, please specify which device, revision of silicon and data sheet (include literature number) you are

using.

Customer Notification System

Register on our web site at www.microchip.com to receive the most current information on all of our products.

DS39755A-page 6 Preliminary © 2006 Microchip Technology Inc.

Page 9

PIC18F2423/2523/4423/4523

1.0 DEVICE OVERVIEW

This document contains device-specific information for

the following devices:

• PIC18F2423

• PIC18F2523

• PIC18F4423

• PIC18F4523

This family offers the advantages of all PIC18

microcontrollers – namely, high computational performance at an economical price – with the addition of

high-endurance, Enhanced Flash program memory.

On top of these features, the PIC18F2423/2523/4423/

4523 family introduces design enhancements that

make these microcontrollers a logical choice for many

high-performance, power sensitive applications.

1.1 New Core Features

1.1.1 nanoWatt TECHNOLOGY

All of the devices in the PIC18F2423/2523/4423/4523

family incorporate a range of features that can significantly reduce power consumption during operation.

Key items include:

• Alternate Run Modes: By clocking the controller

from the Timer1 source or the internal oscillator

block, power consumption during code execution

can be reduced by as much as 90%.

• Multiple Idle Modes: The controller can also run

with its CPU core disabled but the peripherals still

active. In these states, power consumption can be

reduced even further, to as little as 4% of normal

operation requirements.

• On-the-Fly Mode Switching: The

power-managed modes are invoked by user code

during operation, allowing the user to incorporate

power-saving ideas into their application’s

software design.

• Low Consumption in Key Modules: The

power requirements for both Timer1 and the

Watchdog Timer are minimized. See

Section 26.0 “Electrical Characteristics”

for values.

1.1.2 MULTIPLE OSCILLATOR OPTIONS AND FEATURES

All of the devices in the PIC18F2423/2523/4423/4523

family offer ten different oscillator options, allowing

users a wide range of choices in developing application

hardware. These include:

• Four Crystal modes, using crystals or ceramic

resonators.

• Two External Clock modes, offering the option of

using two pins (oscillator input and a divide-by-4

clock output) or one pin (oscillator input, with the

second pin reassigned as general I/O).

• Two External RC Oscillator modes with the same

pin options as the External Clock modes.

• An internal oscillator block which provides an

8 MHz clock and an INTRC source (approximately

31 kHz), as well as a range of six user-selectable

clock frequencies, between 125 kHz to 4 MHz, for

a total of 8 clock frequencies. This option frees the

two oscillator pins for use as additional general

purpose I/O.

• A Phase Lock Loop (PLL) frequency multiplier,

available to both the High-Speed Crystal and

Internal Oscillator modes, which allows clock

speeds of up to 40 MHz from the HS clock

source. Used with the internal oscillator, the PLL

gives users a complete selection of clock speeds,

from 31 kHz to 32 MHz, all without using an

external crystal or clock circuit.

Besides its availability as a clock source, the internal

oscillator block provides a stable reference source that

gives the family additional features for robust

operation:

• Fail-Safe Clock Monitor: This option constantly

monitors the main clock source against a reference signal provided by the internal oscillator. If a

clock failure occurs, the controller is switched to

the internal oscillator block, allowing for continued

operation or a safe application shutdown.

• Two-Speed Start-up: This option allows the

internal oscillator to serve as the clock source

from Power-on Reset, or wake-up from Sleep

mode, until the primary clock source is available.

© 2006 Microchip Technology Inc. Preliminary DS39755A-page 7

Page 10

PIC18F2423/2523/4423/4523

1.2 Other Special Features

• 12-Bit A/D Converter: This module incorporates

programmable acquisition time, allowing for a

channel to be selected and a conversion to be

initiated without waiting for a sampling period and

thus, reducing code overhead.

• Memory Endurance: The Enhanced Flash cells

for both program memory and data EEPROM are

rated to last for many thousands of erase/write

cycles – up to 100,000 for program memory and

1,000,000 for EEPROM. Data retention without

refresh is conservatively estimated to be greater

than 40 years.

• Self-Programmability: These devices can write

to their own program memory spaces under internal software control. By using a bootloader routine located in the protected Boot Block at the top

of program memory, it becomes possible to create

an application that can update itself in the field.

• Extended Instruction Set: The PIC18F2423/

2523/4423/4523 family introduces an optional

extension to the PIC18 instruction set, which adds

eight new instructions and an Indexed Addressing

mode. This extension, enabled as a device configuration option, has been specifically designed

to optimize re-entrant application code originally

developed in high-level languages, such as C.

• Enhanced CCP module: In PWM mode, this

module provides 1, 2 or 4 modulated outputs for

controlling half-bridge and full-bridge drivers.

Other features include auto-shutdown, for disabling PWM outputs on interrupt or other select

conditions and auto-restart, to reactivate outputs

once the condition has cleared.

• Enhanced Addressable USART: This serial

communication module is capable of standard

RS-232 operation and provides support for the LIN

bus protocol. Other enhancements include

automatic baud rate detection and a 16-bit Baud

Rate Generator for improved resolution. When the

microcontroller is using the internal oscillator

block, the EUSART provides stable operation for

applications that talk to the outside world without

using an external crystal (or its accompanying

power requirement).

• Extended Watchdog Timer (WDT): This

enhanced version incorporates a 16-bit prescaler,

allowing an extended time-out range that is stable

across operating voltage and temperature. See

Section 26.0 “Electrical Characteristics” for

time-out periods.

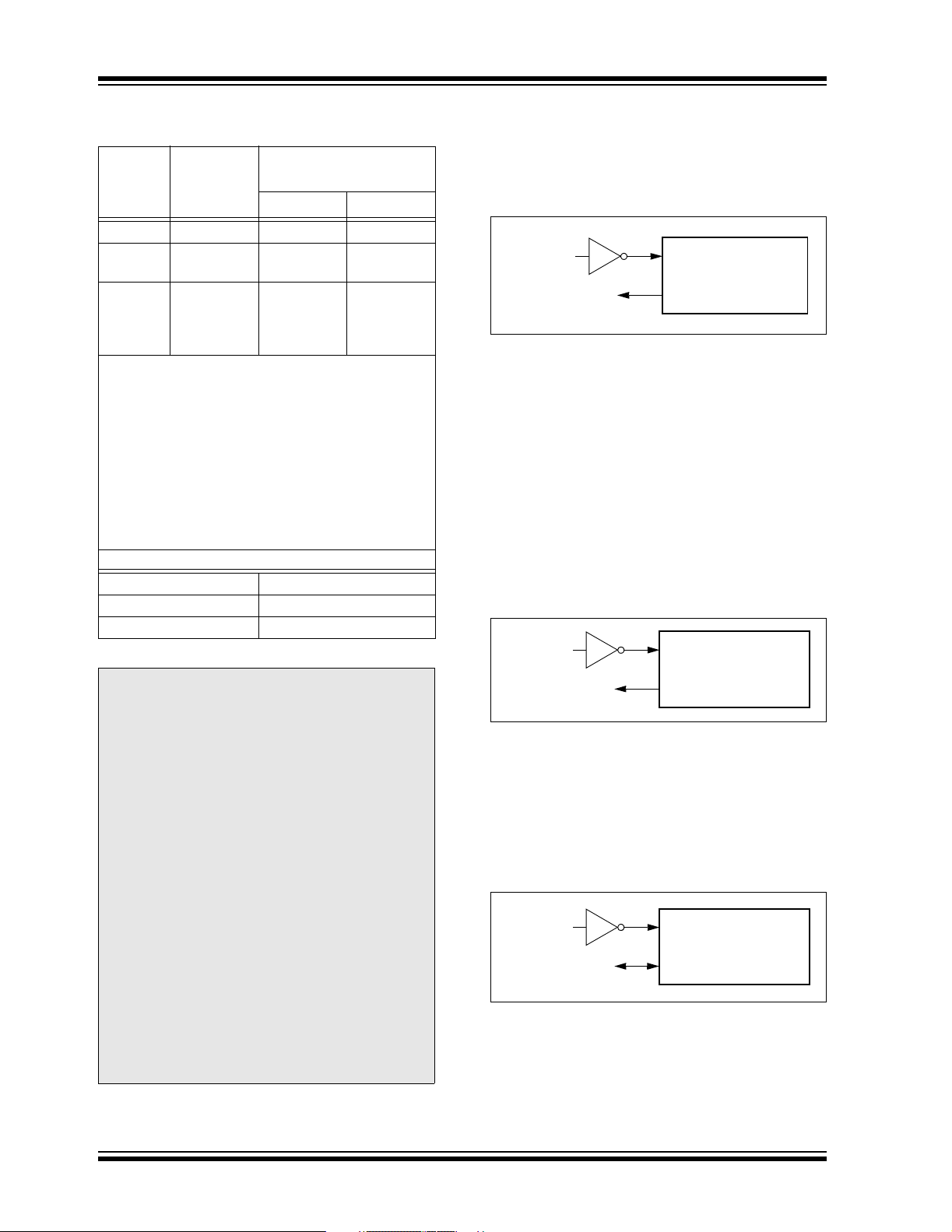

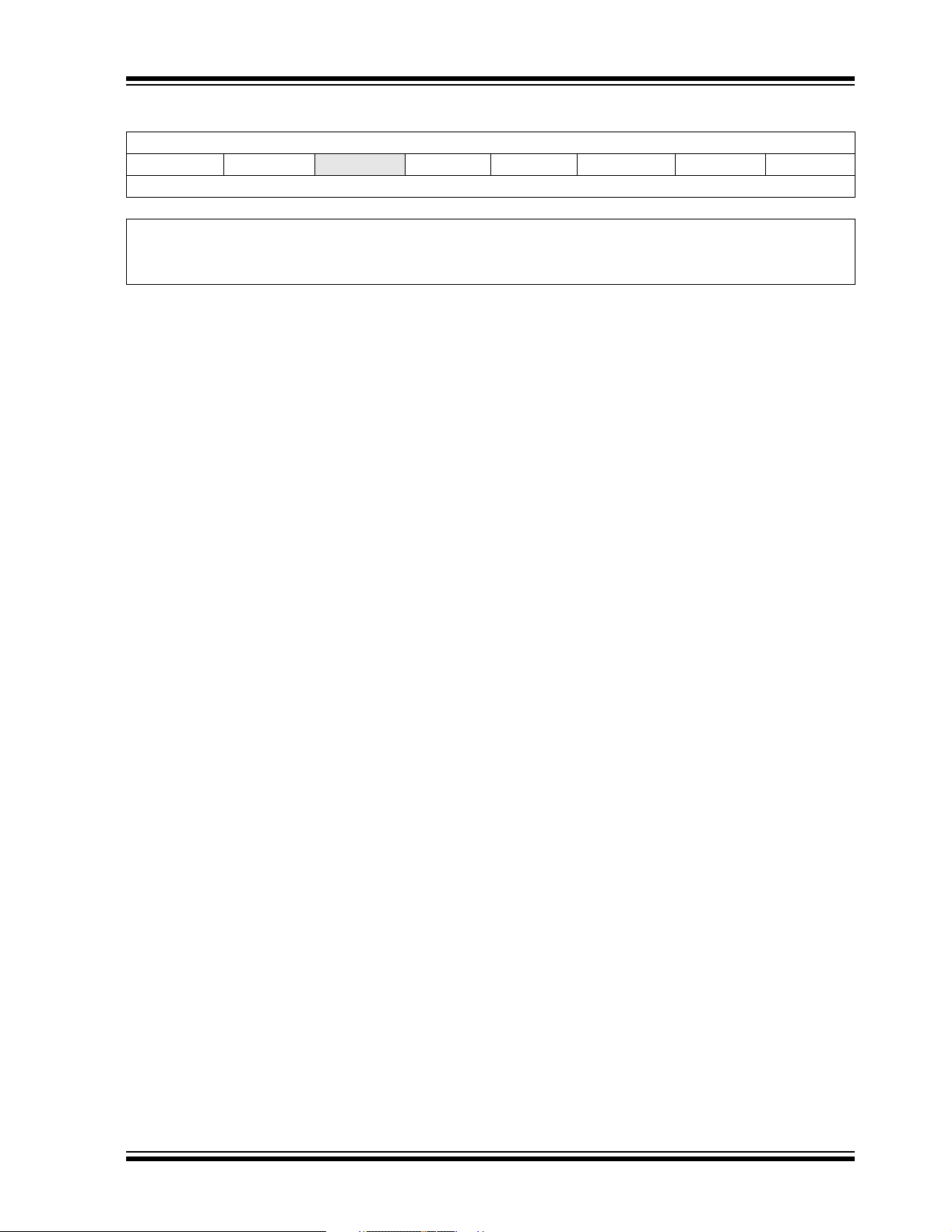

1.3 Details on Individual Family Members

Devices in the PIC18F2423/2523/4423/4523 family are

available in 28-pin and 40/44-pin packages. Block

diagrams for the two groups are shown in Figure 1-1

and Figure 1-2.

The devices are differentiated from each other in five

ways:

1. Flash program memory (16 Kbytes for

PIC18F2423/4423 devices and 32 Kbytes for

PIC18F2523/4523).

2. A/D channels (10 for 28-pin devices, 13 for

40/44-pin devices).

3. I/O ports (3 bidirectional ports on 28-pin devices,

5 bidirectional ports on 40/44-pin devices).

4. CCP and Enhanced CCP implementation

(28-pin devices have 2 standard CCP modules, 40/44-pin devices have one standard CCP

module and one ECCP module).

5. Parallel Slave Port (present only on 40/44-pin

devices).

All other features for devices in this family are identical.

These are summarized in Table 1-1.

The pinouts for all devices are listed in Table 1-2 and

Table 1-3.

Members of the PIC18F2423/2523/4423/4523 family

are available only as low-voltage devices, designated

by “LF” (such as PIC18LF2423), and function over a

DD range of 2.0V to 3.6V.

V

DS39755A-page 8 Preliminary © 2006 Microchip Technology Inc.

