Mettler Toledo WXTS3DU, XP26, XP26DR, XP205DR, XP105DR Outstanding Weighing Performance Even Under Harsh Conditions—White Paper

...Page 1

White Paper

Outstanding Weighing Performance

Even under Harsh Conditions

Reducing the impact of air drafts

This white paper describes the influences of air flow during the weighing process. Recent

innovations in the design of the weighing pan for precision balances and scales help to minimize any errors due to air drafts. The innovative new weighing pan makes it possible to

deliver results up to twice as fast, even under harsh conditions. What's more, the results show

an outstanding 86% improvement in repeatability (precision) for a 1 mg readability balance

under harsh conditions (inside a safety cabinet).

Content

1 Introduction 2

2 Considerations when Weighing with Precision Balances 2

3 Experimental Procedure 5

4 Summary of Results 10

5 Conclusion 16

6 Tips and Recommendations for Reliable Weighing 16

7 Further Information on External Influences 19

8 About the Author 19

Page 2

1. Introduction

Weighing is one of the most common activities carried out in the laboratory. An electronic balance does not

directly measure a mass, rather the force of its weight. The uncertainty of this force depends not only on the

technical specification of the measuring instrument but also on many environmental effects such as temperature

variations and air drafts.

White Paper

The environmental conditions have an important impact on precision weighing. Air drafts from open doors or

windows, air conditioning units or fans, as well as air escape in a fume hood or safety cabinet when working

with malodorous, toxic or aggressive substances, and even movement of people around the balance, can

influence the weighing performance. Drafts can cause slower settling times and drift of measurements. In these

situations, the operators of a scale or balance cannot rely on accurate and reliable measurements. For more

than ten years, state-of-the-art analytical balances have been equipped with glass draft shields using motorized

opening for precise weighing, even in unstable environments. The user has access to the weighing pan via a

partially opening glass draft shield. The balance stabilizes faster because there is less disturbance from air

currents than in an unshielded environment. Additionally, there is the option to use cleverly designed hanging

weighing pans, SmartGrid™, with a grid structure. These pans present less surface area for air turbulence in the

weighing chamber to act upon, than conventional weighing pans. The result is shorter settling times and faster

availability of the results. But what measures can be taken to optimize weighing on precision balances?

2. Considerations When Weighing with Precision Balances

Precision balances are mainly used in open environments of laboratories and production sites where the

user has only limited possibilities to shield his equipment against air drafts.

I

n general, modern precision balances provide a high weighing performance. This means fast and reliable

weighing

from different sources like people moving, opening of doors, heating radiators, and fans from computer and

laboratory equipment influences this performance. The most critical metrics to determine the effect of these

external influences on a balance are the "average settling time" and the "average repeatability". The inherent

risk in this situation is that not enough care will be taken to prevent disturbing influences.

The air currents can be minimized using weighing pans which are specifically designed. An open grid

structure may seem, on the face of it, to address the issue of air drafts on precision balances. However,

there are inherent drawbacks to this approach. One issue, in particular, is the difficulty to clean and

maintain a weighing pan with an open grid structure. The latest innovation in design of weighing pan is a

sturdy quadruped platform. This simple, yet proven geometry, was developed based on consideration of

four primary design criteria:

results, coupled with a level of security that meets the demands of regulatory bodies. Air flow

1) Performance (speed and precision)

