Page 1

Operation Manual

Multiparameter

Transmitter M300 ISM

Transmitter Multiparameter M300

52 121 365

Page 2

Transmitter Multiparameter M300 ISM 2

© 03/08 Mettler-Toledo AG, CH-8606 Greifensee, Switzerland Transmitter Multiparameter M300 ISM

Printed in Switzerland 52 121 365

Page 3

Transmitter Multiparameter M300 ISM 3

Operation Manual

Multiparameter

Transmitter M300 ISM

© 03/08 Mettler-Toledo AG, CH-8606 Greifensee, Switzerland Transmitter Multiparameter M300 ISM

Printed in Switzerland 52 121 365

Page 4

Transmitter Multiparameter M300 ISM 4

Content

1 Introduction ___________________________________________________________________________________________ 7

Safety instructions ______________________________________________________________________________________ 7

2

2.1 Definition of equipment and documentation symbols and designations ________________________________________ 7

2.2 Correct disposal of the unit _________________________________________________________________________ 8

Unit overview __________________________________________________________________________________________ 9

3

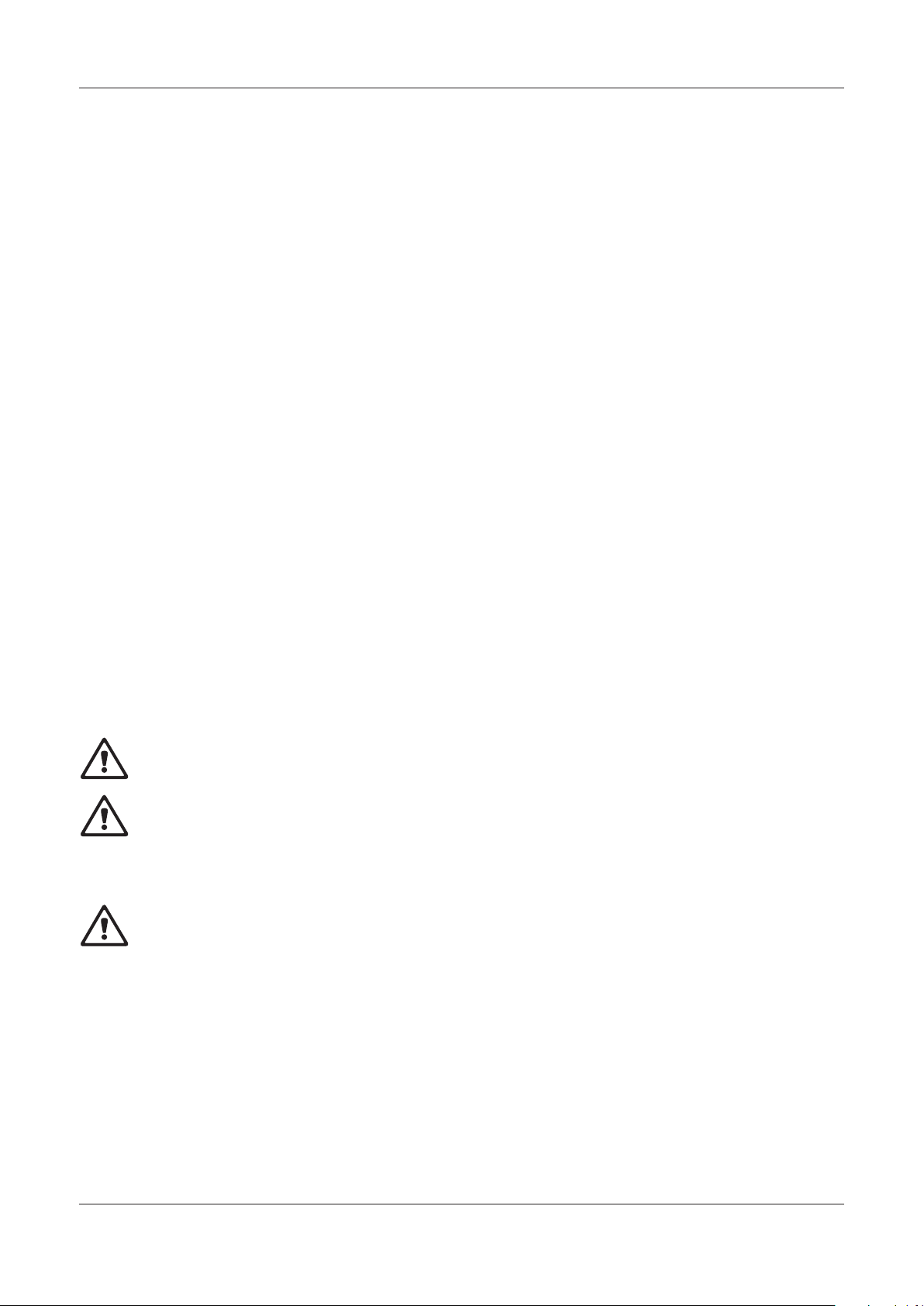

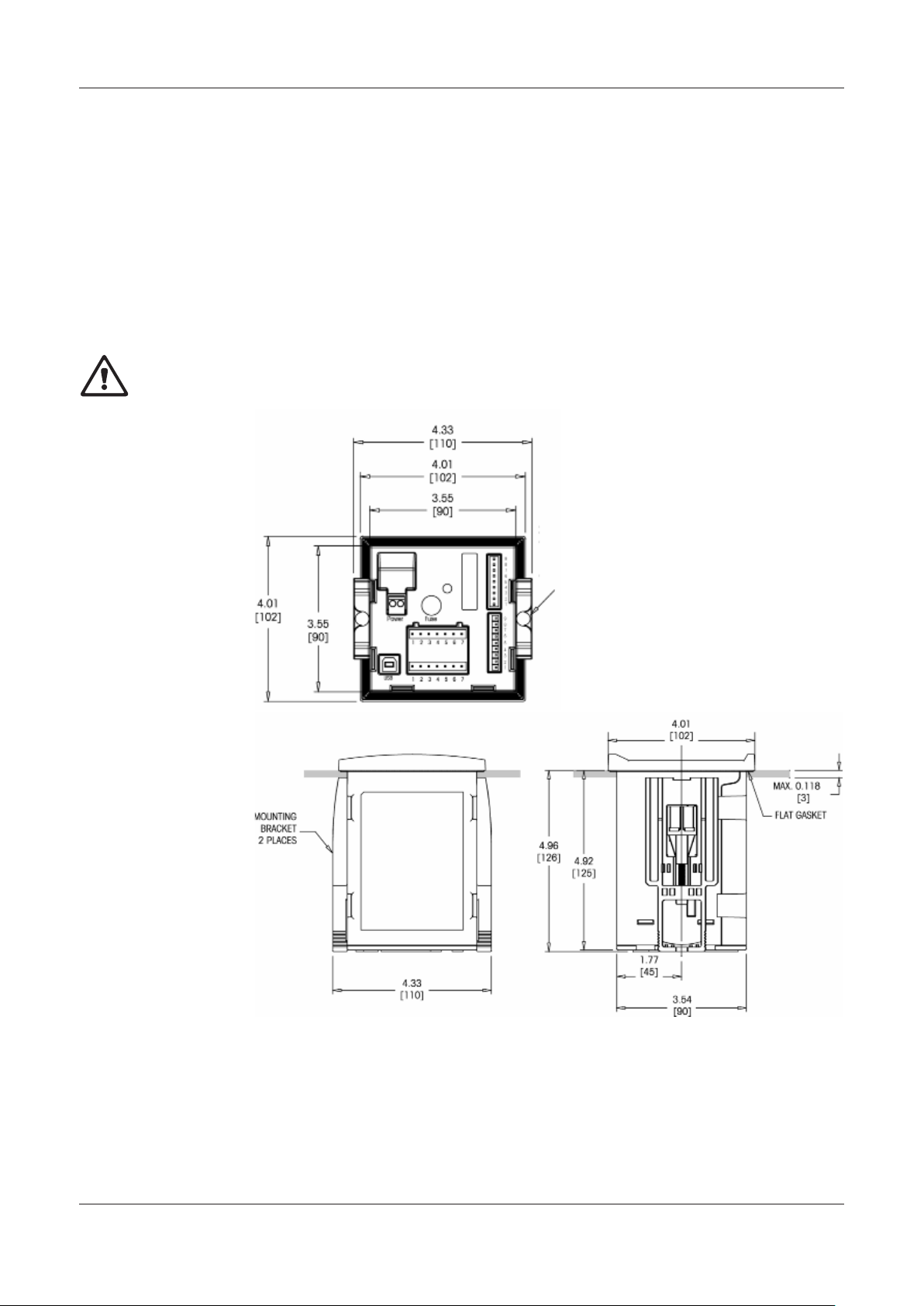

3.1 Overview 1/4DIN __________________________________________________________________________________ 9

3.2 Overview 1/2DIN __________________________________________________________________________________ 9

3.3 Control/Navigation Keys ___________________________________________________________________________ 10

3.3.1 Menu Structure ___________________________________________________________________________ 10

3.3.2 Navigation keys __________________________________________________________________________ 10

3.3.2.1 Navigating the menu tree _________________________________________________________ 10

3.3.2.2 Escape _______________________________________________________________________ 11

3.3.2.3 Enter _________________________________________________________________________ 11

3.3.2.4 Menu _________________________________________________________________________ 11

3.3.2.5 Calibration mode _______________________________________________________________ 11

3.3.2.6 Info mode _____________________________________________________________________ 11

3.3.3 Navigation of data entry fields _______________________________________________________________ 11

3.3.4 Entry of data values, selection of data entry options ______________________________________________ 11

3.3.5 Navigation with

3.3.6 “Save changes” dialog _____________________________________________________________________ 12

