Mettler Toledo WXS, WXS204, WXT, WXT205, WXS26 Installation Manual

...

Installation Manual

Weigh Modules

WXS/WXT

Table of Contents

1 Safety Information 3

1.1 Intended use ............................................................................................................... 3

1.2 Definitions of signal warnings and warning symbols........................................................ 3

1.3 Product specific safety notes ......................................................................................... 3

2 Installation 5

2.1 Overview..................................................................................................................... 5

2.2 Assembling the WXS weigh module ............................................................................... 7

2.3 Weigh module WXT setup............................................................................................. 9

2.4 Installing the weighing pan ........................................................................................... 10

2.5 Installing the wind shield (only for WXTS3DU) ................................................................ 12

2.6 Weighing below the balance ......................................................................................... 13

2.7 Overload protection...................................................................................................... 15

2.8 Connect load cell and electronic unit.............................................................................. 15

2.9 Connect terminal and adjust settings.............................................................................. 15

2.10 Connect unit to the power supply................................................................................... 17

2.2.1 Load cell installation ..................................................................................... 7

2.2.2 Electronic unit assembly and mounting ........................................................... 9

2.3.1 Choosing a location ...................................................................................... 9

2.3.2 Levelling load cell ......................................................................................... 9

2.4.1 Installing standard weighing pan .................................................................... 10

2.4.2 Installing adapter weighing pan ...................................................................... 11

2.9.1 SWT terminal................................................................................................ 15

2.9.2 PWT terminal................................................................................................ 16

3 Configuring the Weigh Module 19

3.1 Extended SICS command set for WXS/WXT weigh modules without terminal ....................... 20

3.2 Preparatory steps for configuration................................................................................. 20

3.3 Configuring weigh module ............................................................................................ 22

3.3.1 Adjusting weigh module................................................................................. 22

3.3.2 Set readability............................................................................................... 22

3.3.3 Set stability criteria ........................................................................................ 23

3.3.4 Activating and defining fixed filter .................................................................... 23

3.3.5 Adjustments to ambient conditions (Filter damping).......................................... 24

3.3.6 Setting the update rate for continuous weight transmission................................. 25

3.3.7 Recording user settings.................................................................................. 25

3.3.8 Resetting user-specific settings to factory default............................................... 26

4 Weighing Operation 28

4.1 Operation limits ........................................................................................................... 28

4.2 Transmission of weight values ...................................................................................... 28

4.3 Taring function ............................................................................................................ 28

4.4 Zeroing functions ......................................................................................................... 29

4.5 Troubleshooting weigh module errors and malfunctions ................................................... 29

4.5.1 If your weigh module doesn’t perform correctly until it has been powered up for

quite a while................................................................................................. 29

4.5.2 If the weigh module does not transmit the expected weight readings ................... 29

4.5.3 If the weigh module doesn’t react to your commands at all ................................ 29

5 Technical Data 31

5.1 General data ............................................................................................................... 31

5.2 Model-specific Data ..................................................................................................... 33

5.3 Key to types and list of available models........................................................................ 36

5.4 Dimensions................................................................................................................. 39

5.4.1 WXS204/WXS205DU/WXS205 load cell.......................................................... 39

Table of Contents 1Weigh Modules

5.4.2 WXS26 micro load cell .................................................................................. 39

5.4.3 WXT204/WXT205DU/WXT205 load cell .......................................................... 40

5.4.4 WXT26 micro load cell .................................................................................. 40

5.4.5 WXTS3DU load cell with wind shield ............................................................... 41

5.4.6 WXS204/WXS205DU/WXS205, WXT204/WXT205DU/WXT205 adapter weighing

pan ............................................................................................................. 41

5.4.7 WXS26/WXT26 adapter weighing pan............................................................. 42

5.4.8 WXSE, WXS Electronic Unit (including mounting bracket) .................................. 42

5.4.9 WXTE, WXT Electronic Unit (including terminal holder) ...................................... 43

5.4.10 SWT Terminal (mounted using terminal holder)................................................ 44

5.4.11 PWT Terminal .............................................................................................. 45

5.4.12 WXS204/WXS205DU/WXS205, WXT204/WXT205DU/WXT205 adapter for

weighing below (optional) ............................................................................. 46

5.4.13 WXS26/WXT26/WXTS3DU adapter for weighing below (optional)....................... 46

5.5 RS232C Interface (Standard Interface) Specifications ....................................................... 47

5.6 Specification for Aux Connections .................................................................................. 47

6 Accessories and Spare Parts 48

6.1 Accessories................................................................................................................. 48

6.2 WXS204/WXS205DU/WXS205, WXT204/WXT205DU/WXT205 spare parts ....................... 49

6.3 WXS26/WXT26 spare parts........................................................................................... 51

6.4 WXTS3DU spare parts .................................................................................................. 53

Index 55

Table of Contents2 Weigh Modules

1 Safety Information

1.1 Intended use

• Use the product only for weighing in accordance with this User manual.

