Meyer Sound LYON-M-RMS-RIG, LYON-WXT-RMS-RIG-WP, LYON-WXT-RMS-RIG, LYON-W-RMS-RIG-WP, LYON-W-RMS-RIG Quick Start Guide

...Page 1

OPERATING INSTRUCTIONS

Pull Back Rigging

Keep these important operating instructions. Check www.meyersound.com for updates.

Page 2

2018

©

Meyer Sound. All rights reserved.

Pull Back Rigging Operating Instructions, PN 05.083.008.01 Rev A

The contents of this manual are furnished for informational purposes only, are subject to change without notice, and should not be construed as a commitment by Meyer Sound Laboratories Inc. Meyer Sound assumes no responsibility or liability for any errors or inaccuracies that may appear in this manual. Except as permitted by applicable copyright law, no part of this publication may be reproduced,

stored in a retrieval system, or transmitted, in any form or by any means, electronic, mechanical, recording or otherwise, without prior

writ-ten permission from Meyer Sound.

Compass RMS, GuideALink, Intelligent AC, LEO-M, LYON, LINA, MAPP, QuietCool, RMS, RMServer, and all alpha-numeric designations

for Meyer Sound products and accessories are trademarks of Meyer Sound. Callisto, Galileo, LEO, Meyer Sound, the Meyer Sound wave

logo, MICA, QuickFly, REM, SIM, and TruPower are registered trademarks of Meyer Sound Laboratories Inc. (Reg. U.S. Pat. & Tm. Off.). All

third-party trademarks mentioned herein are the property of their respective trademark holders.

ii

Page 3

CHAPTER 1: INTRODUCTION

!

HOW TO USE THIS ASSEMBLY GUIDE

Make sure to read this assembly guide in its entirety before

configuring a loudspeaker system using pull-back.

In particular, pay close attention to material related to safety

issues. As you read this assembly guide, you will encounter

the following icons for notes, tips, and cautions:

As you read these instructions, you will encounter the following icons for notes, tips, and cautions:

NOTE: A note identifies an important or useful

piece of information relating to the topic under

discussion.

TIP: A tip offers a helpful tip relevant to the topic

at hand.

CAUTION: A caution gives notice that an

action may have serious consequences and

could cause harm to equipment or personnel, or

could cause delays or other problems.

Information and specifications are subject to change.

Updates and supplementary information are available at

www.meyersound.com

.

FACTOR OF SAFETY DISCLAIMER

Important: Read Carefully

Rated load capacities of the Meyer Sound rigging assembly

for different splay angle settings are based on testing performed by an independent testing agency, and on 5 to 1

safety limit analysis to ultimate load performed by an independent structural engineering firm. The ratings apply to the

Meyer Sound rigging only. You are responsible for the safety

factor required by local law for your installation, and for

determining the adequacy of supporting structure "above

the hook." PERMANENT INSTALLATIONS MUST BE CERTIFIED BY THE ENGINEER OF RECORD FOR WIND AND

SEISMIC LOADING.

MAPP assumes the top grid is picked up by a front and rear

motor along the perimeter of the grid, either directly to the

middle pickup points or bridled at 45 degrees or greater to

the grid's outermost pickup points. Other rigging configurations may have reduced load capacity. These cases should

be reviewed by proper personnel to verify load capacities for

alternate configurations.

Bridle angles are measured between the bridle cable and

top grid plane.

Meyer Sound Technical Support is available at:

■ Tel: +1 510 486.1166

■ Tel: +1 510 486.0657 (after hours support)

■ Web: www.meyersound.com/support

■ Email: techsupport@meyersound.com

Center Bar Pickup Points

MAPP Factor of Safety calculations are made for peripheral

top grid points -- either corner or middle -- depending on

the top grid configuration. Using the center bar pickup

points will result in reduced load capacity. These cases

should be reviewed by proper personnel to validate the configuration.

Pull-Back Load Status

MAPP Load Status -- when using Pull-Back -- additionally

takes into account the Pull-Back Load Status as an additional pass/fail criteria to determine the overall Load Status

condition. The Vertical Pull-Back Load Status is the pass/fail

criteria. The -10º/+10º status indicators provide the user of

the tolerance that exists to each side of the vertical. For all

purposes Pull-Back should be as close to vertical as possible as loads will vary. Deviations from a vertical Pull-Back

should be reviewed by proper personnel to verify load

capacities for alternate configurations.

3

Page 4

CHAPTER 1: INTRODUCTION

Rig Point Spacing

When using Pull-Back, Rig Point Spacing values are calculated with reference to the front of grid position, which is the

Reference Point Position value for the array at its final resting configuration.

