Mettler Toledo XS2002S, XS4002S, XS603S, XS6002SDR, XS6002S Operating Instructions Manual

...Page 1

Precision Balances

XS models

Operating Instructions

Page 2

Page 3

Table of Contents

1 Introduction 9

2 Safety Information 10

3 Design and Function 12

4 Installation and Putting into Operation 20

1.1 Conventions and symbols used in these operating instructions 9

2.1 Definition of signal warnings and symbols 10

2.2 Product safety information 10

3.1 Overview 12

3.1.1 S weighing platform 12

3.1.2 L weighing platform 13

3.1.3 Terminal 14

3.2 User interface 15

3.2.1 Display 15

3.2.2 Input dialog boxes 16

3.2.3 Firmware 17

3.2.3.1 System settings 17

3.2.3.2 Applications 17

3.2.4 Security system 18

4.1 Unpacking 20

4.1.1 Unpacking the "Magic Cube" draft shield 20

4.2 Scope of delivery 20

4.3 Location 21

4.4 Assembling the balance 22

4.4.1 Installing the "Magic Cube" draft shield and weighing pan to the S weighing platform

22

4.4.2 Placing the terminal on the L weighing platform 23

4.4.3 Setting options with the draft shield glass (1mg Models) 25

4.4.4 Using the additional draft shield door (1mg Models) 25

4.5 Connecting the balance 26

4.6 Setting up the balance 27

4.6.1 Weighing for the first time 27

4.6.1.1 Switching on the balance 27

4.6.1.2 Leveling the balance 27

4.6.1.3 Performing a simple weighing 28

4.7 Transporting the balance 28

4.7.1 Transport over short distances 29

4.7.2 Transport over long distances 30

4.8 Below-the-balance weighing 30

5 System Settings 32

5.1 Adjustment/Test 34

5.1.1 Test/Adjustment - weight settings 36

5.1.2 Test sequences 36

5.1.2.1 Method 38

5.1.2.2 Action if failure 44

5.1.3 Tasks 45

5.1.3.1 Assigning a test sequence to a task 46

5.1.4 FACT/int. Adjustment 46

5.1.4.1 Definition of parameters for FACT_XS 47

5.1.5 Test history 48

5.1.6 Protocol – Definition of adjustment and test reports 49

5.2 Weighing parameters 49

5.2.1 Weighing mode 49

Table of Contents 3Precision Balances

Page 4

5.2.2 Ambient conditions 50

5.2.3 Measured value release 50

5.2.4 AutoZero 50

5.3 Language 51

5.4 Peripherals 51

5.5 Option 53

5.6 Terminal 54

5.6.1 Brightness 54

5.6.2 Contrast 54

5.6.3 Beep 54

5.6.4 Touch function 55

5.6.5 Touch adjustment 55

5.7 Date/Time 55

5.8 Rights 56

5.9 Standby 57

5.10 Switch 57

5.11 Factory 57

5.12 Info 58

6 Weighing Application 59

6.1 Weighing application settings 59

6.1.1 Selecting function keys 61

6.1.1.1 Function key overview 61

6.1.2 Selecting information fields 62

6.1.3 Specifications for automatic protocol printout 63

6.1.4 Selecting weighing units 63

6.1.5 Defining free weighing units 64

6.1.6 Protocol definition 65

6.1.7 Specifications for manual protocol printout 67

6.1.8 Output data formatting (transfer key) 67

6.1.8.1 Output format 68

6.1.8.2 Data output to the printer 69

6.1.9 Definition of identifications 70

6.1.10 Instructions for processing barcode data 70

6.1.11 Instructions for processing keyboard entries 71

6.1.12 MinWeigh function settings 71

6.2 Working with the weighing application 72

6.2.1 Changing the weighing result resolution 72

6.2.2 Working with the lot counter 72

6.2.3 Working with identifications 73

6.2.4 Working with the "MinWeigh" function 74

6.3 Balance adjustment and testing 75

6.3.1 Adjustment 76

6.3.1.1 Fully automatic adjustment FACT 76

6.3.1.2 Adjustment with internal weight 76

6.3.1.3 Adjustment with external test weight 76

6.3.2 Testing 77

6.3.2.1 Testing the adjustment with internal weight 77

6.3.2.2 Testing the adjustment with external test weight 77

6.3.3 Protocols 78

6.3.3.1 Adjustment and test records (sample records) 78

6.4 Working with the test sequence function 80

6.4.1 Starting a task 80

6.4.1.1 EC - eccentric load test 81

6.4.1.2 RP1 - repeatability test 81

6.4.1.3 RPT1 - repeatability test with tare weight 82

6.4.1.4 SE1 - sensitivity test with one weight 82

6.4.1.5 SE2 - sensitivity test with two weights 82

Table of Contents4 Precision Balances

Page 5

6.4.1.6 SERVICE - reminder 83

6.4.1.7 SET1 - sensitivity test with tare and one test weight 83

6.4.1.8 SET2 - sensitivity test with tare and two test weights 83

7 Statistics Application 85

7.1 Settings for the Statistics application 85

7.1.1 Specific function keys for using statistics 85

7.1.2 Specific information fields for statistics 86

7.1.3 Specific protocol information for statistics 87

7.1.4 Enable additive mode 89

7.2 Working with the Statistics application 90

7.2.1 Capturing statistics from a weighing series 90

7.2.2 Weighing out to a nominal value 92

7.2.3 Example protocol with statistical values 93

7.2.4 Formulas used for the calculation of statistical values 94

8 Formulation Application 96

8.1 Formulation application settings 96

8.1.1 Specific formulation function keys 96

8.1.2 Specific formulation information fields 97

8.1.3 Specific formulation protocol information 98

8.1.4 Specific formulation identifications 99

8.2 Working with the formulation application 100

8.2.1 Initial settings 100

8.2.2 Formulation 101

8.2.3 Sample protocol of a formulation 102

9 Density Application 104

9.1 Density application settings 104

9.1.1 Selecting the density determination method 105

9.1.2 Selecting an auxiliary liquid 105

9.1.3 Activation or deactivation of statistics 105

9.1.4 Specifications for calculation and result display 106

9.1.5 Specific function keys for density determination 106

9.1.6 Specific information fields for density determination 107

9.1.7 Specific protocol information for density determination 108

9.2 Working with the density application 109

9.2.1 Determination of the density of non-porous solids 110

9.2.2 Determination of the density of liquids using a sinker 111

9.2.3 Determination of the density of pasty substances using a gamma sphere 112

9.2.4 Example protocol of a density determination 113

9.3 Using density statistics 114

9.4 Formulae used to calculate density 116

9.4.1 Formulae for determining the density of solids 116

9.4.2 Formulae for determining the density of liquids and pasty substances 116

9.5 Density table for distilled water 117

9.6 Density table for ethanol 117

10 Percent Weighing Application 118

10.1 Settings for percent weighing application 118

10.1.1 Specific function key for percent weighing 118

10.1.2 Specific information fields for percent weighing 119

10.1.3 Additional unit for percent weighing 120

10.1.4 Specific protocol information for percent weighing 120

10.2 Working with the percent weighing application 121

10.2.1 Simple percent weighing 121

10.2.2 Percent weighing to a nominal weight 122

10.2.3 Sample protocol of a percent weighing 123

Table of Contents 5Precision Balances

Page 6

11 Piece Counting Application 124

11.1 Piece counting application settings 124

11.1.1 Defining the fixed reference unit quantity 124

11.1.2 Specific function keys for piece counting 125

11.1.3 Specific information fields for piece counting 126

11.1.4 Additional unit for piece counting 127

11.1.5 Specific protocol data for piece counting 127

11.2 Working with the Piece Counting application 129

11.2.1 Simple piece counting 129

11.2.2 Totalizing and acquiring statistics from piece counts 130

11.2.3 Counting to a nominal value 132

11.2.4 Example protocol of a piece count with statistical values 133

12 Dynamic Weighing Application 135

12.1 Dynamic weighing application settings 135

12.1.1 Specific function keys for dynamic weighing 136

12.1.2 Adapting the application to the dynamic behavior of the weighing material 136

12.1.3 Settings for the start of weighing 137

12.1.4 Settings for the beep at the end of the measurement cycle 137

12.1.5 Settings for the automatic tare function 138

12.1.6 Specific information fields for dynamic weighing 138

12.1.7 Specific protocol data for dynamic weighing 139

12.1.8 Automatic or manual reporting of individual values 140

12.1.9 Selecting the destination for the output data 141

12.1.10 Formatting the output data 141

12.1.11 Activate or deactivate statistics 143

12.2 Working with the Dynamic weighing application 144

12.2.1 Dynamic weighing with automatic start 144

12.2.2 Dynamic weighing with manual start 145

12.2.3 Capturing statistics of dynamic weighing 146

12.2.4 Example protocol of a dynamic weighing 146

13 Maintenance 148

13.1 Cleaning 148

13.2 Disposal 149

13.3 Firmware (Software) Updates 149

13.3.1 How it Works 149

13.3.2 Update Procedure 149

14 Troubleshooting 151

14.1 Error messages 151

14.2 Status messages/Status icons 151

14.3 What to do if....? 152

15 Technical Data 153

15.1 General data S weighing platform 153

15.2 General data L weighing platform 153

15.3 Explanatory notes for the METTLER TOLEDO AC adapter 154

15.4 Model-specific data 155

15.4.1 Balances with readability of 1 mg, S platform with draft shield and SmartPan 155

15.4.2 Balances with readability of 1 mg, S platform with SmartPan 156

15.4.3 Balances with readability of 10 mg, S platform with SmartPan 157

15.4.4 Balances with readability of 0.1 g, S platform 159

15.4.5 Balances with readability of 0.1 g, L platform 161

15.4.6 Balances with readability of 1 g, L platform 163

15.5 Dimensions 164

15.5.1 Balances with readability of 1 mg, S platform with draft shield and SmartPan 164

15.5.2 Balances with readability of 1 mg, S platform with SmartPan 165

Table of Contents6 Precision Balances

Page 7

15.5.3 Balances with readability of 10 mg, S platform with SmartPan 166

15.5.4 Balances with readability of 0.1 g, S platform 167

15.5.5 Balances with readability of 0.1g / 1g, L platform 168

15.6 Interfaces 169

15.6.1 Specifications of RS232C 169

15.6.2 Specifications of "Aux" connection 169

16 Accessories and Spare Parts 170

16.1 Accessories 170

16.2 Spare parts 179

17 Appendix 182

17.1 MT-SICS interface commands and functions 182

17.2 Procedure for certified balances 182

17.3 Recommended printer settings 183

Glossary 185

Index 187

Table of Contents 7Precision Balances

Page 8

Page 9

1 Introduction

Thank you for choosing a METTLER TOLEDO balance.

The balances offers numerous weighing and adjustment options with exceptional operating convenience.

The different models have different characteristics regarding equipment and performance. Special notes in

the text indicate where this makes a difference to operation.

METTLER TOLEDO is a leading manufacturer of balances for laboratory and production use as well as

analytical measuring instruments. A globally present customer service network with highly trained personnel

is always available to assist with the selection of accessories or provide advice on the optimal use of the

balance.

The balance conforms to current standards and directives. It supports requirements, work techniques and

protocols as specified by all international quality assurance systems, e.g. GLP (Good Laboratory Practice),

GMP (Good Manufacturing Practice). The balance has a CE Declaration of Conformity and METTLER

TOLEDO, as the manufacturer, is certified to ISO 9001 and ISO 14001. This provides the assurance that

your capital investment is protected in the long term by high product quality and a comprehensive service

package (repairs, maintenance, servicing, adjustment service).

Finding more information

u www.mt.com/xs-precision

Software version

These operating instructions refer to the originally installed firmware (software) version V 5.40.

1.1 Conventions and symbols used in these operating instructions

Key and button designations are shown in graphic or text form in square brackets (e.g. [

[Define].

These symbols indicate an instruction:

§ prerequisites

1 steps

2 ...

ð results

This symbol indicates press key briefly (less than 1.5 s).

This symbol indicates press and hold key down (longer than 1.5 s).

] or

Introduction 9Precision Balances

Page 10

2 Safety Information

2.1 Definition of signal warnings and symbols

Safety notes are indicated by signal words and warning symbols and contain warnings and information

about safety issues. Ignoring safety notes can lead to personal injury, damage to the instrument,

malfunctions and erroneous results.

Signal words

WARNING

CAUTION

Attention

Note

for a hazardous situation with medium risk, possibly resulting in severe

injuries or death if not avoided.

for a hazardous situation with low risk, resulting in damage to the device

or the property or in loss of data or minor or medium injuries if not

avoided.

(no symbol)

for important information about the product.

(no symbol)

for useful information about the product.

Warning symbols

General hazard Electrical shock

2.2 Product safety information

Intended use

Your balance is used for weighing. Use the balance exclusively for this purpose. Any other type of use and

operation beyond the limits of technical specifications without written consent from Mettler-Toledo AG, is

considered as not intended.

It is not permitted to use the instrument in explosive atmosphere of gases, steam, fog, dust

and flammable dust (hazardous environments).

General safety information

This balance complies with current industry standards and the recognized safety regulations; however, it

can constitute a hazard in use. Do not open the balance housing: The balance contains no user-serviceable

parts. In the event of problems, please contact a METTLER TOLEDO representative.

Always operate and use your instrument only in accordance with the instructions contained in this manual.

The instructions for setting up your new instrument must be strictly observed.

If the instrument is not used according to these Operating Instructions, protection of the instrument

may be impaired and METTLER TOLEDO assumes no liability.

Staff safety

These operating instructions must be read and understood before using the balance. These operating

instructions must be retained for future reference.

The balance must not be altered or modified in any way. Only use METTLER TOLEDO original spare parts

and accessories.

Safety Information10 Precision Balances

Page 11

Safety notes

WARNING

Risk of electric shock

Use only the original universal AC adapter delivered with your balance, and check that the

voltage printed on it is the same as your local power supply voltage. Only plug the

adapter into a socket which is grounded.

CAUTION

Damage to the balance

a) Only use indoors in dry locations.

b) Do not use pointed objects to operate the touch screen!

The balance is of a very sturdy design, but is still a precision instrument. It must be

handled with care.

c) Do not open the balance:

The balance contains no user-serviceable parts. In the event of problems, please

contact a METTLER TOLEDO representative.

d) Only use METTLER TOLEDO original accessories and peripheral devices for the

balance.

These are specifically designed for the balance.

