Page 1

Cermet II

Hygrometer

User’s Manual

°Cdp

°Fdp

Setup

97049 Issue 25.3

October 2016

Cermet II

Advanced Online

©

ª

Page 2

Please fi ll out the form(s) below for each instrument that has been purchased.

Use this information when contacting Michell Instruments for service purposes.

Instrument

Code

Serial Number

Invoice Date

Location of Instrument

Tag No

Instrument

Code

Serial Number

Invoice Date

Location of Instrument

Tag No

Instrument

Code

Serial Number

Invoice Date

Location of Instrument

Tag No

Page 3

°Cdp

°Fdp

Setup

Cermet II

Advanced Online

Cermet II

©

ª

For Michell Instruments' contact information please go to

www.michell.com

© 2016 Michell Instruments

This document is the property of Michell Instruments Ltd. and may not be copied or

otherwise reproduced, communicated in any way to third parties, nor stored in any Data

Processing System without the express written authorization of Michell Instruments Ltd.

Page 4

Cermet II User’s Manual

Contents

Safety ................................................................................................................................vi

Electrical Safety ...........................................................................................................vi

Pressure Safety ............................................................................................................vi

Toxic Materials .............................................................................................................vi

Repair and Maintenance ...............................................................................................vi

Calibration ...................................................................................................................vi

Safety Conformity ........................................................................................................vi

Abbreviations .....................................................................................................................vii

Warnings ...........................................................................................................................vii

1 INTRODUCTION ................................................................................................1

1.1 Features ............................................................................................................ 1

2 INSTALLATION ..................................................................................................2

2.1 Unpacking the Instrument ................................................................................... 2

2.1.1 Unpacking the Cermet II Transmitter .............................................................. 3

2.1.2 Unpacking the Cermet II Monitor ................................................................... 4

2.1.3 Accessories Pack .......................................................................................... 4

2.2 Cermet II Components ....................................................................................... 5

2.3 Monitor .............................................................................................................. 6

2.4 Monitor Panel Layout .......................................................................................... 6

2.5 Preparation of the Transmitter Cable .................................................................... 7

2.6 Transmitter Mounting .......................................................................................... 8

2.6.1 Transmitter Mounting - Sample Block and Gas Connections (Optional) .............. 9

2.6.2 Transmitter Mounting - Direct Pipeline Connection ......................................... 11

2.6.3 Transmitter Mounting - With Additional Process Connection Adapter .............. 12

2.7 Monitor Mounting ............................................................................................. 13

2.8 Electrical Connections ....................................................................................... 14

2.8.1 High Voltage Power Supply Input ................................................................. 14

2.8.2 Low Voltage Power Supply Input ................................................................. 15

2.9 Pressure Transducer Connection (Optional) ........................................................ 15

2.10 Transmitter Cable Connection ............................................................................ 16

3 OPERATION - MONITOR ...................................................................................17

3.1 Set-Up Security Feature .................................................................................... 17

3.2 Selecting the Engineering Units ......................................................................... 18

3.3 Changing the Setpoint Values ............................................................................ 18

3.4 Hysteresis, Make/Break delay & delay type ......................................................... 19

3.5 Analog Output Scaling ...................................................................................... 19

3.6 Display Brightness Adjustment .......................................................................... 20

3.7 Digital Communications..................................................................................... 20

3.8 Pressure Compensation ..................................................................................... 21

3.9 Using a Pressure Transducer ............................................................................. 21

3.9.1 Manual Pressure Input Calibration ................................................................ 22

3.10 Automatic Pressure Input Calibration ................................................................. 22

3.11 Using a Fixed Pressure Input in Single Channel Mode .......................................... 23

4 OPERATION - TRANSMITTER ............................................................................24

5 MAINTENANCE ................................................................................................25

iv 97049 Issue 25.3, October 2016

Page 5

Cermet II User’s Manual

Figures

Figure 1 Unpacking - Monitor and Accessories ...........................................................2

Figure 2 Transmitter Unpacking Method ....................................................................3

Figure 3 Unpacking - Monitor ...................................................................................4

Figure 4 Unpacking - Accessories Pack ......................................................................4

Figure 5 Components ...............................................................................................5

Figure 6 Control Layout and Functions ......................................................................6

Figure 7 Connector Terminal Block Removal ..............................................................7

Figure 8 Sample Block Gas Connections ....................................................................9

Figure 9 Transmitter Mounting - Sensor Block ..........................................................10

Figure 10 Transmitter Mounting - Pipe or Duct...........................................................11

Figure 11 Transmitter Mounting with Adapter ...........................................................12

Figure 12 Mounting the Monitor ...............................................................................13

Figure 13 High Voltage Power Supply Connections .....................................................14

Figure 14 Low Voltage Power Supply Connections ......................................................15

Figure 15 Electrical Connection Detail .......................................................................15

Figure 16 Cable Connections ....................................................................................16

Figure 17 Connector Installation ...............................................................................16

Figure 18 Location of the Lockout Switches ...............................................................17

Figure 19 Installation Location .................................................................................24

Figure 20 Indication of Dead Space ..........................................................................24

Figure 21 Replacement of HDPE Guard .....................................................................25

Tables

Table 1 Cable Connections ..................................................................................... 16

Table 2 Operation Access Levels ............................................................................. 17

Appendices

Appendix A Technical Specifi cations .............................................................................. 27

Appendix B Setup Codes .............................................................................................30

Appendix C Register Settings Accessible by Digital Communication ................................ 33

Appendix D EU Declaration of Conformity......................................................................36

Appendix E Quality, Recycling & Warranty Information ...................................................38

E.1 Pressure Equipment Directive (PED) 97/23/EC ...............................38

E.2 Recycling Policy .......................................................................... 38

E.3 WEEE Compliance ........................................................................ 38

E.4 RoHS2 Compliance ......................................................................39

E.5 Warranty ..................................................................................... 39

E.6 REACH Compliance ...................................................................... 40

E.7 Return Policy ............................................................................... 40

E.8 Calibration Facilities .....................................................................41

E.9 Manufacturing Quality .................................................................. 41

E.10 FCC (EMC REquirements for North America) ..................................41

Appendix F Return Document & Decontamination Declaration ........................................ 43

Michell Instruments v

Page 6

Cermet II User’s Manual

Safety

The manufacturer has designed this equipment to be safe when operated using the procedures

detailed in this manual. The user must not use this equipment for any other purpose than that

stated. Do not apply values greater than the maximum value stated.

This manual contains operating and safety instructions, which must be followed to ensure the safe

operation and to maintain the equipment in a safe condition. The safety instructions are either

warnings or cautions issued to protect the user and the equipment from injury or damage. Use

qualifi ed personnel and good engineering practice for all procedures in this manual.

Electrical Safety

The instrument is designed to be completely safe when used with options and accessories supplied

by the manufacturer for use with the instrument.

Pressure Safety

DO NOT permit pressures greater than the safe working pressure to be applied to the instrument.

The specifi ed safe working pressure is 45 MPa (450 barg / 6500 psig). Refer to the Technical

Specifi cations in Appendix A.

Toxic Materials

The use of hazardous materials in the construction of this instrument has been minimized. During

normal operation it is not possible for the user to come into contact with any hazardous substance

which might be employed in the construction of the instrument. Care should, however, be exercised

during maintenance and the disposal of certain parts.

Repair and Maintenance

The instrument must be maintained either by the manufacturer or an accredited service agent. Refer

to www.michell.com for details of Michell Instruments’ worldwide offi ces contact information.

Calibration

The recommended calibration interval for the Cermet II transmitter is 12 months unless it is to

be used in a mission-critical application or in a dirty or contaminated environment in which case

the calibration interval should be reduced accordingly. The instrument should be returned to the

manufacturer, Michell Instruments Ltd., or one of their accredited service agents for re-calibration.

Michell Instruments can offer a variety of re-calibration and exchange transmitter schemes to suit

your specifi c needs. A local representative will be pleased to provide detailed, custom advice.

Safety Conformity

This product meets the essential protection requirements of the relevant EU directives.

vi 97049 Issue 25.3, October 2016

Page 7

Cermet II User’s Manual

!

DANGER

Electric

Shock Risk

Abbreviations

The following abbreviations are used in this manual:

AC alternating current

atm pressure unit (atmosphere)

barg pressure unit (=100 kP or 0.987 atm) (gauge)

DC direct current

EU European Union

3

grams per cubic meter

g/m

Hz Hertz

lb pound

lbs/MMSCF pounds per million standard cubic feet

Nl/min liters per minute

mA milliampere

Nm nanometer

ppm

psig pound(s) per square inch (gauge)

sec second(s)

°C degrees Celsius

°F degrees Fahrenheit

V Volts

Warnings

The following general warnings listed below are applicable to this instrument. They are

repeated in the text in the appropriate locations.

parts per million (by volume)

V

Where this hazard warning symbol appears in the following

sections, it is used to indicate areas where potentially

hazardous operations need to be carried out.

Where this symbol appears in the following sections it is used to

indicate areas of potential risk of electric shock.

Michell Instruments vii

Page 8

Cermet II User’s Manual

1 INTRODUCTION

The Cermet II hygrometer is an instrument designed for the continuous online

measurement of moisture content in non-corrosive gases, over an operational range

of -100 to +20°C (-148 to +68°F) dew point and equivalent units (see Technical

Specifi cations, Appendix A).

The system comprises a programmable monitor confi gured to accept a unique Michell

data string from the Cermet II transmitter. The zero and span of the monitor are set to

cover the dew-point range -100 to +20°Cdp (-148 to +68°Fdp) at operating pressures

up to 45 MPa (450 barg / 6500 psig).

Two alarm outputs are provided for connection to external systems which are userconfi gurable both in terms of setpoint and operating mode. Current output is standard

and factory set at 4-20 mA (or optionally set at 0-20 mA or 0-10 V).