LIMITATIONS AND DISCLAIMER

The safety limit analysis provided by this program does not

apply, and may not be relied upon, if your loudspeaker system (1) has been improperly installed or maintained, (2) the

rigging or loudspeakers of your system have been damaged

prior to installation, (3) your indicated configuration of the

system has been altered, (4) any weight has been added to

your indicated configuration, or (5) your system is in an outdoor venue and remains installed during strong wind conditions. MEYER SOUND ASSUMES NO RESPONSIBILITY

FOR ANY PART OF AN INSTALLATION "ABOVE THE

HOOK" OR WHERE ANY OF THE FOREGOING LIMITATIONS APPLY.

4

Page 5

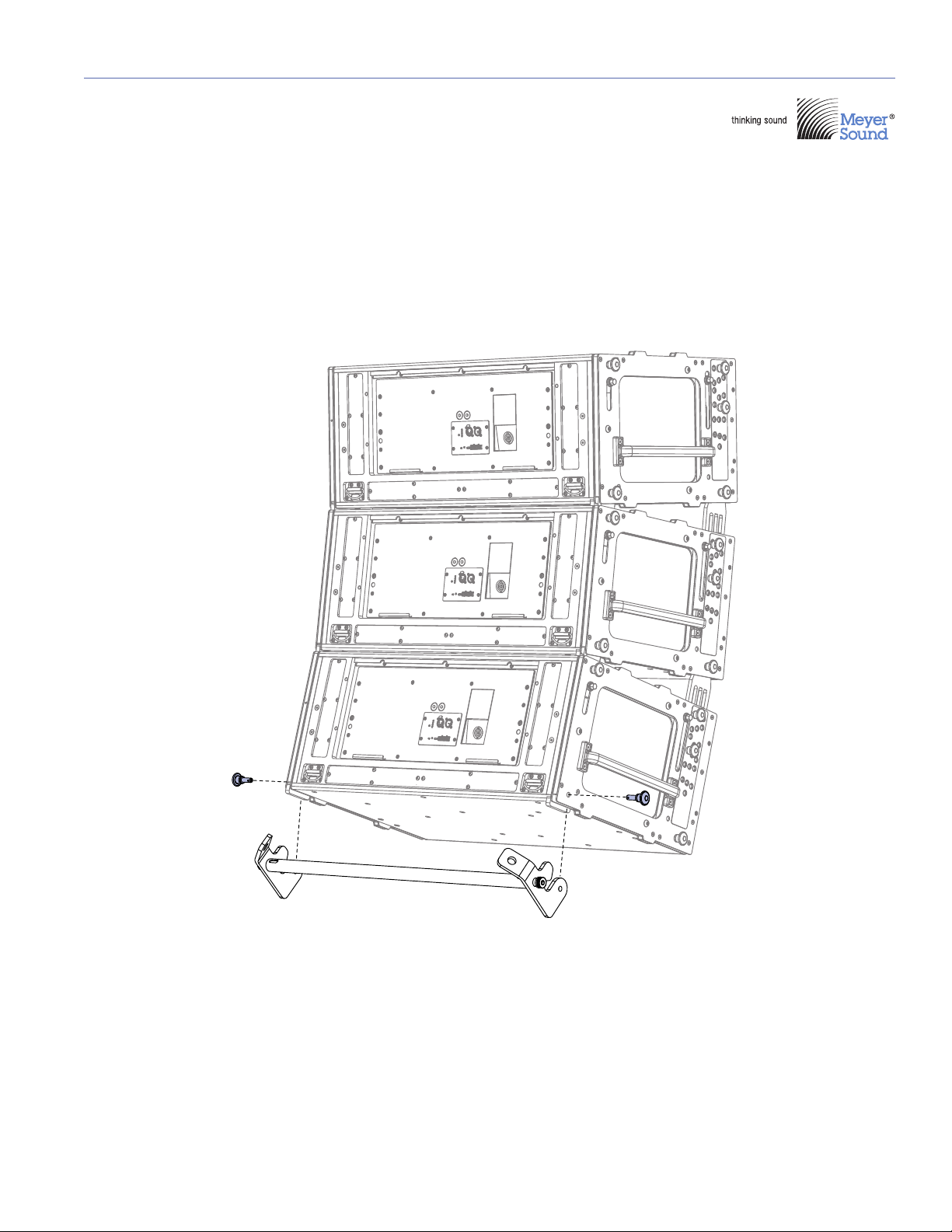

CHAPTER 2: PULL BACK RIGGING INSTRUCTIONS

Executing a pull back requires balancing the loads of suspended arrays. By altering the momentary load on each motor to

achieve a new stable configuration, this dynamically shifts the array’s center of gravity. These procedures ensure a safe tran-

sition from top grid suspension to full pull back.

NOMENCLATURE

The following figures define the rigging points used in these instructions.