3.3.7 Security Passwords _______________________________________________________________________ 12

3.4 Display ________________________________________________________________________________________ 12

4 Installation instruction __________________________________________________________________________________

4.1 Unpacking and inspection of equipment _______________________________________________________________ 13

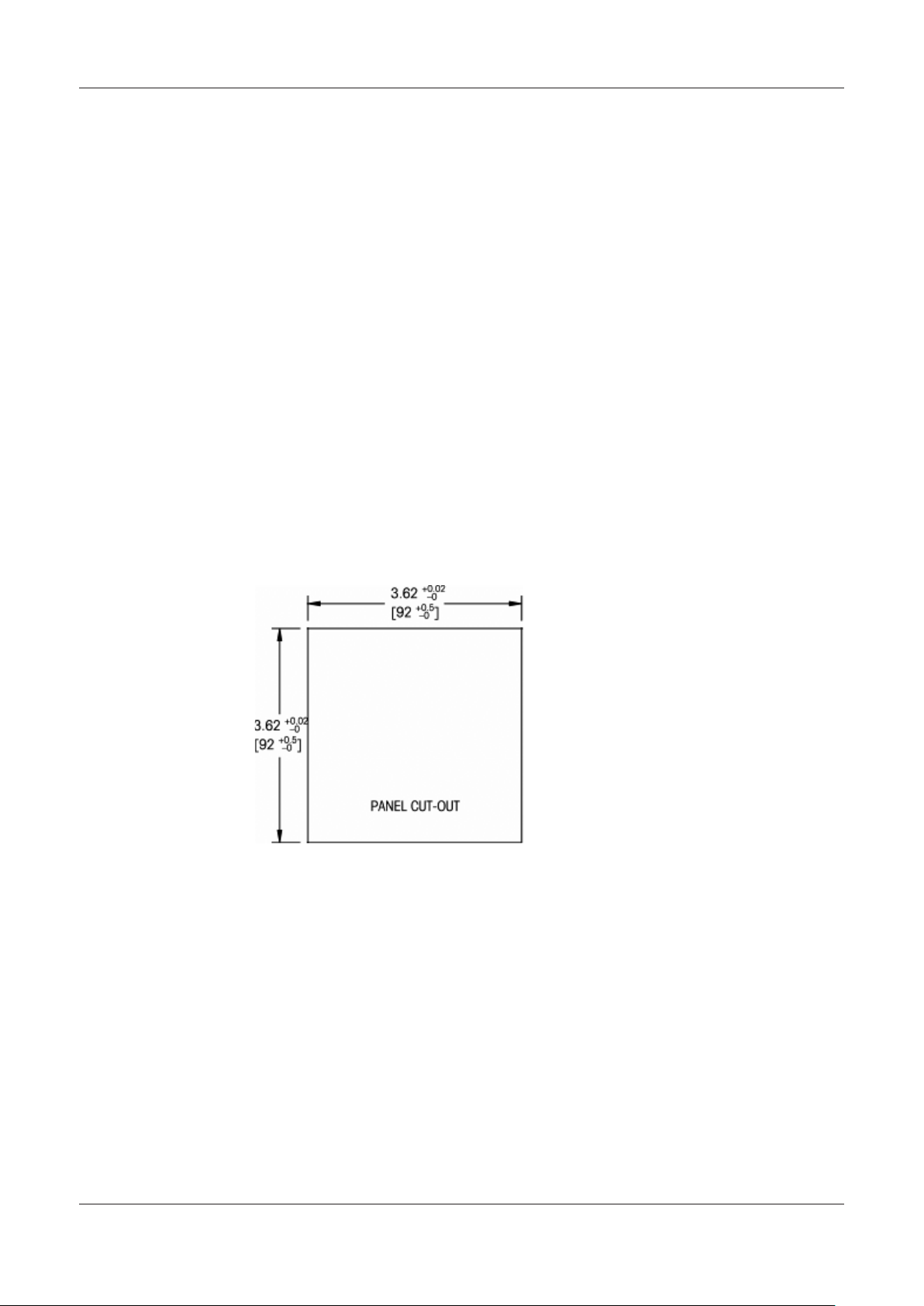

4.1.1 Panel cutout dimensional information – 1/4DIN models ___________________________________________ 13