The monitor has a pressure input channel for any industry standard 2-wire pressure

transmitter. In addition to providing a pressure measurement, the pressure signal can

be used to provide real-time pressure compensation on the primary channel when

displaying ppm values. The customer can also set a fi xed pressure compensation value.

The pressure input only affects the ppmV (parts per million by volume), lbs/MMSCF

(pounds per million standard cubic feet) and g/m3 (grams per cubic meter) units. For

dew point, the displayed value is a pressure dew point.

INTRODUCTION

1.1 Features

• Wide measurement range, calibrated -100 to +20°Cdp

• ±1°Cdp measurement accuracy

• Pressure sensor input

• Up to 4 alarm relays

• User selectable units of measurement

• Easy to read display

• Analog and digital outputs

Michell Instruments 1

Page 9

INSTALLATION

2 INSTALLATION

It is essential that the connection of electrical and gas supplies

!

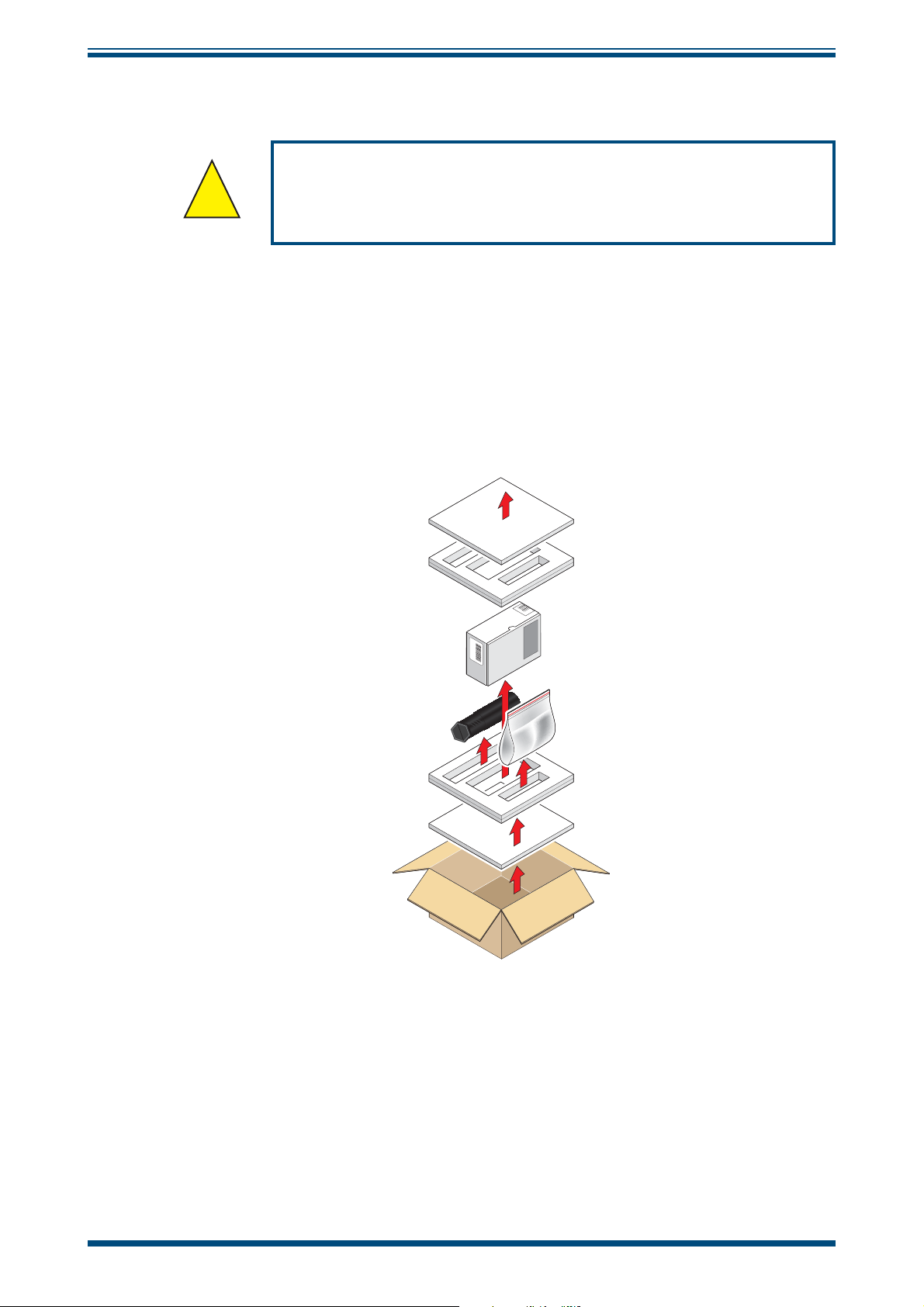

2.1 Unpacking the Instrument

The Cermet II hygrometer and accessories are packed in a box and the method of

unpacking is shown as follows:

to this instrument be undertaken by competent personnel.

Cermet II User’s Manual

Figure 1

2 97049 Issue 25.3, October 2016

Unpacking - Monitor and Accessories

Page 10

Cermet II User’s Manual

2.1.1 Unpacking the Cermet II Transmitter

On delivery, check that all the following standard components are in the packing tube:

• Cermet II Transmitter

• Bonded Seal

• Certifi cate of Calibration

Unpack the dew-point transmitter tube as follows:

INSTALLATION

7653 421

Figure 2

1. Unscrew the cap (1) from the packing tube (7).

2. Remove the foam block (2).

3. Pull out the transmitter (4) from the tube, complete with the two foam

covers (5) and (6) and the red protective cap (3).

4. Remove the foam covers from the transmitter but leave the blue plastic

protective cover (4) and the red cap (3) in place until ready for installation.

NOTE: The transmitter sensing element is protected while in transit by a blue

cover containing a small desiccant capsule. The connection pins are protected

by a red plastic cap. None of these plastic items are required for the operation

of the transmitter.

Transmitter Unpacking Method

Michell Instruments 3

Page 11

INSTALLATION

2.1.2 Unpacking the Cermet II Monitor

The monitor (2) is packed, together with its fi xing clamps (1) as shown below.

Cermet II User’s Manual

°Cdp

Cermet II

Advanced Online

°Fdp

Setup

©

ª

1

2.1.3 Accessories Pack

The accessories pack is shown below:

Figure 3

Unpacking - Monitor

1

2

4

3

2

Figure 4

Unpacking - Accessories Pack

4 97049 Issue 25.3, October 2016

Page 12

Cermet II User’s Manual

Cermet II

Hygrometer

User’s Manual

97049 Issue 25.1

June 2015

°C

dp

°

F

dp

C

e

r

m

e

t I

I

Ad

v

an

c

e

d

O

nl

in

e

©

ª

Setup

2.2 Cermet II Components

On delivery, please check that all the following standard components are present in the

packing box. Report any shortages immediately.

INSTALLATION

1

4

°Cdp

Cermet II

Advanced Online

°Fdp

Setup

©

9

ª

5

8

2

7

3

6

Figure 5

Components

1. Cermet II Monitor

2. Clamps

3. Transmitter cable assembly

4. Cermet II Transmitter

5. Screwdriver

6. Power cable

7. User’s manual

8. Calibration certifi cate

9. Sample block

Michell Instruments 5

Page 13

INSTALLATION

2.3 Monitor

The monitor has a 5-digit display, set-up on delivery to display a dew-point temperature

range of -100° to +20°Cdp (-148° to +68°Fdp).

Dew-point temperature units are displayed by the last LED located to the far right of

the display. On delivery, °Cdp is set-up. If required, the units can be changed to °F. The

method of confi guring the unit for °F is described in Section 3.2.

Optionally, the instrument can be set-up to read moisture content in parts per million

(ppmV), pounds per million standard cubic feet (lbs/MMSCF) or grams per cubic meter

(g/m3). This option requires the hygrometer to be set-up as detailed in Section 3.2.

Four alarm indications are provided by four LEDs located on the bottom of the display.

These are marked SP1, SP2, SP3, SP4. Access to the alarm relay contacts is provided

on the rear panel. The connection for these alarm relay contacts is shown in

NOTE: Every monitor is factory fi tted with 2 alarm relays as standard.

Cermet II User’s Manual

Figure 15

.

