Mettler Toledo WXS205DU/15, WXSS204, WXS205DUV/15, WXS204V/15, WXSS205DU Instructions For Installation And Operation Manual

...Page 1

Instructions for Installation and Operation

METTLER TOLEDO

WXS and WXT Weighing Modules

Page 2

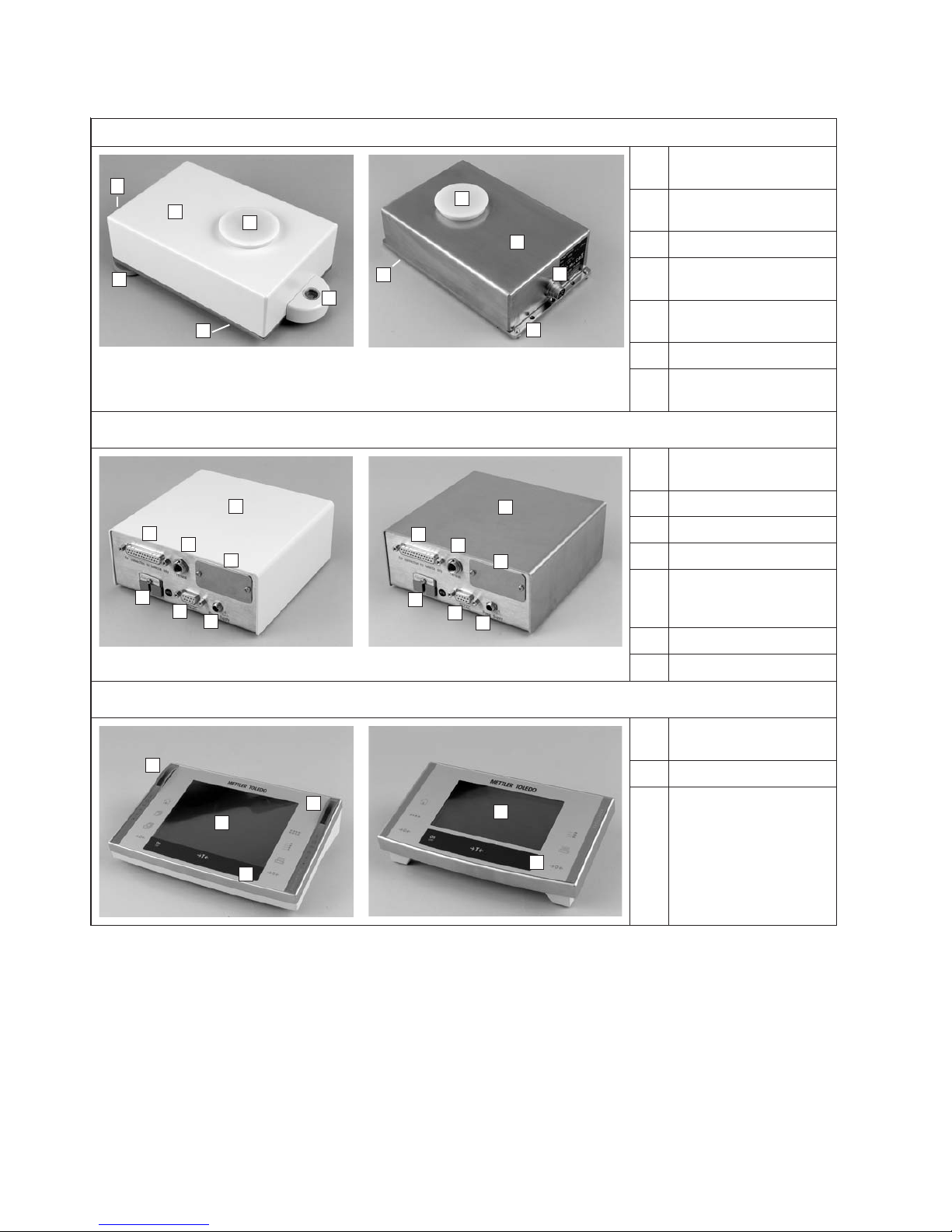

Load Cells

1

3

4

5

6

2

1

2

3

4

7

1 Housing (WXT: white powder-

coated, WXS: stainless steel)

2 Weighing pan retainer

with plastic cover

3 Connector for electronic unit

4 Hanger opening for weighing

below (on bottom side)

5 Level bubble (leveling aid,

on WXT model only)

6 Adjustable feet (WXT only)

7 Base plate with mounting

flange (WXS only)

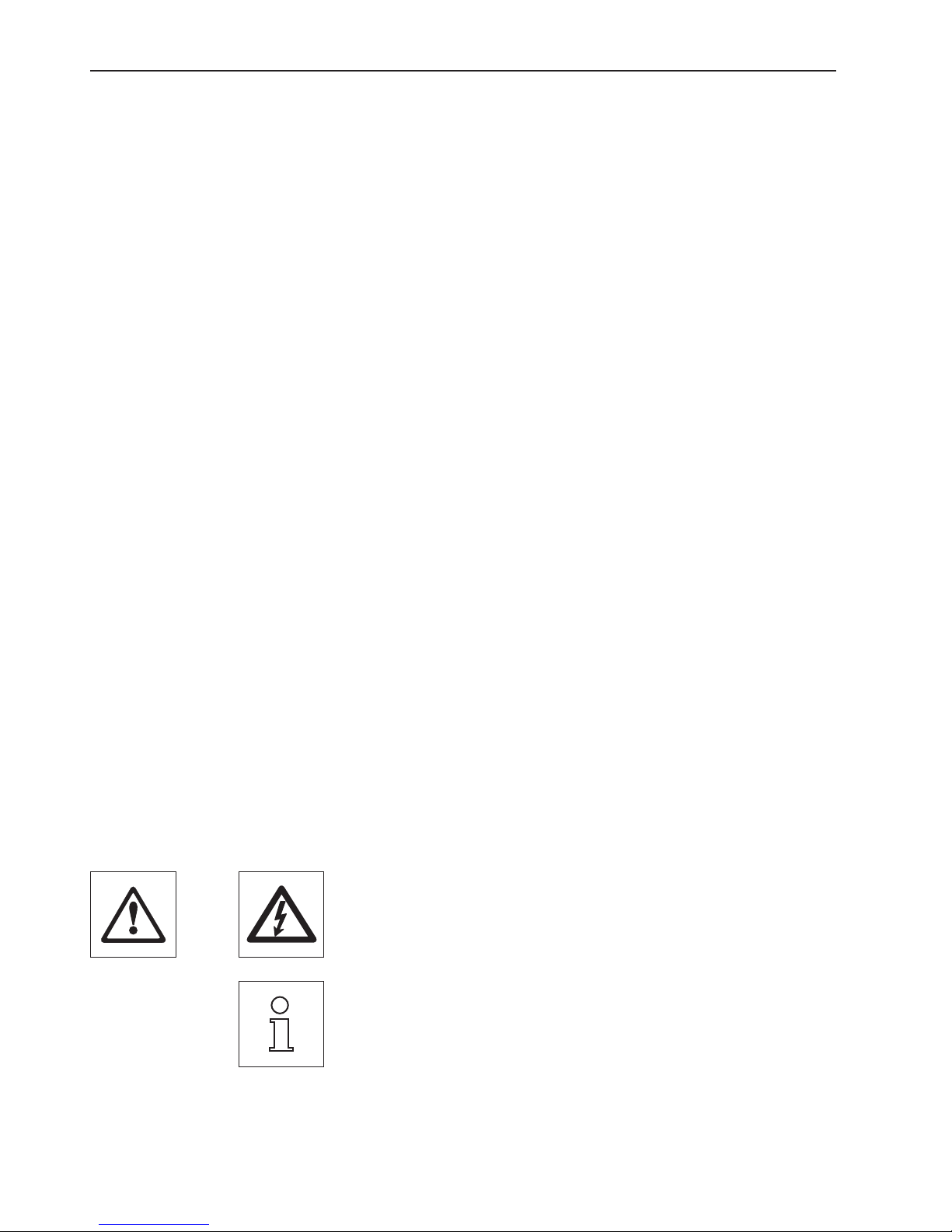

Electronic units

8

9

10

11

12

13

14

8

9

10

11

12

13

14

8 Housing (WXT: white powder-

coated, WXS: stainless steel)

9 Load cell connector

10 Terminal connector

11 Optional interface plug-in

12 “Aux” connectors (for

“ErgoSens,” hand or footoperated buttons)

13 RS232-C standard interface

14 Connector for AC adapter

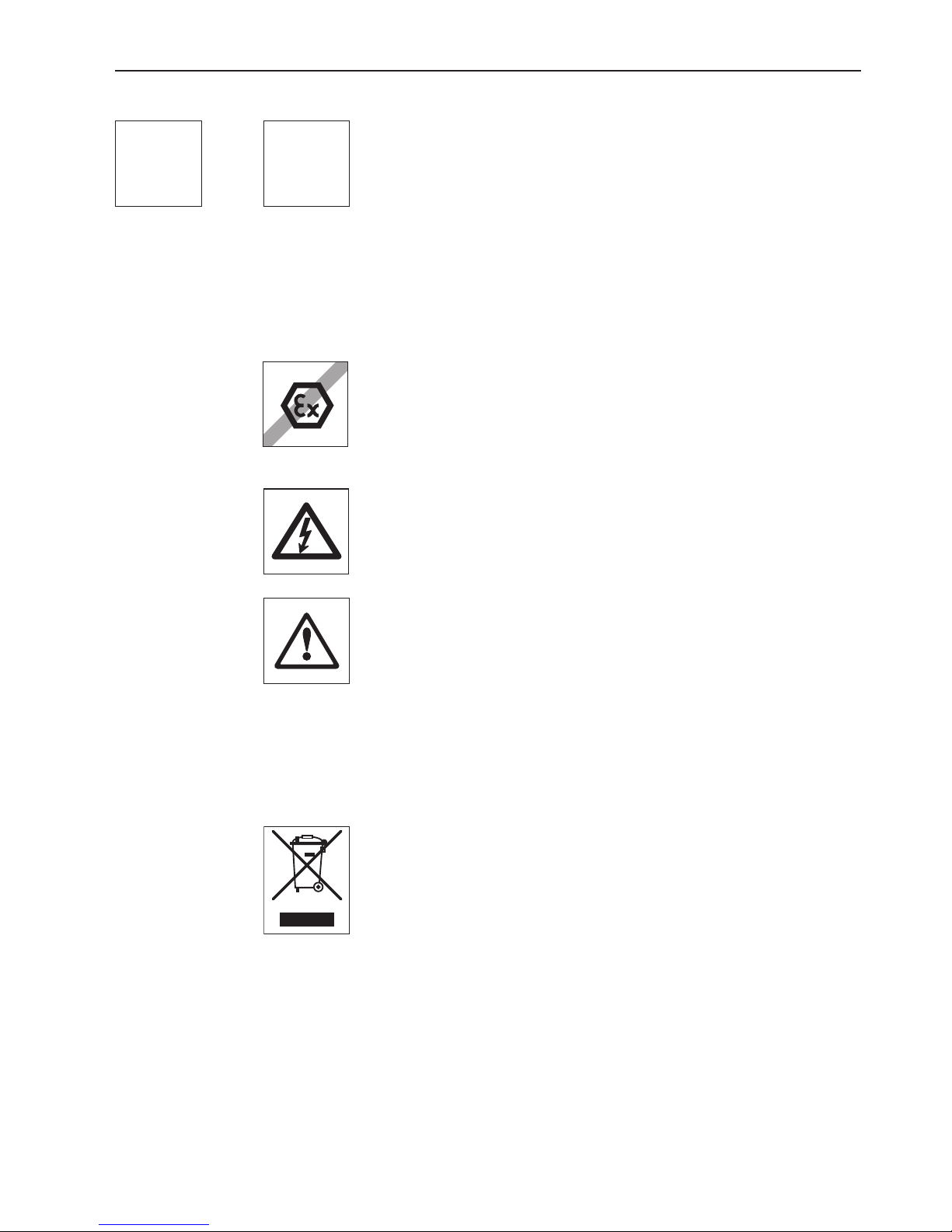

Terminals

15

16

17

17

15

16

15 Display (PWT: color,

SWT: monochrome)

