Page 1

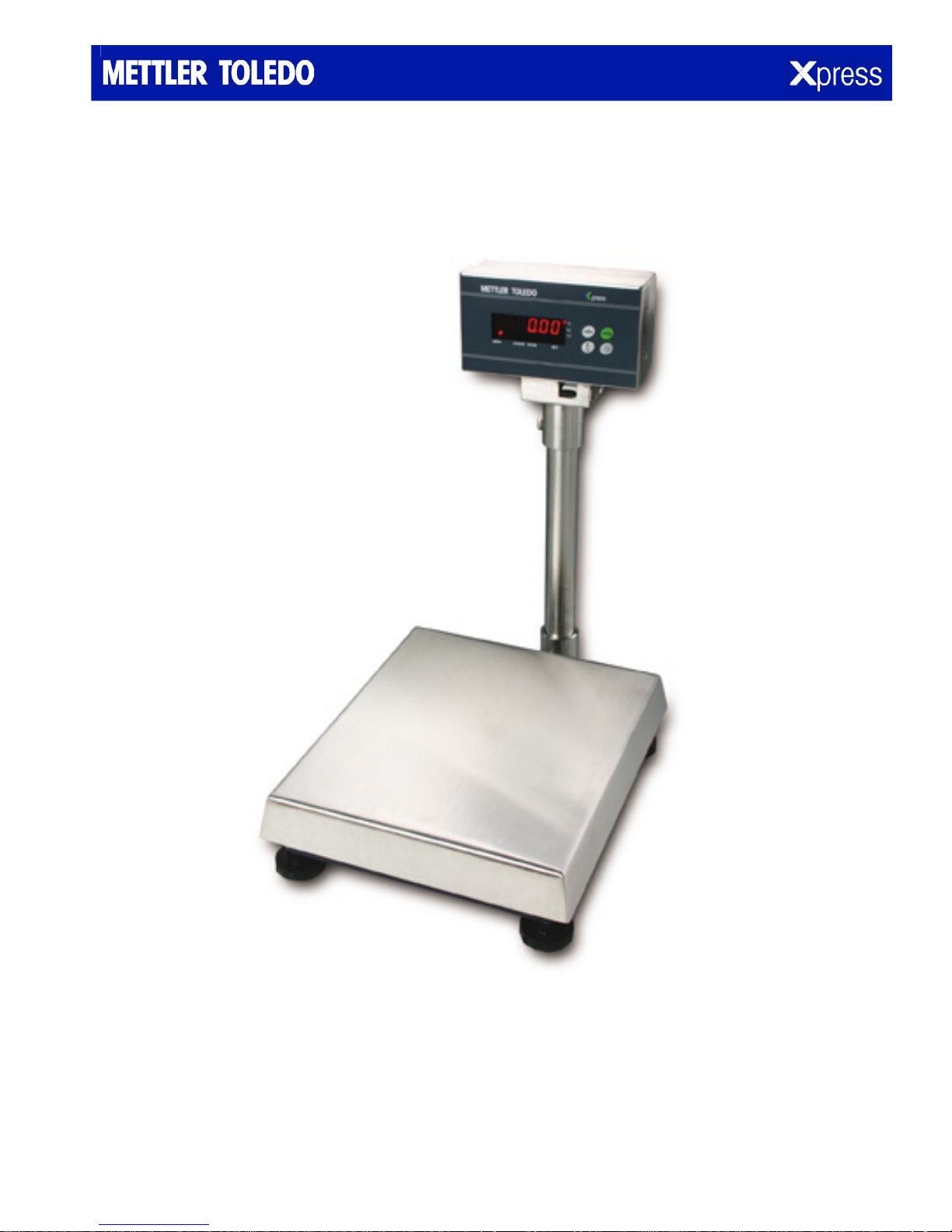

STANDARD BENCH SCALE OPERATION & SERVICE MANUAL

Models XMC/XWS/XWT (-S) -XIS

STANDARD BENCH SCALE www.mt.com/xpress

Page 2

2

STANDARD BENCH SCALE

ABOUT THIS MANUAL AND MT EXPRESS

Thank you for purchasing an MT Xpress product.

All of our equipment is assembled and packed with great care. If you should find any incorrect item, please

contact your Xpress dealer immediately.

MT Xpress products are Weights & Measures approved precision weighing instruments. However, you may

want to obtain official certification through your supplier or local Weights & Measures office.

This MT Xpress product was developed, produced, and tested in a METTLER TOLEDO facility that has been

audited and registered according to international ISO 9001 quality standards and ISO 14000 environment

control program. Properly used and maintained, this product will provide years of accurate weighing.

Handle it as you would any piece of fine electronic equipment.

Please READ this manual BEFORE operating or servicing this equipment. Follow the instructions carefully

and save this manual for future reference.

We at MT Xpress want to make sure you received the product you expected. It is important to us that you

are satisfied with your purchase. If there is anything we can help you with, or if you are not satisfied with

either your product or the services received from the Xpress representative, let us know.

How can you reach us?

XPRESS CUSTOMER CARE CENTER, USA

24/7 Information and Support:

xpress@mt.com

AM to 8 PM EST Toll Free: 1-866-MTXPRESS

8

Xpress

Mettler-Toledo, Inc.

60 Collegeview

Westerville, OH 43081

www.mt.com/xpress

Page 3

STANDARD BENCH SCALE

FCC Approval

This device complies with part 15 of the FCC Rules. Operation is subject to the following two

conditions: (1) this device may not cause harmful interference, and (2) this device must accept

any interference received, including interference that may cause undesired operation.

3

Page 4

4

STANDARD BENCH SCALE

CONTENTS

SAFETY NOTICE ...........................................................................................................................................5

PREPARING THE SCALE FOR USE ...................................................................................................................6

ENVIRONMENT................................................................................................................................... 6

UNPACKING AND ASSEMBLY ............................................................................................................... 6

POWER UP/DOWN SEQUENCE............................................................................................................. 8

YOUR XPRESS SCALE AT A GLANCE ................................................................................................................9

DISPLAY ............................................................................................................................................ 9

KEYPAD ............................................................................................................................................ 9

CURSORS (LED)................................................................................................................................. 9

OPERATING YOUR SCALE ............................................................................................................................10

STRAIGHT WEIGHING........................................................................................................................ 10

RE-ZERO FUNCTION.......................................................................................................................... 10

TARE FUNCTION ............................................................................................................................... 10

SPECIAL MODES - OVER/UNDER ..................................................................................................................11

OVER/UNDER SETUP MODE ............................................................................................................... 11

FUNCTION OF THE KEYS.................................................................................................................... 11

SET OVER AND UNDER VALUES.......................................................................................................... 11

OVER AND UNDER CURSORS ............................................................................................................. 12

OPERATION ..................................................................................................................................... 12

SCALE SOFTWARE SETUP............................................................................................................................13

ACCESS TO SETUP MODE .................................................................................................................. 13

FUNCTION OF THE KEYS.................................................................................................................... 13

PARAMETER LIST.............................................................................................................................. 13

EXIT SETUP MODE ............................................................................................................................ 13

CLEANING & MAINTAINING YOUR SCALE .......................................................................................................14

CLEANING AND MAINTENANCE .......................................................................................................... 14

TROUBLESHOOTING.......................................................................................................................... 14

SERVICING YOUR INDICATOR.......................................................................................................................15

VOLTAGE CHECKS ............................................................................................................................ 15

OPENING THE INDICATOR ................................................................................................................. 15

