Page 1

Process Analyzers

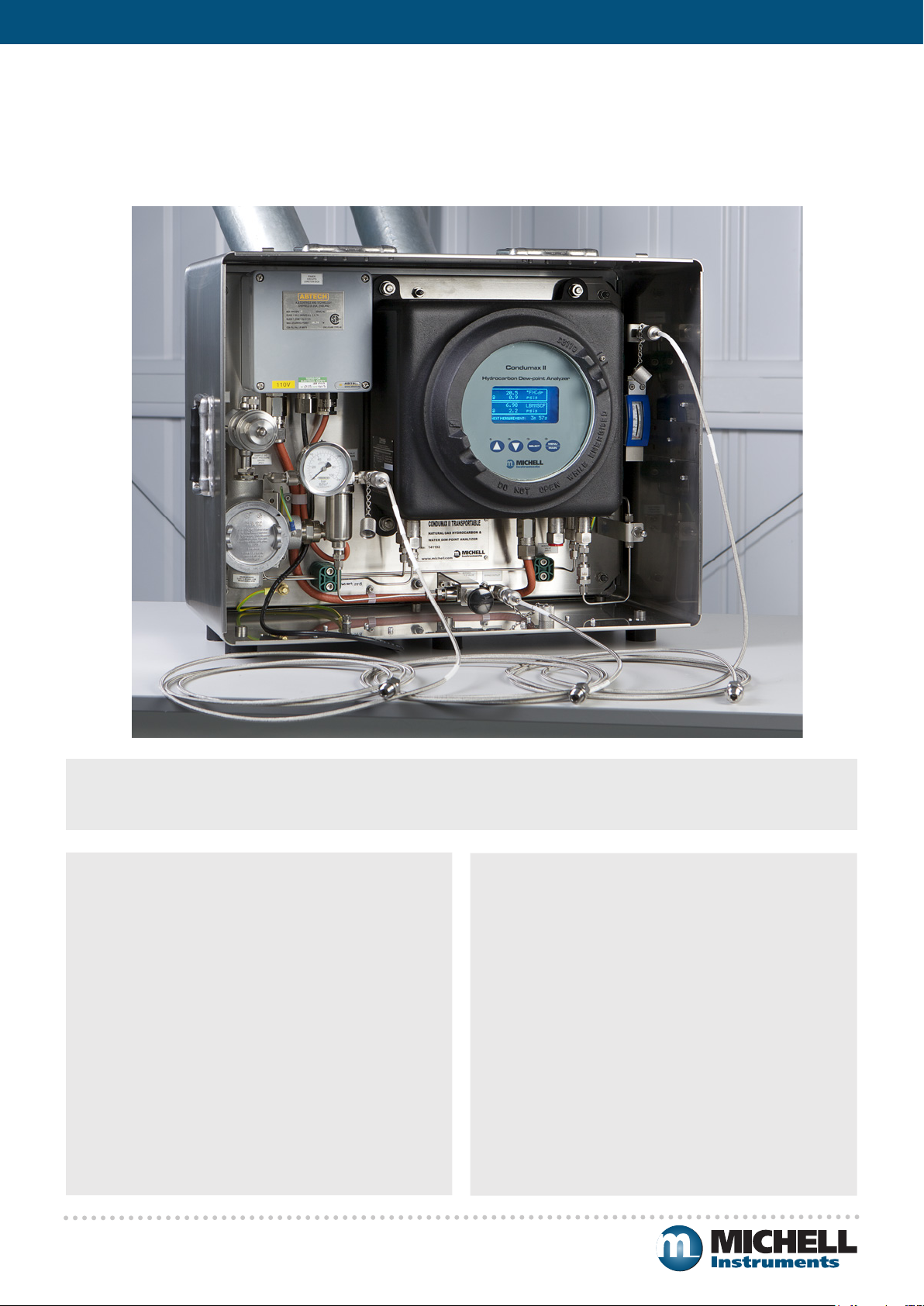

Condumax II Transportable

Hydrocarbon & Water Dew-Point Analyzer

Transportable natural gas dew-point analyzer system for operation in the eld. Suitable for IEC

Zone 1 or 2 hazardous area, NEC Class I, Division 1 Groups B, C, D.

A complete transportable natural gas dew-point analysis system for eld spot-check measurements. Periodic online operation

when located in a temperature maintained analyzer house. Measurements and functionality are instantly accessible through

integrated alphanumeric display and touch-glass HMI interface including log of dew-point readings for operator review.

