Page 1

Micro-Weighing Guide

Maximize Efficiency

in Micro-Weighing

Improve Quality

of Results

Ensure Safer

Operations

10 Steps

to Successful Micro-Weighing

Page 2

2

Page 3

10 Steps to Successful Micro-Weighing

Practical Weighing Guide

1. Which microbalance is right for me? 4

2. Where should I place the microbalance? 6

3. Why is calibration of the microbalance important? 7

4. How can I ensure accurate results every day? 8

5. How can I deal with drifting weight results? 9

6. How can I optimize working with small samples? 10

7. How can I clean my microbalance more easily? 11

8. How can I make the weighing process more efficient? 13

9. What data capture / data transfer options do I have? 14

10. Other helpful tips to optimize micro-weighing 15

3

Page 4

Micro-Weighing Guide

e

le

D

1. Which Microbalance is Right for Me?

Consider which criteria are relevant in choosing the right balance for your needs.

Every measurement on ANY balance is subject to uncertainty. Understanding this uncertainty is the key to

ensuring accurate weighing results and avoiding errors in downstream processing. For a microbalance, the

uncertainty is almost entirely due to repeatability (precision) when weighing small samples (i.e. at the low end

of the weighing range of a specific balance).

It is not the readability that determines the accuracy of a weighing instrument, but rather its repeatability,

ordepending on it, its minimum weight capability.

To find the appropriate microbalance for your needs you should define the smallest amount you want to weigh

and how accurately you need to weigh it (i.e. at what tolerance). From this basic information, the accuracy of the

required microbalance can be determined. Your weighing consultant can calculate this for you and verify that it

meets your daily needs:

Lab Technician

Sulfamidin Prep

Measurement uncertainty [%]

Accuracy limit:

Minimum weight

Methods

03:07

pm

Sulfamidin

B2

Protocol

g

Methods

0.0009999

Sampl

I

Delete protocol Edit method Complete task Add result

Process tolerance

of customer [%]

Smallest

net weight

Lab Technician

Sulfamidin Prep

Samp

I

Delete protocol Edit method Complete task Add result

Methods

Methods

0.005000

Sulfamidin

B2

03:07

pm

Protocol

g

Weight [g] Max.

