Page 1

STANDARD COUNTING SCALE OPERATION & SERVICE MANUAL

Model XTC

STANDARD COUNTING SCALE www.mt.com/xpress

Page 2

2

STANDARD COUNTING SCALE

ABOUT THIS MANUAL AND MT EXPRESS

Thank you for purchasing an MT Xpress product.

All of our equipment is assembled and packed with great care. If you should find any incorrect item,

please contact your Xpress Dealer immediately.

This MT Xpress product was developed, produced, and tested in a METTLER TOLEDO facility that has

been audited and registered according to international ISO 9001 quality standards and ISO 14000

environment control program. Properly used and maintained, this product will provide years of accurate

weighing. Handle it as you would any piece of fine electronic equipment.

Please READ this manual BEFORE operating or servicing this equipment. Follow the instructions carefully

and save this manual for future reference.

We at MT Xpress want to make sure you received the product you expected. It is important to us that you

are satisfied with your purchase. If there is anything we can help you with, or if you are not satisfied with

either your product or the services received from the Xpress representative, let us know.

How can you reach us?

XPRESS CUSTOMER CARE CENTER, USA

24/7 Information and Support: www.mt.com/xpress

xpress@mt.com

8 AM to 8 PM EST Toll Free: 1-866-MTXPRESS

Xpress

Mettler-Toledo, Inc.

60 Collegeview

Westerville, OH 43081

Page 3

STANDARD COUNTING SCALE

FCC Approval

This device complies with part 15 of the FCC Rules. Operation is subject to the following two

conditions: (1) this device may not cause harmful interference, and (2) this device must accept any

interference received, including interference that may cause undesired operation.

3

Page 4

4

STANDARD COUNTING SCALE

CONTENTS

SAFTEY NOTICE...................................................................................................................................... 5

PREPARING THE SCALE FOR USE ............................................................................................................. 6

ENVIRONMENT .......................................................................................................................6

UNPACKING AND ASSEMBLY....................................................................................................6

YOUR XPRESS SCALE AT A GLANCE .......................................................................................................... 8

DISPLAY ................................................................................................................................8

KEYPAD.................................................................................................................................8

DISPLAY WINDOWS ................................................................................................................8

CURSORS (VFD) .....................................................................................................................9

OPERATING YOUR SCALE ...................................................................................................................... 10

STRAIGHT COUNTING ............................................................................................................10

PUSH-BUTTON TARE .............................................................................................................10

KEYBOARD TARE ..................................................................................................................11

DECREMENT COUNTING ........................................................................................................12

SPECIAL OPERATION FUNCTIONS ........................................................................................................... 13

ID FUNCTION........................................................................................................................ 13

ACCUMULATION FUNCTION ....................................................................................................14

RECALL AND EXIT THE ACCUMULATOR ....................................................................................14

AVERAGE PIECE WEIGHT (APW) FUNCTION .............................................................................14

COMMUNICATION FUNCTION..................................................................................................15

DATA OUTPUT.......................................................................................................................15

EXTERNAL COMMANDS .........................................................................................................15

RECALL FUNCTION ................................................................................................................16

COUNT TARGET ALARM..........................................................................................................16

PRESET THE TARGET ZONE ....................................................................................................16

APW ENHANCEMENT ............................................................................................................17

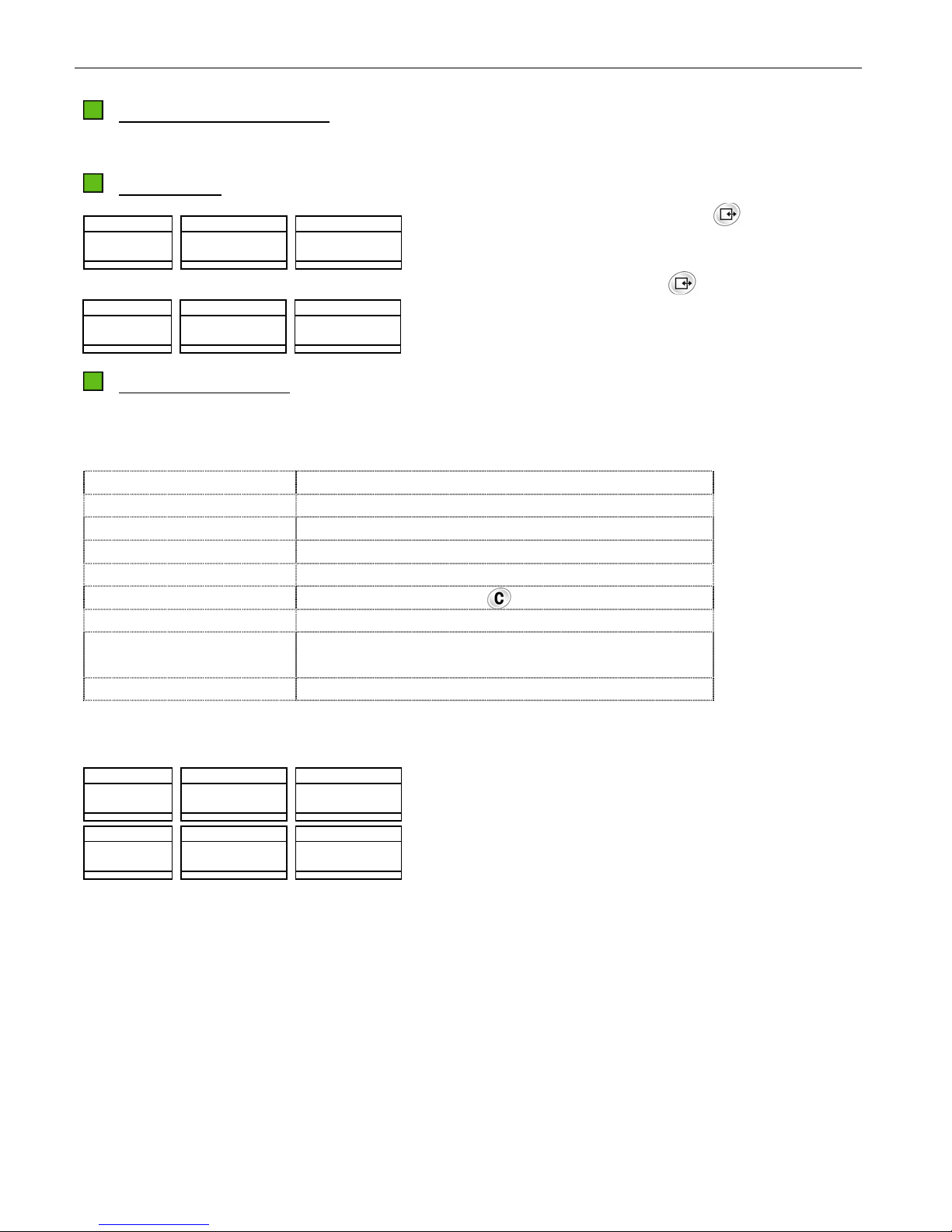

SPECIAL MODES – SETUP MODE............................................................................................................ 18

ENTERING THE SETUP MODE .................................................................................................18

FUNCTION OF THE KEYS ........................................................................................................18

DISPLAY ILLUSTRATION .........................................................................................................19

CONFIGURATION...................................................................................................................19

CLEANING AND MAINTAINING YOUR SCALE.............................................................................................. 23

CLEANING AND MAINTENANCE...............................................................................................23

TROUBLESHOOTING ..............................................................................................................23

SERVICING YOUR SCALE ....................................................................................................................... 24

ENTERING SERVICE MODE ..................................................................................................... 24

FUNCTION OF THE KEYS ........................................................................................................24

CONFIGURATION...................................................................................................................25

COMMUNICATION .................................................................................................................28

APPENDIX........................................................................................................................................... 31

SETUP MODE PARAMETER OVERVIEW .....................................................................................31

ERROR MESSAGES................................................................................................................32

SPECIFICATIONS ...................................................................................................................33

GEO VALUE TABLE ................................................................................................................34

PHYSICAL DIMENSIONS ......................................................................................................... 35

Page 5

STANDARD COUNTING SCALE

SAFTEY NOTICE

Product safety is a fundamental concern at MT Xpress. Use common sense and follow the simple

precautions listed below to ensure your safety and to optimize the use and performance of this product.

− Read this manual before operating or servicing this product. Save this manual for future reference.

− Observe safety warnings located throughout this manual.

− Use caution when lifting or moving heavy equipment.

− This product should only be serviced by qualified personnel. Exercise care when moving, testing, or

adjusting this product.

− Disconnect all power to this product before installing, servicing, or cleaning.

5

− Use only MT Xpress parts for repair.

− Observe electrostatic handling precautions for electronic components. Allow at least 30 seconds

after power is disconnected to allow charges to dissipate before servicing any electronic

components.

− Allow the product to adjust to room temperature before connecting the power source.

FAILURE TO FOLLOW THESE PRECAUTIONS COULD RESULT IN DAMAGE TO OR DESTRUCTION OF THE

EQUIPMENT, OR BODILY HARM.

FCC NOTICE

This equipment has been tested and found to comply with the limits of the United States of America FCC

rules for a Class A digital device, pursuant to Part 15 of the FCC Rules. This equipment generates, uses,

and can radiate radio frequency energy and, if not installed and used in accordance with the instruction

in this manual, may cause harmful interference to radio communications. Operation of this equipment in

a residential area is likely to cause harmful interference in which case the user will be required to correct

the interference at his own expense.

Page 6

6

STANDARD COUNTING SCALE

PREPARING THE SCALE FOR USE

The XTC Standard Counting Scale is a high performance industrial counting scale that accurately and

dependably counts parts of all shapes and sizes.

This manual provides not only the detailed information on how to operate the scale, but also useful

messages for service and maintenance.

Please read this manual thoroughly and familiarize yourself with all the safety requirements. All service

procedures must only be performed by authorized personnel.

This chapter gives detailed instructions and important information regarding the successful installation of

the Xpress Standard Counting Scale.

ENVIRONMENT

Before you install the scale, identify the best location for the equipment. The proper environment

enhances its operation and longevity. Keep in mind the following factors, which might have a negative

influence on the scale's operation:

Vibration: Vibration diminishes the scale’s ability to measure accurately. Electrical machinery such as

conveyors and drill presses can cause inaccurate and non-repeatable readings. The scale may also

read inaccurately if it is not leveled properly.

Air currents: Moving air can cause the scale to read wind movement as an additional force and cause

inconsistency in the weighing results.

Friction: A scale cannot measure accurately if an object is rubbing or pressing against the scale

platform.

UNPACKING AND ASSEMBLY

Please inspect the package immediately upon receipt. If the box is damaged, check for internal damage

and file a freight claim with the carrier if necessary. If the container is undamaged, open the box, remove

the scale and place it on a solid, flat surface. Please keep the packing material and shipping insert in

case you need to return the scale to an Xpress representative.

Package contents for all Xpress Standard Counting Scales include:

Product

− XTC Counting Scale

− Pan (only with XTC1001)

− Platter Supports Kit

(only with XTC1001)

− Scale Platter

− Adapter

− Lead seal wire and lead

Documents

− Quick Start Guide

− Installation Instructions

CD-ROM

− Operation & Service Manual

Page 7

STANDARD COUNTING SCALE

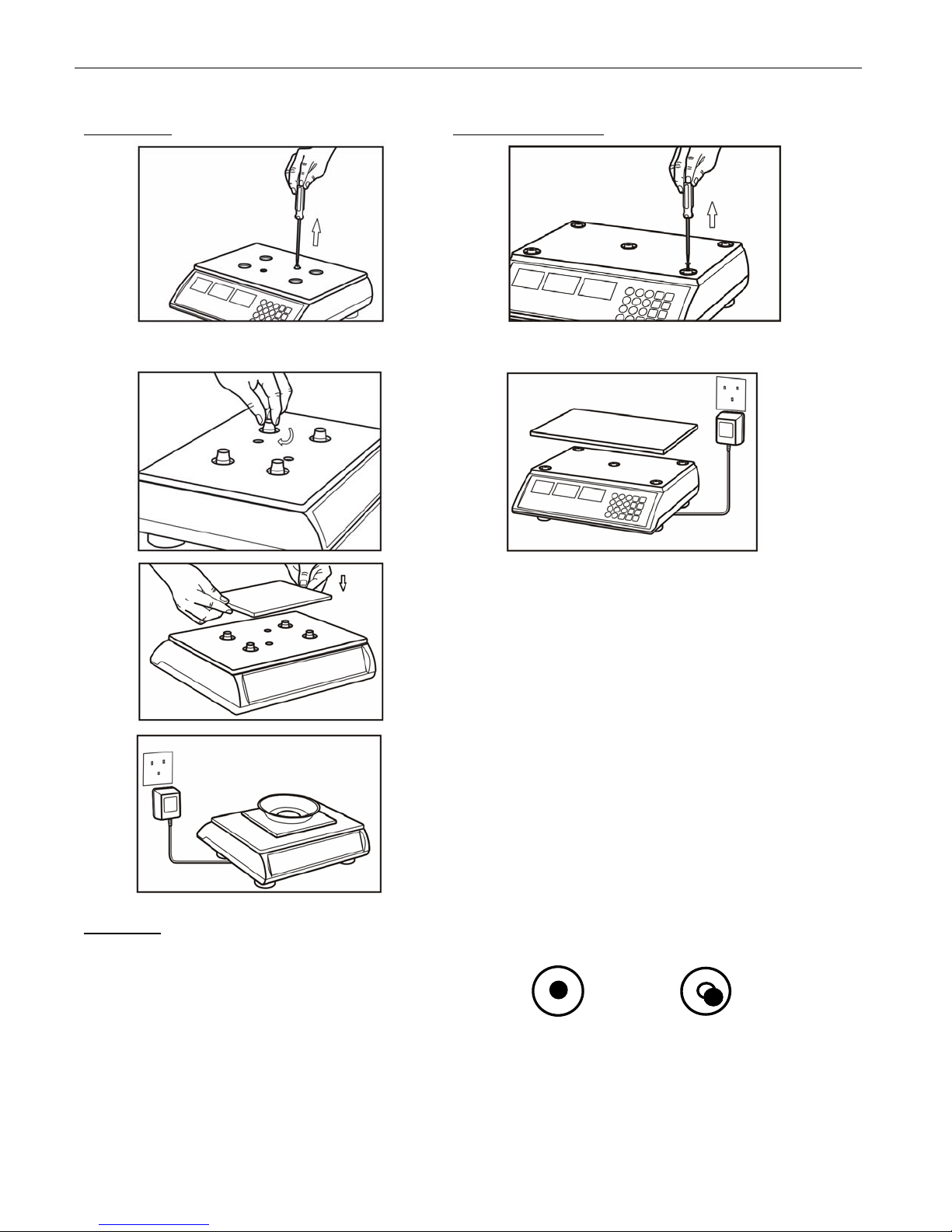

5 lb models 10/20/50 lb models

7

1.

2.

3.

1.

(20/50 lb models skip this step)

2.

4.

All models

Level the scale by adjusting the four rubber feet

until the leveling bubble is centered in the level

indicator.