Page 11

PIC18F2423/2523/4423/4523

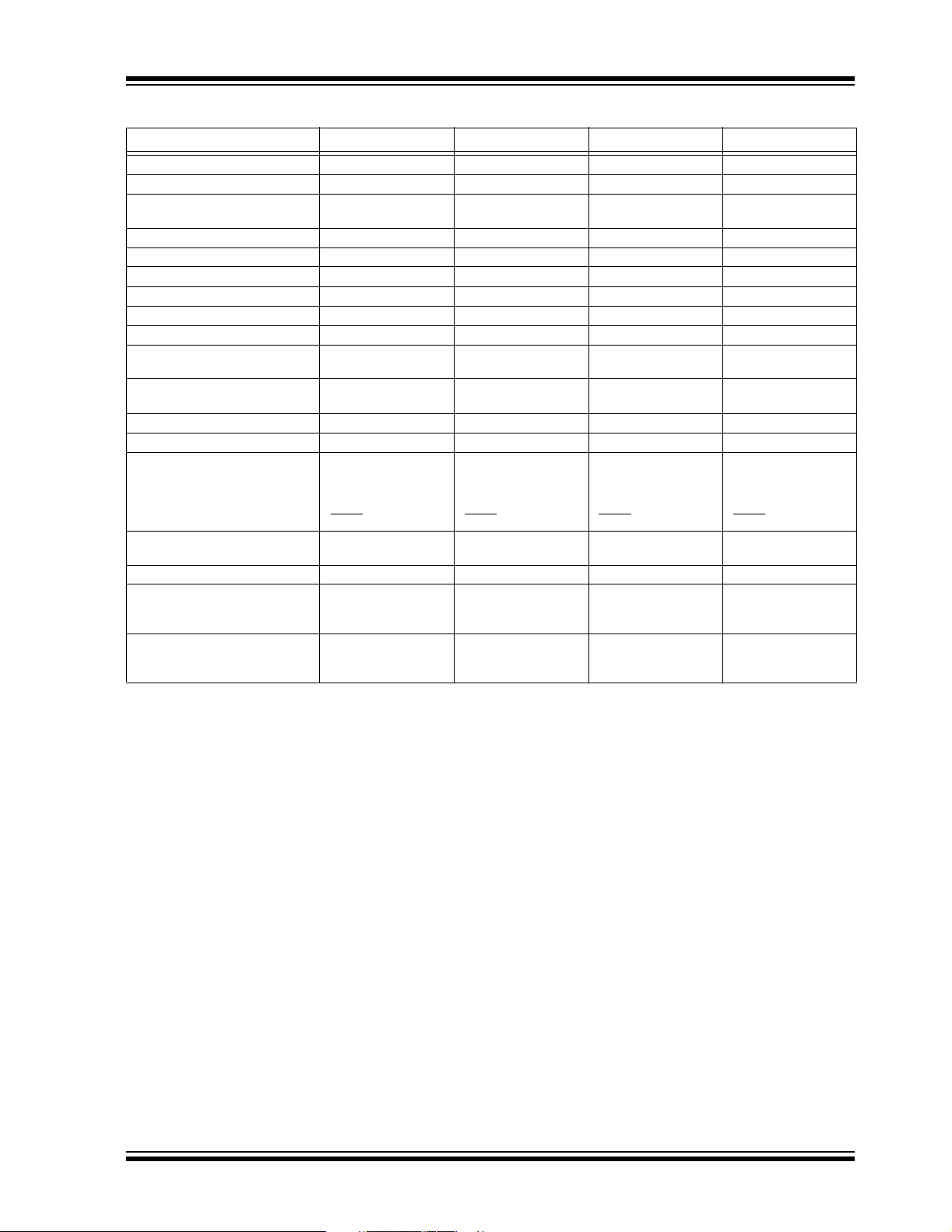

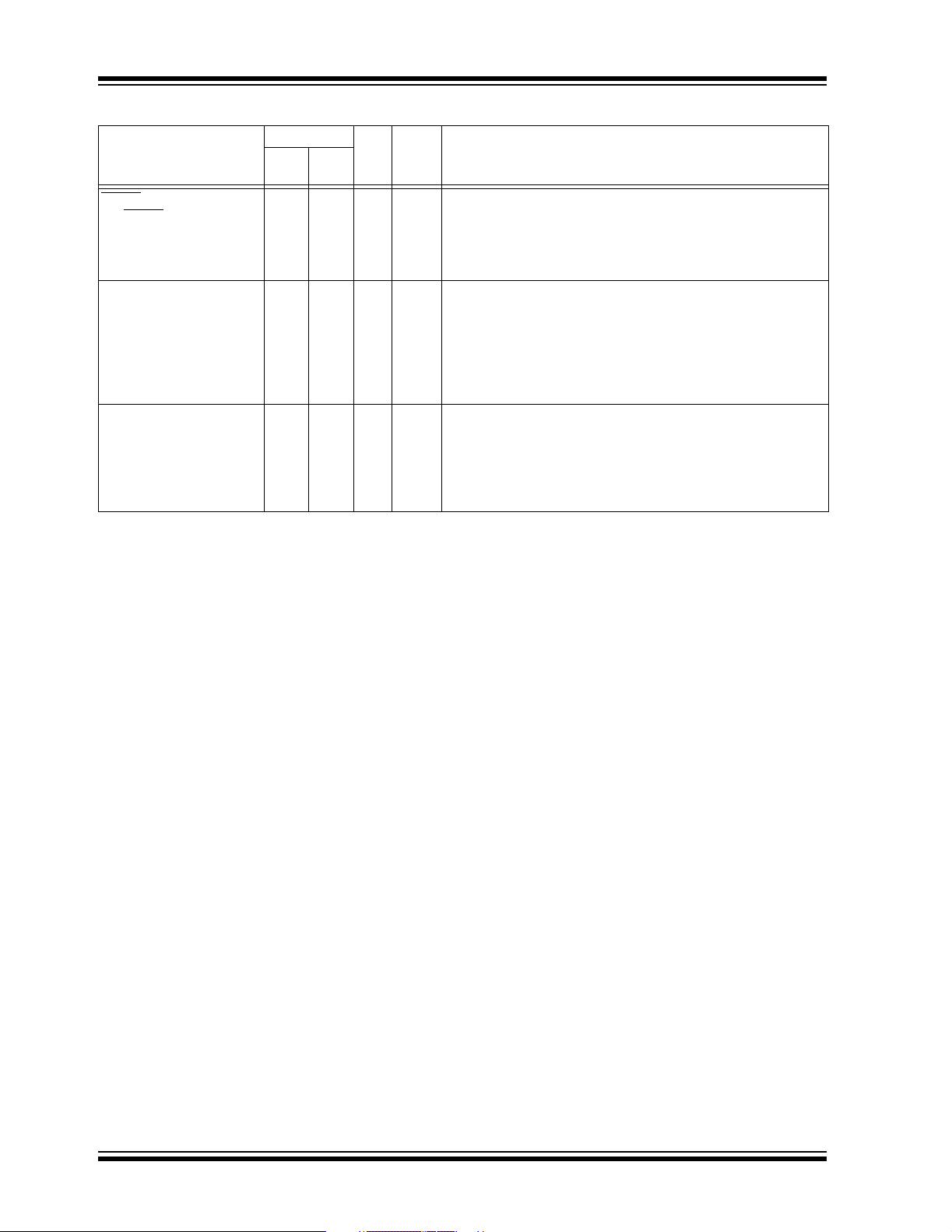

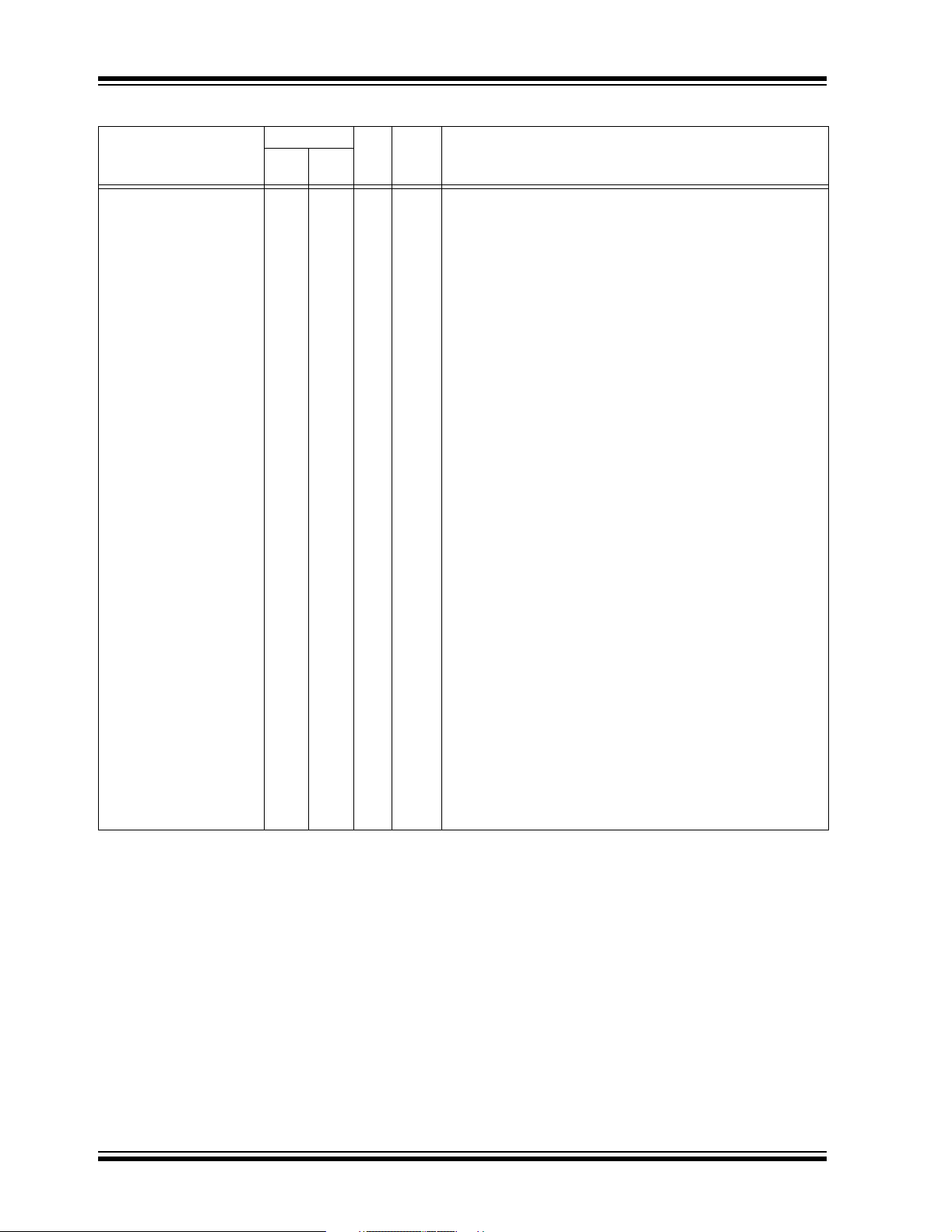

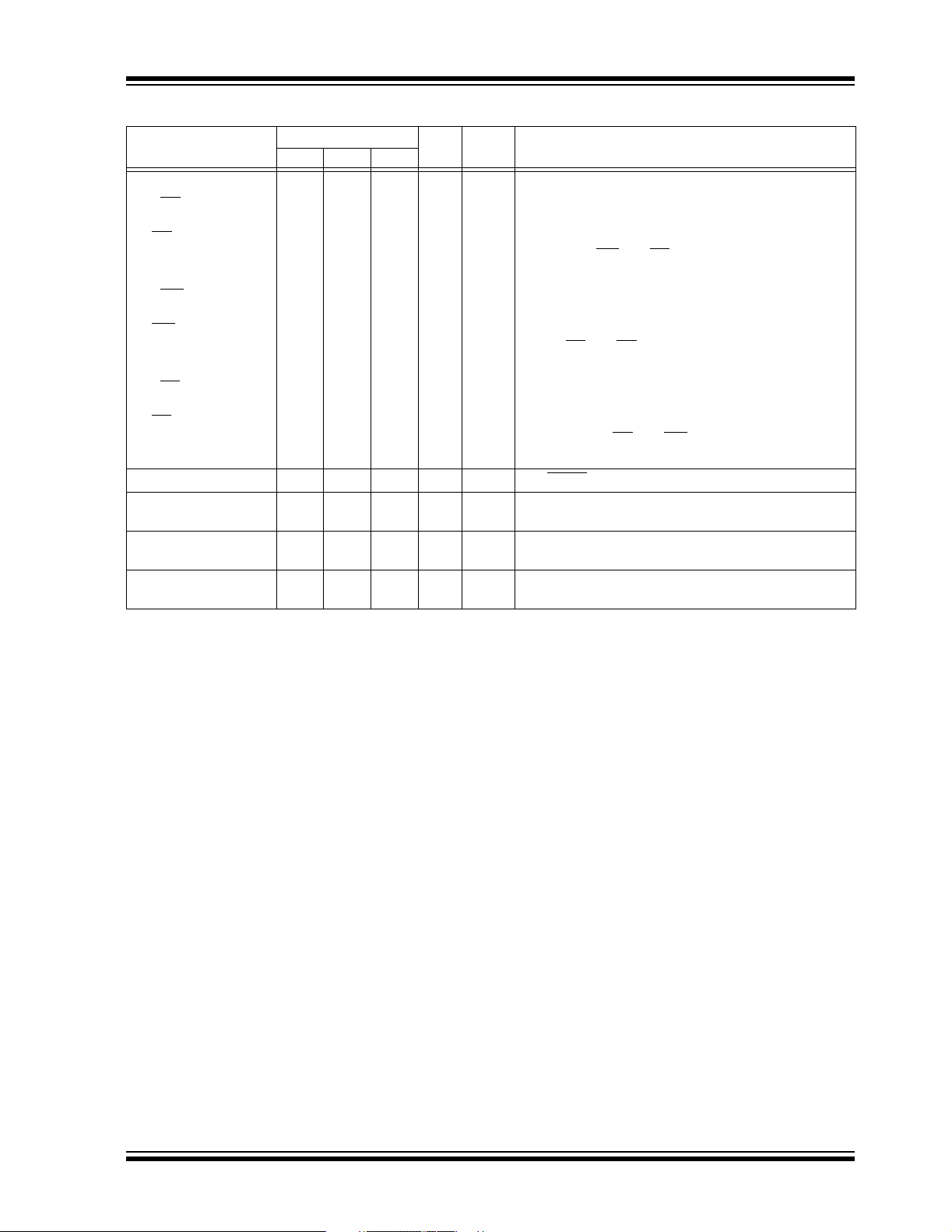

TABLE 1-1: DEVICE FEATURES

Features PIC18F2423 PIC18F2523 PIC18F4423 PIC18F4523

Operating Frequency DC – 40 MHz DC – 40 MHz DC – 40 MHz DC – 40 MHz

Program Memory (Bytes) 16384 32768 16384 32768

Program Memory

(Instructions)

