Page 1

DATA S H E ET

MICA : Compact High-Power Curvilinear Array

Loudspeaker

M S E R IES

MICA™ is a self-powered, three-way loudspeaker designed for vertical curvilinear

arraying. A member of the MILO® family of

high-power curvilinear array loudspeakers,

the MICA loudspeaker is ideal for applications

that do not require quite as much power and

throw distance as MILO and where weight and

size is a concern. The MICA compact highpower curvilinear array loudspeaker is equally

applicable in a wide variety of applications

such as touring, rental and fixed installations.

MICA provides an excellent complement to a

MILO main system for tours that are playing

a variety of venues, being used as sidefills

for large arenas and sheds and as the main

system for smaller venues.

The loudspeaker provides very high acoustic

output, with a single MICA producing a peak

output of 138 dB SPL at one meter. High

output combines with exceptionally flat phase

and frequency response over a wide operating

range of 60 Hz to 18 kHz. MICA’s frequency

response, with its extended high-frequency

characteristics, is quite compatible with MILO

in applications where both loudspeaker types

are used.

The MICA low/low-mid section features two

high-power, neodymium magnet 10-inch

cone drivers with 2-inch voice coils, especially

designed for the power capability of the

system. Both drivers are housed in separate

vented enclosures within the loudspeaker,

located on the left and right sides. The two

high-power 10-inch drivers work in tandem

at lower frequencies to take advantage of

their combined acoustic output, while one

of the drivers rolls off before the crossover

frequency to maintain optimal polar and

frequency response.

The high-frequency section — at the center

between the two cone drivers — consists of

two neodymium magnet compression drivers

with 3-inch diaphragms and 1.2-inch exits.

These newly designed drivers are seamlessly

combined through a custom, patented Meyer

Sound REM™ ribbon emulation manifold,

coupled to a 100-degree horizontal constantdirectivity horn. This horn’s controlled, very

narrow vertical dispersion is ideally suited

for use in curvilinear arrays, allowing minimal

destructive interaction in the high frequencies

between adjacent enclosures. Compared to

other methods, REM produces a smoothly

controlled wavefront with less distortion

and with the far higher output generated by

compression drivers.

All four MICA transducers are designed and

manufactured in-house, and are driven by

an integral, four-channel class AB/H amplifier that provides 3020 watts of total output power (6000 watts peak). The integrated amplifier/processing circuitry includes

TruPower® limiting to protect the drivers

and hold long-term power compression to

less than 1 dB. The field-replaceable electronics module incorporates Meyer Sound’s

Intelligent AC™ power supply, which automatically adjusts for any line voltage world-

wide and provides both soft turn-on and

transient protection. The MICA loudspeaker

comes with the RMS™ remote monitoring

system interface installed. RMS offers comprehensive monitoring of system parameters

on a Windows®-based network.

MICA systems may be deployed in either

flown or ground-stacked configurations.

Newly designed QuickFly® rigging hardware

uses captive GuideALinks™ contained within

recessed guides in the front and rear corners

of the cabinet. A slot and convenient pinned

handle allow the link to be moved and pinned

for arraying or storage. The rear link permits

10 splay angles between 0 and 6 degrees (in

0.5-degree increments from 0 to 3 degrees,

and in 1-degree increments from 3 to 6

degrees); the two-position front link may be

set to add 7 degrees, adjusting coverage to

miss balcony fronts and other architectural

obstacles. The rigid connections allow easy

adjustment of array tilt, and often eliminate

the need for a pullback strap in flown configurations. A single flown array can include up to

22 MICA loudspeakers with a 7:1 safety factor,

and 25 loudspeakers with a 5:1 safety factor.*

Options for MICA include a weather-protected

version with a rain hood to safeguard the

electronics, and custom color finishes. Top

and transition grids, a caster frame for

transporting stacks of multiple units, and

protective covers are available.

*Restrictions apply; see the MG-MICA Assembly Guide for more

information.