16 Keyboard

17 “SmartSens” sensors

(PWT only)

The WXS and WXT weighing modules at a glance

WXT WXS

WXT WXS

PWT SWT

Page 3

Weighing pans

18

19

18 Standard weighing pan

19 Adapter weighing pan

Mounting materials

20

21

20 Mounting bracket for WXS

electronic unit, including

DIN clip and screws

21 Terminal holder for SWT

terminal, including screws

Connecting cables

22

23

22 Electronic unit – load cell

connector cable

(0.5m/1.6ft or

1.5m/5ft long)

Note: The maximum allowable

cable length is 5m/16.4ft.

23 Terminal – electronic

unit connector cable

(0.575m/1.9ft or

2m/6.5ft long)

Note: The maximum allowable

cable length is 5m/16.4ft.

Power supply

24 25

24 AC adapter

25 Power cable (country-

specific)

Page 4

Contents

4

Contents

1 Introduction .................................................................................................................................................... 6

1.1 Introduction to the WXS/WXT weighing modules ............................................................................................................ 6

1.2 What you should know about this manual .....................................................................................................................6

1.3 Safety first! ...................................................................................................................................................................7

1.4 Available documentation ..............................................................................................................................................8

2 Initial startup of weighing modules .................................................................................................................. 9

2.1 Unpacking the weighing module and notes on packaging..............................................................................................9

2.2 Scope of delivery .......................................................................................................................................................10

2.3 Assembling of WXS weighing module .........................................................................................................................11

2.3.1 Load cell installation ..................................................................................................................................................11

2.3.2 Electronic unit assembly and mounting ....................................................................................................................... 12

2.4 Weighing module WXT setup ...................................................................................................................................... 12

2.4.1 Choosing a location ................................................................................................................................................... 12

2.4.2 Levelling the load cell.................................................................................................................................................13

2.5 Place weighing pan....................................................................................................................................................13

2.5.1 Standard weighing pan ..............................................................................................................................................13

2.5.2 Adapter weighing pan ................................................................................................................................................14

2.5.3 Notes on weighing below ...........................................................................................................................................14

2.5.4 Overload protection .................................................................................................................................................... 15

2.6 Connect load cell and electronic unit ..........................................................................................................................16

2.7 Connect terminal and adjust settings .......................................................................................................................... 16

2.7.1 SWT Terminal ............................................................................................................................................................16

2.7.2 PWT Terminal ............................................................................................................................................................17

2.8 Connect the unit to the power supply .......................................................................................................................... 18

3 Configuring the weighing module .................................................................................................................. 19

3.1 Extended SICS command set for WXS/WXT weighing modules without terminal ............................................................21

3.2 Standard SICS command set for WXS/WXT weighing modules without terminal .............................................................21

3.3 Preparatory steps for configuration ..............................................................................................................................24

3.4 Configuring the weighing module ...............................................................................................................................25

3.4.1 Adjusting the weighing module ................................................................................................................................... 25

3.4.2 Set readability ............................................................................................................................................................25

3.4.3 Set stability criteria .....................................................................................................................................................26

3.4.4 Activating and defining the fixed filter .......................................................................................................................... 28

3.4.5 Adjustments to ambient conditions (filter damping) .....................................................................................................29

3.4.6 Setting the update rate for continuous weight transmission ..........................................................................................29

3.4.7 Recording user settings .............................................................................................................................................. 30

3.4.8 Resetting user-specific settings to factory default .........................................................................................................31

3.4.9 Information on the memory location for user-specific settings ...................................................................................... 32

4 Weighing operation ......................................................................................................................................33

4.1 Transmission of weight values ....................................................................................................................................33

4.2 Taring function ........................................................................................................................................................... 34

4.3 Zeroing functions ....................................................................................................................................................... 35

Page 5

Contents

5

4.4 Troubleshooting weighing module errors and malfunctions .........................................................................................36

4.4.1. If your weighing module doesn’t perform correctly until it has been powered up for quite a while .................................. 36

4.4.2 If the weighing module does not transmit the expected weight readings ....................................................................... 36

4.4.3 If the weighing module doesn’t react to your commands at all ..................................................................................... 36

5 Maintenance and Service .............................................................................................................................. 37

5.1 Cleaning the weighing module ...................................................................................................................................37

5.2 Maintenance .............................................................................................................................................................37

6 Technical Data, Accessories, and Replacement Parts ....................................................................................... 38

6.1 General data .............................................................................................................................................................. 38

6.2 Model-specific data ....................................................................................................................................................40

6.3 Key to types and list of available models .....................................................................................................................42

6.4 Dimensions ...............................................................................................................................................................43

6.4.1 WXS load cell dimensional drawing ............................................................................................................................43

6.4.2 WXT load cell dimensional drawing ............................................................................................................................. 44

6.4.3 Adapter weighing pan dimensional drawing ................................................................................................................ 45

6.4.4 WXS electronic unit dimensional drawing (including mounting bracket) ....................................................................... 45

6.4.5 WXT electronic unit dimensional drawing (including terminal holder) ...........................................................................46

6.4.6 SWT terminal dimensional drawing (mounted using terminal holder) ........................................................................... 47

6.4.7 PWT terminal dimensional drawing ............................................................................................................................ 48

6.4.8 Adapter for weighing below (optional), dimensional drawing ........................................................................................49

6.5 RS232C interface (standard interface) specifications ................................................................................................... 50

6.6 Specification for Aux connections ................................................................................................................................ 50

6.7 Accessories and Replacement Parts ............................................................................................................................51

6.7.1 Accessories ...............................................................................................................................................................51

6.7.2 Replacement parts ..................................................................................................................................................... 52

7 Appendix .....................................................................................................................................................53

7.1 Conversion table for weight units ................................................................................................................................ 53

7.2 SOP - Standard Operating Procedure ........................................................................................................................... 54

7.3 Updating firmware ......................................................................................................................................................55

7.4 Glossary ....................................................................................................................................................................55

8 Index ........................................................................................................................................................... 58

Page 6

Introduction

6

1 Introduction

Thank you for choosing a METTLER TOLEDO weighing module.

This section will provide you with basic information on the WXS and WXT weighing modules. Even if you have previous experience with

other scales or METTLER TOLEDO scales, please read this section carefully. It is VERY IMPORTANT that you obey all safety instructions!

1.1 Introduction to the WXS/WXT weighing modules

These instructions apply to all WXS and WXT weighing modules. The models differ in their weighing ranges, resolution, mechanical

structure, features, and the included accessories. The text makes a special point of mentioning items that have an impact on operating

the unit.

The weighing modules are available in two different versions: a benchtop version (WXT) and a component version (WXS).

Each weighing module consists of a load cell, an electronic unit and a terminal (optional). The load cell and electronic unit are avail-

able in either a benchtop or component version. There are two terminals available that can be used with both the benchtop and the

component versions. The smaller SWT terminal has a monochrome display and built-in applications. The large PWT terminal has a

color display, supports multiple user profiles and also has an added “MinWeigh” application. There are separate instruction manuals

available for the terminals.

All WXS/WXT models have the following features:

– “Fact” adjustment and linearization with two internal weights

– Integrated RS232C interface

– Optional interface plug-in

– Standard weighing pan and additional adapter weighing pan provided for users to create their own setups

– Plastic cover provided for cleaning the weighing module and establishing ingress protection of IP65

– A full set of cables and mounting accessories is provided

– A CD-ROM with additional instructions and a PC program for setup and operation of the weighing module are also included

A brief word regarding standards, directives and procedures for quality assurance: The WXS and WXT weighing modules comply with all

commonly accepted standards and guidelines. They support standard processes, requirements and work methodologies in accordance

with GLP (Good Laboratory Practice) and GMP (Good Manufacturing Practice) and allow for the creation of SOPs (Standard Operating

Procedures). The WXS/WXT weighing modules have been issued a CE-Declaration of Conformity. METTLER TOLEDO, the manufacturer,

is both ISO 9001 and ISO 14001certified.

1.2 What you should know about this manual

The following conventions apply to the entire manual:

These symbols mark safety and hazard warnings. Failure to comply with these warnings

may result in personal risk to the user, damage to the weighing module or other property,

or unit malfunction.

This symbol marks additional information and notes. Following these instructions will

make it easier for you to work with the weighing module and ensure proper and efficient

use of the unit.

Page 7

Introduction

7

These symbols mark specific information on setting up, configuring, or operating weighing

modules without a terminal (“–T”) or with a terminal (“+T”).

+T–T

1.3 Safety first!

Please follow the tips and instructions given below on the safe operation of your WXS/WXT weighing module. Always operate and

use your weighing module solely in accordance with the instructions given in this manual. Failure to do so may limit the protection

the unit can offer you. Be sure to follow the instructions on the initial startup of your new weighing module.

WXS/WXT weighing modules may be used only in closed indoor spaces. Never operate

these units in areas where there is any explosion hazard.

METTLER TOLEDO recommends that you use the AC adapter provided with your unit to

operate it. Make sure that the voltage printed on the adapter matches your local power

supply. Plug the adapter into a grounded outlet only.

Your WXS/WXT weighing module is built to be tough, but it is still a precision instrument.

Handle it carefully.

