Page 1

Operation Manual

Multi-parameter Transmitter M800

Transmitter Multi-parameter M800

52 121 825 D

Page 2

© 05/2019 Mettler-Toledo GmbH, Process Analytics

Subject to technical changes.

Printed in Switzerland. 52 121 825 D

Page 3

Transmitter M800 3

Operation Manual

Multi-parameter

Transmitter M800

© 05/2019 Mettler-Toledo GmbH, CH-8606 Greifensee, Switzerland Transmitter M800

Printed in Switzerland 52 121 825 D

Page 4

Transmitter M800 4

© 05/2019 Mettler-Toledo GmbH, CH-8606 Greifensee, Switzerland Transmitter M800

Printed in Switzerland 52 121 825 D

Page 5

Transmitter M800 5

Content

1 Introduction __________________________________________________________________________________________ 11

2 Safety instructions _____________________________________________________________________________________ 13

2.1 Denitionofequipment

and documentation symbols and designations ________________________________________________________________ 13

2.2 Correct disposal of the unit ________________________________________________________________________ 14

3 Unit overview _________________________________________________________________________________________ 15

3.1 Overview _______________________________________________________________________________________ 15

3.1.1 1-Channel Version ________________________________________________________________________ 15

3.1.2 2-Channel and 4-Channel Version ____________________________________________________________ 16

3.2 Display ________________________________________________________________________________________ 17

3.2.1 Start Screen _____________________________________________________________________________ 17

3.2.2 Activation Menu Screen ____________________________________________________________________ 17

3.3 Graphic Trend Measurement ________________________________________________________________________ 18

3.3.1 Activation Trend Display Screen ______________________________________________________________ 18

3.3.2 Settings for Trend Display Screen _____________________________________________________________ 19

3.3.3 Deactivation Trend Display Screen ____________________________________________________________ 19

3.4 Control / Navigation _______________________________________________________________________________ 20

3.4.1 Menu Structure ___________________________________________________________________________ 20

3.4.2 Operating Elements _______________________________________________________________________ 21

3.4.3 Entry of Data ____________________________________________________________________________ 21

3.4.4 Selection Menus __________________________________________________________________________ 21

3.4.5 ”Save changes” Dialog ____________________________________________________________________ 21

3.4.6 Security Passwords _______________________________________________________________________ 22

3.4.7 Display ________________________________________________________________________________ 22

4 Installation instruction __________________________________________________________________________________ 23

4.1 Unpackingandinspectionofequipment _______________________________________________________________ 23

4.2 Mounting 1/2 DIN Versions (PC housing) _____________________________________________________________ 24

4.2.1 Dimensions 1/2 DIN Version (PC housing) _____________________________________________________ 24

4.2.2 Mounting Procedure – 1/2 DIN Version (PC housing) _____________________________________________ 25

4.2.3 1/2 DIN Version (PC housing) – Panel Mounting ________________________________________________ 26

4.2.4 1/2 DIN Version – Wall Mounting ____________________________________________________________ 26

4.2.5 1/2 DIN Version (PC housing) – Pipe Mounting _________________________________________________ 27

4.3 Mounting Stainless Steel Version _____________________________________________________________________ 28

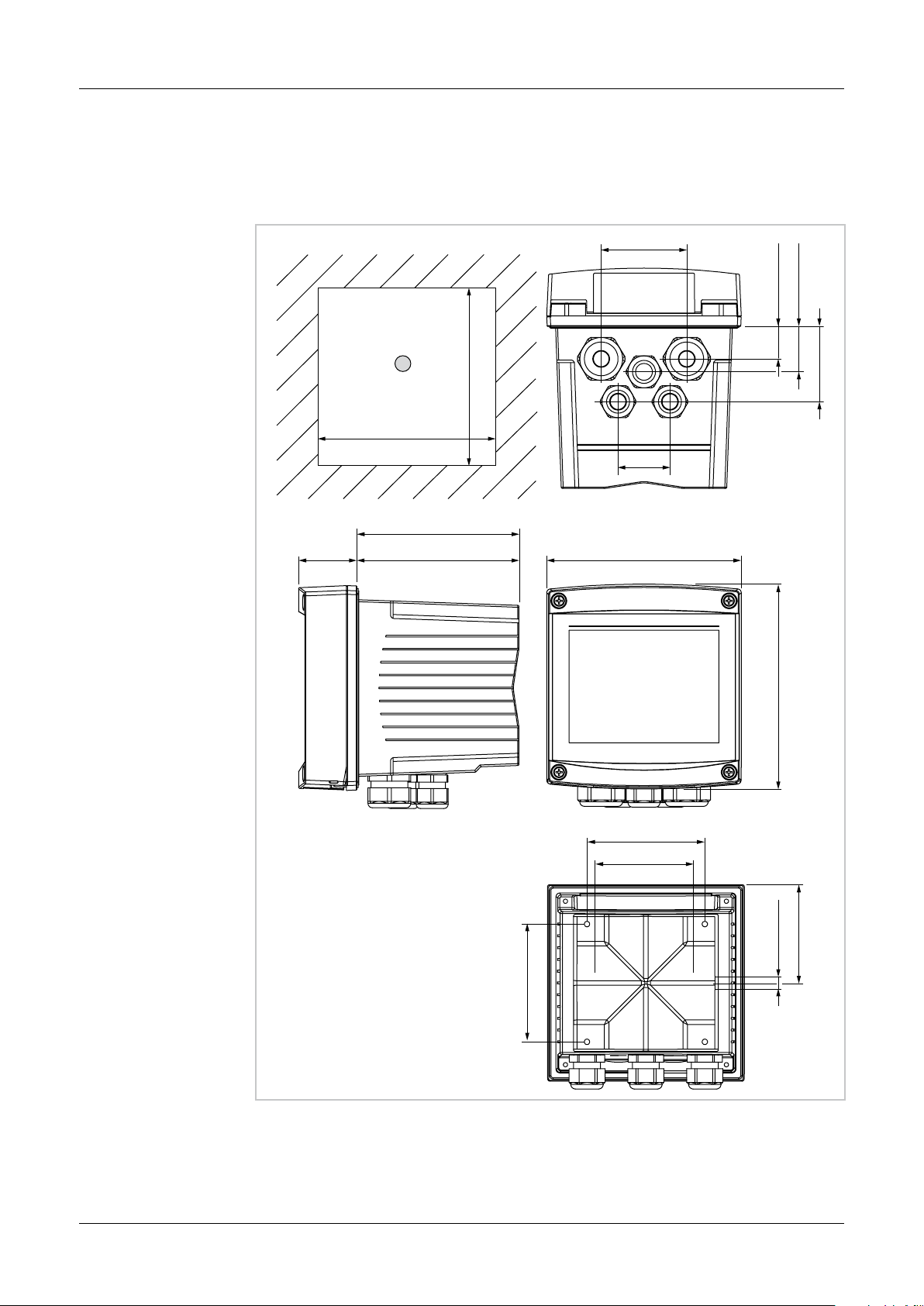

4.3.1 Dimensions Stainless Steel Version ___________________________________________________________ 28

4.3.2 Mounting Procedure – Stainless Steel Version ___________________________________________________ 29

4.3.3 Stainless Steel Version – Wall Mounting _______________________________________________________ 30

4.3.4 Stainless Steel Version – Pipe Mounting _______________________________________________________ 30

4.4 Electrical Connection ______________________________________________________________________________ 31

4.5 TerminalDenition _______________________________________________________________________________ 32

4.5.1 M800 1-Channel _________________________________________________________________________ 32

4.5.1.1 InPro8000 Series Turbidity Sensor __________________________________________________ 33

4.5.2 M800 2-Channel _________________________________________________________________________ 34

4.5.3 M800 4-Channel _________________________________________________________________________ 35

4.5.4 M800 1-Channel: TB2 – Conductivity 2e/4e Analog Sensors _______________________________________ 36

4.5.5 M800 1-Channel: TB2 – pH/ORP Analog Sensors _______________________________________________ 36

4.5.6 M800 1-Channel: TB2 – Oxygen Analog Sensors ________________________________________________ 37

4.5.7 M800 2- and 4-Channel: TB2 and TB4 – Terminal Assignment for Optical Oxygen, CO

d4e and 5000TOCi ISM Sensors ____________________________________________________________________ 38

4.5.8 M800 2- and 4-Channel: TB2 and TB4 – Terminal Assignment for pH, Amp. Oxygen, Cond 4e, CO

Sensors 39

4.5.9 M800 1-Channel: TB3 – Terminal Assignment for Optical Oxygen, CO

hi, UniCond2e and UniCond4e ISM Sen-

2

sors 40

4.5.10 M800 1-Channel: TB3 – Terminal Assignment for pH and Turbidity ISM Sensors ________________________ 41

4.5.11 M800 2- and 4-Channel Water:

TB3 – Terminal Assignment for Flow Sensors ___________________________________________________________ 41

4.6 Connection of Flow Sensor _________________________________________________________________________ 42

4.6.1 Flow Sensor Input Wiring Kit ________________________________________________________________ 42

4.6.2 Kit Contents _____________________________________________________________________________ 42

4.6.3 Flow sensor wiring for Compatible Sensors _____________________________________________________ 42

4.6.4 Wiringfor”HIGH”typeowsensors __________________________________________________________ 43

4.6.5 Wiringfor”LOW”typeowsensors ___________________________________________________________ 45

4.6.6 Wiringfor”TYPE2”owsensors _____________________________________________________________ 45

hi, UniCond2e, UniCon-

2

and O3 ISM

2

© 05/2019 Mettler-Toledo GmbH, CH-8606 Greifensee, Switzerland Transmitter M800

Printed in Switzerland 52 121 825 D

Page 6

Transmitter M800 6

5 Placing transmitter in, or out, of service ___________________________________________________________________ 46

5.1 Placing transmitter in service _______________________________________________________________________ 46

5.2 Placing transmitter out of service ____________________________________________________________________ 46

6 Guided Setup _________________________________________________________________________________________ 47

7 Calibration ___________________________________________________________________________________________ 48

7.1 Sensor Calibration ________________________________________________________________________________ 48

7.2 Calibration of UniCond2e and UniCond4e Sensors (ISM Sensors only) _______________________________________ 48

7.2.1 Conductivity Calibration of UniCond2e and UniCond4e Sensors _____________________________________ 48

7.2.1.1 One-Point Calibration ____________________________________________________________ 50

7.2.1.2 Two-Point Calibration ____________________________________________________________ 51

7.2.1.3 Process Calibration _____________________________________________________________ 52

7.2.2 Temperature Calibration of UniCond2e Sensors and UniCond4e Sensors ______________________________ 53

7.2.2.1 One-Point Calibration ____________________________________________________________ 53

7.2.2.2 Two-Point Calibration ____________________________________________________________ 54

7.3 Calibration of Cond2e Sensors or Cond4e Sensors ______________________________________________________ 56

7.3.1 One-Point Calibration _____________________________________________________________________ 56

7.3.2 Two-Point Calibration _____________________________________________________________________ 57

7.3.3 Process Calibration _______________________________________________________________________ 57

7.4 pH Calibration ___________________________________________________________________________________ 58

7.4.1 One-Point Calibration _____________________________________________________________________ 58

7.4.2 Two-Point Calibration _____________________________________________________________________ 59

7.4.3 Process Calibration _______________________________________________________________________ 60

7.5 ORP Calibration of pH Sensors ______________________________________________________________________ 60

7.6 Calibration of Amperometric Oxygen Sensors ___________________________________________________________ 61

7.6.1 One-Point Calibration _____________________________________________________________________ 61

7.6.2 Process Calibration _______________________________________________________________________ 62

7.7 Calibration of Optical Oxygen Sensors (ISM Sensors only) _________________________________________________ 63

7.7.1 One-Point Calibration _____________________________________________________________________ 63

7.7.2 Two-Point Calibration _____________________________________________________________________ 64

7.7.3 Process Calibration _______________________________________________________________________ 64

7.8 Calibration of Dissolved Carbon Dioxide Sensors (ISM Sensors only) ________________________________________ 65

7.8.1 One-Point Calibration _____________________________________________________________________ 65

7.8.2 Two-Point Calibration _____________________________________________________________________ 66

7.8.3 Process Calibration _______________________________________________________________________ 66

7.9 Calibration of Thermal Conductivity CO

(C02 high) Sensors (ISM Sensors only) _______________________________ 67

2

7.9.1 One-Point Calibration ______________________________________________________________________ 67

7.9.2 Process Calibration _______________________________________________________________________ 68

7.10 Calibration of O

Sensors (ISM Sensors only) ___________________________________________________________ 68

3

7.10.1 One-Point Calibration ______________________________________________________________________ 69

7.10.2 Process Calibration _______________________________________________________________________ 70

7.11 Calibration of Flow Sensors (ISM Sensors only) _________________________________________________________ 71

7.11.1 One-Point Calibration _____________________________________________________________________ 71

7.11.2 Two-Point Calibration _____________________________________________________________________ 72

7.12 Turbidity Calibration (InPro8000 Series) ______________________________________________________________ 73

7.12.1 Multi-Point Calibration _____________________________________________________________________ 74

7.12.2 Process Calibration _______________________________________________________________________ 75

7.12.3 In-Situ Calibration ________________________________________________________________________ 76

7.12.4 Manual Calibration (Edit) __________________________________________________________________ 78

7.13 Turbidity Calibration (InPro8600i) ___________________________________________________________________ 78

7.13.1 Process Calibration _______________________________________________________________________ 79

7.14 SensorVerication ________________________________________________________________________________ 80

7.15 Edit Calibration Constants for Flow Sensors ____________________________________________________________ 80

7.16 UniCond2e Electronics Calibration ___________________________________________________________________ 81

7.17 Meter Calibration _________________________________________________________________________________ 81

7.17.1 Resistance (Analog Sensors only) ____________________________________________________________ 81

7.17.2 Temperature (Analog Sensors only) ___________________________________________________________ 83

7.17.3 Voltage _________________________________________________________________________________ 83

7.17.4 Current _________________________________________________________________________________ 84

7.17.5 Rg ____________________________________________________________________________________ 84

7.17.6 Rr _____________________________________________________________________________________ 84

7.17.7 Flow meter calibration _____________________________________________________________________ 85

7.18 FlowMeterVerication ____________________________________________________________________________ 86

7.19 Analog Output Calibration __________________________________________________________________________ 86

7.20 Analog Input Calibration ___________________________________________________________________________ 87

7.21 Maintenance ____________________________________________________________________________________ 87

© 05/2019 Mettler-Toledo GmbH, CH-8606 Greifensee, Switzerland Transmitter M800

Printed in Switzerland 52 121 825 D

Page 7

Transmitter M800 7

8 Conguration _________________________________________________________________________________________ 88

8.1 Measurement ___________________________________________________________________________________ 88

8.1.1 Channel Setup ___________________________________________________________________________ 88

8.1.2 Derived Measurements ____________________________________________________________________ 90

8.1.2.1 % Rejection measurement ________________________________________________________ 90

