Page 1

Easidew DryCheck

OnLine Dew-Point Hygrometer

User’s Manual

97108 Issue 13

July 2017

Page 2

Please fi ll out the form(s) below for each instrument that has been purchased.

Use this information when contacting Michell Instruments for service purposes.

Instrument

Code

Serial Number

Invoice Date

Location of Instrument

Tag No

Instrument

Code

Serial Number

Invoice Date

Location of Instrument

Tag No

Instrument

Code

Serial Number

Invoice Date

Location of Instrument

Tag No

Page 3

Easidew DryCheck

For Michell Instruments' contact information please go to

www.michell.com

© 2017 Michell Instruments

This document is the property of Michell Instruments Ltd. and may not be copied or

otherwise reproduced, communicated in any way to third parties, nor stored in any Data

Processing System without the express written authorization of Michell Instruments Ltd.

Page 4

Easidew DryCheck User’s Manual

Contents

Safety ................................................................................................................................vi

Electrical Safety ...........................................................................................................vi

Pressure Safety ............................................................................................................vi

Toxic Materials .............................................................................................................vi

Repair and Maintenance ...............................................................................................vi

Calibration ...................................................................................................................vi

Safety Conformity ........................................................................................................vi

Abbreviations .....................................................................................................................vii

Warnings ...........................................................................................................................vii

1 INTRODUCTION ............................................................................................VIII

1.1 General ............................................................................................................ viii

1.2 Features .......................................................................................................... viii

2 INSTALLATION ..................................................................................................1

2.1 Unpacking the Instrument ................................................................................... 1

2.2 DryCheck System Configuration ........................................................................... 2

2.3 Monitor .............................................................................................................. 2

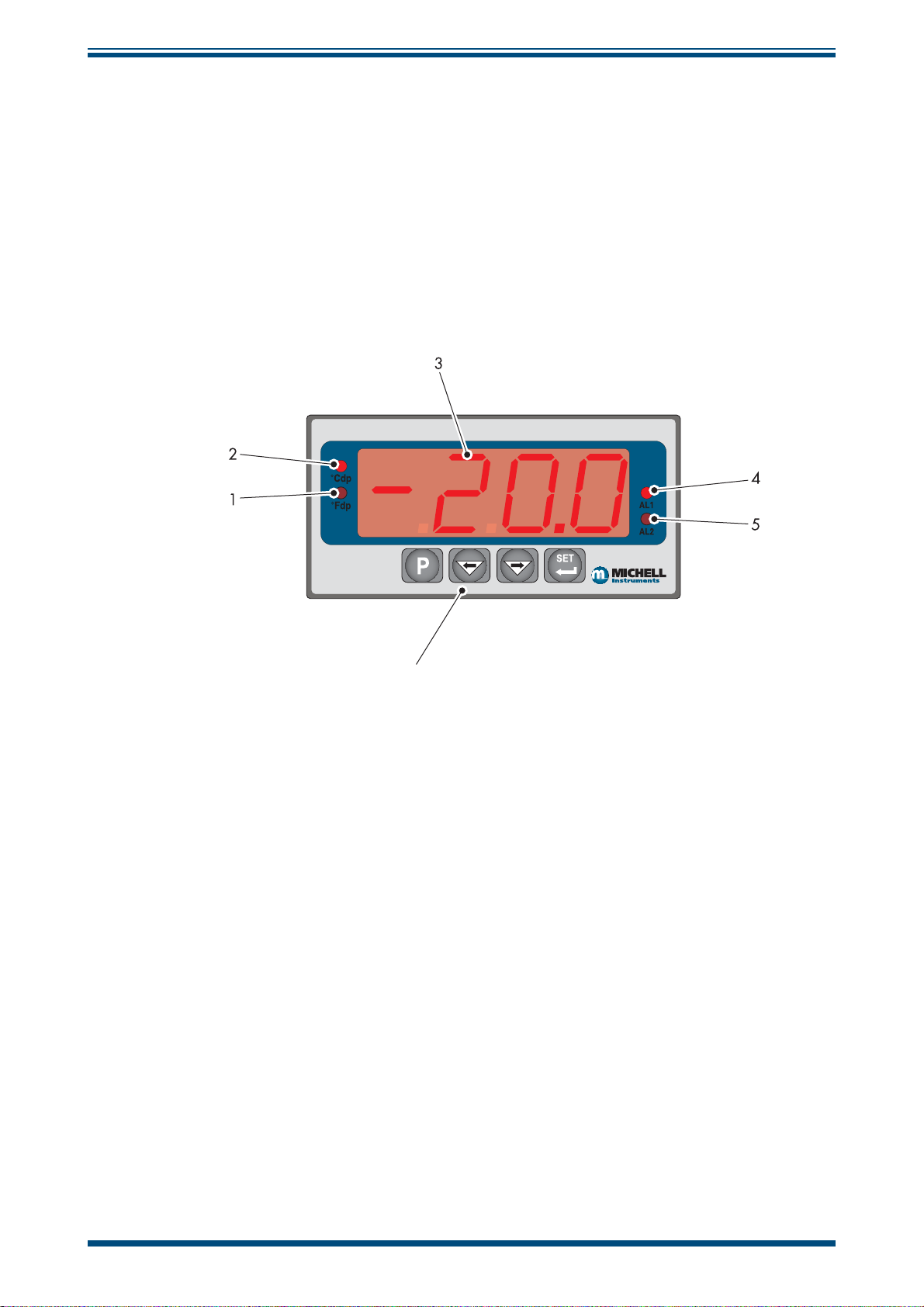

2.4 Monitor Panel Layout .......................................................................................... 3

2.5 Function Keys ..................................................................................................... 5

2.6 Mounting ........................................................................................................... 5

2.7 Power Supply .................................................................................................... 5

2.8 Signal Output Connections ................................................................................. 6

3 OPERATION ......................................................................................................8

3.1 General Operational Information ......................................................................... 8

3.2 Preparation For Operation ................................................................................... 9

3.2.1 First Time Operation ...................................................................................... 9

3.3 System Alarms ................................................................................................. 10

3.3.1 Alarm Switching Logic (Default) ................................................................... 10

3.3.2 Reversal of Alarm Switching Logic ................................................................ 10

3.3.3 Alarm Level Set-Up ..................................................................................... 12

3.3.4 Re-Transmitted Output Current Range Set-Up ............................................... 13

3.4 Operating Temperature / ppmV Range ............................................................... 14

3.4.1 Temperature Range Default ......................................................................... 14

3.4.2 Span and Unit Settings ............................................................................... 15

3.4.3 Alarm Set-Point Limit Configuration .............................................................. 16

3.4.4 Scale Units to ppmV Set-Up .......................................................................... 17

3.4.5 Monitor Limits When Unit Scaled to ppmV .................................................... 18

3.5 Digital Communication Parameters Set-Up .......................................................... 19

3.6 Monitor – Reading the Displayed Value Using Modbus RTU Over RS232 ................ 21

4 GOOD MEASUREMENT PRACTICE .....................................................................22

5 MAINTENANCE ................................................................................................23

5.1 General Maintenance Guidelines ........................................................................ 23

5.2 Calibration ....................................................................................................... 23

5.3 Transmitter Maintenance ................................................................................... 23

5.4 Inspection/Cleaning .......................................................................................... 24

5.5 Fault Conditions ............................................................................................... 25

iv 97108 Issue 13, July 2017

Page 5

Easidew DryCheck User’s Manual

Figures

Figure 1 Easidew DryCheck ................................................................................... viii

Figure 2 Unpacking Method ......................................................................................1

Figure 3 Gas Flow Diagram ......................................................................................2

Figure 4 Monitor Panel Layout ..................................................................................3

Figure 5 Alarm and Communications .........................................................................6

Figure 6 Monitor Rear Panel Connections ..................................................................7

Figure 7 Typical Display ...........................................................................................9