Very high power-to-size ratio

Exceptional fidelity and transient

response for intelligibility and highimpact

Seamless integration with MILO

Wide and even horizontal coverage

pattern across the full bandwidth

QuickFly rigging system with new

captive GuideALinks simplifies use in

flown or ground-stacked arrays

applicationsfeatures & benefits

Performing arts centers, theatres,

churches, and other fixed installations

Touring sound reinforcement for midsized venues

Sidefill hangs with MILO in very large

venues

Page 2

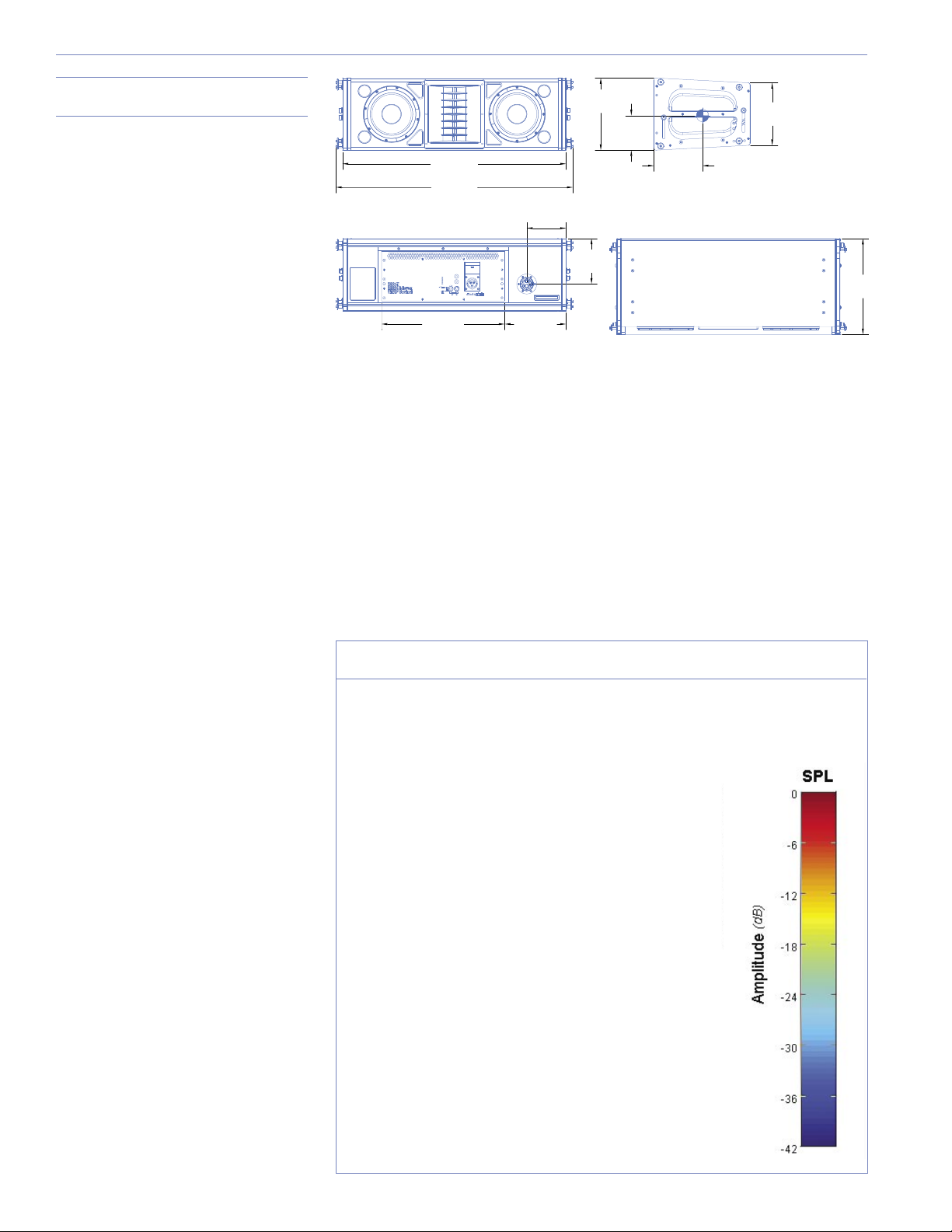

Architect Specifications

41.40

[1052mm]

43.88

[1115mm]

13.37

[340mm]

11.58

[294mm]

9.00

[229mm]

6.40

[163mm]

7.30

[185mm]

8.44

[214mm]

11.38

[289mm]

22.80

[579mm]

17.78

[452mm]

1

Cas

e

220

K

ES

D

10

K

Balanced

Loo

pInput

Auto-Voltage Select

95-125V~ 208-235V

~

50-60Hz 50-60H

z

2000W

RMS MAX 2000W RMS MAX

Operational

Voltage Range:

Turn

on 85V~ Turn off 134V~

Turn

on 165V~ Turn off 264V~

y

t

i

v

i

t

c

A

t

e

s

e

R

k

n

i

W

e

c

i

v

r

e

S

Network

Remote

Monitor System

THIS PRODUCT MUST BE GROUNDED

WARNINGS:

TruPower™

MICA

High Ch Limit

Low

Ch Limit

Activ

e

Ω

3 -

2 +

Earth/Chassi

s

Ω

P

U

S

H

R

E

-

C

I

R

K

-

I

T

ATENCIÓN:

ACCESO INTERNO SOLO

AUTORIZADO

A PERSONAL TÉCNICO CALIFICADO

ACHTUNG:

GEHÄUSE NICHT ÖFFNEN WARTUNG

UND

REPARATUR NUR DURCH ELEKTROFACHKRÄFTE

ATTENTION:

ENTRETIEN ET REPARATIONS

INTERNES NE SONT AUTORISEES QU'AU

PERSONNEL

TECHNIQUE QUALIFIÉ

UK WARNING:

THIS APPARATUS MUST BE EARTHED.

NO

OPERATOR SERVICEABLE PARTS INSIDE.

REFER SERVICING TO QUALIFIED PERSONNEL:

This surface may reach high temperatures while in use.

To

ensure proper operation, allow at least 6 inches

clearance

from this surface and adequate ventilation.

No

operator serviceable parts inside.

Refer

servicing to qualified personnel.

To reduce the risk of fire or electric shock

do

not expose this appliance to rain or moisture.

Meyer Sound, Berkeley, CA, USA

P

U

S

H

R

E

-

C

I

R

K

-

I

T

2 2

3

1 1

The loudspeaker shall be a self-powered, full-range

unit for deployment in line array systems. The low/

low-mid frequency transducers shall consist of two

10-inch cone drivers, rated to handle 1200 watts AES*

(1800 watts peak). The high-frequency transducers

shall consist of two 3-inch diaphragm, 1.2-inch exit

compression drivers, rated to handle 360 watts AES*

(720 watts peak) coupled via a custom manifold to a

100-degree horizontal constant-directivity horn.

The loudspeaker shall incorporate internal processing

and a four-channel amplifier. Processing functions

shall include equalization, phase correction, driver

protection and signal division for the two frequency

sections. The crossover point shall be 1000 Hz. An

additional low-frequency crossover shall cause the

two low/low-mid frequency transducers to work in

combination between 60 Hz and 320 Hz, with only one

working up to the crossover frequency to maintain

optimal polar characteristics.

Each amplifier channel shall be class AB/H with complementary MOSFET output stages. Burst capability

shall be 3020 watts total (6000 watts peak) with two

channels at 950 watts into a nominal 4-ohm load for

the low and low-mid drivers and two channels at

560 watts into a nominal 8-ohm load for the highfrequency drivers. Distortion (THD, IM, TIM) shall

not exceed 0.02%. Protection circuits shall include

TruPower limiting. The audio input shall be electronically balanced with a 10 kOhm impedance and accept

a nominal 0 dBV (1 V rms, 1.4 V pk) signal (+20 dBV to

produce maximum SPL). Connectors shall be XLR (A-3)

type male and female. RF filtering shall be provided.

CMRR shall be greater than 50 dB (typically 80 dB, 50

Hz – 500 Hz).

Performance specifications for a typical production

unit shall be as follows, measured at 1/3-octave

resolution: Operating frequency range shall be 60 Hz

to 18 kHz. Phase response shall be ±30° from 1 kHz to

16 kHz. Maximum peak SPL shall be 138 dB at 1 meter.

Beamwidth shall be 100 degrees horizontal. Vertical

coverage in multi-cabinet arrays shall be dependent

on system configuration.

The internal power supply shall perform automatic

voltage selection, EMI filtering, soft current turn-on

and surge suppression. Powering requirements shall

be nominal 100, 110, or 230 V AC line current at 50 Hz

or 60 Hz. UL and CE operating voltage range shall be

100 to 230 V AC. Maximum peak current draw during

burst shall be 8.7 A at 115 V AC and 4.3 A at 230 V AC.

Current inrush during soft turn-on shall not exceed

11 A at 115 V AC. AC power connectors shall be locking NEMA L6-20, IEC 309 male, PowerCon or VEAM

all-in-one.

The loudspeaker system shall incorporate the electronics module for Meyer Sound’s RMS remote monitoring system.

All loudspeaker components shall be mounted in an

enclosure constructed of premium birch plywood with

a hard and damage-resistant black textured finish.

The front protective grille shall be powder-coated,

hex-stamped steel. To build flown or ground-stacked

loudspeaker arrays, linking to the grid and between

cabinets shall be accomplished with QuickFly rigging

hardware using captive GuideALinks allowing 10 rear

splay angles between 0 and 6 degrees, with a twoposition front link settable at 0 or 7 degrees.

