Page 1

Service Manual

METTLER TOLEDO

Viper M, L, D and T Scales

Viper RM, RL, RD and RT Terminals

On

Off

Zero

Tare

Sam

ple

Print

Sam

ple

Size

Scale

Clear

C

Info

Units

On

O

ff

Zero Tare Sample

P

rin

t

Sam

ple

Size

Scale

Info

U

nits

C

lear

C

Page 2

Page 3

General

About this service manual

Service concept

Product overview

1

2

Viper scales with small platform

Strain Gauge, IP65, MonoBloc, Ex

3

Viper scales with large platform

Strain Gauge, IP65, MonoBloc, Ex

4

5

Technician setup

6

Miscellaneous information

7

8

9

10

11

12

Exploded view drawings

Spare parts lists

Exploded view drawings

Spare parts lists

Accessing scale setup data

Entering scale setup data

Service Manual 21203788C Viper M, L, D and T Scales/Viper RM, RL, RD and RT Terminals

Technical data

Overview of weighing cells an preloads

Geographical table

Software

Software architecture

Error messages

Temperature compensation data

Repair of Viper scales

Repairs and replacement of components

Viper terminals

Exploded view drawings

Spare parts lists

Upgrade kits

Repair of Viper terminals

Repairs and replacement of components

Page 4

Page 5

Contents Page

1 How to use this service manual ........................................................................................................ 1-2

1.1 General ............................................................................................................................................ 1-2

1.2 Layout of the service manual .............................................................................................................. 1-2

1.3 Working with the service manual ........................................................................................................ 1-2

2 Service concept ............................................................................................................................... 1-3

3 Introducing the Viper scales product group ........................................................................................ 1-3

4 The Viper terminals .......................................................................................................................... 1-3

5 Safety.............................................................................................................................................. 1-4

6 Environmental protection .................................................................................................................. 1-4

Section 1

General

Page 6

1-2 09/03 Service Manual 21203788C

Section 1 General Viper M, L, D and T Scales/Viper RM, RL, RD and RT Terminals

1 How to use this service manual

1.1 General

This service manual contains instructions for the repair and maintenance work to be performed by service engineers.

It is assumed that the reader is familiar with the operation of the scales and terminals, and can refer to the relevant operating

instructions when necessary.

1.2 Layout of the service manual

This manual comprises nine main sections:

• General: Section 1gives instructions on using the service manual, and also provides an overview of the Viper scales and

terminals covered by it.

• Viper scales with small platform: Section 2 contains the exploded view drawings and spare parts lists for Viper scales with

the small platform.

• Viper scales with large platform: Section 3 contains the exploded view drawings and spare parts lists for Viper scales with

the large platform.

• Viper terminals: Section 4 contains the exploded view drawings and spare parts lists for Viper terminals, as well as a list of

available upgrade kits.

• Repair of Viper scales: Section 5 describes all repair work and the replacement of components for Viper scales with large

and small platforms.

• Repair of Viper terminals: Section 6 describes all repair work and the replacement of components for Viper terminals.

• Technician setup: Section 7 describes how to enter scale data, calibrate the weighing system and use the diagnostic

functions.

• Miscellaneous information: Section 8 contains technical information on the Viper product group, plus an overview of all

load cells and preloads and a table of geographical adjustment values. In addition you will find instructions on connecting

weighing platforms to Viper terminals and information on appropriate load cells, as well as important information on

attaching a second weighing platform the the optional analog interface of Viper scales and terminals.

• Software: Section 9 contains information on the various software versions. It also describes typical error messages that can

appear following service work and provides troubleshooting instructions.

1.3 Working with the service manual

The section number and title are printed in the header of every page in the service manual. Each footer shows the order number

for the manual, the date issued and the page number.

The pages are numbered in the footer. First comes the section number, then a hyphen followed by the page number, starting with

1 in every section.

The exploded view drawings are provided as a guide for disassembly and assembly work and for identifying the order numbers

for spare parts.

When ordering spare parts, please use the information given in the spare parts lists. The item numbers in the first column

correspond to those on the exploded view drawing opposite.

Page 7

Service Manual 21203788C 09/03 1-3

Viper M, L, D and T Scales/Viper RM, RL, RD and RT Terminals Section 1 General

2 Service concept

The scales have been designed so that defective components can be replaced with just a few simple tools. The LC-PT45 printer

for service is not required, as almost all parameters can be configured with the keyboard of the scale (in special cases

temperature compensation data of the MonoBloc load cell may need to be entered using a computer).

As you can see, we have kept it simple for efficient servicing.

3 Introducing the Viper scales product group

The Viper scales product group comprises the following models, which are all covered by this manual:

Viper M scales

Viper M scales possess basic weighing functions for simple weighing duties. Special versions of these scales are also available

(Viper EX M and Viper EX M MB) for use in explosion hazard zones (Class 1, Division 1) with the PSUx power supply unit or the

PSU power supply unit/interface.

Viper L scales

In addition to basic weighing functions, Viper L counting scales also have built-in functions for piece counting. An extended

keypad and a display with a visual weighing-in aid are available in order to use these additional functions.

Viper D scales

Viper D scales are counting scales providing an additional numeric keypad and ID functions.

Viper T scales

Viper T scales are the top-of-the-range models in the product group. These counting scales support a wide array of useful

functions. They have a dot matrix display with graphics capability and a numeric keypad. The various menu functions are

controlled by soft keys in the display, i.e. context-sensitive screen buttons which change according to the momentary status of

the menu. This scale type is also available for applications other than piece counting (such as SQC 16 and Remote).

Common features

Apart from the differences with regard to functions and operating and display elements, all models in the Viper product group

have the following common features:

– Depending on the weighing range, some models are only available with the small platform, some only with the large platform

and some with both. The essential difference between the two platform sizes is in their external dimensions and the type of

load cell used.

– All models are designed either for direct connection to the AC power line or contain a built-in rechargeable battery. Recharge-

able battery scales are connected to the AC power line via an AC adapter. Viper EX scales are powered by an external AC

adapter.

– All models are certifiable.

– The load cells are either of the strain gauge or MonoBloc type.

4 The Viper terminals

In terms of functionality and features the Viper RM, RL, RD and RT terminals exactly match the respective scale models (M, L, D

and T, see above). Using appropriate weighing platforms the Viper terminals allow to build customized weighing systems.

Page 8

1-4 09/03 Service Manual 21203788C

Section 1 General Viper M, L, D and T Scales/Viper RM, RL, RD and RT Terminals

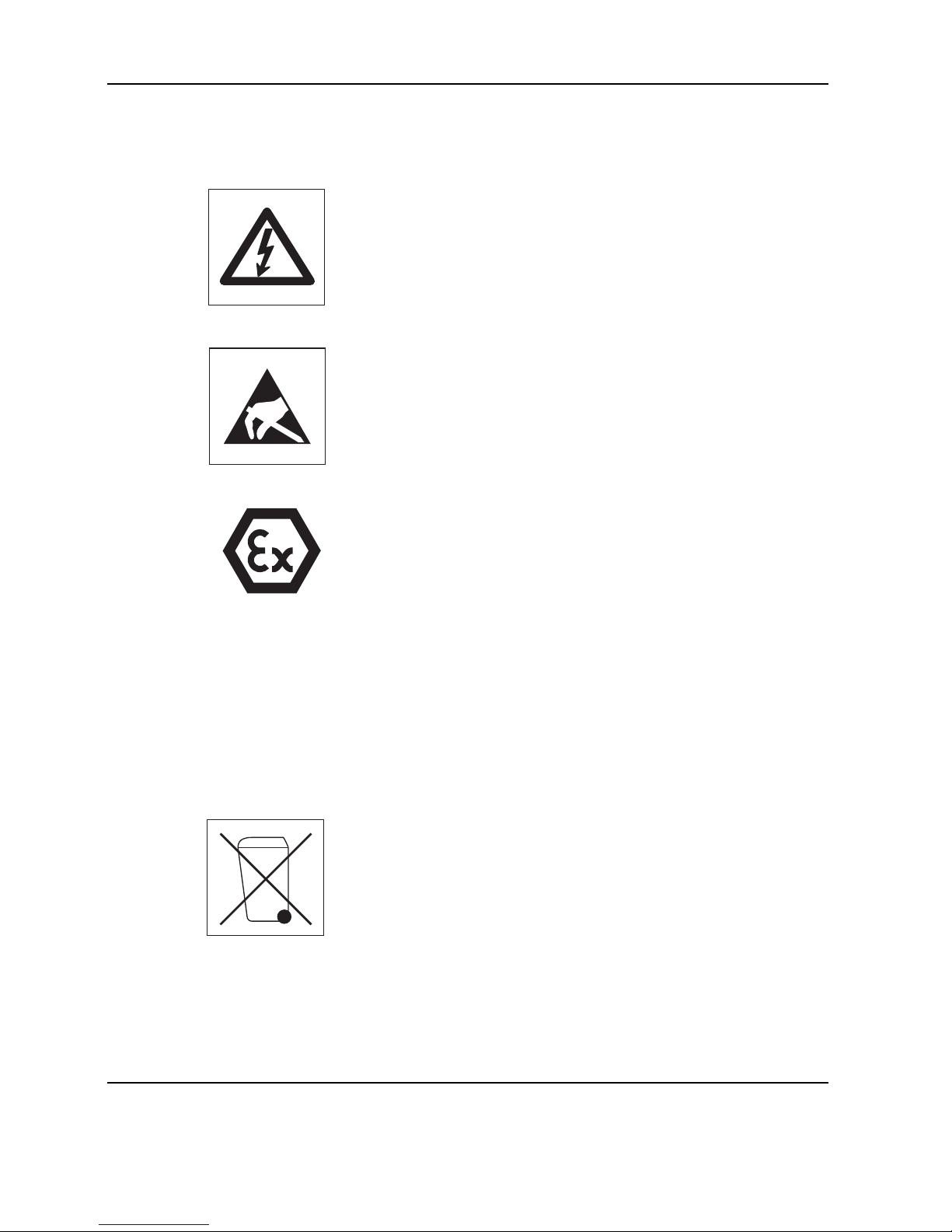

5 Safety

When carrying out service or repair work, always observe the following:

• Before opening the scale or terminal, isolate it from the AC power line (pull out the

plug).

• The scales and terminals contain precision electronic components that are

sensitive to electrostatic discharge. We recommend that you wear a grounding

wrist strap when doing any work in the interior of the scale or terminal, in order to

prevent any electrostatic charge building up. Grounding wrist straps are commercially available from electronic component suppliers.

• Servicing work in explosion hazard zones is strictly prohibited. Ignition power

could inadvertently be generated, causing an explosion. Servicing work should

therefore only be undertaken in secure areas. Please also observe all special

instructions in this Service Manual relating to work on Viper scales that are

approved for use in potentially explosive environments. Such instructions are

indicated by the adjacent symbol.

6 Environmental protection

Disposal of rechargeable batteries

Some models in the Viper product group have a built-in rechargeable battery. This

contains heavy metals which could be hazardous to the environment. The battery is

therefore classified as a hazardous waste, which must not be disposed of as normal

domestic refuse. Please ensure that used batteries are disposed of correctly in

accordance with the relevant local regulations.

Disposal of electronic components

Dispose of defective components in strict compliance with all local and national

regulations! In many countries electronic components are classified as hazardous

waste for whose disposal there are special regulations. In some countries electronic

components are collected separately for recycling. If necessary, find out the applicable regulations from the local authorities!

Page 9

Contents Page

1 Scales ............................................................................................................................................. 2-2

1.1 Scales with strain gauge load cells (not including Ex version) ................................................................ 2-2

1.2 Scales with strain gauge load cells and IP65 protection......................................................................... 2-8

1.3 Scales with strain gauge load cells, Ex version ..................................................................................... 2-12

1.4 Scales with MonoBloc load cells (not including Ex version) ................................................................... 2-16

1.5 Scales with MonoBloc load cells, Ex version ........................................................................................ 2-20

2 Display units.................................................................................................................................... 2-24

2.1 Viper M display unit (not including Ex version) ..................................................................................... 2-24

2.2 Viper EX M display unit ...................................................................................................................... 2-26

2.3 Viper L display unit ............................................................................................................................ 2-28

2.4 Viper D display unit ........................................................................................................................... 2-30

2.5 Viper T display unit ............................................................................................................................ 2-32

3 Fasteners set ................................................................................................................................... 2-34

Repair: see Section 5

Section 2

Viper scales with small platform

Page 10

2-2 09/03 Service Manual 21203788C

Section 2 Viper scales with small platform Viper M, L, D and T Scales/Viper RM, RL, RD and RT Terminals

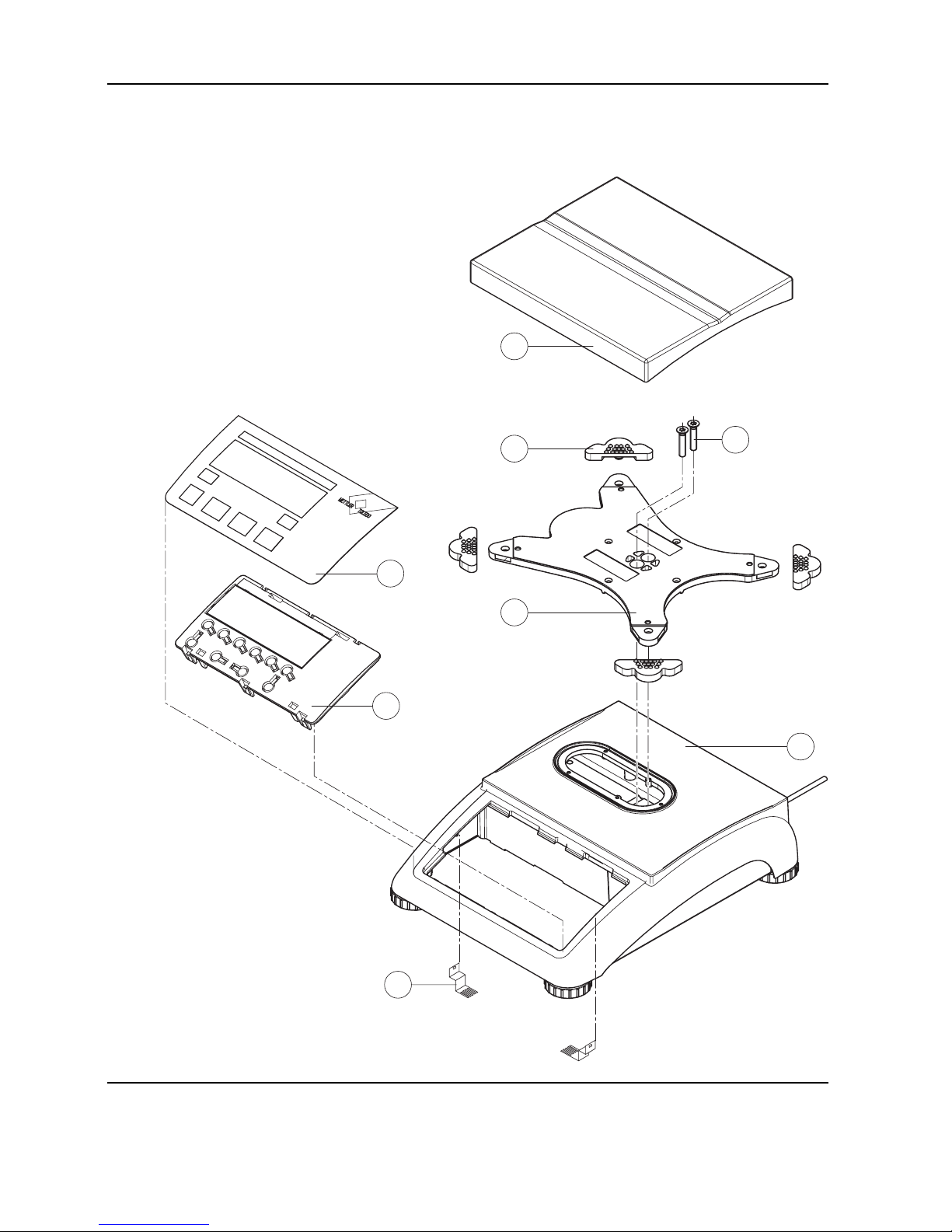

1 Scales

1.1 Scales with strain gauge load cells (not including Ex version)

2

3

4

1

6

7

5

8

Page 11

Service Manual 21203788C 09/03 2-3

Viper M, L, D and T Scales/Viper RM, RL, RD and RT Terminals Section 2 Viper scales with small platform