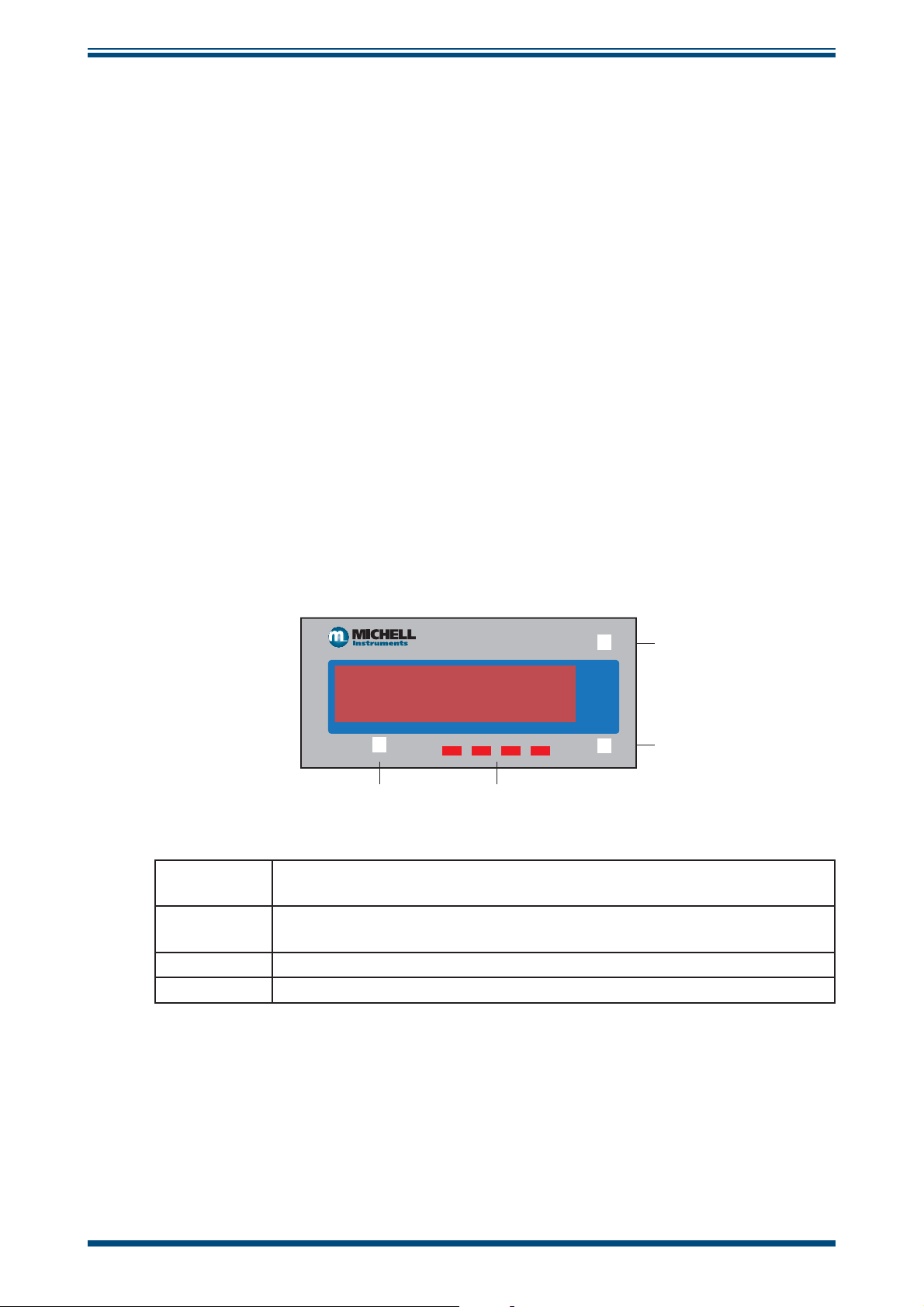

2.4 Monitor Panel Layout

Figure 6

shows the layout of these controls and their respective operational functions.

Setup

1

2

Increases the value of the displayed parameter; moves through each

displayed parameter

Decreases the value of the displayed parameter; moves through each

displayed parameter

3 LED annunciations for Setpoints 1 - 4

4 Saves programming settings, moves between programming steps

h

Cermet II

Advanced Online

ª

h

4

3

©

h

h

1

2

Figure 6

Control Layout and Functions

6 97049 Issue 25.3, October 2016

Page 14

Cermet II User’s Manual

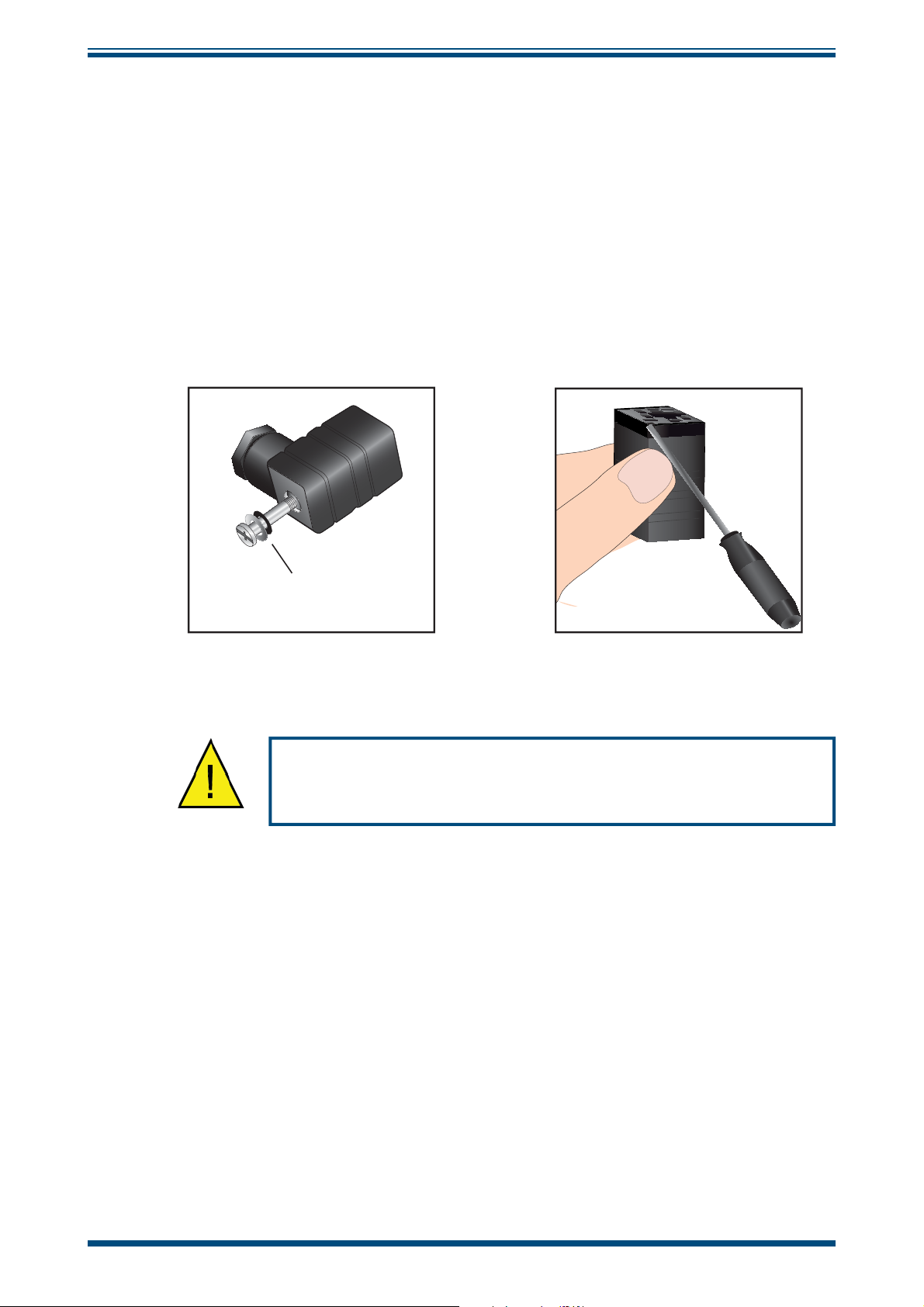

2.5 Preparation of the Transmitter Cable

The transmitter cable is supplied as standard. Replacement of additional cables can be

obtained by contacting your local distributor or Michell Instruments (see www.michell.

com for details).

The cable is pre-wired so no user wiring is required. If the cable needs to be re-wired,

see below:

Cable connection to the Cermet II transmitter is made via the removable connector.

Removing the central screw enables the connector terminal block to be removed from

the outer housing by using a small screwdriver to prise it clear.

INSTALLATION

i

O-ring

and washer

Figure 7

Caution: When removing the central screw ensure that the

small sealing O-ring and the washer are retained on the screw

Connector Terminal Block Removal

and are present during re-installation.

Michell Instruments 7

Page 15

INSTALLATION

2.6 Transmitter Mounting

Prior to installation of the transmitter, unscrew and remove the blue plastic cover and

retain for future use. Take care to prevent any contamination of the transmitter before

installation (handle the transmitter by the main body only, avoiding contact with the

sensor guard).

The transmitter can be mounted into either a fl ow-through sampling block (optional) or

directly inserted into a pipe or duct and can be operated at pressures of up to 45 MPa

(450 barg / 6500 psig) when fi tted with the bonded seal provided.

The recommended gas fl ow rate, when mounted in the optional sampling block, is 1 to

5 Nl/min (2.1 to 10.6 scfh). However, for direct insertion applications, gas fl ow can be

from static to 10 m/sec (32.8 fps).

NOTE: Pass the bonded seal over the 5/8”- 18 UNF mounting thread and

assemble into the sampling location by hand using the wrench fl ats only. DO

NOT grip and twist the transmitter cover when installing the transmitter.

When installed, fully tighten using a wrench until the seal is fully compressed and to the

following torque setting:

Cermet II User’s Manual

5/8” - 18 UNF 30.5 Nm (22.5 ft-lbs)