Safety Information 11Precision Balances

Page 12

3 Design and Function

1

2

3

4

5

6

8

7

9

10

1111

12

10

5

9

10

13

5

9

14

15

9

10

5

16

1819202223 21 17

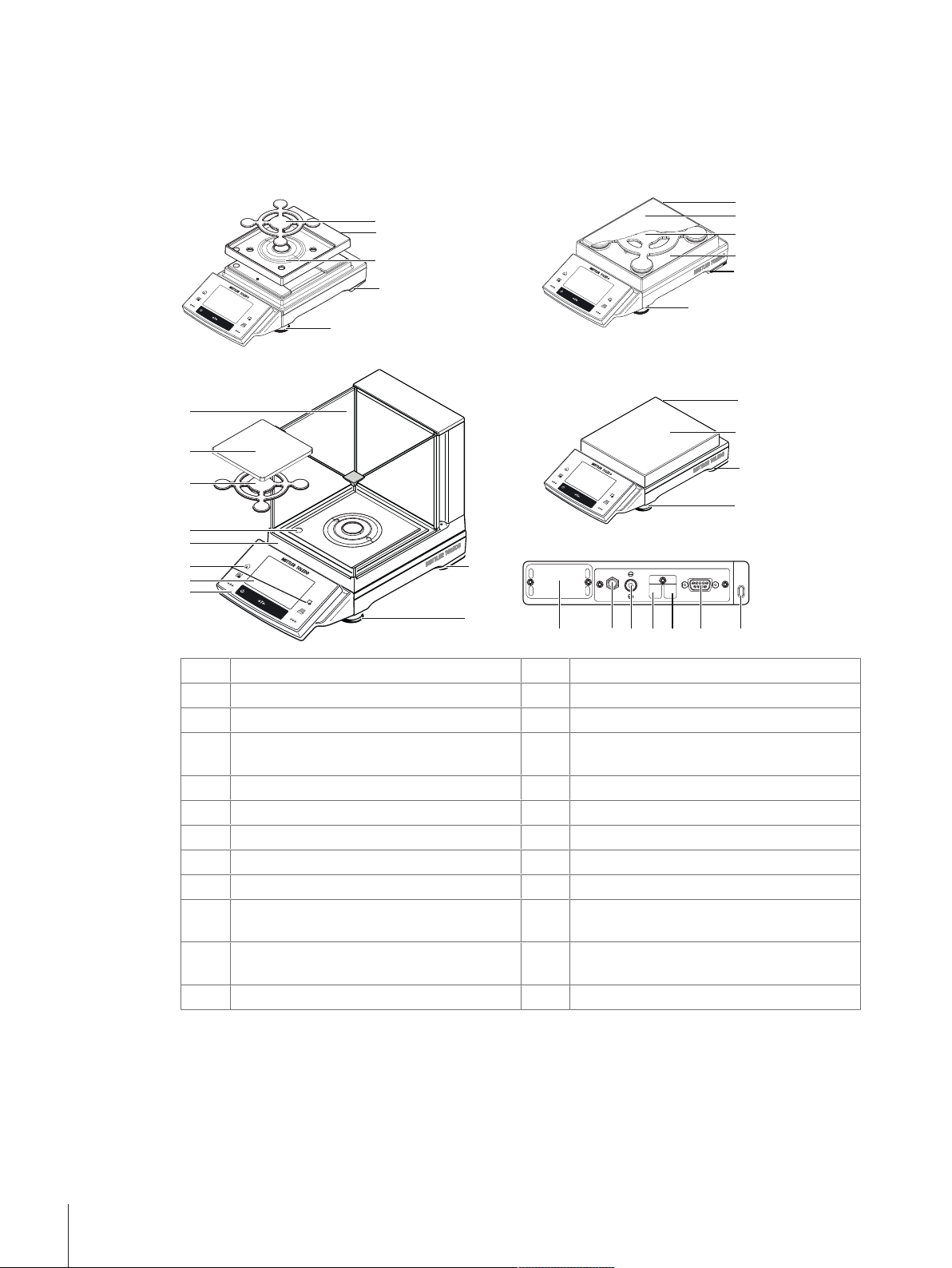

3.1 Overview

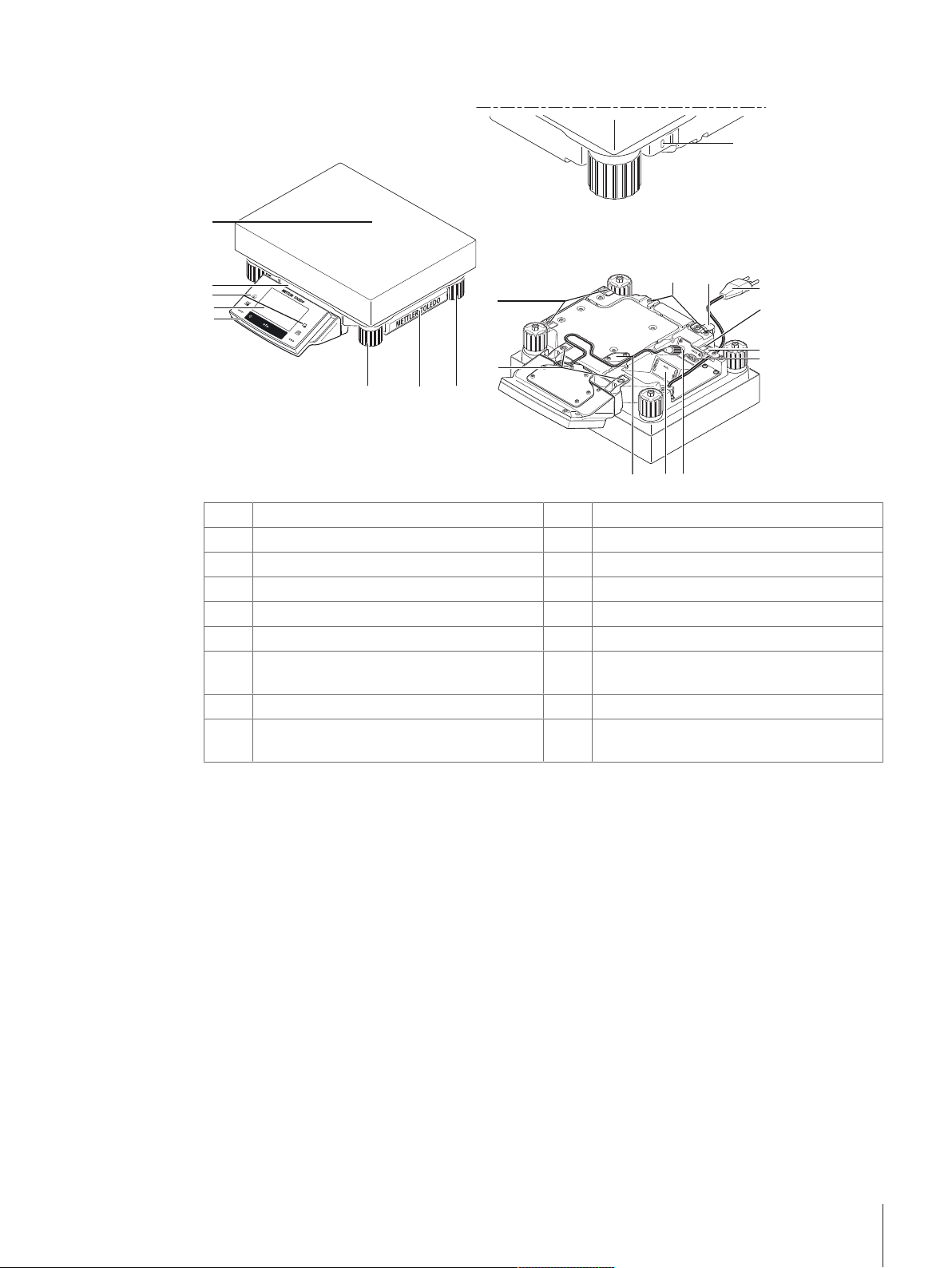

3.1.1 S weighing platform

Terminal

1

Operating keys

3

Level indicator

5

Weighing pan for 1mg models with draft

7

Display “Touch screen”

2

Type designation

4

SmartPan for 1mg models with draft shield

6

Glass draft shield

8

shield

Safety feet

9

SmartPan for 1mg models

11

Weighing pan for 5mg and 10mg models

13

Drip tray for 5mg and 10mg models

15

Fastening point for anti-theft device

17

Aux 1 (connection for “ErgoSens”, hand- or

19

foot-switch)

Fastening for auxiliary display stand or

21

Foot screws

10

Drip tray for 1mg models

12

SmartPan for 5mg and 10mg models

14

Weighing pan for 0.1g models

16

RS232C serial interface

18

Aux 2 (connection for “ErgoSens”, hand- or

20

foot-switch)

Socket for AC adapter

22

terminal stand (optional)

Slot for second interface (optional)

23

Design and Function12 Precision Balances

Page 13

3.1.2 L weighing platform

8

1

2

4

5

67

6

3

9

9

10

11

13

15

14

12

16

17

18

Terminal

1

Operating keys

3

Weighing pan

5

Cover

7

Points of attachment for terminal or cover

9

Level indicator

11

Aux 1 (connection for “ErgoSens”, hand- or

13

foot-switch)

RS232C serial interface

15

Slot for second interface (optional)

17

Display “Touch screen”

2

Type designation

4

Foot screws

6

Fastening point for anti-theft device

8

Fastening for terminal stand (optional)

10

Power cable

12

Aux 2 (connection for “ErgoSens”, hand- or

14

foot-switch)

Connector for terminal cable

16

Cover plate for below-the-balance weighing

18

(hook optional)

Design and Function 13Precision Balances

Page 14

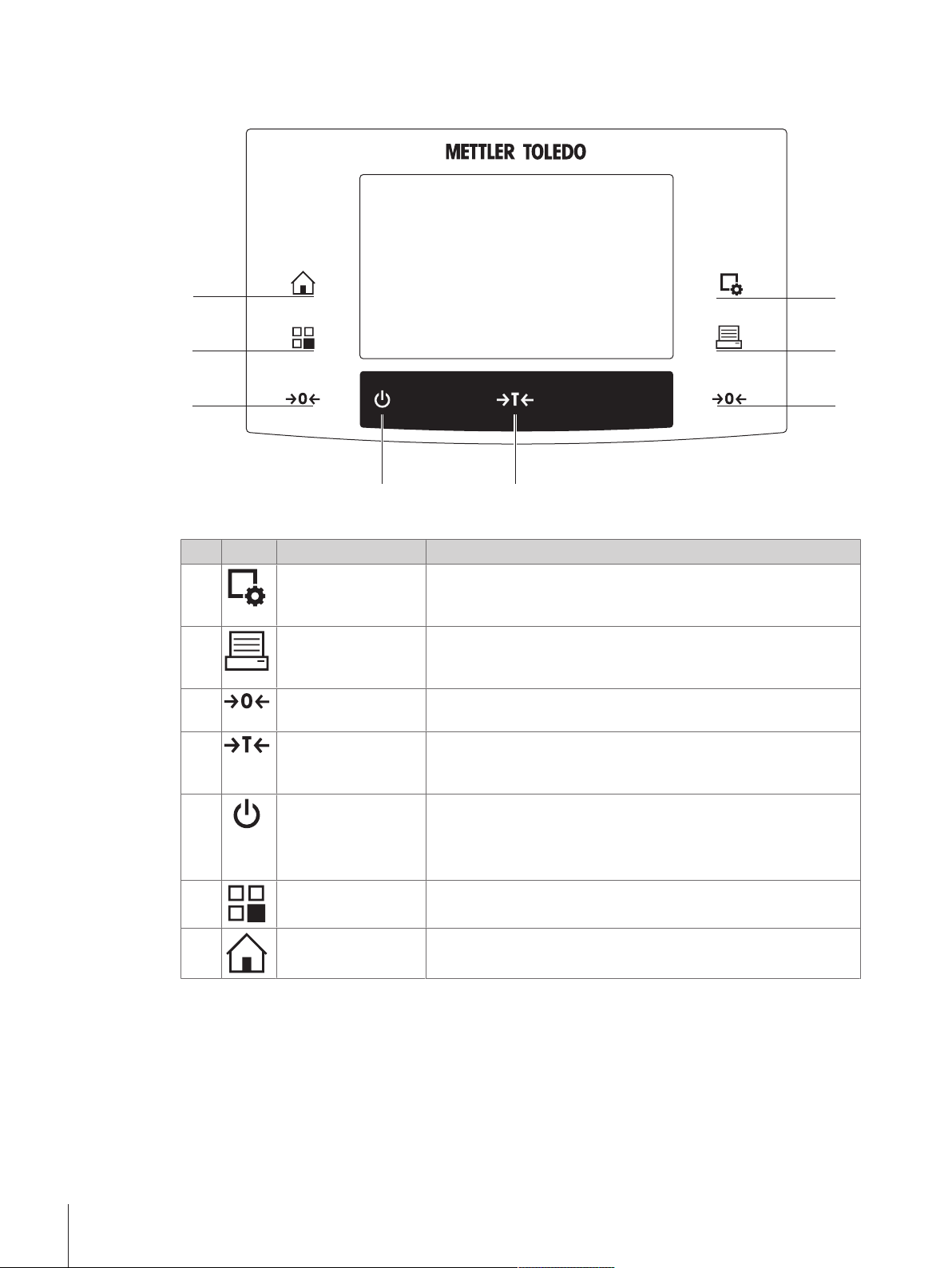

3.1.3 Terminal

5

4

7

6

1

2

3

3

Key assignments and terminal connection.

1: Front view

Designation Explanation

1

2

3

4

5

6

7

Configuration For displaying menus for the configuration of a current application.

The application can be adjusted to a specific task via numerous

settings.

Print This key is used to transfer data via the interface, e.g. to a printer.

Other devices, e.g. a PC can also be connected. The data to be

transferred can be freely defined.

Zeroing This key is used for setting a new zero point manually (only

required if the balance is used for normal weighings).

Tare This key is used to tare the balance manually (only necessary for

normal weighings). When the balance has been tared, the Net

symbol is displayed to indicate that all displayed weights are net.

On/Off For switching the balance on and off (standby mode).

Note

It is recommended not to disconnect the balance from the power

supply unless it is not going to be used for an extended period.

Select

application/System

Home This key takes you directly from any menu level back to the active

This key is used to select a required application.

application.