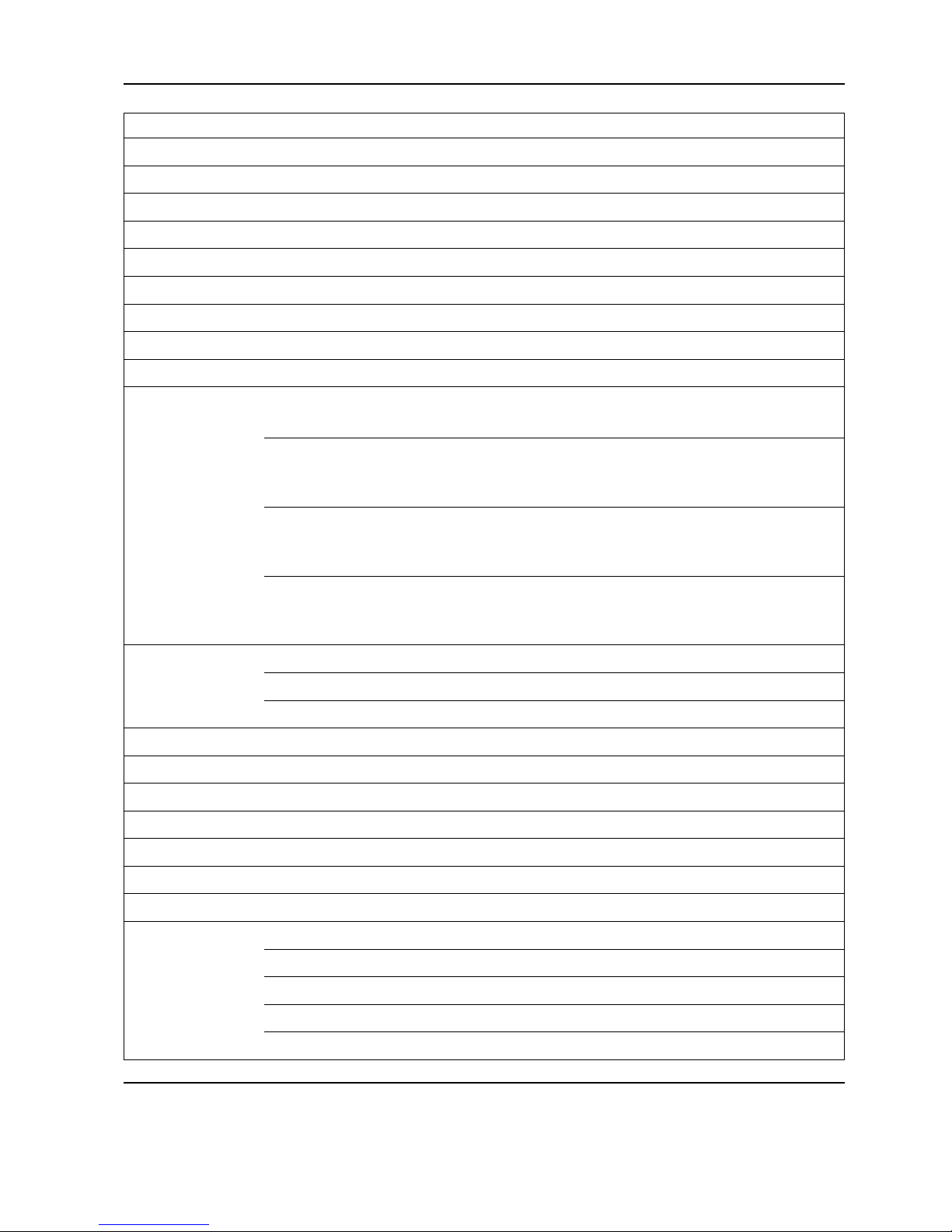

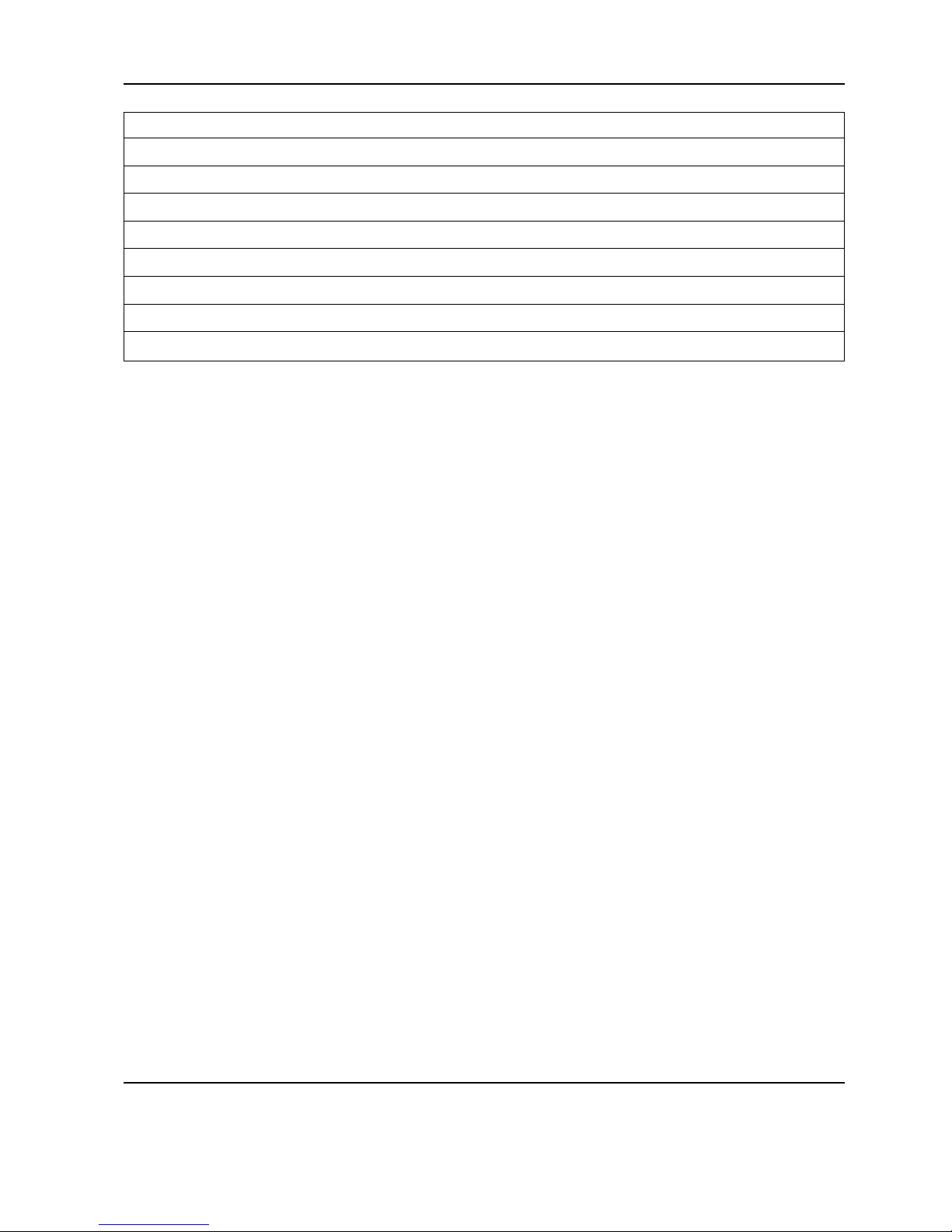

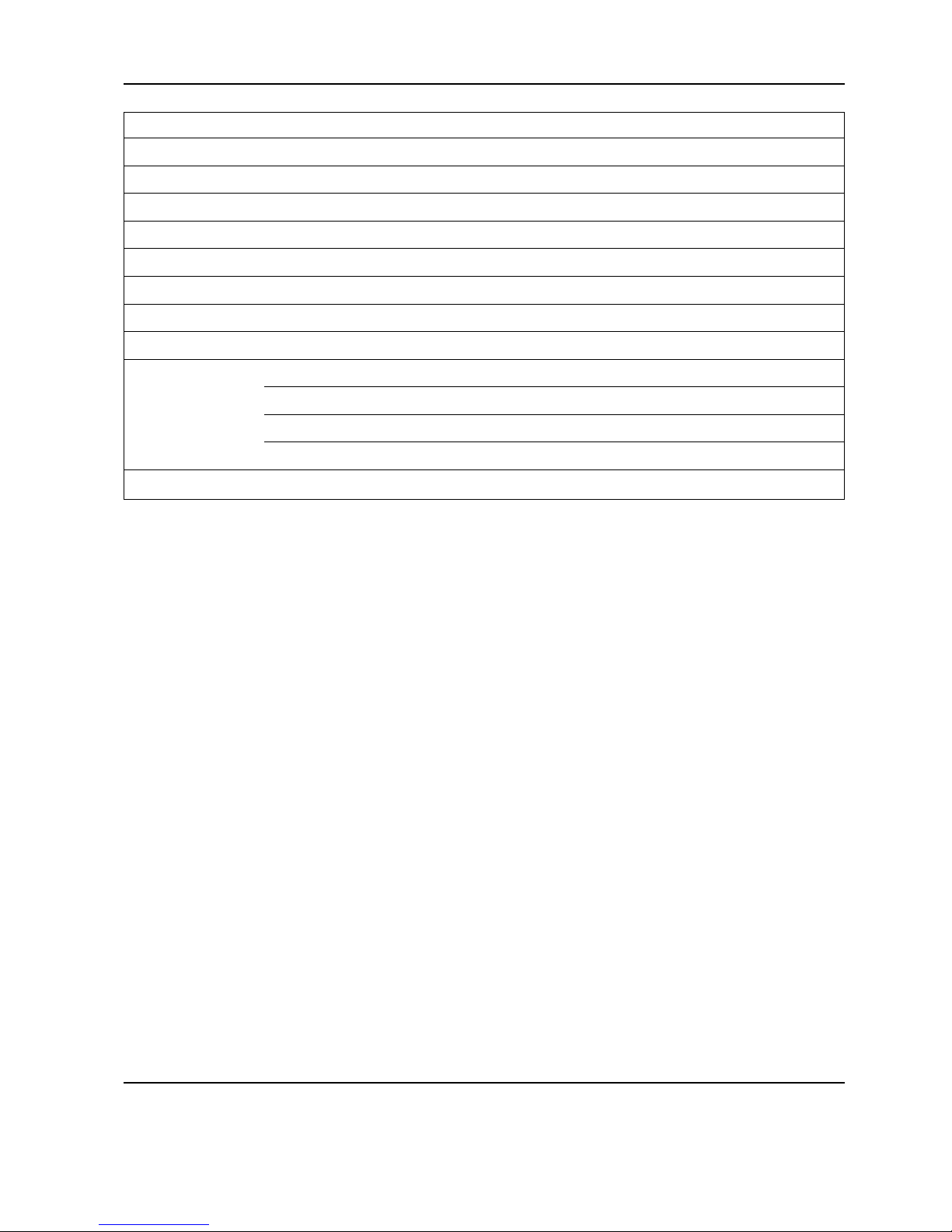

Item Quantity Description Order No.

1 1 platter 7.9" x 9.5" (200 x 240mm) 21203071

2 4 rubber cushion (1 piece)

1)

21203073

3 2 countersunk Torx screw M6 x 30 *

4 1 pan support plate 7.9" x 9.5" (200 x 240mm) –

5 1 housing, VIPER with small platform –

6 1 keypad overlay Chapter 2

7 1 mounting plate and display unit (digital PCB with LCD and back-light unit) Chapter 2

8 2 EMC clamp 21203480

* included in the fasteners set (chapter 3)

– not available as spare part

1)

New rubber cushions have a hole in the surface to assist with assembly. A pin can be used to insert the cushion into the

corresponding drilled hole in the pan support plate. Earlier rubber cushions did not have this assembly aid.

Page 12

2-4 09/03 Service Manual 21203788C

Section 2 Viper scales with small platform Viper M, L, D and T Scales/Viper RM, RL, RD and RT Terminals

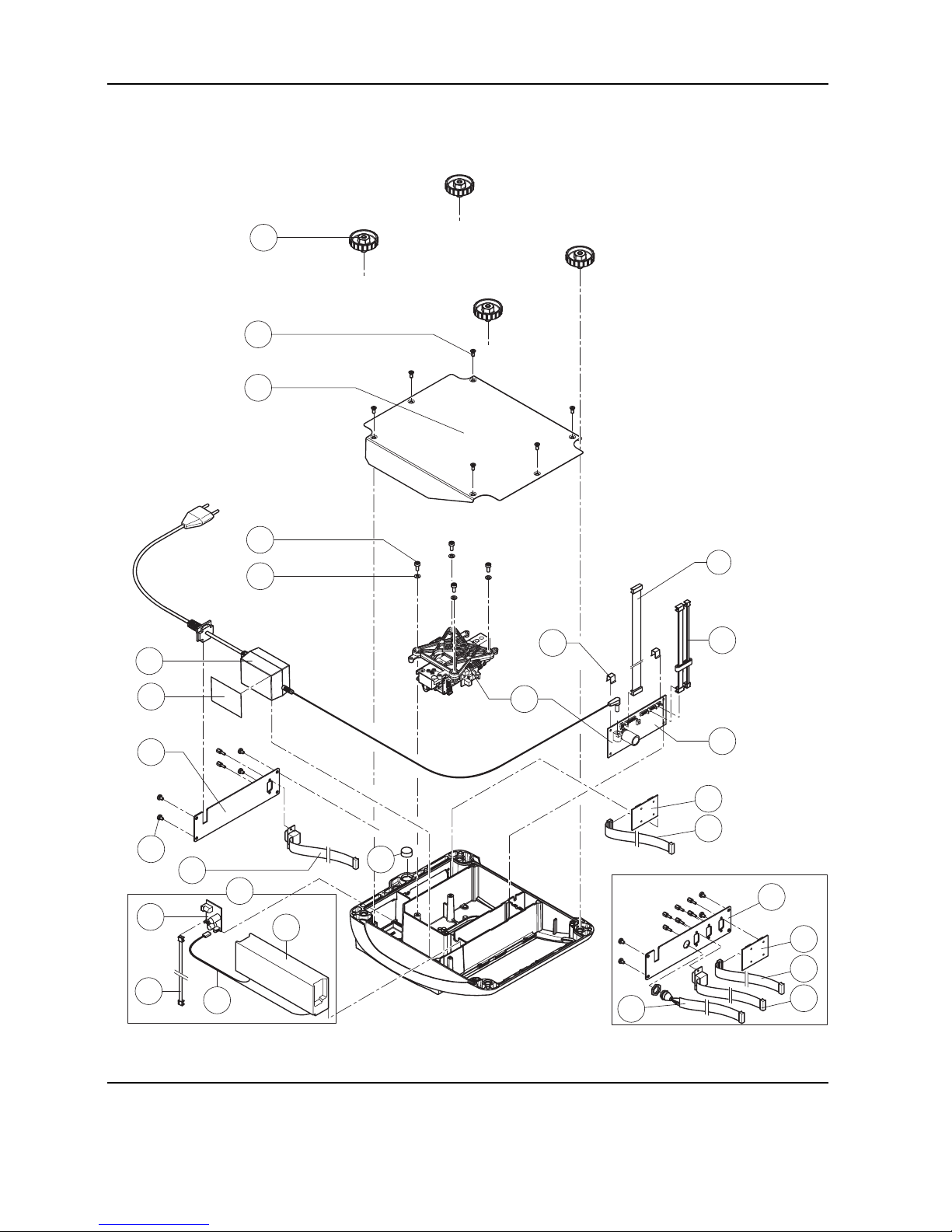

Scales with strain gauge load cells (continued)

11

1

2

5

4

6

8

9

10

16

12

13

14

17

18

3

7

19c

19d

19a

19b

19

15

25

22

23

24

14

26

27

20

21

20

14

21

26

27

Optional analog interface

Page 13

Service Manual 21203788C 09/03 2-5

Viper M, L, D and T Scales/Viper RM, RL, RD and RT Terminals Section 2 Viper scales with small platform

