Page 1

www.mt.com

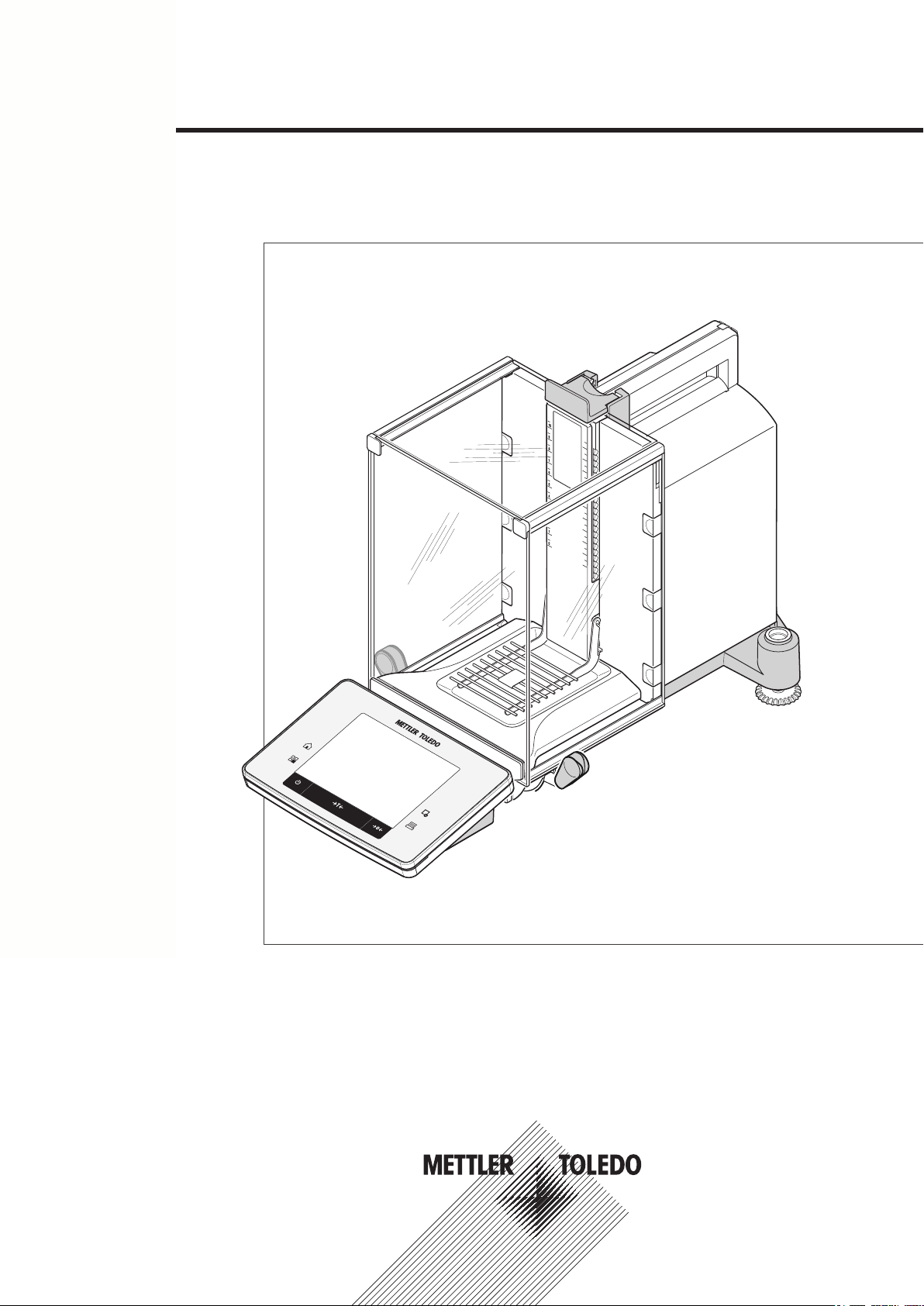

XSE204

F

F

METTLER TOLEDO

Excellence Analytical Balances

Quick Guide

XSE Models

Page 2

Page 3

Table of Contents

Introduction1 5

Safety Information2 6

Design and Function3 8

Installation and Putting into Operation4 17

Maintenance5 25

Technical Data6 26

Explanation of warnings and symbols2.1 6

Product safety information2.2 6

Overview3.1 8

Balance3.1.1 8

Terminal3.1.2 10

User interface3.2 11

Display3.2.1 11

Input dialog boxes3.2.2 12

Text and number entry3.2.2.1 13

Firmware3.2.3 13

User-specific settings3.2.3.1 13

Applications3.2.3.2 14

Application-specific settings3.2.3.3 15

System settings3.2.3.4 15

Security system3.2.4 16

Unpacking4.1 17

Scope of delivery4.2 18

Location4.3 19

Assembling the balance4.4 19

Connecting the balance4.5 21

Setting up the balance4.6 22

Weighing for the first time4.6.1 22

Switching on the balance4.6.1.1 22

Leveling the balance4.6.1.2 22

Performing a simple weighing4.6.1.3 23

Handle for operation of the side draft shield doors4.6.2 23

Cleaning5.1 25

General data6.1 26

Explanatory notes for the METTLER TOLEDO AC adapter6.2 26

Model-specific data6.3 27

Dimensions6.4 30

Table of Contents 3

Page 4

Page 5

1Introduction

Thank you for choosing a METTLER TOLEDO balance.

This balance offers numerous weighing and adjustment options with exceptional operating convenience.

METTLER TOLEDO is a leading manufacturer of balances for laboratory and production use as well as analyti

cal measuring instruments. A globally present customer service network with highly trained personnel is always

available to assist with the selection of accessories or provide advice on the optimal use of the balance.

Various models offering different performance features are available. Models offer different weighing ranges and

resolutions. Special reference is made to these features in these instructions if important for operation.

The following features are common to all models of the XSE line:

●

Fully automatic adjustment "ProFACT" using internal weights.

●

Built-in level sensor, illuminated level indicator and Leveling Assistant for fast and easy leveling.

●

Built-in applications for normal weighing, statistics, formulation, piece numbers, percent weighing, density

determination, differential weighing, pipette test and titration.

●

Integral RS232C interface.

●

Slot for second interface (optional).

●

Touch-sensitive graphic terminal ("Touch screen") with color display.