Proper alignment Improper alignment

Page 8

8

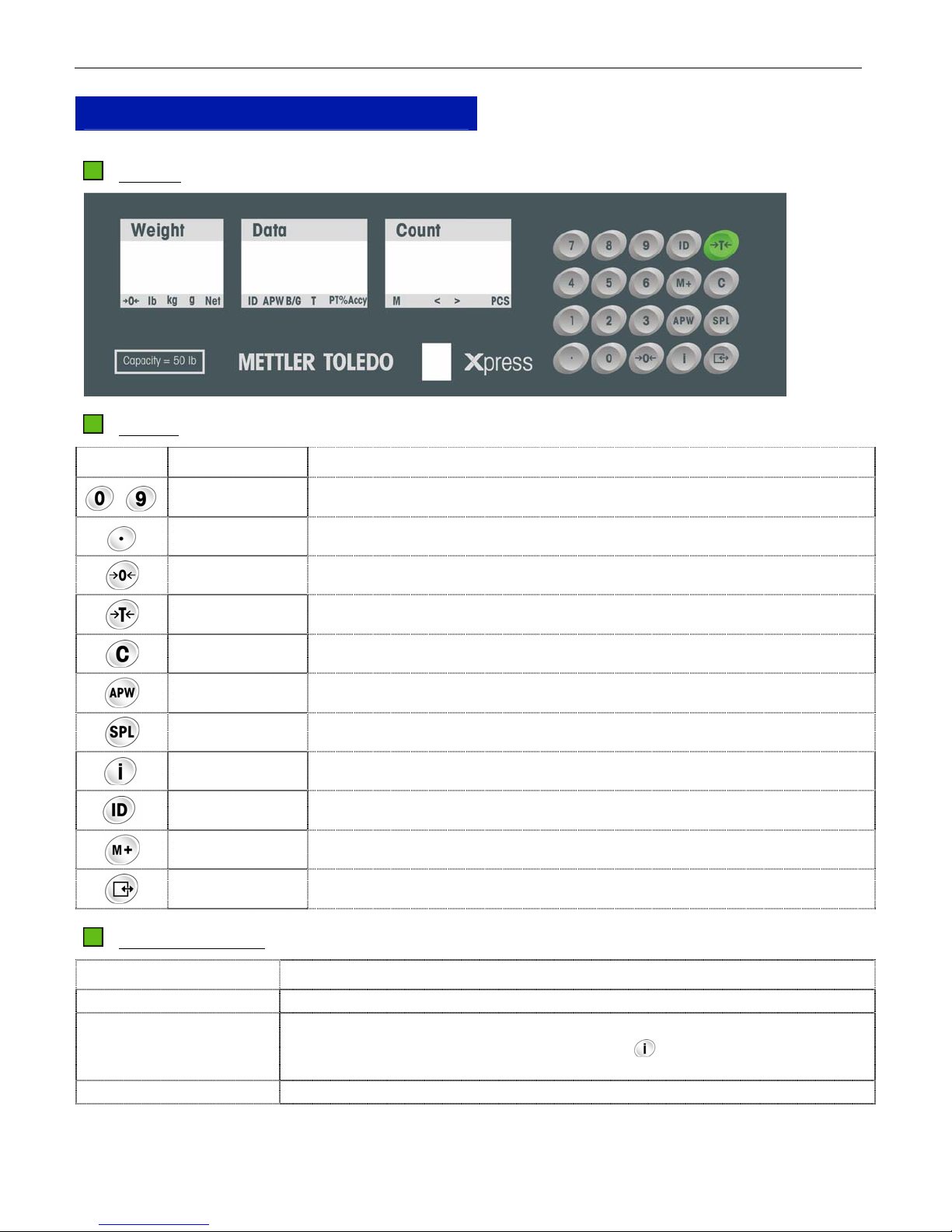

YOUR XPRESS SCALE AT A GLANCE

DISPLAY

KEYPAD

Key Name Function

STANDARD COUNTING SCALE

~

Numeric Data entry (0-9)

Decimal Enters a decimal point/Toggles alarm beep

Zero Zeroes the scale

Tare Subtracts tare value and switches from gross to net mode

Clear Clears data from the display

APW Initiates Average Piece Weight (APW) entry

Sample Initiates sampling

Recall Recalls the accumulated quantity and times

ID Store ID number, APW, tare and item number

Accumulation Adds the accumulator counts or recalls accumulation

Enter/Print Confirms an operation or initiates data output

DISPLAY WINDOWS

Window Description

Weight Display (Weight) Displays the weight.

Data Display (Data) Displays item number, APW, gross weight, tare, push-button tare or accuracy

percentage sequentially with each time the key is pressed. The default

display is APW.

Count Display (Count) Displays the counts.

Page 9

STANDARD COUNTING SCALE

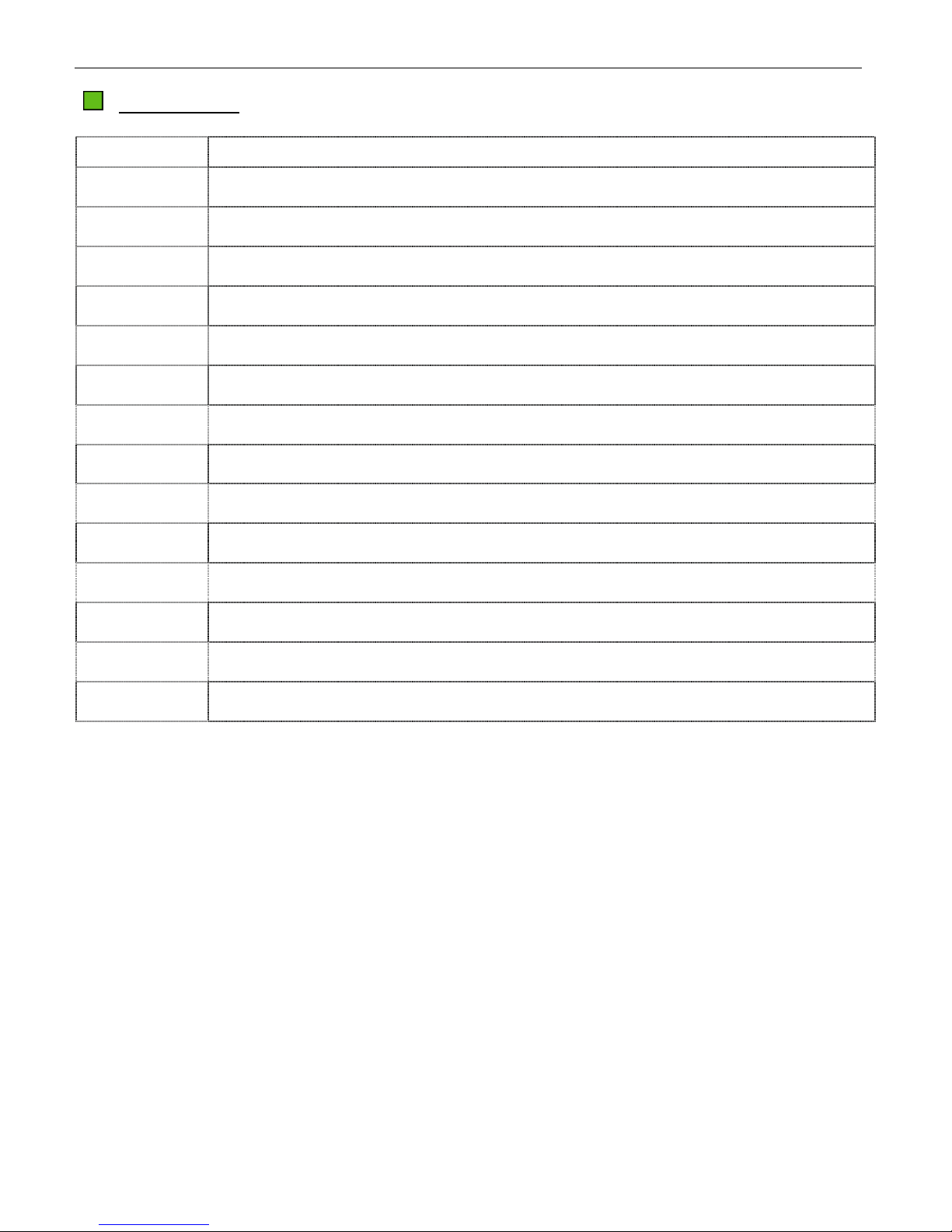

CURSORS (VFD)

Key Description

9

→0←

When the scale is at the gross zero, this cursor will be lit

lb, kg, g Weight unit cursor; Weight unit can be set in Setup Mode

Net When net weight is displayed, this cursor will be lit

ID When item number is recalled, this cursor will be lit

APW When Average Piece Weight (APW) is recalled, this cursor will be lit

B/G When gross weight is recalled, this cursor will be lit

T When push-button tare weight is recalled, this cursor will be lit

PT When keyboard tare is recalled, this cursor will be lit

%Accy When the counting accuracy percentage is recalled, this cursor will be lit

M When the value in the accumulator is not zero, this cursor will be lit

PCS When the count is displayed, this cursor will be lit

> Target Alarm: Indicates the count is above the Over value

< Target Alarm: Indicates the count is below the Under value

< > When both > and < cursors are lit, it indicates that the count is within the target zone

Page 10

10

OPERATING YOUR SCALE

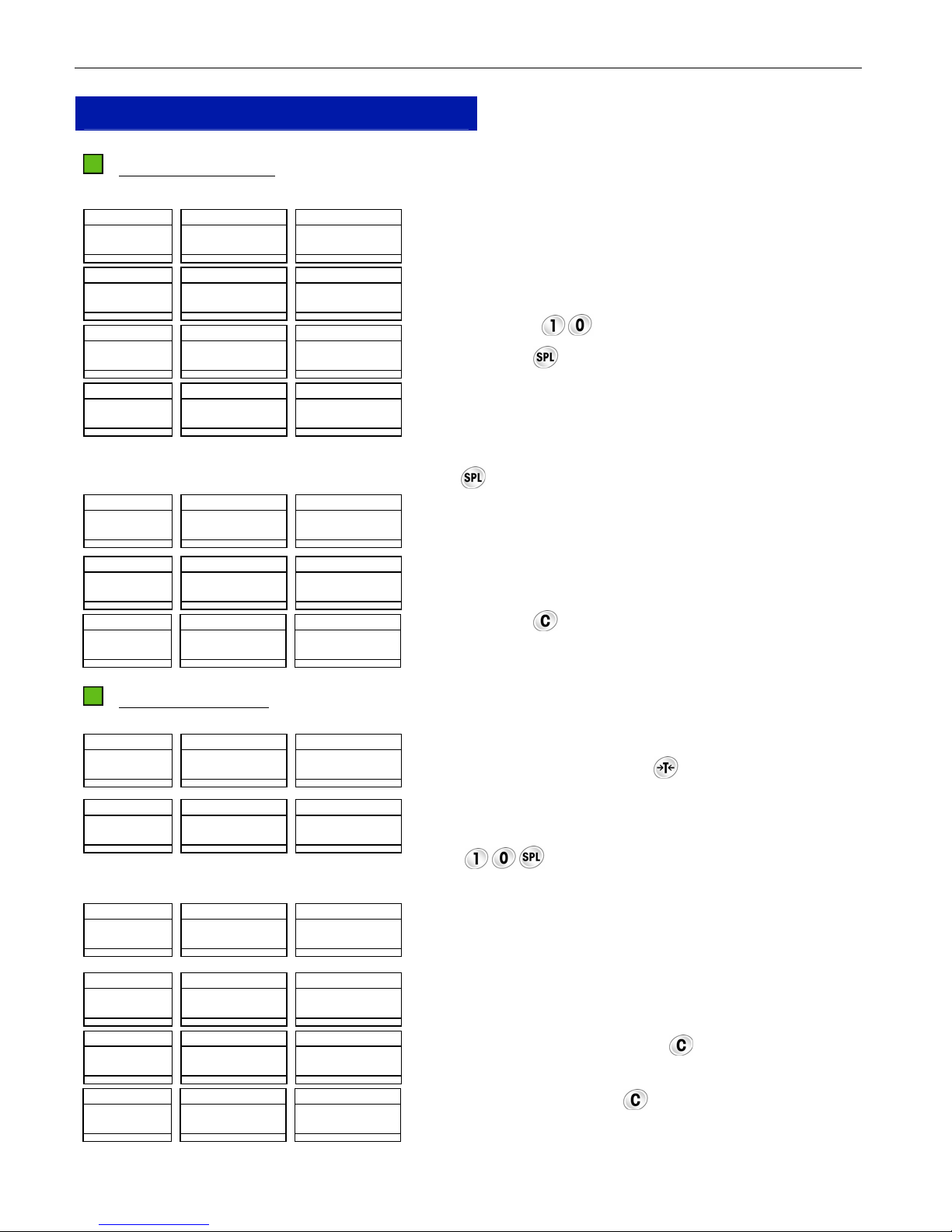

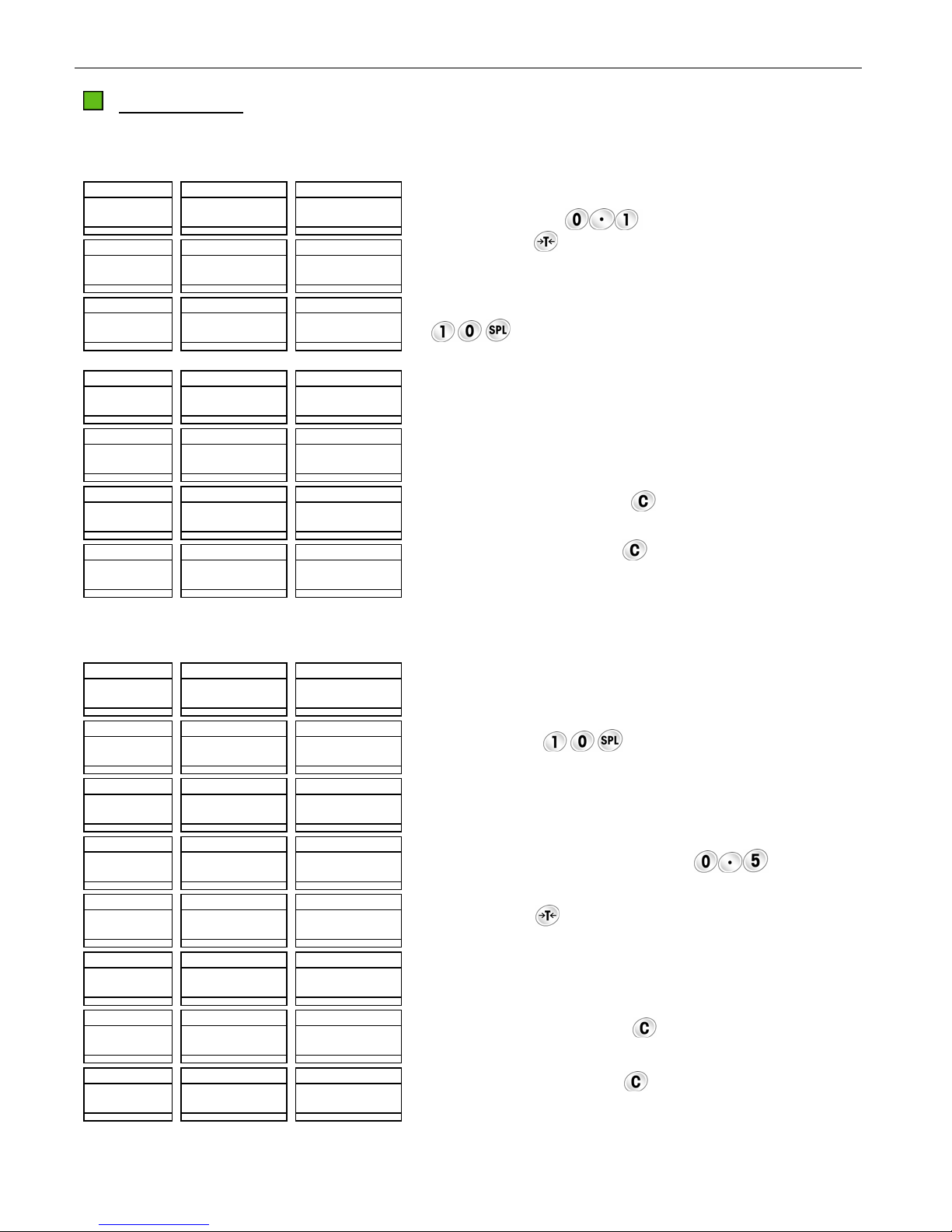

STRAIGHT COUNTING

Weight Data Count

00 0 0 0

u u u

>0< lb kg g Net CN APW B/G T PT

Weight Data Count

00 2 0 0

u u

>0< lb kg g Net CN APW B/G T PT

Weight Data Count

00 2 0 1 0

u

>0< lb kg g Net CN APW B/G T PT

Weight Data Count

00 2 0 00 0 2 0 0 1 0

u u u

>0< lb kg g Net CN APW B/G T PT

Weight Data Count

30 0 0 00 0 2 0 0 1 5 0 0

u u u

>0< lb kg g Net CN APW B/G T PT

Weight Data Count

00 0 0 00 0 2 0 0 0

u u u u

>0< lb kg g Net CN APW B/G T PT

Weight Data Count

00 0 0 0

u u u

>0< lb kg g Net CN APW B/G T PT

M < > PCS

M < > PCS

M < > PCS

M < > PCS

M < > PCS

M < > PCS

M < > PCS

STANDARD COUNTING SCALE

The XTC counting scale is in the weight mode and ready for

counting operation.

