Metz eta plus ELC X6i-60, eta plus ELC X6B-60, eta plus ELC X6-60, eta plus ELC X8-80, eta plus ELC X8B-80 Technical Documentation Manual

...Page 1

our

name is our principle

UV-

TECHNOLOGY

Technical Documentation

®

ELC

X-Series

GB

eta plus electronic gmbh

Lauterstraße 29, 72622 Nürtingen, Telefon +49 7022 6002-80, Fax +49 7022 65854, E-mail: info@eta-uv.de, www.eta-uv.de

Eingetragen unter HRB 724321 AG Stuttgart, USt.-Id.-Nr. DE 146267800, Geschäftsleitung: Uwe Uhlemann, Dr. Markus Roth

Page 2

ELC® („Electronic Lamp Control“) is a registered trademark of

IST Metz GmbH.

ELC X-Series-V1.3-09.16-GB subject to technical alterations

Page 3

Contents page I

Contents

1 Safety ................................................................................................ 1

1.1 Definition of symbols ................................................................................. 1

1.2 Safety advice ............................................................................................... 1

1.3 Correct operation ........................................................................................ 2

1.4 Extended use .............................................................................................. 2

2 Description of functions .................................................................. 3

3 Installation ........................................................................................ 4

3.1 Mounting of casing ..................................................................................... 4

3.1.1 Mounting of single ELC ................................................................................. 4

3.1.2 Mounting in a stack ....................................................................................... 5

3.2 Connection .................................................................................................. 6

3.2.1 Ballast types X4–X8 ...................................................................................... 6

3.2.2 Overview profile of the cable gasket X4-X8 ................................................... 7

3.2.3 Overview power connections X4-X8 .............................................................. 8

3.2.4 Ballast types X12-X24 ................................................................................... 9

3.2.5 Overview profile of the cable gasket X12-X24 ............................................. 10

3.2.6 Overview power connections X12 ............................................................... 11

3.2.7 Overview power connections X24 ............................................................... 12

3.2.8 X100: Mains connection .............................................................................. 13

3.2.9 X600: Connecting the lamp feeder cable ..................................................... 14

3.2.10 Overview of control and bus connections ................................................ 15

3.2.11 X1 / X2: PROFIBUS ................................................................................ 16

3.2.12 X3: PROFIBUS T-coupler ....................................................................... 17

3.2.13 X805 and X806: Control cables ............................................................... 18

3.2.14 X808/X300: Service interface .................................................................. 20

3.3 Comments on the safety functions of the ELC ...................................... 22

3.3.1 Safety relay ................................................................................................. 22

3.3.2 Initialisation signal ....................................................................................... 23

3.4 Configuration ............................................................................................ 23

3.4.1 Setting up the PROFIBUS address ............................................................. 24

3.4.2 Checking the PROFIBUS connection and error indication ........................... 25

3.4.3 Setting lamp power via PROFIBUS ............................................................. 26

3.4.4 Extended temperature and power range ..................................................... 28

3.4.5 To read out ELC serial number and software version .................................. 30

4 Operation of the ELC ..................................................................... 31

4.1 Initial operation ......................................................................................... 31

ELC X-Series-V1.3-09.16-GB subject to technical alterations

Page 4

Contents page II

4.2 Switching on the ELC ............................................................................... 31

4.3 Activating the safety circuits ................................................................... 31

4.4 Switching on the lamp .............................................................................. 32

4.5 Dimming operation ................................................................................... 34

4.6 Switching off the lamp.............................................................................. 34

5 Monitoring, warning, error, repair ................................................ 35

5.1 Mains voltage monitoring ........................................................................ 35

5.2 Earth fault control ..................................................................................... 35

5.3 Warning messages ................................................................................... 37

5.4 Error ........................................................................................................... 39

5.4.1 Error messages ........................................................................................... 39

5.4.2 Display messages and trouble shooting ...................................................... 41

5.4.3 Resetting the error register .......................................................................... 43

5.5 Repair ELC ................................................................................................ 43

6 Technical Data ............................................................................... 44

6.1 ELC X4, X4B .............................................................................................. 44

6.2 ELC X6, X6B, X6i ....................................................................................... 47

6.3 ELC X8, X8B, X8 extended range ............................................................ 50

6.4 ELC X12, X12i, X12B ................................................................................. 53

6.5 ELC X24, X24i, X24B ................................................................................. 56

ELC X-Series-V1.3-09.16-GB subject to technical alterations

Page 5

1 Safety page 1

☞

1 Safety

1.1 Definition of symbols

Stop (Stop Danger). This symbol warns of serious danger of severe injury to

persons. It must be strictly observed.

Attention (Warning). This symbol indicates information the non-observance of

which can lead to extensive damage to property. The safety warning must be

strictly observed.

Information. This symbol indicates key information on use. Non-observance can

lead to failure.

1.2 Safety advice

The ELC must be installed and connected in compliance with existing regulations

and practices. This is e.g. EN 60204-1 in Europe.

Repairs on the ELC may only be carried out by the manufacturer.

The installation and starting up may only be carried out by skilled electricians.

Do not open the ELC before it is disconnected from the mains. BEWARE OF

RESIDUAL VOLTAGE! The unit may still be live up to several minutes (see

chapter 6) after it has been switched off.

ELC X-Series-V1.3-09.16-GB subject to technical alterations

Page 6

1 Safety page 2

The ELC causes a leakage current given in chapter 6.

Safeguarding by means of leakage current protection type A and type AC

according to IEC 60755 is not permitted!

The ELC operates in principle as a frequency converter and is equipped with a

mains filter whose leakage current could trip the earth leakage detector RCD.

Contact to the grounding connector must always be ensured.

Additional measures must be taken to ensure that there is no danger when

touching the appliance. This could be by means of a universal leakage current

protection type B, taking into consideration the increased response threshold, or

by means of an independent equipotential connection.

The leakage current through the interference suppression capacitors demands

as per EN 50178 the use of a second protective earth conductor in parallel to the

first one. The cross-section of each earth conductor corresponds at least to the

cross-section of an outer conductor.

1.3 Correct operation

The ELC is conceived as an electronic ballast exclusively for the operation of

lamps approved for this ELC type.

Any other use is deemed as misuse. The manufacturer will not assume liability

for damage resulting from misuse.

A pre-requisite for authorised operation of the ELC is the observance of both the

operating and maintenance instructions and the safety advice.

1.4 Extended use

Extended use beyond the operating specifications as stated is not permitted.

The manufacturer will not assume liability if the equipment is used in any other

way. The operator acts at his own risk.

Any operation beyond the scope of the authorised operation is considered to be

misuse.

ELC X-Series-V1.3-09.16-GB subject to technical alterations

Page 7

2 Description of functions page 3

2 Description of functions

The electronic ballast ELC is designed to operate medium pressure discharge lamps as

described in chapter 6.

In contrast to conventional ballasts (inductive lamp ballast or transformer or transformer with

transductor), with an ELC the lamp is operated with high frequency (approx. 100 kHz). The

lamp does not flicker and dimming is infinitely adjustable within a wide power range (see

chapter 6).

Dimming

The possibility of dimming the lamp has two advantages. Firstly the lamp can be switched to

minimum load (standby operation) during longer idle times and energy can thus be saved.

Secondly the optimum lamp power can be determined and adjusted as appropriate.

Power control

The ELC offers a high level of lamp power constancy due to its integrated power control.

Variations in operating voltage of 400-480V ± 10 % do not affect lamp power. Between 310360V a reduction of output power according to chapter 6 has to be taken into account.

Ignition device

When the lamp is switched on the ELC initiates trigger pulses to fire the lamp; a separate

ignition device is not required.

Other performance characteristics

• High level of electrical efficiency.

• Low harmonic distortion of the mains current due to integrated power factor corrector.

• Configuration, control and monitoring of the ELC is carried out via PROFIBUS-interface.

• The ELC monitors the insulation resistance of the lamp output wiring (earth fault control).

• The potential of both lamp outputs is isolated from that of the supply voltage.

• The ELC is both short-circuit proof and safe in open circuit operation at the lamp output.

ELC X-Series-V1.3-09.16-GB subject to technical alterations

Page 8

3 Installation page 4

equipment. An appropriate distance must be maintained to scatter field

☞

☞

3 Installation

3.1 Mounting of casing

The ELC may only be installed as described in 3.1.1 and in 3.1.2, allowing for at

least the minimum spacing as shown in Fig. 2.

Horizontal mounting upside down is not allowed. All vertical mounting orientations

are possible.

The ELC should not be mounted in the immediate proximity of sensitive electronic

transformers or other inductors.

The ELC is equipped with built-in fans to ensure forced air cooling. Air ducts and

optional filters must be designed to allow the air flow described in chapter 6. The

ambient temperature must not exceed the values described in chapter 6. The

ambient temperature is measured by the ELC and will be stored within the internal

error memory.

3.1.1 Mounting of single ELC

The side surfaces of the housing contain 2 T-slots each, which are suitable for sliding blocks

6mm groove, M5 by Bosch Rexroth (available as accessories). Fig. 1 indicates the relative

interspace of the two T-slots and distance to the outer face of the housing. Fig. 2 shows the

horizontal mounting orientation including the minimum spacing at the back of the ELC.

Alternatively the ELC may be mounted flush with the rear panel if a cut out for the ventilation

is ensured.

Fig. 1: Position of the T-slots

ELC X-Series-V1.3-09.16-GB subject to technical alterations

Page 9

3 Installation page 5

Fig. 2: Mounting of the ELC, horizontal orientation

3.1.2 Mounting in a stack

Up to 12 ELC may be mounted on top of each other. To fasten the ballasts onto each other a

custom-built connector has to be used (available as accessories):

Fig. 3: Connector for stack mounting

ELC X-Series-V1.3-09.16-GB subject to technical alterations

Page 10

3 Installation page 6

X805

X806

3.2 Connection

To gain access to the electrical contacts the front hood has to be removed.

Loosen the screwing (6 x TX20-screw) and

detach the front hood.

The following paragraphs describe the electrical connections.

