MG Chemicals 841AR Technical Data Sheet

841AR-Aerosol

Super ShieldTM

Nickel Conductive Coating

841AR Technical Data Sheet

Description

• Sensors

• Controllers

• Receivers

• Test Equipment

• Scientific equipment

• Medical Equipment

• Communication devices

• Satellite dishes and radar systems

• Antennas

• Aerospace applications

• Electric vehicles

• Cable boxes

• Networking gear, firewalls

• Military equipment

• Cellphones, laptops, PDA’s

• GPS’s, navigation systems

• TV’s, monitor’s, and displays

• Consumer electronics

• Electronic sporting equipment

• Audio equipment

• Electric guitars and other amplified

instruments

• Drones and other RC vehicles

• Repairing damage to existing shielding

• Conductive undercoat for electroplating

• Protecting metal surfaces from oxidation

• Providing electric continuity for circuits

• Grounding

ENVIRONMENT

RoHS Compliant

Low-VOC

The 841AR Super ShieldTM Nickel Conductive Coating is a one-part durable acrylic lacquer pigmented with

a highly conductive nickel flake, packaged in convenient aerosol format. It utilizes a solvent based system

with no heat cure necessary. The cured coating is smooth, hard, and abrasion resistant. It provides strong

adhesion to plastics, excellent conductivity, and strong corrosion resistance, even in marine environments.

Applications & Usages

The 841AR is designed to provide a conductive coating to the interior of plastic electronic enclosures to

suppress EMI/RFI emissions. It excels when corrosion resistance is a concern.

The 841AR is commonly used by manufacturers of these devices:

Other applications for 841AR include:

Benefits and Features

• UL Recognized (File # E202609)

• Provides effective EMI/RFI shielding over a broad frequency range

• Volume resistivity of 0.0076 cm

• Smooth, durable and, abrasion resistant

• Available in liquid format

• Quick dry time, no heat cure required

• Mild solvent system

• Strong adhesion to acrylic, ABS, polycarbonate, and other injection molded plastics