4.1.2 Installation procedure – 1/4DIN models _______________________________________________________ 14

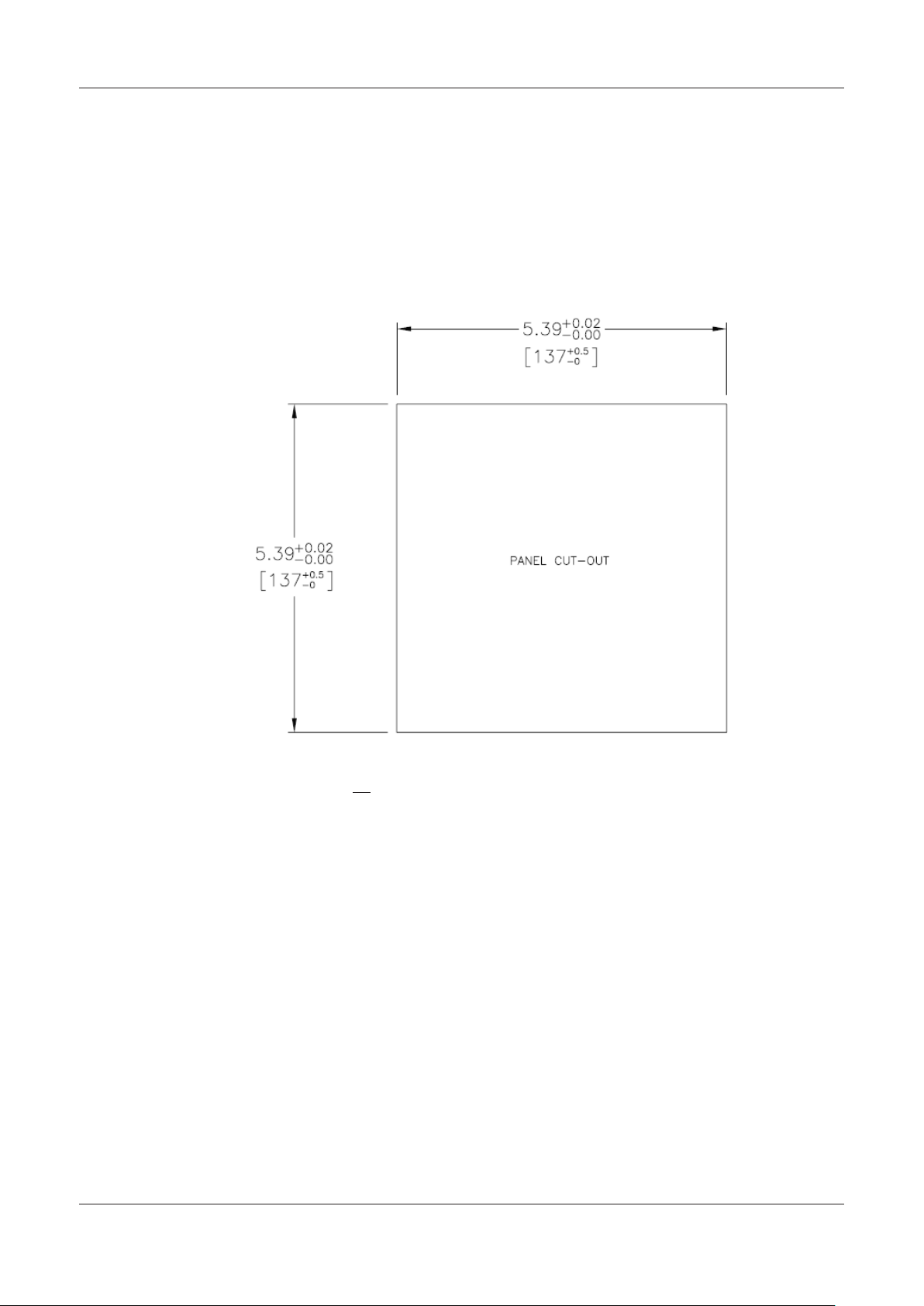

4.1.3 Panel cutout dimensional information – 1/2DIN models ___________________________________________ 15

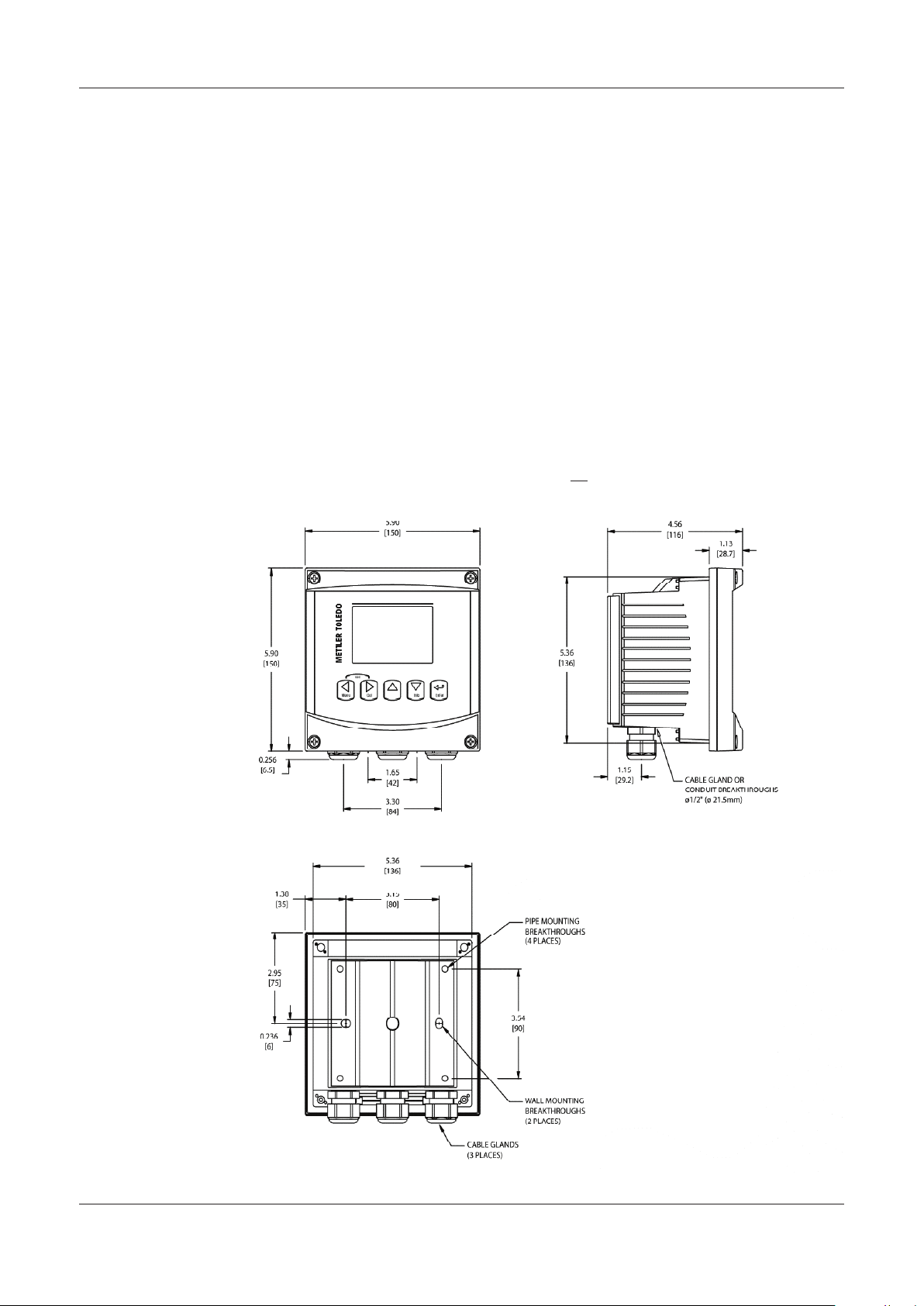

4.1.4 Installation procedure – 1/2DIN models _______________________________________________________ 16

4.2 Connection of power supply ________________________________________________________________________ 17

4.2.1 1/4DIN Housing (panel mount) _____________________________________________________________ 17