Place the samples on the platter (e.g. 10 pieces, total weight

is 0.020 lb).

Press the keys

to input the sample pieces.

Press the key to initiate Average Piece Weight (APW).

Note: If the sample weight is less than the minimum sample

weight set in the Setup Mode, the count window will show

“ADD XX” indicating that “XX” more pieces should be added

on the platter. After adding the required quantity, press the

key to re-sample.

Place the items to be counted on the platter (e.g. 1500

pieces including samples).

Remove all the items from the platter.

Press the key to clear the APW.

PUSH-BUTTON TARE

Weight Data Count

00 0 0 0

u u u

>0< lb kg g Net CN APW B/G T PT

Weight Data Count

00 2 0 00 0 2 0 0 1 0

u u u u

>0< lb kg g Net CN APW B/G T PT

Weight Data Count

30 0 0 00 0 2 0 0 1 5 0 0

u u u u

>0< lb kg g Net CN APW B/G T PT

Weight Data Count

- 02 0 0 00 0 2 0 0 1 0 0

u u u u

>0< lb kg g Net CN APW B/G T PT

Weight Data Count

- 02 0 0 0

u u u

>0< lb kg g Net CN APW B/G T PT

Weight Data Count

00 0 0 0

u u u

>0< lb kg g Net CN APW B/G T PT

M < > PCS

M < > PCS

M < > PCS

M < > PCS

M < > PCS

M < > PCS

Place the empty container or wrapping material on the platter

(e.g., 0.2 lb), and then press .

Place the samples in the container or on the wrapping

material and then onto the platter (e.g. 10 pieces, total

weight is 0.02 lb). Initiate APW by pressing the

keys

.

Place the items to be counted in the container or on the

wrapping material and then onto the platter (e.g. 1500

pieces including samples).

Remove all the items from the platter.

Clear the APW data by pressing .

Clear the tare by pressing again.

Page 11

STANDARD COUNTING SCALE

3

5

3

5

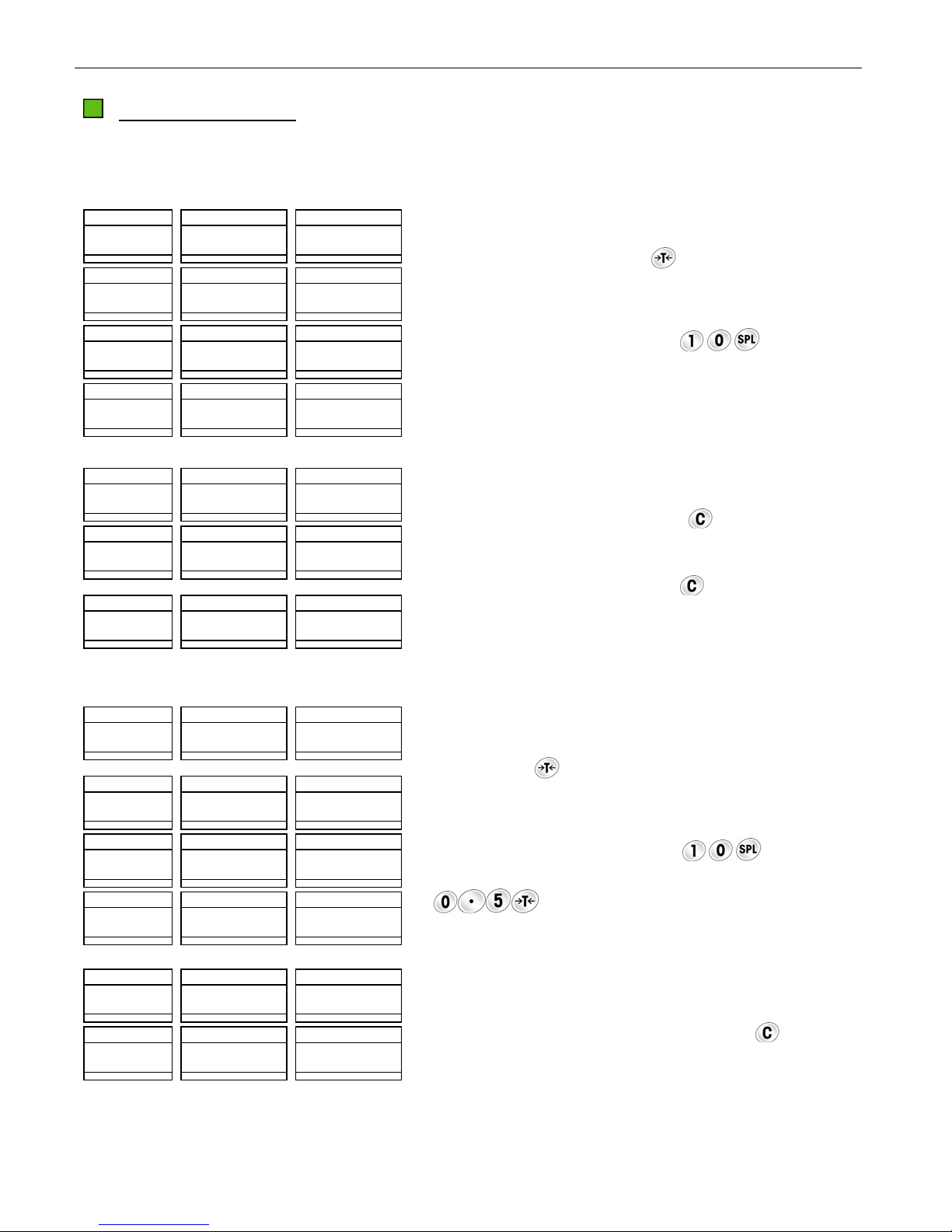

KEYBOARD TARE

There are two operation procedures for this function.

Operation Procedure 1

Weight Data Count

00 0 0 01

u u u

>0< lb kg g Net CN APW B/G T PT

Weight Data Count

- 01 0 0 0

u u u

>0< lb kg g Net CN APW B/G T PT

M < > PCS

M < > PCS

Weight Data Count

00 2 0 00 0 2 0 0 1 0

u u u u

>0< lb kg g Net CN APW B/G T PT

M < > PCS

Weight Data Count

30 0 0 00 0 2 0 0 1 5 0 0

u u u u

>0< lb kg g Net CN APW B/G T PT

M < > PCS

Weight Data Count

- 01 0 0 00 0 2 0 0 5 0

u u u u

>0< lb kg g Net CN APW B/G T PT

M < > PCS

Weight Data Count

- 01 0 0 0

u u u

>0< lb kg g Net CN APW B/G T PT

M < > PCS

Weight Data Count

00 0 0 0

u u u

>0< lb kg g Net CN APW B/G T PT

M < > PCS

Press the appropriate keys for the known tare value (e.g. 0.1

lb, press the keys to input tare value 0.1).

Press the key to initiate the input value as tare.

Place the samples in the container or on the wrapping

material and then onto the platter (e.g. 10 pieces, total

weight is 0.02 lb). Initiate APW by pressing the keys

Place the items to be counted in the container or on the

wrapping material and then onto the platter (e.g. 1500

pieces including samples).

Remove all the items and the container or wrapping material

from the platter.

Clear the APW by pressing .

Clear the tare by pressing again.

11

.

Operation Procedure 2

Weight Data Count

00 2 0 0

u u

>0< lb kg g Net CN APW B/G T PT

Weight Data Count

00 2 0 00 0 2 0 0 1 0

u u u

>0< lb kg g Net CN APW B/G T PT

Weight Data Count

0 0 00 0 2 0 0 1 7 5 0

u u u

>0< lb kg g Net CN APW B/G T PT

Weight Data Count

0 0 05

u

>0< lb kg g Net CN APW B/G T PT

Weight Data Count

30 0 0 00 0 2 0 0 1 5 0 0

u u u u

>0< lb kg g Net CN APW B/G T PT

Weight Data Count

- 05 0 0 00 0 2 0 0 2 5 0

u u u u

>0< lb kg g Net CN APW B/G T PT

Weight Data Count

- 05 0 0 0

u u u

>0< lb kg g Net CN APW B/G T PT

Weight Data Count

00 0 0 0

u u u

>0< lb kg g Net CN APW B/G T PT

M < > PCS

M < > PCS

M < > PCS

M < > PCS

M < > PCS

M < > PCS

M < > PCS

M < > PCS

Place the samples on the platter (e.g. 10 pieces, total

weight is 0.02 lb).

Press the keys

to initiate APW.

Place the items to be counted in the container or on

the wrapping material and then onto the platter, (e.g.

1500 pieces including samples).

Input the data by pressing the keys

.

Press the key

to initiate the tare as 0.5lb.

Remove all the items and the container or wrapping

material from platter.

Clear the APW by pressing

.

Clear the tare by pressing again.

Page 12

12

DECREMENT COUNTING

There are two decrement counting modes.

Mode 1

Weight Data Count

00 0 0 0

u u u

>0< lb kg g Net CN APW B/G T PT

M < > PCS

Weight Data Count

- 00 2 0 0

u u u

>0< lb kg g Net CN APW B/G T PT

M < > PCS

Weight Data Count

- 00 2 0 00 0 2 0 0 1 0

u u u u

>0< lb kg g Net CN APW B/G T PT

M < > PCS

Weight Data Count

- 20 0 0 00 0 2 0 0 1 0 0 0

u u u u

>0< lb kg g Net CN APW B/G T PT

M < > PCS

Weight Data Count

- 30 0 0 00 0 2 0 0 1 5 0 0

u u u u

>0< lb kg g Net CN APW B/G T PT

M < > PCS

Weight Data Count

- 30 0 0 0

u u u

>0< lb kg g Net CN APW B/G T PT

M < > PCS

Weight Data Count

00 0 0 0

u u u

>0< lb kg g Net CN APW B/G T PT

M < > PCS

Mode 2

Weight Data Count

00 0 0 0

u u u

>0< lb kg g Net CN APW B/G T PT

Weight Data Count

- 00 2 0 0

u u u

>0< lb kg g Net CN APW B/G T PT

Weight Data Count

- 00 2 0 00 0 2 0 0 1 0

u u u u

>0< lb kg g Net CN APW B/G T PT

Weight Data Count

29 8 0 00 0 2 0 0 1 4 9 0

u u u u

>0< lb kg g Net CN APW B/G T PT

Weight Data Count

- 05 0 0 00 0 2 0 0 2 5 0

u u u u

>0< lb kg g Net CN APW B/G T PT

Weight Data Count

00 0 0 0

u u u

>0< lb kg g Net CN APW B/G T PT

M < > PCS

M < > PCS

M < > PCS

M < > PCS

M < > PCS

M < > PCS

STANDARD COUNTING SCALE

Place the items to be counted in the container or on the

wrapping material and then onto the platter (e.g. 3 lb

including tare). Press the key .

Remove the samples from the platter (e.g. 10 pieces, total

weight is 0.02 lb).

Initiate APW by pressing the keys .

Remove all the items from the container or the wrapping

material (e.g. 1000 pieces including the samples). The

count stands for the pieces removed from the platter

including the sample.

Remove the container or wrapping material from the platter.

Clear the APW by pressing the key .

Clear the tare by pressing the key again.

Place the items in the container or on the wrapping material

and then onto the platter (e.g. 3.5 lb including tare), then

press the key

.

Remove the samples from the platter (e.g. 10 pieces, total

weight is 0.02 lb).

Initiate APW by pressing the keys .

Input the known tare (e.g. 0.5 lb) by pressing the keys

. The count stands for the pieces in the

container or on the wrapping material, not including the

samples already removed.

Remove all the items and the container or wrapping material

from the platter.

Clear the APW and tare by pressing the key

twice.

Page 13

STANDARD COUNTING SCALE

A

SPECIAL OPERATION FUNCTIONS

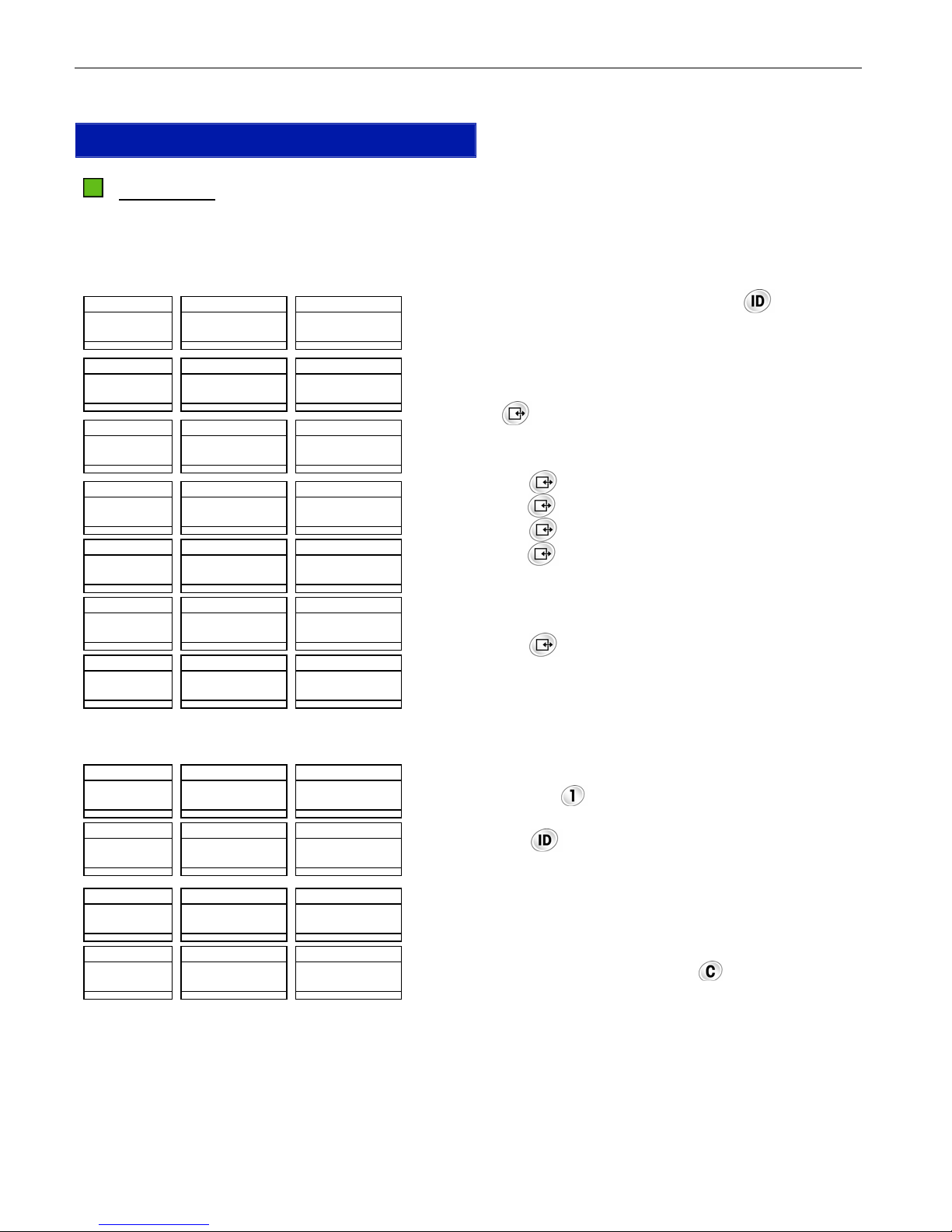

ID FUNCTION

20 ID can be stored with 2-digit ID No. and APW and 6-digit item No. and tare. ID data will not be lost

when power is off. Emptying the item No. can clear an ID. The tare stored in the ID is keyboard tare.