LOAD CELL WIRING .......................................................................................................................... 16

KEYBOARD REPLACEMENT ................................................................................................................ 16

CONTROLLER PCB REPLACEMENT...................................................................................................... 17

ACCESSING THE SERVICE MODE ........................................................................................................ 17

FUNCTION OF THE KEYS.................................................................................................................... 17

PARAMETER LIST.............................................................................................................................. 18

CALIBRATION ................................................................................................................................... 19

GRAVITY ADJUSTMENT...................................................................................................................... 20

SERVICING YOUR SCALE BASE..................................................................................................................... 21

LOAD CELL REPLACEMENT ................................................................................................................ 21

OVERLOAD STOP ADJUSTMENT.......................................................................................................... 22

SHIFT TEST ...................................................................................................................................... 23

APPENDIX.................................................................................................................................................24

ERROR MESSAGES ........................................................................................................................... 24

INDICATOR SPECIFICATIONS .............................................................................................................. 24

BASE SPECIFICATIONS ...................................................................................................................... 25

GEO VALUE TABLE ............................................................................................................................ 26

PHYSICAL DIMENSIONS..................................................................................................................... 27

Page 5

STANDARD BENCH SCALE

SAFETY NOTICE

Product safety is a fundamental concern at MT Xpress. Use common sense and follow the simple

precautions listed below to ensure your safety and optimize the use and performance of this product.

− Read this manual before operating or servicing this product. Save this manual for future reference.

− Observe safety warnings located throughout this manual.

− Use caution when lifting or moving heavy equipment.

− This product should be serviced by qualified personnel. Exercise care when moving, testing, or

adjusting this product.

− Disconnect all power to this product before installing, servicing, or cleaning.

5

− Use only MT Xpress parts for repair.

− Observe electrostatic handling precautions for electronic components. Allow at least 30 seconds after

power disconnection to allow charges to dissipate before servicing any electronic components.

− Allow the product to stabilize at ambient room temperature before applying power.

FAILURE TO FOLLOW THESE PRECAUTIONS COULD RESULT IN DAMAGE TO EQUIPMENT OR BODILY HARM.

Page 6

6

PREPARING THE SCALE FOR USE

STANDARD BENCH SCALE

Xpress Standard Bench Scales are designed to meet the real world requirements of manufacturing,

agricultural, packaging, and general weighing applications, and are ready to use right out of the box.

The Xpress Standard Indicator is a rugged, reliable electronic weighing indicator in an IP65 washdown

enclosure designed for easy operation in washdown applications. The Xpress Standard Bench stainless

steel platforms (XMC-S, XWS-S and XWT-S) are also manufactured to be used in washdown applications.

Xpress Standard Bench mild steel platforms (XMC, XWS and XWT) are intended for use in general purpose

industrial and commercial environments. For the best performance, they should not be used in

environments requiring washdown, immersion in liquids, or exposure to corrosive chemicals

This chapter gives detailed instructions and important information regarding the successful installation of

the Xpress Standard Bench Scale.

ENVIRONMENT

Before you install the scale, identify the best location for the equipment. The proper environment enhances

its operation and longevity. Keep in mind the following factors, which might have a negative influence on

the scale's operation:

Vibration: Vibration diminishes the scale’s ability to measure accurately. Electrical machinery such as

conveyors and drill presses can cause inaccurate and non-repeatable readings. The scale may also read

inaccurately if it is not leveled properly.

Air currents: Moving air can cause the scale to read wind movement as an additional force and cause

inconsistency in the weighing results.

Friction: A scale cannot measure accurately if an object is rubbing or pressing against the scale platform.

UNPACKING AND ASSEMBLY

Thank you for purchasing an MT Xpress product. Please inspect the package immediately upon receipt. If

the box is damaged, check for internal damage and file a freight claim with the carrier if necessary. If the

container is undamaged, open the box, remove the scale and place it on a solid, flat surface. Please keep

the packing material and shipping insert in case you need to return the scale to an Xpress representative.

Package contents for all Xpress Standard Bench Scales include:

Product

− Xpress Standard Indicator

− Xpress Base

Documents

− Quick Start Guide

− Installation Instructions

CD-ROM

− Operation & Service Manual

− Column kits

− Accessory bag (seal screws, lead

seal wires, leads, column mounting

screws, flat washers, spring

washers, cable clamp, cable

protective baffle, Allen key)

Page 7

STANDARD BENCH SCALE

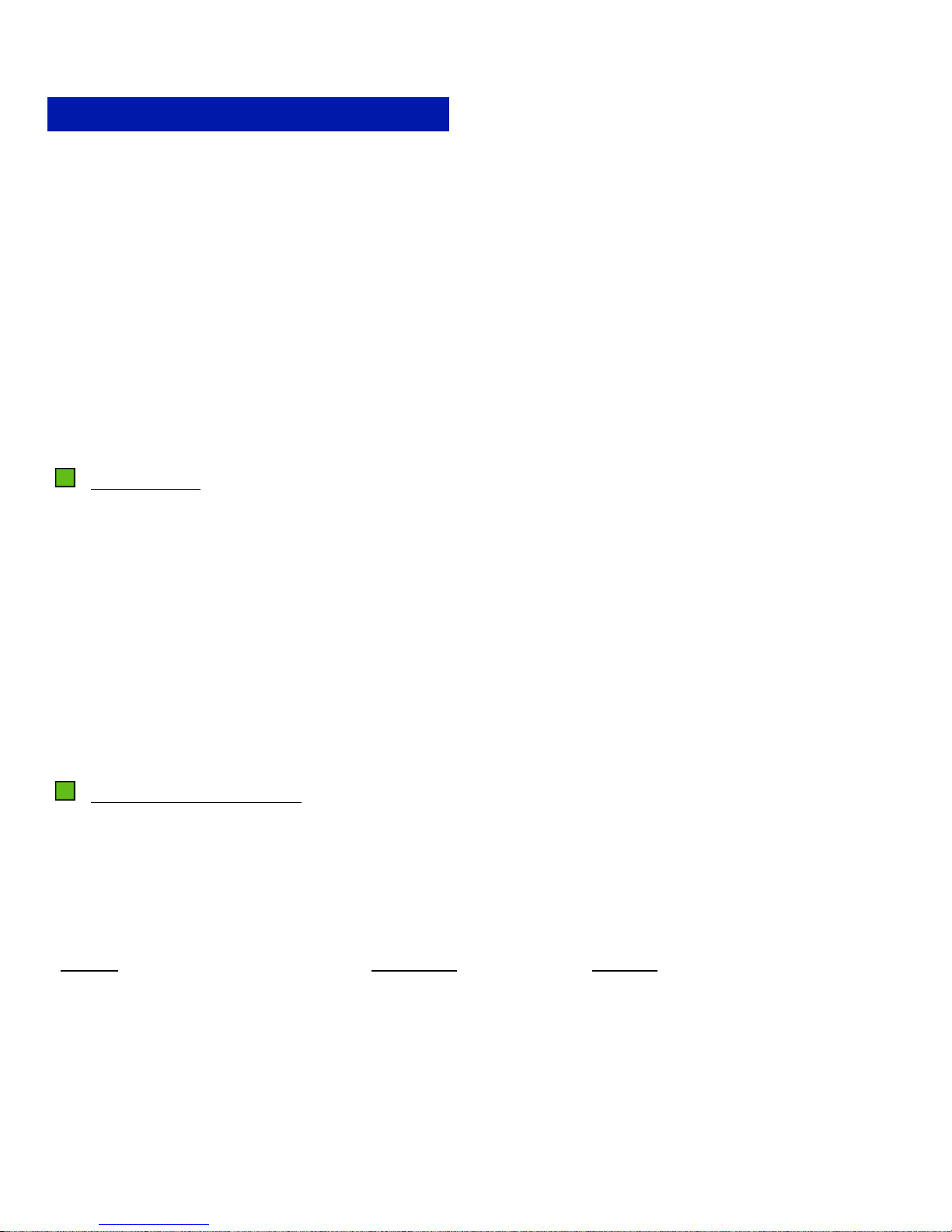

Instructions Models XWS (-S) Models XWT (-S)

1. Open the box and take out the scale.

Remove the packing material from

each side of the scale.

