Page 1

Operator Manual

METTLER TOLEDO

Viper EX M and Viper EX M MB Scales

On

O

ff

Zero

Tare

Print

Units

Clear

C

Page 2

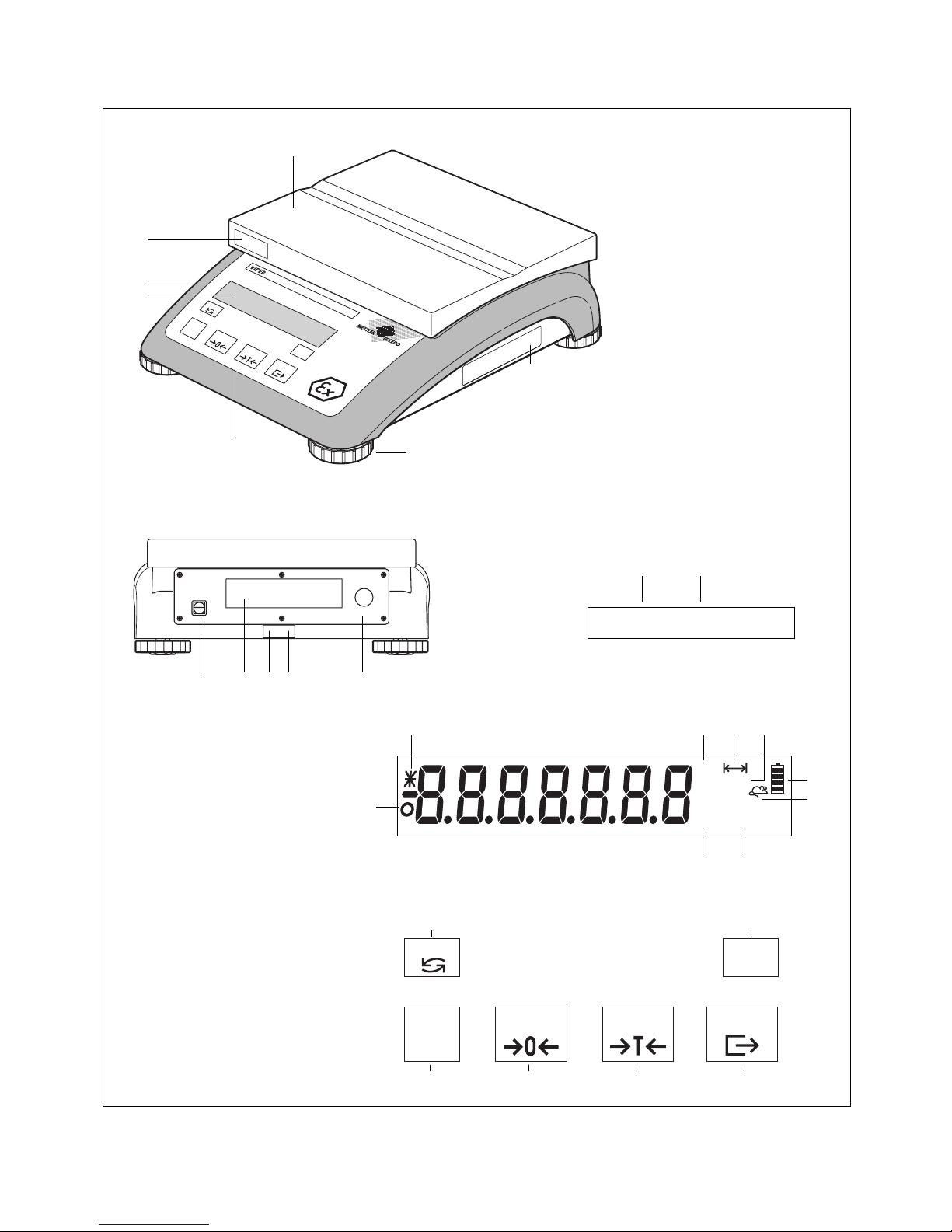

Overview of your Viper EX M / Viper EX M MB scale

Rear view Scale specifications

Overview

Display

Keypad

O

n

Off

Zero

Tare

Print

Units

Clear

C

On

Off

Zero Tare Print

Units Clear

C

Max: 6 kg d = 0.001 kg

Max: 12 lb d = 0.002 lb

1

2

3

5

7

91012

13 14

15

17

18 19 20 21

22

23

24252627

28 29

4

6

8

kg

tbz

P

CS

NET

12

C

om

16

11

Page 3

Overview

1 Keypad

2 Display

3 Scale specifications (see detailed illustration)

4 “MonoBloc” label (if applicable)

5 Platter (6lb version with small platter and draft shield)

6 Ex rating plate

7 Leveling feet

Rear view

8 Opening for cable gland

– power cable from PSUx power unit

– power/data cable from PSU power unit

9 Level indicator

10 Hole for antitheft device (accessory)

11 Type plate/certification plate

12 Grounding screw

Scale specifications (adhesive label)

13 Maximum load (in kg and lb)

14 Readability (display increment, in kg and lb)

Display

15 Unit for piece-counting (has no function)

16 Weighing units

17 Stability detector

18 Information mode indicator (has no function)

19 Data transfer (lights up while data is transmitted or

received via the interface)

20 Weighing range (has no function)

21 Net weight symbol

22 Internal battery charge status (has no function)

23 “Dynamic weighing” indicator (has no function)

Keypad

24 Transmits the weighing result to a connected device

(computer, printer, etc.) via the interface. If held down,

calls up the setup mode, and when working in setup,

functions as the “Yes” key to accept an option.

25 Tares the weighing container on the scale and sets the

display to zero. When working in setup, this key is

used as the “No” key to reject an option.

26 Sets the display to zero. When working in setup, this

key can be used to navigate backward. Each time the

key is pressed, the previous setup item is shown.

27 Switches the balance on and off. This key does not

function while working in setup mode.

28 Switches between the two weighing units specified in

setup.

29 Clears the current tare weight. When working in setup,

this key can be used to jump to the end of the setup for

rapid exit from the setup mode.

Page 4

Contents

4

Contents

1 Setting up the scale ....................................................................................................................................... 6

1.1 Unpacking and checking the delivered items ...................................................................................................... 6

1.2 Safety and environment.................................................................................................................................... 6

1.3 Selecting a location and leveling the scale ......................................................................................................... 7

1.4 Connecting the power supply and grounding cable ............................................................................................. 8

2 Weighing ....................................................................................................................................................... 9

2.1 Switching on/off and setting to zero ...................................................................................................................9

2.2 Simple weighing ............................................................................................................................................. 9

2.3 Weighing with tare ........................................................................................................................................ 10

2.4 Taring options............................................................................................................................................... 11

2.4.1 Multiple taring ............................................................................................................................................... 11

2.4.2 Automatic taring ............................................................................................................................................ 11

2.4.3 Automatic tare clearance ................................................................................................................................11

2.5 Recording the weighing result .........................................................................................................................11

3 Setup .......................................................................................................................................................... 12

3.1 Calling up the setup mode and entering the password ....................................................................................... 12

3.2 Setup structure ..............................................................................................................................................12

3.3 Working with the setup mode ......................................................................................................................... 13

3.4 Scale settings (“SCALE” block)........................................................................................................................ 15

3.4.1 Selecting the weighing units (“Units”) .............................................................................................................. 15

3.4.2 Settings for taring (“Tare”) ..............................................................................................................................16

3.4.3 Settings for zeroing (“Zero”)............................................................................................................................ 17

3.4.4 Adaptation to surrounding conditions (“Filter”) .................................................................................................. 18

3.4.5 Resetting the scale settings to the factory settings (“Scale Reset”) ....................................................................... 18

3.5 Scale settings (“TERMINAL” block) .................................................................................................................. 18

3.5.1 Settings for the display (“Device”) ................................................................................................................... 19

3.5.2 Settings for authorizing access to the setup mode (“Access”) ............................................................................. 19

3.6 Settings for the interface (“COMMUNICATION” block) ......................................................................................... 20

3.6.1 Selecting the communication mode (“Mode”) ................................................................................................... 21

3.6.2 Setting the communication parameters (“Parameters”) ...................................................................................... 22

3.6.3 Settings for the printed reports, or tickets (“Format”) .......................................................................................... 23

3.6.4 Settings for data transfer (“Control”) ................................................................................................................ 24

3.6.5 Resetting the communication settings (“Communication Reset”) ......................................................................... 24

3.7 Printing out the settings (“DIAGNOSTICS” block) ............................................................................................... 25

3.8 Saving the settings and quitting the setup mode (“END” block) ........................................................................... 26

3.9 Setup overview.............................................................................................................................................. 27

Page 5

Contents

5

4 Additional important information................................................................................................................... 28

4.1 SICS interface commmands ............................................................................................................................ 28

4.1.1 Preconditions for communication between scale and computer .......................................................................... 28

4.1.2 SICS standard commands supported by Viper................................................................................................... 28

4.2 “TOLEDO Continuous” mode ...........................................................................................................................29

4.2.1 “TOLEDO Continuous” output format ................................................................................................................29

4.2.2 “TOLEDO Continuous” commands ................................................................................................................... 30

4.3 Warning and error messages.......................................................................................................................... 30

4.4 Cleaning instructions ..................................................................................................................................... 31

5 Technical data and accessories..................................................................................................................... 32

5.1 Technical data .............................................................................................................................................. 32

5.2 Dimensions ..................................................................................................................................................33

5.3 Interface specifications ...................................................................................................................................34

5.4 Accessories .................................................................................................................................................. 34

5.5 Standards and directives ................................................................................................................................34

5.5.1 Safety regulations .......................................................................................................................................... 34

5.5.2 FCC Compliance ........................................................................................................................................... 35

5.5.3 Canadian Radio Interference Regulations ......................................................................................................... 35

5.6 Control Drawing Viper Ex 21204099............................................................................................................... 36

5.7 Installation Drawing Viper Ex Canada 21204100 ............................................................................................. 37

Page 6

Chapter 1: Setting up the scale

6

1 Setting up the scale

Please read these operating instructions carefully and follow them exactly! If you find that any items are missing or incorrect, or if

you have any other problems with your scale, please contact your authorized METTLER TOLEDO representative.