• Excellent adhesion to wood and ceramics

• Corrosion resistant, suitable for marine environments

• Low VOC; HAP Free; Does not contain toluene, xylene, or MEK

Date: 15 June 2017 / Ver. 2.02

Page 1 of 8

841AR-Aerosol

Super ShieldTM

Nickel Conductive Coating

841AR Technical Data Sheet

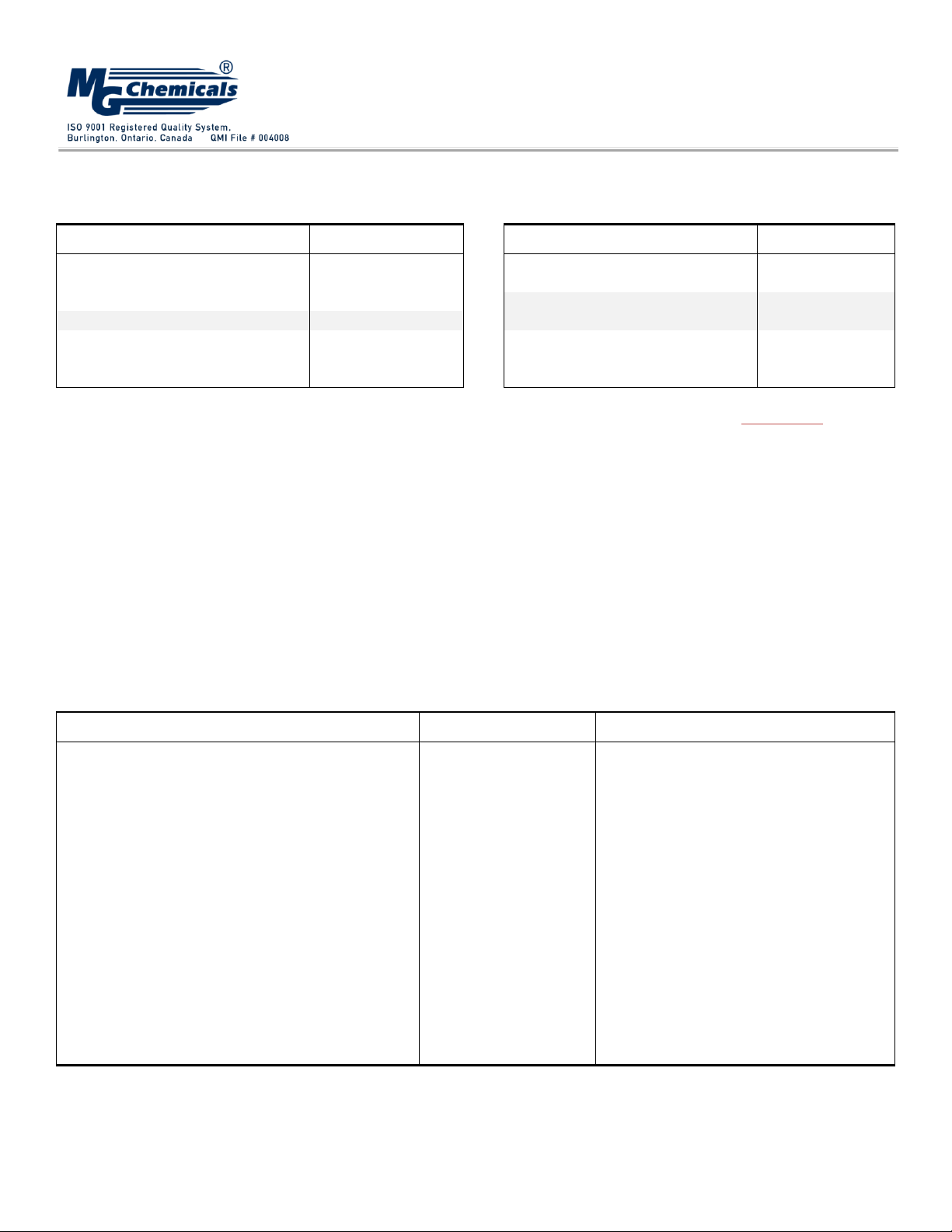

Properties

Value

Recoat time (liquid)

3 min

Drying Time @22 °C [72 °F]

24 h

Drying Time @65 °C [149 °F]

30 min

Shelf Life

2 y

Theoretical 340G Spray

≤2 500 cm2

Can Coverage a)

≤390 in2

Properties

Value

Constant Service

Temperature

-40 to 120 °C

[-40 to 248 °F]

Intermittent Temperature

-50 to 125 °C

Limits

[-58 to 257 °F]

Storage Temperature Limits b)

-5 to 40 °C

[23 to 104 °F]

Electrical & Magnetic Properties

Method

Value

Volume Resistivity

Method 5011.5

in MIL-STD-883H

0.0076 cm

130 S/cm

Surface Resistance

Resistance a)

Conductance

a)

Surface Resistance : 1 coat @2.1 mil

Square probe

0.62 /sq

1.6 S

Surface Resistance : 2 coats @4.2 mil

Square probe

0.38 /sq

2.6 S

Surface Resistance : 3 coats @6.1 mil

Square probe

0.34 /sq

2.9 S

Magnetic Class

Ferromagnetic

Relative Permeability

≥100

Shielding Attenuation for 51 m [2.0 mil]

IEEE STD 299-1997

Shielding Attenuation >10 to 100 kHz

"

84 dB to 89 dB

Shielding Attenuation >100 kHz to 1 MHz

"

65 dB to 88 dB

Shielding Attenuation >1 MHz to 10 MHz

"

39 dB to 60 dB

Shielding Attenuation >10 MHz to 100 MHz

"

32 dB to 52 dB

Shielding Attenuation >100 MHz to 1 GHz

"

52 dB to 61 dB

Shielding Attenuation >1 GHz to 10 GHz

"

56 dB to 74 dB

Shielding Attenuation >10 GHz to 18 GHz

"

49 dB to 68 dB

Usage Parameters

a) Idealized estimate based on a coat thickness

of 50 m [2.0 mil] and 50% transfer

efficiency

Temperature Ranges

b) The product must stay within the storage

temperature limits stated. ATTENTION! Aerosol

container will be crushed at ≤-26.5 °C

[≤15.7 °F].

Principal Components

Name CAS Number

Nickel Flake (high purity) 7440-02-0

Acrylic Resin 25608-33-7

Acetone 67-64-1

Dimethyl carbonate 616-38-6

Heptan-2-one 110-43-0

Properties of Cured 841AR

Date: 15 June 2017 / Ver. 2.02

Page 2 of 8

841AR-Aerosol

Super ShieldTM

Nickel Conductive Coating

841AR Technical Data Sheet

Physical Properties

Method

Value

Paint Type

—

Lacquer (Thermoplastic)

Color

Visual

Dark grey

Abrasion Resistant

—

Yes

Blister Resistant

—

Yes

Peeling Resistant

—

Yes

Water Resistant

—

Yes

Mechanical Properties

Method

Value

Adhesion b)

ASTM D3359

5B

Pencil Hardness b)

ASTM D3363

HB, soft

Environmental & Ageing Study

Method

Value

Salt Fog Test @35 °C [95 °F], 96 h b)

ASTM B117-2011

SalResistivity before

MG-ELEC-120

380 msq

SalResistivity after

"