Set the unit on a sturdy workplace.

2. Remove the platter, and remove the red

plastic shipping tabs in the corner of

the scale. (XMC (-S) model skip this

step).

3. Models XWS (-S): Attach the column

bracket beneath the bottom scale frame

by tightening the four socket head

screws.

Models XWT (-S):Attach the column

bracket near to the side of bottom scale

frame by tightening the two hex head

screws.

XMC (-S) model skip this step.

4. Coil the excess load cell cable and

insert it into the column. A small length

of tape applied to the ends of the coils

allows the cable to slide into the

column easier Mount the indicator onto

the column. Adjust the indicator to the

proper angle and fasten the bolt. (XMC

(-S) model skip this step).

5. Apply power to the indicator.

7

6. Level the scale by adjusting four

adjustable feet.

Proper alignment Improper alignment

Page 8

8

STANDARD BENCH SCALE

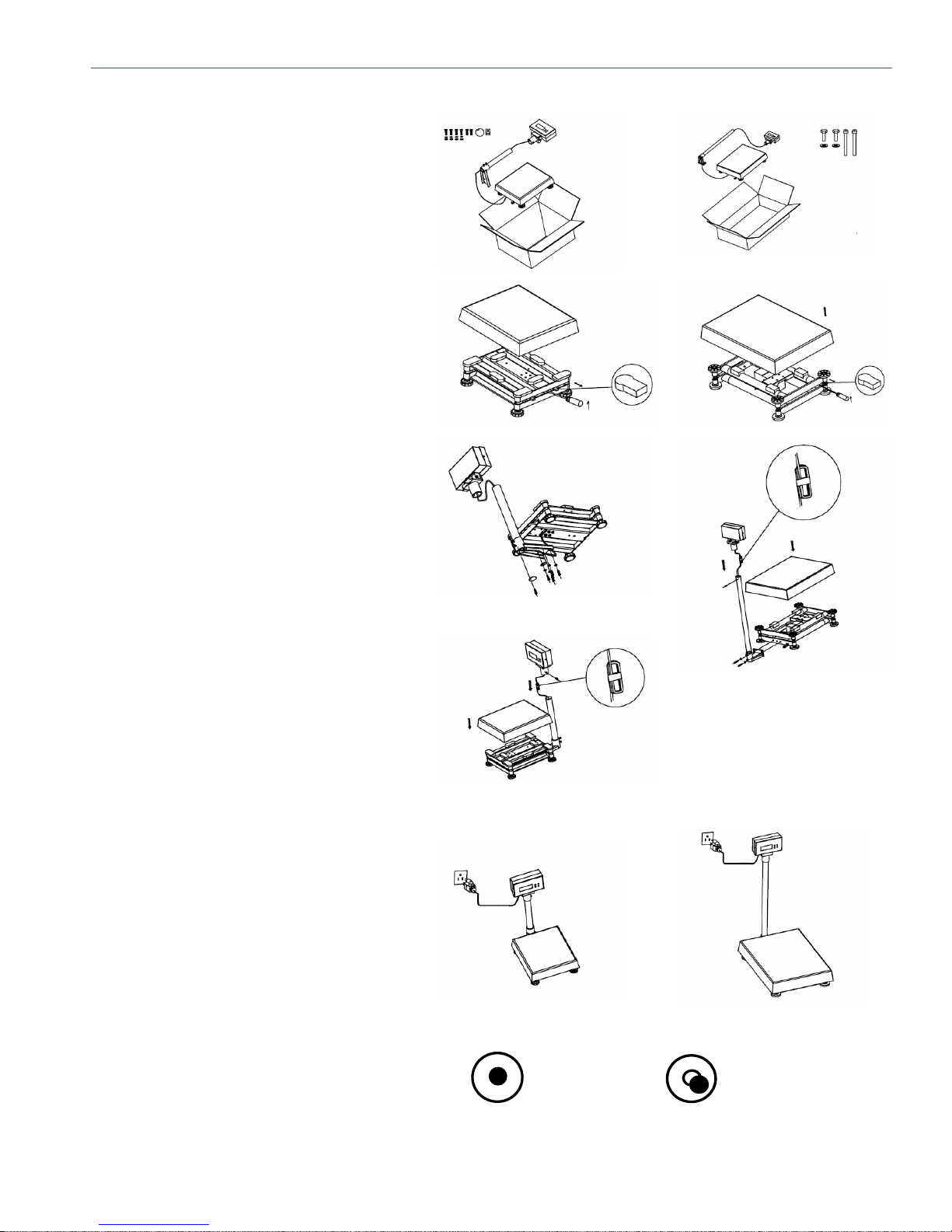

POWER UP/DOWN SEQUENCE

Power Up: Press the power key to turn on the Xpress XIS. It goes through a series of self-tests when it is

turned on. The scale performs diagnostics on its internal memory, and precedes to normal the operating

mode. The power up sequence is as follows:

z All segments of the display segments and cursors light to verify operation.

z Next the unit displays the software part number; revision number, geo value and country one by one.

z The unit captures zero and is ready for normal operation.

Note: Before switching on the scale, always make sure there is nothing on the platter. If you have powered

up the unit with something on the scale, the scale may not find the zero value, and shows “------“. To clear

this condition remove the item, press the power key until the unit displays “off”, then press the power key

again, the scale will then capture the correct zero value.

Power Down: Press the power key until “OFF” is shown on the display to turn off the scale.

