Page 1

M 700(X)

Instruction manual

Order number: 52 121 216

Page 2

Warranty

Defects occurring within 1 year from delivery date shall be remedied free of charge at our plant

(carriage and insurance paid by sender).

©2005 Subject to change without notice

Return of products under warranty

Please contact Mettler-Toledo before returning a defective device. Ship the cleaned device to the address

you have been given. If the device has been in contact with process fluids, it must be decontaminated/

disinfected before shipment.

In that case, please attach a corresponding certificate, for the health and safety of our service personnel.

Disposal

Please observe the applicable local or national regulations concerning the disposal of

“waste electrical and electronic equipment”.

Registered trademarks

The following registered trademarks are used in this instruction manual

without further marking

CalCheck

Calimatic

Sensocheck

Sensoface

ServiceScope

VariPower

SMARTMEDIA

is a registered trademark of Toshiba Corp., Japan

®

InPro

is a registered trademark of Mettler-Toledo GmbH, Switzerland

®

Mettler-Toledo GmbH, Process Analytics, Industrie Nord,

CH-8902 Urdorf, Tel. +41 (44) 736 22 11 Fax +41 (44) 736 26 36

Subject to technical changes. Mettler-Toledo GmbH, 07/05.

Printed in Germany.

TA-201.011-MTE05 180705 Software version: 6.x

Page 3

Page 4

Page 5

Page 6

Contents

for the M 700(X) modular process analysis system

EC Declaration of Conformity...................................................................................3

Software version ......................................................................................................6

Modular concept and instruction manuals................................................................7

System overview ......................................................................................................8

Latest product information.....................................................................................10

How to order an additional function ......................................................................11

Intended use ..........................................................................................................12

Package contents ...................................................................................................12

Safety information (Application in hazardous locations)..........................................13

Information on commissioning/start-up ..................................................................14

Conformity with FDA 21 CFR Part 11.....................................................................15

Product line............................................................................................................16

Short description

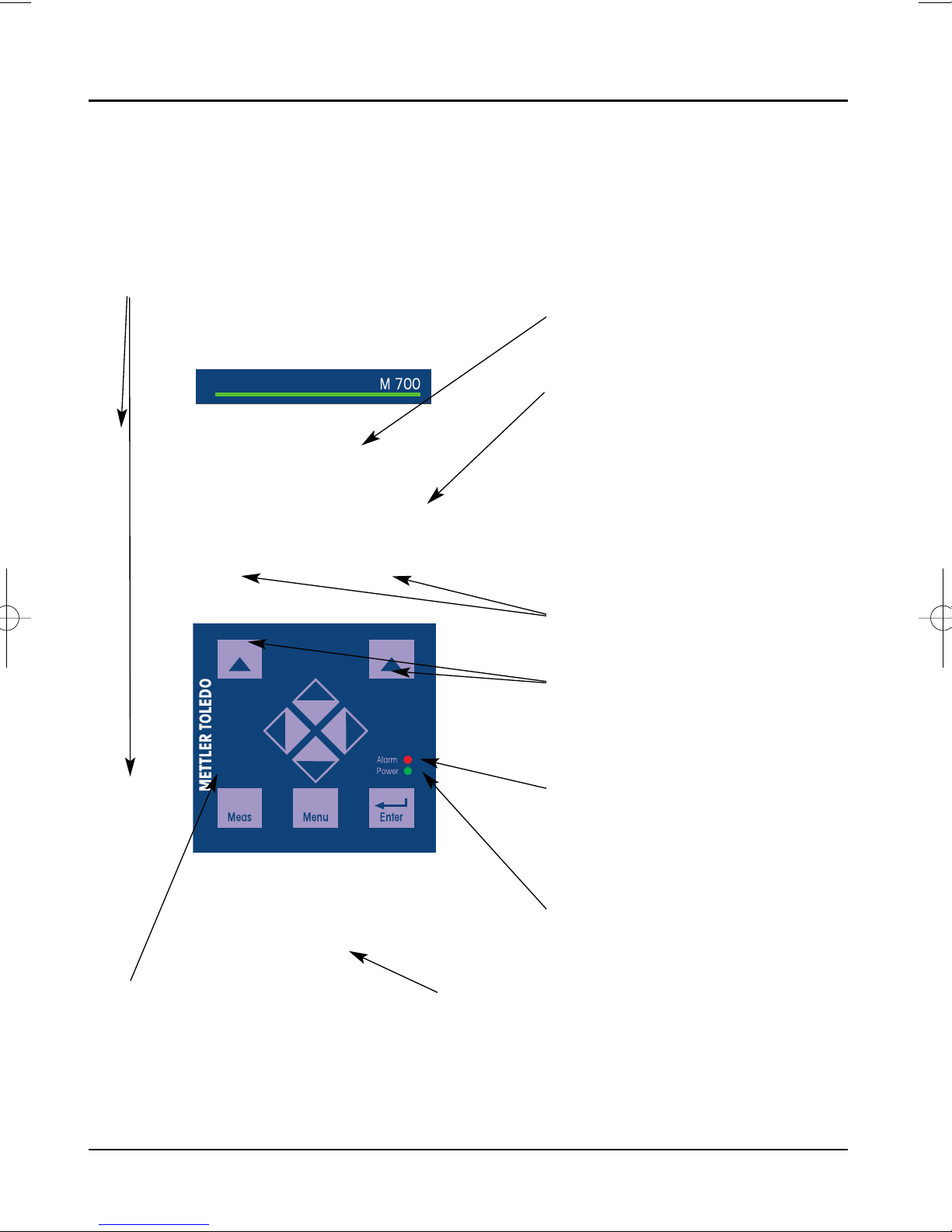

M 700 FRONT ........................................................................................................18

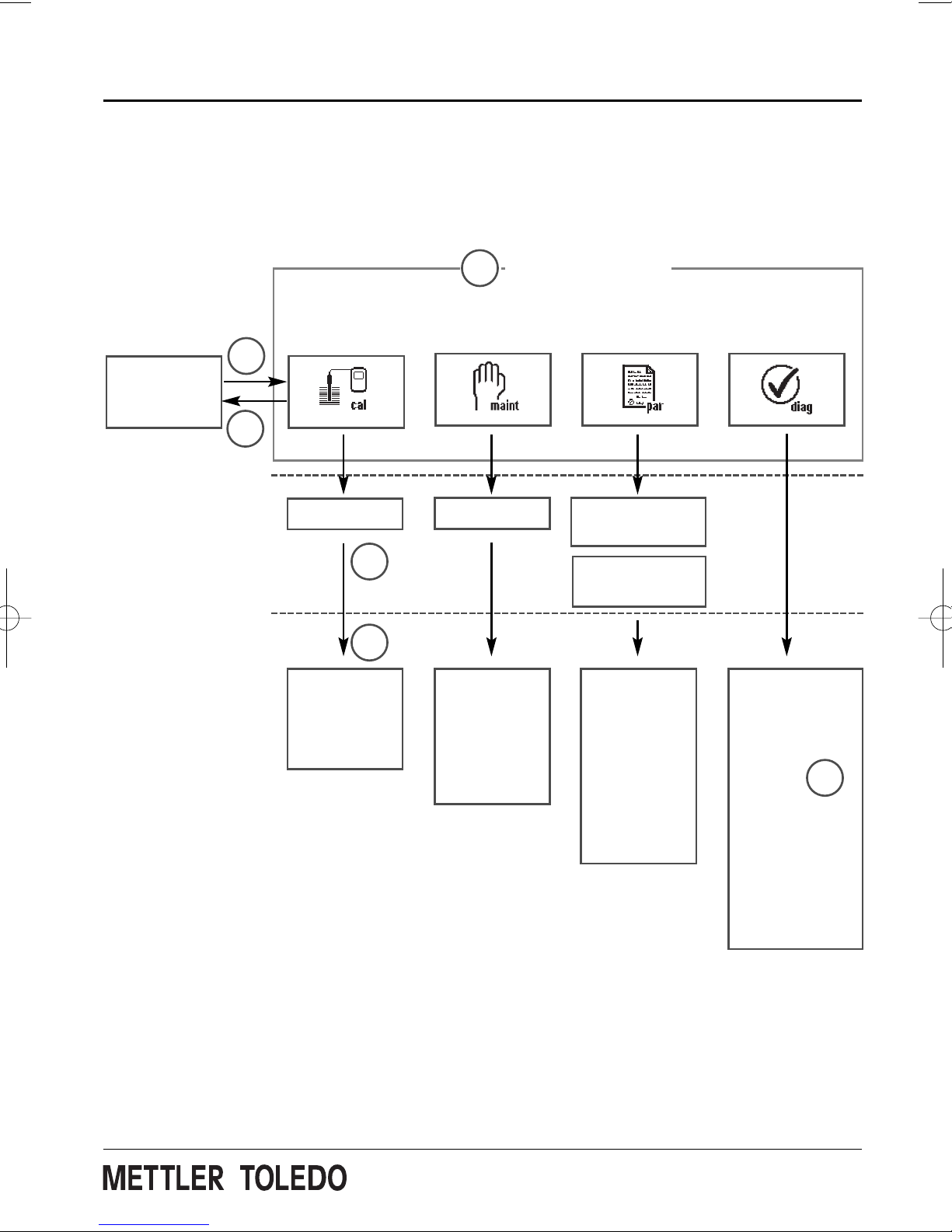

Menu structure ......................................................................................................19

Opened device, M 700 FRONT: SmartMedia card ...................................................20

Opened device, M 700 BASE: Module equipment ..................................................21

Connection of power supply

M 700 BASE 700 C/S (non-IS) ................................................................................23

M 700 BASE 700X (C/S)/VPW (IS) ...........................................................................24

M 700 BASE 700X (C/S)/24V (IS) ............................................................................25

Hazardous-area connection M 700X

Hazardous-area connection, hazardous-area components (examples) .................26

Dimension drawings

Panel mounting...................................................................................................28

Wall mounting, post mounting ...........................................................................29

Operation

Menu structure ......................................................................................................30

Menu selection.......................................................................................................31

Icons ......................................................................................................................31

How to enter numbers and text .............................................................................32

Configuring the measurement display ....................................................................34

Softkey usage (function control).............................................................................36

Favorites menu.......................................................................................................37

Selected diagnostics functions for quality management..........................................38

Diagnostics functions

Sensoface............................................................................................................39

Message list, logbook, device description ............................................................40

4

M 700(X)

Page 7

Contents

for the M 700(X) modular process analysis system

Parameter setting

Operating levels: Viewing level, Operator level, Administrator level ........................42

Parameter setting: Lock functions ..........................................................................43

Function control matrix, time/date..........................................................................44

Point of measurement, passcodes, release of options.............................................45

Inserting the SmartMedia card ...............................................................................46

SmartMedia card: Application ................................................................................47

System control: Parameter sets A, B ......................................................................48

SmartMedia card: Parameter sets ..........................................................................49

SmartMedia card: Memory card ............................................................................51

SmartMedia card: Software update ........................................................................52

SmartMedia card: Save firmware............................................................................54

SmartMedia card: Format card ...............................................................................55

SmartMedia card: Remove card..............................................................................56

Factory setting, logbook.........................................................................................57

Language, measurement display, viewing angle ....................................................58

Current outputs, contacts, OK inputs .....................................................................59

Current outputs: Current output curves .................................................................60

Current outputs: Behavior during messages ...........................................................63

NAMUR signals (failure, maintenance request, function check)..............................64

Relay contacts: Protective wiring ............................................................................65

Relay contacts: Usage.............................................................................................66

Relay contacts: Limit value, hysteresis, contact type................................................67

OK1,OK2 inputs: Switching level ............................................................................68

Switching parameter sets via OK2 ..........................................................................69

Signaling active parameter set via relay contact...................................................69

Calculation Blocks ..................................................................................................71

pH value calculation by means of dual conductivity measurement.......................73

USP function

Monitoring of ultrapure water in the pharmaceutical industry.............................75

Maintenance

Current source, Open/close memory card ...............................................................76

Specifications ....................................................................................................77

Glossary .............................................................................................................81

Index....................................................................................................................86

5

Page 8

Software version

Device software M 700(X)

Software version 6.x

Modules supported

For modules which are not listed here, refer to corresponding module

instruction manual.

Module Software version

pH 2700 (X) 2.x

pH 2700i (X) 1.x

Cond 7700(X) 2.x

Cond Ind 7700(X) 2.x

O2 4700(X) 2.x

O2 4700(X) ppb 2.x

O2 4700i(X) 1.x

O2 4700i(X) ppb 1.x

Out 700(X) 1.x

PID 700(X) 1.x

PA 700(X) 1.x

EC 700(X) 1.x

Query actual device/module software

When the analyzer is in measuring mode: press menu key, open Diagnostics

menu.

Menu Display Device description

0.003 mS/cm

22.7 °C

Device description

Module FRONT M 700-011

Operating panel M 700

Hardware: 2, Software: 6.0

Serial number: 0000815

Provides information about all modules installed: Module type and function, serial number, hardware and

software version and device options.

Select the different modules (FRONT,

Module

FRONT

Return

BASE

Options

BASE, slots 1 - 3) using the arrow

keys.