8 97049 Issue 25.3, October 2016

Page 16

Cermet II User’s Manual

INSTALLATION

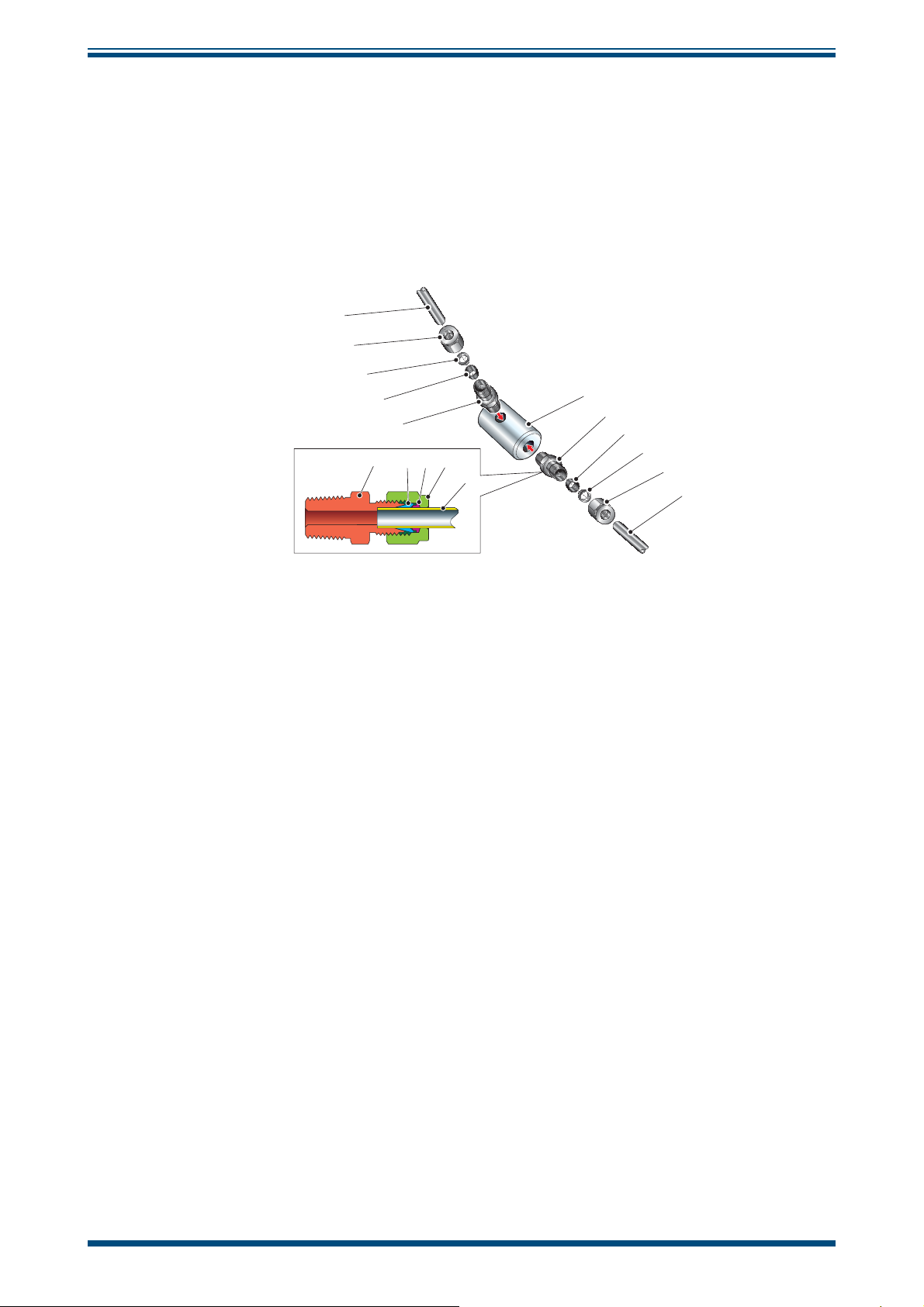

2.6.1 Transmitter Mounting - Sample Block and Gas Connections (Optional)

Sample gas connections are made to the Gas In and Gas Out ports on the sample block

see

Figure 8.

Either port on the sample block may be used as the Gas Input port (i.e.

for connection purposes the ports are interchangeable).

Normally, connections are made via stainless steel pipework, in which case the sensor

block/transmitter assembly will be self supporting. If Tefl on tubing is used it may be

necessary to support the assembly with a body clip.

1

2

3

4

5

2345

1

6

5

4

3

2

1

Figure 8

Sample Block Gas Connections

Both the Input and Output gas connections are ⅛” NPT. It is recommended that both

the Gas Input and Output connections are made made via ⅛” NPT to 6mm or ⅛” NPT

to ¼” stainless steel tube adaptors (2 to 5 -

Figure 8)

. The method of connection to the

sensor block (6) is as follows:

NOTE: The following description relates to 6mm tube fi xings. The sample

block ports are both ⅛” NPT female process connections. Tube adaptors are

not supplied with the equipment but can be obtained by contacting your local

distributor or Michell Instruments (see www.michell.com for details).

1. Cut a suitable length of 6mm (¼” U.S.) stainless steel tubing (1) to the

correct length and, if necessary, bend to shape to suit the location of the

sensor block assembly. NOTE: To facilitate ease of connection to the

port, at least 75mm (3”) of the tubing coming out of the Gas In

port must be straight.

2. Clean off any burrs or metal shavings adhering to the tubing.

3. Screw the ⅛” NPT (¼” U.S.) NPT Swagelok adaptor (5) into the ⅛” NPT

(¼” U.S.) NPT inlet port in the sensor block (6) and tighten to a torque

setting of 35 Nm (25 lbf-ft).

4. Pass the stainless steel tubing (1) through the locking nut (2). NOTE:

Threads towards the gas port.

5. Fit the back ferrule (3) over the stainless steel tubing (1) with the bevelled

end facing the back of the front ferrule (4).

6. Place the front ferrule (4) over the stainless steel tubing (1), bevelled end

towards the adaptor (5).

Michell Instruments 9

Page 17

INSTALLATION

7. Push the stainless steel tubing (1) as far as it will go into the adaptor (5)

and tighten up the locking nut (2) fi nger tight.

8. Hold the adaptor (5) fl ats with a spanner and tighten up the locking

nut (2) to a torque setting of 35 Nm (25 lbf-ft) (1¼ turns). This action

compresses the front ferrule (4) and back ferrule (3) onto the tubing to

form a gas tight seal.

9. Connect up the other gas port as described in steps 1 to 8 above.

To mount the transmitter into the sample block (preferred method), proceed as follows,

refer to

1. Remove the blue protective cover (2) and its desiccant capsule (2a), from

Figure 9.

the tip of the transmitter.

Cermet II User’s Manual

The following procedure must be carried out by a

qualifi ed installation engineer.

2. Fit the bonded seal (3) over the threaded part of the transmitter body.

WARNING: Under no circumstances should the sensor

guard be handled with the fi ngers.

3. Screw the transmitter (1) into the sample block (4) and tighten to a

minimum torque setting of 30.5 Nm (22.5 ft-lbs). NOTE: Use the fl ats

of the hexagonal nut and not the transmitter body.

4. Fit the transmitter cable/connector assembly to the plug located on the

base of the transmitter and tighten the fi xing screw (see Section 2.10).

2

2a

1

4

3

Figure 9

Transmitter Mounting - Sensor Block

10 97049 Issue 25.3, October 2016

Page 18

Cermet II User’s Manual

2.6.2 Transmitter Mounting - Direct Pipeline Connection

INSTALLATION

The transmitter may be directly mounted into a pipe or duct, as shown in

Figure 10.

CAUTION: Do not mount the transmitter too close to the

bottom of a bend where any condensate in the pipeline

might collect and saturate the probe.

The pipe or duct will require a thread to match the transmitter body thread. Fixing

dimensions are shown in

Figure 10

. For circular pipework, to ensure the integrity of a

gas tight seal, a mounting fl ange will be required on the pipework in order to provide a

fl at surface to seal against.

The following procedure must be carried out by

competent personnel.

1. Ensure that the blue protective cover (and its desiccant capsule) has been

removed from the tip of the transmitter.

WARNING: Under no circumstances should the

sensor guard be handled with the fi ngers.

2. Fit a bonded seal (2) over the threaded part of the transmitter body.

3. Screw the transmitter (3) into the pipe (1). Tighten enough to obtain a

gas tight seal. (Torque will depend upon the pipeline material.) NOTE: Do

not overtighten or the thread on the pipework may be stripped.

V

1

2

3

1

L

2

48mm

3

(1.9”)

Figure 10

Transmitter Mounting - Pipe or Duct

Michell Instruments 11

Page 19

INSTALLATION

2.6.3 Transmitter Mounting - With Additional Process Connection Adapter

Cermet II User’s Manual

!

To mount the adapter into the transmitter, proceed as follows (see

1. Ensure that the protective cover (2), and its desiccant capsule (2a), have

been removed from the tip of the transmitter.

2. Fit the bonded seal (3) over the threaded part of the transmitter body.

3. Screw the adapter (4) onto the threaded part of the transmitter and tighten

to 30.5 Nm (22.5 ft-lbs). NOTE: Use the fl ats of the hexagonal nut and

not the transmitter body.

!

4. Screw the transmitter (1) with its seal (3) and adapter (4) into the sample

block (see Section 2.6.1) or pipeline (see Section 2.6.2) and fully tighten

using a wrench until the seal is fully compressed and to the following torque

settings:

The following procedure must be carried out by a qualifi ed

installation engineer.

Figure 11)

WARNING: Under no circumstances should the sensor guard be

handled with the fi ngers.

:

G 1/2” BSP 56 Nm (41.3 ft-lbs)

3/4” - 16 UNF ` 40 Nm (29.5 ft-lbs)

1/2” NPT Use a suitable sealant e.g. PTFE tape using

correct taping procedures

NOTE: Use the fl ats of the hexagonal nut and not the transmitter

body.

2

2a

4

1

3

Figure 11

Transmitter Mounting with Adapter

12 97049 Issue 25.3, October 2016

Page 20

Cermet II User’s Manual

2.7 Monitor Mounting

The monitor is designed for panel mounting and requires a panel cut-out of 46 x 92mm

(1.8 x 3.6”). The recommended panel thickness is 2 to 5mm (0.08 to 0.2”).

To mount the unit, proceed as follows:

°Cdp

Cermet II

Advanced Online

°Fdp

Setup

INSTALLATION

Cermet II

°Cdp

Advanced Online

°Fdp

©

ª

Setup

©

ª

1

3

Figure 12

2

Mounting the Monitor

1. Pass the monitor (1) through the front of the panel (2).

2. Support the monitor and attach mounting fi xing brackets onto the

side of the monitor.

3. Tighten the fi xing screw (3) fi nger tight, against the back of the

panel.

4. Ensure that the monitor is sitting fl ush to the front of the panel (2)

and tighten the fi xing screws evenly against the back of the panel.

Caution: Do not overtighten the screws as this could cause the case to crack.

Michell Instruments 13

Page 21

INSTALLATION

2.8 Electrical Connections

The power supply voltage is indicated on the connection detail label located on the

monitor. As the monitor is provided for continuous operation it does not have an ON/

OFF switch.

The power supply to the monitor may be one of the following, dependant on the type

ordered.

2.8.1 High Voltage Power Supply Input

For high voltage powered display

• 85 to 265 V AC 50/60 Hz and 95 to 370 V DC

It is essential that the connection of electrical supplies to this

instrument be undertaken by competent personnel.