Page 9

STANDARD BENCH SCALE

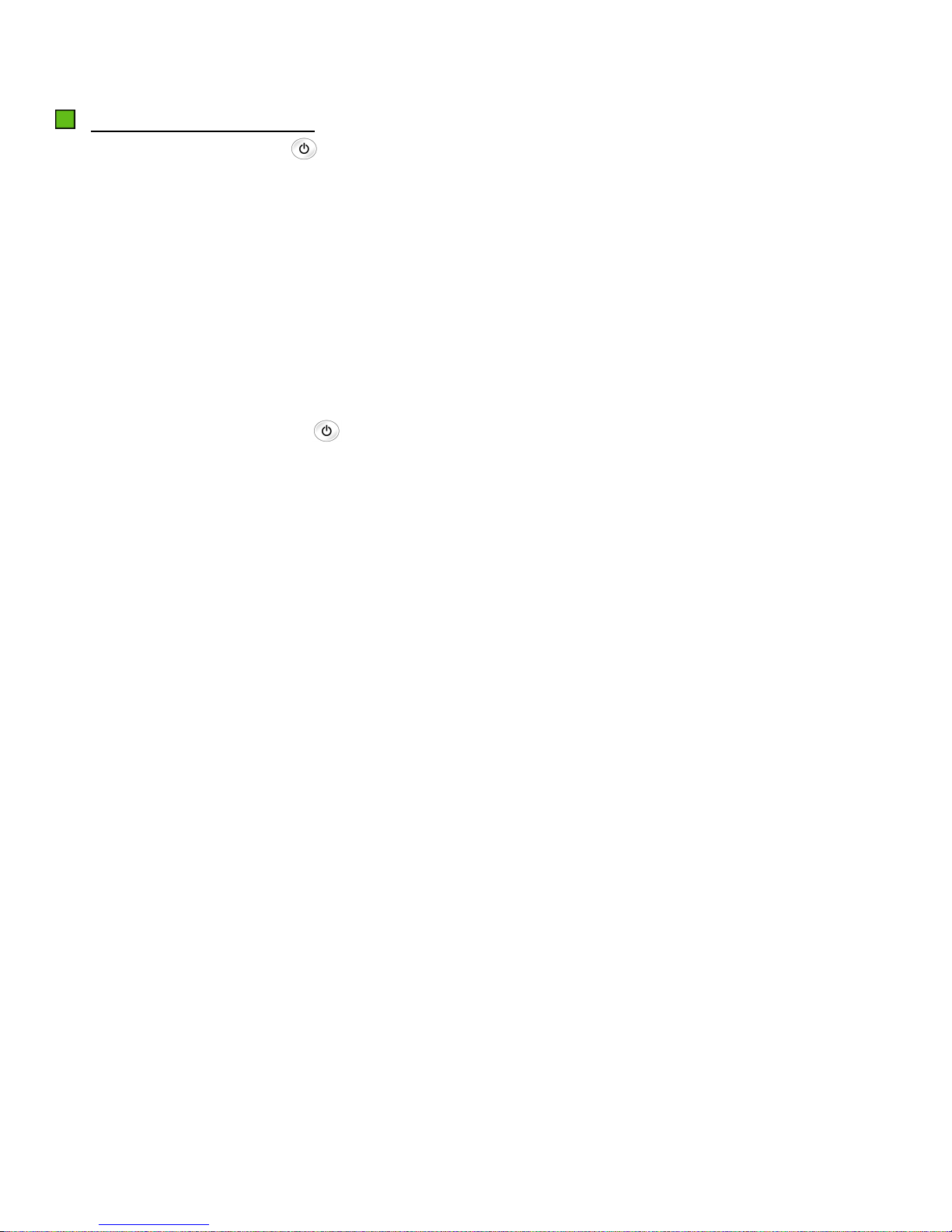

YOUR XPRESS SCALE AT A GLANCE

DISPLAY

9

KEYPAD

Key Name Function Over/Under Setting

Zero key To return the scale to gross zero.

Tare key

Function key To enter OVER/UNDER mode.

Power key To turn the scale on or off.

To tare the scale. Pressing this key at zero

clears the tare value from memory.

Setting complete exit

Increment one digit (up 1, 2, 3..)

Move to the next digit to the right

Confirm choice

CURSORS (LED)

Cursor Description

>0< Illuminates when weight is gross zero (0).

UNDER Illuminates when the weight is less than the programmed UNDER value

OVER Illuminates when the weight is more than the programmed OVER value.

Net Illuminates to indicate the displayed value is net weight (gross minus tare).

lb, kg, oz Indicates current weight unit associated with the displayed value.

Page 10

10

STANDARD BENCH SCALE

OPERATING YOUR SCALE

STRAIGHT WEIGHING

− Place the item to be weighed on the platter.

− Remove the item from the platter and the display will return to 0.000.

RE-ZERO FUNCTION

There are two ways to re-zero the scale:

− Power-up Zero: The scale will automatically capture zero when it is turned on. The power-up zero

capture range is +/-10% of the scale capacity.

Note: When the scale is turned on with a weight on the platter is more than 10% of the capacity, the

scale will not capture zero (the weight display will show "-----") to indicate that the scale will not be

ready for use. After removing the weight the scale will capture "zero".

− Push-button Zero:

The ZERO key sets the gross zero value over a range of +/-2% of the scale

capacity. To use this function, the scale must be in the gross weighing mode (NET cursor dark) and

in a no-motion condition. When the weight on the platter is more then +/-2% of the scale capacity

depressing the zero key will not yield a result until the weight is removed and the Zero key has been

depressed a second time.

TARE FUNCTION

The

key subtracts the weight of the container or wrapping material placed on the scale prior to

weighing a desired item.

− Place the empty container or wrapping material on the platter, e.g. 5 lb.

− Press the

key, it show net weight 0 lb, the net weight cursor should light.

− Place the item to be weighed onto the platter or into the container or wrapping material.

− Note the net weight value and record it if necessary.

− Remove the weighed and container or wrapping material from the platter, the display will show the

negative net weight of the container, e.g. -5 lb. This indicates the net weight of the container.

− Press

key to return the scale back to gross weighing mode, proper execution of this function is

indicated when the net cursor is not illuminated.

Page 11

STANDARD BENCH SCALE

SPECIAL MODES - OVER/UNDER

OVER/UNDER SETUP MODE

11

Press

key to access to over under zone setup mode. The display will show the default 0.000.

− The digits on the both sides of the decimal point vary with the capacity and resolution.

− Over/Under values will reset to zero if you change the scale’s resolution.

− The Standard Bench Indicator will only permit over under values conforming to the minimum resolution

of the scale.

− The Over cursor will light to select the “Over” value, and the Under will light to select the ‘Under’ value.

FUNCTION OF THE KEYS

In Over/Under Setup Mode, the functions of the keys will be as follows:

Key Function Description

Start, then

Increment digit

Increment Increase the value in selected digit.

Confirm choice Confirm the choice and step forward

End setup End Setup mode and return the scale to weighing mode.

Choose Over/Under Setup

Increment the flashing digit one right.

SET OVER AND UNDER VALUES

Example: 5 lb scale, the Over Value is 0.506 lb, Under Value is 0.4 lb:

The Procedure Display Cursor Action

Press to access to Setup mode

Press 1 time

Press 5 times

Press twice

Press 6 times

Press to proceed

Press 1 time

Press 4 times

Press

to back to weighing mode

[ 0.000] OVER Enable setup

[ 0.000] OVER Increment digit right

[ 0.500] OVER Increase digit value

[ 0.500] OVER Increment to the next digit

[ 0.506] OVER Increase digit value

[ 0.000] UNDER Select UNDER range

[ 0.000] UNDER Increment digit right

[ 0.400] UNDER Increase digit value

[ 0.000] Ready to weigh

At zero, both the Over and Under Cursors are dark. At the first increment over zero, the Under cursor will light

up.

Page 12

12

STANDARD BENCH SCALE

OVER AND UNDER CURSORS

UNDER OVER

UNDER OVER

UNDER OVER

UNDER OVER

Scale at Zero

[ 0.000]

UNDER

[ <0.399]

Ok

[ 0.400]Ù[ 0.506]

OVER

[ 0.507 <]

OPERATION

When an Over/Under value exists, the Standard Bench Indicator will beep to indicate the condition

provided that the function is enabled in the scale setup. The below table is a matrix of possible conditions:

Setup S3 is 1 S3 is 2 Cursor

Condition

Actual weight greater than the Over value - Beep Over

Actual weight less than the Under value - Beep Under

Actual Weight between Over/Under Limits* Beep - Over and Under

*When both the Over and Under values are set to 0.000, the cursors and beeper do not function.

