Page 1

EX 5/7/11RT Systems

Installation and User Manual

www.mgeups.com

Page 2

Page 3

Installation and User Manual

iii86-86000-00 B00

EX 5/7/11RT Systems

Installation and User Manual

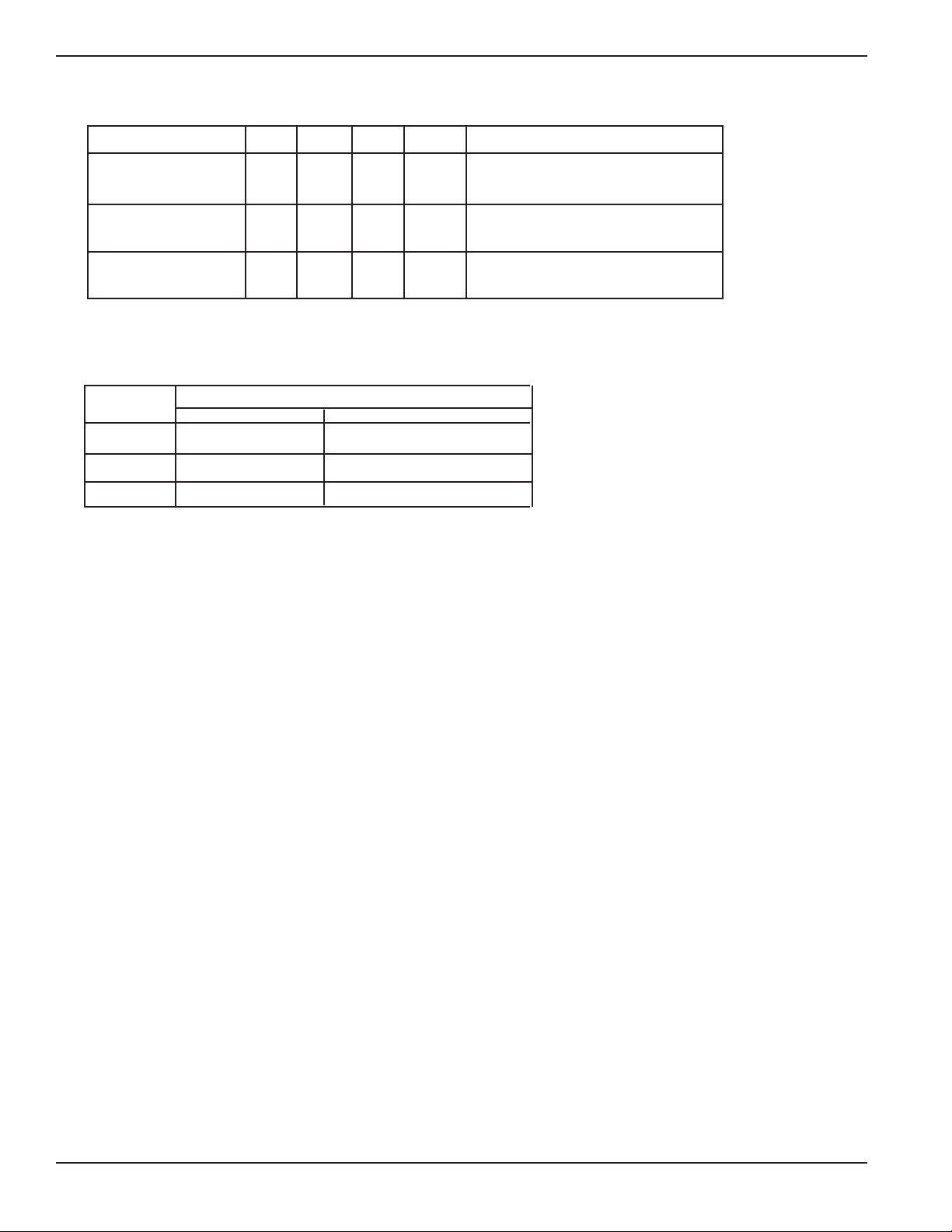

Revision History

EX 5/7/11RT Systems Installation and User Manual, 86-86000-00

Revision: A01 ECN#:003984 07/2004

A02 ECN#:004086 11/2004

A03 ECN#:004284 05/2005

B00 ECN#:004379 01/2006

Copyright © 2006 MGE UPS SYSTEMS, INC.

All rights reserved. Printed in U.S.A.

MGE UPS SYSTEMS, INC.

1660 Scenic Avenue

Costa Mesa, CA 92626

(714) 557-1636

Technical Support:

1-800-

523-0142 (during business hours)

Customer Care Center:

1-800-438-7373

(Hours: 24/7)

Page 4

(This page left blank intentionally)

EX 5/7/11RT Systems

iv

86-86000-00 B00

Page 5

Contents

Contents

c i86-86000-00 B00

section description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .page

Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .iii

IMPORTANT SAFETY INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . .c vi

Certification Standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .c vi

CAUTION: Safety of persons . . . . . . . . . . . . . . . . . . . . . . . . . . . . .c vii

CAUTION: Product Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .c vii

Special Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .c vii

Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .c vii

CAUTION: Record All Serial Numbers! . . . . . . . . . . . . . . . . . . . . . .c viii