3.2.1 Ballast types X4–X8

Cable gasket

X1

X2

X3

X600

Fig. 4: Overview of electrical connections X4-X8

X100

Cable gasket: Place the cables into the

rubber surrounds and fix them onto the

clamp with cable straps

ELC X-Series-V1.3-09.16-GB subject to technical alterations

Page 11

3 Installation page 7

☞

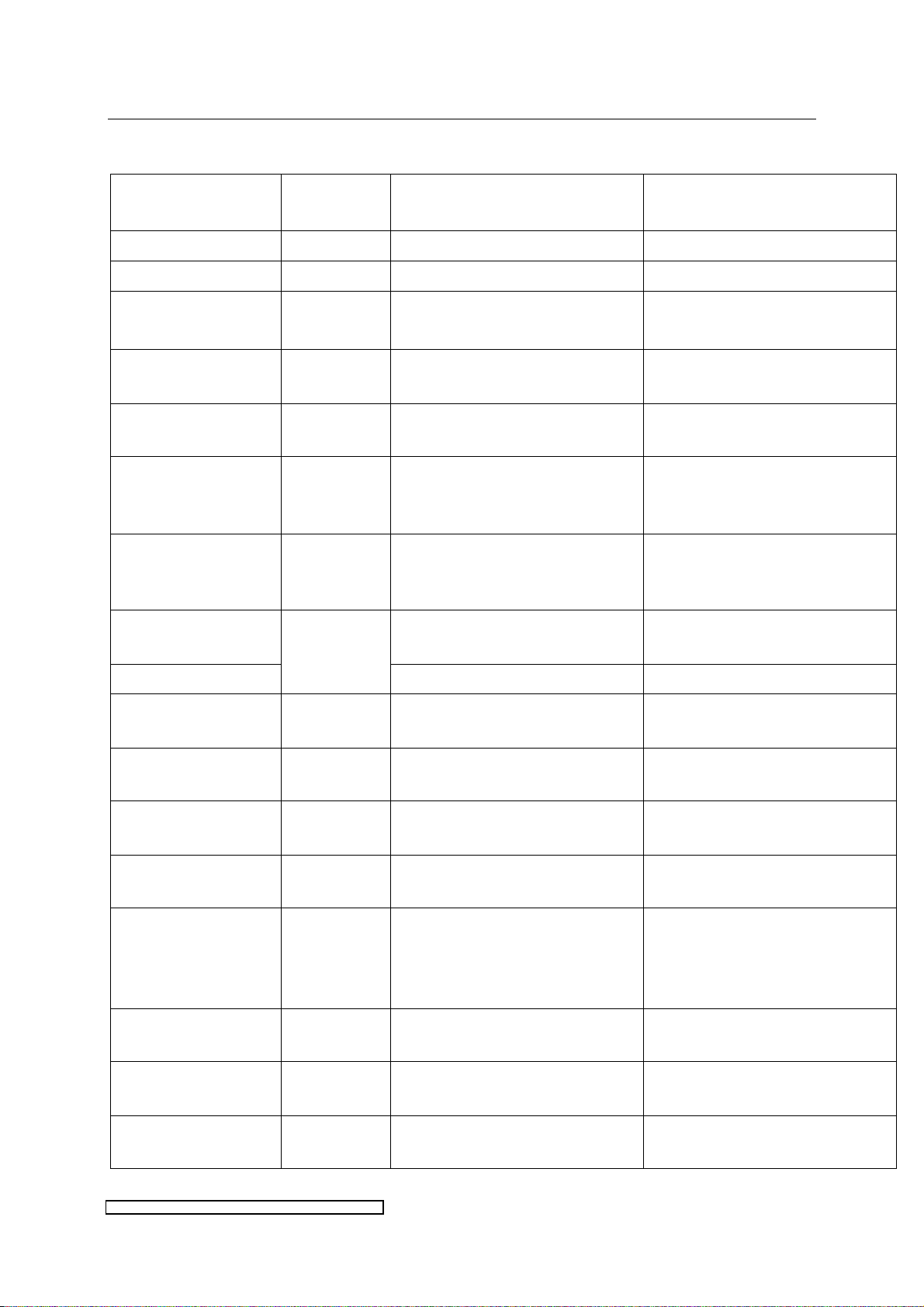

3.2.2 Overview profile of the cable gasket X4-X8

The IP protection level given in chapter 6 is only guaranteed if every cable’s lead-in is

completely sealed. It is therefore necessary to use cables of the nominal diameters given in

the table below.

Cable gasket Cable

diameter

7.5mm ±5%

9.3mm ± 5%

4.9mm ± 5%

5.2mm ± 5%

7.5mm ± 5%

6.7mm ± 5%

Connector

designation

X3

X600 (1, 3) Lamp output

X600 (2) PE

X806 Control 7 9535 130mm

X1 Bus in 4 9545 120mm

X805 Control 11 9536 130mm

Function Connector

no. of pins

Bus out

(T-coupler)

3 9546 120mm

3 9532 155mm

Connector

type eta

ID.:

(gasket to

connector)

Cable

length

Plug contact

blank wire or

ferrule

blank wire or

ferrule

ferrule

blank wire or

ferrule

ferrule

7.5mm ± 5%

12.2mm ± 5%

X100

If the control concept requires fewer control and bus cables the

holes of the rubber surround have to be sealed with blank plugs

ELC X-Series-V1.3-09.16-GB subject to technical alterations

(available as accessories).

X2 Bus out 4 9545 120mm

Mains input

(2 x Phase,

2 x PE)

4 9531 490mm

blank wire or

ferrule

blank wire or

ferrule

Page 12

3 Installation page 8

☞

3.2.3 Overview power connections X4-X8

Fig. 5: Power connection X4-X8

Fig. 5 shows the electrical wiring. Please consider the following aspects:

Voltage balancing: on installing several ELCs the ballasts have to be equally distributed on

all phases (e.g. 1st ballast L1/L2, 2nd ballast L2/L3, 3rd ballast L3/L1 etc.).

Protective conductors: it is strongly recommended to connect both PE-lines to X100. If the

plug is accidentally tilted and not completely locked at least one PE cable will have contact.

Furthermore the required cross-section of 10mm² or more has to be realized with two PE lines

because of the plug type.

Cut-Out and loop impedance: The installation of an automatic cut-out is required for line

protection. It is necessary to check the loop impedance afterwards.

Using an RCD: if an RCD is required we recommend an RCD type B. When using a RCD

consider the leakage current given in chapter 6.

Shielding:

The lamp feeder cable shielding must be connected to the ELC at the designated

shield clamp, see chapter 3.2.9.

If desired, the shielding can also be connected to the lamp unit.

ELC X-Series-V1.3-09.16-GB subject to technical alterations

Page 13

3 Installation page 9

3.2.4 Ballast types X12-X24

Cable gasket

Lamp

connection

Control connections

Mains connection

Fig. 6: Overview of electrical connections X4-X8

Cable gasket: Place the cables into the

rubber surrounds and fix them onto the

clamp with cable straps.

ELC X-Series-V1.3-09.16-GB subject to technical alterations

Page 14

3 Installation page 10

☞

3.2.5 Overview profile of the cable gasket X12-X24

The IP protection level given in chapter 6 is only guaranteed if every cable’s lead-in is

completely sealed. It is therefore necessary to use cables of the nominal diameters given in

the table below.

Cable gasket Cable

diameter

7.5mm ±

5%

9.3mm ±

5%

4.9mm ±

5%

5.2mm ±

5%

7.5mm ±

5%

6.7mm ±

5%

Connector

designation

X3

X600 (1, 3) Lamp output

X600 (2) PE

X806 Control 7 9535 130mm

X1

X805 Control 11 9536 130mm

Function Connector

no. of pins

Bus out

(T-coupler)

Bus in

3 9546 120mm

3 9532 155mm

4 9545 120mm

Connector

type eta

ID.:

(gasket to

connector)

Cable

length

Plug contact

blank wire or

ferrule

blank wire or

ferrule

ferrule

blank wire or

ferrule

ferrule

7.5mm ±

5%

12.2mm ±

5%

X2 Bus out 4 9545 120mm

X100

If the control concept requires fewer control and bus cables the

holes of the rubber surround have to be sealed with blank plugs

(available as accessories).

ELC X-Series-V1.3-09.16-GB subject to technical alterations

(2 x Phase, 2

Mains input

x PE)

4 9531 490mm

blank wire or

ferrule

blank wire or

ferrule

Page 15

3 Installation page 11

☞

3.2.6 Overview power connections X12

Fig. 7: Power connection X12

Please consider the following aspects:

Voltage balancing: on installing several ELCs the ballasts have to be equally distributed on

all phases (e.g. 1st ballast L1/L2, 2nd ballast L2/L3, 3rd ballast L3/L1 etc.).

Cut-Out and loop impedance: The installation of an automatic cut-out is required for line

protection. It is necessary to check the loop impedance afterwards.

Using an RCD: if an RCD is required we recommend an RCD type B. When using a RCD

consider the leakage current given in chapter 6.

Shielding:

The lamp feeder cable shielding must be connected to the ELC at the designated

shield clamp, see chapter 3.2.9.

If desired, the shielding can also be connected to the lamp unit.

ELC X-Series-V1.3-09.16-GB subject to technical alterations

Page 16

3 Installation page 12

3.2.7 Overview power connections X24

Fig. 8: Power connections X24

Please consider the following aspects:

Connecting the lines: The Slave Modul has only to be connected to power supply and one

PE-line on X100. The Master Modul has to be connected to power supply and one PE-line on

X100, and additionally to all bus-, control- and lamp cables.

Voltage balancing: on installing several ELCs the ballasts have to be equally distributed on

all phases (e.g. 1st ballast L1/L2, 2nd ballast L2/L3, 3rd ballast L3/L1 etc.).

Cut-Out and loop impedance: The installation of an automatic cut-out is required for line

protection. It is necessary to check the loop impedance afterwards.

Using an RCD: if an RCD is required we recommend an RCD type B. When using a RCD

consider the leakage current given in chapter 6.

ELC X-Series-V1.3-09.16-GB subject to technical alterations

Page 17

3 Installation page 13

☞

☞

Shielding:

The lamp feeder cable shielding must be connected to the ELC at the designated

shield clamp, see chapter 3.2.9.

If desired, the shielding can also be connected to the lamp unit.

3.2.8 X100: Mains connection

L1

PE

L2

PE

X4-X8: Fix the mains connection cables

within the cable holder beneath the heat

sink with cable straps.

Pay attention not to pinch the cables when closing the front hood.

ELC X-Series-V1.3-09.16-GB subject to technical alterations

X12-X24: Fix the mains connection cables

onto the cable holder with cable straps as

shown in the picture above.

Page 18

3 Installation page 14

☞

3.2.9 X600: Connecting the lamp feeder cable

The lamp feeder cable must correspond with the cable parameters described in

chapter 6.

X4-X8: lamp connector

X12-X24: connections on

main board.

PE may be collected of pin 2 of the

connector in order to earth the lamp

housing. If the lamp-housing is

earthed otherwise, the pin has to be

left open.

ELC X-Series-V1.3-09.16-GB subject to technical alterations

The shield clamp is provided for the

shield of the lamp feeder cable. For

this cable the cable strap is not

necessary.

The lamp feeder cable between the

switch cabinet and lamp assembly

must be laid in a protected way. For

the correct installation of the lamp

assembly and lamp please observe

the corresponding manufacturer’s

instructions.

Page 19

3 Installation page 15

X1/X2 : PROFIBUS

3.2.10 Overview of control and bus connections

The control cables are connected by means of the plug connections available as accessories.

All control circuits must be earthed upon installation.

The connector positions are shown in Fig. 9 or Fig. 10 and will be explained in the following

tables.

X3: PROFIBUS T-coupler

X808: Service interface

X806: Control cable

X805: Control cable

Fig. 9: Control and bus connections X4-X8

X300: Service USB

X1/X2: PROFIBUS

X3: PROFIBUS

T-coupler

X122: int. connection

X805: Control cable

X102: not in use

X123: int. connection

X806: Control cable

X605: int. connection

X104: Service PFC

X604: int. connection

ELC X-Series-V1.3-09.16-GB subject to technical alterations

Fig. 10: Control and bus connections X12-X24

Page 20

3 Installation page 16

☞

1

4

3.2.11 X1 / X2: PROFIBUS

To ensure secure data transmission the use of a PROFIBUS-specific cable is

recommended.

Connector pin assignment:

Fig. 11: Termination of PROFIBUS

The shield has to be put on Pin 1 = BUS GND. Isolate with shrunk-on sleeve.

The PROFIBUS contacts of X1 and X2 are internally connected. According to requirements

apply a terminator in compliance with PROFIBUS-Norm IEC 61158.

Pin assignment X1 / X2:

Designation X1 X2 Description technical

BUS GND X1.1 X2.1 GND isolated for PROFIBUS Shield connection PROFIBUS

BUS A X1.2 X2.2 Data line PROFIBUS A Bus signal A

BUS B X1.3 X2.3 Data line PROFIBUS B Bus signal B

BUS VCC X1.4 X2.4 external supply voltage 5V

isolated for PROFIBUS

+5V DC isolated, output for

terminator

ELC X-Series-V1.3-09.16-GB subject to technical alterations

Page 21

3 Installation page 17

1

3

3.2.12 X3: PROFIBUS T-coupler

Connector pin assignment:

The shield has to be put on Pin 1 = BUS GND.

Isolate with shrunk-on sleeve.

Pin assignment X3:

Designation Number Description technical

BUS GND X3.1 GND isolated for PROFIBUS Shield connection PROFIBUS

BUS A X3.2 Data line PROFIBUS A Bus signal A

BUS B X3.3 Data line PROFIBUS B Bus signal B

The T-coupler connection may be used as a PROFIBUS repeater. Via the T-coupler (see Fig.