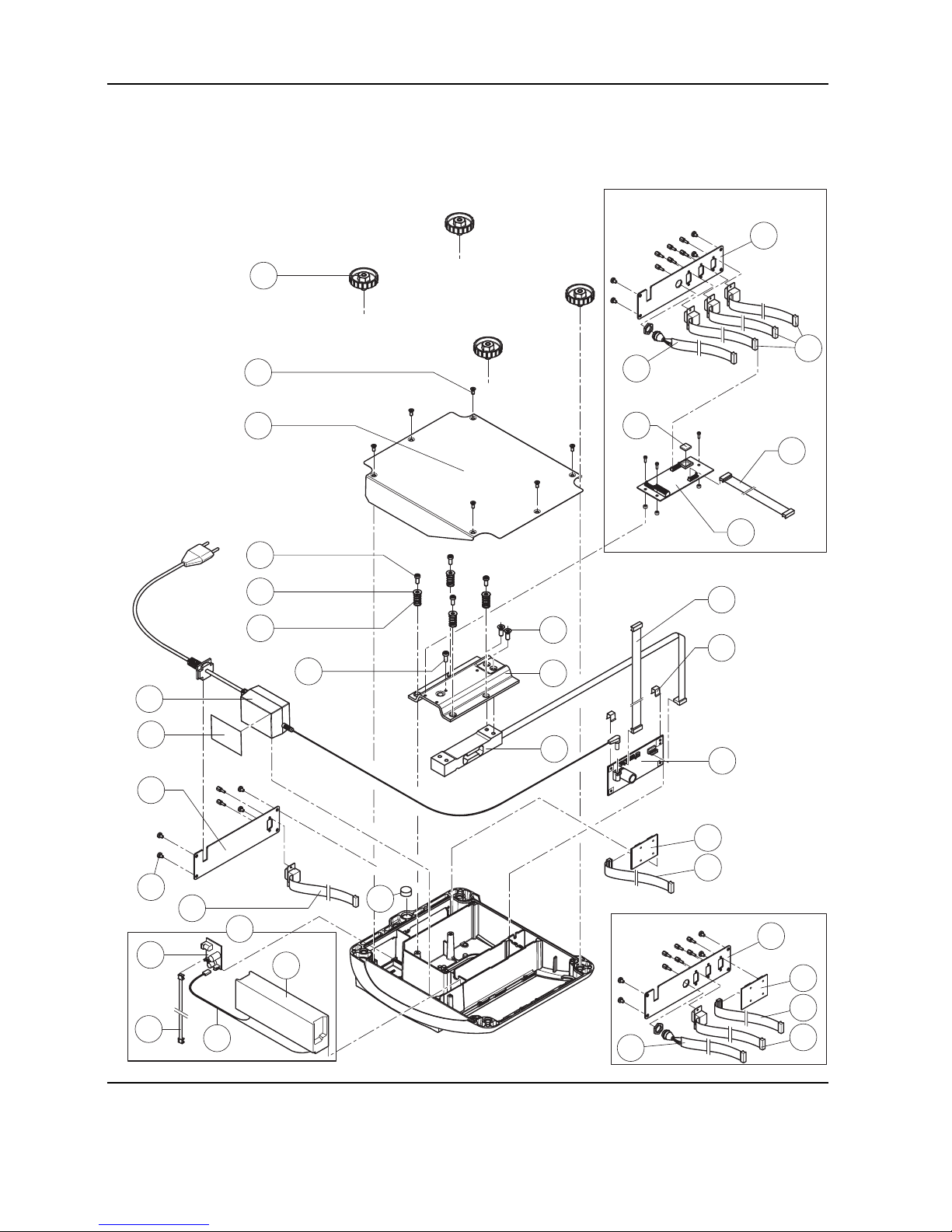

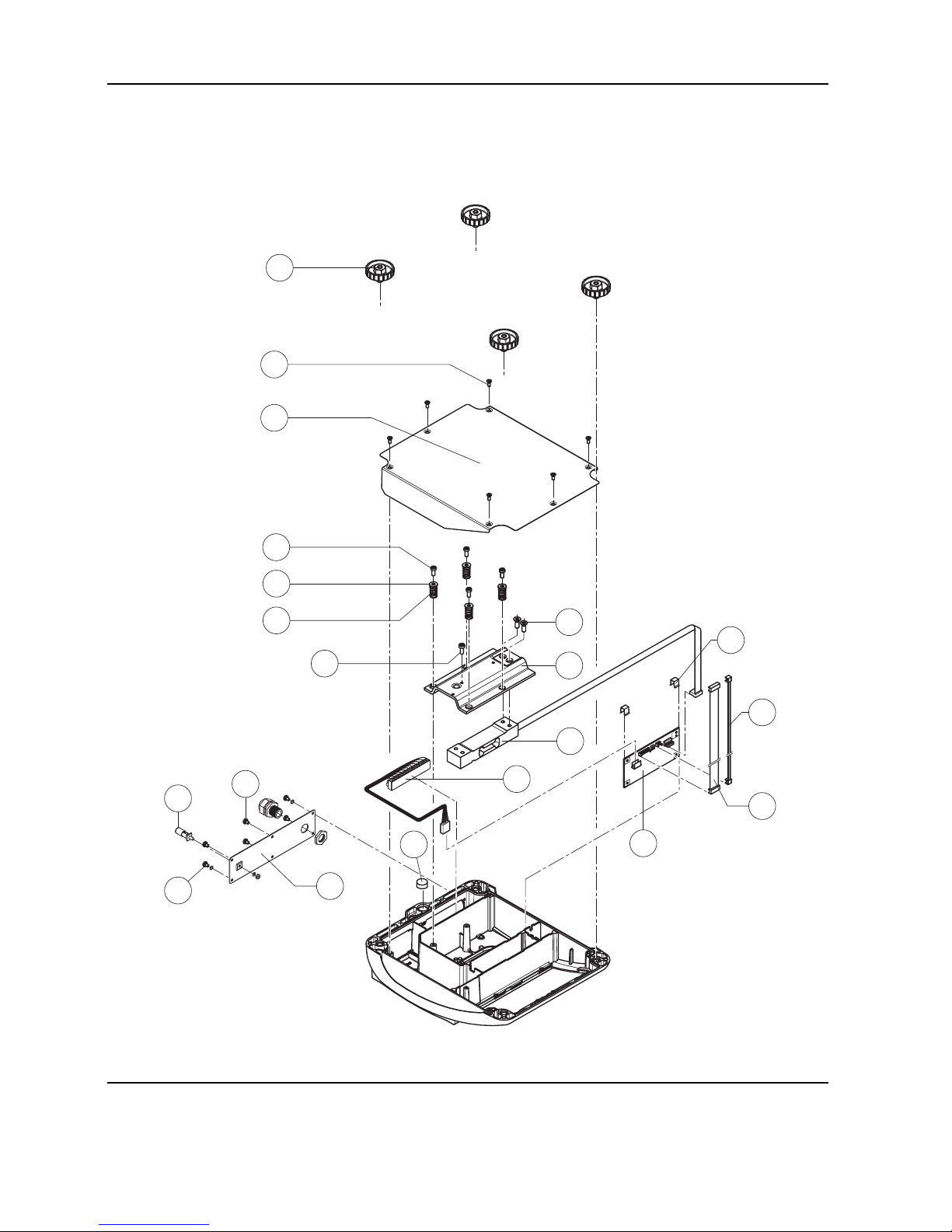

Item Quantity Description Order No.

1 4 adjustable foot ∅ 1.7" (44mm)/ M10 x 0.75mm 21203109

2 6 countersunk Torx screw M4 x 10 *

3 1 bottom plate for small platform model –

4 4 button head Torx screw M4 x 12 *

5 4 wide flange washer 4.3 x 20 *

6 4 overload spring **

7 1 overload stop adjustment screw (with certain production series only) **

8 2 countersunk Torx screw M6 x 16 *

9 1 overload plate for small platform model –

10 1 load cell with cable (certifiable)

(Note: only “LC...” load cells are available as spare parts!)

Weighing range 7.5lb (3kg):

C5MRS or (21203143)

LC0765-5-MRV 21203873

Weighing range 12lb (6kg):

C10MRS or (21203144)

LC0765-10-MRV 21203874

Weighing range 24lb (12kg):

C20MRS or (21203145)

LC0765-20-MRV 21203875

11 1 bench AC adapter:

US version, internal (always order together with item 16) 21203122

US version for scales with rechargeable battery and Viper T scales 21255102

12 2 spring clip * 21203166

13 1 analog PCB Viper DMS 21203092

14 1 RS cable 18.1" (460mm) 21203168

15 1 A/D cable 4.3" (110 mm) for small platform model 21203164

16 1 adhesive patch for AC adapter or battery 21203184

17 1 RS connector plate for Viper M/L/D (various types, depending on the equipment) –

18 4 raised cheese head Torx screw M4 x 6 *

19 For scales with rechargeable battery only:

19a 1 rechargeable battery 12V/2,2Ah (always order together with item 16) 21203232

19b 1 battery cable (charging PCB – battery) 21203231

19c 1 charging circuit print 21204033

19d 1 connection cable (charging PCB – analog PCB) 21203233

Page 14

2-6 09/03 Service Manual 21203788C

Section 2 Viper scales with small platform Viper M, L, D and T Scales/Viper RM, RL, RD and RT Terminals

Scales with strain gauge load cells (continued)

11

1

2

5

4

6

8

9

10

16

12

13

14

17

18

3

7

19c

19d

19a

19b

19

15

25

22

23

24

14

26

27

20

21

20

14

21

26

27

Optional analog interface

Page 15

Service Manual 21203788C 09/03 2-7

Viper M, L, D and T Scales/Viper RM, RL, RD and RT Terminals Section 2 Viper scales with small platform

20 1 PCB RS option (2 x RS232C), standard with Viper T 21203476

21 1 connection cable RS option 15" (380mm) 21203490

22 1 PCB optional analog interface 21203383

23 1 EPROM with interface software (for optional analog interface)

EPROM for Viper L and D analog interface 21203915

EPROM for Viper T analog interface 21255318

24 1 connection cable for optional analog interface 9.9" (250mm) 21203604

25 1 level bubble 21203204

26 1 PS2 cable 18.1"/460mm, (keyboard connection, for Viper T only) 21204107

27 1 connector plate Viper T for 3 RS interfaces and 1 keyboard cable: –

standard scale: 1x PCB RS Option, 1x RS cable 18.1", 1x PS2 cable

scale with optional analog interface: 3x RS cable 18.1", 1x PS2 cable

* included in the fasteners set (chapter 3) ** see section 4 “Replacing the load cell” – not available as spare part

Page 16

2-8 09/03 Service Manual 21203788C

Section 2 Viper scales with small platform Viper M, L, D and T Scales/Viper RM, RL, RD and RT Terminals

1.2 Scales with strain gauge load cells

and IP65 protection

1

2

3

4

5

6

7

8

9

Page 17

Service Manual 21203788C 09/03 2-9

Viper M, L, D and T Scales/Viper RM, RL, RD and RT Terminals Section 2 Viper scales with small platform

Item Quantity Description Order No.

1 1 packing for cover plate 21203235

2 1 cover plate –

3 2 countersunk Torx screw M3 x 8 *

4 1 flange D = 100mm –

5 1 diaphragm 21203077

6 1 flange D = 58mm –

7 3 countersunk Torx screw M3 x 10 *

8 4 countersunk Torx screw M3 x 8 *

9 2 EMC clamp 21203480

* included in the fasteners set (chapter 3)

– not available as spare part

Note: Parts of the scale not numbered in the illustration are included in the normal version (chapter 1.1).

Page 18

2-10 09/03 Service Manual 21203788C

Section 2 Viper scales with small platform Viper M, L, D and T Scales/Viper RM, RL, RD and RT Terminals

Scales with strain gauge load cells and IP65 protection (continued)

6

2

1

7

6

3

5

4

8

10

9

8

10

9

11

Page 19

Service Manual 21203788C 09/03 2-11

Viper M, L, D and T Scales/Viper RM, RL, RD and RT Terminals Section 2 Viper scales with small platform

Item Quantity Description Order No.

1 1 bottom plate for small platform model IP65 version 21203511

2 1 RS connector plate IP65 version (various types, depending on the equipment) –

3 1 air supply/extraction filter 21203860

4 1 packing for RS connector plate 21203236

5 6 raised cheese head Torx screw M4 x 6 *

6 1 RS cable 460mm IP65 21203717

7 1 PCB RS option (2 x RS232C) IP65 21255081

8 1 pressure equalizer 21203611

9 1 pressure equalizer tube LA 21203862

10 1 adhesive patch for pressure equalizer 21203184

11 1 level bubble 21203204

* included in the fasteners set (chapter 3)

– not available as spare part

Note: Parts of the scale not numbered in the illustration are included in the normal version (chapter 1.1).

Page 20

2-12 09/03 Service Manual 21203788C

Section 2 Viper scales with small platform Viper M, L, D and T Scales/Viper RM, RL, RD and RT Terminals

1.3 Scales with strain gauge load cells, Ex version

2

3

4

1

6

7

5

8

Page 21

Service Manual 21203788C 09/03 2-13

Viper M, L, D and T Scales/Viper RM, RL, RD and RT Terminals Section 2 Viper scales with small platform

Item Quantity Description Order No.

1 1 platter 7.9" x 9.5" (200 x 240mm) 21203071

2 4 rubber cushion (1 piece)

1)

21203073

3 2 countersunk Torx screw M6 x 30 *

4 1 pan support plate 7.9" x 9.5" (200 x 240mm) –

5 1 housing, VIPER with small platform –

6 1 keypad overlay Chapter 2

7 1 mounting plate and display unit (digital PCB with LCD and back-light unit) Chapter 2

8 2 EMC clamp 21203480

* included in the fasteners set (chapter 3)

– not available as spare part

1)

New rubber cushions have a hole in the surface to assist with assembly. A pin can be used to insert the cushion into the

corresponding drilled hole in the pan support plate. Earlier rubber cushions did not have this assembly aid.

Page 22

2-14 09/03 Service Manual 21203788C

Section 2 Viper scales with small platform Viper M, L, D and T Scales/Viper RM, RL, RD and RT Terminals

Scales with strain gauge load cells, Ex version (continued)

1

2

5

4

6

8

9

10

3

7

20

14

19

17

12

13

16

15

11

18

Page 23

Service Manual 21203788C 09/03 2-15

Viper M, L, D and T Scales/Viper RM, RL, RD and RT Terminals Section 2 Viper scales with small platform

Item Quantity Description Order No.

1 4 adjustable foot ∅ 1.7" (44mm)/ M10 x 0.75mm 21203109

2 6 countersunk Torx screw M4 x 10 *

3 1 bottom plate for small platform model –

4 4 button head Torx screw M4 x 12 *

5 4 wide flange washer 4.3 x 20 *

6 4 overload spring **

7 1 overload stop adjustment screw (with certain production series only) **

8 2 countersunk Torx screw M6 x 16 *

9 1 overload plate for small platform model –

10 1 load cell with cable (certifiable)

Weighing range 7.5lb (3kg):

LC0765-5-MRV 21203873

Weighing range 12lb (6kg):

LC0765-10-MRV 21203874

Weighing range 24lb (12kg):

LC0765-20-MRV 21203875

11 1 wire harness Ex 21203732

12 2 spring clip * 21203166

13 1 analog PCB Viper Ex DMS 21203577

14 1 grounding screw EX 21050066

15 1 A/D cable 4.3" (110 mm) for small platform model 21203164

16 1 connection cable Ex 4 pins 21203852

17 1 connector plate Ex –

18 4 raised cheese head Torx screw M4 x 6 *

19 2 raised cheese head Torx screw M4 x 8 with tooth lock washer –

20 1 level bubble 21203204

* included in the fasteners set (chapter 3) ** see section 4 “Replacing the load cell” – not available as spare part

Page 24

2-16 09/03 Service Manual 21203788C

Section 2 Viper scales with small platform Viper M, L, D and T Scales/Viper RM, RL, RD and RT Terminals

1.4 Scales with MonoBloc load cells (not including Ex version)

7

8

3

1

2

4

5

6

9

9a

9b

9c

10

Page 25

Service Manual 21203788C 09/03 2-17

Viper M, L, D and T Scales/Viper RM, RL, RD and RT Terminals Section 2 Viper scales with small platform

Item Quantity Description Order No.

1 1 platter 7.9" x 9.5" (200 x 240mm) for 12lb scale (6kg) 21203071

2 4 pan mount (rubber cushion) 21203238

3 1 hexagon screw for load plate support –

4 1 fastener spring –

5 1 load plate support 7.9" x 9.5" (200 x 240mm) –

6 1 housing VIPER with small platform –

7 1 keypad overlay Chapter 2

8 1 mounting plate and display unit (digital PCB and display compl.) Chapter 2

9 For 6lb (3kg) model only:

9a 1 draft shield and screen 21203849

9b 1 platter 6.5" x 6.5" (165 x 165mm) 00225158

9c 1 load plate support 16.5" x 6.5" (165 x 165mm) –

10 2 EMC clamp 21203480

* included in the fasteners set (chapter 3)

– not available as spare part

Page 26

2-18 09/03 Service Manual 21203788C

Section 2 Viper scales with small platform Viper M, L, D and T Scales/Viper RM, RL, RD and RT Terminals

Scales with MonoBloc load cells (continued)

8

1

2

5

4

13

9

10

11

14

15

12

3

16c

16d

16a

16b

16

6

7

19

17

18

17

11

18

20

21

Page 27

Service Manual 21203788C 09/03 2-19

Viper M, L, D and T Scales/Viper RM, RL, RD and RT Terminals Section 2 Viper scales with small platform

Item Quantity Description Order No.

1 4 adjustable foot ∅ 1.7" (44mm)/ M10 x 0.75mm 21203109

2 6 countersunk Torx screw M4 x 10 *

3 1 bottom plate for small platform model –

4 4 cylinder head Torx screw M4 x 12 *

5 4 flange washer 4.3 x 9 –

61 weighing modules (load cell and analog PCB):

weighing module 3002 for 6lb scale (3kg) 11102685

weighing module 6001 for 12lb scale (6kg) 11102686

7 1 cell cable MB SM with ferrite ring 21203289

81 bench AC adapter:

US version, internal (always order together with item 13) 21203122

US version for scales with rechargeable battery and Viper T scales 21255102

9 2 spring clip * 21203166

10 1 analog PCB Viper MonoBloc 21203100

11 1 RS cable 18.1" (460mm) 21203168

12 1 A/D cable 4.3" (110 mm), for small platform model 21203164

13 1 adhesive strip for AC adapter or battery 21203184

14 1 RS connector plate for Viper M/L/D (various types, depending on the equipment) –

15 4 raised cheese head Torx screw M4 x 6 *

16 For scales with rechargeable battery only:

16a 1 rechargeable battery 12V/2,2Ah (always order together with item 13) 21203232

16b 1 battery cable (charging PCB – battery) 21203231

16c 1 charging circuit print 21204033

16d 1 connection cable (charging PCB – analog PCB) 21203233

17 1 PCB RS option (2 x RS232C), standard with Viper T 21203476

18 1 connection cable RS option 15" (380mm) 21203490

19 1 level bubble 11101335

20 1 PS2 cable 18.1"/460mm, (keyboard connection, for Viper T only) 21204107

21 1 connector plate Viper T for 3 RS interfaces and 1 keyboard cable –

(1x PCB RS Option, 1x RS cable 18.1", 1x PS2 cable)

* included in the fasteners set (chapter 3)

– not available as spare part

Page 28

2-20 09/03 Service Manual 21203788C

Section 2 Viper scales with small platform Viper M, L, D and T Scales/Viper RM, RL, RD and RT Terminals

1.5 Scales with MonoBloc load cells, Ex version

7

8

3

1

2

4

5

6

9

9a

9b

9c

10

Page 29

Service Manual 21203788C 09/03 2-21

Viper M, L, D and T Scales/Viper RM, RL, RD and RT Terminals Section 2 Viper scales with small platform

Item Quantity Description Order No.