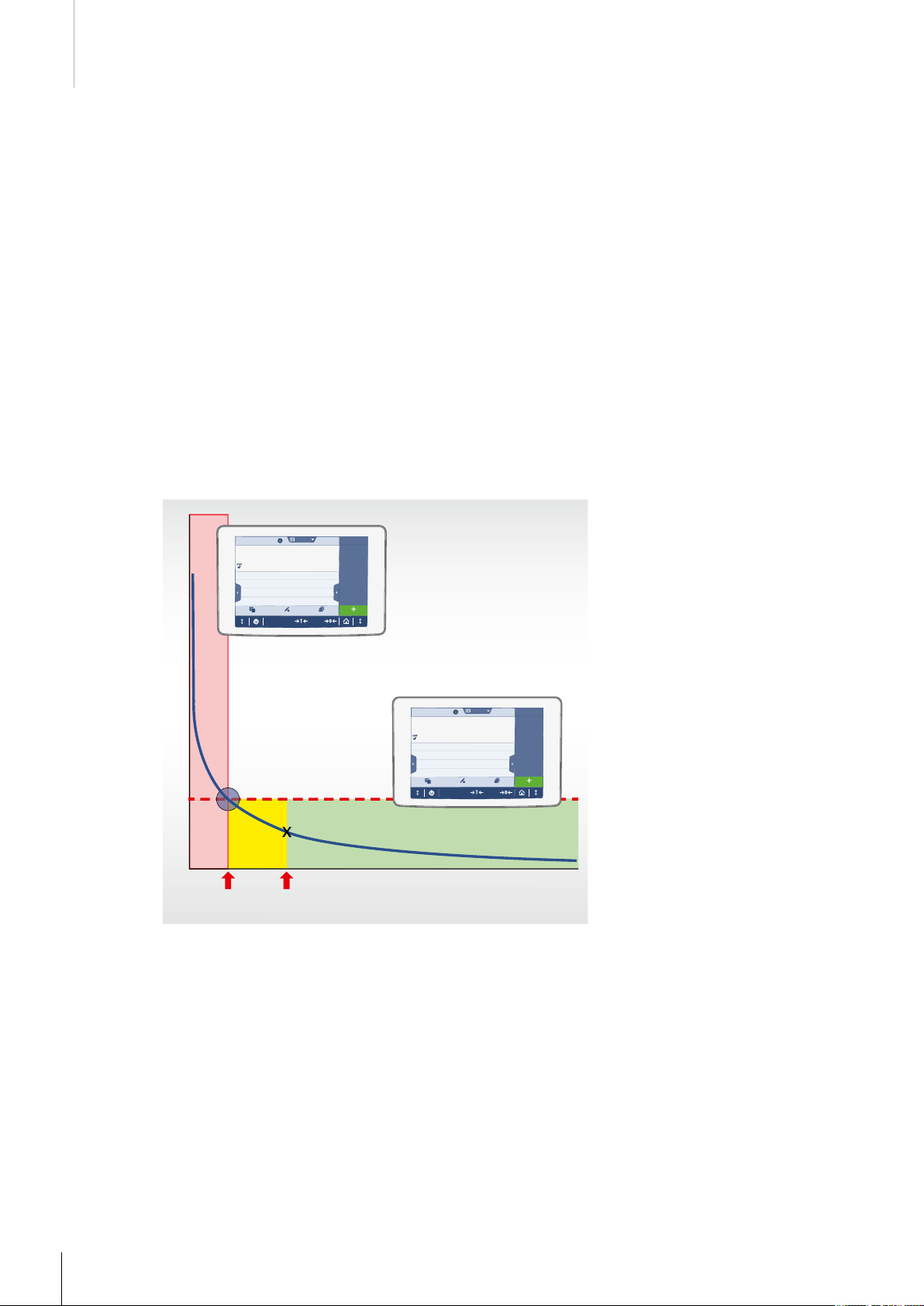

Fig. 1: Typical measurement uncertainty curve of

atypical ultra-microbalance. At the accuracy limit

the relative measurement uncertainty increases with

decreasing sample weights above the user defined

tolerances. The yellow area represents a safety margin between user formulated smallest net weight

and accuracy limit.

4

Page 5

Example

• Smallest sample typically weighed in (defined by user).

(smallest net weight = 2 mg)

• Tolerance required = 2 mg ± 10 μg [= 0.5%]

Formula applied to fulfill user requirement

Smallest net weight ≥ minimum weight * safety factor

Minimum weight = Repeatability of the balance * k / Required tolerance [%]

• For a safety factor of 2, select a balance with a repeatability ≤ 2.5 μg

Explanation of terms:

Safety factor: A safety margin to protect against variations in the weighing process, environmental conditions or

user influence. A safety factor of 2 is recommended for typical processes. For higher risk processes, a higher

safety factor is recommended.

Expansion factor (k): Typically an expansion factor k = 2 is used.

(For a Gaussian distribution, 95% of the results statistically fall within the k = 2 range;

99.7% of the results fall within k = 3).

Recommendation

A microbalance is advised for use in this application. An analytical balance has a repeatability of 7 µg and

is not accurate enough for this task, and an ultra-microbalance with a repeatability of 0.15 µg would allow

weighing much smaller amounts of sample as required and might not be needed. The XPR2 microbalance with

arepeatability of 0.5 μg fulfills the requirements perfectly.

Special Tip

• Ask your METTLER TOLEDO consultant about GWP® Recommendation which helps you select the right

weighing instrument based on your weighing requirements: www.mt.com/gwp-recommendation.

5

Page 6

Micro-Weighing Guide

2. Where Should I Place the Microbalance?

Several factors should be considered when choosing a suitable location for accurate weighing.

When choosing a location for your microbalance, take into consideration the three main external influences that

have an impact on the accuracy of microweighing: vibrations, air drafts and temperature variations. The impact

of these external influences can be prevented or minimized by taking simple precautions:

0.0000000 g

Administ

rator

Genera

l

W

eighing

Methods

0.0000000

03:07

pm

Press her

Sample

Delet

e protocol

Protocol

e

to e

nter target weight

g

Enter

her

e

E

di

t meth

od

C

om

plet

e

task

Add result

Fig.2: Microbalances are sensitive against environmental influences

and the installation place should be selected carefully.

• Vibrations

Use a solid, stable weighing table to reduce vibrations. Damper plates can be helpful in some cases.

Avoidpositioning the balance near mechanical equipment, such as pumps, etc.

• Air Drafts

Avoid locating the balance near an opening door or in a position where many people walk past.

Avoidpositioning near or under an air conditioning unit. Always close the draft shield during weighing

(andtare weighing) operations.

• Temperature Variations

Avoid locating the balance near any direct heat sources, such as radiators, or near to windows.