The balance conforms to current standards and directives. It supports requirements, work techniques and proto

cols as specified by all international quality assurance systems, e.g. GLP (Good Laboratory Practice), GMP

(Good Manufacturing Practice). The balance has a CE Declaration of Conformity and METTLER TOLEDO, as the

manufacturer, is certified to ISO 9001 and ISO 14001. This provides the assurance that your capital investment

is protected in the long term by high product quality and a comprehensive service package (repairs, mainte

nance, servicing, adjustment service).

Finding more information

u www.mt.com/excellence

Detailed operating instructions are on the CD-ROM.

Software version

These operating instructions refer to the originally installed firmware (software) version V 1.00.

5Introduction

Page 6

2Safety Information

2.1Explanation of warnings and symbols

Safety notes are indicated by signal words and warning symbols and contain warnings and information about

safety issues. Ignoring safety notes can lead to personal injury, damage to the instrument, malfunctions and

erroneous results.

Signal words

WARNING for a hazardous situation with medium risk, possibly resulting in severe

injuries or death if not avoided.

CAUTION for a hazardous situation with low risk, resulting in damage to the device or

the property or in loss of data or minor or medium injuries if not avoided.

Attention (no symbol)

for important information about the product.

Note (no symbol)

for useful information about the product.

Warning symbols

General hazard Electrical shock

Mandatory signs

2.2Product safety information

Intended use

Your balance is used for weighing. Use the balance exclusively for this purpose. Any other type of use and

operation beyond the limits of technical specifications without written consent from Mettler-Toledo AG, is con

sidered as not intended.

It is not permitted to use the instrument in explosive atmosphere of gases, steam, fog, dust

and flammable dust (hazardous environments).

General safety information

This balance complies with current industry standards and the recognized safety regulations; however, it can

constitute a hazard in use. Do not open the balance housing: The balance contains no user-serviceable parts.

In the event of problems, please contact a METTLER TOLEDO representative.

Always operate and use your instrument only in accordance with the instructions contained in this manual. The

instructions for setting up your new instrument must be strictly observed.

If the instrument is not used according to these Operating Instructions, protection of the instrument may

be impaired and METTLER TOLEDO assumes no liability.

Gloves must be worn

Staff safety

These operating instructions must be read and understood before using the balance. These operating instruc

tions must be retained for future reference.

The balance must not be altered or modified in any way. Only use METTLER TOLEDO original spare parts and

accessories.

6 Safety Information

Page 7

Safety notes

WARNING

Risk of electric shock

Use only the original universal AC adapter delivered with your balance, and check that the

voltage printed on it is the same as your local power supply voltage. Only plug the adapter

into a socket which is grounded.

CAUTION

Damage to the balance

a) Only use indoors in dry locations.

b) Do not use pointed objects to operate the keyboard!

The balance is of a very sturdy design, but is still a precision instrument. It must be han

dled with care.

c) Do not open the balance:

The balance contains no user-serviceable parts. In the event of problems, please contact

a METTLER TOLEDO representative.

d) Only use METTLER TOLEDO original accessories and peripheral devices for the balance.

These are specifically designed for the balance.

7Safety Information

Page 8

3Design and Function

METTLER TOLEDO

1

2

3

4

5

7

6

3

8 9

10

11

12

13

www.mt.com

XSE204

F

F

METTLER TOLEDO

This section describes the balance, operating and indicating elements of the terminal and the operating concept

of the balance firmware.

3.1Overview

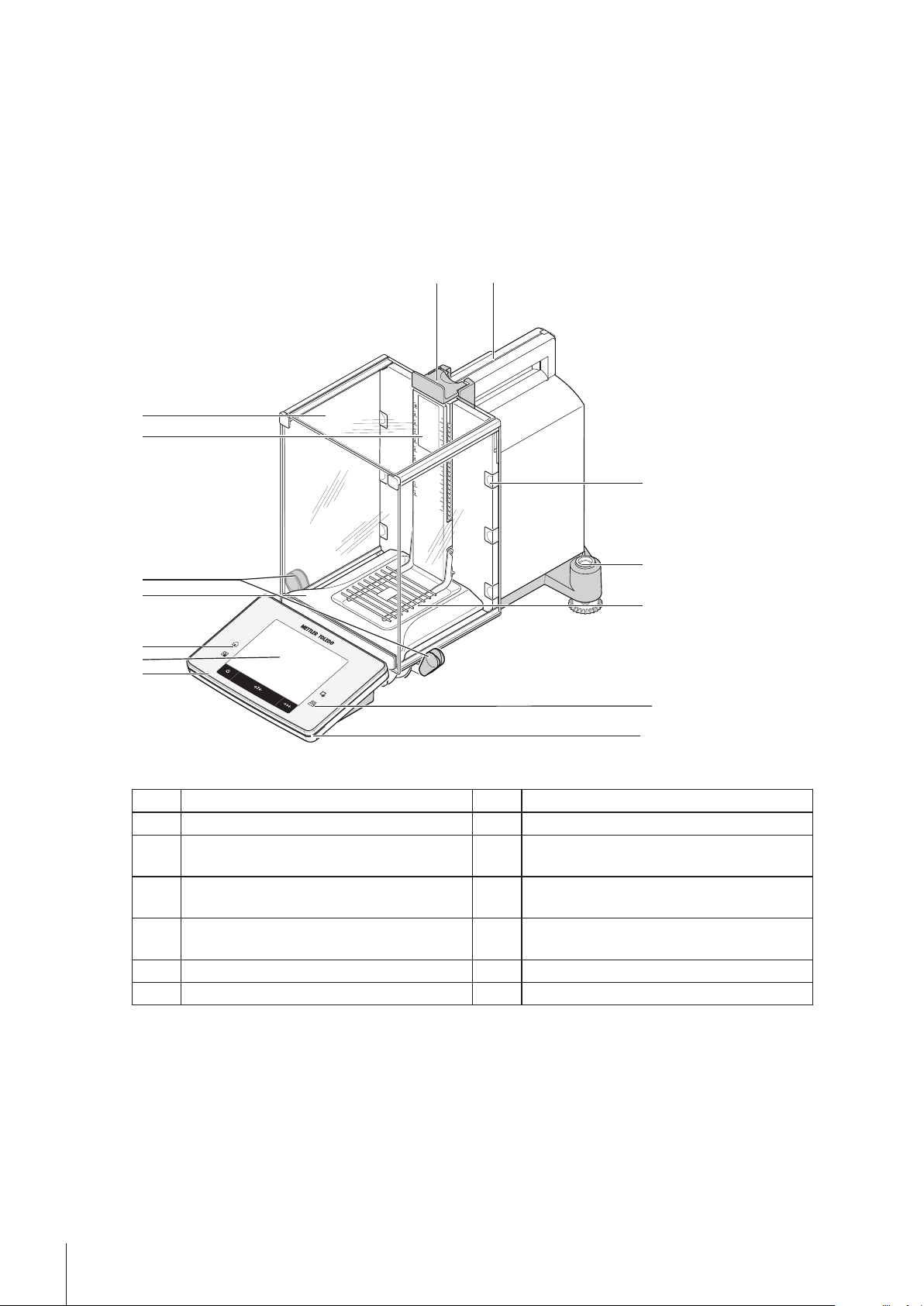

3.1.1Balance

Balance with rear connections.