• The weigh module is intended for indoor use only.

• Any other type of use and operation beyond the limits of technical specifications is considered as not

intended.

1.2 Definitions of signal warnings and warning symbols

Safety notes contain important information on safety issues. Ignoring the safety notes may lead to personal

injury, damage to the instrument, malfunctions and false results. Safety notes are marked with the following

signal words and warning symbols:

Signal words

DANGER

A hazardous situation with high risk, resulting in death or severe injury if not avoided.

WARNING

CAUTION

NOTICE

A hazardous situation with medium risk, possibly resulting in death or severe injury if

not avoided.

A hazardous situation with low risk, resulting in minor or moderate injury if not avoided.

A hazardous situation with low risk, resulting in damage to the instrument, other

material damage, malfunctions and erroneous results, or loss of data.

Warning symbols

General hazard: read the User Manual or the Reference Manual for information about the hazards

and the resulting measures.

Electrical shock

1.3 Product specific safety notes

Your weigh module meets the state of the art technology and complies with all recognized safety rules,

however, certain hazards can arise.

Do not open the weigh module: It does not contain any parts which can be maintained, repaired or replaced by

the user. If you ever have problems with your weigh module, contact your authorized METTLER TOLEDO dealer

or service representative.

Observe instructions

Always operate and use your weigh module only in accordance with the instructions contained in the product

documentation. The instructions for setting up your weigh module must be strictly observed.

If the weigh module is not used according to the product manuals, protection of the weigh module may be

impaired and METTLER TOLEDO assumes no liability.

Staff safety

Use only METTLER TOLEDO accessories and peripheral devices, these items are designed to work optimally

with your weigh module.

Explosion hazard

It is not permitted to use the weigh module in explosive atmospheres of gases, steam, fog, dust and flammable

dust (hazardous environments).

Safety Information 3Weigh Modules

Safety notes

CAUTION

Risk of electric shock

The weigh modules may only be connected to DC power sources that meet the 12VDC

+/-3% at all times.

The power supply must be approved by the respective national test center of the country in

which the weigh module will be used.