Data Memory (Bytes) 768 1536 768 1536

Data EEPROM Memory (Bytes) 256 256 256 256

Interrupt Sources 19 19 20 20

I/O Ports Ports A, B, C, (E) Ports A, B, C, (E) Ports A, B, C, D, E Ports A, B, C, D, E

Timers 4 4 4 4

Capture/Compare/PWM Modules 2 2 1 1

Enhanced

Capture/Compare/PWM Modules

Serial Communications MSSP,

Parallel Communications (PSP) No No Yes Yes

12-Bit Analog-to-Digital Module 10 Input Channels 10 Input Channels 13 Input Channels 13 Input Channels

Resets (and Delays) POR, BOR,

Underflow (PWRT, OST),

Programmable

High/Low-Voltage Detect

Programmable Brown-out Reset Yes Yes Yes Yes

Instruction Set 75 Instructions;

Packages 28-pin PDIP

8192 16384 8192 16384

0011

Enhanced USART

RESET Instruction,

Stack Full, Stack

MCLR

(optional), WDT

Ye s Ye s Ye s Ye s

83 with Extended

Instruction Set enabled

28-pin SOIC

28-pin QFN

MSSP,

Enhanced USART

POR, BOR,

RESET Instruction,

Stack Full, Stack

Underflow (PWRT, OST),

MCLR (optional), WDT

75 Instructions;

83 with Extended

Instruction Set enabled

28-pin PDIP

28-pin SOIC

28-pin QFN

MSSP,

Enhanced USART

POR, BOR,

RESET Instruction,

Stack Full, Stack

Underflow (PWRT, OST),

MCLR (optional), WDT

75 Instructions;

83 with Extended

Instruction Set enabled

40-pin PDIP

44-pin QFN

44-pin TQFP

MSSP,

Enhanced USART

POR, BOR,

RESET Instruction,

Stack Full, Stack

Underflow (PWRT, OST),

MCLR (optional), WDT

75 Instructions;

83 with Extended

Instruction Set enabled

40-pin PDIP

44-pin QFN

44-pin TQFP

© 2006 Microchip Technology Inc. Preliminary DS39755A-page 9

Page 12

PIC18F2423/2523/4423/4523

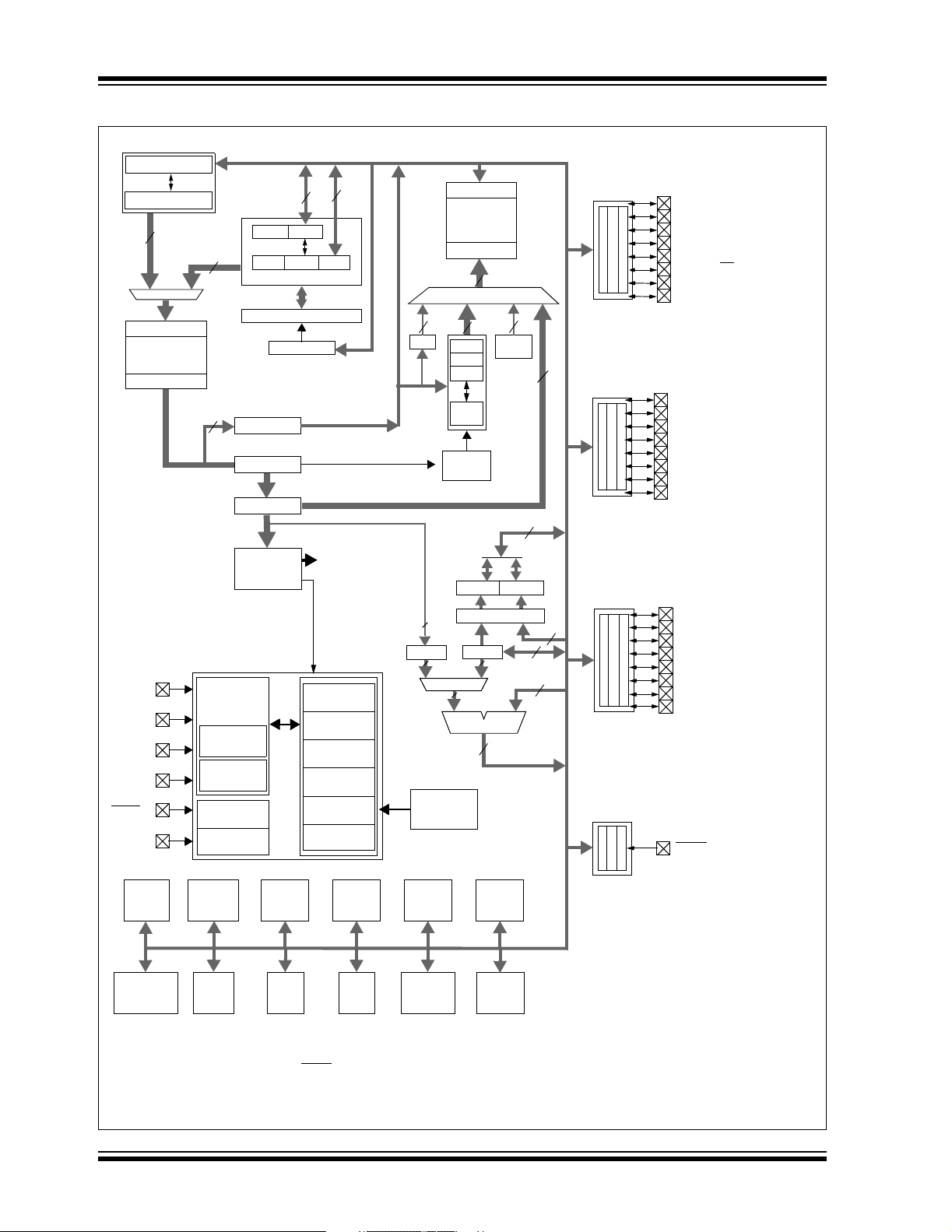

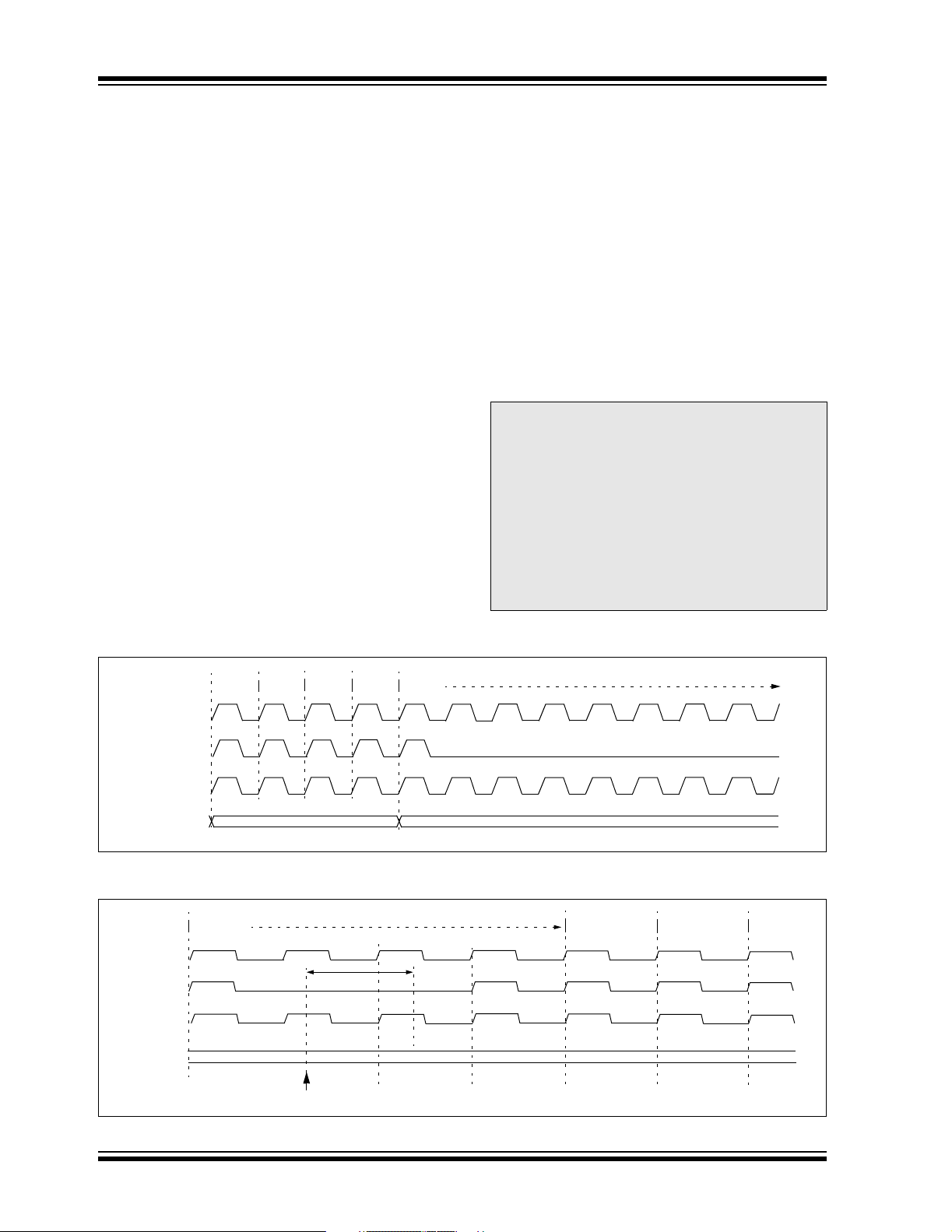

FIGURE 1-1: PIC18F2423/2523 (28-PIN) BLOCK DIAGRAM

Table Pointer<21>

inc/dec logic

21

Address Latch

Program Memory

(16/32 Kbytes)

Data Latch

Instruction Bus <16>

(3)

OSC1

(3)

OSC2

T1OSI

T1OSO

(2)

MCLR

V

VDD,

SS

20

8

Table Latch

ROM Latch

Instruction

Decode and

Control

Internal

Oscillator

Block

INTRC

Oscillator

8 MHz

Oscillator

Single-Supply

Programming

In-Circuit

Debugger

8

PCLATH

PCLATU

PCH PCL

PCU

Program Counter

31 Level Stack

STKPTR

IR

Power-up

Oscillator

Start-up Timer

Power-on

Watchdog

Brown-out

Fail-Safe

Clock Monitor

Data Bus<8>

8

State Machine

Control Signals

Timer

Reset

Timer

Reset

Data Latch

Data Memory

( 3.9 Kbytes )

Address Latch

Data Address<12>

4

BSR

FSR0

FSR1

FSR2

inc/dec

logic

Address

Decode

3

BITOP

8

Precision

Band Gap

Reference

12

12

Access

Bank

PRODLPRODH

8 x 8 Multiply

W

8

8

ALU<8>

8

PORTA

RA0/AN0

RA1/AN1

RA2/AN2/VREF-/CVREF

RA3/AN3/VREF+

RA4/T0CKI/C1OUT

RA5/AN4/SS

OSC2/CLKO

OSC1/CLKI

/HLVDIN/C2OUT

(3)

/RA6

(3)

/RA7

4

12

PORTB

RB0/INT0/FLT0/AN12

RB1/INT1/AN10

RB2/INT2/AN8

RB3/AN9/CCP2

(1)

RB4/KBI0/AN11

RB5/KBI1/PGM

RB6/KBI2/PGC

RB7/KBI3/PGD

8

PORTC

8

8

RC0/T1OSO/T13CKI

RC1/T1OSI/CCP2

(1)

RC2/CCP1

RC3/SCK/SCL

RC4/SDI/SDA

RC5/SDO

8

RC6/TX/CK

RC7/RX/DT

PORTE

MCLR/VPP/RE3

(2)

BOR

HLVD

Data

EEPROM

CCP1

CCP2

MSSP

Timer2Timer1 Tim er3Timer0

EUSARTComparator

ADC

12-Bit

Note 1: CCP2 is multiplexed with RC1 when Configuration bit CCP2MX is set, or RB3 when CCP2MX is not set.

2: RE3 is only available when MCLR

3: OSC1/CLKI and OSC2/CLKO are only available in select oscillator modes and when these pins are not being used as digital I/O.

Refer to Section 2.0 “Oscillator Configurations” for additional information.

functionality is disabled.

DS39755A-page 10 Preliminary © 2006 Microchip Technology Inc.