Figure 8 Change Alarm Switching Logic ...................................................................11

Figure 9 Set-up Alarm Levels ..................................................................................12

Figure 10 Configure Analog Output ...........................................................................13

Figure 11 Span and Unit Settings .............................................................................15

Figure 12 Set-up Alarm Set-Point Limits ....................................................................16

Figure 13 Set-up Monitor (to read ppm

Figure 14 Set-up Data Communications Parameters ...................................................20

Figure 15 Sensor Removal .......................................................................................23

Figure 16 Inspection/Cleaning ..................................................................................24

Figure 17 System Drawings ......................................................................................29

) ...................................................................18

V

Tables

Table 1 Monitor Front Panel Controls and Indicators ..................................................4

Table 2 Function Keys ..............................................................................................5

Table 3 Summary of Electrical Connections ...............................................................7

Appendices

Appendix A Technical Specifications .............................................................................. 27

Appendix B System Drawing ........................................................................................ 29

Appendix C Quality, Recycling & Warranty Information ................................................... 31

Appendix D Return Document & Decontamination Declaration ........................................ 33

Appendix E EU Declaration of Conformity...................................................................... 35

Michell Instruments v

Page 6

Easidew DryCheck User’s Manual

Safety

The manufacturer has designed this equipment to be safe when operated using the procedures

detailed in this manual. The user must not use this equipment for any other purpose than that

stated. Do not apply values greater than the maximum value stated.

This manual contains operating and safety instructions, which must be followed to ensure the safe

operation and to maintain the equipment in a safe condition. The safety instructions are either

warnings or cautions issued to protect the user and the equipment from injury or damage. Use

competent personnel using good engineering practice for all procedures in this manual.

Electrical Safety

The instrument is designed to be completely safe when used with options and accessories supplied

by the manufacturer for use with the instrument.

Pressure Safety

DO NOT permit pressures greater than the safe working pressure to be applied to the instrument.

The specifi ed safe working pressure is 10 barg (145 psig).

Toxic Materials

The use of hazardous materials in the construction of this instrument has been minimized. During

normal operation it is not possible for the user to come into contact with any hazardous substance

which might be employed in the construction of the instrument. Care should, however, be exercised

during maintenance and the disposal of certain parts.

Repair and Maintenance

The instrument must be maintained either by the manufacturer or an accredited service agent. Refer

to www.michell.com for details of Michell Instruments’ worldwide offi ces’ contact information.

Calibration

The recommended calibration interval for this instrument is 12 months unless it is to be used in a

mission-critical application or in a dirty or contaminated environment in which case the calibration

interval should be reduced accordingly. The instrument should be returned to the manufacturer,

Michell Instruments Ltd., or one of their accredited service agents for re-calibration.

Safety Conformity

This product meets the essential protection requirements of the relevant EU directives. Further

details of applied standards may be found in the product specifi cation.

vi 97108 Issue 13, July 2017

Page 7

Easidew DryCheck User’s Manual

Abbreviations

The following abbreviations are used in this manual:

AC alternating current

barg pressure unit (=100 kP or 0.987 atm)

°C degrees Celsius

°F degrees Fahrenheit

dp dew point

Hz Hertz

mA milliampere

Nl/min normal liters per minute

psig pound(s) per square inch (gauge)

V volts

VA volt-ampere

Warnings

The following general warnings listed below are applicable to this instrument. They are

repeated in the text in the appropriate locations.

Where this hazard warning symbol appears in the following

sections, it is used to indicate areas where potentially hazardous

operations need to be carried out.

Michell Instruments vii

Page 8

APPENDIX D

1 INTRODUCTION

1.1 General

The Easidew DryCheck is an instrument designed for continuous, online measurement

of moisture content in compressed air and other gases over an operating range of over

either -100 to +20°Cdp (-148 to -4°Fdp) / -60 to +60°Cdp (-76 to 140°Fdp) / -50 to

+50°Cdp (-58 to 122°Fdp). The Easidew DryCheck is protected within an IP65-rated,

wall-mounted enclosure with a hinged lid. The lid allows access to a panel-mounted,

process indicator with a °C dew-point display.

Easidew DryCheck User’s Manual

Figure 1

Easidew DryCheck

1.2 Features

Integrated instrument and sampling system

• Simple installation

• Wide measurement range

• Dew point or moisture content

• Analog output, display and alarm

• IP65 (NEMA 4x) enclosure

viii 97108 Issue 13, July 2017

Page 9

Easidew DryCheck User’s Manual

2 INSTALLATION

2.1 Unpacking the Instrument

It is essential that the connection of electrical and gas supplies

to this instrument be undertaken by competent personnel.

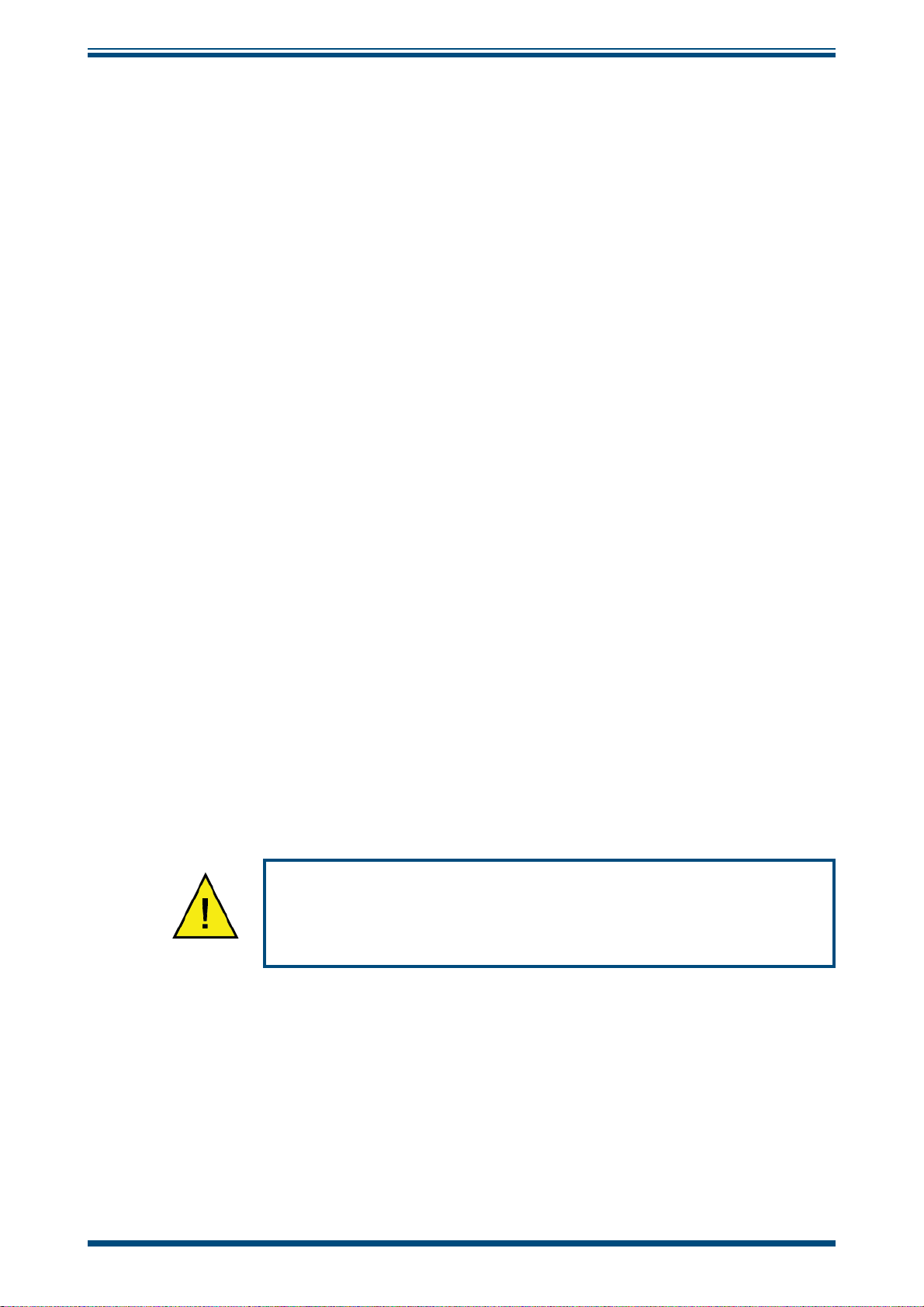

The Easidew DryCheck instrument and its accessories are packed into a box and the

method of unpacking is shown as follows:

1

INTRODUCTION

4

2

3

Figure 2

Open the box and unpack carefully (see

Unpacking Method

Figure 2)

:

1. Remove the accessories box (4).

2. Lift out the instrument (2) together with its end packing pieces (1) and

(3).