12) the PROFIBUS-data lines A and B as well as their reference ground may be applied

(galvanically isolated) to another slave device. The T-coupler already contains a termination

according to Fig. 11. Solely a bitrate of 500kbit is applicable. If the T-coupler connection is not

required X3 may be left open.

1.4

X1

Fig. 12: Schematic of the T-coupler connection

1.3

1.2

1.1

galvanic isolation

T-coupler

3.1 3.2 3.3

X3

2.4

2.3

2.2

2.1

X2

ELC X-Series-V1.3-09.16-GB subject to technical alterations

Page 22

3 Installation page 18

Continuous contact, connected

time buffer voltage after

1

7

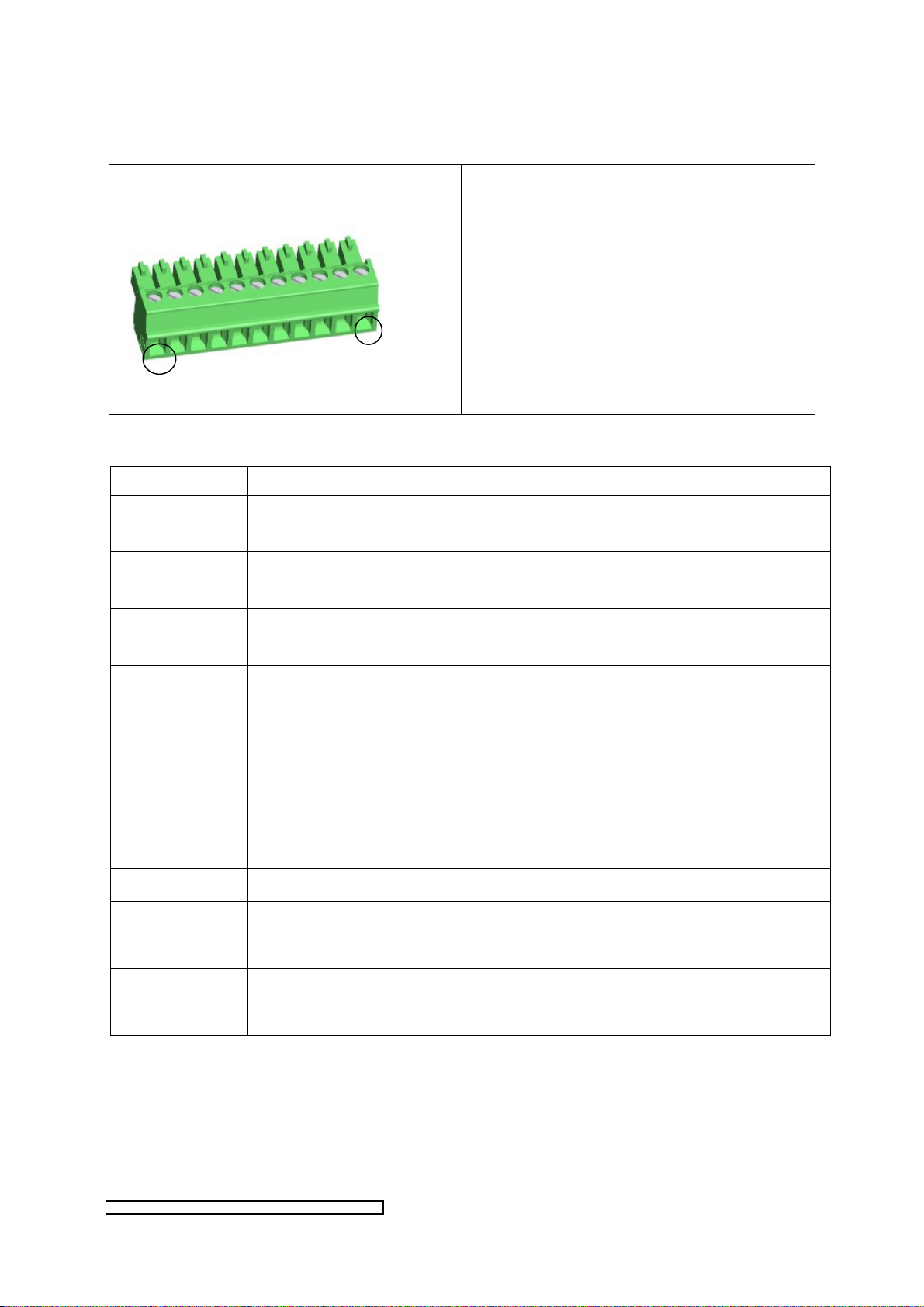

3.2.13 X805 and X806: Control cables

Fig. 13 on page 21 shows the interconnection of X805 and X806. Comments on the wiring are

given in the following tables.

X806:

Connector pin assignment:

Connection torque:

min. 0.22 Nm

max. 0.25 Nm

Pin assignment X806:

Designation Number Description technical

Interconnection

OUT

Safety Relay IN X806.2 Control signal input safety relay

X806.1

to X805.1

+24V DC

max. 1A, 24V DC

Control signal (+24V DC ±

10% / 35mA) for the safety

relay in reference to X806.7

(GND)

Init Signal IN X806.3 Input initialisation signal for

safety shutdown +24Vext.

Shield X806.4 Continuous contact, connected

24V DC ± 10% external supply

in reference to X806.7 (GND)

max. 1A, 24V

to X805.4, usable for shield of

the control cable

24V_OUT X806.5 Output 24V DC,

connected to X805.5

24V_USV* X806.6 Short-

emergency shutdown/switch-off

24V DC ± 10%,

max. 1.8A

Capacitance 47mF +/-20%

24V +/-10%

24V_GND X806.7 Common (GND) GND

* 24V_USV available for certain ELC-types only

ELC X-Series-V1.3-09.16-GB subject to technical alterations

Page 23

3 Installation page 19

1

X805:

Connector pin assignment:

Connection torque:

min. 0.22 Nm

max. 0.25 Nm

11

PIN-assignment X805:

Designation Number Description technical

Interconnection

IN

Safety NC 1 X805.2 Feedback contact 1 safety relay Normally closed contact

Safety NC 2 X805.3 Feedback contact 2 safety relay Normally closed contact

X805.1 Continuous contact, connected

to X806.1

max. 1A, 24V

24V / 1A

24V / 1A

Shield X805.4 Continuous contact, connected

max. 1A, 24V

to X806.4, usable for shield of

the control cable

24V_IN X805.5

Connection for external supply

voltage, connected to X806.5

24V DC ± 10%, current

consumption of the ELC control

circuitry see chapter 6

24V_GND X805.6

Common (GND),

GND

connected to X806.7

not connected X805.7 Not connected

UV Select NO 2 X805.8 Feedback contact 2 UV-select Normally open contact 24V/1A

UV Select NO 1 X805.9 Feedback contact 1 UV-select Normally open contact 24V/1A

UV Ready NO 2 X805.10 Feedback contact 2 UV-ready Normally open contact 24V/1A

UV Ready NO 1 X805.11 Feedback contact 1 UV-ready Normally open contact 24V/1A

ELC X-Series-V1.3-09.16-GB subject to technical alterations

Page 24

3 Installation page 20

NB: X805.8 to X805.11: the contacts which are normally open (cp. Fig. 13) will be closed as

soon as the corresponding bit is set in Register [Lamp Control] of the PROFIBUS output-data

(cp. paragraph 3.4). Bit 6 closes UV Select, Bit 7 closes UV Ready. Use if required, not

essential for operating the ELC.

PROFIBUS-output-data (Master → ELC)

ByteNr.

Name

0 1 2 3

[Power

Set

Value]

[Installed

Lamp

Power]

4

[Lamp

Control]

5

[Reserved]

↓

Bit 7 6

Name UV

Ready

3.2.14 X808/X300: Service interface

For use by the manufacturer.

UV

Select

5 4 3 2 1 0

n/a Extended

Range

n/a n/a Clear

Error

Start

Lamp

ELC X-Series-V1.3-09.16-GB subject to technical alterations

Page 25

3 Installation page 21

Fig. 13: Circuit diagram of the control connectors X805 and X806

ELC X-Series-V1.3-09.16-GB subject to technical alterations

Page 26

3 Installation page 22

3.3 Comments on the safety functions of the ELC

In addition to the safety functions included in all previous ELC-types such as earth fault

detection, temperature limit, safe operation in both short-circuit and open circuit at the lamp

output, the ELC X-Series includes an additional function in the form of the definite lamp

shutdown. To date this function was assured by external components, e.g. a power contactor

cutting off the mains supply voltage of the ELC.

The definite lamp shutdown is implemented using two independent circuits which can be

regarded as redundant functions in terms of the safety assessment of the installation. The first

lamp shutdown function contains a safety relay which cuts the voltage-output of the ELC via

hardware. This safety function can be monitored by appropriate processing of the feedback

contacts „Safety NC1 + Safety NC2“.

A second safety shutdown may be realized with the input „Init Signal IN“. Here the cut off of

the output voltage is based on software.

The status of both safety circuits may be read out by PROFIBUS. However they can not be

deactivated via software. It is therefore necessary to apply 24V to both inputs „Safety Relay

IN“ and „Init Signal IN“. If the safety fuctions are not used it is possible to set wire jumpers

between „24V_Out“ (X806.5) and „Safety Relay IN“ (X806.2) and „Init Signal IN“ (X806.3).

Fig. 13 on page 21 shows an overview of the circuits.

3.3.1 Safety relay

To set the ELC ready for operation, the safety relay K1 has to be activated by applying +24V

to pin X806.2.

As long as the safety relay is not activated, lamp operation is not possible! There are two

feedback paths:

• a normally closed relay contact. It may be tapped on pins X805.2 and X805.3.

• the [Warning Register] of the PROFIBUS-input-data (see below and paragraph 5.3: Bit

4 {Safety Relay Open})

If the safety relay is deactivated during lamp operation, lamp operation will be shut down. After

reactivating the safety relay, the lamp has to be restarted.

ELC X-Series-V1.3-09.16-GB subject to technical alterations

Page 27

3 Installation page 23

3.3.2 Initialisation signal

Furthermore lamp operation will not be allowed unless +24V are applied to pin X806.3. This is

an additional monitoring function for the safe operation of the installation. The status of pin

X806.3 is visualized in the [Warning Register] of the PROFIBUS-input-data (see below and

paragraph 5.3: Bit 7 {Init Signal Ok}).

If the initialisation signal is deactivated during lamp operation, lamp operation will be shut

down. After re-applying the initialisation signal, the lamp has to be restarted.