Do not open the weighing module. There are no user-servicable parts inside. If you should

ever have a problem with your weighing module, please contact the METTLER TOLEDO

office nearest you.

Use only METTLER TOLEDO accessories and peripheral devices with your weighing module;

these items are designed to work optimally with your WXS/WXT weighing module.

Disposal

In compliance with the requirements of the EU Waste Electrical and Electronic Equipment

Directive 2002/96/EU (WEEE), this unit may not be disposed of with household waste.

The spirit of this Directive also applies to countries outside the EU in accordance with

currently valid national regulations.

Please dispose of this product in compliance with local regulations in a separate collection

for electrical and electronic equipment.

If you have any questions, please contact the responsible authority or the dealer from

whom you purchased your unit.

If you sell or give your unit to someone else (e.g., for private or commercial/industrial use),

this stipulation must be made known to the new owner as appropriate.

Thank you for helping protect the environment.

Page 8

Introduction

8

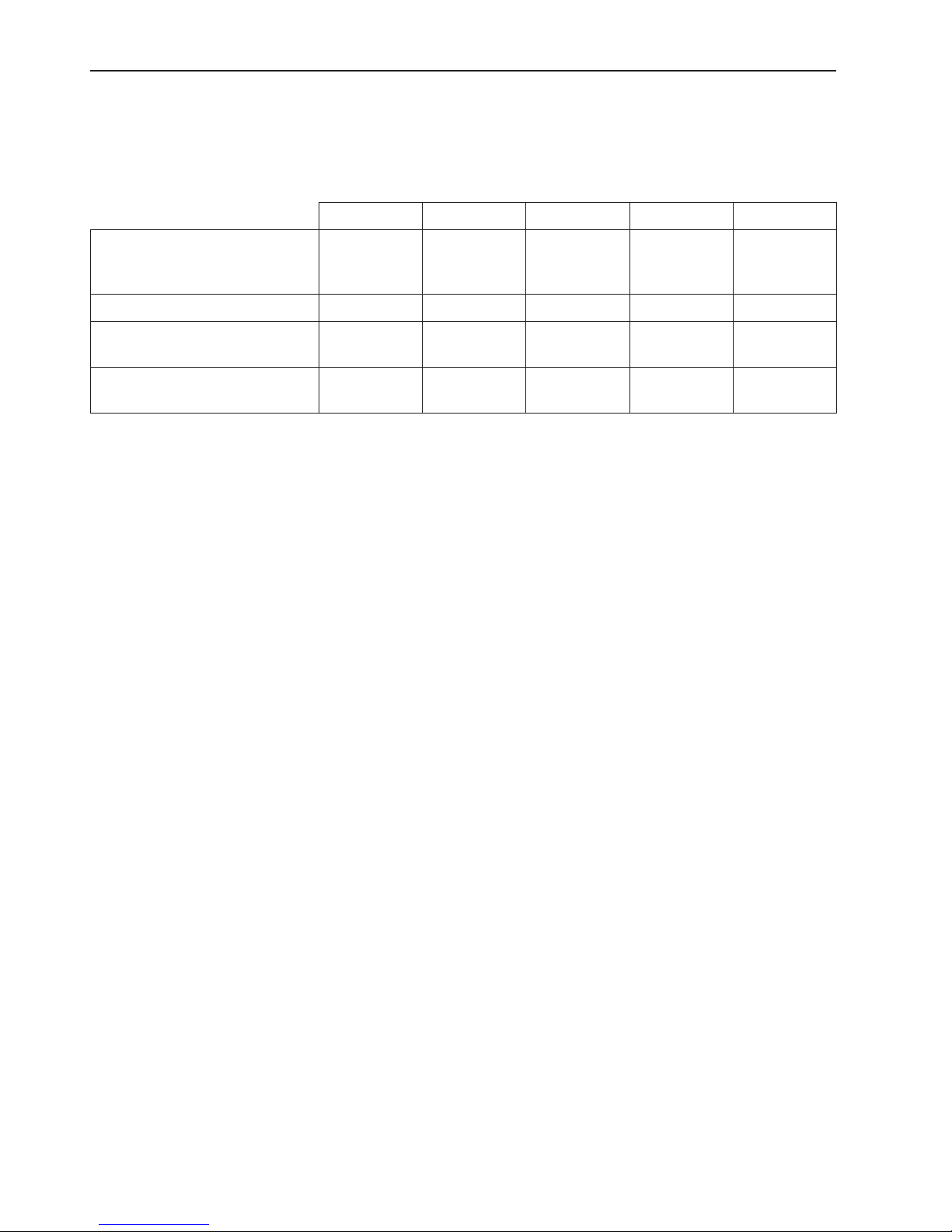

1.4 Available documentation

The table below lists all documentation available for the WXS and WXT weighing modules, along with the document numbers for each

document.

German English French Spanish Italian

Instructions for Installation and

Operation of the WXS and WXT

weighing modules (this document)

11780991 11780992 – – –

MT-SICS reference manual – 11780711 – – –

Instructions for SWT terminal

(XS scale instruction manual, Part 2)

11781117 11781118 11781119 11781120 11781121

Instructions for PWT terminal

(XP scale instruction manual, Part 2)

11781076 11781077 11781078 11781079 11781080

The CD-ROM (11781008) provided with your unit includes all of the documents listed above. Also, printed copies of all instructions are

provided in the language of the country to which the unit is delivered. Printed instructions for SWT or PWT terminals are included only

for weighing modules with terminals.

Page 9

Initial startup of weighing modules

9

2 Initial startup of weighing modules

This section tells you how to unpack your new weighing module, set it up, and prepare it for operation.

2.1 Unpacking the weighing module and notes on packaging

The load cell, the electronic unit, and the terminal are each packed in separate cardboard boxes along with the associated hardware

and appropriate mounting materials. The boxes are labeled with their contents as follows: “Weighing Module,” “Electronic Unit,” and

“Terminal”.

Depending on whether you’ve ordered a weighing module with or without a terminal, you will receive either 2 or 3 boxes that are placed

inside a large transport box.

Unpacking the electronic unit and terminal:

Remove the top foam cushion and remove the electronic unit and the hardware.

Unpacking the load cell:

Remove the black foam cushion and take out the hardware.

Carefully lift the white cushion containing the load cell out of the box and place it on a

level surface.

Carefully pull the white cushioning material a few inches apart and remove the load

cell.

Keep all packaging in case you need to ship the module in the future; the weighing

module should only be transported in its original packaging.

Page 10

Initial startup of weighing modules

10

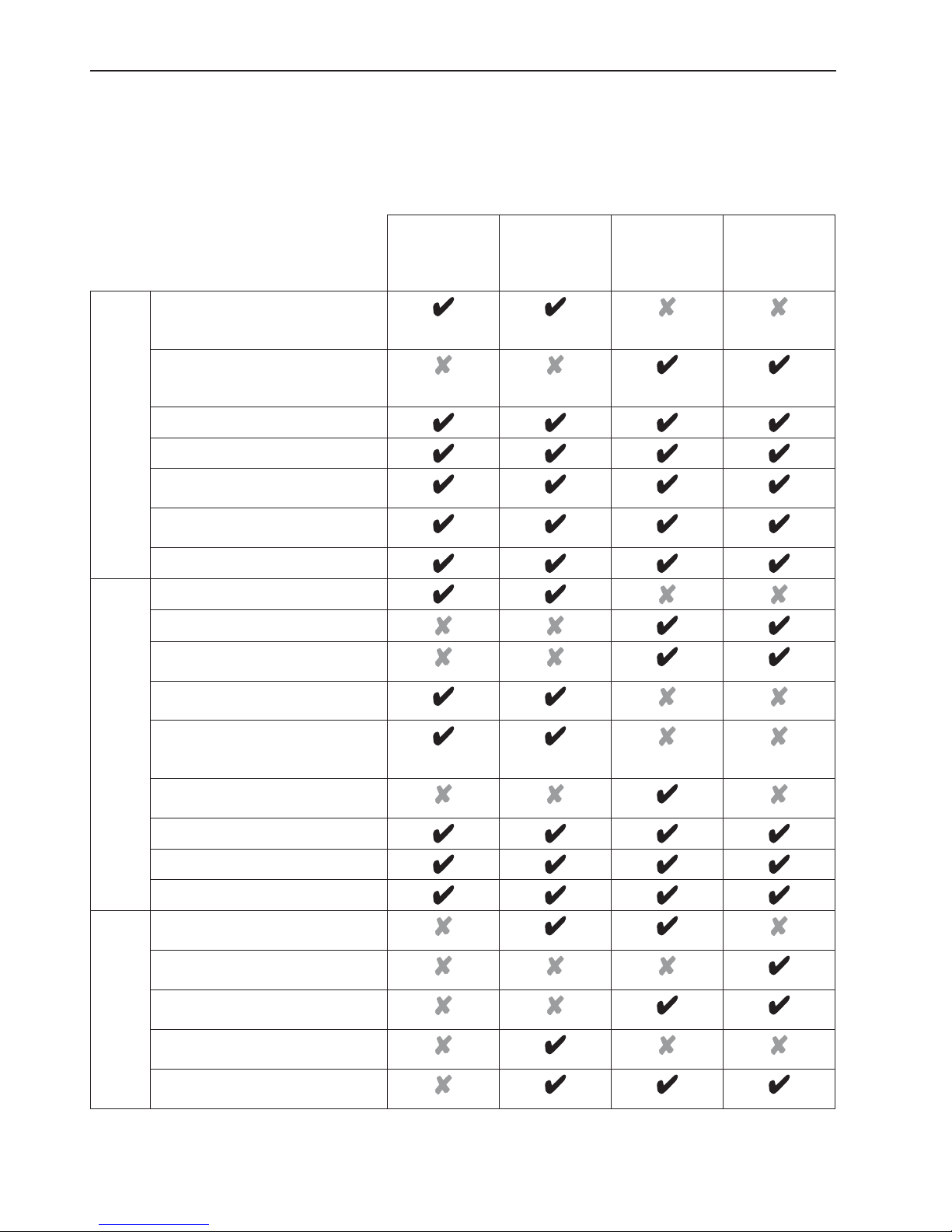

2.2 Scope of delivery

The scope of delivery for your weighing module depends on the specific model that you ordered. Please check the scope of delivery

using the following table. If any parts are missing or defective, please report this to your METTLER TOLEDO representative or the shipper

immediately.

WXS204/15

WXS205DU/15

WXS204V/15

WXS205DUV/15

WXSS204

WXSS205DU

WXSS204V

WXSS205DUV

WXTS204

WXTS205DU

WXTS204V

WXTS205DUV

WXTP204

WXTP205DU

WXTP204V

WXTP205DUV

“Weighing Module” Box

WXS load cell (component version) with

attached plastic cover to cover the weighing

pan retainer.