6

M 700(X)

Page 9

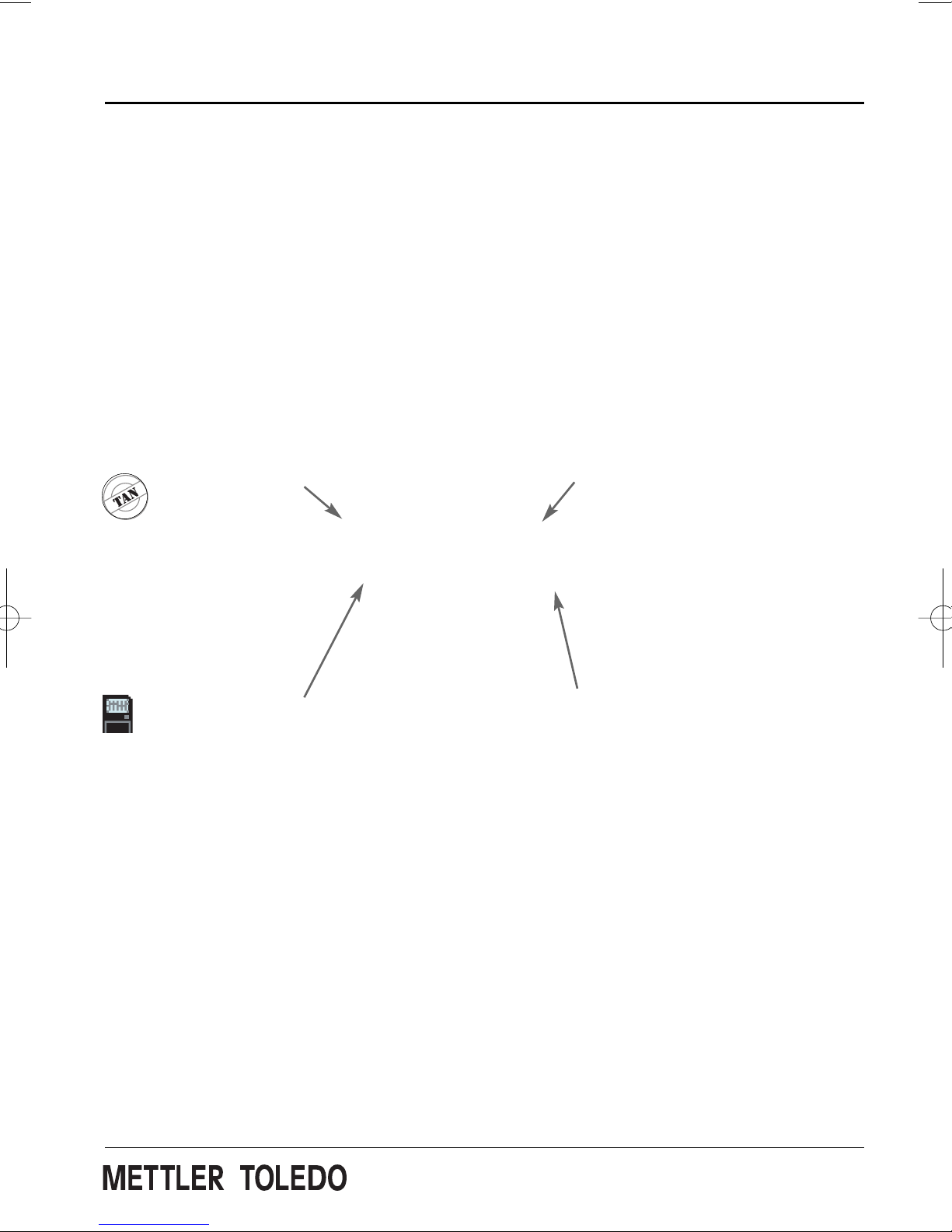

Modular concept and instruction manuals

Instruction manuals for basic unit, measuring module, additional functions.

The M 700(X) is an expandable modular process analysis system.

The basic unit (M 700(X) FRONT and M 700(X) BASE) provides three slots

which can be equipped by the user with any combination of measuring or

communication modules. The software capabilities can be expanded by additional functions (options). Additional functions must be ordered separately.

They are supplied with a device-specific TAN for function release.

M 700(X) modular process analysis system

n

o

i

t

Additional functions

p

O

Activation via device-

e

l

b

a

r

it

e

f

t

o

r

specific TAN

Measuring modules

• pH / ORP / Temp

•02/Temp

• Noncontacting conductivity / Temp

• Contacting conductivity / Temp

SmartMedia card

Data recording

3 module slots

for free combination of

measuring and

communication modules

Communication modules

• Out 700 (additional switching and

current outputs)

• PID 700 (analog and digital controller)

•PA 700 (Profibus PA)

• The instruction manual for the M 700(X) describes how to install,

commission and operate the basic unit.

• The instruction manual for the measuring or communication module

describes all functions required for commissioning and working with

the respective measuring or communication module.

• Additional functions are supplied with a function description.

7

Page 10

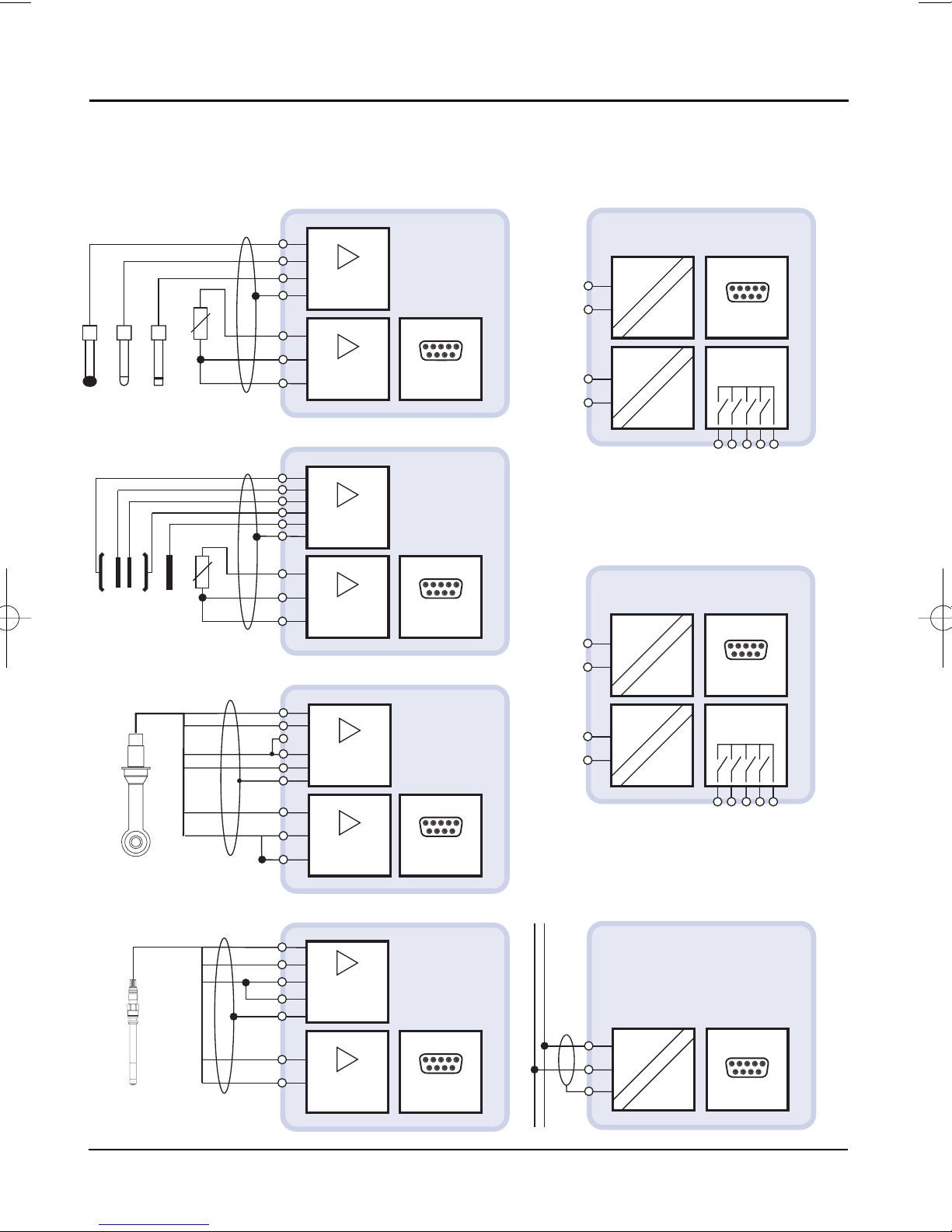

System overview

M 700(X) modular process analysis system:

Measuring modules and communication modules

pH 2700(X)

module

pH, ORP

MΩ, kΩ

I 3

mA

Out 700(X)

module

Interface

Glass

2 EL / 4 EL

Reference

ORP

RTD

RTD

Temp

µS, mS/cm

% by wt

Temp

µS, mS/cm

% by wt

Interface

Cond 7700(X)

module

Interface

Cond Ind

7700(X)

module

I 4

IV 1

IV 2

mA

mA

mA

Electronic

contacts

PID 700(X)

module

Interface

Electronic

contacts

Electrodeless sensor

O2, %

µg/l, ppb

mg/l, ppm

O2 sensor

8

Temp

Temp

Interface

O2 4700(X)

O2 4700(X) ppb

module

Interface

PA 700(X)

module

PROFIBUS-PA

COMPA

Interface

M 700(X)

Page 11

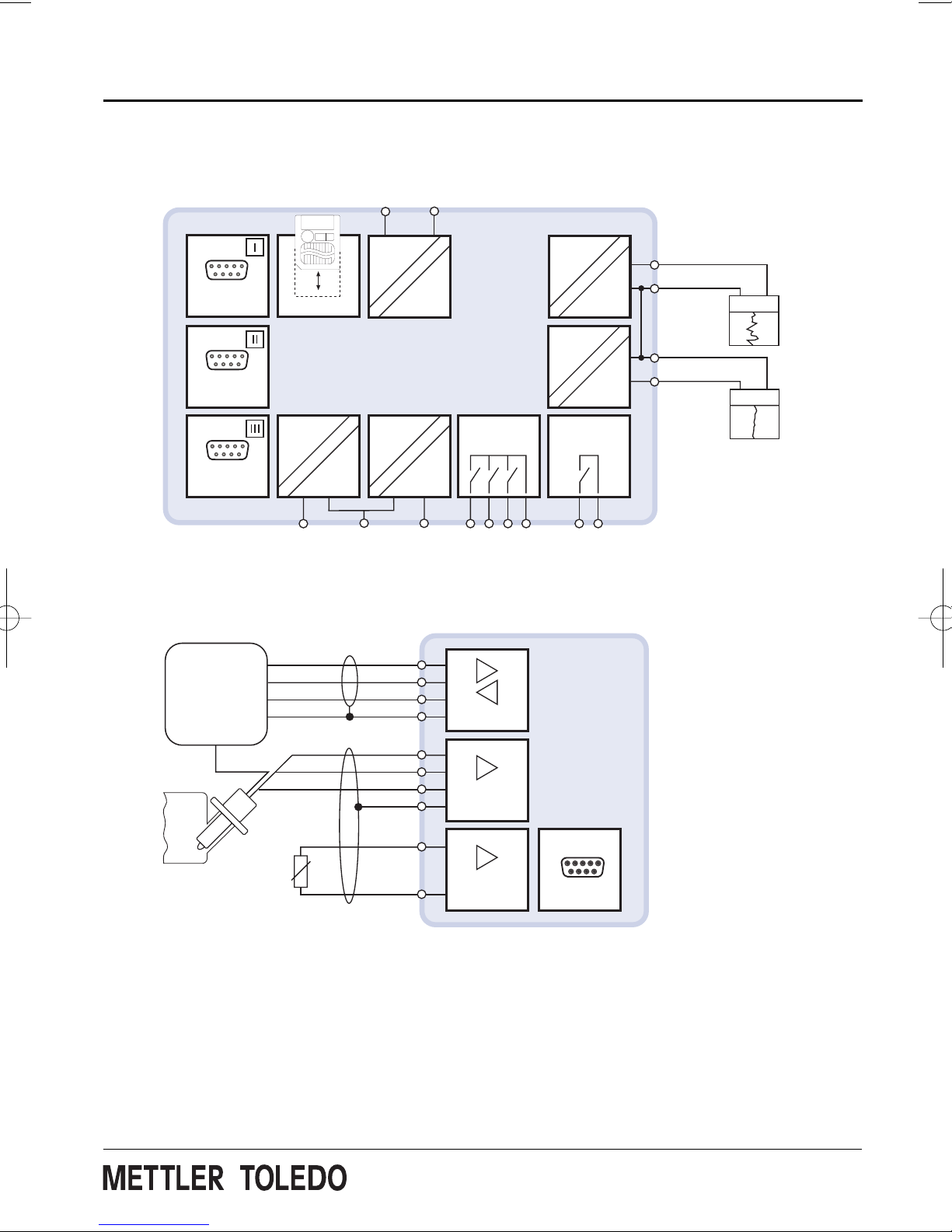

System overview

M 700(X) modular process analysis system:

Basic unit and control module for retractable housings

Module

slot

Module

slot

Module

slot

EC 400(X)

SMARTMEDIA

OK 1

VariPower

M 700 (X)

OK 2

Contacts

K1, K2, K3

I 1

I 2

Alarm

K4

EC 700(X)

mA

mA

0(4) ... 20 mA

pH

0(4) ... 20 mA

Temp

Probe

RTD

EC 400(X)

pH, ORP

MΩ, kΩ

Temp

Interface

9

Page 12

Latest product information

Additional functions

The M 700(X) is an expandable modular process analysis system.

For latest product information, please refer to:

www.mtpro.com

Additional functions

A current version of the respective function description is available as pdf for

download.