Safety Information4 Weigh Modules

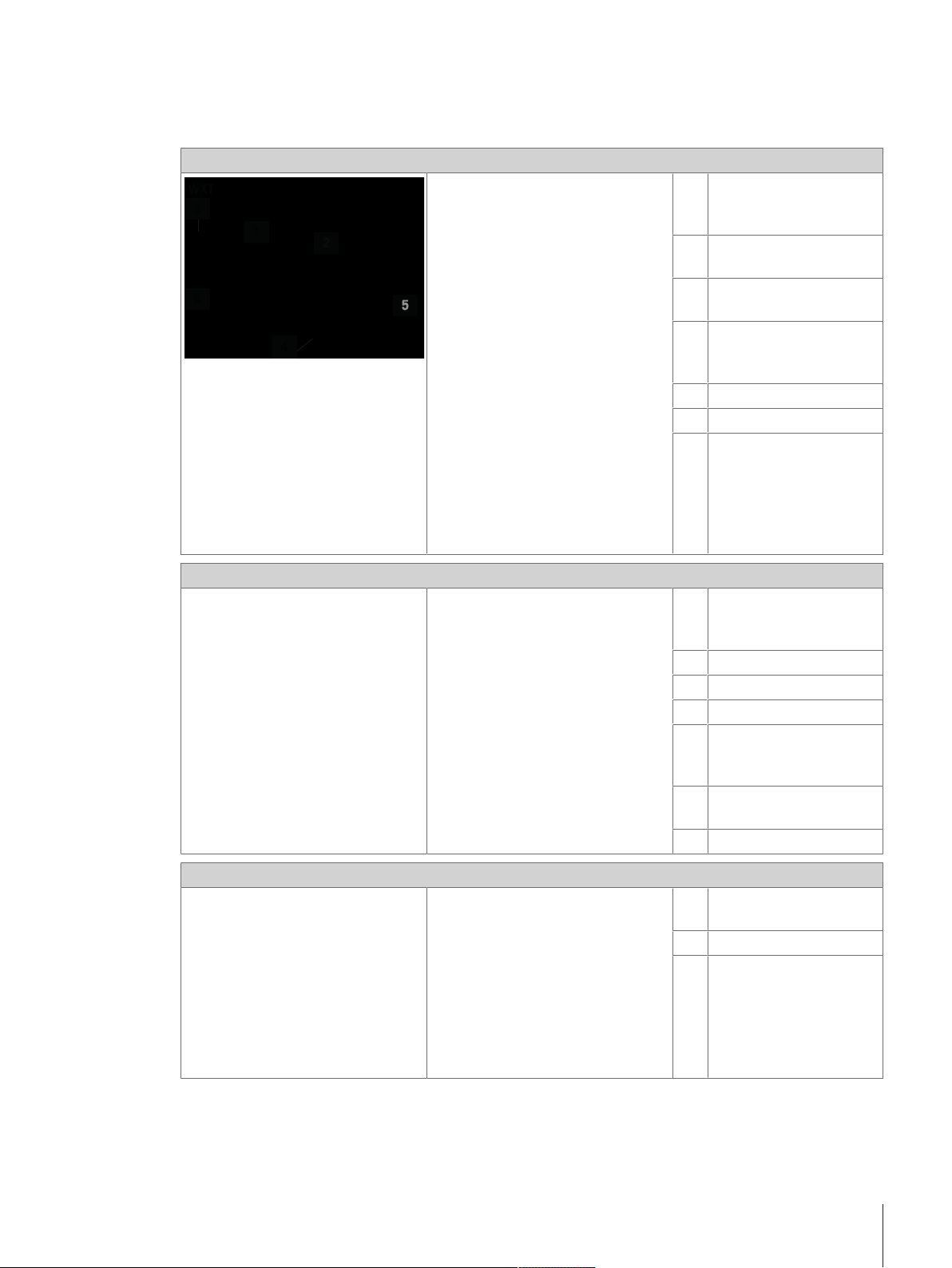

2 Installation

2.1 Overview

Load Cells

Housing (WXT: white

1

powder-coated, WXS:

stainless steel)

Weighing pan retainer with

2

plastic cover

Connector for electronic

3

unit

Hanger opening for

4

weighing below (on

bottom side)

Level bubble

5

Adjustable feet (WXT only)

6

Base plate with mounting

7

flange (WXS only)

Electronic units

Terminals

Housing (WXT: white

8

powder-coated, WXS:

stainless steel)

Load cell connector

9

Terminal connector

10

Optional interface plug-in

11

“Aux” connectors (for

12

“ErgoSens,” hand or footoperated buttons)

RS232-C standard

13

interface

Connector for AC adapter

14

Display (PWT: color, SWT:

15

monochrome)

Keyboard

16

“SmartSens” sensors

17

(PWT only)

Installation 5Weigh Modules

Connecting cables

Weighing pans

Electronic unit – load cell

18

connector cable (0.5m,

1.5m or 5m)

Note

Maximum allowable cable

length: 5m.

Terminal – electronic unit

19

connector cable (0.5m,

1m or 2m)

Note

Maximum allowable cable

length: 2m.

Standard weighing pan

20

Adapter weighing pan (not

21

for WXTS3DU)

Wind ring

Mounting materials

Wind ring

22

Mounting bracket for WXS

23

electronic unit, including

DIN clip and screws (not

for WXTS3DU)

Terminal holder for SWT

24

terminal, including screws

(not for WXTS3DU)

Installation6 Weigh Modules

Power supply

27

Wind shield

AC adapter

25

Power cable (country-

26

specific)

WXTS3 wind shield (only

27

for WXTS3DU)

2.2 Assembling the WXS weigh module

The WXS (component version) weigh modules can be integrated into higher-level systems (machines,

systems, etc.). Be sure to follow the tips in the following sections to select the optimal installation method.

2.2.1 Load cell installation

The weigh modules were designed to record weights very quickly and accurately under normal conditions and

communicate the result using the integrated interface and/or display the result on a terminal. In practice,

ambient conditions (vibration, oscillations, shocks, air movements and temperature changes) affect weighing

time and achievable accuracy as well as the repeatability.

You can adjust various parameters on your weigh module. We recommend that you adjust the settings to the

levels needed for your application; higher requirements increase the weighing time (period between the

placement of the weight and the availability of a stable result). Filter settings must be stricter to compensate for

unfavorable ambient conditions, this also has a negative impact on weighing time. See [Configuring weigh

module}Page22].

Therefore, be sure to note the following:

Installation 7Weigh Modules

Note

• The location of the load cell should not be in areas that are

exposed to drafts, direct sunlight, or severe temperature fluctuations.

Make sure that any vibrations in the building are not transferred

through the floor and to the load cell.

• Make sure that the load cell is as perfectly horizontal as possible.

1 Mount the load cell on a base that is mechanically decoupled from

the system and therefore free of shocks and vibration.