Front view

1 Terminal 2 Display (touch-sensitive "Touch screen")

3 Operating keys 4 Drip tray

5 Handle for operating the draft shield side

6 Type designation

doors

7 Glass draft shield 8 Handle for operation of the top draft shield

door

9 Guide for top draft shield door and transport

handle

11 Level indicator/Level sensor 12 SmartGrid weighing pan

13 Status indicator

10 Removable clips for feeding cables or hoses

8 Design and Function

Page 9

6

7

5

4

3

2

1

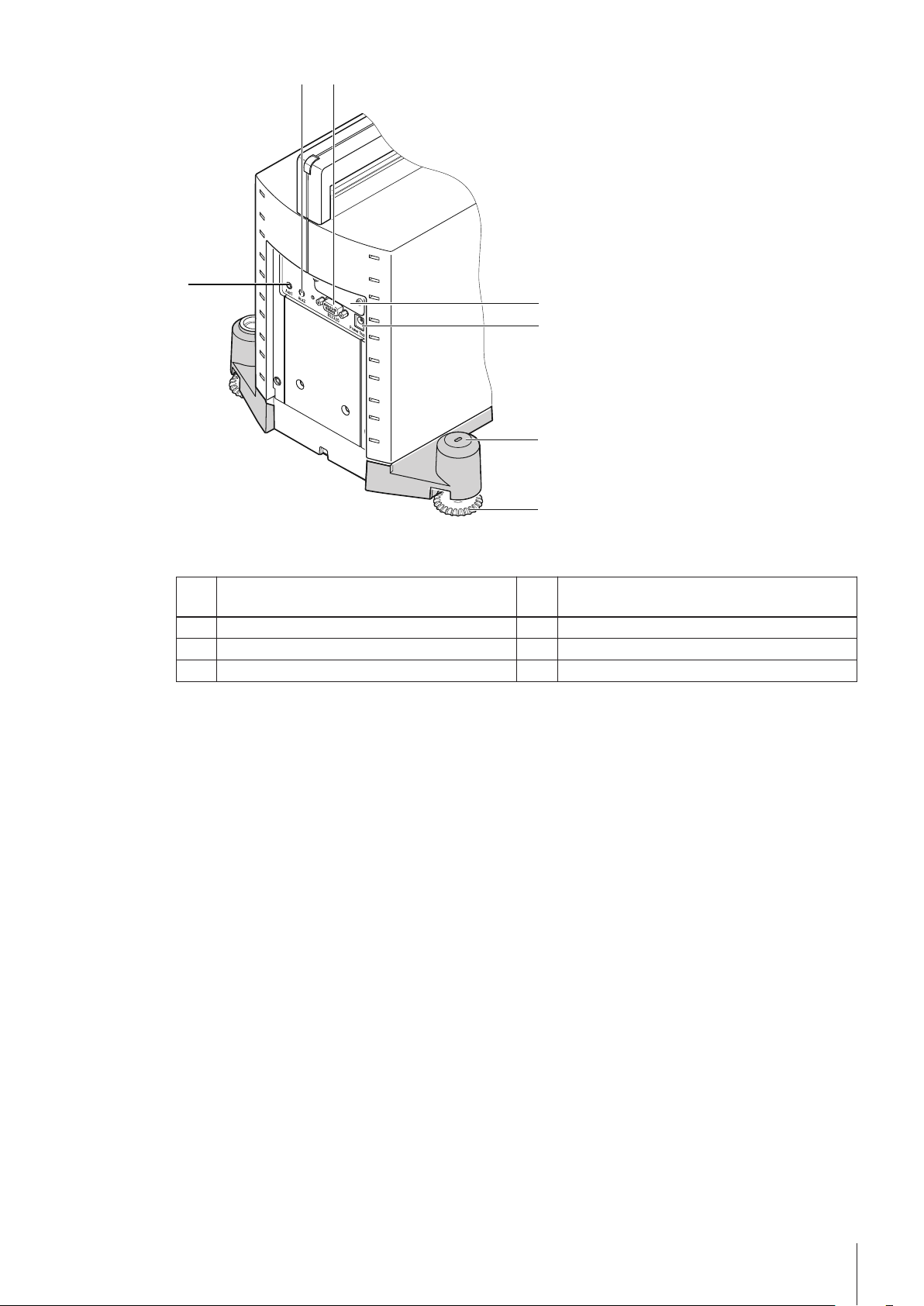

Rear

1 Aux 1 (connection for "ErgoSens", hand or foot

switch)

2 Aux 2 (connection for "ErgoSens", hand or foot

switch)

