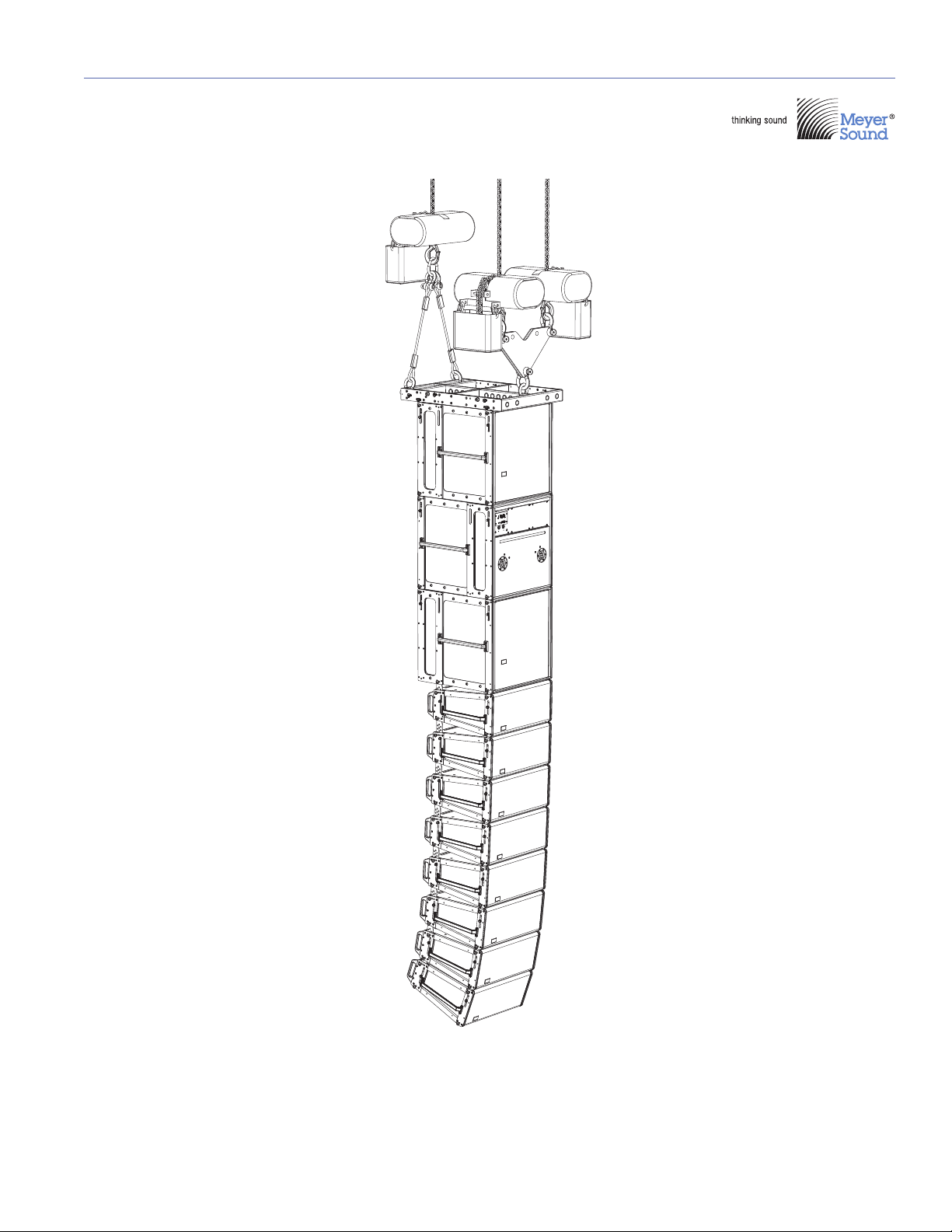

Page 1

ASSEMBLY GUIDE

MG-LEOPARD/900 Multipurpose Grid and Accessories

LINE ARRAY

Keep these important operating instructions.

Check www.meyersound.com for updates.

Page 2

© 2015

Meyer Sound. All rights reserved.

MG-LEOPARD/900 Multipurpose Grid and Accessories Assembly Guide, PN 05.243.080.01 A

The contents of this manual are furnished for informational purposes only, are subject to change without notice, and should not be construed as a commitment by Meyer Sound Laboratories Inc. Meyer Sound assumes no responsibility or liability for any errors or inaccuracies that may appear in this manual. Except as permitted by applicable copyright law, no part of this publication may be reproduced,

stored in a retrieval system, or transmitted, in any form or by any means, electronic, mechanical, recording or otherwise, without prior written permission from Meyer Sound.

Compass RMS, GuideALink, LEO-M, LEOPARD, LYON, MAPP, RMS, RMServer, and all alpha-numeric designations for Meyer Sound

products and accessories are trademarks of Meyer Sound. Callisto, Galileo, LEO, Meyer Sound, the Meyer Sound wave logo, MICA,

QuickFly, SIM, and Thinking Sound are registered trademarks of Meyer Sound Laboratories Inc. (Reg. U.S. Pat. & Tm. Off.). All third-party

trademarks mentioned herein are the property of their respective trademark holders.

ii

Page 3

CONTENTS

Chapter 1: Introduction 5

How to Use This Manual 5

Safety Statement for QuickFly Rigging 5

LEOPARD and 900-LFC Rigging Options 7

Chapter 2: 900-LFC Groundstacks and Cardioid Arrays 11

Groundstacking 900-LFC Loudspeakers (Without Grid) 11

900-LFC Cardioid Arrays 12

Chapter 3: MRK-900 Rigging Upgrade Kit 15

MRK-900 Rigging Upgrade Kit Contents 15

Installing the MRK-900 Rigging Upgrade Kit 16

Chapter 4: Loudspeaker GuideALinks 19

LEOPARD GuideALinks 19

900-LFC GuideALinks 23

Chapter 5: MG-LEOPARD/900 Multipurpose Grid 27

MG-LEOPARD/900 Grid Kit Contents 28

MG-LEOPARD/900 Grid Dimensions 29

MG-LEOPARD/900 Grid Load Ratings 30

Additional Requirements for MG-LEOPARD/900 Grid Load Ratings 32

Chapter 6: Flying Arrays 33

Grid Orientation for Flown Arrays 33

Attaching Flown Arrays to the MG-LEOPARD/900 34

MG-LEOPARD/900 Pickup Configurations 35

Using MAPP to Calculate Single Pickup Points 41

Chapter 7: MVP Motor Vee Plate 43

MVP Motor Vee Plate Kit Contents 44

MVP Motor Vee Plate Load Ratings 44

Chapter 8: MTF-LYON/LEOPARD Transition Frame 45

MTF-LYON/LEOPARD Transition Frame Kit Contents 46

MTF-LYON/LEOPARD Transition Frame Dimensions 46

Collapsing the MTF-LYON/LEOPARD Transition Frame 47

MTF-LYON/LEOPARD Transition Frame Load Ratings (Loudspeaker) 48

MTF-LYON/LEOPARD Transition Frame Load Ratings (Pull-Back) 49

Using the MTF-LYON/LEOPARD Transition Frame for Pull-Back and Pull-Up 49

Chapter 9: PBF-LEOPARD Pull-Back Frame 51

PBF-LEOPARD Kit Contents 52

PBF-LEOPARD Transition Frame Dimensions 52

PBF-LEOPARD Transition Frame Load Ratings 52

Verifying Pull-Back Requirements in MAPP 53

iii

Page 4

Chapter 10: Groundstacking with the MG-LEOPARD/900 Grid 55

Configuring GuideALinks for the MG-LEOPARD/900 Grid 57

Grid Orientation and Groundstacks 58

Adding Groundstack Tilt with the Angle Feet 59

Groundstacking LEOPARDs on the 900-LFC 60

Chapter 11: MCF-LEOPARD Caster Frame 65

MCF-LEOPARD Caster Frame Dimensions 67

MCF-LEOPARD Truck Packing Examples 68

Safety Guidelines for the MCF-LEOPARD Caster Frame 69

Chapter 12: MCF-900 Caster Frame 71

MCF-900 Caster Frame Dimensions 74

MCF-900 Truck Packing Examples 75

Reconfiguring the MCF-900 Caster Frame 76

Safety Guidelines for the MCF-900 Caster Frame 77

Appendix A: Assembling Arrays with the MG-LEOPARD/900 Grid 79

Appendix B: Laser Bracket 83

iv

Page 5

CHAPTER 1: INTRODUCTION

!

HOW TO USE THIS MANUAL

Make sure to read these instructions in their entirety before configuring a Meyer Sound loudspeaker system. In particular,

pay close attention to material related to safety issues.

As you read these instructions, you will encounter the following icons for notes, tips, and cautions:

NOTE: A note identifies an important or useful piece of information relating to the topic under discussion.

TIP: A tip offers a helpful tip relevant to the topic at hand.

CAUTION: A caution gives notice that an action may have serious consequences and could cause harm to

equipment or personnel, or could cause delays or other problems.

Information and specifications are subject to change. Updates and supplementary information are available at

www.meyersound.com

Meyer Sound Technical Support is available at:

■ Te l: +1 510 486.1166

■ Te l: +1 510 486.0657 (after hours support)

■ Web: www.meyersound.com/support

.

■ Email: techsupport@meyersound.com

SAFETY STATEMENT FOR QUICKFLY RIGGING

Please read this Statement carefully and in its entirety. It contains important information regarding safety issues, including

guidelines for general safe use of rigging systems as well as advisories on government regulations and liability laws.

This Statement assumes that the owners and/or users of a QuickFly

®

system are knowledgeable and experienced in the areas

of rigging and flying loudspeaker systems. Many issues of crucial concern, such as the determination of appropriateness and

condition of venue rigging points, cannot be addressed here. Therefore, the user must assume all responsibility for the appropriate use of QuickFly systems in any particular location or circumstance.

The suspension of large, heavy objects in public places is subject to numerous laws and regulations at the national/federal,

state/provincial, and local levels. The user must assume responsibility for making sure that use of any QuickFly system and

its components in any particular circumstance or venue conforms to all applicable laws and regulations in force at the time.

Load Ratings and Specifications

Long-term safe operation is a central concern in the design and manufacture of any rigging/flying system. Meyer Sound has

taken great care in material selection and component design. In all critical cases, load points are redundant, with a safety margin that allows one or more load points to fail while maintaining system integrity. After manufacture, all load-critical system

components are individually inspected.

All load ratings and other specifications given in this manual are the result of accepted engineering practice and careful testing. However, such specifications and ratings are subject to change. Users are advised to check the QuickFly section of the

Meyer Sound website at

www.meyersound.com

or contact Technical Support at regular intervals to check for updated or revised information.

5

Page 6

CHAPTER 1: INTRODUCTION

Regulatory Compliance

The design and safe working load (SWL) ratings of the QuickFly system are intended to be in compliance with all known regulatory statutes currently applicable in the United States. Unless otherwise specified, all working loads are based on a 7:1

safety factor. However, as noted above, there are wide variations internationally in the regulations and practices applying to

suspension of sound systems in public places. Although regulations in the United States are generally among the most

stringent, safety codes may be even stricter in a few localities (such as those highly prone to earthquakes). In addition, applicable safety codes are open to interpretation: Government officials in one location may have a stricter interpretation than

another local official, even when operating under the same regulations and in the same legal jurisdiction.

Consequently, users of QuickFly rigging systems should be prepared to take additional safety assurance measures beyond

those outlined in this Statement. IN ALL CASES, IT IS THE RESPONSIBILITY OF THE USER TO MAKE CERTAIN THAT ANY

MEYER SOUND LOUDSPEAKER SYSTEM IS SUSPENDED IN ACCORDANCE WITH ALL APPLICABLE NATIONAL/FEDERAL, STATE/PROVINCIAL, AND LOCAL REGULATIONS.

Safety Responsibilities “Above the Hook”

In most touring applications of rigging systems, the touring sound provider is normally responsible for ensuring the safety of

the suspension system only below the attachment point. The safety and suitability of the attachment point is generally seen

as the responsibility of the venue owner or operator. However, this distinction (“above the hook” versus “below the hook”)

can be open to interpretation. Touring system operators should double-check to make certain that attachment points are

approved and suitably load rated, and that the points used are those identified as such by the venue owner or operator. As

an extra precaution, careful inspection of the attachment points is advised before flying, particularly in older venues or those

hosting frequent events using large sound and lighting systems. IN ANY CASE, MEYER SOUND QUICKFLY SYSTEMS ARE

INTENDED ONLY FOR SUSPENSION FROM APPROVED RIGGING POINTS, EACH KNOWN TO HAVE AMPLE SWL MARGINS FOR THE SYSTEM COMPONENTS SUSPENDED BELOW THEM.

Inspection and Maintenance

The Meyer Sound QuickFly systems are an assembly of mechanical devices, and are therefore subject to wear and tear over

prolonged use, as well as damage from corrosive agents, extreme impact, or inappropriate use.

BECAUSE OF THE SAFETY ISSUES INVOLVED, USERS MUST ADOPT AND ADHERE TO A SCHEDULE OF REGULAR

INSPECTION AND MAINTENANCE. IN TOURING APPLICATIONS, KEY COMPONENTS MUST BE INSPECTED BEFORE

EACH USE. Such inspection includes examination of all load-bearing components for any sign of undue wear, twisting, buckling, cracking, rusting, or other corrosion. In regard to rust and corrosion, the main components of a QuickFly system are either

protected by an exterior coating or made from stainless steel, which is impervious to rust and resistant to most corrosive fluids. Nevertheless, normal use and shipping vibrations can wear through the protective coatings, and extremely corrosive fluids

(such as battery acid) can cause severe damage with prolonged exposure even to protected parts. Particular attention should

be given to screws, bolts, and other fasteners to make certain the fittings are tight and secure. Metal seams and welds should

be examined for any sign of separation or deformation. Meyer Sound strongly recommends that written documentation be

maintained on each QuickFly system, noting date of inspection, name of inspector, points of system checked, and any anomalies discovered.

Annual Comprehensive Examination and Test Program

In addition to routine checks on the road for touring systems, Meyer Sound also recommends a careful, comprehensive system examination and testing “at home” in the warehouse or other appropriate location at regular intervals. Such at home

examinations and tests should occur at least once a year, and should include a careful inspection of each component under

ideal lighting conditions, and then a final comprehensive check of the entire system after it has been flown.

If any anomalies or defects are discovered that could possibly affect the safety or integrity of the system, affected parts or subsystems should be replaced in their entirety before that part of the system is flown again.

6

Page 7

MG-LEOPARD/900 GRID ASSEMBLY GUIDE

Replacement Parts

Any component found to be defective, or any safety-related component you even suspect might be defective, should be

replaced with the equivalent, approved part. Parts specific to a QuickFly system should be ordered directly from Meyer

Sound. No attempt should be made to substitute what appears to be equivalent or “mostly the same” generic replacements.

Some parts used in QuickFly systems are identical to those used in other rigging applications. To the best of our knowledge,

most of these suppliers are reputable and their products are reliable. However, Meyer Sound has no way of assuring the

quality of products made by these various suppliers. Therefore, Meyer Sound is not responsible for problems caused by

components that were not supplied by Meyer Sound.

Training

QuickFly systems are relatively straightforward and easy to use. However, they should only be used by persons trained in

the use of loudspeaker rigging systems, who have mastered key points of assembly, rigging and flying.

