Page 1

A variation on the popular MILO™ high-

power curvilinear loudspeaker, the MILO 60

high-power narrow coverage curvilinear

array loudspeaker excels where controlled

horizontal coverage is needed. The self-

powered MILO 60 is a compact, lightweight

four-way system that provides 60 degrees

of horizontal coverage, and vertical cover-

age matching the original MILO. The cover-

age pattern is optimized for applications

requiring tight horizontal cover age, such

as at the top in mixed arrays with standard

MILO or M3D line array loudspeaker sys-

tems, or for side fill hangs where keeping

sound off of side walls is important.

The MILO 60 shares the same dimensions

and rig ging components as the MILO and

MILO 120 expanded coverage high-power

curvilinear array loudspeakers to facilitate

seamless integration. The flexibility of the

MILO 60 allows it to be configured with

other Meyer Sound loud speakers in com-

plex systems. MILO 60 arrays and combined

Curvilinear Array Loudspeaker

DAT A S HEET

arrays with other M Series models are easy

to deploy using the MILO QuickFly

rigging

accessories, such as the MG-3D/M multi-

array tilt is easy to adjust, often elimi nating

the need for a pullback strap in flown con-

figurations.

SPL with exceptionally flat phase and fre-

cy section (4.2 kHz to 18 kHz) that renders

delicate transient information with detailed

acoustical charac teristics are designed to

facilitate seamless integration when used

with other MILO cur vilinear array elements.

A combined MILO 60/MILO/MILO 120 array

with M3D-Subs affords the precise low-

M S E RIE S

frequency directional control that has won

widespread acclaim for M3D systems. The

erage pattern to 30 Hz, assuring that very

the stage or cause excessive reverberation.

ation, a MILO array can be flown adjacent to

or ground stacked with 700-HP subwoofers.

The 700-HP's power and bandwidth handle

treme transient informa tion with minimal

distortion in its operating frequency range.

system is fitted as standard, providing com-

A weather-protected version with a folding

optionally available.