Special Tips

• Avoid vibrations and use an appropriate weighing table.

• Strong air drafts can be avoided by using an external draft shield.

• Find more useful accessories for controlling external influences at: www.mt.com/accessories.

6

Page 7

3. Why is Calibration of the Microbalance Important?

Ensure the accuracy of your microbalance in your laboratory.

The accuracy of the weighing device is determined by calibration. The calibration certificate is the basis

to prove that your microbalance is working correctly in accordance to your weighing requirements.

Manufacturer's specifications (or tolerances) are measured under standardized and stable conditions.

Asmicrobalances can be influenced by several external factors, it is important to understand how a specific

balance performs in its actual working environment.

± 0.005

± 0.001

± 0.002

5.000000 g

Fig. 3: At different locations the balance measurement uncertainty

may be different as well. With a calibration certificate you make

sure your microbalance is working correctly in accordance to your

weighing requirements.

• Balance calibration by a qualified service provider determines the measurement uncertainty over the whole

weighing range at the actual weighing location.

• The calibration certificate includes the reported measurement uncertainty:

U = U0 + C * I

(U0 is the measurement uncertainty at zero load, C is the parameter that describes the increase of the

measurement uncertainty with the load and I is the net load indication).

Since the external conditions and the balance performance can change over time, the calibration should be

carried out periodically.

Special Tips

• The XPR microbalance stores the parameters of the measurement uncertainty for full traceability:

www.mt.com/xpr-microbalances.

• GWP® Verification gives you clear advice how often you should calibrate your equipment. This advice is

based on your specific risk and process requirements: www.mt.com/gwp-verification.

• A qualified calibration certificate is provided by METTLER TOLEDO (e.g. Accuracy Calibration Certificate).

For more information go to www.mt.com/service or contact your local METTLER TOLEDO service office.

7

Page 8

Micro-Weighing Guide

4. How Can I Ensure Accurate Results Every Day?

It is important to perform routine testing on your balance even though it has been calibrated.

In addition to regular calibration, weighing instruments also require periodic routine testing between calibrations

and should be tested regularly with an external weight for two reasons:

• Within the calibration period, changes of the balance performance may occur. A routine test is a quick and

traceable check that the balance still performs according to the required user defined process tolerance.

• By following a routine test procedure you might elongate the time between calibration cycles (based on

therisk of the weighing application), i.e. annually rather than every 6 months.

12

93

D

e

l

ete pr

o

t

oco

Press here to enter target weight

Sample

l

E

dit meth

Administrator

General Weighing

5.000000

Enter here

o

d

Complet

e

task

6

Methods

03:07

p

m

Protocol

g

A

d

d result

5.000000 g

Fig. 4: Conditions can change within the long calibration intervals.

Aroutine test detects changes in the conditions which would have an

impact on your results.

The overall measurement uncertainty (short: MU) consists of four main contributing factors − repeatability,

sensitivity, eccentricity, and non-linearity. All of these factors are measured during calibration, but typically

repeatability and sensitivity should be checked routinely by the user, as defined by Good Weighing Practice™,

the science-based global weighing standard.

Repeatability Testing (RP)

With test weights up to 5% of the balance capacity, repeatability (also called "precision") is the dominant

contributor to measurement uncertainty and is constant. Repeatability is measured by performing 10 replicate

weighings under the same conditions using a test weight at 5% of the balance capacity.

Sensitivity Testing (SE)

With test weights close 100% of the balance capacity, sensitivity (also called "error of indication") is thedominant contributor to measurement uncertainty. Sensitivity is measured by placing a test weight close to thecapac-

ity on the balance and comparing it with the mass value of the weight.

8

Page 9

10

RP SE

1

Adm

i

nistrator

G

en

er

al Weig

h

i

n

g

M

etho

ds

0.0000000

Pr

e

ss

h

e

re

S

am

p

l

0.1

e

Delet

e pr

o

tocol

E

03:07

p

m

Prot

o

c

o

t

o e

nte

r

tar

g

e

t

we

di

t

m

et

h

od

l

g

i

g

h

t

Ente

r

here

C

o

m

plet

e

tas

k

Add

res

ult

0.0000000 g

0.01

0.001

Measurement uncertainty in [%]

0.0001

Fig. 5: A typical measurement uncertainty curve of a typical

0.00001

0.00001

0.0001

0.001 0.01 0.1 1 10

Sample weight [g]

microbalances. With sample weights below 5% of the capacity

therepeatability is the biggest error where as around maximum

capacity the sensitivity is dominant.