Store an ID

Weight Data Count

I d ?

>0< lb kg g Net ID APW B/G T PT %Accy

Weight Data Count

I d ?

>0< lb kg g Net ID APW B/G T PT %Accy

Weight Data Count

P U ? 00 0 0 0 0

>0< lb kg g Net ID APW B/G T PT %Accy

Weight Data Count

M < > PCS

M < > PCS

M < > PCS

t A r E ? 00 0 0

>0< lb kg g Net ID APW B/G T PT %Accy

Weight Data Count

M < > PCS

I t n o ? 0

>0< lb kg g Net ID APW B/G T PT %Accy

Weight Data Count

M < > PCS

I t n o ? 7 8 9 0 1 2

>0< lb kg g Net ID APW B/G T PT %Accy

Weight Data Count

00 0 0 0 0

u u u

>0< lb kg g Net ID APW B/G T PT %Accy

M < > PCS

M < > PCS

In the count or weight mode, press the key to enter the

ID entry mode.

Enter a numeric value 1 (acceptable from 1 to 20).

Press key

to display the existing APW (if this ID has

existed) or current APW (if this ID is a new one) to

waiting new APW input.

Press the key

directly or input the known APW then

press the key to wait for new tare input.

Press the key directly or input the known tare then

press the key to wait for the item No. input.

Input the item No. up to 6 digits (e.g. 789012)

Press the key to accept the input and return the scale

the previous mode.

Recall an ID

Weight Data Count

0 00 0 0 1

>0< lb kg g Net ID APW B/G T PT %Accy

Weight Data Count

-

00 2 0 00 0 2 0 0 1 0

u u u u

>0< lb kg g Net ID APW B/G T PT %Accy

Weight Data Count

n o I d

>0< lb kg g Net ID APW B/G T PT %Accy

Weight Data Count

00 0 0 0

u u u

>0< lb kg g Net ID APW B/G T PT %Accy

0

u

M < > PCS

M < > PCS

M < > PCS

M < > PCS

In count or weight mode, press the desired numeric

key (e.g.: the key

) to input ID No. (e.g. ID No.

is 1).

Press the key to recall the desired ID (e.g.: ID1),

the data in ID1 will be recalled from the memory,

while active the accumulator with the same No.

If no ID, the Weight window shows “no id” for 2

seconds, then back to previous mode.

After finishing all transactions, press

key to clear

ID and active accumulator 0.

Note: the recalled APW or tare can be modified

temporarily.

13

Page 14

14

y

y

STANDARD COUNTING SCALE

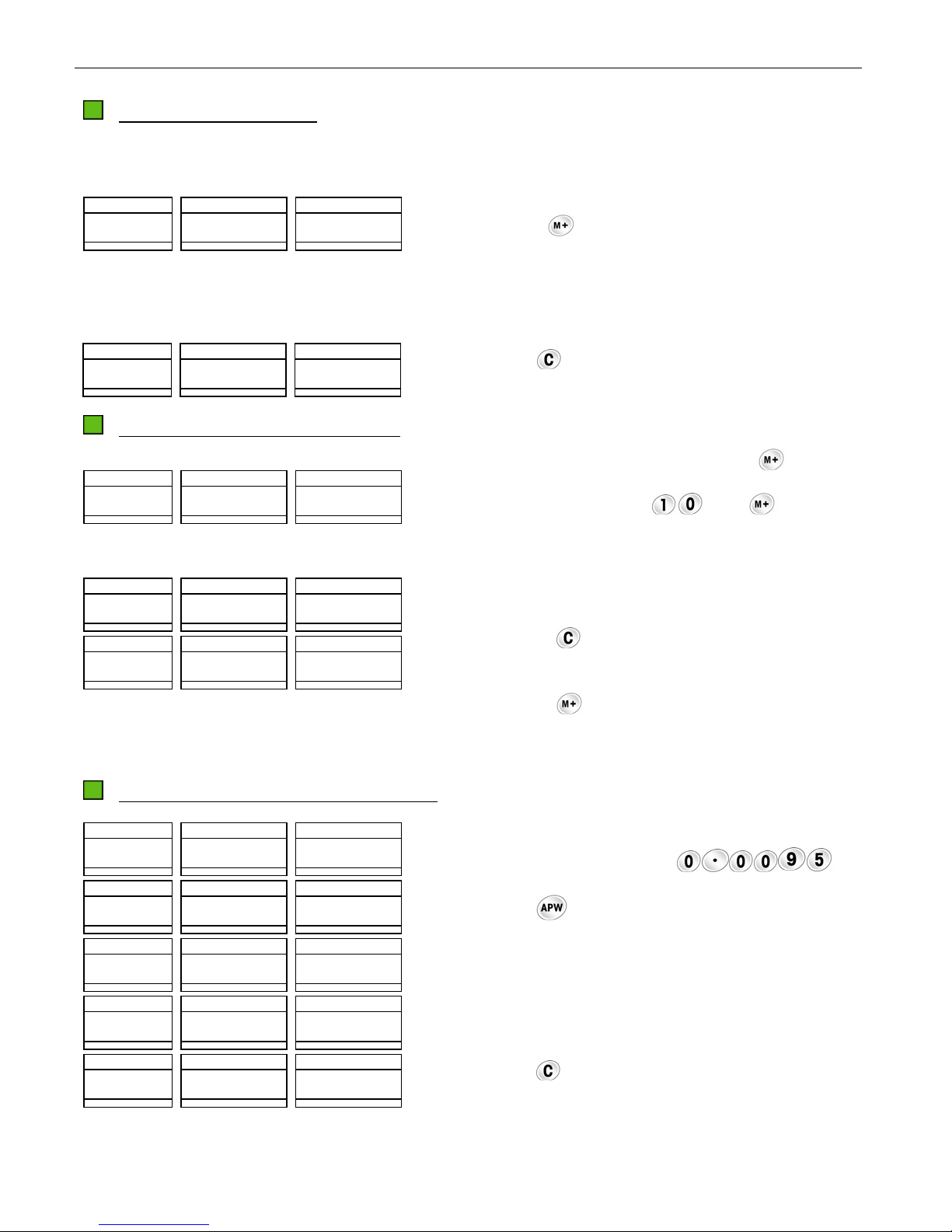

ACCUMULATION FUNCTION

There are 21 accumulators to store the total counts. The data in the accumulator will be lost when power

to the scale is lost.

Weight Data Count

30 0 0 00 0 2 0 0 1 5 0 0

u u u u

>0< lb kg g Net CN APW B/G T PT %Acc

M < > PCS

Weight Data Count

00 0 0 0

u u u u

>0< lb kg g Net CN APW B/G T PT %Accy

M < > PCS

When the scale is in the count mode and the count is not

zero, press the key. The beeper will give a double beep

to indicate the displayed counts have been added into the

accumulator and the “M” cursor will be lit.

Repeat above steps until all transactions are accumulated.

Note: The weight should return to zero before the next

accumulation.

Press the key

to clear the APW.

RECALL AND EXIT THE ACCUMULATOR

Weight Data Count

t O t A L C n 2 3 2 5 0

>0< lb kg g Net CN APW B/G T PT %Acc

u

M < > PCS

Weight Data Count

00 0 0 0

u u u

>0< lb kg g Net CN APW B/G T PT %Accy

M < > PCS

Weight Data Count

00 0 0 0

u u u u

>0< lb kg g Net CN APW B/G T PT %Accy

M < > PCS

AVERAGE PIECE WEIGHT (APW) FUNCTION

Weight Data Count

00 0 0 00 0 9 5

u u

>0< lb kg g Net CN APW B/G T PT %Accy

Weight Data Count

00 0 0 00 0 9 5 0 0

u u u u

>0< lb kg g Net CN APW B/G T PT %Accy

Weight Data Count

09 5 0 00 0 9 5 0 1 0 0

u u u

>0< lb kg g Net CN APW B/G T PT %Accy

Weight Data Count

00 0 0 00 0 9 5 0 0

u u u u

>0< lb kg g Net CN APW B/G T PT %Accy

Weight Data Count

00 0 0 0

u u u

>0< lb kg g Net CN APW B/G T PT %Accy

M < > PCS

M < > PCS

M < > PCS

M < > PCS

M < > PCS

In weight mode, press the key Press the key

to recall the

accumulated count in the temporary accumulator.

Press the numeric keys (e.g.: ) and to recall the

accumulated count in the corresponding accumulator (e.g.:

accumulator 10).

In accumulation display mode, there are two ways to return

the scale to the previous mode.

Pressing the key to clear the accumulator and return the

scale back to the previous mode.

Pressing the key to return the scale back to the previous

mode without clearing the accumulator.

In the count and weight mode, enter the APW data (e.g.

0.0095 lb) by pressing the keys .

Press the key

to initiate APW.

Place the items to be counted on the platter.

Remove all the items from the platter.

Press the key to clear the APW.

Page 15

STANDARD COUNTING SCALE

COMMUNICATION FUNCTION

With the optional RS-232 cable kit, the XTC can communicate to a printer or a PC.

DATA OUTPUT

15

Weight Data Count

t o t A L C n 3 4 5 0 0

>0< lb kg g Net CN APW B/G T PT %Accy

Weight Data Count

- 00 2 0 00 0 2 0 0 1 0

u u u u

>0< lb kg g Net CN APW B/G T PT %Accy

u

M < > PCS

M < > PCS

In accumulation display mode, press to print the total

counts and CN or transmit the data to a PC.

In count or weight mode, press

to print the APW, tare,

pieces, and/or gross weight (The items depend on the soft

switch setting in the Setup Mode.) or transmit the data to

a PC.

EXTERNAL COMMANDS

The XTC can accept some ASCII coded commands from a host PC. The commands are identified as

follows:

Keys Description

[T][Enter] Equal to push-button tare operation

[Z][ Enter] Equal to zero operation

[P][ Enter] Equal to print operation

[C][ Enter] Equal to clearing operation

[C][C][ Enter] Equal to pressing the key twice

[T][XXXXXX][Enter] Initiate XXXXXX as the tare

[S][XXXXXX][Enter] Initiate an APW. XXXXXX is the sample pieces and the

weight on the platter is the sample weight

[A][XXXXXXXX][Enter] Initiate XXXXXXXX as the APW

For example:

Weight Data Count

09 5 0 00 0 9 5 0 1 0 0

u u u

>0< lb kg g Net CN APW B/G T PT %Accy

Weight Data Count

00 0 0 00 0 9 5 0 0

u u u u

>0< lb kg g Net CN APW B/G T PT %Accy

M < > PCS

M < > PCS

The scale is in the count mode.

Press the keys [T][Enter] on the keyboard of a PC. The XTC

will accept this command and tare the scale.

Page 16

16

3

5

y

y

y

y

y

y

A

RECALL FUNCTION

STANDARD COUNTING SCALE

The XTC can subtract some data via the key

Weight Data Count

30 0 0 00 0 2 0 0 1 5 0 0

u u u u

>0< lb kg g Net CN APW B/G T PT %Accy

Weight Data Count

30 0 0

u u u u

>0< lb kg g Net CN APW B/G T PT %Accy

0 0 0 1 5 0 0

Weight Data Count

30 0 0 05 00 0 1 5 0 0

u u u u

>0< lb kg g Net CN APW B/G T PT %Accy

Weight Data Count

30 0 0 00 00 0 1 5 0 0

u u u u

>0< lb kg g Net CN APW B/G T PT %Accy

Weight Data Count

30 0 0 9 99 5 1 5 0 0

u u u u

>0< lb kg g Net ID APW B/G T PT %Acc

Weight Data Count

30 0 0 8 1 5 0 0

u u u u

>0< lb kg g Net CN APW B/G T PT %Accy

Weight Data Count

30 0 0 00 0 2 0 0 1 5 0 0

u u u u

>0< lb kg g Net CN APW B/G T PT %Accy

M < > PCS

M < > PCS

M < > PCS

M < > PCS

M < > PCS

M < > PCS

M < > PCS

. The default data is APW when the scale powers up.

The scale is in the count or weight mode. (Weight window

shows the weight value.)

Press the key . The B/G cursor will light and the Data

window will display gross weight (e.g. 3.5 lb).

Press the key and the T cursor will light. If the current tare

is a push-button tare, the Data display will show the tare

value. If the tare is a keyboard tare or no tare exists, it will

be 0.0000.

Press the key and the PT cursor will light. The Data

display will show the tare that was input via the keyboard. If

the tare is a push-button tare or no tare exists, it will show

0.0000.

Press the key , the %Accy cursor is lit, the Data display

will show the counting accuracy percentage.

Press the key , the ID cursor is lit, the Data display will

show the value of the item No..

Press the key and the APW cursor will light. The Data

display will show the APW.

COUNT TARGET ALARM

A target zone (>/<) can be preset via keyboard. If the target alarm is enabled in the Setup Mode, the

scale will beep continually when the piece count is within or outside of this range depending on the soft

switch setting. If the target zone has been preset, the under cursor “< “ will be lit when the piece count is

below the Under value. When the piece count is above the Over value, the over cursor “>“ will be lit. If

both, the Over and Under values are 0, the target alarm will be disabled.