LEOPARD AND 900-LFC RIGGING OPTIONS

This assembly guide documents the following rigging options:

■ MRK-900 rigging upgrade kit (PN 40.246.168.01)

■ MG-LEOPARD/900 multipurpose grid (PN 40.243.080.01)

■ MVP motor Vee plate (PN 40.215.184.01)

■ MTF-LYON/LEOPARD transition frame (PN 40.232.140.01)

■ PBF-LEOPARD pull-back frame (PN 40.243.185.01)

■ MCF-LEOPARD caster frame (PN 40.243.130.01)

■ MCF-900 caster frame (PN 40.246.130.01)

7

Page 8

CHAPTER 1: INTRODUCTION

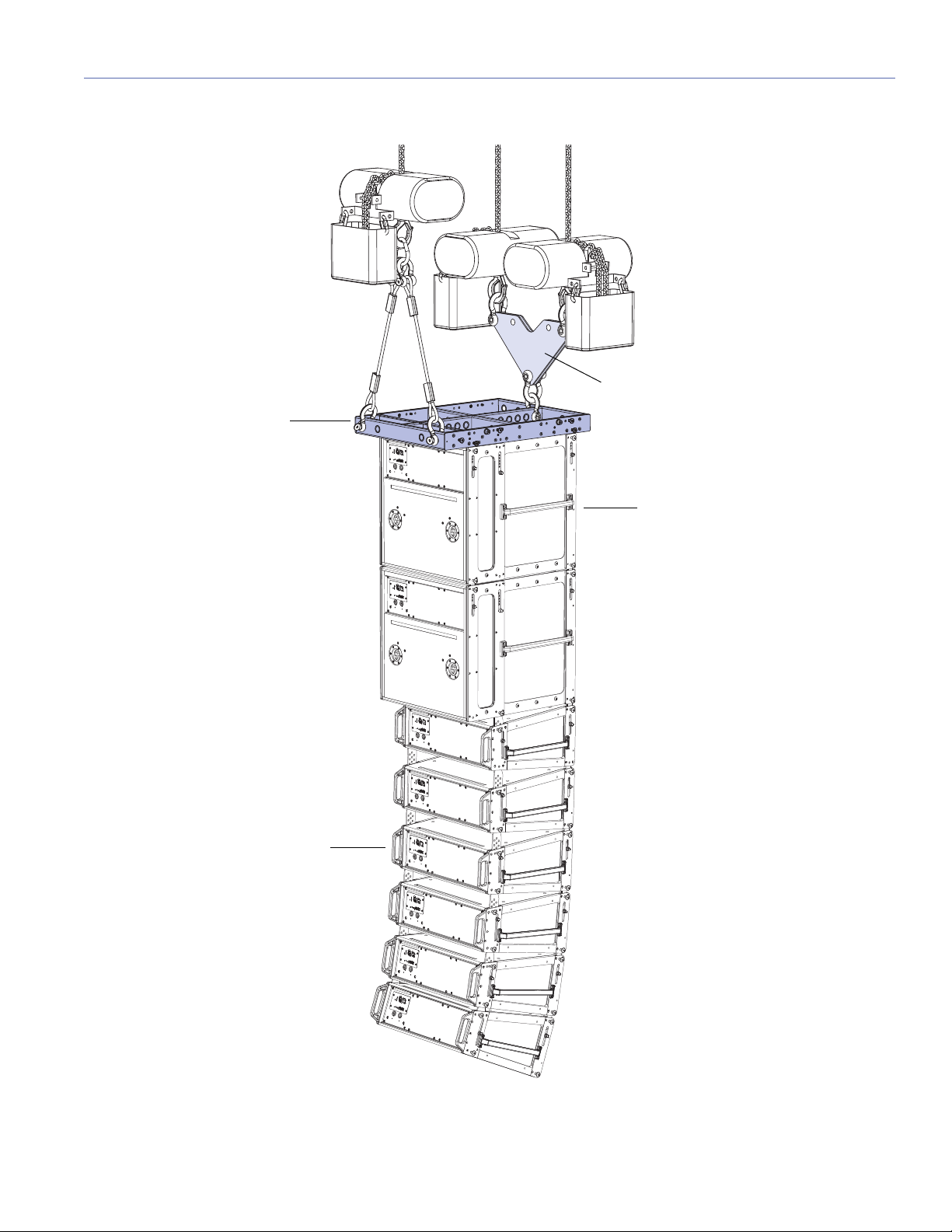

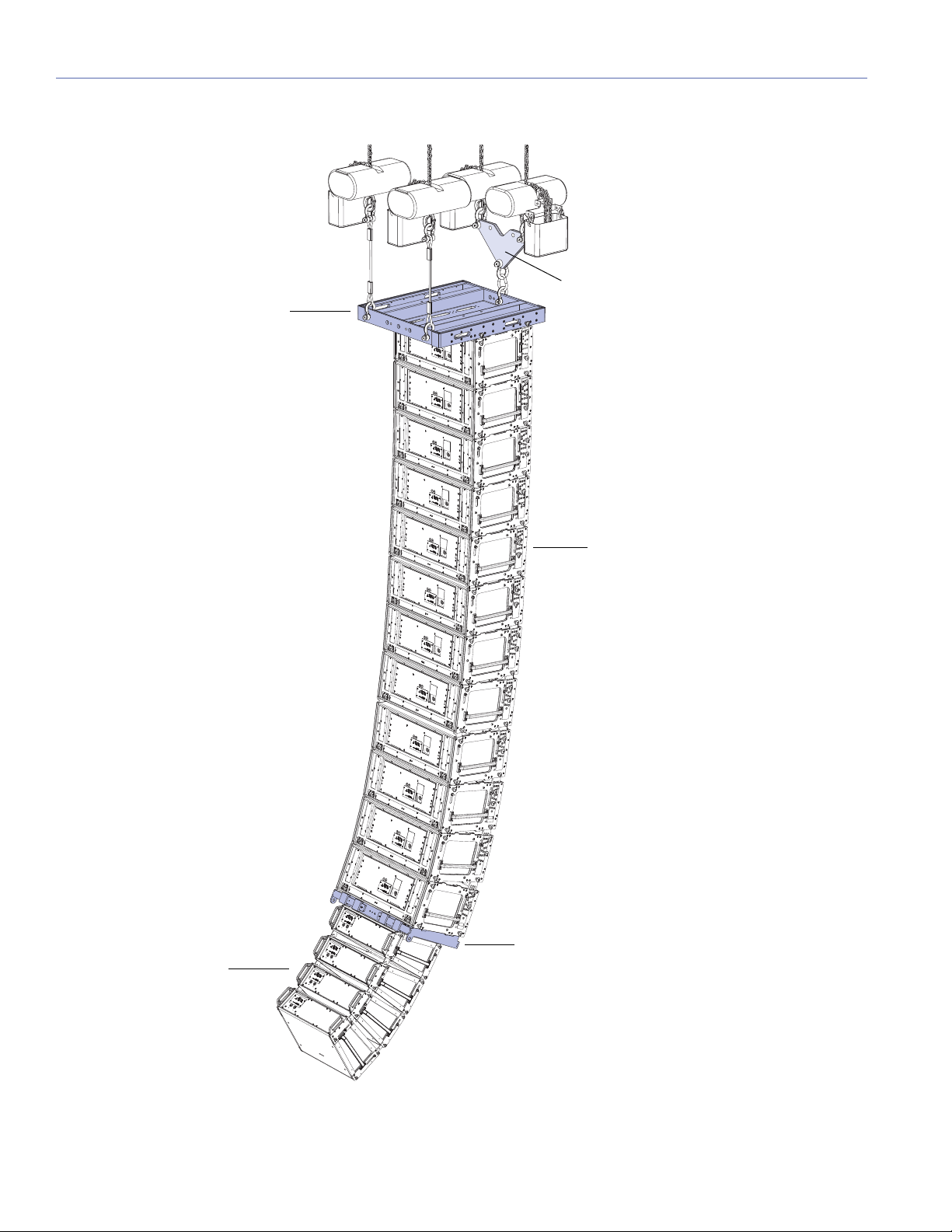

MG-LEOPARD/900

Multipurpose Grid

Oriented for maximum

array downtilt with four

pick-up points and two

motors

(12) LEOPARDs

Primary array

coverage

PBF-LEOPARD

Pull-Back Frame

Attached to bottom

cabinet to provide

pull-back for extreme

array downtilt

Rigging Example, LEOPARD Array with Pull-Back

8

Page 9

Rigging Example, Mixed Array with 900-LFCs and LEOPARDs

MG-LEOPARD/900

Multipurpose Grid

Oriented for maximum

array downtilt with three

pick-up points and

three motors

MVP Motor Vee Plate

Attached to front center

of grid with two motors

to adjust the horizontal

aim of the array

(2) 900-LFCs

Low-frequency

enhancement

(6) LEOPARDs

Primary array

coverage

MG-LEOPARD/900 GRID ASSEMBLY GUIDE

9

Page 10

CHAPTER 1: INTRODUCTION

MVP Motor Vee Plate

Attached to front center

of grid with two motors

to adjust the horizontal

aim of the array

MTG-LYON Top Grid

Oriented for maximum

array downtilt with three

pick-up points

(12) LYON-Ms

Primary array

coverage

(4) LEOPARDs

Downfill coverage

MTF-LYON/LEOPARD

Transition Frame

Transitions from last LYON to

first LEOPARD (for downfill);

includes two rear attachment

points for array pull-back

Rigging Example, LYON Array with LEOPARD Downfill

10

Page 11

CHAPTER 2: 900-LFC GROUNDSTACKS AND CARDIOID ARRAYS

!

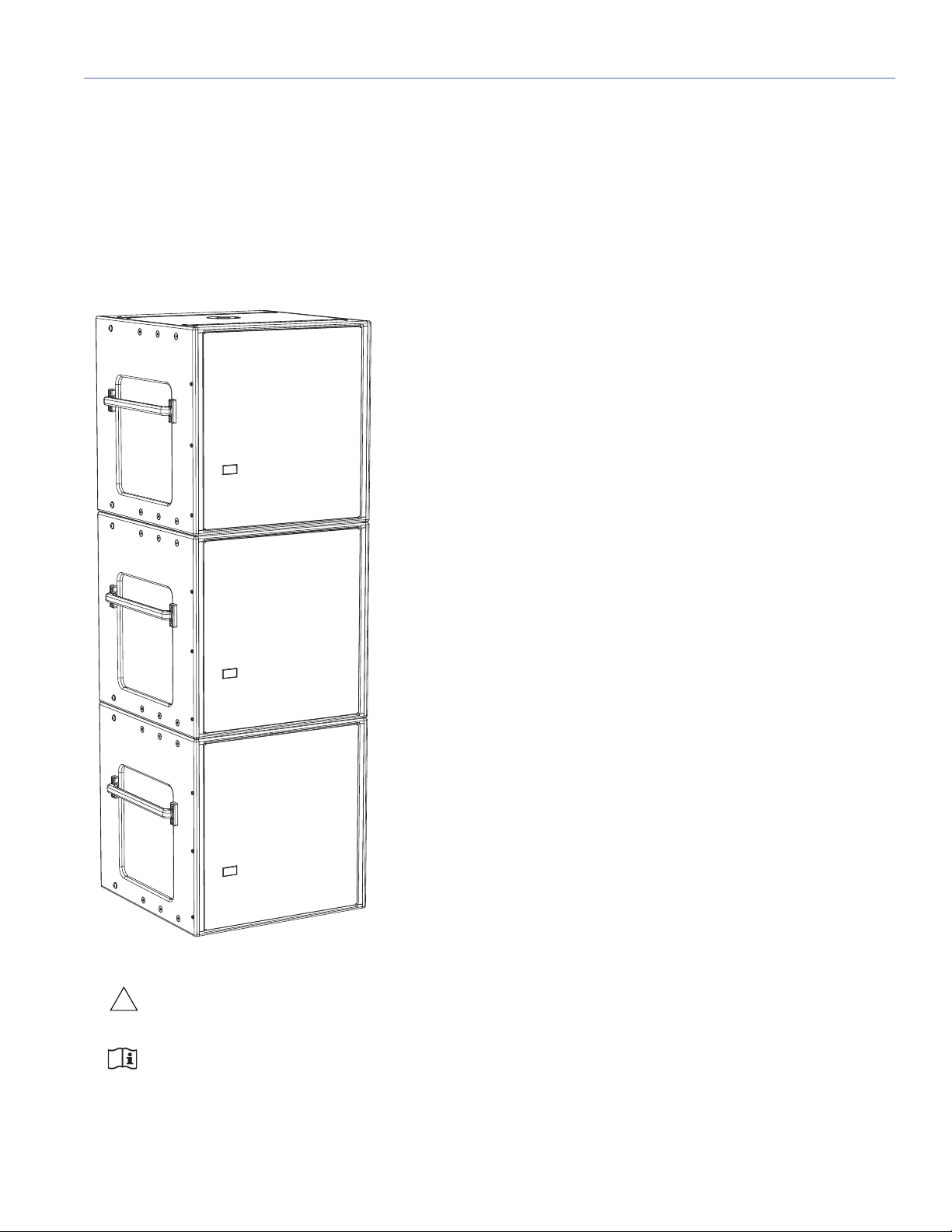

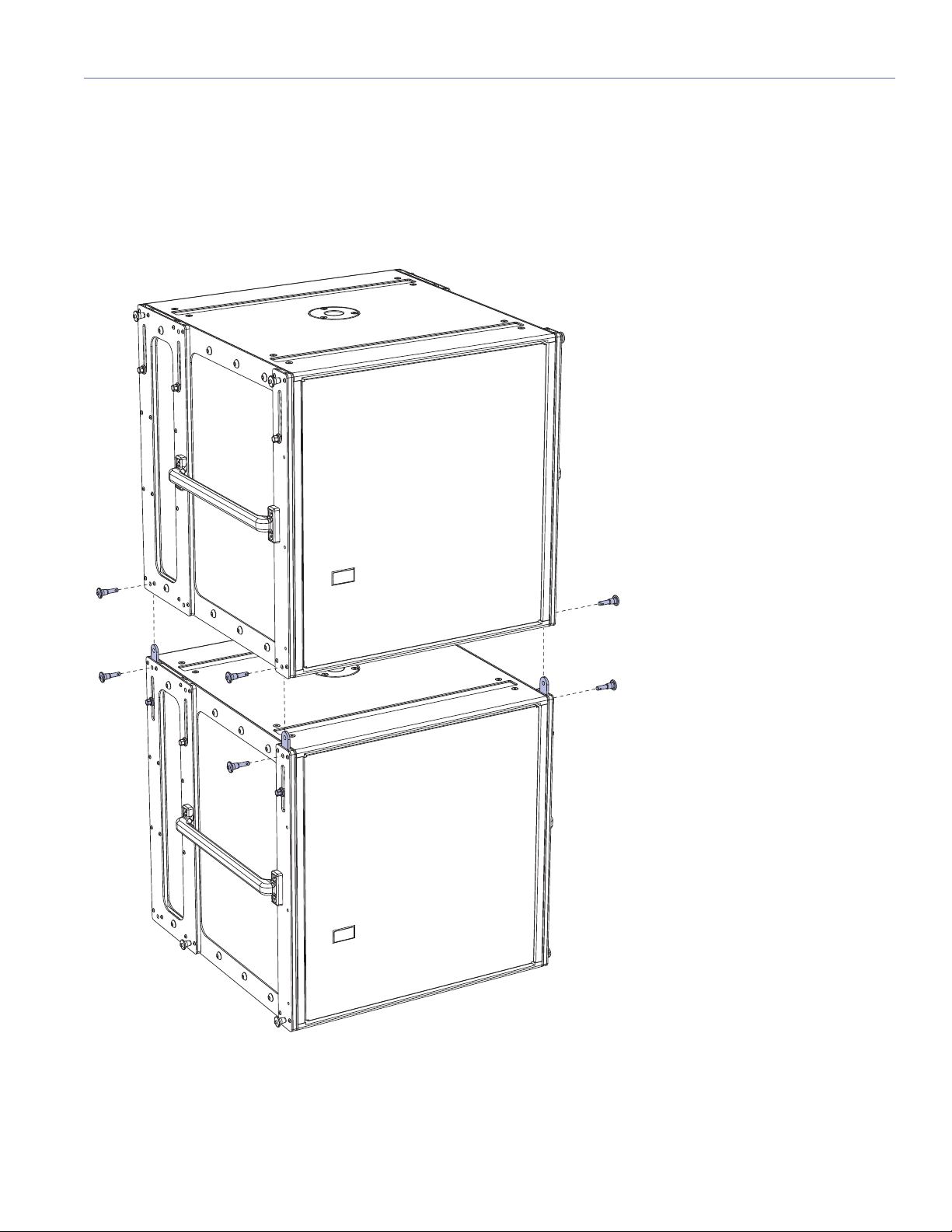

GROUNDSTACKING 900-LFC LOUDSPEAKERS (WITHOUT GRID)

900-LFCs can be groundstacked up to three units high, with or without the MRK-900 rigging kit. Protective plastic skids are

included on the bottom of the 900-LFC cabinet that align with the slots on the cabinet top. Units can be stacked normally or

reversed for cardioid configurations. When groundstacking 900-LFCs, make sure the skids for each unit align with the slots

in the cabinet tops. When equipped with the MRK-900 rigging kit, the 900-LFC can be groundstacked on the MG-LEOPARD/

900 grid with LEOPARDs for mixed groundstacks (see Chapter 10, “Groundstacking with the MG-LEOPARD/900 Grid”).

900-LFC Groundstack (Without Rigging)

CAUTION: As a safety precaution, to avoid tipping, a maximum of three cabinets is supported for ground-

stacked 900-LFCs.

NOTE: 900-LFCs need not be equipped with the MRK-900 rigging kit for secure groundstacking of up to three

cabinets.