10

M 700(X)

Page 13

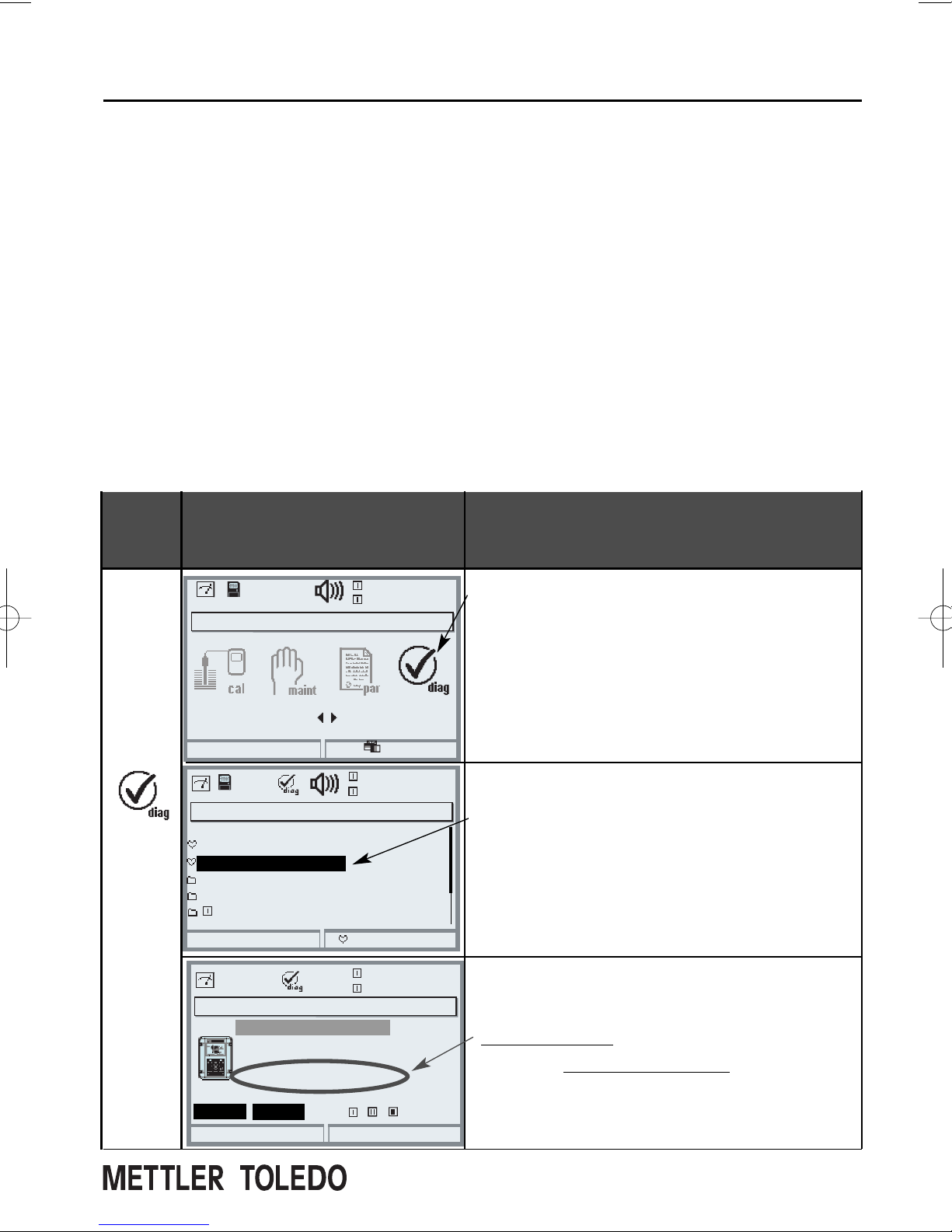

How to order an additional function

Device-specific TAN (transaction number)

Additional functions expand the device capabilities.

The additional functions are device-specific. When ordering an additional

function, you therefore have to specify the serial number and hardware

version of your FRONT module in addition to the respective order number.

The manufacturer then supplies a TAN (transaction number) to release the

additional function.

Serial number M 700 FRONT

Menu

Display Serial number M 700 FRONT

0.002 mS/cm

23.7 °C

Menu selection

Menu selection

Call up diagnostics.

From the measuring mode:

Press menu key to select menu.

Select diagnostics using arrow keys,

Select:

[enter]

confirm with enter.

Return to meas

Diagnostics

Message list

Logbook

Device description

M 700 FRONT

M 700 BASE

Module Cond Ind 7700

Return

Device description

Module FRONT 700-011

Operating panel M 700

Hardware: 2, Software: 6.0

Serial number: 0000815

Lingua

0.003 mS/cm

23.7 °C

Set favorite

0.003 mS/cm

22.7 °C

Diagnostics

Select Device description using arrow

keys, confirm with enter.

Device description

Please specify this

serial number

and the hardware version when

ordering an additional function.

Module

FRONT

Return

BASE

11

Page 14

Intended use

The M 700(X) modular process analysis system is preferably used to measure

and process electrochemical quantities in liquids. It has a modular design and

consists of the BASE power supply unit, the FRONT door and different measuring and communication modules.

The M 700X is intended for operation in locations subject to explosion hazards which require equipment of Group II, device category 2(1), gas/dust.

The M 700(X) is a flexible measuring system for continuous measurements in

the field of liquid analysis. Thanks to its modular design, the M 700(X) can

easily be adapted to your measuring task. Flexible use of plug-in modules

allows combined measurements as well as later expansions or modifications.

The measured variables depend on the measuring modules installed.

Communication modules are available for further processing of the output

signals. The rugged enclosure (IP 65) can be wall or pipe mounted or fixed

into a control panel. The M 700 version with hygienic, polished stainless steel

enclosure allows application in the field of biotechnology, food processing,

and in the pharmaceutical industry. The M 700 version with coated steel

enclosure – extremely corrosion resistant – has been developed for application in the chemical industry, environmental engineering, water and wastewater treatment, and for application in power plants .

Caution!

Never expose the display to direct sun light! Only operate the display within

the temperature range of 0 °C up to 50 °C max.

Package contents

• M 700(X) basic unit (FRONT and BASE)

• Wall-mount kit

• Test Certificate

• This instruction manual

• EC Declaration of Conformity

• EC-Type-Examination Certificate (M 700X)

Modules as ordered (each in a separate package with Instruction Manual,

Test Certificate, EC Declaration of Conformity):

12

M 700(X)

Page 15

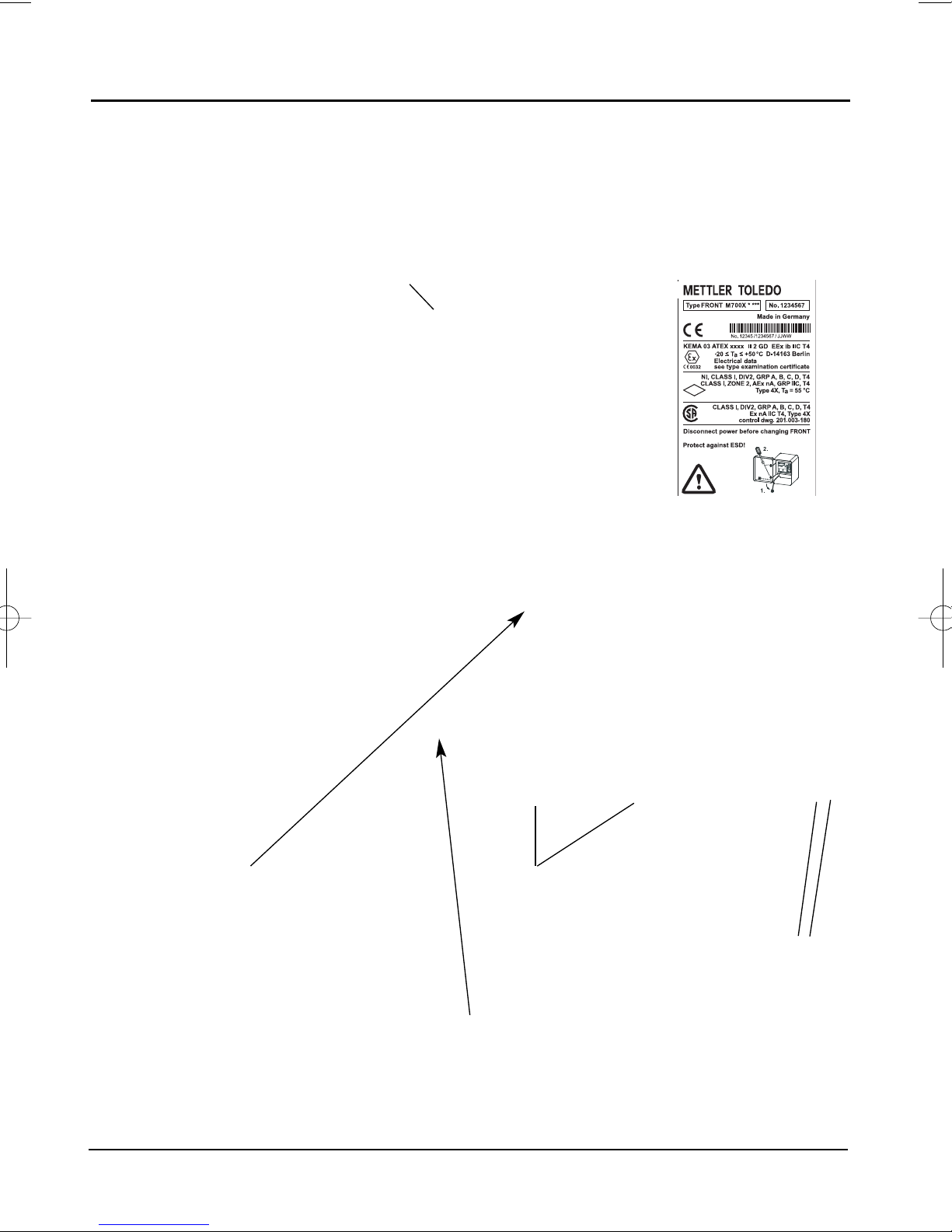

Safety information

Application in hazardous locations

M 700X modular process analysis system

The M 700X modular process analysis system is intended for operation in

specific environments and specific fields of application. These are listed in the

instruction manual as specifications for environment, installation and commissioning, intended use (= application), assembly and dismantling, and

maintenance.

Observe the influences of humidity, ambient temperature, chemicals and corrosion. If the specifications in the instruction manual are not sufficient for

assessing the safety of operation, e.g. because your specific applications are

not described, please contact the manufacturer to make sure that the application is possible and safe.

Prerequisite to safe use of the equipment is the observance of the specified

ambient conditions and temperature ranges.

When using the M 700X modular process analysis system, the stipulations

for electrical installations in hazardous areas (EN 60079-14) must be

observed. When installing the device outside the range of applicability of the

94/9/EC directive, the appropriate standards and regulations in the country

of use must be observed.

The module has been developed and manufactured in compliance with the

applicable European guidelines and standards. Compliance with the

European Harmonized Standards for use in hazardous locations is confirmed

by the EC-Type-Examination Certificate. Compliance with the European

guidelines and standards is confirmed by the EC Declaration of Conformity.

The EC Declaration of Conformity and the EC-Type-Examination Certificate

are included in the instruction manual.

There is no particular direct hazard caused by the operation of the device in

the specified environment.

13

Page 16

Safety information

During operation, the M 700(X)

modular process analysis system

may be opened briefly to replace

the SmartMedia card. The mains terminal cover must be opened only

when the unit is de-energized.

Installation:

The power supply must be disconnectable using a 2-pole disconnect

switch installed near the M700(X).

This switch must meet the requirements of EN 60947-1 and EN 60947-3,

be marked as disconnecting device for M 700(X) and be easily accessible by

the user.

Information on commissioning/start-up

Caution!

• Before commissioning it must be proved that the device may be

connected with other equipment.

• Commissioning must only be performed by authorized and trained personnel!

• The combination of hazardous-area and safe-area modules

(mixed configuration) is not permitted.

Whenever it is likely that protection has been impaired, the device shall be

made inoperative and secured against unintended operation. The protection is

likely to be impaired if, for example:

• the device shows visible damage

• the device fails to perform the intended measurements

• after prolonged storage at temperatures above 70 °C

• after severe transport stresses

Before recommissioning the device, a professional routine test in accordance

with EN 61010-1 must be performed. This test should be carried out by the

manufacturer.

14

M 700(X)

Page 17

Conformity with FDA 21 CFR Part 11

In their directive “Title 21 Code of Federal Regulations, 21 CFR Part 11,

Electronic Records; Electronic Signatures” the US American health agency

FDA (Food and Drug Administration) regulates the production and processing

of electronic documents for pharmaceutical development and production.

This results in requirements for measuring devices used for corresponding

applications. The following features ensure that the M 700(X) modular

process analysis system meets the demands of FDA 21 CFR Part 11:

Electronic Signature

Access to the device functions is regulated and limited by individually

adjustable codes – “Passcodes”. This prevents unauthorized modification of

device settings or manipulation of the measurement results. Appropriate use

of these passcodes makes them suitable as electronic signature.

Audit Trail Log

Every change of device settings can be automatically recorded and documented in the Audit Trail Log on the SmartMedia card. The recording can be

encoded.

15

Page 18

Product line

Device (Standard version) Order No.