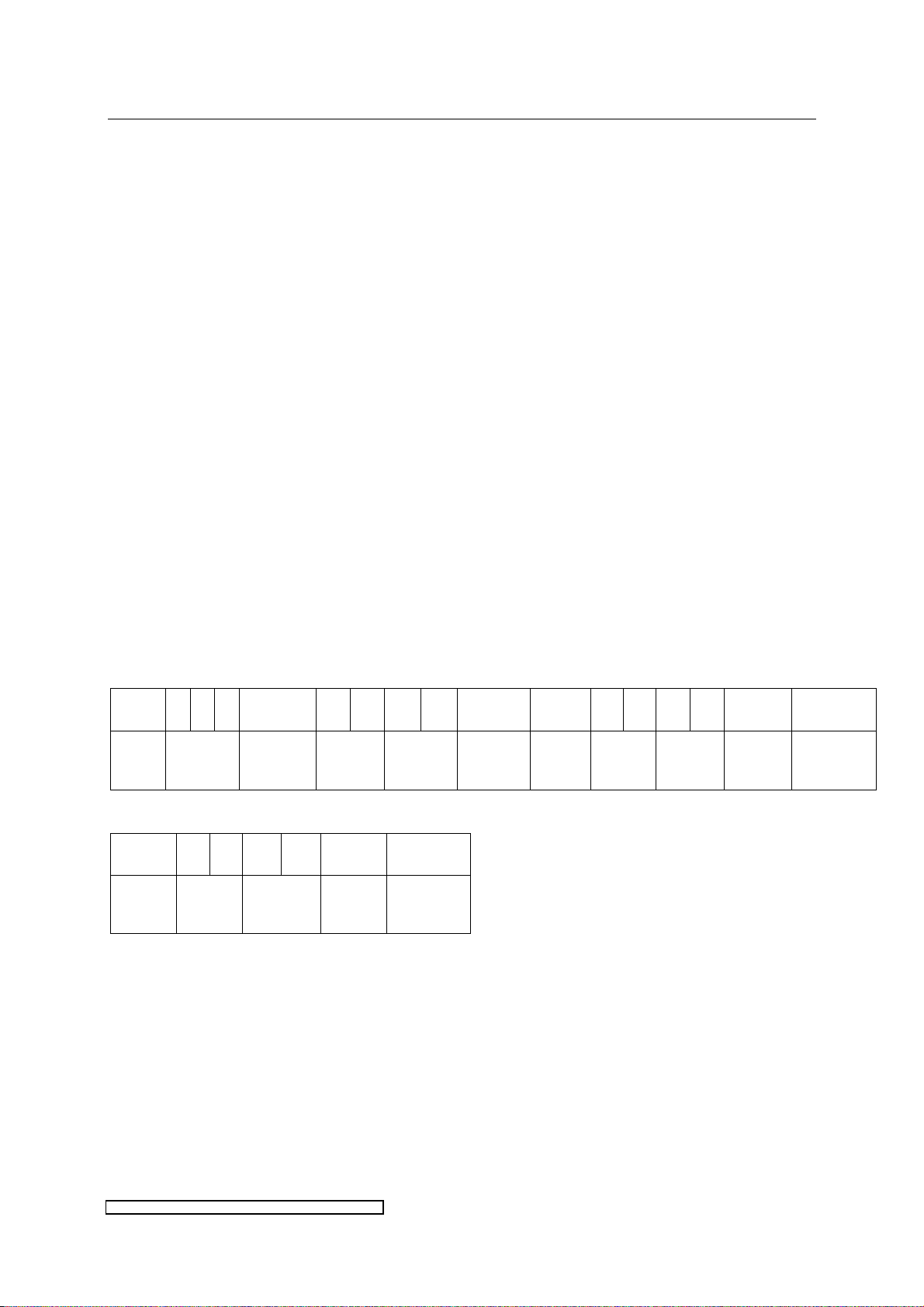

3.4 Configuration

Communication between ELC and installation control is carried out via PROFIBUS DPV0. The

ELC represents a non-modular DPV0-Slave, the installation control functions as the Master.

For configuration, control and monitoring of the ELC 16 input registers (Master receiving data

from ELC) were implemented, as well as 6 output registers (Master sending data to ELC). For

registers overlapping more than one byte, the byte order was determined according to ”BigEndian“.

The ELC software is capable of supporting a baud rate according to chapter 6.

The necessary adjustments during the installing of the ELC will be explained in this paragraph,

the adjustments for lamp operation will follow in chapter 4.

PROFIBUS-Register:

PROFIBUS-input-data (ELC → Master)

ByteNo.

Name

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

[ELC

Serial

Number]

[Software

Version]

[ELC

Nominal

Power]

[Error

Register]

[Warning

Register]

[Lamp

Status]

[Actual

Power]

[Actual

Voltage]

[Actual

Current]

[Reserved]

PROFIBUS-output-data (Master → ELC)

ByteNo.

Name

0 1 2 3 4 5

[Power

Set

Value]

[Installed

Lamp

Power]

[Lamp

Control]

[Reserved]

ELC X-Series-V1.3-09.16-GB subject to technical alterations

Page 28

3 Installation page 24

the menu item to set the high nibble will be entered.

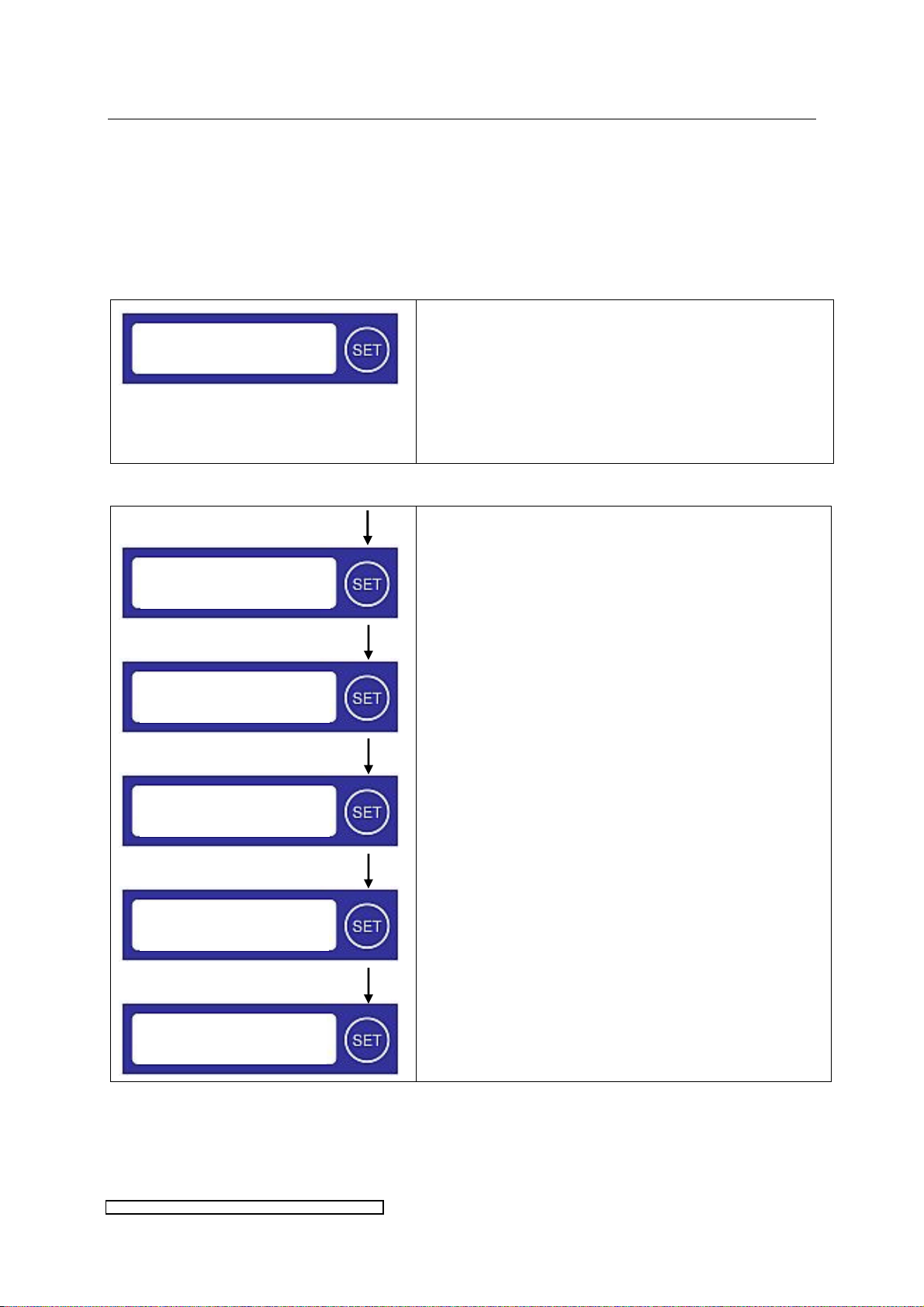

3.4.1 Setting up the PROFIBUS address

To set up the address the display and the pertaining SET button are used. The address space

extends from 01

per installation.

To leave the stand-by-status press the SET-button. The display lighting will be activated and

shows the following text:

hex

to 7D

(corresponding to 1 to 125). Each address may be used only once

hex

ELC ready

No Bus 01h

long as the ELC is free of defects, it displays ”ELC

ready“.

The second line shows on the left side the status of

the bus connection, on the right side the appointed

bus address (default-value 01

To increment the address, the SET-button is used:

The first line gives account of the system status. As

Hold > 5sec

Profibusaddress:

01 hex 1 dec

Press < 2sec

If the SET-button is pressed longer than 5 seconds,

Alongside the hexadecimal value the decimal value

is displayed.

To increment the high nibble press the SET-button

briefly (<2sec) once per step.

Profibusaddress:

11 hex 17 dec

Hold > 2sec

As soon as the desired value of the high nibble is

reached, hold the SET-button (>2sec) to jump to the

Profibusaddress:

11 hex 17 dec

Press < 2sec

low nibble.

To increment the low nibble briefly press the SET-

Profibusaddress:

12 hex 18 dec

Hold > 2sec

button (<2sec) once per step.

To save the address hold the SET-button (>2sec).

hex

).

ELC ready

BUS connected 12h

To assume the address the 24V supply has to be removed and re-applied.

ELC X-Series-V1.3-09.16-GB subject to technical alterations

Page 29

3 Installation page 25

Display won’t turn on

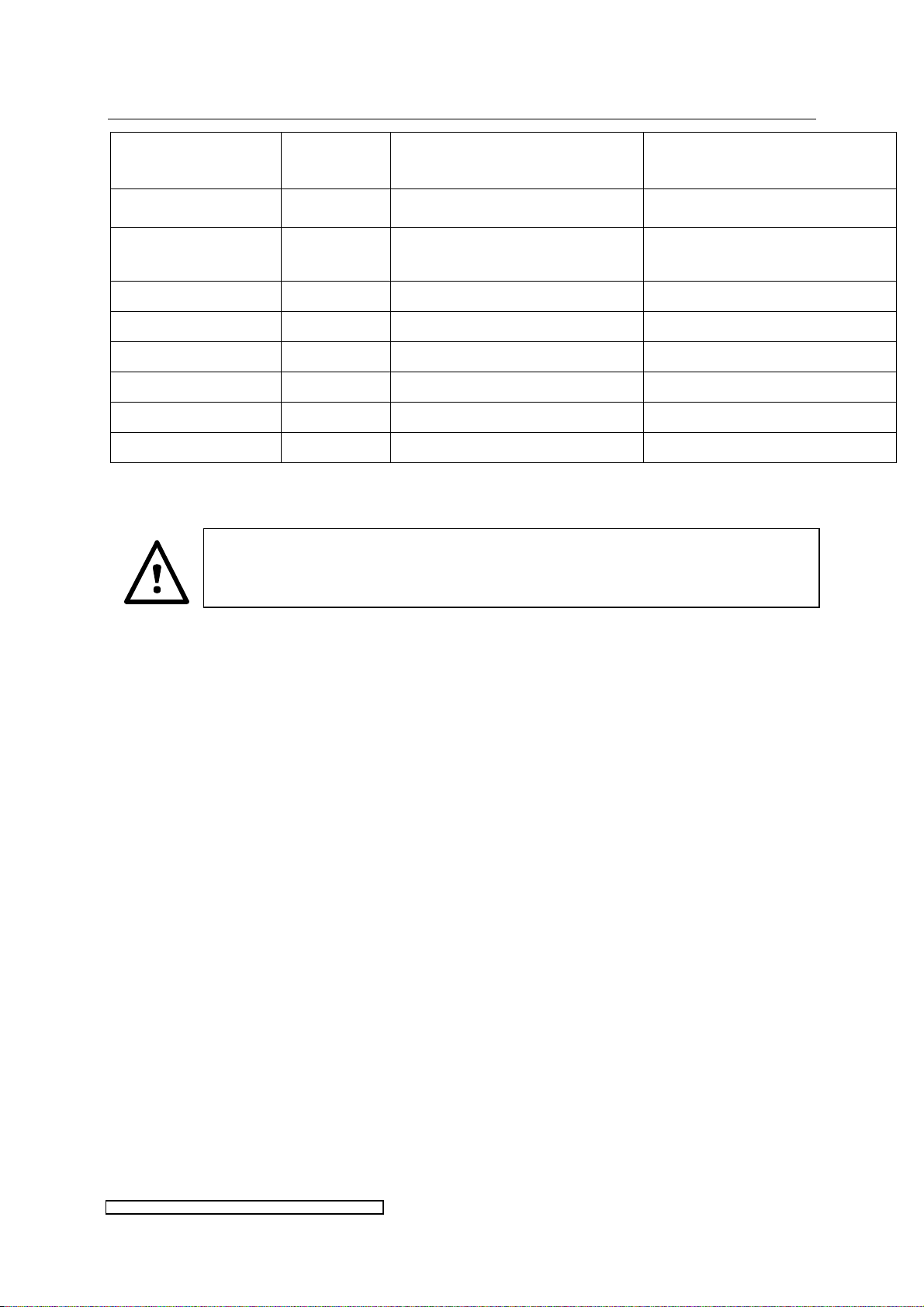

3.4.2 Checking the PROFIBUS connection and error indication

The display may be used to check the successful connection of ELC and Master and

furthermore the existence of an error (ELC not ready for operation). It is also possible to read

out error messages within the [Error Register] see paragraph 5.4.1 (detailed explanations may

be found there).