Design and Function14 Precision Balances

Page 15

1

1

2

Levers

5

6

7

4

3

1

2

8

1

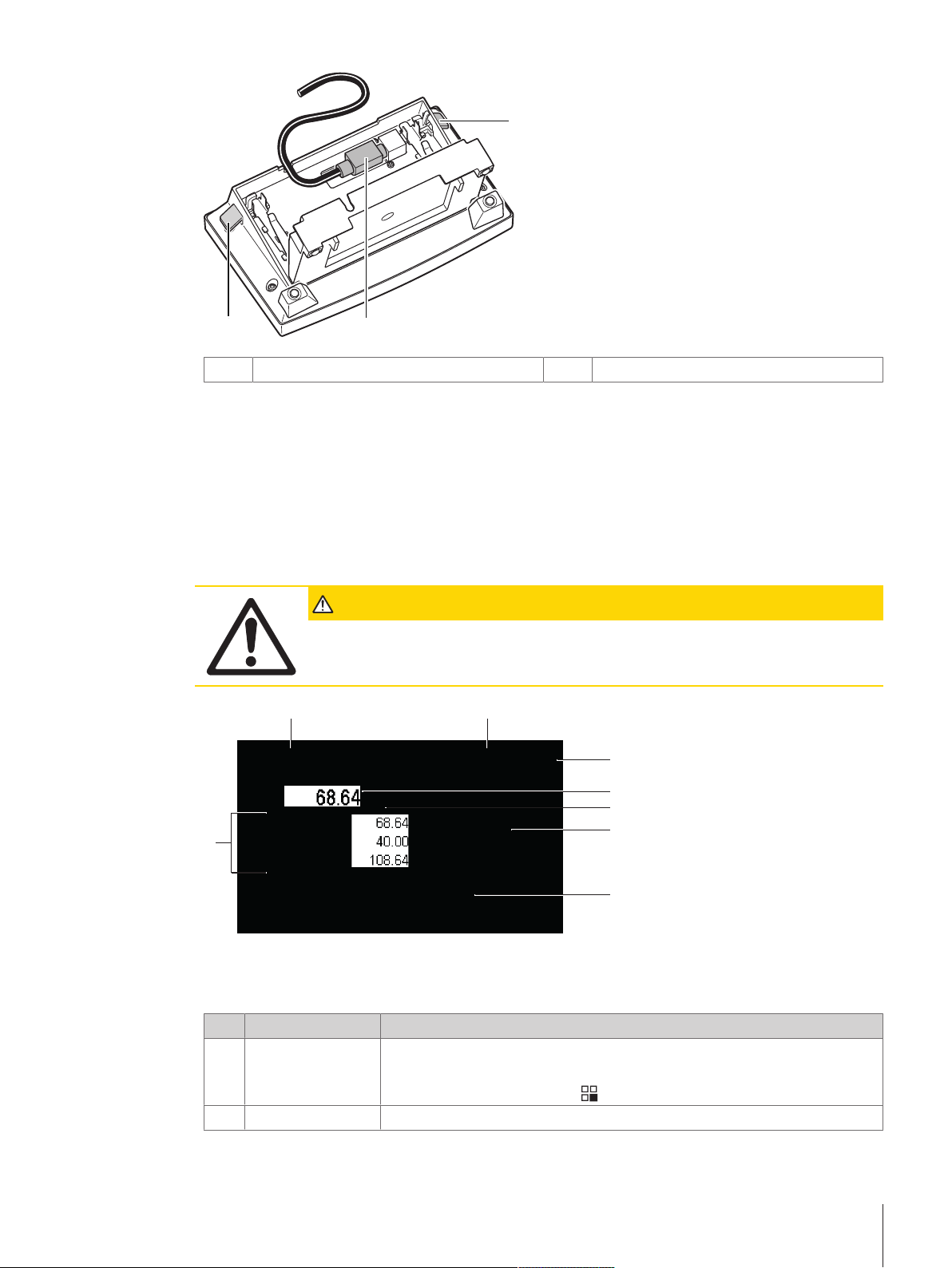

3.2 User interface

3.2.1 Display

The illuminated display of the terminal is a touch screen, i.e. a touch-sensitive screen. It can be used for

displaying data, entering settings and selecting functions by tapping the screen.

Note

Depending on country-specific requirements, non-calibrated decimal places are highlighted on approved

balances.

System connection (terminal cable)

2

CAUTION

Do not touch the touch screen with pointed or sharp objects!

This may damage the touch screen.

Note

The factory setting of the balance displays the weighing result at a large size, without SmartTrac and

information fields.

Designation Explanation

1

2

Application name Select application.

Date The date can be changed by tapping this zone.

The application menu can be selected by tapping this zone. This menu can

also be displayed by pressing [

].

Design and Function 15Precision Balances

Page 16

Status icons These status icons indicate special balance statuses (e.g. service due,

1

2

3

3

adjustment required, battery replacement, out of level).

If you tap the icon, the function is explained.

Weight value Tapping the weight displays a window showing the result in a large format.

4

This is useful for reading a weight from a certain distance.

Weighing unit The required weighing unit can be changed by tapping the weighing unit, e.g.

5

from mg to g.

SmartTrac SmartTrac is a graphic weighing-in aid, which shows at a glance an already

6

used and still available weighing range.

Function keys

7

Information fields

8

This area is reserved for Function Keys enabling direct access to frequently

required functions and application settings. If more than 5 function keys are

activated, these can be selected with the arrow keys.

This area is used for displaying additional information (information fields)

relating to an active application.

Large display

By pressing the function key [Display], the weighing result can be displayed larger and still allow the use of

the terminal function keys.

Screen saver

If the balance is not used for 15 minutes, the display is automatically dimmed and the pixels are inverted

about every 15 seconds. When the balance is used again (e.g. load weight, press key), the display returns

to a normal state.

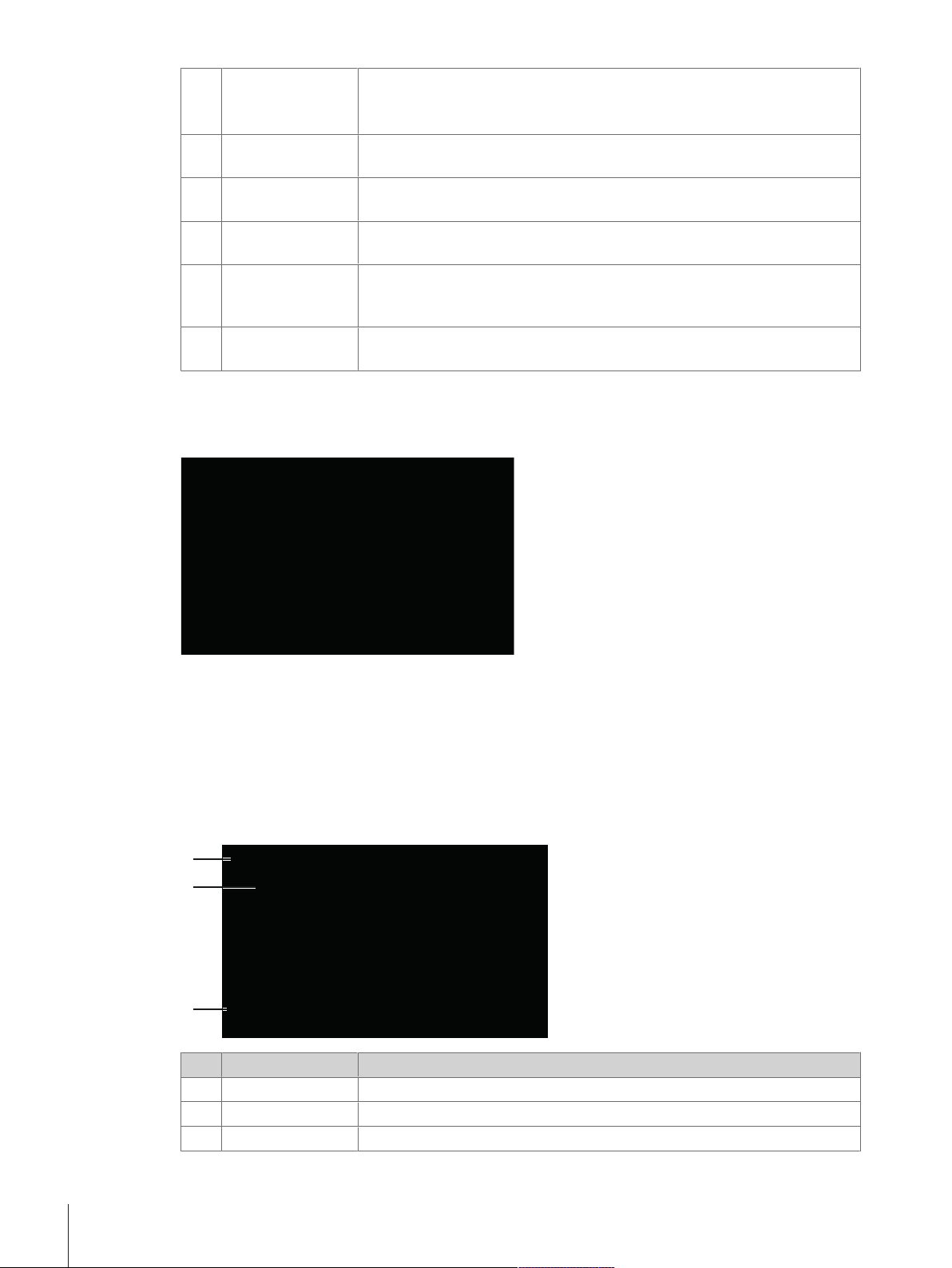

3.2.2 Input dialog boxes

The keyboard dialog box is used to enter characters such as letters, numbers and special characters.

Designation Explanation

Data field Displays (entered) alphanumeric and numeric characters.

1

Keyboard Data input area

2

Selection Select various keyboard layouts.

3

Design and Function16 Precision Balances

Page 17

1 Enter the designation.

1

2

3

2 Confirm with [OK].

3.2.3 Firmware

The firmware controls all balance functions. It enables the balance to be adjusted to a specific working

environment.

The firmware is divided as follows:

• System settings

• Applications

• Application-specific settings

Note

A displayed menu can be left at any time by repressing the same menu key.

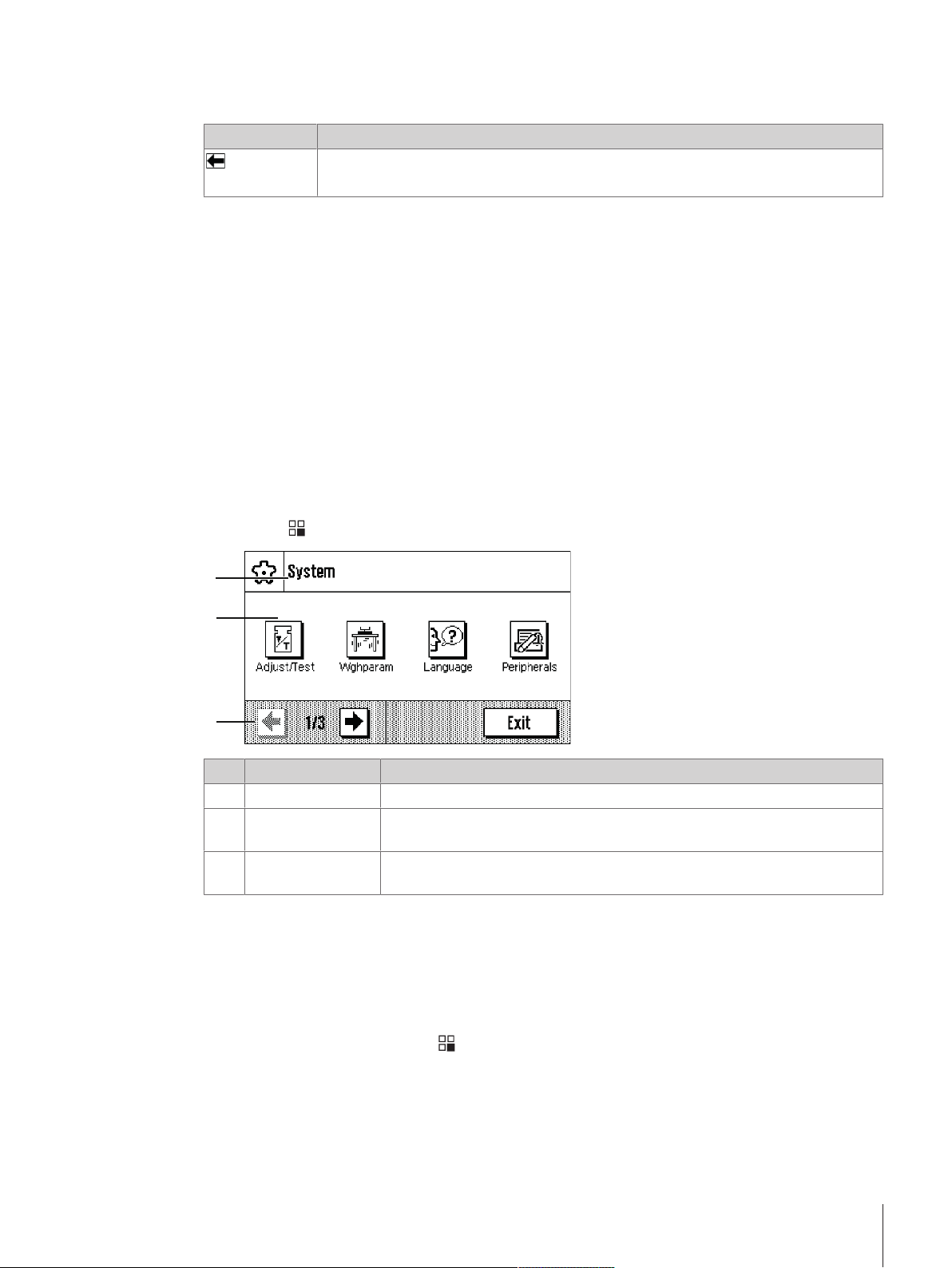

3.2.3.1 System settings

System settings (e.g. settings for peripheral devices) are independent of the applications and apply to the

entire weighing system.

Function

Delete last character

Tap once to place the cursor at the end of the data field.

Navigation: [

Designation Explanation

Title bar The title bar displays elements for user orientation and information.

1

Contents area The contents area is the main work area for menus and applications. The

2

Action bar The action bar contains action buttons for performing specific actions required

3

1 Settings can be changed by tapping the respective button.

2 To leave the settings, tap [Exit].

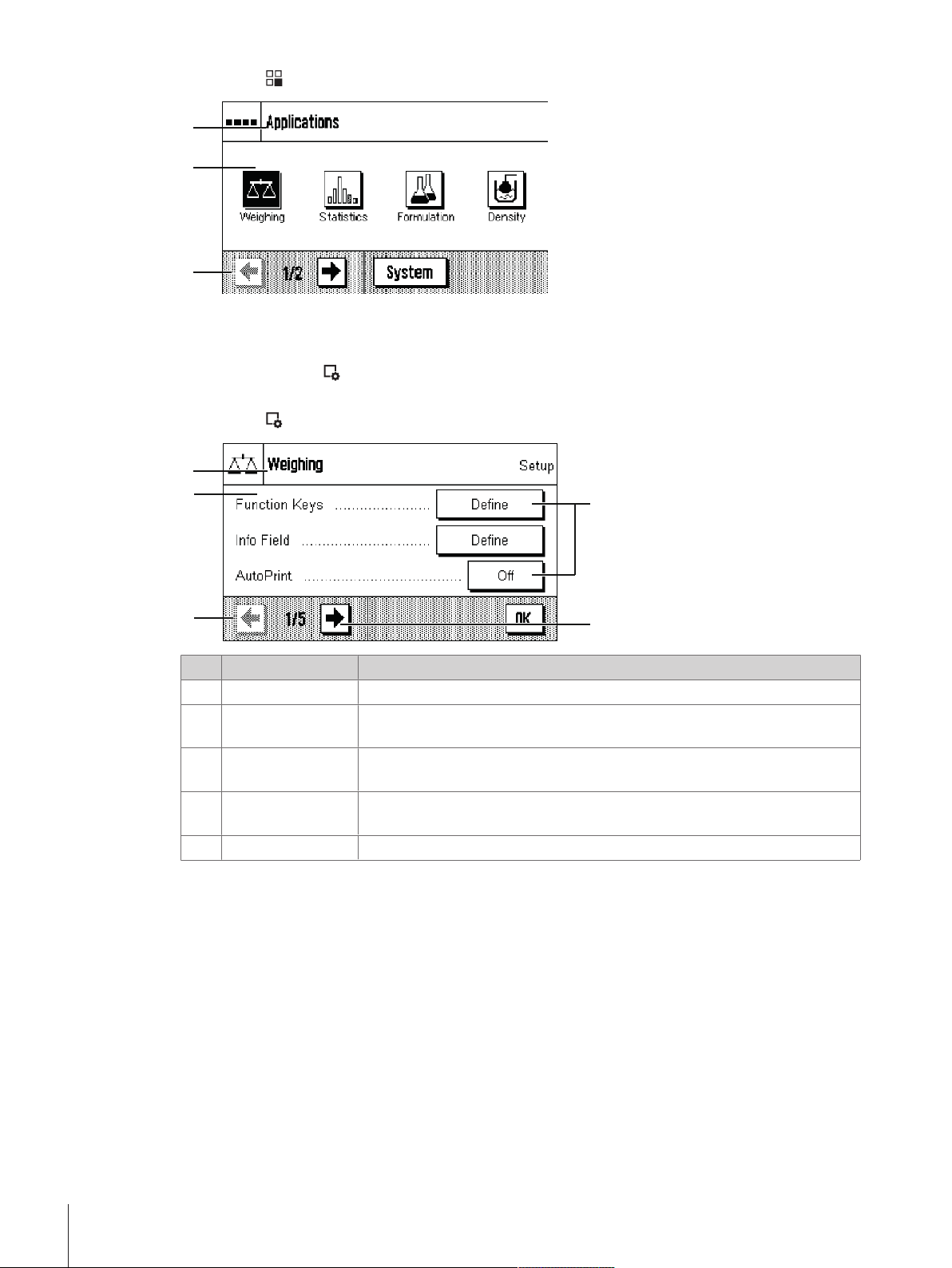

3.2.3.2 Applications

] > [System]

contents depend on the specific application or initiated action.

in the active dialog box and are available (e.g. [Exit], [STD], [C], [OK]).