––––––––––––––––––––––––––––––– l––––––––––––––––––––––––––––––––––––––

l

M 700 S Basic unit, stainless steel enclosure 52121174

M 700 C Basic unit, coated steel enclosure 52121171

pH 2700 Module: pH 52121182

pH 2700i Module: pH, ISM 52121161

Cond 7700 Module: Conductivity 52121184

Cond Ind 7700 Module: Electrodeless cond. 52121186

O

4700 Module: Oxygen (standard) 52121188

2

O

4700 ppb Module: Oxygen (traces) 52121190

2

O

4700i Module: Oxygen (standard, ISM) 52121163

2

O

4700i ppb Module: Oxygen (traces, ISM) 52121165

2

Out 700 Module: Output expansion 52121177

PA 700 Module: Profibus PA 52121210

PID 700 Module: PID controller 52121179

–––––––––––––––––––––––––––

l

Device (hazardous-area version) Order No.

––––––––––––––––––––––––––––––– l––––––––––––––––––––––––––––––––––––––

l

–––––––––––––––––––––––––––

l

M 700X S/VPW Basic unit, stainless steel enclosure 52121175

with VariPower power supply unit

M 700X S/24V Basic unit, stainless steel enclosure 52121176

with 24 V power supply unit

M 700X C/VPW Basic unit, coated steel enclosure 52121172

with VariPower power supply unit, AC

M 700X C/24V Basic unit, standard enclosure 52121173

with 24 V power supply unit, AC/DC

pH 2700X Module: pH 52121183

pH 2700X Module: pH 52121162

Cond 7700X Module: Conductivity 52121185

Cond Ind 7700X Module: Electrodeless cond. 52121187

O

4700X Module: Oxygen (standard) 52121189

2

O

4700X ppb Module: Oxygen (traces) 52121191

2

O

4700iX Module: Oxygen (standard, ISM) 52121164

2

O

4700iX ppb Module: Oxygen (traces, ISM) 52121166

2

Out 700X Module: Output expansion 52121178

PA 700X Module: Profibus PA 52121181

PID 700X Module: PID controller 52121180

16

M 700(X)

Page 19

Additional functions Order No.

–––––––––––––––––––––––––––––––––––––––

l

––––––––––––––––––––––––––––––––––––––l–––––––––––––––––––––––––––

l

KI recorder TAN SW 700-001 52121198

Buffer sets to be entered (pH) TAN SW 700-002 52121199

Adaptive cal timer (pH) TAN SW 700-003 52121200

ServiceScope (pH) TAN SW 700-004 52121201

Tolerance band recorder (pH) TAN SW 700-005 52121202

Current characteristic definable TAN SW 700-006 52121203

TC ultrapure water (Cond) TAN SW 700-008 52121204

Concentration determination (Cond) TAN SW 700-009 52121205

High CO

compensation (O2)TAN SW 700-011 52121250

2

ISFET for module pH 2700i(X) TAN SW 700-012 52121274

5 loadable parameter sets TAN SW 700-102 52121192

Measurement recorder TAN SW 700-103 52121193

Extended logbook TAN SW 700-104 52121194

Software update TAN SW 700-106 52121195

AuditTrail to FDA 21 CFR Part 11 AuditTrail card/TAN, SW 700-107 52121196

Accessories Order No.

–––––––––––––––––––––––––––––––––––––––

l

––––––––––––––––––––––––––––––––––––––l–––––––––––––––––––––––––––

l

SmartMedia card ZU 0543 52121207

Pipe-mount kit ZU 0544 52121208

Panel-mount kit ZU 0545 52121209

VP input socket 52201114

17

Page 20

Short description: M 700 FRONT

M 700

Modular hardware and software system for liquid analysis.

4 captive scews

for opening the analyzer

(Caution! Make sure that the gasket

between FRONT and BASE is properly seated and clean!)

Transflective LC graphic display

(240 x 160 pixels)

white backlighting, high resolution

and high contrast.

Measurement display

For parameter setting, see Pg 35

User interface

with plaintext menus as recommended by NAMUR.

Menu texts can be switched to:

German, English, French, Italian,

Swedish, and Spanish.

Intuitively acquirable menu logic,

based on Windows standards.

Secondary displays

For parameter setting, see Pg 36

Control panel

3 function keys

(menu, meas, enter)

and 4 arrow keys for menu selection

and data entries

2 softkeys

with context-sensitive functions.

Red LED

signals failure (On) or

maintenance request/function check

(flashing) according to NE 44.

Green LED

Voltage supply okay

5 self-sealing cable glands

M20 x 1.5

for entry of voltage supply and signal lines

18

M 700(X)

Page 21

Short description: Menu structure

Basic functions: Calibration, maintenance, parameter setting, diagnostics

Measuring

Passcode:

Selection of

further

menu items:

3

Calibration Maintenance Parameter setting Diagnostics

1

2

1147

4

5

Module 1

Module 2

Module 3

2958

BASE

Module 1

Module 2

Module 3

Menu groups

1246

Operator level

1989

Admin. level

SYSTEM

FRONT

BASE

Module 1

Module 2

Module 3

Message list

Meas. point

description

Logbook

Device description

6

FRONT

BASE

Module 1

Module 2

Module 3

Legend:

(1) Pressing the menu key accesses menu selection

(2) Pressing the meas key returns to measurement

(3) Menu groups are selected using the arrow keys

(4) Press enter to confirm, enter passcode

(5) Further menu items are displayed

(6) Selected functions of the Diagnostics menu can be

recalled via softkey even when in measuring mode (Pg 34)

19

Page 22

Short description: M 700 FRONT

M 700

View into the open device (M 700 FRONT)

Slot for SmartMedia card

• Data recording

The SmartMedia card expands the

measurement recorder capacity to

> 50000 records.

• Exchange of parameter sets

5 parameter sets can be stored

on the SmartMedia card, 2 of them

can be loaded to the M 700

and switched by remote control.

Configurations can be transferred

from one M 700 to the other.

• Function expansions

are possible with additional software

modules which are released using

transaction numbers (TAN).

• Software updates

Terminal plates

of “hidden” modules

Each module comes with an adhesive

label containing the contact assignments.

This label should be sticked to the inner

side of the front (as shown).

Then, the terminal assignments remain

visible even if further modules are

inserted.

Replacing the front module

Pull off power cord and ground wire.

To separate the M 700 FRONT from

the M 700 BASE, turn the retaining screws

of the pivot hinge by 90°.

The circumferential sealing

guarantees IP 65 protection and allows spray

cleaning / disinfection.

Caution! Keep clean!

20

M 700(X)

Page 23

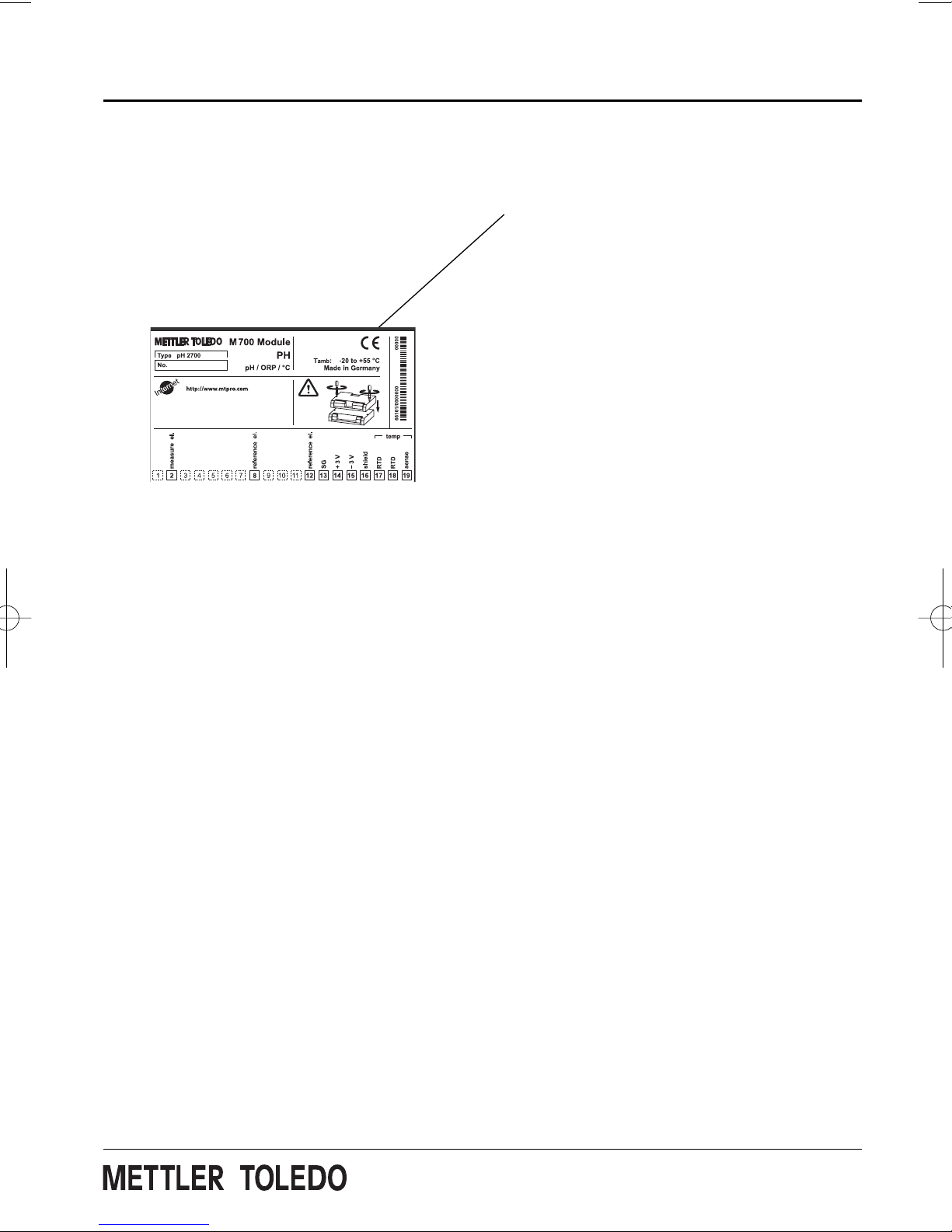

Short description: M 700 BASE

M 700

View into the open device (M 700 BASE, 3 function modules installed)

Module equipment

Module identification: Plug & Play

Up to 3 modules can be combined as

desired. Several input and communication

modules are available

(Overview on Page 16)

M 700 BASE

2 current outputs (free assignment of

process variable) and 4 relay contacts,

2 digital inputs.

VariPower broad-range power supply

unit, 20 ... 265 V AC/DC, suitable for all

public mains supplies in the world.

Power supply units, IS version:

100 ... 230 V AC or

24 V AC/DC

Warning!

Do not touch the terminal compartment, there may be

dangerous contact voltages!

Important note concerning SmartMedia card

The SmartMedia card may be inserted or replaced with the power supply

switched on. Before a memory card is removed, it must be “closed” in the

maintenance menu. When closing the device, make sure that the sealing is

properly seated and clean.

21

Page 24

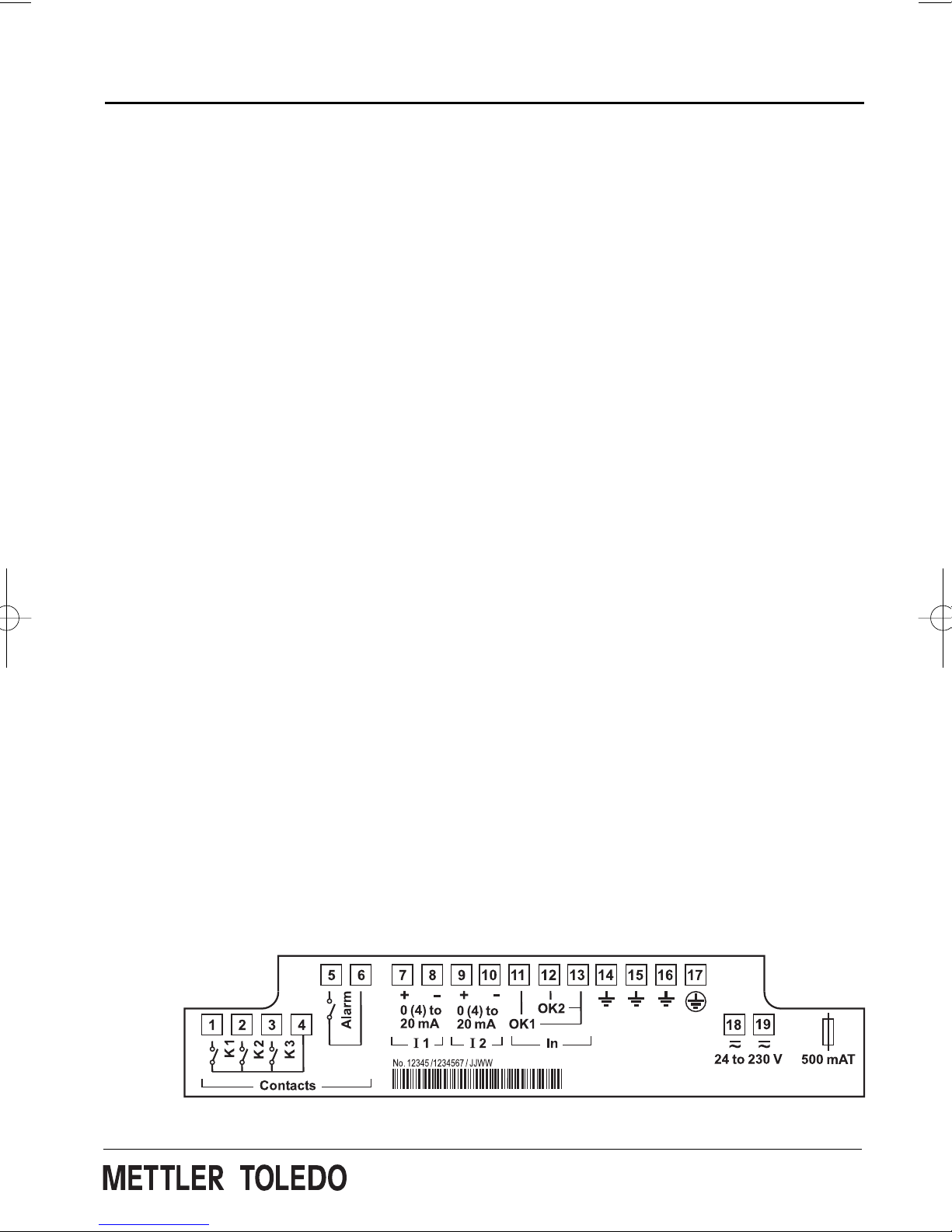

Connection of power supply

Module M 700 C / M 700 S (non-IS)