8.1.2.2 Calculated pH (Power Plant Applications only) ________________________________________ 90

8.1.2.3 Calculated CO

(Power plant applications only) ________________________________________ 91

2

8.1.3 Display Mode ____________________________________________________________________________ 91

8.1.4 Parameter related Settings __________________________________________________________________ 92

8.1.4.1 Conductivity Settings _____________________________________________________________ 92

8.1.4.2 pH Settings ____________________________________________________________________ 93

8.1.4.3 Settings for Oxygen Measurement Based on Amperometric Sensors _________________________ 94

8.1.4.4 Settings for Oxygen Measurement Based on Optical Sensors ______________________________ 95

8.1.4.5 Dissolved Carbon Dioxide Settings __________________________________________________ 96

8.1.4.6 Settings for Thermal Conductivity Dissolved CO

Measurement (CO2 hi) _____________________ 97

2

8.1.4.7 Settings for TOC Measurement _____________________________________________________ 97

8.1.4.8 Settings for Flow Measurement _____________________________________________________ 98

8.1.4.9 Settings for Turbidity Sensors (InPro8000 Series) ______________________________________ 98

8.1.4.10 Settings for Turbidity Sensors (InPro8600i) ___________________________________________ 98

8.1.4.11 Deionization Capacity (DI-Cap™) __________________________________________________ 99

8.1.5 Concentration Curve Table _________________________________________________________________100

8.2 Temperature Source (Analog Sensors only) ___________________________________________________________100

8.3 Analog Outputs _________________________________________________________________________________ 101

8.4 Set Points _____________________________________________________________________________________ 102

8.5 ISM Setup (ISM Sensors only) _____________________________________________________________________ 103

8.5.1 Sensor Monitor __________________________________________________________________________ 103

8.5.2 CIP Cycle Limit __________________________________________________________________________ 105

8.5.3 SIP Cycle Limit __________________________________________________________________________ 106

8.5.4 AutoClave Cycle Limit ____________________________________________________________________ 107

8.5.5 DLI Stress Adjustment ____________________________________________________________________ 107

8.5.6 SAN Cycle Parameters ____________________________________________________________________ 108

8.5.7 Reset Counters for UniCond2e Sensors _______________________________________________________ 108

8.5.8 Set Calibration Interval for UniCond2e Sensors _________________________________________________ 109

8.6 General Alarm __________________________________________________________________________________ 109

8.7 ISM / Sensor Alarm ______________________________________________________________________________ 109

8.8 Clean ________________________________________________________________________________________ 110

8.9 Display Setup __________________________________________________________________________________ 110

8.10 Digital Inputs ___________________________________________________________________________________ 111

8.11 System _______________________________________________________________________________________ 111

8.12 PID Controller __________________________________________________________________________________ 112

8.13 Service _______________________________________________________________________________________ 116

8.13.1 Set Analog Outputs ______________________________________________________________________ 116

8.13.2 Read Analog Outputs

_____________________________________________________________ 116

8.13.3 Read Analog Inputs ______________________________________________________________________ 116

8.13.4 Set Relay ______________________________________________________________________________ 116

8.13.5 Read Relay ____________________________________________________________________________ 116

8.13.6 Read Digital Inputs ______________________________________________________________________ 116

8.13.7 Memory _______________________________________________________________________________ 117

8.13.8 Display _______________________________________________________________________________ 117

8.13.9 Calibrate TouchPad ______________________________________________________________________117

8.13.10 Channel Diagnostic ______________________________________________________________________117

8.14 Technical Service _______________________________________________________________________________117

8.15 User Management _______________________________________________________________________________ 118

8.16 Reset _________________________________________________________________________________________ 118

8.16.1 System Reset ___________________________________________________________________________ 118

8.16.2 Reset Sensor Calibration for Optical DO Sensors ________________________________________________ 119

8.16.3 Reset Sensor Calibration for UniCond2e Sensors ________________________________________________ 119

8.16.4 Reset Total Flow _________________________________________________________________________ 119

8.16.5 Reset for CO

hi Measurement ______________________________________________________________ 120

2

8.16.6 Reset for Turbidity Sensor __________________________________________________________________120

8.17 RS485 Output __________________________________________________________________________________ 120

8.17.1 PrinterOutputConguration ________________________________________________________________ 121

8.17.2 DataLogConguration ___________________________________________________________________ 121

8.18 USB Measurement Interface _______________________________________________________________________ 122

© 05/2019 Mettler-Toledo GmbH, CH-8606 Greifensee, Switzerland Transmitter M800

Printed in Switzerland 52 121 825 D

Page 8

Transmitter M800 8

9 ISM ________________________________________________________________________________________________ 123

9.1 iMonitor _______________________________________________________________________________________ 123

9.2 Messages _____________________________________________________________________________________ 124

9.3 ISM Diagnostics ________________________________________________________________________________ 124

9.3.1 pH/ORP, Oxygen, O

and Cond4e Sensors ____________________________________________________ 125

3

9.3.2 UniCond2e and UniCond4e Sensors _________________________________________________________ 125

9.4 Calibration Data ________________________________________________________________________________ 126

9.4.1 Calibration Data for All ISM Sensors excluding UniCond2e and UniCond4e ___________________________ 126

9.4.2 Calibration Data for UniCond2e and UniCond4e Sensors _________________________________________ 127

9.5 Sensor Info ____________________________________________________________________________________ 127

9.6 HW / SW Version _______________________________________________________________________________128

9.7 Log Book _____________________________________________________________________________________ 128

10 Wizards _____________________________________________________________________________________________ 129

10.1 Set Wizard ____________________________________________________________________________________ 129

10.2 Access to Wizards ______________________________________________________________________________ 129

11 Maintenance _________________________________________________________________________________________ 130

11.1 Front panel cleaning _____________________________________________________________________________ 130

12 Software History ______________________________________________________________________________________ 130

12.1 M800 Process _________________________________________________________________________________ 130

12.2 M800 Water ___________________________________________________________________________________130

13 Troubleshooting ______________________________________________________________________________________131

13.1 Cond (resistive) Error messages /

Warning- and Alarm list for analog sensors _________________________________________________________________131

13.2 Cond (resistive) Error messages /

Warning- and Alarm list for ISM sensors ____________________________________________________________________ 132

13.3 pH Error messages / Warning- and Alarm list __________________________________________________________132

13.3.1 pH sensors except dual membrane pH electrodes _______________________________________________ 132

13.3.2 Dual membrane pH electrodes (pH / pNa) ____________________________________________________ 133

13.3.3 ORP messages _________________________________________________________________________ 133

13.4 Amperometric O

Error messages /

2

Warning- and Alarm list ________________________________________________________________________________134

13.4.1 High level oxygen sensors _________________________________________________________________ 134

13.4.2 Low level oxygen sensors _________________________________________________________________ 134

13.4.3 Trace oxygen sensors ____________________________________________________________________135

13.5 Warning- and Alarm Indication _____________________________________________________________________ 135

13.5.1 Warning Indication_______________________________________________________________________135

13.5.2 Alarm Indication _________________________________________________________________________ 136

14 Ordering Information __________________________________________________________________________________ 137

14.1 Transmitter Overview _____________________________________________________________________________ 137

14.2 Accessories and Spare Parts _______________________________________________________________________ 137

15 Specications ________________________________________________________________________________________ 138

15.1 Generalspecications ____________________________________________________________________________ 138

15.2 Electricalspecications ___________________________________________________________________________ 142

15.3 Mechanicalspecications _________________________________________________________________________ 143

15.3.1 Polycarbonate (PC) Versions _______________________________________________________________ 143

15.3.2 Stainless Steel Versions ___________________________________________________________________143

15.4 Environmentalspecications ______________________________________________________________________ 143

15.5 ExClassication ________________________________________________________________________________ 144

15.5.1 M800 4-Channel and 2-Channel versions ____________________________________________________ 144

15.5.2 Type plate M800 1-Channel versions ________________________________________________________145

16 Warranty ____________________________________________________________________________________________ 146

© 05/2019 Mettler-Toledo GmbH, CH-8606 Greifensee, Switzerland Transmitter M800

Printed in Switzerland 52 121 825 D

Page 9

Transmitter M800 9

17 Buffer tables _________________________________________________________________________________________ 147

17.1 Standard pH buffers _____________________________________________________________________________ 147

17.1.1 Mettler-9 _______________________________________________________________________________147

17.1.2 Mettler-10 _____________________________________________________________________________148

17.1.3 NIST Technical Buffers ____________________________________________________________________148

17.1.4 NIST standard buffers (DIN and JIS 19266: 2000–01) __________________________________________ 149

17.1.5 Hach buffers ___________________________________________________________________________ 149

17.1.6 Ciba (94) buffers ________________________________________________________________________ 150

17.1.7 Merck Titrisole, Riedel-de-Haën Fixanale _____________________________________________________150

17.1.8 WTW buffers ___________________________________________________________________________ 151

17.1.9 JIS Z 8802 buffers _______________________________________________________________________ 151

17.2 Dual membrane pH electrode buffers ________________________________________________________________ 152

17.2.1 Mettler-pH / pNa buffers (Na+ 3.9M) _________________________________________________________ 152

© 05/2019 Mettler-Toledo GmbH, CH-8606 Greifensee, Switzerland Transmitter M800

Printed in Switzerland 52 121 825 D

Page 10

Transmitter M800 10

© 05/2019 Mettler-Toledo GmbH, CH-8606 Greifensee, Switzerland Transmitter M800

Printed in Switzerland 52 121 825 D

Page 11

Transmitter M800 11

1 Introduction

Statement of Intended Use – The M800 Multi-parameter transmitter is an online process instrument for measuring various properties of fluids and gases. These include conductivity, dissolved

oxygen, O2 gas, dissolved ozone, dissolved carbon dioxide, pH / ORP, flow and turbidity. The

M800 is available in different versions. The version indicates the amount of measurement parameters which can be covered and the kind of parameter. The version are indicated through

there part numbers on the label of the transmitter.

The M800 version with hygienic, polished stainless steel housing allows application in the field

of biotechnology, food processing and in the pharmaceutical industry.

M800 parameter fit guide for 2-channel and 4-channel version

These versions are compatible with the following (digital) ISM and flow sensors.

1)

Parameter

Water Process

2-channel 4-channel 2-channel 4-channel

pH/ORP • • • •

pH/pNa – – • •

UniCond 2-e • • • •

Conductivity 4-e • • • •

Amp. Dissolved Oxygen

– / • / –

3)

– / • / –

3)

• / • / •

2)

• / • / •

ppm / ppb / trace

Amp. Oxygen gas

– / • / – 3) – / • / –

3)

• / • / •

2)

• / • / •

ppm / ppb / trace

Optical Dissolved Oxygen •

Dissolved Carbon Dioxide

3)

– – • •

3)

•

2), 4)

•

•

(InPro5000i)

hi (InPro5500i) – – •

CO

2

4)

•

TOC • • – –

Dissolved Ozone • • – –

Flow • • – –

1) Process models are provided with PC housing or stainless steel housing

2) INGOLD sensors

3) THORNTON sensors

4) 2-channel: An opt. dissolved sensor or a CO

Optical dissolved sensors and CO

hi sensors have to be connected to channel 2 and / or to channel 4.

2

hi sensor has to be connected to channel 2. 4-channel:

2

2)

2)

2), 4)

4)

© 05/2019 Mettler-Toledo GmbH, CH-8606 Greifensee, Switzerland Transmitter M800

Printed in Switzerland 52 121 825 D

Page 12

Transmitter M800 12

M800 parameter fit guide for 1-channel version

These version is compatible with the following (digital) ISM and analog sensors.

1)

Parameter

Process 1-channel

Analog ISM

pH/ORP • •

pH/pNa – •

UniCond 2-e / UniCond 4-e – / – • / •

Conductivity 2-e /

• / • – / •

Conductivity 4-e

Amp. Dissolved Oxygen

• / • / •

2)

• / • / •

2)

ppm / ppb / trace

Amp. Oxygen gas

• / • / •

2)

• / • / •

2)

ppm / ppb / trace

Optical Dissolved Oxygen – •

Dissolved Carbon Dioxide

– •

2)

(InPro5000i)

hi (InPro5500i) – •

CO

2

Turbidity • (backscatter) •

1) Process models are provided with PC housing or stainless steel housing

2) INGOLD sensors

A colored touch screen conveys measuring data and setup information. The menu structure allows the operator to modify all operational parameters by using the touch screen. A menu-lockout feature, with password protection, is available to prevent the unauthorized use of the meter.

The M800 Multi-parameter transmitter can be configured to use up to eight analog and / or up to

eight relay outputs for process control.

TheM800Multi-parametertransmitterisequippedwithaUSBcommunicationinterface.Thisinterface provides up- and download capabilities of the transmitter configuration via a Personal

Computer (PC).

This description corresponds to the firmware release, version 1.2. Changes are taking place

constantly, without prior notification.

© 05/2019 Mettler-Toledo GmbH, CH-8606 Greifensee, Switzerland Transmitter M800

Printed in Switzerland 52 121 825 D

Page 13

Transmitter M800 13

2 Safety instructions

This manual includes safety information with the following designations and formats.

2.1 Denitionofequipment

and documentation symbols and designations

WARNING: POTENTIAL FOR PERSONAL INJURY.

a

CAUTION: Possible instrument damage or malfunction.

a

NOTE: Important operating information.

h

On the transmitter or in this manual text indicates: Caution and / or other possible hazard includ-

ing risk of electric shock (refer to accompanying documents).

a

The following is a list of general safety instructions and warnings. Failure to adhere to these in-

structionscanresultindamagetotheequipmentand/orpersonalinjurytotheoperator.

a

– The M800 Transmitter should be installed and operated only by personnel familiar with

thetransmitterandwhoarequalifiedforsuchwork.

– The M800 Transmitter must only be operated under the specified operating conditions

(see chapter 15 “Specifications”).

– Repair of the M800 Transmitter must be performed by authorized, trained personnel only.

– With the exception of routine maintenance, cleaning procedures, as described in this manu-

al, the M800 Transmitter must not be tampered with or altered in

any manner.

– Mettler-Toledo accepts no responsibility for damage caused by unauthorized modifications

to the transmitter.

– Follow all warnings, cautions, and instructions indicated on and supplied with this product.

– Installequipmentasspecifiedinthisinstructionmanual.Followappropriatelocalandna-

tional codes.

– Protective covers must be in place at all times during normal operation.

– Ifthisequipmentisusedinamannernotspecifiedbythemanufacturer,theprotectionpro-

vided by it against hazards may be void.

WARNINGS:

– Installationofcableconnectionsandservicingofthisproductrequireaccesstoshockhazard

voltage levels.

– Main power and relay contacts wired to a separate power source must be disconnected be-

fore servicing.

– Switchorcircuitbreakershallbeincloseproximitytotheequipmentandwithineasyreach

oftheOPERATOR;itshallbemarkedasthedisconnectingdevicefortheequipment.

– Main power must employ a switch or circuit breaker as the disconnecting device for the

equipment.

– Electrical installation must be in accordance with the National Electrical Code and / or any

other applicable national or local codes.