Page 13

STANDARD BENCH SCALE

13

SCALE SOFTWARE SETUP

Several parameters in the scale can be changed to enable you to setup the scale to your individual needs.

ACCESS SETUP MODE

− Turn off the scale by pressing the Power key until the display displays “Off”; the display should be dark.

− Press the Power key while continuously pressing the

until “S1 OFF” is displayed.

FUNCTION OF THE KEYS

Key Name Function

Finish key Finish Setup

Toggle key Chose parameter

Back key Step backwards to last step

Accept key Confirm choice and step forwards to next step

PARAMETER LIST

Soft-

Switch

S3 Beep range

S4 Filter strength

S5 Weight unit lb/kg/oz lb

S6 LED brightness 0 = Normal. Each additional value yields a dimmer display 0

S7 Display type Off = Continuous display update; On: quick weight Off

Description Available Parameter Default

0 = No beep

1 = Beep when weight is between over and under value.

2 = Beep when weigh is out of range of over and under

0 = Light

1 = Normal

2 = Strong

3 = Very strong

0

2

EXIT SETUP MODE

Press the Finish key

to finish setup. “SAVE” is displayed to save all changes. Press to toggle

between “Save” (Save changes) and “Abort” (Abort all changes). Press

mode.

to return the scale to weighing

Page 14

14

STANDARD BENCH SCALE

CLEANING & MAINTAINING YOUR SCALE

WARNING

DISCONNECT ALL POWER TO THIS UNIT

BEFORE INSTALLING, SERVICING,

CLEANING, OR REMOVING THE FUSE.

FAILURE TO DO SO COULD RESULT IN

BODILY HARM AND/OR PROPERTY

DAMAGE.

CLEANING AND MAINTENANCE

− DO NOT allow untrained personnel to operate, clean, inspect, maintain, service, or tamper with this

equipment.

− DO NOT attempt to remove the cover or perform service or maintenance on the internal parts of the

scale.

− ALWAYS DISCONNECT this equipment from the power source before cleaning or performing

maintenance.

− KEEP the scale clean. Periodically clean the keyboard and covers with a soft clean cloth that has been

dampened with a mild window cleaner or detergent. DO NOT USE ANY TYPE OF INDUSTRIAL SOLVENT

OR CHEMICALS. DO NOT SPRAY CLEANER DIRECTLY ONTO THE UNIT.

TROUBLESHOOTING

If operational difficulties are encountered, first obtain as much information as possible regarding the

problem. Failures and malfunctions often may be traced to simple causes such as loose connections or

improper setup.

Additional troubleshooting can be performed for you by an authorized MT Xpress representative.

Page 15

STANDARD BENCH SCALE

A

15

SERVICING YOUR INDICATOR

For the following services, please contact your Xpress representative at www.mt.com/xpress.

VOLTAGE CHECKS

WARNING

DISCONNECT ALL POWER TO THIS UNIT

BEFORE INSTALLING, SERVICING, CLEANING,

OR REMOVING THE FUSE. FAILURE TO DO

SO COULD RESULT IN BODILY HARM

AND/OR PROPERTY DAMAGE.

BEFORE CONNECTING OR DISCONNECTING ANY INTERNAL

ELECTRONIC COMPONENTS OR INTERCONNECTING WIRING

BETWEEN ELECTRONIC EQUIPMENT, ALWAYS REMOVE POWER

AND WAIT AT LEAST THIRTY (30) SECONDS BEFORE ANY

CONNECTIONS OR DISCONNECTION’S ARE MADE. FAILURE TO

OBSERVE THESE PRECAUTIONS COULD RESULT IN DAMAGE TO

OR DESTRUCTION OF THE EQUIPMENT, OR BODILY HARM.

CAUTION

AC Power Test: Using a Multi-meter, check the AC input power. Input power must be within -15% and

+10% of the nominal AC line voltage.

Controller PCB Input Voltage Test: Confirm the universal power supply is outputting a voltage of at least 12

VDC. If the XIS indicator has power and the Controller PCB does not function properly, replace the PCB.

OPENING THE INDICATOR

To access the Controller PCB for

internal wiring and switch setting:

1. Unscrew the four screws

located on the each side of

enclosure and separate the

front panel from the enclosure.

2. The figure on the right shows

the location of the screws and

the Load Cell and AC power

cable connections.

Screws

Loadcell Cable

C Power

Page 16

16

STANDARD BENCH SCALE

LOAD CELL WIRING

After opening the XIS terminal enclosure, the main circuit board is mounted on the front panel. Refer to the

figure for the detail cable connection:

The following diagrams show the load cell terminal strip wiring for the XIS terminal on connector J-1.

GND -EXE -SIG +SIG +EXE

Refer to the below information for the load cell cable color code:

Signal

Load cell color code for

MT1022/SSP1022 series

Load cell color code for

MT/SSP series

+EXC GREEN GREEN

+SEN BLUE

+SIG RED RED

CGND YELLOW

-SIG WHITE WHITE

-SEN BROWN

-EXC BLACK BLACK

KEYBOARD REPLACEMENT

− Disconnecting the AC power adapter.

− Remove the four screws securing the front and back portions of the cover.

− Unscrew the controller PCB from the old front cover.

− Replace the new front cover assembly (including keyboard) and secure controller PCB on it.

− Secure the front cover to the back cover with the four screws.

− Apply power then press and hold the ON/OFF key for three seconds.

− Test the operation of the new keyboard.

Page 17

STANDARD BENCH SCALE

17

CONTROLLER PCB REPLACEMENT

If the Controller PCB is suspected to be faulty, use the following procedure to replace the PCB.

− Disconnecting the AC power.

− Remove the four screws securing the front and back halves of the cover.

− Disconnect the power harness from the Controller PCB and set the front cover aside.

− Remove the four screws that secure the Controller PCB to the front cover.

− Using proper static electricity precautions carefully remove the Controller PCB and place it in a protective

static bag.

− Install the new Controller PCB using the same four screws removed in the previous step.

− Reconnect the AC adapter harnesses removed previously.

− Secure the front cover to the back cover with the four screws.

− Apply power to the XIS indicator then press and hold the ON/OFF key for three seconds.

− Reprogram, recalibrate, and test the operation of the new Controller PCB.

ACCESSING THE SERVICE MODE

The Service Mode allows an authorized Xpress representative to access the Service Mode switches in the

software setup.

Open the terminal enclosure by unscrewing the four Phillips screws. Shorten the two pins of K5 on the

main board. The display will show “SETUP” for a short time, and then show “DEF NO”. This means the

scale has accessed the Service Mode.