11

Page 12

CHAPTER 2: 900-LFC GROUNDSTACKS AND CARDIOID ARRAYS

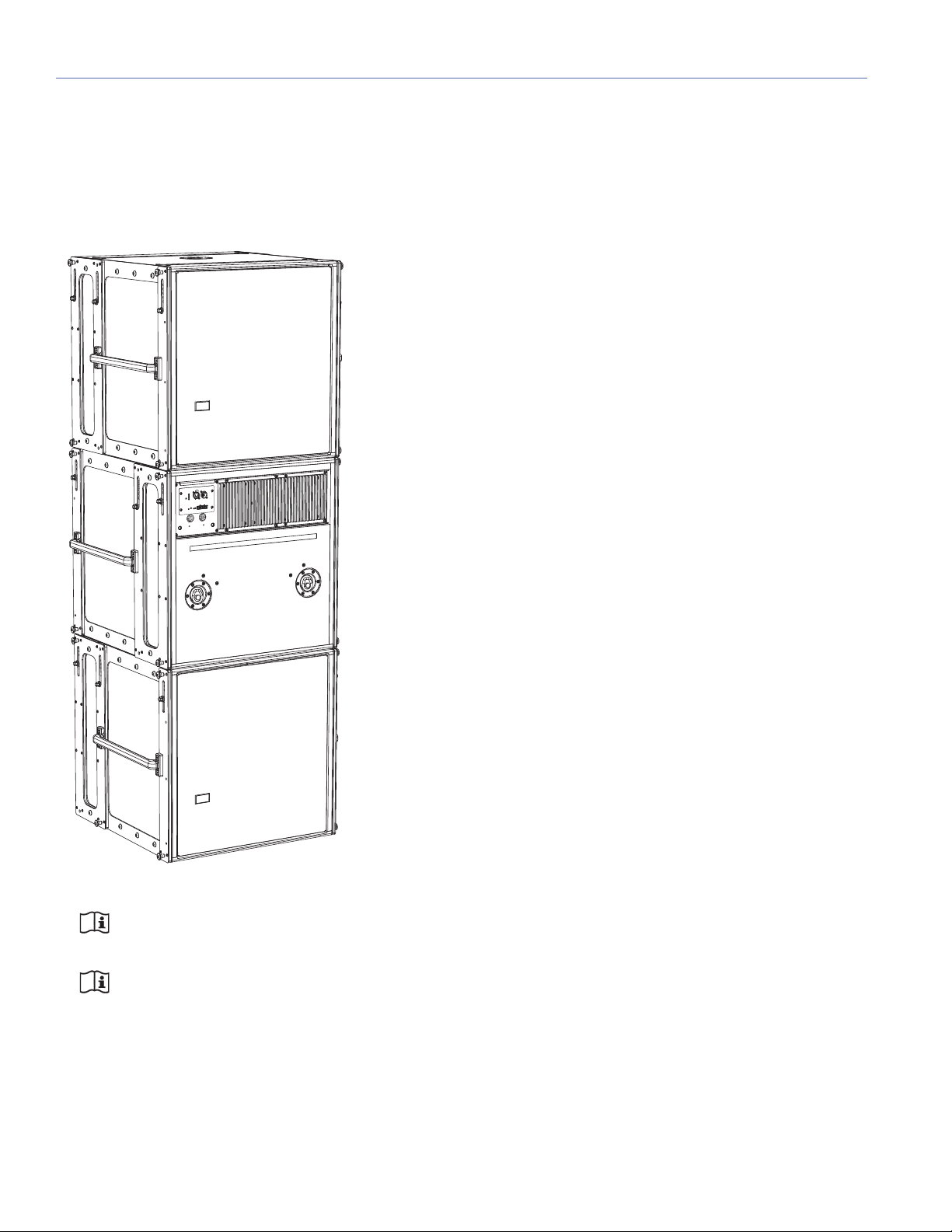

900-LFC CARDIOID ARRAYS

The 900-LFC can be configured in cardioid arrays to reduce output heard behind the loudspeakers. The loudspeaker’s linearity

ensures that cardioid patterns behave accurately even at very high levels. Cardioid arrays are achieved by placing three units

coplanar to each other (in either a groundstacked or flown array) with one unit facing the opposite direction. Polarity and delay

processing is applied to the rear-facing unit, which yields output that cancels output from the other loudspeakers normally present behind the units.

900-LFC Cardioid Groundstack (With Rigging)

NOTE: 900-LFCs need not be equipped with the MRK-900 rigging kit for groundstacked cardioid configura-

tions of up to three cabinets.

NOTE: 900-LFC cardioid arrays can also be flown from the MG-LEOPARD/900 multipurpose grid. For more infor-

mation, see Chapter 5, “MG-LEOPARD/900 Multipurpose Grid.”

12

Page 13

MG-LEOPARD/900 GRID ASSEMBLY GUIDE

NOTE: To achieve an accurate cardioid pattern, Meyer Sound’s MAPP prediction software and the Galileo®

Callisto 616 array processor are required. Use MAPP to calculate the appropriate ratio of forward to rear-facing

loudspeakers, as well as the Callisto 616 settings for polarity and delay. A myriad of cardioid and directional configurations are possible and can be calculated and predicted with MAPP. For more information, contact Meyer Sound

Technical Support.

13

Page 14

CHAPTER 2: 900-LFC GROUNDSTACKS AND CARDIOID ARRAYS

14

Page 15

CHAPTER 3: MRK-900 RIGGING UPGRADE KIT

The optional MRK-900 rigging upgrade kit allows the 900-LFC to be flown from the MG-LEOPARD/900 grid. The rigging kit

is available as a factory-installed option or as a field upgrade and uses rugged GuideALinks and intuitive quick-release pins

to securely link adjacent loudspeakers in flown and groundstacked array configurations.

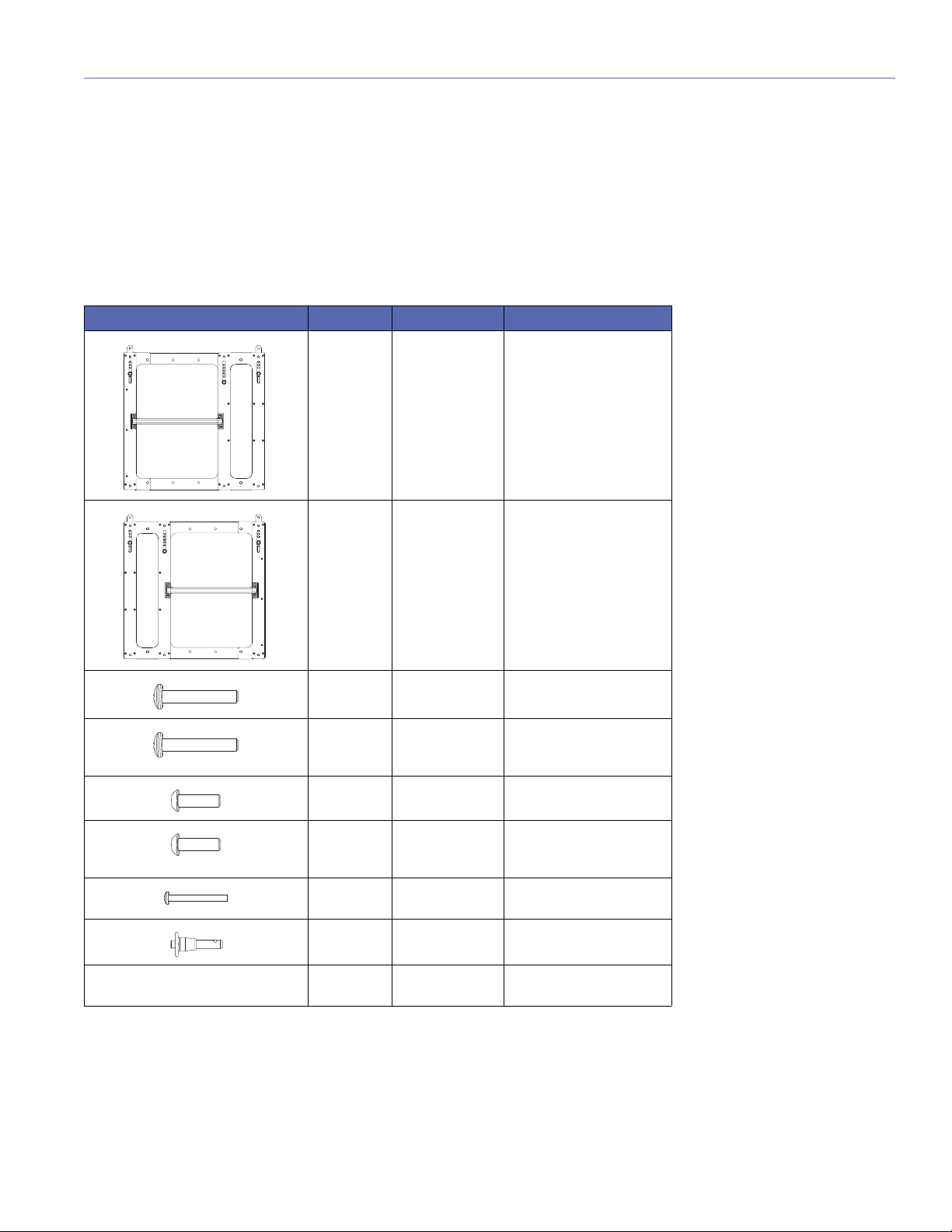

MRK-900 RIGGING UPGRADE KIT CONTENTS

MRK-900 Rigging Upgrade Kit, PN 40.246.168.01

Quantity Part Number Item

1 45.246.083.01 MRK-900 rigging endframe

with handle (right)

1 45.246.082.01 MRK-900 rigging endframe

with handle (left)

8 101.719 3/8-16 x 2.25-inch pan-

head socket bolts (black)

8 101.219 3/8-16 x 2.25-inch pan-

head socket bolts (silver,

weather protected)

8 101.695 3/8-16 x 1.25-inch pan-

head socket bolts (black)

8 101.195 3/8-16 x 1.25-inch pan-

head socket bolts (silver,

weather protected)

6 101.689 10-32 x 1.75-inch panhead

screws

8 134.024 5/16 x 0.63-inch quick-

release pins (black button)

1 640.096 Loctite Medium Strength

Threadlocker

15

Page 16

CHAPTER 3: MRK-900 RIGGING UPGRADE KIT

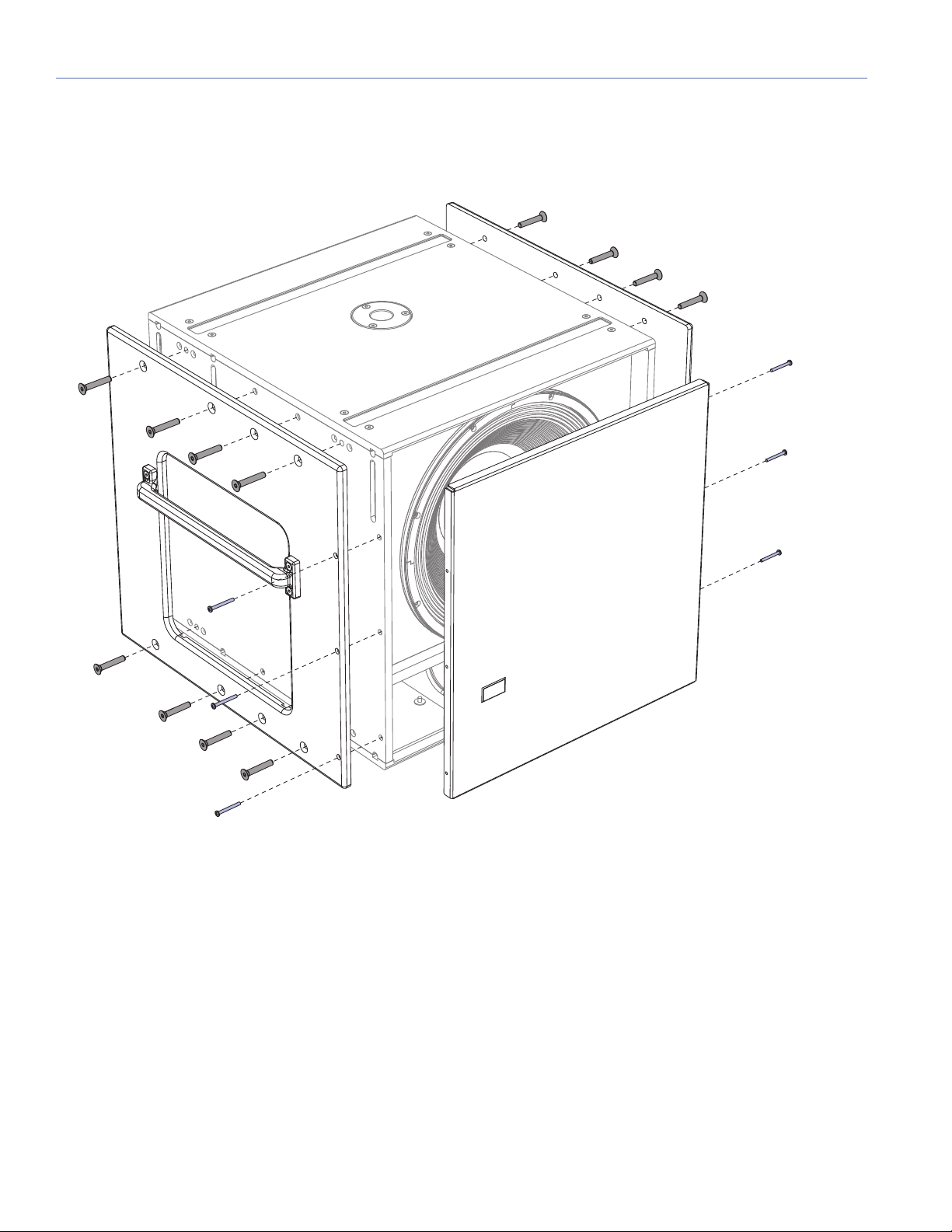

INSTALLING THE MRK-900 RIGGING UPGRADE KIT

To install the MRK-900 rigging upgrade kit:

1. Remove the standard endframes and temporarily remove the grille frame:

■ Use a Phillips screwdriver to remove the six 10-32 x 2.5-inch panhead screws (three each side) securing the grille frame

to the cabinet front. Remove the grille frame.

■ Use a 7/32-inch hex wrench to remove the (16) 3/8-16 x 2.25-inch flathead socket bolts (eight each side) from the cabi-

net sides. Remove the cabinet sides.

■ Set the removed fasteners aside. They will not be used for the MRK-900 endframes.

16

Page 17

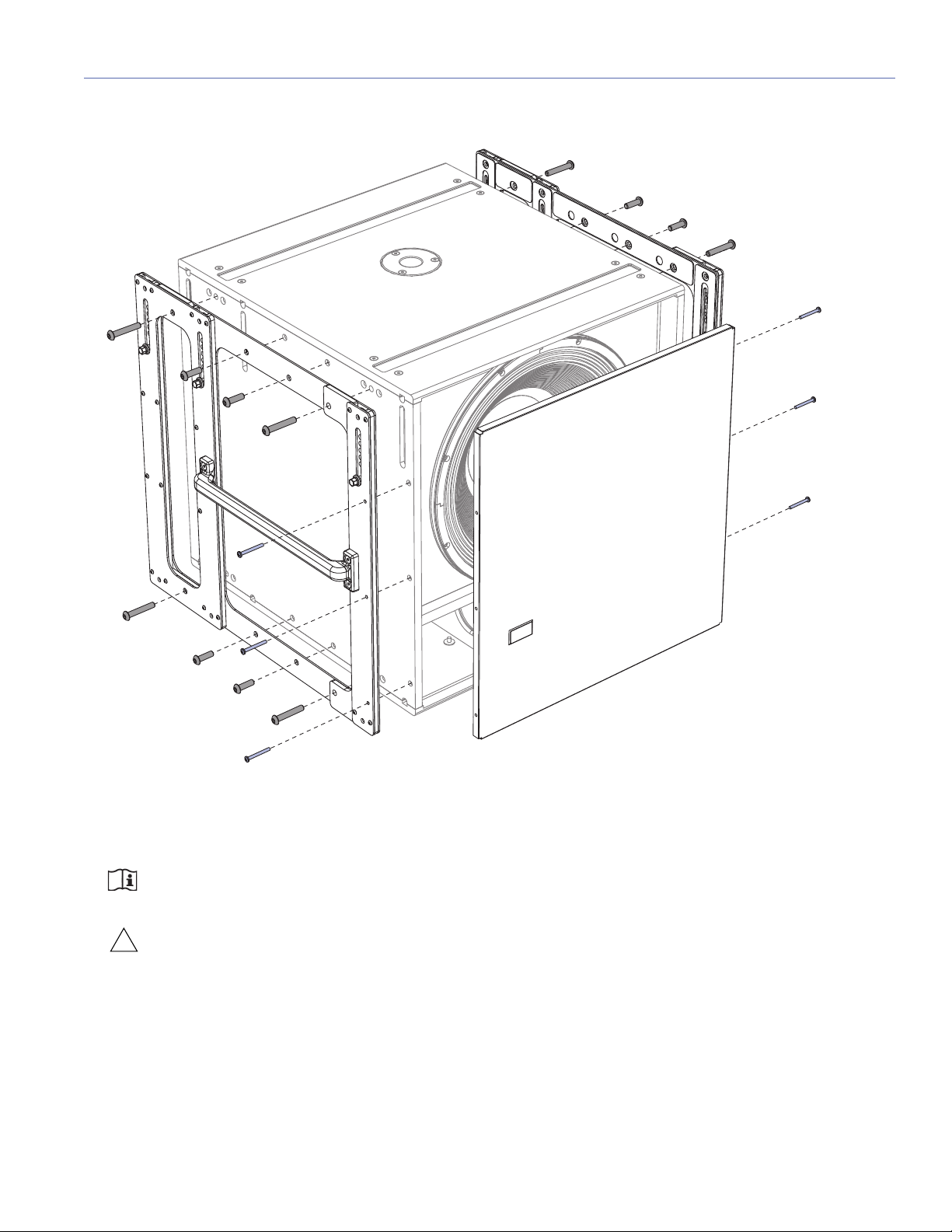

2. Attach the MRK-900 endframes and the previously removed grille frame:

!

MG-LEOPARD/900 GRID ASSEMBLY GUIDE

■ Use a 7/32-inch hex wrench to secure the MRK-900 end frames to the cabinet with the eight outer 3/8-16 x 2.25-inch

panhead socket bolts (PN 101.719) (four each side) and eight inner 3/8-16 x 1.25-inch panhead socket bolts (101.695)

(four each side). Apply one or two drops of Loctite to each of the socket bolts before installing them.

NOTE: For all-weather, outdoor installations, use the silver weather-protected panhead socket bolts

(PN 101.219 and PN 101.195).

CAUTION: Make sure the socket bolts are securely tightened but do not over-tighten them. Approximately

15 foot-pounds of torque is recommended.

■ Use a Phillips screwdriver to secure the grille frame to the cabinet with the six 10-32 x 1.75-inch panhead screws (three

each side). Apply one or two drops of Loctite to each of the panhead screws before installing them.