Special Tips

• METTLER-TOLEDO's GWP® Verification is a risk-based assessment. It provides you with a personalized

recommendation on how to test your balance and how often to perform each routine test:

www.mt.com/gwp-verification.

• CarePacs® include the two correct test weights needed for the user to perform routine repeatability

andsensitivity balance tests for any balance model: www.mt.com/carepacs.

5. How Can I Deal With Drifting Weight Results?

What to do if the balance settings are correct, all tests are passed, but your weighing results

are still drifting.

The influence of the sample or weighing vessel on the measurement result is often overlooked, and can

frequently be a cause of drifting results. Most of these external influences can be prevented or reduced by

thefollowing simple measures:

Observed Problem Possible Reason Recommended Actions

Weight reading shows steady

(linear) increase

Weight reading shows steady

(linear) decrease

Weight reading shows small,

sometimes stepwise, increase

or decrease

Weight reading shows unpredictable

drift (jumping up and down)

Sample is hygroscopic and

absorbing moisture, causing steady

increase in mass

Sample is evaporating and losing

moisture, causing steady decrease

in mass

Temperature differences between

sample and environment cause

heating or cooling effects in the

weighing chamber, and therefore

change in mass

Electrostatic effects typically produce

chaotic drift patterns

• Close the vessel

• Keep air humidity constant and store sample

under these conditions before weighing

• Close the vessel

• Keep air humidity constant and store sample

under these conditions before weighing

• Use tweezers to handle the weighing vessel

• Allow suf ficient acclimatization time of

the samples and vessels in the weighing

environment (at least 30 minutes)

• Avoid the use of plastic or PTFE weighing vessels

wherever possible Use a good ionizer to dissipate

static charges in the sample and vessel.

Discharge the samples for several seconds

9

Page 10

Displayed Weight

to

G

2.433601 g

Ad

mi

nis

trator

Genera

l Weighing

Methods

03:07

2.433601

pm

Pr

P

r

ess

h

ere

to

enter ta

Sam

pl

e

D

e

lete

pro

t

oc

o

l

E

dit

met

h

o

d

otocol

g

rge

t

wei

gh

t

E

nter

h

e

re

C

o

m

p

lete task

Add

result

Micro-Weighing Guide

Fig. 6: Typical weight changes over the time due to different influences

time

by the sample itself.

Special Tips

• The XPR6UD5 or XPR10 balances have sufficient capacity to allow a flask to be weighed with a cap or lid on.

• Use an ionizer to remove charges from samples and weighing vessels. METTLER TOLEDO offers various

ionizer options: www.mt.com/accessories.

6. How Can I Optimize Working With Small Samples?

Weighing very small samples can be tricky, but there are tools available to make this task easier.

Weighing out small amou

small objects, such as crucibles can also be difficult. Accessories that are specifically designed for the app

can make these tricky tasks easier:

nts on a microbalance can be challenging, especially when wearing gloves. Handling

lication

0.0000 000 g

A

dministrator

eneral Weighing

enter target weight

method

000

Enter here

Co

mpl

ete

task

Methods

03:07

p

m

g

Protocol

Add result

Fig. 7: Sample sizes, flasks or crucibles are tiny. Using the appropriate tools will have an positive influence on your weighing in terms of

speed, accuracy and convenience.

10

Page 11

• A micro spatula with a thick handle supports precise sample transfer.

• Specially shaped tweezers can be a big help in transferring the sample into the balance smoothly.

• Flat-bottomed weighing dishes can be positioned safely on the weighing pan.

• Using a foot switch for opening and closing the balance door frees up yours hands and aids concentration.

• A tubular weighing pan kit makes the weighing of tubular samples, such as stents, springs and wires, much

easier (available for the XPR microbalance).

Special Tip

• Specialized tweezers, weighing pans and all the latest accessories for micro-weighing can be found at:

www.mt.com/accessories

7. How Can I Clean My Microbalance More Easily?

Use recommended procedures for cleaning toxic or sticky substances.

• Switch off the balance.

• Coarse cleaning can be done with brush and tissues (only for non-toxic samples). Fine cleaning should be

done with detergents or suitable solvents.

• The inner parts of the draft shield can be brushed out. To clean more thoroughly, dismantle the drip tray

and the weighing pan. These parts may also be cleaned in sonic water baths if required.

• Usually use common cleaning agents such as 70% alcohol or isopropanol, or common detergents.