4.2.2 1/2DIN housing (wall mount) _______________________________________________________________ 18

4.3 Connector PIN definition ___________________________________________________________________________ 19

4.3.1 TB1 and TB2 for 1/2DIN and 1/4DIN versions __________________________________________________ 19

4.3.2 TB3/TB4* – ISM (digital) Sensors, pH and Dissolved Oxygen ______________________________________ 19

4.4 Connection of Sensor _____________________________________________________________________________ 20

4.4.1 Connection of ISM Sensor, pH and Dissolved Oxygen _____________________________________________ 20

4.4.2 AK9 Cable Assignment ____________________________________________________________________ 20

5 Placing transmitter in, or out, of service ___________________________________________________________________

5.1 Placing transmitter in service _______________________________________________________________________ 21

5.2 Placing transmitter out of service ____________________________________________________________________ 21

6 Quick Setup __________________________________________________________________________________________

↑ in Display _______________________________________________________________ 11

13

21

22

© 03/08 Mettler-Toledo AG, CH-8606 Greifensee, Switzerland Transmitter Multiparameter M300 ISM

Printed in Switzerland 52 121 365

Page 5

Transmitter Multiparameter M300 ISM 5

7 Sensor Calibration _____________________________________________________________________________________ 23

7.1 Enter Calibration Mode ____________________________________________________________________________ 23

7.2 Conductivity Calibration ___________________________________________________________________________ 23

7.2.1 One-point Sensor Calibration _______________________________________________________________ 24

7.2.2 Two-point Sensor Calibration (4-electrode sensors only) __________________________________________

24

7.3 Oxygen Calibration _______________________________________________________________________________ 24

7.3.1 One-Point Sensor Calibration ________________________________________________________________ 24

7.3.2 Process Calibration _______________________________________________________________________ 25

7.4 pH Calibration ___________________________________________________________________________________

7.4.1 One point calibration _____________________________________________________________________

25

26

7.4.2 Two point calibration _____________________________________________________________________ 26

7.4.3 Process calibration _______________________________________________________________________ 27

7.4.4 mV calibration __________________________________________________________________________ 27

7.5 Sensor Temperature Calibration _____________________________________________________________________

7.5.1 One-Point Sensor Temperature Calibration ______________________________________________________

27

28

7.5.2 Two – Point Sensor Temperature Calibration ____________________________________________________ 28

7.6 Edit Sensor Calibration Constants ____________________________________________________________________ 29

7.7 Sensor Verification________________________________________________________________________________ 29

8 Configuration _________________________________________________________________________________________

8.2 Measurement ___________________________________________________________________________________

30

30

8.2.1 Channel Setup ___________________________________________________________________________ 30

8.2.2 pH/O2 Parameter related settings _____________________________________________________________ 31

8.2.2.1 Conductivity Temperature Compensation _____________________________________________ 31

8.2.2.2 pH Parameters _________________________________________________________________ 31

8.2.2.3 Dissolved Oxygen Parameters _____________________________________________________ 33

8.2.4 Set Averaging ____________________________________________________________________________ 33

8.3 Analog Outputs __________________________________________________________________________________ 34

8.4 Setpoints ______________________________________________________________________________________ 35

8.5 Alarm/Clean ____________________________________________________________________________________ 36

8.5.1 Alarm __________________________________________________________________________________ 36

8.5.2 Clean __________________________________________________________________________________ 37

8.6 Display ________________________________________________________________________________________ 37

8.6.1 Measurement ____________________________________________________________________________ 37

8.6.2 Resolution ______________________________________________________________________________ 38

8.6.3 Backlight _______________________________________________________________________________ 38

8.6.4 Name __________________________________________________________________________________ 38

8.7 Hold Analog Outputs ______________________________________________________________________________ 39

9 System ______________________________________________________________________________________________

40

9.1 Set Language ___________________________________________________________________________________ 40

9.2 USB ___________________________________________________________________________________________ 40

9.3 Passwords _____________________________________________________________________________________ 41

9.3.1 Changing Passwords ______________________________________________________________________ 41

9.3.2 Configuring Menu Access for Operator _________________________________________________________ 41

9.4 Set/Clear Lockout ________________________________________________________________________________ 42

9.5 Reset __________________________________________________________________________________________ 42

9.5.1 Reset System ____________________________________________________________________________ 42

9.5.2 Reset Meter Calibration ____________________________________________________________________ 42

9.5.3 Reset Analog Calibration ___________________________________________________________________ 43

10 PID Setup ____________________________________________________________________________________________

44

10.1 Enter PID Setup __________________________________________________________________________________ 45

10.2 PID Auto/Manual _________________________________________________________________________________ 45

10.3 Mode __________________________________________________________________________________________ 46

10.3.1 PID Mode _______________________________________________________________________________ 46

10.4 Tune Parameters _________________________________________________________________________________ 47

10.4.1 PID Assignment & Tuning __________________________________________________________________ 47

10.4.2 Setpoint & Deadband ______________________________________________________________________ 48

10.4.3 Proportional Limits ________________________________________________________________________ 48

10.4.4 Corner Points ____________________________________________________________________________ 48

10.5 PID Display _____________________________________________________________________________________ 48

© 03/08 Mettler-Toledo AG, CH-8606 Greifensee, Switzerland Transmitter Multiparameter M300 ISM