Applications are firmware modules for performing specific weighing tasks. The balance is delivered with

various applications pre-installed. After switching on the balance, the last used application are loaded. The

applications are available under the [

provided in the respective sections.

] key. Instructions for working with standard applications are

Design and Function 17Precision Balances

Page 18

Navigation: [

1

2

3

1

2

3

5

4

]

Application-specific settings

These settings can be used to adjust the applications. The available setting options depend on the selected

application. Pressing [

Information on the individual setting options is provided in the section relating to the respective application.

] opens the multipage menu with settings for a currently active application.

Navigation: [

Designation Explanation

Title bar The title bar displays elements for orientation and information.

1

Contents area The contents area is the main work area for menus and applications. The

2

Action bar The action bar contains action buttons for performing specific actions required

3

Button

4

Arrow The arrow buttons are used to page forward or back.

5

1 Settings can be changed by tapping the respective button.

]

contents depend on the specific application or initiated action.

in the active dialog box and are available (e.g. [Exit], [STD], [C], [OK]).

Edit/Select settings (e.g. [Define], [On], [Off]). The contents depend on the

application.

2 Confirm with [OK].

3 To leave the settings, select [Exit].

4 To change the system settings, tap [System].

3.2.4 Security system

The balance has a comprehensive security system with which individual access rights can be defined at

administrator. Access to protected menu areas requires the entry of a password. On delivery of the balance,

a password is defined. The menu settings are chosen, so that you have unrestricted access to all system

Design and Function18 Precision Balances

settings.

When an password protected menu area is selected, an alphanumeric keyboard is initially displayed for

entry of the password.

Page 19

CAUTION

Remember passwords!

Protected menu areas cannot be accessed without password.

a) Note passwords and keep them in a safe place.

1 Enter your password.

- Case sensitive, tap the [a...z] and [A...Z] button to switch between upper and lower case.

- To enter numbers, tap the [0...9] button.

- Incorrect entries can be deleted character by character with the arrow key

Note

Entry can be interrupted at any time by tapping [C].

2 Enter the password (for security reasons, this is displayed with asterisks instead of plain text) and

confirm with [OK].

ð If the password are correct, the selected menu area is displayed or the required action initiated. If these

are incorrect, an error message is displayed with a request to enter them again.

.

Design and Function 19Precision Balances

Page 20

4 Installation and Putting into Operation

1

3

2

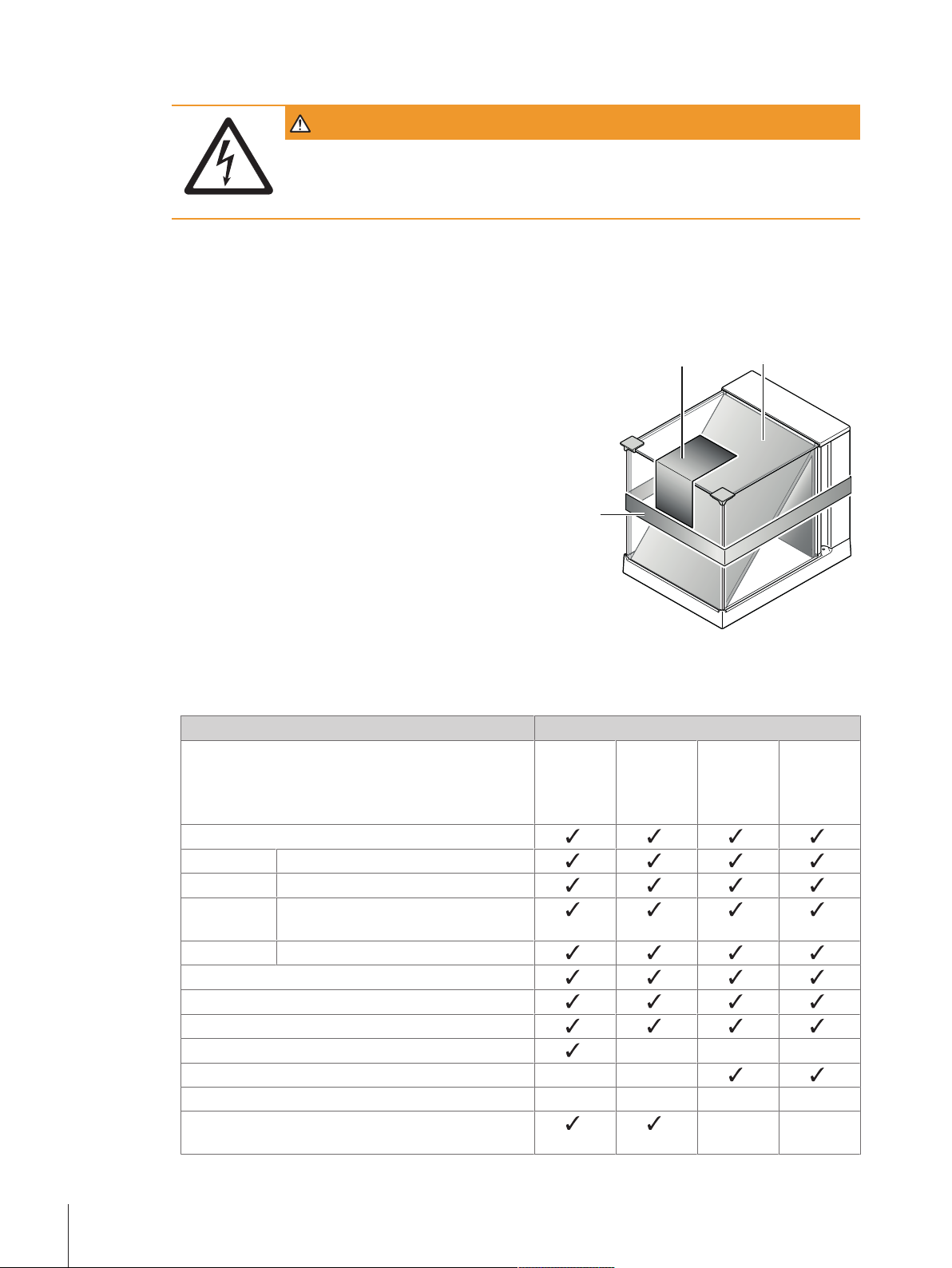

WARNING

Electrical shock

The balance must be disconnected from the power supply when carrying out all setup

and mounting work.

4.1 Unpacking

Open the packaging and carefully remove all components.

4.1.1 Unpacking the "Magic Cube" draft shield

1 Place the draft shield horizontally on a clean surface.

2 Remove the adhesive tape (1).

3 Open the draft shield cover.

4 Pull the cardboard (2) upwards out of the weighing

chamber.

5 When removing the cardboard (2), hold the U-shaped draft

shield glass so that it is not pulled away with it.

6 Close the draft shield cover.

7 Release the holding strip (3) and pull it upwards to remove

it.

4.2 Scope of delivery

The standard scope of delivery contains the following items:

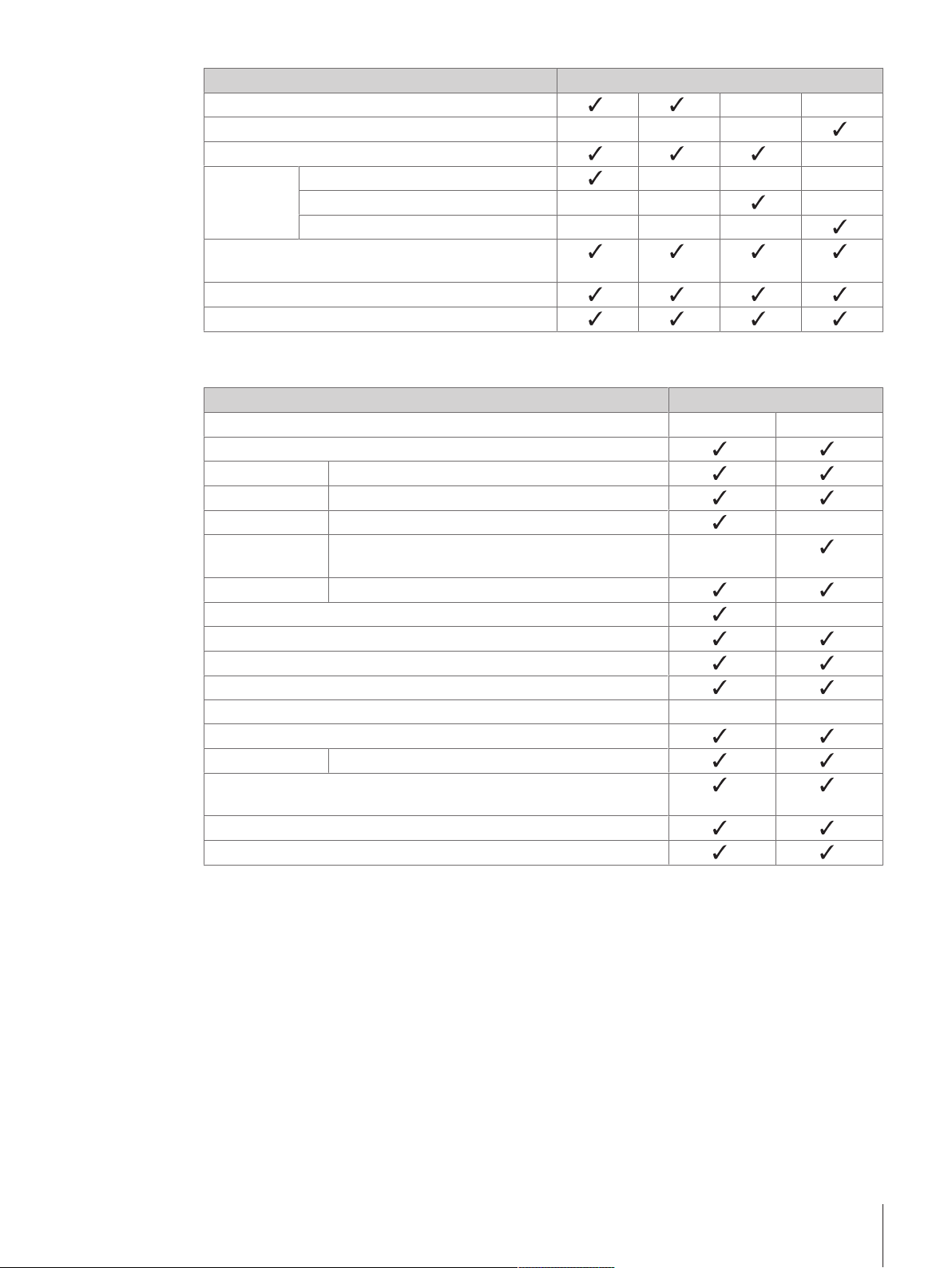

Components S platform

1 mg with

draft

shield

Weighing plaftorm

RS232C interface

Slot for second interface (optional)

Feedthroughs for below-the-balance

weighing

Feedthroughs for antitheft device

AC adapter

Country-specific power cable

Terminal

Protective cover for terminal – – –

Protective cover for weighing platform – –

Terminal support – – – –

"Magic Cube" draft shield with an additional draft

shield door

1 mg

without

draft

shield

10 mg 0.1 g

– –

Installation and Putting into Operation20 Precision Balances

Page 21

Components S platform

Bottom plate – –

Weighing pan support – – –

SmartPan with drip tray –

Weighing

pan

Operating instructions or Quick Guide; printed or on

CD-ROM, depending on country of use

Production certificate

CE declaration of conformity

Components L platform

Weighing plaftorm

AC adapter –

Country-specific power cable

Terminal

Protective cover for terminal

Protective cover for weighing platform – –

Terminal support

Weighing pan 280×360mm

Operating instructions or Quick Guide; printed or on CD-ROM,

depending on country of use

Production certificate

CE declaration of conformity

127×127mm – – –

172×205mm – – –

190×223mm – – –

0.1 g 1 g

RS232C interface

Slot for second interface (optional)

Feedthroughs for below-the-balance weighing –

Ready for below-the-balance weighing (hook

optional)

Feedthroughs for antitheft device

–

4.3 Location

An optimal location will ensure accurate and reliable operation of the balance. The surface must be able to

safely take the weight of the balance when fully loaded. The following local conditions must be observed:

Note

If the balance is not horizontal at the outset, it must be leveled during commissioning.

Installation and Putting into Operation 21Precision Balances

Page 22

• The balance must only be used indoors and up to a

1

2

3

4

1

2

maximum altitude of 4,000m above sea level.

• Before switching on the balance, wait until all parts are at

room temperature (+5 to 40°C).

The humidity must be between 10% and 80% noncondensing.

• The power plug must be accessible at all times.

• Firm, horizontal and vibration-free location.

• Avoid direct sunlight.

• No excessive temperature fluctuations.

• No strong drafts.