If a mechanical decoupling is not possible, place appropriate

cushioning between the system and the load cell mount.

2 Use the built-in precision level to achieve exact leveling.

It is acceptable to have a unit that is not perfectly horizontal if its

position is not altered after it has been adjusted (e.g., if it is

mounted in a fixed position in the system). If a weigh module is

installed permanently (not moveable), it can be approved even

without having an integrated level bubble.

Weighing module WXS204/205 and WXT204/205

1 Attach the load cell to the base across as wide an area as

possible.

2 Use the appropriate bores in the front part of the cell’s base plate

(4 × M5 screws, tightening torque 4 – 6Nm).

The base must be perfectly planar to avoid putting tension on the

load cell base plate.

3 Make sure that vibrations cannot be transferred across the

connector cable between the load cell and the electronic unit.

4 Make sure that the load cell housing is connected in an electrically

conductive manner with the machine structure.

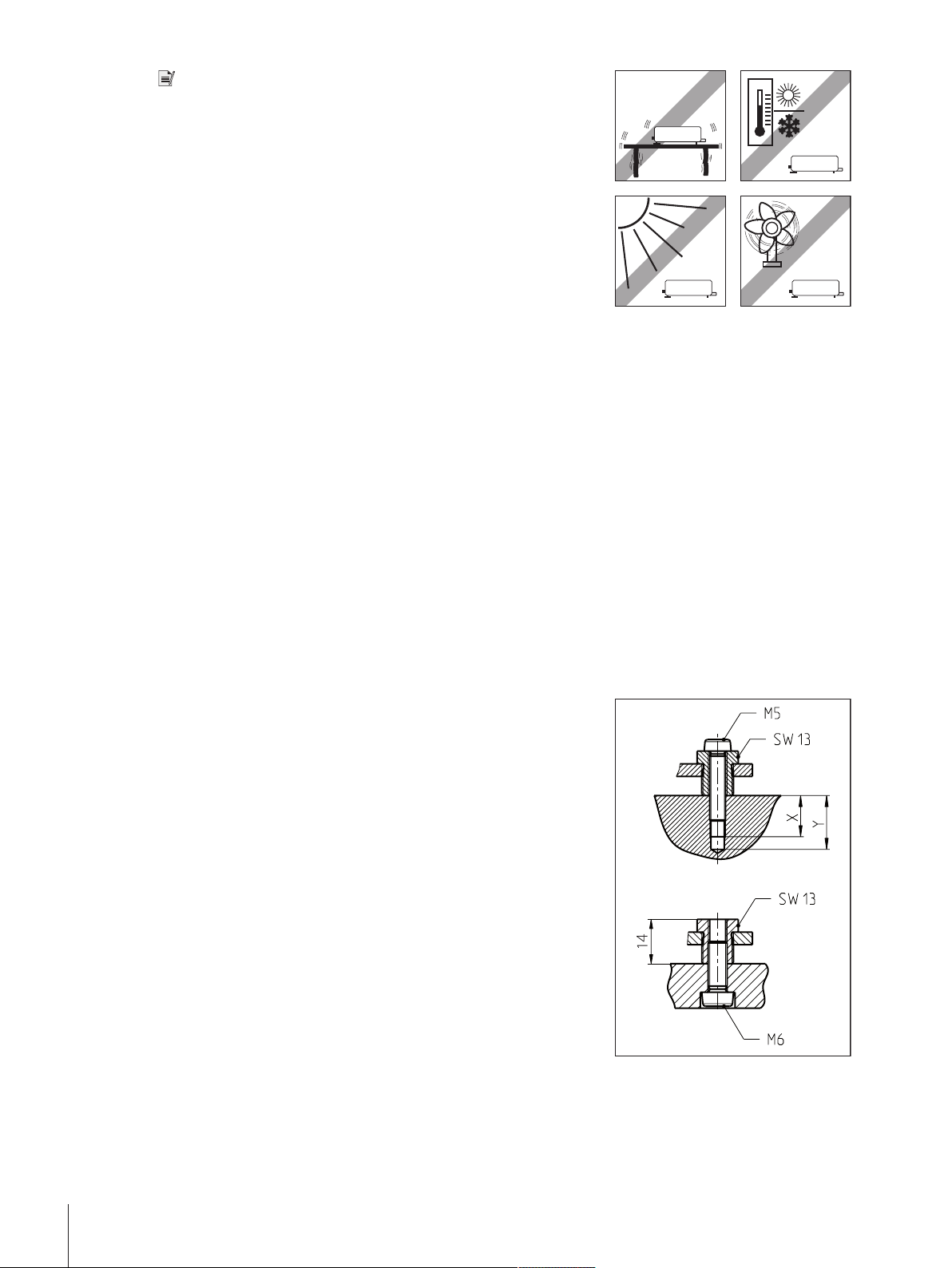

Weighing module WXS26, WXT26, WXTS3DU

1 Place the weigh module on a flat surface.

2 Levelling the module with the three leveling nuts (SW13).

3 Fix the weigh module from above by means of screws M5 × 22 or

from below with M6 screws.