Page 13

PIC18F2423/2523/4423/4523

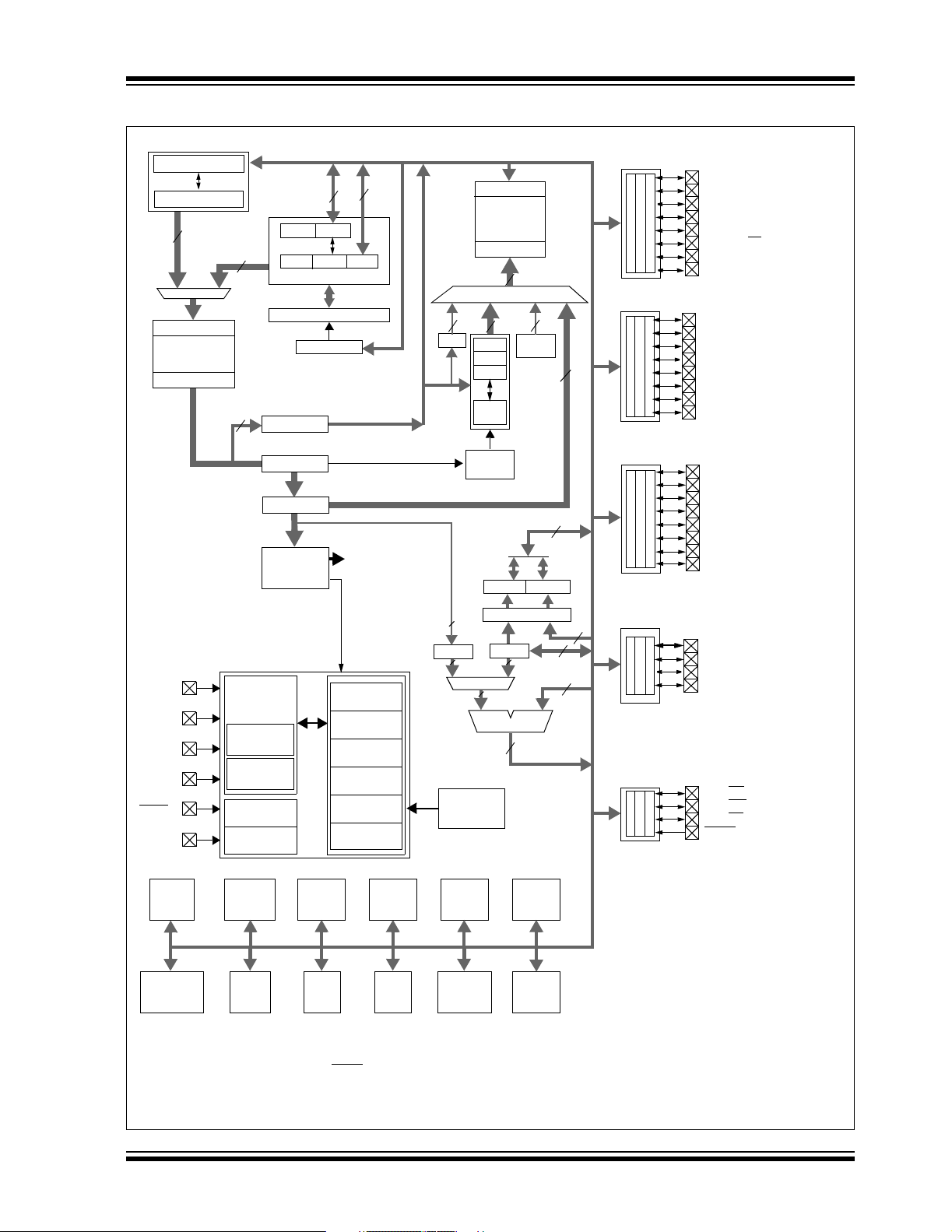

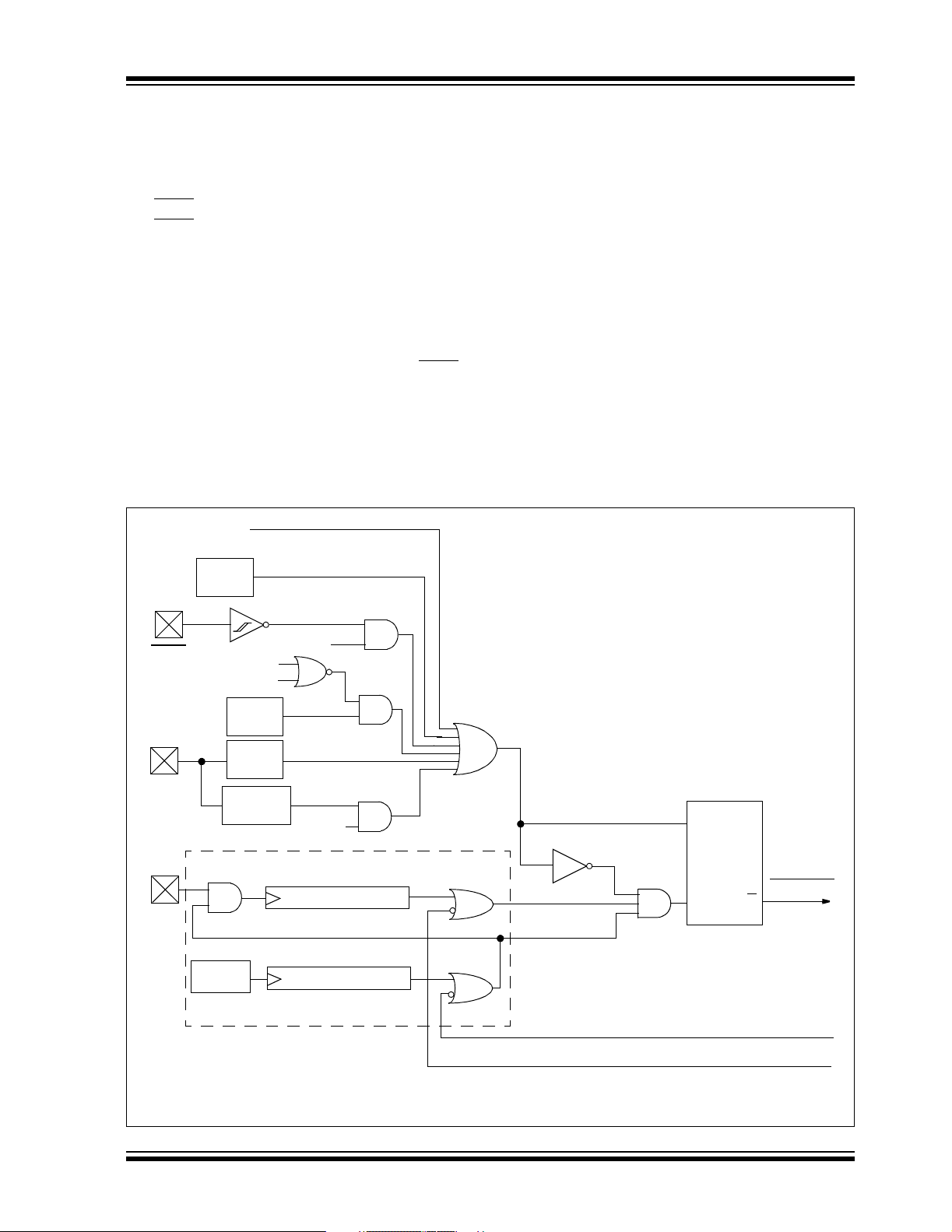

FIGURE 1-2: PIC18F4423/4523 (40/44-PIN) BLOCK DIAGRAM

Table Pointer<21>

inc/dec logic

21

20

Address Latch

Program Memory

(16/32 Kbytes)

Data Latch

8

Instruction Bus <16>

PCLATH

PCLATU

PCU

Program Counter

31 Level Stack

STKPTR

Table Latch

ROM Latch

IR

Instruction

Decode and

Control

Data Bus<8>

8

PCH PCL

State Machine

Control Signals

PORTA

8

Data Latch

Data Memory

( 3.9 Kbytes )

Address Latch

12

Data Address<12>

4

BSR

FSR0

FSR1

FSR2

inc/dec

logic

Address

Decode

4

12

Access

Bank

12

PORTB

PORTC

RA0/AN0

RA1/AN1

RA2/AN2/VREF-/CVREF

RA3/AN3/VREF+

RA4/T0CKI/C1OUT

RA5/AN4/SS

OSC2/CLKO

OSC1/CLKI

/HLVDIN/C2OUT

(3)

/RA6

(3)

/RA7

RB0/INT0/FLT0/AN12

RB1/INT1/AN10

RB2/INT2/AN8

RB3/AN9/CCP2

(1)

RB4/KBI0/AN11

RB5/KBI1/PGM

RB6/KBI2/PGC

RB7/KBI3/PGD

RC0/T1OSO/T13CKI

RC1/T1OSI/CCP2

(1)

RC2/CCP1/P1A

RC3/SCK/SCL

RC4/SDI/SDA

8

RC5/SDO

RC6/TX/CK

RC7/RX/DT

PRODLPRODH

OSC1

OSC2

T1OSI

T1OSO

MCLR

V

VDD,

BOR

HLVD

8 x 8 Multiply

3

BITOP

(3)

(3)

(2)

SS

Internal

Oscillator

Block

INTRC

Oscillator

8 MHz

Oscillator

Single-Supply

Programming

In-Circuit

Debugger

Data

EEPROM

ECCP1

Start-up Timer

Clock Monitor

CCP2

Power-up

Timer

Oscillator

Power-on

Reset

Watchdog

Timer

Brown-out

Reset

Fail-Safe

MSSP

Precision

Band Gap

Reference

Timer2Timer1 Timer3Timer0

EUSARTComparator

W

8

8

8

8

8

ALU<8>

8

ADC

12-Bit

PORTD

8

RD0/PSP0

RD5/PSP5/P1B

RD6/PSP6/P1C

RD7/PSP7/P1D

PORTE

RE0/RD/AN5

RE1/WR/AN6

RE2/CS/AN7

MCLR/VPP/RE3

Note 1: CCP2 is multiplexed with RC1 when Configuration bit CCP2MX is set, or RB3 when CCP2MX is not set.

2: RE3 is only available when MCLR

functionality is disabled.

3: OSC1/CLKI and OSC2/CLKO are only available in select oscillator modes and when these pins are not being used as digital I/O.

Refer to Section 2.0 “Oscillator Configurations” for additional information.

:RD4/PSP4

(2)