4.4 Assembling the balance

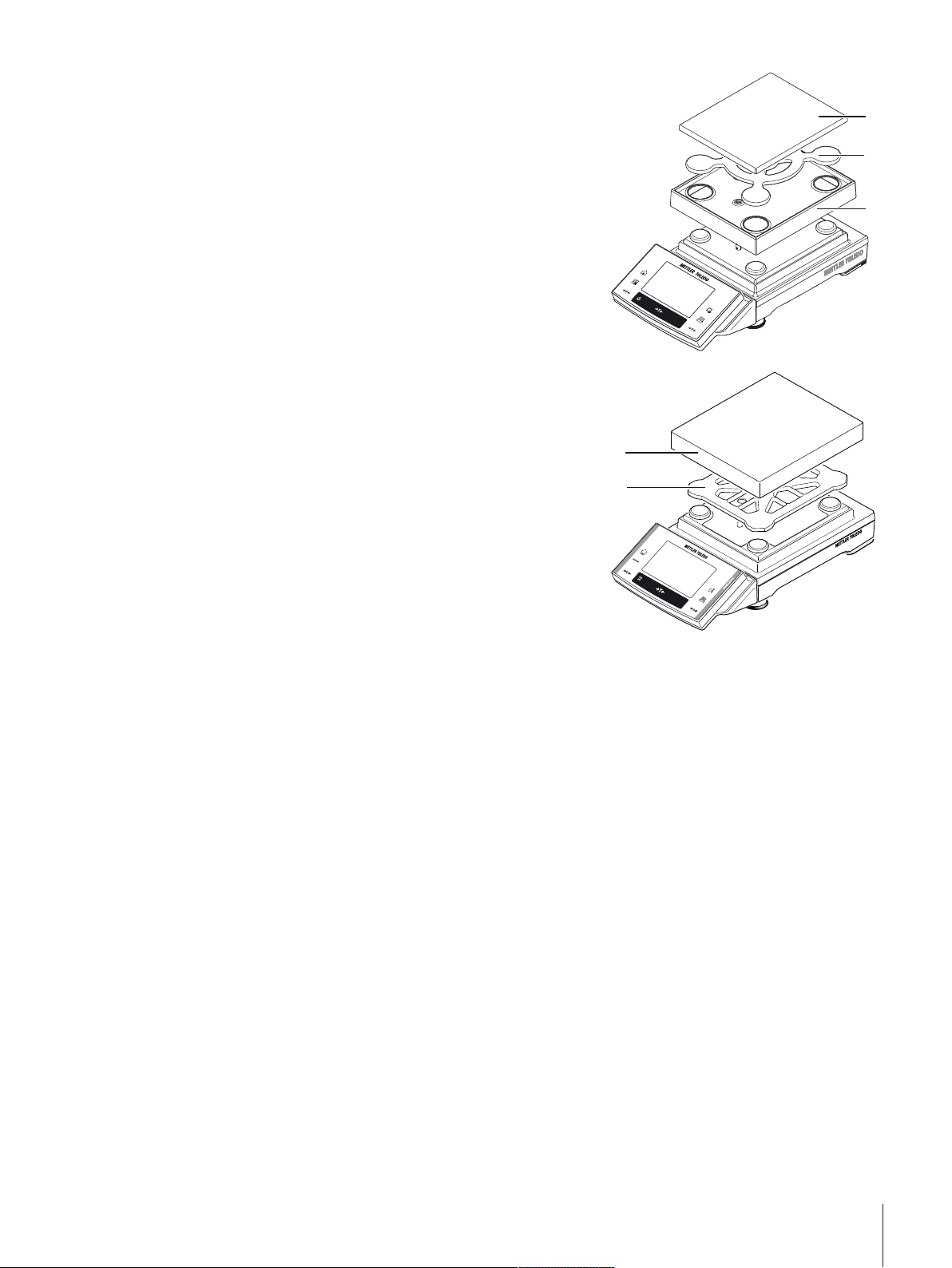

4.4.1 Installing the "Magic Cube" draft shield and weighing pan to the S weighing platform

Balances with readability of 1mg, S platform with draft

shield and SmartPan

1 Place the following components on the balance in the

specified order:

2 Place draft shield (1) with closed cover, and then open.

Attention

The U-shaped draft shield glass is not permanently connected

to the draft shield housing.

1 Always close the cover before picking up the draft shield.

2 Hold the entire draft shield by the housing at the back.

3 Always hold the draft shield with both hands and keep in a

horizontal position.

• Bottom plate (2).

• SmartPan (3).

• Weighing pan (4) (optional).

Balances with readability of 1 mg with SmartPan

- Place the following components on the balance in the

specified order:

• Drip tray (1)

• SmartPan (2)

Installation and Putting into Operation22 Precision Balances

Page 23

Balances with readability of 10mg, S platform with

2

1

3

1

2

SmartPan

- Place the following components on the balance in the

specified order:

• Drip tray (1).

• SmartPan (2).

• Standard weighing pan (3) (optional).

Note

For the minimization of the air drafts, faster stabilization time

and improved reproducibility, work without the standard

weighing pan.

Balances with readability of 0.1g, S platform

- Place the following components on the balance in the

specified order:

• Weighing pan support (1).

• Weighing pan (2).

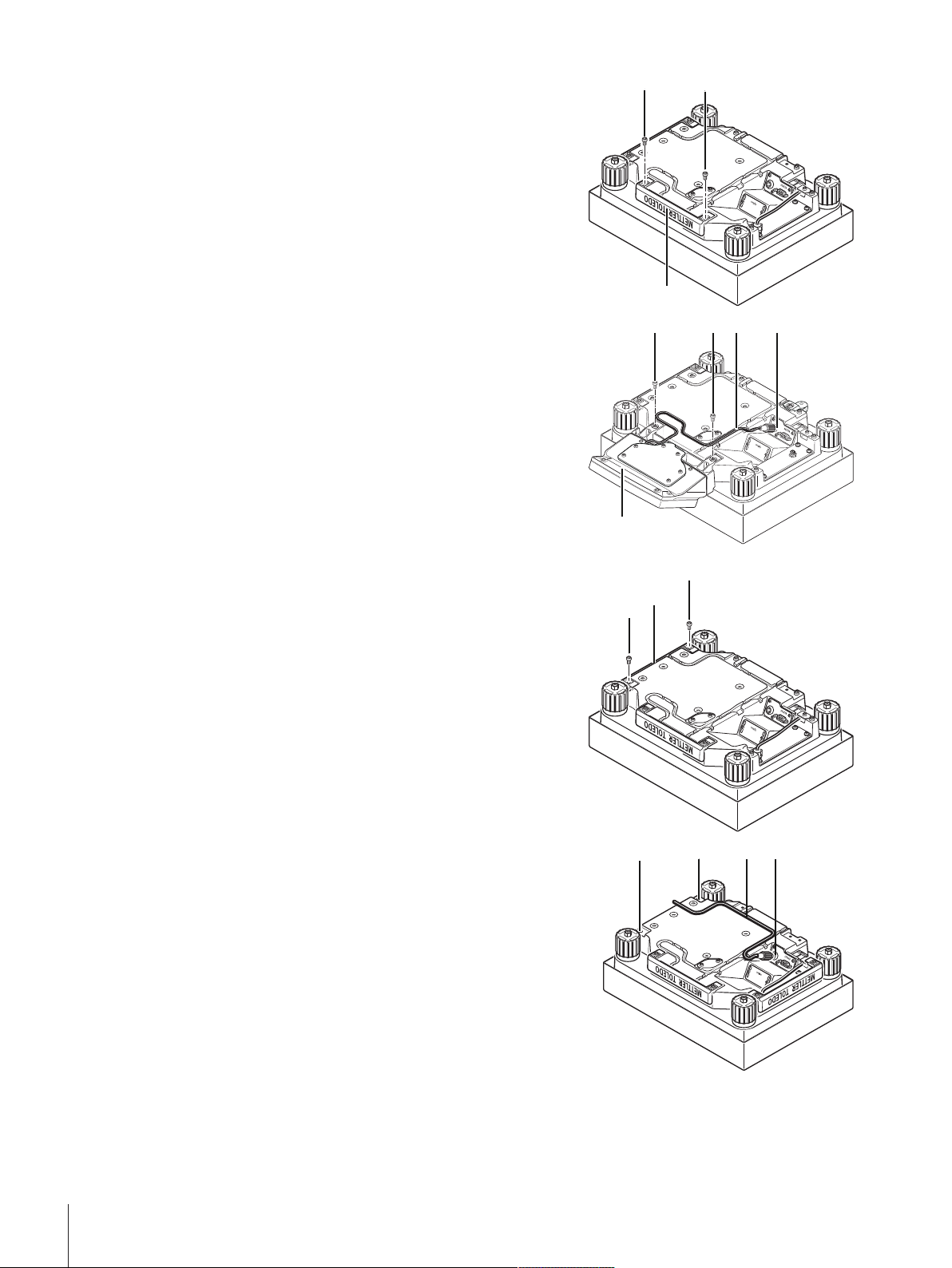

4.4.2 Placing the terminal on the L weighing platform

The terminal can be attached to the long or short side of the balance.

1 Mount the weighing pan.

2 Carefully turn the weighing platform over onto the weighing

pan.

Installation and Putting into Operation 23Precision Balances

Page 24

Attaching the terminal to the long side

A

1

2

2

22

5

3

4

2

2

1

3

46

6

1 Dismantle the cover (1) by removing the 2 screws (2).

2 Attach the terminal to the terminal support (5) as shown,

using the screws (2) from the cover that was removed.

3 Insert the terminal cable (3) into the cable channel, as

shown.

4 Screw the connector of the terminal cable into the socket

(4).

5 Turn the balance back over into position.

Attaching the terminal to the short side

1 Dismantle the cover (1) by removing the 2 screws (2).

2 Attach the terminal with terminal support to the points of

attachment (6) with the screws (2).

3 Insert the terminal cable (3) into the cable channel, as

shown.

4 Screw the connector of the terminal cable into the socket

(4).

5 Turn the balance back over into position.

Installation and Putting into Operation24 Precision Balances

Page 25

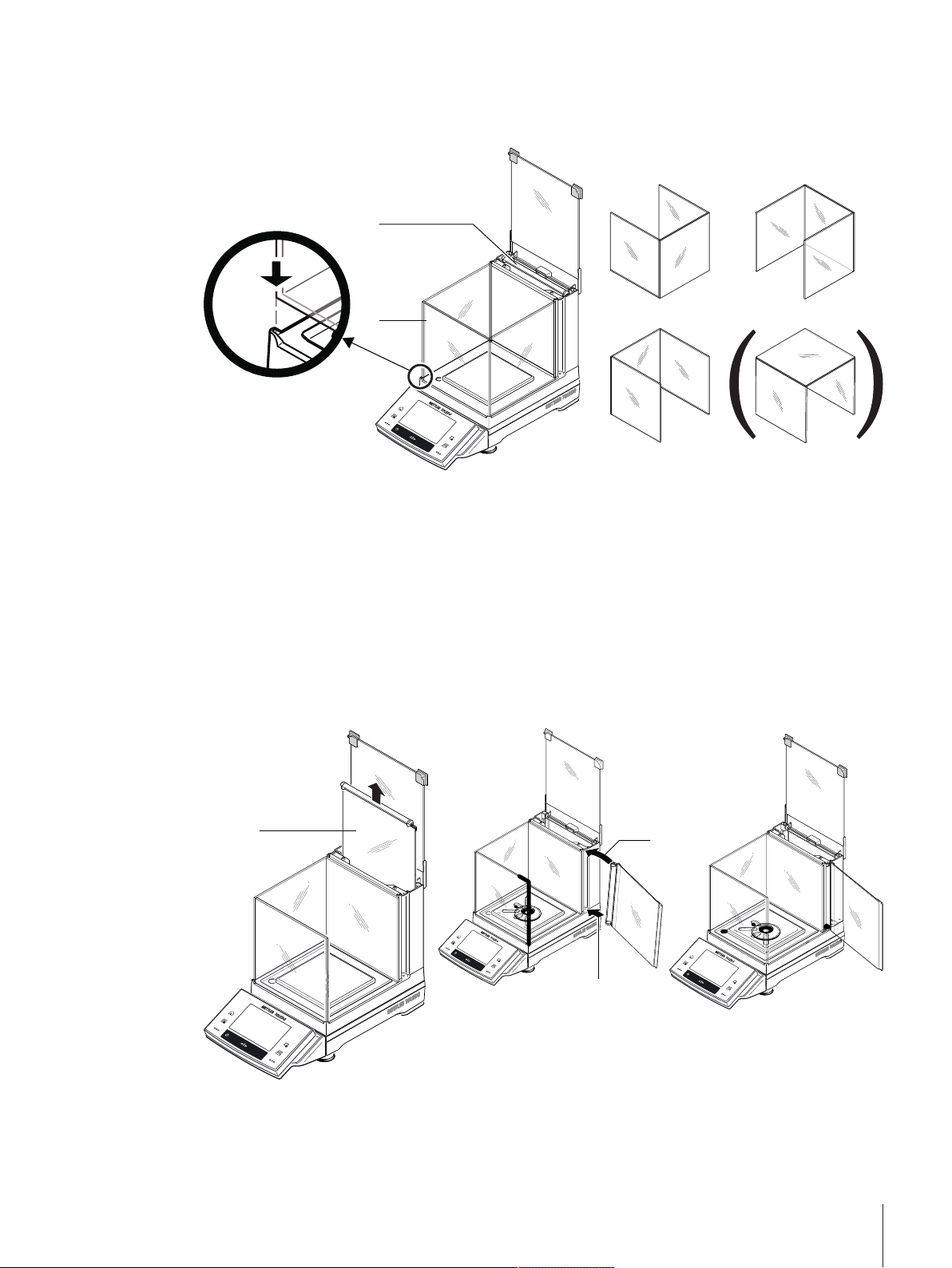

4.4.3 Setting options with the draft shield glass (1mg Models)

2

1

3

2

1

The U-shaped draft shield glass (1) supports different setting options. The draft shield housing contains an

additional draft shield pane (2), which can be used as required.

4.4.4 Using the additional draft shield door (1mg Models)

1 Open the draft shield cover.

2 Pull the draft shield door (1) upwards out of the rear panel.

3 Insert the draft shield door into the housing from the side (left or right).

4 First position the draft shield door at the bottom (2) and then swivel it upwards (3) until you feel it

snap into place, see diagram.

Attention

Check that the draft shield door is inserted correctly. The door must close easily. When transporting the

balance, except for the terminal, also hold the draft shield, as this is fitted and not permanently

connected to the weighing platform.

Installation and Putting into Operation 25Precision Balances

Page 26

4.5 Connecting the balance

1

2

WARNING

Risk of electric shock

a) To connect the balance, only use the supplied three-core power cable with equipment

grounding conductor.

b) Only connect the balance to a three-pin power socket with earthing contact.

c) Only standardized extension cable with equipment grounding conductor must be used

for operation of the balance.

d) Intentional disconnection of the equipment grounding conductor is forbidden.

S weighing platform

The balance is supplied with an AC adapter and country-specific power cable. The AC adapter is suitable for

use with the following voltage range:

100 – 240 VAC, 50/60Hz.

Attention

• Check whether your local power supply falls within this range. If this is not the case, under no circumstances connect the AC adapter to the power supply, but contact a METTLER TOLEDO representative.

• The power plug must be accessible at all times.

• Prior to use, check the power cable for damage.

• Route the cable in such a way that it cannot be damaged or cause a hindrance when working.

• Ensure that no liquid comes into contact with the AC adapter.

Connecting S weighing platform

§ Balance and terminal are at the final location.