Top Front and Rear of Array Center Rigging Points (left); Top Front and Rear of Array Bridled Rigging Points (right)

Rear View of Bridled Pull-Back Points

3

Page 6

PULL BACK RIGGING OPERATING INSTRUCTIONS

TOP GRID TO PULL BACK RIGGING ARRANGEMENT

Assemble the Array

Before you can achieve a pull back rigging configuration, the full array must first be set up as a regular top grid rigging system.

1. Maneuver the top grid motors to assemble the full array with the intended splay angles.

2. Fasten any locking pins in place when appropriate.

NOTE: Refer to each product’s rigging manual/operating instructions for specific rigging instructions and pro-

cedures.

Get the System Off the Ground

When the array is fully assembled including the pull back bar:

3. Raise the array slightly above the ground.

4. Inspect all links, pins, and rigging accessories.

5. Raise the array to trim height (resting height of array).

During the transition, only the top rear of array rigging points will remain at a constant height. It is therefore essential to

measure and set the trim height for these reference points.

TRANSITIONING

Transitioning can be divided into movement and load procedures. The symbols used are shown below.

Symbols used for movement and load procedures

4

Page 7

Movement

Step 1 Step 2 Step 3 Step 4 Step 5

Movement to transition from top grid to pull back

To transition from top grid to pull back:

PULL BACK RIGGING OPERATING INSTRUCTIONS

1. Use the top grid motors to raise the array to trim height.

2. Slack the front motor until achieving the maximum natural downward tilt.

Make sure there is enough slack in the top front of array motor(s) to allow the added rotation introduced by the pull back.

3. Pick up the slack of the pull back motor until it is under tension.

4. Without exceeding the rated pull back load, take the pull back motor up to the desired downward tilt angle.

NOTE: Make sure the downward tilt angle does not exceed the simulated configuration in MAPP XT. This may

result in an unstable array or exceed the maximum rated pull back load.

5. Pick up the slack of the top front of array motor points.

Do not use the top front of array motors to pick up the top grid, change the trim height, or change the angle as that will

alter the MAPP XT calculated loads.

NOTE: Removing the slack is only to ensure that any failure of the top rear of array motor will result in the load

being picked up by the top front of array motor points.

5

Page 8

PULL BACK RIGGING OPERATING INSTRUCTIONS

Step 1 Step 2 Step 3 Step 4 Step 5

Load

Load transition

1. Engage both top grid motors to take the complete load of the array.

2. When at trim height (top rear of array motor point reference), the load is fully transitioned to the top rear of array motor

point(s).

3. Total array load is distributed between the top rear of array motor point(s) and the pull back rigging point.

4. The pull back rigging motor point load increases until it reaches the desired array downward tilt angle.

5. The top front of array motor point(s) should be tensioned with minimal load to avoid rattling and provide an extra safety

rigging point.

NOTE: Changing the top of array pickup point from the rear to the front increases the pull back rigging motor point

load and reduces array stability.

6

Page 9

TRANSITIONING FROM PULL BACK TO TOP GRID RIGGING

Step 1 Step 2 Step 3 Step 4 Step 5

!

!

Movement

Pull back to top grid rigging

PULL BACK RIGGING OPERATING INSTRUCTIONS

To transition from a pull back to standard top grid rigging configuration:

1. The is array is resting at the pull back position.

2. From the pull back position, slack the pull back motor until the array is hanging only from the top rear of array motor points.

Make sure there is enough slack in the pull back motor so this motor will never be under tension.

3. Pick up the slack of the top front of array motor points until the weight is distributed by all top grid motor points.

4. Lower all top grid and pull back motors at the same time.

Make sure there is enough slack in the pull back motor so it will never be under tension.

If necessary stop the downward motion on all motors and increase the slack of the pull back motor.

5. When the array is close to the ground, disconnect the pull back and disassemble the array.

CAUTION: To minimize potentially dangerous situations and prevent accidents, you must maintain all rigging

gear and follow all safety procedures and local regulations. Replace worn or damaged parts and accessories

immediately.

CAUTION: Factor of Safety Intermediate Data calculations provided by the MAPP XT program for Meyer Sound

rigging configurations depend on the proper installation, maintenance, and use of the rigging. Read all rigging

instructions provided by Meyer Sound. Failure to follow these Operating Instructions, or failure to inspect, maintain, and

repair all rigging parts and accessories will void Factor of Safety calculations.

NOTE: Local rigging regulations may require dead hanging all loads or providing safety links that bypass all

motors. A dead hang uses a steel wire or chain to remove all load from the motor unit used to take the load to

its dead hung position.

7

Page 10

Meyer Sound Laboratories Inc.

2832 San Pablo Avenue

Berkeley, CA 94702

+1 510 486.1166

www.meyersound.com

© 2018

Meyer Sound. All rights reserved.

Pull Back RiggingOperating Instructions

PN 05.083.008.01 RevA

Loading...

Loading...