510 msq

Sal% Conductivity after

"

75%

Cross-Hatch Adhesion

ASTM D3359-2009

5B

Cracking, unwashed area

ASTM D661-93

None

Visual Color, unwashed area

ASTM D1729-96

Slightly darker

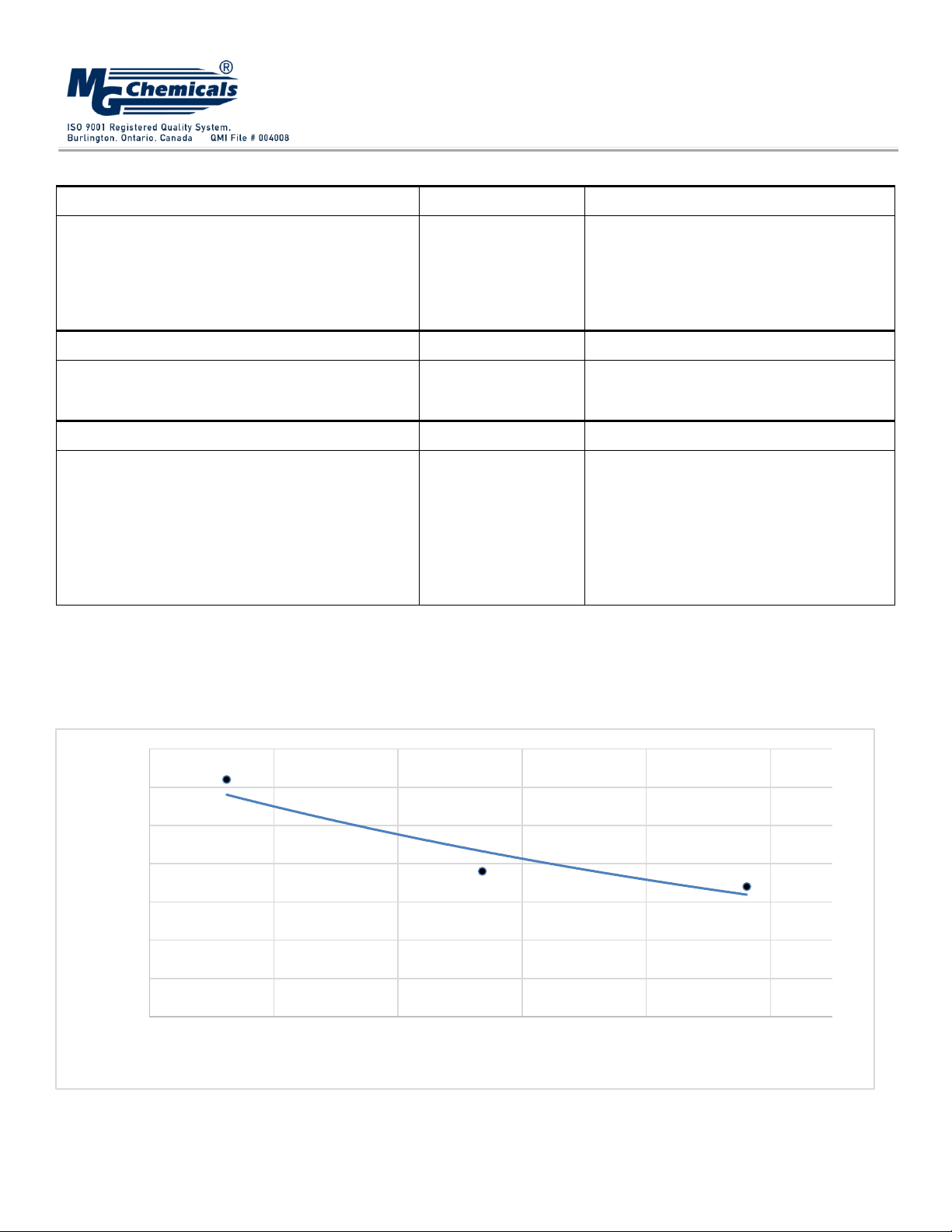

0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

1.5 2.5 3.5 4.5 5.5 6.5

Surface Resistance (Ω/sq)

Thickness (mil)

a) Surface resistance is given in sq and the corresponding conductance in Siemens (S or -1

b) Tested using HVLP spray gun application on acrylonitrile butadiene styrene (ABS) coupons

The coating surface resistance and attenuation are plotted in Figures 1 and 2.

Surface Resistance by Coating Thickness

Figure 1. Nickel conductive coating surface resistance at different thicknesses (the dots indicate typical

successive coat thicknesses)

Date: 15 June 2017 / Ver. 2.02

Page 3 of 8

Loading...

Loading...