3. Remove the end packing pieces and set the instrument down at the site

of installation.

Save all the packing materials for the purpose of returning the instrument for

re-calibration or any warranty claims.

The accessories box (4) should contain the following items

:

• Traceable calibration certificate

• User manual

• Country specific power cable

On delivery please check that all the standard components shown above are present in

the packing box. Immediately report any shortages to Michell Instruments.

Michell Instruments 1

Page 10

INSTALLATION

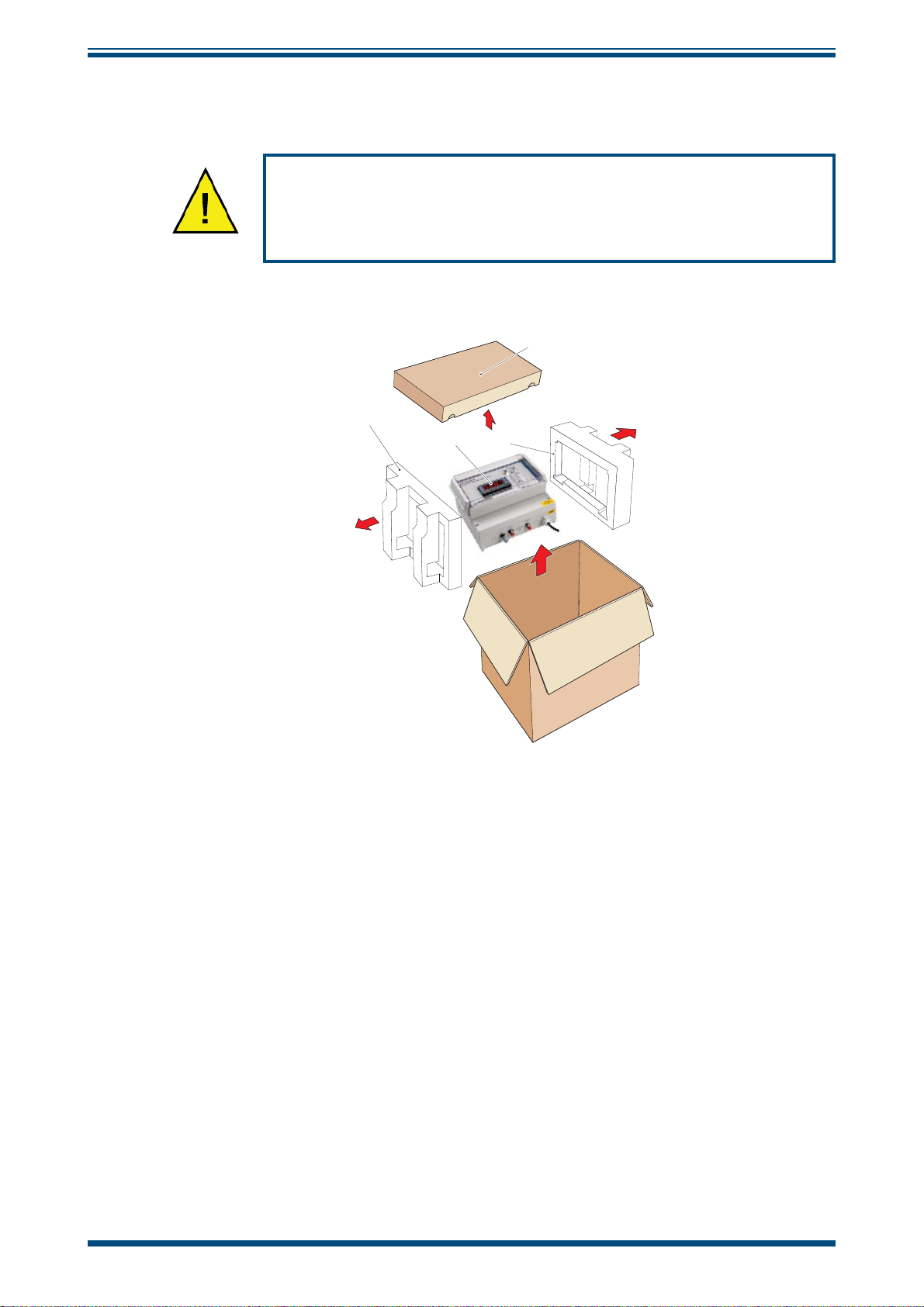

2.2 DryCheck System Configuration

The DryCheck sampling system includes a 0.3 m particulate filter element, a monolithic

sampling block to house the transmitter, and a valve and flowmeter for setting the sample

flow. The filter element is easily replaceable to ensure that the sensor is protected. All

components are rated to 1 MPa (10 barg) and the DryCheck can be configured for

measurement of dew point at either system or atmospheric pressure.

All components are housed in a rugged IP65 (NEMA 4x) rated polycarbonate case. This

can easily be wall mounted at a convenient point close to the gas sample.

A clear cover protects the display and the sample flowmeter. Gas connection (gas in and

gas out) is provided using quick connect push fittings suitable for use with 6mm (¼”)

OD Teflon tubing. Mains power input and connection to the 4-20 mA analog output and

the two user programmable voltage free relay contacts are all easily accessible behind

the lower panel.

Easidew DryCheck User’s Manual

NOTE: The DryCheck is designed to measure dew point at standard instrument

air pressure or 7 barg.

A barometric version is available on request, please contact Michell Instruments (see

www.michell.com for contact details).

2.3 Monitor

The controls and indicators associated with the Easidew DryCheck are located on the

front panel of the monitor.

Easidew

Online

Easidew

TX Sensor

Sample

Block

Gas Inlet

Figure 3

Needle

Valve

Flowmeter

Gas Flow Diagram

Gas Outlet

Connections to the monitor and the external power supply are made to the rear panel

of the monitor and are replicated on two terminal blocks.

Figure 4

shows the layout of these controls and Tables 1 and 2 describe their respective

operational functions.

Dew-point temperature units are displayed by one of the two LEDs located to the left

of the display. On delivery, °Cdp is set-up as standard. If required, the units can be

changed to °F. The method of configuring the unit for °F is described in Section 3.4.

Optionally, the instrument can be set-up to read dew point in parts per million (ppm

range 0 to 3000 ppm

. This option requires the transmitter to be set-up for ppmV either

V

V

at the time of ordering or subsequently via Michell application software. NOTE: No

specific ppm

LED indicator is provided on the monitor; ppmV is selected if

V

neither the °Cdp nor the °Fdp temperature indicators are illuminated.

2 97108 Issue 13, July 2017

),

Page 11

Easidew DryCheck User’s Manual

Two temperature alarm indications are provided by two LEDs located on the right hand

side of the display. These are marked ALr1 (low) and ALr2 (high). Access to the alarm

relay contacts is provided on the rear panel. The connection for the ALr2 contact is

shown in Section 2.8.