Symbol Usage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .c ix

Section Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .c ix

Section 1 Introduction

1.0 Scope . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 — 1

1.1 System Electrical Characteristics . . . . . . . . . . . . . . . . . . . . . . . .1 — 3

1.2 Standard Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 — 4

1.2.1 Tower Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 — 4

1.2.2 Rack Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 — 5

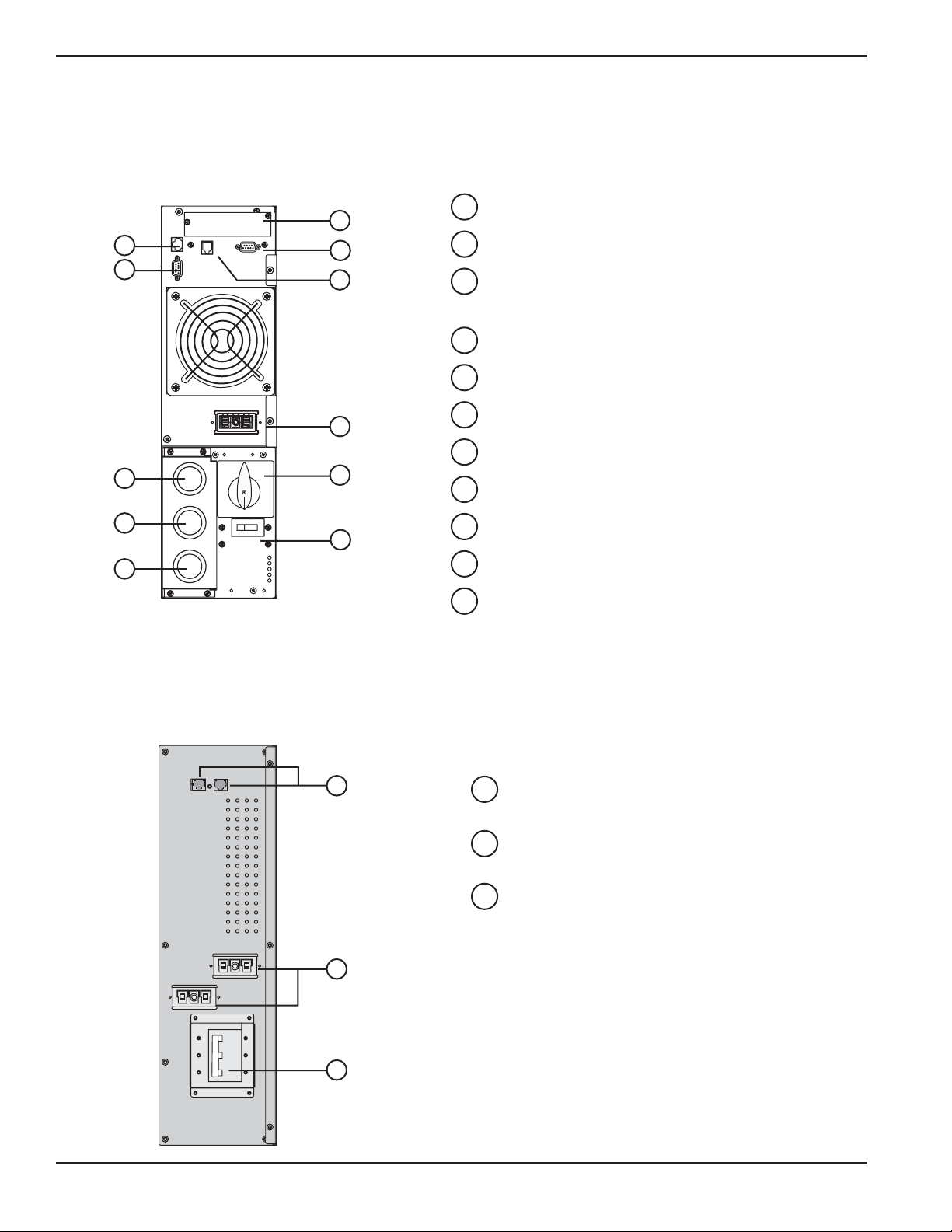

1.3 Rear Panel Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 — 6

1.3.1 Power Module EX 5/7/11 RT . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 — 6

1.3.2 Battery Module EXB 5/7/11RT With Remote

Emergency Power Off (REPO) Function . . . . . . . . . . . . . . . . . . .1 — 6

1.3.3 EX RT Transformer Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 — 7

1.4 Power Module Display and Control Panel . . . . . . . . . . . . . . . . . .1 — 7

1.5 Optional Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 — 8

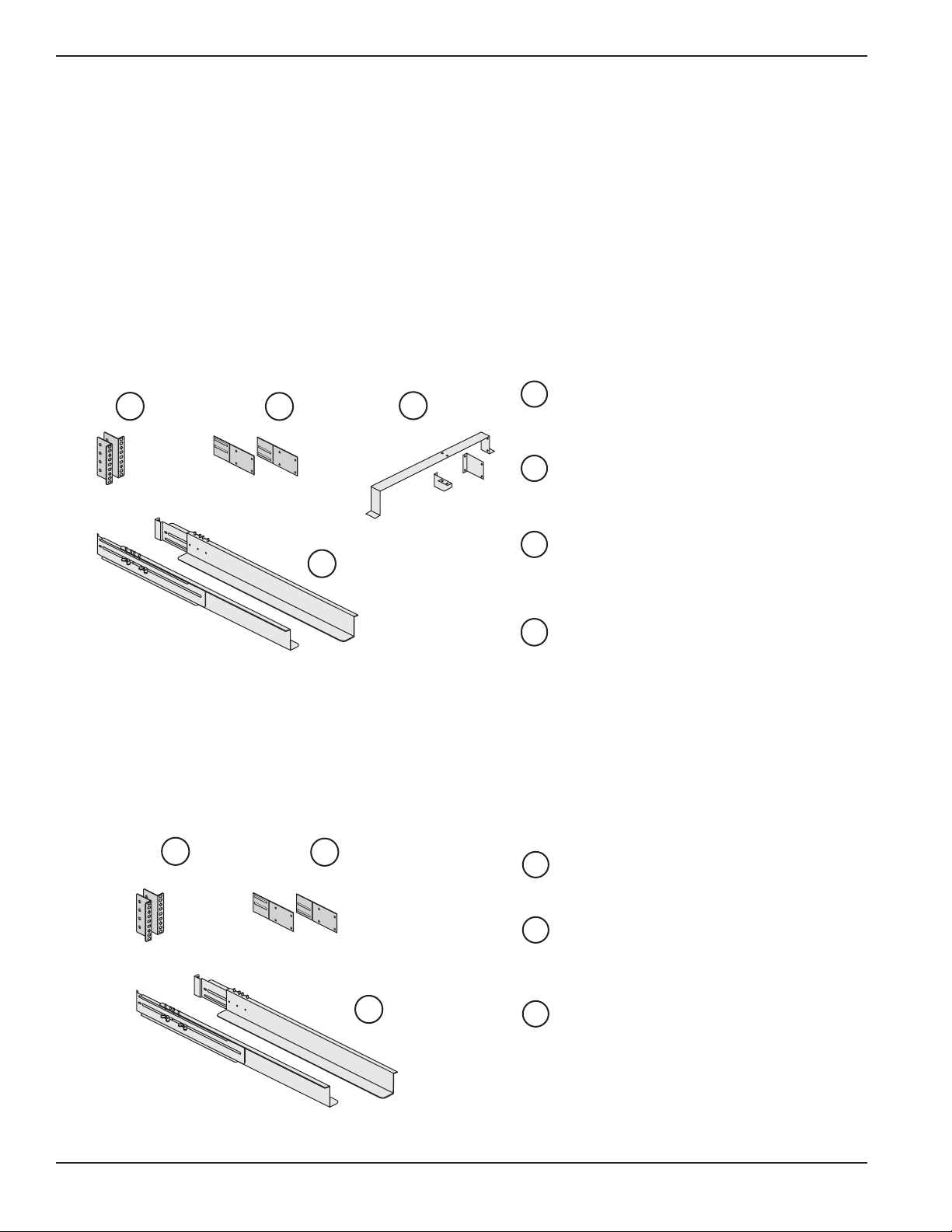

1.5.1 Power Module Rail Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 — 8

1.5.2 Battery/Transformer/CLA Module Rail Kit . . . . . . . . . . . . . . . . . . .1 — 8

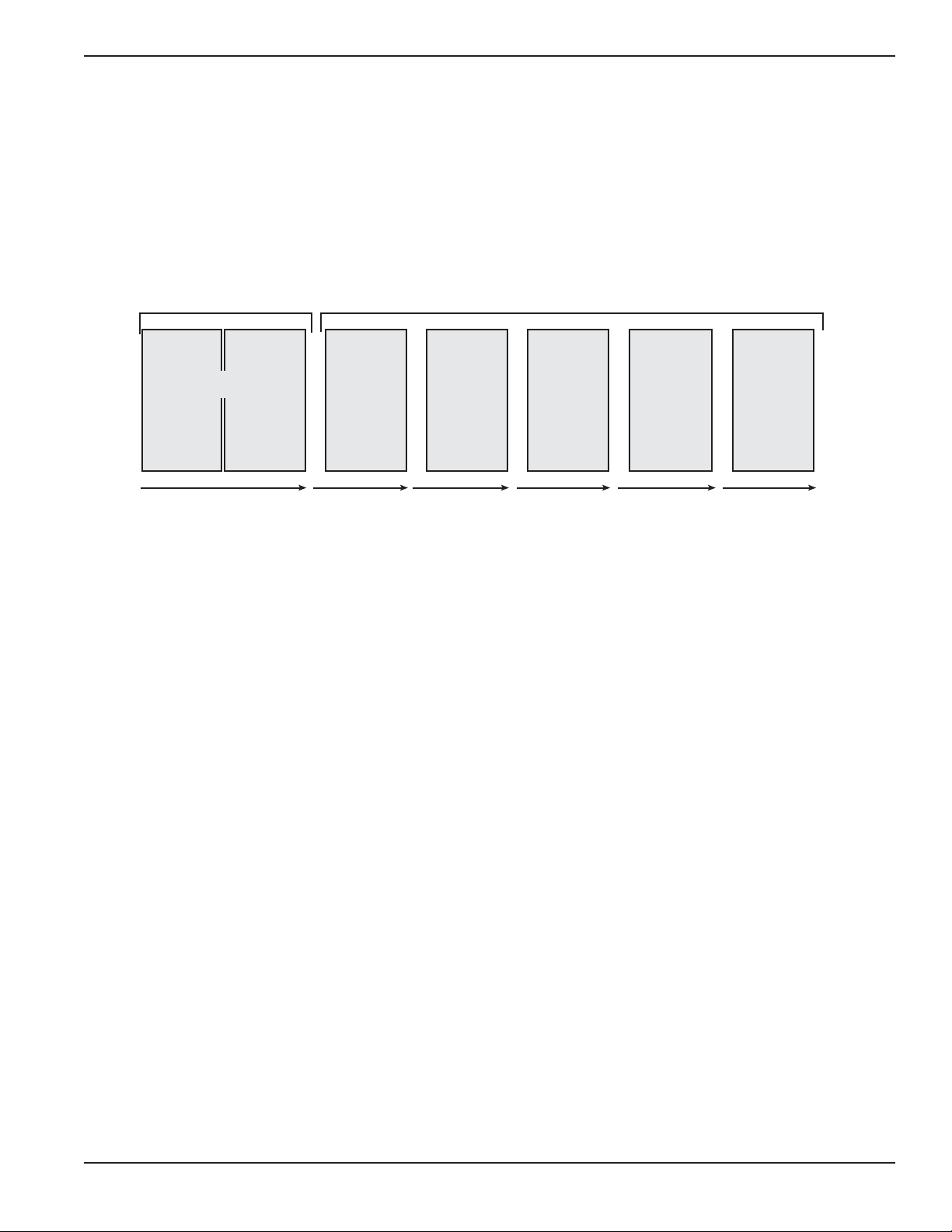

1.5.3 Multiple Battery Module Backup Time at Full Load . . . . . . . . . . .1 — 9

1.5.4 Battery Extension Cable Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 — 9

1.5.5 Battery Integration Kit with Casters . . . . . . . . . . . . . . . . . . . . . .1 — 10

1.5.6 Input/Output Box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 — 10

1.5.7 Transformer Module - For use with EX 5/7/11RT

Power Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 — 11

1.5.8 CLA Charger Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 — 12

Page 6

EX 5/7/11RT Systems

Contentsc ii 86-86000-00 B00

section description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .page

Section 2 Setup and Installation

2.0 Scope . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 — 1

2.1 Unpacking and Parts Check . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 — 1

2.2 Contents of Standard EX 5/7/11RT Systems . . . . . . . . . . . . . . .2 — 2

2.3 Installation in Tower Configuration . . . . . . . . . . . . . . . . . . . . . . . .2 — 4

2.4 Installation in Rack Mounting Configuration . . . . . . . . . . . . . . . . .2 — 5

2.4.1 Adjustment of front panel logo and control panel

for rack orientation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 — 5

2.4.2 Prepare Battery Module for Rack Mounting . . . . . . . . . . . . . . . .2 — 6

2.4.3 Power, Battery, Transformer, and CLA Charger Module

Rack Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 — 7

2.5 Communication Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 — 9

2.5.1 Connecting the RS232 Communication Port . . . . . . . . . . . . . . .2 — 9

2.5.2 Connecting the Dry (Relay) Contact Communication Port . . . .2 — 10

2.5.3 Installation of Optional Transverse Card . . . . . . . . . . . . . . . . . .2 — 10

2.6 Remote Emergency Power Off (REPO) Communication Port . .2 — 12

2.7 System Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 — 13

2.7.1 Connections with Common Normal and Bypass AC

sources (Single Mains) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 — 13

2.7.2 Connecting EX RT Transformer Module . . . . . . . . . . . . . . . . . .2 — 15

2.7.3 Connections with Separate Normal and Bypass AC

sources (2 Mains) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 — 16

2.7.4 System Connections as Frequency Converter

(without Bypass AC source) . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 — 17

2.8 Connection of Battery Module EXB . . . . . . . . . . . . . . . . . . . . . .2 — 18

2.9 Connection of Optional CLA Module . . . . . . . . . . . . . . . . . . . . .2 — 19

Section 3 Operation

3.0 Scope . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 — 1

3.1 Initial Startup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 — 1

3.2 UPS Personalization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 — 2

3.2.1 Accessing personalization with front panel buttons . . . . . . . . . . .3 — 2

3.3 Information Technology (IT) Network and Industrial

Operating Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 — 5

3.3.1 UPS personalization through external software . . . . . . . . . . . . . .3 — 6

3.3.2 Final startup sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 — 6

3.4 Operating Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 — 7

3.4.1 Normal (double conversion) Mode . . . . . . . . . . . . . . . . . . . . . . . .3 — 7

3.4.2 ECO Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 — 8

3.5 Operation on Battery Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 — 9

3.5.1 Transfer to Battery Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 — 9

3.6 Return of Normal AC source . . . . . . . . . . . . . . . . . . . . . . . . . . .3 — 10

3.7 Shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 — 10

Page 7

Installation and User Manual

section description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .page

Section 4 Maintenance

4.0 Scope . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 — 1

4.1 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 — 1

4.2 Hot Swapping the Power Module . . . . . . . . . . . . . . . . . . . . . . . . .4 — 3

4.3 Re-connecting the Power Module . . . . . . . . . . . . . . . . . . . . . . . .4 — 4

4.4 Hot Swapping the Battery Module . . . . . . . . . . . . . . . . . . . . . . . .4 — 5

4.4.1 Disconnecting the Battery Module . . . . . . . . . . . . . . . . . . . . . . . .4 — 5

4.4.2 Re-connecting the Battery Module . . . . . . . . . . . . . . . . . . . . . . . .4 — 5

Section 5 Appendix

5.0 Electrical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 — 1

5.1 System Input/Output Power Ratings . . . . . . . . . . . . . . . . . . . . . .5 — 1

5.2 System Overload Characteristics . . . . . . . . . . . . . . . . . . . . . . . . .5 — 1

5.3 System Backup Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . .5 — 2

5.4 System Short Circuit Protection . . . . . . . . . . . . . . . . . . . . . . . . . .5 — 2

5.5 Accessories Electrical Characteristics . . . . . . . . . . . . . . . . . . . . .5 — 2

5.6 Heat Rejection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 — 4

5.7 Environmental Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . .5 — 4

MGE Warranty & Proprietary Rights for Single Phase Products

MGE Standard Single Phase Warranty

Proprietary Rights Statement

Warranty and Product Registration

User Information

Product information

Warranty Extension (Warranty+) not available on products

Customer Care Center - Single Phase Products

Technical Support and Product Services

Who to Contact

Scheduling Field Service Engineer Support

Return Policy for Repair of Single Phase Products (RGA)

Glossary

Reorder Form

Contents c iii86-86000-00 B00

Page 8

Figures

figure description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .page

1-1: Tower Configuration with Power Module, Battery Module,

and optional Transformer Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 — 4

1-2: Rack Configuration with Power Module, Battery Module,

and optional Transformer Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 — 5

1-3: Rear panel of the Power Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 — 6

1-4: Rear Panel of the Battery Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 — 6

1-5: Rear Panel of the optional Transformer Module. (PN 86211) . . . . . . . . .1 — 7

1-6: View of typical control panel interface. . . . . . . . . . . . . . . . . . . . . . . . . . . .1 — 7

1-7: Power Module Rail Kit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 — 8

1-8: Battery/Transformer/CLA Module Rail Kit. . . . . . . . . . . . . . . . . . . . . . . . .1 — 8

1-9: Typical back-up time with multiple EXB’s at full load. . . . . . . . . . . . . . . .1 — 9

1-10: Typical Battery Integration kit with casters setup. . . . . . . . . . . . . . . . . .1 — 10

1-11: Typical Transformer Module contents and connections. . . . . . . . . . . . .1 — 11

1-12: CLA Module Contents and Connections. . . . . . . . . . . . . . . . . . . . . . . . .1 — 12

2-1: Contents of EX 5/7/11RT Power Module. . . . . . . . . . . . . . . . . . . . . . . . .2 — 2

2-2: Contents of EXB 5/7/11RT Battery Module. . . . . . . . . . . . . . . . . . . . . . . .2 — 3

2-3: Tower Configuration of Standard System and

Optional Transformer Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 — 5

2-4: Typical orientation of the logo and control panel.

(Power Module shown) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 — 6

2-5: Accessing Battery Pack. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 — 6

2-6: Rack mounting of the Power Module onto the rails. . . . . . . . . . . . . . . . .2 — 7

2-7: Input/Output Box Bracket System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 — 8

2-8: RS232 Communication Cable Connection. . . . . . . . . . . . . . . . . . . . . . . .2 — 9

2-9: Relay Pin Connections for Communication Port. . . . . . . . . . . . . . . . . . .2 — 10

2-10: Communication Card Slot with Network

Management Card installed. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 — 10

2-10a: Activation of Remote Emergency Power Off function

using a contact normally open switch. . . . . . . . . . . . . . . . . . . . . . . . . . .2 — 12

2-10b: Activation of Remote Emergency Power Off using a

contact normally closed switch. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 — 12

2-11: Power Module I/O Box Terminal Block Diagram. . . . . . . . . . . . . . . . . . .2 — 13

2-12: Normal AC Input and Output Cables installation. . . . . . . . . . . . . . . . . . .2 — 14

2-13: View of EX RT Transformer Module connected downstream

for 120/208/240 Vac outputs (shown with one EXB). . . . . . . . . . . . . . . .2 — 15

2-14: Normal AC Input, Bypass AC, and Output Cables Installation,

and Simplified Connection Diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . .2 — 16

2-15: Accessing Terminal Blocks for Input and Output power cables. . . . . . .2 — 17

2-16: Rear view of Battery Module cable connections. . . . . . . . . . . . . . . . . . .2 — 18

2-17: Rear view of CLA Module cable battery and AC input connections . . . .2 — 19

EX 5/7/11RT Systems

Contentsc iv 86-86000-00 B00

Page 9

Installation and User Manual

Figures (continued)

figure description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .page

3-1: Initial Startup Display. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 — 1

3-2: Control Panel with scroll up and down buttons. . . . . . . . . . . . . . . . . . . . .3 — 2

3-3: Configuration used to provide cascade redundancy to critical loads . . . .3 — 3

3-4: Normal (double conversion) mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 — 7

3-5: ECO mode display. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 — 8

3-6: Transfer, Threshold and End of backup time . . . . . . . . . . . . . . . . . . . . . .3 — 9

3-7: Shutdown display, circuit breaker, and AC source switch. . . . . . . . . . . .3 — 10

4-1: Disconnecting the Power Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 — 3

4-2: Reconnect the Power Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 — 4

4-3: Rear view of the Battery Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 — 5

5-1: Power supplied as a function of input voltage (left),

and permissible UPS overloads as a function of time (right) . . . . . . . . . .5 — 1

Tables

table description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .page

1-1: EX RT Model Descriptions and Contents. . . . . . . . . . . . . . . . . . . . . . . . .1 — 1

1-2: Optional Accessories (See section 1.5 for description) . . . . . . . . . . . . . .1 — 2

1-3: UPS Characteristics System Ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 — 3

1-4: Transformer Module Characteristics Ratings . . . . . . . . . . . . . . . . . . . . . .1 — 3

1-5: Battery Module Ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 — 4

1-6: System Dimensions and Weights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 — 5

1-7: Battery backup time chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 — 12

3-1: Local Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 — 3

3-2: Output Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 — 3

3-3: ON/OFF Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 — 4

3-4: Battery Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 — 4

3-5: System Operation in I/T and Industrial Modes. . . . . . . . . . . . . . . . . . . . .3 — 5

4-1: Troubleshooting not requiring MGE after-sales support . . . . . . . . . . . . .4 — 1

4-2: Troubleshooting requiring MGE after-sales support . . . . . . . . . . . . . . . .4 — 2

5-1: EX 5/7/11 RT Voltages and Frequency Characteristics . . . . . . . . . . . . . .5 — 1

5-2: Backup Time (in minutes) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 — 2

5-3: Battery Recharge time to recover 90% of the rated backup time

after discharge at full load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 — 3

5-4: Efficiency online (RL load) and batteries fully charged . . . . . . . . . . . . . .5 — 3

5-5: Efficiency online (RCD load) and batteries fully charged . . . . . . . . . . . . .5 — 3

5-6: Efficiency on battery (RCD load). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 — 3

5-7: Efficiency on ECO mode (all kinds of load) and batteries fully charged. .5 — 4

5-8: Full load heat rejection in BTUs/hr . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 — 4

Contents c v86-86000-00 B00

Page 10

EX 5/7/11RT Systems

c vi 86-86000-00 B00

IMPORTANT SAFETY INSTRUCTIONS

SAVE THESE INSTRUCTIONS. This manual contains important instructions

that should be followed during installation and maintenance of the UPS and batteries.