PRESET THE TARGET ZONE

Weight Data Count

u n d E r ? 1 2 0 0

>0< lb kg g Net CN APW B/G T PT %Acc

Weight Data Count

M < > PCS

u n d E r ? 1 8 0 0

>0< lb kg g Net CN APW B/G T PT %Acc

Weight Data Count

M < > PCS

O U E r ? 1 2 5 0

>0< lb kg g Net CN APW B/G T PT %Acc

Weight Data Count

M < > PCS

O U E r ? 1 8 3 0

>0< lb kg g Net CN APW B/G T PT %Acc

Weight Data Count

30 0 0 00 0 2 0 0 1 5 0 0

u u u u u

>0< lb kg g Net CN APW B/G T PT %Acc

Note: Both Over and Under values equal to 0 will disable the Target Alarm function.

M < > PCS

M < > PCS

u u

u u

u u

u u

In count or weight mode, press and hold the key

for

about three seconds, then release the key. The scale will

enter into target zone setting mode.

Press the key to accept the displayed value, or enter a

new value and then press

to accept it.

fter entering the Under value, the display will show prompts

as the illustrated.

Press the key

new value and then press

to accept the displayed value, or enter a

to accept it.

After entering the Over value, the scale will return to the

previous mode automatically.

Page 17

STANDARD COUNTING SCALE

17

APW ENHANCEMENT

APW enhancement improves the accuracy of an APW. APW enhancement is based on the fact that an

inaccurate APW, while not able to accurately count large numbers of parts, will reliably count a small

number. This allows a determination of APW based on a larger weight. Given enough enhancements,

the APW becomes very accurate.

This function permits the operator to continuously update the APW based on larger and larger samples.

As additional pieces are placed on the scale, a new APW can be calculated based on the new total

sample weight and count.

The APW can be enhanced constantly up to 4% of the scale capacity. To ensure a minimum APW initial

accuracy, a sample weight of at least five display increments must be used. There is a selection in setup

mode which increases the minimum sample to 0.015%, 0.1% or 0.2% of capacity.

When using APW enhancement, you must not add more pieces to the scale than what can be counted

accurately using the current APW (about the same pieces, which have already been counted). If this

maximum is exceeded, a warning of [OVER] will be displayed for approximately two seconds then will

automatically clear. The operator can remove parts until [OVER] will not be displayed again.

If the operator ignores the [OVER] display and adds more pieces (or removes more in count-out sample

mode), no further APW enhancement will be done for the current transaction. If the proper procedure is

followed, the scale will continue to enhance the APW until 4% of the scale capacity is reached. Once the

counting weight reaches 4%, APW enhancement is discontinued.

Notice: The APW inputted via keyboard or recalled from an ID can not be enhanced.

Page 18

18

STANDARD COUNTING SCALE

SPECIAL MODES – SETUP MODE

ENTERING THE SETUP MODE

The operating parameters can be configured in the Setup Mode. When “Full Operator Access” is enabled

in the Service Mode, step S3.1, the Setup Mode can be accessed by pressing and holding the key

for about seven seconds and then releasing the key.

FUNCTION OF THE KEYS

After Setup Mode is accessed, use the four keys, FINISH, BACKUP, TOGGLE and ACCEPT, to configure the

parameters.

In the Setup Mode, the functions of the keys will be as follows:

Key Function Description

Finish

Used to end scale configuration and proceed to End Block.

Backup

Toggle

Used to step back through program blocks and sub-blocks.

Used to step through the blocks. Once a block is accessed, this key is used to

toggle settings On and Off or to step through the setting options of the sub-block.

Used to access the program block or to accept the displayed option. Once a

Accept

displayed sub-block option is accepted, the scale will step forward to the next

sub-block or block.

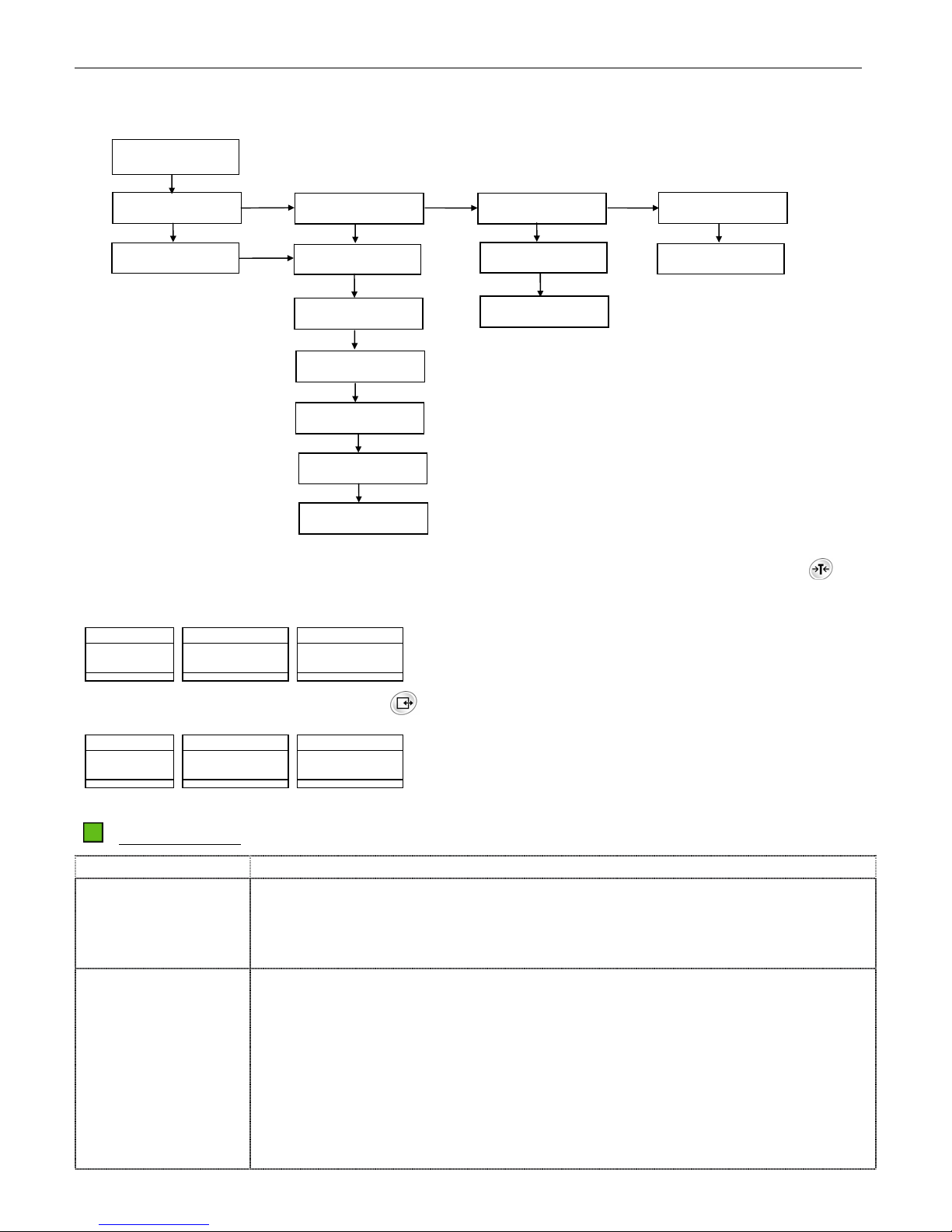

The following diagram gives an overview of the program blocks and sub-blocks.

Setup Mode

Page 19

STANDARD COUNTING SCALE

g

g

19

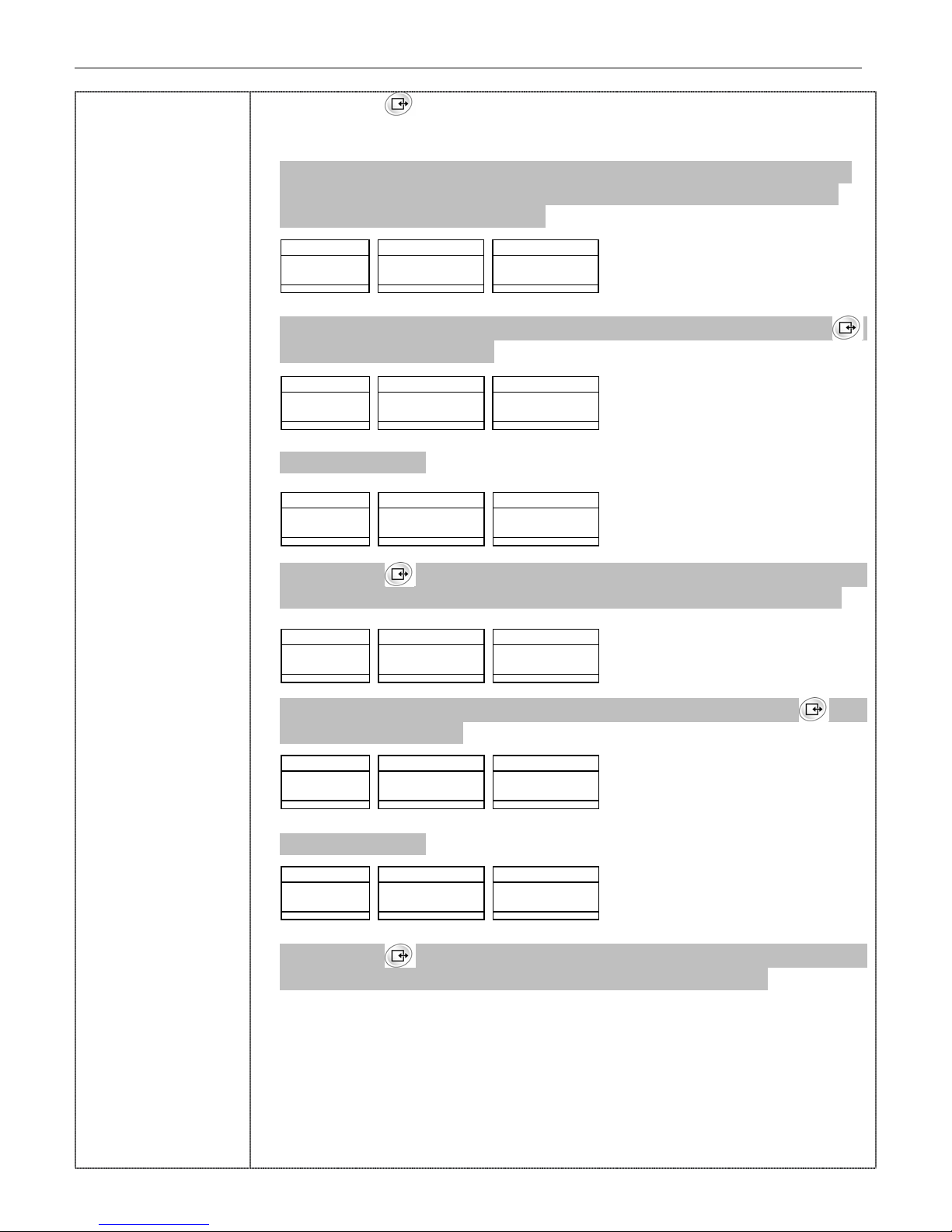

DISPLAY ILLUSTRATION

The scale automatically moves to the first block as soon as the master mode is accessed. Press the key

to toggle among blocks [SCALE], [tArE], [SAMPLE], [dAtA], [SEriAL], [id] and [End]. When a block

is displayed, press the key to access the first sub-block or to go to end block.

Setup Mode Sample Display—Major block Setup Mode Sample Display—Sub-block

Weight Data Count

F 1 u S E r

>0< lb kg g Net CN APW B/G T PT

M < > PCS

Weight Data Count

F11 oFF

>0< lb k

Net CN APW B/G T PT

M < > PCS

CONFIGURATION

Blocks Sub Blocks/Parameters

F1 User Block F1.1 Beeper

Off = Disable beeper

On = Enable beeper

F2 Scale Block

F2.1 Power-up Weight Units

1 = kg

2 = lb

3 = g

The cursor corresponding to the selected unit should be “on” during this block.

F2.3 Digital Filter

0 = No filtering

1 = Light filtering

2 = Heavy filtering

F2.4 Blank Count Blank

Off = The count display will show whatever residual count is existing based on

the scale internal divisions and the APW entered, regardless of the weight

displayed.

On = When the weight display (gross and net) is reading zero, the count

display will be zero.

F2.5 Displayed Resolution Choice

0 = 5 lb/0.002 lb, 10 lb/0.005 lb, 20 lb/0.01 lb, 50 lb/0.02 lb

1 = 5 lb/0.001 lb, 10 lb/0.002 lb, 20 lb/0.005 lb, 50 lb/0.01 lb

2 = 5 lb/0.0005 lb, 10 lb/0.001 lb, 20 lb/0.002 lb, 50 lb/0.005 lb

3 = 5 lb/0.0002 lb, 10 lb prohibit, 20 lb/0.001 lb, 50 lb/0.002 lb

F3 Tare Block

F3.1 Tare

Off = Disable tare

On = Enable tare

F3.2 Keyboard Tare

Off = Disable keyboard tare

On = Enable keyboard tare

Page 20

20

F3.3 Auto Clear Tare

Off =Disable auto clear tare

On = Enable auto clear tare

Automatic clear of tare occurs when net weight exceeds 9d. It settles to no

motion and then returns to within +/-3d from gross zero.

F4 Sample Block F4.1 Minimum Sample

Off = No minimum sample weight is required. The APW will “flash”, if the

sample weight is below 0.05% of the capacity until the weight used to

calculate the new APW due to APW enhancement goes above 0.05%.

0.05 = Minimum sample is 0.05% of capacity. If the sample weight is below

this minimum sample weight, the count display will show “add XX” to require

additional samples and data display will blank out to indicate APW

calculation is forbidden until the sample weight is more than 0.05% of

capacity and the new APW is calculated.

0.10 = Minimum sample is 0.10% of the capacity.

0.20 = Minimum sample is 0.20% of the capacity.

F4.2 Average Piece Weight (APW) Enhancement

Off = Disable APW enhancement

On = Enable APW enhancement

F4.3 Auto Clear APW

Off = Disable automatic clear of APW

On = Enable automatic clear of APW

Automatic clear of APW occurs when gross weight (or net weight if a tare has

been taken) exceeds 9d, settles to no motion, and then returns to within +/3d from gross zero.

F5 Data Block

F5.1 Accumulation

Off = Disable accumulation

On = Enable accumulation

F5.2 Clear Accumulator after Print

Off = Disable clear after print

On = Enable clear after print

F5.3 Target Alarm

Off = Disable target alarm

On = Enable target alarm

F5.4 Alarm Mode

Off = Scale beeps continuously when count is within the target range

On = Scale beeps continuously when count is out of target range

F5.5 Alarm Type

Off = Weight alarm

On = Quantity alarm

F6 Serial Interface F6.1 Baud Rate

STANDARD COUNTING SCALE

Page 21

STANDARD COUNTING SCALE

Block

300 = 300 baud

1200 = 1200 baud

2400 = 2400 baud

4800 = 4800 baud

9600 = 9600 baud

F6.2 Print Line Format

Off = Multiple line format

On = Single line format

F6.3 Print ID

Off = Disable printing of ID

On = Enable printing of ID

F6.4 Print Gross

Off = Disable printing of gross weight

On = Enable printing of gross weight

F6.5 Print Tare

Off = Disable printing of tare

On = Enable printing of tare

F6.6 Print Net

Off = Disable printing of net weight

On = Enable printing of net weight

F6.7 Print Average Piece Weight (APW)

Off = Disable printing of APW

On = Enable printing of APW

F6.8 Print Pieces

Off = Disable printing of pieces

On = Enable printing of pieces

F6.9 Print Item No.

Off = Disable printing of Item No.

On = Enable printing of field Item No.