Display Status Corrective action

ELC ready

BUS connected 19h

ELC ready

No BUS 19h

Error message

BUS connected 19h

(If there is more than one error

message at hand, briefly press the

SET-button to jump to the next error

message.)

Error message

No BUS 19h

ELC ready for

operation, PROFIBUSconnection ok

ELC ready for

operation, no

PROFIBUS-connection

ELC not ready for

operation, PROFIBUSconnection ok

ELC not ready for

operation, no

PROFIBUS-connection

Check plug contact, bus

termination (see

paragraph 3.2.11), check

address and panelprogramming.

The error cause

detected by the ELC is

displayed and may be

read out additionally in

the Error Register (see

paragraph 5.4.1).

Check PROFIBUSconnection.

Detach ELC from mains

and restart.

ELC X-Series-V1.3-09.16-GB subject to technical alterations

(display defect or no

supply)

Check 24V supply,

switch off and on again.

Page 30

3 Installation page 26

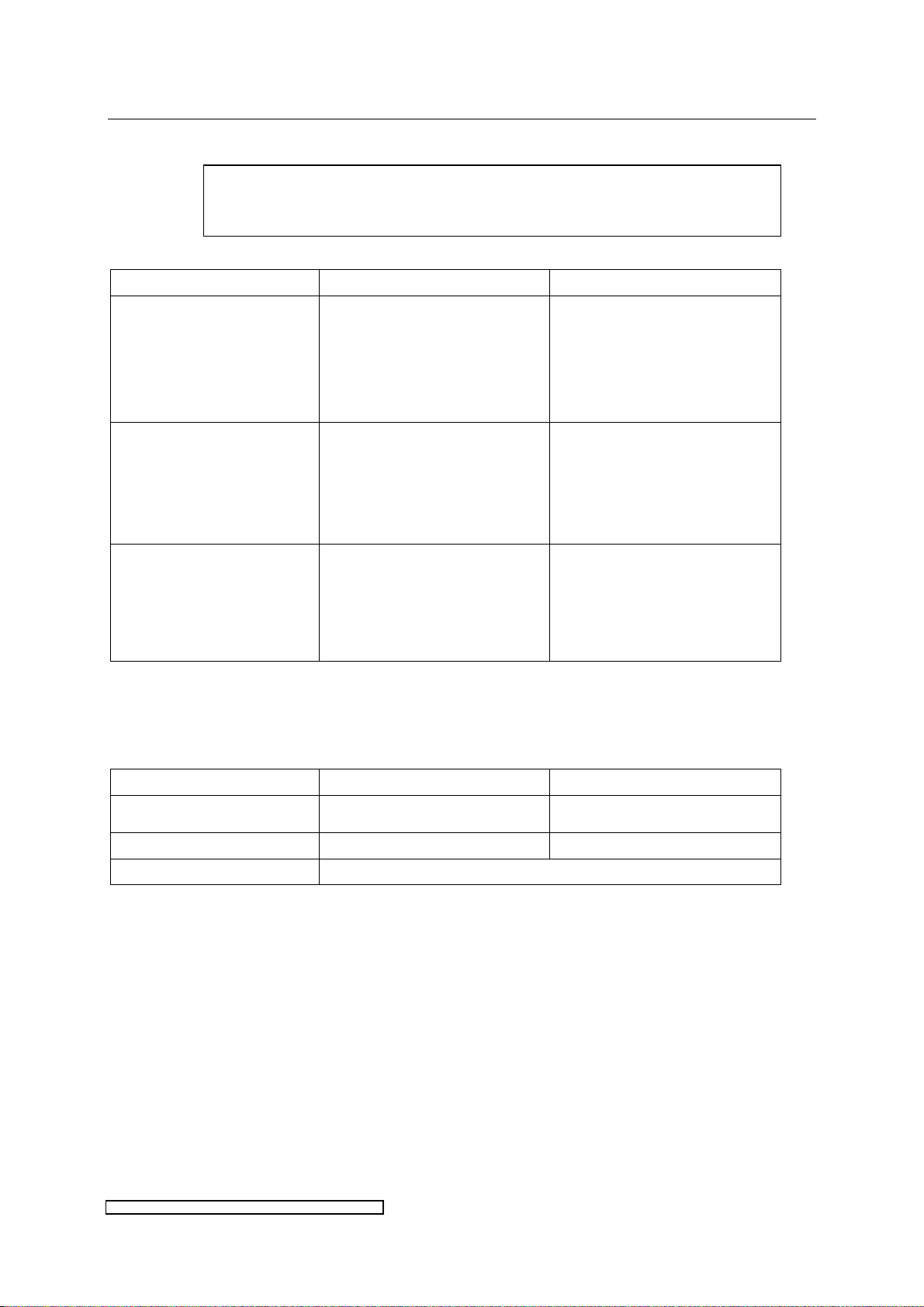

3.4.3 Setting lamp power via PROFIBUS

PROFIBUS-output-data (Master → ELC)

ByteNo.

Name [Power

0 1

Set

Value]

2 3 4 5

[Installed

Lamp

Power]

[Lamp

Control]

[Reserved]

The set value for lamp power has to be written into the register [Power Set Value]. The ELC’s

output power is defined by the control characteristic of Fig. 14.

Lamp power

Lamp power

ELC-nominal-

ELC-nominalpower

power

14% ELC-nominal-power

14% ELC-nominal-power

[Power Set

[Power Set

Value]

14% ELC-nominal-power

14% ELC-nominal-power

ELC-nominal-

ELC-nominalpower

power

Value]

Fig. 14: Control characteristic, showing the dimming range of X6 (for the dimming range of other power

classes see chapter 6)

The ELC’s nominal power is written into the register [ELC Nominal Power] of the PROFIBUS-

input-data:

PROFIBUS-input-data (ELC → Master)

ByteNo.

Name

0 1 2 3

[ELC

Serial

Number]

[Software

Version]

4 5

[ELC

Nominal

Power]

6 7 8 9 10 11 12 13 14 15

[Error

Register]

[Warning

Register]

[Lamp

Status]

[Actual

Power]

[Actual

Voltage]

[Actual

Current]

[Reserved]

ELC X-Series-V1.3-09.16-GB subject to technical alterations

Page 31

3 Installation page 27

☞

PROFIBUS-output-data (Master → ELC)

ByteNo.

Name

0 1

[Power

Set

Value]

2 3

[Installed

Lamp

Power]

4 5

[Lamp

Control]

[Reserved]

To limit the maximum output power, use the register [Installed Lamp Power] (see Fig. 15).

This function is appropriate if the nominal power of the lamp is lower than the nominal power

of the ELC.

Lamp power

Lamp power

ELC-nominal-

ELC-nominalpower

power

[Installed Lamp

[Installed Lamp

Power]

Power]

14% ELC-nominal-power

14% ELC-nominal-power

Sollleistungs-

Sollleistungs-

[Power Set

[Power Set

vorgabe

vorgabe

Value]

14% ELC-nominal-power

14% ELC-nominal-power

Installed lamp

Installed lamp

power

power

ELC-nominal-

ELC-nominalpower

power

Value]

[Power Set

[Power Set

Value]

Value]

Fig. 15: Limited output power characteristic, showing the dimming range of X6 (for the dimming range

of other power classes see chapter 6)

The control characteristic of Fig. 14 comes into effect, if the register [Installed

Lamp Power] is

• not set

• below minimum dimming range (given in % of ELC nominal power in

chapter 6)

• above ELC nominal power

ELC X-Series-V1.3-09.16-GB subject to technical alterations

Page 32

3 Installation page 28

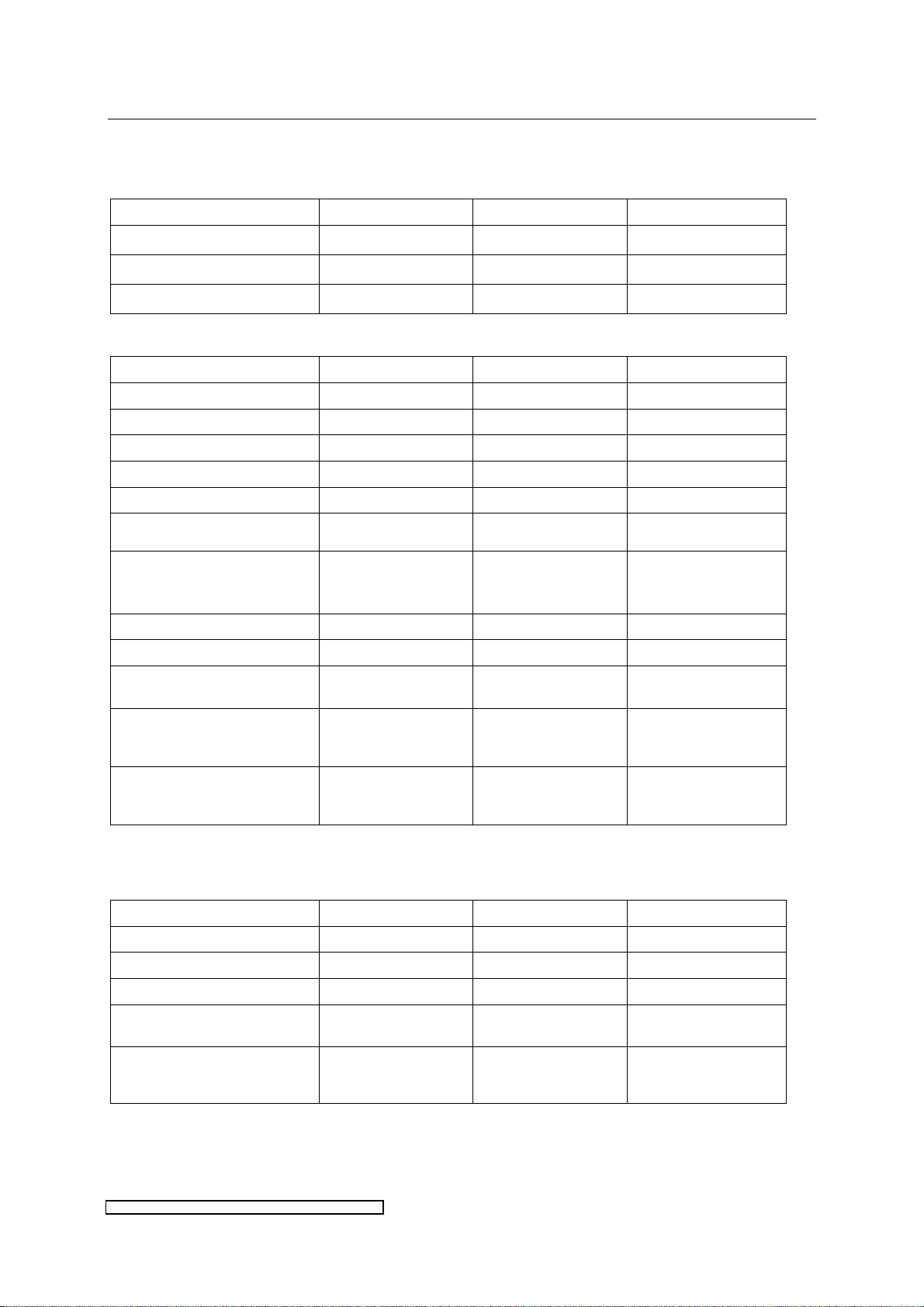

3.4.4 Extended temperature and power range

The ambient temperature range for standard operation is Ta = 5°C to 45°C. At a temperature

of 47°C the lamp is switched off automatically.