The EX 5/7/11RT models that are covered in this manual are intended for installation in an environment within

0 to 40° C, free of conductive contaminant.

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to Part

15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference

when the equipment is operated in a commercial environment. This equipment generates, uses, and can radiate

radio frequency energy and, if not installed and used in accordance with the instruction manual, may cause

harmful interference to radio communications. Operation of this equipment in a residential area is likely to cause

harmful interference in which case the user will be required to correct the interference at his own expense.

Certification Standards

◗ IEEE 587-1980/ANSI C62.41 1980 Standards for Surge Withstand Ability

◗ FCC rules and regulations of Part 15, Subpart J, Class A

◗ UL listed under 1778, Standards for Uninterruptible Power Supply Equipment

◗ IEC 61000-4-2 (ESD): level 4.

◗ IEC 61000-4-3 (Radiated field): level 3.

◗ IEC 61000-4-4 (EFT): level 4.

◗ IEC 61000-4-5 (Fast transients): level 4.

◗ IEEE-C6241 Category B (ring wave).

◗ IEC 61000-4-6 (electromagnetic field).

◗ IEC 61000-4-8 (conducted magnetic field).

Important Safety Information and Standards

Page 11

Installation and User Manual

c vii86-86000-00 B00 Safety of Persons

CAUTION: Safety of persons

◗

The system has its own power source (the battery). Consequently, the power outlets may be energized even if the

systems is disconnected from the AC power source.

◗

Dangerous voltage levels are present within the system. It should be opened exclusively by qualified service personnel.

◗

The system must be properly grounded.

◗

The battery supplied with the system contains small amounts of toxic materials. To avoid accidents, the directives listed

below must be observed:

-Never burn the battery (risk of explosion).

-Do not attempt to open the battery (the electrolyte is dangerous for the eyes and skin).

-Comply with all applicable regulations for the disposal of the battery.

-Batteries constitute a danger (electrical shock, burns). The short-circuit current may be very high. Precautions must be

taken for all handling: remove watches, rings, bracelets and any other metal objects, use tools with insulated handles.

-Do not lay tools or metal parts on top of batteries.

CAUTION: Product Safety

◗

The UPS connection instructions and operation described in the manual must be followed in the indicated order.

◗

A protection circuit breaker must be installed upstream and be easily accessible. The system can be disconnected from the

AC power source by opening this circuit breaker.

◗

Check that the indications on the rating plate correspond to your AC powered system and to the actual electrical

consumption of all the equipment to be connected to the system.

◗

Never install the system near liquids or in an excessively damp environment.

◗

Never let a foreign body penetrate inside the system.

◗

Never block the ventilation grates of the system.

◗

Never expose the system to direct sunlight or source of heat.

◗

If the system must be stored prior to installation, storage must be in a dry place.

◗

The admissible storage temperature range is -25ºC to +55ºC.

Special Precautions

◗

All handling operations will require at least two people (unpacking, installation in rack system).

◗

Before and after the installation, if the UPS remains de-energized for a long period, the UPS must be energized for a

period of 24 hours, at least once every 6 months (for a normal storage temperature less than 25°C). This charges the

battery, thus avoiding possible irreversible damage.

◗

During the replacement of the Battery Module, it is imperative to use the same type and number of element as the original

Battery Module provided with the UPS to maintain an identical level of performance and safety. In case of doubt, don’t hesitate

to contact your MGE representative.

Environment

◗ This product has been designed to respect the environment:

It does not contain any Chlorofluorocarbon (CFC) or Hydrochlorofluorocarbon (HCFC).

◗ UPS recycling at the end of service life:

MGE UPS SYSTEMS, INC. undertakes to recycle, by certified companies and in compliance with all applicable

regulations, all UPS products recovered at the end of their service life (contact your MGE UPS SYSTEMS, INC.

branch office).

◗ Packing:

UPS packing materials must be recycled in compliance with all applicable regulations.

WARNING: This product contains lead-acid batteries. Lead is a dangerous substance for the environment if it is not

properly recycled by specialized companies.

Page 12

EX 5/7/11RT Systems

c viii 86-86000-00 B00 CAUTION: Record all serial numbers!

CAUTION: Record All Serial Numbers!

RECORD ALL SERIAL NUMBERS FOR EX 5/7/11RT AND ACCESSORIES.

THESE SERIAL NUMBERS WILL BE REQUIRED IF YOUR SYSTEM NEEDS SERVICE.

KEEP THIS MANUAL IN A PLACE WHERE YOU CAN REFERENCE THE SERIAL

NUMBERS IF SERVICE IS REQUIRED!

EX 5RT System EX 7RT System EX 11RT System

Power Module SERIAL NUMBER: ___________________________________________________

Battery Module SERIAL NUMBER: ____________________________________________________

Transformer Module SERIAL NUMBER: _______________________________________________

CLA Module SERIAL NUMBER: ______________________________________________________

ADDITIONAL MODULES SERIAL NUMBERS:

____________________________ ______________________________

____________________________ ______________________________

____________________________ ______________________________

____________________________ ______________________________

____________________________ ______________________________

____________________________ ______________________________

____________________________ ______________________________

____________________________ ______________________________

____________________________ ______________________________

____________________________ ______________________________

Page 13

Installation and User Manual

Symbol Usage c ix86-86000-00 B00

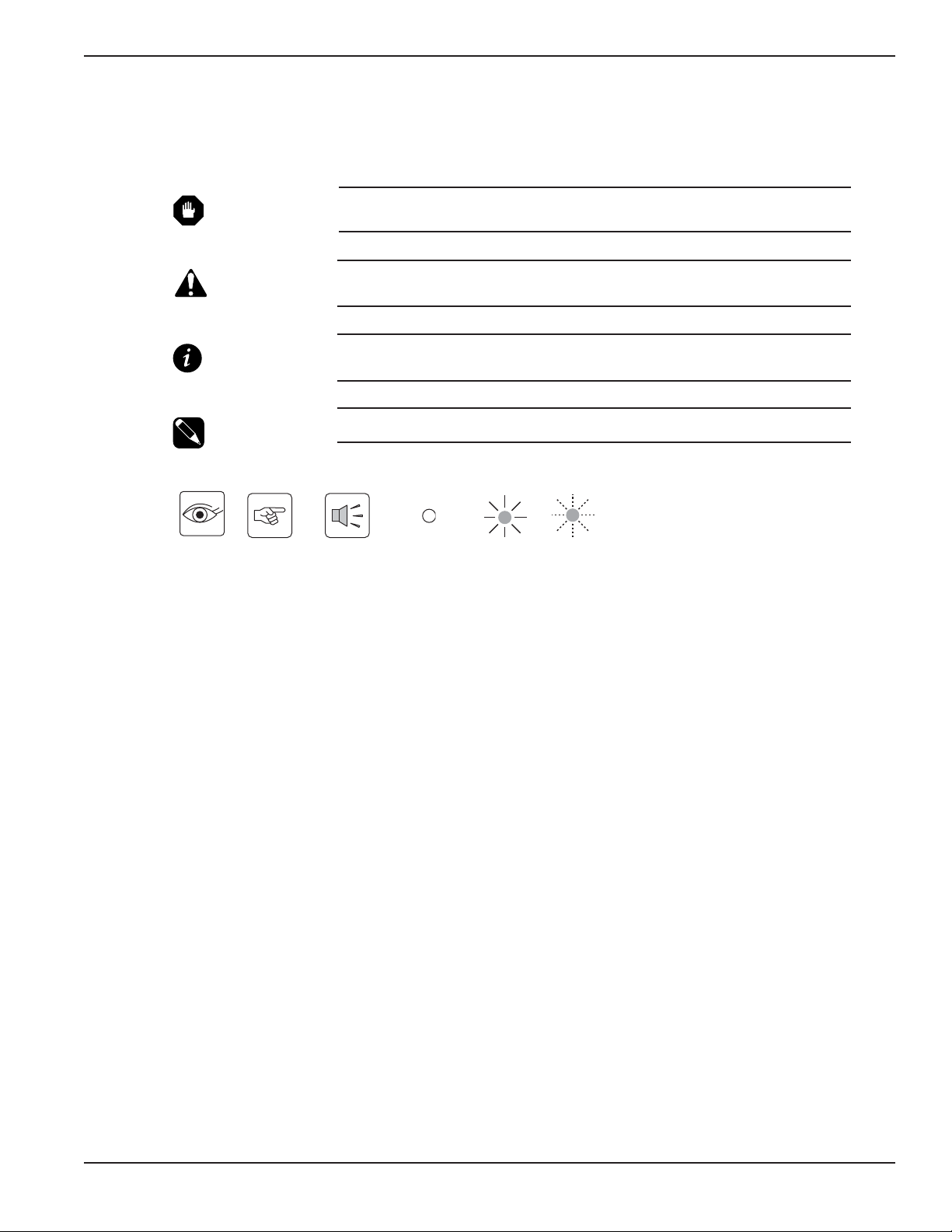

Symbol Usage

This manual uses the following icon symbols with text to convey important information and tips.

WARNING Indicates information provided to protect the user and service personnel

against safety hazards and/or possible equipment damage.

CAUTION Indicates information provided to protect the user and service personnel

against possible equipment damage.

IMPORTANT Indicates information provided as an operating instruction, or as an

operating tip.

NOTE Indicates information provided as an operating tip or an equipment feature.

Section Descriptions

1 Introduction

Introduction is a general description of system configurations of the EX 5/7/11RT, and its mechanical

electrical characteristics. Additionally there is an optional accessories section with important information on MGE

products that will enhance the performance of the EX 5/7/11RT. Please contact your MGE representative for

detailed information on these options.

2 Setup and Installation

Setup and Installation guides the user through tools and equipment required for connecting the EX 5/7/11RT and

battery installation or replacement. Included are assembly instructions, power cable connections with wire diagrams

for configuring the product to hardware specifications.

3 Operation

Operation describes the EX 5/7/11RT systems characteristics of indicators and controls, modes and specifications.

The user procedures include performing software programming that will maintain optimal performance.

4 Maintenance

Maintenance includes a troubleshooting guide of symptoms and possible solutions, hot swapping the Power

module, Battery module, and testing scenarios.

5 Appendix

Electrical and Mechanical specifications for the EX 5/7/11RT.

Visual Action Audio LED OFF LED ON LED Flashing

Page 14

(This page left blank intentionally)

EX 5/7/11RT Systems

c x

86-86000-00 B00

Page 15

Introduction

1.0 Scope

Introduction is a general description of system configurations of the EX 5/7/11RT, and its mechanical

electrical characteristics. Additionally there is an optional accessories section with important information on MGE

products that will enhance the performance of the EX 5/7/11RT. Please contact your MGE representative for detailed

information on these options.