FUNCTION OF THE KEYS

Key Name Function

Finish key Finish Setup

Toggle key Chose parameter

Back key Steps backward to last (previous) step

Accept key Confirm choice and move forwards to next step

Page 18

18

STANDARD BENCH SCALE

PARAMETER LIST

Soft-Switch Description Available Parameter Default

Def Initiate default

S3 Beep range

S4 Filter strength

No = Don’t initiate the default

Yes = Initiate the default

0 = No beep

1 = Beep when weight is between over and under value

2 = Beep when weigh is out of range of over and under

0 = Light

1 = Normal

2 = Strong

3 = Very strong

No

0

2

S5 Weight unit lb/kg/oz

S6 LED brightness 0 = Normal. Each additional value yields a dimmer display

S7 Display type

S8 Resolution

S9

Access to S8 in

setup mode

S10 Expanded display

Off = Continuous display update

On = Quick weight

On = 10000 / 12500 (for oz is 8000)

0ff = 5000 (for oz is 4000)

On = Enable

Off = Disable

On = Expanded display (50,000 quantity)

Off = Normal display

GEO GEO 0 to 31

Cal Calibrate

YES = Calibrate scale

NO = Don’t calibrate scale

lb

0

Off

Off

Off

Off

12

No

Page 19

STANDARD BENCH SCALE

CALIBRATION

Example using a 50 lb scale:

Step Operation Display Description

[CAL YES]

Press

1

Press

[ lb]

[ kg]

Default calibration weight unit

Choose suitable parameter

19

Press

2

Press

Press

3

Press

3.1 If choice NO

3.1.1

3.1.2

Press

Press

3.1.3

3.1.4

Press

Press

3.2 If choice YES

3.2.1

3.2.2

Press

Press

3.2.3

3.2.4

Press

3.2.5

3.2.6

Press

4

Press

[ 5]

[ 50]

[Lin NO]

[Lin yes]

[------]

[ 5]

[LD 25]

[LD 30]

[ 5]

[------]

[ 5]

[ 30]

[ 5]

[ 50]

[ 5]

[ save]

[ abort]

Capacity of the scale

Choose suitable parameter

Choose non-linearity calibration

Choose linearity calibration

Capture zero, make sure the platter is empty before press [>0<]

The scale count down from 5 to 0, if the scale isn’t stable, it will

count again until find stable zero.

Put the weight of 25 lb (1/2 of the full capacity) on the platter

Choose the suitable weight value you prefer, can be 1/2, 3/5 or full

capacity

The scale count down from 5 to 0, if the scale isn’t stable, it will

count again until find stable zero.

Capture zero, make sure the platter is empty before press [>0<]

The scale count down from 5 to 0, if the scale isn’t stable, it will

count again until find stable zero.

Put the weight of 30 lb (3/5 of the full capacity) on the platter

The scale count down from 5 to 0, if the scale isn’t stable, it will

count again until find stable zero.

Put the weight of 50 lb (full capacity) on the platter

Capture span. The scale count down from 5 to 0, if the scale isn’t

stable, it will count again until find stable zero.

Save calibration and all setting changes

Abort calibration and all setting changes

5

Press

The lines highlighted in gray are for reference of parameter choice.

[ 0.00]

Finish calibration and enter into Weight Display Mode

Page 20

20

STANDARD BENCH SCALE

The available capacities calibrated in pounds (lb) are as follows:

Capacity (lb) 5 10 25 50 100 250 500

Normal Resolution 5000 5000 5000 5000 5000 5000 5000

Increment size (lb) 0.001 0.002 0.005 0.01 0.02 0.05 0.1

High Resolution 10,000 10,000 12,500 10,000 10,000 12,500 10,000

Increment size (lb) 0.0005 0.001 0.002 0.005 0.01 0.02 0.05

Required added weight when choosing non-linearity calibration

1/2 FS (lb) - 5 - 25 50 125 250

3/5 FS (lb) 3 6 15 30 60 150 300

FS (lb) 5 10 25 50 100 250 500

Required added weight when choosing linearity calibration

First point (3/5 FS) 3 6 15 30 60 150 300

Second point (FS) 5 10 25 50 100 250 500

The available capacities calibrated in kilograms (kg) are as follows:

Capacity (kg) 2.5 5 10 25 50 100 250

Normal Resolution 5000 5000 5000 5000 5000 5000 5000

Increment size (kg) 0.0005 0.001 0.002 0.005 0.01 0.02 0.05

High Resolution 12,500 10,000 10,000 12,500 10,000 10,000 12,500

Increment size (kg) 0.0002 0.0005 0.001 0.002 0.005 0.01 0.02

Required added weight when choosing non-linearity calibration

1/2 FS (kg) - - 5 - 25 50 125

3/5 FS (kg) 1.5 3 6 15 30 60 150

FS (kg) 2.5 5 10 25 50 100 250

Required added weight when choosing linearity calibration

First point (3/5 FS) 1.5 3 6 15 30 60 150

Second point (FS) 2.5 5 10 25 50 100 250

The available capacities displayed in ounces (oz) are as follows:

Capacity (oz) 80 160 400 800 1600 4000 8000

Normal Resolution 4000 4000 4000 4000 4000 4000 4000

Increment size (oz) 0.02 0.05 0.1 0.2 0.5 1 2

High Resolution 8000 8000 8000 8000 8000 8000 8000

Increment size (oz) 0.01 0.02 0.05 0.1 0.2 0.5 1

GRAVITY ADJUSTMENT

The Standard Indicator has built in compensation provisions to allow factory calibration with destination

correction capabilities to compensate for variances on gravitational forces. If the Standard Indicator is

subjected to a different gravitational force at its destination location, this can be compensated for

electronically by adjusting the geo value. The geo value has 32 settings. The geo value for any world

location can be found in the Geo Value Table in the Appendix as long as the geographical coordinates and

elevation above sea level are known.

Page 21

STANDARD BENCH SCALE

SERVICING YOUR SCALE BASE

For the following services, please contact your Xpress representative at www.mt.com/xpress.

DISCONNECT ALL POWER TO THIS UNIT BEFORE

INSTALLING, SERVICING, CLEANING, OR

REMOVING THE FUSE. FAILURE TO DO SO

COULD RESULT IN BODILY HARM AND/OR

PROPERTY DAMAGE.

WARNING

BEFORE CONNECTING OR DISCONNECTING ANY INTERNAL

ELECTRONIC COMPONENTS OR INTERCONNECTING

WIRING BETWEEN ELECTRONIC EQUIPMENT, ALWAYS

REMOVE POWER AND WAIT AT LEAST THIRTY (30)

SECONDS. FAILURE TO OBSERVE THESE PRECAUTIONS

COULD RESULT IN DAMAGE TO OR DESTRUCTION OF THE

EQUIPMENT, OR BODILY HARM.

CAUTION

LOAD CELL REPLACEMENT

− Disconnect the power.

− Remove the stainless steel platform from the base.

− Loosen and remove the top load cell mounting bolts that secure the top frame to the load cell.

− Set the top frame and the load cell spacer aside.

21

− Turn the scale on its side to access the bottom load cell bolts.

− Loosen and remove the bottom load cell mounting bolts.

− Remove the load cell from the base and pull the excess cable out through the bottom of the column.

− Reinstall a new load cell by following the steps above in reverse order.

Note: Lubricate the threads and under the head of the load cell mounting bolts before reinstalling.

− Using a torque wrench, tighten the load cell mounting bolts to the specifications shown in this table:

Base Model Metric English

XMC03, XMC03S

XMC06, XMC06S

XMC15, XMC15S

XWS30R, XWS30RS

XWS60R, XWS60RS

XWS60M, XWS60MS

XWS150M, XWS150MS

XWT150M, XWT150MS

XWT300M, XWT300MS

10 N•m

10 N•m

10 N•m

10 N•m

10 N•m

10 N•m

15 N•m

25 N•m

30 N•m

7.5 ft/lb

7.5 ft/lb

7.5 ft/lb

7.5 ft/lb

7.5 ft/lb

7.5 ft/lb

11 ft/lb

18 ft/lb

22 ft/lb

− After replacing a load cell, the overload stops must be checked and adjusted (if needed). Refer to the

next section for the overload stop adjustment procedure.

− Thread the load cell cable through the column from the bottom.

− Connect load cell cable to terminal.