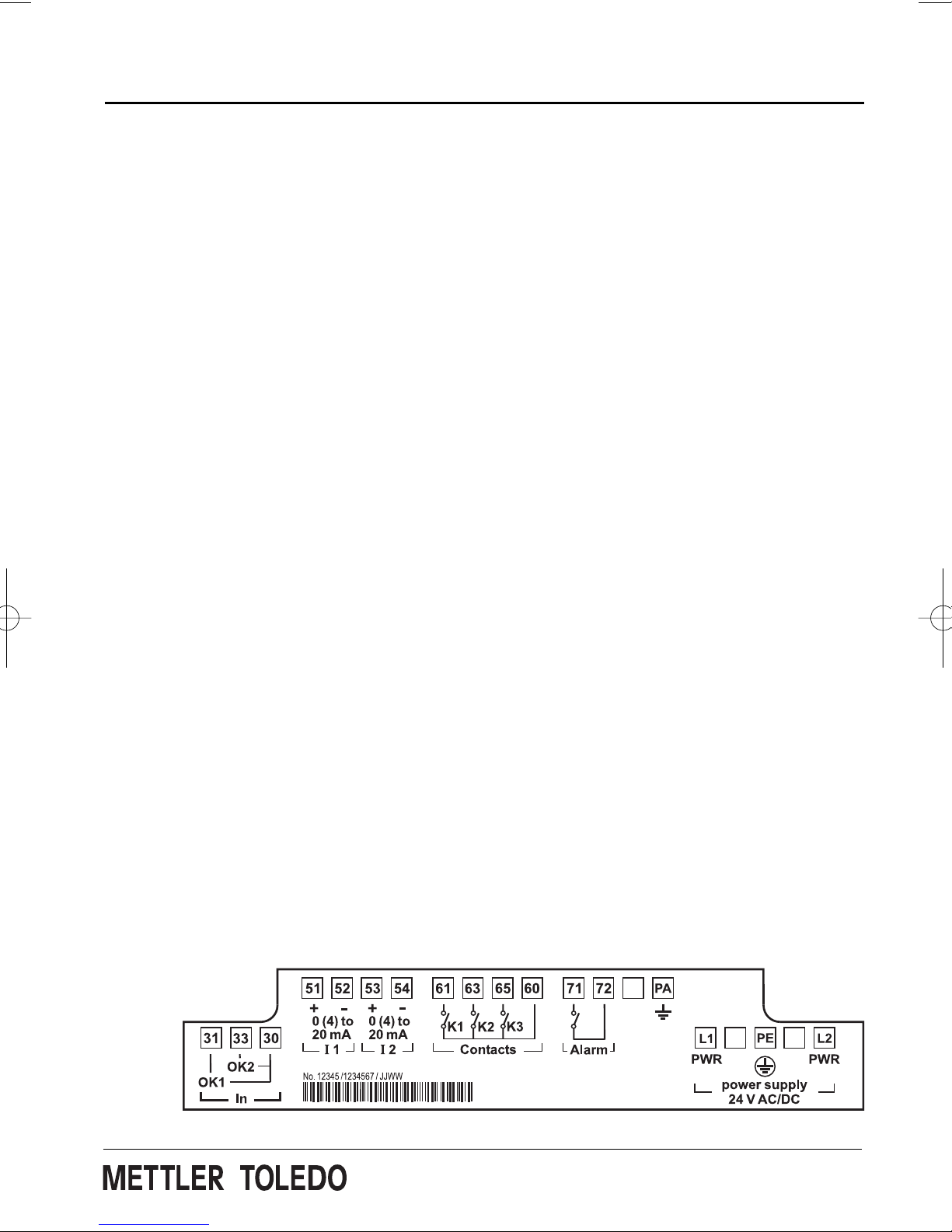

Connection of power supply (BASE M 700 C / M 700 S, non-IS)

The M 700(X) comes in three different versions.

The terminal plates and wirings are shown on the following pages.

1. BASE M 700 C / M 700 S (standard version, non-IS)

VariPower broad-range power supply unit, 24 (-15 %) ... 230 (+15%) V AC/DC

2. BASE M 700X C/VPW / M 700X S/VPW (IS version)

VariPower broad-range power supply unit

3. BASE M 700X C/24V / M 700X S/24V (IS version)

24 V power supply unit

22

M 700(X)

Page 25

1. BASE M 700 C / M 700 S (non-IS)

Standard version. Not suitable for hazardous-area applications!

Information on installation

Caution!

• Installation may only be carried out by trained and authorized

experts in accordance with this instruction manual and as per

applicable local and national codes.

• Be sure to observe the technical specifications and input ratings.

• Be sure not to notch the conductor when stripping the insulation.

• All parameters must be set by the system administrator

prior to commissioning.

Connection of power supply

With the VariPower broad-range power supply unit, the analyzer can

be operated with a power supply of 24 (-15 %) to 230 (+15 %)

V AC/DC making it suitable for all public mains supplies in the

world.

The terminals are suitable for single wires and flexible leads up to

2

2.5 mm

Terminal plate BASE M 700

Standard version. Not suitable for hazardous-area applications!

Connection of power supply. Contact assignment of inputs/outputs.

(AWG 14).

23

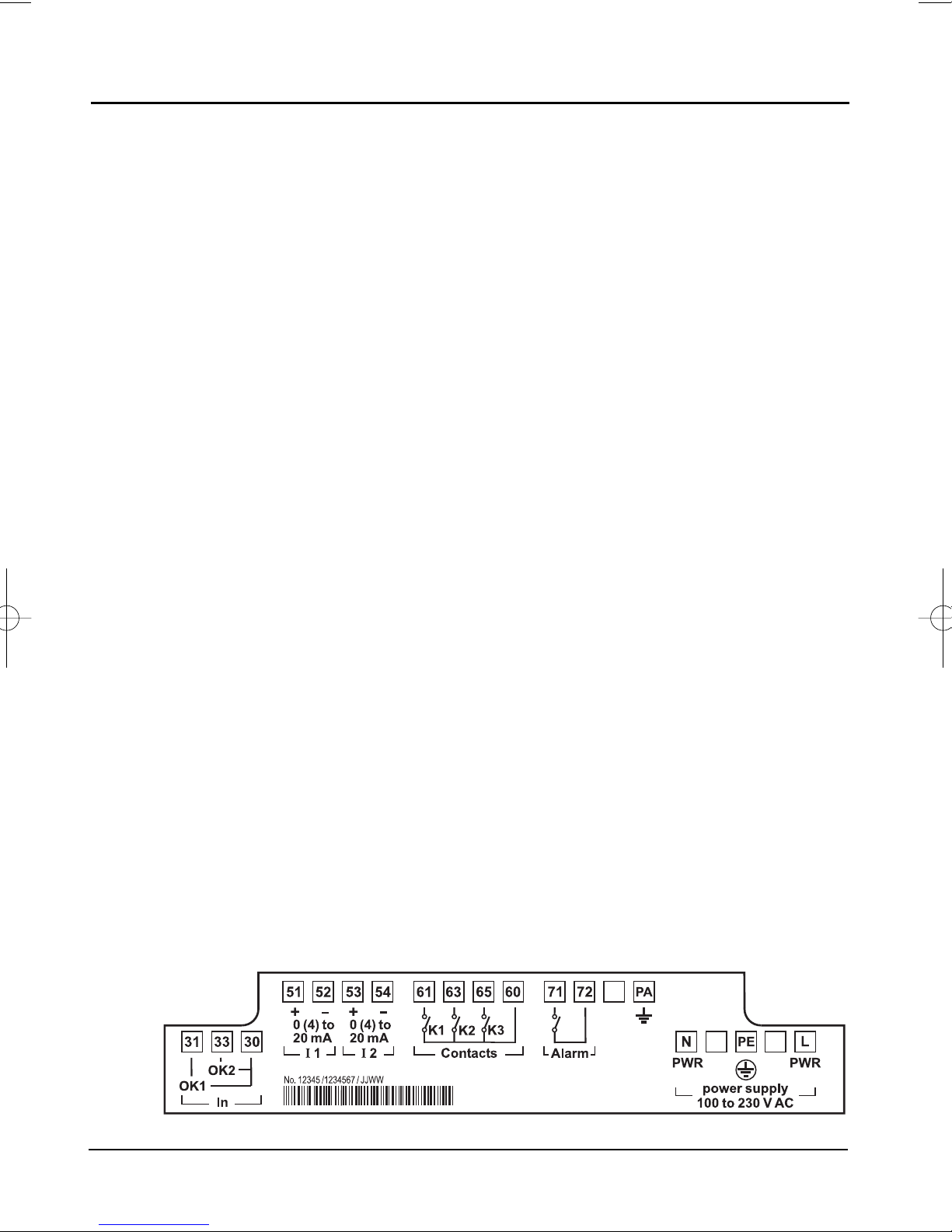

Page 26

2. BASE M 700X C/VPW / M 700X S/VPW

IS version with VariPower power supply unit

Information on installation

When using the M 700X modular process analysis system, the stipulations for electrical installations in hazardous areas (EN 60079-14) must

be observed. When installing the device outside the range of applicability of the 94/9/EC directive, the appropriate standards and regulations in the country of use must be observed.

Caution!

• Installation may only be carried out by trained and authorized experts

in accordance with this instruction manual and as per applicable local

and national codes.

• Be sure to observe the technical specifications and input ratings.

• Be sure not to notch the conductor when stripping the insulation.

• All parameters must be set by the system administrator prior to

commissioning.

Connection of power supply

With the VariPower broad-range power supply unit, the analyzer can

be operated with a power supply of 100 to 230 V AC (-15 %, +10 %)

(EEx em IIC).

The terminals are suitable for single wires and flexible leads up to

2

2.5 mm

Terminal plate BASE M 700X C/VPW / M 700X S/VPW

(IS version with VariPower power supply unit)

Connection of power supply. Contact assignment of inputs/outputs.

(AWG 14).

24

M 700(X)

Page 27

3. BASE M 700X C/24V / M 700X C/24V

IS version with 24 V power supply unit

Information on installation

When using the M 700X modular process analysis system, the stipulations for electrical installations in hazardous areas (EN 60079-14) must

be observed. When installing the device outside the range of applicability of the 94/9/EC directive, the appropriate standards and regulations in the country of use must be observed.

Caution!

• Installation may only be carried out by trained and authorized

experts in accordance with this instruction manual and as per

applicable local and national codes.

• Be sure to observe the technical specifications and input ratings.

• Be sure not to notch the conductor when stripping the insulation.

• All parameters must be set by the system administrator

prior to commissioning.

Connection of power supply

With the power supply unit, the analyzer can be operated with a

power supply of 24 V AC (-15 %, +10%) or 24 V DC (-15 %, +20%).

The terminals are suitable for single wires and flexible leads up to

2

2.5 mm

Terminal plate BASE M 700X (C/S)/24V

(IS version with 24 V power supply unit)

Connection of power supply. Contact assignment of inputs/outputs.

(AWG 14).