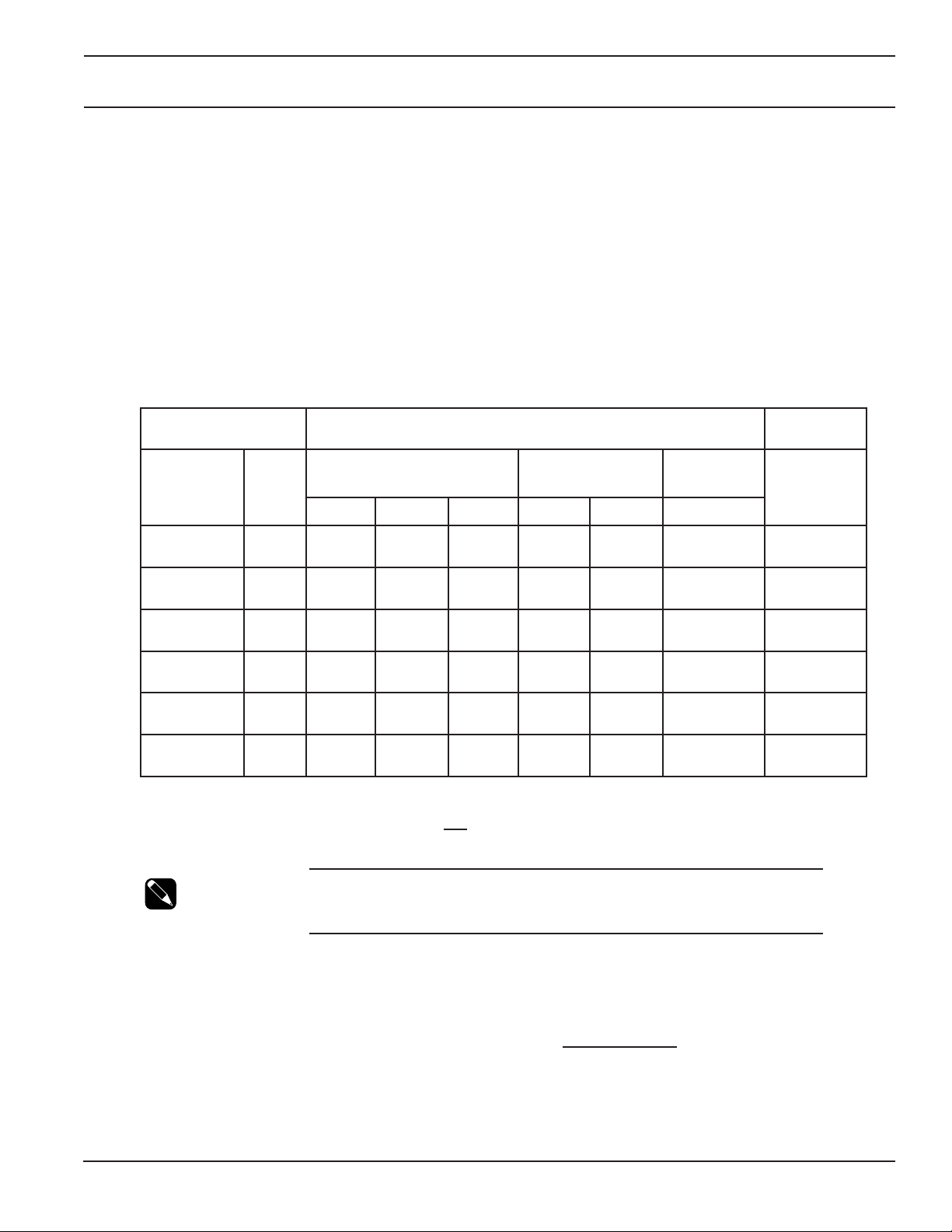

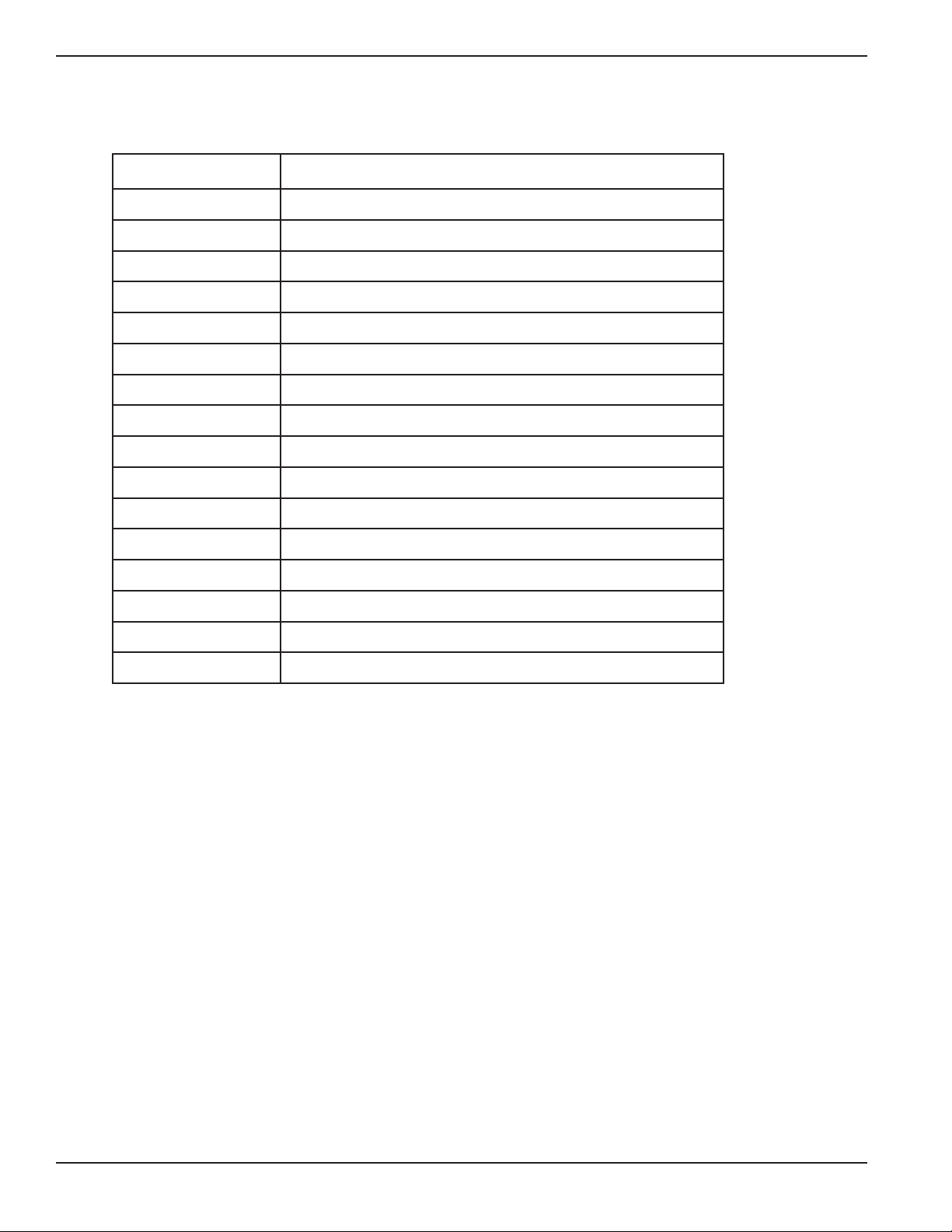

Table 1-1: EX RT Model Descriptions and Contents.

Also: All units include rail kits for rack mounting and

stabilizing feet for tower configuration.

NOTE The Power Module is factory configured for single Mains input at 208VAC,

60Hz. Other input-output voltage settings are available. See section 3.2.1.

Input voltage must be the same as output voltage on HV units!

Thank you for selecting an MGE UPS SYSTEMS, INC. (MGE) product to protect your electrical equipment.

The product you selected is a part of the EX RT series. The EX RT series is a family of Uninterruptible Power Supply

(UPS) designed to provide safe, and reliable AC power backup for sensitive electrical equipment. To discover the

entire range of MGE products, we invite you to visit our website at www

.mgeups.com or contact your representa-

tive at (800) 523-0142.

For a complete description of the EX RT product family and its available options, please refer to the following tables.

1 — 186-86000-00 B00 Introduction

System Description System Contents

Output

Voltage

Model # Part #

Power Module Battery Module

Transformer

Module

86215 86216 86217 86207 86209 86211

5 kVA

HV EX 5RT

86050 X X

200/208/220/

230/240/250

5 kVA

LV EX 5RT

86201 X X X 120/208/240

7 kVA

HV EX 7RT

86070 X X

200/208/220/

230/240/250

7 kVA

LV EX 7RT

86203 X X X 120/208/240

11 kVA

HV EX 11RT

86110 X X

200/208/220/

230/240/250

11 kVA

LV EX 11RT

86205 X X X 120/208/240

Page 16

Table 1-2: Optional Accessories (See section 1.5 for description)

EX 5/7/11RT Systems

Introduction1 — 2 86-86000-00 B00

Part Number Description

86001 Rail Kit for Power Module EX 5/7/11RT

86002 Rail Kit for Battery/Transformer/CLA Module

86005 Battery Integration Kit with Casters

86006 Battery Extension Cable Kit

86008 Empty Battery Chassis EXB RT W/EPO

86009 I/O Box 5/7kVA UL/US

86010 I/O Box 11kVA UL/US

86012 I/O Box Bracket System

86013 Rear Bracket Supports

86207 Battery Module EXB 5/7RT

86209 Battery Module EXB 11RT

86211 EX RT Transformer Module

86213 CLA Charger Module

86215 5kVA Power Module EX 5RT

86216 7kVA Power Module EX 7RT

86217 11kVA Power Module EX 11RT

Page 17

Installation and User Manual

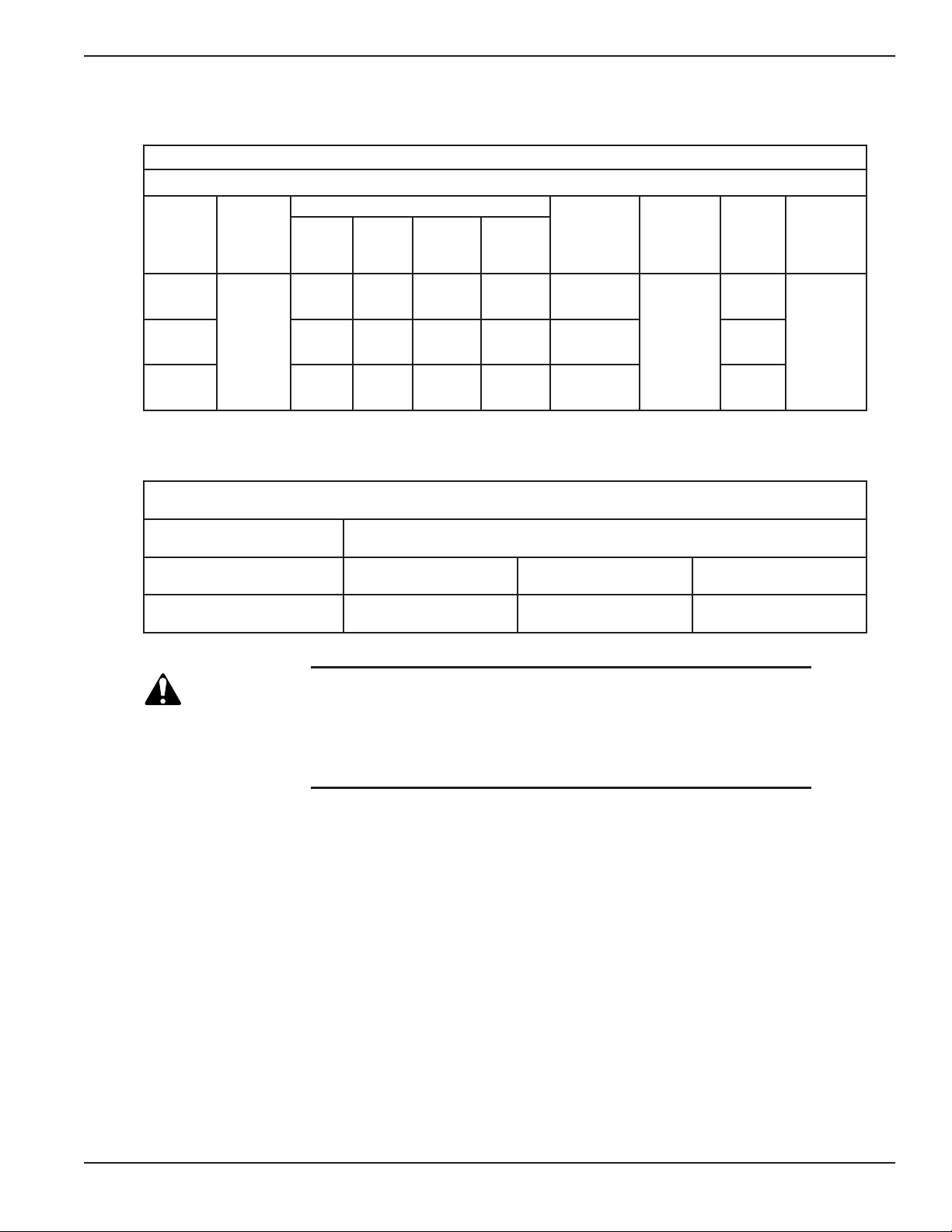

1.1 System Electrical Characteristics

Table 1-3: UPS Characteristics System Ratings.

Table 1-4: Transformer Module Characteristics Ratings.

CAUTION Power Module is factory configured at 208Vac, 60 Hz input and output.

Without transformer, Input and Output of the UPS must always be

the same.

On 11KVA, 10% de-rating for 200/208VAC. Isolated 120/208/240VAC are

available with EX RT Transformer Module.