Cermet II User’s Manual

Connect the power supply to the monitor (1) as shown in

V

L

Figure 13.

LV

Wiring Connection:

L Brown wire

V Blue wire

Figure 13

High Voltage Power Supply Connections

14 97049 Issue 25.3, October 2016

Page 22

Cermet II User’s Manual

2.8.2 Low Voltage Power Supply Input

For low voltage powered display

• 18 to 36 V AC and 9 to 60 V DC

INSTALLATION

Connect the power supply to the monitor (1) as shown in

V

L

Figure 14

Low Voltage Power Supply Connections

Figure 14.

LV

Wiring Connection:

L Brown wire

V Blue wire

2.9 Pressure Transducer Connection (Optional)

The monitor provides excitation voltage (24 V DC @ 20 mA) for an auxiliary 2-wire

transmitter used in the dual channel confi guration. Connect (+) of the pressure

transmitter to pin 6 of the monitor and (-) of the pressure transmitter to pin 5 of the

monitor. Refer to

Figure 15

Red

Blue

for details.

RELAY

RELAY

RELAY

SP1

SP3

C

N

O

NON

N

O

C

M

30

29 28 27 26 25 24 23 17

1 2 3 4 5 6 8 9 10 11

3 1 2

DEW-POINT

SENSOR

SP2

N

O

C

PRESSURE SENSOR

- +

PRESSURE

SENSOR

RELAY

C

O

M

SP4

N

O

CONTROL INPUTS

Green

Yellow

SERIAL

INTERFACE

ANALOG

OUTPUT

- +

14

N E

L

POWER

16

15

Figure 15

Electrical Connection Detail

Michell Instruments 15

Page 23

INSTALLATION

2.10 Transmitter Cable Connection

The diagram below shows the identity of the connector terminals.

GREEN

Signal (B)

PIN 1

RED

+Power

PIN 3

PIN 2

BLUE

Ground

YELLOW

Signal (A)

YELLOW

GREEN

BLUE

RED

Cermet II User’s Manual

4

3

2

1

YELLOW Signal (A)

GREEN Signal (B)

BLUE Ground

RED +Power

Figure 16

Cable Connections

The transmitter cable connections are shown in the table below and in the fi gure above.

Connection Red wire Blue wire Green wire Yellow wire

Monitor Pin 1 Pin 2 Pin 3 Pin 4

Transmitter Pin 3 GND Pin 1 Pin 2

Table 1 Cable Connections

When installing the connector, and to ensure that full ingress protection is achieved, the

securing screw (with the O-ring and washer) must be tightened to a minimum torque

setting of 3.4 Nm (2.5 ft-lbs). The transmitter cable used must be a minimum diameter

of 4.6mm (0.2”).

i

O-ring

and washer

Figure 17

Connector Installation

16 97049 Issue 25.3, October 2016

Page 24

Cermet II User’s Manual

3 OPERATION - MONITOR

NOTE: When the instrument is fi rst powered up the display may show a zero

value for about 1 second, followed by a fl ashing

5 seconds, before showing a dew-point value. This is normal and does not

indicate a problem with the instrument.

There are two levels of operation:

OPERATION

OPEN for approximately

User

(No access to programming codes)

Changing display brightness Advanced setpoint programming

Monitoring setpoint values Analog output calibration and scaling

Table 2 Operation Access Levels

3.1 Set-Up Security Feature

To prevent unauthorized access, the monitor has two DIP-switches that can be accessed

by removal of the faceplate (refer to

ON position protects that mode, OFF makes alterations possible.

The

Transmitter connection fault relay set-up

Figure 18)

Advanced

(Access to programming codes)

Auxiliary (optional) channel set-up

Setting the engineering units

Other related advanced functions

.

• The

SETPOINT LOCKOUT switch (SW1) enables or disables Setpoint

Programming mode.

• The

PROGRAM LOCKOUT switch (SW2) enables or disables Code

Programming mode.

Figure 18

MONITOR WITHOUT FACEPLATE

h

O

2

F

1

-73.5C

SP1 SP2 SP3 SP4

F

h

Location of the Lockout Switches

PROGRAM

LOCKOUT

SW2

SETPOINT

LOCKOUT

SW1

Michell Instruments 17

Page 25

OPERATION

3.2 Selecting the Engineering Units

1. Enter the PROGRAM UNLOCK mode (Section 3.1).

Cermet II User’s Manual

2. Press

SETUP and to scroll through the menus.

The monitor can display Dew point in °C or °F, PPM(V), lbs/MMSCF or g/m3 (Natural

Gas). The selection of these units is achieved by setting

CODE 4 and CODE 7 as shown

below:

Required Display Unit CODE 7 CODE 4

Dew point in °C 000 207

Dew point in °F 000 217

PPM

V

100 -

lbs/MMSCF 200 -

3

g/m

(Natural Gas) 300 -

To set the range and resolution for PPM(V), lbs/MMSCF and g/m3 , set digit 3 of

CODE

7 to:

0123

0 1 – 9999 0.1 – 999.9 0.01 – 99.99 0.001 – 9.999

For example, by setting

CODE 7 to 102, displays PPM

maximum of 99.99. Should the measured value exceed 100 PPM

will be displayed.

3.3 Changing the Setpoint Values

1. Enter the SETPOINT UNLOCK mode as described in Section 3.1.

2. Press

are altered by setting

to the required trip level. These are entered directly in the appropriate

engineering units. When displaying PPM(V), then the setpoints are set in

PPM(V) units.

The full matrix of codes for alarm confi guration can be seen in Appendix B, Setpoint

control.

SETUP and simultaneously to access. The setpoints of the relays

SP_n (where n = 1 to 4 and represent SP1 to 4),

with a resolution of 0.01 to a

V

with this setting, oVEr

V

18 97049 Issue 25.3, October 2016

Page 26

Cermet II User’s Manual

3.4 Hysteresis, Make/Break delay & delay type

Associated with each setpoint is a Hysteresis Value, Make delay time, Break delay time

and a Delay type. To gain access to these parameters, set

the features by pressing the or buttons.

The hysteresis value is the value above and below the nominal setpoint at which the

relay trips.

The Make delay time is the time delay between the setpoint being reached and the relay

energizing. The Break delay time is the time delay between the relay being energized

and it de-energizing. The maximum make and break delay time is 9 hours, 6 minutes,

6 seconds, in increments of 1 second.

The setpoint can have four different Delay types:

NorM (normal)

•

•

rEPt (repeat)

OPERATION

SPC_n = xx7, and scroll to

•

1Shot

• PuLSE

If Delay = NorM

If Delay =

If Delay =

If Delay =

rEPt

1Shot

PuLSE

The relay will function normally with the inclusion of the time delays

The make and break delays will repeat continually until the setpoint

source returns to a level that deactivates the setpoint

The relay will energize after the entered delay period and remain

energized

The relay will energize, de-energize after the period entered and

thereafter will remain de-energized

3.5 Analog Output Scaling

1. Enter the PROGRAM UNLOCK mode (see Section 3.1).

2. Press

SETUP, followed by the button, then SETUP again.

3. Press the or buttons to scroll through to the

analog output can be scaled by setting

zero value to the required output at 4 mA (or 0 V) and the full scale

value to the output required at 20 mA (or 10 V).

4. To exit the

button to scroll through the menus.

See Appendix B - Setup Codes for more information on output scaling options.

CAL menu press SETUP, set CAL to 000 and use the

CAL to 061 and setting the

CAL menu. The

Michell Instruments 19

Page 27

OPERATION

3.6 Display Brightness Adjustment

1. To adjust the display brightness press the SETUP and buttons

simultaneously.

Cermet II User’s Manual

2. The display toggles between [

setting.

3. Adjust the display brightness required (from 0 to 7) by pressing the

or buttons.

4. Press

SETUP seven times to exit the programming mode.

3.7 Digital Communications

The monitor is fi tted with ASCII RS232 communication interface as standard (RS485

optional). Communication settings are found as follows:

1. Set CAL to

2. Press SETUP once and then the or buttons to change the baud rate.

Baud rates are 300, 600, 1200, 2400, 4800, 9600, 19,200 and 57.6 K.

3. Press

buttons to change the parity bit. Parity settings are odd, even or off.

100.

SETUP again to advance to the parity bit and then the or

bri] and [5], where 5 is the default

4. Press

are 0 to 255. NOTE: address 0 is not a valid RS485 address.

5. Press

The default communication confi guration is:

The commands used to read and write to the monitor follow the protocol shown below:

Start Character

Meter Address An ASCII number from

SETUP again to advance to the address settings. Address settings

SETUP again to return to CAL.

Baudrate 9600

Data bits 8

Parity none

Flow control none

s or S for the start character (must be fi rst character in

string).

0 to 255 for the meter address.

Read/Write The next character must be an ASCII

w for write. Any other character will abort the operation.

or

R or r for read, or an ASCII W

20 97049 Issue 25.3, October 2016

Page 28

Cermet II User’s Manual

Register Address The register address for the read/write operation is specifi ed

next. It can be either an ASCII number from

registers 1 - 18 can be accessed by entering and ASCII letter

from

character is omitted in a read command, the meter will always

respond with the data value currently on the display. (The

register address must be specifi ed for a write command).

For a full list of the register, that can be read or written to,

see Appendix C.

Separator After the register address in a write command, the next character

must be something other than an ASCII number. This is used

to separate the register address from the data value. It can

be a space or a

*.

a

Data Value After the separator character, the data value is sent. It must be an

ASCII number in the range of

OPERATION

0 to 255 or

A to R (or a to r, not case sensitive). If the address

comma or any other character except a $ or

-32766 to 32766.

Terminate The last character in the message is the message terminator and this

must be either a

a minimum delay of 50mS is inserted before a reply is sent.

If the

inserted before a reply is sent. (the

not appear anywhere else in the message string).

* is used as a terminator, a minimum delay of 2mS is

3.8 Pressure Compensation

Enter the PROGRAM UNLOCK mode as described in Section 3.1.