© 05/2019 Mettler-Toledo GmbH, CH-8606 Greifensee, Switzerland Transmitter M800

Printed in Switzerland 52 121 825 D

Page 14

Transmitter M800 14

NOTE: RELAY CONTROL ACTION

h

NOTE: PROCESS UPSETS

h

NOTE: This is a 4-wire-product with an active 4–20 mA analog output.

h

theM800Transmitterrelayswillalwaysde-energizeonlossofpower,equivalenttonormal state, regardless of relay state setting for powered operation. Configure any control

system using these relays with fail-safe logic accordingly.

Because process and safety conditions may depend on consistent operation of this transmitter, provide appropriate means to maintain operation during sensor cleaning, replacement, or sensor or instrument calibration.

Please do not supply power to terminal 3 to 10 of TB1 and terminal 1 to 8 of TB3.

2.2 Correct disposal of the unit

When the transmitter is finally removed from service, observe all local environmental regulations

for proper disposal.

© 05/2019 Mettler-Toledo GmbH, CH-8606 Greifensee, Switzerland Transmitter M800

Printed in Switzerland 52 121 825 D

Page 15

Transmitter M800 15

3 Unit overview

The M800 models are available as follows:

– in 1/2 DIN case size in polycarbonate

– in stainless steel.

The M800 1/2 DIN polycarbonate versions are suitable for panel-, wall- or pipe mount. The

M800 stainless steel versions are suitable for wall- or pipe mount.

3.1 Overview

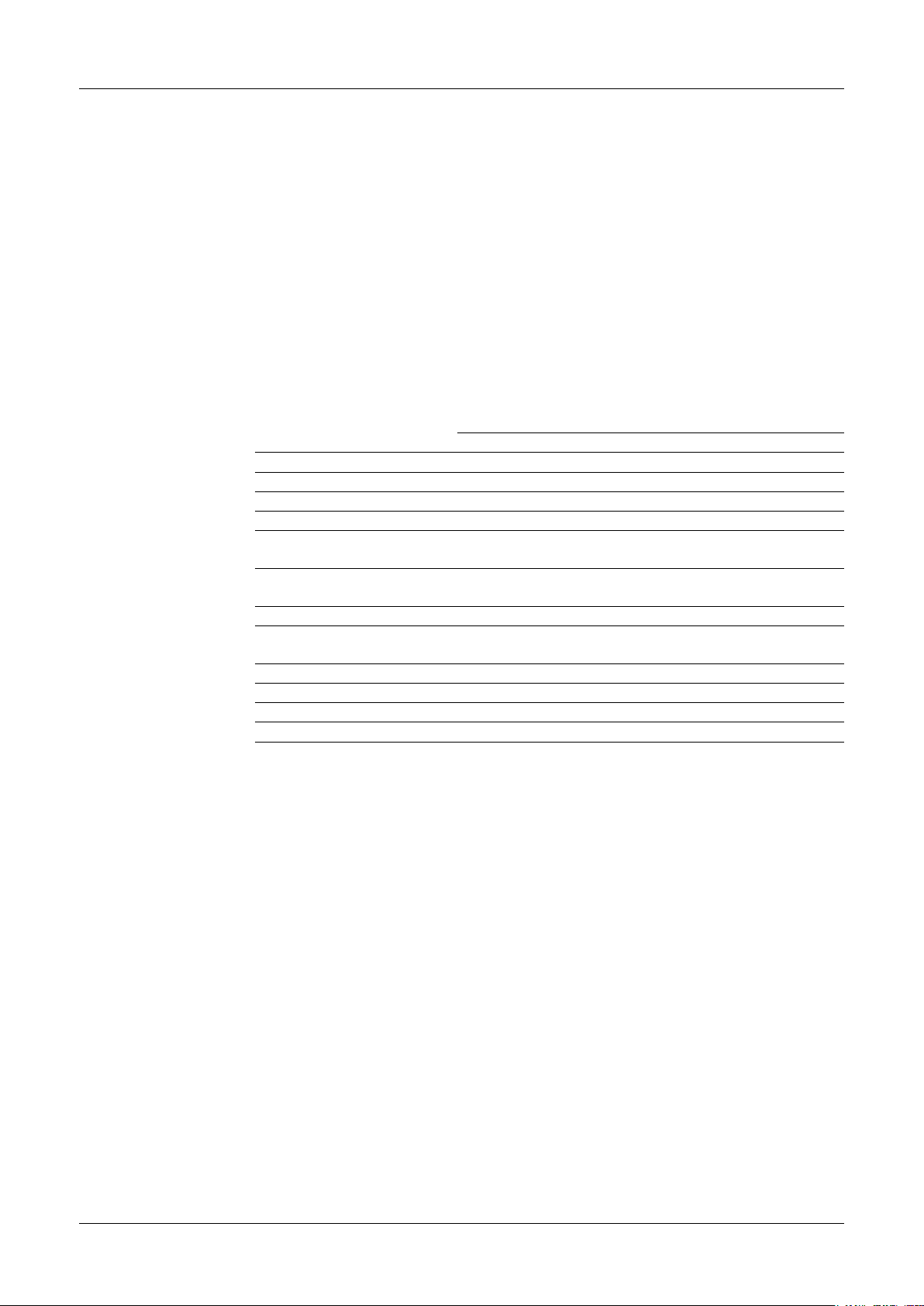

3.1.1 1-Channel Version

1

METTLER TOLEDO

M800

TB1

6 6

5

TB2

2

7

RECEIVER

TB3

TB4

EMITTER

TB5

3

4

Fig. 1: Overview 1-channel version

1 Housing, polycarbonate or stainless steel

2 VGA screen

3 Power supply terminals

4 Relay output terminals

5 Analog output / Digital input terminals

6 Sensor input terminals

7 Connection Turbidity sensor (InPro8000 Series)

© 05/2019 Mettler-Toledo GmbH, CH-8606 Greifensee, Switzerland Transmitter M800

Printed in Switzerland 52 121 825 D

Page 16

Transmitter M800 16

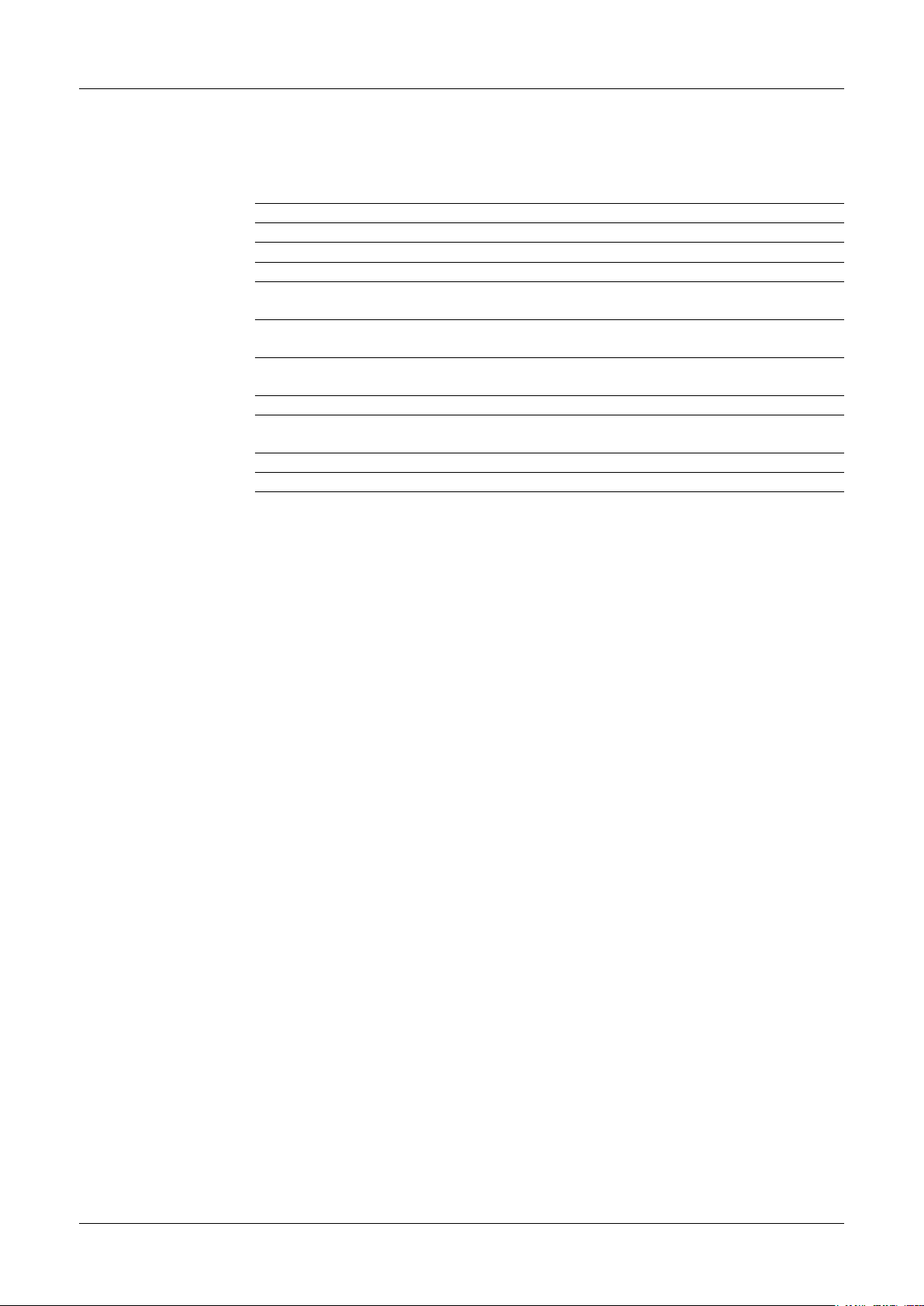

3.1.2 2-Channel and 4-Channel Version

1

TB2

M800

METTLER TOLEDO

2

Fig. 2: Overview 1-channel version

1 Housing, polycarbonate or stainless steel

2 VGA screen

3 Power supply terminals

4 Relay output terminals

5 Analog output / Digital input terminals

6 Sensor input terminals

TB1

5

TB3 TB4 TB5

6 6

TB6

3

4

© 05/2019 Mettler-Toledo GmbH, CH-8606 Greifensee, Switzerland Transmitter M800

Printed in Switzerland 52 121 825 D

Page 17

Transmitter M800 17

3.2 Display

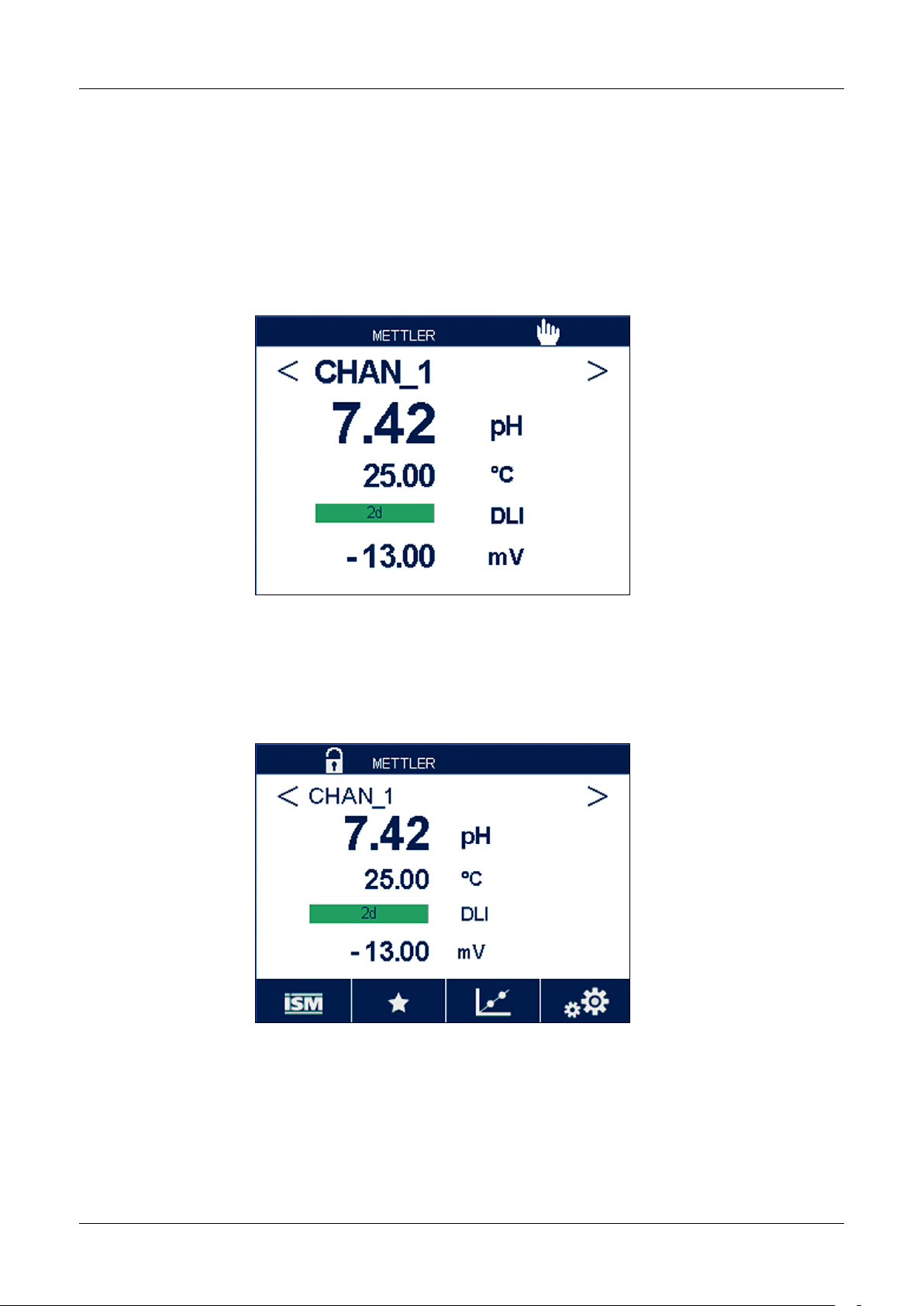

3.2.1 Start Screen

After starting the M800, the following Start Screen (logout screen) is shown automatically. To re-

turn form the Menu Screen to the Start Screen press s. The M800 will return automatically after

240 seconds from the Menu Screen or any configuration screen to the Start Screen if the user

has not pressed the touch screen.

3.2.2 Activation Menu Screen

While the M800 shows the Start Screen (logout screen) touch the display to activate the Menu

Screen. To return to the Menu Screen from other menus press H.