Introduction 1 — 386-86000-00 B00

UPS Characteristics

MAIN 1 (Normal AC Source) default

Power

Rating

Input

Voltage

(VAC)

Input Current (A)

Input

Breaker

(A)

Output

Voltage

(VAC)

Output

Current

(A)

Inrush

Current

Min Max Online Bypass

5 kVA

208

18 32 21.6 19 40

208

19.25

200A/1ms7 kVA 25 45 30.3 26.65 50 23.5

11 kVA 38 64 44 42 70 47.5

Transformer Module Characteristics

Input Voltage (VAC) 208/240

Output Voltage (VAC) 120/120 208 240

Max. Output Current (A) 33.3/33.3 52 45

Page 18

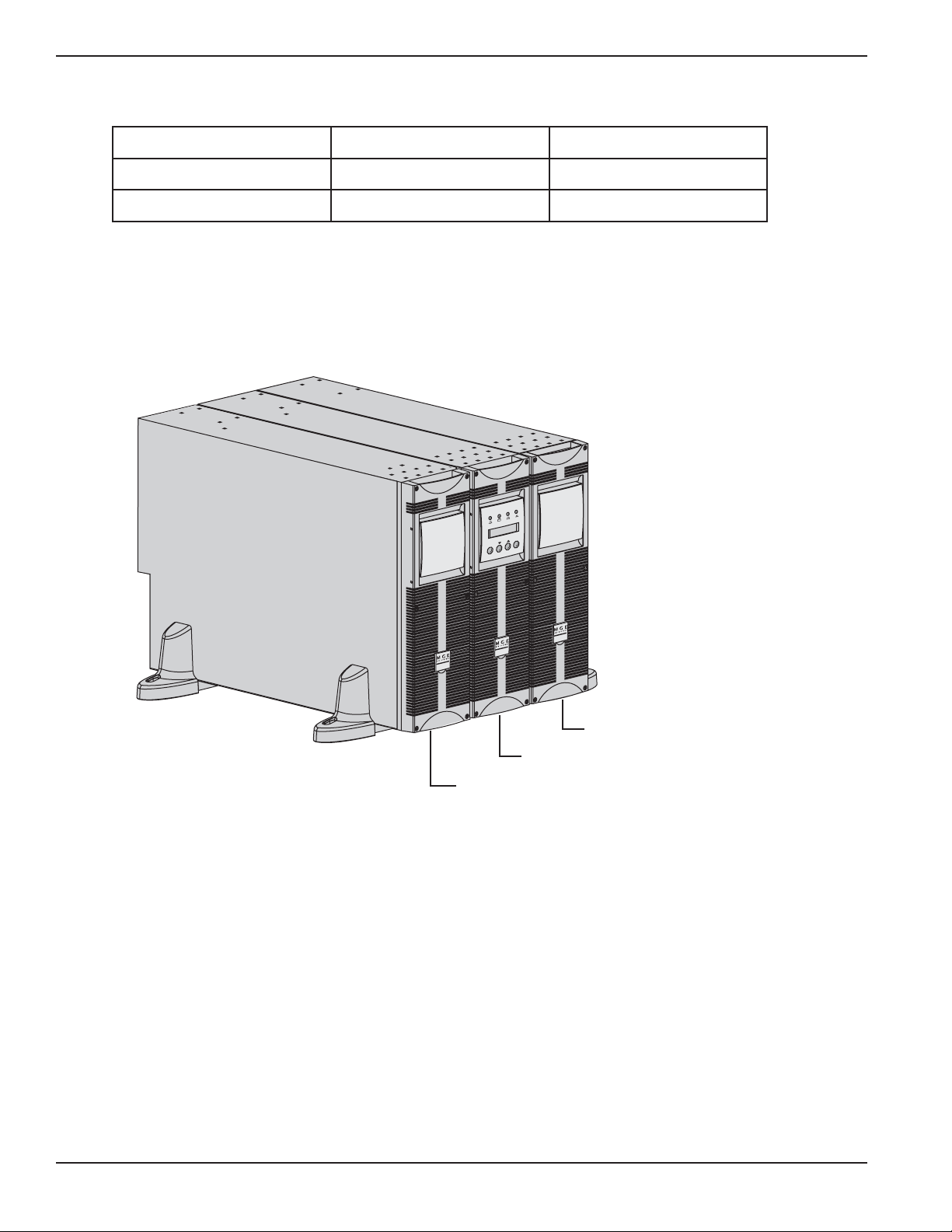

Table 1-5: Battery Module Ratings.

1.2 Standard Configuration

The EX 5/7/11RT systems can be set up in tower or rack configurations.

1.2.1 Tower Configuration

Figure 1-1: Tower Configuration with Power Module, Battery Module, and optional Transformer Module.

EX 5/7/11RT Systems

Introduction1 — 4 86-86000-00 B00

Part Number 86207 86209

Battery Type 12VDC/7Ah 12VDC/9Ah

Battery Output Voltage 240VDC 240VDC

T

R

XB

E

T

R

11

X

E

r

e

form

T Trans

R

X

E

m

o

c

.

ps

u

e

g

m

.

w

w

w

ON

FF

O

m

o

s.c

p

u

ge

m

.

w

w

m

o

c

.

ps

u

e

g

m

.

ww

w

w

POWER MODULE

TRANSFORMER MODULE

BATTERY MODULE

Page 19

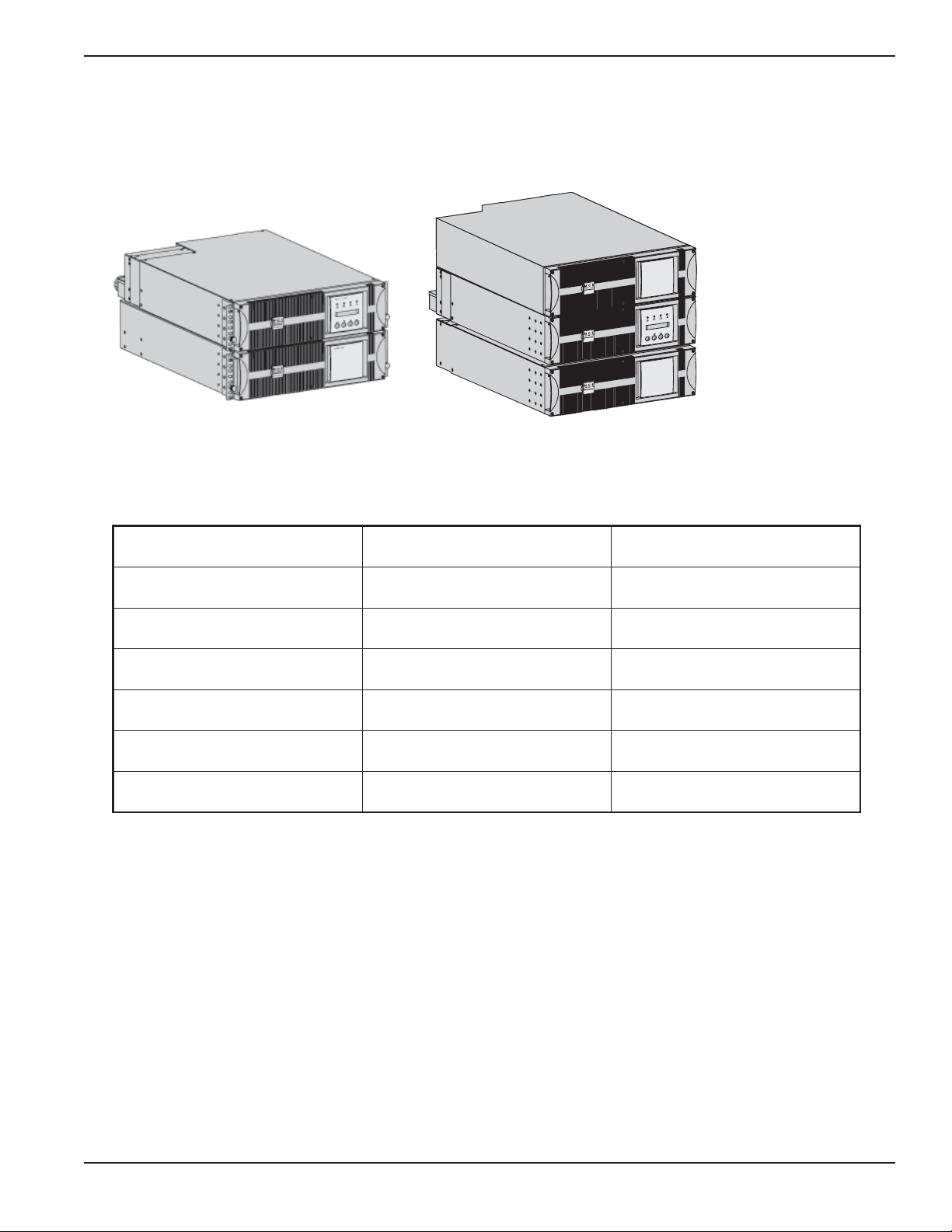

Installation and User Manual

1.2.2 Rack Configuration

Figure 1-2: Rack Configuration with Power Module, Battery Module, and optional Transformer Module.

Table 1-6: System Dimensions and Weights.

(*) For depth constraint applications, a shorter version of I/O Box for Power Module is available. With this

version of I/O Box, the overall depth of the EX 5/7/11RT is only 24.75” (629mm). Call Customer Care

Center at 1-800 438-7373 for more details.

Introduction 1 — 586-86000-00 B00

Model Dimensions (HxWxD) Weights

EX 5/7RT Power Module

(3U) 5.16” x 17.49” x 26.25”(*)

(131 x 444 x 667mm)

49.6 lbs (22.5 kg)

EX 11RT Power Module

(3U) 5.16” x 17.49” x 26.25”(*)

(131 x 444 x 667mm)

60.6 lbs (27.6 kg)

EXB 5/7RT Battery Module

(3U) 5.16” x 17.49” x 25”

(131 x 444 x 635mm)

142 lbs (64.5 kg)

EXB 11RT Battery Module

(3U) 5.16” x 17.49” x 25”

(131 x 444 x 635mm)

151 lbs (68.5 kg)

EX RT Transformer Module

(3U) 5.16” x 17.49” x 25”

(131 x 444 x 635mm)

173 lbs (78.5 kg)

CLA Charger Module (3U) 5.16” x 17.5” x 25 26.5 lbs (12 kg)

Standard Configuration Configuration with Transformer

POWER MODULE

(EX 5/7/11 RT)

former

Trans

BATTERY MODULE

(EXB 5/7/11 RT)

EX RT

m

o

c

.

s

p

u

e

g

.m

w

w

w

T

EX 11 R

F

F

m

o

c

.

s

p

u

e

g

m

.

w

w

w

m

o

c

.

s

p

u

e

g

m

.

w

w

w

O

RT

XB

E

TRANSFORMER MODULE

POWER MODULE

(EX 5/7/11 RT)

N

O

BATTERY MODULE

(EXB 5/7/11 RT)

Page 20

1.3 Rear Panel Components

1.3.1 Power Module EX 5/7/11 RT

Figure 1-3: Rear panel of the Power Module.

1.3.2 Battery Module EXB 5/7/11RT With Remote Emergency Power Off (REPO) Function

Figure 1-4: Rear Panel of the Battery Module.

EX 5/7/11RT Systems

Introduction1 — 6 86-86000-00 B00

Connectors for automatic detection of additional battery

module(s) (to the UPS or to other Battery Modules).

Battery power connectors (to the UPS or to other

Battery Modules).

Battery Circuit Breaker with shunt trip.

14

13

12

Slot for optional communication cards.

Dry (relay) contacts Communication Port.

Remote Emergency Power Off (REPO) function.

(See section 2.6.)

Connector for automatic detection of Battery Module(s).

RS232 communication port.

Battery/CLA Module power connector.

Manual Bypass switch.

Normal AC source circuit breaker.

Knockout for entry of AC Output conduit.

Knockout for entry of Normal AC source conduit.

Knockout for entry of Bypass AC source conduit.