The monitor has the ability to measure pressure in order to provide a pressure

compensated value for PPM(V), lbs/MMSCF or g/m3.

3.9 Using a Pressure Transducer

In order to enable the use of a pressure transducer set CODE 4 to 307 (dual channel

mode), and while pressing

pressing

SETUP until CODE 4 is displayed.

SETUP, press once. Release both buttons and keep

$ or a *. If the $ is used as a terminator,

$ and * characters must

• To display dew point whilst measuring pressure, set

show dew point in °C; or 317 for dew point in °F.

• To display pressure in psig set

barg set

CODE 6 to 100.

CODE 6 to 000; or to display pressure in

CODE 4 to 307 to

Michell Instruments 21

Page 29

OPERATION

3.9.1 Manual Pressure Input Calibration

The pressure input channel must be confi gured to the range of the pressure transducer.

This is achieved by setting

SCA_2.

SCA_2 = 0.0062 per 100 psig

OFF_2 = pressure range – ((20,000 x (pressure range\1000))\16)

For example, for a pressure transducer with a range of 0 to 1000 psig:

SCA_2 = 0.0062 x 10 = 0.0620

OFF_2 = 1000 – ((20,000 x (1000\1000))\16) = -250

If you are using a pressure transducer in barg, convert the value to psig using a multiplier

of 14.5. For example, for a pressure transducer with a range of 0 to 100 barg:

CAL to 012 and entering values for offset OFF_2 and scale

Cermet II User’s Manual

SCA_2 = 0.0062 x 14.5 = 0.0899

OFF_2 = 1450 – ((20,000 x (1450\1000))\16 = -362

To exit the

screen.

CAL menu, set CAL to 000 and press SETUP six times to return to the main

3.10 Automatic Pressure Input Calibration

Alternatively, the pressure input can be calibrated using a 4-20 mA source.

1. Connect the current source between pin 2 (-ve) and pin 5 (+ve).

2. Set

CAL to 022 and press SETUP. The monitor will then display

ZEro and fl ash 0.

3. Set the mA source to 4.0 mA and press

4. Press

scale pressure value.

5. Set the mA source to 20.0 mA and use the or buttons to set

the required pressure range.

SETUP and the monitor will display SPAn and fl ash the full

SETUP to set 0 at 4 mA.

6. Press

7. Set

SETUP to set the required pressure for 20.0 mA.

CAL to 000 and press the button to leave the menu.

22 97049 Issue 25.3, October 2016

Page 30

Cermet II User’s Manual

3.11 Using a Fixed Pressure Input in Single Channel Mode

In order to display pressure compensated values of ppmV without the use of a pressure

transducer, enter the pressure value manually.

OPERATION

1. Enter the

2. Press

select

3. Select the required pressure compensated value, i.e.

10X for ppm

4. Exit the menus (see Section 3.1) and exit the

mode.

5. Press

pressure. To change the pressure, use the or buttons and

then press

PROGRAM UNLOCK mode (see Section 3.1).

SETUP and the button to scroll through the menus and

CODE 7.

/ ppbV and CAL = 052 (see Table 3).

V

PROGRAM UNLOCK

SETUP for two seconds. The display will show the set

SETUP to confi rm.

CODE 7 =

Michell Instruments 23

Page 31

OPERATION

4 OPERATION - TRANSMITTER

Operation is very simple assuming the following installation techniques are adhered to:

Sampling Hints

Be Sure the Sample is Representative of the Gas Under Test:

The sample point should be as close to the critical measurement point as possible. Also,

never sample from the bottom of a pipe as entrained liquids may be drawn into the

sensing element.

Cermet II User’s Manual

Figure 19

Minimize Dead Space in Sample Lines:

Dead space causes moisture entrapment points, increased system response times and

measurement errors, as a result of the trapped moisture being released into the passing

sample gas and causing an increase in partial vapor pressure.

Figure 20

Remove Any Particulate Matter or Oil from the Gas Sample:

Particulate matter at high velocity can damage the sensing element and similarly, at

low velocity, they may 'blind' the sensing element and reduce its response speed. If

particulate, such as degraded desiccant, pipe scale or rust is present in the sample gas,

use an in-line fi lter, as a minimum level of protection. For more demanding applications

Michell Instruments offers a range of sampling systems (for more information contact

www.michell.com).

Installation Location

Deadspace

Indication of Dead Space

Use High Quality Sample Tube and Fittings:

Michell Instruments recommends that, wherever possible, stainless steel tubing and

fi ttings should be used. This is particularly important at low dew points since other

materials have hygroscopic characteristics and adsorb moisture on the tube walls,

slowing down response and, in extreme circumstances, giving false readings. For

temporary applications, or where stainless steel tubing is not practical, use high quality

thick walled PTFE tubing.

Position Transmitter away from Heat Source:

It is recommended, as good instrumentation practice, that the transmitter is placed

away from any heat source to avoid adsorption/desorption.

24 97049 Issue 25.3, October 2016

Page 32

Cermet II User’s Manual

5 MAINTENANCE

Calibration

Routine maintenance of the Cermet II Transmitter is confi ned to regular re-calibration

by exposure of the transmitter to sample gases of known moisture content to ensure

that the stated accuracy of the transmitter is maintained. Calibration services traceable

to the UK

and Technology

Michell Instruments offers a variety of re-calibration and exchange transmitter schemes

to suit specifi c needs. A Michell representative can provide detailed, custom advice (for

Michell Instruments’ contact information go to www.michell.com).

Transmitter Guard Replacement

The transmitter is supplied with a white HDPE guard (standard) or a stainless steel

guard (if specifi ed at time or order). The method of replacement is the same for both

types.

National Physical Laboratory

(NIST) are provided by Michell Instruments.

(NPL) and the US

MAINTENANCE

National Institute of Standards

HDPE Guard

The HDPE guard provides <10μm protection to the dew-point sensor. It is designed

to show any contamination and the guard should be changed if the surface becomes

discolored.

When replacing the guard, care should be taken to handle the guard by the bottom part

only. Replacement guards (EA2-HDPE) - pack of 10 - can be obtained by contacting

Michell Instruments (www.michell.com) or your local distributor.

HANDLE,

USING

x

GLOVES, BY

BLACK PART

ONLY

E

n

e

H

m

C

u

I

r

6

t

s

0

M

n

9

I

0

Figure 21

Replacement of HDPE Guard

r

Stainless Steel Guard

The stainless steel guard provides <80μm protection to the dew-point sensor. It is

designed to show any contamination and the guard should be changed if the surface

becomes discolored.

When replacing the guard, care should be taken to handle the guard by the bottom part

only. A replacement guard (SSG) can be obtained by contacting Michell Instruments

(www.michell.com) or your local distributor.

Bonded Seal

If the installed bonded seal gets damaged or lost, a pack of 5 replacement bonded seals

can be obtained by contacting Michell Instruments, or your local distributor, and quoting

part number BS-58-PK5.

Michell Instruments 25

Page 33

APPENDIX A

Cermet II User’s Manual

Appendix A

Technical Specifi cations

26 97049 Issue 25.3, October 2016

Page 34

Cermet II User’s Manual

Appendix A Technical Specifi cations

Monitor

APPENDIX A

Display

5 digit LED

7-segment digit, 14.2 mm(0.56”)

Display Color Red

Temperature and Alarm

Indicators

Red LED’s

Performance Specifi cations

Measurement Ranges -19999 to 99999

Dew point ±0.5°C (±1.0°F)

Accuracy

ppm

, lbs/MMSCF and g/m3 ±1% of reading

V

Pressure ±0.5% full-scale reading

Electrical Specifi cations

Dew-Point Input Channel Digital signal from Michell dew-point transmitter

Pressure Input Channel

(optional)

2-wire pressure transducer, 4-20 mA (loop-powered)

Dew point: -100 to +20°C

Output Scaled Range

Moisture content in gas: 0 to 9999 ppm

and g/m

3

, 0 to 1000 lbs/MMSCF

V

Non-standard available upon request

Standard: 4-20 mA

Re-transmittion Output

Signals

Optional: 0-20 mA (max load 500 Ω) or 0 - 10 V optional (min

load 5 K Ω)

User scaleable

Standard: Two relays SP1 and SP2, fully user programmable

Form C contacts rated 10 A, 240 V AC or 8 A, 24 V DC

Alarm Relays

Non-inductive load

Optional: Two extra relays, SP3 and SP4, fully user programmable

Form A contacts rated 5 A, 240 V AC or 5 A, 30 V DC

Non-inductive load

Power Connection 2m (6.56ft), 3 wire

Power Supply

Standard: 85 to 265 V AC, 50/60 Hz or 95 to 370 V DC

Optional: 18 to 36 V AC or 9 to 60 V DC

Power Consumption 10 W max

Copper braid screened cable, 4 core 7/0.2 (0.22mm²), stranded,

tinned copper conductors, PVC, insulated, Melinex taped, black

Transmitter Cable

PVC outer

Fitted with transmitter connector and terminations for monitor

Max length 1000m (3280ft)

Operating Specifi cations

Operating Mode Continous

Operating Temperature 0 to +50°C (+32 to +122°F)

Mechanical Specifi cations

Ingress Protection

Standard: IP54 / NEMA 12 (at front),

Optional: Extra protection cover IP66 / NEMA 4

Dimensions 96 x 48 x 142mm (3.8 x 1.9 x 5.6")

Mounting Panel mounting (1/8 DIN cut out 92 x 45mm (3.62 x 1.77”))

Weight 0.6kg (1.32lbs)

Michell Instruments 27

Page 35

APPENDIX A

Cermet II User’s Manual

Transmitter

Performance Specifi cations

Measurement Range -100 to +20°Cdp (-148 to +68°Fdp) dew point

Accuracy

±1°C dew point (+20 to -60°C) (+68 to -76°F)

±2°C dew point (-60 to -110°C) (-76 to -166°F)

Response Time 5 mins to T95 (dry to wet)