2) Placement of tare container

3) Weighing pan material and construction

4) Ease of cleaning

2

2.1 Performance

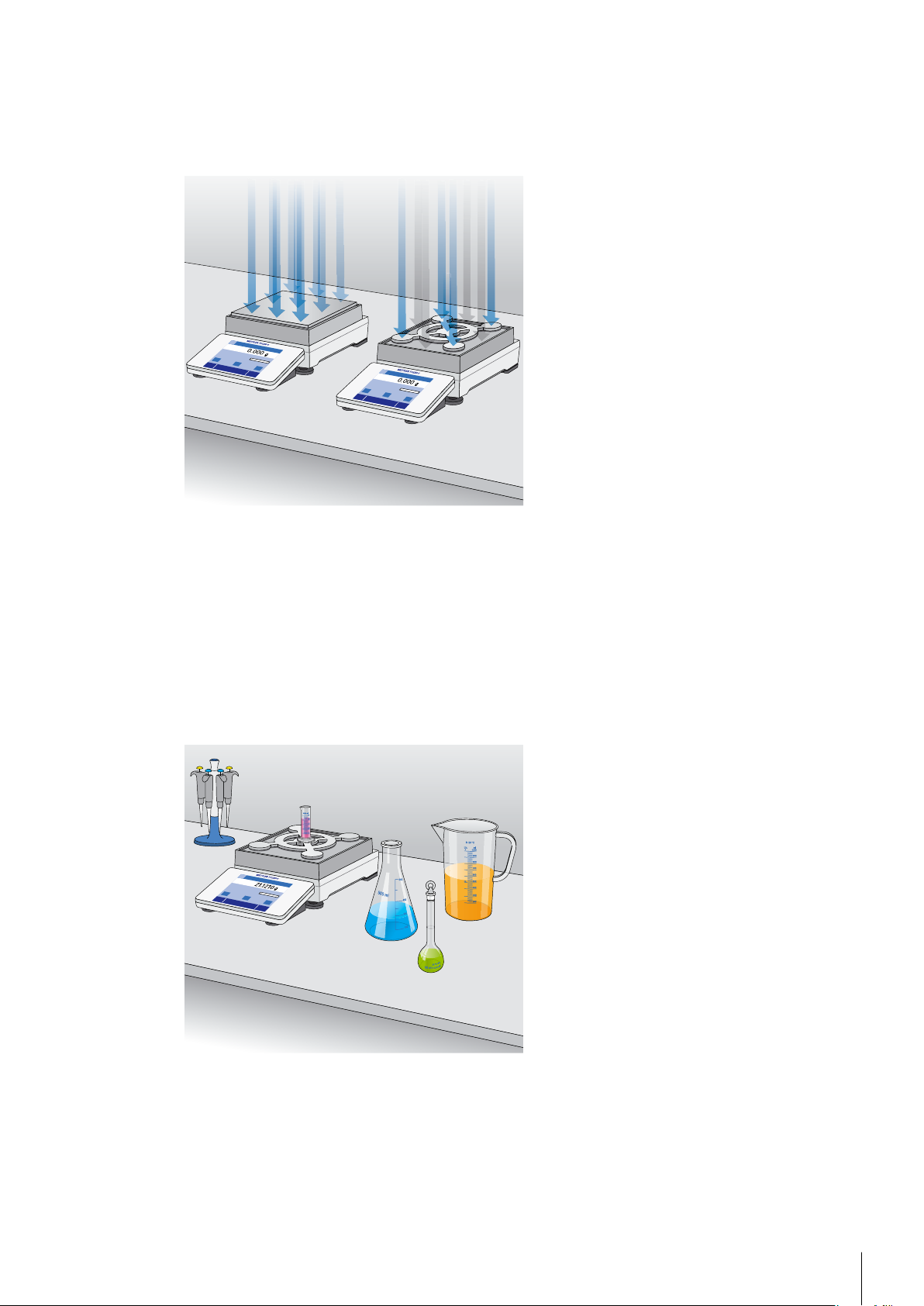

Air currents act as a force on the weighing pan and will influence the weighing results. Minimizing the effect of this

perturbing force with a clever geometry of the pan improves the above mentioned performance (Fig. 1). The pan is

primarily designed to minimize the negative effects of air currents without the need for any draft shield. The driptray beneath also includes a draft ring which provides an additional mechanical protection against air flow influence on the weighing pan. Experiments under different environmental conditions demonstrate the positive effect

White Paper

METTLER T OLEDO

Page 3

on the weighing performance (see Chapter 3). Speed and precision are key performance metrics of interest to the

balance user. The parameters used to measure these elements are settling time of the balance (speed) and repeatability of the balance measurement (precision).

Figure 1: Forces caused by air currents on standard pan versus

SmartPan™. The SmartPan™ displays less air resistance

2.2 Placement of Tare Container

The SmartPan™ is compatible with any kind of tare container without any danger of spillage (Fig. 2).

As precision balances are used in a wide range of applications in different industry segments and workplaces,

various sizes of tare container, such as vials, flasks, beakers, petri capsules, cylinders, boxes or buckets could

be used every day to contain and weigh samples.

Figure 2: The SmartPan™ is compatible with many different types

of tare container

Whether small, large or bulky tare containers need to be used, the SmartPan™ geometry offers a considerable

flat

support surface where any kind of tare container or sample can be easily placed in a stable position without risk

(Fig. 2).

To prevent or minimize eccentricity errors, the cross-shaped design of this weighing pan provides the user

with an easy and intuitive guide to correctly place the tare container or sample right in the center of the weighing pan.

White Paper

METTLER T OLEDO

3

Page 4

2.3 Weighing Pan Material and Construction

Weighing pan material and construction were carefully considered in the design of the innovative SmartPan™.

A zinc alloy was selected as the ideal material for the new weighing pan design, because of its better machinability

and superior tensile and impact strength, compared to the conventional aluminium weighing pan. This leads to a more

rugged construction.

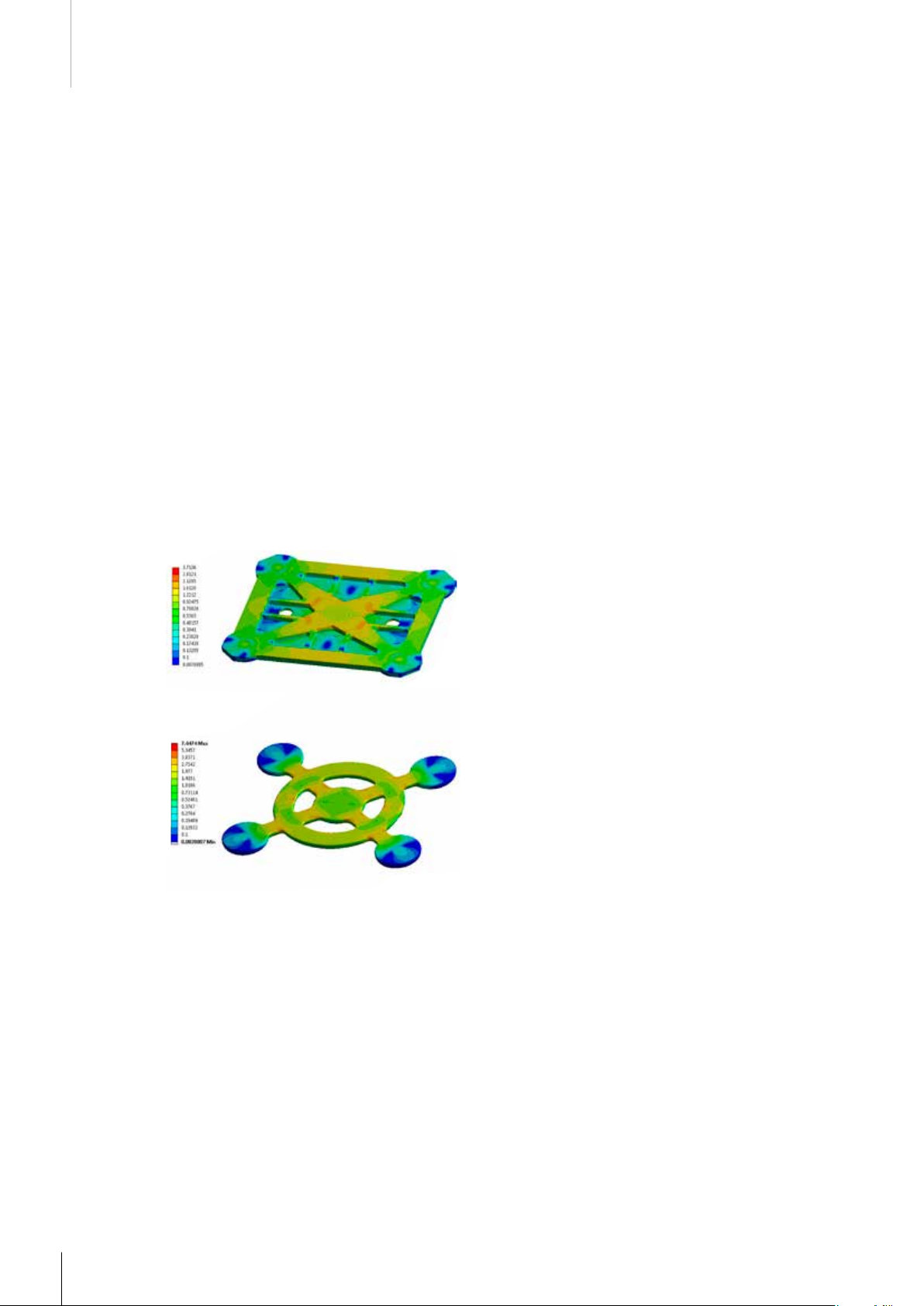

Finite Element (FE) Analysis is a computer simulation technique that is often used in mechanical design processes to

predict an optimize the behaviour of complex objects. It allows a highly detailed analysis of any product or equipment

design, in order to carry out many physical tests, such as stress, vibration or heat transfer analysis, for example.