F6.10 Output

0 = Command output

1 = Stable output

F7 ID Block F7.1 ID

21

Page 22

22

Off = Disable ID

On = Enable ID

F7.2 Auto Clear ID

Off = Disable auto clear ID

On = Enable auto clear ID

End Block

This block is used to exit the Setup Mode. After exiting the Setup Mode, the scale

will self-test automatically and enter into weight mode.

Save = Save all the changes and exit Setup Mode.

Abort = Abort any changes and exit Setup Mode.

Default = Reset all parameters to the factory defaults and exit the Setup Mode.

STANDARD COUNTING SCALE

Page 23

STANDARD COUNTING SCALE

CLEANING AND MAINTAINING YOUR SCALE

WARNING

DISCONNECT ALL POWER TO THIS UNIT

BEFORE INSTALLING, SERVICING,

CLEANING, OR REMOVING THE FUSE.

FAILURE TO DO SO COULD RESULT IN

BODILY HARM AND/OR PROPERTY

DAMAGE.

CLEANING AND MAINTENANCE

− DO NOT allow untrained personnel to operate, clean, inspect, maintain, service, or tamper with this

equipment.

− DO NOT attempt to remove the cover or to perform service/maintenance on the internal parts of the

scale.

23

− ALWAYS DISCONNECT this equipment from the power source before cleaning or performing

maintenance.

− KEEP the scale clean. Periodically clean the keyboard and cover with a soft clean cloth that has

been dampened with a mild window cleaner or detergent. DO NOT USE ANY TYPE OF INDUSTRIAL

SOLVENT OR CHEMICALS. DO NOT SPRAY CLEANER DIRECTLY ONTO THE UNIT.

− DO NOT put the scale under water. Use a damp cloth to clean the scale.

TROUBLESHOOTING

If operational difficulties are encountered, first obtain as much information as possible regarding the

problem. Failures and malfunctions can often be traced to simple causes such as loose connections or

improper setup.

Additional troubleshooting can be performed by your authorized Xpress Service representative.

Page 24

24

SERVICING YOUR SCALE

For the following services, please contact your Xpress representative at www.mt.com/xpress.

WARNING

DISCONNECT ALL POWER TO THIS UNIT BEFORE INSTALLING, SERVICING,

CLEANING, OR REMOVING THE FUSE. FAILURE TO DO SO COULD RESULT IN

BODILY HARM AND/OR PROPERTY DAMAGE.

CAUTION

BEFORE CONNECTING OR DISCONNECTING ANY INTERNAL ELECTRONIC COMPONENTS OR

INTERCONNECTING WIRING BETWEEN ELECTRONIC EQUIPMENT, ALWAYS REMOVE POWER AND

WAIT AT LEAST THIRTY (30) SECONDS. FAILURE TO OBSERVE THESE PRECAUTIONS COULD

RESULT IN DAMAGE TO OR DESTRUCTION OF THE EQUIPMENT, OR BODILY HARM.

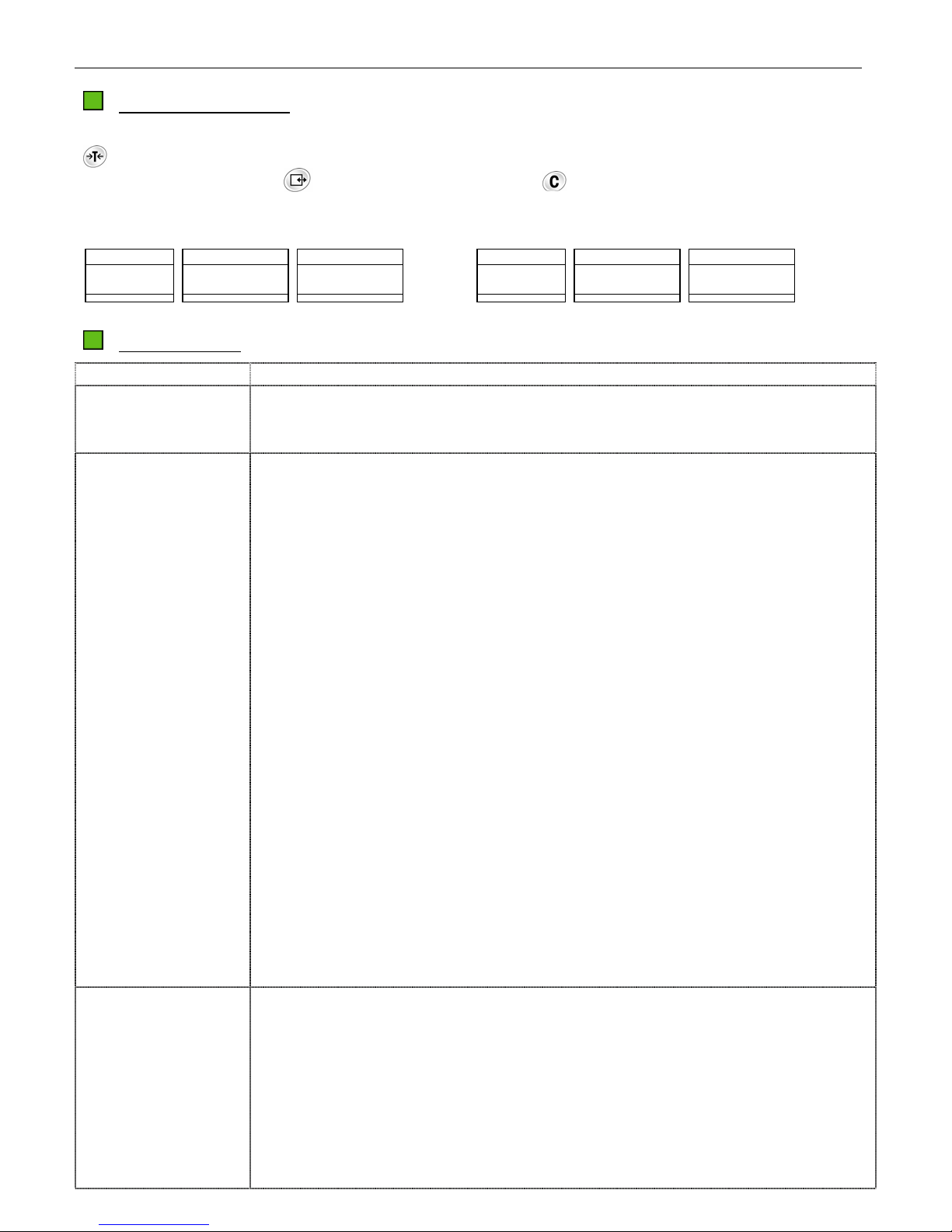

ENTERING SERVICE MODE

STANDARD COUNTING SCALE

1: Remove the calibration plate on the bottom right side of the scale.

2: Slide the set up switch backward to back side, the weight and data displays will show “S1” and “tESt”

respectively.

FUNCTION OF THE KEYS

After the Service Mode is accessed, use the four keys, FINISH, BACKUP, TOGGLE, and ACCEPT, to

configure the parameters.

In the Service Mode, the functions of the keys will be as follows:

Key Function Description

Finish

Back

Toggle

Used to end scale configuration and proceed to End Block.

Used to step back through program blocks and sub-blocks.

Used to step through the blocks. Once a block is accessed, this key is used to

toggle settings on and off or step through the setting options of the sub-block.

Used to access the program block or accept the displayed option. Once a

Accept

displayed sub-block option is accepted, the scale will step forward to the next

sub-block or block.

Page 25

STANDARD COUNTING SCALE

25

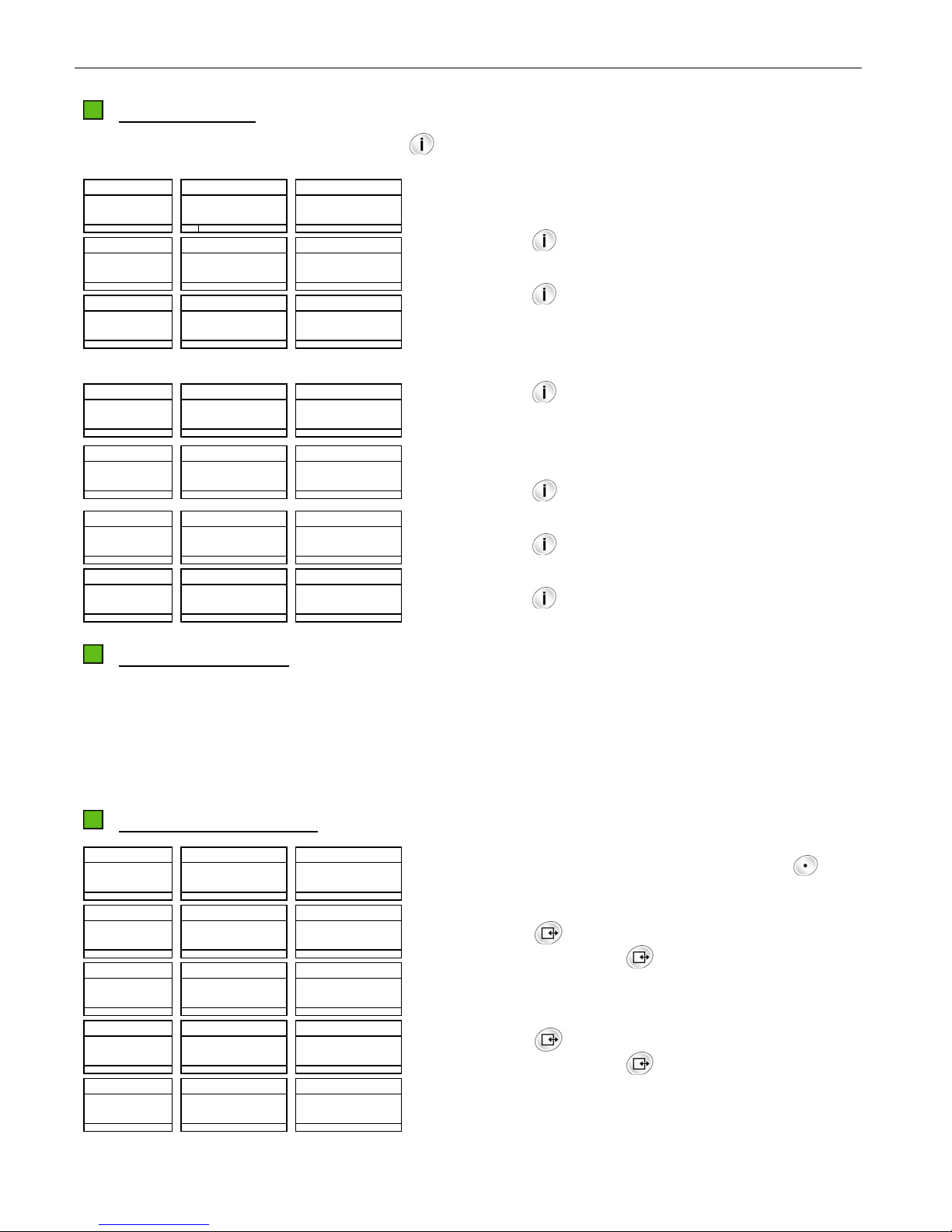

The following diagram gives an overview of the program blocks and sub-blocks.

Service Mode

Test Block

Calibration Block

Control Block

End Block

Expended Weight

CAL Units

Operator Access

Save/Abort

GEO Code

Country

Capacity

Increment

Linearity

Calibration

Once the Service Mode is accessed, the scale directly prompts to the first block. Press the key to

toggle among blocks [tESt], [CALIbr], [COntrL] and [End].Service Mode sample display - Test block

Weight Data Count

S 1 t E S t

>0< lb kg g Net ID APW B/G T PT %Accy

M < > PCS

When a block is displayed, press the key key to access the first sub- block.

Weight Data Count

S 11 o F F

>0< lb kg g Net ID APW B/G T PT %Accy

M < > PCS

CONFIGURATION

Blocks Sub Blocks / Parameters

S1 Test Block S1.1 Expanded Mode

Off = Normal weight mode

On = Expanded mode, the display division is 100000

S2 Calibration

Block

In this block you can configure the parameters related to calibration and calibrate

the TC.

S2.1 Calibration Unit

1 = kg

2 = lb

The weight unit cursor under the weight display window will indicate the unit being

selected.

Page 26

26

y

y

y

y

STANDARD COUNTING SCALE

S2.2 GEO Code

GEO. = xx

Select the GEO code according to your location. Please refer to Appendix for

your local GEO code. The scale has been calibrated at the factory. In most

cases, the scale doesn't have to be recalibrated. If the scale is found out of

tolerance after GEO code adjustment, perform the calibration.

S2.3 Capacity

Choose the capacity in accordance with the model.

lb - 5, 10, 20, 50

S2.4 Increment

Display the increment.

5 lb/0.0005 lb, 10 lb/0.001 lb, 20 lb/0.002 lb, 50 lb/0.005 lb

S2.5 Linearity

No = Normal Calibration

YES = Linearity Calibration

S2.6 Calibration

No = Skip Calibration

YES = Perform Calibration

Chose “Yes” to begin calibration and directly enter the first step “Empty Scale”.

The calibration procedure is as follows (take 5lb scale as example):

STEP 1 Empty scale.

Weight Data Count

S 26 E SCL

>0< lb kg g Net ID APW B/G T PT %Acc

M<>PCS

Remove all the items from the platter.

STEP 2 Capture zero

Press the key , the scale will start capturing zero and counting down from 5

to 0.

Weight Data Count

S 26 5

>0< lb kg g Net ID APW B/G T PT %Acc

M<>PCS

STEP 3 Add weight

The display reads as follows. Apply more than 2/3 capacity test weights on the

platter.

Weight Data Count

S 26 0

>0< lb kg g Net ID APW B/G T PT %Acc

M<>PCS

STEP 4 Input the weight data via keyboard

Input the weight data which to be weighted on the platter:

Weight Data Count

S 26 5

>0< lb kg g Net ID APW B/G T PT %Acc

M<>PCS

Page 27

STANDARD COUNTING SCALE

y

y

y

y

y

y

Press the key , the scale will start capturing span and counting down from

5 to 0. Then scale will automatically step forward to the next block.

If “yes” in S2.5 is chosen, the scale needs two points for calibrating the scale.

The procedure to add weight will be as follows (take 5lb scale as example):

After capturing the zero, it will show:

Weight Data Count

S 26 ADD HALF

>0< lb kg g Net ID APW B/G T PT %Acc

M<>PCS

Apply test weight (35%FS~65%FS) on the platter and then press the key .

The display reads as follows:

Weight Data Count

S 26 0HALF

>0< lb kg g Net ID APW B/G T PT %Acc

M<>PCS

Input a weight data.

Weight Data Count

S 26 2 half

>0< lb kg g Net ID APW B/G T PT %Acc

M<>PCS

Press the key , the scale will start capturing span and counting down from

5 to 0. Then scale will automatically step forward to the next step and show:

Weight Data Count

S 26 ADD FULL

>0< lb kg g Net ID APW B/G T PT %Acc

M<>PCS

Apply test weight (>85%FS) on the platter and then press the key . The

display reads as follows:

Weight Data Count

S 26 0 FULL

>0< lb kg g Net ID APW B/G T PT %Acc

M<>PCS

Input a weight data.

Weight Data Count

S 26 5 full

>0< lb kg g Net ID APW B/G T PT %Acc

M<>PCS

Press the key , the scale will start capturing span and counting down from

5 to 0. Then scale will automatically step forward to the next block

Note: If no calibration is done, the changes on the calibration weight and

capacity will be ignored.