WXT load cell (benchtop version) with attached plastic cover to cover the weighing

pan retainer.

Standard weighing pan

Adapter weighing pan

WXS/WXT weighing module instructions

(this document)

Production certificate and CE Declaration of

Conformity

CD-ROM with instructions and PC software

“Electronic Unit” Box

WXS electronic unit (component version)

WXT electronic unit (benchtop version)

Electronic unit-load cell connector cable,

0.5m/1.6ft long

Electronic unit-load cell connector cable,

1.5m/5ft long

Mounting bracket for electronic unit,

including clip and screws for attaching

to DIN standardized rail

Terminal holder, including screws (for

attaching the terminal to the electronic unit)

AC adapter

Power cable (country-specific)

MT-SICS reference manual

“Terminal” Box

SWT terminal (monochrome display),

including protective covering

PWT terminal (color display), including

protective covering

Terminal-electronic unit connector cable,

0.575m/1.9ft long

Terminal-electronic unit connector cable,

2m/6.5ft long

Terminal instruction manual

(XS/XP instructions, Part 2)

Page 11

Initial startup of weighing modules

11

2.3 Assembling of WXS weighing module

The WXS (component version) weighing modules can be integrated into higher-level systems (machines, systems, etc.). Be sure to

follow the tips in the following sections to select the optimal installation method

2.3.1 Load cell installation

The weighing modules were designed to record weights very quickly and accurately under normal conditions and communicate the

result using the integrated interface and/or display the result on a terminal. In practice, ambient conditions (vibration, oscillations, shocks,

air movements and temperature changes) affect weighing time and achievable accuracy as well as the repeatability.

You can adjust various parameters on your weighing module (Section 3). We recommend that you adjust the settings to the levels

needed for your application; higher requirements increase the weighing time (period between the placement of the weight and the

availability of a stable result).

Filter settings must be stricter to compensate for unfavorable ambient conditions (Section 3); this also has a negative impact on weigh-

ing time. Therefore, be sure to note the following:

– Mount the load cell on a base that is mechanically decoupled from the system and therefore free of shocks and vibration. If a

mechanical decoupling is not possible, place appropriate cushioning between the system and the load cell mount.

– The location of the load cell should not be in areas that are exposed to drafts, direct

sunlight, or severe temperature fluctuations.

– Make sure that any vibrations in the building are not transferred through the floor and

to the load cell

– Make sure that the load cell is as perfectly horizontal as possible. Use a precision level

to achieve exact leveling. It is acceptable to have a unit that is not perfectly horizontal

if its position is not altered after it has been adjusted (e.g., if it is mounted in a fixed

position in the system).

– Attach the load cell to the base across as wide an area as possible. Use the appropri-

ate bores in the front part of the cell’s base plate (4x M5 screws, tightening torque

4 – 6Nm). The base must be perfectly planar to avoid putting tension on the load cell

base plate.

– Make sure that vibrations cannot be transferred across the connector cable between

the load cell and the electronic unit.

– Make sure that the load cell housing is connected in an electrically conductive manner

with the machine structure.

If your requirements are extremely demanding (short weighing time, high accuracy),

we recommend that you try a test setup first and test the entire system under real-world

conditions using various settings (Section 3). This will allow you to tweak the system and

optimize it bit by bit.

Page 12

Initial startup of weighing modules

12

Pick a location that is stable, vibration-free and shock-free, and as horizontal as possible.

The floor beneath the weighing module must be able to safely hold the weighing module

with the maximum possible load on the load cell.

Take care to ensure the proper ambient conditions (Section 6).

Avoid:

– Direct sunlight

– Strong drafts (e.g. from fans or climate-control systems)

– Extreme temperature fluctuations.

2.4 Weighing module WXT setup

The WXT weighing module (benchtop version) does not require any assembly work. Note the information in the following sections about

choosing an optimal location and leveling the load cell.

2.4.1 Choosing a location

Your weighing module is a precision instrument. Provided with an optimal location, it will reward you with great accuracy and

reliability.

Remove the two existing screws from the bottom side of the electronic unit (Torx T-20)

and use the provided Torx T-20 countersunk head screws (A) to secure the mounting

bracket.

Secure the clip (B) to the front face or underside of the mounting bracket. Use the two

provided M4 pan head screws (Torx T-20) to do so.

Note: The electronic unit can also be attached directly to the mounting bracket (without

a clip) via the M4 thread using a support.

Important: The electronic unit meets the requirements for protection class IP40. If required,

appropriate protective measures must be taken to protect the unit from dirt.

Additional assembly items:

– Place weighing pan (Section 2.5)

– Connect load cell and electronic unit (Section 2.6)

– Connect terminal and adjust settings (Section 2.7)

– Connect the unit to the power supply (Section 2.8)

A

B

A

2.3.2 Electronic unit assembly and mounting

The electronic unit can be mounted in any position you wish. A mounting bracket and clip for attaching the unit to a DIN standardized

rail are provided. Proceed as follows for mounting:

Page 13

Initial startup of weighing modules

13

2.4.2 Levelling the load cell

Once the load cell has been set up at the desired location, the load cell must be horizontally aligned (leveled).

The load cell is equipped with a level (level bubble) and two adjustable feet. The load cell

is completely horizontal when the bubble is precisely in the middle of the level window

(left image = properly level, right image = not properly level).

Adjust both feet as necessary until the air bubble is right in the middle of the level

window.

Note:You should always level the load cell after moving it to a new location.

Additional tasks:

– Place weighing pan (Section 2.5)

– Connect load cell and electronic unit (Section 2.6)

– Connect terminal and adjust settings (Section 2.7)

– Connect the unit to the power supply (Section 2.8)

2.5 Place weighing pan

The WXS and WXT weighing modules come with two weighing pans: a standard weighing pan and an adapter weighing pan for users

to create their own setups.

2.5.1 Standard weighing pan

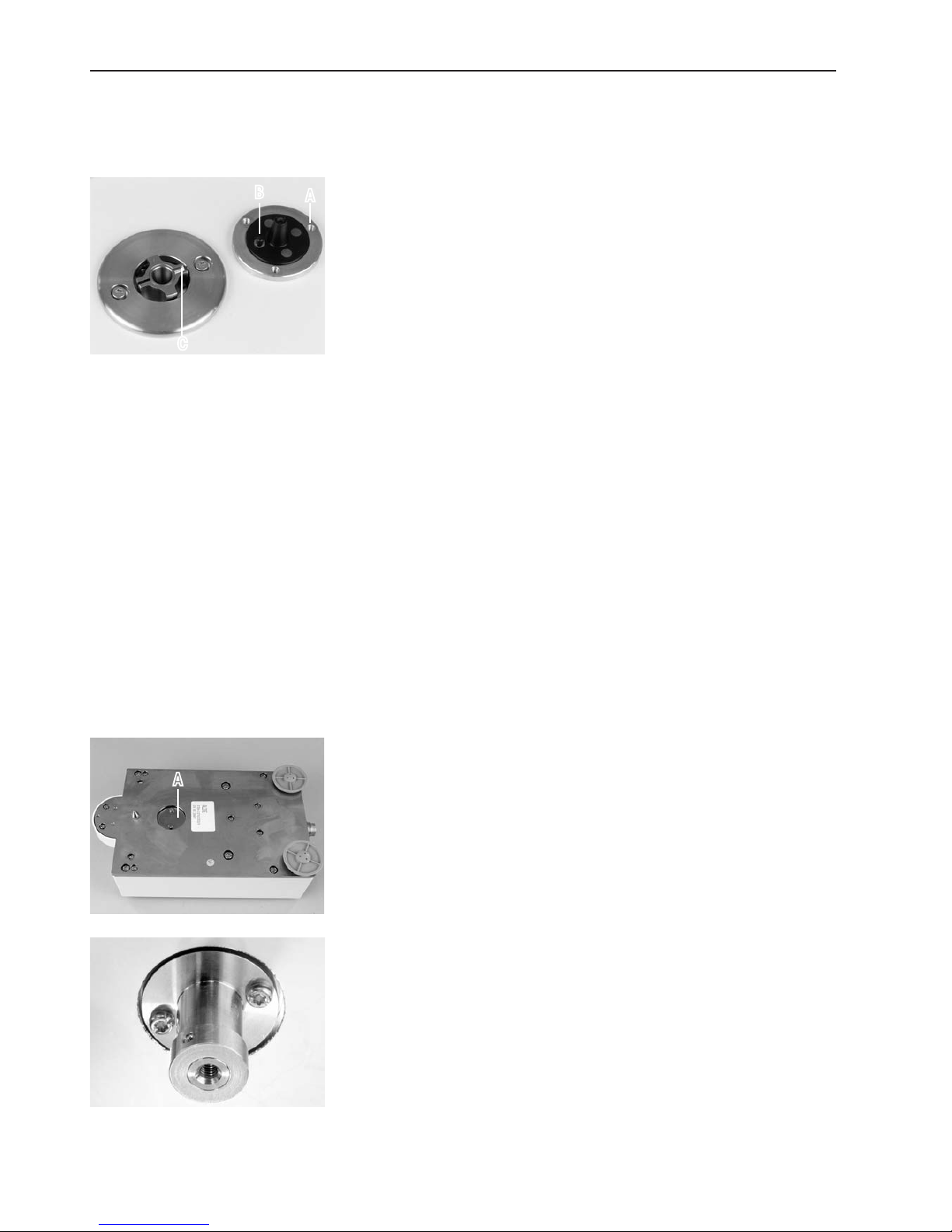

Remove the white plastic cover (A) from the load cell. This cover protects the weighing

pan retainer (B) from damage during transport and keeps liquid out of the load cell during

cleaning. Make sure you keep the cover in a safe place!

Place the weighing pan cone into the weighing pan retainer. You do not need to insert it

in any specific position; the standard weighing pan will turn freely.

A

B

Page 14

Initial startup of weighing modules

14

2.5.2 Adapter weighing pan

The adapter weighing pan is used for customer-specific setups to hold the object to be weighed.

The customer-specific setup can be attached to the weighing pan using the three 120°

offset M3 threaded holes (A). See Section 6 for the exact dimensions of the adapter

weighing pan.

Keep in mind that your setup must weigh at least 55 g to ensure that the required dead

load of 65 g (weighing pan + setup) is reached. If the required dead load is not reached,

the weighing module will output an underload error message upon startup.

To preserve the full weighing range, the total preload (weighing pan + setup) may not

exceed 88 g. Heavier preloads will take away from the available weighing range.

Because customer-specific setups generally remain in a fixed position, the adapter weighing

pan has a positioning pin (B). This pin fits perfectly in the wider of the two grooves in the

weighing pan retainer (C) and prevents the weighing pan from turning freely. However, this

anti-displacement measure works only up to a certain torque. If this torque is exceeded,

the weighing pan and weighing pan retainer turn together to prevent damage to the load

cell. At the same time, the weighing pan retainer serves a protection from lateral forces.