− Coil the excess load cell cable and insert it into the column. A small length of tape applied to the ends

of the coils allows the cable to slide into the column easier.

− Apply power to the scale.

− Recalibrate and test the operation of the new load cell.

Page 22

22

STANDARD BENCH SCALE

OVERLOAD STOP ADJUSTMENT

The overload stops must be checked and reset if the top or bottom frame or the load cell has been replaced.

− Remove the stainless steel platform from the base.

− Using the proper size feeler gauge, check all six overload stops as shown in the figure below. The

correct gap measurements can be found in the table below.

− If the gaps are not set properly, proceed to the following steps.

− Loosen the overload screw jam nuts. Refer to the figures below.

− Using the proper size feeler gauge, turn the screw until you feel a slight drag on the feeler gauge.

− Tighten the jam nut and recheck the gap. Readjust if necessary.

− Adjust all six overload stops using this procedure.

− Reinstall the platform and make sure the scale weighs to full capacity.

A

A

B

B

A

A

A

A

A

A

A

A

A

A

A

B

B

B

B

A

A

A

A

A

A

A

XMC, XMC-S models XWS, XWS-S models XWT, XWT-S model

A

B

B

B

B

A

A

A

Set screw

Set screw

Gap

Gap

Jam nut

Jam nut

Overload stop

Overload stop

Overload screw jam nuts Gap measurement points

Position

XMC03, XMC03S

Overload Gap

XMC06, XMC06S

Overload Gap

A 1 mm (0.04 in.) 1 mm (0.04 in.) 1.5 mm (0.06 in.)

B 0.5 mm (0.02 in.) 0.5 mm (0.02 in.) 0.5 mm (0.02 in.)

XWS60R, XWS60RS

Overload Gap

Position

XWS30R, XWS30RS

Overload Gap

A 2 mm (0.078 in.) 2 mm (0.078 in.) 3 mm (0.118 in.) 3 mm (0.118 in.)

B 0.5 mm (0.02 in.) 0.5 mm (0.02 in.) 0.75 mm (0.03 in.) 0.75 mm (0.03 in.)

Position

XWT150M, XWT150MS

Overload Gap

XWT300M, XWT300MS

Overload Gap

A 4 mm (0.157 in.) 6 mm (0.236 in.)

B 1 mm (0.04 in.) 1 mm (0.04 in.)

Gap B

Gap B

Gap A

Gap A

XMC15, XMC15S

Overload Gap

XWS60M, XWS60MS

Overload Gap

XWS150M, XWS150MS

Overload Gap

Page 23

STANDARD BENCH SCALE

SHIFT TEST

23

A shift test verifies that the scale weighs correctly irrespective of load

placement. If the scale does not pass the shift test, verify the overload

stops gaps before replacing the load cell. No adjustment for the shift is

possible. If the scale does not pass the shift test, the load cell must be

replaced.

For NTEP and Canadian Weights and Measures tests, use weights equal

to 1/2 the scale’s capacity. Place the test weight sequentially at each of

the positions A, B, C, D and E as shown in figure in the right. These

positions are the centers of the four quadrants of the platform and the

center of the platform. Note the terminal’s reading of the weight at each

position. The difference between any two positions in the shift test cannot

exceed the tolerance shown in the table below.

SCALE

CAPACITY

DISPLAY

INCREMENT

USA and CANADA

TEST WEIGHT

XMC03(S) 5 lb/2.5 kg 0.001 lb/0.0005 kg 2.5 lb/1.25 kg

XMC06(S) 10 lb/5 kg 0.002 lb/0.001 kg 5 lb/2.5 kg

XMC15(S) 25 lb/10 kg 0.005 lb/0.002 kg 12.5 lb/5 kg

XWS30R(S) 50 lb/25 kg 0.01 lb/0.005 kg 25 lb/12.5 kg

XWS60R(S) 100 lb/50 kg 0.02 lb/0.01 kg 50 lb/25 kg

XWS60M(S) 100 lb/50 kg 0.02 lb/0.01 kg 50 lb/25 kg

XWS150M(S) 250 lb/100 kg 0.05 lb/0.02 kg 125 lb/50 kg

XWT150M(S) 250 lb/100 kg 0.05 lb/0.02 kg 125 lb/50 kg

XWT300M(S) 500 lb/250 kg 0.1 lb/0.05 kg 250 lb/125 kg

D

TOLERANCE

(NEW)

±0.001 lb

±0.0005 kg

±0.002 lb

±0.001 kg

±0.005 lb

±0.002 kg

±0.01 lb

±0.005 kg

±0.02 lb

±0.01 kg

±0.02 lb

±0.01 kg

±0.05 lb

±0.02 kg

±0.05 lb

±0.02 kg

±0.1 lb

±0.05 kg

A

E

C

TOLERANCE

(IN SERVICE)

B

±0.002 lb

±0.001 kg

±0.004 lb

±0.002 kg

±0.01 lb

±0.004 kg

±0.02 lb

±0.01 kg

±0.04 lb

±0.02 kg

±0.04 lb

±0.02 kg

±0.1 lb

±0.04 kg

±0.2 lb

±0.04 kg

±0.2 lb

±0.1 kg

Page 24

24

STANDARD BENCH SCALE

APPENDIX

ERROR MESSAGES

The XIS indicator will display an error message if a problem or incorrect keyboard entry is sensed. The

error codes are:

E 11 RAM error

E 16 ROM error

E 18 EEPROM error

E 48 Alarm setup error Review setup.

ERROR Software running error Restart the scale by pressing the power key.

------ Unsteadily or can’t find zero

nnnnn Overload indication

uuuuu Underload indication

Dark display No power

1. Power off and power up again.

2. Recalibrate the scale.

3. Replace the main board or load cell.

1. Power-up when the platter is empty.

2. Recalibrate the scale.

3. Replace the main board or load cell.

Weight is more than full capacity plus 9e. Remove items from platter

and re-zero the scale.

Weight on scale is below gross zero by more than 9e.

Increase load on scale.

Check that the transformer is plugged in the wall.

Insure that the transformer is plugged in the scale.

INDICATOR SPECIFICATIONS

Feature Description

Displayed Resolution Up to 12,500d

Physical Dimensions

(w x d x h)

8” x 6” x 3”

Construction 304 stainless steel

Power 100 to 240VAC universal power supply, 50 to 60Hz

Environmental Protection

Equal to IP65

The indicator is NOT intrinsically safe!

Display 6 digits, 12 mm height, bright red LED

Analog:

Scale Type

Suitable for 2mV/V and 3mV/V load cells

Can power up to one (1) 350 ohm load cells

Keypad

4 membrane keyboard:

ON/OFF, ZERO, TARE, FUNCTION

Operating Temperature 14°F to 104°F (-10°C to 40°C) with10 to 95% relative humidity, non-condensing

Storage Temperature –4°F to 140°F (-20°C to 60°C) with 10 to 95% relative humidity, non-condensing

Data Output None

Weighing Units pounds, kilograms, and ounce

Specifications are subject to change without notice.