17

Page 18

CHAPTER 3: MRK-900 RIGGING UPGRADE KIT

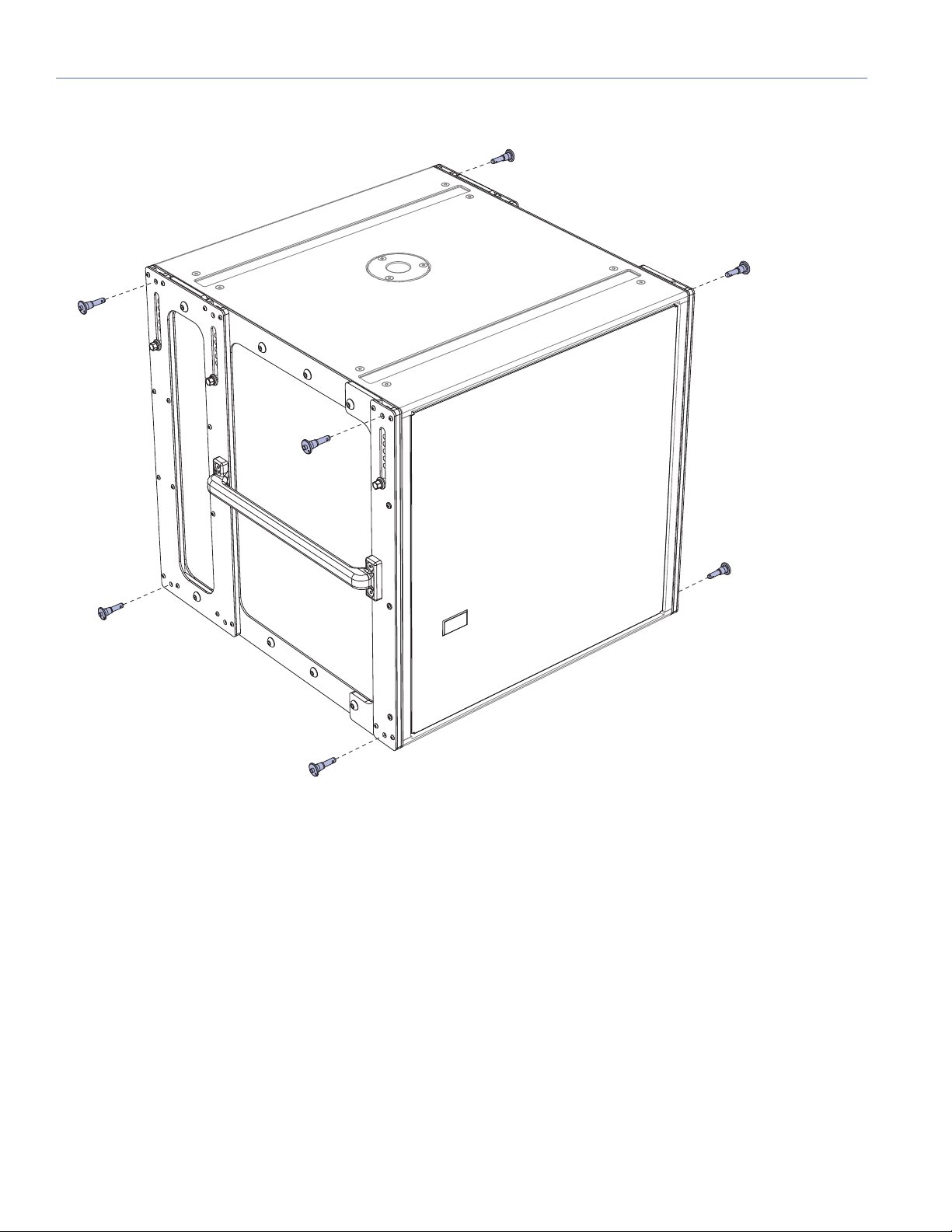

3. Insert the eight 5/16 x 0.63-inch quick-release pins in the cabinet corners (four each side).

18

Page 19

CHAPTER 4: LOUDSPEAKER GUIDEALINKS

!

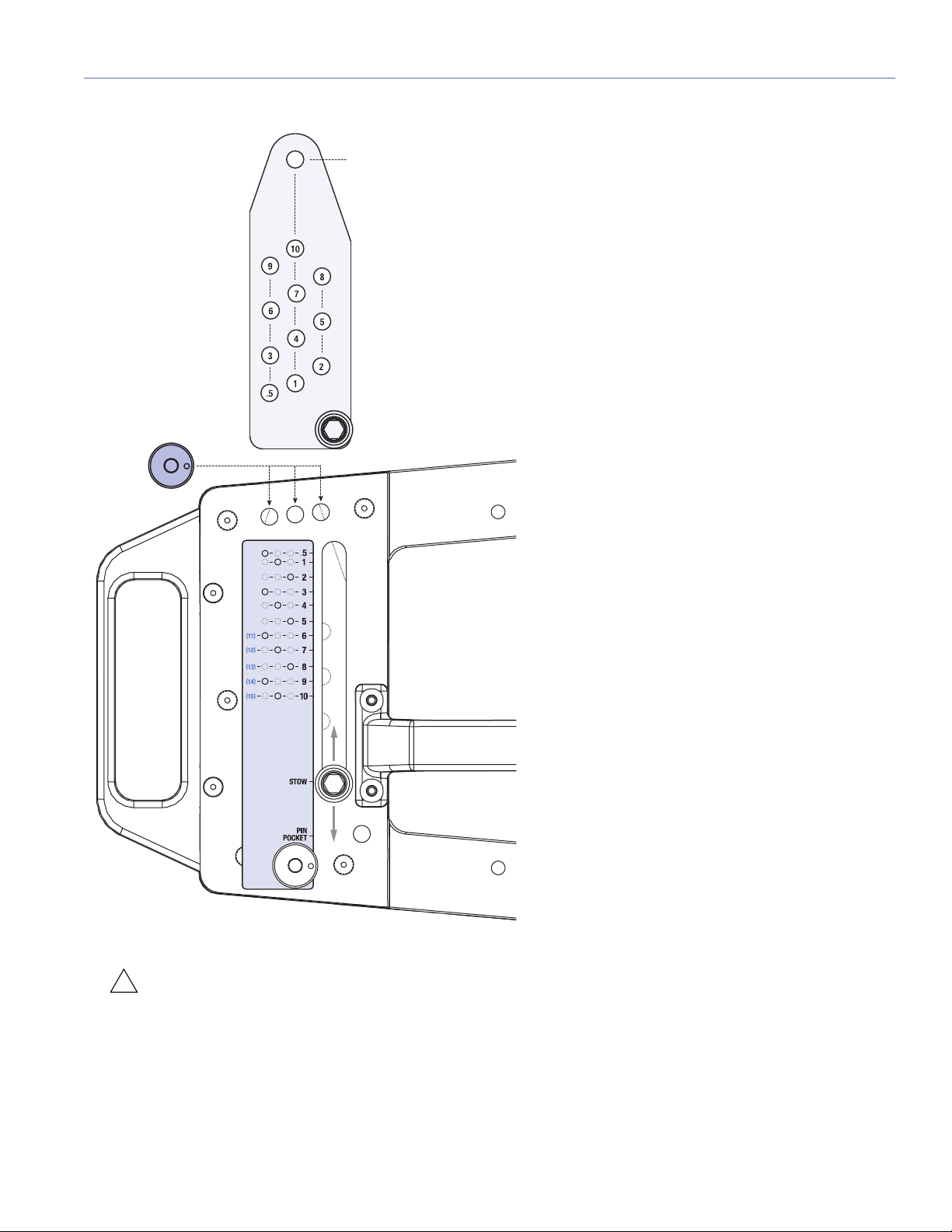

LEOPARD GUIDEALINKS

LEOPARD is equipped with four captive GuideALinks that link to adjacent LEOPARDs or 900-LFCs in flown and groundstacked arrays. Located at the top corners of the cabinet, GuideALinks extend up and into the link slots of the cabinet

above it, or into the link slots of the MG-LEOPARD/900 grid or MTF-LYON/LEOPARD transition frame. GuideALinks extend

and retract with knobs and are secured with two quick-release pins: one each in the top and bottom cabinets. Each

LEOPARD loudspeaker ships with eight 5/16 x 0.063-inch quick-release pins (black button) (PN 134.024).

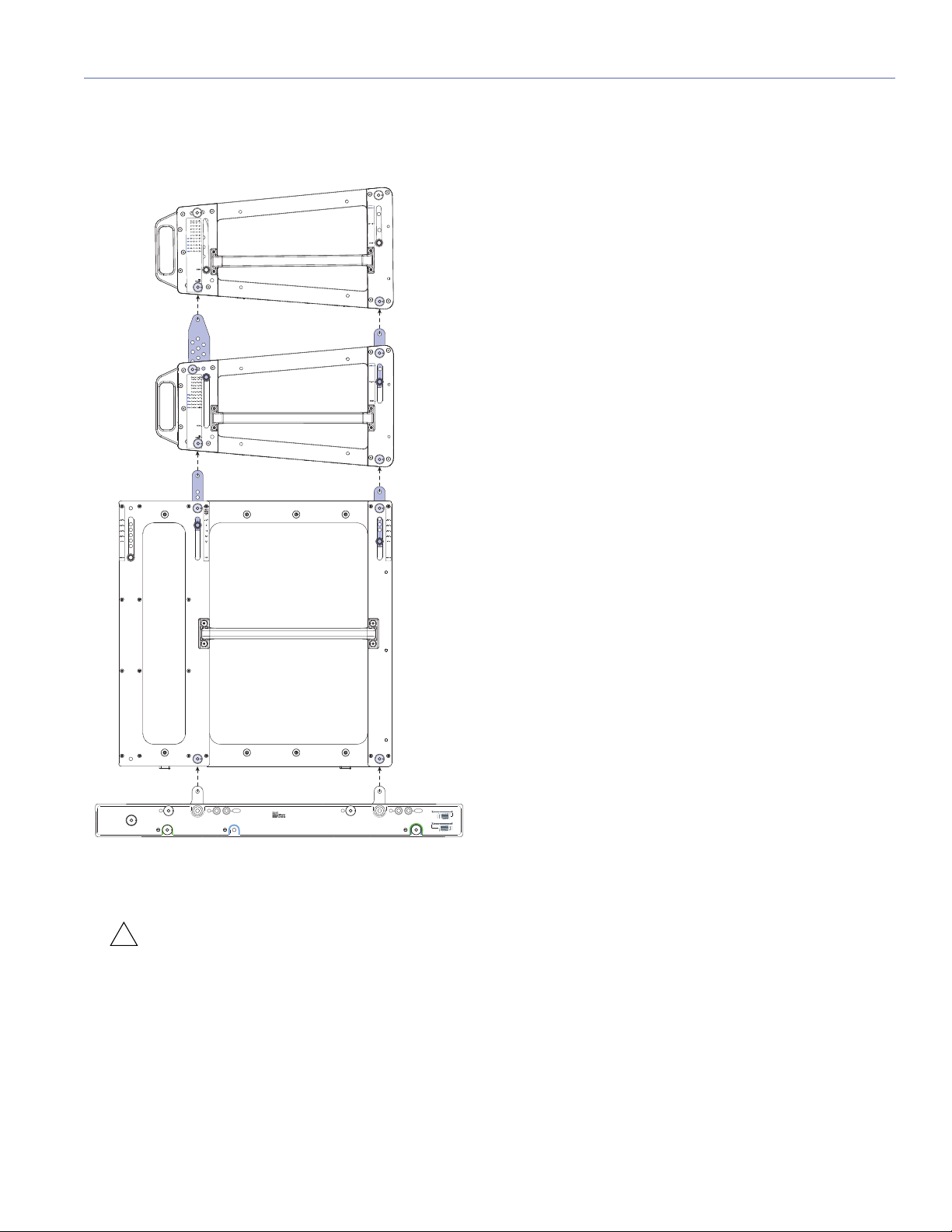

LEOPARD GuideALinks with Quick-Release Pins, Exploded View

CAUTION: GuideALinks must be secured with the included quick-release pins. At no time should the weight of

the loudspeaker rest on the GuideALink knobs when the links are fully extended (without the pins inserted). GuideALink knobs are for extending and retracting the links only.

19

Page 20

CHAPTER 4: LOUDSPEAKER GUIDEALINKS

LEOPARD Splay Angles

Front GuideALinks attach at splay angles of 0 or +5 degrees. However, the front GuideALinks should almost always be

attached at 0 degrees, to ensure that coverage between linked cabinets is continuous. When attached at 0 degrees, the

front GuideALinks act as a pivot point between the linked LEOPARDs, with the splay angle between the units determined by

the rear GuideALink positions. When attached at +5 degrees, the front GuideALinks add 5 degrees to the splay angle configured with the rear GuideALinks, making it possible to achieve splay angles of 11 to 15 degrees. To stow the front GuideALinks, move them all the way down to STOW and pin them.

TIP: Wide splay angles of 11 to 15 degrees should only be used for downfill coverage, or for steering coverage

away from structures like balconies.

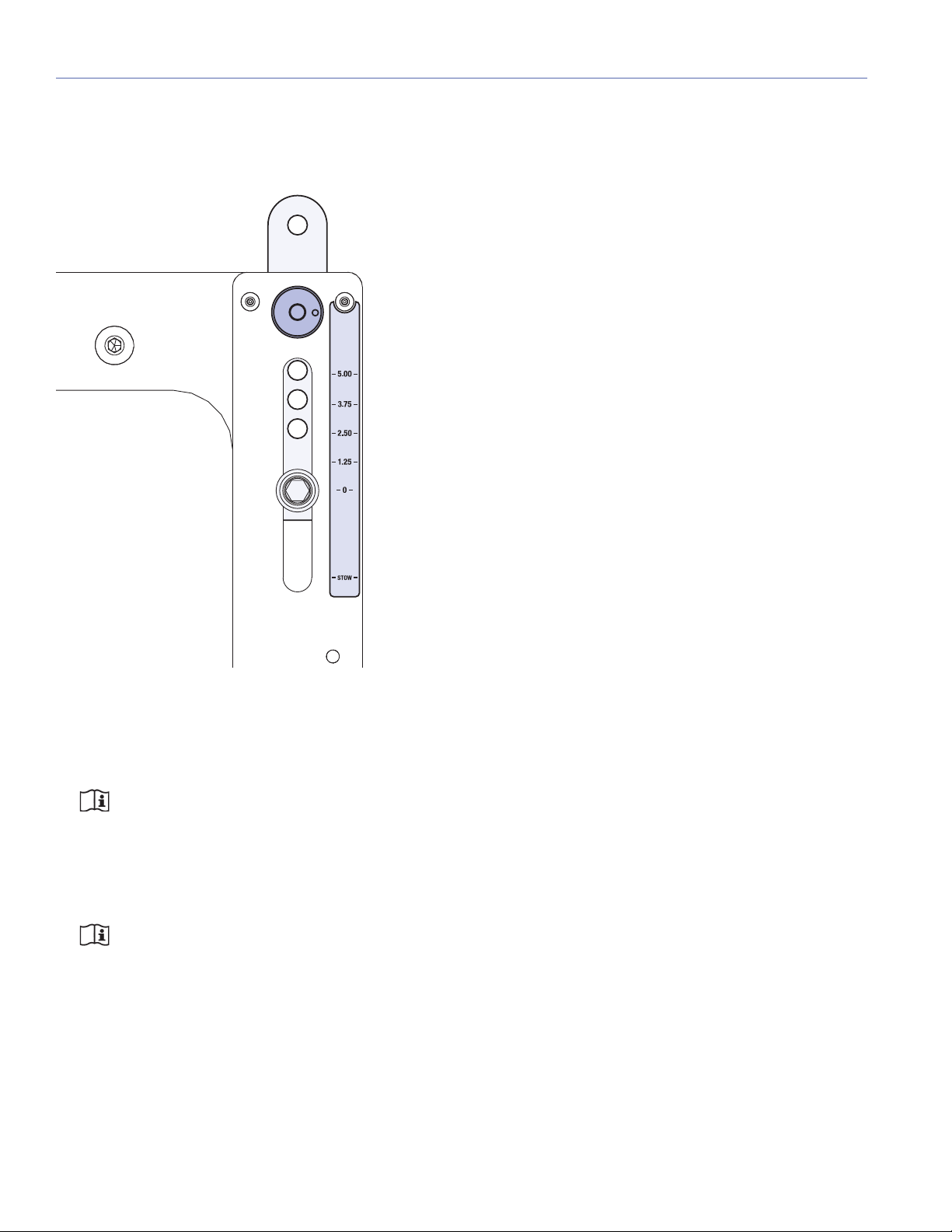

LEOPARD GuideALinks (Exposed) Attached at 0.5 Degrees

Rear GuideALinks attach at splay angles of 0.5 to 10 degrees. The labels next to the rear GuideALinks indicate the splay angle

between cabinets and provide a guide for which of the three pinning positions to use to secure the links (see Figure 1 on

page 21). As the links are moved down, the splay angle increases. To stow the rear GuideALinks, move them all the way down

to STOW and pin them to the center pin position.

NOTE: The splay angles listed on the GuideALink labels are for relative angles between the center axes of the

linked units. For example, setting the GuideALinks to 5 degrees yields a 5-degree downtilt of the lower unit to

the upper unit. How the loudspeakers relate to the floor, stage, and seating angles in the venue depends on the orientation of the grid, the angles of the loudspeakers in the array above them, and other factors. MAPP prediction software

should be used to calculate optimum splay angles for loudspeakers and to predict coverage patterns for arrays.