1.1 Unpacking and checking the delivered items

Remove the scale and accessories from the packaging. Check that all items have been delivered. The package should include:

– Viper scale

– Platter (and draft shield on 6lb version)

– Operating instructions (this document)

– Labels for noting the weighing range and readability after setting

– Special accessories per packing list (if applicable)

1.2 Safety and environment

To ensure safe, environmentally compatible operation of your scale, please observe the following:

The scale is designed for operation in hazardous areas Class I, Division 1, Groups A, B, C, D. However, for

this purpose the scale must be connected to a certified METTLER TOLEDO power supply unit:

– PSUx power supply unit (if not using the data interface)

– PSU power supply unit (if using the data interface)

The installation instructions for the respective power supply unit must always be observed and followed.

The regulations for operating equipment in hazardous areas must always be observed and followed.

Never undo the fastening screws of the load plate support under the platter!

Never insert a rigid object under the load plate support when the platter is removed.

Do not open the scale by undoing the screws in the base.

Use only the recommended accessories and peripherals.

Treat the scale carefully. It is a precision instrument. Avoid knocking the platter or placing excessively heavy

loads on it.

Important if the Viper scale will be used in food processing areas: Those parts of the scale which may come

into contact with food have a smooth surface and are easy to clean. The materials used do not shatter and

contain no harmful substances.

Because of the danger of static charge, a protective cover may only be used if it is made from anti-static

material.

When disposing of the scale, observe the applicable environmental regulations.

Page 7

Chapter 1: Setting up the scale

7

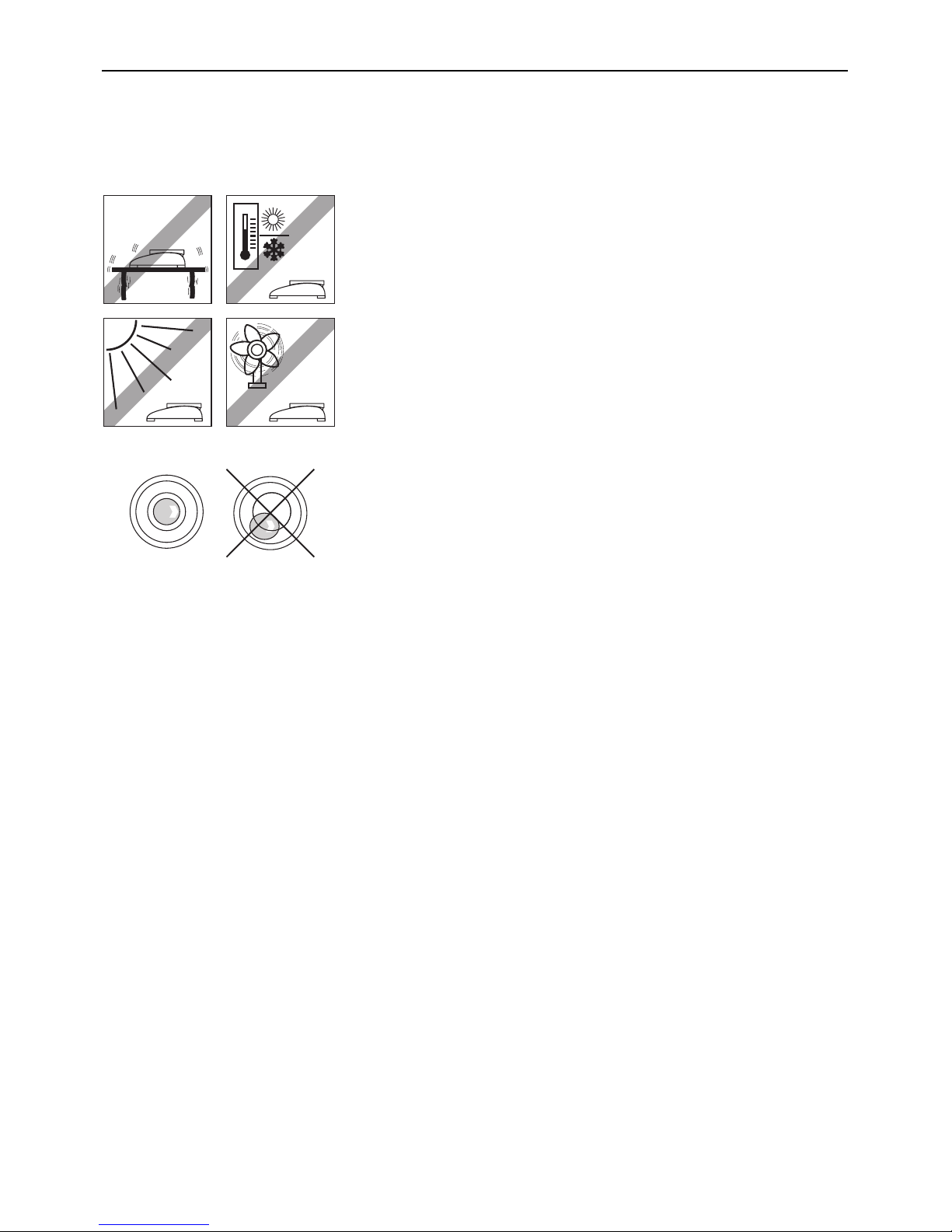

1.3 Selecting a location and leveling the scale

Choosing the proper location for your scale will guarantee high weighing accuracy!

Choose a stable, vibration-free, flat surface (this is especially important for highresolution scales and balances with METTLER TOLEDO MonoBloc technology). This

surface must be able to safely bear the weight of the fully loaded scale.

Pay attention to environmental conditions.

Avoid:

– direct sunlight

– strong drafts (e.g. from fans or air conditioning)

– excessive temperature fluctuations

– the use of radio equipment in close proximity to the scale.

Adjust the scale horizontally by turning the leveling feet. If there is a level indicator, the

air bubble must lie inside the inner circle.

Major changes of geographical location

Each scale is adjusted by the manufacturer for the local gravitational conditions (geo

value) of the geographical zone to which the instrument is shipped. If there is a major

change of geographical location, this adjustment must be corrected by a service

technician, or the scale must be readjusted. Certified scales must also be recertified in

accordance with applicable regulations for certification.