Repeatability 0.5°Cdp (0.9°Fdp)

Calibration 13 point calibration with traceable 7 point calibration certifi cate

Electrical Specifi cations

Output Signal

4-wire connection, digital signal

User-confi gurable over range

Output Dew point

Dew point: -100 to +20°C

Output Scaled Range

Moisture content in gas: 0 to 9999 ppm

and g/m

3

, 0 to 1000 lbs/MMSCF

V

Non-standard available upon request

Supply Voltage 12 to 28 V DC

Load Resistance Max 250 Ω @ 12 V (500 Ω @ 24 V)

Current Consumption 20 mA max

CE Conformity 2004/108/EC

Operating Specifi cations

Operating Temperature -40 to +60°C (-40 to +140°F)

Operating Pressure 45 MPa (450 barg ) max

Mounted in standard sampling block: 1 to 5 Nl/min (2.1 to 10.6

Flow Rate

scfh)

Direct insertion: 0 to 10 m/sec (0 to 32.8 fps)

Temperature Coeffi cient Temperature compensated across operating temperature range

Mechanical Specifi cations

Ingress Protection

IP66 in accordance with standard BS EN60529:1992

NEMA 4 in protection accordance with standard NEMA 250-2003

Housing Material 316 stainless steel

Filter (sensor protection)

Process Connection &

Material

Standard: HDPE Guard < 10μm

Optional: 316 stainless steel sintered guard < 80μm

5/8” - 18 UNF 316 stainless steel

Weight 150g (5.3oz)

Interchangeability Fully interchangeable transmitter

Electrical Connection Hirschmann GDS series (DIN 4350-C)

Diagnostic Conditions

(factory programmed)

Digital Diagnostic

Communications

Condition

Sensor fault

Under-range dew point

Over-range dew point

Communications RS485, 2-wire Modbus RTU

Output

23 mA

4 mA

20 mA

28 97049 Issue 25.3, October 2016

Page 36

Cermet II User’s Manual

APPENDIX B

Appendix B

Setup Codes

Michell Instruments 29

Page 37

APPENDIX B

Appendix B Setup Codes

CAL Calibration modes for input and output

DEFAULT VALUE = 052

Cermet II User’s Manual

Digit 1st digit (left most)

Calibration Mode

Calibration functions as

0

per 2nd and 3rd digit

Set baud rate, parity and

1

serial address

2 N/A N/A Pressure input

3 N/A N/A N/A

4 N/A N/A N/A

5 N/A Manual adjust N/A

6 N/A

2nd digit

Calibration Function

No function No function

Manual calibration (channel as per 3rd

digit)

Analog output scaling (analog channel

as per 3rd digit)

3rd digit

Object for Calibration

Processed result (dew

point, ppm

g/m3)

N/A

, lbs/MMSCF,

V

CODE 1 Tendency Indication, Additional LED’s, Display data source, Flashing,

Decimal points, Rounding

DEFAULT VALUE = 200

Digit 1st digit (left most)

Additional LED’s

LED annunciators are

0

always off

LED annunciators are

on when relays are de-

1

energized

LED annunciators are on

2

when relays are energized

2nd digit

Display Data Source

Processed data - result (dew point,

ppmV, lbs/MMSCF, g/m3)

Processed data - channel 1 (dew

point only)

Processed data - pressure N/A

3rd digit

0 only (No Function)

N/A

N/A

CODE 3 Serial mode and analog output source

DEFAULT VALUE = 000

Digit 1st digit (left most)

Serial Mode

0 ASCII mode

1 N/A

2 N/A

2nd digit

Analog Output 1 Source

Analog output 1 from processed

result data (dew point, ppmV, lbs/

MMSCF, g/m3)

Analog output 1 from processed data

(dew point only)

Analog output 1 from processed data

(pressure)

3rd digit

0 only (No Function)

N/A

N/A

N/A

30 97049 Issue 25.3, October 2016

Page 38

Cermet II User’s Manual

CODE 4 Channel 1 Measurement task, Sampling rate

DEFAULT VALUE = 207

APPENDIX B

Digit 1st digit (left most)

Analog Sample Rate

0 N/A Dew point in degrees C N/A

1 N/A Dew point in degrees F N/A

2 Single channel (50 Hz) N/A N/A

3 Dual channel (50 Hz) N/A N/A

2nd digit

Analog Output 1 Source

3rd digit

0 only (No Function)

CODE 6 Channel 2 Measurement task

DEFAULT VALUE = 000

Digit 1st digit (left most)

Measurement Task

0 Pressure in psig N/A N/A

1 Pressure in barg N/A N/A

2nd digit

0 only (No Function)

3rd digit

0 only (No Function)

CODE 7 Result processing

DEFAULT VALUE = 000

Digit 1st digit (left most)

Measurement Task

0 Dew point N/A 1 – 9999

1 ppm

2 lbs/MMSCF N/A 0.01 – 99.99

3 g/m

V

3

(Natural Gas) N/A 0.001 – 9.999

2nd digit

0 only (no function)

N/A 1 – 999.9

3rd digit

Range for Result

Setpoint control 1 – 6 Relay latching, relay setup, source

DEFAULT VALUE = 000 (Prog/Down menu after setpoints)

Digit 1st digit (left most)

Relay Sense

Relay energized above

0

setpoint value

Relay energized below

1

setpoint value

2 N/A Pressure De-energized relay

3 N/A Open transmitter connection N/A

4 N/A Open / short circuit transmitter

5 N/A Open / short circuit thermistor

6 N/A All transmitter faults

7 N/A N/A

2nd digit

Setpoint Source

Processed result data (dew point,

ppmV, lbs/MMSCF, g/m3)

Dew point only Relay latched

3rd digit

Setpoint Function SP1 – SP4

No function

Relay off for open transmitter

connection

Relay on for open transmitter

connection

Relay toggles at 1 Hz for

transmitter connection fault

Set-up hysteresis, make/

break delay and delay type

Michell Instruments 31

Page 39

APPENDIX C

Cermet II User’s Manual

Appendix C

Register Settings Accessible

by Digital Communication

32 97049 Issue 25.3, October 2016

Page 40

Cermet II User’s Manual

APPENDIX C

Appendix C Register Settings Accessible by Digital Communication

Register

Number

1 Alarm Status

2 N/A

3 Processed Data – Result

4 Processed Data – Channel 1 (dew-point)

5 Processed Data – Channel 2 (pressure)

6 Setpoint 1

7 Setpoint 2

8 Setpoint 3

9 Setpoint 4

10 to 23 N/A

24 Scale Value – Result

25 Scale Value – Channel 1

26 Scale Value – Channel 2

27 Offset Value – Result

28 Offset Value – Channel 1

29 Offset Value – Channel 2

30 to 33 N/A

34 D/A Zero – Analogue O/P 1

35 N/A

36 D/A Full Scale – Analogue O/P 1

37 to 64 N/A

65 Hysteresis - Setpoint 1

66 Hysteresis - Setpoint 2

67 Hysteresis - Setpoint 3

68 Hysteresis - Setpoint 4

69 to 70 N/A

71 Make Delay - Setpoint 1

72 Make Delay - Setpoint 2

73 Make Delay - Setpoint 3

74 Make Delay - Setpoint 4

75 to 76 N/A

77 Break Delay - Setpoint 1

78 Break Delay - Setpoint 2

79 Break Delay - Setpoint 3

80 Break Delay - Setpoint 4

81 to 128 N/A

129 Cal Mode

130 Code 1

131 Code 2

132 Code 3

Function Read Only

Michell Instruments 33

Page 41

APPENDIX C

138 to 141 Reserved

146 to 147 N/A

151 to 152 N/A

155 to 192 N/A

133 Code 4

134 Code 5

135 Code 6

136 Code 7

136 Code 8

142 Setpoint 1 Control Register

143 Setpoint 2 Control Register

144 Setpoint 3 Control Register

145 Setpoint 4 Control Register

148 Brightness

149 Baudrate Settings

150 Serial Address

153 Model Number

154 Version Number

193 Delay Type – Setpoint 1

194 Delay Type – Setpoint 2

195 Delay Type – Setpoint 3

196 Delay Type – Setpoint 4

Cermet II User’s Manual

34 97049 Issue 25.3, October 2016

Page 42

Cermet II User’s Manual

APPENDIX D

Appendix D

EU Declaration of Conformity

Michell Instruments 35

Page 43

APPENDIX D

Appendix D EU Declaration of Conformity

Cermet II User’s Manual

36 97049 Issue 25.3, October 2016

Page 44

Cermet II User’s Manual

APPENDIX E

Appendix E

Quality, Recycling

& Warranty

Information

Michell Instruments 37

Page 45

APPENDIX E

Cermet II User’s Manual

Appendix E Quality, Recycling & Warranty Information

E.1 Pressure Equipment Directive (PED) 97/23/EC

The above Directive has been implemented in United Kingdom Law by the Pressure Equipment

Regulations 1999.

The Regulations require that all pressure equipment and assemblies within the scope of the Pressure

Equipment Directive must be safe when placed on the market or put into service.

Michell Instruments’ products have been assessed and, as referenced against the Classifi cation Charts

detailed in Annex II of the Directive, do not fall into the requirements for CE marking compliance

with the Pressure Equipment Directive.

Article 3, paragraph 3 states that any product containing a pressurized fl uid that does not qualify for

compliance should, nevertheless, be constructed with Sound Engineering Practice (SEP).

Michell Instruments attests here that its products have been designed, manufactured & tested to

assure safe operation, and in accordance with Sound Engineering Practices.

E.2 Recycling Policy

Michell Instruments is concerned with the protection of the environment. It is our commitment to

reduce and eliminate from our operations, wherever possible, the use of substances which may be

harmful to the environment. Similarly, we are increasingly using recyclable and/or recycled material

in our business and products wherever it is practical to do so.