In this case FE was employed to determine the force distribution, and therefore strength and robustness, of the new

weighing pan design.

Figures 3 and 4 show a finite element simulation with the static force distribution of the conventional pan compared

to the new weighing pan design. The finite element method calculates component displacements, strains, and

White Paper Performance

stresses under internal and external loads. Thus it is ensured that the geometry remains in the linear elastic range.

The simulations were executed with a 5 kg weight put in the middle of the balance XPE6003SD5

(6100 g maximum capacity and 5 mg readability).

Figure 3: Finite element simulation of the force distribution of the conventional aluminium pan geometry

Figure 4: Finite element simulation of the force distribution of the new zinc weighing pan geometry

The observed maximum stress on the SmartPan

cal and negligible value. This value is far below the critical proof stress value of 300 Mpa which means irreversible deflection of the material. One can easily observe, from the colour maps in Figs. 3 & 4, that the quadruped

pan has the same force distribution as the standard pan; therefore the SmartPan™ is very robust and the factor

of safety is retained.

2.4 Ease of Cleaning

This innovative new weighing pan with quadruped design (SmartPan™) has many advantageous features for

improving the weighing performance and the ease of cleaning. In order to allow an excellent cleaning performance the pan is made of die cast zinc. The choice of material offers a high resistance to acid and aggressive

cleaning agents. The design incorporates a drip-tray underneath, similar to that on the analytical balances, to

collect any substances which are accidentally spilled. The rounded edges and the gap-free design of all components enable convenient cleaning operations.

™

is approximately 7.45 Mpa (Megapascal) which is a non-criti-

4

White Paper

METTLER T OLEDO

Page 5

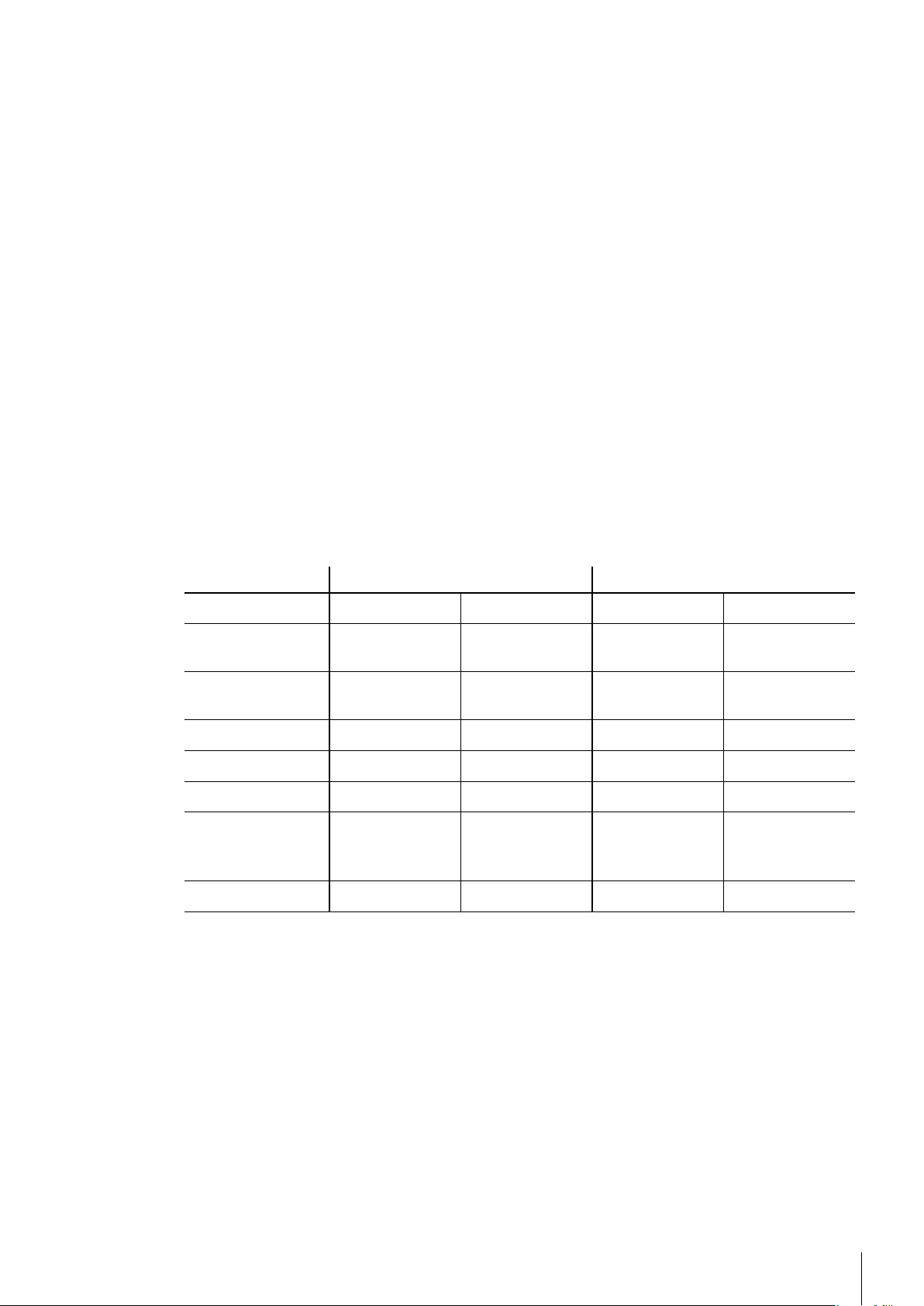

3 Experimental Procedure

The experiments described in Table 1 were carried out to demonstrate the performance of the new geometry of

weighing pan compared with the conventional weighing pan design (standard pan). The key performance metrics measured were settling time and repeatability of the balance.