Theinner draft shield parts are made from stainless steel and are chemically resistant and robust.

Note: stainless steel is not compatible with strong acids.

• Acetone should NOT be used, even for highly sticky substances. This solvent can dissolve plastics and

attack the glued surfaces of the draft shield. Keep acetone away from the plastic handles and balance

terminal screen.

• Balance manufacturers will usually provide a chemical compatibility list.

• Always check the instructions given in the operating manual.

11

Page 12

0.0000000 g

Micro-Weighing Guide

Fig. 8: Keeping your microbalance clean helps to protect your balance

for many years to come.

H2O

Wind ring • • • • – – • •

Draft shield

glass uncoated

Draft shield

glass coated

Draft shield

frame

Draft shield

bottom

Paint housing • • • – • • • •

Display

SmartView

Display

terminal

Protective cover • • • – • • • •

Feet • • • – • • – –

Iso–

propanol Ethanol 70% Acetone

• • • • • • • •

• • • – – – – –

• • • • – – • •

• • • • – – • •

• • • – – – • •

• • • – – – • •

Hydro–chloric

acid (half

concentrated)

Sodium–

hydroxide

(half

concentrated)

Peracetic

acid (2%)

Sodium

hypo–chlori t e (0.5 %)

12

Top housing • • • • • • • •

Cooling fins • • • • – – – –

The data indicated in the table exclusively apply to the XPR Microbalance.

• Can be applied

– Can not be applied

These data are subject to technical changes.

Special Tip

• Find more details in our e-learning: "Lab Balances: External influences and Cleaning", which can be found at:

www.mt.com/lab-elearning-influences.

Page 13

8. How Can I Make the Weighing Process More Efficient?

Adm

i

nis

tr

a

t

or

Press

h

ere to enter

target we

ight

Sa

mple

Enter here

D

elete pro

tocol

Edit

method

C

omp

le

te ta

s

k

General

Weighing

Met

hods

0

3:

0

7

p

m

Protocol

A

dd re

su

lt

0.00000

0.000000

g

Some simple balance functions can make life easier.

Most microbalances contain built-in software which provides useful features to accelerate and simplify

weighing, but sometimes configuring them may be difficult or time-consuming. Check out the user manual

ofyour specific balance for more information.

The weighing time can be decreased by optimizing the Weighing Mode, Environment, Value Release settings.

Asthese changes will also have an influence on the measurement uncertainty, a calibration should be made

toensure weighings are within the required tolerances.

• Separate User Profiles

For XP microbalances, individual user accounts can be used to preconfigure certain parameters. Use

theright account for your weighing tasks. For XPR microbalances, tolerance profiles can be programmed.

These profiles are linked to all necessary quality and weighing settings including the correct preventive

maintenance procedures.

User Management

User 1

User 2

User 3

User 4

User 5

User 6

Calculator

+

Add user

Confirm Start method

Protocol

Test 1-1

1.551 mg

Test 1-2

1.531 mg

Test 1-3

1.509 mg

Methods

Sulfadimidin Prep

Methionin Prep

Benzylcystein Prep

CHNS Prep

CHNS Reference

Calibration Standard A

Add result

Feb 2 2016 - 06:47 PM

Feb 3 2016 - 02:45 PM

Feb 3 2016 - 02:47 PM

Feb 3 2016 - 02:52 PM

Feb 3 2016 - 02:54 PM

Feb 3 2016 - 02:54 PM

+

Fig. 9: Modern microbalances provide many helpful features and

functions to support the efficiency of your daily weighing tasks.

• Method Storage

The XPR user interface (short UI) offers the possibility to store general sample parameters in "methods" which

can be selected by a single click. Click directly on important parameter fields and directly type in required

values and start directly your weighing tasks. This is especially helpful for repetitive weighing tasks.

• Select Parameters with One Click

On the XPR, you can click directly on important parameter fields (e.g. target weights, sample ID's, ± tolerances)

and type the required values. Efficient data input is supported by state-of-the-art touch screen user interfaces

which simplify typing and method enable swiping.

Special Tips

• With the XPR microbalances you can do simple calculations such as concentration to sample weight

conversions.

• Many functions can be accessed directly from the touchscreen. Take a closer look at all the options

onthedisplay and explore the possibilities.

13

Page 14

Micro-Weighing Guide

9. What Data Capture / Data Transfer Options Do I Have?

Time consuming and error prone manual data capture and transfer processes can be improved.

Usually the weight data are recorded and used in subsequent calculations or steps downstream in the process.