3 RS232C serial interface 4 Slot for second interface (optional)

5 Socket for AC adapter 6 Fastening point for anti-theft device

7 Foot screw

9Design and Function

Page 10

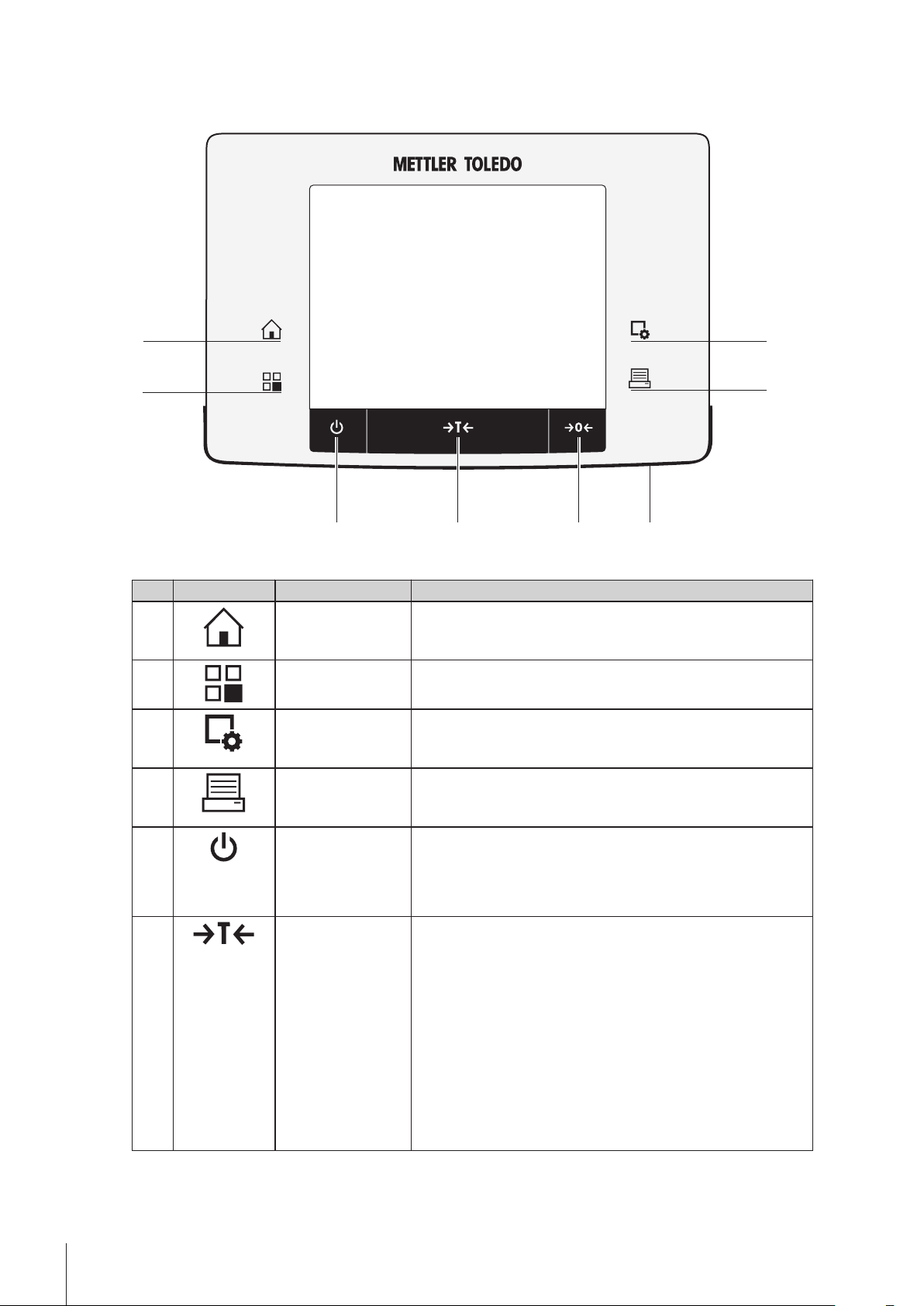

3.1.2Terminal

8

7

5

6

1

2

3

4

Key assignments and terminal connection.

Front view

Designation Explanation

1 Home This key is used to return to the user profile from any menu level

in any application. All changes made and confirmed up to this

point are automatically stored.

2 Select application This key is used to select a required application.

3 Configuration For displaying menus for the configuration of a current applica

tion. The application can be adjusted to a specific task via

numerous settings.

4 Pressure This key is used to transfer data via the interface, e.g. to a print

er. Other devices, e.g. a PC can also be connected. The data to

be transferred can be freely defined.

5 On/Off For switching the balance on and off (standby mode).

Note

It is recommended not to disconnect the balance from the power

supply unless it is not used for an extended period.

6 Tare This key is used to tare the balance manually (only necessary

for normal weighings). When the balance has been tared, the

Net symbol is displayed to indicate that all displayed weights

are net.

Note

A negative weight is not permitted. An error message is generat

ed.

When the stability detector icon extinguishes (small ring on the

left of the weight display), a stable weight is indicated.

The procedure for taring the balance is not the same as for zero

ing.

10 Design and Function

Page 11

7 Zeroing This key is used for setting a new zero point manually (only

1 22

required if the balance is used for normal weighings). After zero

ing "Zeroing", all weights (also the tare weight) apply to this

new zero point and the following applies: tare weight = 0, net

weight (= gross weight) = 0.

8 Status indicator Indicates the current balance status. The status indicator shows

that the balance is ready to use.

Green = balance is busy.

Flashing green = balance is busy, e.g. internal/external adjust

ment in progress.

Yellow = task pending, e.g. automatic external adjustment

pending when a reminder date for a service or test is reached.

Red = balance cannot/must not be used, if e.g. the balance is

not correctly leveled. The balance has underload or overload

when starting.

Rear

1 System connection (terminal cable) 2 Foot

3.2User interface

3.2.1Display

The illuminated, color display of the terminal is a touch screen, i.e. a touch-sensitive screen. It can be used for

displaying data, entering settings and selecting functions by tapping the screen.

Note

Depending on country-specific requirements, non-calibrated decimal places are highlighted on calibrated bal

ances.

CAUTION

Do not touch the touch screen with pointed or sharp objects!

This may damage the touch screen.

11Design and Function

Page 12

Designation Explanation

1 Application name Select application.

The application menu can be selected by touching this zone. The application can

be selected here. This menu can also be displayed by pressing [ ].

2 Date The date can be changed by tapping this zone.

3 Time The time can be changed by tapping this zone.

4 Status icons These status icons indicate special balance statuses (e.g. service due, adjust

ment required, battery replacement).

A separate selection window is displayed when the icons are tapped. When the

icons are tapped, their functions are explained.

5 Weight value Tapping the weight displays a window showing the result in a large format. This

is useful for reading a weight from a certain distance.

6 Weighing unit The required weighing unit can be changed by tapping the weighing unit, e.g.

from mg to g.

7 SmartTrac SmartTrac is a graphic weighing-in aid, which shows at a glance an already

used and still available weighing range. Various display modes can be selected

for SmartTrac or deactivated by tapping this area.

8 Function keys This area is reserved for Function Keys enabling direct access to frequently

required functions and application settings. If more than 5 function keys are acti

vated, these can be selected with the arrow keys.

9 Information fields This area is used for displaying additional information (information fields) relat

ing to an active application. Tapping the information field enables Information

fields and Function Keys to be displayed directly via menu selection. The level

ing assistant can also be started.