1 Connect the AC adapter (1) to the connection socket (2) at

the rear of the balance.

2 Connect the AC adapter (1) to the power supply.

ð The balance performs a self-test after connection to the

power supply and is then ready to use.

L weighing platform

• The balance is supplied with a country-specific power cable.

• Check whether your local power supply falls within this range. If this is not the case, under no circumstances connect the balance to the power supply, but contact a METTLER TOLEDO representative.

• The power plug must be accessible at all times.

Installation and Putting into Operation26 Precision Balances

Page 27

• Prior to use, check the power cable for damage.

• Route the cable in such a way that it cannot be damaged or cause a hindrance when working.

• Ensure that the connectors can never come into contact with liquids.

Connecting L weighing platform

§ Balance and terminal are at the final location.

- Connect the balance to the power supply.

ð The balance performs a self-test after connection to the power supply and is then ready to use.

4.6 Setting up the balance

4.6.1 Weighing for the first time

After commissioning the new balance, the first weighing can be carried out. This will also familiarize you

with the operation of the balance.

4.6.1.1 Switching on the balance

§ Balance is connected to the power supply.

§ Terminal and balance are interconnected.

- To switch on, press [

ð Display appears.

ð Balance is ready to use.

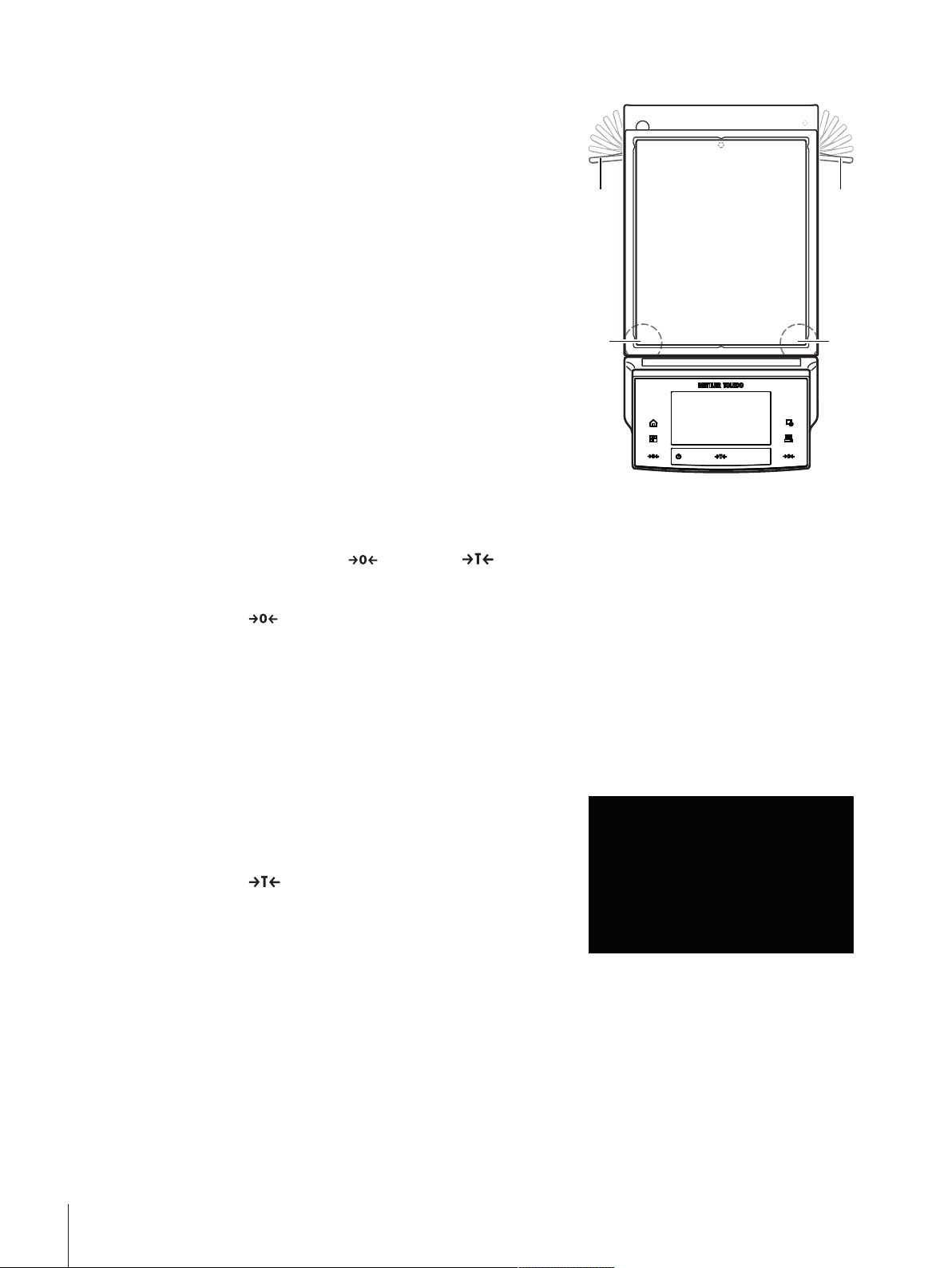

4.6.1.2 Leveling the balance

Balances with readability of 1 mg, S platform and L platform

1 Align the balance horizontally.

2 Turning the leveling screws of the housing until the air

bubble is in the inner circle of the level indicator.

ð The position of the air bubble illustrates which leveling

screw you need to turn (L = left leveling screw, R = right

leveling screw) and in which direction so that the air

bubble moves to the center.

Example

In this example, turn the left leveling screw counterclockwise.

].

Installation and Putting into Operation 27Precision Balances

Page 28

Balances with safety feet

11

22

1 Remove the clamps (1) for the safety feet by turning them

outwards.

Attention

Turn the clamps (1) outwards as far as they will go (~

90°), so that the safety feet can move freely.

2 Now level the balance by turning both leveling screws (2)

as shown above until the air bubble is in the inner circle of

the level indicator.

3 Secure the safety feet by turning the clamps (1) inwards as

far as they will go.

Note

The balance must be leveled and adjusted each time it is

moved to a new location.

4.6.1.3 Performing a simple weighing

To perform a simple weighing, only the keys in the lower part of the terminal are required. The balance has

separate keys for zeroing [

] and taring [ ].

Zeroing

- Press [

ð Zeroing

After zeroing, all weights also the tare weight apply to this new zero point and the following apply: tare

weight = 0, net weight = gross weight = 0.

].

Taring

Note

A negative weight is not permitted. An error message is generated. When the stability detector icon

extinguishes (small ring left of the weight display), the indication is stable. The weight is displayed.

§ If a weighing container is used, the balance must first be set

to zero.

1 Place the container on the balance.

2 Press [

ð The balance is tared.

ð The weight of the container is set as the new tare weight and

the previous tare (if available) is overwritten.

ð The Net display signals that all indicated weights are net

weights.

].

Congratulations!

The first weighing is now complete. The following sections contain further information about the extensive

functions and applications of this balance.

4.7 Transporting the balance

Observe the following instructions to transport your balance to a new location.

Installation and Putting into Operation28 Precision Balances

Page 29

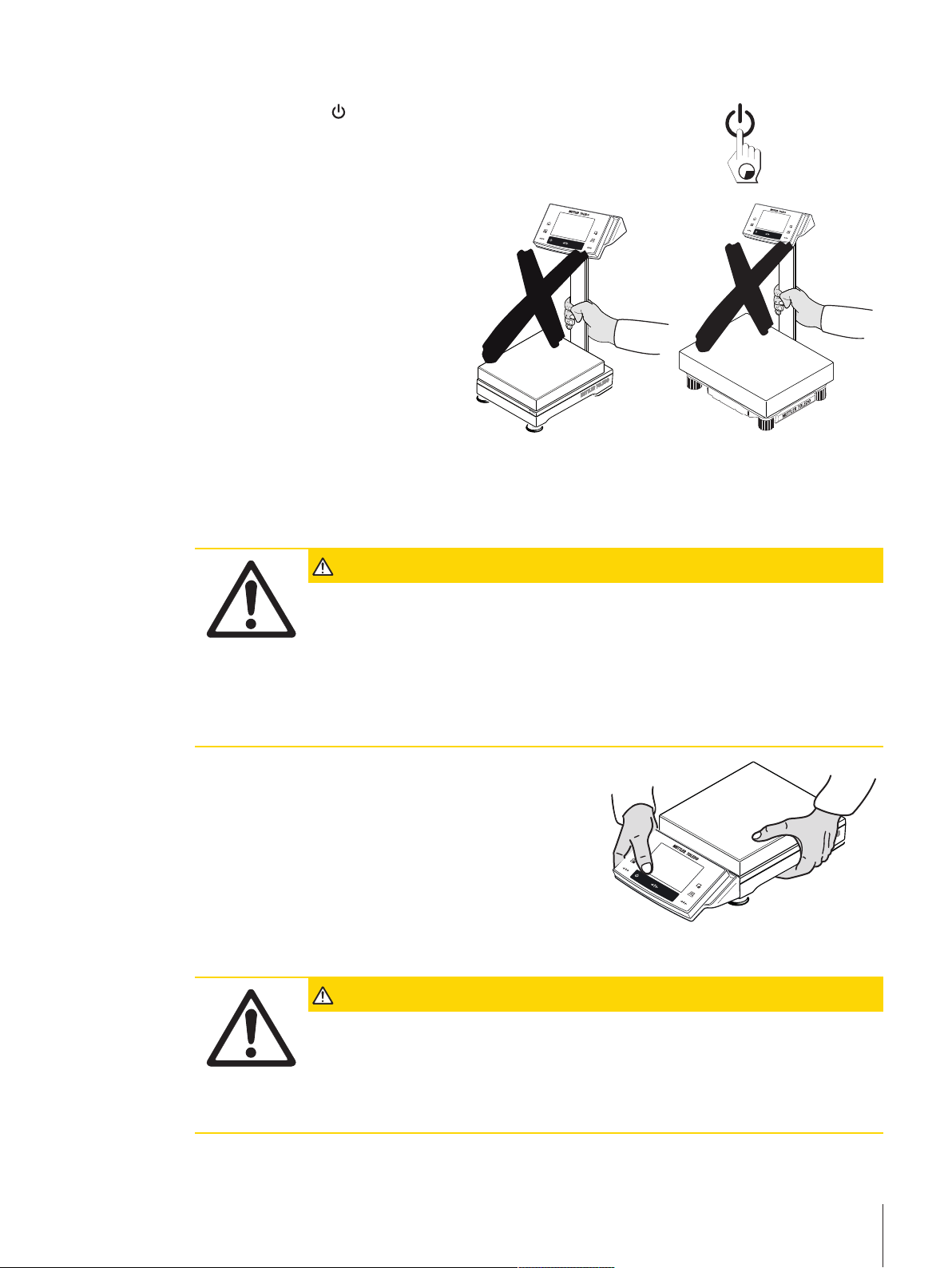

Switching off the balance

1 Press and hold [

2 Disconnect the balance from the power supply.

3 Disconnect all interface cables.

Attention

Alway carry the body of the balance. Do

not hold the balance by the stand.

] until Off appears in the display.

4.7.1 Transport over short distances

If you wish to move your balance over a short distance to a new location, proceed as follows.

S weighing platform

CAUTION

Damage of device

Never lift the balance by the glass draft shield or terminal stand, as this can cause

damage! The draft shield or terminal stand is not fastened to the balance.

Never lift the balance by the terminal stand, as this can cause damage! The terminal

stand is not fastened to the balance.

If the terminal is not permanently connected to the weighing platform, the balance must

therefore be carried horizontally.

1 Hold the weighing platform with both hands and lift

horizontally.

2 Carry the balance horizontally to the new location.

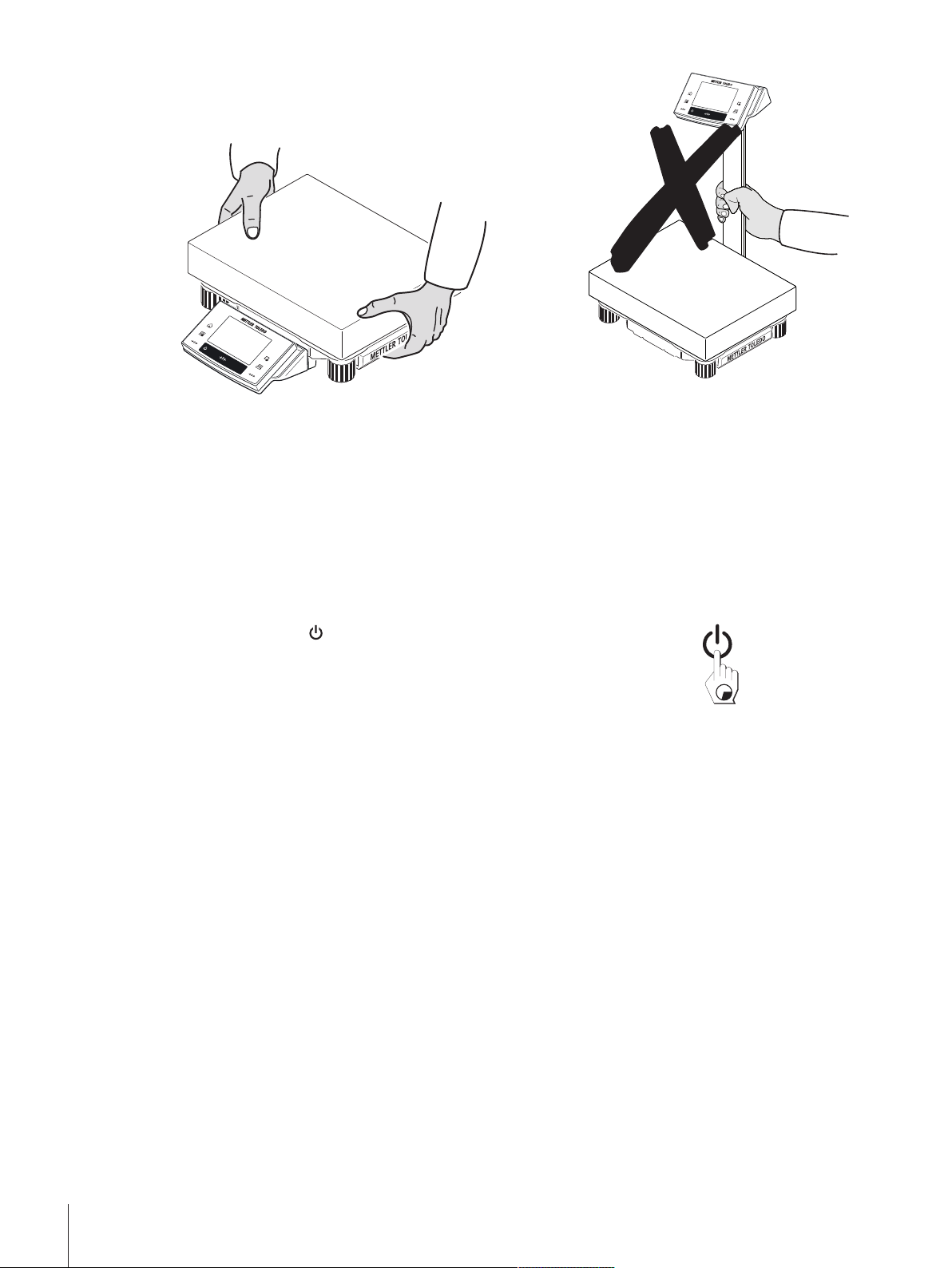

L weighing platform

CAUTION

Damage of Device

Never lift the balance by the terminal stand, as this can cause damage! The terminal

stand is not fastened to the balance.