Page 8

Chapter 1: Setting up the scale

8

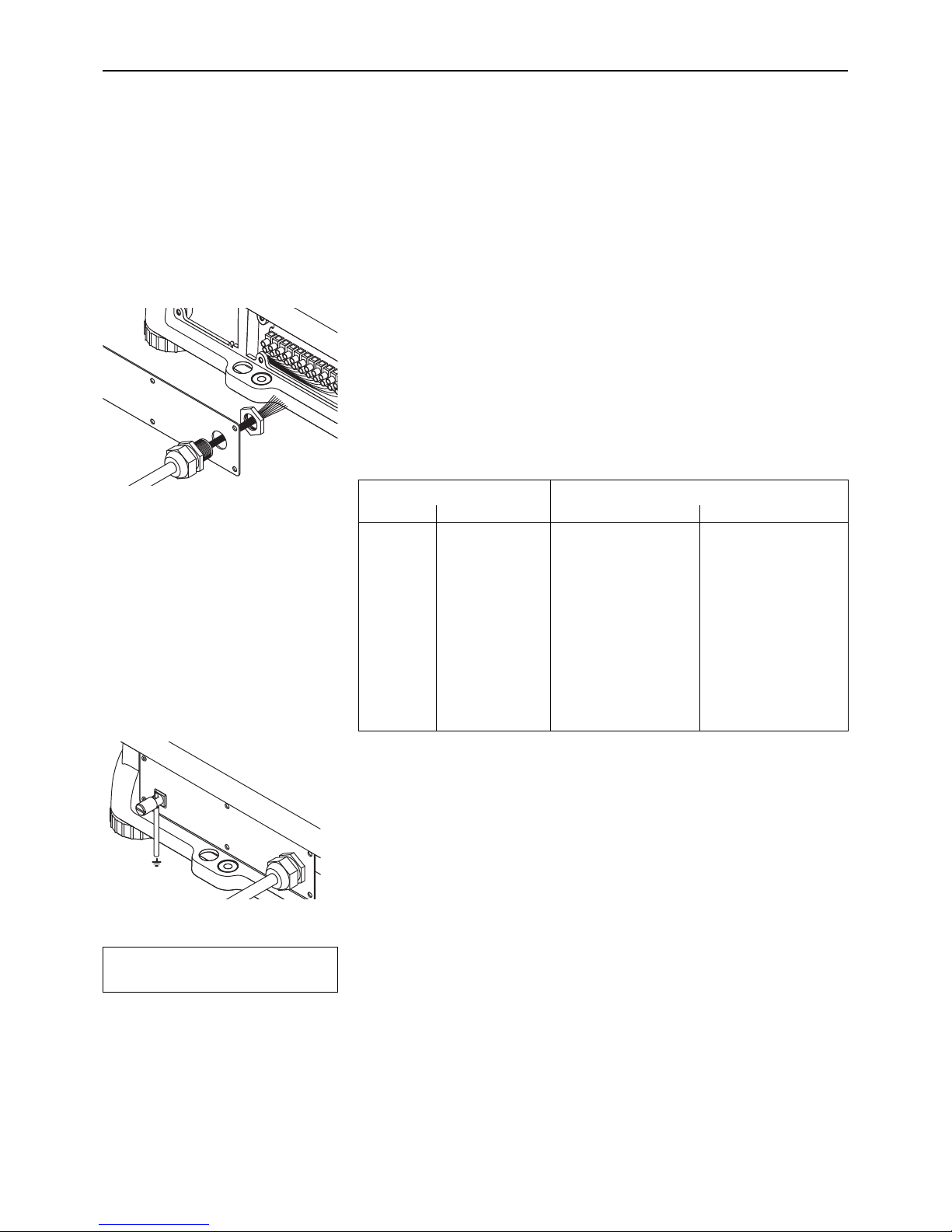

1.4 Connecting the power supply and grounding cable

To ensure protection against explosions, the scale may only be operated with either the PSUx or PSU power supply unit, and must

be connected to the building ground by a cable with a cross section of 1–4 mm2.

Important: When making the connection, always observe and follow the separate installation instructions for the PSUx or PSU power

supply unit respectively.

To connect the cable of the power supply unit and the grounding cable proceed as

follows:

Unscrew the screws in the back plate and remove the back plate.

Fasten the screwed connector on the blue cable of the power supply unit to the back plate

with the locking nut.

Connect the nine-core cable to the screw terminals of the scale according to the following

table.

Scale Power supply unit

No. Function PSUx PSU

1U1 white white

2 GND yellow yellow

3U2 green green

4 GND brown brown

5 Ubl gray black

6 TXD+ red red

7 TXD– blue blue

8 RXD– –– pink

9 RXD+ –– gray

10 NC black ––

11 NC pink ––

Replace the back plate and fasten it with the screws. When doing so, take care not to

trap any wires.

Using a cable with a cross section of 1–4 mm2 connect the grounding screw on the back

of the scale to the building ground. Make sure the grounding cable is correctly connected

to the scale and the building ground.

Powering up the scale initiates a display test in which all the segments and then the

software version are briefly displayed. Once the decimal zero appears in the display,

the scale is ready to operate.

For maximum possible precision, the scale must be adjusted/calibrateed by a service

technician after installing it. Note: Certified scales must be adjusted by an authorized

organization. Please consult your dealer.

=000

¬

Page 9

Chapter 2: Weighing

9

2Weighing

This chapter explains how you switch the scale on and off, adjust the zero setting, tare the scale, carry out weighings, and record

weighing results.

2.1 Switching on/off and setting to zero

You switch the scale on and off by pressing the «On/Off» key.

After it has been switched on, the scale carries out a display test. When the weight

display appears, the scale is ready for weighing and is automatically set to zero.

Note: If necessary, you can use the «Zero» key to set the scale to zero at any time.

On

Off

=000

¬

Zero

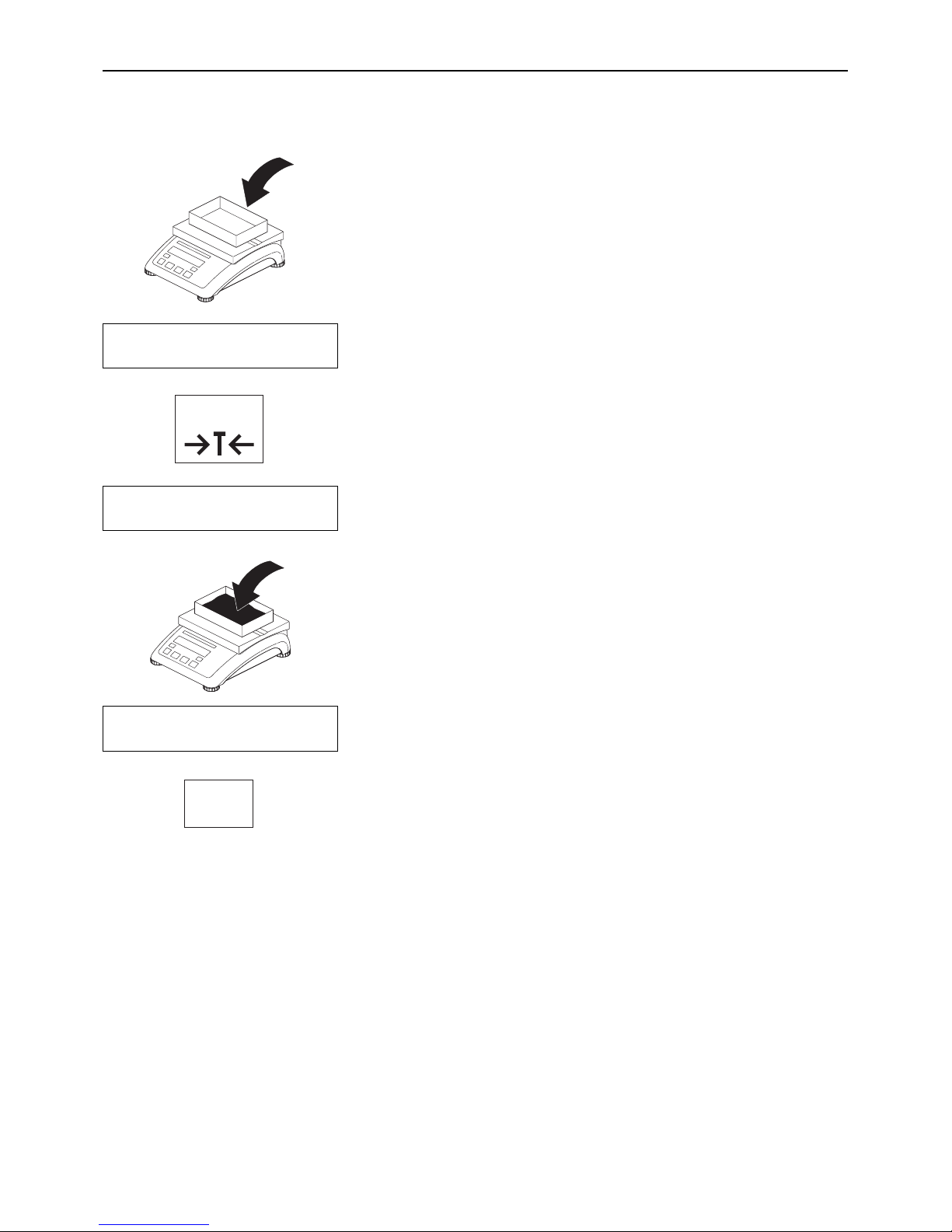

2.2 Simple weighing

Place the weighing sample on the platter.

Wait until the stability detector (small ring at left-hand edge of display) goes off and

then ...

... read the weighing result.

You can use the «Units» key at any time to switch between the two weight units

preselected in setup.