1 1 platter 7.9" x 9.5" (200 x 240mm) for 12lb scale (6kg) 21203071

2 4 pan mount (rubber cushion) 21203238

3 1 hexagon screw for load plate support –

4 1 fastener spring –

5 1 load plate support 7.9" x 9.5" (200 x 240mm) –

6 1 housing VIPER with small platform –

7 1 keypad overlay Chapter 2

8 1 mounting plate and display unit (digital PCB and display compl.) Chapter 2

9 For 6lb (3kg) model only:

9a 1 draft shield and screen 21203849

9b 1 platter 6.5" x 6.5" (165 x 165mm) 00225158

9c 1 load plate support 16.5" x 6.5" (165 x 165mm) –

10 2 EMC clamp 21203480

* included in the fasteners set (chapter 3)

– not available as spare part

Page 30

2-22 09/03 Service Manual 21203788C

Section 2 Viper scales with small platform Viper M, L, D and T Scales/Viper RM, RL, RD and RT Terminals

Scales with MonoBloc load cells, Ex version (continued)

1

2

5

4

3

6

17

9

7

13

10

12

8

11

16

14

13

15

Page 31

Service Manual 21203788C 09/03 2-23

Viper M, L, D and T Scales/Viper RM, RL, RD and RT Terminals Section 2 Viper scales with small platform

Item Quantity Description Order No.

1 4 adjustable foot ∅ 1.7" (44mm)/ M10 x 0.75mm 21203109

2 6 countersunk Torx screw M4 x 10 *

3 1 bottom plate for small platform model –

4 4 cylinder head Torx screw M4 x 12 *

5 4 flange washer 4.3 x 9 –

61 weighing modules (load cell and analog PCB):

weighing module 3002 Ex for 6lb scale (3kg) 21204011

weighing module 6001 Ex for 12lb scale (6kg) 21204012

7 1 cell PCB cable Ex 21203990

8 1 wire harness Ex 21203732

9 2 spring clip * 21203166

10 1 analog PCB Viper Ex MonoBloc 21203576

11 1 grounding screw EX 21050066

12 1 A/D cable 4.3" (110 mm), for small platform model 21203164

13 2 connection cable Ex 4 pins, for small platform model 21203852

14 1 connector plate Ex –

15 4 raised cheese head Torx screw M4 x 6 *

16 2 raised cheese head Torx screw M4 x 8 with tooth lock washer –

17 1 level bubble 11101335

* included in the fasteners set (chapter 3)

– not available as spare part

Page 32

2-24 09/03 Service Manual 21203788C

Section 2 Viper scales with small platform Viper M, L, D and T Scales/Viper RM, RL, RD and RT Terminals

2 Display units

2.1 Viper M display unit (not including Ex version)

1

2

3

4

5

7

6

Page 33

Service Manual 21203788C 09/03 2-25

Viper M, L, D and T Scales/Viper RM, RL, RD and RT Terminals Section 2 Viper scales with small platform

Item Quantity Description Order No.

1 1 keypad overlay for Viper M small platform model 21203440

2 1 display mounting plate for Viper M (always order together with item 1) 21203120

3 1 LCD for Viper M 21203134

4 1 back-light unit for Viper M 21203136

51 digital PCB Viper M

1)

VIPER DIG M digital PCB for scales with strain gauge load cell

2)

21203098

VIPER MB DIG digital PCB with FLASH Memory chip (soldered)

for scales with MonoBloc load cell

3)

21204025-MBM

6 1 EPROM with scale program for Viper M scales with strain gauge load cell 21203583

7 1 retaining screw *

* included in the fasteners set (chapter 3)

1)

without LCD and back-light unit (these parts must be ordered separately)

2)

without EPROM (must be ordered separately)

3)

the digital PCB with FLASH memory chip is always supplied with scale-specific software. The designation “MBM” following

the order number specifies the scale software that is is loaded into the FLASH Memory chip prior to shipping.

Page 34

2-26 09/03 Service Manual 21203788C

Section 2 Viper scales with small platform Viper M, L, D and T Scales/Viper RM, RL, RD and RT Terminals

2.2 Viper EX M display unit

1

2

3

4

5

7

6

8

8

Page 35

Service Manual 21203788C 09/03 2-27

Viper M, L, D and T Scales/Viper RM, RL, RD and RT Terminals Section 2 Viper scales with small platform

Item Quantity Description Order No.

1 1 keypad overlay for Viper M small platform model 21203440

2 1 display mounting plate for Viper Ex 21203734

3 1 LCD for Viper M 21203134

4 1 back-light unit for Viper M 21203136

5 1 VIPER Ex DIG digital PCB

1)

21203593

61 EPROM with scale program:

EPROM for Viper M scales with strain gauge load cell 21203583

EPROM for Viper M scales with MonoBloc load cell 21203584

7 1 retaining screw *

8 1 set of blank labels Viper Ex 22007836

* included in the fasteners set (chapter 3)

1)

supplied without software, LCD and back-light unit (these parts must be ordered separately)

Page 36

2-28 09/03 Service Manual 21203788C

Section 2 Viper scales with small platform Viper M, L, D and T Scales/Viper RM, RL, RD and RT Terminals

2.3 Viper L display unit

1

2

3

4

5

7

6

Page 37

Service Manual 21203788C 09/03 2-29

Viper M, L, D and T Scales/Viper RM, RL, RD and RT Terminals Section 2 Viper scales with small platform

Item Quantity Description Order No.

1 1 keypad overlay for Viper L small platform model 21203441

2 1 display mounting plate for Viper L (always order together with item 1) 21203491

3 1 LCD for Viper L/D 21203687

4 1 back-light unit for Viper L/D 21203137

51 digital PCB Viper L

1)

VIPER DIG L digital PCB for scales with strain gauge load cell

2)

21203097

VIPER MB DIG digital PCB with FLASH Memory chip (soldered)

for scales with MonoBloc load cell

3)

21204025-MBL

6 1 EPROM with scale program for Viper L scales with strain gauge load cell 21203588

7 1 retaining screw *

* included in the fasteners set (chapter 3)

1)

without LCD and back-light unit (these parts must be ordered separately)

2)

without EPROM (must be ordered separately)

3)

the digital PCB with FLASH memory chip is always supplied with scale-specific software. The designation “MBL” following the

order number specifies the scale software that is is loaded into the FLASH Memory chip prior to shipping.

Page 38

2-30 09/03 Service Manual 21203788C

Section 2 Viper scales with small platform Viper M, L, D and T Scales/Viper RM, RL, RD and RT Terminals

2.4 Viper D display unit

1

2

4

5

6

7

3

Page 39

Service Manual 21203788C 09/03 2-31

Viper M, L, D and T Scales/Viper RM, RL, RD and RT Terminals Section 2 Viper scales with small platform

Item Quantity Description Order No.

1 1 keypad overlay for Viper D small platform model 21203442

2 1 display mounting plate for Viper D (always order together with items 1 and 3) 21203448

3 1 pressure sensitive membrane for numeric keypad (15 keys)

1)

21203439

4 1 LCD for Viper L/D 21203687

5 1 back-light unit for Viper L/D 21203137

61 digital PCB Viper D with FLASH Memory chip (soldered)

2)

VIPER DIG D digital PCB for scales with strain gauge load cell

3)

21203524-STD

VIPER DIG D digital PCB for scales with MonoBloc load cell

3)

21203524-MBD

7 1 retaining screw *

* included in the fasteners set (chapter 3)

1)

always order together with item 1

2)

supplied without LCD and back-light unit (these parts must be ordered separately)

3)

the digital PCB with FLASH memory chip is always supplied with scale-specific software. The designations “STD” and “MBD”

following the order number specify the scale software that is is loaded into the FLASH Memory chip prior to shipping.

Page 40

2-32 09/03 Service Manual 21203788C

Section 2 Viper scales with small platform Viper M, L, D and T Scales/Viper RM, RL, RD and RT Terminals

2.5 Viper T display unit

1

2

3

4

7

5

6

7

Page 41

Service Manual 21203788C 09/03 2-33

Viper M, L, D and T Scales/Viper RM, RL, RD and RT Terminals Section 2 Viper scales with small platform

Item Quantity Description Order No.

1 1 keypad overlay for Viper T small platform model 21203129

2 1 pressure sensitive keypad membrane for numeric keypad (25 keys) 21203501

3 1 display mounting plate for Viper T (always order together with items 1 and 2) 21203507

4 1 spacer plate 21255046

5 1 LCD module 240 x 64 dots CCFL 21203515

61 digital PCB:

Viper T (counting scale) 21203996

SQC 16 21203772

Smart Remote 21203997

7 5 retaining screw *

* included in the fasteners set (chapter 3)

Page 42

2-34 09/03 Service Manual 21203788C

Section 2 Viper scales with small platform Viper M, L, D and T Scales/Viper RM, RL, RD and RT Terminals

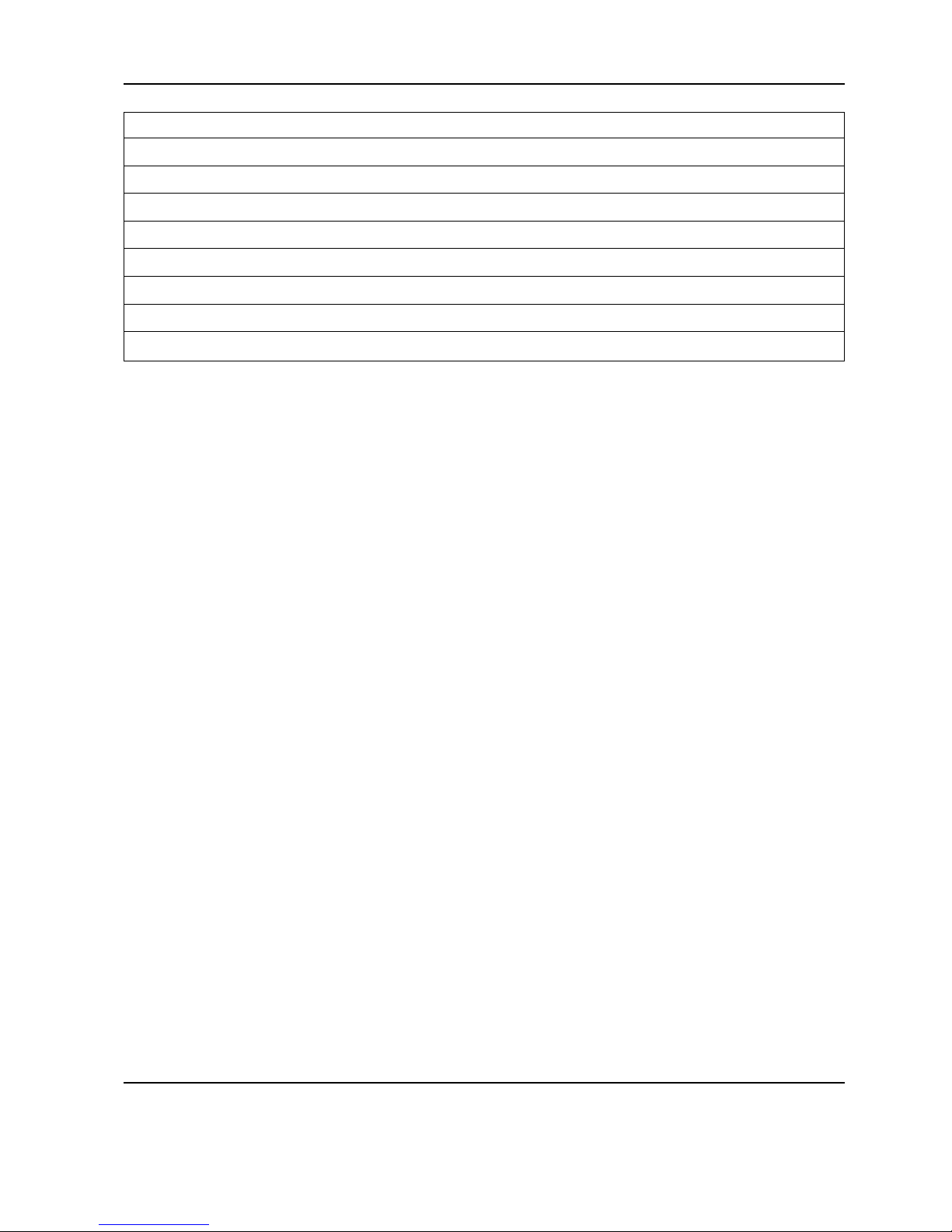

3 Fasteners set

The fasteners set comprises all the standard components (screws and washers) required for service work on Viper scales and

terminals, plus the spring clips that hold the analog PCB in place.

Quantity Description Order No.

1 fasteners set: 21203404

20 countersunk Torx screw M3 x 8 –

20 countersunk Torx screw M3 x 10 –

20 countersunk Torx screw M6 x 30 –

50 countersunk Torx screw M4 x 10 –

10 countersunk Torx screw M4 x 12 –

20 button head Torx screw M3 x 6 –

30 button head Torx screw M4 x 12 –

30 button head Torx screw M5 x 12 –

20 wide flange washer 4.3 x 20 –

20 wide flange washer 5.3 x 20 –

20 countersunk Torx screw M6 x 16 –

20 spring clip –

50 raised cheese head Torx screw M4 x 6 –

10 screw lock –

10 Torx oval head tapping screw 2.9 x 13 –

Page 43

Contents Page

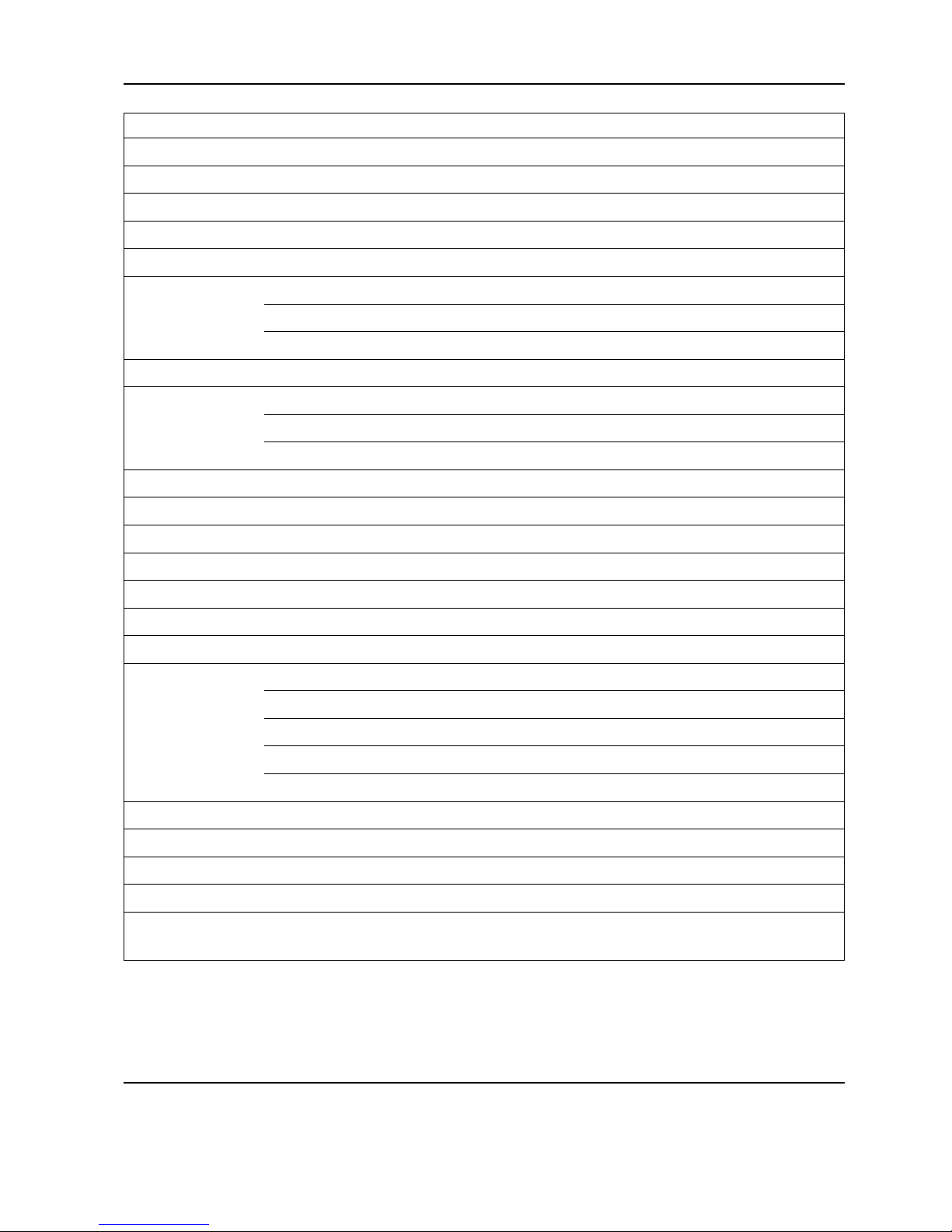

1 Scales ............................................................................................................................................. 3-2