11

10

9

8

7

6

5

4

3

2

1

4

5

9

1

2

3

6

7

10

8

11

12

13

14

Page 21

Installation and User Manual

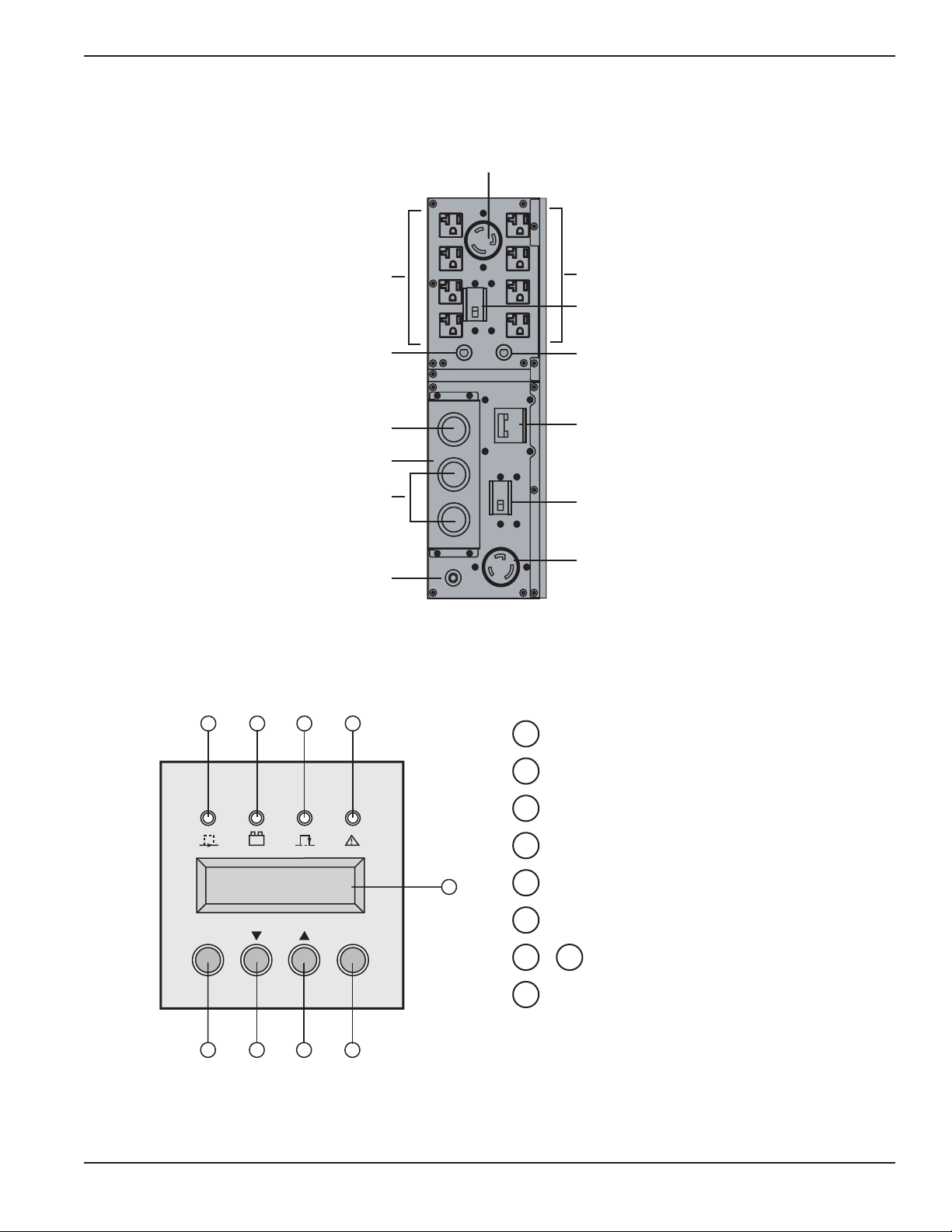

1.3.3 EX RT Transformer Module

Figure 1-5: Rear Panel of the optional Transformer Module. (PN 86211)

1.4 Power Module Display and Control Panel

Figure 1-6: View of typical control panel interface.

Introduction 1 — 786-86000-00 B00

Load 3

NEMA L6-30R, 240V

Load protected/On-line Operation LED.

Operation on battery LED.

Operation on bypass LED.

Fault LED.

LCD display.

UPS OFF button.

Function buttons (scroll up/scroll down).

UPS ON button (or function button in personalization

mode).

23

2221

20

19

18

17

16

15

Load 4: 4 NEMA 5-15/20R, 120Vac

Load 4 Circuit Breaker

AC Input

Transformer I/O Box

AC Output

Transformer Protect

Breaker

: 1

ac

Load 2: 4 NEMA 5-15/20R, 120Vac

Load 3 Circuit Breaker

Load 2 Circuit Breaker

Main Output Circuit Breaker

Load 1 Circuit Breaker

Load 1: 1 NEMA L6-30R, 208Vac

15 16

E X 1 1 R T

OFF

20 21 22 23

17 18

19

ON

Page 22

1.5 Optional Accessories

Optional Accessories describes the options available for upgrades and enhancement of the EX 5/7/11RT systems.

Detailed installation of the unit is described in following sections.

To ensure a successful installation, all procedures should be followed in their correct sequence. Note that any

unauthorized installation may cause damage to the UPS(s) and void the MGE warranty.

1.5.1 Power Module Rail Kit

(Part Number 86001)

This kit is for rack mounting the Power Module in a 19" enclosure. See section 2.4.3 for rack installation of Power

Module.

Figure 1-7: Power Module Rail Kit.

Front mounting brackets.

Rear support brackets, part number 86013.

This can be ordered separately.

Telescopic rails, 25.16" to 39.61"

length (639 mm to 1005 mm).

Input/Output Box bracket system, part

number 86012.

1.5.2 Battery/Transformer/CLA Module Rail Kit

(Part number 86002)

This kit is for rack mounting of the Battery/Transformer/CLA Module in 19" enclosure. See section 2.4.3 for rack

installation of module.

Figure 1-8: Battery/Transformer/CLA Module Rail Kit.

Front mounting brackets.

Rear support brackets, part number

86013. This can be ordered separately.

Telescopic rails, 25.16" to 39.61"

length (639 mm to 1005 mm).

26

25

24

27

26

25

24

EX 5/7/11RT Systems

Introduction1 — 8 86-86000-00 B00

24

25

27

26

24

25

26

Page 23

Installation and User Manual

1 — 986-86000-00 B00

EX 5/7/11RT Systems

1.5.3 Multiple Battery Module Backup Time at Full Load

Standard EX 5/7/11RT systems (one Power Module, and one Battery Module), offers a standard backup time of 5

to 12 minutes at full load.

To increase backup time, it is possible to connect up to 5 additional Battery Modules to the standard system. See

section 2.8 for connections between standard system and Battery Module (EXB 5/7/11RT)

Figure 1-9: Typical back-up time with multiple EXB’s at full load.

See Appendix for additional Back-up time information.

1.5.4 Battery Extension Cable Kit

(6 ft./1.8 m, Part number 86006)

This extended battery cable kit will be used instead of the standard battery cable when Battery Modules (EXBs) are

distant from each other (located in two different enclosures, for instance).

The battery extension cable kit includes a 6 ft. long, straight connector battery power cable and a 6 ft. long battery

detection cable.

Introduction

Standard

EX 5/7/11RT systems

EX 5/7/11RT EXB 5/7/11RT

5 kVA :

7 kVA :

11 kVA:

9 min

7 min

5 min

EXB 5/7/11RT EXB 5/7/11RT EXB 5/7/11RT EXB 5/7/11RT EXB 5/7/11RT

+++

25 min 45 min

20 min

14 min

32 min

22 min

Optional

Configurations

60 min 84 min 100 min

45 min

30 min

+ +

57 min

42 min

72 min

53 min

Page 24

EX 5/7/11RT Systems

1 — 10 86-86000-00 B00

1.5.5 Battery Integration Kit with Casters

(Part number 86005)

Battery Integration Kit is a cart, designed to hold up to 8 modules. It has swivel wheels with brakes, leveling feet,

seismic floor mount panels, plates to lock modules and hardware included. Modules not included.

Figure 1-10: Typical Battery Integration kit with casters setup.

1.5.6 Input/Output Box

Introduction

TRANSFORMER MODULE

(optional)

POWER MODULE

BATTERY MODULES

(up to 6)

(Modules Not Included In Kit)

F

F

O

O

- I/O Box 5/7kVA Part number 86009

- I/O Box 11kVA Part number 86010

Page 25

Installation and User Manual

1 — 1186-86000-00 B00

EX 5/7/11RT Systems

1.5.7 Transformer Module - For use with EX 5/7/11RT Power Module

This module provides isolated 120/208/240Vac outputs.

Figure 1-11: Typical Transformer Module contents and connections.

Introduction

EX RT Transformer Module Contents

Transformer Module

Quick Start Manual

Transformer

Cable

BATTERY MODULE

EXB RT

POWER MODULE

EX 5/7/11RT

Tower Stand Expanders

Stabilizer Bracket

(4 screws included)

Transformer Rail Kit

41

AC NORMAL

INPUT

TRANSFORMER

MODULE EX RT

TRANSFORMER MODULE

OUTPUT TO LOAD

Page 26

EX 5/7/11RT Systems

1 — 12 86-86000-00 B00

1.5.8 CLA Charger Module

Extended back-up time (up to 8 hours at full load) requires a high power battery cabinet connected to the EX

5/7/11RT via the CLA Module.

IMPORTANT The CLA can not be used to charge the Battery Module (EXB). It is designed to

charge the customer provided high power battery cabinet.

Figure 1-12: CLA Module Contents and Connections.

Table 1-7: Battery backup time chart.

Total battery voltage : 240 VDC (20 x 12VDC, one string).

IMPORTANT The battery capacity must be set within the UPS (5 Ah increment)

See UPS Personalization section 3.2.

Battery Backup Time

Recommended Batteries

EX 5RT EX 7RT EX 11RT

2 hours 50 Ah 65 Ah 100 Ah

4 hours 100 Ah 130 Ah 200 Ah

8 hours 200 Ah 260 Ah 400 Ah

Introduction

CLA Module Contents

15A Utility

AC Source

(cable not included)

~

sf

n

ra

T

T

R

X

E

m

o

.c

s

p

u

ge

m

.

w

w

w

CLA

CLA Module Quick Start

r

e

rm

o

EX 5/7/11RT

Tower Stand Expanders

Battery Power Cable

Battery Detection Cable

Typical High Power

Battery Cabinet

(not included)

Transformer Rail Kit

41

Stabilizer Bracket

(4 screws included)

50A

(see section 2.10 for cable

connection information)

(cable not included)

Page 27

Setup and Installation

2.0 Scope

Setup and Installation guides the user through tools and equipment required for connecting the EX 5/7/11RT and

battery installation or replacement. Included are assembly instructions, power cable connections with wire diagrams

for configuring the product to hardware specifications.

2.1 Unpacking and Parts Check

Once the EX 5/7/11RT systems has been inspected and received from the shipping courier, the unit should be

moved to a position as close to the final installation location as possible. See Figures 2-1, on page 2-2.

All Modules are shipped in separate boxes.

Prior to any installation, the following items should be observed upon receipt of the EX 5/7/11RT.

1. Inspect shipment for any damage prior to receipt. Damage claims should be filed directly with the courier.

Replacements for damaged components should be ordered through MGE Customer Support Services at

1-800-438-7373.

2. Remove wrapping and foam corners to verify that the equipment nameplate (located on the rear of the units)

details a system that corresponds with the equipment ordered.

2 — 186-86000-00 B00 Installation

Page 28

EX 5/7/11RT Systems

2 — 2 86-86000-00 B00

2.2 Contents of Standard EX 5/7/11RT Systems

IMPORTANT Packaging must be destroyed according to waste management standards.

Recycling icons are displayed for easy selection.

Figure 2-1: Contents of EX 5/7/11RT Power Module.

Installation

Contents of EX 5/7/11RT Power Module: (PN 86215 / 86216 / 86217)

EX 5/7/11RT Power Module.

Two sets of tower stands.

RS232 communication cable.

Product documentation.

Input/Output Box. (PN 86009 for EX 5/7RT; 86010 for EX 11RT)

Solution-Pac 2 CD.

Power Module Rail Kit, PN 86001.

36

35

34

33

32

31

30

30

T

R

1

1

X

E

31 32

33 35

36

(see 1.5.1)

34

FF

O

O

- I/O Box 5/7kVA Part number: 86009

- I/O Box 11kVA Part number: 86010

Page 29

Installation and User Manual

Figure 2-2: Contents of EXB 5/7/11RT Battery Module.

Installation 2 — 386-86000-00 B00

Contents of EXB 5/7/11RT Battery Module: (PN 86207 /86209)

Stabilizer Bracket and hardware.

EXB 5/7/11RT.

Tower stand expanders.

Battery Power cable.

Battery/EX RT Transformer/CLA Module rail kit, PN 86002.

Battery detection cable.

EXB Documentation.

Bezel hex drive.

44

43

42

41

40

39

38

29

38

T

R

B

X

E

29

- EXB 5RT Battery Module Part number: 86207.

- EXB 7RT Battery Module Part number: 86207.

- EXB 11RT Battery Module Part number: 86209.

39 40 42

41

43

(not to scale)

44

Page 30

2.3 Installation in Tower Configuration

Follow the numerical sequence to assemble tower stands and tower stand expanders, shown in Figure 2-3.

Figure 2-3: Tower Configuration of Standard System and Optional Transformer Module.

EX 5/7/11RT Systems

Installation2 — 4 86-86000-00 B00

Tower Configuration with Standard System

5

T

R

B

X

E

T

R

1

1

X

E

N

O

F

F

O

m

o

c

.

s

p

u

e

g

m

.

w

w

w

m

o

c

.

s

p

u

e

g

m

.

w

w

w

Battery Module

Power Module

3

4

4

3

4

4

2

1

2

1

Tower Configuration with Optional Transformer Module

5

T

R

B

X

E

T

R

1

1

X

E

ON

F

F

O

Battery Module

Power Module

m

o

.c

s

p

u

e

g

m

.

w

w

w

m

o

c

.

s

p

u

e

g

m

.

w

w

w

m

o

.c

ps

u

e

g

m

.

w

w

w

Transformer Module

Use the same procedure

for tower mounting multiple

battery modules, if applicable.

3

4

4

3

4

4

2

1

2

1

Page 31

Installation and User Manual

2.4 Installation in Rack Mounting Configuration

2.4.1 Adjustment of front panel logo and control panel for rack orientation.

NOTE If system includes the Transformer Module, we recommend to mount the Battery

Module on the bottom, then mount the Power Module above the Battery Module

and mount the Transformer Module on top for optimum stability.

To prepare the front panel logo and LCD display for rack orientation, of all modules. (including Transformer or CLA

Module, if equipped).