© 05/2019 Mettler-Toledo GmbH, CH-8606 Greifensee, Switzerland Transmitter M800

Printed in Switzerland 52 121 825 D

Page 18

Transmitter M800 18

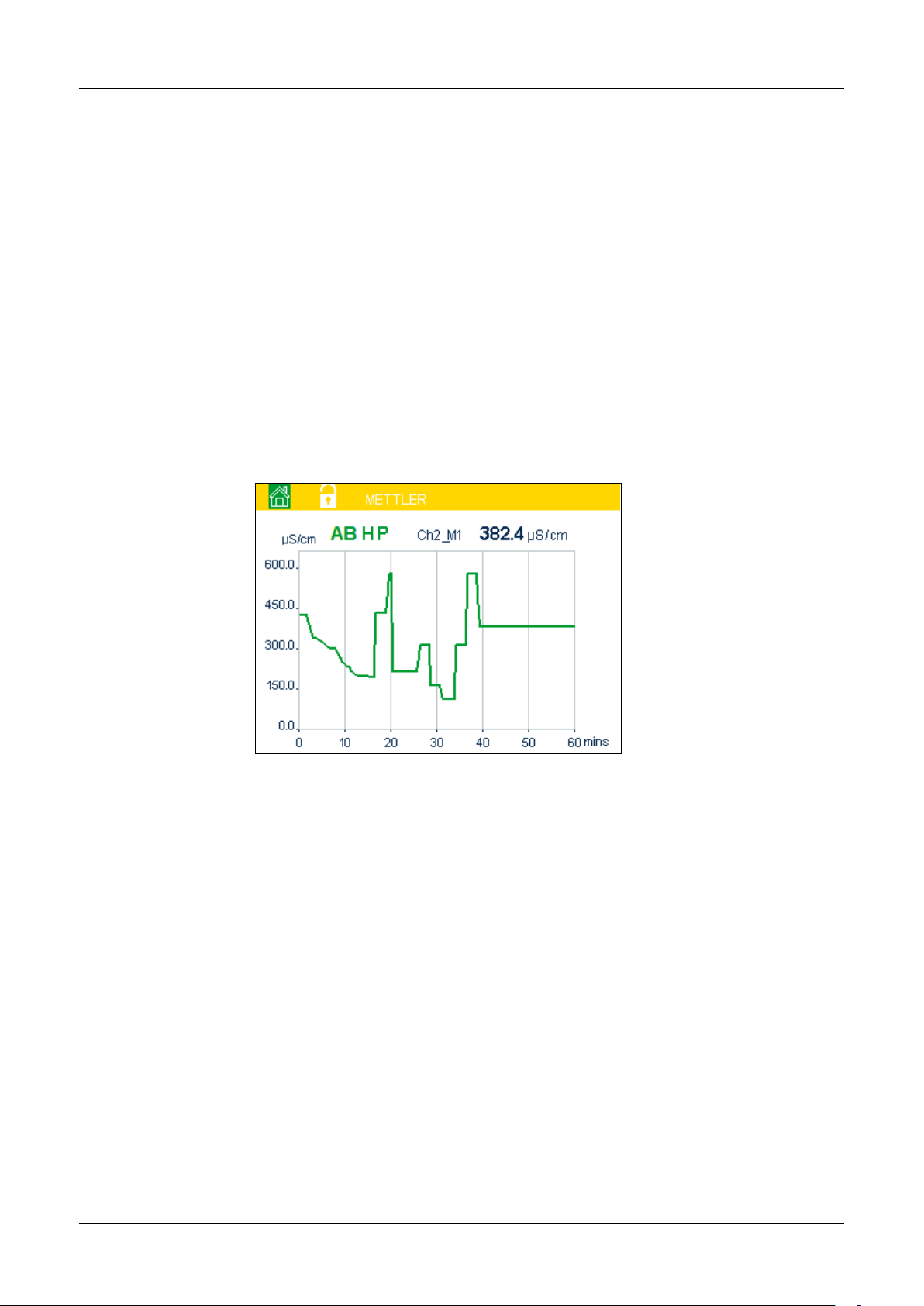

3.3 Graphic Trend Measurement

Any single measurement may be displayed as a trend measurement over time. Measurement

values will be indicated by a value on the Y-axis and time elapsed on the X-axis of the graph

displayed. An actual measurement for the selected value will also be displayed numerically

above the graphic trend display. The measurement value is refreshed once per second.

Graphic trending will only display the data within maximum/minimum range. Out of range values or invalid values will not be displayed. The Y-axis will display the maximum value unit with

its range; X-axis unit uses “mins” for minutes for measurements less than one hour and “hrs” for

one day. 4 scales for X/Y-axis. The maximum value on Y-axis is one decimal place.

3.3.1 Activation Trend Display Screen

While the M800 displays the Menu Screen, touch any measurement value line of the display

screen twice (1-chan, 2-chan, 4-meas, 8-meas) to activate the trend display for that measurement.

If a sensor is disconnected/connected a pop-up window come up; after closing the window, it

will go back to the Menu Screen.

Red/yellow bar on top line will display for any message occurring during trending. ‘H’, ‘P’,”AB”

will display when this channel is in hold or process.

© 05/2019 Mettler-Toledo GmbH, CH-8606 Greifensee, Switzerland Transmitter M800

Printed in Switzerland 52 121 825 D

Page 19

Transmitter M800 19

3.3.2 Settings for Trend Display Screen

For setting configurations, touch any area of the graphic trend display to go to the pop-up window of this measurement parameter. Settings are at the default values. However, these settings

may be changed when options are available, as needed.

Time: Option button. For graphic display time (X-axis)

1-h (default value)

1-day

NOTE: 1 h means: 1 meas storage/15 seconds, totally 240 measurements for 1h. 1 day

h

means: 1 meas storage/6 minutes, totally 240 measurements for 1 day;

Range: Option button

Default(default value)

Individual

When “Default” modes are set for the maximum or minimum value, this indicates the full measurement range for this unit. A Max or Min button is not displayed. If setting is selectable, the

user can set maximum and minimum settings manually.

Max: Edit button.

Maximum value of this unit on Y-axis. xxxxxx, floating decimal point.

Min: Edit button.

Minimum value of this unit on Y-axis. xxxxxx, floating decimal point.

Max Value > Min Value

NOTE: Settings for Y-and Y-axis and the corresponding measurement values are stored the trans-

h

mitters memory. A power down returns to default settings.

3.3.3 Deactivation Trend Display Screen

Press H in activated graphic trend screen to return to Menu Screen.

NOTE: If a sensor is disconnected/connected a pop-up window come up; after closing the win-

h

dow, it will go back to the Menu Screen.

© 05/2019 Mettler-Toledo GmbH, CH-8606 Greifensee, Switzerland Transmitter M800

Printed in Switzerland 52 121 825 D

Page 20

Transmitter M800 20

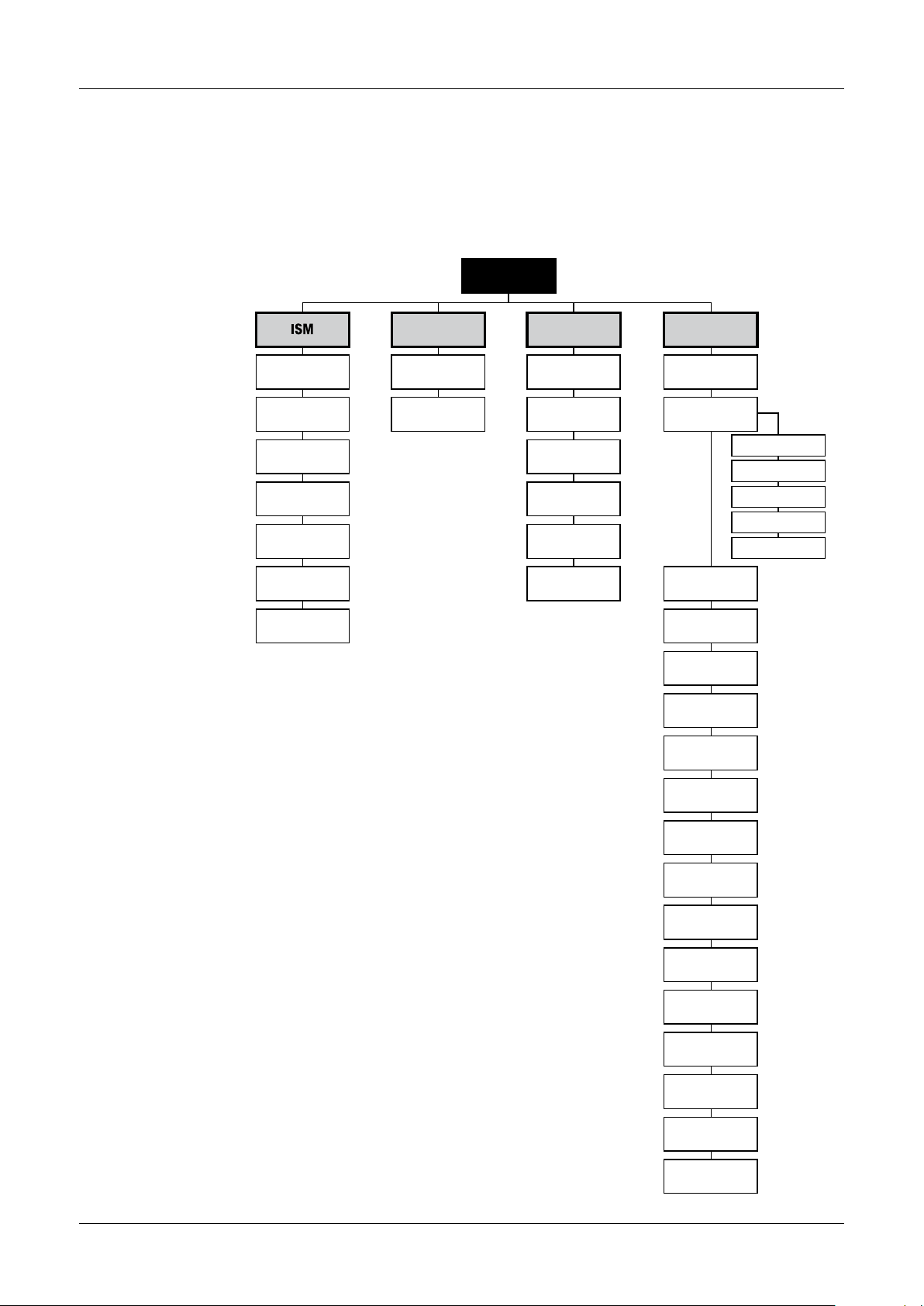

3.4 Control / Navigation

3.4.1 Menu Structure

Below is the structure of the M800 menu tree:

Menu Screen

M800

iMonitor

Messages

ISM Diagnostics

Calibration Data

Sensor Info

HW/SW Version

Log Book

S

Wizard

Favorite 1…4

Set Wizard

c

Calibration

Calibrate Sensor

Calibrate

Electronics

Calibrate Meter

Calibrate

Analog Outputs

Calibrate

Analog Inputs

Maintenance

C

Configuration

Guided Setup

Measurement

Temperature Source

Analog Outputs

Set Points

ISM Setup

General Alarm

ISM/Sensor Alarm

Channel Setup

Display Mode

Parameter Setting

Concentration

Curve Table

Clean

Display Setup

Digital Inputs

System

PID Controller

Service

Tech Service

User Management

Reset

RS485 Output

© 05/2019 Mettler-Toledo GmbH, CH-8606 Greifensee, Switzerland Transmitter M800

Printed in Switzerland 52 121 825 D

Page 21

Transmitter M800 21

3.4.2 Operating Elements

Operating element Description

F

s

S

c

C

H

c

p

< >

e

Enter Menu screen

Enter Start screen

Enter ISM menu

Enter Favorite menu

Enter Calibration menu

EnterCongurationmenu

Return to Menu screen (see chapter 3.2.2 “Activation Menu Screen”)

Enter next-lower menu level, here e.g. iMonitor, Messages or ISM Diagnostics

Return to next-higher menu level

Change between pages within one menu level

2-channel and 4-channel: Change between the channels

Conrmvaluesandselectedoptions.PressESCandthechangesarenot

stored.

3.4.3 Entry of Data

The M800 displays a keypad for modifying values. Press the e button and the transmitter will

store the value. Press the ESC button to exit the keypad without changing data.

NOTE: For some values, the units can be modified. In this case the keypad shows a button with

h

NOTE: For some entries letters and/or numbers can be used. In this case the keypad shows a

h

a U. To select another unit for the entered value on the keypad press the U button. To return

again press the 0–9 button.

button ‘A,a,0’. Press this button to change between capital letters, small letters and numbers on

the keypad.

3.4.4 Selection Menus

Somemenusrequireaselectionofaparameter/data.Inthiscasethetransmitterdisplaysa

pop up window. Press the according field to select the value. The pop-up window will be closed

and the selection will be stored.

3.4.5 ”Save changes” Dialog

If the M800 brings up the ”Save changes” dialog there are the following options. No will discard

the entered values, Yes will save changes made and Cancel will bring you back to continue

configuring.

© 05/2019 Mettler-Toledo GmbH, CH-8606 Greifensee, Switzerland Transmitter M800

Printed in Switzerland 52 121 825 D

Page 22

Transmitter M800 22

3.4.6 Security Passwords

The M800 Transmitter allows a security lock-out of various menus. If the security lock-out

feature of the transmitter has been enabled, a security password must be entered to allow access to the menu. See chapter 8.15 “User Management”.

3.4.7 Display

NOTE: In the event of an alarm or other error conditions the M800 Transmitter will display a

h

NOTE: During calibrations, clean, Digital In with Analog Output / Relay / USB in HOLD state, a

h

flashing bar graph on the display. This bar graph will remain until the condition that caused it

has been cleared (see chapter 13.5 “Warning- and Alarm Indication”).

flashing ”H” (HOLD) will appear in the upper right corner of the display for the corresponding

channel. This symbol will remain for 20 sec., after end of calibration. This symbol will remain

for 20 seconds until after the calibration or clean is completed. This symbol will also disappear

when Digital In is deactivated.

© 05/2019 Mettler-Toledo GmbH, CH-8606 Greifensee, Switzerland Transmitter M800

Printed in Switzerland 52 121 825 D

Page 23

Transmitter M800 23

4 Installation instruction

4.1 Unpackingandinspectionofequipment

Inspect the shipping container. If it is damaged, contact the shipper immediately for instructions.

Do not discard the box.

If there is no apparent damage, unpack the container. Be sure all items shown on the packing

list are present.

If items are missing, notify Mettler-Toledo immediately.