• (642

¬

(644

¬

Units

*921∆

Page 10

Chapter 2: Weighing

10

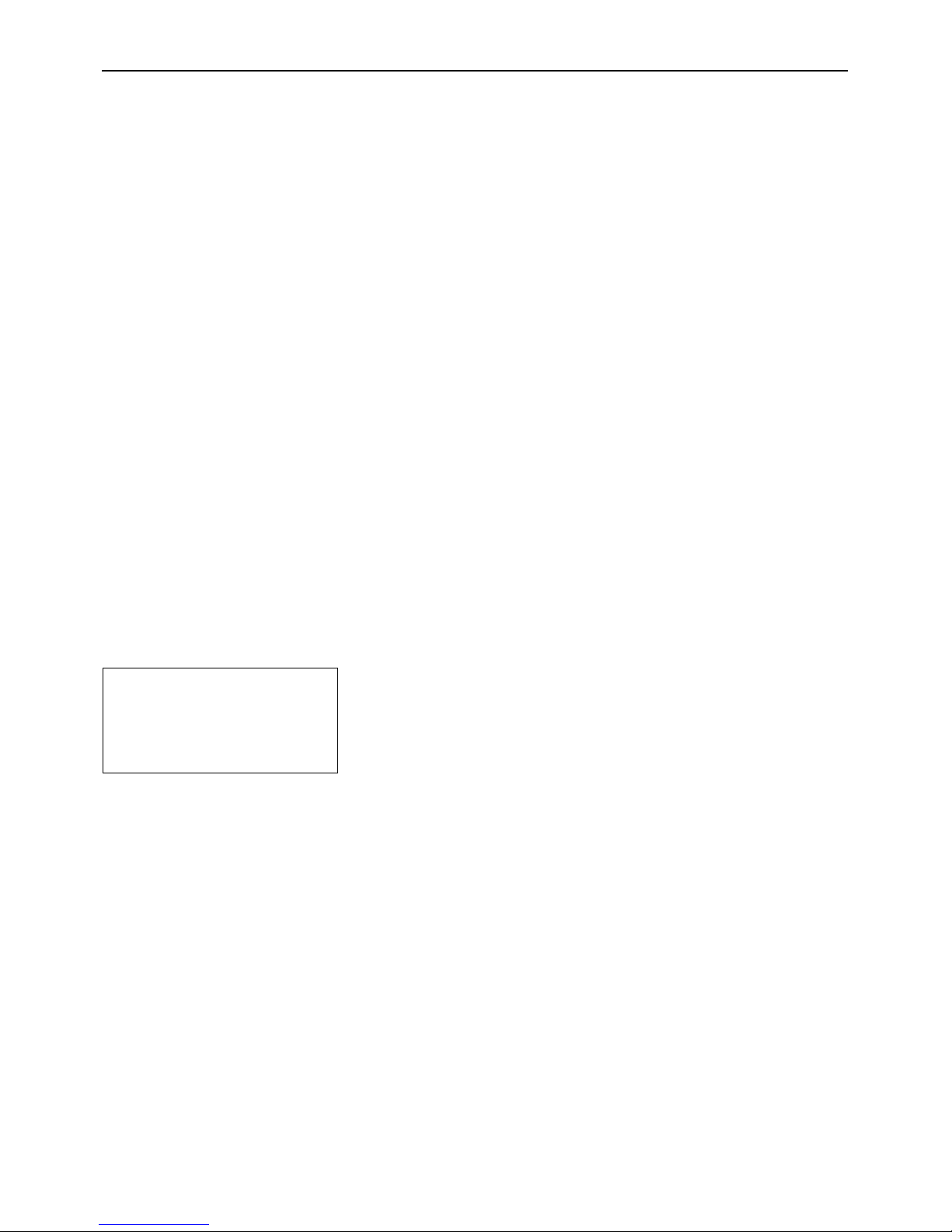

2.3 Weighing with tare

Place the empty weighing container or the packaging material on the platter.

The display shows the weight of the container on the pan.

Press the «Tare» key to tare the scale.

The zero display and the “NET” (net weight) symbol appear. Note: If the automatic taring

function has been activated in setup (Section 3.4.2), it is not necessary to press the

«Tare» key.

Place the weighing sample on the platter ...

... and read the result (net weight of the weighing sample).

When you have completed the weighing, press the «Clear» key to clear the weighing

result and the tare memory. The scale is now ready for the next weighment.

=223

¬

B/G

=000

¬

NET

ç653

¬

NET

Clear

C

Tare

Page 11

Chapter 2: Weighing

11

4.876 lb G

0.223 lb T

4.653 lb NET

2.4 Taring options

At the factory, the scale is set so that taring is carried out using the «Tare» key as described in the previous section. However, other

taring options can be activated in setup (Section 3.4.2); these are described below.

2.4.1 Multiple taring

If the “Chain tare” function is activated, you can re-tare the scale at any time by pressing the «Tare» key. Each time the key is pressed,

the value in the tare memory is overwritten with the current weight value. This allows you to place an additional weighing container

on the pan at any time and tare it. Note: On noncertified scales, this function is activated at the factory; on certified scales, this function

is not available.

If the “Chain tare” function has been switched off in setup, only one single taring is allowed for each weighing operation. If you

nevertheless attempt to tare the scale a second time, the error message “No” appears. You can only tare again after the current

weighing result has been cleared with the «Clear» key or the display has been reset to zero using the «Zero» key.

2.4.2 Automatic taring

If the “Autotare” function is activated, the scale automatically interprets the first weight placed on the pan as the tare weight. When

weighing is complete and all items have been removed from the platter, after a few seconds, the tare value is cleared and the scale

is ready for the next taring and weighment. Note: The “Autotare” function is turned off at the factory. On noncertified scales, it can

be activated in setup; on certified scales, this function is not available.

2.4.3 Automatic tare clearance

If this function is activated, the tare value is automatically cleared when the weighing container is removed from the platter, provided

that a weighment has previously been carried out. Note: At the factory, automatic tare clearance is turned off. This function can only

be activated in setup if the automatic taring function is turned off.

2.5 Recording the weighing result

Pressing the «Print» key transmits the current weighing result via the interface to the

peripheral device (printer, computer). At the factory the interface is configured for connection of a printer. Refer to Section 3.6 for information about configuring the interface.

The example on the left shows a record of a weighment with tare. “G” indicates the gross

weight, “T” the tare, and “NET” the net weight.

Page 12

Chapter 3: Setup

12

3 Setup

You can use the setup mode to change the settings of the scale and to activate functions. This makes it possible to adapt the scale

to your individual weighing needs. To prevent incorrect operation during day-to-day work, setup is reserved for the supervisor and

can only be accessed with a password (Exception: Parts of the “Terminal” block can be accessed by the user, see Section 3.5.2).

3.1 Calling up the setup mode and entering the password

Press the «Print» key and hold it down until ...

... the prompt to enter the password appears.

The password comprises a series of keystrokes. At the factory, the password for the

supervisor has been set to «Zero» «Zero» «Zero». We recommend you to replace this

password with one of your own as soon as possible (Section 3.5.2).

To call up the setup mode using the password set at the factory, briefly press the «Zero»

key three times.

Each keystroke you enter is shown in the display as a double horizontal dash.

Confirm the password with the «Print» key.

If you entered the password correctly, the first main block of the setup now appears.

Note:

– Enter the password as soon as you are prompted with “Code”; otherwise, the scale

returns to normal operation after a few seconds.

– If the password you entered is incorrect, an error message (“no”) appears, and

shortly after this you will be prompted to reenter the password.

– If you do not operate any key for approximately 3 minutes, the scale automatically

returns to weighing mode.

Zero

3x

CodE

≠≠≠

SCALE

- - no - - -

SCALE

3.2 Setup structure

The setup of the Viper scale is divided into 5 main blocks, each of which has a number of subblocks.

The first main block of the setup contains scale-specific settings (Section 3.4).

The second main block of the setup contains settings for the scale terminal and for

access authorizations (Section 3.5).

Print

tErMinL

Print

Page 13

Chapter 3: Setup

13

In the third main block, you can specify the settings for the interface (Section 3.6).

The fourth main block can be used to print out the settings (Section 3.7).

In the fifth main block, you can save your settings and quit the setup (Section 3.8).

You will find a complete overview of the setup mode in Section 3.9.

COMM

diAGnOS

End

3.3 Working with the setup mode

To work with the setup you use the following keys:

In the setup you use the «Print» key to confirm that you wish to accept a proposed option

(entry to a setup block or selection of a particular setting). This key has the meaning

“YES”.

You use the «Tare» key to reject a proposed option (entry to a setup block or selection

of a particular setting). This key has the meaning “NO”.

You use the «Zero» key to move back through the setup. Each time you press the key

it calls up the previous setup block.

The «Clear» key takes you directly to the end of the setup, where you can decide whether

you want to save the changes before you quit the setup mode.

Example

In the following example you want to turn off the backlighting of the display. This setting

is in the main block “Terminal” (the complete path to this setting is: Terminal –> Device

–> Backlight –> On/Off).

When you enter the setup, the first main block is displayed.

Now press the «Tare» (“No”) key repeatedly until the block appears in which you wish

to make a setting (in this example the main block “Terminal”).

Press the «Print» key. By doing so, you confirm that you want to enter the selected setup

block.

○○○○○○○○○○○○○○

Zero

Clear

C

SCALE

tErMinL

Print

Print

Tare

Tare

Page 14

Chapter 3: Setup

14

The first subblock of the “Terminal” appears.

Since the setting you want to change is in this block, press the «Print» (“Yes”) key.

The first subblock of the “Device” block appears in the display.

Since the desired setting is not in this block, press the «Tare» (“No”) key.

The second subblock of the “Device” setup is displayed. It is in this block that you make

the setting for the backlighting.

Press the «Print» key to enter this setup block.

The current setting for backlighting appears in the display. At the factory, backlighting

of the display is turned on (“On”).

Press the Tare» (“No”) key to switch the backlighting off.

The new setting is displayed.

Confirm the new setting (“OFF”) with the «Print» key. The backlighting is immediately

turned off.

Since you do not wish to make any more settings in setup at present, now press the

«Clear» key ...

... and you arrive at the last block in the setup.

Press the «Print» (“YES”) key to confirm that you wish to quit the setup mode.

You are now asked whether you wish to save the changed setting.

Press the «Print» (“Yes”) key to save the new setting and ...

... the scale returns to weighing mode. (If you do not wish to save the changed settings,

press the «Tare» (“No”) key instead, and the scale continues to use the former settings).

dEViCE

SLEEP

b-LiGht

On

OFF

End

SAVE ?

Clear

C

Print

Tare

Tare

Print

Print

Print

Print

Page 15

Chapter 3: Setup

15

3.4 Scale settings (“SCALE” block)

You use this block to make scale-specific settings. These include specifying weighing units, defining settings for taring and zeroing,

as well as special filter settings to adapt the scale to its environmental conditions.

The “SCALE” main block contains the following subblocks:

Selects the weighing units (Section 3.4.1)

Defines settings for taring (Section 3.4.2)

Defines settings for zeroing (Section 3.4.3)

Adapts the scale to environmental conditions (Section 3.4.4)

Resets the settings in the “SCALE” block to the factory settings (Section 3.4.5)

SCALE

3.4.1 Selecting the weighing units (“Units”)

In the “Units” block, you specify the weighing units with which your Viper scale should

operate. This block contains the following two subblocks:

In this subblock, you specify the weighing unit which should be displayed as standard.