20

Page 21

STOW

!

MG-LEOPARD/900 GRID ASSEMBLY GUIDE

Figure 1: LEOPARD Rear GuideALinks Label, Splay Angles and Pinning Positions

CAUTION: GuideALinks must be secured with the included quick-release pins. At no time should the weight of

the loudspeaker rest on the GuideALink knobs when the links are fully extended (without the pins inserted). Guide-

ALink knobs are for extending and retracting the links only.

21

Page 22

CHAPTER 4: LOUDSPEAKER GUIDEALINKS

LEOPARD Splay Angles for Top Flown Cabinets

When flying LEOPARDs below the 900-LFC, MG-LEOPARD/900 grid, or MTF-LYON/LEOPARD transition frame, splay

angles of –4.5 to +10 degrees are possible for the top cabinet with the following GuideALink configurations.

Table 1: LEOPARD (Top Cabinet) GuideALink Configurations

Rear

GuideALinks

Set To

.5° 0° –4.5°

1° 0° –4°

2° 0° –3°

3° 0° –2°

4° 0° –1°

5° 0° 0°

6° 0° 1°

7° 0° 2°

8° 0° 3°

9° 0° 4°

10° 0° 5°

6° +5° 6°

7° +5° 7°

8° +5° 8°

9° +5° 9°

10° +5° 10°

Front

GuideALinks

Set To

Resulting Angle

of Attachment

NOTE: When flying LEOPARDs from the MG-LEOPARD/900 grid, a splay angle of 0 degrees is recommended

for the top cabinet (rear GuideALinks set to 5, front GuideALinks set to 0) to ensure that the cabinet aligns with

any lasers or inclinometers mounted on the grid. To add tilt to the top cabinet, the actual grid should instead be tilted

with motors attached to the front and rear of the grid. If just one motor is available, you can attach it to one of the 13

center pickup points offset from the center of the grid to achieve the desired tilt (see “Using MAPP to Calculate Single

Pickup Points” on page 41).

22

Page 23

MG-LEOPARD/900 GRID ASSEMBLY GUIDE

900-LFC GUIDEALINKS

When equipped with the MRK-900 rigging kit, the 900-LFC includes six captive GuideALinks and six mating link slots that

link to adjacent units in flown and groundstacked arrays. Located at the top of the cabinet, GuideALinks extend up and into

the link slots of the cabinet above it, or into the link slots of the MG-LEOPARD/900 grid, making it easy to link cabinets once

they are stacked. GuideALinks extend and retract with knobs and are secured with two quick-release pins: one each in the

top and bottom cabinets. GuideALinks accommodate reversed units for cardioid arrays. The MRK-900 rigging kit includes

eight 5/16 x 0.63-inch quick-release pins (black button) (PN 134.024).

900-LFCs with MRK-900 Rigging Kit, GuideALinks and Quick-Release Pins, Exploded View

23

Page 24

CHAPTER 4: LOUDSPEAKER GUIDEALINKS

FLOWN:

LEOPARD or 900-LFC LINK

FLOWN:

LEOPARD LINK

FLOWN:

900-LFC LINK

MG-LEOPARD/900

Multipurpose Grid

MAXIMUM DOWNTILT

MAXIMUM UPTILT

GROUNDSTACK

DOWNTILT / UPTILT 3º to 8º

STOW

B

A

GROUNDSTACK

LINK

GROUNDSTACK

LINK

STOW

B

A

MAXIMUM DOWNTILT

MAXIMUM UPTILT

MAXIMUM DOWNTILT

MAXIMUM UPTILT

The 900-LFC’s GuideALinks accommodate both 900-LFCs and LEOPARDs without transition hardware. The front and rear

GuideALinks are used when flying the 900-LFC below the MG-LEOPARD/900 grid, or when flying it below another 900-LFC

(see Figure 2). The configuration of the 900-LFC’s GuideALinks, front and rear, determines its splay angle.

Figure 2: Flown 900-LFC with GuideALink Attachments

The 900-LFC’s four corner link slots on the bottom of the cabinet accept GuideALinks from flown 900-LFCs. The front and

middle link slots accept LEOPARD GuideALinks when flying LEOPARDs below the 900-LFC (see Figure 2). The configuration

of LEOPARD’s GuideALinks, front and rear, determines its splay angle.

24

Page 25

MG-LEOPARD/900 GRID ASSEMBLY GUIDE

FLOWN:

LEOPARD or 900-LFC LINK

FLOWN:

LEOPARD LINK

FLOWN:

900-LFC LINK

MG-LEOPARD/900

Multipurpose Grid

MAXIMUM DOWNTILT

MAXIMUM UPTILT

GROUNDSTACK

DOWNTILT / UPTILT 3º to 8º

STOW

B

A

GROUNDSTACK

LINK

GROUNDSTACK

LINK

STOW

B

A

MAXIMUM DOWNTILT

MAXIMUM UPTILT

MAXIMUM DOWNTILT

MAXIMUM UPTILT

!

The 900-LFC’s front and middle link slots also accept links from the MG-LEOPARD/900 grid when groundstacking the

900-LFC (see Figure 3). The configuration of the grid’s links, whether set to A or B, determines the angle of attachment for

the groundstacked 900-LFC (see “Configuring GuideALinks for the MG-LEOPARD/900 Grid” on page 57).

Figure 3: Groundstacked 900-LFC with GuideALink Attachments

The 900-LFC’s front and middle GuideALinks are used when stacking LEOPARDs on top of the 900-LFC (see Figure 3).

CAUTION: Do not use the 900-LFC’s middle GuideALinks when flying the loudspeaker below the MG-

LEOPARD/900 grid or when flying it below another 900-LFC. Always use the front and rear GuideALinks when

flying the 900-LFC.

25

Page 26

CHAPTER 4: LOUDSPEAKER GUIDEALINKS

900-LFC Splay Angles

Front and rear GuideALinks attach at angles of 0.00, 1.25, 2.50, 3.75, or 5.00 degrees, thereby allowing curved arrays for the

900-LFC. Because the 900-LFC GuideALinks are symmetrical, curved arrays can also include cardioid configurations.

900-LFC Front GuideALinks Label

The labels next to the front and rear GuideALinks indicate the splay angle between cabinets (when the opposing links are set

to 0 degrees). As the links are moved up, the splay angle increases. To stow the GuideALinks, move them all the way down

to STOW and pin them.

NOTE: When flying 900-LFCs from the MG-LEOPARD/900 grid, a splay angle of 0 degrees is recommended

for the top cabinet (rear GuideALinks set to 0, front GuideALinks set to 0) to ensure that the cabinet aligns with

any lasers or inclinometers mounted on the grid. To add tilt to the top cabinet, the actual grid should instead be tilted

with motors attached to the front and rear of the grid. If just one motor is available, attach it to one of the 13 center

pickup points offset from the center of the grid to achieve the desired tilt (see “Using MAPP to Calculate Single

Pickup Points” on page 41).

NOTE: The curved array capability of the 900-LFC is provided to complement (aesthetically) the curvature of

adjacent LEOPARD, LYON, and LEO-M arrays, and to ensure that the physical cabinets of the 900-LFC array

do not obstruct the neighboring array's coverage. Curved 900-LFC arrays do not provide directionality for low-frequency content.

26

Page 27

CHAPTER 5: MG-LEOPARD/900 MULTIPURPOSE GRID

5/8-inch or 3/4-inch shackles

required for pickup points

!

!

With some restrictions, the optional MG-LEOPARD/900 multipurpose grid flies arrays of up to:

■ 23 LEOPARDs at a 5:1 safety factor

■ 20 LEOPARDs at a 7:1 safety factor

■ 16 900-LFCs at a 5:1 safety factor

■ 11 900-LFCs at a 7:1 safety factor

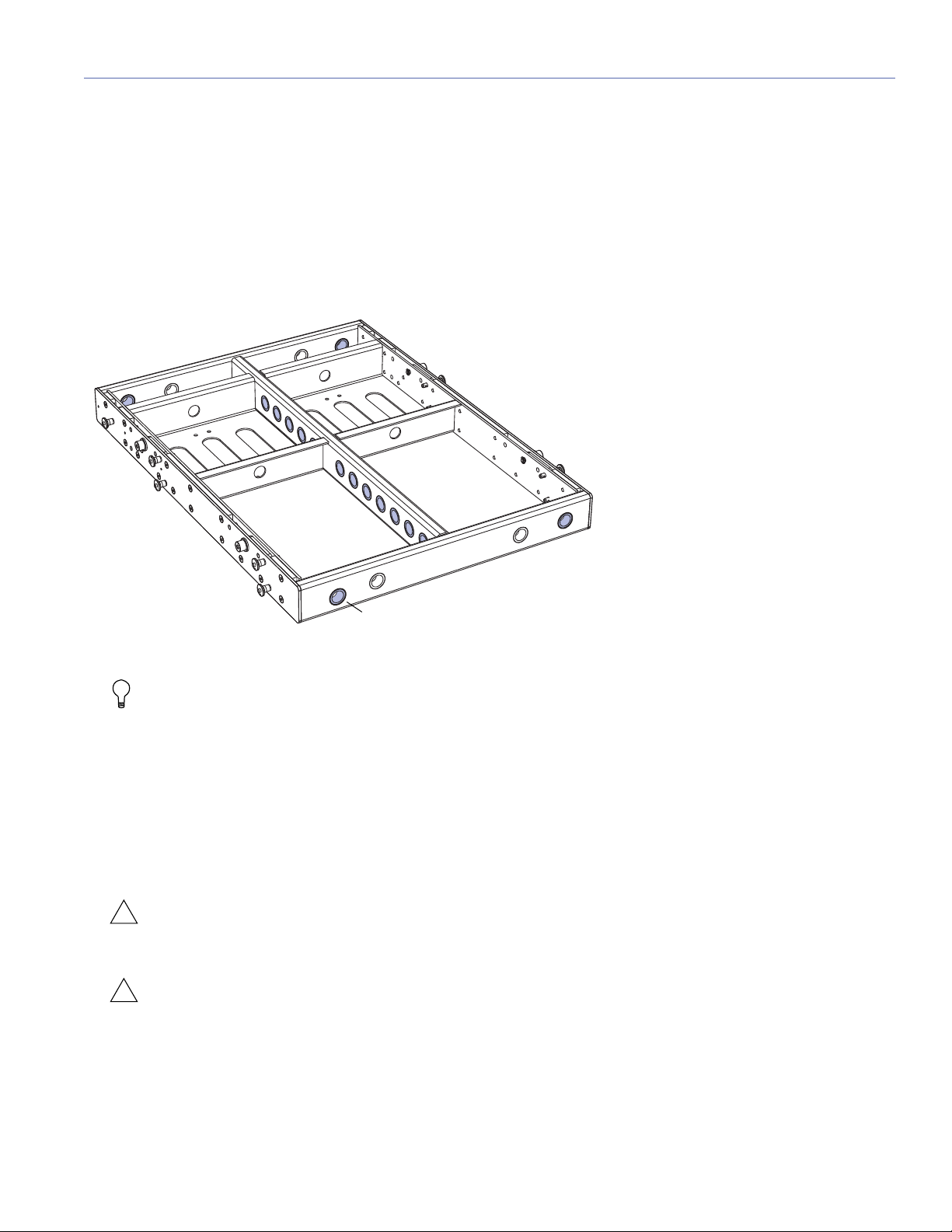

MG-LEOPARD/900 Grid (Valid Pickup Points Highlighted in Blue)

TIP: The MG-LEOPARD/900 grid supports mixed arrays of LEOPARDs and 900-LFCs without transition hard-

ware. The grid can also be used for groundstacks.

The MG-LEOPARD/900 grid accommodates a variety of pickup configurations with its four corner and 13 center pickup

points. To add tilt to the array, attach motors to the front and rear of the grid. If just one motor is available, attach it to one of

the 13 center pickup points offset from the center of the grid to achieve the desired tilt (see “Using MAPP to Calculate Single

Pickup Points” on page 41). The grid can also be oriented to provide either maximum array downtilt or maximum array uptilt

(see “Grid Orientation for Flown Arrays” on page 33).

The MG-LEOPARD/900 grid includes attachment points to accommodate brackets and adapters for lasers and inclinometers (see Appendix B, “Laser Bracket”).

CAUTION: Always use the 5/16 x 0.875-inch quick-release pins (red button) included with the MG-LEOPARD/

900 grid to secure the attached LEOPARD or 900-LFC. Do not use the 5/16 x 0.063-inch quick-release pins (black

button) included with the loudspeakers in the grid as they are shorter and will not lock in place.

CAUTION: Always use properly rated rigging hardware. The MG-LEOPARD/900 grid requires 5/8-inch or 3/4-

inch shackles for its pickup points.

27

Page 28

CHAPTER 5: MG-LEOPARD/900 MULTIPURPOSE GRID

!

CAUTION: Potential risk of personal injury and damage to equipment. The two holes to the left and right of

the center pickup bar are for aiming lasers or inclinometers (see, Appendix B, “Laser Bracket”). These holes are

not rated to support the weight of the array and should not be used as pickup points.

TIP: The MG-LEOPARD/900 grid can travel installed on top of LEOPARD stacks on the MCF-LEOPARD caster

frame, or on top of 900-LFC stacks with the MCF-900 caster frame.

MG-LEOPARD/900 GRID KIT CONTENTS

MG-LEOPARD/900 Grid Kit, PN 40.243.080.01

Quantity Part Number Item

1 45.243.080.01 MG-LEOPARD/900 grid

10 134.025 5/16 x 0.875-inch quick-

release pins (red button)

28

Page 29

MG-LEOPARD/900 GRID DIMENSIONS

24.70

[627 mm]

20.00

[508 mm]

17x Ø0.91

[Ø23 mm]

26.50

[673 mm]

32.50

[826 mm]

28.00

[711 mm]

2.00

[51 mm]

33.50

[851 mm]

1.18

[30 mm]

8.27

[210 mm]

8x Ø0.28

[Ø7 mm]

3.00

[76 mm]

3° to 8°

Optional

Angle Feet

for Groundstack Tilt

MG-LEOPARD/900 GRID ASSEMBLY GUIDE

MG-LEOPARD/900 Grid Dimensions

MG-LEOPARD/900 Grid Weight: 60.5 lbs (27.5 kg)

29

Page 30

CHAPTER 5: MG-LEOPARD/900 MULTIPURPOSE GRID

!

!

MG-LEOPARD/900 GRID LOAD RATINGS

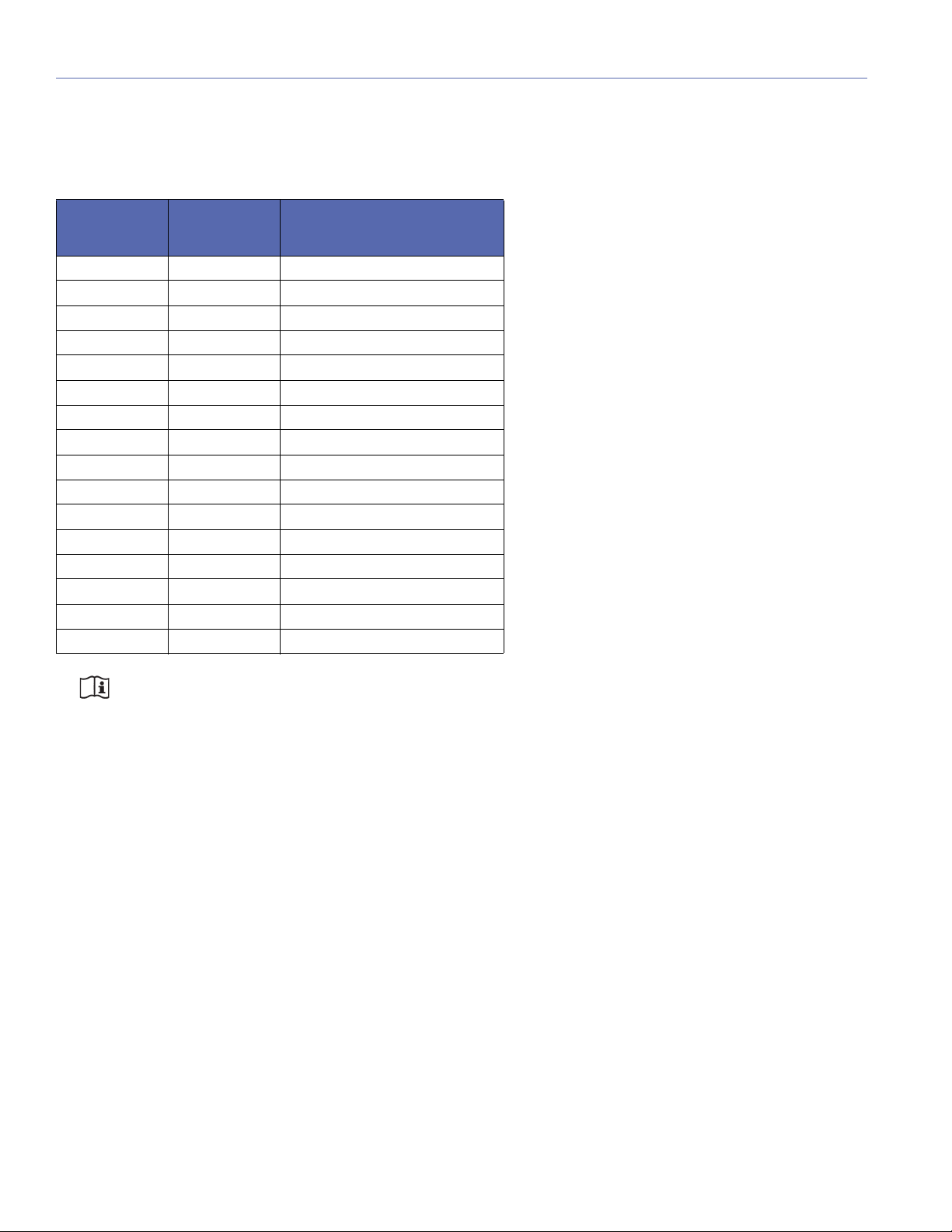

Table 2 lists the maximum number of loudspeakers that can be flown from the MG-LEOPARD/900 grid. These load ratings are

only supported when observing the “Additional Requirements for MG-LEOPARD/900 Grid Load Ratings” on page 32. For load

ratings for LEOPARD/900-LFC mixed arrays, see “MG-LEOPARD/900 Grid Load Ratings for Mixed Arrays” on page 31.