© 05/2019 Mettler-Toledo GmbH, CH-8606 Greifensee, Switzerland Transmitter M800

Printed in Switzerland 52 121 825 D

Page 24

Transmitter M800 24

66 mm/2.59"

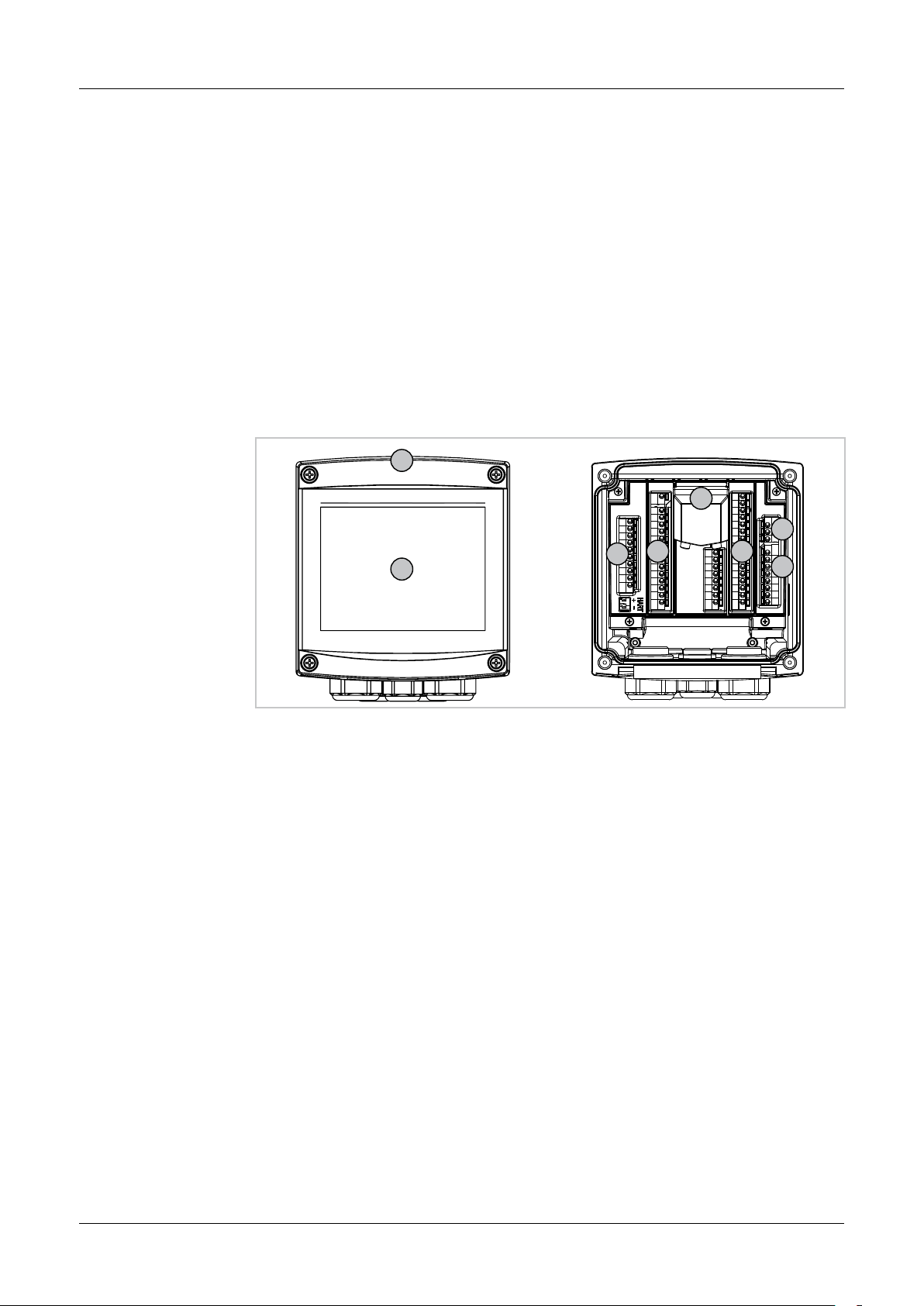

4.2 Mounting 1/2 DIN Versions (PC housing)

4.2.1 Dimensions 1/2 DIN Version (PC housing)

25 mm/0.98”

35 mm/1.38”

+0.5 mm

+0.02"

5.39"

137 mm

58 mm/2.28”

40 mm/

1.58"

137 mm

5.39"

1

+0.5 mm

+0.02"

45 mm/

1.77"

170 mm/6.69"

125 mm/4.92"

METTLER TOLEDO

35 mm/

1.38"

150 mm/5.9"

90 mm/3.54"

80 mm/3.15"

M800

158 mm/6.22"

6 mm/0.236"

75 mm/2.95"

90 mm/3.54"

Fig. 3: Dimensions 1/2 DIN version (PC housing)

1 Dimensions for panel coutout

© 05/2019 Mettler-Toledo GmbH, CH-8606 Greifensee, Switzerland Transmitter M800

Printed in Switzerland 52 121 825 D

Page 25

Transmitter M800 25

1

2

3

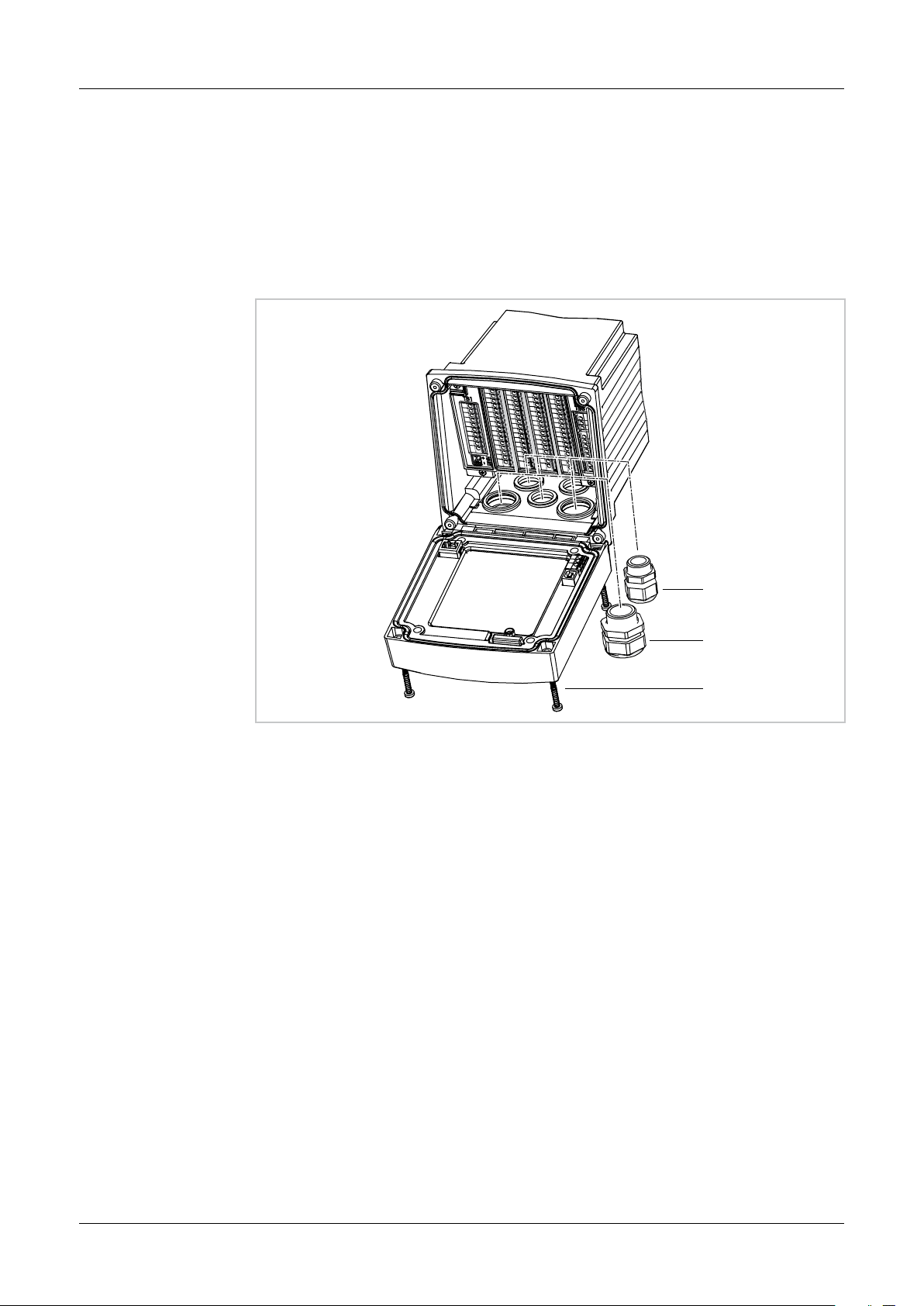

4.2.2 Mounting Procedure – 1/2 DIN Version (PC housing)

1/2 DIN versions transmitters are designed for the following mounting versions: panal mount,

wall mount or pipe mount. For wall mount the integral rear cover is used.

Optional hardware accessories are available that allow for panel- or pipe-mount.

Refer to section „14.2 Accessories and Spare Parts“.

Assembly

Fig. 4: Assembly – 1/2 DIN version (PC housing)

1 1 piece M25 x 1.5 cable gland

2 4 pieces M20 x 1.5 cable glands

3 4 pieces screws

General:

– Orient the transmitter so that the cable grips face downward.

– Wiring routed through the cable grips shall be suitable for use in wet locations.

– In order to provide IP66 enclosure ratings, all cable glands must be in place. Each cable

gland must be filled using a UL rated cable marked “wet”, “wet location” or “outdoor”, measuring0.36”(6.6mm)orlargerdiameter,employedwithinthespecifiedstrainreliefclamping range. Do not use metal conduit.

– Tightenthescrewsofthefrontpanelwithatighteningtorqueof2Nm.

© 05/2019 Mettler-Toledo GmbH, CH-8606 Greifensee, Switzerland Transmitter M800

Printed in Switzerland 52 121 825 D

Page 26

Transmitter M800 26

4.2.3 1/2 DIN Version (PC housing) – Panel Mounting

To insure a good seal, the panel or door must be flat and have a smooth finish. Textured or

rough surfaces are not recommended and may limit the effectiveness of the gasket seal provided.

1. Make cutout in panel. For dimensions refer to 4.2.1 “Dimensions 1/2 DIN Version (PC

housing)”.

– Be sure surface surrounding cutout is clean, smooth and free of burrs.

2. Slide face gasket around transmitter from the back of the unit.

3. Place transmitter into cutout hole. Be sure there are no gaps between the transmitter

and panel surface.

4. Place the two mounting brackets on either side of the transmitter as shown.

5. While holding transmitter firmly into the cutout hole, push the mounting brackets toward

the backside of panel.

6. Once secure, use a screwdriver to tighten the brackets against the panel. In order to pro-

vide IP66 environmental enclosure rating, the two clamps provided shall be securely tight-

enedtocreateanadequatesealbetweenthepanelenclosureandtransmitter.

– Face gasket will compress between transmitter and panel.

a

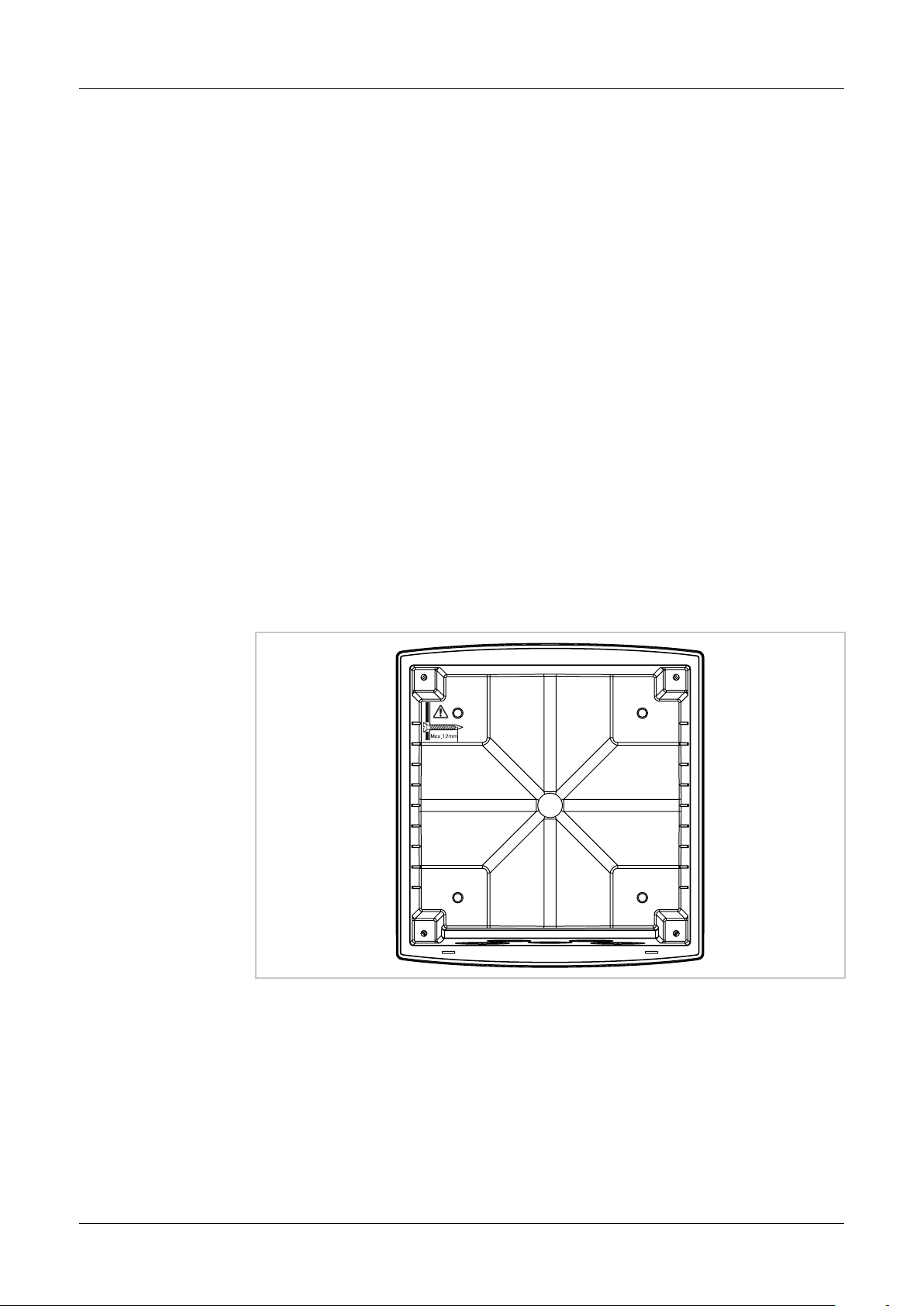

4.2.4 1/2 DIN Version – Wall Mounting

DANGER! Mortal danger by electric shock or risk of electrical shock:Themaximumscrew-in

depthofthemountingholesinthehousingis12mm(0.47inch).Donotexceedmaximum

screw-in depth.

Fig. 5: Maximum screw-in depth

© 05/2019 Mettler-Toledo GmbH, CH-8606 Greifensee, Switzerland Transmitter M800

Printed in Switzerland 52 121 825 D

Page 27

Transmitter M800 27

∅ 40 … ∅ 60 mm

1. Mount wall mounting kit to the housing. Do not exceed maximum screw-in depth.

2. Mount wall mounting kit with the housing to the wall.

Attach to wall using appropriate mounting hardware for wall surface. Be sure it is level and

securely fastened and the installation adheres to any and all clearance dimensions re-

quiredfortransmitterserviceandmaintenance.Orientthetransmittersothatthecable

grips are facing downward.

Fig. 6: Wall mounting with wall mounting kit – 1/2 DIN version (PC housing)

4.2.5 1/2 DIN Version (PC housing) – Pipe Mounting

∅ 1.57 … ∅ 2.36"

Fig. 7: Pipe mounting – 1/2 DIN version (PC version)

– Use only manufacturer-supplied components for pipe-mounting the M800 transmitter. See

section „14.2 Accessories and Spare Parts“ for ordering information.