1.1 Scales with strain gauge load cells (not including Ex version) ................................................................ 3-2

1.2 Scales with strain gauge load cell and IP65 protection .......................................................................... 3-8

1.3 Scales with strain gauge load cells, Ex version ..................................................................................... 3-12

1.4 Scales with MonoBloc load cells (not including Ex version) ................................................................... 3-16

1.5 Scales with MonoBloc load cells, Ex version ........................................................................................ 3-20

2 Display units.................................................................................................................................... 3-24

2.1 Viper M display unit (not including Ex version) ..................................................................................... 3-24

2.2 Viper EX M display unit ...................................................................................................................... 3-26

2.3 Viper L display unit ............................................................................................................................ 3-28

2.4 Viper D display unit ........................................................................................................................... 3-30

2.5 Viper T display unit ............................................................................................................................ 3-32

3 Fasteners set ................................................................................................................................... 3-34

Repair: see Section 5

Section 3

Viper scales with large platform

Page 44

3-2 09/03 Service Manual 21203788C

Section 3 Viper scales with large platform Viper M, L, D and T Scales/Viper RM, RL, RD and RT Terminals

1 Scales

1.1 Scales with strain gauge load cells

(not including Ex version)

2

3

4

1

6

7

5

8

Page 45

Service Manual 21203788C 09/03 3-3

Viper M, L, D and T Scales/Viper RM, RL, RD and RT Terminals Section 3 Viper scales with large platform

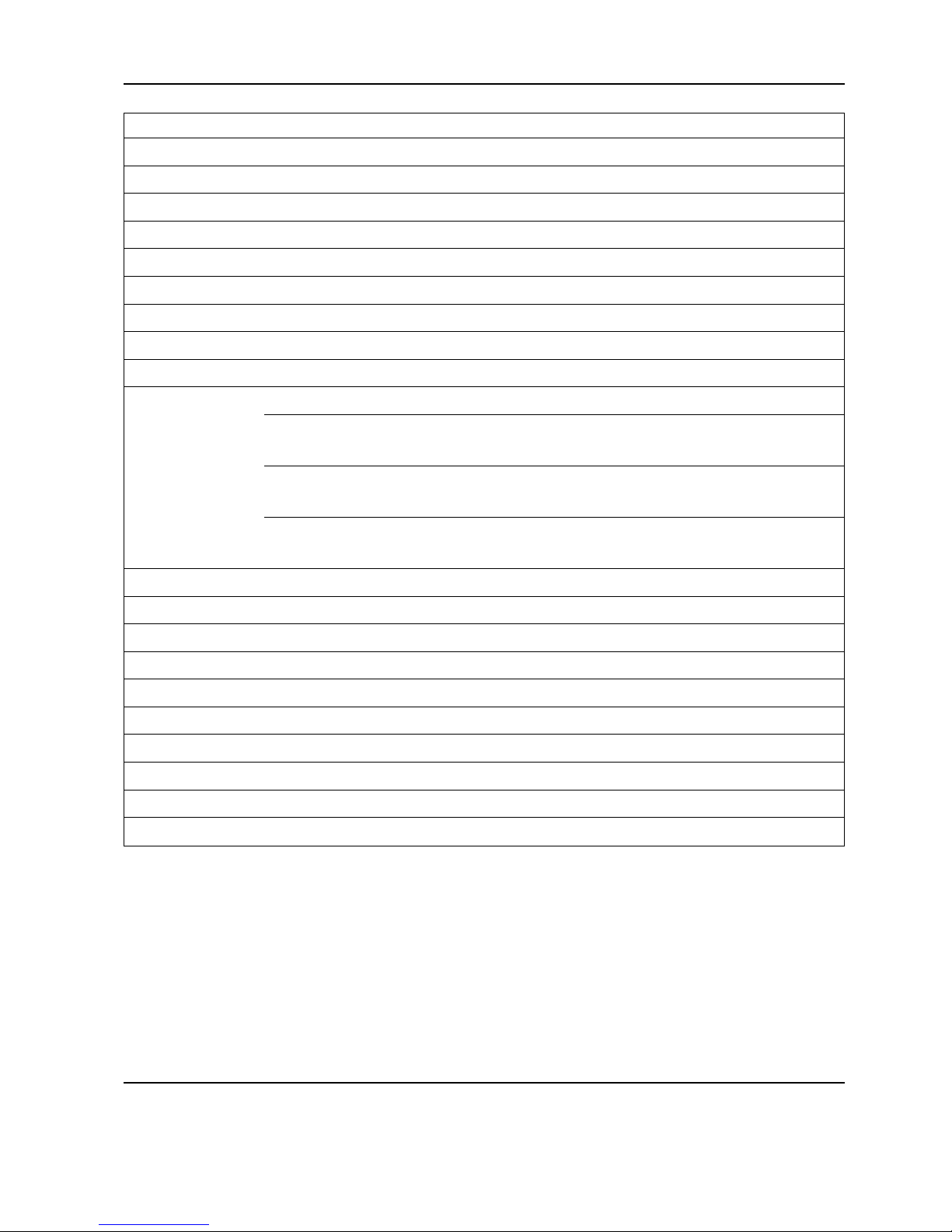

Item Quantity Description Order No.

1 1 platter 9.5" x 13.8" (240 x 350mm) 21203072

2 4 rubber cushion (1 piece)

1)

21203073

3 2 countersunk Torx screw M6 x 30 *

4 1 pan support plate 9.5" x 13.8" (240 x 350mm) 21203075

5 1 housing, VIPER with large platform –

6 1 keypad overlay Subsection 2

7 1 mounting plate and display unit (digital PCB with LCD and back-light unit) Subsection 2

8 2 EMC clamp 21203480

* included in the fasteners set (chapter 3)

– not available as spare part

1)

New rubber cushions have a hole in the surface to assist with assembly. A pin can be used to insert the cushion into the

corresponding drilled hole in the pan support plate. Earlier rubber cushions did not have this assembly aid.

Page 46

3-4 09/03 Service Manual 21203788C

Section 3 Viper scales with large platform Viper M, L, D and T Scales/Viper RM, RL, RD and RT Terminals

Scales with strain gauge load cells (continued)

11

1

2

3

5

4

8

9

16

13

14

17

18

10

6

19c

19d

19a

19b

19

7

12

15

25

22

23

24

14

26

27

20

21

20

14

21

26

27

Optional analog interface

Page 47

Service Manual 21203788C 09/03 3-5

Viper M, L, D and T Scales/Viper RM, RL, RD and RT Terminals Section 3 Viper scales with large platform

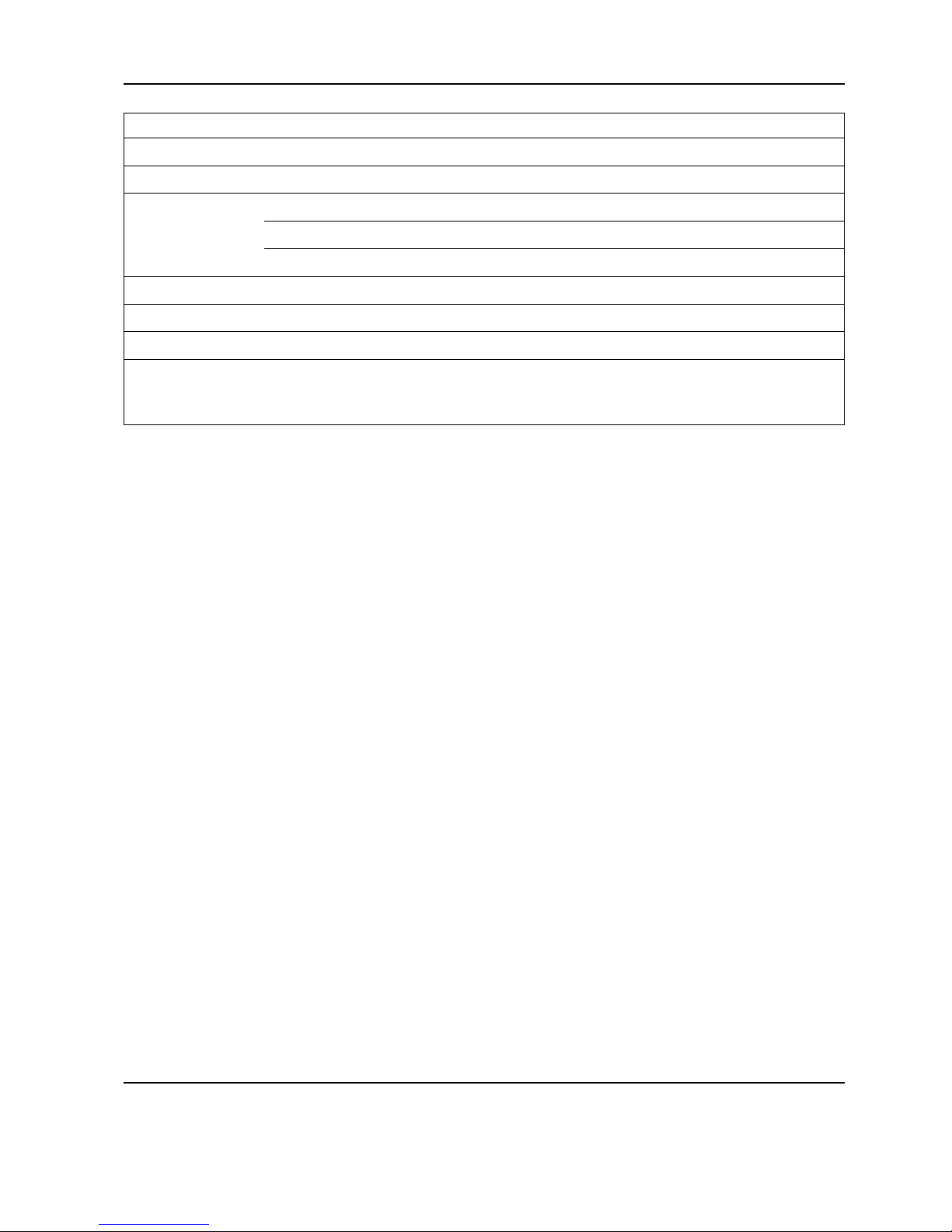

Item Quantity Description Order No.

1 4 adjustable foot ∅ 2.2" (55mm)/M10 x 0.75mm 21203110

2 11 countersunk Torx screw M4 x 10 *

3 1 bottom plate for large platform model –

4 4 button head Torx screw M5 x 12 *

5 4 wide flange washer 5.3 x 20 *

6 4 overload spring **

7 1 overload stop adjustment screw (with specific production series only) **

8 2 countersunk Torx screw M6 x 16 *

9 1 overload plate for large platform model –

10 1 load cell with cable (certifiable)

(Note: only “LC...” load cells are available as spare parts!)

Weighing range 24lb (12kg):

C20MRL or (21203151)

LC0785-20-MRV 21203885

Weighing range 75lb (30kg):

C50MRL or (21203152)

LC0785-50-MRV 21203886

Weighing range 120lb (60kg):

C100MRL or (21203153)

LC0785-100-MRV 21203887

11 1 bench AC adapter:

US version, internal (always order together with item 16) 21203122

US version for scales with rechargeable battery and Viper T scales 21255102

12 2 spring clip * 21203166

13 1 analog PCB Viper DMS 21203092

14 1 RS cable 18.1" (460mm) 21203168

15 1 A/D cable 11.8" (300mm) for large platform model 21203167

16 1 adhesive patch for AC adapter or battery 21203184

17 1 RS connector plate for Viper M/L/D (various types, depending on the equipment) –

18 4 raised cheese head Torx screw M4 x 6 *

19 For scales with with rechargeable battery only:

19a 1 rechargeable battery 12V/2,2Ah (always order together with item 16) 21203232

19b 1 battery cable (charging PCB – battery) 21203231

19c 1 charging circuit print 21204033

19d 1 connection cable (charging PCB – analog PCB) 21203233

Page 48

3-6 09/03 Service Manual 21203788C

Section 3 Viper scales with large platform Viper M, L, D and T Scales/Viper RM, RL, RD and RT Terminals

Scales with strain gauge load cells (continued)

11

1

2

3

5

4

8

9

16

13

14

17

18

10

6

19c

19d

19a

19b

19

7

12

15

25

22

23

24

14

26

27

20

21

20

14

21

26

27

Optional analog interface

Page 49

Service Manual 21203788C 09/03 3-7

Viper M, L, D and T Scales/Viper RM, RL, RD and RT Terminals Section 3 Viper scales with large platform

20 1 PCB RS option (2 x RS232C), standard with Viper T 21203476

21 1 connection cable RS option 15" (380mm) 21203490

22 1 PCB optional analog interface 21203383

23 1 EPROM with interface software (for optional analog interface)

EPROM for Viper L and D analog interface 21203915

EPROM for Viper T analog interface 21255318

24 1 connection cable for optional analog interface 9.9" (250mm) 21203604

25 1 level bubble 21203204

26 1 PS2 cable 18.1"/460mm, (keyboard connection, for Viper T only) 21204107

27 1 connector plate Viper T for 3 RS interfaces and 1 keyboard cable: –

standard scale: 1x PCB RS Option, 1x RS cable 18.1", 1x PS2 cable

scale with optional analog interface: 3x RS cable 18.1", 1x PS2 cable

* included in the fasteners set (chapter 3) ** see section 4 “Replacing the load cell” – not available as spare part

Page 50

3-8 09/03 Service Manual 21203788C

Section 3 Viper scales with large platform Viper M, L, D and T Scales/Viper RM, RL, RD and RT Terminals

1.2 Scales with strain gauge load cell

and IP65 protection

8

1

2

3

4

5

6

7

9

Page 51

Service Manual 21203788C 09/03 3-9

Viper M, L, D and T Scales/Viper RM, RL, RD and RT Terminals Section 3 Viper scales with large platform

Item Quantity Description Order No.

1 1 packing for cover plate 21203235

2 1 cover plate –

3 2 countersunk Torx screw M3 x 8 *

4 1 flange D = 100mm –

5 1 diaphragm 21203077

6 1 flange D = 58mm –

7 3 countersunk Torx screw M3 x 10 *

8 4 countersunk Torx screw M3 x 8 *

9 2 EMC clamp 21203480

* included in the fasteners set (chapter 3)

– not available as spare part

Note: Parts of the scale not numbered in the illustration are included in the normal version (chapter 1.1).

Page 52

3-10 09/03 Service Manual 21203788C

Section 3 Viper scales with large platform Viper M, L, D and T Scales/Viper RM, RL, RD and RT Terminals

Scales with strain gauge load cells and IP65 protection (continued)

1

6

2

7

6

3

5

4

8

10

9

11

Page 53

Service Manual 21203788C 09/03 3-11

Viper M, L, D and T Scales/Viper RM, RL, RD and RT Terminals Section 3 Viper scales with large platform

Item Quantity Description Order No.

1 1 bottom plate for large platform model IP65 version 21203512

2 1 RS connector plate IP65 version (various types, depending on the equipment) –

3 1 air supply/extraction filter 21203860

4 1 packing for RS connector plate 21203236

5 6 raised cheese head Torx screw M4 x 6 *

6 1 RS cable 460mm IP65 21203717

7 1 PCB RS option (2 x RS232C) IP65 21255081

8 1 pressure equalizer 21203611

9 1 pressure equalizer tube LA 21203862

10 1 adhesive patch for pressure equalizer 21203184

11 1 level bubble 21203204

* included in the fasteners set (chapter 3)

– not available as spare part

Note: Parts of the scale not numbered in the illustration are included in the normal version (chapter 1.1).

Page 54

3-12 09/03 Service Manual 21203788C

Section 3 Viper scales with large platform Viper M, L, D and T Scales/Viper RM, RL, RD and RT Terminals

1.3 Scales with strain gauge load cells, Ex version

2

3

4

1

6

7

5

8

Page 55

Service Manual 21203788C 09/03 3-13

Viper M, L, D and T Scales/Viper RM, RL, RD and RT Terminals Section 3 Viper scales with large platform

Item Quantity Description Order No.

1 1 platter 9.5" x 13.8" (240 x 350mm) 21203072

2 4 rubber cushion (1 piece)

1)

21203073

3 2 countersunk Torx screw M6 x 30 *

4 1 pan support plate 9.5" x 13.8" (240 x 350mm) 21203075

5 1 housing, VIPER with large platform –

6 1 keypad overlay Subsection 2

7 1 mounting plate and display unit (digital PCB with LCD and back-light unit) Subsection 2

8 2 EMC clamp 21203480

* included in the fasteners set (chapter 3)

– not available as spare part

1)

New rubber cushions have a hole in the surface to assist with assembly. A pin can be used to insert the cushion into the

corresponding drilled hole in the pan support plate. Earlier rubber cushions did not have this assembly aid.