Page 25

STANDARD BENCH SCALE

BASE SPECIFICATIONS

Base size

Xpress Standard Bench Scales are available in four sizes with seven capacities:

Size/Capacity 5 lb 10 lb 25 lb 50 lb 100 lb 250 lb 500 lb

9” x 9”

12” x 14”

16” x 20”

20” x 28”

X X X

X X

X X

X X

Construction

Platform

XMC, XMC-S: Fabricated of stainless steel

XWS, XWS-S: Fabricated of stainless steel

XWT, XWT-S: Fabricated of stainless steel

Scale Base

XMC, XWS: Formed and welded mild steel, painted blue, aluminum load cell

XWT: Welded tubular mild steel, painted blue, aluminum load cell

XMC-S, XWS-S: Formed and welded stainless steel, stainless steel load cell

XWT-S: Welded tubular stainless steel, stainless steel load cell

Overloading Corner loading: 100% of full capacity

Safe Overload: 150% of full capacity

Ultimate Overload: 300% of full capacity

25

Operating Temperature 10° to 104°F (–10 °C to +40 °C)

Humidity XMC, XWS and XWT base: 0 to 95% relative humidity

XMC-S, XWS-S and XWT-S base: Washdown applications

Page 26

26

STANDARD BENCH SCALE

GEO VALUE TABLE

Use the following geo codes if you relocate the XMC/XWS/XWT (-S) -XIS to a site other than the original

location where it was calibrated.

Northern

and

Southern

0

325

325

650

650

975

latitude in

degrees and

minutes

0° 0′ — 5° 46′ 5 4 4 3 3 2 2 1 1 0 0

5° 46′ — 9° 52′ 5 5 4 4 3 3 2 2 1 1 0

9° 52′ — 12° 44′ 6 5 5 4 4 3 3 2 2 1 1

12° 44′ — 15° 6′ 6 6 5 5 4 4 3 3 2 2 1

15° 6′ — 17° 10′ 7 6 6 5 5 4 4 3 3 2 2

17° 10′ — 19° 2′ 7 7 6 6 5 5 4 4 3 3 2

19° 2′ — 20° 45′ 8 7 7 6 6 5 5 4 4 3 3

20° 45′ — 22° 22′ 8 8 7 7 6 6 5 5 4 4 3

22° 22′ — 23° 54′ 9 8 8 7 7 6 6 5 5 4 4

23° 54′ — 25° 21′ 9 9 8 8 7 7 6 6 5 5 4

25° 21′ — 26° 45′ 10 9 9 8 8 7 7 6 6 5 5

26° 45′ — 28° 6′ 10 10 9 9 8 8 7 7 6 6 5

28° 6′ — 29° 25′ 11 10 10 9 9 8 8 7 7 6 6

29° 25′ — 30° 41′ 11 11 10 10 9 9 8 8 7 7 6

30° 41′ — 31° 56′ 12 11 11 10 10 9 9 8 8 7 7

31° 56′ — 33° 9′ 12 12 11 11 10 10 9 9 8 8 7

33° 9′ — 34° 21′ 13 12 12 11 11 10 10 9 9 8 8

34° 21′ — 35° 31′ 13 13 12 12 11 11 10 10 9 9 8

35° 31′ — 36° 41′ 14 13 13 12 12 11 11 10 10 9 9

36° 41′ — 37° 50′ 14 14 13 13 12 12 11 11 10 10 9

37° 50′ — 38° 58′ 15 14 14 13 13 12 12 11 11 10 10

38° 58′ — 40° 5′ 15 15 14 14 13 13 12 12 11 11 10

40° 5′ — 41° 12′ 16 15 15 14 14 13 13 12 12 11 11

41° 12′ — 42° 19′ 16 16 15 15 14 14 13 13 12 12 11

42° 19′ — 43° 26′ 17 16 16 15 15 14 14 13 13 12 12

43° 26′ — 44° 32′ 17 17 16 16 15 15 14 14 13 13 12

44° 32′ — 45° 38′ 18 17 17 16 16 15 15 14 14 13 13

45° 38′ — 46° 45′ 18 18 17 17 16 16 15 15 14 14 13

46° 45′ — 47° 51′ 19 18 18 17 17 16 16 15 15 14 14

47° 51′ — 48° 58′ 19 19 18 18 17 17 16 16 15 15 14

48° 58′ — 50° 6′ 20 19 19 18 18 17 17 16 16 15 15

50° 6′ — 51° 13′ 20 20 19 19 18 18 17 17 16 16 15

51° 13′ — 52° 22′ 21 20 20 19 19 18 18 17 17 16 16

52° 22′ — 53° 31′ 21 21 20 20 19 19 18 18 17 17 16

53° 31′ — 54° 41′ 22 21 21 20 20 19 19 18 18 17 17

54° 41′ — 55° 52′ 22 22 21 21 20 20 19 19 18 18 17

55° 52′ — 57° 4′ 23 22 22 21 21 20 20 19 19 18 18

57° 4′ — 58° 17′ 23 23 22 22 21 21 20 20 19 19 18

58° 17′ — 59° 32′ 24 23 23 22 22 21 21 20 20 19 19

59° 32′ — 60° 49′ 24 24 23 23 22 22 21 21 20 20 19

60° 49′ — 62° 9′ 25 24 24 23 23 22 22 21 21 20 20

62° 9′ — 63° 30′ 25 25 24 24 23 23 22 22 21 21 20

63° 30′ — 64° 55′ 26 25 25 24 24 23 23 22 22 21 21

64° 55′ — 66° 24′ 26 26 25 25 24 24 23 23 22 22 21

66° 24′ — 67° 57′ 27 26 26 25 25 24 24 23 23 22 22

67° 57′ — 69° 35′ 27 27 26 26 25 25 24 24 23 23 22

69° 35′ — 71° 21′ 28 27 27 26 26 25 25 24 24 23 23

71° 21′ — 73° 16′ 28 28 27 27 26 26 25 25 24 24 23

73° 16′ — 75° 24′ 29 28 28 27 27 26 26 25 25 24 24

75° 24′ — 77° 52′ 29 29 28 28 27 27 26 26 25 25 24

77° 52′ — 80° 56′ 30 29 29 28 28 27 27 26 26 25 25

80° 56′ — 85° 45′ 30 30 29 29 28 28 27 27 26 26 25

85° 45′ — 90° 00′ 31 30 30 29 29 28 28 27 27 26 26

0

1060

1060

2130

2130

3200

Height above sea-level in meters

975

1300

1300

1625

1625

1950

Height above sea-level in feet

3200

4260

4260

5330

5330

6400

1950

2275

6400

7460

2275

2600

7460

8530

2600

2925

8530

9600

2925

3250

9600

10660

3250

3575

10660

11730

Page 27

STANDARD BENCH SCALE

PHYSICAL DIMENSIONS

Indicator:

27

Platform:

Model L W H L1 L2 L3 W1 W2 H1 4-φ

XMCxx-XIS

XMCxxS-XIS

XWSxxR-XIS

XWSxxRS-XIS

XWSxxM-XIS

XWSxxMS-XIS

XWTxxM-XIS

XWTxxMS-XIS

9” 9” 3.1” 7.1” 9” 11.6” 7.1” 9” 15.7” 1.2”

14” 12” 3.7” 12.3” 14.8” 19.2” 10.4” 12.8” 20.9” 2.0”

20” 16” 4.1” 18.0” 20.5” 25.0” 14.1” 16.5” 33.7” 2.0”

28” 20” 5.6” 24.6” 28.3” 32.2” 16.7” 20.5” 36.6” 2.8”

Page 28

28

Notes

STANDARD BENCH SCALE

Page 29

STANDARD BENCH SCALE

Notes

29

Page 30

Xpress

Mettler-Toledo, Inc.

60 Collegeview

Westerville, OH 43081

5/2004

MTX04-OM040.1E

STANDARD BENCH SCALE www.mt.com/xpress

Loading...

Loading...