B

C

A

2.5.3 Notes on weighing below

For weighing beneath the work area (weighing below), the load cell is equipped with a hanger opening. For weighing below, the item

to be weighed is not placed on the weighing pan; it is placed on an application-specific receptacle attached beneath the load cell. For

weighing below, the standard weighing pan is removed, and the weighing pan retainer is closed up using the plastic cover so that dirt

and foreign matter cannot penetrate the load cell.

Here are some examples of when weighing below is used:

– when it is difficult or impossible to put the material to be weighed on the weighing pan

– when space will not allow for items to be weighed from above

– when weighing from above might soil or contaminate the load cell.

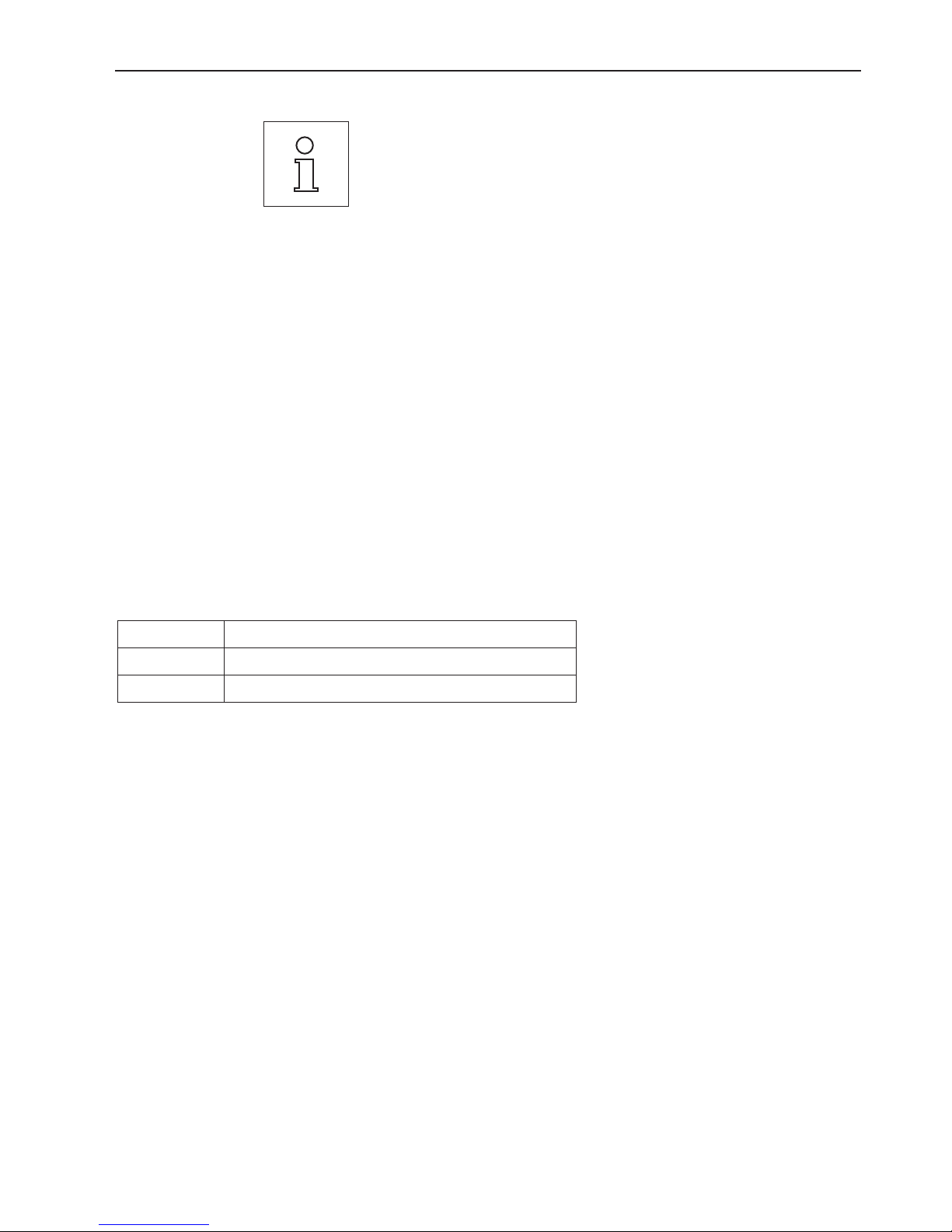

The hanger opening is on the bottom of the cell under a round cover (A).

You’ll need the optional weighing below adapter, which should be installed by a

METTLER TOLEDO service technician if possible, to attach the customer-specific receptacle

(see Section 6 for information on how to order).

A

Page 15

Initial startup of weighing modules

15

Please keep the following in mind when planning a weighing below receptable for objects

to be weighed:

– The fixture must weigh at least 52 g, to ensure that the required dead load of 65 g

(weighing below adapter + fixture). If the required dead load is not reached, the weighing

module will output an underload error message upon startup. To preserve the full weighing range, the total weight of the weighing below adapter and fixture may not exceed

88 g. Heavier preloads will take away from the available weighing range.

– Secure the fixture to the M4 thread of the weighing below adapter (max. penetration

depth: 8mm, max. tightening torque: 1 Nm, see also dimensional drawing in Section

6.4.8).

– Position the fixture’s center of gravity as close to and vertically beneath the attachment

point as possible.

– The weighing receptacle must hang freely from the attachment point of the weighing

below adapter without touching non-moving parts of the load cell or the system. The

maximum diameter or cross-section of the fixture at the attachment point is 8 mm.

– Limit the vertical and horizontal movement and/or torsion of the fixture by using me-

chanical stops to prevent overload of the load cell.

– To minimize weighing time, avoid vibrations and shocks to the fixtures and the objects

to be weighed.

2.5.4 Overload protection

The WXS/WXT weighing modules have overload protection that is effective in all directions up to the following limit values:

Vertical load: 5 kg (all types; centered load)

Lateral load: 1 kg (protected by torsion protection; see Section 2.5.2)

Torsion: Protected by torsion protection (see Section 2.5.2)

Page 16

Initial startup of weighing modules

16

2.6 Connect load cell and electronic unit

Use the provided cable (0.5 m or 1.5 m long) to connect the load cell to the electronic

unit (a 5 m cable is available as an accessory).

Tighten the plugs on both devices.

Note: The load cell and the electronic unit can be replaced independently of each other

if necessary.

Lay the cable so that no one will trip over it and so that no vibration can travel up the

cable and be transferred to the load cell.

2.7 Connect terminal and adjust settings

You’ll need this section only if your weighing module was delivered with a terminal.

2.7.1 SWT Terminal

Place the terminal on a flat surface with the display face down.

Press the two tabs (A) on the back of the terminal to open it, and open the bottom of the

terminal (B).

Feed the terminal cable through the cutout in the back of the terminal and plug in the

jack (C). Make sure that the strain relief (D) is inside the terminal.

If you want to permanently affix the terminal to the electronic unit, you can also attach

the terminal holder now:

Place the terminal holder (E) into the corresponding cutout on the bottom of the terminal

and use the knurled screw (F) provided to secure it from the inside of the terminal.

A A

B

D

C

E

F

Page 17

Initial startup of weighing modules

17

Close the bottom of the terminal. Then push in the two side tabs to completely close the

terminal.

Note: You can also use the two tabs on the back side to adjust the viewing angle of the

terminal while it is in operation: Press both buttons simultaneously and pull the top of

the terminal gently upwards, or press it down until it clicks into the desired position. You

can choose from three different positions.

Remove the two screws (Torx T-20) in the bottom of the electronic unit and store them in

a safe place. Align the terminal holder exactly with the two bores and secure it with the

Torx T-20 countersunk head screws (G).

Plug the terminal cable plug (H) into the appropriate jack on the back of the electronic

unit and screw in to tighten. Try to run the terminal cable as close as parallel as possible

to the terminal holder.

G

G

H

2.7.2 PWT Terminal

Place the terminal on a flat surface with the display face down.

Press the two tabs (A) on the back of the terminal to open it, and open the bottom of the

terminal (B).

Feed the terminal cable through the cutout (C) in the bottom of the terminal and plug in

the jack (D). Make sure that the strain relief (E) is inside the terminal.

Close the bottom of the terminal. Then press the two tabs (A) on the back of the terminal

to completely close the terminal.

Note: You can also use the two tabs on the back side to adjust the viewing angle of the

terminal while it is in operation: Press both tabs simultaneously and pull the top of the

terminal gently upwards, or press it down until it clicks into the desired position. You can

choose from three different positions.

Plug the terminal plug into the appropriate jack on the back of the electronic unit and

screw in to tighten.