The units available are shown at left. The factory setting is “lb”.

Note: On certified scales, the settings “g” and “oz” are not available.

In this subblock, you specify the second weighing unit which in weighing mode will be

displayed when you press the «Units» key.

The units available are the same as the standard weighing units, but with the additional

setting “OFF” (no second weighing unit). The factory setting is “kg”. On certified scales

the settings “g” and “oz” are also not available as second weighing units.

diSPLAY

lb

g

kg

oz

2nd

OFF

lb

g

kg

oz

UnitS

UnitS

tArE

2Ero

FiLtEr

SrESEt?

Page 16

Chapter 3: Setup

16

3.4.2 Settings for taring (“Tare”)

On

Pb - tArE

OFF

In the “Tare” block, you specify settings which control how your scale tares. This block

contains the following four subblocks:

In this subblock (“Pushbutton Tare”), you can activate or deactivate the «Tare» key:

The «Tare» key is active. This is the factory setting.

The «Tare» key is inactive; if it is pressed, no taring takes place.

In this subblock, you specify whether multiple taring (“Chain tare”) during a weighing

operation is allowed. Note: On certified scales, this block is not available!

The scale can be re-tared at any time. Each time the key is pressed, the value in the tare

memory is overwritten with the current weight value. This is the factory setting.

For each weighing operation, only one taring is allowed. Re-taring is only possible after

the current weighing result is cleared with the «Clear» key or the display is set to zero

with the «Zero» key.

In this subblock, you can turn the autotare function on or off.

The autotare function is turned off; taring is done manually using the «Tare» key. This

is the factory setting.

The autotare function is turned on. The scale automatically interprets the first weight

placed on the scale as the tare.

In this subblock, you specify whether the tare should be automatically cleared (“Auto

Clear Tare”). Note: This block is not avilable if the autotare function is active!

Automatic tare clearance is turned off. The current tare value is cleared with the «Clear»

key or by retaring. This is the factory setting.

The tare value is automatically cleared when the weighing container is removed from

the scale, provided that a weighing has been carried out.

On

ChAin

OFF

On

A-tArE

OFF

On

ÅCL - tr

OFF

tArE

Page 17

Chapter 3: Setup

17

OFF

3.4.3 Settings for zeroing (“Zero”)

In the “Zero” block, you specify the settings for zeroing the scale. This block contains

the following three subblocks:

In this subblock (“Autozero Mode”), you can turn automatic zeroing on and off and

specify how it operates. The autozero function automatically corrects the zero point of

the scale and thereby compensates for minor soiling of the platter. The following settings

are available:

Automatic zeroing is only active when no tare is present. This prevents small changes

in weight (e.g. when dispensing small quantities into a weighing container) from being

automatically compensated and the display being set to zero. This is the factory setting.

Automatic zeroing is always active.

Automatic zeroing is turned off.

In this subblock (“Auto Capture”), you can specify whether the scale should automa-

tically zero when it is turned on, and set the allowable zeroing range. If the weight on

the platter is within the selected range, the display is set to zero when the scale is

switched on; otherwise, an error message appears. The following settings are available:

Zeroing range at switch-on: ±10% of scale capacity. This is the factory setting.

Automatic zeroing of the scale at switch-on is deactivated.

Zeroing range at switch-on: ±2% of scale capacity.

In this subblock (“Pushbutton Zero”, not available on certified scales), you can use

the «Zero» key to set zeroing on and off and to set the allowable zero range. If the weight

on the platter is within the selected range, when the «Zero» key is pressed the display

is set to zero; otherwise, an error message appears. The following settings are possible:

Zeroing range: ±10% of scale capacity. This is the factory setting for noncertified

scales.

Zeroing range: +20% /–2 % of scale capacity.

Zeroing with the «Zero» key is deactivated.

Zeroing range: ±2% of scale capacity.

2Ero

OFF

GrOSS

GrS - nEt

A2M

2

$

10

$

A-CAPt

OFF

2

$

10

$

Pb - 2ErO

20

$

Page 18

Chapter 3: Setup

18

3.5 Scale settings (“TERMINAL” block)

In this main block, you can specify scale-specific settings. These include settings for the display, and for authorizing access to the

setup mode.

The “TERMINAL” main block contains the following subblocks:

Settings for the display (Section 3.5.1)

Settings for authorizing access to the setup mode (Section 3.5.2)

tErMinL

dEViCE

ACCESS

3.4.4 Adaptation to surrounding conditions (“Filter”)

You can use the “Filter” block to adapt your scale to the surrounding conditions (vibration, drafts). This block contains no subblocks; you arrive immediately at the following

settings:

Setting for normal surrounding conditions. This is the factory setting. The scale

operates at medium speed.

Setting for unstable surroundings. The scale operates more slowly than with the factory

setting, but is less sensitive to external disturbance.

Setting for very stable and stable surroundings. The scale operates very fast, but is

more sensitive to external disturbance.

FiLtEr

LO

MEd

hiGh

3.4.5 Resetting the scale settings to the factory settings (“Scale Reset”)

You can use the “S-Reset” (“Scale Reset”) block to reset all the settings in the “SCALE”

block to the factory settings.

To reset the settings, press the «Print» (“Yes”) key. If you do not wish to reset the

settings, press the «Tare» (“No”) key instead.

You are asked again whether you really want to reset the settings in the “SCALE” block.

If you want to reset, press the «Print» (“Yes”) key again. Otherwise, press the «Tare»

(“No”) key. This is your last chance to cancel the reset.

When you press the «Print» key as confirmation, all the settings in the “SCALE” block

are reset and the scale immediately operates with the factory settings.

SrESEt?

SurE?

Print

Print

Page 19

Chapter 3: Setup

19

3.5.1 Settings for the display (“Device”)

In the “Device” block, you can specify settings for the display. This block contains the

following two subblocks:

The setting in this subblock (“Sleep”) does not have any effect for Viper EX M and EX M

MB scales.

In this subblock (“Backlight”), you can switch the backlighting of the display on and

off:

Backlighting of the display is switched on. This is the factory setting.

Backlighting of the display is switched off.

OFF

SLEEP

dEViCE

On

OFF

b-LiGht

On

3.5.2 Settings for authorizing access to the setup mode (“Access”)

In the “Access” block, you specify authorizations and passwords for the setup mode.

This block contains the following two subblocks:

In this subblock (“User”), you can specify whether the operator should have access to

a part of the setup:

The operator has restricted access to the setup mode, specifically to the “TERMINAL”

block with the settings for energy-saving mode and backlighting. This is the factory

setting.

The operator has no access to the setup mode.

In this subblock (“Codes”), you can specify your own supervisor password for access

to the setup mode. Proceed as follows:

Call up the “Codes” block with the «Print» (“Yes”) key and ...

OFF

uSEr

ACCESS

On

COdES

SuPr - Cd

Page 20

Chapter 3: Setup

20

3.6 Settings for the interface (“COMMUNICATION” block)

Your scale has a built-in current loop interface which the PSU power supply unit converts into a user-selectable interface (refer to

the installation instructions for the PSU power supply unit). This main block is where you specify the settings for this interface.

The “COMMUNICATION” main block contains the following subblocks:

Selects the communication mode (Section 3.6.1)

Settings for the communication parameters (Section 3.6.2)

Settings for printed reports (Section 3.6.3)

Settings for data transmission (Section 3.6.4)

Resetting “COMMUNICATION” block to the factory settings (Section 3.6.5)

COMM

ModE

PArAMS

FOrMAt

COntrOL

CrESEt?

... you will be prompted to enter your new password. Enter the sequence of keystrokes

you wish to use as your password. You can use up to 6 keys. Important: The «Print»

key cannot be used in the password! Do not press this key, as it is used to terminate

input and confirm the new password!

Each keystroke is symbolized in the display by two double horizonal dashes. Confirm

the new password by pressing the «Print» (“Yes”) key.

You will now be prompted to enter the password again. Retype the new password and

confirm it again with the «Print» (“Yes”) key.

Definition of the password is now complete, and the next time you attempt to enter the

setup mode you will be asked for it. Important: Make a note of your password! If you

forget it, the service technician will have to define a new supervisor password before you

can use the setup again!

EntEr

≠≠≠≠≠≠

rEtYPE

Page 21

Chapter 3: Setup

21

3.6.1 Selecting the communication mode (“Mode”)

In the “Mode” block, you specify how your Viper scale should communicate through the

interface. This block contains the following two subblocks:

In this subblock, you specify the format in which data should be output through the

interface. This depends on the device you have connected to the interface.

The following settings are available:

Data output to a printer. This is the factory setting. Note: If you select this setting, a

further block with settings for the report printout is also available (Section 3.6.3).

The weight value is continuously transmitted through the interface in TOLEDO format

(“Continuous Weight”). This setting can be used to record weighing results on a computer.

The “TOLEDO Continuous Format” is explained in Chapter 4.2.

Bidirectional communication with an external device using MT-SICS commands. This

setting can be used to control the Viper scale from a computer. Refer to Section 4.1 for

information about the SICS interface commands.

In this block, you can make settings for the input line of the interface.