applications

Stadiums, arenas, concert halls and

theatres

Touring sound reinforcement

features & benefits

Controlled horizontal coverage angle of 60

degrees

dramatically minimize distortion

assure clean, high-impact response

Seamless integration with other M Series

QuickFly rigging system simplifies use in

flown or ground-stacked arrays

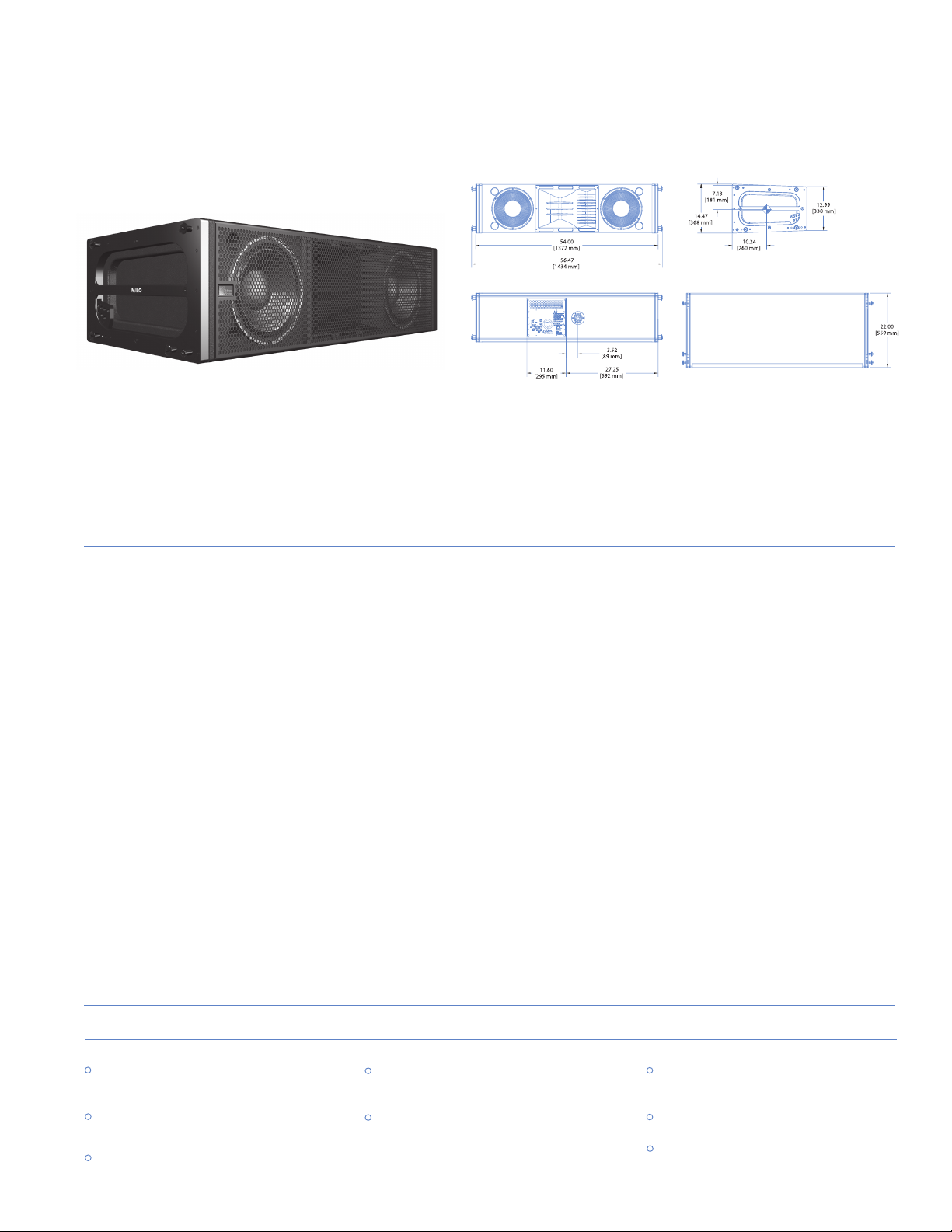

54.00" w x 14.47" h x 22.00" d

Black textured

Powder-coated hex-stamped steel

connectors and quick release pins

�

�

�

�

�

�

�

�

�

�

MILO 60 :

Dimensions

Weight

Enclosure

Finish

Protective Grille

Rigging

Page 2

1. The low-frequency power response of

the system will increase according to

the length of the array.

2. Recommended maximum operating

frequency range. Response depends

upon loading conditions and room

acoustics.

3. Free field, measured with 1/3 octave

frequency resolution at 4 meters.

4. Measured with music at 1 meter.

5. At these frequencies, the transducers

produce equal sound pressure levels:

560 Hz for the low-mid and mid-high

and 4.2 kHz for the mid-high and

very-high frequency drivers.

6. Power handling is measured under

AES standard conditions: transducer

driven continuously for two hours with

band limited noise signal having a 6 dB

peak-average ratio.

7. To eliminate interference at short

wavelengths, the two 12-inch cone

drivers work in combination at low

frequencies (60 Hz – 300 Hz). At mid

frequencies (300 Hz – 560 Hz) only one

cone driver is fed from the crossover

to maintain optimal polar and

frequency response characteristics.

8. The three drivers are coupled to a

constant-directivity horn through

a proprietary acoustical combining

manifold (REM).

9. Amplifier wattage rating is based

on the maximum unclipped burst

sine-wave rms voltage the amplifier

will produce in to the nominal load

impedance. Low, low-mid and very-

high frequency channels 67 V rms (95

channel 67 V rms (95 V pk) into 8 ohms.

10. AC power cabling must be of sufficient

gauge so that under burst current rms

conditions, cable transmission losses

do not drop voltage below specified

operating range at the speaker.

meyer sound laboratories inc.