© 2006 Microchip Technology Inc. Preliminary DS39755A-page 11

Page 14

PIC18F2423/2523/4423/4523

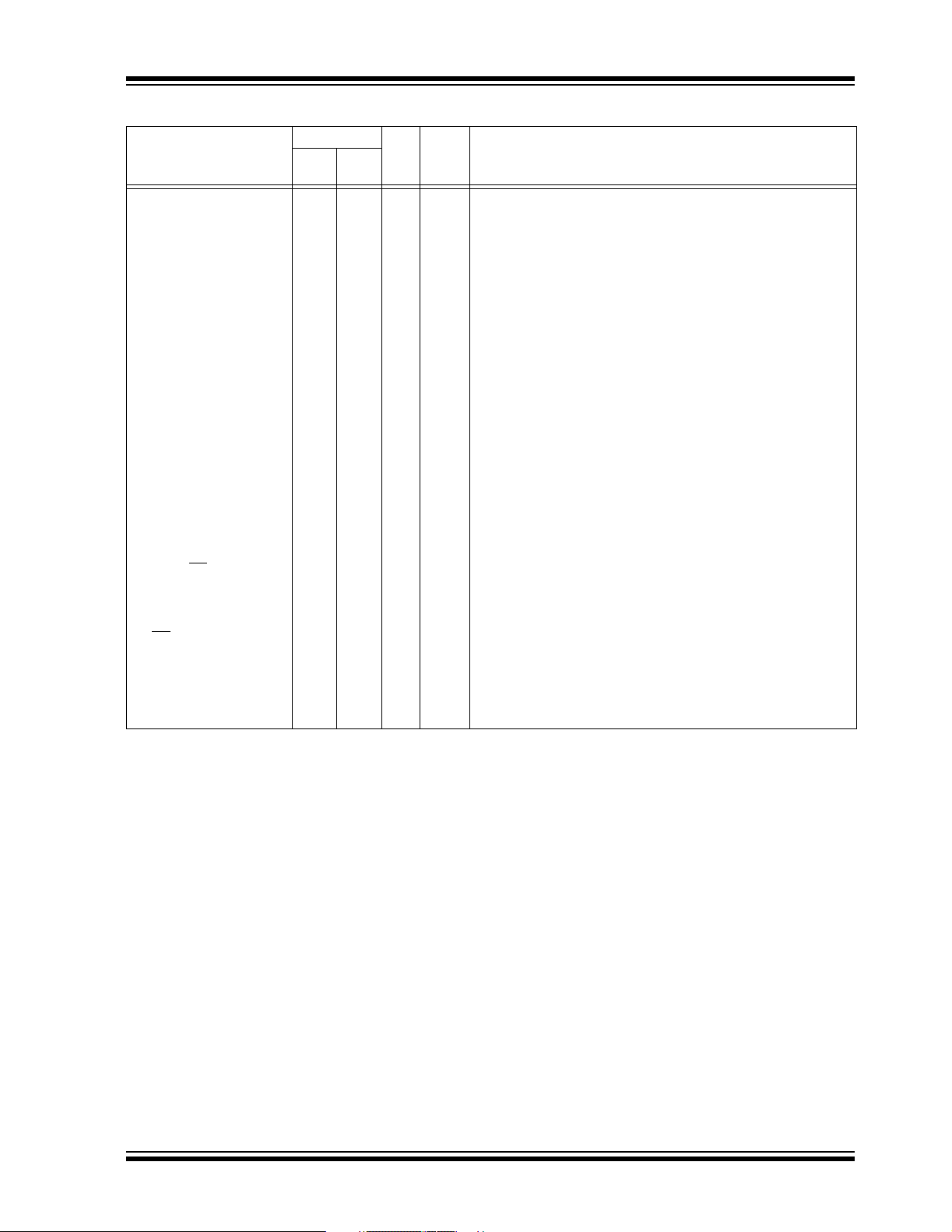

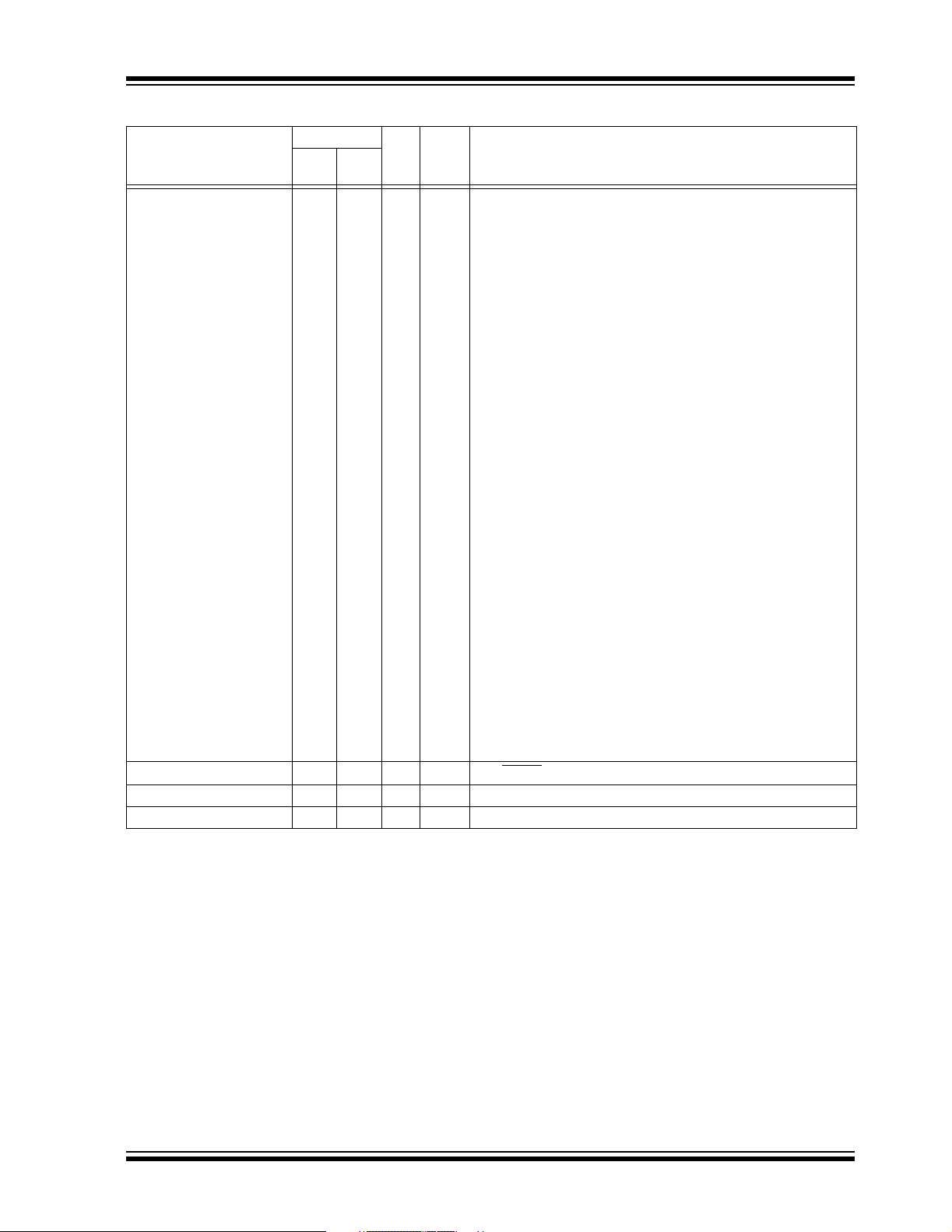

TABLE 1-2: PIC18F2423/2523 PINOUT I/O DESCRIPTIONS

Pin Number

Pin Name

MCLR

/VPP/RE3

MCLR

VPP

RE3

OSC1/CLKI/RA7

OSC1

CLKI

RA7

OSC2/CLKO/RA6

OSC2

CLKO

RA6

Legend: TTL = TTL compatible input CMOS = CMOS compatible input or output

ST = Schmitt Trigger input with CMOS levels I = Input

O=Output P =Power

Note 1: Default assignment for CCP2 when Configuration bit CCP2MX is set.

2: Alternate assignment for CCP2 when Configuration bit CCP2MX is cleared.

PDIP,

SOIC

126

96

10 7

QFN

Pin

Typ e

I

P

I

I

I

I/O

O

O

I/O

Buffer

Type

ST

ST

ST

CMOS

TTL

—

—

TTL

Description

Master Clear (input) or programming voltage (input).

Master Clear (Reset) input. This pin is an active-low

Reset to the device.

Programming voltage input.

Digital input.

Oscillator crystal or external clock input.

Oscillator crystal input or external clock source input.

ST buffer when configured in RC mode; CMOS otherwise.

External clock source input. Always associated with pin

function OSC1. (See related OSC1/CLKI, OSC2/CLKO

pins.)

General purpose I/O pin.

Oscillator crystal or clock output.

Oscillator crystal output. Connects to crystal or

resonator in Crystal Oscillator mode.

In RC mode, OSC2 pin outputs CLKO which has 1/4 the

frequency of OSC1 and denotes the instruction cycle rate.

General purpose I/O pin.

DS39755A-page 12 Preliminary © 2006 Microchip Technology Inc.

Page 15

PIC18F2423/2523/4423/4523

TABLE 1-2: PIC18F2423/2523 PINOUT I/O DESCRIPTIONS (CONTINUED)

Pin Number

Pin Name

RA0/AN0

RA0

AN0

RA1/AN1

RA1

AN1

RA2/AN2/VREF-/CVREF

RA2

AN2

REF-

V

CV

REF

RA3/AN3/VREF+

RA3

AN3

REF+

V

RA4/T0CKI/C1OUT

RA4

T0CKI

C1OUT

RA5/AN4/SS

C2OUT

RA5

AN4

SS

HLVDIN

C2OUT

RA6 See the OSC2/CLKO/RA6 pin.

RA7 See the OSC1/CLKI/RA7 pin.

Legend: TTL = TTL compatible input CMOS = CMOS compatible input or output

Note 1: Default assignment for CCP2 when Configuration bit CCP2MX is set.

/HLVDIN/

ST = Schmitt Trigger input with CMOS levels I = Input

O=Output P =Power

2: Alternate assignment for CCP2 when Configuration bit CCP2MX is cleared.

PDIP,

SOIC

227

328

41

52

63

74

QFN

Pin

Buffer

Typ e

Type

I/OITTL

Analog

I/OITTL

Analog

I/O

TTL

I

Analog

I

Analog

O

Analog

I/O

TTL

I

Analog

I

Analog

I/O

I

O

I/O

TTL

I

Analog

I

TTL

I

Analog

O

PORTA is a bidirectional I/O port.

Digital I/O.

Analog input 0.

Digital I/O.

Analog input 1.

Digital I/O.

Analog input 2.

A/D reference voltage (low) input.

Comparator reference voltage output.

Digital I/O.

Analog input 3.

A/D reference voltage (high) input.

ST

ST

—

—

Digital I/O.

Timer0 external clock input.

Comparator 1 output.

Digital I/O.

Analog input 4.

SPI slave select input.

High/Low-Voltage Detect input.

Comparator 2 output.

Description

© 2006 Microchip Technology Inc. Preliminary DS39755A-page 13

Page 16

PIC18F2423/2523/4423/4523

TABLE 1-2: PIC18F2423/2523 PINOUT I/O DESCRIPTIONS (CONTINUED)

Pin Number

Pin Name

RB0/INT0/FLT0/AN12

RB0

INT0

FLT0

AN12

RB1/INT1/AN10

RB1

INT1

AN10

RB2/INT2/AN8

RB2

INT2

AN8

RB3/AN9/CCP2

RB3

AN9

(1)

CCP2

RB4/KBI0/AN11

RB4

KBI0

AN11

RB5/KBI1/PGM

RB5

KBI1

PGM

RB6/KBI2/PGC

RB6

KBI2

PGC

RB7/KBI3/PGD

RB7

KBI3

PGD

Legend: TTL = TTL compatible input CMOS = CMOS compatible input or output

ST = Schmitt Trigger input with CMOS levels I = Input

O=Output P =Power

Note 1: Default assignment for CCP2 when Configuration bit CCP2MX is set.

2: Alternate assignment for CCP2 when Configuration bit CCP2MX is cleared.

PDIP,

SOIC

21 18

22 19

23 20

24 21

25 22

26 23

27 24

28 25

QFN

Pin

Typ e

I/O

I

I

I

I/O

I

I

I/O

I

I

I/O

I

I/O

I/O

I

I

I/O

I

I/O

I/O

I

I/O

I/O

I

I/O

Buffer

Type

TTL

ST

ST

Analog

TTL

ST

Analog

TTL

ST

Analog

TTL

Analog

ST

TTL

TTL

Analog

TTL

TTL

ST

TTL

TTL

ST

TTL

TTL

ST

Description

PORTB is a bidirectional I/O port. PORTB can be software

programmed for internal weak pull-ups on all inputs.

Digital I/O.

External interrupt 0.

PWM Fault input for CCP1.

Analog input 12.

Digital I/O.

External interrupt 1.

Analog input 10.

Digital I/O.

External interrupt 2.

Analog input 8.

Digital I/O.

Analog input 9.

Capture 2 input/Compare 2 output/PWM 2 output.

Digital I/O.

Interrupt-on-change pin.

Analog input 11.

Digital I/O.

Interrupt-on-change pin.

Low-Voltage ICSP™ Programming enable pin.

Digital I/O.

Interrupt-on-change pin.

In-Circuit Debugger and ICSP programming clock pin.

Digital I/O.

Interrupt-on-change pin.

In-Circuit Debugger and ICSP programming data pin.

DS39755A-page 14 Preliminary © 2006 Microchip Technology Inc.

Page 17

PIC18F2423/2523/4423/4523

TABLE 1-2: PIC18F2423/2523 PINOUT I/O DESCRIPTIONS (CONTINUED)

Pin Number

Pin Name

RC0/T1OSO/T13CKI

RC0

T1OSO

T13CKI

RC1/T1OSI/CCP2

RC1

T1OSI

(2)

CCP2

RC2/CCP1

RC2

CCP1

RC3/SCK/SCL

RC3

SCK

SCL

RC4/SDI/SDA

RC4

SDI

SDA

RC5/SDO

RC5

SDO

RC6/TX/CK

RC6

TX

CK

RC7/RX/DT

RC7

RX

DT

RE3 — — — — See MCLR

VSS 8, 19 5, 16 P — Ground reference for logic and I/O pins.

DD 20 17 P — Positive supply for logic and I/O pins.

V

Legend: TTL = TTL compatible input CMOS = CMOS compatible input or output

ST = Schmitt Trigger input with CMOS levels I = Input

O=Output P =Power

Note 1: Default assignment for CCP2 when Configuration bit CCP2MX is set.

2: Alternate assignment for CCP2 when Configuration bit CCP2MX is cleared.

PDIP,

SOIC

11 8

12 9

13 10

14 11

15 12

16 13

17 14

18 15

QFN

Pin

Buffer

Typ e

Type

I/O

O

I

I/O

I

Analog

I/O

I/O

I/OSTST

I/O

I/O

I/O

I/O

I

I/O

I/OOST

I/O

O

I/O

I/O

I

I/O

PORTC is a bidirectional I/O port.

ST

—

ST

ST

ST

ST

ST

ST

ST

ST

ST

—

ST

—

ST

ST

ST

ST

Digital I/O.

Timer1 oscillator output.

Timer1/Timer3 external clock input.

Digital I/O.

Timer1 oscillator input.

Capture 2 input/Compare 2 output/PWM 2 output.

Digital I/O.

Capture 1 input/Compare 1 output/PWM 1 output.

Digital I/O.

Synchronous serial clock input/output for SPI mode.

Synchronous serial clock input/output for I

Digital I/O.

SPI data in.

2

C data I/O.

I

Digital I/O.

SPI data out.

Digital I/O.

EUSART asynchronous transmit.

EUSART synchronous clock (see related RX/DT).

Digital I/O.

EUSART asynchronous receive.

EUSART synchronous data (see related TX/CK).

/VPP/RE3 pin.

Description

2

C™ mode.

© 2006 Microchip Technology Inc. Preliminary DS39755A-page 15

Page 18

PIC18F2423/2523/4423/4523

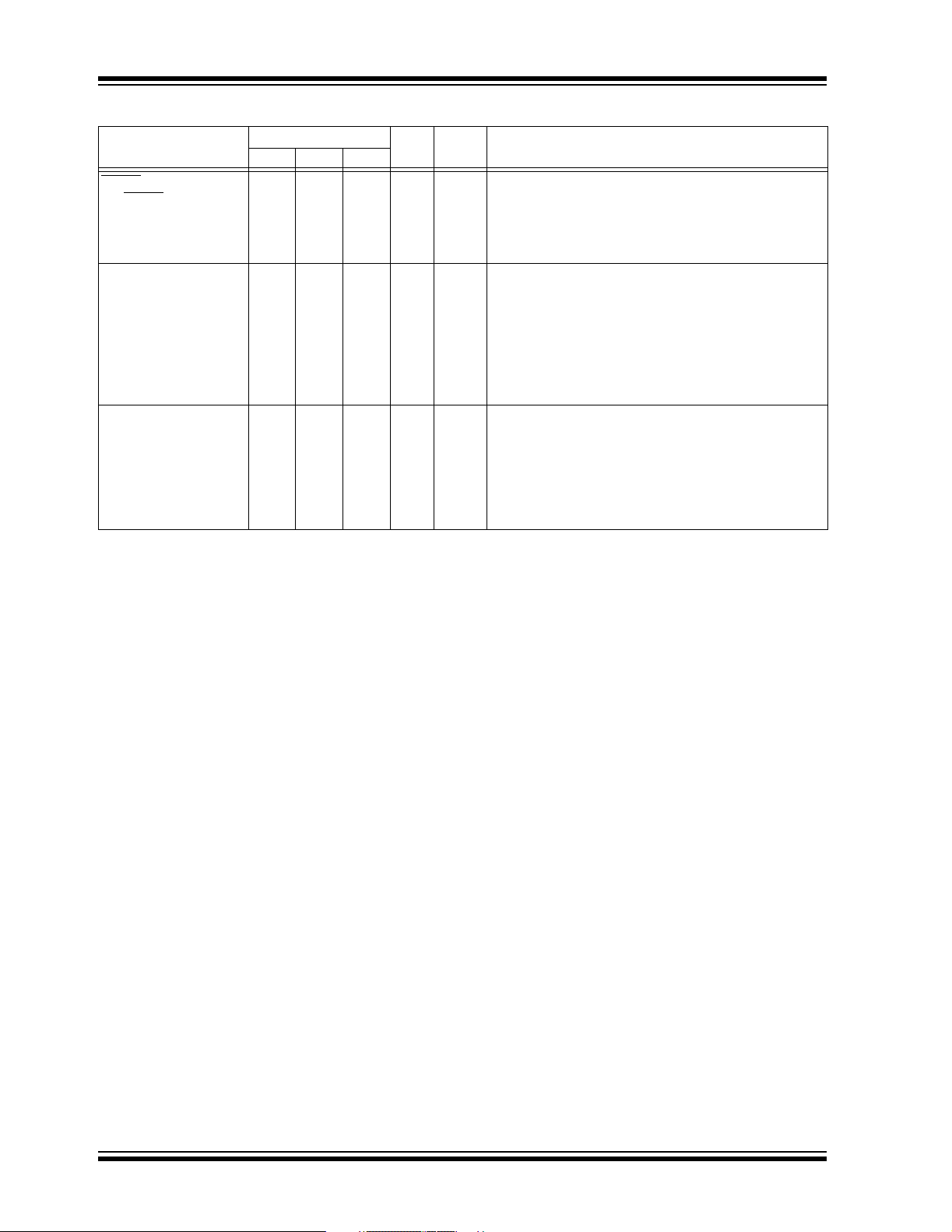

TABLE 1-3: PIC18F4423/4523 PINOUT I/O DESCRIPTIONS

Pin Name

/VPP/RE3

MCLR

MCLR

VPP

RE3

OSC1/CLKI/RA7

OSC1

CLKI

RA7

OSC2/CLKO/RA6

OSC2

CLKO

RA6

Legend: TTL = TTL compatible input CMOS = CMOS compatible input or output

ST = Schmitt Trigger input with CMOS levels I = Input

O = Output P = Power

Note 1: Default assignment for CCP2 when Configuration bit CCP2MX is set.