Each test was carried out was repeated with (a) the balance fitted with a standard weighing pan and (b) the

same balance fitted with a SmartPan™. For every test carried out, three replicates were each weighed 20 times

and the reported results are the average values.

Tests were made in different environmental situations (standard – on open lab bench; harsh – under air conditioning unit or in safety cabinet), in order to represent specific environmental situations that may be realistically

encountered in a laboratory environment, as well as with different balance models (5 mg readability and 1 mg

readability).

The balance settings used during these experiments were:

• Weighing mode: universal

• Environment: standard

• Value release: reliable and fast

Experiment 1 2 3 4

Conditions Standard Harsh Standard Harsh

Description On open

lab bench

Weighing pan (a) Standard pan

(b) SmartPan™

Under air

conditioning unit

(a) Standard pan

(b) SmartPan™

On open

lab bench

(a) Standard pan *

(b) SmartPan™

In safety

cabinet

(a) Standard pan *

(b) SmartPan™ *

Balance model XPE6003SD5 XPE6003SD5 XPE12 0 3 S XPE12 0 3 S

Capacity of balance 6100 g 6100 g 1210 g 1210 g

Readability of balance 5 mg 5 mg 1 mg 1 mg

Test weights 400 g

2 kg

5 kg

400 g

2 kg

5 kg

200 g

500 g

200 g

500 g

Number of weighings 60 60 60 60

*

Tabele 1: Description of Experiments comparing Standard weighing pan with new SmartPan™ design

equipped with draft shield

3.1 Experiment 1: Weighing on a 5 mg readability balance under standard conditions

Experiments 1(a) and 1(b) were carried out using a 5 mg readability precision balance (XPE6003SD5) on an

open lab bench. The experimental set-up is illustrated in Fig. 5. All necessary factors were taken into

account to ensure that the balance was working in the best possible environment, such as positioning the balance: on a stable lab bench; in a laboratory temperature of 20 – 23 °C; in a relative humidity of 35 – 45%; in

vibration-free surroundings (i.e. not located near any vibration sources such as fans, vacuum pumps or generators); and in a suitable location (i.e. not too close to doors and with minimal passing foot-traffic).

This weighing environment was defined as being under "Standard conditions".

For recommendations on the ideal environment for the best weighing results, see Chapter 6.

White Paper

METTLER T OLEDO

5

Page 6

In Experiment 1(a) the balance was equipped with a standard weighing pan. Test weights of 5 kg, 2 g, and 400 g

were placed repeatedly on the weighing pan of the balance under test. Three replicates were each weighed 20

times, with a total of 60 measurements made. In Experiment 1(b) the balance was equipped with the new SmartPan™ design and the same tests were carried out. The settling time and the first stable digit were automatically

recorded and average values are reported, as shown in Fig. 6.

White Paper

Figure 5: Experiment 1(b): 5 mg readability precision balance with SmartPan™ on

open lab bench

Weighing on a 5 mg readability balance with a SmartPan™ compared to standard

weighing pan in a standard environment (on a open lab bench)

20

15

10

StandardPan

5

Repeatability (First Stable) [mg]

SmartPan™

0 1 2 3 4 5 6

Setting Time [s]

l Smart 400 g

l Smart 2 kg

l Smart 5 kg

n Std 400 g

n Std 2 kg

n Std 5 kg

6

White Paper

METTLER T OLEDO

Figure 6: Results of Experiment 1: Effect of SmartPan™ on settling time (Speed) and repeatability (Precision) of a 5 mg readability precision balance on open lab bench (Standard Conditions)

The results of Experiment 1, shown in Fig. 6, demonstrate a decrease in the global average settling time and an

improvement in the repeatability achieved using the new weighing pan design. This clearly shows that the SmartPan™ offers faster and more precise weighing performance than a standard weighing pan under standard laboratory conditions for weighing on a 5 mg readability precision balance.

Page 7

3.2 Experiment 2: Weighing on a 5 mg readability balance under harsh conditions

Experiment 2 was carried out using a 5 mg readability precision balance (XPE6003SD5) placed directly beneath

an air conditioning unit. The experimental set-up is illustrated in Fig. 7. Although this type of weighing environment

is seen quite frequently, it is a less than ideal for achieving stable weighing results, due to disruptive air currents

and is termed "Harsh conditions" for the purpose of this white paper. In this situation, the new weighing pan design

has the potential to have a significant positive impact on the speed and precision of weighing.

In Experiment 2(a) the balance was equipped with a standard weighing pan. Test weights of 5 kg, 2 g, and 400 g

were placed repeatedly on the weighing pan of the balance under test. Three replicates were each weighed 20

times, with a total of 60 measurements made.

In Experiment 2(b) the balance was equipped with the new SmartPan™ design and the same tests were carried out. The

settling time and the first stable digit were automatically recorded and average values are reported, as shown in Fig. 8

Figure 7: Experiment 2(b): 5 mg readability

precision balance with SmartPan™ exposed

to air currents caused by air conditioning unit

Weighing on a 5 mg readability balance with a SmartPan™ compared to standard

weighing pan in a HARSH environment (under air conditioning unit)

20

StandardPan

15

10

SmartPan™

5

Repeatability (First Stable) [mg]

l Smart 400 g

l Smart 2 kg

l Smart 5 kg

n Std 400 g

n Std 2 kg

n Std 5 kg

0 1 2 3 4 5 6

Setting Time [s]

Figure 8: Results of Experiment 2: Effect of SmartPan™ on settling time (Speed) and repeatability (Precision) of a 5 mg readability

precision balance under an air-conditioning unit (Harsh Conditions)

White Paper

METTLER T OLEDO

7

Page 8

The results of Experiment 2 (Fig. 8) demonstrate a decrease in the global average settling time and a marked

improvement in the repeatability achieved using the new weighing pan design. This proves that the SmartPan™

offers faster and significantly more precise weighing performance than a standard weighing pan under harsh

laboratory conditions for weighing on a 5 mg readability precision balance.

3.3 Experiment 3: Weighing on a 1 mg readability balance under standard conditions

White Paper

As the results of SmartPan™ tests for the 5 mg balance were so positive, the effect of the new weighing pan

design was investigated further. More demanding weighing processes (in terms of balance type and conditions)

were explored.

So, Experiment 3 was carried out using a 1 mg readability precision balance (XPE1203S) under the same standard environmental conditions as described in Experiment 1. The experimental set-up is illustrated in Fig. 9.