Screen saver

If the balance is not used for 15 minutes, the display is automatically dimmed and the pixels are inverted about

every 15 seconds. When the balance is used again (e.g. load weight, press key), the display returns to a nor

mal state.

3.2.2Input dialog boxes

The keyboard dialog box is used to enter characters such as letters, numbers and special characters.

12 Design and Function

Page 13

3.2.2.1Text and number entry

1

2

3

Designation Explanation

1 Data field Displays (entered) alphanumeric and numeric characters.

2 Keyboard Data input area

3 Selection Selects various keyboards.

1 Enter the designation.

2 Confirm with [OK].

Delete last character

Tap once to place the cursor at

the end of the data field.

Function

3.2.3Firmware

The firmware controls all balance functions. It enables the balance to be adjusted to a specific working environ

ment.

The firmware is divided as follows:

●

Applications

●

Application-specific settings

●

System settings

●

User-specific settings

Note

A displayed menu can be left at any time by repressing the same key as used for its selection.

3.2.3.1User-specific settings

These settings can be used to adjust the balance to suit the tasks and work techniques of individual users.

13Design and Function

Page 14

>

1

2

3

1

2

3

System

>

Designation Explanation

1 Title bar The title bar displays elements for user orientation and information.

2 Contents area The contents area is the main work area for menus and applications. The con

tents depend on the specific application or initiated action.

3 Action bar The action bar contains action buttons for performing specific actions required in

the active dialog box and are available (e.g. [Exit], [STD], [C], [OK]).

1 Settings can be changed by tapping the respective button.

2 To leave the settings, select [Exit].

3 To change the system settings, tap [System].

Function

Exit Exit settings

System Display system settings

3.2.3.2Applications

Applications are firmware modules for performing specific weighing tasks. The balance is provided with various

applications on delivery. After switching on the balance, the last active user profile and last used application are

loaded. The applications are available under the [ ] key. Instructions for working with standard applications

are provided in the respective sections.

Designation Explanation

1 Title bar The title bar displays elements for user orientation and information.

2 Contents area The contents area is the main work area for menus and applications. The con

tents depend on the specific application or initiated action.

3 Action bar The action bar contains action buttons for performing specific actions required in

the active dialog box and are available (e.g. [Exit], [STD], [C], [OK]).

– An application can be selected by tapping the corresponding button.

14 Design and Function

Page 15

Function

5

4

1

2

3

System Display system settings

3.2.3.3Application-specific settings

These settings can be used to adjust the applications to suit specific requirements. The available setting options

depend on the selected application. Pressing the [ ] key opens the multipage menu with settings for a cur

rently active application. Information on the individual setting options is provided in the section relating to the

respective application.

Designation Explanation

1 Title bar The title bar displays elements for user orientation and information.

2 Contents area The contents area is the main work area for menus and applications. The con

3 Action bar The action bar contains action buttons for performing specific actions required in

4 Button Edit/Select settings (e.g. [Define], [On], [Off]). The contents depend on the

5 Arrow The arrow buttons are used to page forward or back.

1 Settings can be changed by tapping the respective button.

2 Confirm with [OK].

3.2.3.4System settings

System settings (e.g. settings for peripheral devices) are independent of the applications and apply to the entire

weighing system. System settings can be displayed by pressing [ ] and subsequently the [System] button.

tents depend on the specific application or initiated action.

the active dialog box and are available (e.g. [Exit], [STD], [C], [OK]).

application.

Function

Page forward

Page back

15Design and Function

Page 16

>

1

2

3

System

Designation Explanation

1 Title bar The title bar displays elements for user orientation and information.

2 Contents area The contents area is the main work area for menus and applications. The con

tents depend on the specific application or initiated action.

3 Action bar The action bar contains action buttons for performing specific actions required in

the active dialog box and are available (e.g. [Exit], [STD], [C], [OK]).

1 Settings can be changed by tapping the respective button.

2 To leave the settings, tap [Exit].

3.2.4Security system

The balance has a comprehensive security system with which individual access rights can be defined at

administrator and user level. Access to protected menu areas requires the entry of an identification (ID) and a

password. On delivery of the balance, only the [Administrator] settings in the system settings are protected.

When an ID and password protected menu area is selected, an alphanumeric keyboard is initially displayed for

entry of the ID.

1 Enter your ID.

- Case sensitive, tap the [a...z] and [A...Z] button to switch between upper and lower case.

- To enter numbers, tap the [0...9] button.

- Incorrect entries can be deleted character by character with the arrow key .

Note

Entry can be interrupted at any time by tapping [C].

2 After entering the full ID, tap [OK].

A further dialog box is displayed for entering the password.

3 Enter the password (for security reasons, this is displayed with asterisks instead of plain text) and confirm

with [OK].

If the ID and password are correct, the selected menu area is displayed or the required action initiated. If

these are incorrect, an error message is displayed with a request to enter them again.

CAUTION

Remember IDs and passwords!

Protected menu areas cannot be accessed without ID or password.

– Note IDs and passwords and keep them in a safe place.

16 Design and Function

Page 17

4Installation and Putting into Operation

8

1

2

3

4

5

67

4.1Unpacking

Open the balance packaging. Check the balance for transport damage. Immediately inform a METTLER TOLEDO

representative in the event of complaints or missing accessories.

Note

Retain all parts of the packaging. This packaging offers the best possible protection for transporting the bal

ance.

– Use the lifting strap to lift the balance out of the packaging box.

Overview

1 Lifting strap

2 Top packaging

3 Operating instructions and other important documents

4 Balance

5 Set with draft-shield doors and terminal support

6 Set with AC adapter, power supply cable, drip tray, Smart

Grid, SmartGrid cover, SmartPrep single-use funnel and

ErgoClip "Basket" (basket for small weighing objects)

7 Terminal

Note

The terminal is connected to the balance with a cable.

8 Bottom packaging

1 Remove the lifting strap (1).

2 Remove the top packaging (2).

1 Remove the operating instructions (3).

2 Remove the set with AC adapter (6).

3 Remove the set with draft shield doors (5).

17Installation and Putting into Operation

Page 18

1 Carefully remove the terminal from the bottom packaging.

2 Remove the protective cover.

Note

Since the terminal is connected to the balance with a cable, only

withdraw the balance slightly from the packaging in order to

remove the protective cover.