Highlights

• Field transportable self-contained dew-point

analyzer system

• Simultaneous HC and water dew-point

measurements in a single analyzer

• Automatic objective measurements by industry

proven principles

• Parameter specic sensors ensure continuity of

HC and water dew-point readings

• Self-contained sample handling, conditioning and

analysis package

• 0.5°C HC dew-point accuracy

• Fundamental cooled mirror principle

Applications

• Spot-check measurements of HC and water dew

point

• Field verication of installed on-line dew-point

analyzers

• Flexibility for periodic measurements at any gas

source

• Producer process stage proling to optimize

eciency

www.michell.com

Page 2

Process Analyzers

The Industry Standard HCDP/WDP

Analyzer

The Condumax II fullls the demands of natural gas

producers and pipeline transmission companies for reliable

on-line monitoring of natural gas hydrocarbon and water

dew point.

Condumax II is the industry’s analyzer of choice to

ensure conformance of these key gas quality parameters,

from production processing, through trans-continental

pipeline networks into nal distribution and utilization by

major consumers such as power generators. Throughout

the midstream industry Michell hydrocarbon dew-point

analyzers are installed as permanent analyzers, providing

measurements six times every hour 24/7/365.

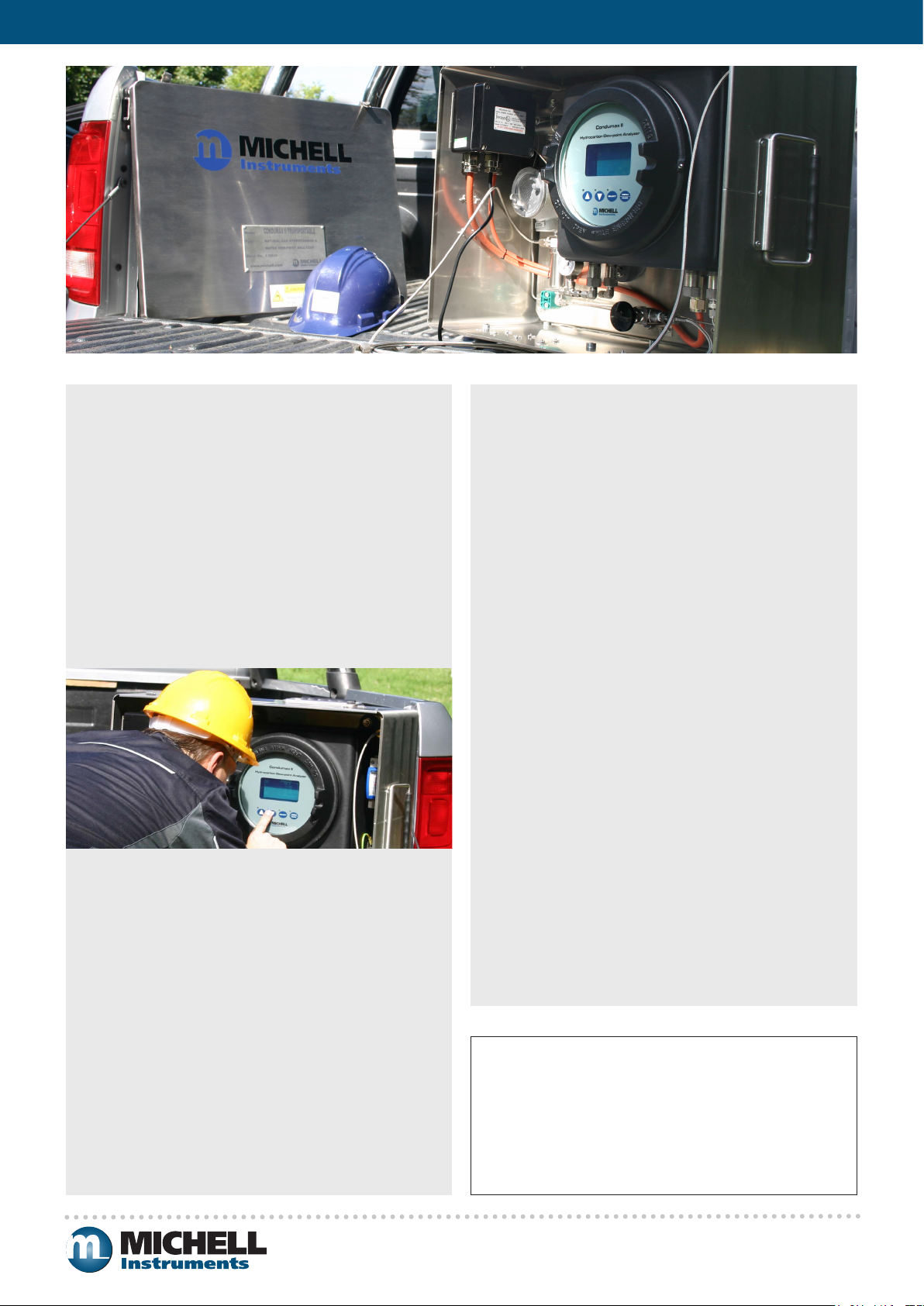

Transportable Condumax II for Field

Validation

The Condumax II Transportable addresses the further

needs of natural gas users as the industry evolves. With

an increased proportion of alternative fuel sources such

as biogas, and greater reliance on LNG imports into gas

networks which traditionally received gas solely from

xed upstream producers, the attention to ensuring

accurate measurement of dew point has never been more

critical. This increased complexity of supply chains has

expanded the number of potential measurement points

each requiring conformity to specication. The Condumax

II Transportable oers the exibility to make investigative

spot-check measurements at any location, to even the

smallest and most remote gas source. Furthermore, for

the gas producer, the Condumax II Transportable can be

used to prole individual process stages to ensure optimum

eciency.

Quality Assurance with a New Transfer

Standard

The Condumax II Transportable also enables established

users of permanent on-line dew-point analyzers to carry

out periodic comparative measurements in the eld to