2: Alternate assignment for CCP2 when Configuration bit CCP2MX is cleared.

Pin Number

PDIP QFN TQFP

11818

13 32 30

14 33 31

Pin

Type

I

P

I

I

I

I/O

O

O

I/O

Buffer

Typ e

ST

ST

ST

CMOS

TTL

—

—

TTL

Description

Master Clear (input) or programming voltage (input).

Master Clear (Reset) input. This pin is an active-low

Reset to the device.

Programming voltage input.

Digital input.

Oscillator crystal or external clock input.

Oscillator crystal input or external clock source input.

ST buffer when configured in RC mode;

analog otherwise.

External clock source input. Always associated with

pin function OSC1. (See related OSC1/CLKI,

OSC2/CLKO pins.)

General purpose I/O pin.

Oscillator crystal or clock output.

Oscillator crystal output. Connects to crystal

or resonator in Crystal Oscillator mode.

In RC mode, OSC2 pin outputs CLKO which

has 1/4 the frequency of OSC1 and denotes

the instruction cycle rate.

General purpose I/O pin.

DS39755A-page 16 Preliminary © 2006 Microchip Technology Inc.

Page 19

PIC18F2423/2523/4423/4523

TABLE 1-3: PIC18F4423/4523 PINOUT I/O DESCRIPTIONS (CONTINUED)

Pin Name

RA0/AN0

RA0

AN0

RA1/AN1

RA1

AN1

RA2/AN2/VREF-/CVREF

RA2

AN2

VREF-

REF

CV

RA3/AN3/V

RA3

AN3

V

RA4/T0CKI/C1OUT

RA4

T0CKI

C1OUT

RA5/AN4/SS

C2OUT

RA5

AN4

SS

HLVDIN

C2OUT

RA6 See the OSC2/CLKO/RA6 pin.

RA7 See the OSC1/CLKI/RA7 pin.

Legend: TTL = TTL compatible input CMOS = CMOS compatible input or output

Note 1: Default assignment for CCP2 when Configuration bit CCP2MX is set.

REF+

REF+

/HLVDIN/

ST = Schmitt Trigger input with CMOS levels I = Input

O = Output P = Power

2: Alternate assignment for CCP2 when Configuration bit CCP2MX is cleared.

Pin Number

PDIP QFN TQFP

21919

32020

42121

52222

62323

72424

Pin

Buffer

Type

Typ e

I/OITTL

Analog

I/OITTL

Analog

I/O

I

Analog

I

Analog

O

Analog

I/O

I

Analog

I

Analog

I/O

I

O

I/O

I

Analog

I

I

Analog

O

PORTA is a bidirectional I/O port.

Digital I/O.

Analog input 0.

Digital I/O.

Analog input 1.

TTL

TTL

ST

ST

—

TTL

TTL

—

Digital I/O.

Analog input 2.

A/D reference voltage (low) input.

Comparator reference voltage output.

Digital I/O.

Analog input 3.

A/D reference voltage (high) input.

Digital I/O.

Timer0 external clock input.

Comparator 1 output.

Digital I/O.

Analog input 4.

SPI slave select input.

High/Low-Voltage Detect input.

Comparator 2 output.

Description

© 2006 Microchip Technology Inc. Preliminary DS39755A-page 17

Page 20

PIC18F2423/2523/4423/4523

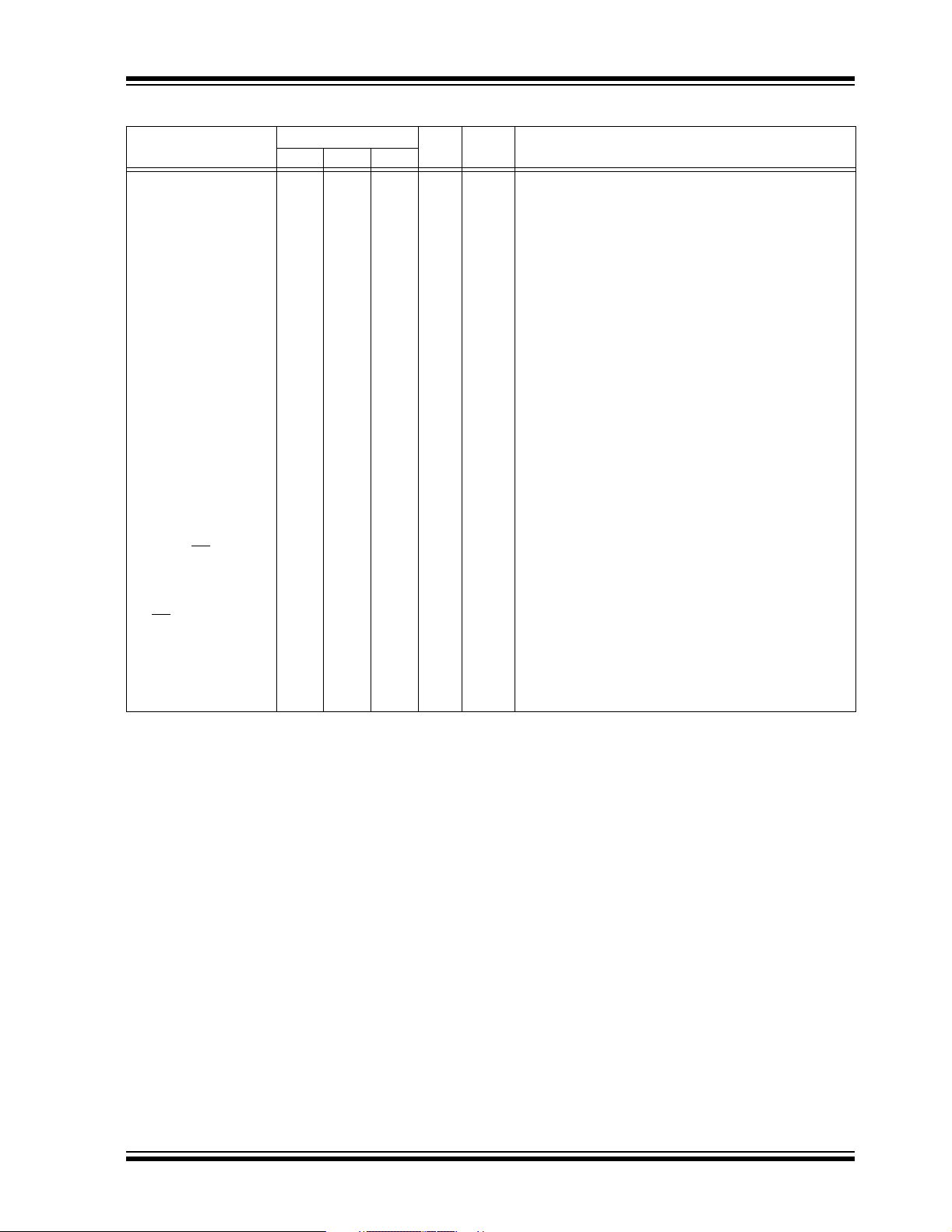

TABLE 1-3: PIC18F4423/4523 PINOUT I/O DESCRIPTIONS (CONTINUED)

Pin Name

RB0/INT0/FLT0/AN12

RB0

INT0

FLT0

AN12

RB1/INT1/AN10

RB1

INT1

AN10

RB2/INT2/AN8

RB2

INT2

AN8

RB3/AN9/CCP2

RB3

AN9

(1)

CCP2

RB4/KBI0/AN11

RB4

KBI0

AN11

RB5/KBI1/PGM

RB5

KBI1

PGM

RB6/KBI2/PGC

RB6

KBI2

PGC

RB7/KBI3/PGD

RB7

KBI3

PGD

Legend: TTL = TTL compatible input CMOS = CMOS compatible input or output

ST = Schmitt Trigger input with CMOS levels I = Input

O = Output P = Power

Note 1: Default assignment for CCP2 when Configuration bit CCP2MX is set.

2: Alternate assignment for CCP2 when Configuration bit CCP2MX is cleared.

Pin Number

PDIP QFN TQFP

33 9 8

34 10 9

35 11 10

36 12 11

37 14 14

38 15 15

39 16 16

40 17 17

Pin

Type

I/O

I

I

I

I/O

I

I

I/O

I

I

I/O

I

I/O

I/O

I

I

I/O

I

I/O

I/O

I

I/O

I/O

I

I/O

Buffer

Typ e

TTL

ST

ST

Analog

TTL

ST

Analog

TTL

ST

Analog

TTL

Analog

ST

TTL

TTL

Analog

TTL

TTL

ST

TTL

TTL

ST

TTL

TTL

ST

Description

PORTB is a bidirectional I/O port. PORTB can be

software programmed for internal weak pull-ups on all

inputs.

Digital I/O.

External interrupt 0.

PWM Fault input for Enhanced CCP1.

Analog input 12.

Digital I/O.

External interrupt 1.

Analog input 10.

Digital I/O.

External interrupt 2.

Analog input 8.

Digital I/O.

Analog input 9.

Capture 2 input/Compare 2 output/PWM 2 output.

Digital I/O.

Interrupt-on-change pin.

Analog input 11.

Digital I/O.

Interrupt-on-change pin.

Low-Voltage ICSP™ Programming enable pin.

Digital I/O.

Interrupt-on-change pin.

In-Circuit Debugger and ICSP programming

clock pin.

Digital I/O.

Interrupt-on-change pin.

In-Circuit Debugger and ICSP programming

data pin.

DS39755A-page 18 Preliminary © 2006 Microchip Technology Inc.

Page 21

PIC18F2423/2523/4423/4523

TABLE 1-3: PIC18F4423/4523 PINOUT I/O DESCRIPTIONS (CONTINUED)

Pin Name

RC0/T1OSO/T13CKI

RC0

T1OSO

T13CKI

RC1/T1OSI/CCP2

RC1

T1OSI

(2)

CCP2

RC2/CCP1/P1A

RC2

CCP1

P1A

RC3/SCK/SCL

RC3

SCK

SCL

RC4/SDI/SDA

RC4

SDI

SDA

RC5/SDO

RC5

SDO

RC6/TX/CK

RC6

TX

CK

RC7/RX/DT

RC7

RX

DT

Legend: TTL = TTL compatible input CMOS = CMOS compatible input or output

ST = Schmitt Trigger input with CMOS levels I = Input

O = Output P = Power

Note 1: Default assignment for CCP2 when Configuration bit CCP2MX is set.

2: Alternate assignment for CCP2 when Configuration bit CCP2MX is cleared.

Pin Number

PDIP QFN TQFP

15 34 32

16 35 35

17 36 36

18 37 37

23 42 42

24 43 43

25 44 44

26 1 1

Pin

Buffer

Type

I/O

O

I

I/O

I

CMOS

I/O

I/O

I/O

O

I/O

I/O

I/O

I/O

I

I/O

I/OOST

I/O

O

I/O

I/O

I

I/O

Typ e

PORTC is a bidirectional I/O port.

ST

—

ST

ST

ST

ST

ST

—

ST

ST

ST

ST

ST

ST

—

ST

—

ST

ST

ST

ST

Digital I/O.

Timer1 oscillator output.

Timer1/Timer3 external clock input.

Digital I/O.

Timer1 oscillator input.

Capture 2 input/Compare 2 output/PWM 2 output.

Digital I/O.

Capture 1 input/Compare 1 output/PWM 1 output.

Enhanced CCP1 output.

Digital I/O.

Synchronous serial clock input/output for

SPI mode.

Synchronous serial clock input/output for I

Digital I/O.

SPI data in.

2

C data I/O.

I

Digital I/O.

SPI data out.

Digital I/O.

EUSART asynchronous transmit.

EUSART synchronous clock (see related RX/DT).

Digital I/O.

EUSART asynchronous receive.

EUSART synchronous data (see related TX/CK).

Description

2

C™ mode.

© 2006 Microchip Technology Inc. Preliminary DS39755A-page 19

Page 22

PIC18F2423/2523/4423/4523

TABLE 1-3: PIC18F4423/4523 PINOUT I/O DESCRIPTIONS (CONTINUED)

Pin Name

RD0/PSP0

RD0

PSP0

RD1/PSP1

RD1

PSP1

RD2/PSP2

RD2

PSP2

RD3/PSP3

RD3

PSP3

RD4/PSP4

RD4

PSP4

RD5/PSP5/P1B

RD5

PSP5

P1B

RD6/PSP6/P1C

RD6

PSP6

P1C

RD7/PSP7/P1D

RD7

PSP7

P1D

Legend: TTL = TTL compatible input CMOS = CMOS compatible input or output

ST = Schmitt Trigger input with CMOS levels I = Input

O = Output P = Power

Note 1: Default assignment for CCP2 when Configuration bit CCP2MX is set.

2: Alternate assignment for CCP2 when Configuration bit CCP2MX is cleared.