Page 56

3-14 09/03 Service Manual 21203788C

Section 3 Viper scales with large platform Viper M, L, D and T Scales/Viper RM, RL, RD and RT Terminals

Scales with strain gauge load cells, Ex version (continued)

1

2

3

5

4

8

9

10

6

7

20

13

16

15

11

14

19

17

12

18

Page 57

Service Manual 21203788C 09/03 3-15

Viper M, L, D and T Scales/Viper RM, RL, RD and RT Terminals Section 3 Viper scales with large platform

Item Quantity Description Order No.

1 4 adjustable foot ∅ 2.2" (55mm)/M10 x 0.75mm 21203110

2 11 countersunk Torx screw M4 x 10 *

3 1 bottom plate for large platform model –

4 4 button head Torx screw M5 x 12 *

5 4 wide flange washer 5.3 x 20 *

6 4 overload spring **

7 1 overload stop adjustment screw (with specific production series only) **

8 2 countersunk Torx screw M6 x 16 *

9 1 overload plate for large platform model –

10 1 load cell with cable (certifiable)

Weighing range 24lb (12kg):

LC0785-20-MRV 21203885

Weighing range 75lb (30kg):

LC0785-50-MRV 21203886

Weighing range 120lb (60kg):

LC0785-100-MRV 21203887

11 1 wire harness Ex 21203732

12 2 spring clip * 21203166

13 1 analog PCB Viper Ex DMS 21203577

14 1 grounding screw EX 21050066

15 1 A/D cable 11.8" (300mm) for large platform model 21203167

16 1 connection cable Ex 4 pins, for large platform model 21203733

17 1 connector plate Ex –

18 4 raised cheese head Torx screw M4 x 6 *

19 2 raised cheese head Torx screw M4 x 8 with tooth lock washer –

20 1 level bubble 21203204

* included in the fasteners set (chapter 3) ** see section 4 “Replacing the load cell” – not available as spare part

Page 58

3-16 09/03 Service Manual 21203788C

Section 3 Viper scales with large platform Viper M, L, D and T Scales/Viper RM, RL, RD and RT Terminals

1.4 Scales with MonoBloc load cells (not including Ex version)

2

3

4

1

6

7

5

8

Page 59

Service Manual 21203788C 09/03 3-17

Viper M, L, D and T Scales/Viper RM, RL, RD and RT Terminals Section 3 Viper scales with large platform

Item Quantity Description Order No.

1 1 platter 9.5" x 13.8" (240 x 350mm) 21203072

2 4 pan mount (rubber cushion) 21203238

3 2 countersunk screw M6 x 30 *

4 1 load plate support 9.5" x 13.8" (240 x 350mm) –

5 1 housing VIPER with large platform –

6 1 keypad overlay Chapter 2

7 1 mounting plate and display unit (digital PCB and display compl.) Chapter 2

8 2 EMC clamp 21203480

* included in the fasteners set (chapter 3)

– not available as spare part

Page 60

3-18 09/03 Service Manual 21203788C

Section 3 Viper scales with large platform Viper M, L, D and T Scales/Viper RM, RL, RD and RT Terminals

Scales with MonoBloc load cells (continued)

10

1

2

3

5

4

15

12

13

16

17

6

7

8

18c

18d

18a

18b

18

9

11

14

21

19

20

19

13

20

22

23

Page 61

Service Manual 21203788C 09/03 3-19

Viper M, L, D and T Scales/Viper RM, RL, RD and RT Terminals Section 3 Viper scales with large platform

Item Quantity Description Order No.

1 4 adjustable foot ∅ 2.2" (55mm)/M10 x 0.75mm 21203110

2 11 countersunk Torx screw M4 x 10 *

3 1 bottom plate for large platform model –

4 8 cylinder head Torx screw M5 x 12 *

5 1 overload plate –

6 1 overload stop: adjustment screw –

7 1 overload stop: arrestment screw –

81 weighing modules (load cell and analog PCB):

weighing module 32001 for 24lb and 75lb scales (12kg and 30kg) 11102687

9 1 cell cable MB-LA with ferrite ring 21203290

10 1 bench AC adapter:

US version, internal (always order together with item 15) 21203122

US version for scales with rechargeable battery and Viper T scales 21255102

11 2 spring clip * 21203166

12 1 analog PCB Viper MonoBloc 21203100

13 1 RS cable 18.1" (460mm) 21203168

14 1 A/D cable 11.8" (300mm), for large platform model 21203167

15 1 adhesive patch for AC adapter or battery 21203184

16 1 RS connector plate for Viper M/L/D (various types, depending on the equipment) –

17 4 raised cheese head Torx screw M4 x 6 *

18 For scales with rechargeable battery only:

18a 1 rechargeable battery 12V/2,2Ah (always order together with item 15) 21203232

18b 1 battery cable (charging PCB – battery) 21203231

18c 1 charging circuit print 21204033

18d 1 connection cable (charging PCB – analog PCB) 21203233

19 1 PCB RS option (2 x RS232C), standard with Viper T 21203476

20 1 connection cable RS option 15" (380mm) 21203490

21 1 level bubble 11101335

22 1 PS2 cable 18.1"/460mm, (keyboard connection, for Viper T only) 21204107

23 1 connector plate Viper T for 3 RS interfaces and 1 keyboard cable –

(1x PCB RS Option, 1x RS cable 18.1", 1x PS2 cable)

* included in the fasteners set (chapter 3)

– not available as spare part

Page 62

3-20 09/03 Service Manual 21203788C

Section 3 Viper scales with large platform Viper M, L, D and T Scales/Viper RM, RL, RD and RT Terminals

1.5 Scales with MonoBloc load cells, Ex version

2

3

4

1

6

7

5

8

Page 63

Service Manual 21203788C 09/03 3-21

Viper M, L, D and T Scales/Viper RM, RL, RD and RT Terminals Section 3 Viper scales with large platform

Item Quantity Description Order No.

1 1 platter 9.5" x 13.8" (240 x 350mm) 21203072

2 4 pan mount (rubber cushion) 21203238

3 2 countersunk screw M6 x 30 *

4 1 load plate support 9.5" x 13.8" (240 x 350mm) –

5 1 housing VIPER with large platform –

6 1 keypad overlay Chapter 2

7 1 mounting plate and display unit (digital PCB and display compl.) Chapter 2

8 2 EMC clamp 21203480

* included in the fasteners set (chapter 3)

– not available as spare part

Page 64

3-22 09/03 Service Manual 21203788C

Section 3 Viper scales with large platform Viper M, L, D and T Scales/Viper RM, RL, RD and RT Terminals

Scales with MonoBloc load cells, Ex version (continued)

1

2

3

5

4

6

7

8

19

12

9

11

15

18

16

10

14

13

17

Page 65

Service Manual 21203788C 09/03 3-23

Viper M, L, D and T Scales/Viper RM, RL, RD and RT Terminals Section 3 Viper scales with large platform

Item Quantity Description Order No.

1 4 adjustable foot ∅ 2.2" (55mm)/M10 x 0.75mm 21203110

2 11 countersunk Torx screw M4 x 10 *

3 1 bottom plate for large platform model –

4 8 cylinder head Torx screw M5 x 12 *

5 1 overload plate –

6 1 overload stop: adjustment screw –

7 1 overload stop: arrestment screw –

81 weighing modules (load cell and analog PCB):

weighing module 32001 Ex for 24lb and 75lb scales (12kg and 30kg) 21204013

9 1 cell PCB cable Ex, for large platform model 21203851

10 1 wire harness Ex 21203732

11 2 spring clip * 21203166

12 1 analog PCB Viper Ex MonoBloc 21203576

13 2 connection cable Ex 4 pins, for large platform model 21203733

14 1 A/D cable 11.8" (300mm), for large platform model 21203167

15 1 grounding screw EX 21050066

16 1 connector plate Ex –

17 4 raised cheese head Torx screw M4 x 6 *

18 2 raised cheese head Torx screw M4 x 8 with tooth lock washer –

19 1 level bubble 11101335

* included in the fasteners set (chapter 3)

– not available as spare part

Page 66

3-24 09/03 Service Manual 21203788C

Section 3 Viper scales with large platform Viper M, L, D and T Scales/Viper RM, RL, RD and RT Terminals

2 Display units

2.1 Viper M display unit (not including Ex version)

1

2

3

4

5

7

6

Page 67

Service Manual 21203788C 09/03 3-25

Viper M, L, D and T Scales/Viper RM, RL, RD and RT Terminals Section 3 Viper scales with large platform

Item Quantity Description Order No.

1 1 keypad overlay for Viper M large platform model 21203443

2 1 display mounting plate for Viper M (always order together with item 1) 21203120

3 1 LCD for Viper M 21203134

4 1 back-light unit for Viper M 21203136

51 digital PCB Viper M

1)

VIPER DIG M digital PCB for scales with strain gauge load cell

2)

21203098

VIPER MB DIG digital PCB with FLASH Memory chip (soldered)

for scales with MonoBloc load cell

3)

21204025-MBM

6 1 EPROM with scale program for Viper M scales with strain gauge load cell 21203583

7 1 retaining screw *

* included in the fasteners set (chapter 3)

1)

without LCD and back-light unit (these parts must be ordered separately)

2)

without EPROM (must be ordered separately)

3)

the digital PCB with FLASH memory chip is always supplied with scale-specific software. The designation “MBM” following

the order number specifies the scale software that is is loaded into the FLASH Memory chip prior to shipping.

Page 68

3-26 09/03 Service Manual 21203788C

Section 3 Viper scales with large platform Viper M, L, D and T Scales/Viper RM, RL, RD and RT Terminals

2.2 Viper EX M display unit

1

2

3

4

5

7

6

8

8

Page 69

Service Manual 21203788C 09/03 3-27

Viper M, L, D and T Scales/Viper RM, RL, RD and RT Terminals Section 3 Viper scales with large platform

Item Quantity Description Order No.

1 1 keypad overlay for Viper M large platform model 21203443

2 1 display mounting plate for Viper Ex 21203734

3 1 LCD for Viper M 21203134

4 1 back-light unit for Viper M 21203136

5 1 VIPER Ex DIG digital PCB

1)

21203593

61 EPROM with scale program:

EPROM for Viper M scales with strain gauge load cell 21203583

EPROM for Viper M scales with MonoBloc load cell 21203584

7 1 retaining screw *

8 1 set of blank labels Viper Ex 22007836

* included in the fasteners set (chapter 3)

1)

supplied without software, LCD and back-light unit (these parts must be ordered separately)

Page 70

3-28 09/03 Service Manual 21203788C

Section 3 Viper scales with large platform Viper M, L, D and T Scales/Viper RM, RL, RD and RT Terminals

2.3 Viper L display unit

1

2

3

4

5

7

6

Page 71

Service Manual 21203788C 09/03 3-29

Viper M, L, D and T Scales/Viper RM, RL, RD and RT Terminals Section 3 Viper scales with large platform

Item Quantity Description Order No.

1 1 keypad overlay for Viper L large platform model 21203444

2 1 display mounting plate for Viper L (always order together with item 1) 21203491

3 1 LCD for Viper L/D 21203687

4 1 back-light unit for Viper L/D 21203137

51 digital PCB Viper L

1)

VIPER DIG L digital PCB for scales with strain gauge load cell

2)

21203097

VIPER MB DIG digital PCB with FLASH Memory chip (soldered)

for scales with MonoBloc load cell

3)

21204025-MBL

6 1 EPROM with scale program for Viper L scales with strain gauge load cell 21203588

7 1 retaining screw *

* included in the fasteners set (chapter 3)

1)

without LCD and back-light unit (these parts must be ordered separately)

2)

without EPROM (must be ordered separately)

3)

the digital PCB with FLASH memory chip is always supplied with scale-specific software. The designation “MBL” following the

order number specifies the scale software that is is loaded into the FLASH Memory chip prior to shipping.

Page 72

3-30 09/03 Service Manual 21203788C

Section 3 Viper scales with large platform Viper M, L, D and T Scales/Viper RM, RL, RD and RT Terminals

2.4 Viper D display unit

1

2

4

5

6

7

3

Page 73

Service Manual 21203788C 09/03 3-31

Viper M, L, D and T Scales/Viper RM, RL, RD and RT Terminals Section 3 Viper scales with large platform

Item Quantity Description Order No.

1 1 keypad overlay for Viper D large platform model 21203445

2 1 display mounting plate for Viper D (always order together with items 1 and 3) 21203448

3 1 pressure sensitive membrane for numeric keypad (15 keys)

1)

21203439

4 1 LCD for Viper L/D 21203687

5 1 back-light unit for Viper L/D 21203137

61 digital PCB Viper D with FLASH Memory chip (soldered)

2)

VIPER DIG D digital PCB for scales with strain gauge load cell

3)

21203524-STD

VIPER DIG D digital PCB for scales with MonoBloc load cell

3)

21203524-MBD

7 1 retaining screw *

* included in the fasteners set (chapter 3)

1)

always order together with item 1

2)

supplied without LCD and back-light unit (these parts must be ordered separately)

3)

the digital PCB with FLASH memory chip is always supplied with scale-specific software. The designations “STD” and “MBD”

following the order number specify the scale software that is is loaded into the FLASH Memory chip prior to shipping.

Page 74

3-32 09/03 Service Manual 21203788C

Section 3 Viper scales with large platform Viper M, L, D and T Scales/Viper RM, RL, RD and RT Terminals

2.5 Viper T display unit

1

2

3

4

7

5

6

7

Page 75

Service Manual 21203788C 09/03 3-33

Viper M, L, D and T Scales/Viper RM, RL, RD and RT Terminals Section 3 Viper scales with large platform

Item Quantity Description Order No.

1 1 keypad overlay for Viper T large platform model 21203132

2 1 pressure sensitive keypad membrane for numeric keypad (25 keys) 21203501

3 1 display mounting plate for Viper T (always order together with items 1 and 2) 21203507

4 1 spacer plate 21255046

5 1 LCD module 240 x 64 dots CCFL 21203515

61 digital PCB:

Viper T (counting scale) 21203996

SQC 16 21203772

Smart Remote 21203997

7 5 retaining screw *

* included in the fasteners set (chapter 3)

Page 76

3-34 09/03 Service Manual 21203788C

Section 3 Viper scales with large platform Viper M, L, D and T Scales/Viper RM, RL, RD and RT Terminals

3 Fasteners set

The fasteners set comprises all the standard components (screws and washers) required for service work on Viper scales and

terminals, plus the spring clips that hold the analog PCB in place.

Quantity Description Order No.

1 fasteners set: 21203404

20 countersunk Torx screw M3 x 8 –

20 countersunk Torx screw M3 x 10 –

20 countersunk Torx screw M6 x 30 –

50 countersunk Torx screw M4 x 10 –

10 countersunk Torx screw M4 x 12 –

20 button head Torx screw M3 x 6 –

30 button head Torx screw M4 x 12 –

30 button head Torx screw M5 x 12 –

20 wide flange washer 4.3 x 20 –

20 wide flange washer 5.3 x 20 –

20 countersunk Torx screw M6 x 16 –

20 spring clip –

50 raised cheese head Torx screw M4 x 6 –

10 screw lock –

10 Torx oval head tapping screw 2.9 x 13 –

Page 77

Repair: see section 6

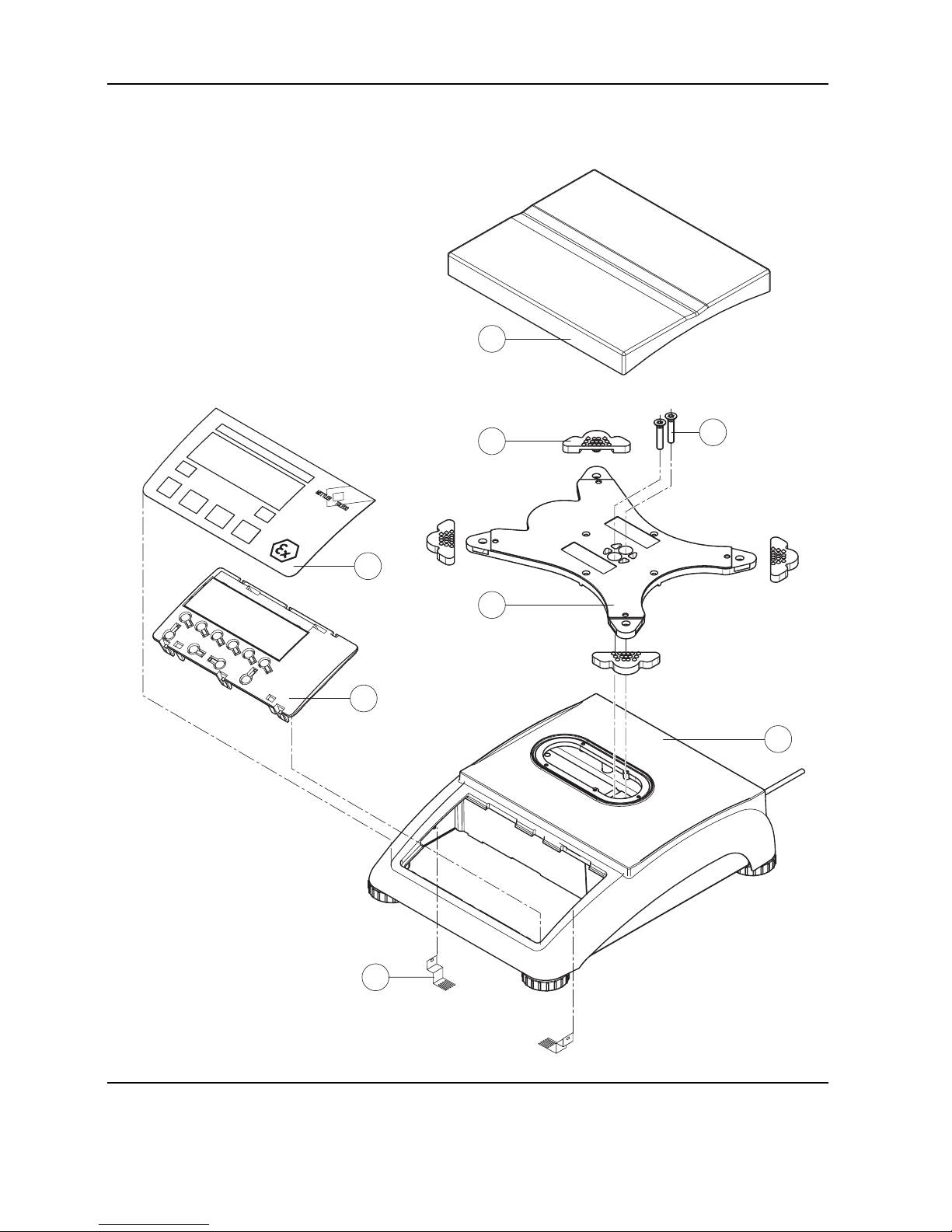

Contents Page

1 Terminals: spare parts and exploded view drawings .......................................................................... 4-2