PROFIBUS-output-data (Master → ELC)

ByteNo.

Name

0 1 2 3

[Power

Set

Value]

[Installed

Lamp

Power]

4

[Lamp

Control]

5

[Reserved]

↓

Bit

Name

7 6 5

UV

Ready

UV

Select

n/a

4

Extended

Range

3 2 1

n/a n/a Clear

Error

0

Start

Lamp

If the {Extended Range}-Bit in Register [Lamp Control] is set to 1, extended functions are

activated:

Type Max. ambient

temperature for

lamp operation

Max. possible

output power

(mains voltage >

Note

400V)

ELC X6 55°C 6kW Note that with ELC X6 no operation

beyond 6kW is enabled.

ELC X8 55°C 8.8kW To keep the internal temperatures on a

constant level the maximum output

power (P

) is decreased linearly from

max

8.8 kW to 8kW between 45°C and 55°C

as shown in Fig. 16.

There is an additional reduction of the output power if the mains voltage falls below 400 V. This

voltage dependent output power reduction is added to the temperature dependent derating.

ELC X-Series-V1.3-09.16-GB subject to technical alterations

Page 33

3 Installation page 29

8,8 kW

max. lamp power

8,0 kW

7,2 kW

6,4 kW

6,0 kW

5,6 kW

X8: Mains voltage

dependant power

reduction 20 W / V

45°C

45°C

55°C

55°C

X8: Temp. dependant derating

80 W /°C

X6: Mains voltage

4,8 kW

dependant power

reduction 18 W / V

4,0 kW

300V 320V 340V 360V

-20%

(max. 1,5sec.)

-10%

-20%

Max. 1,5 seconds

(Under developement)

380V 400V 420V 440V

380 V

-10%

400 V

-10%

-20%

460V 480V 500V 520V

+20%+10%

+20%+10%

440 V-20% +20%+10%

-10% 480 V

mains voltage

+10%

540V

Fig. 16: Mains voltage and temperature depending power reduction (exemplarily for X6 and X8)

This bit must be set permanently to 1 when high temperature or (at ELC X8) high power

operation is needed.

ELC X-Series-V1.3-09.16-GB subject to technical alterations

Page 34

3 Installation page 30

month

year

consecutive number

3.4.5 To read out ELC serial number and software version

These data may be accessed via display or PROFIBUS and may be of interest e.g. for service

and in case of a defect.

1. Display

ELC ready

Bus connected 19h

Drücken < 5sek

Lamp off

Drücken < 5sek

Serial Number

Software Version

Shortly press the SET-button to reach the next menu

item.

Lamp operation data see paragraph 4.4.

Serial number and currently installed software version

in decimal values.

2. PROFIBUS-input-data (ELC → Master)

ByteNo.

Name [ELC

0 1 2 3

Serial

Number]

[Software

Version]

4 5 6 7 8 9 10 11 12 13 14 15

[ELC

Nominal

Power]

[Error

Register]

[Warning

Register]

[Lamp

Status]

[Actual

Power]

[Actual

Voltage]

[Actual

Current]

[Reserved]

↓

Byte 2 Byte 1 Byte 0

7 6 5 4 3 2 1 0 7 6 5 4 3 2 1 0 7 6 5 4 3 2 1 0

[ELC Serial Number is indicated by the first three registers. The exact division of the bits into

year, month and consecutive number is defined by the brackets.

Example: 01F30516 stands for: consecutive number = 62, month = 6 and year = 5.

[Software Version] contains the currently installed software version. The high nibble

represents the main version (e.g. 10), the low-nibble the secondary version (e.g. 2).

Accordingly the example Version 10.2 is written as A216.

ELC X-Series-V1.3-09.16-GB subject to technical alterations

Page 35

4 Operation of the ELC page 31

the electrolytic capacitors with limited current (max. 30mA) before initial

power supply or variable

4 Operation of the ELC

4.1 Initial operation

• The operative parameters of the ELC, such as the scope of the trigger pulse when

switching on the lamp, are set by the manufacturer.

• You must always ensure that the correct lamp type is used (see chapter 6) and that all

wiring is properly connected!

4.2 Switching on the ELC

Special procedure necessary for initial operation after long-time storage!

If the ELC was in storage or not connected to mains voltage longer than the

maximum storage period given in chapter 6 elevated leakage currents may arise

on the electrolytic capacitors which could damage the ELC in the worst case.

Preventive measure:

Reform

operation. Slowly increase mains voltage with a DCtransformer e.g.

• The ELC is switched on by applying the operating mains voltage and the 24V supply.

4.3 Activating the safety circuits

• Activate the safety relay

• Apply the initialisation signal

ELC X-Series-V1.3-09.16-GB subject to technical alterations

Page 36

4 Operation of the ELC page 32

In case of an error the ELC will not try to ignite the lamp. After eliminating the error

☞

☞

☞

4.4 Switching on the lamp

PROFIBUS-output-data (Master → ELC)

ByteNo.

Name [Power

↓

• Before starting the lamp it is necessary to write the desired lamp power into the register

[Power Set Value] in Watts. To transfer the lamp and its surrounding into a thermally

stable condition, it is recommended to choose the maximum lamp power for [Power Set

Value] during the lamp run-up period.

• To ignite the lamp set the {Start Lamp}-Bit in register [Lamp Control] to 1.

• {n/a}: not available. These bits are reserved for future applications.

0 1

Set

Value]

2 3

[Installed

Lamp

Power]

After switching on the ELC take account of the charge time given in chapter 6,

before starting the lamp.

4

[Lamp

Control]

Bit

Name

5

[Reserved]

7 6 5 4 3 2 1

UV

Ready

UV

Select

n/a Extended

Range

n/a n/a Clear

Error

0

Start

Lamp

the [Error Register] has to be cleared additionally (see paragraph 5.4).

As long as the safety circuits are not activated the ELC will not try to ignite the

lamp (see paragraph 5.3).

During warm-up the lamp power stays at a very low level over a longer period of time and after

approximately 60 seconds rapidly increases to its nominal power. The lamp is operated with

increased current until the nominal power is reached.

The actual condition of the lamp may be read out via the display (only actual power and power

set value), and also from register [Lamp Status] of the PROFIBUS-input-data.

ELC X-Series-V1.3-09.16-GB subject to technical alterations

Page 37

4 Operation of the ELC page 33

1. Display

ELC ready

Bus connected 19h

Press < 5sec

Shortly press the SET-button to get the lamp

operation data.

PLamp: 5200 W

PSet: 5200 W

• [Actual Power]: actual power in Watts

• [Power Set Value]: required power in Watts

2. Register [Lamp Status]

PROFIBUS-input-data (ELC → Master)

Lamp operation data on display:

ByteNo.

Name

0 1 2 3 4 5 6 7 8

[ELC

Serial

Number]

[Software

Version]

[ELC

Nominal

Power]

[Error

Register]

[Warning

Register]

9 10 11 12 13 14

[Lamp

Status]

[Actual

Power]

[Actual

Voltage]

[Actual

Current]

↓

Bit

Name

7 6 5 4 3

n/a n/a n/a n/a n/a

2 1 0

Lamp

Ignition

Run

Up

Lamp

On

Bits in use in register [Lamp Status]:

• Bit 2 {Lamp Ignition}: during the ignition phase of the lamp the ”ignition“ bit is set (value =

1, otherwise 0).

15

[Reserved]

• Bit 1 {Run Up}: during warm-up of the lamp the “run-up“-bit is set (value = 1, otherwise 0).

• Bit 0 {Lamp On}: as soon as the lamp has reached the required power and lamp voltage is

in a steady state, the ”lamp-on“-bit will be set (value = 1, otherwise 0).

Further operation data of the continuous operation state may be read out from the registers

[Actual Power], [Actual Voltage] and [Actual Current]:

• [Actual Power] returns the actual power in Watts.

• [Actual Voltage] gives account of the actual lamp voltage in Volts.

• [Actual Current] contains the actual current in Ampère*10 with an accuracy of 100 mA

(e.g.: [Actual Current] = 12 means 1,2 A).

ELC X-Series-V1.3-09.16-GB subject to technical alterations

Page 38

4 Operation of the ELC page 34

☞

☞

☞

4.5 Dimming operation

After having reached nominal operation the desired lamp power can be infinitely adjusted

within the dimming range given in chapter 6.

• Enter the desired power in Watts in register [Power Set Value].

A set value of less than the minimum dimming range will automatically be

increased by the ELC to the minimum dimming range.

The warm-up time from standby operation to nominal operation depends on the

lamp's ambient conditions. If cooling is too intensive during dimming operation,

the acceleration time is prolonged.

4.6 Switching off the lamp

• The lamp is switched off by setting the {Start Lamp}-bit to 0 in register [Lamp Control].

In order to avoid heat accumulation in the ELC the 24V supply should be left on

for a few minutes. Before restarting, the lamp must be sufficiently cooled down as

it cannot be fired otherwise.

ELC X-Series-V1.3-09.16-GB subject to technical alterations

Page 39

5 Monitoring, warning, error, repair page 35

☞

☞

5 Monitoring, warning, error, repair

5.1 Mains voltage monitoring

The mains voltage (L1, L2 of connector X100) is monitored during lamp operation.

In case of continuous input undervoltage the lamp power is reduced by the ELC

in order to prevent an overcurrent on the input side (see output power reduction

in chapter 6).

In case of mains voltage dropouts the ELC may stop lamp operation to prevent

damage of the inverter caused by undefined supply conditions.

5.2 Earth fault control

Supplementary to the safety functions of paragraph 3.3 which prevent danger to the operator,

the earth fault control of the ELC lamp circuit represents another monitoring function.

An earth fault occurs when the insulation resistance

R_

(see Fig. 17) drops below approx. 200 kOhm.

error

The ELC will shut down the lamp automatically in

case of an earth fault.

Earth Fault Bit

Lamp

Error Register

PROFIBUS-connection

R_erro r

In order for the earth fault control to function properly

it is essential that it is connected as prescribed,

particularly the earth connectors.

An earth fault is reported by the {Earth Leakage

Fault}-bit in the [Error Register] (in normal

operation status the bit value is 0). Additionally the

display is blinking and shows the earth fault error

message.

Earth fault monitoring is also active if the lamp is not

running.

Fig. 17: Earth fault monitoring

ELC X-Series-V1.3-09.16-GB subject to technical alterations

Page 40

5 Monitoring, warning, error, repair page 36

☞

PROFIBUS input data (ELC → Master)

ByteNo.

Name

0 1 2 3 4 5

[ELC

Serial

Number]

[Software

Version]

[ELC

Nominal

Power]

6 7

[Error

Register]

↓

Byte

Bit

Name

Byte

Bit

Name

15 14 13 12 11

n/a n/a Lamp

Power

Low

7 6 5 4 3 2 1 0

Lamp

Voltage

High

Overvoltage

Bus

Connection

Error

In order to avoid an unwanted reaction of the earth fault control during faultless

operation, the insulation resistance of the lamp cables and all lamp connectors

must be greater than 10 MΩ.