In Experiment 3(a) the balance was equipped with a standard weighing pan AND a draft shield. Test weights of

500 g and 200 g were placed repeatedly on the weighing pan of the balance under test. Three replicates were

each weighed 20 times, with a total of 60 measurements made.

In Experiment 3(b) the balance was equipped with the new SmartPan™ design, but had NO draft shield. The

same tests were carried out. The settling time and the first stable digit were automatically recorded and average

values are reported, as shown in Fig. 10.

Figure 9: Experiment 3(b): 1 mg readability

precision balance with SmartPan™ on open

lab bench

Weighing on a 1 mg readability balance with a SmartPan™ compared to standard

weighing pan in STANDARD environment (on a open lab bench)

6.00

5.00

4.00

3.00

StandardPan

n Std 200 g

n Std 500 g

Smart 200 g

Smart 500 g

2.00

SmartPan™

1.0 0

Repeatability (First Stable) [mg]

0.00

0.00 0.50 1.0 0 1.5 0 2.00 2.50 3.00

Setting Time [s]

Figure 10: Results of Experiment 3: Effect of SmartPan™ on set tling time (Speed) and repeatabilit y (Precision) of a 1 mg readability

precision balance on an open lab bench (Standard Conditions)

8

White Paper

METTLER T OLEDO

Page 9

The results of Experiment 3 (Fig. 10) demonstrate a decrease in the global average settling time and an improvement in the repeatability achieved using the new weighing pan design. This proves that the SmartPan™ offers

faster and more precise weighing performance than a standard weighing pan under standard laboratory conditions for weighing on a 1 mg readability precision balance.

3.4 Experiment 4: Weighing on a 1 mg readability balance under harsh conditions

Experiment 4 was carried out using a 1 mg readability precision balance (XPE1203S) placed inside a safety

cabinet under a 0.35 m/s laminar air flow. Under these harsh conditions, weighing using a balance with a readability of 1 mg is especially challenging, and requires a draft shield to be fitted both for the conventional weighing pan and the SmartPan™. The experimental set-up is illustrated in Fig. 11.

In Experiment 4(a) the balance was equipped with a standard weighing pan and equipped with a draft shield.

Test weights of 500 g and 200 g were placed repeatedly on the weighing pan of the balance under test. Three

replicates were each weighed 20 times, with a total of 60 measurements made.

In Experiment 4(b) the balance was equipped with the new SmartPan™ design and a draft shield and the same

tests were carried out. The settling time and the first stable digit were automatically recorded and average values

are reported, as shown in Fig. 17.

Note: The balance was equipped with a draft shield in tests 4(a) and 4(b), because it is unrealistic to use a

3-place balance without a draft shield in a safety cabinet. However, the draft shield had the right-hand door open

throughout these tests (as illustrated in Fig. 11).

Figur e 11: Experiment 4(b): 1 mg readability precision balance

with SmartPan™ in a safety cabinet

White Paper

METTLER T OLEDO

9

Page 10

Weighing on a 1 mg readability balance with a SmartPan™ compared to standard

weighing pan in HARSH environment (in a safety cabinet)

7.0 0

StandardPan

6.00

5.00

White Paper

4.00

3.00

n Std 200 g

n Std 500 g

Smart 200 g

Smart 500 g

2.00

Repeatability (First Stable) [mg]

1.0 0

SmartPan™

0.00

0.00 1.0 0 2.00 3.00 4.00 5.00 6.00

Setting Time [s]

Figu re 12: Results of Experiment 4: Effect of SmartPan™ on settling time (Speed) and repeatability (Precision) of a 1 mg readability

precision balance in a safety cabinet (Harsh Conditions)

The results of Experiment 4 (Fig. 12) demonstrate a remarkable effect on both the global average settling time

and the repeatability achieved using the new weighing pan design. This proves that the SmartPan™ offers much

faster and significantly more precise weighing performance than a standard weighing pan under harsh laboratory conditions for weighing on a 1 mg readability precision balance.

4 Summary of Results

4.1 Results from 5 mg readability balance testing (Experiments 1 and 2)

The results of Experiments 1 and 2 carried out on a 5 mg readability precision balance (XPE6003SD5) are

shown in Table 2 for Settling time (Speed) and Table 3 for Repeatability (Precision).