1.1 Viper RM terminal .............................................................................................................................. 4-2

1.2 Viper RL terminal ............................................................................................................................... 4-4

1.3 Viper RD terminal .............................................................................................................................. 4-6

1.4 Viper RT terminal ............................................................................................................................... 4-8

2 OptionPac ........................................................................................................................................ 4-12

3 Small parts set ................................................................................................................................ 4-14

4 Upgrade kits .................................................................................................................................... 4-15

4.1 Upgrade kits for Viper RM, RL and RD terminals .................................................................................... 4-15

4.1.1 “Analog Interface Option Viper RL/RD” upgrade kit ................................................................................. 4-15

4.1.2 “AccuPac Viper RM/RL/RD” upgrade kit ................................................................................................ 4-16

4.2 Upgrade kits for Viper RT terminal........................................................................................................ 4-17

4.2.1 “Analog Interface Option Viper RT” upgrade kit ...................................................................................... 4-17

4.2.2 “USB Interface Viper RT” upgrade kit .................................................................................................... 4-17

4.2.3 “Ethernet Interface Viper RT” upgrade kit ............................................................................................... 4-18

4.2.4 “AccuPac Viper RT” upgrade kit ........................................................................................................... 4-18

4.3 Certification set for Viper terminals and scales ...................................................................................... 4-18

Section 4

Viper terminals

Page 78

4-2 09/03 Service Manual 21203788C

Section 4 Viper terminals Viper M, L, D and T Scales/Viper RM, RL, RD and RT Terminals