1 Place the terminal at the front of the balance.

2 Hold the balance by the guide or handle. Hold the terminal

firmly with the other hand. Pull out both components together

from the bottom packaging.

1 Place the balance with the terminal at the site of use.

2 Remove the cover from the balance.

3 Remove the transport protection (9) of the weighing pan sup

port.

4.2Scope of delivery

Check the delivery for completeness. The following accessories are part of the standard equipment of the bal

ance:

●

Balance with terminal

•

RS232C interface

•

Slot for second interface (optional)

•

Feedthroughs for below-the-balance weighing and for antitheft device

●

Set with draft-shield doors and terminal support

●

SmartGrid

●

SmartGrid cover, chromium-nickel steel

●

SmartPrep single-use funnel (2 pieces)

●

Drip tray

●

AC adapter with country-specific power cable

●

Protective cover for the terminal

●

Cleaning brush

●

ErgoClip "Basket" (basket for small weighing objects)

18 Installation and Putting into Operation

Page 19

●

2

1

2

1

Production certificate

●

CE declaration of conformity

●

Operating instructions or Quick Start Guide; printed or on CD-ROM, depending on country of use

4.3Location

An optimal location will ensure accurate and reliable operation of the balance. The surface must be able to

safely take the weight of the balance when fully loaded. The following local conditions must be observed:

Note

If the balance is not horizontal at the outset, it must be leveled during commissioning.

●

The balance must only be used indoors and up to a maxi

mum altitude of 4,000 m above sea level.

●

Before switching on the balance, wait until all parts are at

room temperature (+5 to 40°C).

The humidity must be between 10% and 80% non-condens

ing.

●

The power plug must be accessible at all times.

●

Firm, horizontal and vibration-free location.

●

Avoid direct sunlight.

●

No excessive temperature fluctuations.

●

No strong drafts.

Further information can by found in Weighing the Right Way.

4.4Assembling the balance

1 Remove the transport protection (1).

2 Insert the drip tray (2).

Insert the tray from the front above the bottom plate up to the

partition.

1 Insert the SmartGrid from the front.

2 Check that the SmartGrid (1) (2) is correctly hooked in on

both sides.

19Installation and Putting into Operation

Page 20

1 Insert the top draft shield door (1) at an angle (slightly below

1

2

A

A

4

2

3

1

30 degrees) into the rear guide.

2 Carefully fold the draft shield door (2) downwards, see fig

ure.

The handles (A) must be folded outwards to mount the side

draft shield doors.

1 Mount the draft shield side doors according to the following

instructions, see figure below.

2 Mount the side doors at an angle of about 30° in the 2 open

ings, see following figure.

3 Check that the side doors are correctly mounted as described.

4 Mount the side door so that it clicks in place in the balance.

The side door will move easily when correctly mounted.

5 Fold the handle of the side draft shield door inwards.

6 Mount the second draft shield side door. The procedure is

identical.

7 Move the side doors fully back.

1 Fit the front draft shield glass (2).

Insert the glass at an angle into the bottom of the balance at

the front until the two hooks of the front draft shield glass rest

on the rollers (1).

2 Move the front draft shield glass upwards until it engages.

20 Installation and Putting into Operation

Page 21

1 Insert the terminal support.

2 Place the cable in the guide of the terminal support.

3 Insert the terminal support into the opening in the front draft

shield glass.

The terminal support must engage with a click.

1 Mount the terminal.

2 Place the terminal in the center of the support.

3 Push the terminal against the balance until it folds down eas

ily at the front of the terminal support.

4 Insert the cable into the balance.

Attention

The balance and terminal are not connected by the terminal support! Always hold the balance and terminal

firmly during transport.

Note

The terminal can also be placed in the area of the balance without the terminal support if the cable is of suffi

cient length.

4.5Connecting the balance

WARNING

Risk of electric shock

a) To connect the balance, only use the supplied three-core power cord with equipment

grounding conductor.

b) Only connect the balance to a three-pin power socket with earthing contact.

c) Only standardized extension cable with equipment grounding conductor must be used for

operation of the balance.

d) Intentional disconnection of the equipment grounding conductor is forbidden.

The balance is supplied with an AC adapter and country-specific power cord. The AC adapter is suitable for use

with the following voltage range:

100 – 240 VAC, 50/60Hz.

Attention

●

Check whether your local power supply falls within this range. If this is not the case, under no circum

stances connect the AC adapter to the power supply, but contact a METTLER TOLEDO representative.

●

The power plug must be accessible at all times.

●

Prior to use, check the power cord for damage.

●

Route the cable in such a way that it cannot be damaged or cause a hindrance when working.

●

Ensure that no liquid comes into contact with the AC adapter.

21Installation and Putting into Operation

Page 22

Balance and terminal are at the final location.

1 Connect the AC adapter (1) to the connection socket (2) at

the rear of the balance.

2 Connect the AC adapter (1) to the power supply.

The balance performs a self-test after connection to the power

supply and is then ready to use.

4.6Setting up the balance

4.6.1Weighing for the first time

After commissioning the new balance, the first weighing can be carried out. This will also familiarize you with

the operation of the balance.

If the balance is not aligned exactly horizontal, a warning text is generated after switching on the balance with

the request to level the balance.

4.6.1.1Switching on the balance

Startup

Balance is connected to the power supply.

Terminal and balance are interconnected.

– Press [ ].

Display appears.

Balance is ready to use.

4.6.1.2Leveling the balance

The balance has a built-in level sensor which permanently monitors correct horizontal alignment.

If the level sensor detects incorrect leveling, the status indicator at

the terminal shows red. A warning text is displayed and an audi

ble warning generated. A status icon also appears in the top right

corner of the display.

22 Installation and Putting into Operation

Page 23

1 To start the leveling assistant, tap [LevelGuide] in the warn

ing message.

Window with level indicator is displayed in real-time.

2 Observe the level indicator on the screen.

The air bubble in the level indicator shows red with incor

rect alignment.

The leveling assistant indicates with red arrows the direc

tion in which the two foot screws at the rear of the balance

must be turned.

3 Turn the foot screw until the air bubble is located in the inner

circle of the level indicator.

The air bubble in the level indicator shows green with cor

rect alignment.

The status indicator at the terminal shows green.

4 Tap [OK].

A message recommending adjustment of the balance is

displayed.

5 Tap [Adjust.int] to adjust the balance.

4.6.1.3Performing a simple weighing

To perform a simple weighing, only the keys in the lower part of the terminal are required. The balance has sep

arate keys for zeroing [ ] and taring [ ].