The weight is often noted down by hand, or typed into a spreadsheet or other instrument software. Manual data

transcription is time-consuming and a major source of errors. Especially transcription errors can quickly lead

toextended rework.

Most balances offer useful functions to simplify and automate data transfer from the balance to another system:

• How to Identify the Sample?

Sample IDs can be scanned with a barcode reader (1D or 2D) to avoid manually recording the sample.

• How to Transfer the Data to Microsoft Excel (or other MS Program)?

Simple software (e.g. LabX direct) allows transfer of results easily into MS programs, such as MS Excel

(forXP/XS microbalances). For latest XPR balances, the data can be transferred easily without need for

special software or drivers.

• How to Transfer the Data to an External Software Package?

XP balances can export data such as weights fast and error free to an external software (e.g. analytical

instrument) over the so-called transfer key using a standardized output protocol. A helpful function especially

when weighing numerous samples.

0.0000000 g

Administ

rator

Gener

a

l

W

eighing

Methods

0.0000000

03:07

pm

Protoco

Press her

e

to e

Sample

Delete protocol

E

dit meth

l

nter

target weight

g

Enter

her

e

od

C

om

plete

task

Add result

Fig. 10: Data transfer is cumbersome and prone to errors. Use

thedata transfer opportunities provided by your microbalance to

remove this time consuming task.

14

Page 15

• For Remote Control of the Balance?

For complex integration into customer's data systems (e.g. LIMS) the user can use the METTLERTOLEDO

Standard Interface Command Set (MT-SICS). The balance can be completely controlled remotely. Please

download the MT-SICS command set or contact your local weighing consultant for more information.

• What is the Most Secure Data Transfer Option?

For data centralization and to ensure 21 CFR part 11 compliance LabX software is recommended. LabX

can be used not only to record all results but also to control the weighing process, balance data and

record the audit trail for all balances in the laboratory. LabX ensures that raw data cannot be manipulated.

LabX is currently available for XP/XS microbalances.

Special Tips

• For maximum data transfer security, use LabX software: www.mt.com/labx.

• For complex integration to LIMS ask the MT-SICS.

10. Other Helpful Tips to Optimize Micro-Weighing

Only unplug a balance if absolutely necessary. For best weighing results a microbalance needs 24 hours to

warm up and stabilize after being plugged in.

Ensure the balance is leveled. XPR LevelControl should always be active.

Work faster and more conveniently with touch-free weighing. IR sensor allows automatic opening/closing of the

door by waving hand in front of sensor alternatively use a footswitch to leave hands completely free.

Use an appropriate weighing pan for your sample e.g. use a filter weighing pan or a filter weighing kit for determining particulate matter, and a dedicated weighing pan for tubular samples such as wires, stents, springs etc.

Always close the balance door whilst weighing to avoid drafts causing instability in the weighing result.

15

Page 16

Benefit From Our Weighing Expertise

With decades of experience in laboratory weighing, METTLER TOLEDO can offer

you a wide range of online learning resources. Take advantage of our expertise to

enhance your weighing know-how and make the most of your balance. Check out

the documentation on our internet page for a range ofrelevant materials.

Laboratory Expertise

Valuable know-how is at your fingertips on our

competence pages. Learn about:

• USP Revisions

• Electrostatic Influences

• Calibrating Your Weighing Device

www.mt.com/lab-exper tise

eLearning

Online training is a cost effective way to train new

employees and fulfill GLP/GMP/ISO re-training

requirements. Get going with:

• USP Compliance

• Lab Balances – External Influences and Cleaning

Mettler-Toledo GmbH

Laboratory Weighing

8606 Greifensee, Switzerland

Tel. +41 44 944 22 11

Fax. +41 44 944 30 60

Subject to technical changes

© 04/2016 Mettler-Toledo GmbH

30323853A

Global MarCom 1874 PH/MD

www.mt.com/lab-elearning

On-demand Webinars

Learn directly from our weighing experts and guest

speakers. It’s easy to register.

For starters, we recommend:

• Minimizing Out-of-Specification Errors

• Good Weighing Practice

• Calibration of Laboratory Instruments

www.mt.com/webinars

www.mt.com/xpr-microbalances

GWP

Good Weighing Practice™

The global weighing guideline GWP® reduces risks

associated with your weighing processes and helps to

• choose the appropriate balance

• reduce costs by optimizing testing procedures

• comply with the most common regulatory requirements

*30323853*

For more information

®

www.mt.com/gwp

Loading...

Loading...