Dimensions shall be 41.40" wide by 13.37" high (cabinet

front) by 17.78" deep (1052 mm x 340 mm x 452 mm).

Weight shall be 150 lbs (68.04 kg).

The loudspeaker shall be the Meyer Sound MICA.

*Both transducers driven continuously for two hours with bandlimited noise signal having a 6 dB peak-average ratio.

Dimensions

41.40" w x 13.37" h x 17.78" d

(1052 mm x 340 mm x 452 mm)

Weight

150 lbs (68.04 kg)

Enclosure

Protective Grille

Rigging

Premium birch plywood

Finish

Black textured

Powder-coated hex-stamped steel

MRF-MICA rigging frame, with captive

GuideALink connectors and quick-

release pins

About the Vertical Directivity Plots

The color images accompanying the upper diagram on the facing page are sound

intensity plots made using the Meyer Sound MAPP Online® acoustical prediction

program, a unique and highly accurate visualization tool for professional sound

system designers.

Using an Internet-connected personal computer, the designer

specifies Meyer Sound loudspeaker models, their locations,

how they are aimed and, optionally, the locations and

composition of walls. This information travels over the Internet

to a powerful server computer at Meyer Sound headquarters

in Berkeley, California. Running a sophisticated algorithm

and using highly accurate measured data that describe each

loudspeaker’s directional characteristics, the server predicts

the sound field that the loudspeakers will produce, forms

a color representation, and sends the result back for the

designer’s computer to display.

In these sound field plots, the color spectrum is used to represent

levels of sound intensity, with red being the loudest and blue

being the softest, as shown in the scale to the immediate right.

These examples illustrate coverage characteristics for an array

whose splay angles have been tailored to the actual venue; a

section view of the venue has been superimposed on the MAPP

Online plots.

Page 3

MICA Vertical Splay and Coverage

DigitalDelay

2 In x 6 Out

Digital Delay/EQ

LD-3

Channel A

IN SUB OUT

CH 1 OUT

CH 2 OUT

CH 3 OUT

Channel B

IN SUB OUT

CH 1 OUT

CH 2 OUT

CH 3 OUT

Channel A

INSERTS SENDS

IN SUB OUT

Full Range

IN CH 1 OUT

Post Array

IN CH 2 OUT

Post Array

IN CH 3

Post HPF

Channel B

INSERTS SENDS

IN SUB OUT

Full Range

IN CH 1 OUT

Post Array

IN CH 2 OUT

Post Array

IN CH 3

Post HPF

Main

Left

Main

Right

Optional

Subwoofer

Mono

(6) 700-HP (6) 700-HP

(12) MICA (12) MICA

These illustrations show how the splay between adjacent cabinets in a MICA

array may be adjusted to tailor coverage for a specific venue. The MAPP

Online plots on the right illustrate the vertical directivity characteristics of the

array on the left, with a section view of an example venue superimposed.

125 Hz

250 Hz

500 Hz

1 kHz

2 kHz

4 kHz

8 kHz

Signal Flow for a Typical Reinforcement System

MICA loudspeakers permit versatile arrays and are compatible with other Meyer Sound reinforcement loudspeakers, giving sound designers

maximum freedom to customize systems for their needs. This block diagram illustrates the signal flow for a typical sound reinforcement

system using 12 MICA cabinets per side for the main arrays.

Page 4

MICA Specifications

European Office:

Meyer Sound Lab. GmbH

Carl Zeiss Strasse 13

56751 Polch, Germany

Made by Meyer Sound Laboratories

Berkeley,California USA

Acoustical

Operating Frequency Range

Free Field Frequency Response

Coverage

Crossover

4

Transducer s

Low/Low-Mid Frequency

Audio I nput

Maximum Common Mode Range

Nominal Input Sensitivity

Amplifier

AC Power

Automatic Voltage Selection

Safety Agency Rated Operating Range

Turn-on and Turn-off Points

Max Long-Term Continuous Current (>10 sec)

Burst Current (<1 sec)

Ultimate Short-Term Peak Current Draw

RMS Net work

Phase Response

Maximum Peak SPL

Dynamic Range

Horizontal Coverage

Vertical Coverage

High Frequency

Type

Connectors

Input Impedance

Wiring

DC Blocking

CMRR

RF Filter

TIM Filter

Input Level

Type

Output Power

Total Output

THD, IM, TIM

Load Capacity

Cooling

Connector

Current Draw:

Idle Current

Inrush Current

1

60 Hz - 18 kHz

2

75 Hz - 17 kHz ±4 dB

1 kHz - 16 kHz ±30°

3

138 dB

>110 dB

100°

Varies, depending on array length and configuration

1000 Hz

Two high-power 10" cone drivers with neodymium magnets

Nominal impedance: 4 Ω

Voice coil size: 2"

Power handling capability: 1200 W (AES)5; 1800 W peak

7

Two 3" compression drivers

Nominal impedance: 8 Ω

Voice coil size: 3"

Diaphragm size: 3"

Exit size: 1.2"

Power handling capability: 360 W (AES)5; 720 W peak

Differential, electronically balanced

±15 V DC, clamped to earth for voltage transient protection

Female XLR input with male XLR loop output or VEAMall-in-one

connector (integrates AC, audio and network)

10 kΩ differential between pins 2 and 3

Pin 1: Chassis/earth through 220 kΩ, 1000 pF, 15 V clamp network

to provide virtual ground lift at audiofrequencies

Pin 2: Signal +

Pin 3: Signal -

Case: Earth ground and chassis

None on output, DC blocked through signal processing

>50 dB, typically 80 dB (50 Hz–500 Hz)

Common mode: 425 kHz

Differential mode: 142 kHz

Integral to signal processing (<80 kHz)

0 dBV (1 V rms, 1.4 V pk) continuous is typically the onset of

limiting for noise and music

Audio source must be capable of producing a minimum of +20 dBV

(10 V rms, 14 V pk) into 600 Ω inorder to produce maximum peak

SPL over the operating bandwidth of the loudspeaker

Four-channel complementary MOSFET output stages (class AB/H)

8

3020 W (four channels; 2 x 950 W, 2 x 560 W)

9

6000 W peak

<.02%

4 Ω low and mid channels; 8 Ω high channels

Forced air cooling, four fans (two ultrahigh-speed reserve fans)

250 V AC NEMA L6-20 twistlock, IEC-309 male, PowerCon, or VEAM

Automatic, two ranges, each with high-low voltage tap

(uninterrupted)

95 V AC - 125 V AC; 208 V AC - 235 V AC, 50/60 Hz

85 V AC - 134 V AC; 165 V AC - 264 V AC

1.1 A rms (115 V AC); 0.55 A rms (230 V AC); 1.3 A rms (100 V AC)

5.4 A rms (115 V AC); 2.7 A rms (230 V AC); 6.2 A rms (100 V AC)

10

8.7 A rms (115 V AC), 4.3 A rms (230 V AC), 10.0 A rms (100 V AC)

24.6 A rms (115 V AC), 12.3 A rms (230 V AC), 28.3 A rms (100 V AC)

11 A rms (115 and 100 V AC), 15 A rms (230 V AC)

Equipped with two-conductor twisted-pair network, reporting

all operating parameters of amplifiers to system operator’s host

computer

Notes:

1. Recommended maximum operating

frequency range. Response depends

on loading conditions and room

acoustics.

2. Free field, measured with 1/3-octave

frequency resolution at 4 meters.

3. Measured with music referred to 1

meter.

4. At these frequencies, the transducers

produce equal sound pressure levels.

5. Power handling is measured under

AES standard conditions: both

transducers driven continuously for

two hours with band-limited noise

signal having a 6 dB peak-average

ratio.

6. Peak power handling is measured

with both transducers driven for 100

milliseconds with pink noise signal

having a 12 dB peak-average ratio.

6

6

7. The two drivers are coupled to a

100-degree horizontal constantdirectivity horn through a proprietary acoustical combining manifold

(REM).

8. Amplifier wattage rating based on

the maximum unclipped burst sinewave rms voltage that the amplifier

will produce for at least 0.5 seconds

into the nominal load impedance: 62

V rms low channels and 67 V rms high

channels.

9. Peak power based on the maximum

unclipped peak voltage that the

amplifier will produce for at least

100 milliseconds into the nominal

load impedance: 87 V pk low channels

and 95 V pk high channels.

10. AC power cabling must be of sufficient gauge so that under burst

current rms conditions, cable transmission losses do not drop voltage

below specified operating range at

the speaker.

MICA — 04.147.004.01 A

Copyright © 2005

Meyer Sound Laboratories Inc.

meyer sound laboratories inc.

2832 San Pablo Avenue

Berkeley, CA 94702

T: +1 510 486.1166

F: +1 510 486.8356

techsupport@meyersound.com

www.meyersound.com

Loading...

Loading...