Zeroing

– Press [ ].

Zeroing

After zeroing, all weights (also the tare weight) apply to this new zero point and the following apply: tare weight

= 0, net weight (= gross weight) = 0.

Taring

Note

A negative weight is not permitted. An error message is generated. When the stability detector icon extinguishes

(small ring left of the weight display), the indication is stable. The weight is displayed.

If a weighing container is used, the balance must first be set to zero.

1 Place the container on the balance.

2 Press [ ].

The balance is tared.

The weight of the container is set as the new tare weight and the previous tare (if available) is overwritten.

The Net display signals that all indicated weights are net weights.

Congratulations!

The first weighing is now complete. The following sections contain further information about the extensive func

tions and applications of this balance.

4.6.2Handle for operation of the side draft shield doors

The draft shield of the balance can be adjusted to the ambient conditions, weighing method and material to be

weighed.

The position of the handles determines which draft shield doors (left, right or both) are opened.

Try out different combinations by moving the handles up or down. We recommend setting the glass draft shield

so that only the door required for loading is opened. The balance then operates faster due to less disturbing air

flows than with a fully open glass draft shield.

23Installation and Putting into Operation

Page 24

Note

It is recommended to make connections when the draft shield is closed.

1 Move the side door handle downwards.

2 Move the doors fully back.

24 Installation and Putting into Operation

Page 25

5Maintenance

5.1Cleaning

Periodically clean the weighing pan, the drip tray, the housing, and the terminal of your balance using the

brush supplied with it. The maintenance interval depends on your standard operating procedure (SOP).

Please observe the following notes:

WARNING

Risk of electric shock

a) Disconnect the balance from the power supply prior to cleaning and maintenance.

b) Only use METTLER TOLEDO power cords, if these need to be replaced.

c) Ensure that no liquid comes into contact with the balance, terminal or AC adapter.

d) Do not open the balance, terminal or AC adapter.

These contain no user-serviceable parts.

CAUTION

Damage to balance

Under no circumstances use cleaning agents containing solvents or abrasive agents, as this

can damage the terminal overlay.

Cleaning

Your balance is made from high quality, resistant materials and can therefore be cleaned with a commercially

available, mild cleaning agent.

1 To clean the weighing chamber thoroughly, swing out the draft shield glass panels from the balance and

remove them from their fastening points.

2 Carefully lift the front of the weighing pan and lift it out of the guide.

3 Remove the drip tray from the balance.

4 Ensure that these parts are correctly positioned when refitted.

Note

Contact a METTLER TOLEDO representative to find about the service options available – regular maintenance

by an authorized service engineer will ensure consistent weighing accuracy over the long term and extend the

service life of the balance.

25Maintenance

Page 26

6Technical Data

6.1General data

Power supply

AC adapter: Primary: 100–240VAC, -15%/+10%, 50/60Hz

Cable for AC adapter: 3-core, with country-specific plug

Balance power supply: 12VDC ±3%, 2.25A, maximum ripple: 80mVpp

Protection and standards

Overvoltage category: II

Degree of pollution: 2

Protection: Protected against dust and water

Standards for safety and EMC: See Declaration of Conformity

Range of application: For use only in closed interior rooms

CAUTION

Only use an approved AC adapter with a current-limited SELV output.

Ensure correct polarity

Secondary: 12 V DC ±3%, 2.5 A (with electronic overload pro

tection)

Environmental conditions

Height above mean sea level: Up to 4000m

Ambient temperature: 5–40°C

Relative air humidity: Max. 80% up to 31°C, linearly decreasing to 50% at 40°C,

noncondensing

Warm-up time: At least 120 minutes after connecting the balance to the power

supply; when switched on from standby-mode, the balance is

ready for operation immediately

Materials

Housing: Die-cast aluminum, plastic, chrome steel and glass

Terminal: Die-cast zinc, chromed and plastics

SmartGrid: Chrome-nickel steel X5CrNi18-10

6.2Explanatory notes for the METTLER TOLEDO AC adapter

The certified external power supply which conforms to the requirements for Class II double insulated equipment

is not provided with a protective earth connection but with a functional earth connection for EMC purposes. This

earth connection IS NOT a safety feature. Further information about conformance of our products can be found

in the brochure "Declaration of Conformity" which is coming with each product.

In case of testing with regard to the European Directive 2001/95/EC the power supply and the balance have to

be handled as Class II double insulated equipment.

Consequently an earth bonding test is not required. Similarly it is not necessary to carry out an earth bonding

test between the supply earth conductor and any exposed metalwork on the balance.

Because the balance are sensitive to static charges a leakage resistor, typically 10 kΩ, is connected between

the earth connector and the power supply output terminals. The arrangement is shown in the equivalent circuit

diagram. This resistor is not part of the electrical safety arrangement and does not require testing at regular

intervals.

26 Technical Data

Page 27

10 kΩ coupling resistor for

electrostatic discharge

Input 100…240 V

AC Output 12 VDC

Double Insulation

Plastic Housing

P

N

E

AC

DC

Equivalent circuit diagram

6.3Model-specific data

Limit values

Maximum capacity 120 g 220 g

Readability 0.1 mg 0.1 mg

Tare range (from…to) 0 … 120 g 0 … 220 g

Maximum capacity in fine range 41 g 81 g

Readability in fine range 0.01 mg 0.01 mg

Repeatability (at nominal load) sd 0.1 mg (100 g) 0.1 mg (200 g)

Repeatability (at low load) sd 0.05 mg (5 g) 0.05 mg (10 g)

Repeatability in fine range (at low load) sd 0.02mg (5g) 0.02mg (5g)

Linearity deviation 0.2 mg 0.2 mg

Eccentric deviation (test load)

Sensitivity offset (test weight) 0.8 mg (100 g) 0.8 mg (200 g)

Sensitivity temperature drift

Sensitivity stability

3)

Typical values

Repeatability (at low load) sd 0.04 mg 0.04 mg

Repeatability in fine range sd 0.01 mg (5g) 0.01 mg (10g)

Linearity deviation 0.13 mg 0.13 mg

Eccentric deviation (test load)

Sensitivity offset (test weight) 0.4 mg (100 g) 0.6 mg (200 g)