A A

B

C

D

E

A A

Page 18

Initial startup of weighing modules

18

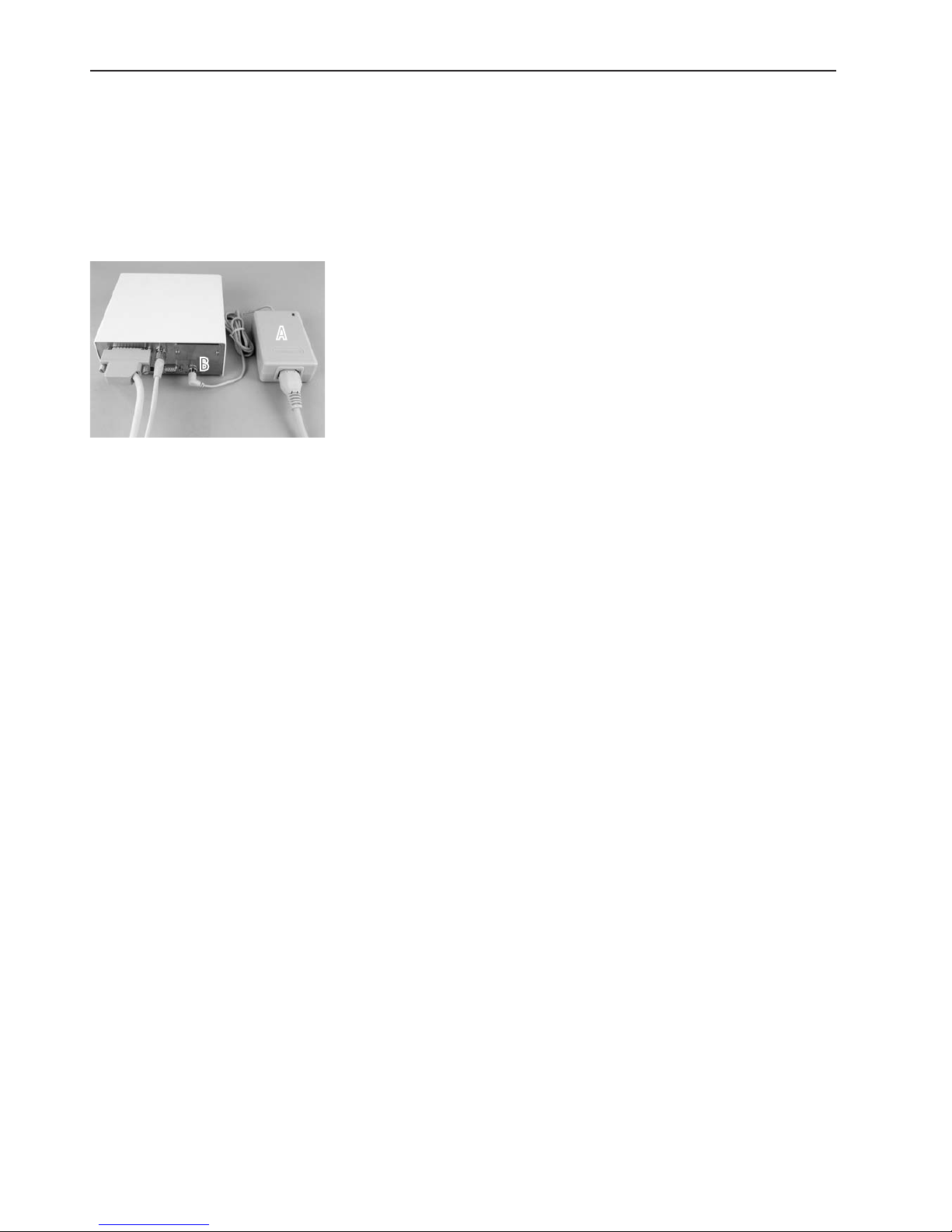

2.8 Connect the unit to the power supply

The electronic unit for your weighing module is delivered with an AC adapter and a power cord for your country. The AC adapter is suit-

able for use with the following voltage range:

100 – 240 VAC, 50/60Hz (see Section 6 for exact specifications).

Check whether your local power supply falls within this range. If it does not, DO NOT connect the electronic unit or the AC adapter

to your power supply and contact your local METTLER TOLEDO office.

Connect the AC adapter (A) to the connector (B) on the back of the electronic unit and to

your power supply. Tighten the connector to ensure a good connection to the electronic

unit.

Important: Be sure to lay the cables so that they cannot be damaged or get in your

way while you’re working! Remember that the AC adapter may NOT come into contact

with any liquids!

Once the weighing module has been connected to the power supply, the weighing module

will perform a self-test, and then it will be ready to operate.

B

A

Page 19

Configuring the weighing module

19

3 Configuring the weighing module

Once the weighing modules have been installed, they must be configured, i.e., prepared for operation. For weighing modules with

terminals, nearly all configuration work can be performed via the terminal; weighing modules without a terminal are configured using

MT-SICS commands issued from a host computer. An expansion of the MT-SICS command set is available for product-specific configu-

ration work.

All weighing modules come from the factory with a built-in RS232C interface. In addition, the modules can be equipped with a second

optional interface (Section 6) that is inserted into the electronic unit. The optional interfaces are delivered with their own instructions

describing installation and all configuration work needed.

The procedure for configuring the weighing modules and interface functionality depend on how the individual weighing module

is equipped. There are four possible configurations:

1 Weighing module without terminal, with built-in RS232C standard interface

2 Weighing module without terminal, with built-in RS232C standard interface and additional optional interface

3 Weighing module with terminal and built-in RS232C standard interface

4 Weighing module with terminal, built-in RS232C standard interface, and additional optional interface.

The following page provides an overview of the various configurations and the available settings.

Page 20

Configuring the weighing module

20

Configuration

Interface/commands

1 2 3 4

HOST interface Built-in RS232C Optional interface (the built-in

RS232C can be used during

operation to connect a printer,

for example).

Built-in RS232C (can be configured via the terminal for “host”,

see Terminal instructions)

Choice of built-in RS232C or

optional interface (the terminal

can be used to configure one of

the interfaces for the “host,” see

terminal instructions).

Setting interface parameters via MT-SICS “COM” command Host interface: Configured

using SICS command “COPT”

via the built-in RS232C (if

present—otherwise, a terminal

can be hooked up and used to

configure the interface).

Built-in RS232C: Not configurable; will always work with

the factory settings..

Via terminal (as per terminal

instructions)

Via terminal (as per terminal

instructions)

Extended SICS Level 3 instruction set for the HOST

interface

Commands as in Section 3.1.

Note: All SICS commands in

the list in Section 3.2 are also

supported.

Commands as in Section 3.1.

Note: All SICS commands in

the list in Section 3.2 are also

supported.

Not available Not available

Expanded SICS Level 3 commands for second interface

––– Commands as in Section 3.1.

Note: All SICS commands in

the list in Section 3.2 are also

supported (including the “COPT”

command to configure the

“Host” interface) EXCEPT “SIR,”

“SR,” and “SNR”..

––– Not available

“FastHost” commands (as per

MT-SICS reference manual)

Available on host interface Available on host interface Available on built-in RS232C,

assuming it is configured as

host interface

Available on built-in RS232C,

assuming it is configured as

host interface

Notes When the terminal is removed,

the system behaves like a

weighing module without a

terminal, with a RS232C standard

interface (Configuration 1)

When the terminal is removed,

the system behaves like a

weighing module without a

terminal, with a RS232C standard

interface and additional optional

interface (Configuration 2)

Page 21

Configuring the weighing module

21

3.1 Extended SICS command set for WXS/WXT weighing modules without terminal

The following commands were added to the MT-SICS Level 3 command set specifically for the configuration of WXS/WXT weighing

modules:

Command Meaning

FCUT Set filter characteristics (limit frequency)

RDB Set readability

USTB Set stability criteria

FSET Restore factory settings

LST List user settings

3.2 Standard SICS command set for WXS/WXT weighing modules without terminal

The following list provides an overview of the commands from the standard SICS command set that WXS/WXT weighing modules with-

out terminals support. For more detailed information on the individual commands and their parameters, refer to the MT-SICS manual

provided with your system:

Command Meaning

SICS Level 0

I0 Lists all commands supported by SICS levels 0-3

I1 Lists supported MT-SICS level and MT-SICS versions

I2 Inquiry of weighing module data

I3 Inquiry ofSW version and type definition number

I4 Inquiry ofserial number

I5 Inquiry of software verification number

S Send stable net weight

SI Send current net weight without regard for stability

SIR Send continuous current net weight without regard for stability. Note: This command is not available in the built-in

RS232C standard interface on weighing modules without a terminal and with the optional interface.

Z Zero

ZI Zero without waiting for stability

@ Cancel current commands and send serial number to host

SICS Level 1

SR Send stable weight when weight changes (repeatedly). Note: This command is not available in the built-in RS232C

standard interface on weighing modules without a terminal and with the optional interface.

T Trigger taring

TA Inquire and set tare memory

TAC Clear tare memory

TI Trigger taring without waiting for stability. Note: Only permitted on non-calibrated modules.

SICS Level 2

C0 Inquiry/setting of adjustment status Note: Only possible when adjustment is permitted.

C1 Adjust using current configuration. Note: Only possible when adjustment is permitted.

C2 Adjust using external weight. Note: Only possible when external adjustment is permitted.

C3 Adjust using internal weight. Note: Only possible when internal adjustment is permitted.

Page 22

Configuring the weighing module

22

Command Meaning

COM Configuration command for built-in RS232C standard interface. Note: This command is only available for weighing

modules without a terminal and without the optional interface.

COPT Configuration command for optional interface. Note: This command is only available for weighing modules without

a terminal and with the optional interface. The command is only available via the built-in RS232C standard

interface.

DAT Inquiry/setting of date

I10 Inquiry/setting of weighing module ID

I11 Inquiry/setting of module type

I14 Inquiry of information on the weighing module

I15

1)

Inquire duration of operation of the weighing module in minutes since startup

I16

1)

Inquiry of next service date

I21

1)

Inquiry of assortment tolerance dataset version

I22

1)

Inquiry of linearity tolerance

I23

1)

Inquiry of repeatability tolerance

I24

1)

Inquiry of sensitivity tolerance

I25

1)

Inquiry of shift tolerance

I26

1)

Inquiry of operating mode

M01 Inquiry/setting of weighing mode (filter characteristics)

M02 Inquiry/setting of ambient parameters (filter damping)

M03 Inquiry and activation/deactivitation of AutoZero (automatic zeroing)

M17 Inquiry/setting of FACT time criterion. Note: Only possible when time-controlled FACT adjustment is permitted.

M18 Inquiry/setting of FACT temperature criterion. Note: Only possible when temperature-controlled FACT adjustment

is permitted.

M19 Inquiry/setting of external adjustment weight. Note: Only possible when external adjustment is permitted

M20 Inquiry/setting of external test weight.

M21 Inquiry/setting of weighing units

M27 Inquiry of user adjustment history

M28 Inquiry of temperature values

M29 Inquiry/setting of reading release

M31

1)

Operating mode of the weighing module following restart. Note: Only parameters of 0 (standard) or 3 (diagnostic

mode) are allowed

M32

1)

Inquiry/setting of FACT time criteria. Note: Only possible when time-controlled FACT adjustment is permitted. The

“M32” command is the same as the “M17” command, but it has additional setting options.

M33

1)

Inquiry/setting of ProFACT days of the week. Note: Only possible when time-controlled FACT adjustment is permit-

ted.

M35

1)

Define zero at power-up (0 = normal, 1 = start in the future with a momentary zero). Note: Command permitted

only on non-calibrated weighing modules.

SIS Send net weight with weighing unit and additional information

SNR Send continuous stable weight following a defined change in weight. Note: This command is not available in the

integrated RS232C standard interface on weighing modules without a terminal and with the optional interface.

TIM Inquiry/setting of time

TST0 Inquiry/setting of test configuration (check adjustment with external test weight)

Page 23

Configuring the weighing module

23

Command Meaning

TST1 Start test sequence with current configuration

TST2 Start test sequence with external weight

TST3 Start test sequence with internal weights. Note: Only possible if internal test weight is present

UPD Inquiry of host interface update rate

FAST Host

B00 Lists all available FastHost commands (“Bxx”)

B01 Inquiry of individual reading

B02 Start/stop continuous data transmission

B03 Inquiry of reading counter time base (SV counter)

B04 Inquiry/setting of FastHost format specification

B05 Inquiry/setting of FastHost stability criteria

B06 Inquiry/setting of FastHost output reduction (output cycle)

B07 Inquiry/setting of automatic sending following restart

B08 Zeroing using FastHost stability criterion (“B05”)

1)

These commands are not yet listed in the current MT-SICS reference manual. For more information, please contact your local

METTLER TOLEDO sales office.