Printed in Switzerland 52 121 365

Page 6

Transmitter Multiparameter M300 ISM 6

11 Service ______________________________________________________________________________________________ 49

11.1 Diagnostics _____________________________________________________________________________________ 49

11.1.1 Model/Software Revision ___________________________________________________________________ 49

11.1.2 Digital Input _____________________________________________________________________________ 49

11.1.3 Display ________________________________________________________________________________

50

11.1.4 Keypad ________________________________________________________________________________ 50

11.1.5 Memory ________________________________________________________________________________ 50

11.1.6 Set Relay _______________________________________________________________________________ 50

11.1.7 Read Relays _____________________________________________________________________________

11.1.8 Set Analog Outputs _______________________________________________________________________

51

51

11.1.9 Read Analog Outputs ______________________________________________________________________ 51

11.2 Calibrate _______________________________________________________________________________________ 52

11.2.1 Calibrate Meter ___________________________________________________________________________ 52

11.2.1.1 Temperature ___________________________________________________________________

11.2.1.2 Current _______________________________________________________________________

52

53

11.2.1.3 Voltage _______________________________________________________________________ 53

11.2.1.4 Rg Diagnostic __________________________________________________________________ 54

11.2.1.5 Rr Diagnostics _________________________________________________________________ 54

11.2.2 Calibrate Analog _________________________________________________________________________

11.2.3 Calibrate Unlock __________________________________________________________________________

55

55

11.3 Tech Service ____________________________________________________________________________________ 55

12 Info _________________________________________________________________________________________________

56

12.1 Messages ______________________________________________________________________________________ 56

12.2 Calibration Data _________________________________________________________________________________ 56

12.3 Model/Software Revision ___________________________________________________________________________ 57

12.4 ISM Sensor Info __________________________________________________________________________________ 57

13 Maintenance __________________________________________________________________________________________

58

13.1 Front Panel Cleaning ______________________________________________________________________________ 58

14 Troubleshooting _______________________________________________________________________________________

59

14.1 Changing the Fuse _______________________________________________________________________________ 59

15 Accessories and Spare Parts _____________________________________________________________________________

16 Specifications _________________________________________________________________________________________

60

61

16.1 General specifications ____________________________________________________________________________ 61

16.2 Electrical specifications for 1/2DIN and 1/4DIN version ___________________________________________________62

16.4 Mechanical specifications for 1/2DIN version ___________________________________________________________ 62

16.5 Environmental specifications for 1/2DIN and 1/4DIN version _______________________________________________ 63

Default tables _________________________________________________________________________________________ 64

17

18 Waranty _____________________________________________________________________________________________

19 UL Statement _________________________________________________________________________________________

20 Buffer tables __________________________________________________________________________________________

65

66

67

20.1 Mettler-9 _______________________________________________________________________________________ 67

20.2 Mettler-10 ______________________________________________________________________________________ 67

20.3 NIST Technical Buffers _____________________________________________________________________________ 68

20.4 NIST standard buffers (DIN 19266: 2000-01) __________________________________________________________ 68

20.5 Hach buffers ___________________________________________________________________________________ 69

20.6 Ciba (94) buffers ________________________________________________________________________________ 69

20.7 Merck Titrisols, Reidel Fixanals ______________________________________________________________________ 70

20.8 WTW buffers ____________________________________________________________________________________ 70

© 03/08 Mettler-Toledo AG, CH-8606 Greifensee, Switzerland Transmitter Multiparameter M300 ISM

Printed in Switzerland 52 121 365

Page 7

Transmitter Multiparameter M300 ISM 7

1 Introduction

Statement of Intended Use – The M300 for ISM transmitter is a single or dual- channel online

process instrument for measuring various properties of fluids. These include Conductivity*,

Dissolved Oxygen and pH/ORP. It will interface with ISM (Intelligent Sensor Management)

sensors from Mettler-Toledo, which connect to the transmitter using cables of varied lengths.

The transmitter features the Plug and Measure functionally. That means the calibration and

configuration data of each ISM sensor are stored in the sensor head and will be uploaded to the

transmitter after connection.

* Q4/2008

A large four line backlit Liquid Crystal Display conveys measuring data and setup information.

The menu structure allows the operator to modify all operational parameters by using keys on

the front panel. A menu-lockout feature, with password protection, is available to prevent the

unauthorized use of the meter. The M300 Multiparameter transmitter can be configured to use

its four analog and/or six relay outputs for process control.

The M300 Multiparameter transmitter is equipped with a USB communication interface. This

interface provides real-time data output and complete instrument configuration capabilities for

central monitoring via Personal Computer (PC).

2 Safety instructions

This manual includes safety information with the following designations and formats.

2.1 Definition of equipment and documentation symbols and

designations

WARNING: POTENTIAL FOR PERSONAL INJURY.

CAUTION: possible instrument damage or malfunction.

NOTE: Important operating information.

C

On the transmitter or in this manual text indicates: Caution and/or other possible hazard

including risk of electric shock (refer to accompanying documents)

The following is a list of general safety instructions and warnings. Failure to adhere to these

instructions can result in damage to the equipment and/or personal injury to the operator.

– The M300 Transmitter should be installed and operated only by personnel familiar with

the transmitter and who are qualified for such work.

– The M300 Transmitter must only be operated under the specified operating conditions

(see section 16).

– Repair of the M300 Transmitter must be performed by authorized, trained personnel only.

– With the exception of routine maintenance, cleaning procedures or fuse replacement, as

described in this manual, the M300 Transmitter must not be tampered with or altered in

any manner.

© 03/08 Mettler-Toledo AG, CH-8606 Greifensee, Switzerland Transmitter Multiparameter M300 ISM

Printed in Switzerland 52 121 365

Page 8

Transmitter Multiparameter M300 ISM 8

– Mettler-Toledo accepts no responsibility for damage caused by unauthorized modifications

to the transmitter.

– Follow all warnings, cautions, and instructions indicated on and supplied with this product.

– Install equipment as specified in this instruction manual. Follow appropriate local and

national codes.

– Protective covers must be in place at all times during normal operation.

– If this equipment is used in a manner not specified by the manufacturer, the protection

provided by it against hazards may be impaired.

WARNINGS:

Installation of cable connections and servicing of this product require access to shock hazard

voltage levels.

Main power and relay contacts wired to separate power source must be disconnected before

servicing.

Switch or circuit breaker shall be in close proximity to the equipment and within easy reach of

the OPERATOR; it shall be marked as the disconnecting device for the equipment.

Main power must employ a switch or circuit breaker as the disconnecting device for the

equipment.

Electrical installation must be in accordance with the National Electrical Code and/or any other

applicable national or local codes.

NOTE: RELAY CONTROL ACTION: the M300 transmitter relays will always de-energize on loss of

C

power, equivalent to normal state, regardless of relay state setting for powered operation.

Configure any control system using these relays with fail-safe logic accordingly.

NOTE: PROCESS UPSETS: Because process and safety conditions may depend on consistent

C

operation of this transmitter, provide appropriate means to maintain operation during sensor

cleaning, replacement or sensor or instrument calibration.

2.2 Correct disposal of the unit

When the transmitter is finally removed from service, observe all local environmental regulations

for proper disposal.

© 03/08 Mettler-Toledo AG, CH-8606 Greifensee, Switzerland Transmitter Multiparameter M300 ISM

Printed in Switzerland 52 121 365

Page 9

Transmitter Multiparameter M300 ISM 9

4

5

6

7

8

4

5

6

7

8

3 Unit overview

M300 models are available in both a 1/4DIN and 1/2DIN case size. The 1/4DIN is a panelmount only design and the 1/2DIN models provide an integral IP65 housing for wall-, or pipemount.