4 Make sure that vibrations cannot be transferred across the

connector cable between the load cell and the electronic unit.

5 Make sure that the load cell housing is connected in an electrically

conductive manner with the machine structure.

If your requirements are extremely demanding (short weighing time, high accuracy), we recommend that you

try a test setup first and test the entire system under real-world conditions using various settings. This will allow

you to tweak the system and optimize it bit by bit.

Installation8 Weigh Modules

2.2.2 Electronic unit assembly and mounting

1

1

2

The electronic unit can be mounted in any position you wish. A mounting bracket and clip for attaching the unit

to a DIN standardized rail are provided. Proceed as follows for mounting:

Note

The electronic unit meets the requirements for protection class IP40. If required, appropriate protective measures

must be taken to protect the unit from dirt.

1 Remove the two existing screws from the bottom side of the

electronic unit (Torx T-20).

2 Use the provided Torx T-20 countersunk head screws (1) to secure

the mounting bracket.

3 Secure the clip (2) to the front face or underside of the mounting

bracket.

4 Use the two provided M4 pan head screws (Torx T-20) to do so.

Note

The electronic unit can also be attached directly to a support (without

the clip) via the M4 threads of the mounting bracket.

2.3 Weigh module WXT setup

The WXT weigh module (benchtop version) does not require any assembly work. Note the information in the

following sections about choosing an optimal location and leveling the load cell.