Page 24

Configuring the weighing module

24

3.3 Preparatory steps for configuration

For weighing modules with terminals, the configuration tasks described in the following sections are performed

using the terminal. Therefore, no preparatory work is required; however, it is assumed that you have the terminal

instructions handy and are already familiar with how to operate the terminal and use the menu structure.

On SWT terminals, the menu options for configuring the weighing module are with the system settings.

On PWT terminals, part of the configuration menu is also with the system settings. Because the PWT terminal

supports multiple users, additional configuration options are located with the user-specific settings.

The configuration tasks described in the following section are for weighing modules without a terminal. At the

end of each section, you will see a note for users of weighing modules with terminals telling you where the

equivalent settings can be found on the terminal.

Weighing modules without a terminal are confugred via the interface with MT-SICS commands. You’ll need a

host computer (PC) and a terminal program to do this. Under Microsoft Windows XP® , you can use HyperTerminal,

which is included with Windows. Microsoft Windows Vista® does not come with a terminal program. In this case,

you can use the “WM_term_disp” program (“WM Terminal Display”) provided on the CD-ROM. You can use this

program to configure the PC interface and transmit SICS commands, among other things. Please read the help

file on the CD-ROM before you install “WM_term_disp.”

Connect the host computer with the built-in RS232C standard interface on the weighing module. Set the

communications parameters of the terminal program as follows:

Baud rate: 9600

Data bits: 8

Stop bits: 1

Parity: None

End of line: <CR><LF>

Handshake: Xon/Xoff

These are the factory settings for the built-in RS232C standard interface on the weighing module.

For weighing modules that have only a RS232C standard interface, you can change the RS232C standard

interface communications parameters using the “COM” command (SICS level 2). Once you have made your

changes, you must adjust the terminal program’s communications parameters accordingly so that you can

continue to communicate with the weighing module.

For weighing modules that have an additional optional interface, you can configure them using the “COPT”

command “SICS level 2). Only the RS232C standard interface supports the “COPT” command; therefore, for this

configuration, the weighing module must first be connected with the host computer via the standard interface.

Once you have configured your system, you can connect the host computer with the optional interface. The

RS232C standard interface itself cannot be configured; it always uses the factory settings (see above). If an

optional interface is available, the RS232C standard interface is used as a service interface.

Note: If you have a terminal, you can connect it temporarily and configure the optional interface using the terminal. This is easier and faster than configuring it with the “COPT” command. Once you’ve configured the optional

interface, you can disconnect and remove the terminal.

The next section describes the most important configuration task (user settings) with special consideration given

to the expanded MT-SICS command set for WXS/WXT weighing modules without a terminal (Section 3.1). The

standard SICS commands are available for additional configuration work (Section 3.2).

+T

–T

Page 25

Configuring the weighing module

25

3.4 Configuring the weighing module

It is recommended that the weighing modules are configured before they are used in order to achieve best weighing performance. The

following sections provide information on the most important configuration tasks.

3.4.1 Adjusting the weighing module

Following initial startup, the weighing module must be adjusted using a built-in or external weight. Various parameters can be set for

the adjustment. The WXS/WXT weigh modules have the ProFACT fully automatic adjustment function. During operation, ProFACT adjusts

the module automatically on the basis of specified criteria.

+T

–T

For weighing modules without a terminal, the commands “C0,” “C1,” “C2,” and “C3” (SICS level 2) are used for

the adjustment and the corresponding settings. If you use an external adjustment weight, you can set its weight

using the “M19” command. The fully automatic ProFACT adjustment function can be configured with the “M17”

and “M18” commands. You can find the corresponding explanations in the MT-SICS reference manual.

Weighing module with terminals: The settings for manual adjustment and the ProFACT fully automatic adjustment function are part of the system settings. See the description of the “Weighing” application for how to perform

the adjustment. You can find more information in the terminal instructions.

3.4.2 Set readability

Readability refers to the smallest difference in weight that the weighing module can still measure and transmit via the interface and/or

show on the display (see also the technical data in Section 6). The factory-set readability (= maximum possible number of places after

the decimal point) can be reduced if necessary to shorten weighing time.

For weighing modules without a terminal , use the “RDB” command to set readability:

Command: RDB Inquire current readability

Answer: RDB A dp Readability expressed as the number of places after the decimal point (dp)

when weighing in grams (g).

Command: RDB dp Set readability (dp = number of places after the decimal point)

Responses: RDB A Command executed, readability set

I4 A "..." Restart performed (the system always restarts after readability has been

set)

Responses (errors): RDB L Incorrect “dp” parameter

RDB I Command cannot be executed right now

ES Terminal connected

For example: RDB 2 Set readability to 2 places after the decimal point (0.01 g)

Responses: RDB A Command executed

I4 A "..." Restart performed

–T

Page 26

Configuring the weighing module

26

Notes:

– The definition of readability always uses grams (g) as the unit, regardless of what the current unit of display

is.

– The “RDB” command will let you reduce readability by a maximum of 3 places after the decimal point below

the maximum resolution of the weighing module.

– Once an “RDB” command has been executed, the weighing module automatically restarts, a new zero point

is set, and the tare memory is cleared.

– The selected readability affects various other settings and functions such as stability criteria for weighing,

taring, and zeroing as well as adjustment.

For weighing modules with a terminal, use the “1/10d” function key to set readability. Note: Depending on

your particular weighing module, you may have several of these function keys available, such as “1/100d” and

“1/1000d”. For more information on these function keys, see the description for the “Weighing” application

(terminal instructions).

+T

3.4.3 Set stability criteria

The stability criterion specifies when a weighing result is considered stable. A stability criterion must also be fulfilled to perform the

zeroing and taring functions. A separate stability criterion can be defined for every mode (weighing, zeroing, and taring). A value is

considered to be stable when it moves within a defined bandwidth during a specified observation period. These two parameters (length

of observation and bandwidth) define the stability criterion.

For weighing modules without a terminal, use the “M29” command (refer to the MT-SICS reference manual)

or the “USTB” command (explained below) to set stability criteria.

Important: This command is not available to users with calibrated scales!

Command: USTB Inquire all stability criteria

Response: USTB B 0 0.000 0.000

USTB B 1 0.000 0.000

USTB A 2 0.000 0.000

Current stability criteria for weighing, taring, and zeroing

Command: USTB x Inquire stability criterion for specific mode:

x = 0: Weighing

x = 1: Taring

x = 2: Zeroing

Response: USTB A 1 0.000 0.000 Current stability criterion (Example “Taring”)

Command: USTB x y z Set stability criterion:

x: Modes (0, 1 or 2, see above)

y: Bandwidth (in digits of current readability)

z: Observation period (in seconds)

Response: USTB A Command executed, stability criterion set

Responses (errors): USTB L Incorrect parameter (e.g. bandwidth > 100d, observation

period > 10s )

ES Calibrated scale or terminal connected

For example: USTB 0 5.0 0.3 Set stability criterion for weighing with a bandwidth of 5 digits

and an observation period of 0.3 seconds

Response: USTB A Command executed

–T

Page 27

Configuring the weighing module

27

The figure below illustrates how the stability criterion works.

Notes:

– At the factory, all “USTB” stability criteria are set to 0.0000 (in this case, the settings for reading release are

used that were set with the “M29” command).

– A bandwidth of <0.001d and an observation period of <0.001 s are interpreted as 0.0.

– If one of the parameters for the “USTB” command is not equal to zero, the setting for reading release (“M29”

command for the corresponding mode (weighing, taring, or zeroing) is invalidated.

– The observation period is event-oriented; it restarts each time the reading falls outside the defined

bandwidth

– The stability criteria apply to the entire weighing range; it is not possible to adjust them when the weighing

range (gross/fine range for dual-range weighing modules) changes.

– The user-specific stability criteria take effect only when the system is operated without a terminal. If a terminal

is later connected, the settings saved in the terminal become effective.

– For adjustment, factory-set stability criteria are always used, with consideration given to the reading release

setting (“M29” command).

For weighing modules with a terminal, stability criteria settings (reading release) are part of the weighing

parameters. On the SWT terminal, you’ll find these settings in the system settings; on the PWT terminal, they are

under the user-specific setttings.

+T

0.0 0.1

0.2 0.3

5d

0.0 0.1

0.2 0.3

5d

The value measured at the end of the observation period is

transmitted as a stable value or saved as a tare value.

Time [s]

Tolerance exceeded.

Wait until the stability criterion is met.

Criterion met Criterion not met

Time [s]

Page 28

Configuring the weighing module

28

+T

3.4.4 Activating and defining the fixed filter

Use the “M01” command to set the weighing type and the “M02” command to set the ambient conditions (Section 3.4.5). These two

settings determine the type and strength of signal filtering that will occur.

For the “Sensor mode” weighing type, the “FCUT” command offers an additional option for defining filter behavior. Filtering in “Sensor

mode” is chronologically linear (fixed, non-adaptive filter) and is appropriate for continuous reading processing.

Important: The “FCUT” command is only available for the “sensor mode” weighing type. The fixed filter is deactivated at the

factory.

Command: FCUT Inquire cut-off frequency of the fixed filter

Response: FCUT A frq frq = currently set cut-off frequency (in the 0.1 Hz – 10.0 Hz range)

Command: FCUT frq Set cut-off frequency for the fixed filter (frq = 0.1 Hz – 10.0 Hz)

Response: FCUT A Command executed, cut-off frequency set

Responses (errors): FCUT L Incorrect parameter (outside the allowed range)

FCUT I Command cannot be executed right now

ES Terminal connected

Example 1: FCUT 0 Set cut-off frequency to 0 (= fixed filter deactivated = factory setting)

Response: FCUT A Command executed, cut-off frequency set to 0

Example 2: FCUT 3.4 Set cut-off frequency to 3.4 Hz

Response: FCUT A Command executed, cut-off frequency set to 3.4Hz

Notes:

– The fixed filter is deactivated at the factory, and the filtering is defined by setting the ambient conditions (“M02”

command, see Section 3.4.5).

– If the fixed filter is activated (frq ≠ 0), it will override any settings for ambient conditions (“M02” command)

in sensor mode.

– Values for frq < 0.05 will be interpreted as zero (in this case, the filter frequency will be used in accordance

with the “M02” command)

For weighing modules with a terminal, selecting the weighing type is part of the weighing parameters. On

the SWT terminal, you’ll find these settings in the system settings; on the PWT terminal, they are under the userspecific settings. The ambient conditions (Section 3.4.5) determine filter damping of the weighing signal. These

two settings determine the filtering of the weighing signal. When you activate the sensor mode, the weighing

module automatically works with a factory-defined fixed filter with 5 selectable levels.