25

Page 28

Hazardous-area connection M 700X

24 V

GND

24 V

GND

Logic input

Logic input

Safe area

A

A

B

B

B

Hazardous

area

31

33

30

61

63

65

60

M 700X

OK1

OK1

OK1 ... OK2

K1

K2

K3

K1 ... K3

B

0/4 ... 20 mA

0/4 ... 20 mA

Mains connection: laid in Ex „e”

C

C

71

72

51

52

53

54

L1

PE

L2

K4 (Alarm)

I1

I2

Ex „i”

N

L

Ex „e”

26

M 700(X)

Page 29

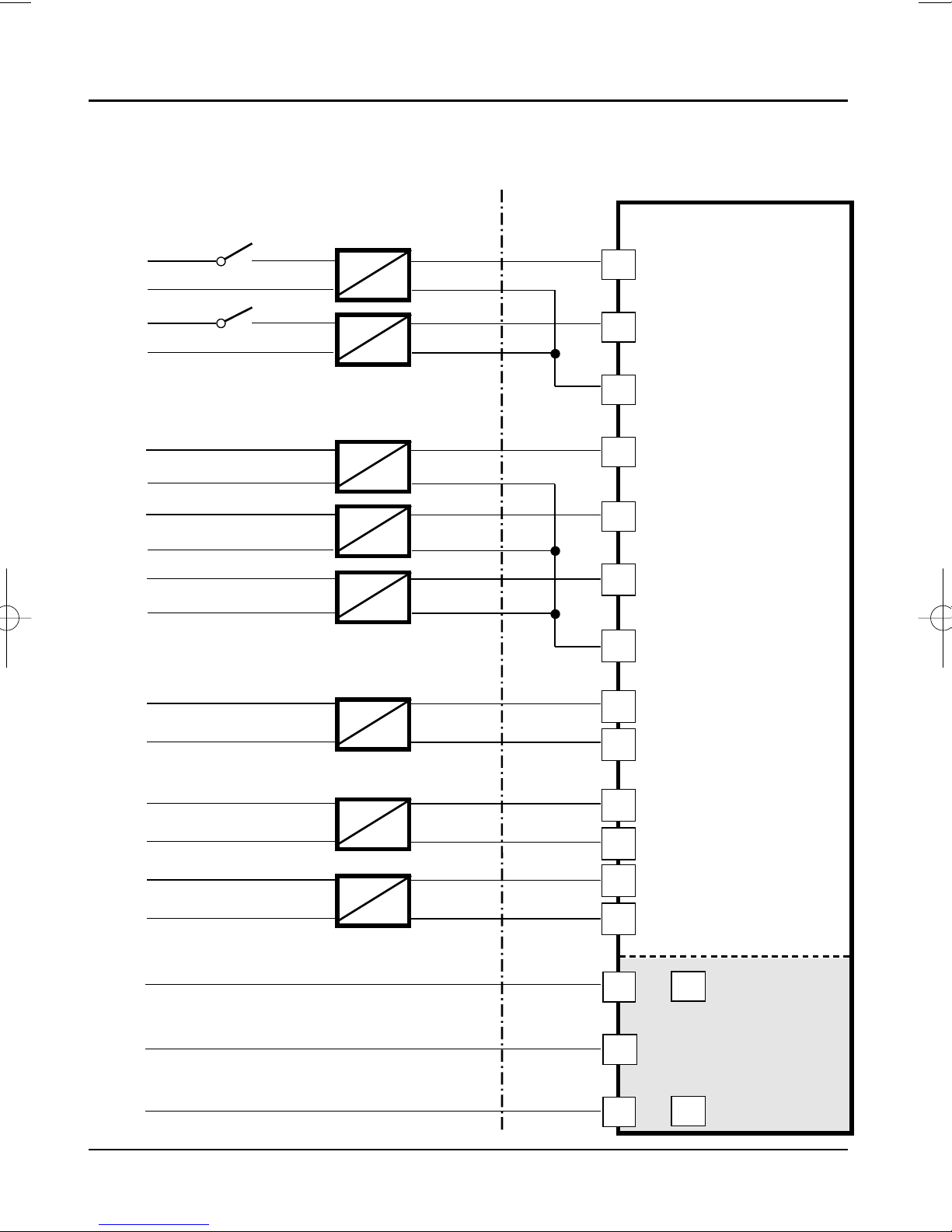

Hazardous-area control modules (examples)

Designation Model Manufacturer

Valve control module KFD2-SL-Ex 1.48**** Pepperl + FuchsA

Valve control module MK 72-S17-Ex0/24VDC TURCK

Switch amplifier KF**-SR2-Ex1.W.** Pepperl + FuchsB

Switch amplifier MK1-22Ex0-R/** TURCK

Loop-powered isolator IsoTrans®36A7 KnickC

27

Page 30

Panel mounting

Dimension drawings

159,5

Front view

45,5

163

72

147,5

39,5

213

Side view

144

70,5

28

M6 internal (4x)

Rear view

141

72

189

194

r15 ± 3

Control panel cutout

Contour

of

enclosure

Control

panel cutout

Contour of

enclosure

front

M 700(X)

Page 31

Wall mounting, pipe mounting

Dimension drawings

Ø 30 ... 65

72

Ø 6.5 (4x)

72

150

Wall mounting

Ø 30 ... 65 mm

for vertical or horizontal mounting

Pipe mounting

Ø 30 ... 65 mm

Ø 30 ... 40 mm

Ø 40 ... 62 mm

Ø 62 ... 65 mm

M6x50

X

M6x70

X

X

without nut

ZU 0544 pipe-mount kit

29

Page 32

Menu structure

M 700 FRONT

Measuring

Passcode:

(here:

factory setting)

Selection of

further

menu items:

3

Calibration Maintenance Parameter setting Diagnostics

1

2

1147

4

5

Module 1

Module 2

Module 3

2958

BASE

Module 1

Module 2

Module 3

Menu groups

1246

Operator level

1989

Admin. level

SYSTEM

FRONT

BASE

Module 1

Module 2

Module 3

Message list

Point of

measurement

Logbook

Device description

FRONT

BASE

Module 1

Module 2

Module 3

6

Legend:

(1) Pressing the menu key accesses menu selection

(2) Pressing the meas key returns to measurement

(3) Menu groups are selected using the arrow keys

(4) Press enter to confirm, enter passcode

(5) Further menu items are displayed

(6) Selected functions of the Diagnostics menu can be

recalled via softkey even when in measuring mode (Pg 34)

30

M 700(X)

Page 33

man

Menu selection

M 700 FRONT

After switching on, the M 700 performs an internal test routine and

automatically detects the number and

type of modules installed. Then,

the M 700 goes to measuring mode

(Pg 34).

• Configure measurement display (7)

Pg 34

• Secondary displays/softkeys (8)

Pg 36

Menu selection

(1) Pressing the menu key accesses menu selection

(2) Pressing the meas key returns to measurement

1

Menu selection

01.02.03

2

7.00

25.6 °C

1

7

pH

8

3

4

7.00 pH

25.6 °C

7.00

13.20

24.3°C

(Measuring mode)

Select the desired menu group using the arrow keys (3).

Press enter (4) to confirm your choice.

An overview of the menu structure is given on Pg 30.

pH

%Air

1014 mbar

2

Select:

Return to meas

(Menu selection)

[enter]

Lingua

31

Page 34

Mode indicators in the display

Icons

The plain-text user interface is supplemented by icons which provide

information on the operating status:

HOLD

Function check is active

SmartMedia card

located in M 700 FRONT

Mode indicator

Parameter setting

Module BASE (Administrator)

Output current I1

Output current I2

Contact K4

Contact K3

Contact K2

Contact K1

Return

(NAMUR Failure)

(NAMUR maintenance)

(NAMUR function check)

(Limit)

0.003 mS/cm

19.0 °C

Block

Module identification

After a menu has been called up, the currently measured values of the respective modules

are displayed here. (number of module slot,

no module designation)

Menu level (Administrator level)

Current selection

is displayed in reverse video.

(Parameters represented in gray cannot be

edited, they have been blocked at the

Administrator level.)

Safety of operation

To ensure increased safety of operation, the

M 700 provides three operating levels:

• Administrator level

Access to all device parameters.

Settings can be blocked against access

from the Operator level.

• Operator level

Access to all functions which have been

released at the Administrator level.

Blocked functions are displayed in gray and

cannot be edited.

•Viewing level

Display of all settings.

No editing possible.

32

M 700(X)

Page 35

How to enter numbers and text

M 700 FRONT: Operation

Select the position using the left/right keys,

then edit the number or letter using the up/down keys.

Confirm with enter.

Example:

Entering a tag number (point of measurement)

• Open the menu selection (menu)

• Select parameter setting

• Administrator level, enter passcode

• Select point of measurement:

0.003 mS/cm

25.6 °C

Point of measurement (Administrator)

Enter 0...9A...Z-+/

using [ ] [ ]

Meas.point

Note

Abort

M402.......................M402.......................

MAINT...07/01/02...

OK

Point of measurement

(“Meas. point description”)

You can enter a tag number for the

measurement point and notes

using the arrow keys.

Function

which is assigned to the softkey

underneath.

Arrow keys

For selection of menu lines or entry of

letters and numbers.

meas menu

enter

33

Page 36

Configuring the measurement display

Select menu: Parameter setting/M 700 FRONT/Measurement display

Pressing meas (1) returns the M 700 to the measuring mode from any

function. (Pressing meas in measuring mode, successively displays the

activated special functions such as measurement recorder or KI recorder).

All process variables coming from the modules can be displayed. The table

on the next page describes how to configure the measurement display.

Measurement display

Typical measurement display

, pH modules)

(O

2

7.00

13.20

24.3°C

1

pH

%Air

1014 mbars

Secondary displays

Additional values, also date and

time, can be displayed depending

on the modules installed. They

are selected using the softkeys

(Pg 36).

Softkeys

The softkeys allow selection of

values for the secondary displays.

In addition, Diagnostics functions

which are set as “Favorites” can

be called up.

(Pg 37)

If required, you can also change

the parameter set via softkey

(Pg 37)

Furthermore, the softkeys include

self-explaining, context-sensitive

functions, e.g. with measurement

or KI recorder activated.

34

M 700(X)

Page 37

Menu Display Configure measurement display

7.00 pH

25.6 °C

Menu selection

Select:

Return to meas

Parameter setting (Administrator)

System control

Module FRONT M 700-011

Module BASE M 700-021

Module O2 4700

Module PH 2700

Module Cond Ind 7700

Return

Module FRONT (Administrator)

Languages

Measurement display

Measurement recorder

[enter]

16.9 %Air

25.6 °C

16.8 %Air

25.6 °C

English

Configure meas. display

Press menu key to select menu.

Select parameter setting using arrow

keys, confirm with enter. Select:

“Administrator level”: Passcode 1989

(For passcodes, see Pg 55)

Lingua

Parameter setting:

Select “M 700 FRONT”

M 700 FRONT:

Select “Measurement display”

Return

16.9 %Air

16.9 %Air

25.6 °C

Measurement display (Administrator)

Main display

1st primary value

2nd primary value

Viewing angle

Abort

Measurement display (Administrator)

Main display

1st primary value

2nd primary value

Viewing angle

Abort

1 primary value

2 primary values

OK

16.9 %Air

25.6 °C

2

mg/l

mg/l

ppm

mbar

pH

values

K

%Air

%O

°C

Measurement display:

Set the number of primary values

(large display) to be displayed

Select process variable(s) to be

displayed and confirm with enter.

Pressing the meas key returns to

measurement.

35

Page 38

Softkey function (function control)

Select menu: Parameter setting / System control / Function control matrix

In measuring mode you can use the

softkeys (1) to control functions.

The functions are assigned in the

function contr

ol matrix (Fig.)

(Parameter setting/System control).

Softkeys which have not been assigned to

a certain function are automatically used

for selecting the secondary displays.

Secondary display (2)

Display of additional values in the measuring mode when the respective softkey is

pressed. Always active.

You can choose one of the process

variables supplied by the modules (and

Calculation Blocks) or the date or time.

Favorites menu

Selected Diagnostics functions can be

called up directly from the measuring

mode using a softkey. The following table

(Pg 37) explains how to select favorites.

2

1

7.00 pH

25.6 °C

Function control matrix (Administrator)

ParSet KI rec. Fav

Input OK2

Left softkey

Right softkey

Profibus DO 2

Return

Example:

“Parameter set” to be selected with

“Left softkey”

–

–

Connect

Further functions which can be controlled

via softkey:

• Parameter set

• KI recorder

• EasyClean 400

36

To select a softkey function:

Select desired function using arrow

keys, press “Connect” softkey

and confirm with enter.

Deselect function:

Press “Disconnect” softkey,

confirm with enter.

M 700(X)

Page 39

Menu Display Select favorites

Favorites menu

Diagnostics functions can be called

7.00

11.00

24.3°C

Menu selection

Select:

Return to meas

Diagnostics

Message list

Return

Meas. point description

Logbook

Device description

Module FRONT

Module BASE

pH

pH

Favor ites menu

7.00 pH

25.6 °C

[enter]

Lingua

16.8 %Air

25.0 °C

Set favorite

up directly from the measuring mode

using a softkey.

The “Favorites” are selected in the

Diagnostics menu.

Select favorites

Press menu key to select menu.

Select diagnostics using arrow keys,

confirm with enter.

Set/delete favorite:

“Set favorite” allows activation of

the selected diagnostic function

directly from the measuring mode via

softkey. The respective function is

marked with a heart icon.

(See Softkey usage, Pg 36)

7.00

11.00

24.3°C

Note:

When one of the softkeys has been assigned to the “Favorites menu” function, diagnostic functions which have been set as “Favorite” can be directly

called up from the measuring mode.

pH

pH

Favor ites menu

Pressing the meas key returns to

measurement. When the softkey has

been assigned to “Favorites”,

“Favorites menu” is read in the

secondary display

(see Softkey usage, Pg 36).

37

Page 40

Diagnostics functions: Overview

Selected diagnostics functions for quality management

Diagnostics functions (quality management, ISO 9000)

To meet the quality management requirements to ISO 9000, the M 700

provides comprehensive diagnostics and safety functions such as Sensocheck

sensor monitoring and CalCheck monitoring of calibration ranges, a logbook

for time- and date-stamped recording of function activations, warning and

failure messages. Further features are:

7 pH 25°C

5 pH

20°C

2-channel measurement recorder

Can be called up directly from the measuring mode.

Allows detailed evaluation of events by placing the

cursor on measured values of interest.

S/cm

14/06/02 11:32, Status: Measurement

0.003mS/cm, 23.7°C

Sensor network diagram

1 - Slope

2 - Zero point

3 - Ref impedance

4 - Glass impedance

5 - Response time

6 - Cal timer

7 - Calcheck

Return

ServiceScope

Fail

Noise level

Return

1min/pixel

Info

7.0pH

24.1°C

Info

7.00 pH

0.2 °C

10x

°C

Sensor network diagram

(pH 2700, O24700 modules)

Graphical representation of the sensor parameters in a

network diagram – with slope, zero, reference impedance, glass impedance, response time, calibration timer,

deviation from calibration range (Calcheck).