– Tightenthefixingscrewswithatighteningtorqueof2to3Nm.

© 05/2019 Mettler-Toledo GmbH, CH-8606 Greifensee, Switzerland Transmitter M800

Printed in Switzerland 52 121 825 D

Page 28

Transmitter M800 28

90 mm/3.54"

90 mm/3.54" 70 mm/2.76"

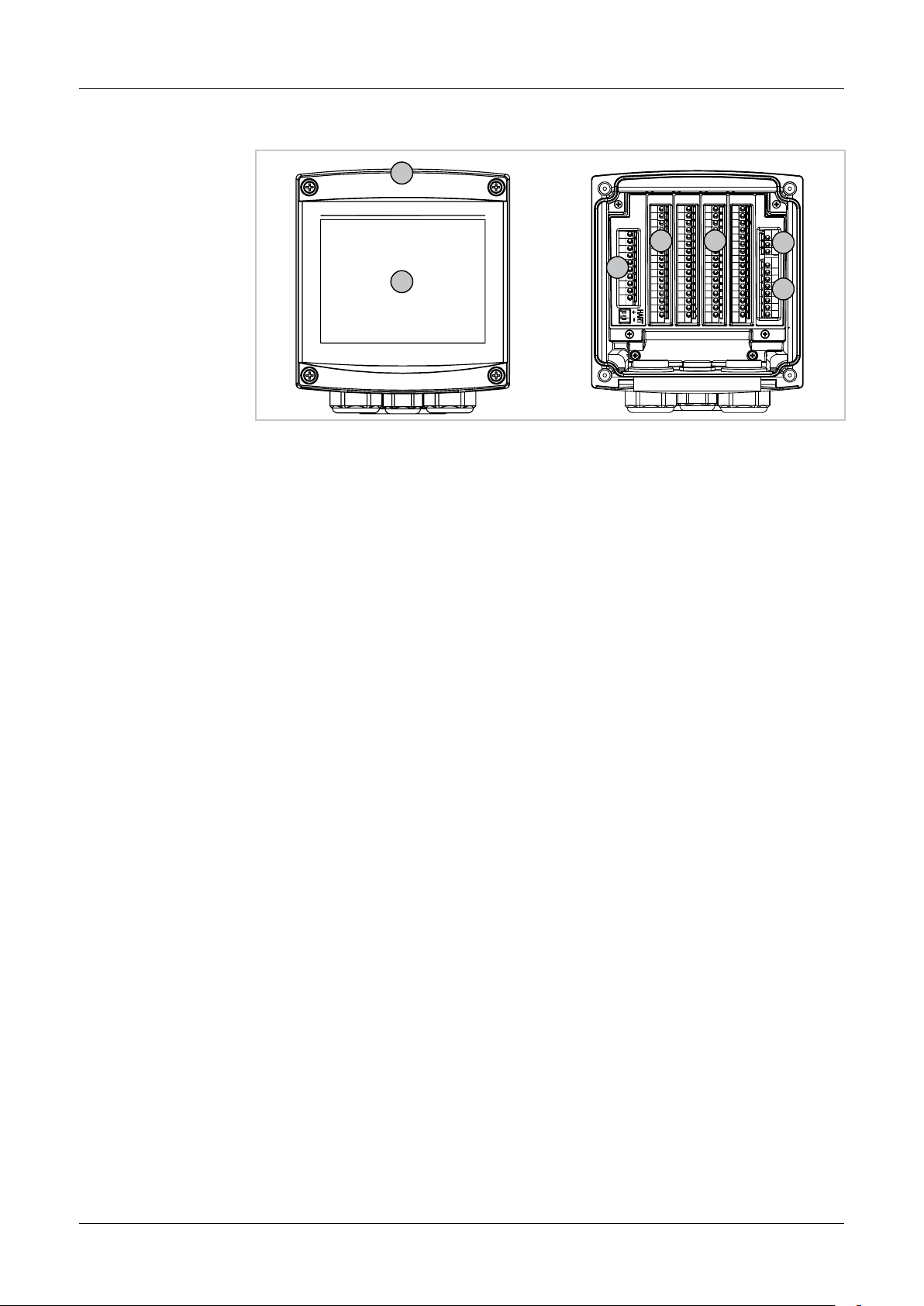

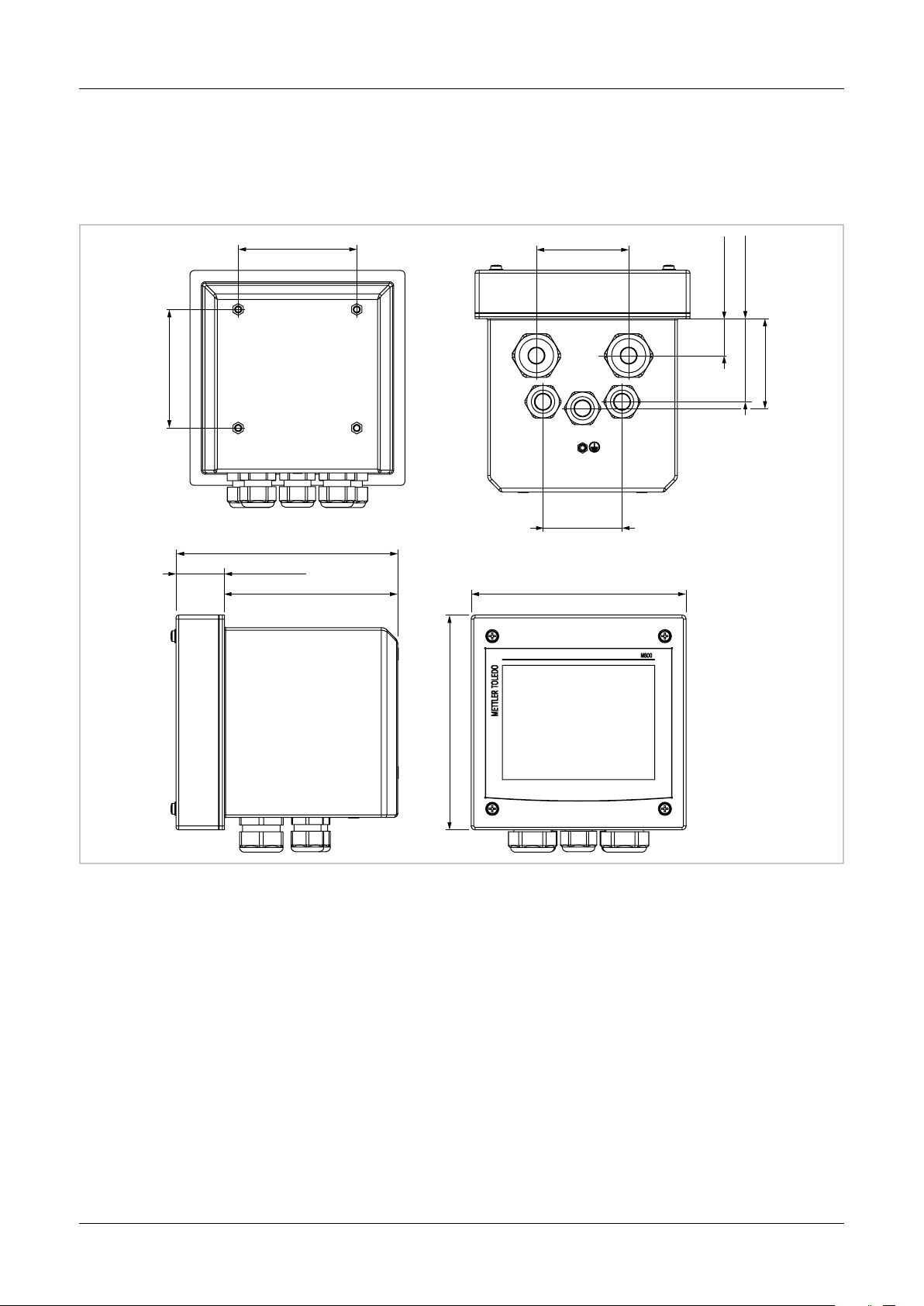

4.3 Mounting Stainless Steel Version

4.3.1 Dimensions Stainless Steel Version

28 mm/1.10"

63 mm/2.48"

68 mm/2.68"

60 mm/2.36"

168 mm/6.61"

37 mm/1.46"

131 mm/5.16"

163 mm/6.42"

163 mm/6.42"

Fig. 8: Dimensions stainless steel version

© 05/2019 Mettler-Toledo GmbH, CH-8606 Greifensee, Switzerland Transmitter M800

Printed in Switzerland 52 121 825 D

Page 29

Transmitter M800 29

1

2

3

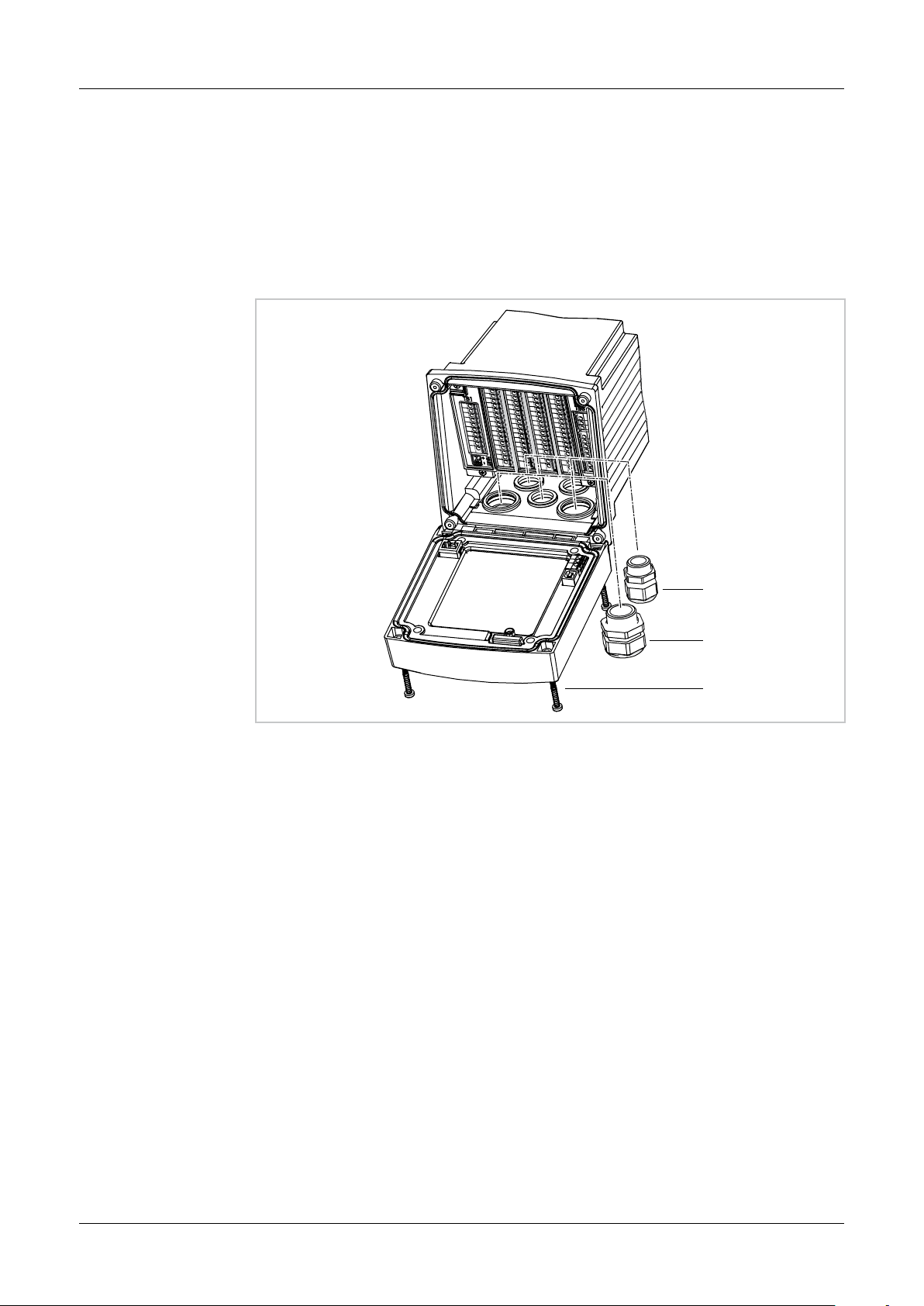

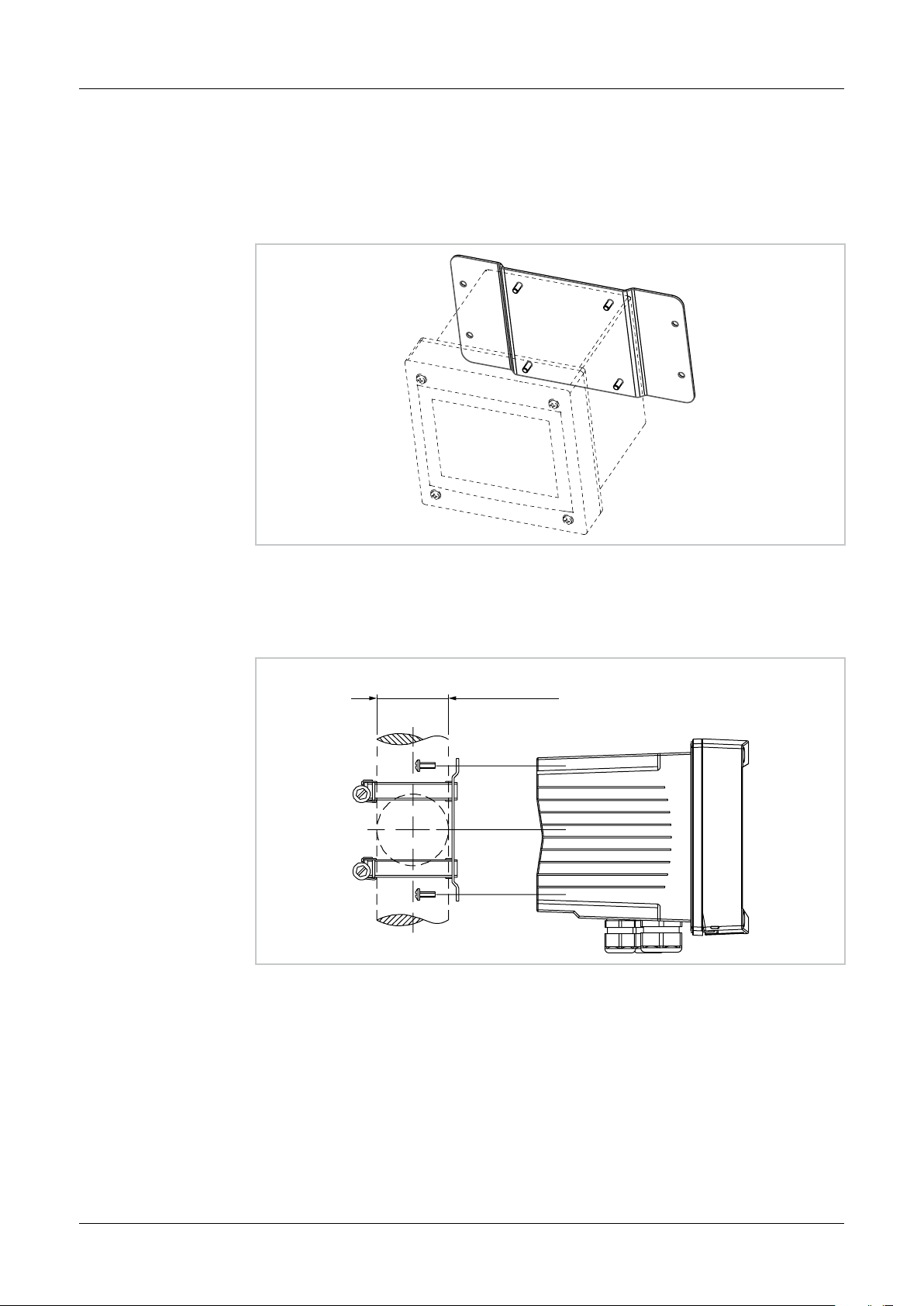

4.3.2 Mounting Procedure – Stainless Steel Version

Stainless steel versions transmitters are designed for the following mounting versions: wall

mount or pipe mount. For wall mount the integral rear cover is used.