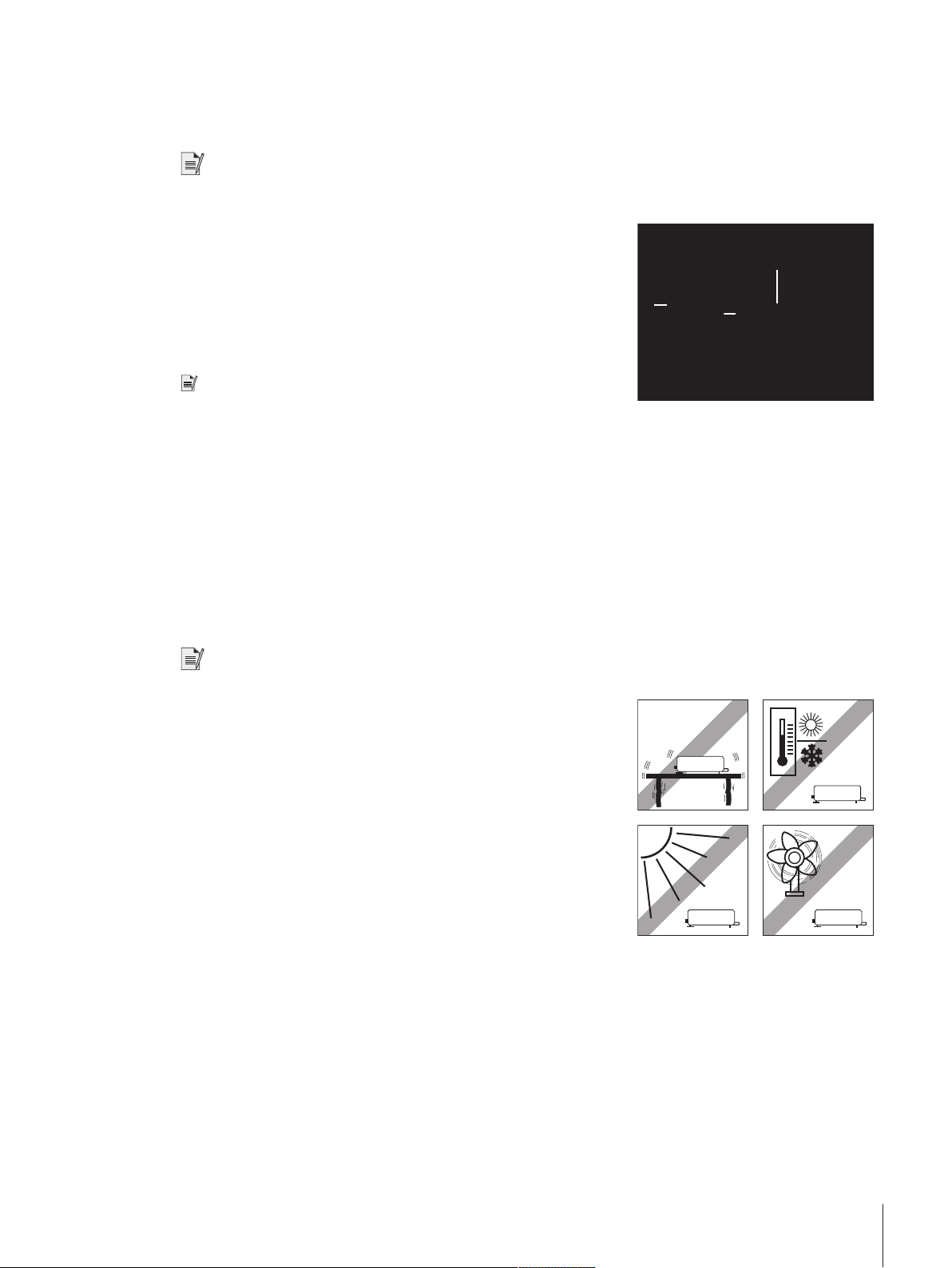

2.3.1 Choosing a location

An optimal location will ensure accurate and reliable operation of the weigh module. The surface must be able

to safely take the weight of the weigh module when fully loaded. The following local conditions must be

observed:

Note

If the weigh module is not horizontal at the outset, it must be leveled during commissioning.

• The weigh module must only be used indoors and up to a

maximum altitude of 4000 m above sea level.

• Before switching on the weigh module, wait until all parts are at

room temperature (+5 to 40°C).

The humidity must be between 10% and 80% non-condensing.

• The power plug must be accessible at all times.

• Firm, horizontal and vibration-free location.

• Avoid direct sunlight.

• No excessive temperature fluctuations.

• No strong drafts.

2.3.2 Levelling load cell

Once the load cell has been set up at the desired location, the load cell must be horizontally aligned (leveled).

The load cell have a level (level bubble) and two adjustable leveling feet to compensate for slight irregularities

in the surface of the weighing bench.

Installation 9Weigh Modules

The load cell is exactly horizontal when the air bubble is in the

1

2

1

3

2

§

middle of the level glass.

1 Adjust the two leveling feet appropriately until the air bubble comes

to rest exactly in the middle of the glass:

Air bubble at "12 o'clock" turn both feet counterclockwise. Air

bubble at "3 o'clock" turn left foot clockwise, right foot counterclockwise.

Air bubble at "6 o'clock" turn both feet clockwise. Air bubble at "9

o'clock" turn left foot counterclockwise, right foot clockwise.

2 The load cell must be leveled and adjusted each time it is moved

to a new location.

2.4 Installing the weighing pan

The WXS and WXT weigh modules come with two weighing pans: a standard weighing pan and an adapter

weighing pan for users to create their own setups.

2.4.1 Installing standard weighing pan

Weighing module WXS204/205 and WXT204/205

1 Remove the white plastic cover (1) from the load cell.

This cover protects the weighing pan retainer (2) from damage

during transport and keeps liquid out of the load cell during

cleaning.

2 Make sure you keep the cover in a safe place!

− Place the standard weighing pan into the weighing pan retainer.

No specific position needed; the standard weighing pan turns

freely.

Weighing module WXS26, WXT26, WXTS3DU

1 Remove the white plastic cover (1) from the load cell.

This cover protects the weighing pan retainer (2) from damage

during transport and keeps liquid out of the load cell during

cleaning.

2 Make sure you keep the cover in a safe place!

Note

Do not remove any spacers (3)!

Installation10 Weigh Modules

− Place the wind ring.

1

2

3

Adapter weiging pan: approx. 10 g

:

55 g ... 78 g

without loosing weighing range

− Install the standard weighing pan. Turn it until it snaps into place.

2.4.2 Installing adapter weighing pan

The adapter weighing pan is used for customer-specific setups to hold the object to be weighed.

Weighing module WXS204/205 and WXT204/205

1 Attach the customer-specific setup to the adapter weighing pan

using the three 120° offset M3 threaded holes (1).

For the exact dimensions of the adapter weighing pan, see

[WXS204/WXS205DU/WXS205, WXT204/WXT205DU/WXT205

adapter weighing pan}Page41].

2 Keep in mind that your setup must weigh at least 55g. Ensure

that the required dead load of 65g (adapter weighing pan +

setup) is reached.

ð If the required dead load is not reached, the weigh module will

output an underload error message upon startup.

3 To preserve the full weighing range, the total preload (adapter

weighing pan + setup) may not exceed 88g.

Heavier preloads will take away from the available weighing range.