Pin Number

PDIP QFN TQFP

19 38 38

20 39 39

21 40 40

22 41 41

27 2 2

28 3 3

29 4 4

30 5 5

Pin

Buffer

Type

Typ e

I/O

I/OSTTTL

I/O

I/OSTTTL

I/O

I/OSTTTL

I/O

I/OSTTTL

I/O

I/OSTTTL

I/O

I/O

TTL

O

I/O

I/O

TTL

O

I/O

I/O

TTL

O

Description

PORTD is a bidirectional I/O port or a Parallel Slave

Port (PSP) for interfacing to a microprocessor port.

These pins have TTL input buffers when the PSP

module is enabled.

Digital I/O.

Parallel Slave Port data.

Digital I/O.

Parallel Slave Port data.

Digital I/O.

Parallel Slave Port data.

Digital I/O.

Parallel Slave Port data.

Digital I/O.

Parallel Slave Port data.

ST

—

ST

—

ST

—

Digital I/O.

Parallel Slave Port data.

Enhanced CCP1 output.

Digital I/O.

Parallel Slave Port data.

Enhanced CCP1 output.

Digital I/O.

Parallel Slave Port data.

Enhanced CCP1 output.

DS39755A-page 20 Preliminary © 2006 Microchip Technology Inc.

Page 23

PIC18F2423/2523/4423/4523

TABLE 1-3: PIC18F4423/4523 PINOUT I/O DESCRIPTIONS (CONTINUED)

Pin Name

RE0/RD

RE1/WR

RE2/CS

RE3 — — — — — See MCLR/VPP/RE3 pin.

VSS 12, 31 6, 30, 316, 29 P — Ground reference for logic and I/O pins.

/AN5

RE0

RD

AN5

/AN6

RE1

WR

AN6

/AN7

RE2

CS

AN7

Pin Number

PDIP QFN TQFP

82525

92626

10 27 27

Pin

Type

I/O

I

I

I/O

I

I

I/O

I

I

Buffer

Typ e

ST

TTL

Analog

ST

TTL

Analog

ST

TTL

Analog

Description

PORTE is a bidirectional I/O port.

Digital I/O.

Read control for Parallel Slave Port

(see also WR

Analog input 5.

Digital I/O.

Write control for Parallel Slave Port

(see CS

Analog input 6.

Digital I/O.

Chip Select control for Parallel Slave Port

(see related RD

Analog input 7.

and CS pins).

and RD pins).

and WR).

V

DD 11, 32 7, 8,

28, 29

NC — 13 12, 13,

Legend: TTL = TTL compatible input CMOS = CMOS compatible input or output

ST = Schmitt Trigger input with CMOS levels I = Input

O = Output P = Power

Note 1: Default assignment for CCP2 when Configuration bit CCP2MX is set.

2: Alternate assignment for CCP2 when Configuration bit CCP2MX is cleared.

7, 28 P — Positive supply for logic and I/O pins.

— — No connect.

33, 34

© 2006 Microchip Technology Inc. Preliminary DS39755A-page 21

Page 24

PIC18F2423/2523/4423/4523

NOTES:

DS39755A-page 22 Preliminary © 2006 Microchip Technology Inc.

Page 25

PIC18F2423/2523/4423/4523

2.0 OSCILLATOR CONFIGURATIONS

2.1 Oscillator Types

PIC18F2423/2523/4423/4523 devices can be operated

in ten different oscillator modes. The user can program

the Configuration bits, FOSC3:FOSC0, in Configuration

Register 1H to select one of these ten modes:

1. LP Low-Power Crystal

2. XT Crystal/Resonator

3. HS High-Speed Crystal/Resonator

4. HSPLL High-Speed Crystal/Resonator

with PLL Enabled

5. RC External Resistor/Capacitor with

F

OSC/4 Output on RA6

6. RCIO External Resistor/Capacitor with I/O

on RA6

7. INTIO1 Internal Oscillator with F

on RA6 and I/O on RA7

8. INTIO2 Internal Oscillator with I/O on RA6

and RA7

9. EC External Clock with F

10. ECIO External Clock with I/O on RA6

OSC/4 Output

OSC/4 Output

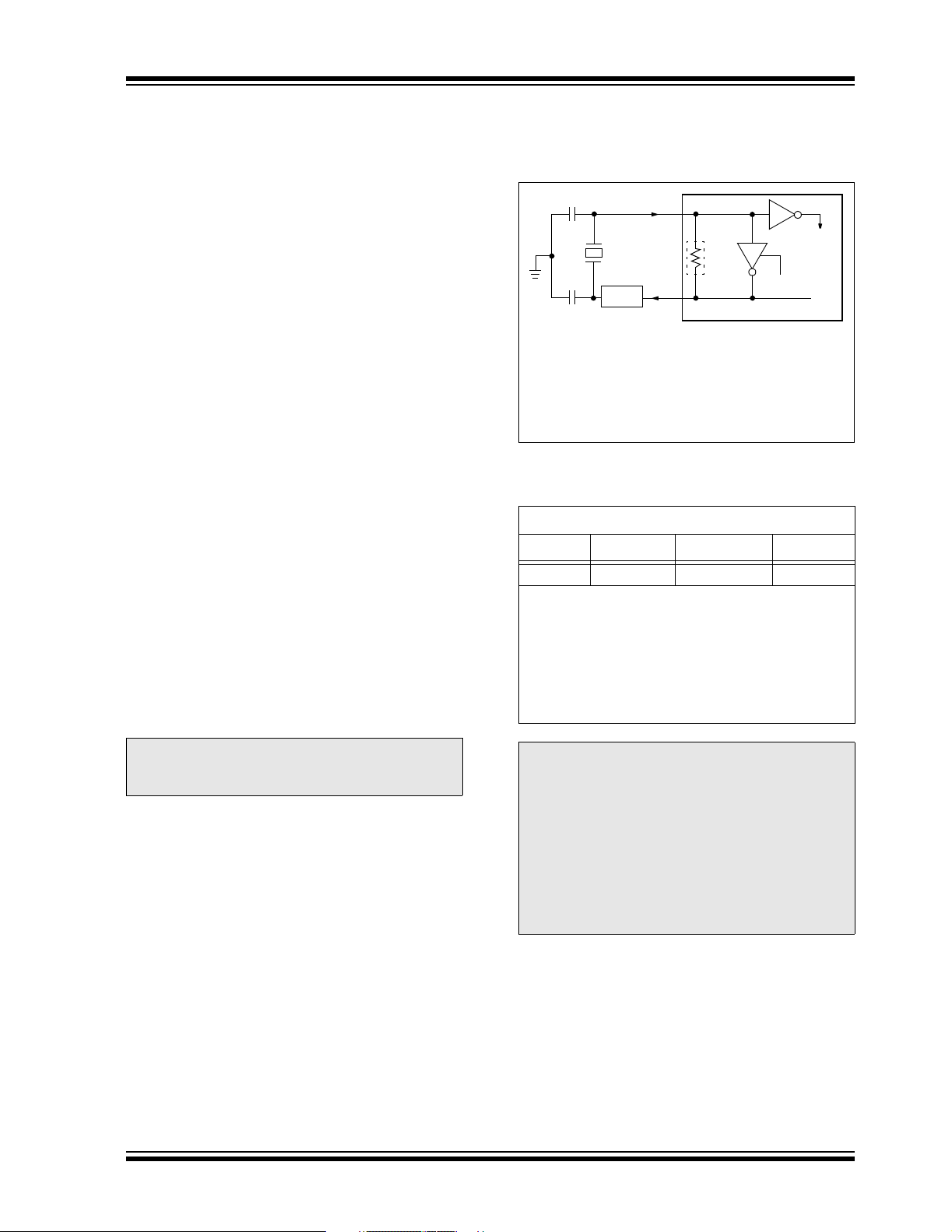

FIGURE 2-1: CRYSTAL/CERAMIC

RESONATOR OPERATION

(XT, LP, HS OR HSPLL

CONFIGURATION)

(1)

C1

(1)

C2

Note 1: See Table 2-1 and Table 2-2 for initial values of

2: A series resistor (R

3: R

OSC1

XTAL

(2)

RS

OSC2

C1 and C2.

strip cut crystals.

F varies with the oscillator mode chosen.

(3)

RF

Sleep

PIC18FXXXX

S) may be required for AT

To

Internal

Logic

TABLE 2-1: CAPACITOR SELECTION FOR

CERAMIC RESONATORS

Typical Capacitor Values Used:

Mode Freq. OSC1 OSC2

2.2 Crystal Oscillator/Ceramic Resonators

In XT, LP, HS or HSPLL Oscillator modes, a crystal or

ceramic resonator is connected to the OSC1 and

OSC2 pins to establish oscillation. Figure 2-1 shows

the pin connections.

The oscillator design requires the use of a parallel cut

crystal.

Note: Use of a series cut crystal may give a fre-

quency out of the crystal manufacturer’s

specifications.

XT 3.58 MHz 15 pF 15 pF

Capacitor values are for design guidance only.

Different capacitor values may be required to produce

acceptable oscillator operation. The user should test

the performance of the oscillator over the expected

DD and temperature range for the application.

V

See the notes following Table 2-2 for additional

information.

Note: When using resonators with frequencies

above 3.6 MHz, the use of HS mode,

rather than XT mode, is recommended.

HS mode may be used at any V

DD for

which the controller is rated. If HS is

selected, it is possible that the gain of the

oscillator will overdrive the resonator.

Therefore, a series resistor should be

placed between the OSC2 pin and the

resonator. As a good starting point, the

recommended value of R

S is 330Ω.

© 2006 Microchip Technology Inc. Preliminary DS39755A-page 23

Page 26

PIC18F2423/2523/4423/4523

TABLE 2-2: CAPACITOR SELECTION FOR

CRYSTAL OSCILLATOR

Osc.

Typ e

Crystal

Freq.

LP 32 kHz 18 pF 18 pF

XT 1 MHz

4 MHz

HS 4 MHz

10 MHz

20 MHz

25 MHz

Capacitor values are for design guidance only.

These capacitors were tested with the crystals listed

below for basic start-up and operation. These values

are not optimized.

Different capacitor values may be required to produce

acceptable oscillator operation. The user should test

the performance of the oscillator over the expected

DD and temperature range for the application.

V

See the notes following this table for additional

information.

Crystals Used:

32 kHz 4 MHz

25 MHz 10 MHz

1 MHz 20 MHz

Note 1: When operating below 3V VDD, or when

using ceramic resonators above 3.6 MHz

at any voltage, it may be necessary to use

the HS mode or switch to a crystal

oscillator.

2: Since each resonator/crystal has its own

characteristics, the user should consult

the resonator/crystal manufacturer for

appropriate values of external

components.

S may be required to avoid overdriving

3: R

tuning fork crystals, such as those commonly used in LP mode or with the Timer1

oscillator. R

crystal drive in other modes where

waveform distortion could be an issue.

AN949, “Making Your Oscillator

See

.

Work”

4: Always verify oscillator performance over

the VDD and temperature range that is

expected for the application. See

“Making Your Oscillator Work”

methods.

Typical Capacitor Values

Tested:

C1 C2

15 pF

15 pF

15 pF

15 pF

15 pF

15 pF

S may also be used to reduce

15 pF

15 pF

15 pF

15 pF

15 pF

15 pF

AN949,

for testing

An external clock source may also be connected to the

OSC1 pin in the HS mode, as shown in Figure 2-2.

FIGURE 2-2: EXTERNAL CLOCK INPUT

OPERATION (HS OSC.

CONFIGURATION)

Clock from

Ext. System

Open

OSC1

OSC2

PIC18FXXXX

(HS Mode)

2.3 External Clock Input

The EC and ECIO Oscillator modes require an external

clock source to be connected to the OSC1 pin. There is

no oscillator start-up time required after a Power-on

Reset or after an exit from Sleep mode.

In the EC Oscillator mode, the oscillator frequency

divided by 4 is available on the OSC2 pin. This signal

may be used for test purposes or to synchronize other

logic. Figure 2-3 shows the pin connections for the EC

Oscillator mode.

FIGURE 2-3: EXTERNAL CLOCK

INPUT OPERATION

(EC CONFIGURATION)

Clock from

Ext. System

F

OSC/4

The ECIO Oscillator mode functions like the EC mode,

except that the OSC2 pin becomes an additional general purpose I/O pin. The I/O pin becomes bit 6 of

PORTA (RA6). Figure 2-4 shows the pin connections

for the ECIO Oscillator mode.

FIGURE 2-4: EXTERNAL CLOCK

Clock from

Ext. System

RA6

OSC1/CLKI

PIC18FXXXX

OSC2/CLKO

INPUT OPERATION

(ECIO CONFIGURATION)

OSC1/CLKI

PIC18FXXXX

I/O (OSC2)

DS39755A-page 24 Preliminary © 2006 Microchip Technology Inc.

Page 27

PIC18F2423/2523/4423/4523

2.4 RC Oscillator

For timing insensitive applications, the “RC” and

“RCIO” device options offer additional cost savings.

The actual oscillator frequency is a function of several

factors:

• supply voltage

• values of the external resistor (R

capacitor (C

EXT)

• operating temperature

Given the same device, operating voltage and temperature and component values, there will also be unit-to-unit

frequency variations. These are due to factors such as:

• normal manufacturing variation

• difference in lead frame capacitance between

package types (especially for low C

• variations within the tolerance of limits of R

EXT

and C

In the RC Oscillator mode, the oscillator frequency

divided by 4 is available on the OSC2 pin. This signal

may be used for test purposes or to synchronize other

logic. Figure 2-5 shows how the R/C combination is

connected.

FIGURE 2-5: RC OSCILLATOR MODE

VDD

REXT

OSC1

CEXT

VSS

F

Recommended values: 5K ≤ REXT ≤ 100 kΩ

OSC/4

OSC2/CLKO

EXT > 20 pF

C

The RCIO Oscillator mode (Figure 2-6) functions like

the RC mode, except that the OSC2 pin becomes an

additional general purpose I/O pin. The I/O pin

becomes bit 6 of PORTA (RA6).

FIGURE 2-6: RCIO OSCILLATOR MODE

VDD

REXT

OSC1

EXT) and

EXT values)

EXT

Internal

Clock

PIC18FXXXX

Internal

Clock

2.5 PLL Frequency Multiplier

A Phase Locked Loop (PLL) circuit is provided as an

option for users who wish to use a lower frequency

oscillator circuit, or to clock the device up to its highest

rated frequency from a crystal oscillator. This may be

useful for customers who are concerned with EMI due

to high-frequency crystals, or users who require higher

clock speeds from an internal oscillator.