NOTE: Every monitor is factory fitted with 2 alarm relays as standard. On the

DryCheck product only 1 relay (

2.4 Monitor Panel Layout

Easidew Hygrometer

INSTALLATION

ALr2) is brought to the terminal strip.

6

Figure 4

Monitor Panel Layout

Michell Instruments 3

Page 12

INSTALLATION

Item Description

°Fdp

Easidew DryCheck User’s Manual

1

2

3

4

When illuminated, this LED indicates that the displayed dew-point reading is in degrees

Fahrenheit.

NOTE: If neither the °Fdp or °Cdp LED is lit, ppm

°Cdp

When illuminated, this LED indicates that the displayed dew-point reading is in degrees

Celsius.

NOTE: if neither the °Cdp nor °Fdp LED is lit, ppm

Main dew-point temperature display

Flashes to alternately indicate ErrL (error low) and temperature reading for low

temperatures under-range (lower than -100°Cdp (-148°Fdp) or -129.9°Cdp (199.9°Fdp)

for an open loop condition).

Flashes to alternately indicate

temperature over-range.

ALr1 Output

Only available directly from the back of the Monitor panel.

ALr2

ErrH (error high) and temperature reading for high

is selected.

V

is selected.

V

When illuminated this LED indicates that the dew-point temperature programmed for

Alarm 2 has exceeded the programmed threshold. Under these conditions the alarm

relay changeover contacts associated with this alarm will change state and will remain in

this state until the temperature moves back to within the programmed operational limit.

5

Alarm 2 is usually allocated to the High Alarm setting.

These changeover relay contacts are rated at 240 V, 3 A and are connected as shown

in Section 2.8.

Section 3.4.3 details the setting up of

6

P

Table 1 Monitor Front Panel Controls and Indicators

SET

ALr2 trip points.

The four function keys are used for setting up the

monitor.

Table 2 describes the operation of the keys.

4 97108 Issue 13, July 2017

Page 13

Easidew DryCheck User’s Manual

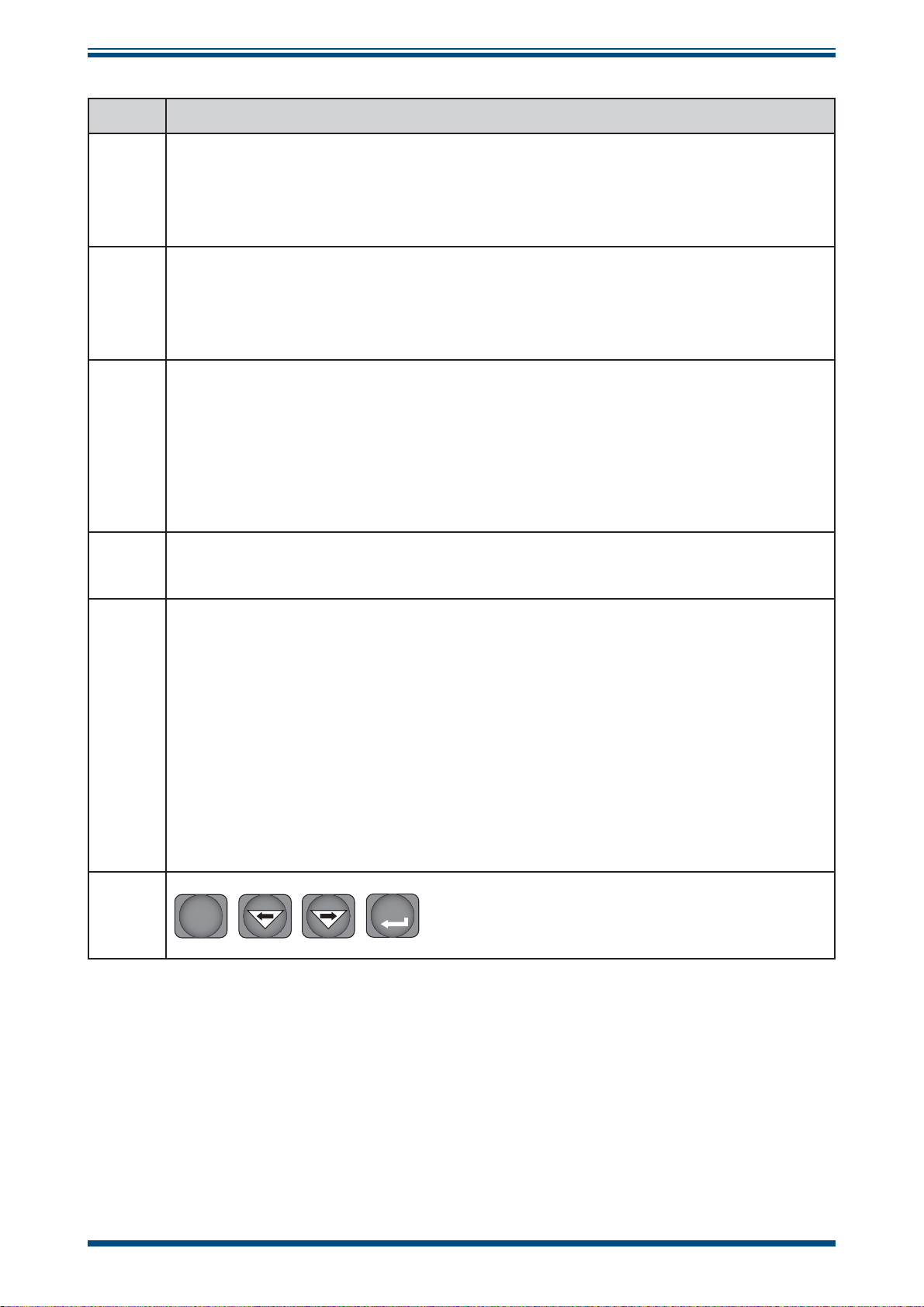

2.5 Function Keys

INSTALLATION

The function key panel is shown in

Table 2 describes the operation of the keys.

Item Description

Figure 4

P (Program) key

P

This key is used to access the programming menus and to select submenus within the list.

Left arrow (decrement) key

This key is used to access sub-menus and, within individual sub-menus,

to decrease the numeric value of the selected parameter.

Right arrow (increment) key

This key is used to access sub-menus and, within individual sub-menus,

to increase the numeric value of the selected parameter.

SET key

SET

Depending upon the context, this key is used to access the set value

of the selected process fi eld and as an Accept key for new parameter

values.

.

2.6 Mounting

The instrument is designed for wall or panel-mounting and has 3 fixing points. Mounting

fasteners are not supplied. See the System Drawing in Appendix B for wall-mount fixing

points.

2.7 Power Supply

A single-phase mains power supply of 100 to 240 V (-15% / +10%), 50/60 Hz, 6 VA is

required to power the Easidew DryCheck.

Loosen the 2 screws and remove the access cover at the lower front of the instrument

(Figure 5)

passed.

The power supply cable should then be connected to the terminal strip which is mounted

on the right hand side.

. A cable gland is provided, through which the power supply cable should be

Table 2 Function Keys

Terminals are marked:

7 8 9 101112

Earth Not Used Neutral Not used Live Not used

Michell Instruments 5

Page 14

INSTALLATION

2.8 Signal Output Connections

The Easidew DryCheck has 1 signal output Alarm 2 (ALr2) and the re-transmitted

input signal (4-20 mA or 0-20 mA current loop signal depending upon instrument

configuration).

Loosen the 2 screws and remove the access cover at the lower front of the instrument

(Figure 5)

mounted on the

Terminals are marked:

. The signal cable should then be connected to the terminal strip which is

left hand side.

Easidew DryCheck User’s Manual

For Alarm Connections

123456

Normally

Closed

Normally

Open

Figure 5

COM Not used + mA - mA

Alarm and Communications

For mA Signal

Connections

The signal outputs will be connected to external systems that

can potentially influence the operation of the process.