Optional hardware accessories are available that allow for pipe-mount.

Refer to section „14.2 Accessories and Spare Parts“.

Assembly

Fig. 9: Assembly – stainless steel version

1 1 piece M25 x 1.5 cable gland

2 4 pieces M20 x 1.5 cable glands

3 4 pieces screws

General:

– Orient the transmitter so that the cable grips face downward.

– Wiring routed through the cable grips shall be suitable for use in wet locations.

– In order to provide IP66 enclosure ratings, all cable glands must be in place. In order to pro-

vide IP66 enclosure ratings, all cable glands must be in place. Each cable gland must be

filled using a UL rated cable marked “wet”, “wet location” or “outdoor”, measuring 0.36”

(6.6mm)orlargerdiameter,employedwithinthespecifiedstrainreliefclampingrange.Do

not use metal conduit.

© 05/2019 Mettler-Toledo GmbH, CH-8606 Greifensee, Switzerland Transmitter M800

Printed in Switzerland 52 121 825 D

Page 30

Transmitter M800 30

∅ 40 … ∅ 60 mm

4.3.3 Stainless Steel Version – Wall Mounting

1. Mount wall mounting kit to the housing. Do not exceed maximum screw-in depth.

2. Mount wall mounting kit with the housing to the wall.

Attach to wall using appropriate mounting hardware for wall surface. Be sure it is level and

securely fastened and the installation adheres to any and all clearance dimensions re-

quiredfortransmitterserviceandmaintenance.Orientthetransmittersothatthecable

grips are facing downward.

Fig. 10: Wall mounting with wall mounting kit – stainless steel version (PC housing)

4.3.4 Stainless Steel Version – Pipe Mounting

∅ 1.57 … ∅ 2.36"

Fig. 11: Pipe mounting – stainless steel version

– Use only manufacturer-supplied components for pipe-mounting the M800 transmitter. See

section „14.2 Accessories and Spare Parts“ for ordering information.

© 05/2019 Mettler-Toledo GmbH, CH-8606 Greifensee, Switzerland Transmitter M800

Printed in Switzerland 52 121 825 D

Page 31

Transmitter M800 31

4.4 Electrical Connection

DANGER! Mortal danger by electric shock:Poweroffinstrumentduringelectricalconnection.

a

NOTE: This is a 4-wire-product with an active 4–20 mA analog output.

h

Do not supply power to the analog output terminals (Aout). These are terminals 3 to 10

of TB1 and additionally, for 2-channel and 4-channel version terminals 1 to 8 of TB3.

The terminals are placed inside the housing.

AllM800transmittersaredesignedtooperatefroma20to30VDCora100to240VAC

powersource.Refertospecificationsforpowerrequirementsandratingsandsizepowerwiring

accordingly.

The terminals are suitable for single wires and flexible leads with a wire cross-section from

0.2 mm2 up to 1.5 mm2, (16–24 AWG).

1. Switch off supply voltage.

2. Connect mains supply as follows:

– 20to30VDC:N (–) for Neutral and L (+) for Line

1-channel versions to terminal TB5, 2-channel or 4-channel versions to terminal TB6

– 100to240VAC:N for Neutral and L for Line

1-channel versions to terminal TB5, 2-channel or 4-channel versions to terminal TB6.

3. For stainless steel version: Connect protective earth to the PE terminal according to Fig. 12

on Page 31. The cross-section of the PE wire must be above 0.8 mm

4. Connect sensor, analog output signals, digital input signals and relay output signals ac-

cording to chapter „4.5 Terminal Definition“.

5. For stainless steel version: Secure that the internal ground wiring between housing and

front cover is securely connected.

2

(18 AWG).

a

DANGER! Mortal danger by electric shock:Forstainlesssteelhousingconnect protective earth

to the PE terminal. Secure that the internal ground wiring between housing and front cover is

securely connected.

2

1

Fig. 12: Connection of protective earth to PE terminal and internal ground wiring

1 PE terminal for protective earth

2 Terminal for internal ground wiring between housing and front cover

© 05/2019 Mettler-Toledo GmbH, CH-8606 Greifensee, Switzerland Transmitter M800

Printed in Switzerland 52 121 825 D

Page 32

Transmitter M800 32

4.5 TerminalDenition

4.5.1 M800 1-Channel

Power connections: N (–) for Neutral and L(+) for Line for 20 to 30 VDC. N for Neutral and L for

Linefor100to240VAC.

For stainless steel version: Connect protective earth to the PE terminal according to Fig. 12 on

Page 31.

Terminal number TB1 TB2 TB3 TB4 TB5

L (+)

N (–)

Ground

1 DI1+ 1-Wire AI1+ Relay1_NC

2 DI1– GND5V AI1- Relay1_COM

3 Aout1+ RS485B DI4+ Relay2_NO

4 Aout1– RS485A DI4– Relay2_COM

5 Aout2+ GND5V DI5+ Relay3_NO

6 Aout2– 5V DI5– Relay3_COM

7 Aout3+ 24V DI6+ Relay4_NO

8 Aout3– GND24V DI6– Relay4_COM

9 Aout4+ n. a. Relay5_NO n. a.

10 Aout4– n. a. Relay5_COM n. a.

11 n. a. n. a. Relay6_NO n. a.

12 n. a. n. a. Relay6_COM n. a.

13 n. a. n. a. Relay7_NO n. a.

14 n. a. n. a. Relay7_COM n. a.

15 n. a. n. a. Relay8_NC n. a.

16 n. a. n. a. Relay8_COM n. a.

For analog

sensors sensorspecific.

For ISM sensors

not used.

TB2

TB1

RECEIVER

TB3

TB4

TB5

EMITTER

NO: normally open (contact open if un-actuated).

NC: normally closed (contact closed if un-actuated).

n.a. not available

NOTE: This is a 4-wire-product with an active 4–20 mA analog output.

h

© 05/2019 Mettler-Toledo GmbH, CH-8606 Greifensee, Switzerland Transmitter M800

Printed in Switzerland 52 121 825 D

Please do not supply power to terminal no. 3 to 10 of TB1.

Page 33

Transmitter M800 33

4.5.1.1 InPro8000 Series Turbidity Sensor

Use the two connections labeled EMITTER and RECEIVER for connecting METTLER TOLEDO

InPro8000sensorsonly.Patchcordsareavailableupto170m(558ft)inlength.Mismatching the two ends of a sensor cable is not possible. Only hand-screwed fixing of the two SMA

connectors of the sensor cable on the transmitter connectors is recommended.

CAUTION: Do not cut or shorten fiber optic cables. Cutting of fiber optic cables and assembly of

a

SMAconnectorsrequirespecialtools.Whereitisdesiredtouseshorterpatchcables,consult

your METTLER TOLEDO supplier.

See the appropriate sensor instruction manual for detailed information regarding installation and

specific use of fiber optic sensors.

© 05/2019 Mettler-Toledo GmbH, CH-8606 Greifensee, Switzerland Transmitter M800

Printed in Switzerland 52 121 825 D

Page 34

Transmitter M800 34

4.5.2 M800 2-Channel

Power connections: N (–) for Neutral and L (+) for Line for 20 to 30 VDC. N for Neutral and L

forLinefor100to240VAC.

For stainless steel version: Connect protective earth to the PE terminal according to Fig. 12 on

Page 31.

Terminal

number

1 DI1+ DI2+ Aout5+ AI1+ Relay1_NC

2 DI1– DI2– Aout5– AI1- Relay1_COM

3 Aout1+ 1-Wire_Ch1 Aout6+ DI4+ Relay2_NO

4 Aout1– GND5V_Ch1 Aout6– DI4– Relay2_COM

5 Aout2+ RS485B_Ch1 Aout7+ DI5+ Relay3_NO

6 Aout2– RS485A_Ch1 Aout7– DI5– Relay3_COM

7 Aout3+ GND5V_Ch1 Aout8+ DI6+ Relay4_NO

8 Aout3– 5V_Ch1 Aout8- DI6– Relay4_COM

9 Aout4+ 24V_Ch2 Ain_Ch3 Relay5_NO n. a.

10 Aout4– GND24V_Ch2 AJ_Ch3 Relay5_COM n. a.

11 n. a. 1-Wire_Ch2 5V_Ch3 Relay6_NO n. a.

12 n. a. GND5V_Ch2 GND5V_Ch3 Relay6_COM n. a.

13 n. a. RS485B_Ch2 Bin_Ch4 Relay7_NO n. a.

14 n. a. RS485A_Ch2 BJ_Ch4 Relay7_COM n. a.

15 n. a. GND5V_Ch2 5V_Ch4 Relay8_NO n. a.

16 n. a. 5V_Ch2 GND5V_Ch4 Relay8_COM n. a.

TB1

TB2

(ISM Ch1,2)

TB3 TB4 TB5 TB6

L (+)

N (–)

Ground

Not installed

TB2 TB3

TB1

TB4

TB5

TB6

NO: normally open (contact open if un-actuated).

NC: normally closed (contact closed if un-actuated).

n.a. not available

NOTE: This is a 4-wire-product with an active 4–20 mA analog output.

h

Please do not supply power to terminal no. 3 to 10 of TB1 and 1 to 8 of TB3.

© 05/2019 Mettler-Toledo GmbH, CH-8606 Greifensee, Switzerland Transmitter M800

Printed in Switzerland 52 121 825 D

Page 35

Transmitter M800 35

4.5.3 M800 4-Channel

Power connections: N (–) for Neutral and L (+) for Line for 20 to 30 VDC. N for Neutral and L

forLinefor100to240VAC.

For stainless steel version: Connect protective earth to the PE terminal according to Fig. 12 on

Page 31.

Terminal

number

1 DI1+ DI2+ Aout5+ DI3+ AI1+ Relay1_NC

2 DI1– DI2– Aout5– DI3– AI1- Relay1_COM

3 Aout1+ 1-Wire_Ch1 Aout6+ 1-Wire_Ch3 DI4+ Relay2_NO

4 Aout1– GND5V_Ch1 Aout6– GND5V_Ch3 DI4– Relay2_COM

5 Aout2+ RS485B_Ch1 Aout7+ RS485B_Ch3 DI5+ Relay3_NO

6 Aout2– RS485A_Ch1 Aout7– RS485A_Ch3 DI5– Relay3_COM

7 Aout3+ GND5V_Ch1 Aout8+ GND5V_Ch3 DI6+ Relay4_NO

8 Aout3– 5V_Ch1 Aout8- 5V_Ch3 DI6– Relay4_COM

9 Aout4+ 24V_Ch2 Ain_Ch5 24V_Ch4 Relay5_NO n. a.

10 Aout4– GND24V_Ch2 AJ_Ch5 GND24V_Ch4 Relay5_COM n. a.

11 n. a. 1-Wire_Ch2 5V_Ch5 1-Wire_Ch4 Relay6_NO n. a.

12 n. a. GND5V_Ch2 GND5V_Ch5 GND5V_Ch4 Relay6_COM n. a.

13 n. a. RS485B_Ch2 Bin_Ch6 RS485B_Ch4 Relay7_NO n. a.

14 n. a. RS485A_Ch2 BJ_Ch6 RS485A_Ch4 Relay7_COM n. a.

15 n. a. GND5V_Ch2 5V_Ch6 GND5V_Ch4 Relay8_NC n. a.

16 n. a. 5V_Ch2 GND5V_Ch6 5V_Ch4 Relay8_COM n. a.

TB1

TB2

(ISM Ch1,2)

TB3

TB4

(ISM Ch3,4)

TB5 TB6

L (+)

N (–)

Ground

TB2

TB3 TB4 TB5

TB1

TB6

NO: normally open (contact open if un-actuated).

NC: normally closed (contact closed if un-actuated).

n.a. not available

NOTE: This is a 4-wire-product with an active 4–20 mA analog output.

h

Please do not supply power to terminal no. 3 to 10 of TB1 and 1 to 8 of TB3.

© 05/2019 Mettler-Toledo GmbH, CH-8606 Greifensee, Switzerland Transmitter M800

Printed in Switzerland 52 121 825 D

Page 36

Transmitter M800 36

4.5.4 M800 1-Channel: TB2 – Conductivity 2e/4e Analog Sensors

Cond 4-E or 2-E

Terminal Function Color

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

Cnd inner1

Not used –

Cnd outer1

Cnd outer1 –

Not used –

Cnd outer2 –

Cnd inner2

Cnd outer2 (GND)

Not used –

Not used –

Not used –

RTD ret/GND bare shield

RTD sense red

RTD green

Not used –

5V output –

1)

1)

2)

2)

white

white/blue

blue

black

1) ForthirdpartyCond2esensorsajumperbetween1and3mayberequired.

2) ForthirdpartyCond2esensorsajumperbetween7and8mayberequired.

4.5.5 M800 1-Channel: TB2 – pH/ORP Analog Sensors

pH Redox (ORP)

Terminal Function Color 1

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

Glass transparent Platinum transparent

Not used – – –

Not used – – –

Not used – – –

Not used – – –

Reference red Reference red

Reference

Solution GND

2)

– Reference

2)

blue

Not used –

Shield (GND) green/yellow Shield (GND) green/yellow

Not used – – –

RTD ret/GND white – –

RTD sense – – –

RTD green

Not used – – –

5 V output – – –

1)

3)

Function Color

2)

Solution GND

–

2)

–

1) Grey wire not used.

2) Install jumper between 7 and 8 for ORP sensors and pH electrodes without SG.

3) Blue wire for electrode with SG.