Proceed as follows:

1. Unclip logo plate, and pull the LCD display from front panel.

2. Rotate them 90 degree counter clockwise as shown.

3. Place items back onto the panel.

Figure 2-4: Typical orientation of the logo and control panel. (Power Module shown)

Installation 2 — 586-86000-00 B00

T

R

1

1

X

E

X

O

F

1

F

1

R

w

w

w

.

m

g

e

u

p

s.

c

o

m

T

O

N

m

o

c

.

s

p

u

e

g

m

.

w

w

w

E

N

O

F

F

O

FINISHED PANEL

(rack orientation)

E

X

O

F

1

F

1

R

1

1

w

w

w

.

m

g

e

u

p

s

.

c

o

m

m

o

c

.

s

p

u

e

g

m

.

w

ww

2

3

T

O

N

T

R

1

1

X

E

N

O

F

F

O

2

3

Page 32

2.4.2 Prepare Battery Module for Rack Mounting

IMPORTANT This step requires two people.

The Battery Module is very heavy (151 lbs.). To ease its rack mounting, you can remove the battery pack from the

Battery Module, as explained below.

Proceed as follows:

1. Unscrew the six screws securing front panel using Bezel hex driver .

2. Unscrew the brackets securing the battery connectors.

3. Disconnect Battery plugs.

4. Unscrew the brackets securing the battery pack. Remove battery bracket pack covers.

5. Pull the left and right battery packs out and set aside for reinstalling after the Battery Module cabinet has been

rack mounted.

6. Mount Battery Module cabinet on rack.

7. Re-install the battery pack in reverse order.

Figure 2-5: Accessing Battery Pack.

44

EX 5/7/11RT Systems

Installation2 — 6 86-86000-00 B00

3

2

2

m

o

.c

s

p

u

e

g

.m

w

w

w

T

R

B

X

E

3

4

4

x 6

1

1

1

44

(not to scale)

5

Page 33

Installation and User Manual

2.4.3 Power, Battery, Transformer, and CLA Charger Module Rack Mounting

The following steps apply to all modules. For simplicity, only Power Module is shown.

Proceed as follows:

1. Attach both front mounting ear brackets to module with supplied screws. (For this step, it is possible to

adjust the position of both front mounting brackets.)

2. Attach rear support brackets to module. These brackets prevent the module from sliding out of the rack.

3. Attach rails together and secure with wing nuts, and finger tighten. (both sides).

4. Attach both rails to rear and front of rack with supplied flathead screws (as shown).

5. Use caution when sliding unit into rack. Temporarily secure unit to rack with thumb screws on front mounting

brackets.

6. Secure rear support brackets to rails.

Figure 2-6: Rack mounting of the Power Module onto the rails.

26

25

24

Installation 2 — 786-86000-00 B00

4

4

3

4

2

4

1

2

4

5

1

4

6

6

6

6

Page 34

NOTE:

This step is unique to the Power Module. It involves the installation of the I/O Box

Bracket System.

The I/O Box bracket system keeps the I/O Box stationary while hot swapping the Power Module. It will then be

easier to slide the replacement module into the connectors of the I/O Box.

1&2. Secure small brackets to larger bracket from the underside .

3. Secure small attached brackets to the I/O Box with four screws.

4. Secure large bracket to rails at the rear of module with four nuts.

Figure 2-7: Input/Output Box Bracket System.

27

27

EX 5/7/11RT Systems

Installation2 — 8 86-86000-00 B00

1

2

3

OFF

4

4

Install input/output cables

per section 2.7 prior to this step.

Page 35

Installation and User Manual

2.5 Communication Ports

EX 5/7/11RT Power Module provides 3 communication method's that can be used simultaneously:

◗ A female DB9 provides RS232 communications using MGE Serial HID UPS Transfer (SHUT)

protocol. This COM Port is compatible with Solution Pac 2 to perform graceful shutdown.

◗ The Dry Contact Port is used for basic signaling or for protection of IT systems like IBM iSeries

(formerly AS400) and more.

◗ The slot is compatible with most MGE UPS SYSTEMS, INC. Transverse communication card (see

section 2.7.3 or check www.mgeups.com for the complete list of compatible cards).

2.5.1 Connecting the RS232 Communication Port

1. Connect the RS232 communications cable to the serial port on the computer.

2. Connect the other end of the communications cable to the RS232 communications port on the

EX 5/7/11RT.

The EX 5/7/11RT systems can now communicate with Solution Pac 2 for power management. UPS configuration

settings are done by Personal Solution Pac for Windows or through the LCD screen on the front panel (see section

3.2).

Figure 2-8: RS232 Communication Cable Connection.

532

32

1

2

5

Installation 2 — 986-86000-00 B00

32

1

5

2

Page 36

2.5.2 Connecting the Dry (Relay) Contact Communication Port

The system status is indicated by the connection of common pin (Pin 5) to the appropriate pins. Refer to the pin

explanations below for details.

Figure 2-9: Relay Pin Connections for Communication Port.

2.5.3 Installation of Optional Transverse Card

It is not necessary to shut down the UPS to install the optional communications card, except for USB card. Following

is a typical installation of the Transverse card (optional Network Management card PN 66074 is shown below).

Proceed as follows:

1. Remove the slot cover secured by two screws.

2. Insert the Transverse card into the slot .

3. Secure the card with both screws.

4. Refer to user manual of the Network Management Card for set-up.

Figure 2-10: Communication Card Slot with Network Management Card installed.

1

2

EX 5/7/11RT Systems

Installation2 — 10 86-86000-00 B00

Pin 1, 2: not used.

Pin 3: Remote Power Off signal (5 to 27 VDC, 10 mA max).

Pin 4: Operation on mains (not on battery). (48VDC, 2A max.)

Pin 5: User common.

Pin 6: Operation on automatic bypass.

Pin 7: Low battery.

Pin 8: Load protected

Pin 9: Operation on battery.

Legend:

NO: contact normally open.

NC: contact normally closed.

45

NC

common

When the status is active, the contact between

the common (Pin 5) and the relevant information

pin is closed.

123

6789

NONO NONO

1

Page 37

Installation and User Manual

A wide range of optional cards will allow your UPS to talk to nearly all equipment management systems, making

integration faster and easier. All these cards can plug directly into the UPS, saving time and money on your next

UPS project. (Meta UPS Card and U-Talk/Basic Acquisition Cards are used exclusively with Multi-slot.)

Dual U-Talk/Basic Card (PN: 66060) CAN NOT BE USED WITH THIS UPS.

JBus Card (PN: 66061) Provides RS232 and RS485 connections for using the JBUS/ModBus

protocol. Both connections are female DB9. Only one connector can be used for

proper operation.

Dual port SHUT Card (PN: 66066) Has two independent female DB9 communication ports that use Serial

HID UPS Transfer (SHUT) protocol. Used with the UPS Control LCD display.

USB Card (PN: 66067) For direct communications (via USB) with the customer’s server and

automatic UPS recognition by the power management software of Windows 2000,

XP or 2003 Server, or Macintosh OS 9 and 10.

Dual port AS/400 Relay (PN: 66068) CAN NOT BE USED WITH THIS UPS.

Status Card

6 Alarm Relay Card (PN: 66069) Provides status in the form of 6 Alarm relays (250V 2A rated relays).

Connection provided are 12 terminal block wire clips.

XML-Web Card (PN: 66073) Features a web interface and keeps log files about UPS operation.

Network Management Card (PN: 66074) Features a web interface, Simple Network Management Protocol

(SNMP), Simple Mail Transfer Protocol (SMTP) email notification and keeps log files

about UPS operation.

Environmental Sensor (PN:66846) For Network Management Card: Monitors temperature, humidity, and

status of 2 dry contact inputs.

Installation 2 — 1186-86000-00 B00

Page 38

2.6 Remote Emergency Power Off (REPO) Communication Port

The end user is responsible for the installation of a Remote Emergency Power Off function. Installation must be

carried out in compliance with local code regulations.

To shutdown the entire system completely in case of emergency:

◗ Disconnect the AC input to the Power Module by opening up the upstream circuit breaker connecting the

utility power to the Power Module.

◗ Turn off the circuit breaker of the Battery Module connecting to the Power Module.

◗ Turn off the circuit breaker of the subsequent Battery Modules, if applicable.

All these steps above should be performed via a single device.

To simplify the last two steps, the Power Module provides an RJ-11, six contact connector on the back panel, called

Remote Emergency Power Off (REPO) port. Upon applying a voltage source (5-27VDC, 10mA max.) to pins 2, 4 of

this port, the Power Module will send a signal to trip off the shunt trip on each circuit breaker of all Battery Modules

via the battery detection cable simultaneously. Refer to the diagram below for details.

Figure 2-10a: Activation of Remote Emergency Power Off function using a contact normally open switch.

Figure 2-10b: Activation of Remote Emergency Power Off using a contact normally closed switch.

3

EX 5/7/11RT Systems

Installation2 — 12 86-86000-00 B00

RJ 11

3

6

5432

1

Connections provided by user.

5VDC to 27VDC

10mA (max.)

+

_

RJ 11

3

6

5432

1

Connections provided by user.

5VDC to 27VDC

10mA (max.)

+

_

Page 39

Installation and User Manual

2.7 System Connections

WARNING This type of connections must be carried out by qualified electrical personnel.

Before carrying out any connections, check that battery circuit breaker is

OFF and that the upstream protection devices (Normal and Bypass AC

sources) are open (OFF/OPEN).

2.7.1 Connections with Common Normal and Bypass AC Sources (Single Mains)

Figure 2-11: Power Module I/O Box Terminal Block Diagram.

NOTE ◗ The Power Module is factory configured for single input, whereas both Normal AC

and Bypass AC sources are identical, by means of jumper between L1 and L3.

◗ Jumper must be removed for separate Normal AC and Bypass AC sources

(2 Mains) or with Frequency Converter application.

◗ Keep Manual Bypass Switch at Normal position.

7

14

Installation 2 — 1386-86000-00 B00

Terminal tightening torque:

– 18 lb-in. for EX 5/7RT Power Module

– 35 lb-in. for EX 11RT Power Module

Output

200/208/220/230/240Vac

200/208/220/230/240Vac

L6 L5 L2 L1 L1 L4 L3

Terminal block capacity:

- Max. 4AWG (EX 11RT)

- Max. 6AWG (EX 5/7RT)

Bypass AC source

200/208/220/230/240Vac

Normal AC source

Jumper

(see note)

Page 40

Proceed as follows:

1. For normal AC input, make connections to L1, L2 and terminals only. No connections are required for

Bypass AC input. Make connections to , L5, L6 terminals for output.

CAUTION: Always connect the earth ground wire first.

Jumper must be between L1 and L3. System is factory configured for 208VAC

output.

2. Attach I/O Box to the Power Module with three screws.

Figure 2-12: Normal AC Input and Output Cables installation.

EX 5/7/11RT Systems

Installation2 — 14 86-86000-00 B00

Power Module I/O Box

Output

200/208/220/230/240Vac

L6 L5 L2 L1 L1 L4 L3

To Load

208VAC

Normal AC source

200/208/220/230/240Vac

200/208/220/230/240Vac

66074

Card Settings

data

UPS

ETHERNET

100 10

Reset

ON

1 2

RS232 Download

MAC=00E0D8FF855E

IP=

Bypass AC source

Jumper

From Utility

208 VAC

Output to Load

or

Transformer Module

(if applicable)

F

OF

O

1

Normal AC Input

Output

2

F

F

O

O

Simplified Connection Diagram

Bypass AC

Normal AC

AC INPUT

UPSTREAM

CIRCUIT

BREAKER

(NOT SUPPLIED)

To Load or

Transformer Module

(if applicable)

Page 41

2.7.2 Connecting EX RT Transformer Module

(Part number 86211)

This module is to provide isolated 120/208/240 VAC outputs to the protected loads.

Figure 2-13: View of EX RT Transformer Module connected downstream for 120/208/240 Vac outputs (shown

with one EXB).

Installation and User Manual

Installation 2 — 1586-86000-00 B00

BATTERY MODULE

EXB 5/7/11 RT

POWER MODULE

EX 5/7/11 RT

TRANSFORMER

MODULE EX RT

Transformer Module I/O Box

L3 L2 L1 Lb Ld N Lc La

AC NORMAL

INPUT

TRANSFORMER MODULE

OUTPUT TO LOAD

WARNING To avoid overloading transformer windings, provide branch over current

protection for all transformer output terminals.

To avoid overloading 120VAC output windings, distribute loads evenly

between Load 2 and Load 4 (on rear of Transformer Module ) and between

120VAC output terminals (Lb-N, La-N.)

Terminal Block Transformer Module Connection diagram

(located on bottom of Transformer I/O Box)

L3 L2 L1 Lb Ld N Lc La

208Vac

240Vac

AC Input

120Vac

208Vac

240Vac

AC Output

Simplified Connection Diagram

AC Input from

Power Module

(208VAC shown)

120Vac

AC Output to Load

(120VAC shown)

Terminal Block capability :

AWG 4 solid or stranded wire.

AC INPUT

UPSTREAM

CIRCUIT

BREAKER

(NOT SUPPLIED)

Bypass AC

Normal AC

Transformer Module

To Load

Page 42

2.7.3 Connections with Separate Normal and Bypass AC sources (2 Mains)

CAUTION: This connection requires isolation Transformer Module. Call MGE

Technical Support for details.