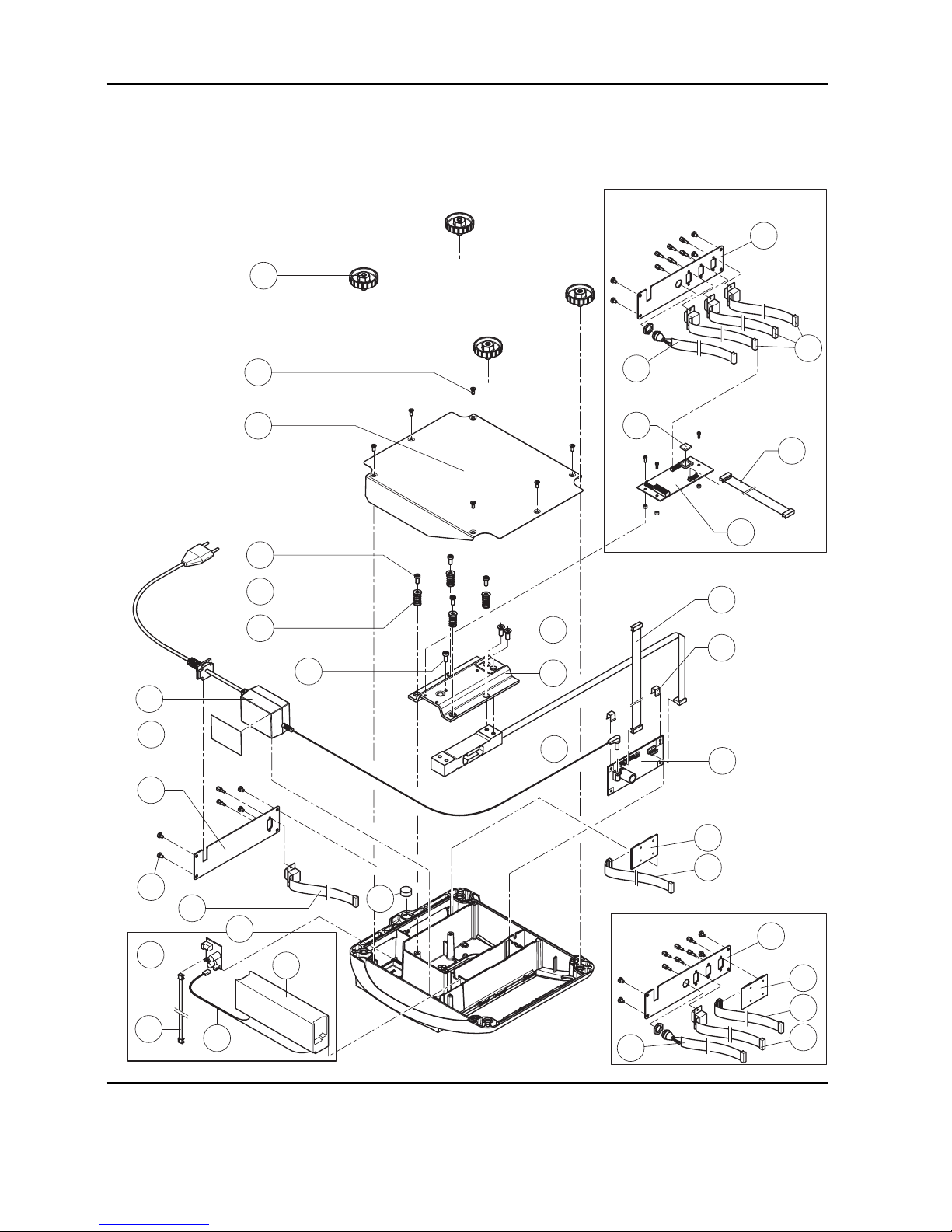

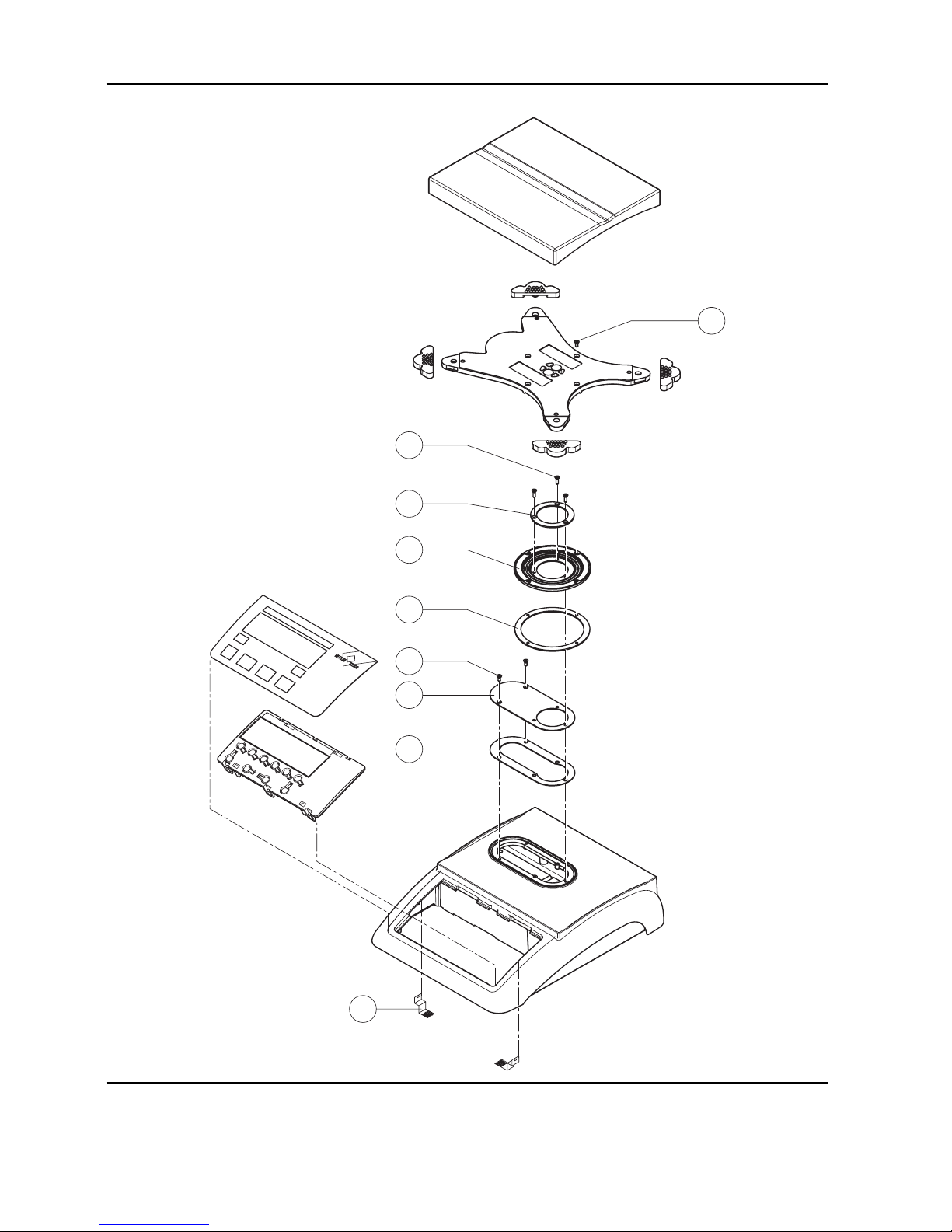

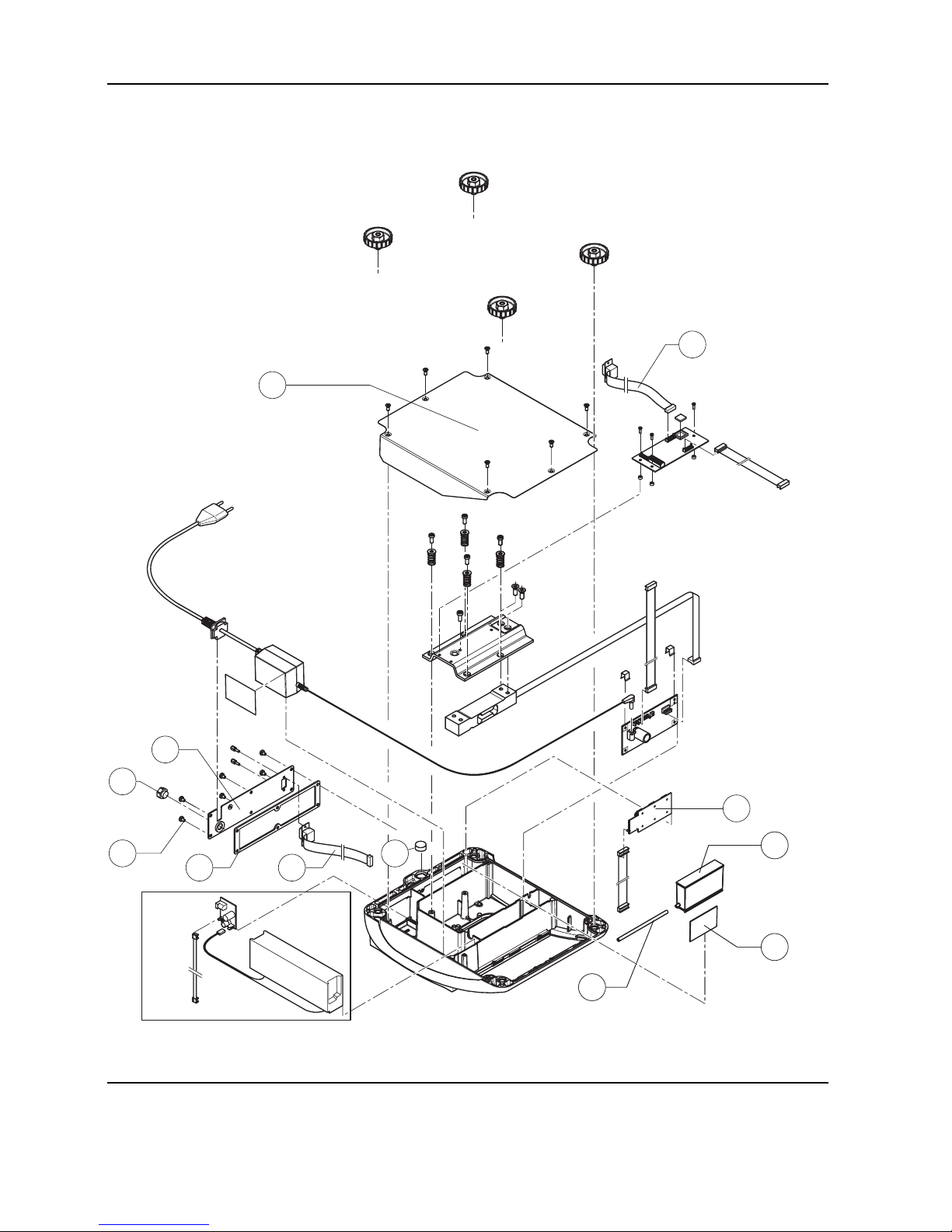

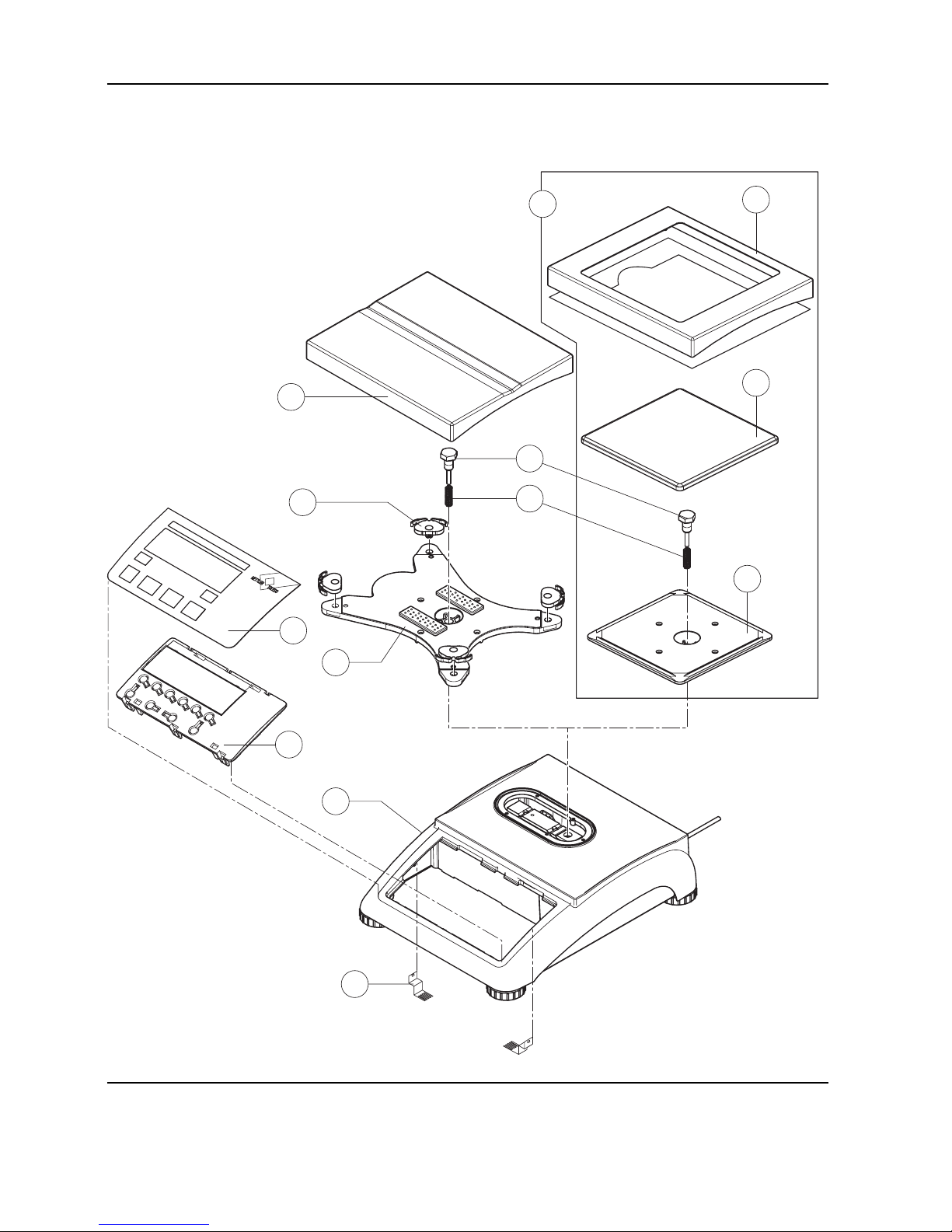

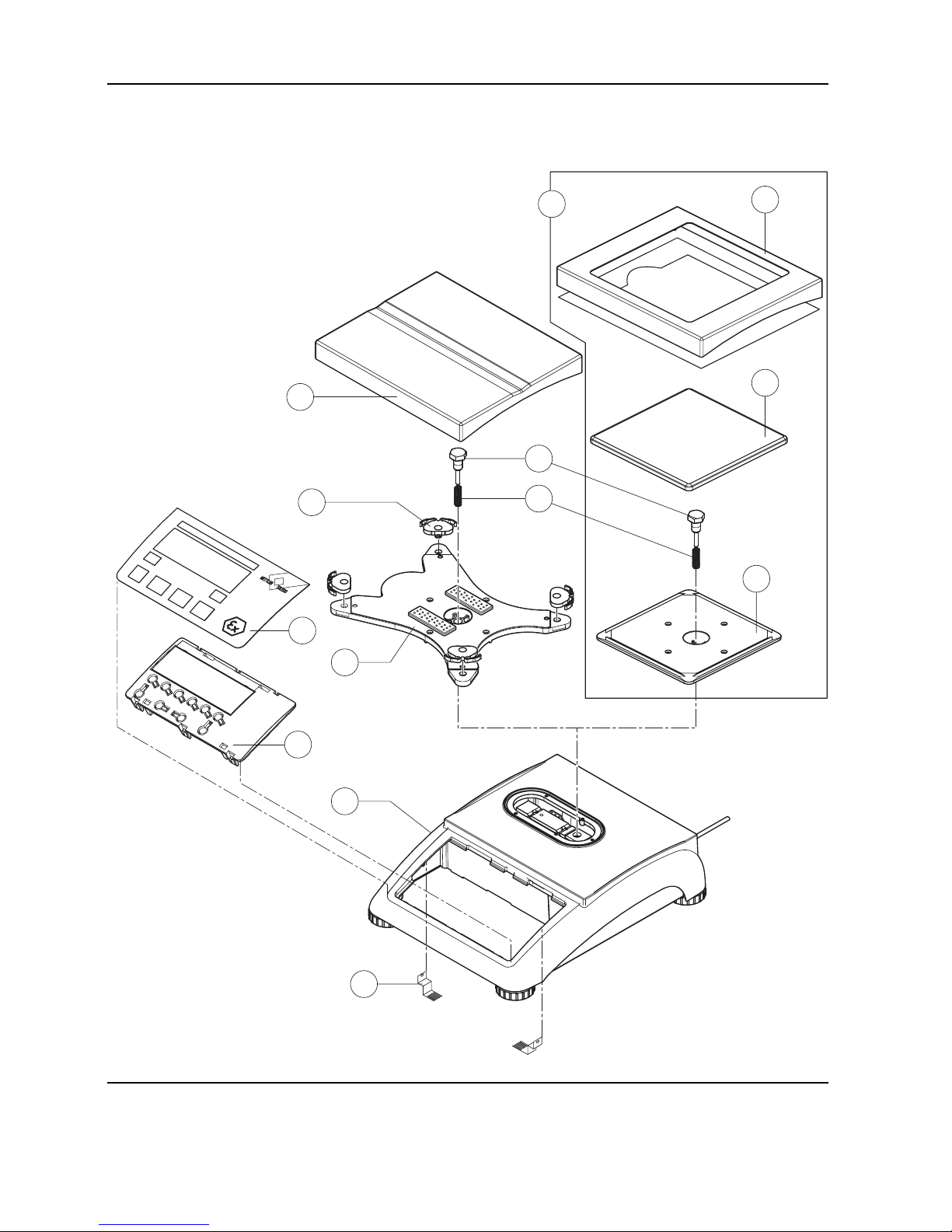

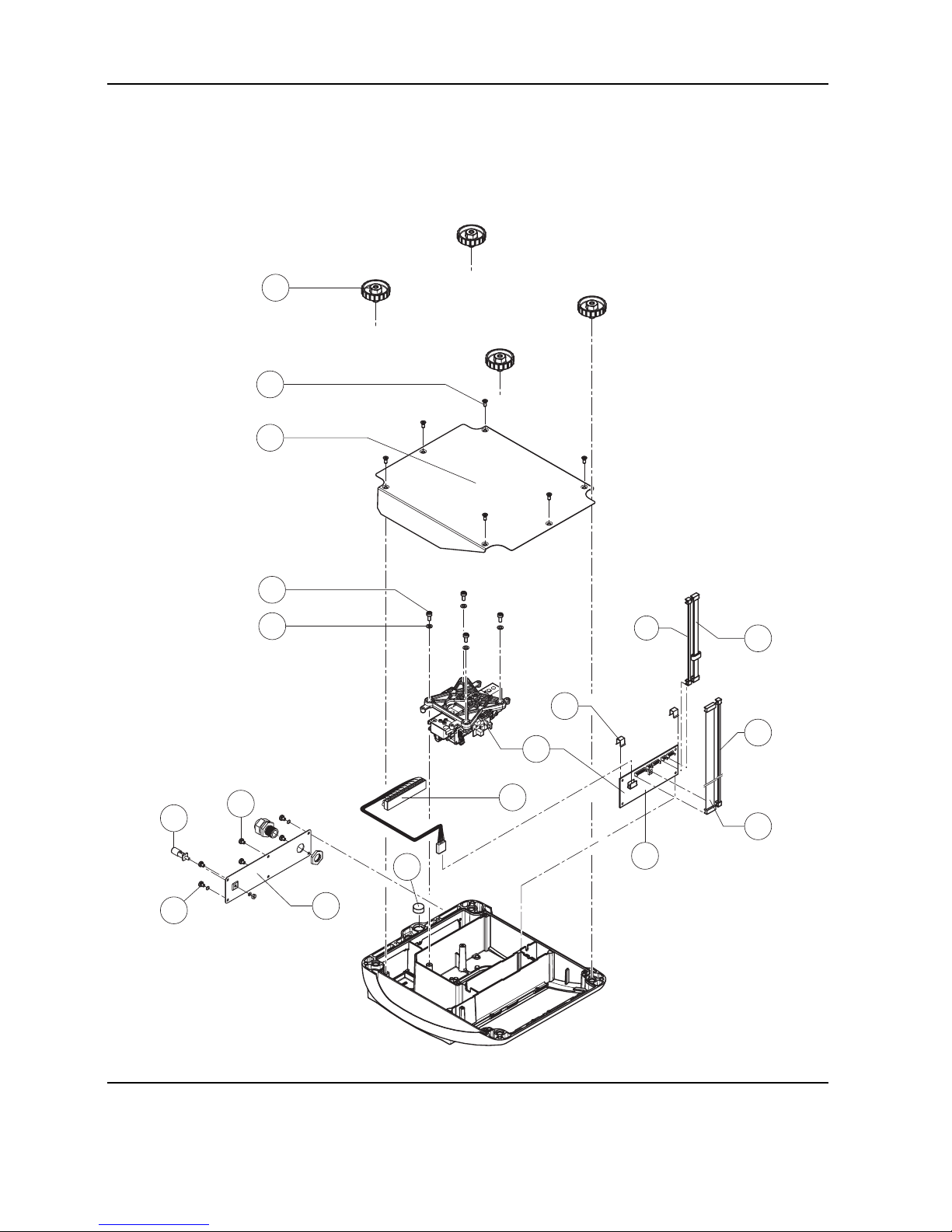

1 Terminals: spare parts and exploded view drawings

1.1 Viper RM terminal

1

3

23

22

5

4

6

7

8

910

12

14

15

16

17

18

13

19

20

21

2

24

26

25

27b

27a

11

Page 79

Service Manual 21203788C 09/03 4-3

Viper M, L, D and T Scales/Viper RM, RL, RD and RT Terminals Section 4 Viper terminals

Item Quantity Designation Part no.

1 1 base plate with seal attached 21255118

2 4 rubber foot 00200068

3 8 countersunk screw M4 x 8 Torx T20 *

4 1 AC adapter 10W USA/Japan version 21255102

5 1 adhesive tape for AC adapter 21203184

6 1 seal for terminal rear panel 21255012

7 1 connector plate for 2 interfaces (RS232C/load cell) 22010041

8 1 countersunk screw M4 x 12 Torx T20 *

9 5 fillister head screw M4 x 8 Torx T20 *

10 1 RS232C interface IP65 with cable (soldered) 21203717

11 2 dust cover for interfaces 11101560

12 1 keypad overlay Viper RM 22010046

13 1 display mounting plate BC (always order together with item 12) 21255041

14 1 LC display SW 21203134

15 1 backlighting SW 21203136

16 1 digital board Viper DIG M 21203098

17 1 EPROM with software for Viper RM 21203583

18 2 Torx oval head tapping screw 2.9 x 13 *

19 1 analog board 7k 21255054

20 1 fastening clamp for analog board * 21203166

21 1 A/D cable 300 mm 21203167

22 1 EMC clamp short 21203480

23 1 EMC clamp long 21255047

24 4 screw lock *

25 1 EMC clamp for analog board 22007948

26 1 load cell connection cable with Sub D-socket and plug for analog board 22010055

27 – 9-pin Sub-D connector (for connecting the load cell to the terminal): ––––––

27a 1 Sub-D standard housing (dismantled) 22007870

27b 1 pin base 22007869

* Included in small parts set (section 3).

Page 80

4-4 09/03 Service Manual 21203788C

Section 4 Viper terminals Viper M, L, D and T Scales/Viper RM, RL, RD and RT Terminals

1.2 Viper RL terminal

Option

Connector plate for optional

analog interface

1

3

23

22

5

4

7

910

12

14

15

16

17

18

13

19

20

21

7a

8

2

24

25

6

26

9

8

24

26

10

27b

27a

11

11

Page 81

Service Manual 21203788C 09/03 4-5

Viper M, L, D and T Scales/Viper RM, RL, RD and RT Terminals Section 4 Viper terminals

Item Quantity Designation Part no.

1 1 base plate with seal attached 21255118

2 4 rubber foot 00200068

3 8 countersunk screw M4 x 8 Torx T20 *

4 1 AC adapter 10W USA/Japan version 21255102

5 1 adhesive tape for AC adapter 21203184

6 1 seal for terminal rear panel 21255012

71 standard: connector plate for 2 interfaces (RS232C/load cell) 22010041

7a 1 option: connector plate for 3 interfaces (RS232C/load cell/analog interface option) 22010043

8 1 countersunk screw M4 x 12 Torx T20 *

9 5 fillister head screw M4 x 8 Torx T20 *

10 1 RS232C interface IP65 with cable (soldered)

1)

21203717

11 2 dust cover for interfaces 11101560

12 1 keypad overlay Viper RL 22010047

13 1 display mounting plate RL (always order together with item 12) 22010038

14 1 LC display FC 21203687

15 1 backlighting BC/FC 21203137

16 1 digital board Viper DIG L 21203097

17 1 EPROM with software for Viper RL 21203588

18 2 Torx oval head tapping screw 2.9 x 13 *

19 1 analog board 7k 21255054

20 1 fastening clamp for analog board * 21203166

21 1 A/D cable 300 mm 21203167

22 1 EMC clamp short 21203480

23 1 EMC clamp long 21255047

24 4 screw lock *

25 1 EMC clamp for analog board 22007948

26 1 load cell connection cable with Sub D-socket and plug for analog board 22010055

27 – 9-pin Sub-D connector (for connecting the load cell to the terminal): ––––––

27a 1 Sub-D standard housing (dismantled) 22007870

27b 1 pin base 22007869

* Included in small parts set (section 3).

1)

If an analog interface option is built into the OptionPac (see chapter 2), a second cable of this type is used to connect the

analog interface option board to the connector plate of the terminal (item 7a above).

Page 82

4-6 09/03 Service Manual 21203788C

Section 4 Viper terminals Viper M, L, D and T Scales/Viper RM, RL, RD and RT Terminals

1.3 Viper RD terminal

Option

Connector plate for optional

analog interface

1

3

23

22

5

4

12

15

16

17

18

14

19

20

21

13

2

25

7

910

8

24

6

26

27b

27a

7a

9

8

24

26

10

11

11

Page 83

Service Manual 21203788C 09/03 4-7

Viper M, L, D and T Scales/Viper RM, RL, RD and RT Terminals Section 4 Viper terminals

Item Quantity Designation Part no.

1 1 base plate with seal attached 21255118

2 4 rubber foot 00200068

3 8 countersunk screw M4 x 8 Torx T20 *

4 1 AC adapter 10W USA/Japan version 21255102

5 1 adhesive tape for AC adapter 21203184

6 1 seal for terminal rear panel 21255012

71 standard: connector plate for 2 interfaces (RS232C/load cell) 22010041

7a 1 option: connector plate for 3 interfaces (RS232C/load cell/analog interface option) 22010043

8 1 countersunk screw M4 x 12 Torx T20 *

9 5 fillister head screw M4 x 8 Torx T20 *

10 1 RS232C interface IP65 with cable (soldered)

1)

21203717

11 2 dust cover for interfaces 11101560

12 1 keypad overlay Viper RD 22010048

13 1 numeric membrane keypad (always order together with item 12) 21203439

14 1 display mounting plate RD (always order together with items 12 and 13) 22010039

15 1 LC display FC 21203687

16 1 backlighting BC/FC 21203137

17 1 digital board Viper DIG D (incl. soldered FLASH Memory chip with software) 21203524-STD

18 2 Torx oval head tapping screw 2.9 x 13 *

19 1 analog board 7k 21255054

20 1 fastening clamp for analog board * 21203166

21 1 A/D cable 300 mm 21203167

22 1 EMC clamp short 21203480

23 1 EMC clamp long 21255047

24 4 screw lock *

25 1 EMC clamp for analog board 22007948

26 1 load cell connection cable with Sub D-socket and plug for analog board 22010055

27 – 9-pin Sub-D connector (for connecting the load cell to the terminal): ––––––

27a 1 Sub-D standard housing (dismantled) 22007870

27b 1 pin base 22007869

* Included in small parts set (section 3).

1)

If an analog interface option is built into the OptionPac (see chapter 2), a second cable of this type is used to connect the

analog interface option board to the connector plate of the terminal (item 7a above).

Page 84

4-8 09/03 Service Manual 21203788C

Section 4 Viper terminals Viper M, L, D and T Scales/Viper RM, RL, RD and RT Terminals

1.4 Viper RT terminal

1

3

5

4

26

27

29

18

2

28

6

9

8

16

31

7

17

11

12

10

13

32b

32a

9

8

16

31

7a

17

10

13

15 a

12

9

8

16

31

7

17

10

13

14 a

12

19

20

22

21

24

23

30

30

30

14 b

24

25

USB option Ethernet option

Page 85

Service Manual 21203788C 09/03 4-9

Viper M, L, D and T Scales/Viper RM, RL, RD and RT Terminals Section 4 Viper terminals

Item Quantity Designation Part no.

1 1 base plate with seal attached 21255118

2 4 rubber foot 00200068

3 8 countersunk screw M4 x 8 Torx T20 *

4 1 AC adapter 10W USA/Japan version 21255102

5 1 adhesive tape for AC adapter 21203184

6 1 seal for terminal rear panel 21255012

71 standard: connector plate for 3 x RS232C/PS2/load cell

1)

22010040

7a 1 option: connector plate for 2 x RS232C/Ethernet/PS2/load cell 22010042

8 1 countersunk screw M4 x 12 Torx T20 *

9 5 fillister head screw M4 x 8 Torx T20 *

Standard interfaces:

10 1 RS232C interface IP65 with cable (soldered)

2)

21203717

11 1 board with 2x RS232C IP65 (requires connecting cable item 12) 21255081

12 1 connecting cable for 2 RS interfaces 21203490

13 1 PS2 cable 18.1"/460mm (keyboard connection) 21204107

14 USB option (upgrade kit see chapter 4.2.2)

14a 1 board USB option (1 Sub-D socket for RS232C / 1 Sub-D connector for USB)

3)

21204114

14b 1 USB cable (with Sub-D and USB type B sockets) 21204031

15 1 Ethernet option (requires connector plate item 7a) (upgrade kit see chapter 4.2.3):

15a: 1 board Ethernet option (1x RS232C /1 x Ethernet RJ45)

3)

21204027

16 4 dust cover for interfaces 11101560

17 1 dust cover for PS2 interface 22010058

18 1 keypad overlay Viper RT 22010049

19 1 numeric keypad membrane (25 keys) (always order together with item 18) 21203501

20 1 display mounting plate RT/SC (always order together with items 18 and 19) 21255043

21 1 spacer plate 21255046

22 1 LCD module 240 x 64 dots CCFL 21203515

23 2 Torx oval head tapping screw 2.9 x 13 *

24 1 digital board Viper T/RT (incl. soldered FLASH Memory chip with software) 21203996

25 5 fillister head screw M3 x 6 Torx T10 *

26 1 analog board 7k 21255054

27 1 fastening clamp for analog board * 21203166

28 1 EMC clamp for analog board 22007948

29 1 A/D cable 300 mm 21203167

continues on next page

Page 86