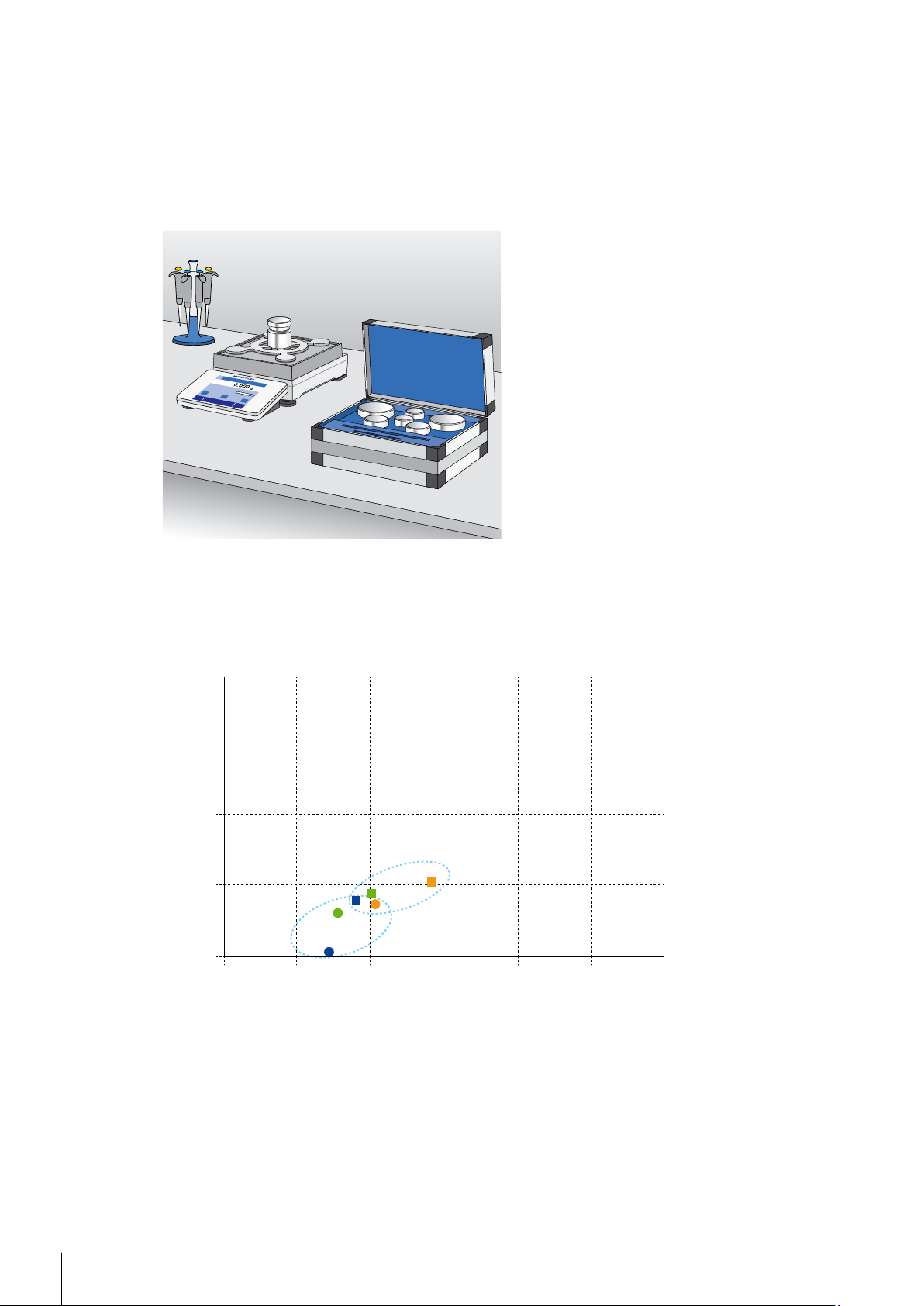

Figure 13: Precision balance with standard

weighing pan (5 mg readability, XPE6003SD5) –

used in Tests 1(a) and 2(a)

Figure 14: Precision balance with SmartPan™

(5 mg readability, XPE6003SD5) – used in

Tests 1(b) and 2(b)

10

White Paper

METTLER T OLEDO

Page 11

4.1.1 Effect on Speed (Settling Time)

Experimental Conditions Settling Time (Speed) Effect of SmartPan™

(a) Standard Pan (b) SmartPan™

Experiment 1 – Standard conditions (on open lab bench)

2.3 se c 1.7 s e c

Experiment 2 – Harsh conditions

(under air conditioning unit)

Table 2: Summary of Settling Time results when weighing on a SmartPan™ compared to standard pan under standard

and harsh weighing conditions (average values)

3.6 sec 1.7 se c

26% faster

than standard pan

53% faster

than standard pan

This proves that the SmartPan™ has a very positive impact on the speed of the weighing process. A stable

weighing result can be obtained 26% faster on an open lab bench using the SmartPan™ compared to the standard weighing pan. However, in harsh conditions where the air currents from an air conditioning unit are disrupting the weighing process, a stable weighing result can be obtained 53% faster using the SmartPan™ compared

to the standard weighing pan. These results from Table 2 are displayed graphically in Fig.

15.

Effect of SmartPan™ on Settling Time (Speed) for 5 mg readability balance

4.0

3.5

3.0

2.5

2.0

1.5

Setting Time [s]

n Standard pan

n SmartPan

TM

1.0

0.5

> 2 times

faster

0.0

Experiment 1: Standard Conditions Experiment 2: Harsh Conditions

Figure 15: Performance comparison of settling time (average values) for 1 mg balance with SmartPan™ compared to stan-

dard pan under standard and harsh weighing conditions

Fig. 15 shows that a stable weighing result can be obtained 1.4 times faster using the SmartPan™ under stan-

dard conditions. However, in harsh conditions a stable weighing result can be obtained 2.1 times faster using

the SmartPan™ compared to the standard weighing pan.

White Paper

METTLER T OLEDO

11

Page 12

4.1.2 Effect on Precision (Repeatability)

Experimental Conditions Repeatability (Precision) Effect of SmartPan™

(a) Standard Pan (b) SmartPan™

Experiment 1 – Standard condi-

tions (on open lab bench)

4.5 mg 2.9 mg

36% more precise

than standard pan

White Paper

Experiment 2 – Harsh conditions

(under air conditioning unit)

Table 3: Summary of Repeatability results when weighing on a SmartPan™ compared to standard pan under standard and

harsh weighing conditions (average values)

14.7 m g 6.2 mg

This proves that the SmartPan™ has a very positive impact on the precision of the weighing process.

Repeatability is 36% better on an open lab bench using the SmartPan™ compared to the standard weighing

pan. However, in harsh conditions where the air currents from an air conditioning unit are disrupting the

weighing process, repeatability is 57% better using the SmartPan™ compared to the standard weighing

pan. The results from Table 3 are displayed in Fig. 16.

Effect of SmartPan™ on Repeatability (Precision) for 5 mg readability balance

16.0

14.0

57% more precise

than standard pan

12.0

10.0

8.0

6.0

Repeatability [mg]

n Standard pan

n SmartPan

4.0

2.0

> 2 times

precise

0.0

Experiment 1: Standard Conditions Experiment 2: Harsh Conditions

Figure 16: Performance comparison of repeatability (average values) for 5 mg balance with SmartPan™ compared to stan-

dard pan under standard and harsh weighing conditions

Fig. 16 shows that a weighing precision (repeatability) is 1.5 times better using the SmartPan™ under stan-

dard conditions. However, in harsh conditions, the repeatability is 2.4 times better using the SmartPan™

compared to the standard weighing pan.

With the 5 mg readability balance, the new weighing pan design has a superior performance compared to

the standard weighing pan, in terms of speed (settling time) and precision (repeatability) of the results,

under the experimental conditions investigated. The difference is even more significant when weighing under

harsh environmental conditions (such as under an air conditioning unit).

In this case, the weighing result can be obtained at least twice as fast (Fig. 15) and more than twice as pre-

cisely (Fig. 16) by using the new SmartPan™ instead of a standard weighing pan.

TM

12

White Paper

METTLER T OLEDO

Page 13

4.2 Results from 1 mg readability balance testing (Experiments 3 and 4)

The results of Experiments 3 and 4, carried out on a 1 mg readability precision balance (XPE1203S) are

shown in Table 4 for Settling time (Speed) and Table 5 for Repeatability (Precision). The balance configurations used for these tests are shown in Figs. 17 – 19.