Alarm level signals could be at mains potential so it is essential

that, before connecting these signal lines, checks are made

to ensure that these inputs are not live and that it is safe to

handle them.

Alarm Output

Alarm 2 comprises a set of changeover contacts. Connect incoming signal lines to

terminal 3 (common), terminal 2 (normally open) and terminal 1 (normally closed).

Figure 6

electrical connections to the monitor.

shows the relevant rear panel connections. Table 3 shows a summary of all the

6 97108 Issue 13, July 2017

Page 15

Easidew DryCheck User’s Manual

INSTALLATION

Figure 6

Monitor Rear Panel Connections

Re-transmission Output

The re-transmission output is current sourcing. Connect the positive output to terminal

14 and the negative output to terminal 13. Use appropriately colored wires eg. red

(positive), black (negative).

Terminal Wire Color Signal Supply Information

1 Blue 0 V (GND)

3 Green 4-20 mA loop current Default 4-20 mA

4Red

7 User defi ned ALr2 (normally closed)

8 User defi ned ALr2 (normally open)

9 User defi ned ALr2 (common)

Transmitter loop supply

(+ve)

+24 V DC w.r.t. terminal 1

8

7

9

13 User defi ned Current loop out (-ve) Default 4-20 mA

14 User defi ned Current loop out (+ve) Default 4-20 mA

16 User defi ned ALr1 (common)

17

17 User defi ned ALr2 (normally open)

16

23 (AC Version) Blue Power in (neutral) 100 – 240 V, 50/60 Hz

24 (AC Version) Brown Power in (live) 100 – 240 V, 50/60 Hz

23 (DC Version) Black Negative (-) 0 V

24 (DC Version) Red Positive (+) 24 V

NOTE: There are no terminals in positions

5, 6, 10, 11, 12, 15, 18, 19, 20, 21 and 22

Table 3 Summary of Electrical Connections

Michell Instruments 7

Page 16

INSTALLATION

3 OPERATION

As supplied, the instrument is ready for operation and has been set-up with default

parameters. This section describes both the general operation of the instrument and

the method of setting it up and changing the default parameters should this become

necessary.

The default parameters are as follows:

• Span -100 to +20°Cdp (-148 to +68°Fdp), -60 to +60°Cdp (-76 to

140°Fdp) / -50 to +50°Cdp (-58 to 122°Fdp) or 0 to 3000 ppm

• Temperature units °Cdp

• Current loop input, 4-20 mA (7.5°C/mA or 13.5°F/mA)

• Re-transmission current loop output, 4-20 mA (7.5°C/mA or 13.5°F/mA)

• Alarm 2 set-point -40°Cdp (-40°Fdp)

Easidew DryCheck User’s Manual

V

For the supplied dew-point transmitter, the span and current loop input setting should

not be changed. The span will require changing if the instrument is to be ranged in °F,

if a different transmitter is employed, if the user chooses to re-range the transmitter or

if ppm

is selected.

V

The instrument must also have been installed as detailed in Section 2 and connected to

a sample gas supply that is representative of the process being monitored.

3.1 General Operational Information

Operation of the Easidew DryCheck is completely automatic and, once set-up, requires

little or no operator intervention.

The dew-point transmitter is designed to operate in a flowing gas stream of between 1

to 5 Nl/min (2.1 to 10.6 scfh) when mounted in a sample block, at operating pressures

up to a maximum of 10 barg (145 psig).

The sample gas is taken into the sample block via the Gas In port and, in flowing

through the sample block, comes into contact with the dew-point transmitter which,

in turn, produces a current loop output signal proportional to the measured dew-point

temperature. This output signal is converted to a dew-point temperature reading by the

monitor.

If necessary, gas flow through the sample block must be controlled outside the

instrument, typically by means of a needle valve located in the sample gas input line.

8 97108 Issue 13, July 2017

Page 17

Easidew DryCheck User’s Manual

3.2 Preparation For Operation

3.2.1 First Time Operation

To commence operation, proceed as follows:

1. Check that electrical power supply and the relevant analog and alarm

outputs are connected to external systems as required and as described

in Section 2.8.

2. Check that the gas sample flow rate through the sample block, or the

pipeline in which the transmitter is located, is within the operational

limits. (Adjust any external flow control valves, located in the gas sample

input line to the instrument to achieve required flow rate.)

3. Switch on the power supply to the instrument. The instrument display

will now come on, typically showing the default parameters and units as

detailed in

The instrument is now operational and after a few seconds, in which all the segments of

the display are tested, the monitor will display the measured dew-point temperature as

a steady reading within the range -100 to +20°Cdp (-148 to +68°Fdp), -60 to +60°Cdp

(-76 to 140°Fdp) / -50 to +50°Cdp (-58 to 122°Fdp) or 0 to 3000 ppm

how the instrument has been set-up. The default setting is °C.

Figure 7

.

OPERATION

depending upon

V

In the absence of any error indications the instrument will now be operational using the

default parameters.

Easidew Hygrometer

Figure 7

If the display is flashing, a fault condition exists. The following operational error

conditions may be encountered:

Typical Display

ErrL - If the display is alternately flashing (e.g.) ErrL and -103.3, this

indicates that the measured dew point is outside the lower operational limit

(-100°Cdp/-148°Fdp).

If the display is alternately flashing

temperature in °F), this could be an indication that the input current loop to

the monitor is open or that there may be a transmitter fault. Check that the

transmitter is wired correctly as detailed in Section 2.8.

ErrL and -129.9 (-199.9 if set-up to read

ErrH - If the display is alternately flashing (e.g.) ErrH and 021.4, this

indicates that the measured dew point is outside the upper operational

limit (+20°Cdp/+68°Fdp).

Michell Instruments 9

Page 18

OPERATION

3.3 System Alarms

3.3.1 Alarm Switching Logic (Default)

The Easidew DryCheck has one alarm output. As supplied, the default alarm set-point

and the alarm switching logic are as follows (the default temperature units are degrees

Celsius):

Easidew DryCheck User’s Manual

Alarm 2 (High Alarm) is set to switch

wetter) than its set-point value. For the default set-points therefore, the operation of

this alarm would be as follows:

Alarm 2 Temp < -40 Alarm 2 = OFF

Temp > -40 Alarm 2 = ON

Depending upon the application, if required, it is possible to reverse the switching logic

for either or both of the alarm channel outputs to provide the following alarm output

configurations:

Alarm 2 Temp < -40 Alarm 2 = ON

Temp > -40 Alarm 2 = OFF

Section 3.3.2 describes the method for reversing the default switching logic and Section

3.3.3 describes the method for setting up individual alarm set-points.

3.3.2 Reversal of Alarm Switching Logic

ON when the temperature reading is higher (gas

As described in Section 3.3.1, the switching logic for the alarm channel may, if required,

be reversed.

Starting at the default state, the method of reversing the switching logic for the alarm

is as follows:

1. Press the

2. Press the

3. Press the key three times and the display will flash between

P key once and the display will read tECH.

SET key and the display will flash between ConF and PinP.

ConF and

Alr2.

4. Press the

5. Press the key once to display a flashing 4 digit number. For the Alarm

2 default setting this will be 0000.

6. Press the key once to change the display to 0001.

7. Press the

8. Press the

SET key twice to display Alt2.

SET key to store the new value.

P key twice to return.

10 97108 Issue 13, July 2017

Page 19

Easidew DryCheck User’s Manual

OPERATION

Main

Display

P

SET

x3

SET

SET

P

x2

P

Main

Display

Figure 8

Michell Instruments 11

Change Alarm Switching Logic

Page 20

OPERATION

3.3.3 Alarm Level Set-Up

The alarm set-point levels are set-up

from the program menu as follows

(to exit to the Main Display without

saving any new settings press the

key):

Figure 9

sequence.

To set-up the alarm set-point:

shows the operational key

Easidew DryCheck User’s Manual

Main display

P

Set x2

SET

1. Press the

SET key twice.