If the terminal is not permanently connected to the weighing platform, the balance must

therefore be carried horizontally.

Installation and Putting into Operation 29Precision Balances

Page 30

1 Hold the weighing platform with both hands and lift

horizontally.

2 Carry the balance horizontally to the new location.

4.7.2 Transport over long distances

The complete original packaging must be used for transportation or shipment of the balance over long

distances or if it cannot be ensured that the balance will be transported upright.

4.8 Below-the-balance weighing

Your balance is equipped with a hanger for carrying out weighings below the work surface (weighing below

the balance).

Switching off the balance

1 Press and hold [

2 Disconnect the balance from the power supply.

3 Disconnect all interface cables.

] until Off appears in the display.

S weighing platform

1 Attention

Models with a glass draft shield:

Carefully lift the draft shield from the weighing platform and put it aside.

2 Remove the weighing pan (model dependent).

3 Remove the draft shield element (0.1 mg models).

4 Remove the weighing pan and pan support (model dependent).

5 Remove the SmartPan and drip tray (model dependent).

6 Lift the terminal from the terminal support (optional).

7 Place the terminal to the side of the weighing platform.

8 Remove the terminal support (optional).

Installation and Putting into Operation30 Precision Balances

Page 31

9 Tilt the weighing platform backwards until the cover plate

2

1 1

2

1

1

(2) is visible.

Attention

Do not place the weighing platform on the location bolt for

the pan support (0.1 mg and 1 mg models).

10 Remove the 2 screws (1) and the cover plate (2).

ð The hanger is now accessible.

11 Fasten the hooks (option) with screws.

12 Return the balance to its normal position and simply reinstall all components in the reverse order.

L weighing platform

Note

For below-the-balance weighing you will need hook 11132565 from the accessories range. Thread size

M4.

1 Carefully turn the weighing platform over onto the weighing

pan.

2 Remove the 2 screws (1) and the cover plate (2).

ð The hanger is now accessible.

3 Fasten the hooks (optional) with screws.

4 Return the balance to its normal position and simply reinstall

all components in the reverse order.

Installation and Putting into Operation 31Precision Balances

Page 32

5 System Settings

System

Adjust/Test

FACT On

FACT

FACT

Temp.Criterion 2 Kelvin

Protocol Trigger On

History

Adj. History

Adj. History Selection

Selection

Adjust.int x

Adjust.ext Temperature x

Time Adjust. x

Display Datasets Last 50

Protocol

Date/Time x

Balance Type x

SNR x

SW-Version Balance ID Weight ID Certificate No. -

Temperature Nominal Weight x

Actual Weight x

Diff. x

Signature x

Weighing parameters

Weighing Mode Universal

Environment Standard

Value Release Fast

AutoZero On

Language

Language English

Peripherals

Printer RS232 built-in

Host Off

LabX Off

LabX Controlled Device

Off

Secondary Display Off

Bar Code Off

Ext. Keyboard Off

Terminal

Brightness 100

Contrast 50

Sound 70

Touch Function On

Date/Time

Date Format D.MMM YYYY

Time Format 24:MM

Date/Time Display Date

Access Rights

System No Protection

Weighing parameters

No Protection

Application

No Protection

Application Setup

No Protection

Access Rights

No Protection

Standby

Standby Off

Switch

Aux 1 Off

Aux 2 Off

Balance Info

Balance ID

Balance Info

Navigation: [

] > [System]

This section describes the procedure for adapting the balance to suit specific requirements. The system

settings apply to the entire weighing system and therefore to all applications.

- The system settings can be displayed by pressing [

] and subsequently the [System] button.

ð The [System] window is displayed.

Printing all System settings

§ A printer is connected and activated.

- If you are in the root of the System settings, press [

].

Note

• The detail of the protocol depends on the point at which printout is activated in the system settings.

When [

] is pressed in the uppermost level of the system settings, all system settings are recorded. If

printing is started in the [Peripherals] submenu for example, only the settings for the peripheral devices

are recorded.

• The Test/Adj. Weights, Test Sequences and Tasks submenus in the [Adjust/Test] menu must be

printed separately.

Example: Printout

System Settings32 Precision Balances

System settings overview

Designation Explanation

Adjust/Test

Wghparam

Language

Settings for adjustment and test functions for verification of

adjustments.

Settings for adjusting the balance to specific weighing

conditions.

Select dialog language.

Page 33

Peripherals

Configuration of interface for various peripheral devices.

Option

Terminal

Date/Time

Rights

Standby

Switch

Factory

Info

Menu structure

Main menu Submenu Further information

Adjust/Test Test/Adj. Weights See Settings for adjustments and

Test Sequences See Test sequences [}36]

Tasks See Tasks [}45]

FACT / Int. Adj. See FACT/int. Adjustment [}46]

Test History See Test history [}48]

Protocol See Protocol – Definition of

Wghparam Weighing Mode See Weighing parameters [}49]

Environment

Value Release

AutoZero

Language Language See Language [}51]

Peripherals Printer See Peripherals [}51]

Host

LabX

LabX Controlled Device

Secondary Display

Bar Code

Ext. Keyboard

Option DHCP See Option [}53]

IP-Address

Subnet Mask

Standard Gateway

Domain Name Server

Hostname

Configuration of the optional interface.

Settings for the display (e.g. brightness) and for the behavior

of the terminal.

Entry of date and time and selection of required display

formats.

Assignment of access rights and passwords for weighing

functions and menus.

Settings for the standby mode.

Settings for external momentary contact switches.

Reset the factory settings.

Display/printing of balance information.

tests [}35]

adjustment and test reports [}49]

System Settings 33Precision Balances

Page 34

Terminal Brightness See Terminal [}54]

Contrast

Sound

Touch Function

Touchadjust

Date/Time Date Format See Date/Time [}55]

Date

Time Format

Time

Date/Time

Rights Password See Rights [}56]

System

Weighing parameters

Application

Application Setup

Access Rights

Standby Standby See Standby [}57]

Switch Aux 1 See Switch [}57]

Aux 2

Factory Factory See Factory [}57]

Info Balance ID See Info [}58]

Info

5.1 Adjustment/Test

Introduction for adjustment and tests

This section applies to the configuration of the balance for carrying out adjustments and tests.

§ The balance is assembled and installed as stated in the operating instructions.

§ The balance is leveled.

1 Connect the printer to printout settings or reports.

2 Activate the printer as an output device in the peripheral device settings.

Principles for carrying out adjustments and tests

Balances play a decisive role in research, development, quality assurance and production. Weighing errors

cost time and money and non-compliance with legal requirements can be detrimental to health. Good

Weighing Practice™ (GWP®) is the science based global weighing standard for the efficient life cycle

management of weighing systems. The risk-based approach allows you to improve control of your whole

measuring process, which in turn helps to avoid costly out of specification results. Our Feasible Cost

Savings Optimized routine testing based on your risk management ensures consistently good quality in

critical applications. Additionally, a sound testing scheme saves costs by eliminating unnecessary tests in

lower risk processes.

Test Manager was specially developed, as part of our balance firmware, to simplify routine tests. In

combination with GWP® Verification, efficient balance testing is ensured and specific audit requirements

can be fulfilled more easily.

u www.mt.com/GWPVerification

System Settings34 Precision Balances

Page 35

Test Manager

Test Manager is a collection of security functions for the balance. These individually programmable

functions help to maintain measuring accuracy via e.g. routine testing of the balance with external test

weights. By providing active support with respect to test requests and predefined guided sequences will

ensure that outstanding tests are not forgotten and complex tasks such as repeatability tests can be carried

out easily.

Additional functions were developed to prevent measuring errors. These are, e.g. temperature sensors that

can register possible temperature changes in the measuring cell and initiate adjustment by using internal

weights which facilitate and maintain consistent accuracy.

The flexibility and customization of the test manager results in user guidance and appropriate messages,

while performing specific operations, followed by complete records and documentation via printout or in

conjunction with PC software.

The configuration process

In order to prepare the balance for a routine test and adjustment, a straightforward 3-stage process is

required:

1 Register the test weights.

ð Information relating to all test weights is stored in a balance database.

2 Define the test sequence.

ð Describes the type of test (method) and the test weight and tolerance to be carried out.

3 Carry out the test sequence.

ð The task defines when and how the test sequence must be started and carried out.

Documentation and storage

To ensure the traceability of adjustments and tests, it is important to print the settings and periodically the

results of the test history.

The results are stored in the test history up to a maximum of 120 entries. When this limit is reached, the

oldest results are overwritten.

Each time the test sequence is changed, the version number is increased and displayed in the right top

corner of the display. It is recommended to print and file each new version in a folder.

A complete list of individual settings can be printed by pressing the [

open.

] key while the respective menu is

Settings for adjustments and tests

Navigation: [

This section describes all menu options and parameters relating to adjustment and testing of the balance.

For carrying out adjustments and tests, see Balance adjustment and testing [}75].

The arrow buttons can be used to page forward or back to a menu page.

You can define the following parameters:

Menu item Explanation Further information

Test/Adj.

Weights

Test Sequences

Tasks

FACT / Int. Adj.

Test History

Protocol

] > [System] > [Adjust/Test]

Define the test weights and parameters for

adjustment. Procedures for testing or adjustment.

Defines the parameters of a test sequence for

testing and behavior of the balance.

Defines the task of a test sequence.

Fully automatic internal balance adjustment.

Defines the settings for the test history.

Defines the settings for the adjustment and test

protocols.

See Test/Adjustment - weight

settings [}36]

See Test sequences [}36]

See Tasks [}45]

See FACT/int. Adjustment [}46]

See Test history [}48]

See Protocol – Definition of

adjustment and test reports [}49]

System Settings 35Precision Balances

Page 36

5.1.1 Test/Adjustment - weight settings

Navigation: [

This menu can be used to enter the designations or numbers of the certificate supplied with the respective

test weight. This enables each external test weight to be clearly assigned to a specific certificate. Up to 12

external test weights can be configured. These test weights are used to carry out external tests and

adjustments.

1 Tap [Define].

ð Test/Adj. Weights window is displayed.

2 Select an undefined weight or the name of the weight, the parameters of which are to be updated.

3 Tap [Define].

4 Change the settings and confirm with [OK].

ð The defined weights are available for selection in the test sequences.

Note

When the weight list is displayed, all parameters of the 12 test weights can be printed out with [

] > [System] > [Adjust/Test] > Test/Adj. Weights

].

Test/Adj. Weight 1...Test/Adj. Weight12

You can define the following parameters:

Parameters Explanation Values

Name

Weight ID

Class

Certificate No.

Weight Set No.

Actual Value

Next Recalibration

* Factory setting

Defines a name for a test weight (max. 20 characters). Any

(Test/Adj. Weights)*

Defines the identification (ID) of the weight (max. 20

characters).

Defines the class of the weight.

Note

Own can be selected if no other class can be used.

Defines the certificate number of the external test weight used

(max. 20 characters).

Defines the identification number of the set of weights if the test

weight belongs to a set of weights (max. 20 characters).

Weight from the weight certificate. Irrespective of the type of

balance, the full value should be taken over without taking the

decimal places of the balance into account (e.g. 20.00124

g).

Note

Methods use the actual value; this is rounded to the maximum

decimal places of the balance and used for calculation.

Entry of the date of the next weight calibration.

Note

If no weight calibration is planned, the default value

(31.12.2099) should be maintained .

Any

E1* | E2 | F1 | F2 | M1

| M2 | M3 | ASTM1 |

ASTM2 | ASTM3 |

ASTM4 | ASTM5 |

ASTM6 | ASTM7 | Own

Any

Any

Weight

(0 g)*

DD.MM.YYYY

(31.12.2099)*

5.1.2 Test sequences

Navigation: [

Test sequences define which test is carried out with which test weight. The user is guided through.

System Settings36 Precision Balances

] > [System] > [Adjust/Test] > Test Sequences

Page 37

Note

The test should be carried out according to GWP® or another QM systems.

When Test Sequences is selected, a list of test sequences, the parameters of which can be adapted or

overwritten, appears.

Up to 12 test sequences can be defined.

Note

In the test sequence you define among others the type of the test (= Method) and the weights to be used for

this method. Before these weights can be selected, they have to be defined in [

Test] > Test/Adj. Weights.

§ The test weights are defined.

1 Tap [Define].

ð Test Sequences window appears.

2 Select an undefined or existing test sequence, for example Test Sequence 1 to be configured or

adapted.

3 Tap [Define].

ð Test Sequence window appears.

4 Enter the designations and parameters and confirm with [OK].

ð The test sequence is stored in the Test Sequence menu.

ð Each time a test sequence is stored, the version number is increased by 1. The version number is

shown at the top right of the display.

The arrow buttons can be used to page forward or back to a menu page.

Note

When the test sequence list is displayed, all parameters of the 12 test sequences can be printed with [

] > [System] > [Adjust/

].

Configuration of test sequence parameters

Navigation: [

You can define the following parameters:

Parameters Explanation Values

Name

Preparation

Instructions

] > [System] > [Adjust/Test] > Test Sequences > Test Sequence 1

Defines a designation for a test sequence (max. 20

characters).

Note

Choose a comprehensible name to enable clear identification

and easy traceability.

Selection of preparatory instructions.

None = no preparatory instructions are displayed in the test

sequence.

This is normally used for test sequences requiring no user

actions, e.g. test sequences with the SERVICE method.

Standard = the following preparatory instructions are

displayed. These correspond to the typical SOP standard.

1 Clean the weighing pan.

2 Level the balance.

3 Switch on the printer.

4 Have the test weights ready.

Any

(Test Sequence 1)*

None* | Standard

5 Have the weight tweezers/fork ready.

System Settings 37Precision Balances

Page 38

Method

Action if Failure

Instructions if

Failure

Code to

Unblock

Entry in GWP

History

* Factory setting

For more details about Method see Method [}38], and Action if Failure see Action if failure [}44]

Describes the type of test to be carried out and defines the

main purpose of a test sequence. The test weights and

respective tolerances to be used must be defined as part of the

method.

Defines how the balance should react if the test fails or is

aborted.

Defines the instructions.

This setting is independent of the parameters Action if Failure

and is displayed each time a test sequence fails.

None = the test sequence Name has failed.

Standard = the test sequence Name has failed.

The balance is outside the defined tolerances.

Contact a responsible person within your company or

METTLER TOLEDO service.

System release.

Note

If Action if Failure None is selected, a failed test sequence will

never block the balance.

Defines whether the test result is stored in the GWP history.

Yes = result of test sequence is stored.

No = result of test sequence is not stored.

Note

If 120 entries are exceeded, the oldest result is overwritten with

the newest result.