27

Page 28

28

STANDARD COUNTING SCALE

S3 Control Block S3.1 Operator Access to Master Mode

Off = No access is allowed to Setup Mode by pressing the key .

On = Full access is allowed to Setup Mode when the key is pressed and

held for about 7 seconds Enable tare

S3.2 Country

2 = Export version

3 = China version

End Block

This block is used to save or abort the changed parameters, and then exit the

Service Mode

Save = Save all the changes and exit Service Mode.

Abort = Exit Service Mode without saving any changes

Exit Service Mode Pressing the key in Service Mode will lead to the end block.

In the end block, press the key

to enter the sub-block. Press the key to

toggle between save or abort. Press the key to accept the choice and exit the

Service Mode. Then the Weight window and Data window will display “SEtuP” and

“OFF” message respectively. Slide the calibration switch back to the normal

position, then the scale will go through a power-up sequence and enter into weight

mode.

COMMUNICATION

The XTC support bi-directional RS-232 serial communication. Using the optional cable with RS-232

convert circuit, the XTC can communicate with a printer or host like PC.

Serial port wiring diagram

DB-9 Female DB-9 Male DB-9 Female

5

2

GND

TXD

RXD

Optional Cable

MIROPCB

RS-232

5

1

3

2

TTL Cable Inside Scale

1

3

4

5

DB-25 Female

7

2

Optional Cable

GND

TXD

RXD

DB-9 Male DB-9 Female

5

MIROPCB

RS-232

1

3

2

TTL Cable Inside Scale

Communication parameter format

Baud rate: 300, 1200, 2400, 4800 and 9600 can be selected via softswitch setting.

Data: 11 bits ASCII codes, among these, there is 1 start bit, 7 ASCII coded data bits, 1 even parity bit

and 2 stop bits.

Data Output Format

There are two data output formats are available: single line output and multi-line output. It can also be

selected to disable output of some data.

1

3

4

5

Page 29

STANDARD COUNTING SCALE

Single Line Output

Format

29

The following is the outputted contents and the related format.

CN: Add one after each printing operation.

STX X X X SP SP

Item No.

X X X X X X SP I T E M SP N o . SP

Gross weight

X X X X X X SP l b SP

Tare weight

X X X X X X SP l b SP T R SP

Net weight

X X X X X X SP l b SP N E T SP

Average piece weight (APW)

X X X X X X X SP l b SP A P W SP

Pieces

X X X X X X SP P C S CR LF

Note:

• [STX] Document Head, ASCII Code 02H.

Multi-line Output

Format

• [SP] Space Bar, ASCII Code 20H.

• [CR] Enter Key, ASCII Code 0DH.

• [LF] Line Feed, ASCII Code 0AH.

• The actual weight unit printed depends on the softswitch setting of

Power-up Weight Unit.

The meaning of the same characters in the following charts will not be illustrated.

CN: Add one after each printing operation.

STX X X X CR LF

Item No.

STX X X X X X X SP I T E M SP N o . CR LF

Gross weight

X X X X X X SP l b CR LF

Tare weight

X X X X X X SP l b SP T R CR LF

Net weight

X X X X X X SP l b SP N E T CR LF

Page 30

30

STANDARD COUNTING SCALE

Average piece weight

X X X X X X X SP l b SP A P W CR LF

Pieces

X X X X X X SP P C S CR LF

Notice: The actual weight unit printed depends on the softswitch setting of Powerup Weight Unit.

When the weight unit is g, the APW should be:

X X X X X X X X X X SP k g SP A P W CR LF

Accumulation Output

Format

STX C N SP X X X SP SP

I T E M SP N o . SP X X X X X X SP SP

T O T SP P C S SP X X X X X X CR LF

External Control Input

External ASCII coded commands input are acceptable to complete the Tare, Zero, Clear, Print and

Sampling operations. The commands are detailed as below.

[T][CR] Push-button tare

[Z][CR] Zero Command

[P][CR] Print Command

[C][CR] Clear APW, if APW is not zero, clear tare if APW is zero.

[C][C][CR] Clear Command. Clear the APW, then clear tare.

[T][XXXXXX][CR] Enter tare. XXXXXX is the value of tare. The last digit of the tare entered should

agree

with the scale divisions. Otherwise, it shall be invalid.

[S][XXXXXX][CR] Enter the number of pieces (XXXXXX) as the sample count.

[A][XXXXXXXX][CR] Enter the value XXXXXXXX as the APW.

Page 31

STANDARD COUNTING SCALE

APPENDIX

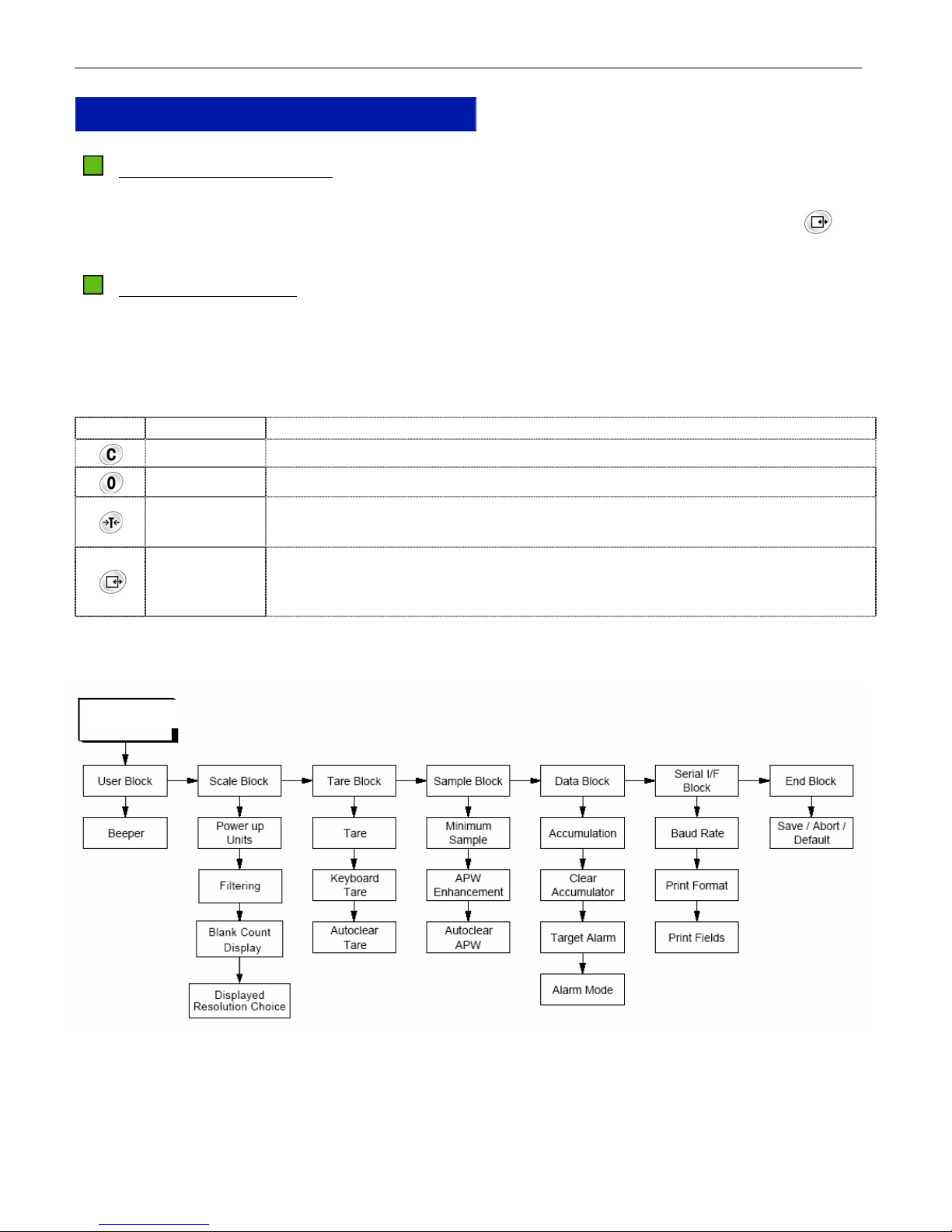

SETUP MODE PARAMETER OVERVIEW

Block Soft Switch Description Default

F1 User Block

F1.1 Beeper ON

F2 Scale Block

F2.1 Power-up Weight Unit 2

F2.3 Digital Filter 1

F2.4 Blank Count Display ON

F2.5 Displayed Resolution Choice 2

F3 Tare Block

F3.1 Tare ON

F3.2 Keyboard Tare ON

F3.3 Auto Clear Tare OFF

F4 Sample Block

F4.1 Minimum Sample 0.20

F4.2 APW Enhancement OFF

F4.3 Auto Clear APW OFF

F5 Data Block

F5.1 Accumulation ON

F5.2 Clear Accumulation after Print OFF

F5.3 Target Alarm ON

F5.4 Alarm Mode OFF

F5.5 Alarm Type ON

F6 Serial Interface Block

F6.1 Baud Rate 9600

F6.2 Print Line Format OFF

F6.3 Print CN ON

F6.4 Print Gross ON

F6.5 Print Tare ON

F6.6 Print Net ON

F6.7 Print APW ON

F6.8 Print Pieces ON

F6.9 Print Item No. ON

F6.10 Output 0

F7 ID Block

F7.1 ID ON

F7.2 Auto Clear ID OFF

F7 End Block

End Save/Abort SAVE

31

Page 32

32

STANDARD COUNTING SCALE

ERROR MESSAGES

The scale will display an error message if a problem or an incorrect keyboard entry is sensed. The error

codes are:

Display Possible Cause Troubleshooting

E11 RAM error 1. Restart the scale.

2. Recalibrate the scale.

3. Change the main PCB.

E16 ROM checksum error 1. Restart the scale.

2. Recalibrate the scale.

3. Change the main PCB.

E18 EPROM checksum error 1. Restart the scale.

2. Recalibrate the scale.

3. Change the main PCB.

uuuuu Under capacity 1. Put the scale pan on.

→

←

0

to zero scale.

nnnnn Count data or total counts

are above 999,999, the

2. Press the key

Remove the items until error message disappears or

clear the accumulator.

weight on the platter is 5d

above the full capacity.

------ Cannot capture zero 1. Restart the scale with no weight.

2. Recalibrate the scale.

3. Change the load cell or main PCB.

Page 33

STANDARD COUNTING SCALE

SPECIFICATIONS

33

Display

3 part display (5 digit Weight, 6 digit Data, 6 digit

Count)

12 mm height, green VFD

Internal Resolution

1/500,000

Displayed Resolution

Default: 1/10’000

Maximum: 1/25’000

Keyboard

20 membrane keyboard

Platter

5 lb model: 6.6” x 7.7” Stainless Steel

10/20/50 lb models: 9.5” x 13.5” Stainless Steel

Scale Dimensions

13.6” (L) x 13.6” (W) x 4.8” (H)

Specifications are subject to change without notice.

Units

lb, kg, g

Interface

RS232 (Accessory)

Power

External adapter 12V/600mA

Recommended APW

>1/5d (0.2d)

APW Enhanced

Operating Temperature

32°F to 104°F (0°C to +40°C)

10 to 90% humidity, non-condensing

Page 34

34

STANDARD COUNTING SCALE

GEO VALUE TABLE

Use the following geo codes if you relocate your scale to a site other than the original location where it

was calibrated.