2832 San Pablo Avenue

Berkeley, CA 94702

T: +1 510 486.1166

F: +1 510 486.8356

techsupport@meyersound.com

www.meyersound.com

MILO 60 - 04.132.096.02 A

Copyright © 2004

Meyer Sound Laboratories Inc.

Operating Frequency Range

60 Hz - 18 kHz

65 Hz - 17.5 kHz ±4 dB

750 Hz - 16 kHz ±30°

140 dB

>110 dB

60° horiz.; vertical

varies depending on array length & configuration

560 Hz, 4.2 kHz

Two 12" cone drivers with neodymium magnets

Nominal impedance: 4

Ω

Voice coil size: 4"

Power-handling capability: 1200 W (AES)

6

One 4" compression driver

Nominal impedance: 8

Ω

Voice coil size: 4"

Diaphragm size: 4"

Exit size: 1.5"

Power handling capability: 250 W (AES)

6

on REM

Three 2" compression drivers

Nominal impedance: 12

Voice coil size: 2"

Diaphragm size: 2"

Exit size: 0.75"

Power handling capability: 100 W (AES)

6

on REM

Differential, electronically balanced

Female XLR input with male XLR loop output or VEAMall-in-one

connector (integrates AC, audio and network)

10 k

Ω

differential between pins 2 and 3

Pin 1: Chassis/earth through 220 k

, 1000 pF, 15 V clamp network to

provide virtual ground lift at audiofrequencies

Pin 2: Signal +

Pin 3: Signal -

Case: Earth ground and chassis

None on input, DC blocked through signal processing

>50 dB, typically 80 dB (50 Hz–500 Hz)

Common mode: 425 kHz

Differential mode: 142 kHz

0 dBV (1 V rms, 1.4 V pk) continuous is typically the onset of limiting

for noise and music

Audio source must be capable of producing a minimum of +20 dBV

Ω

inorder to produce maximum peak

SPL over the operating bandwidth of the loudspeaker

Complementary power MOSFET output stages (class AB/H)

3935 W (four channels; three x 1125 W, one x 560 W)

9

<.02%

4

Ω

low, low-mid and very-high channels; 8

Ω

mid-high channel

Forced air cooling, four fans (two ultrahigh-speed reserve fans)

Automatic, two ranges, each with high-low voltage tap

95 V AC – 125 V AC, 208 V AC - 235 V AC; 50/60 Hz

85 V AC – 134 V AC; 165 V AC - 264 V AC

1.1 A rms (115 V AC);0.55 A rms (230 V AC);1.3 A rms (100 V AC)

11.2 A rms (115 V AC);5.6 A rms (230 V AC);12.9 A rms (100 V AC)

14.4 A rms (115 V AC);7.2 A rms (230 V AC);16.6 A rms (100 V AC)

32 A pk (115 V AC);16 A pk (230 V AC);37 A pk (100 V AC)

7 A (115 V AC and 110 V AC); 10 A (230 V AC)

Equipped for two conductor twisted-pair network, reporting amplifier

operating parameters to system operator’s host computer.

Notes

European Office:

Meyer Sound Lab. GmbH

Carl Zeiss Strasse 13

56751 Polch, Germany

Made by Meyer Sound Laboratories

Berkeley,California USA

architect specifications

The loudspeaker shall be a self-powered, full-range unit for

deployment in line array systems. The low/low-mid frequency

transducers shall consist of two 12-inch cone drivers, each

rated to handle 1200 watts AES*. The mid-high frequency

transducer shall be one 4-inch diaphragm (1.5-inch exit) com-

pression driver, rated to handle 250 watts AES, coupled via a

custom manifold to a 60° horizontal constant directivity horn.

The very-high frequency transducers shall consist of three

2-inch diaphragm (0.75-inch exit) compression drivers, each

rated to handle 100 watts AES, coupled via a patented custom

manifold to a 60° horizontal constant directivity horn.