Figure 2-14: Normal AC and Bypass AC inputs, Output Cables Installation, and Simplified Connection Diagram.

EX 5/7/11RT Systems

Installation2 — 16 86-86000-00 B00

Proceed as follows:

1. Remove the cover plate under the I/O Box. Loosen the

terminal blocks L1 and L3, and remove the jumper.

CAUTION: Always connect the earth ground wire

first.

2. Install Normal AC, Bypass AC and output cables as shown.

3. Reinstall the cover plate under the I/O Box with four screws.

4. Secure the I/O Box to the Power Module with three screws.

See section 2.7.2 for connecting EX RT Transformer

module, if applicable.

F

OF

O

1

L1

F

F

O

O

2

L3

Bypass

3

Output

Normal

4

F

F

O

O

66074

Card Settings

data

UPS

ETHERNET

100 10

Reset

ON

1 2

RS232 Download

MAC=00E0D8FF855E

IP=

To Load or

Transformer Module

(if applicable)

With separate Normal and Bypass AC inputs, supplied by separate sources.

BYPASS AC

MAINS 2

MAINS 1

Isolation

Transformer

(PN 86211)

LOAD

NORMAL AC

Page 43

Installation and User Manual

2.7.4 System Connections as Frequency Converter (without Bypass AC source)

Figure 2-15: Accessing Terminal Blocks for Input and Output power cables.

Installation 2 — 1786-86000-00 B00

CAUTION: Always connect the

earth ground wire first.

1. Remove the cover plate under the I/O Box.

Remove the jumper connecting L3 and L1.

CAUTION: Removing the jumper will

disable the Bypass AC

source. Do not connect

anything to the Bypass AC

terminal block.

2. Refer to section 2.7.1 to install Normal AC source

and output wires per I/O Box Terminal diagram.

Re-install the cover plate under the I/O Box.

3. Secure the I/O Box to Power Module with three

screws.

See section 2.7.2 for connecting EX RT

Transformer Module, if necessary.

Power Module I/O Box

Output

200/208/220/230/240Vac

Normal AC source

200/208/220/230/240Vac

L6 L5 L2 L1 L1 L4 L3

F

OF

O

1

Bypass AC source

200/208/220/230/240Vac

F

F

O

O

1

Normal AC Input

OUTPUT

To L oa d

208VAC

Jumper

INPUT

From Utility

208 VAC

Output

2

F

OF

O

66074

Card Settings

data

UPS

ETHERNET

100 10

Reset

ON

1 2

RS232 Download

MAC=00E0D8FF855E

IP=

Output to Load

or

Transformer Module

(if applicable)

Page 44

2.8 Connection of Battery Module EXB

1. Check that the battery circuit breaker (5) is OFF (“0”) position.

2. Connect the battery power cable to the connectors and of the Power and Battery

Modules.

3. Connect the battery detection cable between connectors and of the Power and Battery

Modules.

Figure 2-16: Rear view of Battery Module cable connections.

124

42

13640

14

EX 5/7/11RT Systems

Installation2 — 18 86-86000-00 B00

12

4

42

40

13

6

14

Page 45

Installation and User Manual

2.9 Connection of Optional CLA Module

1. Connect the battery power cable and battery detection cable (provided with the CLA Module)

between the Power Module and the CLA Module.

2. Connect the DC Input of the CLA Module to high power battery cabinet.

◗ DC Input Cable cross-section (not provided): maximum 4 AWG solid or stranded wire.

3. Connect the utility AC input to terminal blocks L1 and L2 of the CLA.

◗ AC input cable cross-section (not provided): maximum 16 AWG solid or stranded wires.

Field wiring connections to terminal block shall be made using the following:

– No. 14 AWG, 60º C copper wires for AC inputs.

– No. 10 AWG, 75º C copper wires for DC inputs.

Figure 2-17: Rear view of CLA Module cable battery and AC input connections

4240

Installation 2 — 1986-86000-00 B00

Connection Diagram

(inside CLA Module)

- +

DC INPUT

240Vdc

N L

(L2) (L1)

AC INPUT

156-280Vac

42

40

Terminal tightening torque:

– 5 lb-in. for AC input terminals

– 18 lb-in. for DC input terminals

Separate, 15A Utility

Use 15A DBL. Pole CB

DC Input to

High Power

Battery Cabinet

AC Source

@ 208 or 240

Page 46

(This page left blank intentionally)

EX 5/7/11RT Systems

2 — 20

86-86000-00 B00

Page 47

Operation

3.0 Scope

Operation describes EX 5/7/11RT systems characteristics of indicators and controls, modes and specifications and

theory of operating the EX 5/7/11RT. The user procedures include performing software programming that will

maintain smooth performance. Refer to Figure 1.6 for descriptions of circled numbers.

3.1 Initial Startup

NOTE Both AC and DC sources must be present for normal startup of EX 5/7/11RT

systems. If the system is configured for cold start, the AC and DC sources are

required for initial startup only.

1. Check that the manual bypass switch is on Normal position.

2. Set the Normal AC source circuit breaker to the ON position.

3. Set the battery circuit breaker to the ON position.

The load is powered via the Bypass AC source, but not protected by the UPS.

Batteries are recharging, an eight-hours recharge period is necessary to get full backup time.

LED is ON.

Figure 3-1: Initial Startup Display.

17

14

8

7

3 — 186-86000-00 B00 Operation

OFF

17

ON

Page 48

3.2 UPS Personalization

WARNING Before changing items from Tables, 3-1, 3-2, 3-3, and 3-4, the UPS system

must be turned OFF.

IMPORTANT If specific settings are required, it is recommended to enter the UPS

personalization mode at this stage.

It is possible to enter this mode through the front panel buttons or the

Solution-Pac 2 software for Windows included in the MGE UPS

SYSTEMS, INC. Solution-Pac 2 CD-ROM.

3.2.1 Accessing personalization with front panel buttons

◗ Press "scroll down" and "scroll up" function buttons together for more than 3 seconds.

◗ Press the function button placed under the “ENT” word to enter the set up mode and follow the

LCD messages using the buttons now defined as select keys. See Tables: 3-1, 3-2, 3-3, and 3-4 for

settings.

Figure 3-2: Control Panel with scroll up and down buttons.

22

2221

EX 5/7/11RT Systems

Operation3 — 2 86-86000-00 B00

OFF

UPS SET UP

EXIT ENT

ON

21 22

Page 49

Installation and User Manual

Table 3-1: Local Settings.

Display Factory setting Options

Language English French, Spanish, German, Italian

Date/time format International US

Date/time change (DD-MM-YYYY/HH:MM) MM-DD-YYYY/HH:MM adjustable

Audible alarm Quick beeps Slow beeps

Table 3-2: Output Features.

Display Factory setting Options Comments

Output voltage 208 Volts AC (***) 200/208/220/230/240/250 Input voltage must be equal to

output voltage

Frequency converter Disabled Enabled Bypass AC source disabled

Output frequency Auto ranging 50/60 Hz User selectable under

frequency converter mode

ECO mode Disabled Enabled See section 3.4.2.

Hot standby Disabled Enabled Full redundancy (see Figure 3-3)

Operating mode Industrial IT Network (*) See Table 3-5.

Bypass When bypass NOK When bypass OK (**) (*) See Table 3-5.

Transfer

Interrupt time 10 ms 10 to 200 ms Interrupt time calibration during

(by steps of 10 ms) during load transfer when

Bypass AC source

is out of tolerances

Overload level 102% 50/70%

(*) : - Select "IT Network" for computer loads. Select “Industrial” for other applications or when there exists and absolute need

for service continuity (with potential 10msec. interrupt) when Bypass AC source is not within set tolerances.

See table 3-5 for more details

(**) UPS will switch to Bypass AC Source if it is within the set tolerances.

(***) Input voltage must be equal to output voltage.

Figure 3-3: Configuration used to provide cascade redundancy to critical loads.

Operation 3 — 386-86000-00 B00

BYPASS AC

Cascade redundancy configuration

Protective Device

NORMAL AC

offers better protection to critical

load, whereas the first UPS acts as

the Bypass AC Source for the

second UPS.

Utility

AC Source

Protective Device

NORMAL AC

LOAD

Page 50

Table 3-3: ON/OFF Features.

Display Factory setting Options Comments

Cold start Disabled Enabled Start on battery.

Forced reboot Enabled Disabled UPS restarts automatically

when normal AC source

is restored.

Automatic restart Enabled Disabled UPS restarts automatically

when normal AC source

is restored.

Sleep mode Disabled Enabled Automatic shutdown on battery

if output load level <10%

Remote Command Enabled Disabled Enables shutdown or restart

orders from software.

Table 3-4: Battery Features.

Display Factory setting Options Comments

Battery test Every week No test/daily/monthly

Pre-Alarm 20% 0 to 100% Low battery signal;1% increment

Runtime choice UPS reads # and type From 50 to 400 Ah Requires CLA Module if using

of Battery Modules options (see section 1.5.8)

connected.

Battery deep discharge Enabled Disabled If disabled, loss of

protection MGE UPS SYSTEMS, INC.

warranty.

EX 5/7/11RT Systems

Operation3 — 4 86-86000-00 B00

Page 51

Installation and User Manual

3.3 Information Technology IT Network and Industrial Operating Modes

Table 3-5: System Operation in IT Netowrk and Industrial Modes.

Symptoms IT Network mode Industrial mode

Overload, and Bypass Load is transferred to Bypass AC source. Same as IT Network mode, but AC

source in tolerance. UPS returns to normal mode if overload to the UPS does not return to

is removed. normal mode if overload

is removed.

Overload, and Bypass The UPS shuts down and load is not Load is transferred to Bypass

AC source not in tolerance. transferred to Bypass AC source. AC source with 10 milli-

seconds output break.

The UPS does not return to

normal mode if overload

is removed.

Output short circuit and Bypass The load remains powered by the UPS. Load is transferred to Bypass

AC source in tolerance. The UPS shuts down after 3 minutes AC source. The UPS does not

if the short circuit remains. return to normal mode if the

short circuit is removed.

Output short circuit and Bypass The load remains powered by the UPS. The load is transferred to

AC source not in tolerance. The UPS shuts down after 3 minutes Bypass AC source with

if the short circuit remains. 10 milliseconds output break.

The UPS does not return to

normal mode if the short circuit

is removed.

Operation 3 — 586-86000-00 B00

Page 52

3.3.1 UPS personalization through external software

Insert the Solution-Pac 2 CD ROM in your CD drive.

◗ At the first Navigator Screen, select "Installation" and follow the instructions to install

Solution-Pac 2 for Windows.

◗ If nothing appears, launch startup.exe

◗ Then go to "Advanced settings" and "UPS settings".

Please note that the Linux/Unix/MacOS versions of Personal Solution-Pac do not include this feature.

3.3.2 Final Startup sequence

Press the <ON> button more than 3 seconds.

◗ After UPS internal test sequence, the green LED goes on.

CAUTION During the startup, if the Bypass AC source is out of

tolerance, there will be a 10msec output interrupt.

15

EX 5/7/11RT Systems

Operation3 — 6 86-86000-00 B00

Page 53

Installation and User Manual

3.4 Operating Modes

3.4.1 Normal (double conversion) Mode

Figure 3-4: Normal (double conversion) mode.

Operation 3 — 786-86000-00 B00

This is the standard operating mode, set by the

factory.

Two possible cases.

1. If Normal AC source available:

LED is ON.

The load is protected by the UPS.

Scroll down or scroll up function buttons

allow you to read the UPS measurements (Normal

AC source voltage, Bypass AC source voltage,

operating mode, battery capacity and UPS Serial

Number).

2. If Normal AC source not available:

CAUTION: Do not operate the Manual

Bypass switch when the UPS is

in Normal mode.

LED flashes.

LED is ON.

The audible alarm sounds intermittently.

The load is now powered by the UPS battery.

This display shows remaining back-up time.

16

15

2221

15

15

LOAD LEVEL

4kW / 5 kVA

OFF ON

21 22

15 16

REMAINING TIME

10 minutes

OFF ON

Page 54

3.4.2 ECO Mode

Figure 3-5: ECO mode display.

EX 5/7/11RT Systems

Operation3 — 8 86-86000-00 B00

The main advantage of the ECO mode is that it

reduces the consumption of electrical power by not

running in the online mode. When this mode is

selected, the system works as an offline UPS

system, powered by Bypass source if Bypass source

is inside user’s defined range. Outside this range,

the UPS system will switch to online mode with 10ms

interrupt.

Three possible cases:

1. If Normal AC source (Mains 1) and Bypass AC

Source (Mains 2) are available:

and LED are ON.

The load is supplied with AC power but not protected

in ECO mode.

2. If Normal AC source (Mains 1) is available, but

Bypass AC source (Mains 2) is not available:

LED is ON.

The audio alarm sounds intermittently.

The load is automatically supplied in Normal

mode via the Normal AC input.

3. Both Normal and Bypass AC sources not

available or out of tolerance:

LED is ON.

LED is ON.

The audio alarm sounds intermittently.

The load is powered by the battery power from

the UPS.

The LCD display indicates the battery remaining

backup time.

16

15

15

1715

15 17

OFF

15

OFF

15 16

ON