Important: This subblock is only available if the setting you selected in the preceding

“Output” block uses only the output line of the interface: These settings are “Print” or

“Continuous Weight”. With these settings, the input line can be used separately. (This

is not possible with the “SICS” setting, because this mode is bidirectional and therefore

also uses the input line of the interface). You can, for example, connect a printer but still

send commands from a PC to the scale through the same interface. (This requires a Tpiece which allows connection of the two devices and separates the input and output

lines of the interface).

The following settings are available:

The input line of the interface is used for the software handshake (Xon/Xoff protocol).

This setting must be used if the connected device requires a software handshake. This

is the factory setting.

The input line of the interface is not used.

The input side of the interface is used to receive commands in TOLEDO format (see

chapter 4.2.2).

OutPut

ModE

COnt - Wt

Print

SiCS

inPut

OFF

HOn.HOFF

COMMAnd

Page 22

Chapter 3: Setup

22

PAritY

ChECSuM

On

OFF

3.6.2 Setting the communication parameters (“Parameters”)

In the “Parameters” block, you specify the communication parameters for the interface.

Important: Make sure that these parameters are set to the same values on the external

device (printer, PC) which is connected to the scale. This block contains the following

three subblocks:

The “Baud” subblock is used to set the data transmission rate of the interface.

The available settings are shown at left.

The factory setting is 9600 baud.

The “Parity” subblock is used to specify the number of data bits and the parity.

The available settings are shown below:

7 data bits, even parity. This is the factory setting.

7 data bits, no parity.

8 data bits, no parity.

7 data bits, odd parity.

In the “Checksum” subblock, you specify whether the integrity of the values transmitted

through the interface should be verified by means of a checksum. Important: This sub-

block is only available if you have set the communication mode to “Continuous Weight”

(Section 3.6.1). The following settings are available:

Data validation turned off. This is the factory setting.

Data validation turned on.

bAud

PArANS

9600

300

600

2400

1200

4800

19200

7 nO P

7 EVEn

8 nO P

7 Odd

Page 23

Chapter 3: Setup

23

○○○○○○○

3.6.3 Settings for the printed reports, or tickets (“Format”)

In the “Format” block, you can specify the settings for printing reports.

Important: This block is only available if you have set the communication mode to

“Print” (Section 3.6.1). This block contains the following eight subblocks:

In the “Line Format” subblock, you specify how the printout should be formatted. The

following settings are available:

Multi-line printing. Each value in the report is printed on a separate line. This is the

factory setting.

Single-line printing. Several values (e.g. net weight, tare, and gross weight) are printed

on a single line.

A report can contain a maximum of 6 data fields. You use subblocks “Field 1” to “Field 6”

to specify which data should be printed on the report.

In each of the 6 blocks “Field 1” to “Field 6” the following settings are available:

The gross weight is printed on the report (factory setting for data field 1).

The tare weight is printed on the report (factory setting for data field 2).

The net weight is printed on the report (factory setting for data field 3).

The current weight value (“Display”) is printed on the report.

Instead of the value of the data field being printed on the report, blanks (“Spaces”) are

inserted in its place. This setting is useful if there is a particular data field you do not

wish to print out, but all the other fields should still be printed in the same positions.

The data field is not printed out (“Not Used”, factory setting for printing fields 4 to 6).

In contrast to the previous setting (“Spaces”) where blanks are inserted, printing of the

field is suppressed. The next field follows directly after the preceding field.

In this subblock (“Line Feed”), you can insert additional empty lines between the

reports, for example to leave space for adding handwritten notes to the printed values.

You can insert from 0 to 9 empty lines. The factory setting is “0” (no additional lines

are printed).

Ln FOr

FOrMAt

SinGLE

MuLti

FiELd - 1

FiELd - 6

○○○○

tArE

GrOSS

nEt

diSP

Not.uSEd

SPACES

Ln - FEEd

0

9

Page 24

Chapter 3: Setup

24

3.6.4 Settings for data transfer (“Control”)

In the “Control” block you specify the conditions under which data should be transmitted

through the interface. This block contains the following two subblocks:

In this subblock (“Auto Print”), you specify whether the data should be transmitted automatically or by pressing a key.

Automatic data transmission is switched off. The data is only transmitted when the

«Print» key is pressed. This is the factory setting.

The data is automatically transmitted as soon as the weighing result ist stable. Note:

This function is not available with early Viper M scales.

In this subblock (“Print Interlock”), you specify whether data can be transmitted only

once, or several times, during a single weighing operation. The following settings can

be selected:

An unlimited number of data transmissions is allowed per weighing operation. Data is

transmitted each time the «Print» key is pressed. This is the factory setting.

Data can only be transmitted again when the platter is completely empty or the «Clear»

key has been pressed.

A-Print

COntrOL

intrLOC

OFF

On

OFF

On

In the “C-Reset” (“Communication Reset”) block, you can reset all the settings in the

“COMMUNICATION” block to the factory settings.

To reset the settings, press the «Print» (“Yes”) key. If you do not wish to reset the settings,

press «Tare» (“No”) instead.

You are asked again whether you really want to reset the settings in the “COMMUNICATION” block.

If you want to reset, press the «Print» (“Yes”) key again. Otherwise press the «Tare»

(“No”) key. This is your last chance to cancel the reset.

When you press the «Print» key as confirmation, all the settings in the “COMMUNICATION” block are reset and the scale immediately operates with the factory settings.

CrESEt?

SurE?

3.6.5 Resetting the communication settings (“Communication Reset”)

Print

Print

Page 25

Chapter 3: Setup

25

3.7 Printing out the settings (“DIAGNOSTICS” block)

In this main block you can print out your settings on a printer.

The “DIAGNOSTICS” main block has only one subblock:

Print the settings.

To print out the settings on a printer, press the «Print» key.

Shown below is an example of a printout with the factory settings.

diAGnOS

LiSt

Print

Sw. ver M-1.00

SCALE

SNR : 99

MEtrOLO : nOnE

buiLd

CAP : 6.000 lb

rESOLu : 0.002 lb

GEO : 16

UNIT

DiSPLAy : lb

2nd : kg

tArE

Pb-tArE : On

ChAin : On

A-tArE : OFF

A.CL-tr : OFF

ZErO

AZM : GrOSS

A-CAPt : 10 %

Pb-ZErO : 10 %

FiLtEr : MEd

tErMinL

dEViCE

SLEEP : OFF

b-LiGht : On

ACCESS

uSEr : On

SuPEr : On

COMM

MOdE

OutPut : Print

inPut : XOn.XOFF

PArAMS

bAud : 9600

PArity : 8 no P

ChECSuM : OFF

FOrMAt

Ln FOr : MuLti

FiELd-1 : GrOSS

FiELd-2 : tArE

FiELd-3 : nEt

FiELd-4 : nOt.uSEd

FiELd-5 : nOt.uSEd

FiELd-6 : nOt.uSEd

Ln-FEEd : 0

COntrOL

A-Print : OFF

intrLOC : OFF

▼

Page 26

Chapter 3: Setup

26

3.8 Saving the settings and quitting the setup mode (“END” block)

In the last main block, you can save your settings and quit the setup mode. Note: Whenever you press the «Clear» key at any point

in setup, you return directly to this block.

To save your settings and quit the setup mode, proceed as follows:

Press the «Print» (“Yes”) key to confirm that you want to quit the setup mode.

You are then asked whether you want to save the changed settings.

Press the «Print» (“Yes”) key to save the settings, or if you want to reject the changes

you have made, press the «Tare» (“No”) key instead.

The scale then returns to weighing mode.

End

SAVE ?

=000

¬

Print

Print

Page 27

Chapter 3: Setup

27

3.9 Setup overview

Shown below is an overview of the complete setup mode of your Viper EX M or EX M MB scale. The factory settings are marked with an

asterisk (*).

Level 1 Level 2 Level 3 Level 4

SCALE Units Displayed lb*, g, kg, oz

1)

2nd lb, g, kg*, oz

1)

Tare Pushbutton On*, Off

Chain Tare

2)

On*, Off

Auto Tare On, Off*

Auto Clear Tare On, Off*

Zero Auto Zero Mode (AZM) Off, Gross*, Gross/Net

Auto Capture ±2%, ±10%*, Off

Pushbutton Zero ±2%, ±10%*, +20/–2%, Off

Filtering Low, Medium*, High

SCALE Reset Sure?

TERMINAL Device Sleep no effect

Backlight On*, Off

Access User On*, Off

Codes Supervisor Code

4)

–> Enter code

–> Retype code

COMMUNICATION Mode Output Print*, Cont. Weight, SICS

Input

5)

Command, Handshake*, Off

Parameters Baud 300, 600, 1200, 2400, 4800, 9600*, 19200

Bits/Parity 7/even*, 7/none, 8/none, 7/odd

Checksum

6)

On, Off*

Format

7)

Line Multiple*, Single

Field 1 Gross*, Tare, Net, Display, Spaces, Not Used

Field 2 Gross, Tare*, Net, Display, Spaces, Not Used

Field 3 Gross, Tare, Net*, Display, Spaces, Not Used

Field 4 Gross, Tare, Net, Display, Spaces, Not Used*

Field 5 Gross, Tare, Net, Display, Spaces, Not Used*

Field 6 Gross, Tare, Net, Display, Spaces, Not Used*

Extra Line Feeds 0*, 1, 2, 3, 4, 5, 6, 7, 8, 9

Control Auto Print On, Off*

Print Interlock On, Off*

COMM Reset Sure?