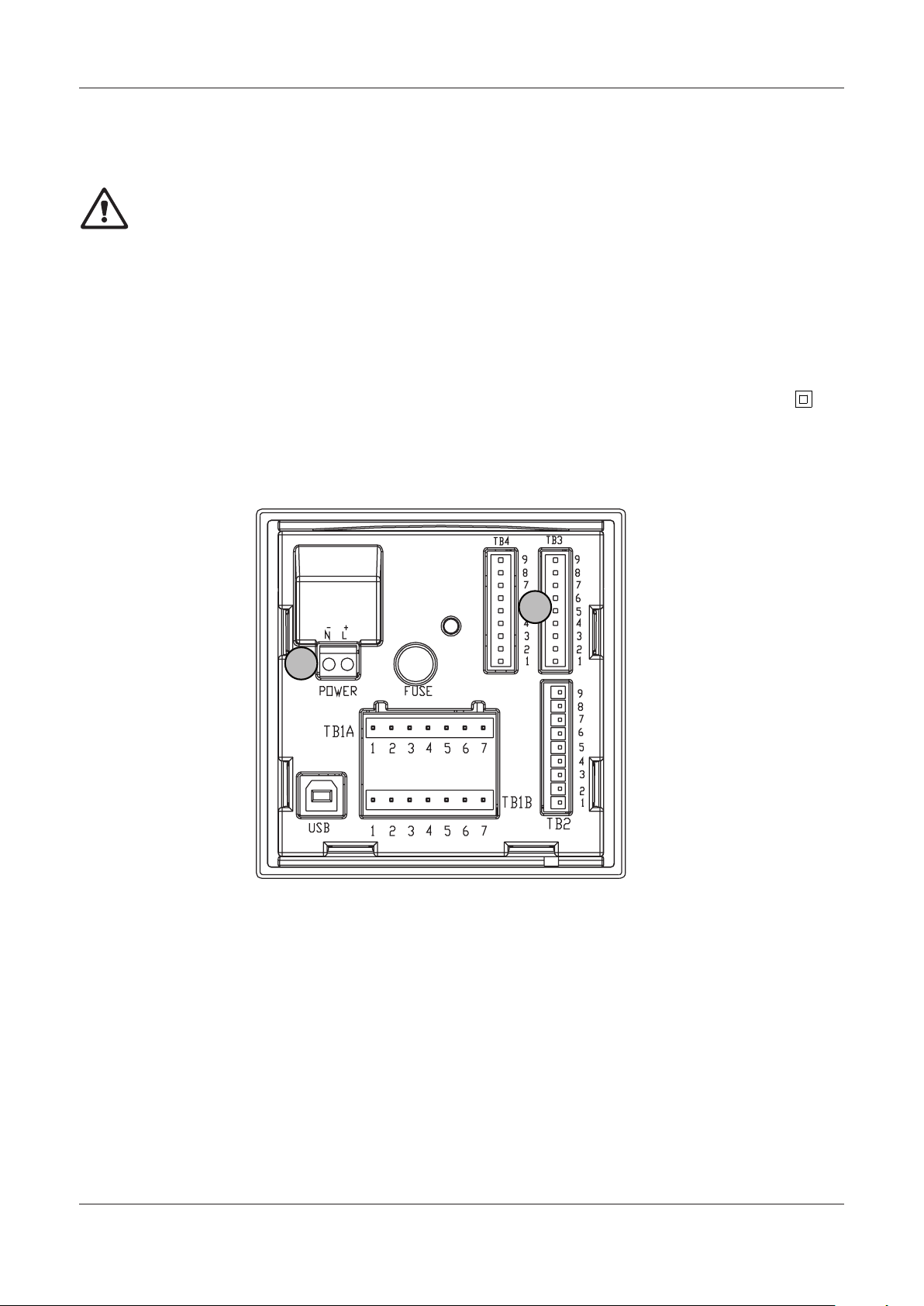

3.1 Overview 1/4DIN

1 – Hard Polycarbonate case 5 – USB Interface Port

2 – Five Tactile-Feedback Navigation Keys 6 – Relay Output Terminals

3 – Four-line LCD Display 7 – Analog Output/Digital Input Terminals

4 – Power Supply Terminals 8 – Sensor Input Terminals

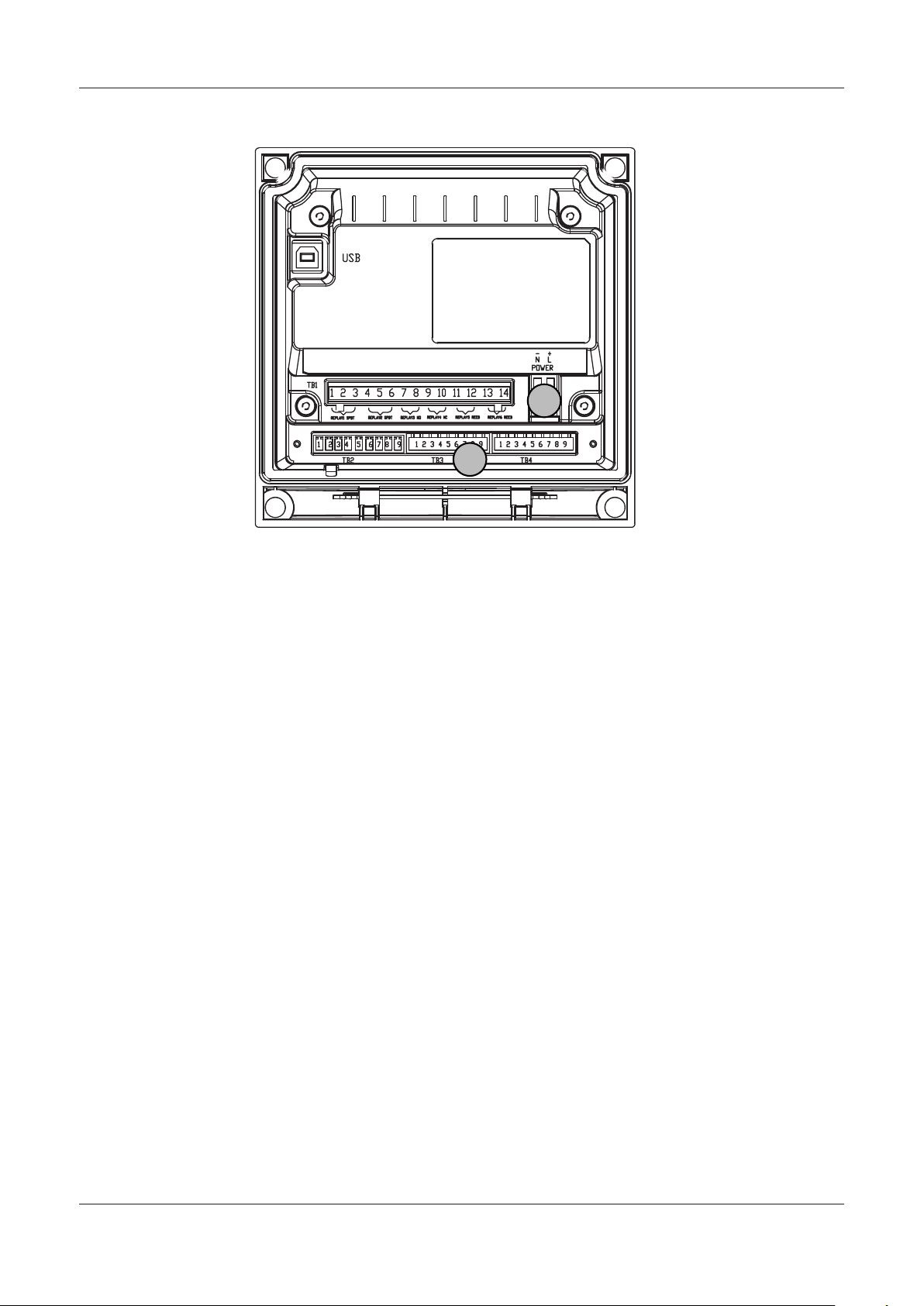

3.2 Overview 1/2DIN

1 – Hard Polycarbonate case 5 – USB Interface Port

2 – Five Tactile-Feedback Navigation Keys 6 – Relay Output Terminals

3 – Four-line LCD Display 7 – Analog Output/Digital Input Terminals

4 – Power Supply Terminals 8 – Sensor Input Terminals

© 03/08 Mettler-Toledo AG, CH-8606 Greifensee, Switzerland Transmitter Multiparameter M300 ISM