Northern

and

Southern

latitude

in

degrees and minutes

0° 0′ —5° 46′

5° 46′ — 9° 52′

9° 52′ — 12° 44′

12° 44′ — 15° 6′

15° 6′ — 17° 10′

17° 10′ — 19° 2′

19° 2′ — 20° 45′

20° 45′ — 22° 22′

22° 22′ — 23° 54′

23° 54′ — 25° 21′

25° 21′ — 26° 45′

26° 45′ — 28° 6′

28° 6′ — 29° 25′

29° 25′ — 30° 41′

30° 41′ — 31° 56′

31° 56′ — 33° 9′

33° 9′ — 34° 21′

34° 21′ — 35° 31′

35° 31′ — 36° 41′

36° 41′ — 37° 50′

37° 50′ — 38° 58′

38° 58′ — 40° 5′

40° 5′ — 41° 12′

41° 12′ — 42° 19′

42° 19′ — 43° 26′

43° 26′ — 44° 32′

44° 32′ — 45° 38′

45° 38′ — 46° 45′

46° 45′ — 47° 51′

47° 51′ — 48° 58′

48° 58′ — 50° 6′

50° 6′ — 51° 13′

51° 13′ — 52° 22′

52° 22′ — 53° 31′

53° 31′ — 54° 41′

54° 41′ — 55° 52′

55° 52′ — 57° 4′

57° 4′ — 58° 17′

58° 17′ — 59° 32′

59° 32′ — 60° 49′

60° 49′ — 62° 9′

62° 9′ — 63° 30′

63° 30′ — 64° 55′

64° 55′ — 66° 24′

66° 24′ — 67° 57′

67° 57′ — 69° 35′

69° 35′ — 71° 21′

71° 21′ — 73° 16′

73° 16′ — 75° 24′

75° 24′ — 77° 52′

77° 52′ — 80° 56′

80° 56′ — 85° 45′

85° 45′ — 90° 00′

0

325

0

1060

5 4 4 3 3 2 2 1 1 0 0

5 5 4 4 3 3 2 2 1 1 0

6 5 5 4 4 3 3 2 2 1 1

6 6 5 5 4 4 3 3 2 2 1

7 6 6 5 5 4 4 3 3 2 2

7 7 6 6 5 5 4 4 3 3 2

8 7 7 6 6 5 5 4 4 3 3

8 8 7 7 6 6 5 5 4 4 3

9 8 8 7 7 6 6 5 5 4 4

9 9 8 8 7 7 6 6 5 5 4

10 9 9 8 8 7 7 6 6 5 5

10 10 9 9 8 8 7 7 6 6 5

11 10 10 9 9 8 8 7 7 6 6

11 11 10 10 9 9 8 8 7 7 6

12 11 11 10 10 9 9 8 8 7 7

12 12 11 11 10 10 9 9 8 8 7

13 12 12 11 11 10 10 9 9 8 8

13 13 12 12 11 11 10 10 9 9 8

14 13 13 12 12 11 11 10 10 9 9

14 14 13 13 12 12 11 11 10 10 9

15 14 14 13 13 12 12 11 11 10 10

15 15 14 14 13 13 12 12 11 11 10

16 15 15 14 14 13 13 12 12 11 11

16 16 15 15 14 14 13 13 12 12 11

17 16 16 15 15 14 14 13 13 12 12

17 17 16 16 15 15 14 14 13 13 12

18 17 17 16 16 15 15 14 14 13 13

18 18 17 17 16 16 15 15 14 14 13

19 18 18 17 17 16 16 15 15 14 14

19 19 18 18 17 17 16 16 15 15 14

20 19 19 18 18 17 17 16 16 15 15

20 20 19 19 18 18 17 17 16 16 15

21 20 20 19 19 18 18 17 17 16 16

21 21 20 20 19 19 18 18 17 17 16

22 21 21 20 20 19 19 18 18 17 17

22 22 21 21 20 20 19 19 18 18 17

23 22 22 21 21 20 20 19 19 18 18

23 23 22 22 21 21 20 20 19 19 18

24 23 23 22 22 21 21 20 20 19 19

24 24 23 23 22 22 21 21 20 20 19

25 24 24 23 23 22 22 21 21 20 20

25 25 24 24 23 23 22 22 21 21 20

26 25 25 24 24 23 23 22 22 21 21

26 26 25 25 24 24 23 23 22 22 21

27 26 26 25 25 24 24 23 23 22 22

27 27 26 26 25 25 24 24 23 23 22

28 27 27 26 26 25 25 24 24 23 23

28 28 27 27 26 26 25 25 24 24 23

29 28 28 27 27 26 26 25 25 24 24

29 29 28 28 27 27 26 26 25 25 24

30 29 29 28 28 27 27 26 26 25 25

30 30 29 29 28 28 27 27 26 26 25

31 30 30 29 29 28 28 27 27 26 26

325

650

1060

2130

650

975

2130

3200

Height above sea-level in meters

975

1300

1300

1625

Height above sea-level in feet

3200

4260

4260

5330

1625

1950

5330

6400

1950

2275

6400

7460

2275

2600

7460

8530

2600

2925

8530

9600

2925

3250

9600

10,660

3250

3575

10,660

11,730

Page 35

STANDARD COUNTING SCALE

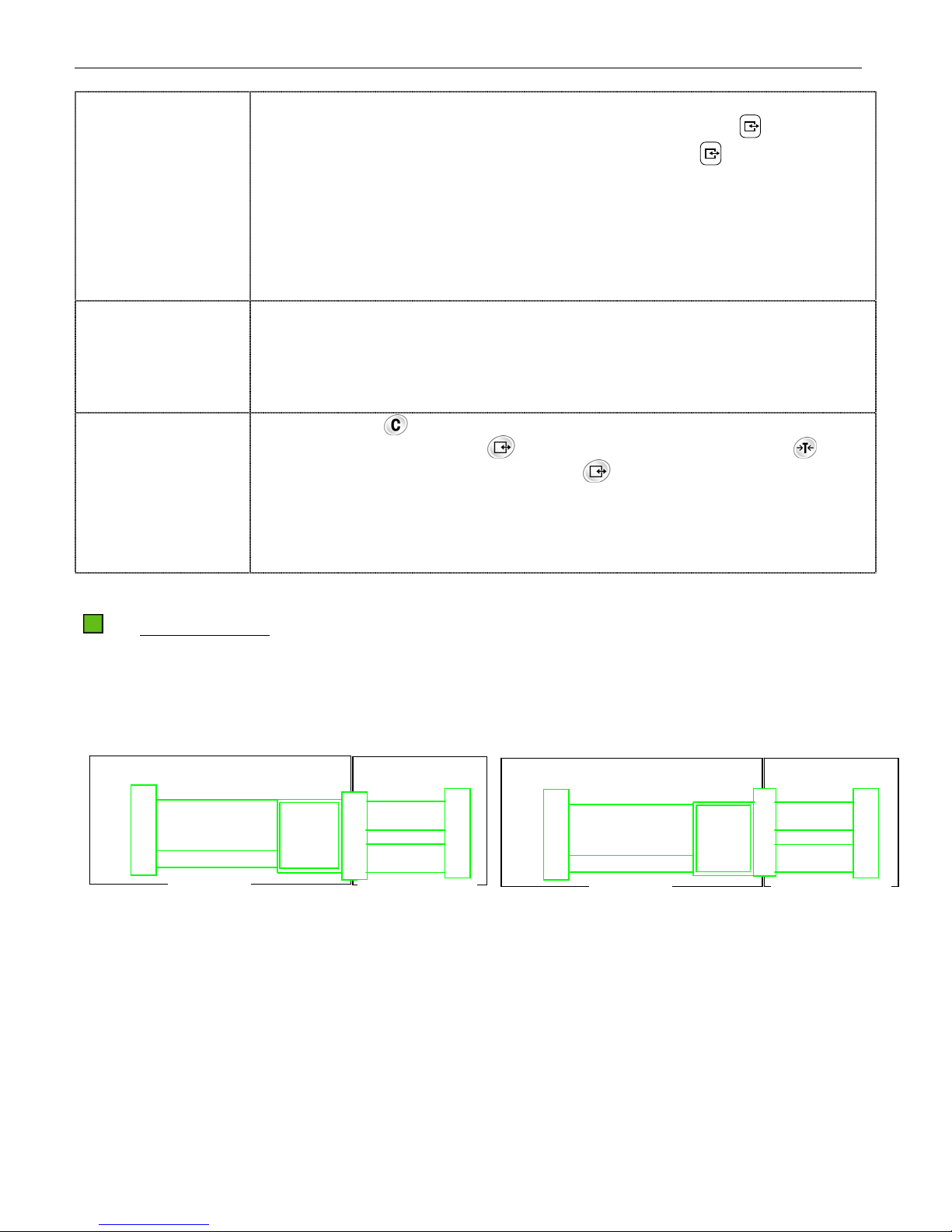

PHYSICAL DIMENSIONS

WeightData Count

35

XTC-1001

Count Data Weight

XTC-2001, XTC-3001, XTC-4001

Page 36

36

Notes

STANDARD COUNTING SCALE

Page 37

STANDARD COUNTING SCALE

Notes

37

Page 38

Xpress

Mettler-Toledo, Inc.

60 Collegeview

Westerville, OH 43081

5/2004

MTX04-OM007.1E

STANDARD COUNTING SCALE www.mt.com/xpress

Page 39

THERMAL PRINTER

TSP600 SERIES

USER’S MANUAL

MODE D’EMPLOI

BEDIENUNGSANLEITUNG

MANUALE DI ISTRUZIONI

Page 40

Federal Communications Commission

Radio Frequency Interference

Statement

This equipment has been tested and found to comply with the limits for a Class A digital

device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference when the equipment is operated in a

commercial environment. This equipment generates, uses and can radiate radio frequency

energy and, if not installed and used in accordance with the instruction manual, may cause

harmful interference to radio communications. Operation of this equipment in a residential

area is likely to cause harmful interference in which case the user will be required to correct

the interference at his own expense.

For compliance with the Federal Noise Interference Standard, this equipment requires a

shielded cable.

This statement will be applied only for the printers marketed in U.S.A.

Statement of

The Canadian Department of Communications

Radio Interference Regulations

This digital apparatus does not exceed the Class A limits for radio noise emissions from

digital apparatus set out in the Radio Interference Regulations of the Canadian Department

of Communications.

Le présent appareil numérique n’émet pas de bruits radioélectriques dépassant les limites

applicables aux appareils numériques de la classe A prescrites dans le Règlement sur le

brouillage radioélectrique édicté par le ministère des Communications du Canada.

The above statement applies only to printers marketed in Canada.

CE

Manufacturer’s Declaration of Conformity

EC Council Directive 89/336/EEC of 3 May 1989

This product, has been designed and manufactured in accordance with the International

Standards EN 50081-1/01.92 and EN 50082-1/01.92, following the provisions of the

Electro Magnetic Compatibility Directive of the European Communities as of May 1989.

EC Council Directive 73/23/EEC and 93/68/EEC of 22 July 1993

This product, has been designed and manufactured in accordance with the International

Standards EN 60950, following the provisions of the Low Voltage Directive of the

European Communities as of July 1993.

The above statement applies only to printers marketed in EU.

Trademark acknowledgments

TSP600: Star Micronics Co., Ltd.

ESC/POS: Seiko Epson Corporation

Notice

• All rights reserved. Reproduction of any part of this manual in any form whatsoever,

without STAR’s express permission is forbidden.

• The contents of this manual are subject to change without notice.

• All efforts have been made to ensure the accuracy of the contents of this manual at the

time of going to press. However, should any errors be detected, STAR would greatly

appreciate being informed of them.

• The above notwithstanding, STAR can assume no responsibility for any errors in this

manual.

©

Copyright 2001 Star Micronics Co., LTD.

Page 41

TABLE OF CONTENTS

1. Parts Identification and Nomenclature .........................................................1

2. Consumable Parts and AC Adapter ..............................................................4

3. Connecting Cables and AC Adapter..............................................................6

3-1. Interface Cable .......................................................................................6

3-2. Connecting to a Peripheral Unit.............................................................8

3-3. Connecting the Optional AC Adapter ....................................................9

3-4. Turning Power On ...............................................................................10

4. Control Panel and Other Functions.............................................................11

4-1. Control Panel .......................................................................................11

4-2. Errors ...................................................................................................11

4-3. Self Printing .........................................................................................13

5. Loading the Roll Paper .................................................................................14

6. Adjusting the Near-end Sensor ....................................................................17

7. Preventing and Clearing Paper Jams ..........................................................19

7-1. Preventing Paper Jams .........................................................................19

7-2. Removing Paper Jam ...........................................................................19

7-3. Releasing a locked Cutter (Auto Cutter Mode only) ...........................20

8. Periodical Cleaning .......................................................................................22

8-1. Cleaning the Thermal Head .................................................................22

8-2. Cleaning the Paper Holder ...................................................................22

Appendix A: Specifications...............................................................................95

A-1. General Specifications .........................................................................95

A-2. Auto Cutter Specifications...................................................................96

A-3. Interface ...............................................................................................96

A-4. Electrical Characteristics .....................................................................96

A-5. Option...................................................................................................96

A-6. Environmental Requirements...............................................................97

A-7. Reliability.............................................................................................97

Appendix B: Dip Switch Setting.......................................................................98

B-1. Parallel Interface Type .........................................................................99

B-2. Serial Interface Type ..........................................................................101

Appendix C: Parallel Interface ......................................................................104

Appendix D: Serial Interface..........................................................................105

D-1. RS-232C Connector ...........................................................................106

D-2. Cable Connections .............................................................................107

D-3. Electrical Characteristics ...................................................................107

Appendix E: Periheral Unit Drive Circuit ....................................................108

Appendix F: Memory Switch Settings ...........................................................109

Please access the following URL

http://www.star-micronics.co.jp/service/frame_sp_spr_e.htm

for the lastest revision of the manual.

ENGLISH

Page 42

– 1 –

ENGLISH

1. Parts Identification and Nomenclature

Roll paper

User’s manual

Cover open lever

Pull this lever in the

direction of the

arrow to open the

printer cover.

Control panel

Features LED indicators to indicate printer

status and switches to

operate the printer.

Ferrite core Fastener

(Parallel interface

model only)

(Parallel interface

model only)

Power switch

Used to turn on/off

power to the printer.

Power connector

For connection of

the AC adapter.

Never unplug the

AC adapter while

the printer is on.

Peripheral drive connector

Connects to peripheral

units such as cash

drawers, etc.

Do not connect this to a

telephone.

Interface connector

For connection to a

host computer.

Printer cover

Open this cover to load or

replace paper.

Auto Cutter Model

Page 43

– 2 –

ENGLISH

Tear Bar Model

Roll paper

User’s manual

Cover open lever

Pull this lever in the

direction of the

arrow to open the

printer cover.

Control panel

Features LED indicators to indicate printer

status and switches to

operate the printer.

Ferrite core Fastener

(Parallel interface

model only)

(Parallel interface

model only)

Power switch

Used to turn on/off

power to the printer.

Power connector

For connection of

the AC adapter.

Never unplug the

AC adapter while

the printer is on.

Peripheral drive connector

Connects to peripheral

units such as cash

drawers, etc.

Do not connect this to a

telephone.

Interface connector

For connection to a

host computer.

Printer cover

Open this cover to load or

replace paper.

Page 44

– 3 –

ENGLISH

Choosing a place for the printer

Before actually unpacking the printer, you should take a few minutes to

think about where you plan to use it. Remember the following points

when doing this.

✓ Choose a firm, level surface where the printer will not be exposed to

vibration.

✓ The power outlet you plan to connect to for power should be nearby

and unobstructed.

✓ Make sure that the printer is close enough to your host computer for

you to connect the two.

✓ Make sure that the printer is not exposed to direct sunlight.

✓ Make sure that the printer is well away from heaters and other sources

of extreme heat.

✓ Make sure that the surrounding area is clean, dry, and free of dust.

✓ Make sure that the printer is connected to a reliable power outlet. It

should not be on the same electric circuit as copiers, refrigerators, or

other appliances that cause power spikes.

✓ Make sure that the room where you are using the printer is not too

humid.

Page 45

– 4 –

ENGLISH

2. Consumable Parts and AC Adapter

When consumable parts have run out, use those specified in the table below.

Make sure that the AC adapter specified in the table is used.

Use of consumable parts or AC adapter which are not specified in the table may

result in damage to the printer, fire or electric shock.

(1) Roll paper specification

Thermal paper

Thickness: 65~85

µ

m

Width: 79.5±0.5 mm (57.5±0.5 mm when the optional paper roller

holder is used)

Outer roll diameter: ø90 mm or less

Take up paper roll width: 80 mm or (58 mm when the optional

paper roller holder is used)

Core outer/inner diameter

Paper thickness Core outer Core inner

65~85

µ

m ø18±1 mm ø12±1 mm

Printed surface: Outer edge of roll

Tail end handling: Do not use paste or glue to secure the roll paper or

its core.

Do not fold the tail end of the paper.

(2) Recommended paper

Mitsubishi Paper Mills Limited

P220AG (normal type paper), 65 µm (thickness)

HP220A (high image stability paper), 65 µm (thickness)

HP220AB-1 (high image stability paper), 75 µm (thickness)

P220AB (normal type paper, card ticket), 85 µm (thickness)

Oji Paper Co., Ltd.

PD150R (normal type paper), 75 µm (thickness)

PD160R (high image stability paper), 65/75 µm (thickness)

Nippon Paper Industries

TF50KS-E2C (normal type paper), 65 µm (thickness)

Depending on the type and thickness of the paper, it may be necessary to change

the settings for printing darkness. To change the darkness settings, use the

printing darkness settings command <ESC><RS> ‘d’ n. Refer to the separate

programmer’s manual for details.

+0.5

-1

+0.5

-1

Page 46

– 5 –

ENGLISH

(3) AC adapter (option)

Model name: PS60-24 A

Input: 100 to 240 V AC, 50/60 Hz

Output: DC24±5%, 2.0 A (5.0 A Load 10 sec. Max)

Important!

Access the following URL for the information of the recommended paper.

http://www.star-micronics.co.jp/

Page 47

– 6 –

ENGLISH

3. Connecting Cables and AC Adapter

3-1. Interface Cable

3-1-1. Fer rite Core Installation (Parallel interface model only)

(1)For only the parallel interface model,

affix the ferrite core onto the cable

as shown in the illustration below.

(2)Pass the fastener through the ferrite

core.

(3)Loop the fastener around the cable

and lock it. Use scissors to cut off

any excess.

Ferrite core

Interface cable

5 cm

maximum

Fastener

Pull and cut

Page 48

– 7 –

ENGLISH

3-1-2. Connecting the Interface Cable

Note: Before connecting/disconnecting the interface cable, make sure that

power to the printer and all the devices connected to the printer is

turned off.

Also make sure the power cable plug is disconnected from the

AC outlet.

(1)Connect the interface cable to the connector on the rear panel of the printer.

(2)In the case of a serial interface, tighten the connector screws. In the case of a

parallel interface, fasten the connector clasps.

Serial interface cable

Parallel interface cable

Page 49

– 8 –

ENGLISH

3-2. Connecting to a Peripheral Unit

You can connect a peripheral unit to the printer using a modular plug. The

following describes how to install the ferrite core and make the actual connection.

See “Modular plug” on page 108 for details about the type of modular plug that

is required. Note that this printer does not come with a modular plug or wire, so