DIAGNOSTICS List

END Save?

1) On certified scales only “lb” and “kg” are available.

2) On certified scales this block is not available.

3) Factory setting for battery-operated scales.

4) Factory setting for the supervisor code is «Zero» «Zero» «Zero».

5) This block is not available if “SICS” has been selected in the “Output” block.

6) This block is only available if “Continuous Weight” has been set in the “Output” block.

7) This block is only available if “Print” has been set in the “Output” block.

Page 28

Chapter 4: Additional important information

28

4 Additional important information

In this chapter, you will find information about the interface commands, error messages, and cleaning your scale.

4.1 SICS interface commmands

Your scale can be configured, queried, and operated from a computer via the RS232C interface of the PSU power supply unit.

4.1.1 Preconditions for communication between scale and computer

For communication between the scale and a computer, the following preconditions must be fulfilled:

– The scale must be connected to the PSU power supply unit.

– The PSU power supply unit must be connected by a suitable cable to the RS232C interface of a PC (see section 5.4).

– The interface of the scale must be set to “SICS” mode (Section 3.6.1).

– The computer must have a terminal program (e.g. “Hyper Terminal”) installed on it.

– The communication parameters (data transmission rate, bits, and parity) in the computer terminal program must be set to the

same values as on the scale (Section 3.6.2).

4.1.2 SICS standard commands supported by Viper

Your scale supports the METTLER TOLEDO Standard Interface Command Set (MT-SICS). You will find detailed information about

the interface commands in the MT SICS Reference Manual (available in English only, ME-705184). The following SICS standard

commands are implemented:

Command Response Description

I0 I0_B_x1 Send list of implemented SICS commands

I1 I1_A_“x1”_“x2”_“x3”_“x4”_“x5” Inquiry of SISC level and versions

I2 I2_A_“text” Inquiry of scale data

I3 I3_A_“text” Inquiry of scale software version and type definition

I4 I4_A_“text” Inquiry of serial number

S S_S_WeightValue_Unit Send the current stable net weight value

SI S_S_WeightValue_Unit Send the current net weight value immediately

SIR S_S_WeightValue_Unit Send the net weight value repeatedly

Z Z_A Zero the scale

ZI ZI_D Zero the scale immediately

@ I4_A_“text” Reset the scale

D_“text” D_A Write text into scale display

DW DW_A Switch main display to weight mode

D_x see MT SICS Reference Manual

SR_PresetValue_Unit see MT SICS Reference Manual

T T_S_WeightValue_Unit Tare

TA TA_A_TareWeightValue_Unit Inquiry of the tare weight value

TAC TAC_A Clear tare value

TI TI_S_WeightValue_Unit Tare immediately

Page 29

Chapter 4: Additional important information

29

Character Status

2

Field 1

3

Field 2

4

11234567891011121314151617518

6

Data

S

T

X

S

W

A

S

W

B

S

W

C

M

S

D

————

L

S

D

M

SD—

———

L

S

D

CRC

H

K

Table Notes: MSD Most significant digit

LSD Least significant digit

1. STX: ASCII start of text character, hex value 02.

2. SWA, SWB, and SWC: Status Words A, B, and C. See below.

3. Field 1: In weight mode, this will be six digits of displayed weight data

including leading zeroes. No decimal point in field. In count mode, this

will be six digits of count (no leading zeroes) when the scale is in the count

mode or six spaces if not in the count mode.

4. Field 2: In weight mode, this will be six digits of tare weight data including

leading zeroes. No decimal point in field. In count mode, this will always

be six zeroes.

5. CR: ASCII carriage return, hex value 0D.

6. CHK: Optional checksum character defined as the 2's compliment of the

low 7 order bits of the binary sum of all characters preceding the

checksum.

Status Word A Bit Definitions (N/A = not applicable)

Status Bit

Function Selection 6 5 4 3 2 1 0

Decimal

Point

or

Dummy

Zero

X00

X0

X

0.X

0.0X

0.00X

0.000X

0.0000X

01

N/A

0

0

0

0

1

1

1

1

0

0

1

1

0

0

1

1

0

1

0

1

0

1

0

1

Display

Increment

Size

X1

X2

X5

0

1

1

1

0

1

N/A

Status Word B Bit Definitions Status Word C Bit Definitions

Function/Value Bit Function/Value Bit

Gross/Net: Net = 1

Negative = 1

Over Capacity = 1

Motion = 1

Lb/Kg: Kg = 1

1

Powerup = 1

0

1

2

3

4

5

6

0

0

0

Print Request = 1

Expanded Weight Mode = 1

1

Manual Tare Kg Only = 1

0

1

2

3

4

5

6

4.2 “TOLEDO Continuous” mode

4.2.1 “TOLEDO Continuous” output format

This section contains an explanation of the structure of “TOLEDO Continuous Output Format”.

Page 30

Chapter 4: Additional important information

30

î_no_ï

òãnoãô

NOtion

ããnoãã

4.3 Warning and error messages

In this section you will find general error messages together with instructions for correcting their causes.

Overload

Reduce the load on the scale or reduce the preload.

Underload

Place the platter on the scale and ensure it can move freely.

Result not stable

This message always appears if the scale has not yet become stable (when zeroing,

taring, etc.) so it is not a true error message. If the balance still does not become stable

after a long time, the “Motion” message described below appears.

Stability not possible (“Motion”)

While zeroing or taring, stability was not attained even after a long time.

1. Ensure that the surroundings are stable.

2. Ensure that the platter can move freely.

3. Change the filter setting (Section 3.4.4).

Function not allowed

The requested function could not be executed. This is usually because an attempt was

made to execute the function at a time when it is not allowed.

Zeroing not possible

Make sure that zeroing is being performed in the allowed range and not with overload

or underload.

гггггг

î____ï

неееем

4.2.2 “TOLEDO Continuous” commands

In “TOLEDO Continuous” mode (selectable in the menu:

Communication – [Port 1/2] – Mode – Input – Command

), your scale

supports the input commands listed below. Important: Each command must be terminated with Carriage Return (<CR>).

P <CR> Prints out the current result (equivalent to the «Print» key)

T <CR> Tares the scale (equivalent to the «Tare» key)

Z <CR> Zeroes the display (equivalent to the «Zero» key)

C <CR> Clears the current value (equivalent to the «Clear» or «C» key)

T

x.xxx

<CR> Specifies the tare (

x.xxx

= tare weight)

Page 31

Chapter 4: Additional important information

31

Err 6

Err 53

Not calibrated/adjusted

Disconnect the PSU or PSUx power supply unit from the power supply and then

reconnect it. If the message appears again, have the scale calibrated/adjusted by a

service technician.

EAROM checksum error

Disconnect the PSU or PSUx power supply unit from the power supply and then

reconnect it. If the message reappears, contact your authorized METTLER TOLEDO

representative.

4.4 Cleaning instructions

Before you start to clean your scale, disconnect it from the power supply!

Use a moist cloth (no acids, caustics, or strong solvents).

Do not use abrasive cleaning agents, they can scratch the display.

Do not clean the scale with a high-pressure cleaner or under running water.

If heavily soiled, remove the platter, protective cover (if present), and leveling feet, and

clean them separately.

Never insert a rigid object under the load plate support when the platter is removed!

Observe all applicable regulations with regard to cleaning intervals and permitted cleaning

agents.

Page 32

Chapter 5: Technical data and accessories

32

5Technical data and accessories

In this chapter you will find technical specifications for your scale, information about standards and directives, and a list of currently

available accessories.

5.1 Technical data

Functions and settings 4 weighing units (with switchover between two active units)

Filter for adaptation to environmental conditions

Automatic taring, multiple taring, automatic tare clearance

Automatic zeroing (at switch-on and during operation)

Switch-off function

Display backlighting

Display Liquid crystal display (LCD), 20 mm high with backlighting

Environmental conditions Performance is guaranteed in the following ranges:

Temperature range: 14 ... 104 °F (–10 ... +40 °C) for scales with strain gauge cells

50 ... 86 °F (+10 ... +30 °C) for scales with MonoBloc cells

Relative air humidity: 15 ... 85% rh (noncondensing)

Overvoltage category: II

Pollution degree: 2

Explosion classification Intrinsically Safe

CL I, DIV 1, GP A, B, C, D T

amb

–10 ... +40 °C , FMRC, CSA

II 2 G EEx ib IIC T4 KEMA 00 ATEX 1116X

Power supply Connect only to PSUx or PSU power supply unit!

intrinsically safe Terminal 1: Ui: 8.7 V Ii: 133 mA Pi: 1.15 W

Terminal 3: Ui: 12.6 V Ii: 42 mA Pi: 0.35 W

Terminal 5: Ui: 10.5 V Ii: 74 mA Pi: 0.78 W

Total weight Strain gauge cell MonoBloc cell

Compact model: 9.7 lb (4.4kg) 9.9 lb (4.5 kg)

Large model: 17.6lb (8.0 kg) 22.7 lb (10.3 kg)

Standard delivery package Complete scale, Operating instructions

Page 33

Chapter 5: Technical data and accessories

33

5.2 Dimensions

ABC*DE

Compact model 13.19 in 10.43in 3.94 in 9.45 in 7.87 in

(335 mm) (265mm) (100 mm) (240 mm) (200mm)

Large model 14.56in 14.17in 4.53 in 13.78 in 9.45 in

(370 mm) (360mm) (115 mm) (350 mm) (240mm)

* with leveling feet completely screwed in

FGHI

Compact model 1.81 in 10.87in 8.19 in 8.46 in

(46 mm) (276 mm) (208 mm) (215 mm)

Large model 2.05in 12.24 in 12.01in 12.24 in

(52 mm) (311 mm) (305 mm) (311 mm)

C

B

D

A

E

HI

G

F

Page 34

Chapter 5: Technical data and accessories

34

5.3 Interface specifications

The scale is equipped with a current loop interface as standard, which in the PSU power supply unit is electrically isolated and

converted into a user-selectable voltage interface (e.g. according to EIA RS-232C, CCITT V24/V.28). Further details together with pin

assignments will be found in the separate installation instructions for the PSU power supply unit.