To protect natural resources and to promote material reuse, please separate batteries from other

types of waste and recycle responsibly. If batteries are not properly disposed of, these substances

can cause harm to human health and the environment

The product that you have purchased may contain recyclable and/or recycled parts and we will be

happy to provide you with information on these components if required. For further information

please see the following sections.

E.3 WEEE Compliance

Directive 2012/19/EU 4 July 2012 on Waste Electronic and Electrical Equipment (WEEE)

The Waste Electronic and Electrical Equipment (WEEE) Directive places rules upon European

manufacturers of electrical and electronic equipment. The directives’ aim is to reduce the impact

that electronic devices have on the environment.

Michell Instruments is in full compliance with the WEEE Directive and is registered with an approved

recycler (Registration No. WEE/JB0235YW) and treats the requirement of the directive and the

protection of the environment with the utmost importance. All Michell Instruments’ products are

appropriately marked indicating their requirement for recycling.

It may be required to return certain instruments for treatment at the end of their working life.

Feb 2013

38 97049 Issue 25.3, October 2016

Page 46

Cermet II User’s Manual

E.4 RoHS2 Compliance

Directive 2011/65/EU of the European Parliament and of the Council of 8 June 2011

The Restriction of Hazardous Substances (RoHS) Directive places rules upon European manufacturers

of electrical and electronic equipment. The directives’ aim is to reduce the impact that electronic

devices have on the environment.

According to the EC Directive 2002/95/EC, Michell Instruments’ products qualify as Category 9,

Control and Monitoring Equipment. Under the 2002/95/EC Directive, Category 9 products are exempt

from compliance with the Directive.

However, the careful design of all Michell Instruments’ products takes into consideration the

requirements of the Directive and, wherever possible, compliance is achieved. All future products

will be developed entirely using compliant materials. Furthermore, Michell Instruments is taking

active steps to remove non-compliant materials and components from existing products wherever

these may occur. Presently, none of the non-compliant materials are known to occur in Michell

Instruments’ products.

APPENDIX E

The new Directive 2011/65/EU (RoHS2) entered into force on 21 July 2011 and required all Member

States to transpose the provisions into their respective national laws by 2 January 2013.

Under the provisions of the RoHS2 EU Directive 2011/65/EU (Article 3, [24]) defi nes ‘Control and

Monitoring Equipment’ specifi cally as ‘monitoring and control instruments designed exclusively for

industrial or professional use’.

RoHS2 EU Directive 2011/65/EU states the closing date for compliance of any Control and Monitoring

Equipment product sold into the EU market place as 22nd July 2017.

However, the careful design policy of all Michell Instruments’ products continues to attain compliance

in the shortest practical timescales and strives to ensure that less than 0.1% of total mass per

product, of all non-compliant materials, appear within them. Michell Instruments continues to

monitor suppliers and material sources to ensure that compliance of goods provided is maintained.

January 2013

E.5 Warranty

Unless otherwise agreed, the Supplier warrants that, as from the date of delivery for a period of 12

months, the goods and all their component parts, where applicable, are free from any defects in

design, workmanship, construction or materials.

The Supplier warrants that the services undertaken shall be performed using reasonable skill and

care, and be of a quality conforming to generally accepted industry standards and practices.

Except as expressly stated, all warranties whether express or implied, by operation of law or

otherwise, are hereby excluded in relation to the goods and services to be provided by the Supplier.

All warranty services are provided on a return to base basis. Any transportation costs for the return

of a warranty claim shall reside with the Customer.

Michell Instruments 39

Page 47

APPENDIX E

E.6 REACH Compliance

Regulation (EC) No. 1907/2006

Registration, Evaluation, Authorisation and Restriction of Chemicals (REACH)

Michell Instruments is a manufacturer of moisture measurement and gas analysis instrumentation

and is a ‘downstream’ user of chemicals, as described by the EU Council Directive 76/769/EEC. The

products we supply are not raw chemical products (goods).

Under normal and reasonably foreseeable circumstances of application, the goods supplied to you

shall not contain or release any prohibited chemicals. No listed SVHC (Substances of Very High

Concern) appear within products manufactured by Michell Instruments. Therefore the 0.1% mass

per product, or total usage of 1 tonne/year, will never be exceeded. For these reasons we are neither

required by obligation for registration nor for the creation of material safety data sheets (MSDS) for

our products.

Cermet II User’s Manual

Our continued review of the SVHC Candidate List and

compliant.

Michell Instruments maintains a hazardous material register in which MSDS data sheets are collated,

and we will check that our suppliers will comply to REACH requirements for all materials and

substances we use in the processes of our manufacturing.

In the unlikely event that any chemicals of concern appear in our products in quantities greater than

0.1% of total mass per product we will immediately inform you by correspondence according to the

REACH Article 33 requirements. Our current appraisal is, however, that we do not expect or foresee

such an incidence.

January 2013

E.7 Return Policy

If a Michell Instruments’ product malfunctions within the warranty period, the following procedure

must be completed:

1. Notify a Michell Instruments’ distributor, giving full details of the problem, the

model variant and the serial number of the product.

latest additions is to ensure we remain

2. If the nature of the problem indicates the need for factory service then the

instrument should be returned to Michell Instruments, carriage prepaid, preferably

in the original packaging, with a full description of the fault and the customer

contact information.

3. Upon receipt, Michell Instruments will evaluate the product to determine the cause

of the malfunction. Then, one of the following courses of action will be taken:

• If the fault is covered under the terms of the warranty, the

instrument will be repaired at no cost to the owner and returned.

• If Michell Instruments determines that the fault is not covered

under the terms of the warranty, or if the warranty has expired,

an estimate for the cost of the repairs, at standard rates, will be

provided. Upon receipt of the owner’s approval to proceed, the

product will be repaired and returned.

40 97049 Issue 25.3, October 2016

Page 48

Cermet II User’s Manual

E.8 Calibration Facilities

Michell Instruments’ calibration facilities are among the most sophisticated in the world and have

been recognized for their excellence.

Traceability to the National Physical Laboratory (NPL) UK is achieved through our UKAS Accreditation

(Number 0179). This covers dew point over the range -90 to +90°C (-130 to +194°F) and also

Relative Humidity.

Dew-point calibrations are also traceable to the National Institute for Standards & Technology (NIST)

USA over the range -75 to +20°C (-103 to +68°F).

NOTE: Standard traceable calibration certifi cates for instruments and sensors are not

issued under our UKAS accreditation.

E.9 Manufacturing Quality

Michell Instruments is registered with the British Standards Institute for Quality Assurance to:

APPENDIX E

BS EN ISO 9001: 2008

Rigorous procedures are performed at every stage of production to ensure that the materials of

construction, manufacturing, calibration and fi nal test procedures meet the requirements laid down

by our BSI approved Quality System.

Please contact Michell Instruments (www.michell.com) if the product does not arrive in perfect

working order.

E.10 FCC (EMC Rquirements for North America)

This device complies with part 15 of the FCC Rules. Operation is subject to the following two

conditions:

1. This device may not cause harmful interference.

2. This device must accept any interference, including interference that may cause

undesired operation.

This equipment has been tested and found to comply with the limits for a Class A digital device,

pursuant to part 15 of the FCC Rules. These limits are designed to provide reasonable protection

against harmful interference when the equipment is operated in a commercial environment. This

equipment generates, uses, and can radiate radio frequency energy and, if not installed and used

in accordance with the user manual, may cause harmful interference to radio communications.

Operation of this equipment in a residential area is likely to cause harmful interference in which

case the user will be required to correct the interference at his own expense. This product must be

operated as per the operating instructions provided. Do not make any alterations or modifi cations

to the product. Any unauthorized alterations or modifi cations made to this product may require you

to stop operating the product.

Canadian Radio Interference Regulations.

This Class A digital product complies with Canadian ICES-001. Règlement canadien sur les

interférences radio. Ce produit numérique de classe A est conforme à la norme NMB-001.

Michell Instruments 41

Page 49

APPENDIX F

Cermet II User’s Manual

Appendix F

Return Document

&

Decontamination Declaration

42 97049 Issue 25.3, October 2016

Page 50

Cermet II User’s Manual

Appendix F Return Document & Decontamination Declaration

'HFRQWDPLQDWLRQ&HUWL¿FDWH

IMPORTANT NOTE: Please complete this form prior to this instrument, or any components, leaving your

site and being returned to us, or, where applicable, prior to any work being carried out by a Michell

engineer at your site.

Instrument Serial Number

Warranty Repair? YES NO Original PO #

Company Name Contact Name

Address

Telephone # E-mail address

Reason for Return /Description of Fault:

APPENDIX F

Has this equipment been exposed (internally or externally) to any of the following?

Please circle (YES/NO) as applicable and provide details below

Biohazards YES NO

Biological agents YES NO

Hazardous chemicals YES NO

Radioactive substances YES NO

Other hazards YES NO

Please provide details of any hazardous materials used with this equipment as indicated above (use continuation sheet

if necessary)

Your method of cleaning/decontamination

Has the equipment been cleaned and decontaminated? YES NOT NECESSARY

Michell Instruments will not accept instruments that have been exposed to toxins, radio-activity or bio-hazardous

PDWHULDOV)RUPRVWDSSOLFDWLRQV LQYROYLQJVROYHQWVDFLGLFEDVLFÀDPPDEOHRUWR[LFJDVHVDVLPSOHSXUJHZLWKGU\

JDVGHZSRLQW&RYHUKRXUVVKRXOGEHVXI¿FLHQWWRGHFRQWDPLQDWHWKHXQLWSULRUWRUHWXUQ

Work will not be carried out on any unit that does not have a completed decontamination declaration.

Decontamination Declaration

I declare that the information above is true and complete to the best of my knowledge, and it is safe for Michell

personnel to service or repair the returned instrument.

Name (Print) Position

Signature Date

F0121, Issue 2, December 2011

Michell Instruments 43

Page 51

NOTES:

Cermet II User’s Manual

44 97049 Issue 25.3, October 2016

Page 52

http://www.michell.com

Loading...

Loading...