Table 2: MG-LEOPARD/900 Grid Load Ratings

Grid Configuration Maximum Load

5:1 Safety Factor

MG-LEOPARD/900

multipurpose grid

(2, 3, or 4 pickup

points)

MG-LEOPARD/900

multipurpose grid

(single pickup point,

single motor)

Splay Angle

Requirements?

No

Ye s

Splay Angle

Requirements?

No

Ye s

Splay Angle

Requirements?

No

Splay Angle

Requirements?

No

Maximum Flown

LEOPARDs

16

1,200 lbs (545 kg)

23

1,725 lbs (782 kg)

REQUIREMENTS: LEOPARDs in top half of array with

splay angles of 2° or less; LEOPARDs in third

quarter of array (from top) with splay angles of 7°

or less; LEOPARDs in last quarter of array with

any splay angle.

Maximum

Flown 900-LFCs

13

2,067 lbs (940 kg)

16

2,544 lbs (1,156 kg)

REQUIREMENTS: All cabinets with splay angles of 0°.

Maximum

Flown LEOPARDs

16

1,200 lbs (544 kg)

Maximum Flown

900-LFCs

13

2,080 lbs (943 kg)

REQUIREMENTS: LEOPARDs in top half of array with

splay angles of 2° or less; LEOPARDs in third

quarter of array (from top) with splay angles of 7°

or less; LEOPARDs in last quarter of array with

any splay angle.

REQUIREMENTS: All cabinets with splay angles of 0°.

Maximum Load

7:1 Safety Factor

Maximum Flown

LEOPARDs

13

975 lbs (443 kg)

20

1,500 lbs (680 kg)

Maximum Flown

900-LFCs

10

1,590 lbs (723 kg)

11

1,749 lbs (795 kg)

Maximum Flown

LEOPARDs

12

900 lbs (408 kg)

Maximum Flown

900-LFCs

10

1,600 lbs (726 kg)

CAUTION: Potential risk of personal injury and damage to equipment. Do not exceed load ratings.

CAUTION: The load ratings in Table 2 are reduced for pull-back configurations with the PBF-LEOPARD pull-

back frame.

NOTE: Additional array configurations for the MG-LEOPARD/900 grid are possible. Use MAPP prediction soft-

ware to verify whether configurations exceed load ratings. You can also use MAPP to verify whether configurations meet BGV C1 requirements.

TIP: You can use load sensors to measure load points for the MG-LEOPARD/900 grid.

30

Page 31

MG-LEOPARD/900 GRID ASSEMBLY GUIDE

!

!

MG-LEOPARD/900 Grid Load Ratings for Mixed Arrays

Table 3 lists the maximum number of loudspeakers that can be flown in LEOPARD/900-LFC mixed arrays from the

MG-LEOPARD/900 grid. These load ratings are only supported when observing the “Additional Requirements for

MG-LEOPARD/900 Grid Load Ratings” on page 32.

Table 3: MG-LEOPARD/900 Grid Load Ratings with 900-LFCs and LEOPARDs

Grid Configuration Maximum Load

5:1 Safety Factor

MG-LEOPARD/900

multipurpose grid

(2, 3 or 4 pickup

points)

MG-LEOPARD/900

multipurpose grid

(single pickup point,

single motor)

Number of Flown

900-LFCs

REQUIREMENTS: (1) No splay angle requirements for 900-LFCs. (2) No splay angle requirements for LEOPARDs.

114 11

212 10

312 10

411 10

Number of Flown

900-LFCs

REQUIREMENTS: (1) 900-LFCs with splay angles of 0°. (2) LEOPARDs in top half of array with splay angles of 2° or less;

LEOPARDs in third quarter of array (from top) with splay angles of 7° or less; LEOPARDs in last quarter of array with any

splay angle.

122 18

221 17

320 17

419 15

Number of Flown

900-LFCs

REQUIREMENTS: (1) No splay angle requirements for 900-LFCs. (2) No splay angle requirements for LEOPARDs.

114 11

212 10

312 10

411 10

Maximum Flown

LEOPARDs

Maximum Flown

LEOPARDs

Maximum Flown

LEOPARDs

Maximum Load

7:1 Safety Factor

Maximum Flown

LEOPARDs

Maximum Flown

LEOPARDs

Maximum Flown

LEOPARDs

CAUTION: Potential risk of personal injury and damage to equipment. Do not exceed load ratings.

CAUTION: The load ratings in Table 3 are reduced for pull-back configurations with the PBF-LEOPARD pull-

back frame.

NOTE: Additional array configurations for the MG-LEOPARD/900 grid are possible. Use MAPP prediction soft-

ware to verify whether configurations exceed load ratings. You can also use MAPP to verify whether configura-

tions meet BGV C1 requirements.

31

Page 32

CHAPTER 5: MG-LEOPARD/900 MULTIPURPOSE GRID

!

ADDITIONAL REQUIREMENTS FOR MG-LEOPARD/900 GRID LOAD RATINGS

The load ratings in Table 2 on page 30 and Table 3 on page 31 are only supported when the following requirements are

observed:

■ Always use properly rated rigging hardware. The MG-LEOPARD/900 grid requires 5/8-inch or 3/4-inch shackles for its

pickup points.

■ Supported pickup points are: single center point, two center points, three points, and four corner points. For more infor-

mation, see “MG-LEOPARD/900 Pickup Configurations” on page 35.

■ If a bridle is used between pickup points, the bridle angle at the apex must not be greater than 90 degrees.

■ The minimum supported leg length for front-to-rear bridle attachments is 23 inches (584 mm). The minimum supported

leg length for side-to-side bridle attachments is 15 inches (381 mm). Using a bridle leg shorter than the recommended

length reduces the load rating and may damage the MG-LEOPARD/900 grid.

■ The array should not be pulled from points other than those on the grid (except when using the PBF-LEOPARD for pull-

back).

CAUTION: The load ratings in Table 2 on page 30 and Table 3 on page 31 are reduced for pull-back configura-

tions with the PBF-LEOPARD pull-back frame.

■ The maximum number of LEOPARD or 900-LFC loudspeakers that can be flown is based on a weight of 75 lbs (34.0 kg)

for each LEOPARD cabinet and 159 lbs (72.1 kg) for each 900-LFC cabinet.

■ The maximum load ratings regard the MG-LEOPARD/900 grid and flown loudspeakers as a system, including GuideA-

Links and quick-release pins. Thus, the maximum stress point could change from one element to another in the system.

■ The weight of any additional items suspended with the array, such as downfill loudspeakers, transition and pull-back

hardware, and cable, must be considered when calculating the maximum load.

■ The weight of the MG-LEOPARD/900 grid has not been included in Table 2 on page 30. The table rates the maximum

load for the grid. Pickup points and motors that will suspend the grid must be rated to the support the total weight of the

grid (60.5 lbs, 27.5 kg) and its suspended loudspeakers (see Table 2 on page 30).

32

Page 33

CHAPTER 6: FLYING ARRAYS

FLOWN:

LEOPARD or 900-LFC LINK

FLOWN:

LEOPARD LINK

FLOWN:

900-LFC LINK

MG-LEOPARD/900

Multipurpose Grid

MAXIMUM DOWNTILT

MAXIMUM UPTILT

GROUNDSTACK

DOWNTILT / UPTILT 3º to 8º

STOW

B

A

GROUNDSTACK

LINK

GROUNDSTACK

LINK

STOW

B

A

MAXIMUM DOWNTILT

MAXIMUM UPTILT

MAXIMUM DOWNTILT

MAXIMUM UPTILT

Front

MAXIMUM DOWNTILT

MAXIMUM UPTILT

A

A

MAXIMUM DOWNTILT

MAXIMUM UPTILT

GROUNDSTACK

DOWNTILT / UPTILT 3º to 8º

GROUNDSTACK

LINK

GROUNDSTACK

LINK

LEOPARD or 900-LFC LINK

FLOWN:

FLOWN:

LEOPARD LINK

FLOWN:

900-LFC LINK

STOW

B

STOW

B

MG-LEOPARD/900

Multipurpose Grid

MAXIMUM DOWNTILT

MAXIMUM UPTILT

Front

GRID ORIENTATION FOR FLOWN ARRAYS

The MG-LEOPARD/900 grid can be oriented to locate the array’s center of gravity closer to the front or rear of the grid, to

achieve a few more degrees of downtilt or uptilt for flown arrays. The grid’s orientation is also important when accommodating groundstacks with downtilt or uptilt (see “Grid Orientation and Groundstacks” on page 58).

TIP: To add tilt to the grid, you can attach motors to the front and rear of the grid. If just one motor is available,

attach it to one of the 13 center pickup points offset from the center of the grid to achieve the desired tilt (see

“Using MAPP to Calculate Single Pickup Points” on page 41).

MG-LEOPARD/900 Grid Oriented for Maximum Array Downtilt (Forward)

When the MG-LEOPARD/900 grid is oriented forward with the attached loudspeaker near the front of the grid, the array’s center

of gravity is located closer to the front of the grid, thereby allowing the rear pickup points to achieve maximum array downtilt.

MG-LEOPARD/900 Grid Oriented for Maximum Array Downtilt (Forward)

MG-LEOPARD/900 Grid Oriented for Maximum Array Uptilt (Rearward)

When the MG-LEOPARD/900 grid is oriented rearward with the attached loudspeaker near the rear of the grid, the array’s center

of gravity is located closer to the rear of the grid, thereby allowing the front pickup points to achieve maximum array uptilt.

MG-LEOPARD/900 Grid Oriented for Maximum Array Uptilt (Rearward)

33

Page 34

CHAPTER 6: FLYING ARRAYS

!

!

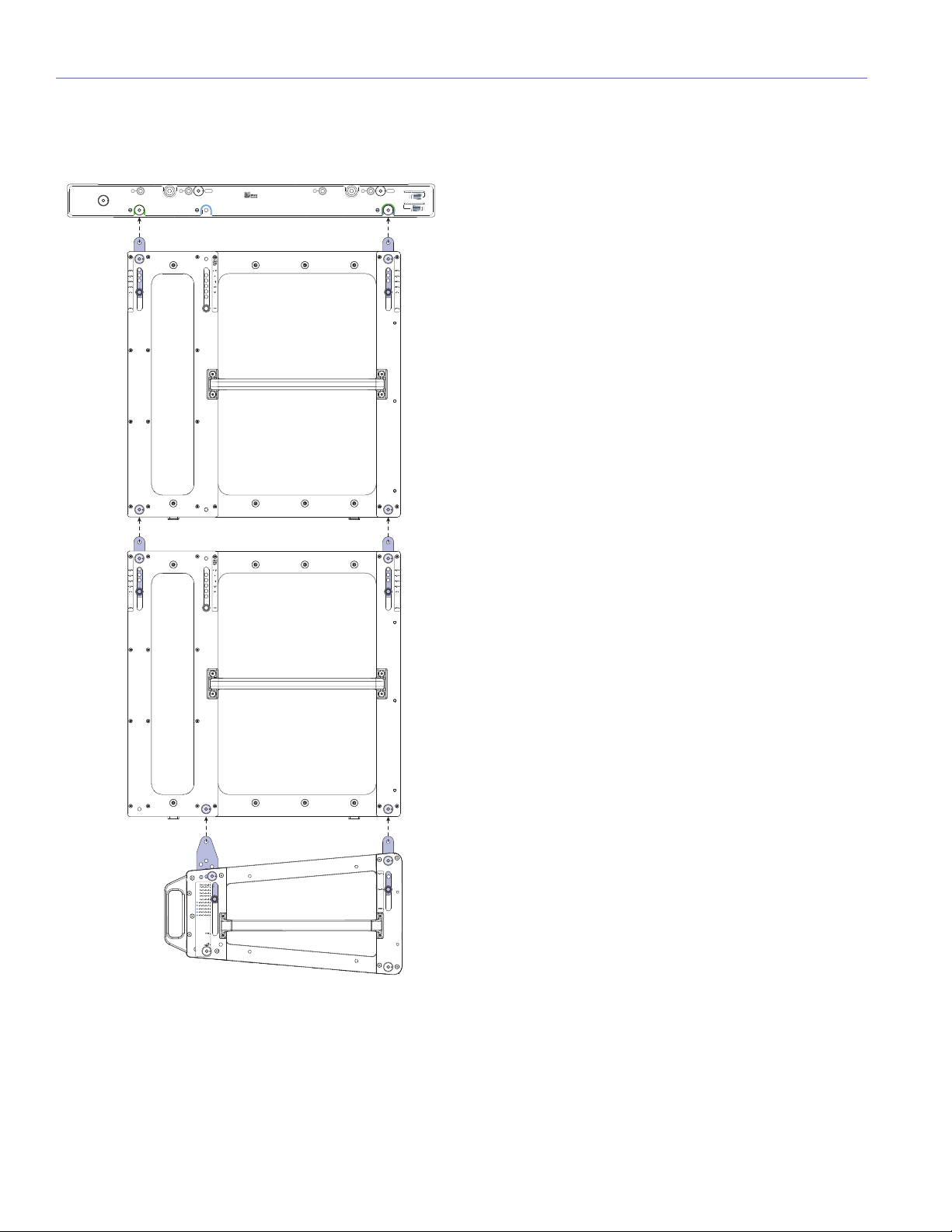

ATTACHING FLOWN ARRAYS TO THE MG-LEOPARD/900

The MG-LEOPARD/900 grid has six bottom link slots, three on each side of the grid, that accept GuideALinks from the top

LEOPARD or 900-LFC cabinet in the array. The configuration of the GuideALinks for the top cabinet determines the angle of

its attachment (see “LEOPARD Splay Angles” on page 20 and “900-LFC Splay Angles” on page 26). The grid includes 10

5/16 x 0.875-inch quick-release pins (red button) for securing the top cabinet and configuring the grid’s links for groundstack attachments.

MG-LEOPARD/900 Grid with LEOPARDs, Exploded View

CAUTION: Always use the 5/16 x 0.875-inch quick-release pins (red button) included with the MG-LEOPARD/900

grid to secure the attached LEOPARD or 900-LFC. Do not use the 5/16 x 0.063-inch quick-release pins (black

button) included with the loudspeakers in the grid as they are shorter and will not lock in place.

CAUTION: Do not use the 900-LFC’s middle GuideALinks when flying the loudspeaker below the MG-

LEOPARD/900 grid or when flying it below another 900-LFC. Always use the front and rear GuideALinks when

flying the 900-LFC.

NOTE: When flying loudspeakers from the MG-LEOPARD/900 grid, a splay angle of 0 degrees is recom-

mended for the top cabinet (for LEOPARD, rear GuideALinks set to 5, front GuideALinks set to 0; for the

900-LFC, rear GuideALinks set to 0, front GuideALinks set to 0) to ensure that the cabinet aligns with any lasers or

inclinometers mounted on the grid. To add tilt to the top cabinet, the actual grid should instead be tilted with motors

attached to the front and rear of the grid. If just one motor is available, attach it to one of the 13 center pickup points

offset from the center of the grid to achieve the desired tilt (see “Using MAPP to Calculate Single Pickup Points” on

page 41).

34

Page 35

MG-LEOPARD/900 GRID ASSEMBLY GUIDE

!

!

!

!

MG-LEOPARD/900 PICKUP CONFIGURATIONS

The MG-LEOPARD/900 grid accommodates a variety of pickup configurations with its four corner and 13 center pickup points.

For greater stability, bridles, suspended from a single motor and attached to two grid pickup points, are recommended. To add

tilt to the array, attach motors to the front and rear of the grid. If just one motor is available, attach it to one of the 13 center

pickup points offset from the center of the grid to achieve the desired tilt (see “Using MAPP to Calculate Single Pickup Points”

on page 41).

CAUTION: When flying MG-LEOPARD/900 arrays, make sure the motors and ceiling attachment point (above

the hook) are rated to hold the total weight of the grid and array, including any additional items suspended with

the array, such as downfill loudspeakers, pull-back accessories, transition accessories, and cable.

CAUTION: Always use properly rated rigging hardware. The MG-LEOPARD/900 grid requires 5/8-inch or 3/4-

inch shackles for its pickup points.

CAUTION: When using bridles between pickup points on the MG-LEOPARD/900, the angle of the bridle at the

apex should not be greater than 90 degrees to avoid damaging the grid.