5.4 Accessories

You can order the following accessories from your authorized METTLER TOLEDO representative:

Accessory Art. no.

Power supply / interface unit PSU / Viper Ex

Antitheft device with bolts 00229175

Antitheft device (steel cord with lock) 00590101

Interface cables for peripheral devices (computer, printer, etc.) see current price-list.

5.5 Standards and directives

Your Viper EX M or Viper EX M MB scale conforms to the standards and directives stated below.

5.5.1 Safety regulations

The manufacturer of this product declares with sole responsibility that the product to which this declaration relates conforms to the

following standards:

Scale line: Viper EX M, Viper EX M MB

Designation Tested according to standard

FM Standard Class No. 3600

FM Standard Class No. 3610 Intrinsically Safe Apparatus

IEC/EN61326-1 Emission Kl. B (FCC, Part 15, Class A)

C22.2 No. 0-M91 General Requirements, CEC, Part II

C22.2 No. 142-M1987 Process Control Equipment

C22.2 No. 157-92 Intrinsically Safe and Non-incendive Equipment

IEC/EN61326-1 Emission Kl. B (CAN/CSA C108.6-91) Emission

FM

APPROVED

Ex ia

Page 35

Chapter 5: Technical data and accessories

35

5.5.2 FCC Compliance

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to both Part 15 of the FCC

Rules and the radio interference regulations of the Canadian Department of Communications. These limits are designed to provide

reasonable protection against harmful interference when the equipment is operated in a commercial environment. This equipment

generates, uses, and can radiate radio frequency energy and, if not installed and used in accordance with the instruction manual,

may cause harmful interference to radio communications. Operation of this equipment in a residential area is likely to cause harmful

interference, in which case the user will be required to correct the interference at his own expense.

5.5.3 Canadian Radio Interference Regulations

ICES-001 Notice for Industrial, Scientific and Medical Radio Frequency Generators:

This ISM apparatus meets all requirements of the Canadian Interference-Causing Equipment Regulations.

Please note that this requirement is only for generators which operate at over 10 000 Hz.

Avis de l’ICES-001, générateurs de radiofréquences dans le domaine industriel, scientifique et médical:

Cet appareil ISM (industriel, scientifique et médical) satisfait à toutes les exigences définies par la réglementation canadienne en

matière d’équipements générant des perturbations radioélectriques.

Veuillez noter qu’il s’agit d’une exigence concernant uniquement les générateurs fonctionnant au-delà de 10 000 Hz.

Page 36

Chapter 5: Technical data and accessories

36

5.6 Control Drawing Viper Ex 21204099

not connected

1

2

3

4

5

6

7

8

9

10

11

Rev. 0, 14.08.2002

Hazardous (classified) location Class I, Div. 1, Groups A,B,C,D Unclassified location

VIPER EX SW

VIPER EX SW MB

VIPER EX M

VIPER EX MB

PSUx/230V

Installation

Drawing:

22006397

U1

GND

U2

GND

U BL

TxD +

TxD –

RxD –

RxD +

N.C.

N.C.

grounding screw

Notes for using the intrinsically safe scales Type Viper Ex:

• Install the scale Type Viper Ex in a hazardous location classified Class I, Division 1, Groups A,B,C,D (or

Zone 1 to European Standards).

•Temperature range: –10 °C to +40 °C.

The useful temperature range of the scale can be restricted in regard to its weighing specifications.

• Installation shall be in accordance with national standards for hazardous locations. In the US, follow the

National Electric Code ANSI/NFPA 70, and ANSI/NFPA RP12.6 “Installation of Intrinsically Safe Systems

for Hazardous (Classified) Locations.

• Warning: substitution of components may impair intrinsic safety.

• No revisions shall be made to this drawing without prior authorization from KEMA or Factory Mutual.

• The connection to the building ground shall be made by using the grounding screw in the backplate of

the scale.

• The Viper Ex must be connected to a power supply unit with approved intrinsically safe outputs and with

mating safety parameters (entity concept).

Viper Ex intrinsically safe input parameters

Viper Ex

pin 1 to pin 2 or 4

pin 3 to pin 2 or 4

pin 5 to pin 2 or 4

pin 6 to pin 7

pin 9 to pin 8

pin 10, pin 11

Ui

8.7 V

12.6 V

10.5 V

15.0 V

15.0 V

Li

0

0

0

0

0

Ci

111 nF

111 nF

1 nF

1 nF

1 nF

Pi

1.15 W

0.53 W

0.78 W

0.36 W

0.36 W

li

133 mA

42 mA

74 mA

24 mA

24 mA

ME-21204099

METTLER TOLEDO

Control Drawing Viper Ex 21204099

PSU

Control

Drawing:

22006477

PSUx/120V

Control Drawing:

22006399

Note: Use either PSUx or PSU

Page 37

Chapter 5: Technical data and accessories

37

5.7 Installation Drawing Viper Ex Canada 21204100

not connected / pas raccordé

1

2

3

4

5

6

7

8

9

10

11

Rev. 0, 14.08.2002

Hazardous (classified) location

Emplacement dangereux

Class I, Div. 1, Groups A,B,C,D

Non-classified location

Emplacement non classifié

VIPER EX SW

VIPER EX SW MB

VIPER EX M

VIPER EX MB

PSUx

Installation

Drawing /

Dessin

d’installation:

22006401

U1

GND

U2

GND

U BL

TxD +

TxD –

RxD –

RxD +

N.C.

N.C.

grounding screw

poste de mise à terre

Notes:

• Installation shall be in accordance with the Canadian Electrical Code Part 1, Appendix F.

“Recommended Installation of Intrinsically Safe Systems for Hazardous (Classified) Locations”.

•No revisions shall be made to this drawing without prior CSA authorization.

• Warning: substitution of components may impair intrinsic safety.

• Install the scale Type Viper Ex in a hazardous area Class I, Division 1, Groups A,B,C,D

•Temperature range: –10 °C to +40 °C. The useful temperature range of the scale can be restricted in regard to its

weighing specifications.

•The connection to the building ground shall be made by using the grounding screw in the back plate of the scale.

•The Viper Ex must be connected to a power supply unit with CSA certified intrinsically safe outputs with mating

safety parameters (entity concept).

Notes:

•Toute installation doit être conforme au Code Canadien d’Electricité, partie 1, annexe F, “Installation recommandée

de systèmes de sécurité intrinsèque en emplacement dangereux”.

•Ce dessin ne doit pas être révisé sans autorisation préalable de CSA.

•Avertissement: la substitution de composants peut compromettre la sécurité intrinsèque.

• La balance Viper Ex peut être installée en zone dangereuse de Classe I, Division 1, Groupes A,B,C,D

• Limites de température: –10 °C à +40 °C. Ces limites peuvent être restreintes grâce aux spécifications de fonctionnement.

• La connexion à la mise à terre du bâtiment s’effectue par le poste de mise à terre au dos du boîtier.

• La balance Viper Ex doit être raccordée à une alimentation dont les sorties sont certifiées en sécurité intrinsèque

par CSA. Les valeurs de raccordement doivent correspondre aux valeurs d’entrée indiquées ci-dessus.

Viper Ex intrinsically safe input parameters / valeurs de raccordement à sécurité intrinsèque

Viper Ex

pin 1 to pin 2 or 4

pin 3 to pin 2 or 4

pin 5 to pin 2 or 4

pin 6 to pin 7

pin 9 to pin 8

pin 10, pin 11

Ui

8.7 V

12.6 V

10.5 V

15.0 V

15.0 V

Li

0

0

0

0

0

Ci

111 nF

111 nF

1 nF

1 nF

1 nF

Pi

1.15 W

0.53 W

0.78 W

0.36 W

0.36 W

li

133 mA

42 mA

74 mA

24 mA

24 mA

ME-21204100

METTLER TOLEDO

Installation Drawing Viper Ex Canada 21204100

Page 38

Page 39

Page 40

To protect your METTLER TOLEDO product’s future:

METTLER TOLEDO service assures the quality, measuring accuracy and

preservation of value of all METTLER TOLEDO products for years to come.

Please send for full details about our attractive terms of service.

Thank you.

Subject to technical changes and availability of the accessories

supplied with the instruments.

Printed on 100% chlorine-free paper.

Because we care.

© Mettler-Toledo GmbH 2002 21204001 Printed in the USA 0209/2.28

METTLER TOLEDO

Scales & Systems

1900 Polaris Parkway

Columbus, Ohio 43240

USA

*P21204001*

Loading...

Loading...