verify measurement performance against the certied

factory laboratory calibration of the Condumax II to all

users.

The Condumax II Transportable oers automatic

measurements of high sensitivity and objectivity wherever

they are needed in a simple to use, self-contained, sample

handling, conditioning and analysis package.

Sample Conditioning System

• Complete integration of Condumax II Main Unit

• System conguration for connection direct to

transmission pipeline natural gas at typically 70 barg

pressure

• Simultaneous water dew-point measurement at process

pressure. Integration of water dew-point sample ow in

series for analysis at full line pressure

• Process pressure gauge, 100 barg scale

• Coalescing lter with by-pass needle valve and system

drain

• Sample gas pressure reduction via electrically-heated

regulator for analysis of HC dew point at intermediate

pressure (cricondentherm condition), adjustment range

up to 35 barg tted (analysis pressure indicated by

Condumax II Main Unit)

• Sample ow control with armored rotameter

*To assure correct measurement performance of

this system in outdoor eld use, the ambient air

temperature must be at least 5°C above both the

hydrocarbon dew-point temperature of the process

gas sample at the cricondentherm condition,

typically 27 barg, and water dew-point at full

process line pressure.

www.michell.com

Page 3

550mm

(21.6”)

335mm

(13.2”)

670mm

(26.4”)

Dimensions

Process Analyzers

System Package

• Custom designed and built carry case of heavy duty

construction in 316 stainless steel with six vibration

absorbing feet on base (for transportation) and on one

edge (for upright analyzer system operation)

• Removable case lid secured by four toggle latches. Six

carry handles for ease of mobility by two persons and

transportation between sites by automobile

• Power consumption: <300 W, 110 V, 60 Hz or 230 V,

50 Hz (dependent on unit purchased)

• Power Connection: Junction box provided with M20

or 1/2” NTP gland entry. Local AC connection to by

customer’s site electrician in accordance with local

codes of practice

• Weight (inclusive of Condumax II Main Unit):

60kg approximately

Condumax II Flow Schematic

PRESSURE

GAUGE

SAMPLE GAS INLET

(100 BARG MAX)

COALESCING

FILTER

PRESSURE

REGULATOR

Weight: 60kg (approx)

System Connections

• Minimess® stainless steel braided, micro-bore hoses

• Sampling system connection: Minimess® quick connect

• Set of 3 hoses: Sample inlet, coalescing lter drain /

• Length: 3m (each hose)