CAUTION: Potential risk of personal injury and damage to equipment. The two holes to the left and right of

the center pickup bar are for aiming lasers or inclinometers (see, Appendix B, “Laser Bracket”). These holes are

not rated to support the weight of the array and should not be used as pickup points.

35

Page 36

CHAPTER 6: FLYING ARRAYS

!

Pickup Configurations with One Motor

The MG-LEOPARD/900 grid supports the following pickup configurations with one motor.

1 Motor – 1 Pickup Point (Left); 1 Motor – 2 Pickup Points, Front-to-Rear Bridle (Right)

CAUTION: The minimum supported leg length for front-to-rear bridle attachments is 23 inches (584 mm).

TIP: For configurations with a single pickup point and single motor, you can add tilt by adjusting the placement

of the pickup point.To add downtilt, attach the motor to a pickup point closer to the rear of the grid. To add

uptilt, attach the motor to a pickup point closer to the front of the grid.

TIP: For configurations with a single pickup point and single motor, you can use MAPP to calculate which

pickup point to use to achieve the desired downtilt, uptilt, or no tilt. For more information, see “Using MAPP to

Calculate Single Pickup Points” on page 41.

36

Page 37

MG-LEOPARD/900 GRID ASSEMBLY GUIDE

!

Pickup Configurations with Two Motors

The MG-LEOPARD/900 grid supports the following pickup configurations with two motors.

2 Motors – 2 Pickup Points, Front and Rear (Left); 2 Motors – 2 Pickup Points, Front and Rear Bridles (Right)

CAUTION: The minimum supported leg length for side-to-side bridle attachments is 15 inches (381 mm).

37

Page 38

CHAPTER 6: FLYING ARRAYS

!

!

2 Motors – 3 Pickup Points, Rear Bridle (Left); 2 Motors – 3 Pickup Points, Front Bridle (Right)

CAUTION: The minimum supported leg length for side-to-side bridle attachments is 15 inches (381 mm).

CAUTION: For configurations with two motors, three pickup points, and a bridle, make sure to place the bridle

on the side with the higher load value.

38

Page 39

MG-LEOPARD/900 GRID ASSEMBLY GUIDE

!

!

!

Pickup Configurations with Three Motors

The MG-LEOPARD/900 grid supports the following pickup configurations with three motors.

3 Motors – 4 Pickup Points, Front Bridle (Left); 3 Motors – 3 Pickup Points, Rear bridle, Front Vee Plate (Right)

CAUTION: The minimum supported leg length for side-to-side bridle attachments is 15 inches (381 mm).

CAUTION: For configurations with three motors, four pickup points, and a bridle, make sure to place the two

motors on the side with the higher load value.

CAUTION: For configurations with the MVP motor Vee plate, which provides horizontal aiming of the array,

make sure to place the Vee plate on the side with the lower load value. For more information, see Chapter 7,

“MVP Motor Vee Plate.”

39

Page 40

CHAPTER 6: FLYING ARRAYS

!

Pickup Configurations with Four Motors

The MG-LEOPARD/900 grid supports the following pickup configurations with four motors.

4 Motors – 4 Pickup Points (Left); 4 Motors – 3 Pickup Points, Rear Bridle, Front Vee Plate (Right)

CAUTION: For configurations with the MVP motor Vee plate, which provides horizontal aiming of the array,

make sure to place the Vee plate on the side with the higher lower value. For more information, see Chapter 7,

“MVP Motor Vee Plate.”

40

Page 41

MG-LEOPARD/900 GRID ASSEMBLY GUIDE

USING MAPP TO CALCULATE SINGLE PICKUP POINTS

The MG-LEOPARD/900 grid has a center pickup bar with 13 pickup points. For configurations with a single pickup point and

single motor, you can use MAPP prediction software to calculate which pickup point to use to achieve the desired downtilt,

uptilt, or no tilt.

To calculate the single pickup point with MAPP:

1. In MAPP, choose Insert > Insert Flown Loudspeaker System.

2. In the Flown Loudspeaker System dialog box, in the elements list, do the following:

■ At the top of the Loudspeaker System Elements section, set the grid to one of the following options, depending on

whether a LEOPARD or 900-LFC is attached to the grid, and whether downtilt or uptilt is required:

– MG-LEOPARD/900 (LEOPARD Forward)

– MG-LEOPARD/900 (LEOPARD Rearward)

– MG-LEOPARD/900 (900-LFC Forward)

– MG-LEOPARD/900 (900-LFC Rearward)

■ To insert additional loudspeakers, click Add Element.

■ To remove a loudspeaker, click the loudspeaker to select it and click Remove Element.

■ To specify the splay angle for a loudspeaker, click in the Splay column and select an angle from the menu (for LEOPARD,

choose from –0.5 to –15 degrees; for the 900-LFC, choose –1.25, –2.50, –3.75, or –5.00 degrees).

3. To specify the grid tilt, in the Rotation About Reference Point section, enter an angle amount. Negative angles yield

downtilt. Positive angles yield uptilt. The Total splay angles for the loudspeakers (relative to horizontal) update.

4. Click Apply and Close. The flown loudspeaker system is inserted in the Sound Field.

5. Select View > Array COG. In the Sound Field, a magenta line representing the array’s center of gravity is displayed.

6. In the Sound Field, use the Zoom tool to draw a rectangle around the grid. The center of gravity line indicates the pickup

point to use to achieve the specified grid tilt amount.

7. Choose View > Center Line. Loudspeaker output lines are displayed in the Sound Field.

8. Adjust further, if necessary, the number of loudspeakers, loudspeaker splay angles, and grid tilt until the system’s acoustical requirements are met and the center of gravity aligns with one of the grid’s center pickup points.

41

Page 42

CHAPTER 6: FLYING ARRAYS

42

Page 43

CHAPTER 7: MVP MOTOR VEE PLATE

Front View

Top View

!

The optional MVP motor Vee plate fine-tunes the horizontal aim of LEOPARD and 900-LFC arrays ±16 degrees. The bottom

of the Vee plate attaches to the MG-LEOPARD/900 grid’s frontmost or rearmost point on the center pickup bar, while the top

corners of the Vee plate attach to two motors, which, when adjusted, affect the horizontal rotation of the grid. The Vee plate’s

attachment points require 3/4-inch or 7/8-inch shackles. The Vee plate should always be placed on the grid side (front or rear)

with the lower load value.

MVP Motor Vee Plate Attached to MTG-LEOPARD/900 Grid

MVP Motor Vee Plate, Pulling Up on Either Motor Rotates the Grid

CAUTION: Always use properly rated rigging hardware. The MVP motor Vee plate requires 3/4-inch or 7/8-inch

shackles for its attachment points.

43

Page 44

CHAPTER 7: MVP MOTOR VEE PLATE

!

!

CAUTION: The MVP motor Vee plate should always be placed on the grid side (front or rear) with the lower

load value.

NOTE: The MVP motor Vee plate is compatible with any Meyer Sound grid with front and rear center pickup

points.

MVP MOTOR VEE PLATE KIT CONTENTS

MVP Motor Vee Plate Kit, PN 40.215.184.01

Quantity Part Number Item

1 45.215.184.01 MVP motor Vee plate

MVP Motor Vee Plate Weight: 20 lbs (9.1 kg)

MVP MOTOR VEE PLATE LOAD RATINGS

The MVP motor Vee plate has the following maximum load ratings:

■ 7,129 lbs (3234 kg) at a 5:1 safety factor

■ 5,092 lbs (2310 kg) at a 7:1 safety factor

CAUTION: Potential risk of personal injury and damage to equipment. Do not exceed load ratings.

44

Page 45

CHAPTER 8: MTF-LYON/LEOPARD TRANSITION FRAME

!

!

!

With some restrictions, the optional MTF-LYON/LEOPARD transition frame flies up to 8 LEOPARDs at a 7:1 safety factor below

LYON arrays for downfill. The transition frame attaches to the bottom cabinet in the LYON array at an angle of 0 degrees and

is secured with the quick-release pins included with LYON. The top LEOPARD cabinet attaches to the transition frame’s inner

link slots and is secured with four 5/16 x 0.875-inch quick-release pins (red button) included with the transition frame. The configuration of GuideALinks for the top LEOPARD cabinet determines the angle of its attachment, from –4.5 to +10 degrees. The

MTF-LYON/LEOPARD transition frame is collapsible for easy transport (see “Collapsing the MTF-LYON/LEOPARD Transition

Frame” on page 47) and also includes rear pickup points for pull-back and pull-up (see “Using the MTF-LYON/LEOPARD Transition Frame for Pull-Back and Pull-Up” on page 49).

MTF-LYON/LEOPARD Transition Frame with LEOPARDs flown below LYON Array, Exploded View

CAUTION: When flying combined arrays, the total weight of the array, including any transition and pull-back

hardware, should be calculated before the array is flown to verify that the weight does not exceed the load ratings for the MTG-LYON grid. For more information, refer to the MTG-LYON Assembly Guide (PN 05.232.097.01) available at www.meyersound.com

CAUTION: Always use the 5/16 x 0.875-inch quick-release pins (red button) included with the MTF-

LYON/LEOPARD transition frame to secure the attached LEOPARD. Do not use the 5/16 x 0.063-inch quickrelease pins (black button) included with LEOPARD in the transition frame as they are shorter and will not lock in place.

CAUTION: Always use properly rated rigging hardware. The MTF-LYON/LEOPARD transition frame requires

1/2-inch or 5/8-inch shackles for its pickup points.

TIP: The MTF-LYON/LEOPARD transition frame can travel installed on top of LEOPARD stacks on the

MCF-LEOPARD caster frame.

.

45

Page 46

CHAPTER 8: MTF-LYON/LEOPARD TRANSITION FRAME

Ø0.88

[Ø22 mm]

Expanded

Collapsed

(Transport)

34.79

[884 mm]

21.98

[558 mm]

7.51

[191 mm]

16.77

[426 mm]

16.60

[422 mm]

28.79

[731 mm]

MTF-LYON/LEOPARD TRANSITION FRAME KIT CONTENTS

MTF-LYON/LEOPARD Transition Frame Kit, PN 40.232.140.01

Quantity Part Number Item

1 45.232.140.01 MTF-LYON/LEOPARD

transition frame

8 134.025 5/16 x 0.875-inch quick-

release pins (red button)

MTF-LYON/LEOPARD TRANSITION FRAME DIMENSIONS

MTF-LYON/LEOPARD Transition Frame Dimensions

MTF-LYON/LEOPARD Transition Frame Weight: 71 lbs (32.2 kg)

46

Page 47

MG-LEOPARD/900 GRID ASSEMBLY GUIDE

COLLAPSING THE MTF-LYON/LEOPARD TRANSITION FRAME

The MTF-LYON/LEOPARD transition frame collapses horizontally so it can travel installed on top of LEOPARD stacks on the

MCF-LEOPARD caster frame. When the transition frame is collapsed, it occupies a smaller footprint than the MCF-LEOPARD

caster frame.

MTF-LYON/LEOPARD Transition Frame Collapsed

Before attaching the MTF-LYON/LEOPARD transition frame to a LYON array, simply expand the frame and lock it with the

included 5/16 x 0.875-inch quick-release pins (red button).

MTF-LYON/LEOPARD Transition Frame Expanded, Exploded View

47

Page 48

CHAPTER 8: MTF-LYON/LEOPARD TRANSITION FRAME

!

!

MTF-LYON/LEOPARD TRANSITION FRAME LOAD RATINGS (LOUDSPEAKER)

Table 4 lists the maximum number of LEOPARDs that can be flown below LYON arrays with the MTF-LYON/LEOPARD transition frame. The LYON array configuration greatly affects the load ratings for the attached MTF-LYON/LEOPARD transition

frame. In addition, the number of LEOPARDs flown below the LYON array greatly affects the load rating for the MTG-LYON

grid. For additional grid requirements, refer to the MTG-LYON Assembly Guide (PN 05.232.097.01) available at

www.meyersound.com

/

Table 4: MTF-LYON/LEOPARD Transition Frame Load Ratings

Number of

Flown

LY ON s

610 8 10 8

79 8 10 8

89 7 10 8

99 5 10 8

10 9 5 10 8

11 9 2 9 7

12 7

13 4

14 2

15 8

16 6

17 4

18 2

.

Maximum Flown LEOPARDs

(No Restrictions)

All Splay Angles Allowed LYONs in Top Half of Array with Splay Angles of 2° or Less,

LYONs in Bottom Half of Array with Splay Angles of 5° or Less,

5:1 Safety Factor 7:1 Safety Factor 5:1 Safety Factor 7:1 Safety Factor

Maximum Flown LEOPARDs

(with Restrictions)

LEOPARDs with Any Splay Angle

94

92

9

CAUTION: Potential risk of personal injury and damage to equipment. Do not exceed load ratings.

CAUTION: When flying combined arrays, the total weight of the array, including any transition and pull-back

hardware, should be calculated before the array is flown to verify that the weight does not exceed the load ratings for the MTG-LYON grid. For more information, refer to the MTG-LYON Assembly Guide (PN 05.232.097.01) available at www.meyersound.com

.

NOTE: Additional array configurations for the MTF-LYON/LEOPARD transition frame (not shown in Table 4) are

possible. Use MAPP prediction software to verify whether configurations exceed load ratings. You can also use

MAPP to verify whether configurations meet BGV C1 requirements.

48

Page 49

MG-LEOPARD/900 GRID ASSEMBLY GUIDE

!

!

!

MTF-LYON/LEOPARD TRANSITION FRAME LOAD RATINGS (PULL-BACK)

When used for pull-back, the MTF-LYON/LEOPARD transition frame has the following maximum load ratings:

■ 1,400 lbs (635 kg) at a 5:1 safety factor

■ 1,000 lbs (454 kg) at a 7:1 safety factor

CAUTION: Potential risk of personal injury and damage to equipment. Do not exceed load ratings. To ver-

ify pull-back load ratings, see “Verifying Pull-Back Requirements in MAPP” on page 53.

CAUTION: When using the MTF-LYON/LEOPARD transition frame for pull-back, the number of flown

LEOPARDs should not exceed four. If more than four LEOPARDs are attached to the transition frame for downfill, and pull-back is required, the PBF-LEOPARD pull-back frame (attached to the bottom LEOPARD in the array)

must instead be used as the pull-back hardware.

CAUTION: The apex angle for the bridle attachment to the MTF-LYON/LEOPARD transition frame must not be

greater than 90 degrees. The minimum supported leg length for the bridle attachment to the MTFLYON/LEOPARD transition frame is 16 inches (406 mm). Using a bridle leg shorter than the recommended length

reduces the load rating and may damage the MTF-LYON/LEOPARD transition frame.

USING THE MTF-LYON/LEOPARD TRANSITION FRAME FOR PULL-BACK AND PULL-UP

The MTF-LYON/LEOPARD transition frame includes two rear pickup points that provide pull-back for extreme array downtilts. The pickup points can also be used for pull-up to expand the LYON array’s splay angles during installation so the blue

locking pins can be more easily inserted. The MTF-LYON/LEOPARD transition frame requires 1/2-inch or 5/8-inch shackles

for its pickup points.

MTF-LYON/LEOPARD Transition Frame with Pull-Back

49

Page 50

CHAPTER 8: MTF-LYON/LEOPARD TRANSITION FRAME

!

!

!

■ When the MTF-LYON/LEOPARD transition frame is used for pull-back, to tilt the array, the transition frame must be pulled

by a motor separate from and behind the MTG-LYON grid. The pull-back motor must not be attached to the grid.

CAUTION: When configuring arrays with pull-back, when in final position, the pull-back chain should not be

greater than ±30 degrees from vertical.

■ When the MTF-LYON/LEOPARD transition frame is used for pull-up, to expand the LYON array’s splay angles during

installation so the blue locking pins can be more easily inserted, the transition frame is pulled by a motor placed between

the transition frame and the RPP-LEO-M rear pull-up plate (attached to the MTG-LYON grid). For more information, refer

to the MTG-LYON Assembly Guide (PN 05.232.097.01) available at available at www.meyersound.com

.

CAUTION: When flying combined arrays, the total weight of the array, including any transition and pull-back

hardware, should be calculated before the array is flown to verify that the weight does not exceed the load ratings for the MTG-LYON grid. For more information, refer to the MTG-LYON Assembly Guide (PN 05.232.097.01) available at www.meyersound.com

.

CAUTION: Always use properly rated rigging hardware. The MTF-LYON/LEOPARD transition frame requires

1/2-inch or 5/8-inch shackles for its pickup points.

50

Page 51

CHAPTER 9: PBF-LEOPARD PULL-BACK FRAME

!

!

!

For applications requiring extreme array downtilt that are not possible with adjustments to the motors attached to the grid,

the optional PBF-LEOPARD pull-back frame can be attached to the bottom cabinet in LEOPARD arrays and pulled by a separate motor. The pull-back frame is secured to the bottom cabinet with the 5/16 x 0.875-inch quick-release pins (black button) included with LEOPARD. The PBF-LEOPARD pull-back frame requires 1/2-inch shackles for its two pickup points.

PBF-LEOPARD Pull-Back Frame Attached to Bottom LEOPARD, Exploded View

CAUTION: When configuring arrays with pull-back, when in final position, the pull-back chain should not be

more than ±30 degrees from vertical.

CAUTION: When flying arrays, the total weight of the array, including any pull-back and pull-up hardware,

should be calculated before the array is flown to verify its weight does not exceed the load ratings for the

MG-LEOPARD/900 grid. For more information, see “MG-LEOPARD/900 Grid Load Ratings” on page 30.