Figure 17: Precision balance with standard

weighing pan and draf t shield (1 mg readability, XPE1203S) – used in Tests 3(a) and 4(a)

Figure 18: Precision balance with SmartPan™ (1 mg readability, XPE1203S) – used

in Test 3(b)

4.2.1 Effect on Speed (Settling Time)

Experimental Conditions Settling Time (Speed) Effect of SmartPan™

(a) Standard Pan (b) SmartPan™

Experiment 3 – Standard conditions (on open lab bench)

Experiment 3 – Harsh conditions

(in safety cabinet)

Table 4: Summary of Settling Time results when weighing on a SmartPan™ compared to standard pan under standard and

harsh weighing conditions (average values)

2.7 sec 1. 9 se c

5.2 sec 1.9 s e c

Figure 19: Precision balance with Smar tPan™ and draft shield (1 mg readability,

XPE1203S) – used in Test 4(b)

30% faster

than standard pan

63% faster

than standard pan

This proves that the SmartPan™ has a very positive impact on the speed of the weighing process. A stable

weighing result can be obtained 30% faster on an open lab bench using the SmartPan™ compared to the

standard weighing pan. However, in harsh conditions where the air currents from working inside a safety

cabinet are disrupting the weighing process, a stable weighing result can be obtained 63% faster using the

SmartPan™ compared to the standard weighing pan. The results from Table 4 are displayed in Fig. 20.

White Paper

METTLER T OLEDO

13

Page 14

Effect of SmartPan™ on Settling Time (Speed) for 1 mg readability balance

6.0

5.0

White Paper

4.0

3.0

Setting Time [s]

2.0

1.0

0.0

Experiment 3: Standard Conditions Experiment 4: Harsh Conditions

Figure 20: Per formance comparison of settling time (average values) for 1 mg balance with Smar tPan™ compared to stan-

dard pan under standard and harsh weighing conditions

Fig. 20 shows that a stable weighing result can be obtained 1.4 times faster using the SmartPan™ under stan-

dard conditions. However, in harsh conditions a stable weighing result can be obtained 2.7 times faster using

the SmartPan™ compared to the standard weighing pan.

4.2.2 Effect on Precision (Repeatability)

n Standard pan

n SmartPan

> 2 times

faster

TM

Experimental Conditions Repeatability (Precision) SmartPan™

(a) Standard Pan (b) SmartPan™

Experiment 4 – Standard conditions (on open lab bench)

1.9 mg 0.8 mg

Experiment 4 – Harsh conditions

(in safety cabinet)

Table 5: Summary of Repeatability results when weighing on a SmartPan™ compared to standard pan under standard and harsh

weighing conditions (average values)

5.6 mg 0.8 mg

Improvement

58% more precise

than standard pan

86% more precise

than standard pan

This proves that the SmartPan™ has a very positive impact on the precision of the weighing process. Repeat-

ability is 58% better on an open lab bench using the SmartPan™ compared to the standard weighing pan.

However, in harsh conditions where the air currents from an air conditioning unit are disrupting the weighing

process, repeatability is 86% better using the SmartPan™ compared to the standard weighing pan. The results

from Table 5 are displayed in Fig. 21.

14

White Paper

METTLER T OLEDO

Page 15

Effect of SmartPan™ on Repeatability (Precision) for 1 mg readability balance

6.0

5.0

4.0

3.0

Repeatability [mg]

2.0

n Standard pan

n SmartPan

TM

1.0

7 times more

precise

0.0

Experiment 3: Standard Conditions Experiment 4: Harsh Conditions

Figure 21: Performance comparison of settling time (average values) for 1 mg balance with Smar tPan™ compared to stan-

dard pan under standard and harsh weighing conditions

Fig. 21 shows that a weighing precision (repeatability) is 2.7 times better using the SmartPan™ under standard conditions. However, in harsh conditions, the repeatability is 7 times better using the SmartPan™ compared to the standard

weighing pan.

With the 1 mg readability balance, the SmartPan™ has a far superior performance compared to the standard weighing pan, in terms of speed (settling time) and precision (repeatability) of the results, under all experimental conditions

investigated. The difference is even more significant when weighing under harsh environmental conditions (such as in

a safety cabinet). In this case, the weighing result can be obtained more than twice as fast (Fig. 20) and seven times

more precisely (Fig. 21) by using the new weighing pan design instead of a standard weighing pan.

White Paper

METTLER T OLEDO

15

Page 16

5 Conclusion

Using a new design of weighing pan, with a quadruped structure, has proved to have a dramatic effect on the optimization of balance performance, in terms of speed and precision, compared to using a standard weighing pan.

Weighing on a 5 mg readability balance:

White Paper

Experiments presented in this white paper show that in harsh weighing environments (such as under an air conditioning unit), using a 5 mg readability balance equipped with a SmartPan™ gives a significant improvement in

speed and precision of weighing results.

• Weighing is more than twice as fast using a SmartPan™.

• Weighing results are more than twice as precise using a SmartPan™.

Weighing on a 1 mg readability balance:

In tests designed to push the limits even further, using a 1 mg readability (3-place) balance equipped with a

SmartPan™ in harsh weighing environments (such as inside a safety cabinet) gives an even greater improvement in speed and precision of weighing results.

• Weighing is more than twice as fast using a SmartPan™.

• Weighing results are seven times more precise using a SmartPan™.

Weighing on an open lab bench without a draft shield

It is even possible to successfully use a 3-place balance on an open lab bench without a draft shield!

In weighing comparisons on an open lab bench (standard conditions), the 3-place balance equipped with a

SmartPan™ but no draft shield is still faster and more precise that the same balance equipped with a standard

weighing pan WITH a draft shield.

• Weighing is almost 1.5 times faster using a SmartPan™, even without a draft shield.

• Weighing results are more than twice as precise using a SmartPan™, even without a draft shield.

Weighing pan design and ease of cleaning

The SmartPan™ has been specifically optimized to minimize the disruptive effects of air drafts and currents and

has minimal flow resistance. It has static force distribution similar to a standard weighing pan structure for the

precision balance. Furthermore, the new weighing pan design is much easier to clean than a grid structure.

Therefore, the new design of weighing pan is proven to be less sensitive to air drafts and presents an innovation with clear benefits to any users of precision balances.

6 Tips and Recommendations for Reliable Weighing

16

This white paper explains how balance users now have a simple, elegant solution for overcoming frequent problems due to air drafts in harsh environments. Nevertheless, there are useful standard tips and recommendations

that the operator can observe to help obtain reliable weighing results.