• Process connection: 316 stainless steel, 1/4” NPT male

• Gas wetted bore: PTFE, 2mm internal diameter

CONDUMAX II

ANALYZER

HC DEW POINT

WATER DEW POINT

by-pass and sample gas exhaust

NON-RETURN

VALVE

METERING

VALVE

NEEDLE

VALVE

FLOWMETER

SAMPLE GAS

OUTLET

BYPASS GAS

OUTLET

Hydrocarbon dew point - measured at cricondentherm condition

Water dew point - measured at line pressure

www.michell.com

Page 4

Process Analyzers

Technical Specications

Condumax II Main Unit

Analyzer

Hydrocarbon Dew-Point Measurement

Measuring technique Dark Spot™ xed sample analysis; Direct

Sensor cooling Automatic via 3-stage Peltier eect

Maximum range Up to Δ 55°C measurement depression from

Resolution 0.1°C, 0.1°F

Accuracy ±0.5°C hydrocarbon dew point (single and

Sample ow 0.03 to 0.06 m3/hr (0.5 to 1.0 Nl/min)

Measurement frequency 6 cycles/hour (recommended)

Operating Pressure Max. 100 barg (1450 psig)

photo-detection of hydrocarbon condensate

at hydrocarbon dew-point temperature

electronic cooler under adaptive control

main unit operating temperature

multiple condensable component analysis)

- low ow alarm standard

12 cycles/hour (maximum)

Water Dew-Point Measurement

Measuring technique Michell Ceramic Moisture Sensor

Unit Selection

Resolution 0.1°C, 0.1°F dew point

Range Calibrated from -100 to +20°C dew point

Accuracy ±1°C from -59 to +20°C dew point

Operating Pressure Max. 138 barg (2000 psig)

Dew point

Moisture content

°C and °F water dew point

lbs/MMscf; mg/m3, ppmV

(conversion method IGT#8 or ISO18453)

0.1 lbs/MMscf, 1 mg/m3 ppm

±2°C from -100 to -60°C dew point

V

Pressure Measurement(s)

Hydrocarbon dew-point analysis pressure

Units MPa, barg, psig

Resolution 0.1 MPa and barg, 1 psig

Accuracy

Hydrocarbon dew point

Water dew point

±0.25 barg

±0.5 barg

Hydrocarbon and Water Dew-Point Analyzer

Sample gas supply Natural gas up to 100 barg, pressure

Enclosure Travel case is stainless steel 316 material

Gas connections Sample inlet, lter by-pass outlet, system

Operating environment Indoors/outdoors 0 to 40°C; Max 95% RH

Power supply 110 or 230 V AC, 50/60 Hz, 300 W

Weight 60kg (approx)

regulated in sampling system

construction with removable lid for access

and rubber feet for transportation /

operation;

Instrument is EExd cast enclosure with

removable viewing port: internally heated

for condensation protection

drain.

Sample system for: 1/4” NPT female ports,

Quick connect Minimess® hoses,

Process connections: 1/4” NTP male

*See cautionary note on page 2

Logged data

Each log

Visual review

Integrated display/

keyboard

Outputs Modbus RTU, RS485 @ 9600 baud rate;

Alarms Process and analyzer status via software

150 data logs, sucient for minimum 24

hour period (stored in volatile memory);

HC dew point and analysis pressure, water

dew point and process line pressure;

HMI display with automatic statistical

analysis; maximum, minimum, average

values for duration of log period

Touch screen with vacuum uorescent

display

Two 4-20 mA linear (non-isolated) outputs,

user congurable for any combination of

dew point or pressure parameters;

Additional connection junction box required

externally

register and display annotation. Integrated

low ow alarms for each sample ow

Analyzer status fault ag 23 mA on mA

output 1;

Comprehensive analyzer status messages

appear on HMI display;

Additional connection junction box required

externally

Certication

Hazardous area

certication

*Available to customer specic order — consult Michell

Instruments.

ATEX: II 2G Ex d e IIB+H2 T3

Gb Ta= -20°C to +40°C

IECEx: Ex d e IIB+H2 T3 Gb

Ta= -20°C to +40°C

Michell Instruments Ltd 48 Lancaster Way Business Park, Ely, Cambridgeshire, CB6 3NW

Tel: +44 (0) 1353 658000, Fax: +44 (0) 1353 658199, Email: uk.info@mi chell.com, Web: www.michell.com/uk

Michell Instruments adopts a continuous development programme which sometimes necessitates specication changes without notice.

Issue no: Condumax II Transportable_97149T_V5_UK_0419

www.michell.com

Loading...

Loading...