2. Press the key to display the

flashing current Alarm 2 set-point

(-40°C in this example).

3. Use the or keys to set the

required value (-50°C in this

example).

4. Press the

SET key once to store the

new value for Alarm 2. The display

then returns to the main dew-point

temperature display.

P

P to exit

without

setting

Figure 9

Current

Value

New

Value

SET

Set-up Alarm Levels

12 97108 Issue 13, July 2017

Page 21

Easidew DryCheck User’s Manual

3.3.4 Re-Transmitted Output Current Range Set-Up

The Easidew DryCheck is provided with an

analog current loop output module which

buffers and re-transmits the current loop

input signal from the dew-point transmitter.

By default, the re-transmission output is set

as a 4-20 mA current loop (to exactly follow

the input signal, i.e. 4 mA in, 4 mA out).

For certain system processes, a 0-20 mA

current loop output may be required. The

set-up method is as follows:

OPERATION

P

SET

Figure 10

shows the operational key

sequence.

Change output from 4-20 mA to 0-20

mA

1. Press the

read

2. Press the

flash between

P key once, the display will

tECH.

SET key and the display will

ConF and PinP.

3. Press the key and the display will

flash between

4. Press the

out1 and ConF.

SET key to display oAt1.

5. Press the key once to display a

flashing 4 digit number. For the default

setting (4-20 mA) this will be 0001.

6. Press the key once to change the

display to 0000. This selects the retransmission output to be 0-20 mA.

7. Press the

SET key to accept the new

value. The output current loop is now

0-20 mA. The display will flash between

out1 and ConF.

8. Press the

main dew-point temperature display.

P key once to return to the

Figure 10

SET

Default setting

0001=4 to 20mA

New setting

0000=0 to20mA

SET

P

Main

Display

Configure Analog Output

NOTE: The transmitter current loop output signal is now scaled at 6 mA per °C

input, while the transmitter input remains scaled at 7.5°C per mA.

Michell Instruments 13

Page 22

OPERATION

Easidew DryCheck User’s Manual

3.4 Operating Temperature / ppmV Range

3.4.1 Temperature Range Default

The default temperature unit for the Easidew DryCheck is in degrees Celsius. This is

indicated by the °Cdp LED indicator. The default settings associated with this temperature

scale are as follows:

• Span -100 to +20°Cdp

• Lower and upper span limits -100 and +20 (display flashes outside this

range)

• Minimum alarm set-point -100°Cdp

• Maximum alarm set-point +20°Cdp

To range the instrument for °F, all the above parameters need

to be changed to their Fahrenheit equivalent values (-148 and

+68°F). It is not sufficient just to change the °F/°C units.

To change the range to Fahrenheit follow the procedures in Section 3.4.2.

14 97108 Issue 13, July 2017

Page 23

Easidew DryCheck User’s Manual

3.4.2 Span and Unit Settings

To change the span and unit settings,

proceed as follows.

Figure 11

operational key sequence.

1. Press the P key once, the display will

tECH.

read

shows the

OPERATION

Main Display (°C)

P

SET

x6

2. Press the

display will read

SET key six times and the

tPoL.

3. Press the key and the display will

flash with the current minimum span

limit (-100.0).

4. Use the or keys to set the

required equivalent Fahrenheit value

(-148.0) and press the

SET key.

tPoH is then displayed.

5. Press the key, the display will

flash the current maximum span

limit (020.0).

6. Use the or keys to set the

required equivalent Fahrenheit value

(068.0) and press the

SET key twice.

unit is then displayed.

7. Press the key, the display will

flash the current unit (°C).

Set Span min

Set Span max

SET

SET

x2

SET

SET

Set alarm lower range limitSet alarm upper range limit

8. Use the or keys to set the

required scale units (°F in this

example) and press the

SET key.

LoL is then displayed.

P

Main Display (°F)

9. Press the key and the display will

flash with the current alarm lower

range limit (-100.0).

Select required temp units

SET

10. Use the or keys to set the

required equivalent Fahrenheit value

(-148) and press the

SET key. uPL is

then displayed.

Figure 11

Span and Unit Settings

11. Press the key, the display will

flash the current alarm upper range

limit (020.0).

12. Use the or keys to set the required equivalent Fahrenheit value

(068.0) and press the

13. Press the

P key twice to return to the Main Display.

SET key. PUoF is then displayed.

x2

The maximum and minimum alarm level limits should now be changed to suit the new

(Fahrenheit) unit values (refer to Section 3.4.3).

Michell Instruments 15

Page 24

OPERATION

3.4.3 Alarm Set-Point Limit Configuration

The following procedure is used to set limits to

which the alarm levels can be set (usually after reconfiguring the instrument’s range for Fahrenheit

readings).

Easidew DryCheck User’s Manual

Main display

P

Figure 12

shows the operational key sequence.

1. Press the P key once, the display will read

tECH.

2. Press the

flash between

3. Press the key four times and the display

will flash between

4. Press the

SET key once and the display will

ConF and PinP.

ConF and GEnn.

SET key once, the display will read

SU-L.

5. Press the key once to display a flashing

4 digit number representing the current

minimum alarm level setting. (The default

setting for the °C range is -100.0).

6. Use the or keys to set the required new

value (e.g. -148.0).

7. Press the

The display will read

SET key to accept the new value.

SU-u.

SET

x4

SET

Set alarm setpoint lower limitSet span alarm setpoint upper limit

SET

8. Press the key once to display a flashing

4 digit number representing the current

maximum alarm level setting. (The default

setting for the °C range is 020.0)

9. Use the or keys to set the required new

value (e.g. 068.0).

10. Press the

followed by the

SET key to accept the new value,

P key to return to the Main

Display.

Figure 12

SET

P

Main display

Set-up Alarm Set-Point Limits

16 97108 Issue 13, July 2017

Page 25

Easidew DryCheck User’s Manual

3.4.4 Scale Units to ppmV Set-Up

To change the monitor to read parts per million by volume (ppmV) proceed as follows:

OPERATION

Figure 13

shows the operational key sequence.

NOTE: The dew-point transmitter must be configured to provide an output

proportional to ppmV which can be set up at the time of order or by using the

Michell application software. Contact Michell Instruments for information

(for contact details see www.michell.com).

1. Press the

2. Press the

P key once, the display will read tECH.

SET key four times and the display will read dPnt.

3. Press the key, the display will flash the current decimal point position

(0001).

4. Press the key to set 0000 on the display (no decimal point), and press

SET key twice. tPoL is then displayed.

the

5. Press the key, the display will flash the current minimum span limit

(-1000)

6. Use the or keys to set the required ppm

and press the

SET key. tPoH is then displayed.

minimum reading (0000)

V

7. Press the key, the display will flash the current maximum span limit

(0200).

8. Use the and keys to set the required ppm

and press the

SET key twice. unit is then displayed.

maximum reading (3000)

V

9. Press the key, the display will flash the current unit (°C).

10. Press the key three times to set the display reading to ‘_’ (ppm

press the

SET key. LoL is then displayed.

) and

V

11. Press the key, the display will flash the current alarm lower range limit

(-1000) (formerly -100.0 with no sign or decimal point showing).

12. Use the or keys to set the required alarm lower range limit (point

where display starts to flash) (0 or different value), and press the

SET

key. uPL is then displayed.

13. Press the key, the display will flash the current alarm upper range limit

(0200) (formerly 020.0 with no decimal point showing).

14. Use the or keys to set the required alarm upper range limit (point

where display starts to flash) (3000 or different value), and press the

PUoF is now displayed.

key.

15. Press the

P key twice and the Main Display, now reading ppm

will show.

V

SET

NOTE: Neither the °C nor the °F LED indicators on the front panel

of the monitor are now lit.