Because customer-specific setups generally remain in a fixed position,

the adapter weighing pan has a positioning pin (2). This pin fits

perfectly in the two grooves in the weighing pan retainer (3) and

prevents the weighing pan from turning freely. However, this antidisplacement measure works only up to a certain torque. If this torque

is exceeded, the weighing pan turns to prevent damage to the load

cell. At the same time, the weighing pan retainer serves a protection

from lateral forces.

Note

Legal-for-trade weigh modules have a start-up dead load range from

65g to 88g (adapter weighing pan + setup). After power up the

available zero setting range is 20g.

Installation 11Weigh Modules

Weighing module WXS26, WXT26, WXTS3DU

1

2

3

Adapter weiging pan: approx. 7.2 g

:

13.8 g ... 15.8 g

without loosing weighing range

1 Attach the customer-specific setup to the adapter weighing pan

using the three 120° offset M3 threaded holes (1).

For the exact dimensions of the adapter weighing pan, see

[WXS204/WXS205DU/WXS205, WXT204/WXT205DU/WXT205

adapter weighing pan}Page41].

2 Keep in mind that your setup must weigh at least 13.8g. Ensure

that the required dead load of 21g (adapter weighing pan +

setup) is reached.

ð If the required dead load is not reached, the weigh module will

output an underload error message upon startup.

3 To preserve the full weighing range, the total preload (adapter

weighing pan + setup) may not exceed 23g.

Heavier preloads will take away from the available weighing range.

Because customer-specific setups generally remain in a fixed position,

the adapter weighing pan has a positioning pin (2). This pin fits

perfectly in the two grooves in the weighing pan retainer (3) and

prevents the weighing pan from turning freely. However, this antidisplacement measure works only up to a certain torque. If this torque

is exceeded, the weighing pan turns to prevent damage to the load

cell. At the same time, the weighing pan retainer serves a protection

from lateral forces.

Note

Legal-for-trade weigh modules have a start-up dead load range from

21g to 23g (adapter weighing pan + setup). After power up the

available zero setting range is 2g.

2.5 Installing the wind shield (only for WXTS3DU)

1 Remove the plastic cover from the pan retainer.

2 Install the wind shield on the load cell.

Installation12 Weigh Modules

3 Install the wind ring in the weighing chamber.

1

Note

Place the wind ring around the pan retainer and turn on the wind ring

until it snaps into place.

4 Install the standard weighing pan.

Note

Place the weighing pan into the pan retainer and turn on the weighing

pan until it snaps into place.

2.6 Weighing below the balance

For weighing beneath the work area (weighing below), the load cell is equipped with a hanger opening. For

weighing below, the item to be weighed is not placed on the weighing pan; it is placed on an applicationspecific receptacle attached beneath the load cell. For weighing below, the standard weighing pan is removed,

and the weighing pan retainer is closed up using the plastic cover so that dirt and foreign matter cannot

penetrate the load cell.

Here are some examples of when weighing below is used:

• when it is difficult or impossible to put the material to be weighed on the weighing pan

• when space will not allow for items to be weighed from above

• when weighing from above might soil or contaminate the load cell

Note

Weighing below is not allowed when using legal-for-trade versions.

The hanger opening is on the bottom of the cell under a round cover

(1).

You’ll need the optional weighing below adapter, which should be

installed by a METTLER TOLEDO service technician if possible, to

attach the customer-specific receptacle. For information on how to

order, see [Accessories}Page48].

Installation 13Weigh Modules

Weighing module WXS204/205 and WXT204/205

Fixture:

52 g ... 75 g without loosing weighing range

Weighing below

adapter: 13 g

Fixture:

52 g ... 75 g without loosing weighing range

Weighing below

adapter: 13 g

Please keep the following in mind when planning a weighing below

receptable for objects to be weighed:

The fixture must weigh at least 52g.

1 Ensure that the required dead load of 65g (weighing below

adapter + fixture).

ð If the required dead load is not reached, the weighing module

will output an underload error message upon startup.

2 To preserve the full weighing range, the total weight of the weighing

below adapter and fixture may not exceed 88g.

3 Take heavier preloads away from the available weighing range.

4 Secure the fixture to the M4 thread of the weighing below adapter

(max. penetration depth: 8mm, max. tightening torque: 1Nm).

5 Position the fixture’s center of gravity as close to and vertically

beneath the attachment point as possible.

ð The weighing receptacle must hang freely from the attachment

point of the weighing below adapter without touching nonmoving parts of the load cell or the system. The maximum

diameter or cross-section of the fixture at the attachment point

is 8mm.

6 Limit the vertical and horizontal movement and/or torsion of the

fixture by using mechanical stops to prevent overload of the load

cell.