8 9 10 11 12 13 14 15

[Warning

Register]

Supply ZVS

Internal ELC

[Lamp

Status]

6

7

Temperature

High

[Actual

Power]

10

Earth

Leakage

Fault

Fan

Error

[Actual

Voltage]

9 8

Measurement Overcurrent

Mains

Voltage

Low

[Actual

Current]

[Reserved]

DC-Link

Undervoltage

ELC X-Series-V1.3-09.16-GB subject to technical alterations

Page 41

5 Monitoring, warning, error, repair page 37

5.3 Warning messages

The bits in the [Warning Register] are divided into two groups:

• Group1-Nibble: the bits 0-3 represent critical operating conditions of the lamp. However

they won’t shut down the lamp.

• Group2-Nibble: If a bit in the Group2-nibble (bits 4-7) is set, the lamp cannot be started

or will be shut down during operation.

The bits of the [Warning Register] will automatically be reset as soon as the triggering status

has been resolved.

PROFIBUS-input-data (ELC → Master)

ByteNo.

Name

0 1 2 3 4 5 6 7

[ELC

Serial

Number]

[Software

Version]

[ELC

Nominal

Power]

[Error

Register]

8

[Warning

Register]

9 10 11 12 13 14 15

[Lamp

Status]

[Actual

Power]

[Actual

Voltage]

[Actual

Current]

↓

Bit 7

Name Init

Signal

Ok

6

n/a

5 4

Lamp

Ignition

Failed

Safety

Relay

Open

3 2

n/a n/a

1 0

Run

Up

Long

Lamp

Voltage

Low

Group 2:

Lamp operation not

possible

Group 1:

No shut down

Bit 0: The {Lamp Voltage Low}-bit is set if the actual lamp voltage is lower than

the threshold voltage given in chapter 6. A possible reason is a strong lamp

cooling especially in dimming operation. This could cause a long run up time

to regain the nominal power.

Please consider that the ELC cannot distinguish lamps of different nominal

voltages. If the ELC is used on purpose to operate a lamp with a lower

nominal voltage the bit will be set although full lamp voltage is reached.

This bit will be reset if the lamp voltage exceeds the threshold voltage.

[Reserved]

Bit 1: During run-up the lamp power normally increases to the desired lamp power

(Register [Power Set Value]). The {Run Up Long}-bit is set, if 95% of the

required lamp power are not reached within 3 min. Possible reasons are an

incorrect lamp type or excessive cooling of the lamp.

Reset occurs as soon as the {Start Lamp}-bit in register [Lamp Control] is

set to 0 (the lamp being thus actively shut down by the operator via the

PROFIBUS output data).

ELC X-Series-V1.3-09.16-GB subject to technical alterations

Page 42

5 Monitoring, warning, error, repair page 38

Bit 4: The {Safety Relay Open} bit is set if the safety relay is not closed (e.g. on

emergency shutdown). There are two different cases:

• If in register [Lamp Control] {Start Lamp} bit is 0, the {Safety Relay Open}

bit is automatically reset as soon as the safety relay is closed.

• During lamp operation ({Start Lamp}=1 in [Lamp Control]) the {Safety

Relay Open} bit remains set and the lamp will be shut down by the ELC. In

this case {Safety Relay Open} will only be reset if {Start Lamp} in [Lamp

Control] is reset and the safety relay has been closed.

Bit 5: If the ELC cannot ignite the lamp the {Lamp Ignition Failed} bit will be set and

remains in this status as long as {Start Lamp}=1 in [Lamp Control]. The

{Lamp Ignition Failed} bit is reset as soon as {Start Lamp} in [Lamp Control]

is reset.

Bit 7: The {Init Signal Ok} bit reflects the status of the Init-Signal-Pin X806.3 of the

initialisation signal (see paragraph 3.3.2).

• {Init Signal Ok}=1 means 24 V on X806.3, the lamp may be ignited and

operated normally.

• {Init Signal Ok}=0 means 0 V on X806.3, the lamp cannot be operated.

To render the ELC operational again in case {Init Signal Ok}=0 the

initialisation signal on X806.3 has to be 24V and the start signal {Start Lamp}

has to be reset.

Bit 2, Bit 3 und Bit 6: {n/a} bits (not available) are reserved for future applications.

ELC X-Series-V1.3-09.16-GB subject to technical alterations

Page 43

5 Monitoring, warning, error, repair page 39

5.4 Error

5.4.1 Error messages

Effects of an error:

• The lamp will be immediately shut down,

• In case of an error the display is blinking and the error is shown in clear text. In case of

several error messages press the SET-button briefly to jump to the next message.

• Bits in the [Error Register] will be set as soon as the correspondent error occurs.

• Errors marked as “internal” are in general not influenced by ambient conditions and have

to be checked by the manufacturer for corrective measures.

PROFIBUS-input-data (ELC → Master)

ByteNo.

Name

0 1 2 3 4 5

[ELC

Serial

Number]

[Software

Version]

[ELC

Nominal

Power]

6 7

[Error

Register]

8 9 10 11 12 13 14 15

[Warning

Register]

[Lamp

Status]

[Actual

Power]

[Actual

Voltage]

[Actual

Current]

[Reserved]

↓

Byte

Bit

Name

Byte

Bit

Name

15 14 13 12 11 10 9 8

CanIntern Slave Lamp

Power

Low

7 6 5 4 3 2 1 0

Lamp

Voltage

High

Overvoltage

Bus

Connection

Error

Supply ZVS Earth

Internal ELC

6

7

Temperature

High

Measure

Leakage

Fault

Fan Error Mains

ment

Voltage

Low

Overcurrent

DC-Link

Undervoltage

Bit 0: {DC-Link-Undervoltage} is set, if the (internal) DC-Link-Voltage is too low.

Possible reasons are low mains voltage, blown internal fuses or other defective

parts inside the ELC.

Bit 1: An error of the mains is recorded in the {Mains Voltage Low}-bit if the mains

voltage falls below the allowed minimum (see chapter 6) during lamp operation.

Bit 2: {Fan Error} indicates an error of the fans (speed monitoring). Possible reasons

are a blocked rotor or squeezed cables.

Bit 3: The {ELC Temperature High} bit is set as soon as the acceptable temperature

is exceeded.

Bit 4: {Internal} stands for problems of internal communication between controllers

or failed self check of controllers.

Bit 5: If the PROFIBUS connection is interrupted during lamp operation the {Bus

Connection Error} bit is set. The bus status is also shown on the display.

ELC X-Series-V1.3-09.16-GB subject to technical alterations

Page 44

5 Monitoring, warning, error, repair page 40

Bit 6: The detection of a short peak {Overvoltage} on the lamp output might be due

to an internal problem of the ELC or damaged cables on lamp circuitry.

Bit 7: If the actual voltage of the lamp is too high the {Lamp Voltage High} bit is set.

Usually the lamp type is not correct.

Bit 8: {Overcurrent} indicates an internal overcurrent.

Bit 9: {Measurement} appears in case of problems with the internal measurement

circuits.

Bit 10: The {Earth Leakage Fault}- is set if a leakage current to ground on R

error

(see

paragraph 5.2) is detected.

Bit 11: {ZVS} gives notice if the power switches are not working in zero voltage

switching mode. Higher switching losses might shorten the ELC lifetime.

Bit 12: {Supply} indicates problems of internal low voltage supply. Apart from internal

damage this might happen with low mains voltage.

Bit 13: If the lamp extinguishes during lamp operation, the {Lamp Power Low} bit is

set.

Bit 14: {Slave} is set if an error in the slave ballast is detected.

Bit 15: {CanIntern} shows an error of the internal Can-connection.

ELC X-Series-V1.3-09.16-GB subject to technical alterations

Page 45

5 Monitoring, warning, error, repair page 41

5.4.2 Display messages and trouble shooting

Display message Bit set in Error

register

ELC ready - ballast is ready for operation

Display is off - no 24V supply or display defect Check 24V supply, switch off and on again.

DC Link Undervoltage Error

Mains Voltage Error

Fan Error

Overtemperature Error

Internal Error

Bus Error

X6CA failure internal communication fails Send back for repair by manufacturer

Bit 0

(0x0001)

Bit 1

(0x0002)

Bit 2

(0x0004)

Bit 3

(0x0008)

Bit 4

(0x0010)

Bit 5

(0x0020)

input voltage measurement detects mains

ambient or internal temperature too high

problems of internal communication

between controllers or failed selfcheck of

field bus connection fails during lamp

Description Corrective action

• Check fuses

internal dc link voltage is low

voltage drop or fluctuations

fan stops

the controllers

operation

• Check mains voltage

• Consider charge time

• Check connections

• Check mains voltage

Check if there are a blocked rotors or

Check ambient temperature and fans of

cabinet (direction of air current, change

Switch off and on the 24V supply.

Check bus termination and connector

squeezed cables

filter mats)

contact

Overvoltage Error

Lamp Voltage High Error

Internal Error

Internal Error

Earthfault Error

Internal Error

Internal Error

Lamp Power Low Error

Bit 6

(0x0040)

Bit 7

(0x0080)

Bit 8

(0x0100)

Bit 9

(0x0200)

Bit 10

(0x0400)

Bit 11

(0x0800)

Bit 12

(0x1000)

Bit 13

(0x2000)

the lamp voltage exceeds nominal ignition

voltage during ignition or operation

actual lamp voltage exceeds a threshold

critical for the ELC

Overcurrent: indicates an internal

overcurrent

Measurement: appears in case of problems

with the internal measurement circuits.

insulation resistance in lamp circuitry gets

lower than 200kOhm (e.g. in case of bad

wiring on the lamp, high air humidity,

polluted cables or connections)

ZVS: gives notice if the power switches are

not working in zero voltage switching mode.

Supply: indicates problems of internal low

voltage supply

lamp extinguishes (e.g. cooling too strong

or lamp defect)

Check lamp wiring concerning insulation

defects

Check lamp type and lamp

connectors/sockets, switch lamp

Check for short in lamp circuit.

Check for short in lamp circuit.

Check lamp wiring and insulation resistance

External reasons might be flashovers in the

lamp circuit

This might happen with low mains voltage.

Check 24V-supply.

Reduce cooling or replace lamp.

Check lamp wiring.

ELC X-Series-V1.3-09.16-GB subject to technical alterations

Page 46

5 Monitoring, warning, error, repair page 42

Display message Bit set in Error

register

Slave

CanIntern

No Profibus - Profibus connection is not detected Check termination and connector.

No Modbus - Modbus connection is not detected Check termination and connector.

Profibus ok - Profibus connection is detected -

Modbus ok - Modbus connection is detected -

Serial: nnnnnnnn - ELC serial number is displayed -

SW Version: nnnnnnnn - ELC software version is displayed -

Bit 14

(0x4000)

Bit 15

(0x8000)

Error detected in Slave ballast. Check internal wiring.

Faulty connection between Master and

Description Corrective action

Slave.

Check internal wiring.

A blown fuse is only to be exchanged by the manufacturer. By using the wrong

fuse type extensive damage might be done to the boards, rendering economic

repairs impossible.

ELC X-Series-V1.3-09.16-GB subject to technical alterations

Page 47

5 Monitoring, warning, error, repair page 43

5.4.3 Resetting the error register

Each error has to be acknowledged by setting the {Clear Error} bit in register [Lamp Control]

to “1”. First of all set the {Start Lamp} bit in register [Lamp Control] to 0. Then only the

transgression of the {Clear Error} bit from “0” to “1” can reset the [Error Register]. After the

PROFIBUS has transmitted the [Lamp Control] Register (check e.g. via the [Error Register]:

if error eliminated all error bits are „0“ again) and after an ELC internal synchronisation time of

additional 15 ms, the {Clear Error}-bit has to be reset to „0“.

PROFIBUS-output data (Master → ELC)

ByteNr.