CAUTION: Always use properly rated rigging hardware. The PBF-LEOPARD pull-back frame requires 1/2-inch

shackles for its pickup points.

TIP: The PBF-LEOPARD pull-back frame can also be used to add downtilt to LEOPARDs groundstacked on top

of the 900-LFC. For more information, see “Adding Groundstack Tilt with the PBF-LEOPARD” on page 62.

51

Page 52

CHAPTER 9: PBF-LEOPARD PULL-BACK FRAME

22.29

[566 mm]

24.92

[633 mm]

3.25

[83 mm]

6.78

[172 mm]

Ø0.81

[Ø21 mm]

!

!

PBF-LEOPARD KIT CONTENTS

PBF-LEOPARD Pull-Back Frame Kit, PN 40.243.185.01

Quantity Part Number Item

1 45.232.125.01 PBF-LEOPARD pull-back

2 134.024 5/16 x 0.63-inch quick-

PBF-LEOPARD TRANSITION FRAME DIMENSIONS

frame

release pins (black button)

PBF-LEOPARD Pull-Back Frame Dimensions

PBF-LEOPARD Transition Frame Weight: 4.9 lbs (2.2 kg)

PBF-LEOPARD TRANSITION FRAME LOAD RATINGS

The PBF-LEOPARD pull-back frame has the following maximum load ratings:

■ 1,400 lbs (635 kg) at a 5:1 safety factor

■ 1,000 lbs (454 kg) at a 7:1 safety factor

CAUTION: Potential risk of personal injury and damage to equipment. Do not exceed load ratings. To ver-

ify pull-back load ratings, see “Verifying Pull-Back Requirements in MAPP” on page 53.

CAUTION: The apex angle for the bridle attachment to the PBF-LEOPARD pull-back frame must not be greater

than 90 degrees. The minimum supported leg length for the bridle attachment to the PBF-LEOPARD pull-back

frame is 16 inches (406 mm). Using a bridle leg shorter than the recommended length reduces the load rating and

may damage the PBF-LEOPARD pull-back frame.

52

Page 53

MG-LEOPARD/900 GRID ASSEMBLY GUIDE

!

VERIFYING PULL-BACK REQUIREMENTS IN MAPP

To verify array pull-back requirements in MAPP:

1. Insert the loudspeaker array and configure loudspeaker splay angles:

■ Choose Insert > Insert Flown Loudspeaker System.

■ In the Flown Loudspeaker System dialog box, at the top of the elements list, set the grid to one of the following options,

depending on whether a LEOPARD or 900-LFC is attached to the grid, and whether downtilt or uptilt is required. The elements list is populated with loudspeakers set to default splay angles.

– MG-LEOPARD/900 (LEOPARD Forward)

– MG-LEOPARD/900 (LEOPARD Rearward)

– MG-LEOPARD/900 (900-LFC Forward)

– MG-LEOPARD/900 (900-LFC Rearward)

■ To insert a transition frame or additional loudspeakers, click Add Element.

■ To remove a loudspeaker, click the loudspeaker to select it and click Remove Element.

■ To specify the splay angle for a loudspeaker, click in the Splay column and select an angle from the menu.

2. Verify whether the array complies with the required safety rating:

■ In the Safety Limits section, select the safety rating with which the array should comply: 7:1, 5:1, or BGV C1.

■ In the Rotation About Reference Point section, reduce the Angle amount for the array (to a negative value) so that the

Front Rigging Load amount is between 0 and +10 lbs.

■ If the Load Status is green (“Loudspeaker Configuration is Within the Rated Load Capacities”), the array is within compli-

ance. Proceed to the next step.

■ If the Load Status turns red (“Loudspeaker Configuration COG is Outside of Grid Pickup Points”), the array is not within

compliance. Return to the previous step and either reduce the number of loudspeakers in the array or adjust the loudspeaker splay angles.

3. Verify the array’s pull-back requirements:

■ In the Rotation About Reference Point section, enter the actual Angle amount required for the array’s downtilt.

■ If the Front Rigging Load amount (at the bottom of the dialog box) is a positive value, no pull-back hardware is required.

■ If the Front Rigging Load amount is a negative value, pull-back hardware is required. Make sure that the Front Rigging

Load amount (the negative value) does not exceed the maximum load ratings for the pull-back hardware (see

“PBF-LEOPARD Transition Frame Load Ratings” on page 52).

CAUTION: For arrays flown from multiple motors (for example, two motors attached to the grid and one motor

attached to the pull-back frame), to achieve the greatest stability, make sure to distribute the load to all motors.

53

Page 54

CHAPTER 9: PBF-LEOPARD PULL-BACK FRAME

54

Page 55

CHAPTER 10: GROUNDSTACKING WITH THE MG-LEOPARD/900 GRID

!

With some restrictions, the MG-LEOPARD/900 grid safely groundstacks up to:

■ 7 LEOPARDs

■ 5 LEOPARDs on top of 1 900-LFC (mixed groundstack)

■ 4 LEOPARDs on top of 2 900-LFCs (mixed groundstack)

■ 3 900-LFCs

CAUTION: Potential risk of personal injury and damage to equipment. Groundstacks with extreme splay

angles that locate the stack's center of gravity outside the grid (for example, seven LEOPARDs, each with 15-

degree splay angles) are not supported.

The loudspeaker at the bottom of the groundstack is secured to the grid’s four captive GuideALinks (two per side) with the

5/16 x 0.063-inch quick-release pins (black button) included with the loudspeaker.

MG-LEOPARD/900 Grid with Groundstacked LEOPARDs, Exploded View

55

Page 56

CHAPTER 10: GROUNDSTACKING WITH THE MG-LEOPARD/900 GRID

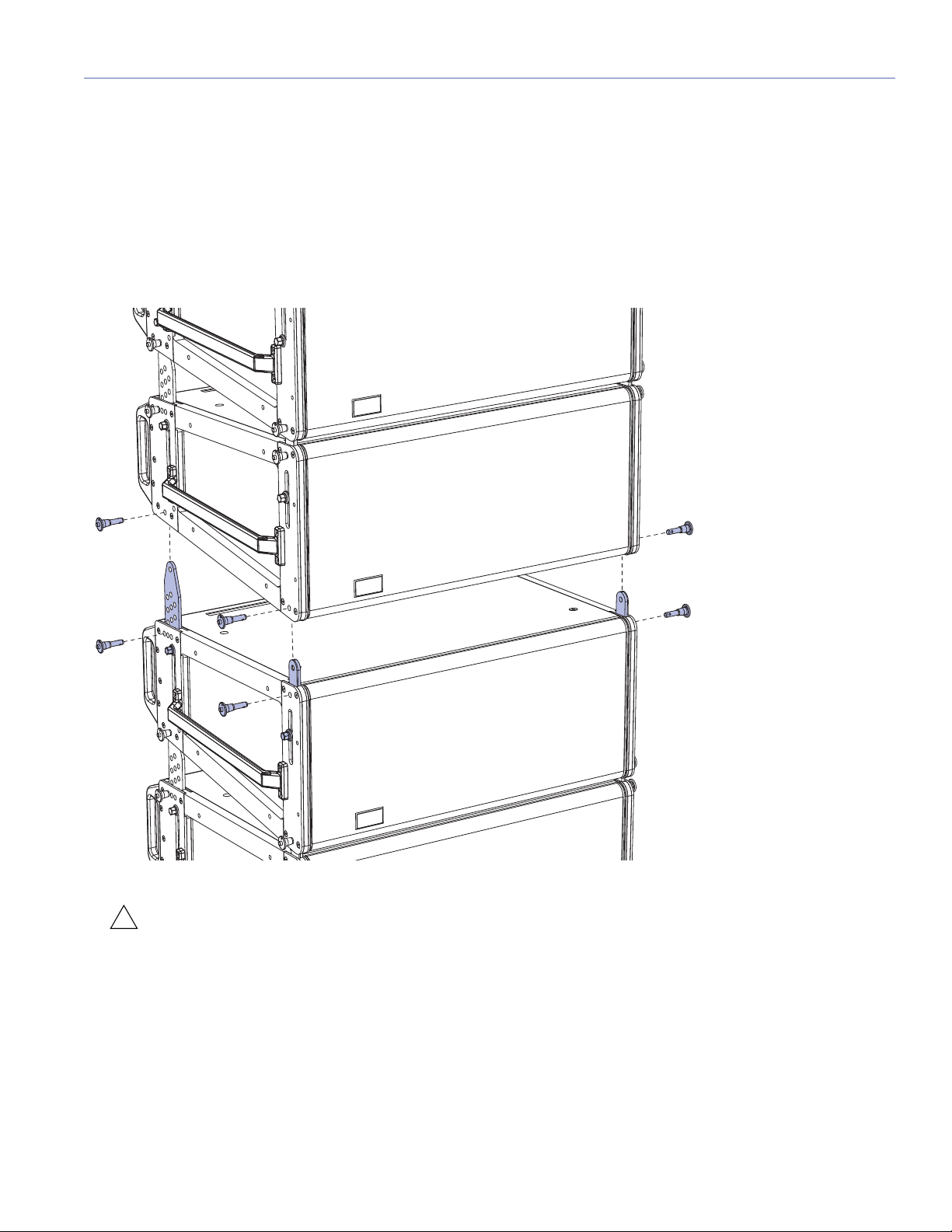

To groundstack 900-LFCs with the MG-LEOPARD/900 grid, the 900-LFCs must be equipped with the MRK-900 rigging kit.

MG-LEOPARD/900 Grid with Groundstacked 900-LFCs, Exploded View

56

Page 57

MG-LEOPARD/900 GRID ASSEMBLY GUIDE

FLOWN:

LEOPARD or 900-LFC LINK

FLOWN:

LEOPARD LINK

FLOWN:

900-LFC LINK

MG-LEOPARD/900

Multipurpose Grid

MAXIMUM DOWNTILT

MAXIMUM UPTILT

GROUNDSTACK

DOWNTILT / UPTILT 3º to 8º

STOW

B

A

GROUNDSTACK

LINK

GROUNDSTACK

LINK

STOW

B

A

MAXIMUM DOWNTILT

MAXIMUM UPTILT

MAXIMUM DOWNTILT

MAXIMUM UPTILT

STOWB

A

GuideALink

1. Remove quick-release pin.

2. Rotate link to A, B, or Stow.

3. Insert quick-release pin.

!

CONFIGURING GUIDEALINKS FOR THE MG-LEOPARD/900 GRID

The configuration of the MG-LEOPARD/900 grid’s GuideALinks, which can be set to A, B, or STOW, determines the angle of

attachment for the loudspeaker at the bottom of the groundstack.

MG-LEOPARD/900 Grid GuideALinks

Table 5 lists the available angles of attachment for groundstacked LEOPARDs and 900-LFCs.

Table 5: MG-LEOPARD/900 Grid, GuideALink Configurations

Rear

GuideALinks

Set To

Front

GuideALinks

Set To

Resulting Angle of Attachment

for Groundstacked

LEOPARD 900-LFC

AA+5°0°

AB+2°–3°

BA+8°+3°

BB+5°0°

TIP: Groundstacks can be curved by adjusting the splay angles between the loudspeakers in the stack. For

more information, see Chapter 4, “Loudspeaker GuideALinks.” Any loudspeaker splay angles within the

groundstack are relative to the angle of attachment of the bottom cabinet.

CAUTION: Potential risk of personal injury and damage to equipment. Groundstacks with extreme splay

angles that locate the stack's center of gravity outside the grid (for example, seven LEOPARDs, each with 15-

degree splay angles) are not supported.

57

Page 58

CHAPTER 10: GROUNDSTACKING WITH THE MG-LEOPARD/900 GRID

FLOWN:

LEOPARD or 900-LFC LINK

FLOWN:

LEOPARD LINK

FLOWN:

900-LFC LINK

MG-LEOPARD/900

Multipurpose Grid

MAXIMUM DOWNTILT

MAXIMUM UPTILT

GROUNDSTACK

DOWNTILT / UPTILT 3º to 8º

STOW

B

A

GROUNDSTACK

LINK

GROUNDSTACK

LINK

STOW

B

A

MAXIMUM DOWNTILT

MAXIMUM UPTILT

MAXIMUM DOWNTILT

MAXIMUM UPTILT

Front

MAXIMUM DOWNTILT

MAXIMUM UPTILT

A

A

MAXIMUM DOWNTILT

MAXIMUM UPTILT

GROUNDSTACK

DOWNTILT / UPTILT 3º to 8º

GROUNDSTACK

LINK

GROUNDSTACK

LINK

LEOPARD or 900-LFC LINK

FLOWN:

FLOWN:

LEOPARD LINK

FLOWN:

900-LFC LINK

STOW

B

STOW

B

MG-LEOPARD/900

Multipurpose Grid

MAXIMUM DOWNTILT

MAXIMUM UPTILT

Front

!

!

GRID ORIENTATION AND GROUNDSTACKS

When groundstacking with the MG-LEOPARD/900 grid, to ensure the greatest stability, the grid should be oriented so the

center of gravity for the groundstack is near the center of the grid. For groundstacks with uptilt, the grid should be oriented

forward. For groundstacks with downtilt, the grid should be oriented rearward. The grid’s orientation also determines

whether downtilt or uptilt can be applied to the groundstack with the optional angle feet (see “Adding Groundstack Tilt with

the Angle Feet” on page 59).

MG-LEOPARD/900 Grid Oriented for Groundstack with Uptilt (Forward)

MG-LEOPARD/900 Grid Oriented for Groundstack with Downtilt (Rearward)

CAUTION: Potential risk of personal injury and damage to equipment. Groundstacks with extreme splay

angles that locate the stack's center of gravity outside the grid (for example, seven LEOPARDs, each with 15degree splay angles) are not supported.

CAUTION: To further secure large groundstacks, particularly in outdoor installations with severe wind conditions,

attach tie-downs or weights to the grid along with a safety system directly to the groundstack.

58

Page 59

MG-LEOPARD/900 GRID ASSEMBLY GUIDE

FLO

W

N

:

L

E

O

P

A

R

D or 90

0-

L

F

C L

INK

FL

O

W

N

:

L

E

O

P

A

R

D L

INK

FLO

W

N

:

90

0

L

F

C L

INK

MG-

LEOPA

R

D

/900

Mul

tipurpose Gr

id

MAXIMUM DOWNTILT

MAXIMUM UPTILT

GROUNDSTACK

DOWNTILT / UPTILT 3º to 8º

STOW

B

A

GROUNDSTACK

LINK

GROUNDSTACK

LINK

STOW

B

A

MAXIMUM DOWNTILT

MAXIMUM UPTILT

MAXIMUM DOWNTILT

MAXIMUM UPTILT

3° to 8°

ADDING GROUNDSTACK TILT WITH THE ANGLE FEET

Tilt can be added to groundstacks with the optional MG-LEOPARD/900 groundstack tilt kit (PN 40.243.163.01). The kit

includes two angle feet that attach to the rear of the MG-LEOPARD/900 grid and add from 3 to 8 degrees of tilt to the entire

groundstack. Loudspeaker splay angles within the groundstack are relative to the tilt added with the angle feet. When the

grid is oriented forward, downtilt is added to the groundstack. When the grid is oriented rearward, uptilt is added to the

groundstack.

MG-LEOPARD/900 Grid with Optional Angle Feet, 8 Degrees of Downtilt

When using the angle feet for downtilt with the 900-LFC attached to the grid, the angle setting for 3 degrees is not avail-

able. In addition, the setting for 4 degrees is only possible when the grid’s GuideALinks are configured with the rear link

set to A and the front link set to B. The angle setting for 5 degrees is only possible when the grid’s GuideALinks are configured

with the rear link set to A and the front link set to A (or B).

59

Page 60

CHAPTER 10: GROUNDSTACKING WITH THE MG-LEOPARD/900 GRID

GROUNDSTACKING LEOPARDS ON THE 900-LFC

Up to five LEOPARDs can be groundstacked on top of a single 900-LFC (when equipped with the MRK-900 rigging kit). Up

to four LEOPARDs can be groundstacked on top of two 900-LFCs. The angle of attachment for the bottom LEOPARD is determined by the configuration of the 900-LFC’s GuideALinks. When the 900-LFC’s front GuideALinks are set to 0 degrees, the

available angles for the bottom LEOPARD are 5.00, 3.25, 1.50, 0, and –1.75 degrees.

LEOPARDs Groundstacked on 900-LFC, Exploded View

60

Page 61

MG-LEOPARD/900 GRID ASSEMBLY GUIDE

!

!!

The labels next to the 900-LFC’s middle GuideALinks indicate the splay angle for the attached LEOPARD (when the 900-LFC’s

front GuideALinks are set to 0 degrees). As the links are moved down, the splay angle increases. To stow the middle GuideALinks, move them all the way down to STOW and pin them.

900-LFC Middle GuideALinks Label

CAUTION: Potential risk of personal injury and damage to equipment. Groundstacks with extreme splay

angles that locate the stack's center of gravity outside the grid (for example, seven LEOPARDs, each with 15-

degree splay angles) are not supported.

CAUTION: To further secure large groundstacks, particularly in outdoor installations with severe wind conditions,

attach tie-downs or weights to the grid along with a safety system directly to the groundstack.

61

Page 62

CHAPTER 10: GROUNDSTACKING WITH THE MG-LEOPARD/900 GRID

Adding Groundstack Tilt with the PBF-LEOPARD