On completion of the above procedure, appropriate alarm levels (relevant to the new

scale) will need to be set-up (refer to Section 3.4.3).

ppm

V

Michell Instruments 17

Page 26

OPERATION

P

SET

Easidew DryCheck User’s Manual

Main Display, e.g. °C

x4

Set decimal point (none)

Set Span min, 0 ppm(v)

SET

SET

x2

SET

SET

x2

x3

Set Span max, 3000 ppm (v)

Select ppm(v)

SET

SET

P

Set alarm lower range limit e.g. zeroSet alarm upper range limit e.g. 3000 ppm(v)

x2

Main Display, ppm(v)

Figure 13

Set-up Monitor (to read ppmV)

3.4.5 Monitor Limits When Unit Scaled to ppmV

When unit is scaled to ppmV the display will read zero when the mA input signal is

between 3 and 4 mA.

18 97108 Issue 13, July 2017

Page 27

Easidew DryCheck User’s Manual

3.5 Digital Communication Parameters Set-Up

The default parameters for the Easidew Drycheck are as follows:

Default Address = 1, Baud rate = 9600, Parity = None, Stop bits = 1

To change these parameters, proceed as follows:

OPERATION

Figure 14

1. Press the

2. Press the

3. Press the key five times, the display will flash between

4. Press the

5. Press the key once to display a flashing 4 digit number. The default

6. Use the or keys to give the required new value (e.g. 0002). NOTE:

shows the operational key sequence.

P key once, the display will read tECH.

SET key and the display will flash between ConF and PinP.

ConF and Corn.

Set-up instrument address

SET key once to display SAdr.

setting is 0001.

The range of possible addresses is between 1 and 247. Press the

SET key to accept the new value.

Set baud rate

bAud will now be displayed. Press the key once to display a flashing 4

7.

digit number. The default setting is 0003, representing 9600 baud.

8. Use the and keys to give the required new value (the range is 0 to

4). 0 = 1200 baud, 1 = 2400 baud, 2 = 4800 baud, 3 = 9600 baud, 4 =

19200 baud. Press the

Set parity

Prty will now be displayed. Press the key once to display a flashing 4

9.

digit number. The default setting is 0000, representing no parity (none).

10. Use the or keys to give the required new value (the range is 0 to 2).

0 = none, 1 = Odd, 2 = Even. Press the

value.

Set number of stop bits

StPb will now be displayed. Press the key once to display a flashing 4

11.

digit number. The default setting is 0000, representing 1 stop bit.

12. Use the or keys to give the required new value (the range is 0 - 1)

0 = 1 stop bit, 1= 2 stop bits.

13. Press the

return to the Main Display.

SET key to accept the selected value, followed by the P key to

SET key to accept the selected value.

SET key to accept the selected

Michell Instruments 19

Page 28

OPERATION

Easidew DryCheck User’s Manual

Main display

P

Set Parity

SET

SET

SET

x 5

Range between

0001 and 0247

Set Address

Set baud

SET

SET

P

Main Display (°F)

0000 = None

0001 = Odd

0002 = Even

Set number of

stop bits

0000 = 1 stop bit

0001 = 2 stop bits

SET

Figure 14

0=1200,

1=2400

2=4800,

3= 9600

4=19200

Set-up Data Communications Parameters

20 97108 Issue 13, July 2017

Page 29

Easidew DryCheck User’s Manual

OPERATION

3.6 Monitor – Reading the Displayed Value Using Modbus RTU Over RS232

It is possible to communicate with the online monitor using Modbus RTU over RS232.

The monitor has a three pin serial port connection on the back – the required cable can

be supplied by Michell.

To read the value displayed on the monitor a byte array must be created, containing

the following bytes:

Instrument

Address

Command

Reg

Address

High

Reg

Address

Low

Number

of Reg

High

Number

of Reg

Low

LRC CRC

0x01 0x04 0x00 0x00 0x00 0x01 0x31 0xCA

Send this to the instrument with the correct delays between characters:

Baud Rate (bps) Min Delay (ms) Max Delay (ms)

1200 9.17 13.76

2400 4.59 6.88

4800 2.30 3.44

9600 1.15 1.72

19200 0.57 0.86

After a few seconds the instrument will send back the following response:

Instrument

Address

Command

Number of

bytes

Display

High

Display

Low

LRC CRC

0x01 0x03 0x02 0x00 0x67 (Varies) (Varies)

Data MSB * 256 + Data LSB = 0 *256 + 103 = 103

This code, written in c, can be used to convert the 103 into a real dew-point value or

10.3:

float ConvertToReal(int Value) //convert dew-point value to real dew-point result

{float result; //declaration

if (Value > 32767) Value=(Value-65536); //convert to negative number

result = (float)(Value/10.0); //divide number by 10 to convert to float

return result; //return real value}

Michell Instruments 21

Page 30

OPERATION

4 GOOD MEASUREMENT PRACTICE

The Easidew DryCheck is designed to operate in a flowing gas stream and is suitable for

the measurement of the moisture content of a wide variety of gases. In general, if the

gas (in conjunction with water vapor) is not corrosive to ceramics or base metals then

it will be suitable for measurement by the Easidew DryCheck.

The system is designed for operation with sample gas flow rates of 1 to 5 Nl/min (2.1 to

10.6 scfh) (sample block). Ideally, the flow rate should be set-up between 4 and 6 Nl/

min. Flow regulation is provided within the Easidew DryCheck system. Always use high

quality valve gear, coupling connections and pipework.

The system will operate successfully at flow rates within its operational range and it is

important to ensure that the flow rate through the sample block is high enough to avoid

long time lags in response to humidity changes at the sample source.

Avoid pressure gradients in the system by placing excessive flow restriction on the

output side of the sample block. In applications where the test gas has a very high

flow rate, an instrument by-pass arrangement is preferable to flow restriction after the

transmitter.

Easidew DryCheck User’s Manual

Flow Rates

Theoretically flow rate has no direct effect on the measured moisture content, but in

practice it can have unanticipated effects on response speed and accuracy.

An inadequate flow rate can:

• Accentuate adsorption and desorption effects on the gas passing

through the sampling system.

• Allow pockets of wet gas to remain undisturbed in a complex sampling

system, which will then gradually be released into the sample flow.

• Increase the chance of contamination from back diffusion: ambient air

that is wetter than the sample can flow from the exhaust back into the

system. A longer exhaust (sometimes called a pigtail) can also help

alleviate this problem.

• Slow the response of the sensor to changes in moisture content.

An excessively high flow rate can:

• Introduce back pressure, causing slower response times and

unpredictable effects on equipment such as humidity generators.

Factory Flow Rate Setting

Internally the gas enters a sample block at which point an adjustable flow valve is

located. This valve is factory set to output 2.5 l/min flow at 7 barg.

22 97108 Issue 13, July 2017

Page 31

Easidew DryCheck User’s Manual

5 MAINTENANCE

5.1 General Maintenance Guidelines

Routine maintenance of the Easidew DryCheck is confined to filter element replacement

and regular recalibration of the dew-point transmitter.

5.2 Calibration

Routine maintenance of the transmitter is confined to regular re-calibration by exposure

of the transmitter to sample gases of known moisture content to ensure that the stated

accuracy is maintained. Calibration services traceable to the UK National Physical

Laboratory (NPL) and the US National Institute of Standards and Technology (NIST) are

provided by Michell Instruments.

Michell Instruments offers a variety of re-calibration and exchange sensor schemes to

suit specific needs. A Michell representative can provide detailed, custom advice (for

Michell Instruments’ contact information go to www.michell.com).

GOOD MEASUREMENT PRACTICE

5.3 Transmitter Maintenance

To replace the transmitter proceed as follows:

Always de-pressurize the system and disconnect any electronic

supplies before commencing maintenance.

1. Open the transparent front cover.

2. Remove the four screws securing the aluminum front panel.

3. Carefully lift the front panel to expose the transmitter.

4. Remove the electrical mini DIN connector from the transmitter by loosening

the connector-securing screw and pulling it away from the transmitter.