7 To minimize weighing time, avoid vibrations and shocks to the

fixtures and the objects to be weighed.

Weighing module WXS26, WXT26, WXTS3DU

Please keep the following in mind when planning a weighing below

receptable for objects to be weighed:

The fixture must weigh at least 8g.

1 Ensure that the required dead load of 21g (weighing below

adapter + fixture).

ð If the required dead load is not reached, the weighing module

will output an underload error message upon startup.

2 To preserve the full weighing range, the total weight of the weighing

below adapter and fixture may not exceed 23g.

3 Take heavier preloads away from the available weighing range.

4 Secure the fixture to the M4 thread of the weighing below adapter

(max. penetration depth: 8mm, max. tightening torque: 1Nm).

5 Position the fixture’s center of gravity as close to and vertically

beneath the attachment point as possible.

ð The weighing receptacle must hang freely from the attachment

point of the weighing below adapter without touching nonmoving parts of the load cell or the system. The maximum

diameter or cross-section of the fixture at the attachment point

is 8mm.

6 Limit the vertical and horizontal movement and/or torsion of the

fixture by using mechanical stops to prevent overload of the load

cell.

7 To minimize weighing time, avoid vibrations and shocks to the

fixtures and the objects to be weighed.

Installation14 Weigh Modules

2.7 Overload protection

1

1

2

The WXS/WXT weigh modules have overload protection that is effective in all directions up to the following limit

values:

Weighing module WXS204/205 and WXT204/205

Vertical load: 5kg * (all types; centered load)

Lateral load: 1kg (protected by torsion protection; see [WXS204/WXS205DU/

WXS205, WXT204/WXT205DU/WXT205 adapter weighing

pan}Page41].

Torsion: Protected by torsion protection, see [WXS204/WXS205DU/WXS205,

WXT204/WXT205DU/WXT205 adapter weighing pan}Page41].

Weighing module WXS26, WXT26, WXTS3DU

Vertical load: 1 kg * (all types; centered load)

Lateral load: 0.1 kg (protected by torsion protection; see [WXS26/WXT26 adapter

weighing pan}Page42].

Torsion: Protected by torsion protection, see [WXS26/WXT26 adapter weighing

pan}Page42].

Weighing below "push": 0.1 kg

Weighing below "pull": 0.1 kg

Weighing below "torsion": No overload protection

* if wind ring and weighing pan are mounted properly.

2.8 Connect load cell and electronic unit

Legal-for-trade

With the exception of legal-for-trade weigh modules the load cell and the electronic unit can be replaced

independently of each other if necessary.

1 Use the provided cable (0.5m or 1.5m) to connect the load cell

to the electronic unit.

2 Tighten the plugs on both devices.

A 5m cable is available as an accessory.

Note

Lay the cable so that no one will trip over it and so that no vibrations

can travel up the cable and be transferred to the load cell.

2.9 Connect terminal and adjust settings

You’ll need this section only if your weigh module was delivered with a terminal.

2.9.1 SWT terminal

1 Place the terminal on a flat surface with the display face down.

2 Press the two tabs (1) on the back of the terminal to open it.

3 Open the bottom of the terminal (2).

Installation 15Weigh Modules

4 Feed the terminal cable through the cutout in the back of the

3

4

6

5

7

8

7

1 1

2

terminal and plug in the jack (3).

5 Make sure that the strain relief (4) is inside the terminal.

If you want to permanently affix the terminal to the electronic unit, you

can also attach the terminal holder now:

6 Place the terminal holder (5) into the corresponding cutout on the

bottom of the terminal.

7 Use the knurled screw (6) provided to secure it from the inside of

the terminal.

8 Close the bottom of the terminal.

9 Push in the two side tabs to completely close the terminal.

ð You can also use the two side tabs to adjust the viewing angle

of the terminal while it is in operation.

10 Press both buttons simultaneously and pull the top of the terminal

gently upwards, or press it down until it clicks into the desired

position.

11 You can choose from three different positions.

12 Remove the two screws (Torx T-20) in the bottom of the electronic

unit and store them in a safe place.

13 Align the terminal holder exactly with the two bores and secure it

with the Torx T-20 countersunk head screws (7).

14 Plug the terminal cable plug (8) into the appropriate jack on the

back of the electronic unit and screw in to tighten.

15 Try to run the terminal cable as close as parallel as possible to the

terminal holder.

2.9.2 PWT terminal

1 Place the terminal on a flat surface with the display face down.

2 Press the two tabs (1) on the back of the terminal to open it.

3 Open the bottom of the terminal (2).

Installation16 Weigh Modules

Loading...

Loading...