Minimum weight (according to USP) 80 mg 80 mg

Minimum weight (according to USP) in fine

range

Minimum weight (U=1%, k=2) 8 mg 8 mg

Minimum weight (U=1%, k=2) in fine range 2mg 2mg

Setting time 1.5 s 1.5 s

Setting time in fine range 3 s 3 s

Dimensions

Balance dimensions (W × D × H) 263 × 482 × 322mm 263 × 482 × 322mm

Weighing pan dimensions 78 × 73 mm (W × D) 78 × 73 mm (W × D)

Typical uncertainties and supplementary data

Repeatability sd 0.04 mg

Repeatability in fine range sd 0.01 mg

Differential linearity deviation sd √(40 pg·Rnt) √(20 pg·Rnt)

Differential eccentric load deviation sd 0.0003%·Rnt 0.00015%·Rnt

Sensitivity offset sd 0.0002%·Rnt 0.00008%·Rnt

Minimum weight (according to USP) 80 mg +0.06%·Rgr 80 mg +0.03%·Rgr

Minimum weight (according to USP) in fine

range

Minimum weight (U=1%, k=2) 8 mg +0.006%·Rgr 8 mg +0.003%·Rgr

Minimum weight (U=1%, k=2) in fine range 2 mg +0.005%·Rgr 2 mg +0.0024%·Rgr

Weighing time 4 s 4 s

1)

2)

1)

XSE105DU XSE205DU

0.3 mg (50 g) 0.3 mg (100 g)

0.00015%/°C 0.00015%/°C

0.0002%/a 0.0002%/a

0.15 mg (50 g) 0.16 mg (100 g)

20mg 20mg

0.04 mg

+0.00003%·Rgr

+0.000015%·Rgr

0.01 mg

+0.000025%·Rgr

+0.000012%·Rgr

20 mg +0.05%·Rgr 20 mg +0.024%·Rgr

27Technical Data

Page 28

XSE105DU XSE205DU

Weighing time in fine range 6 s 6 s

Interface update rate 23/s 23/s

Usable height of draft shield 235 mm 235 mm

Weight of balance 9.1 kg 9.1 kg

Number of built-in reference weights 2 2

Weights for routine testing

OIML CarePac

ASTM CarePac

Weights

Weights

100 g F2, 5 g E2

#11123002

100 g 1, 5 g 1

#11123102

200 g F2, 10 g F2

#11123001

200 g 1, 10 g 1

#11123101

sd = Standard deviation Rnt = Net weight (sample weight)

Rgr = Gross weight a = Year (annum)

1)

Valid for compact objects

3)

On DeltaRange models: fine range starts at zero load (gross)

2)

After adjustment with built-in reference weight

XSE104 XSE204

Limit values

Maximum capacity 120 g 220 g

Readability 0.1 mg 0.1 mg

Tare range (from…to) 0 … 120 g 0 … 220 g

Maximum capacity in fine range – –

Readability in fine range – –

Repeatability (at nominal load) sd 0.1 mg (100 g) 0.1 mg (200 g)

Repeatability (at low load) sd 0.07 mg (5 g) 0.07 mg (10 g)

Repeatability in fine range (at low load) sd – –

Linearity deviation 0.2 mg 0.2 mg

Eccentric deviation (test load)

1)

0.3 mg (50 g) 0.3 mg (100 g)

Sensitivity offset (test weight) 1 mg (100 g) 1 mg (200 g)

Sensitivity temperature drift

Sensitivity stability

2)

3)

0.00015%/°C 0.00015%/°C

0.0002%/a 0.0002%/a

Typical values

Repeatability (at low load) sd 0.04 mg 0.04 mg

Repeatability in fine range sd – –

Linearity deviation 0.13 mg 0.13 mg

Eccentric deviation (test load)

1)

0.15 mg (50 g) 0.16 mg (100 g)

Sensitivity offset (test weight) 0.6 mg (100 g) 0.8 mg (200 g)

Minimum weight (according to USP) 80 mg 80 mg

Minimum weight (according to USP) in fine

– –

range

Minimum weight (U=1%, k=2) 8 mg 8 mg

Minimum weight (U=1%, k=2) in fine range – –

Setting time 1.5 s 1.5 s

Setting time in fine range – –

Dimensions

Balance dimensions (W × D × H) 263 × 482 × 322mm 263 × 482 × 322mm

Weighing pan dimensions 78 × 73 mm (W × D) 78 × 73 mm (W × D)

Typical uncertainties and supplementary data

Repeatability sd 0.04 mg

+0.00003%·Rgr

0.04 mg

+0.000015%·Rgr

Repeatability in fine range sd – –

Differential linearity deviation sd √(40 pg·Rnt) √(20 pg·Rnt)

Differential eccentric load deviation sd 0.0003%·Rnt 0.00015%·Rnt

Sensitivity offset sd 0.0002%·Rnt 0.00012%·Rnt

Minimum weight (according to USP) 80 mg +0.06%·Rgr 80 mg +0.03%·Rgr

Minimum weight (according to USP) in fine

– –

range

Minimum weight (U=1%, k=2) 8 mg +0.006%·Rgr 8 mg +0.003%·Rgr

Minimum weight (U=1%, k=2) in fine range – –

Weighing time 4 s 4 s

Weighing time in fine range – –

Interface update rate 23/s 23/s

28 Technical Data

Page 29

XSE104 XSE204

Usable height of draft shield 235 mm 235 mm

Weight of balance 9.1 kg 9.1 kg

Number of built-in reference weights 2 2

Weights for routine testing

OIML CarePac

ASTM CarePac

Weights

Weights

100 g F2, 5 g E2

#11123002

100 g 1, 5 g 1

#11123102

200 g F2, 10 g F1

#11123001

200 g 1, 10 g 1

#11123101

sd = Standard deviation Rnt = Net weight (sample weight)

Rgr = Gross weight a = Year (annum)

1)

Valid for compact objects

3)

On DeltaRange models: fine range starts at zero load (gross)

2)

After adjustment with built-in reference weight

29Technical Data

Page 30

6.4Dimensions

METTLER TOLEDO

194

57

59

300

150

186

78

322

252176.5

229

482

73

296

263

151

150

262

129

Dimensions in mm.

30 Technical Data

Page 31

Page 32

Mettler-Toledo AG, Laboratory & Weighing Technologies

CH-8606 Greifensee, Switzerland

Tel. +41 (0)44 944 22 11

Fax +41 (0)44 944 30 60

www.mt.com

www.mt.com/excellence

For more information

Subject to technical changes.

© Mettler-Toledo AG 12/2013

30089512B en

*30089512*

Loading...

Loading...