None | EC | RP1 |

RPT1 | SE1 | SE2 |

SERVICE | SET1 |

SET2

None | Warning |

Attempt

None* | Standard

Any

(Z)*

Yes | No*

5.1.2.1 Method

Navigation: [

A method describes the type of test to be carried out and defines the main purpose of a test sequence. The

test weights and respective tolerances to be used must be defined as part of the method. There are 8

different methods available.

You can define the following parameters:

Menu item Explanation Further information

None

EC

RP1

RPT1

SE1

SE2

SERVICE

SET1

] > [System] > [Adjust/Test] > Test Sequences > Test Sequence 1 > Method

No method has been selected.

Method for eccentric load test.

Method for repeatability test.

Method for repeatability test with tare weight.

Method for sensitivity test with one test weight.

Method for sensitivity test with two test weights.

Service method.

Method for sensitivity test with tare weight and

one test weight.

See EC - eccentric load test

[}39]

See RP1 - repeatability test

[}39]

See RPT1 - repeatability test with

tare weight [}40]

See SE1 - sensitivity test with one

weight [}42]

See SE2 - sensitivity test with two

weights [}42]

See SERVICE - reminder [}42]

See SET1 - sensitivity test with tare

and one test weight [}43]

System Settings38 Precision Balances

Page 39

SET2

5.1.2.1.1 EC - eccentric load test

Method for sensitivity test with tare weight and two

test weights.

See SET2 - sensitivity test with tare

and two test weights [}43]

Navigation: [

The purpose of the EC method (eccentric load test) is to ensure that every eccentric load deviation is within

the necessary user SOP tolerances.

The method uses two test tolerances (method tolerances), s T1 and s T2, which are applied to the test

sequence result. They work exactly the same as the weight tolerances T1 and T2.

] > [System] > [Adjust/Test] > Test Sequences > Test Sequence 1 > Method > [EC]

Test Weight

Navigation: [

Test Weight

You can define the following parameters:

Parameters Explanation Values

Test/Adj.

Weight

Tolerances

] > [System] > [Adjust/Test] > Test Sequences > Test Sequence 1 > Method > [EC] >

Selects the predefined test weight.

Test/Adj. Weight 1 … Test/Adj. Weight12 = defined in Test/

Adj. Weights menu item.

It is recommended to set the test weight tolerances to 100%.

Because for this kind of test the test tolerance is relevant.

Test/Adj. Weight 1 |

Test/Adj. Weight 2 | ...

| Test/Adj. Weight12

Tolerance T1 | Name

T1 | Tolerance T2 |

Name T2

Tolerances for eccentric load deviation

Navigation: [

Test Weight > Tolerance for Eccentricity Dev.

You can define the following parameters:

] > [System] > [Adjust/Test] > Test Sequences > Test Sequence 1 > Method > [EC] >

Parameters Explanation Values

Tolerance EC

T1

Name EC T1

Tolerance EC

T2

Name EC T2

* Factory setting

5.1.2.1.2 RP1 - repeatability test

Navigation: [

The RP1 method calculates the mean and standard deviation (Symbol s) of a series of measurements with

a single test weight in order to determine the repeatability of the balance.

The method uses two result tolerances (method tolerances), s T1 and s T2, which are applied to the test

sequence result. They function similar to T1 and T2.

Defines the tolerance EC T1 for the eccentric load deviation.

If the result tolerance (method tolerance) EC T1 is exceeded,

the eccentric load test is passed with a warning.

Defines a designation for EC T1 (max. 20 characters). Any

Defines the tolerance EC T2 for the eccentric load deviation.

If the result tolerance (method tolerance) T2 is exceeded, the

eccentric load test fails.

Defines a designation for EC T2 (max. 20 characters). Any

] > [System] > [Adjust/Test] > Test Sequences > Test Sequence 1 > Method > [RP1]

Any

(0.10 g)*

(Warn Limit)*

Any

(0.10 g)*

(Control Limit)*

System Settings 39Precision Balances

Page 40

Test Weight

Navigation: [

Test Weight > Test/Adj. Weight

You can define the following parameters:

Parameters Explanation Values

Test/Adj.

Weight

Tolerances

] > [System] > [Adjust/Test] > Test Sequences > Test Sequence 1 > Method > [RP1] >

Selects the predefined test weight.

Test/Adj. Weight 1 … Test/Adj. Weight12 = defined in Test/

Adj. Weights menu item.

It is recommended to set the test weight tolerances to 100%.

Because for this kind of test the test tolerance is relevant.

Test/Adj. Weight 1 |

Test/Adj. Weight 2 | ...

| Test/Adj. Weight12

Tolerance T1 | Name

T1 | Tolerance T2 |

Name T2

Tolerances (s) for repeatability test

Navigation: [

Test Weight > Tolerances (s)

You can define the following parameters:

Parameters Explanation Values

Tolerance s T1

Name s T1

Tolerance s T2

Name s T2

* Factory setting

] > [System] > [Adjust/Test] > Test Sequences > Test Sequence 1 > Method > [RP1] >

Defines the tolerance s T1 for the repeatability test.

If the tolerance s T1 is exceeded, the repeatability test is

passed with a warning.

Defines a designation for s T1 (max. 20 characters). Any

Define the tolerance s T2 for the repeatability test.

If the tolerance s T2 is exceeded, the repeatability test fails.

Defines a designation for s T2 (max. 20 characters). Any

Any

(0.000 g)*

(Warn Limit)*

Any

(0.000 g)*

(Control Limit)*

Number of Repetitions

Navigation: [

Test Weight > Number of Repetitions

You can define the following parameters:

Parameters Explanation Values

Number of

Repetitions

* Factory setting

5.1.2.1.3 RPT1 - repeatability test with tare weight

Navigation: [

The RPT1 method calculates the mean and standard deviation (Symbol s) of a series of measurements with

two test weights in order to determine the repeatability. In contrast to the RP1 method, a second test weight

is used to simulate the use of a tare container.

The method uses two test tolerances (method tolerances), s T1 and s T2, which are applied to the test

sequence result. They work exactly the same as the weight tolerances T1 and T2.

] > [System] > [Adjust/Test] > Test Sequences > Test Sequence 1 > Method > [RP1] >

Defines the number of weight measurements of a series. 2 … 15

] > [System] > [Adjust/Test] > Test Sequences > Test Sequence 1 > Method > [RPT1]

(10)*

System Settings40 Precision Balances

Page 41

Tare Weight

Navigation: [

> Tare Weight > Test/Adj. Weight

You can define the following parameters:

Parameters Explanation Values

Tare Weight

Tolerances

] > [System] > [Adjust/Test] > Test Sequences > Test Sequence 1 > Method > [RPT1]

Selects the predefined test weight corresponding to the tare

container weight.

Test/Adj. Weight 1 … Test/Adj. Weight12 = defined in Test/

Adj. Weights menu item.

It is recommended to set the tare weight tolerances to 100%.

Test/Adj. Weight 1 |

Test/Adj. Weight 2 |...

| Test/Adj. Weight12

Tolerance T1 | Name

T1 | Tolerance T2 |

Name T2

Test Weight

Navigation: [

> Test Weight > Test/Adj. Weight

You can define the following parameters:

Parameters Explanation Values

Test/Adj.

Weight

Tolerances

] > [System] > [Adjust/Test] > Test Sequences > Test Sequence 1 > Method > [RPT1]

Selects the predefined test weight.

Test/Adj. Weight 1 … Test/Adj. Weight12 = defined in Test/

Adj. Weights menu item.

It is recommended to set the test weight tolerances to 100%.

Because for this kind of test the test tolerance is relevant.

Test/Adj. Weight 1 |

Test/Adj. Weight 2 | ...

| Test/Adj. Weight12

Tolerance T1 | Name

T1 | Tolerance T2 |

Name T2

Tolerances (s) for repeatability test

Navigation: [

> Test Weight > Tolerances (s)

You can define the following parameters:

Parameters Explanation Values

Tolerance s T1

Name s T1

Tolerance s T2

Name s T2

* Factory setting

] > [System] > [Adjust/Test] > Test Sequences > Test Sequence 1 > Method > [RPT1]

Defines the tolerance s T1 for the repeatability test.

If the tolerance s T1 is exceeded, the repeatability test is

passed with a warning.

Defines a designation for s T1 (max. 20 characters). Any

Define the tolerance s T2 for the repeatability test.

If the tolerance s T2 is exceeded, the repeatability test fails.

Defines a designation for s T2 (max. 20 characters). Any

Any

(0.000 g)*

(Warn Limit)*

Any

(0.000 g)*

(Control Limit)*

Number of Repetitions

Navigation: [

> Test Weight > Number of Repetitions

You can define the following parameters:

Parameters Explanation Values

Number of

Repetitions

* Factory setting

] > [System] > [Adjust/Test] > Test Sequences > Test Sequence 1 > Method > [RPT1]

Defines the number of weight measurements of a series. 2 … 15

(10)*

System Settings 41Precision Balances

Page 42

5.1.2.1.4 SE1 - sensitivity test with one weight

Navigation: [

The SE1 method tests the sensitivity of the balance with one test weight.

] > [System] > [Adjust/Test] > Test Sequences > Test Sequence 1 > Method > [SE1]

Test Weight

Navigation: [

Test Weight > Test/Adj. Weight

You can define the following parameters:

Parameters Explanation Values

Test/Adj.

Weight

Tolerances

5.1.2.1.5 SE2 - sensitivity test with two weights

Navigation: [

The SE2 method tests the sensitivity of the balance with two test weights.

] > [System] > [Adjust/Test] > Test Sequences > Test Sequence 1 > Method > [SE1] >

Selects the predefined test weight.

Test/Adj. Weight 1 … Test/Adj. Weight12 = defined in Test/

Adj. Weights menu item.

The test tolerances are used for the sensitivity test.

] > [System] > [Adjust/Test] > Test Sequences > Test Sequence 1 > Method > [SE2]

Test Weight 1 and Test Weight 2

Test/Adj. Weight 1 |

Test/Adj. Weight 2 | ...

| Test/Adj. Weight12

Tolerance T1 | Name

T1 | Tolerance T2 |

Name T2

Navigation: [

Test Weight 1 or Test Weight 2 > Test/Adj. Weight

You can define the following parameters:

Parameters Explanation Values

Test/Adj.

Weight

Tolerances

5.1.2.1.6 SERVICE - reminder

Navigation: [

[SERVICE]

The SERVICE method is more a reminder than a method. It is normally set to perform regular checks of

various data (dates) in the background. It is used e.g. as a reminder for the next service date or MinWeigh

date. The date is checked on a regular basis and a message appears when the defined task is due. The

SERVICE method can also be used as early pre-warning.

The SERVICE method can also only be used for the display of Preparation Instructions. For example, the

user is requested to level the balance on a daily basis. In this special case, the Preparation Instructions

must be set in the test sequence setting to Standard. Ensure that no elements are selected in the method

status.

Note

To enable this test sequence to be ended without user actions, Preparation Instructions must be set in the

test sequence to None.

You can define the following parameters:

] > [System] > [Adjust/Test] > Test Sequences > Test Sequence 1 > Method > [SE2] >

] > [System] > [Adjust/Test] > Test Sequences > Test Sequence 1 > Method >

Selects the predefined test weight.

Test/Adj. Weight 1 … Test/Adj. Weight12 = defined in Test/

Adj. Weights menu item.

The test tolerances are used for the sensitivity test.

Test/Adj. Weight 1 |

Test/Adj. Weight 2 | ...

| Test/Adj. Weight12

Tolerance T1 | Name

T1 | Tolerance T2 |

Name T2

System Settings42 Precision Balances

Page 43

Parameters Explanation Values

Status Defines the reminder target. This is either an event (Battery

Change, Service...) or a defined task.

Values can be

Early Warning

Alert

* Factory setting

5.1.2.1.7 SET1 - sensitivity test with tare and one test weight

Defines the pre-warning time.

Note

With one SERVICE reminder, several dates can be checked

simultaneously. The same pre-warning time applies to all

dates however. If different pre-warning times are necessary,

several SERVICE methods must be defined.

(deactivated) or (activated).

Battery Change |

Service | MinWeigh |

Weight Cal. | Task 01

… Task 12

1 … 365 days

(7 days)*

Navigation: [

The SET1 method tests the sensitivity of the balance with two test weights. The first test weight is used to

simulate a tare container.

] > [System] > [Adjust/Test] > Test Sequences > Test Sequence 1 > Method > [SET1]

Tare Weight

Navigation: [

> Tare Weight > Test/Adj. Weight

You can define the following parameters:

Parameters Explanation Values

Tare Weight

Tolerances

] > [System] > [Adjust/Test] > Test Sequences > Test Sequence 1 > Method > [SET1]

Selects the predefined test weight corresponding to the tare

container weight.

Test/Adj. Weight 1 … Test/Adj. Weight12 = defined in Test/

Adj. Weights menu item.

It is recommended to set the tare weight tolerances to 100%.

Test/Adj. Weight 1 |

Test/Adj. Weight 2 |...

| Test/Adj. Weight12

Tolerance T1 | Name

T1 | Tolerance T2 |

Name T2

Test Weight

Navigation: [

> Test Weight > Test/Adj. Weight

You can define the following parameters:

Parameters Explanation Values

Test/Adj.

Weight

Tolerances

] > [System] > [Adjust/Test] > Test Sequences > Test Sequence 1 > Method > [SET1]

Selects the predefined test weight.

Test/Adj. Weight 1 … Test/Adj. Weight12 = defined in Test/

Adj. Weights menu item.

The test tolerances are used for the sensitivity test.

Test/Adj. Weight 1 |

Test/Adj. Weight 2 | ...

| Test/Adj. Weight12

Tolerance T1 | Name

T1 | Tolerance T2 |

Name T2

5.1.2.1.8 SET2 - sensitivity test with tare and two test weights

Navigation: [

The SET2 method tests the sensitivity of the balance with three test weights. The first test weight (tare

weight) is used to simulate a tare container.

] > [System] > [Adjust/Test] > Test Sequences > Test Sequence 1 > Method > [SET2]

System Settings 43Precision Balances

Page 44

Test Weight 1 and Test Weight 2

Navigation: [

> Test Weight 1 or Test Weight 2 > Test/Adj. Weight

You can define the following parameters:

Parameters Explanation Values

Test/Adj.

Weight

Tolerances

] > [System] > [Adjust/Test] > Test Sequences > Test Sequence 1 > Method > [SET2]

Selects the predefined test weight.

Test/Adj. Weight 1 … Test/Adj. Weight12 = defined in Test/

Adj. Weights menu item.

The test tolerances are used for the sensitivity test.

Test/Adj. Weight 1 |

Test/Adj. Weight 2 | ...

| Test/Adj. Weight12

Tolerance T1 | Name

T1 | Tolerance T2 |

Name T2

Tare Weight

Navigation: [

> Tare Weight > Test/Adj. Weight

You can define the following parameters:

Parameters Explanation Values

Tare Weight

Tolerances

] > [System] > [Adjust/Test] > Test Sequences > Test Sequence 1 > Method > [SET2]

Selects the predefined test weight corresponding to the tare

container weight.

Test/Adj. Weight 1 … Test/Adj. Weight12 = defined in Test/