ServiceScope

(pH module)

Displays the noise levels over the time. Allows distinction

of individual disturbances, periodic and broadband disturbances, which is helpful for troubleshooting.

An error message is generated if the noise level exceeds

the failure limit.

t

38

M 700(X)

Page 41

Diagnostics functions: Sensoface

Graphical indication of sensor condition

Sensocheck must have been activated during parameter setting

Sensocheck - Sensor monitoring

Module Sensocheck function

4700: Monitoring membrane/electrolyte

O

7.00

pH

2

Cond 7700: Information on sensor condition

11.00

pH

24.3°C

Cond Ind 7700: Information on sensor condition

pH 2700: Automatic monitoring of glass and

reference electrode

The “smileys” provide information on wear and required maintenance of the

sensor (“friendly” – “neutral” – “sad”).

Menu Display Activate Sensocheck

7.00 pH

25.6°C

Menu selection

Open menu selection

Select parameter setting

Enter passcode (Administrator)

Select:

Return to meas

[enter]

Lingua

Parameter setting (Administrator)

System control

M 700 FRONT 700-011

M 700 BASE 700-021

Module O2 4700

Module pH 2700

Return

Sensocheck Ref el (Administrator)

Nominal

Min

Max

Message

Abort

7.00 pH

25.6°C

7.00 pH

25.6°C

005.0 kOhm

003.1 kOhm

100.0 kOhm

Off

Failure

Maint. request

OK

Select module

(“pH 2700” or “O2 4700”)

Confirm with enter.

Select “Sensor data”.

Confirm with enter. Then select

“Sensocheck Ref el”

(Fig.)

Assign function and confirm with

enter.

39

Page 42

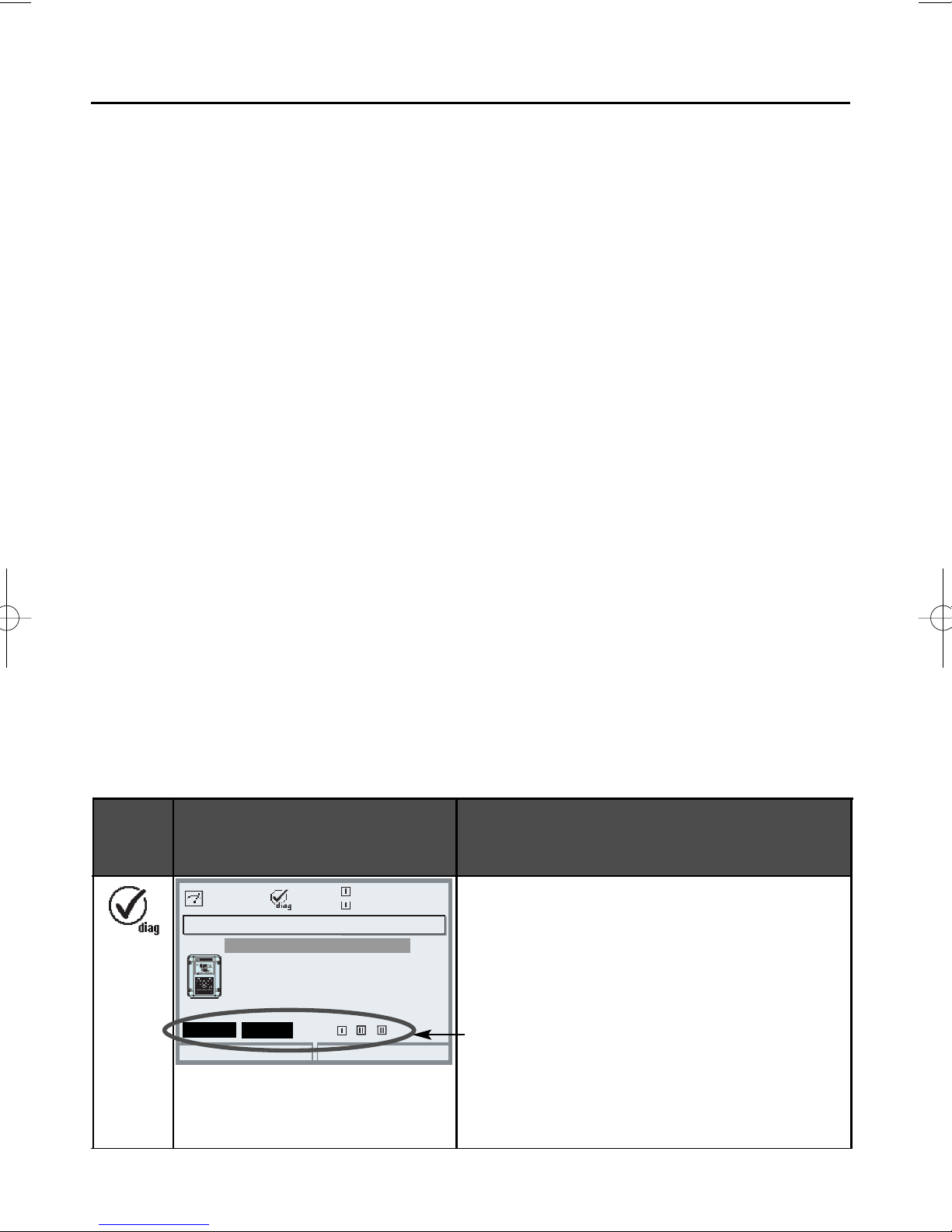

Diagnostics functions

General status information of the measuring system

Select menu: Diagnostics

Menu

Display Diagnostics functions

0.002 mS/cm

23.7 °C

Menu selection

Call up diagnostics

From the measuring mode:

Press menu key to select menu.

Select diagnostics using arrow keys,

confirm with enter.

Select:

Return to meas

Diagnostics

Message list

Logbook

Device description

Module FRONT 700-011

Module BASE 700-021

Module Cond 7700

Return

Message list

Fail Current IV1 load

[enter]

Lingua

0.003 mS/cm

23.7 °C

Set favorite

0.003 mS/cm

23.7 °C

1 messg.

The “Diagnostics” menu gives an

overview of all functions available.

Functions which have been set as

“Favorite” can be directly accessed

from the measuring mode

(see Pg 37).

Message list

Shows the currently activated warning or failure messages in plain text.

Return

Logbook

06/11/02 15:17 Measurement active

06/11/02 15:00 Diagnostics active

06/11/02 10:05 Measurement active

06/11/02 09:50 Parameter setting active

06/11/02 09:42 Wrong passcode

06/10/02 14:33 Measurement active

06/10/02 14:11 Parameter setting active

Return

40

0.003 mS/cm

23.7 °C

Logbook

Shows the last 50 events with date

and time, e.g. calibrations, warning

and failure messages, power failure

etc. This permits quality management

documentation to ISO 9000.

Extended logbook:

SmartMedia card (SW 700-104)

M 700(X)

Page 43

Menu Display Diagnostics functions

Device description

Module FRONT 700-011

Operating panel M 700

Hardware: 2, Software: 6.0

Serial number: 0000815

Module

Module FRONT 700-011

Module diagnostics

Display test

Keypad test

Keypad test

FRONT

Return

Return

BASE

0.003 mS/cm

22.7 °C

0.003 mS/cm

22.7 °C

0.003 mS/cm

22.7 °C

Device description

Provides information about all

modules installed: Module type and

function, serial number, hardware

and software version and device

options (Example: FRONT).

M 700 FRONT

The module the display and keypad

control. Test possibilities:

• Module diagnostics

• Display test

• Keypad test

Example:

M 700 FRONT, keypad test.

Return (2x)

Module BASE 700-021

Module diagnostics

Input/output status

Return

Input/output status

Current load I1

Current load I2

Contact

Input OK1

Input OK2

0.003 mS/cm

22.7 °C

Set favorite

0.003 mS/cm

22.7 °C

ok

ok

K1

K3

Inactive

Inactive

Correct functioning of each key can

be checked by pressing it down.

M 700 BASE

The module generates the standard

output signals. Test possibilities:

• Module diagnostics

• Input/output status

Example:

M 700 BASE, input/output status.

K2

K4

Return

41

Page 44

Parameter setting: Operating levels

Viewing level, Operator level, Administrator level

Note: Function check active

Menu

Display

Menu selection

Select:

Return to meas

Parameter setting

Viewing level

Operator level

Admin. level

Return

25,6° C

0.003 mS/cm

[enter]

Lingua

25.6 °C

0.003 mS/cm

(All Data) view

(Operation Data) opl

(All Data) adm

Viewing level, Operator level,

Administrator level

Call up parameter setting

From the measuring mode:

Press menu key to select menu.

Select parameter setting using arrow

keys, confirm with enter.

Administrator level:

Access to all functions, also passcode

setting.

Releasing or blocking a function for

access from the Operator level.

Module FRONT (Administrator)

Languages

Measurement display

Measurement recorder

KI recorder

Return

Module FRONT

Languages

Measurement display

Measurement recorder

KI recorder

Return

English

Release

English

25.6 °C

0.003 mS/cm

25.6 °C

0.003 mS/cm

Functions which can be blocked for

the Operator level are marked with

the “lock” symbol.

The functions are released or

blocked using the softkey.

Operator level:

Access to all functions which have

been released at the Administrator

level. Blocked functions are displayed

in gray and cannot be edited (Fig.).

Viewing level

Display of all settings.

No editing possible!

42

M 700(X)

Page 45

Parameter setting: Lock functions

Administrator level: Enable / lock functions for Operator level

Note: Function check active

Menu Display

Parameter setting (Administrator)

System control

Module FRONT

Module BASE

Module Cond Ind 7700

Module PID 700

Module Out 700

M 700 BASE (Administrator)

Output current I2

Contact K4 (NAMUR Failure)

Contact K3 (NAMUR maintenance)

Contact K2 (NAMUR function check)

Contact K1 (Limit)

Inputs OK1, OK2

Return

0.003 mS/cm

25.6 °C

7.00 pH

19.2°C

Block

Administrator level:

Enable / lock functions

Example: Blocking access to the configuration of relay contact K1 (M 700 BASE) from

the Operator level

Call up parameter setting

Select Administrator level.

Enter passcode (1989).

Select “M 700 BASE” with arrow

keys, confirm with enter.

Select “Contact K1” with arrow keys,

“Block” with softkey.

M 700 BASE (Administrator)

Output current I2

Contact K4 (NAMUR Failure)

Contact K3 (NAMUR maintenance)

Contact K2 (NAMUR function check)

Contact K1 (Limit)

Inputs OK1, OK2

Return

M 700 BASE

Output current I2

Contact K4 (NAMUR Failure)

Contact K3 (NAMUR maintenance)

Contact K2 (NAMUR function check)

Contact K1 (Limit)

Inputs OK1, OK2

Return

7.00 pH

19.2°C

Release

7.00 pH

19.2°C

Now, the “Contact K1” line is marked

with the “lock” icon. This function

cannot be accessed from the

Operator level any more. The softkey

function changes to “Release”.

Call up parameter setting

Select Operator level

, passcode

(1246), select “M 700 BASE”.

The locked “Contact K1” function is

displayed in gray and marked with the

lock icon.

43

Page 46

Function control matrix, time/date

Select menu: Parameter setting/System control

Note: Function check active

Menu Display

Parameter setting (Administrator)

System control

Module FRONT 700X-015

Module BASE 700X-025/VPW

Module Cond Ind 7700X

Module PID 700X

Module Out 700X

Return

System control (Administrator)

Parameter sets

Function control matrix

Time/date

Meas. point description

Release of options

Factory setting

Return

0.003 mS/cm

25.6 °C

0.003 mS/cm

25.6 °C

Function control matrix,

time/date

Call up parameter setting

Select Administrator level.

Enter passcode (1989).

Select system control using arrow

keys, confirm with enter.

Submenus of system control:

• Parameter sets

• Function control matrix

•Time/date

• Meas. point description (Point of measurement)

• Release of options

• Factory setting

• Passcode entry

• Software update ... more, depending on Options.

7.00 pH

25.6 °C

Function control matrix (Administrator)

ParSet KI rec. Fav

Input OK2

Left softkey

Right softkey

Profibus DO 2

Return

Softkey usage (Administrator)

Date format

Time

Date

Weekday

Abort

DD,MM,YY

DD/MM/YY

MM/DD/YY

YY-MM-DD

Connect

EC 400

––

0.003 mS/cm

25.6 °C

OK

Function control matrix

Clear assignment of function

(parameter sets, KI recorder, Favorites

menu control) to control element

––

(optocoupler, softkey or Profibus).

Time/date

Selection of date format,

adjustment of time and date

44

M 700(X)

Page 47

Point of measurement, passcodes, release of options

Select menu: Parameter setting/System control

Note: Function check active

Menu

Display

0.003 mS/cm

25.6 °C

Point of measurement (Administrator)

Enter 0...9A...Z-+/

using [ ] [ ]

Meas. point

Note

Abort

Passcode entry (Administrator)

cal

maint

opl

Passcode entry (Administrator)

cal

maint

opl

adm

Calibration

Calibration

Change passcode

Maintenance

Operator level

Administrator level

Return

M402.......................

MAINT...07/01/02...

OK

0.003 mS/cm

25.6 °C

Off

On

If you lose your

adm passcode, system

access will be locked!