Printed in Switzerland 52 121 365

Page 10

Transmitter Multiparameter M300 ISM 10

Measurement

Mode M300

CalMenu Info

Quick Setup Configure System PID Setup Service Messages

ISM Sensor

Info

Measurement

Analog Outputs

Set Points

Alarm/Clean

Display

Set Language

USB

Passwords

Set/Clear Lockout

Reset

PID A /M

Tune Parameters

Mode

Calibrate

Tech Service

Diagnostics

Set Date & Time

PID Display Setup

Calibration Data

Model/Software

Revision

Hold Outputs

Menu Cal

Info

Enter

ESC

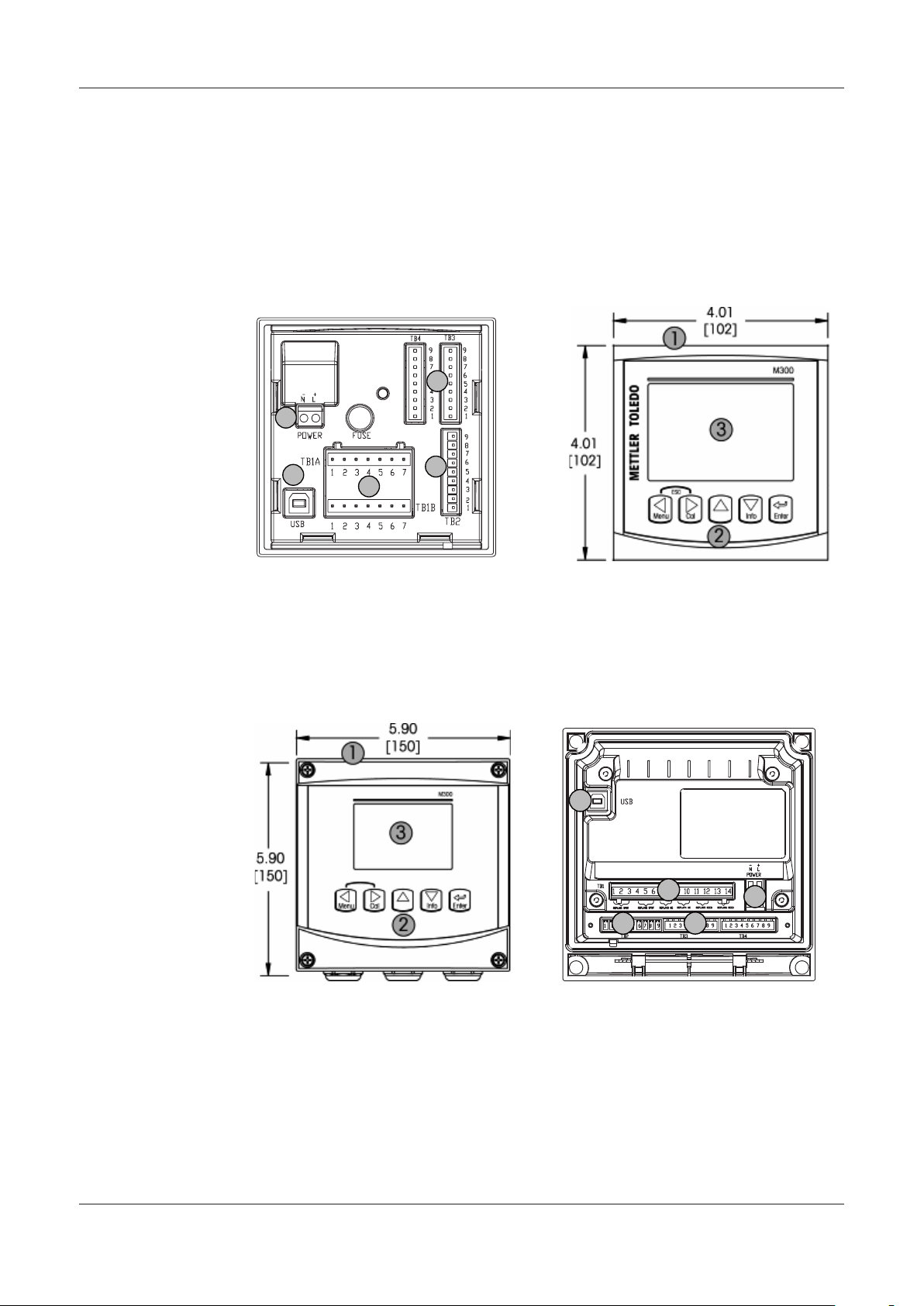

3.3 Control/Navigation Keys

3.3.1 Menu Structure

Below is the structure of the M300 menu tree:

3.3.2 Navigation keys

NOTE: In order to back up one menu page, without escaping to the measurement mode,

C

© 03/08 Mettler-Toledo AG, CH-8606 Greifensee, Switzerland Transmitter Multiparameter M300 ISM

Printed in Switzerland 52 121 365

3.3.2.1 Navigating the menu tree

Enter the desired main Menu branch with the or keys. Use the and keys to

navigate through the selected Menu branch.

move the cursor under the UP Arrow character at the bottom right of the display screen and

press [Enter].

Page 11

Transmitter Multiparameter M300 ISM 11

3.3.2.2 Escape

Press the and key simultaneously (escape) to return to the Measurement mode.

3.3.2.3 Enter

Use the ↵ key to confirm action or selections.

3.3.2.4 Menu

Press the key to access the main Menu.

3.3.2.5 Calibration mode

Press the key to enter Calibration Mode.

3.3.2.6 Info mode

Press the key to enter Info Mode

3.3.3 Navigation of data entry fields

Use the key to navigate forward or the key to navigate backwards within the changeable

data entry fields of the display.

3.3.4 Entry of data values, selection of data entry options

Use the key to increase or the key to decrease a digit. Use the same keys to navigate

within a selection of values or options of a data entry field.

NOTE: Some screens require configuring multiple values via the same data field (ex: configuring

C

multiple setpoints). Be sure to use the or key to return to the primary field and the or

key to toggle between all configuration options before entering to the next display screen.