Recommendations for location of the balance

The precision of weighing results is closely associated with the location of the balance. To ensure that your

balance can work under the best conditions, please observe the following guidelines:

White Paper

METTLER T OLEDO

Page 17

Weighing bench

• Stable (lab bench, lab table, stone bench). Your weighing bench

should not sag when work is carried out on it and should transfer

as few vibrations as possible.

• Antimagnetic (no steel plate).

• Protected against electrostatic charges (no plastic or glass).

• Wall or floor installation: The weighing bench should be fixed either

to the floor or on the wall. Mounting the bench on both places at

once transfers vibrations from wall and floor.

• Reserved for the balance.

The place of installation and the weighing bench must be stable enough

that the balance display does not change when someone leans on the

table or steps up to the weighing station. Do not use soft pads underneath, such as writing mats. It is better to

position the balance directly over the legs of the bench, since the area is subject to the fewest vibrations.

Work room

Temperature

• Vibration-free

• Free from drafts

Place the weighing bench in a corner of a room. These are the most

vibration-free areas of a building. Ideally, the room should be accessed

through a sliding door to reduce the influence of door movements.

• Keep the temperature of the room as constant as possible.

Weighing results are influenced by temperature!

(Typical drift: 1 – 2 ppm/°C)

• Do not weigh near radiators or windows.

METTLER TOLEDO balances with “FACT” (fully automatic motorized selfcalibration) can compensate virtually all the remaining temperature drift.

For this reason, “FACT” should always be switched on.

White Paper

METTLER T OLEDO

17

Page 18

Atmospheric humidity

• Ideally, the relative humidity (% RH) should be between 45%

and 60%. Balances should never be operated above or below the

measuring range of 20% to 80% RH.

• Constant monitoring is advisable with micro balances.

Changes should be corrected whenever possible.

White Paper

Light

• If possible, place the balance on a window-free wall. Direct sunlight

(heat) will influence the weighing result.

• Place the balance a significant distance from lighting fixtures to

avoid heat radiation. This especially applies to light bulbs. Use fluorescent tubes.

18

White Paper

METTLER T OLEDO

Air

• When possible do not place the balance in the air flow of air

conditioners or devices with ventilators, such as computers or large

laboratory devices.

• Place the balance a sufficient distance from radiators. In addition to

the potential temperature drift, strong currents of air could interfere

with operation of the balance. Do not place the balance next to a door.

• Avoid places with high foot traffic. Passers-by will usually create a

draft at the weighing location.

Page 19

7. Further Information on External Influences

7.1 eLearning course "Lab Balances: External Influences and Cleaning"

This course focuses on the six most common external influences which can seriously affect weighing results, and

also offers solutions and tips to eliminate or at least reduce their effects. It also offers guidelines for the proper location of a balance in the lab, as well as proper methods for cleaning. During this course you will learn about:

• The effects of typical external influences acting on the balance

• Choose the proper location for a balance in your lab

• Taking simple corrective measures to eliminate or at least reduce these problems

• Best practices for cleaning your balance

Following successful completion of the final test, a qualification certificate will be automatically generated. This

certificate can be printed and stored for internal training records, especially for GMP qualification, and is valid for

three years.

For more information on this topic:

www.mt.com/lab-elearning-influences

7.2 "Weighing the Right Way – Proper Weighing with Laboratory Balances"

This 36-page pdf guide is available to download free at:

www.mt.com/lab-properweighing

8. About the Author

Dr. Peter Ryser is Professor of Microengineer-

ing at the Swiss Federal Institute of Technology

in Lausanne. He has over three decades of

research and teaching experience from various

corporate and academic institutions. He was

previously a Director at Siemens Building Technologies where he was responsible for R&D,

product innovation and patents. Dr. Ryser has a

Ph.D. in applied Physics from the University of

Geneva, a Master's degree in Experimental

Physics and a MBA.

White Paper

METTLER T OLEDO

19

Page 20

Disclaimer

METTLER TOLEDO provides this White Paper as a service to its customers. In reading or making any use of this

document, you acknowledge and agree to the following:

This document may contain inaccuracies and errors of both a substantive and/or typographical nature. METTLER

TOLEDO does not guarantee the accuracy or completeness of the information or the reliability of any advice, opinion

or statement in this document. If you rely on the information or any advice, opinion or statement, you are doing so

at your sole risk. METTLER TOLEDO does not guarantee that this document or its contents are accurate, complete,

reliable, truthful, current or error-free.

METTLER TOLEDO will not be liable for any decision made or action taken by you or others in reliance on the

information in this document. METTLER TOLEDO and its affiliates are not liable for any Damages based on claims

arising out of or in connection with your use of this document.

METTLER TOLEDO DOES NOT ASSUME ANY RESPONSIBILITY OR RISK FOR YOUR USE OF THE INFORMATION

PROVIDED IN THIS DOCUMENT. THIS INFORMATION IS PROVIDED WITHOUT ANY REPRESENTATIONS,

ENDORSEMENTS, OR WARRANTIES OF ANY KIND WHATSOEVER, EITHER EXPRESS OR IMPLIED, INCLUDING, BUT

NOT LIMITED TO, ANY WARRANTIES OF TITLE OR ACCURACY AND ANY IMPLIED WARRANTIES OF MERCHANTABILITY,

FITNESS FOR A PARTICULAR PURPOSE, OR NON-INFRINGEMENT, WITH THE SOLE EXCEPTION BEING WARRANTIES

(IF ANY) WHICH CANNOT BE EXPRESSLY EXCLUDED UNDER APPLICABLE LAW. In no event will METTLER TOLEDO

or its affiliates be liable for any Damages, even if METTLER TOLEDO is aware of the possibility of such Damages,

arising in connection with the information provided herein. “Damages” includes but is not limited to all losses and

all direct, indirect, incidental, special, consequential and punitive damages arising under a contract, tort or other

theory of liability (including reasonable legal and accounting fees and expenses).

No part of this publication may be reproduced or distributed for any purpose without written permission from

METTLER TOLEDO.

©2015 METTLER TOLEDO. All rights reserved.

Mettler-Toledo GmbH

CH-8606 Greifensee, Switzerland

Tel. +41-44-944 22 11

www.mt.com/precision-balances

For more information

Subject to technical changes

© 12/2015 Mettler-Toledo GmbH

Printed in Switzerland 30216952A

Loading...

Loading...