–T

Page 29

Configuring the weighing module

29

3.4.5 Adjustments to ambient conditions (filter damping)

Adjusting filter damping allows for the weighing module to be otimally adapted to ambient conditions at the site. This setting determines

how quickly the weighing module will react to a change in weight, but also how sensitive the module will be to outside disturbances.

Strong filter damping will cause the module to react more slowly to small changes in weight, but it will also make it less sensitive to

ambient conditions such as air movements and vibration. This also increases the achievable measurement accuracy (repeatability).

You can also affect the effective measurement accuracy and the weighing time by changing the settings for stability criteria (Section

3.4.3).

For weighing modules without a terminal, use the “M02” command to adjust your system to ambient conditions (filter damping). This command from the standard SICS command set (level 2) is described in the MT-SICS

reference manual.

Note: If the “sensor mode” weighing type is active, and the “FCUT” command has been used to define a fixed

filter (Section 3.4.4), the ambient condition settings for the “sensor mode” will not take effect. In this case, the

weigh signal is processed by the fixed filter.

For weighing modules with a terminal, adjusting the system to ambient conditions is part of the weighing

parameters. On the SWT terminal, you’ll find these settings in the system settings; on the PWT terminal, they are

under the user-specific setttings.

–T

+T

3.4.6 Setting the update rate for continuous weight transmission

For weighing applications such as dosing to a specified target weight, the weighing module must constantly record weight changes

and forward the readings regardless of their stability to the dosing system so that it can control the dosing process. In such cases, you

should activate the “send continuous” mode to ensure a continuous flow of weight readings and set the number of weight readings to

be transmitted each second via the interface (update rate).

For weighing modules without a terminal, use the “SIR” command (standard SICS level 0) to activate the

“send continuous mode” mode. Use the “UPD” command (standard SICS level 2) to set the number of weight

readings to be transmitted per second.

Notes:

– For weighing modules with an optional interface, the “SIR” command is available on the optional interface

(host interface), but not on the RS232C standard interface.

– Update rates of up to 92 readings per second are possible.

For weighing modules with a terminal, you can activate the “send continuous” mode and set the update rate

as part of the interface definition in the system settings.

–T

+T

Page 30

Configuring the weighing module

30

3.4.7 Recording user settings

The current user settings can be output through the interface.

For weighing modules without a terminal, use the “LST” command (expanded SICS command set for WXS/WXT

weighing modules) to output a list of all user-specific settings. The following example shows part of such a list:

LST B C0 0 0 ""

LST B FCUT 2.800000

LST B M01 0

LST B M02 2

LST B M03 0

LST B M07 0

LST B M17 00 00 00 0

LST B M18 1

.

LST A USTB 2 0.0000000 0.000000

This list can also be used as follows to restore the settings under the following conditions:

– The command identifier “LST B” or “LST A” at the beginning of each line must be removed, including the space

after it.

– A break of 300 ms must be added after each line.

– Empty text strings (“ ”) and the space before them must be removed. This applies to the parameters “C0” and

“TST0,” for example.

For weighing modules with terminals, both the system settings and the user-specific settings can be recorded.

While viewing the system settings or user-specific settings, simply press the Print key on the terminal (key with

the printer symbol). The current settings will be output via the interface.

–T

+T

Page 31

Configuring the weighing module

31

3.4.8 Resetting user-specific settings to factory default

The current user-specific settings can be reset to the factory default if necessary.

For weighing modules without a terminal, use the “FSET” command to reset:

Command: FSET x Settings to be reset:

x = 0: All settings except communication parameters for the interface(s)

x = 1: All settings including user adjustments and communication para-

meters for the interface(s)

x = 2: All settings except communication parameters for the interface(s) and

user adjustments

Responses: FSET A Command executed, selected settings reset

I4 A "..." Restart performed (the system always restarts after settings have been

reset)

Responses (errors): FSET L Incorrect parameter for “x” (see above)

FSET I Command cannot be executed right now

ES Terminal connected

For example: FSET 1 Reset all settings back to factory defaults

Response: FSET A Command executed

I4 A "..." Restart performed

Notes:

– The date (“DAT”) and the time (“TIM”) are not reset with the “FSET” command.

– If the communications parameters are reset (“FSET 1”), the reset will not occur until there is confirmation that

the command has been executed (response).

– The "FSET" command cannot be cancelled (with the @ command).

Weighing modules with terminals:

On the SWT and PWT terminal, all settings can be reset in the system settings. On the PWT terminal in the userspecific settings area, you also have the option of resetting only the settings for the current user profile. Please

read the notes and warnings on this subject in the terminal instructions.

–T

+T

Page 32

Configuring the weighing module

32

3.4.9 Information on the memory location for user-specific settings

The memory location for user settings depends on whether you have a weighing module with or without a terminal.

For weighing modules without a terminal, some user settings are permanently stored in the electronic unit,

which are the following:

Command Setting

FCUT Fixed filter for sensor mode

I10 ID of the weighing module

M01 Weighing mode (filter properties)

M02 Ambient parameters (filter damping)

M03 AutoZero (automatic zeroing)

M17 ProFACT time criterion

M18 ProFACT temperature criterion

M19 External adjustment weight

M20 External test weight

M21 Weighing unit

M29 Reading release

M31 Operating mode of the weighing module following restart

M32 ProFACT time criteria

M33 ProFACT days of the week

M35 Zeroing upon startup

USTB Stability criteria

UPD Update rate for the interface

Note: The parameters for the “C0” (adjustment status) and “TST0” (test configuration) commands are not permanently stored in the electronic unit.

For weighing modules with a terminal, all user settings are permanently stored in the terminal.

Exceptions: The settings for zeroing upon startup (“M35”) and for the update rate for the interface (“UPD”) are

stored in the electronic unit.

–T

+T

Page 33

Weighing operation

33

4 Weighing operation

This section contains helpful tips for weighing operation and information on possible error messages. Weighing modules with terminals

are operated using the terminal, and all error messages are displayed in plain English on the terminal; consult the terminal instructions

for more information.

Information in this section applies to users with weighing modules without a terminal. The MT-SICS commands listed here are only

some of the available commands you can use in weighing operations. See the MT-SICS reference manual for more information and

detailed command descriptions.

4.1 Transmission of weight values

The readings transmitted via the interface refer either to zero or to the reading created as a result of the tare command, depending

on whether zeroing or taring was the last function performed. Note that the system zeroes automatically each time it is powered up

(zeroing upon startup). Commands that cannot be executed successfully until a stability criterion is met will cancel if stability is not

attained within approx. 40 seconds (timeout).

Weight query and transmission of a single stable weight reading

Command: S Transmits the current stable weight reading. If the weighing module is in

the stabilization phase, the weight reading will not be sent until the stability

criterion for weighing has been met.

Response: S S [current weight reading] g Stable weight value (the second “S” stands for “stable”)

Response (errors): S I Command cannot be executed, e.g., because the stability criterion for weigh-

ing was not met (timeout).

Weight query and immediate transmission of a single weight reading

Command: SI Immediate transmission of the current weight reading, regardless of its

stability.

Responses: S S [current weight reading] g Stable weight value

S D [current weight reading] g Non-stable weight reading (the “d” stands for “dynamic = not

stable”)

Automatic transmission of each stable weight reading after a change in weight

Command: SNR Transmits the current stable weight reading, and automatically sends all

subsequent weight readings that fulfill the stability criterion after any change

in weight. You can input the weight change that is necessary to trigger

transmission as needed.

If you do not want any more readings, cancel automatic transmission with

commands such as “S,” SI,” or “@” (reset).

Response: S S [current weight reading] g Stable weight value. After a change in weight and subsequent stabilization,

the module will automatically transmit the next stable weight reading.

Page 34

Weighing operation

34

Continuous transmission of all weight readings (“continuous mode”)

Command: SIR Continuously transmits all weight readings, regardless of their stability. This

continuous transmission mode is particularly helpful for dosing to a specified target weight because it allows the continuous changes in weight to be

tracked. The effective number of transmitted readings per second may not

deviate more than 1 reading per second from the set transmission rate.

Responses: S S [current weight reading] g Stable weight value

S D [current weight reading] g Dynamic, non-stable weight reading

4.2 Taring function

Taring with fulfillment of the stability criterion

Command: T This command makes the current stable weight reading (that references the

current zero) the tare weight, transfers it to the tare memory, and transmits

it across the interface. The current weight reading will then be set to zero. If

the weighing module is in the stabilization phase, the command will not be

executed until the stability criterion for taring has been met, or it will cancel

in the event of a timeout.

Response: T S [current tare reading] g The current stable weight reading (net weight) has now been set to zero..

Response (error): T I Tare function cannot be carried out. This could occur if the current weight

reading (referencing the current zero) is negative, or if the stability criterion

for taring has not been met (timeout).

Immediate taring without regard for the stability criterion

Command: TI The current weight reading referencing the current zero is immediately

considered to be the tare weight. It is transferred to the tare memory and

transmitted across the interface, regardless of whether the stability criterion

for the taring function has been met. The current weight reading (net weight)

will then be set to zero.

Responses: TI S [current weight reading] g The current stable weight reading (net weight) has now been set to zero.

TI D [current weight reading] g The current dynamic weight reading (net weight) is set to zero (the “D” stands for

“dynamic = not stable”). In this case, the zero is also considered unstable.

Response (error): TI I Command cannot be executed – this may happen if the current weight read-

ing referencing the current zero is negative.

Page 35

Weighing operation

35

4.3 Zeroing functions

Zeroing creates a new zero (reference point), sets the current weight reading to zero, and clears the tare memory.The weighing module

automatically zeroes itself each time it is powered up.

If the weighing module cannot zero upon power-up due to filter settings and prevailing ambient conditions, it will time out, and the

system zero will be used. This means that all weight values will reference this zero. You will not be able to perform a test or an adjustment until a zero command is successfully executed.

Zeroing with fulfillment of the stability criterion

Command: Z Creates a new zero. If the weighing module is in the stabilization

phase, the command will not be executed until the stability criterion

for zeroing has been met.

Response: Z A The current stable weight reading is set to zero and the tare memory

is cleared.

Response (error): Z I Command cannot be executed, e.g., because the stability criterion

for zeroing was not met (timeout).

Immediate zeroing without regard for the stability citerion

Command: ZI A new zero is immediately set, regardless of whether the stability cri-

terion for zeroing has been met. The tare memory is then cleared.

Responses: ZI S Zeroed on the basis of a stable weight reading.

ZI D Zeroed on the basis of a dynamic weight reading (the “D” stands for

“dynamic = not stable”).

Page 36

Weighing operation

36

4.4 Troubleshooting weighing module errors and malfunctions