MGF BABY 6/30, BABY 6/50 Instruction Manual

1/5 Rev 0 14.12.2005

INSTRUCTION MANUAL FOR COMPRESSORS MGF BABY 6/30 and

6/50

1) GENERAL INFORMATION

Compressor to be used only in dry atmosphere protected against

moisture and water.

In case flammable products are sprayed using compressed air

from your compressor : ensure proper ventilation of the

workingarea.

Do NOT alter safety valve (8) - or pressure regulatorsettings (

inside black box (0) ) to avoid dangerous workingconditions.

In case of abnormal noise, overheating or fumes : pull mains out

immediately.

Repairs : should be done by qualified personnel only or contact

Ideefiks vzw

Prior to repair or maintenance : depressurise the compressor – by

means of (4) - and disconnect from mains.

This compressor is suited for 230 V and 50 Hz. ( not for use in

USA ) and should be connected to an earthed electrical outlet.

2) TRANSPORT

New compressor picked-up at Ideefiks vzw – Obeeliks E-Shop :

The compressor is filled with the right amount of oil

The combined oil/airinlet (1) on the compressorhousing is

closed by means of a PVC stopper.

The air-inletfilter (1) is packed in a plastic bag and attached to

the oil/airinlet ( frontside of compressorhousing )

Compressormotorblock is blocked for transport with cardboard

strips between motor and casing.

In this described condition the compressor can be transported

in a safe way.

New compressor shipped to you by Ideefiks vzw – Obeeliks EShop :

The compressor is NOT filled with oil. Oil is contained in the

package.

The combined oil/airinlet (1) on the compressorhousing is

closed by means of a PVC stopper.

The air-inletfilter (1) is packed in a plastic bag and attached to

the oil/airinlet ( frontside of compressorhousing )

Compressormotorblock is blocked for transport with cardboard

strips between motor and casing.

The compressed air outletconnectors (6) on the

pressureregulator + manometer (3) are dismounted /

unscrewed and packed separately.

In this described condition the compressor can be transported

or shipped in a safe way.

Transport of your compressor :

Remove the air-inletfilter (1)

Close off the combined oil/airinlet (1) on the

compressormotorblock with the PVC stopper ; this will avoid

any spill of oil.

Keep the compressor in an upright position.

In this described condition the compressor can be transported

in a safe way.

For extra safety the motorblock can be blocked by means of

cardboard strips to be placed between motor and housing.

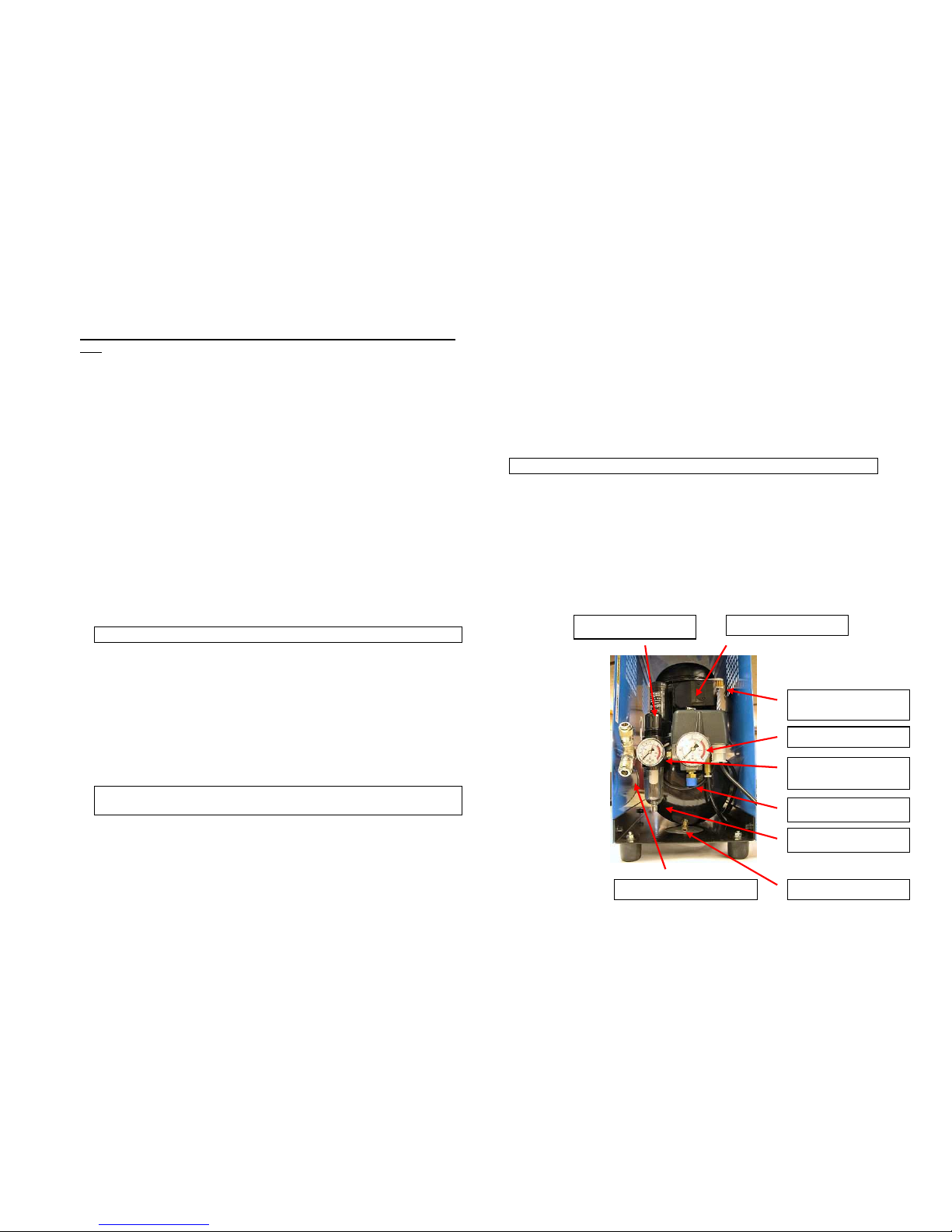

(4) Drain moisturetrap

(5)

Drain

airtank

(1) Airfilter + oil filling

(2)

Pressure in airtank

(3) Outlet pressure

(6) Quick

Couplings NW 5

(0) Start / Stop

(7) Pressurereducer

(8) Safety Valve

2/5 Rev 0 14.12.2005

3) FIRST START-UP

New compressor picked-up at Ideefiks vzw – Obeeliks E-Shop :

Replace the PVC stopper on the combined oil / airinlet (1) on

the compressormotorblock by the air-inletfilter.

Remove cardboard between motorblock and housing.

Check oillevel in sidemounted sightglass ( level should be

somewhat above red mark )

The compressor can be started now ( see section START /

CONTROL of COMPRESSOR )

New compressor shipped to you by Ideefiks vzw – Obeeliks EShop :

Remove cardboard between motorblock and housing.

Remove the PVC stopper on the combined oil / airinlet (1) on

the compressormotorblock

Remove the blue compressorcasing ( 6 screw outside )

Fill-up the compressor with the compressoroil using the

supplied funnel that can be screwed onto the oilbottle. Please

empty the whole content of the bottle into the

compressorcarter ; as a result the oillevel will show up

somewhat above the red halfway mark on the sidemounted

sightglass.

Place the airfilter (1) on the oil/airinlettube with a turning

movement. Press lightly.

Screw the quick connectors (6) into the pressureregulator-

outlet followed by the manometer (3)

Loading...

Loading...