5. Unscrew the transmitter from the block using a 27AF spanner/wrench.

6. Fit a new transmitter and fully tighten to a minimum torque of 30.5Nm.

7. Repeat the above instructions in reverse order.

h

Mini DIN

Connector

h

Transmitter

Figure 15

Michell Instruments 23

Sensor Removal

Page 32

MAINTENANCE

5.4 Inspection/Cleaning

The composition of the gas determines the frequency of the filter element replacement,

i.e. liquid and particulate contaminates, corrosive elements, etc.

A disposable filter element continues to filter at its original efficiency as long as it is

kept in service. The life of the element is determined by the increase in flow resistance

caused by trapped solids in the element. The element should be changed when the flow

falls below an acceptable level, or the pressure drop becomes too high. In any case the

element should be replaced before the pressure drop across it reaches 0.7 barg (10.2

psig).

To replace a particulate filter element (Michell part SSF-PF-10PK (pack of 10)), proceed

as follows:

Always de-pressurize the system and disconnect any electronic

Easidew DryCheck User’s Manual

supplies before commencing maintenance.

1. Unscrew the stainless steel cap and withdraw it from the block.

2. The filter is a push-fit onto a mounting boss. To remove, pull apart from

the cap.

3. Refit a new element. NOTE: Do not touch the element with bare

fingers.

h

h

Filter

Element

Figure 16

24 97108 Issue 13, July 2017

Inspection/Cleaning

Page 33

Easidew DryCheck User’s Manual

5.5 Fault Conditions

MAINTENANCE

Message

Displayed

ErrL

Sbr

ErrH

outR

rurC

Cause Action

Check power supply to transmitter. Check

Sensor failure

Instrument failure

Sensor failure or break in

sensor connection

Gas is wetter than +20°Cdp Check gas source supply.

Sensor contaminated Replace/re-calibrate transmitter.

Input out of range

Reverse input connection

transmitter cable for continuity/damage.

Rectify/replace cable.

Refer to Michell or local representative for

repair.

Check transmitter cable for continuity/

damage.

Rectify/replace cable.

Check gas source supply.

Re-calibrate/replace transmitter.

Swap input connections from the

transmitter to the monitor.

Michell Instruments 25

Page 34

APPENDIX A

Easidew DryCheck User’s Manual

Appendix A

Technical Specifications

26 97108 Issue 13, July 2017

Page 35

Easidew DryCheck User’s Manual

APPENDIX A

Appendix A Technical Specifications

-100 to +20°Cdp

Electrical Specifi cations

Power Supply 85 to 265 V AC, 50/60 Hz

Operating Specifi cations

Operating Temperature -5 to +50°C (+23 to +122°F)

Storage Temperature -40 to +75°C (-40 to +167°F)

-100 to +20°Cdp (-148 to +68°F)

Measurement Range

Accuracy ±2°Cdp

Output 4-20 mA maximum load resistance 500

Alarm 2 volt free contacts 240 V, 3A

Sample Flow Rate 1 to 5 Nl/min (2.1 to 10.6 scfh)

Gas Pressure 1 MPa (10 barg/145 psig) max (high pressure option available)

Mechanical Specifi cations

User Interface Front panel confi guration of alarm points

Display 20mm (¾“) red LED

Ingress Protection IP65 (NEMA 4x)

Mains Cable 2m cable supplied

Filtration 99.5% removal of 0.3m

Gas Connection Quick connect fi ttings for 6mm (¼”) OD Tefl on pipe

3000 ppm

specifi ed at time of order)

(ppmV output or non-standard dew-point range must be

V

-60 to +60°Cdp / -50 to +50°Cdp

Electrical Specifi cations

Power Supply 85 to 265 V AC, 50/60 Hz

Operating Specifi cations

Operating Temperature -5 to +50°C (+23 to +122°F)

Storage Temperature -40 to +75°C (-40 to +167°F)

Measurement Range

Accuracy ±2°Cdp

Output 4-20 mA maximum load resistance 500

Alarm 2 volt free contacts 240 V, 3A

Sample Flow Rate 1 to 5 Nl/min (2.1 to 10.6 scfh)

Gas Pressure 1 MPa (10 barg/145 psig) max (high pressure option available)

Mechanical Specifi cations

User Interface Front panel confi guration of alarm points

Display 20mm (¾“) red LED

Ingress Protection IP65 (NEMA 4x)

Mains Cable 2m cable supplied

Filtration 99.5% removal of 0.3m

Gas Connection Quick connect fi ttings for 6mm (¼”) OD Tefl on pipe

-60 to +60°Cdp (-76 to 140°Fdp) / -50 to +50°Cdp (-58 to +122°Fdp)

Non-standard available on request

Michell Instruments 27

Page 36

APPENDIX B

Easidew DryCheck User’s Manual

Appendix B

System Drawing

28 97108 Issue 13, July 2017

Page 37

Easidew DryCheck User’s Manual

Appendix B System Drawing

APPENDIX B

Figure 17

Michell Instruments 29

System Drawings

Page 38

APPENDIX C

Easidew DryCheck User’s Manual

Appendix C

Quality, Recycling

& Warranty

Information

30 97108 Issue 13, July 2017

Page 39

Easidew DryCheck User’s Manual

APPENDIX C

Appendix C Quality, Recycling & Warranty Information

Michell Instruments is dedicated to complying to all relevant legislation and directives. Full information

can be found on our website at:

www.michell.com/compliance

This page contains information on the following directives:

• ATEX Directive

• Calibration Facilities

• Conflict Minerals

• FCC Statement

• Manufacturing Quality

• Modern Slavery Statement

• Pressure Equipment Directive

• REACH

• RoHS2

• WEEE2

• Recycling Policy

• Warranty and Returns

This information is also available in PDF format.

Michell Instruments 31

Page 40

APPENDIX D

Easidew DryCheck User’s Manual

Appendix D

Return Document

&

Decontamination Declaration

32 97108 Issue 13, July 2017

Page 41

Easidew DryCheck User’s Manual

Appendix D Return Document & Decontamination Declaration

'HFRQWDPLQDWLRQ&HUWL¿FDWH

IMPORTANT NOTE: Please complete this form prior to this instrument, or any components, leaving your

site and being returned to us, or, where applicable, prior to any work being carried out by a Michell

engineer at your site.

Instrument Serial Number

Warranty Repair? YES NO Original PO #

Company Name Contact Name

Address

Telephone # E-mail address

Reason for Return /Description of Fault:

APPENDIX D

Has this equipment been exposed (internally or externally) to any of the following?

Please circle (YES/NO) as applicable and provide details below

Biohazards YES NO

Biological agents YES NO

Hazardous chemicals YES NO

Radioactive substances YES NO

Other hazards YES NO

Please provide details of any hazardous materials used with this equipment as indicated above (use continuation sheet

if necessary)

Your method of cleaning/decontamination

Has the equipment been cleaned and decontaminated? YES NOT NECESSARY

Michell Instruments will not accept instruments that have been exposed to toxins, radio-activity or bio-hazardous

PDWHULDOV)RUPRVWDSSOLFDWLRQVLQYROYLQJVROYHQWVDFLGLF EDVLFÀDPPDEOHRUWR[LFJDVHVDVLPSOHSXUJHZLWK GU\

JDVGHZSRLQW&RYHUKRXUVVKRXOGEHVXI¿FLHQWWRGHFRQWDPLQDWHWKHXQLWSULRUWRUHWXUQ

Work will not be carried out on any unit that does not have a completed decontamination declaration.

Decontamination Declaration

I declare that the information above is true and complete to the best of my knowledge, and it is safe for Michell

personnel to service or repair the returned instrument.

Name (Print) Position

Signature Date

F0121, Issue 2, December 2011

Michell Instruments 33

Page 42

Page 43

http://www.michell.com

Loading...

Loading...