Name

0 1 2 3

[Power

Set

Value]

[Installed

Lamp

Power]

4

[Lamp

Control]

5

[Reserved]

↓

Bit

Name

7 6 5 4 3 2

n/a n/a n/a n/a n/a n/a

1

Clear

Error

0

Start

Lamp

5.5 Repair ELC

Only the manufacturer is permitted to repair the ELC. In case of failure please contact the

following address:

eta plus electronic gmbh

Lauterstraße 29

D-72622 Nürtingen

Tel: +49 7022 / 6002-80

Fax: +49 7022 / 65854

e-mail: Info@eta-uv.de

ELC X-Series-V1.3-09.16-GB subject to technical alterations

Page 48

6 Technical Data page 44

6 Technical Data

6.1 ELC X4, X4B

Output power characteristics

Type ELC X4-40 ELC X4B-40

Power factor Typ. 0.97 Typ. 0.97

Power efficiency > 0.94 > 0.94

Nominal power range 800 W – 4000 W 800 W – 4000 W

Electrical characteristics

Type ELC X4-40 ELC X4B-40

Nominal supply voltage 400 V - 480 V 440 V

Nominal supply current 11.0 – 9.1 A 10.0 A

Max. supply current 12.1 A 11.0 A

Line protection* min. 16 A min. 16 A

Mains frequency

Min. mains voltage (shut down

voltage)

Output power reduction in case

of low mains voltage

Abs. max. mains voltage

Leakage current

Insulation resistance between

primary and PE

Discharching time of residual

voltage after mains

disconnection

Charge time (minimum time

between switch on of the ELC

and starting the lamp)

from approx. 360V – 320V: 13 W /

50 / 60 Hz 50 / 60 Hz

320V 320V

from approx. 400V – 320V: 13 W /

V

528V 528V

typ. 10mA typ. 10mA

>30 MΩ >30 MΩ

5 mins. 5 mins.

12 s 12 s

V (@55°C)

*Line protection: automatic cut-out characteristic C

Lamp characteristics

Type ELC X4-40 ELC X4B-40

Nominal lamp power 4 kW 4 kW

Nominal lamp voltage 400 V 400 V

Tolerance lamp voltage

Threshold voltage of {lamp

voltage low} warning bit

Ignition voltage / period

ELC X-Series-V1.3-09.16-GB subject to technical alterations

nominal voltage ± 5 % nominal voltage ± 5 %

300 V 300 V

approx. 1400 Vpk / 700 ms, 5 trials approx. 1400 Vpk / 700 ms, 5 trials

Page 49

6 Technical Data page 45

☞

Lamp feeder cable: approved types and lengths

The use of cable types which have not been approved by the manufacturer

can lead to malfunction. The possibility of damage to the electronic ballast

cannot be excluded.

Type ELC X4-40 ELC X4B-40

Article no. 8092

U0/U = 0.8/1.4kV

2x2.5 mm²

Ø 9.3 mm

UL AWM Style 21179

Article no. 8044

U0/U = 0.6/1kV

2x2.5 mm²

Ø 9.8 mm

GL-approved

Article no. 8045*

U0/U = 1.8/3kV

2x4mm²

OD-Ø 16.9mm

GL-approved

2-40 m 2-40 m

2-40 m 2-40 m

on request on request

The data refers to the distance between ELC and lamp.

* This cable cannot be connected directly to the ELC due to the diameter.

Mechanical characteristics

Type ELC X4-40 ELC X4B-40

Dimensions

(approx. H x W x D)

Weight (approx.)

Installation position

125 x 470 x 260 mm 125 x 470 x 260 mm

11kg on request

vertical or horizontal as described in 3.1

ELC X-Series-V1.3-09.16-GB subject to technical alterations

Page 50

6 Technical Data page 46

Control characteristics

Type ELC X4-40 ELC X4B-40

Current requirement of 24Vsupply (X805.5)

Baud rate

Output currents of X806 Pins 5 + 6 have to be added

MODBUS: Baud rate 19200, 8 Databits, Even parity, 1 Start/Stop Bit

2.2A max. for ELC control circuitry

PROFIBUS: 500kBit

Ambient conditions

Type ELC X4-40 ELC X4B-40

Humidity Max. 85%, non-condensing Max. 95%

Ambient operation temperature

Ambient storage temperature

Maximum storage period

Air flow

Altitude of site

-20°C to +70°C during storage and transportation, before initial operation

2000m NN to 4000m NN: 1.5% / 100m power reduction effected by

5°C to +45°C 5°C to +55°C

leave at least 4 hrs at room temperature

2 years (also see chapter 4.2)

max. 200 m³ / h at TA >35°C

Typ. 100 m³ / h

Max. 4000m NN

Up to 2000m NN without derating

ELC-control (example: X4 = 2800 W at 4000m NN)

Certification

Type ELC X4-40 ELC X4B-40

Protection

EMC

Safety

Marine approvals

- - on request

pending

pending

pending

ELC X-Series-V1.3-09.16-GB subject to technical alterations

Page 51

6 Technical Data page 47

6.2 ELC X6, X6B, X6i

Output power characteristics

Type ELC X6-60 ELC X6B-60 ELC X6i-60

Power factor Typ. 0.97 Typ. 0.97 Typ. 0.97

Power efficiency > 0.94 > 0.94 > 0.94

Nominal power range 840 W – 6050 W 840 W – 6050 W 840 W – 6050 W

Electrical characteristics

Type ELC X6-60 ELC X6B-60 ELC X6i-60

Nominal supply voltage 400 V - 480 V 440 V 400 - 480 V

Nominal supply current 15.9 A - 13.4 A 15.0 A 15.9 A – 13.4 A

Max. supply current 18 A 16.5 A 18.0 A

Line protection* min. 20 A min. 20 A min. 20 A

Mains frequency

Min. mains voltage (shut down

voltage)

Output power reduction in case

of low mains voltage

Abs. max. mains voltage

Leakage current

Insulation resistance between

primary and PE

Discharching time of residual

voltage after mains

disconnection

Charge time (minimum time

between switch on of the ELC

and starting the lamp)

50 / 60 Hz 50 / 60 Hz 50 / 60 Hz

320V 320V 320V

from approx. 360V –

320V: 18 W / V

528V 528V 528V

typ. 10mA typ. 10mA typ. 10mA

>30 MΩ >30 MΩ >30 MΩ

3 mins. 3 mins. 3 Min.

12s 12s 12s

from approx. 400V –

320V: 18 W / V

(@55°C)

From approx. 360V–

320V:

18 W / V

*Line protection: automatic cut-out characteristic C

Lamp characteristics

Type ELC X6-60 ELC X6B-60 ELC X6i-60

Nominal lamp power 6 kW 6 kW 6 kW

Nominal lamp voltage 600 V 600 V 600 V

Tolerance lamp voltage

Threshold voltage of {lamp

voltage low} warning bit

Ignition voltage / period

ELC X-Series-V1.3-09.16-GB subject to technical alterations

nominal voltage ± 5 % nominal voltage ± 5 % nominal voltage ± 5 %

450 V 450 V 450 V

approx. 2000 Vpk /

700 ms, 5 trials

approx. 2000 Vpk /

700 ms, 5 trials

approx. 2000 Vpk /

700 ms, 5 trials

Page 52

6 Technical Data page 48

☞

Lamp feeder cable: approved types and lengths

The use of cable types which have not been approved by the manufacturer

can lead to malfunction. The possibility of damage to the electronic ballast

cannot be excluded.

Type ELC X6-60 ELC X6B-60 ELC X6i-60

Article no. 8092

U0/U = 0.8/1.4kV

2x2.5 mm²

Ø 9.3 mm

UL AWM Style 21179

Article no. 8044

U0/U = 0.6/1kV

2x2.5 mm²

Ø 9.8 mm

GL-approved

Article no. 8045*

U0/U = 1.8/3kV

2x4mm²

OD-Ø 16.9mm

GL-approved

2-40 m 2-40 m 2-40 m

2-40 m 2-40 m 2-40 m

on request on request on request

The data refers to the distance between ELC and lamp.

* This cable cannot be connected directly to the ELC due to the diameter.

Mechanical characteristics

Type ELC X6-60 ELC X6B-60 ELC X6i-60

Dimensions

(approx. H x W x D)

Weight (approx.)

Installation position

125 x 470 x 320 mm 125 x 470 x 320 mm 125 x 470 x 320 mm

14kg 15kg 14kg

vertical or horizontal as described in 3.1

ELC X-Series-V1.3-09.16-GB subject to technical alterations

Page 53

6 Technical Data page 49

Control characteristics

Type ELC X6-60 ELC X6B-60 ELC X6i-60

2.7A

added

Current requirement of 24Vsupply (X805.5)

Baud rate

2.2A max. for ELC control circuitry

Output currents of X806 Pins 5 + 6 have to be

added

PROFIBUS: 500kBit

MODBUS: Baud rate 19200, 8 Databits, Even parity, 1 Start/Stop Bit

Output currents of X806

Pins 5 + 6 have to be

Ambient conditions

Type ELC X6-60 ELC X6B-60 ELC X6i-60

Humidity

Ambient operation temperature

Ambient storage temperature

Maximum storage period

Air flow

Altitude of site

Max. 85%, non-

condensing

5°C to +45°C 5°C to +55°C 5°C to +45°C

-20°C to +70°C during storage and transportation, before initial operation

leave at least 4 hrs at room temperature

2 years (also see chapter 4.2)

max. 200 m³ / h at TA >35°C

Up to 2000m NN without derating

2000m NN to 4000m NN: 1.5% / 100m power reduction effected by ELC-

control (example: X6= 4200 W at 4000m NN)

Max. 95% Max. 85%, non-

condensing

Typ. 100 m³ / h

Max. 4000m NN

Certification

Type ELC X6-60 ELC X6B-60 ELC X6i-60

IP 54

Protection

EMC

Safety

Marine approvals

Note: protection is only guaranteed if cables of the given diameters are

- - GL (pending) - -

Protection of front fan IP x4

used (see chapter 3.2.2)

EN 55011

EN 61000-3-3

EN 61000-6-2

EN 50178

ELC X-Series-V1.3-09.16-GB subject to technical alterations

Page 54

6 Technical Data page 50

6.3 ELC X8, X8B, X8 extended range

Output power characteristics

Type ELC X8-80 ELC X8B-80

Power factor Typ. 0.97 Typ. 0.97 Typ. 0.97

Power efficiency > 0.94 > 0.94 > 0.94

Nominal power range 1600 W – 8000 W 1600 W – 8000 W 1600 W – 8800W

ELC X8-80 extended

range

Electrical characteristics

Type ELC X8-80 ELC X8B-80

Nominal supply voltage 400 V - 480 V 440 V 400 V -480 V

Nominal supply current 22.0 A – 18.0 A 20.0 A 22.0 A – 18.0 A

Max. supply current 24 A 22 A 24 A

Line protection* min. 25 A min. 25 A min. 25 A

Mains frequency

Min. mains voltage (shut down

voltage)

Output power reduction in case

of low mains voltage

Abs. max. mains voltage

Leakage current

Insulation resistance between

primary and PE

Discharching time of residual

voltage after mains

disconnection

Charge time (minimum time

between switch on of the ELC

and starting the lamp)

50 / 60 Hz 50 / 60 Hz 50 / 60 Hz

320V 320V 320V

from approx. 360V –

320V: 20 W / V

528V 528V 528V

typ. 10mA typ. 10mA typ. 10mA

>30 MΩ >30 MΩ >30 MΩ

10 mins. 10 mins. 10 mins.

12 s 12 s 12 s

from approx. 400V –

320V: 20 W / V

(@55°C)

ELC X8-80 extended

range

from approx. 400V –

320V: 20 W / V

*Line protection: automatic cut-out characteristic C

Lamp characteristics

Type ELC X8-80 ELC X8B-80

Nominal lamp power 8 kW 8 kW 8 kW

Nominal lamp voltage 800 V 800 V 800 V

Tolerance lamp voltage

Threshold voltage of {lamp

voltage low} warning bit

Ignition voltage / period