© 05/2019 Mettler-Toledo GmbH, CH-8606 Greifensee, Switzerland Transmitter M800

Printed in Switzerland 52 121 825 D

Page 37

Transmitter M800 37

4.5.6 M800 1-Channel: TB2 – Oxygen Analog Sensors

InPro6800 InPro6900 InPro6950

Terminal Function Color Color Color

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

Not used – – –

Not used – – –

Anode red red red

Anode –

Reference –

1)

1)

1)

–

1)

–

–

blue

Not used – – –

Not used – – –

Guard – grey grey

Cathode transparent transparent transparent

Shield (GND) green/yellow green/yellow green/yellow

Not used – – –

NTC ret (GND) white white white

Not used – – –

NTC green green green

Not used – – –

5 V output – – –

1) Install jumper between 4 and 5 for InPro6800 and InPro6900.

© 05/2019 Mettler-Toledo GmbH, CH-8606 Greifensee, Switzerland Transmitter M800

Printed in Switzerland 52 121 825 D

Page 38

Transmitter M800 38

4.5.7 M800 2- and 4-Channel: TB2 and TB4 – Terminal

Assignment for Optical Oxygen, CO

hi, UniCond2e,

2

UniCond4e and 5000TOCi ISM Sensors

TB2

(ISM Ch1,2)

Terminal Function Function

1 DI2+ DI6+ – – –

2 DI2– DI6- – – –

3 1-Wire_Ch1 1-Wire_Ch3 – – –

4 GND5V_Ch1 GND5V_Ch3 – – –

5 RS485B_Ch1 RS485B_Ch3 – – black

6 RS485A_Ch1 RS485A_Ch3 – – red

7 GND5V_Ch1 GND5V_Ch3 – – white

8 5V_Ch1 5V_Ch3 – – blue

9 24V_Ch2 24V_Ch4 grey brown –

10 GND24V_Ch2 GND24V_Ch4 blue black –

11 1-Wire_Ch2 1-Wire_Ch4 – – –

12 GND5V_Ch2 GND5V_Ch4 green/yellow grey –

13 RS485B_Ch2 RS485B_Ch4 brown blue black

14 RS485A_Ch2 RS485A_Ch4 pink white red

15 GND5V_Ch2 GND5V_Ch4 – yellow white

16 5V_Ch2 5V_Ch4 – – blue

TB4

(ISM Ch3,4)

Optical Oxygen 1), CO2 hi

VP8 cables

wire color

5-pin cables

wire color

UniCond2e

1)

UniCond4e 2),

5000TOCi

Cables

wire color

2),

1) One O2 optical or thermal conductivity CO2 sensor can be connected to plug TB2 and TB4.

2) Transparent wire not connected.

© 05/2019 Mettler-Toledo GmbH, CH-8606 Greifensee, Switzerland Transmitter M800

Printed in Switzerland 52 121 825 D

Page 39

Transmitter M800 39

4.5.8 M800 2- and 4-Channel: TB2 and TB4 – Terminal

Assignment for pH, Amp. Oxygen, Cond 4e, CO

O

ISM Sensors

3

TB2

(ISM Ch1,2)

Terminal Function Function Cables wire color

1 DI2+ DI6+ –

2 DI2– DI6– –

3 1-Wire_Ch1 1-Wire_Ch3 transparent (cable core)

4 GND5V_Ch1 GND5V_Ch3 red

5 RS485B_Ch1 RS485B_Ch3 –

6 RS485A_Ch1 RS485A_Ch3 –

7 GND5V_Ch1 GND5V_Ch3 –

8 5V_Ch1 5V_Ch3 –

9 24V 24V –

10 GND24V GND24V –

11 1-Wire_Ch2 1-Wire_Ch4 transparent (cable core)

12 GND5V_Ch2 GND5V_Ch4 red

13 RS485B_Ch2 RS485B_Ch4 –

14 RS485A_Ch2 RS485A_Ch4 –

15 GND5V_Ch2 GND5V_Ch4 –

16 5V_Ch2 5V_Ch4 –

TB4

(ISM Ch3,4)

pH, Amp. Oxygen,

Cond 4e, CO2 and O

and

2

3

© 05/2019 Mettler-Toledo GmbH, CH-8606 Greifensee, Switzerland Transmitter M800

Printed in Switzerland 52 121 825 D

Page 40

Transmitter M800 40

4.5.9 M800 1-Channel: TB3 – Terminal Assignment for

Optical Oxygen, CO

hi, UniCond2e and UniCond4e

2

ISM Sensors

TB3 Optical Oxygen, CO2 hi

Terminal Function

1 1-Wire – – –

2 GND5V – yellow –

3 RS485B brown blue black

4 RS485A pink white red

5 GND5V green/yellow grey white

6 5V – – blue

7 24V grey brown –

8 GND24V blue black –

9 Not used – – –

10 Not used – – –

11 Not used – – –

12 Not used – – –

13 Not used – – –

14 Not used – – –

15 Not used – – –

16 Not used – – –

VP8 cables

wire color

5-pin cables

wire color

UniCond2e 1),

UniCond4e

Cables

wire color

1)

1) Transparent wire not connected.

© 05/2019 Mettler-Toledo GmbH, CH-8606 Greifensee, Switzerland Transmitter M800

Printed in Switzerland 52 121 825 D

Page 41

Transmitter M800 41

4.5.10 M800 1-Channel: TB3 – Terminal Assignment for pH and Turbidity ISM Sensors

TB3

Terminal Function

1 1-Wire transparent (cable core)

2 GND5V red green/yellow

3 RS485B – green

4 RS485A – yellow

5 GND5V – –

6 5V – –

7 24V – brown

8 GND24V – white

9 Not used – –

10 Not used – –

11 Not used – –

12 Not used – –

13 Not used – –

14 Not used – –

15 Not used – –

16 Not used – –

pH, Amp. Oxygen, CO2

and Cond 4e

Cables:

wire color

Turbidity (InPro8600i/D1,

InPro8600i/D3)

Cables:

wire color

1) Transparent wire not connected.

4.5.11 M800 2- and 4-Channel Water: TB3 – Terminal Assignment for Flow Sensors

TB3

Terminal Transmitter Function

1 Aout5+ –

2 Aout5- –

3 Aout6+ –

4 Aout6- –

5 Aout7+ –

6 Aout7- –

7 Aout8+ –

8 Aout8- –

9 Ain_Ch3 / Ain_Ch5 Flow Pulse Input

10 AJ_Ch3 / AJ_Ch5 + 10 VDC

11 5V_Ch3 / 5V_Ch5 + 5 VDC

12 GND5V_Ch3 / GND5V_Ch5 Ground

13 Ain_Ch4 / Ain_Ch6 Flow Pulse Input

14 AJ_Ch4 / AJ_Ch6 + 10 VDC

15 5V_Ch4 / 5V_Ch6 + 5 VDC

16 GND5V_Ch4 / GND5V_Ch6 Ground

Flow hi, Flow lo, Flow

Type2

© 05/2019 Mettler-Toledo GmbH, CH-8606 Greifensee, Switzerland Transmitter M800

Printed in Switzerland 52 121 825 D

Page 42

Transmitter M800 42

4.6 Connection of Flow Sensor

The M800 Transmitter is designed to operate with various types of sensors. These sensors re-

quiredifferentwiringconfigurations.Listedbelowareinstructionsforwiringthevarioustypesof

sensors offered by METTLER TOLEDO Thornton for use with this transmitter. Please consult the

factory for assistance if attempting to wire sensors not offered by METTLER TOLEDO Thornton as

some sensors may not be compatible.

4.6.1 Flow Sensor Input Wiring Kit

This kit contains components that may be needed at input terminals to condition sensor signals.

Refer to the following sections or to the instruction manual for wiring details.

4.6.2 Kit Contents

This kit contains the following items:

− 4xWirenuts

− 4x10KohmresistorsforusewithBurket8020and8030typesensors,andGFSignet

2500-series sensors.

− 4x1KohmresistorsforusewithDataIndustrial200-seriesandFluidyneinsertiontype

sensors.

− 4x0.33uF,50VcapacitorsforusewithBerket8020and8030typesensors,DataIndustrial

200-series and 4000-series sensors, GF Signet 2500-series sensors, Sanitary Turbine-Type

sensors, Fluidyne insertion type sensors and Racine Federated (Formerly Asahi/America) vortex-style sensors.

4.6.3 Flow sensor wiring for Compatible Sensors

The following sections provide wiring information to properly connect various compatible flow

sensors to the M800 Transmitter. When using the Configuration menu of the transmitter to setup

the flow sensor, the first prompt asks to select the TYPE of flow sensor being connected.

There are three choices as follows:

High: All flow sensors described in Section 4.4.4

Low: P515 Signet flow sensors only, described in section 4.4.5

Type 2: Asahi flow sensors, described in Section 4.4.6

© 05/2019 Mettler-Toledo GmbH, CH-8606 Greifensee, Switzerland Transmitter M800

Printed in Switzerland 52 121 825 D

Page 43

Transmitter M800 43

4.6.4 Wiringfor”HIGH”typeowsensors

The following wiring information is used when connecting (Burkert 8020 and 8030 type) inline

Hall effect 5VDC, flow sensors. THORNTON models 33901 thru 33935.

THORNTON 33901-33935

58 034 601 - 58 034 635

Pulse output

L+

L–

Burkert 8020, 8030

Hall-Effect Sensor

Type: high

0.33uF

10K

Extension cable not provided. Use 2-conductor twisted pair with shield, 22 AWG (Belden 8451

orequivalent),1,000ft(305m)maximumlength.

The following wiring information is used when connecting Badger (formerly Data Industrial

200-Series) forward-swept paddlewheel type flow sensors.

THORNTON models 33142 thru 33145 and 33159 thru 33162 and 33273.

TB 3

9 Ain_Ch5

10 AJ_Ch5

11 5V_Ch5

12 GND5V_Ch5

M800 transmitter

THORNTON 33142-33145

Red

Black

Shield

(formerly Data Industrial 200 Series)

Badger

Flow Sensors

Type: High

58 034 201 - 58 034 204

0.33uF

1K

TB 3

9 Ain_Ch5

10 AJ_Ch5

11 5V_Ch5

12 GND5V_Ch5

M800 transmitter

Extension cable provided with sensor. Use 2-conductor twisted pair with shield 20 AWG

(Belden9320orequivalent)toextendlengthto2000ft(610m)max.

The following wiring information is used when connecting Badger (formerly Data Industrial

4000-Series) forward-swept paddlewheel type flow sensors.

THORNTON models 33174 thru 33177 and 33171 and 33172.

THORNTON 33174-33177, 33171, 33172

58 034 207 - 58 034 211, 58 034 226

Clear

Red

Black

Shield

(formerly Data Industrial 4000 Series)

Badger

Flow Sensors

Type: High

0.33uF

TB 3

9 Ain_Ch5

10 AJ_Ch5

11 5V_Ch5

12 GND5V_Ch5

M800 transmitter

20 ft (6.1 m) extension cable provided with sensor. Use 3-conductor with shield,

20AWG(Belden9364orequivalent)toextendlengthto2000ft(610m)maximum.

© 05/2019 Mettler-Toledo GmbH, CH-8606 Greifensee, Switzerland Transmitter M800

Printed in Switzerland 52 121 825 D

Page 44

Transmitter M800 44

The following wiring information is used when connecting (GF Signet 2500-Series) Hall Effect

paddlewheel type flow sensors. THORNTON models 33282, 33285, 33287, 33298 thru

33305.

THORNTON 33282, 33285, 33287, 33298 - 33305

58 034 227, 58 034 230, 58 034 232 - 58 034 240

TB 3

9 Ain_Ch5

10 AJ_Ch5

11 5V_Ch5

12 GND5V_Ch5

M800 transmitter

Signet 2507, 2536, 2540

Hall-Effect Sensor

Type: high

Red

Black

Shield

0.33uF

10K

25 ft (7.6 m) extension cable provided with sensor. Use 2-conductor with shield,

22AWG(Belden8451orequivalent)toextendlengthto1000ft(305m)maximum.

The following wiring information is used when connecting Sanitary Turbine type flow sensors.

THORNTON models 33336 thru 33377 (Hoffer) and 33441 thru 33450 (Sponsler).

THORNTON 3336-33348, 33376, 33377

58 034 270 - 58 034 282, 58 034 303, 58 034 304

TB 3

9 Ain_Ch5

10 AJ_Ch5

11 5V_Ch5

12 GND5V_Ch5

M800 transmitter

Hoffer Turbine Sensors

Type: High

White

Red

Black

Shield

0.33uF

20 ft (6.1 m) extension cable provided with sensor. Use 3-conductor with shield,

20AWG(Belden9364orequivalent)toextendlengthto3000ft(915m)maximum.

THORNTON 33441-33450

Sponsler Turbine Sensor

Type: High

58 034 516 - 58 034 525

Orange

Red

Black

Shield

0.33uF

TB 3

9 Ain_Ch5

10 AJ_Ch5

11 5V_Ch5

12 GND5V_Ch5

M800 transmitter

20 ft (6.1 m) extension cable provided with sensor. Use 3-conductor with shield,

20AWG(Belden9364orequivalent)toextendlengthto3000ft(915m)maximum.

© 05/2019 Mettler-Toledo GmbH, CH-8606 Greifensee, Switzerland Transmitter M800

Printed in Switzerland 52 121 825 D

Page 45

Transmitter M800 45

The following wiring information is used when connecting Spirax Sarco/Emco flow (formerly

Fluidyne) insertion type flow sensors. THORNTON models 33358 thru 33375.

THORNTON 33358 - 33375

Spirax Sarco/Emco flow

(formerly Fluidyne)

Insertion Vortex Sensor

Type: High

58 034 285 - 58 034 302

(+)

(–)

Shield

0.33uF

1K

TB 3

9 Ain_Ch5

10 AJ_Ch5

11 5V_Ch5

12 GND5V_Ch5

M800 transmitter

Extension cable not provided. Use 2-conductor twisted pair with shield, 20 AWG (Belden 9320

orequivalent),2000ft(610m)maximumlength.

4.6.5 Wiringfor”LOW”typeowsensors

The following wiring information is used when connecting (GF Signet 515) type flow sensors.

THORNTON models 33189, 33193, 33195, 33196, and 33229.

THORNTON 33189, 33193, 33195, 33196, 33229

58 034 215 , 58 034 219, 58 034 221, 58 034 222, 58 034 224

TB 3

Red

Black

Shield

Signet 515 Sensor

Type: low

9 Ain_Ch5

10 AJ_Ch5

11 5V_Ch5

12 GND5V_Ch5

M800 transmitter

Extension cable not provided. Use 2-conductor twisted pair with shield, 22 AWG (Belden 8451

orequivalent,200ft(61m)maximumlength.

4.6.6 Wiringfor”TYPE2”owsensors

The following wiring information is used when connecting Racine Federated (formerly Asahi/

America) vortex flow sensors. THORNTON models 33308 to 33335.

THORNTON 33308-33335

58 034 242 - 58 034 265

TB 3

9 Ain_Ch5

10 AJ_Ch5

11 5V_Ch5

12 GND5V_Ch5

M800 transmitter

Racine Federated

(formerly Asahi/America)

Vortex Sensor

Type: 2

Signal

(+)Power

(-)Ground

0.33uF