The loudspeaker shall incorporate internal processing electron-

ics and a four-channel amplifier. Processing functions shall

include equalization, phase correction, driver protection and

signal division for the three frequency sections. The crossover

points shall be 560 Hz and 4.2 kHz. An additional low-fre-

quency crossover shall cause the two low/low-mid frequency

transducers to work in combination between 60 Hz and 300 Hz,

with only one working between 300 Hz and 560 Hz, to maintain

optimal polar response characteristics.

Each amplifier channel shall be class AB/H with complementary

MOSFET output stages. Burst capability shall be 3935 watts total

(three channels 1125 watts, one channel 560 watts) with a

nominal 4-ohm load for low, low-mid and very-high frequency

channels and an 8-ohm load for the mid-high frequency chan-

nel. Distortion (THD, IM, TIM) shall not exceed 0.02%. Protection

circuits shall include TruPower limiting. The audio input shall be

electronically balanced with a 10 kOhm impedance and accept

a nominal 0 dBV (1 V rms, 1.4 V pk) signal (+20 dBV to produce

maximum SPL). Connectors shall be XLR (A-3) type male and

female. RF filtering shall be provided. CMRR shall be greater

than 50 dB (typically 80 dB 50 Hz – 500 Hz).

Performance specifications for a typical production unit shall be

as follows, measured at 1/3 octave resolution: Operating fre-

quency range shall be 60 Hz to 18 kHz. Phase response shall be

at 1 meter. Beamwidth shall be 60° horizontal. Vertical cover-

age in multi-cabinet arrays shall be dependent on system con-

figuration. The internal power supply shall perform automatic

voltage selection, EMI filtering, soft current turn-on and surge

suppression. Powering requirements shall be nominal 100, 110

or 230 V AC line current at 50 Hz or 60 Hz. UL and CE operating

voltage range shall be 100 to 240 V AC. Maximum peak current

draw during burst shall be 14.4 A at 115 V AC and 7.2 A at 230

V AC. Current inrush during soft turn-on shall not exceed 7 A

at 115 V AC. AC power connectors shall be locking NEMA con-

nector, IEC male or VEAM all-in-one. The loudspeaker system

shall incorporate the electronics module for Meyer Sound’s RMS

remote monitoring system.

All loudspeaker components shall be mounted in an enclosure

constructed of multi-ply hardwood with a hard black textured

finish. The front protective grille shall be powder-coated, hex-

stamped steel. Dimensions shall be 54.00" wide x 14.47" high

(cabinet front) x 22.00" deep (1372 mm x 368 mm x 559 mm).

Weight shall be 235 lbs (106.60 kg).

The loudspeaker shall be the Meyer Sound MILO 60.

*Loudspeaker driven with a band-limited noise signal with 6 dB

peak-to-average ratio for a period of two hours.

Acoustical

Coverage

Crossover

Crossover

5

Transducer s

Transducer s

Audio I nput

Amplifier

AC Power

RMS Net work

RMS Net work

Frequency Response

Phase Response

Maximum Peak SPL

Dynamic Range

Horizontal Coverage

2

3

4

Low/Low-Mid Frequency

Mid-High Frequency

Very-High Frequency

Maximum Common Mode Range

Input Impedance

Nominal Input Sensitivity

Type

Connectors

Wiring

DC Blocking

CMRR

RF Filter

TIM Filter

Input Level

7

8

Type

Output Power

THD, IM, TIM

Load Capacity

Cooling

Automatic Voltage Selection

Safety Agency Rated Operating Range

Turn-on and Turn-off Points

Max Long-Term Continuous Current (>10 sec)

Ultimate Short-Term Peak Current Draw

Burst Current (<1 sec)

Connector

Current Draw:

Idle Current

Inrush Current

10

Loading...

Loading...