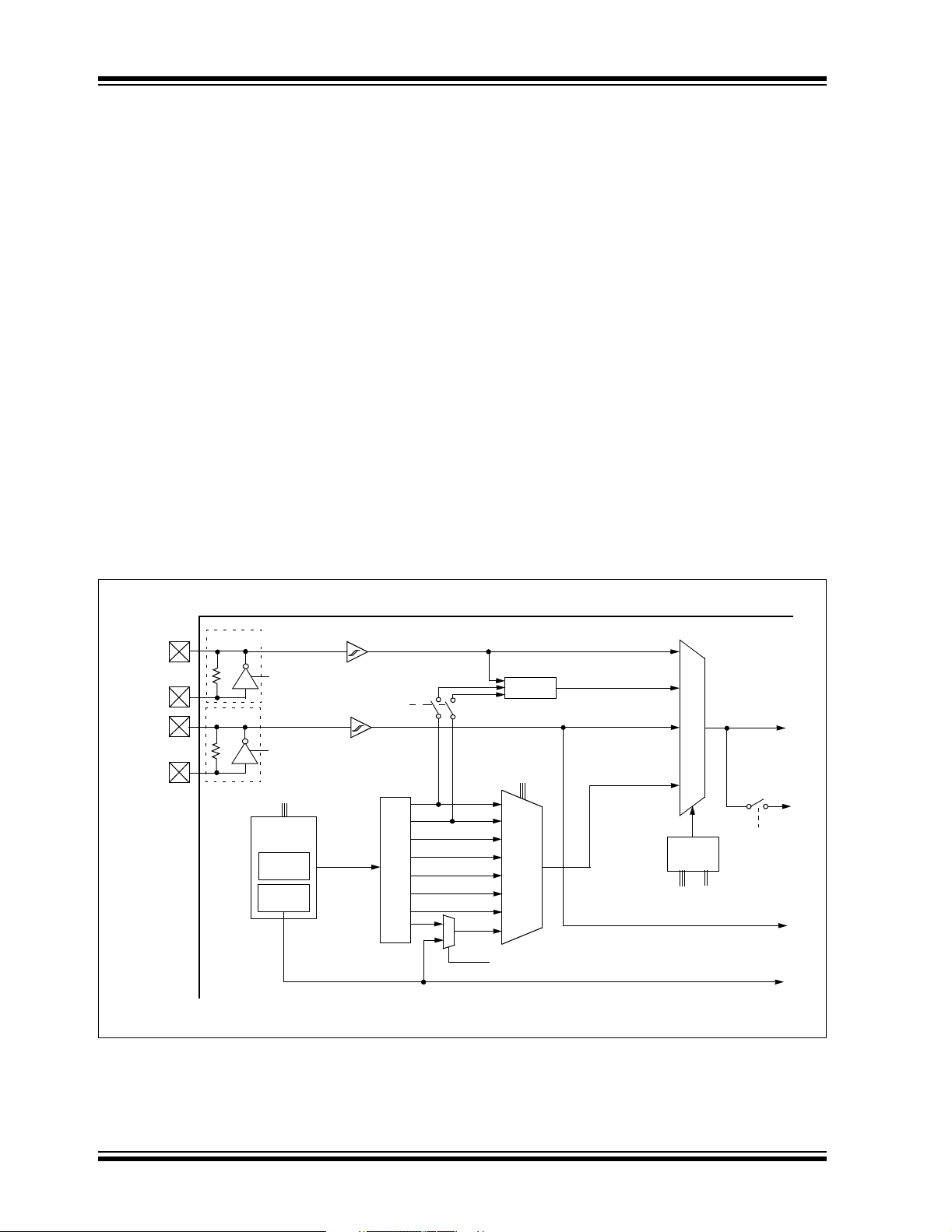

2.5.1 HSPLL OSCILLATOR MODE

The HSPLL mode makes use of the HS mode oscillator

for frequencies up to 10 MHz. A PLL then multiplies the

oscillator output frequency by 4 to produce an internal

clock frequency up to 40 MHz. The PLLEN bit is not

available in this oscillator mode.

The PLL is only available to the crystal oscillator when

the FOSC3:FOSC0 Configuration bits are programmed

for HSPLL mode (= 0110).

FIGURE 2-7: PLL BLOCK DIAGRAM

(HS MODE)

HS Oscillator Enable

PLL Enable

(from Configuration Register 1H)

OSC2

OSC1

HS Mode

Crystal

Osc

IN

F

FOUT

÷4

2.5.2 PLL AND INTOSC

The PLL is also available to the internal oscillator block

when the INTOSC is configured as the primary clock

source. In this configuration, the PLL is enabled in software and generates a clock output of up to 32 MHz.

The operation of INTOSC with the PLL is described in

Section 2.6.4 “PLL in INTOSC Modes”.

Phase

Comparator

Loop

Filter

VCO

SYSCLK

MUX

CEXT

VSS

RA6

Recommended values: 5K ≤ REXT ≤ 100 kΩ

© 2006 Microchip Technology Inc. Preliminary DS39755A-page 25

I/O (OSC2)

EXT > 20 pF

C

PIC18FXXXX

Page 28

PIC18F2423/2523/4423/4523

2.6 Internal Oscillator Block

The PIC18F2423/2523/4423/4523 devices include an

internal oscillator block which generates two different

clock signals; either can be used as the microcontroller’s clock source. This may eliminate the need

for external oscillator circuits on the OSC1 and/or

OSC2 pins.

The main output (INTOSC) is an 8 MHz clock source,

which can be used to directly drive the device clock. It

also drives a postscaler, which can provide a range of

clock frequencies from 31 kHz to 4 MHz. The INTOSC

output is enabled when a clock frequency from 125 kHz

to 8 MHz is selected, and can provide 31 kHz if

required.

The other clock source is the internal RC oscillator

(INTRC) which provides a nominal 31 kHz output.

INTRC is enabled if it is selected as the device clock

source; it is also enabled automatically when any of the

following are enabled:

• Power-up Timer

• Fail-Safe Clock Monitor

• Watchdog Timer

These features are discussed in greater detail in

Section 23.0 “Special Features of the CPU”.

The clock source frequency (INTOSC direct, INTRC

direct or INTOSC postscaler) is selected by configuring

the IRCF bits of the OSCCON register (page 30).

Additionally, the 31 kHz clock can be provided by either

the INTOSC, or INTRC clock sources, depending on

the INTSRC bit (OSCTUNE<7>).

2.6.1 INTIO MODES

Using the internal oscillator as the clock source eliminates the need for up to two external oscillator pins,

which can then be used for digital I/O. Two distinct

configurations are available:

• In INTIO1 mode, the OSC2 pin outputs F

while OSC1 functions as RA7 for digital input and

output.

• In INTIO2 mode, OSC1 functions as RA7 and

OSC2 functions as RA6, both for digital input and

output.

2.6.2 INTOSC OUTPUT FREQUENCY

The internal oscillator block is calibrated at the factory

to produce an INTOSC output frequency of 8.0 MHz.

The INTRC oscillator operates independently of the

INTOSC source. Any changes in INTOSC across

voltage and temperature are not necessarily reflected

by changes in INTRC and vice versa.

OSC/4,

2.6.3 OSCTUNE REGISTER

The internal oscillator’s output has been calibrated at

the factory but can be adjusted in the user’s application. This is done by writing to the OSCTUNE register

(Register 2-1).

When the OSCTUNE register is modified, the INTOSC

frequency will begin shifting to the new frequency. The

INTOSC clock will stabilize within 1 ms. Code execution continues during this shift. There is no indication

that the shift has occurred.

The OSCTUNE register also implements the INTSRC

and PLLEN bits, which control certain features of the

internal oscillator block. The INTSRC bit allows users

to select which internal oscillator provides the clock

source when the 31 kHz frequency option is selected.

This is covered in greater detail in Section 2.7.1

“Oscillator Control Register”.

The PLLEN bit controls the operation of the frequency

multiplier, PLL, in Internal Oscillator modes.

2.6.4 PLL IN INTOSC MODES

The 4x frequency multiplier can be used with the internal oscillator block to produce faster device clock

speeds than are normally possible with an internal

oscillator. When enabled, the PLL produces a clock

speed of up to 32 MHz.

Unlike HSPLL mode, the PLL is controlled through

software. The control bit, PLLEN (OSCTUNE<6>), is

used to enable or disable its operation.

The PLL is available for use with the INTOSC when:

1. The primary clock is the INTOSC clock source

(selected in CONFIG1H<3:0>), and

2. The 4 or 8 MHz INTOSC output is selected.

Writes to the PLLEN bit will be ignored until both these

conditions are met.

2.6.5 INTOSC FREQUENCY DRIFT

The factory calibrates the internal oscillator block

output (INTOSC) for 8 MHz. However, this frequency

may drift as V

affect the controller operation in a variety of ways. It is

possible to adjust the INTOSC frequency by modifying

the value in the OSCTUNE register. This has no effect

on the INTRC clock source frequency.

Tuning the INTOSC source requires knowing when to

make the adjustment, in which direction it should be

made and in some cases, how large a change is

needed. Three compensation techniques are discussed

in Section 2.6.5.1 “Compensating with the

EUSART”, Section 2.6.5.2 “Compensating with the

Timers” and Section 2.6.5.3 “Compensating with the

CCP Module in Capture Mode”, but other techniques

may be used.

DD or temperature changes, which can

DS39755A-page 26 Preliminary © 2006 Microchip Technology Inc.

Page 29

PIC18F2423/2523/4423/4523

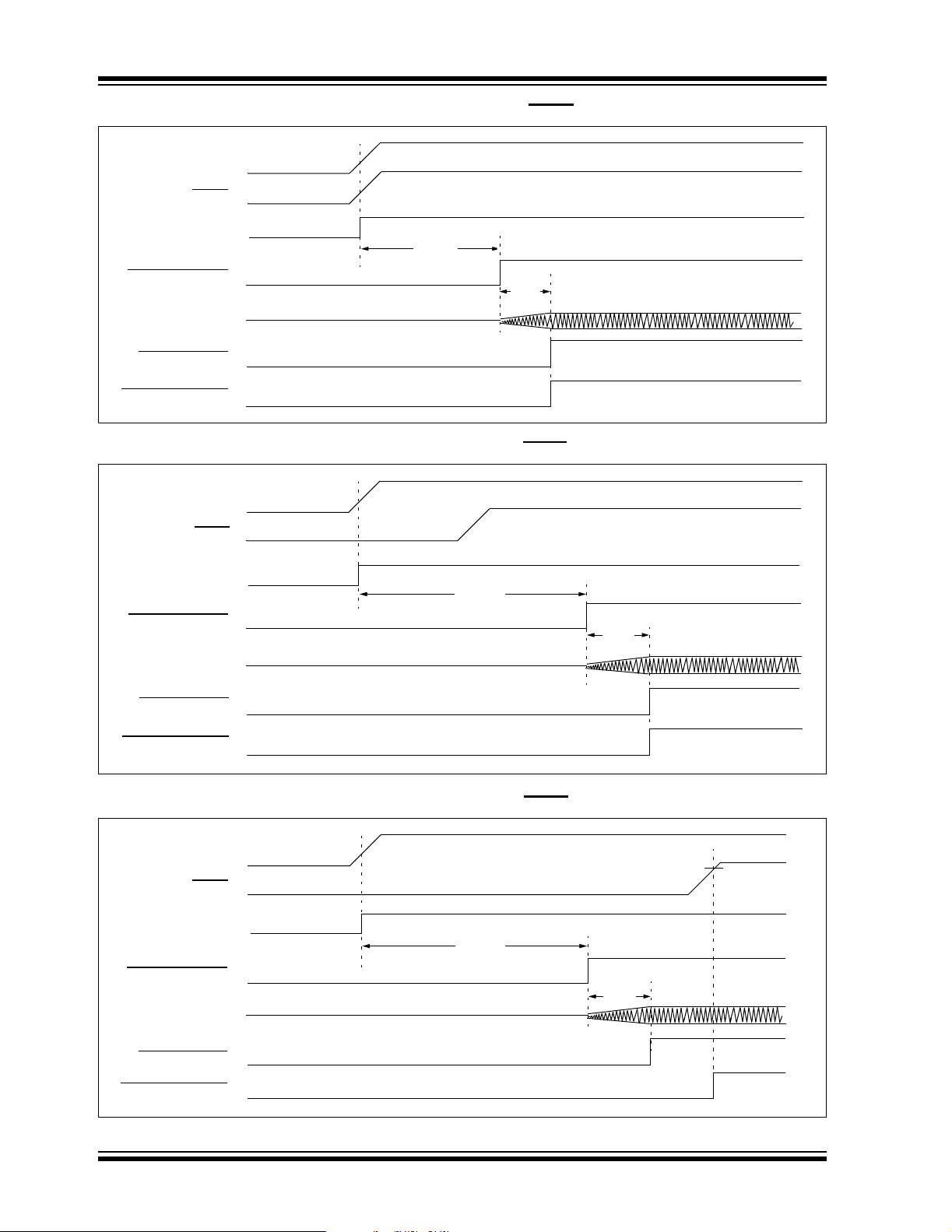

REGISTER 2-1: OSCTUNE: OSCILLATOR TUNING REGISTER

R/W-0 R/W-0

INTSRC PLLEN

bit 7 bit 0

Legend:

R = Readable bit W = Writable bit U = Unimplemented bit, read as ‘0’

-n = Value at POR ‘1’ = Bit is set ‘0’ = Bit is cleared x = Bit is unknown

bit 7 INTSRC: Internal Oscillator Low-Frequency Source Select bit

1 = 31.25 kHz device clock derived from 8 MHz INTOSC source (divide-by-256 enabled)

0 = 31 kHz device clock derived directly from INTRC internal oscillator

bit 6 PLLEN: Frequency Multiplier PLL for INTOSC Enable bit

1 = PLL enabled for INTOSC (4 MHz and 8 MHz only)

0 = PLL disabled

bit 5 Unimplemented: Read as ‘0’

bit 4-0 TUN4:TUN0: Frequency Tuning bits

01111 = Maximum frequency

• •

• •

00001