Close

On

On

On

Off

Off

OK

0.003 mS/cm

25.6 °C

Off

1147

Info

Point of measurement, passcode entry, release of options

Point of measurement

You can enter a tag number or notes

(e.g. date of last maintenance).

Passcode entry

When this menu is opened, the analyzer displays a warning (Fig.).

Passcodes (factory settings):

Calibration (cal) 1147

Maintenance (maint) 2958

Operator level (opl) 1246

Administrator level (adm) 1989

Caution

If you lose the Administrator passcode, system access is locked!

Release of options (Administrator)

SW 700-001 KI recorder

SW 700-002 Buffer sets

SW 700-003 Adaptive timer

SW 700-004 ServiceScope

SW 700-005 Cal tolerance band

SW 700-006 Current charact.

Return

0.003 mS/cm

25.6 °C

Inactive

Inactive

Inactive

Inactive

Inactive

Inactive

Release of options

When you have purchased an option

to be released via TAN:

• Parameter setting, Administrator

• System control

• Select “Release of options”

Set option to “active”. Enter the

TAN at the prompt. The option is

available after the TAN has been

entered.

45

Page 48

Inserting the SmartMedia card

To release an additional function via TAN, see Pg 45, Release of options

Inserting the SmartMedia card

Please note when inserting the SmartMedia card:

The SmartMedia card may be inserted or replaced with the power supply

switched on. Protect against electrostatic discharge! When closing the

device, make sure that the sealing is properly seated and clean.

Warning!

Do not touch the terminal compartment, there may be dangerous contact voltages!

To open the analyzer

• Loosen the 4 front screws

• Open the M 700 FRONT at its right side

(pivot hinge inside at the left)

• The slit for inserting the SmartMedia card is

located at the inner side of the M 700 FRONT

To insert the SmartMedia card

• Remove SmartMedia card from its package

without touching the contact surface

• Insert card in the slit at the inner side of the

M 700 FRONT

Inserting the

SmartMedia card:

The label must be

facing you.

To remove the SmartMedia card

• “Close memory card” (Maintenance menu)

To avoid data loss, please call up the

Maintenance menu.

“Close memory card” to terminate software

access to the SmartMedia card.

Now the card can be taken out.

46

M 700(X)

Page 49

SmartMedia card: Application

Use as memory card in combination with additional functions.

Additional functions must be ordered separately (release via TAN).

Types of SmartMedia cards

The SmartMedia cards are delivered from the manufacturer as

• Softwar

e update (SW 700-106, see Pg 52)

• Memory card (additional function SW 700-1xx, see Pg 56)

Using commercially available SmartMedia cards

Commercially available SmartMedia cards can be used as memor

(Softwar

e updates are supplied by the manufacturer and are device-specific).

y card

The following types of cards are supported: 8 MB, 16 MB, 32 MB, 64 MB

and 128 MB storage capacity. Externally produced files, such as from a

digital camera, are tolerated. Long file names can be read. The M 700

generates file names in the 8.3 format (8 characters file name, 3 characters

program-specific file name extension).

Formatting a commercial SmartMedia card

Some devices (e.g. digital cameras, scanners) cause a formatting of the

SmartMedia card which does not correspond to the SSFDC specification or

the SmartMedia Interface Library (SMIL). The manufacturer therefore recommends to format a commercial SmartMedia card as M 700 memory card

prior to first use.

Menu Display Formatting a SmartMedia card

Memory card (Administrator)

Record logbook

Record recorder

Decimal separator

Card full

Format card

On

On

Point

Record stop

0.003 mS/cm

20.4 °C

Off

Off

Comma

Format card

• Insert SmartMedia card (Pg 46)

• Open menu selection

• Parameter setting, Admin. level

• Enter passcode

• System control: Memory card

Return

(The “Memory card” function is

only available with the SmartMedia

Card inserted!)

• Format card

47

Page 50

System control: Parameter sets A, B

Parameter setting/System control/Parameter sets

Parameter sets A, B

2 complete parameter sets (A, B) can be stored in the analyzer.

An icon in the measurement display shows which parameter set is active:

or

Select “Parameter setting/System control/function control matrix”to select

the control element for switching between the parameter sets (optocoupler,

softkey or PROFIBUS). The currently activated set can be signaled by a relay

contact (see Pg 69).

Menu Display Parameter sets

7.00 pH

25.6 °C

Function control matrix (Administrator)

ParSet KI rec Fav

Input OK2

Left softkey

Right softkey

Profibus DO 2

Return

System control (Administrator)

Memory card

Copy configuration

Parameter sets

Function control matrix

Time/date

Point of measurement

Return

Parameter sets ( Administrator)

For switchover see

“Function control matrix”

––

Connect

7.00 pH

25,6 °C

7.00 pH

25,6 °C

Select control element for switching between the parameter sets

• Call up Menu selection

• Select Parameter setting,

–

–

• Enter passcode

––

Administrator level

• System control

• Select “Function control matrix”

Parameter sets A, B

• Call up Menu selection

• Select Parameter setting,

Administrator level

• Enter passcode

• System control

• Select “Parameter sets”,

confirm with enter.

• Save parameter set

The active parameter set A over-

Parameter sets

Save parameter set

Load parameter set

Return

48

A, B (internal)

writes the internal parameter set B

• Load parameter set

Parameter set B is loaded

M 700(X)

Page 51

SmartMedia card: Parameter sets

Parameter setting/System control/Parameter sets

Note: Additional function SW 700-102 required.

Menu

Display

Parameter sets (Administrator)

Select with softkey

Settings in menu

Softkey usage

Parameter sets

Save parameter set A

Load parameter set A

Abort

Parameter sets (Administrator)

Select with softkey

Settings in menu

Softkey usage

Parameter sets

Save parameter set A

Load parameter set A

Return

A,B (internal)

1,2 (card)

1,2,3 (card)

1,2,3,4 (card)

1,2,3,4,5 (card)

0.003 mS/cm

25.1 °C

OK

0.003 mS/cm

25.0 °C

1,2,3,4 (card)

Load parameter set from

SmartMedia card

Loading a parameter set from

SmartMedia card

• Call up parameter setting

• System control

• Call up “Parameter sets” (Fig)

The M 700(X) provides 2 complete

parameter sets (A, B).

5 parameter sets can be stored on

the SmartMedia card. One of those

can be saved as parameter set A to

the analyzer:

0.003 mS/cm

24.9 °C

Load parameter set A (Administrator)

NOTE: Old parameter set

will be overwritten!

Load from

Abort

0.003

25.0

Time 11:49

B (internal)

1(card)

2(card)

3(card)

4(card)

5(card)

mS/cm

°C

Favor ites menu

SmartMedia card

Set 1

Set A

Set 2 Set 3

Set B

(internal only)

• Select parameter set to be loaded

Activated parameter set is displayed

in measuring mode.

Note: Remote switching between A

and B is possible via the OK2 input.

49

Page 52

SmartMedia card: Parameter sets

Parameter setting/System control/Parameter sets (Table: www.mt.com/M700)

Note: Additional function SW 700-102 required.

Menu Display

Parameter sets (Administrator)

Select with softkey

Settings in menu

Softkey usage

Parameter sets

Save parameter set A

Load parameter set A

Abort

Parameter sets (Administrator)

Select with softkey

Settings in menu

Softkey usage

Parameter sets

Save parameter set A

Load parameter set A

Return

0.003 mS/cm

25.1 °C

A,B (internal)

1,2 (card)

1,2,3 (card)

1,2,3,4 (card)

1,2,3,4,5 (card)

OK

0.002 mS/cm

24.2 °C

1,2,3,4 (card)

Saving parameter set on

SmartMedia card

For parameter settings, refer to

www.mtpro.com.

To save a parameter set on

SmartMedia card

• Call up parameter setting

• System control

• Call up “Parameter sets” (Fig)

The M 700(X) provides 2 complete

parameter sets (A, B).

Up to 5 parameter sets can be

loaded to the SmartMedia card.

To do so, a parameter set (1, 2, 3, 4,

or 5) of the SmartMedia card is overwritten by the M 700(X) parameter

set A.

0.002 mS/cm

24.2 °C

Save parameter set A (Administrator)

NOTE: Old parameter set

will be overwritten!

Save to

Abort

B (internal)

1(card)

2(card)

3(card)

4(card)

5(card)

• Select parameter set

on SmartMedia card

Set A

Set 1

Set 2 Set 3

Set B

(internal only)

SmartMedia card

Copying parameter sets (for similarly equipped M 700)

Parameter sets can be generated with the M700 and then be copied from

the PC to further SmartMedia cards, thus being available for further M 700

units.

50

M 700(X)

Page 53

SmartMedia card: Memory card

Parameter setting/System control/Memory card

Menu Display Using the memory card

To use the memory card

• Insert SmartMedia card

• Open menu selection

• Parameter setting, Admin. level

• Enter passcode

• System control: Memory card

Caution! “Close” memory card before

removing it (Maintenance menu)

0.003 mS/cm

25.6 °C

System control (Administrator)

Memory card

Copy configuration

Parameter sets

Function control matrix

Time/date

Point of measurement

Return

0.003 mS/cm

25.6 °C

Memory card (Administrator)

Record logbook

Record recorder

Decimal separator

Card full

Copy configuration

Format card

Return

Copy configuration (Administrator)

Identical module equipment

required for transfer.

On

On

Point

Record stop

Off

Off

Comma

0.003 mS/cm

25.6 °C

With SmartMedia card inserted, the

display shown on the left appears

(The “Memory card” line is displayed

only if there really is a memory card

in the slot).

• Select “Memory card”,

confirm with enter.

The menu is self-explanatory.

Behavior when the memory

card is full:

Continuous recording (as with a

flight recorder) or Stop (card replacement).

Copy configuration

(see Pg 52)

• Save: Saving all data on

the memory card

Configuration

Return

Save

Load

Execute

• Load: Overwriting all device data

with the data from the memory

card

51

Page 54

Copy configuration

Parameter setting/System control/Copy configuration

Copy configuration from one M 700 to further M 700 units

Prerequisite:

The devices must have the same hardware.The module equipment must be

absolutely identical – the same modules in the same slots!

Options:

All required options must be enabled on the “master device”, this is not

required for the“slave devices”.

It is the parameters of the options that are transferred, not the option itself.

When an option will be enabled on a “slave device” at a later point in time,

the parameters of this option will be preset corresponding to the “master

device”.

SmartMedia card: Software update

Parameter setting/System control/Release of options

Additional functions must be ordered separately (release via TAN).

Additional function SW 700-106: Software update

For a software update (additional function SW 700-106), the manufacturer

supplies a specially formatted SmartMedia card. The M 700 replaces its own

firmware (operating program) by the new version (“Update”).

Caution!

During a software update the analyzer is not operable!

After a software update you should check the configuration.

This icon indicates that a SmartMedia card is inserted in the slot.

UP

The update card allows loading of new software into the device as well

as storing of current device software on the card.

A memory card can be generated by formatting an update card (irreversible!). Formatting erases the update.

52

M 700(X)

Page 55

SmartMedia-Card: Software update

Parameter setting/System control/Software update/Load firmware

Note: Function check active

Menu Display

Release of options (Administrator)

102 Parameter sets

103 Measurement recorder

104 Logbook

106 Software update

Return

Software update (Administrator)

Updating will change the

device characteristics. Perform

verification as appropriate!

Update firmware

Save firmware

Format card

Return

0.003 mS/cm

25.6 °C

Inactive

Inactive

Inactive

Active

0.003 mS/cm

20.4 °C

Software update

(“Load firmware”)

Software update

• Insert SmartMedia card (Pg 46)

• Open menu selection

• Parameter setting, Admin. level

• Enter passcode

• Select System control

1: Select “Release of options”

(Software update SW 700-106)

Set option to “active”. Enter the TAN

at the prompt. The option is available

after the TAN has been entered.

2: Select “Software update”

Check whether your unit really

requires a software update!

To read the current software version,

UP

Update firmware (Administrator)

Select the memory slot for

UP

the chosen firmware

(

indicates the existing version)

Slot

Update firmware (Administrator)

UP

Slot

1: SZ34Z40000/1-V4.1

Abort

UP

Select the memory slot for

the chosen firmware

(

indicates the existing version)

1: SZ34Z40000/1-V4.1

Return

0.003 mS/cm

20.4 °C

OK

0.003 mS/cm

20.4 °C

Load firmware

select:

• Diagnostics

• Device description

• M 700 FRONT

Perform update:

• Parameter setting

• System control

• Software update

• Select slot

• Confirm slot with “OK”.

•Press “Load firmware” softkey

to start software update.

53

Page 56

SmartMedia card: Save firmware

Parameter setting/System control/Software update/Save firmware

Note: Function check active

Menu Display

UP

Software update (Administrator)

Updating will change the

device characteristics. Perform

verification as appropriate!

Update firmware

Save firmware

Format card

Return

UP

Save firmware (Administrator)

Select a free memory slot

UP

or overwrite a stored

firmware version

Slot

2: SZ34Z40000/0-V4.0

Return

0.003 mS/cm

20.4 °C

0.003 mS/cm

20.4 °C

Save

Save firmware

on software update card

Save firmware

• Insert SmartMedia card (Pg 46)

• Open menu selection

• Parameter setting, Admin. level

• Enter passcode

• System control: Software update

Select a free memory slot on the

card:

• Select slot with key

• Select free slot with arrow key.

UP

Save firmware (Administrator)

Select a free memory slot

UP

Slot

Save firmware (Administrator)

UP

Slot

2: SZ34Z40000/0-V4.0

or overwrite a stored

3: <empty>

4: <empty>