3.3.5 Navigation with ↑ in Display

If a ↑ is displayed on the bottom right hand corner of the display, you can use the or the

key to navigate to it. If you click [ENTER] you will navigate backwards through the menu

(go back one screen). This can be a very useful option to move back up the menu tree without

having to exit into the measuring mode and re-enter the menu.

© 03/08 Mettler-Toledo AG, CH-8606 Greifensee, Switzerland Transmitter Multiparameter M300 ISM

Printed in Switzerland 52 121 365

Page 12

Transmitter Multiparameter M300 ISM 12

3.3.6 “Save changes” dialog

Three options are possible for the “Save changes” dialog: Yes & Exit (Save changes and exit to

measuring mode), “Yes & ↑” (Save changes and go back one screen) and “No & Exit” (Don’t

save changes and exit to measuring mode). The “Yes & ↑” option is very useful if you want to

continue configuring without having to re-enter the menu.

3.3.7 Security Passwords

The M300 transmitter allows a security lock-out of various menus. If the security lock-out

feature of the transmitter has been enabled, a security password must be entered to allow

access to the menu. See section 9.3 for more information.

3.4 Display

NOTE: In the event of an alarm or other error condition the M300 Transmitter will display a

C

flashing in the upper right corner of the display. This symbol will remain until the condition

that caused it has been cleared.

NOTE: During calibrations, clean, Digital In with Analog Output/Relay/USB in Hold state,

C

a flashing H will appear in the upper left corner of the display. This symbol will remain for

20 seconds until after the calibration or clean is completed. This symbol will also disappear

when Digital In is deactivated.

© 03/08 Mettler-Toledo AG, CH-8606 Greifensee, Switzerland Transmitter Multiparameter M300 ISM

Printed in Switzerland 52 121 365

Page 13

Transmitter Multiparameter M300 ISM 13

4 Installation instruction

4.1 Unpacking and inspection of equipment

Inspect the shipping container. If it is damaged, contact the shipper immediately for instructions.

Do not discard the box.

If there is no apparent damage, unpack the container. Be sure all items shown on the packing

list are present.

If items are missing, notify Mettler-Toledo immediately

4.1.1 Panel cutout dimensional information – 1/4DIN models

1/4DIN Model transmitters are designed for panel-mount installation only. Each transmitter is

supplied with mounting hardware to provide fast and simple installation to a flat panel or flat

enclosure door. To insure a good seal and maintain NEMA/IP integrity of installation, the panel

or door must be flat and have a smooth finish. Hardware consists of:

Two – Snap-on Mounting brackets

One – Mounting gasket seal

Transmitter dimensions and mounting are shown in the figures below.

© 03/08 Mettler-Toledo AG, CH-8606 Greifensee, Switzerland Transmitter Multiparameter M300 ISM

Printed in Switzerland 52 121 365

Page 14

Transmitter Multiparameter M300 ISM 14

4.1.2 Installation procedure – 1/4DIN models

– Make cutout in panel (see dimensions cutout drawing).

– Be sure surface surrounding cutout is clean, smooth and free of burrs.

– Slide face gasket (supplied with transmitter) around transmitter from the back of the unit.

– Place transmitter into cutout hole. Be sure there are no gaps between the transmitter

and panel surface.

– Place the two mounting brackets on either side of the transmitter as shown

– While holding transmitter firmly into the cutout hole, push the mounting brackets

toward the backside of panel

– Once secure, use a screwdriver to tighten the brackets against the panel

– Face gasket will compress between transmitter and panel

CAUTION: Do not over tighten brackets

© 03/08 Mettler-Toledo AG, CH-8606 Greifensee, Switzerland Transmitter Multiparameter M300 ISM

Printed in Switzerland 52 121 365

Page 15

Transmitter Multiparameter M300 ISM 15

4.1.3 Panel cutout dimensional information – 1/2DIN models

1/2DIN Model transmitters are designed with an integral rear cover for stand-alone wall mount

installation.

The unit may also be wall mounted using the integral rear cover. See installation instructions in

Section 4.1.4.

Below are cut-out dimensions required by the 1/2DIN models when mounted within a flat panel

or on a flat enclosure door. This surface must be flat and smooth. Textured or rough surfaces are

not recommended and may limit the effectiveness of the gasket seal provided.

Optional hardware accessories are available that allow for panel- or pipe-mount.

Refer to Section 15 for ordering information.

© 03/08 Mettler-Toledo AG, CH-8606 Greifensee, Switzerland Transmitter Multiparameter M300 ISM

Printed in Switzerland 52 121 365

Page 16

Transmitter Multiparameter M300 ISM 16

M400

4.1.4 Installation procedure – 1/2DIN models

For Wall Mount:

– Remove rear cover from front housing.

– Start by unscrewing the four screws located on the face of the transmitter, in each corner.

This allows the front cover to swing away from the rear housing.

– Remove the hinge-pin by squeezing the pin from each end.

This allows the front housing to be removed from the rear housing

– Drill out wall-mount breakthroughs in the rear housing.

– Mount rear housing to wall using appropriate mounting hardware for wall surface. Be sure

it is level and securely fastened and the installation adheres to any and all clearance

dimensions required for transmitter service and maintenance.

– Insert two black protective covers (supplied with the M300 transmitter) over the fixing

hardware and into the space on the inside back cover, as shown in the drawing below.

This is necessary to maintain unit integrity.

– Replace the front housing to the rear housing. The unit is ready to be wired.

For Pipe Mount:

– Use only manufacturer-supplied components for pipe-mounting the M300 transmitter and

install per the supplied instructions. See section 15 for ordering information.

© 03/08 Mettler-Toledo AG, CH-8606 Greifensee, Switzerland Transmitter Multiparameter M300 ISM

Printed in Switzerland 52 121 365

Page 17

Transmitter Multiparameter M300 ISM 17

1

2

4.2 Connection of power supply

All connections to the transmitter are made on the rear panel of all models.

Be sure power to all wires is turned off before proceeding with the installation. High voltage may

be present on the input power wires and relay wires.

A two-terminal connector on the rear panel of all M300 models is provided for power

connection. All M300 models are designed to operate from a 20–30 VDC or a 100 to 240 VAC

power source. Refer to specifications for power requirements and ratings and size power wiring

accordingly.

The terminal block for power connections is labeled “Power” on the rear panel of the transmitter.

One terminal is labeled – N for the Neutral wire and the other + L for the Line (or Load) wire.

There is no earth ground terminal on the transmitter. For this reason the internal power wiring

within the transmitter is double insulated and the product label designates this using the

symbol.

4.2.1 1/4DIN Housing (panel mount)

1 Connection of power supply

2 Terminal for sensors

© 03/08 Mettler-Toledo AG, CH-8606 Greifensee, Switzerland Transmitter Multiparameter M300 ISM

Printed in Switzerland 52 121 365

Page 18

Transmitter Multiparameter M300 ISM 18

1

2

4.2.2 1/2DIN housing (wall mount)

1 Connection of power supply

2 Terminal for sensors

© 03/08 Mettler-Toledo AG, CH-8606 Greifensee, Switzerland Transmitter Multiparameter M300 ISM

Printed in Switzerland 52 121 365

Page 19

Transmitter Multiparameter M300 ISM 19

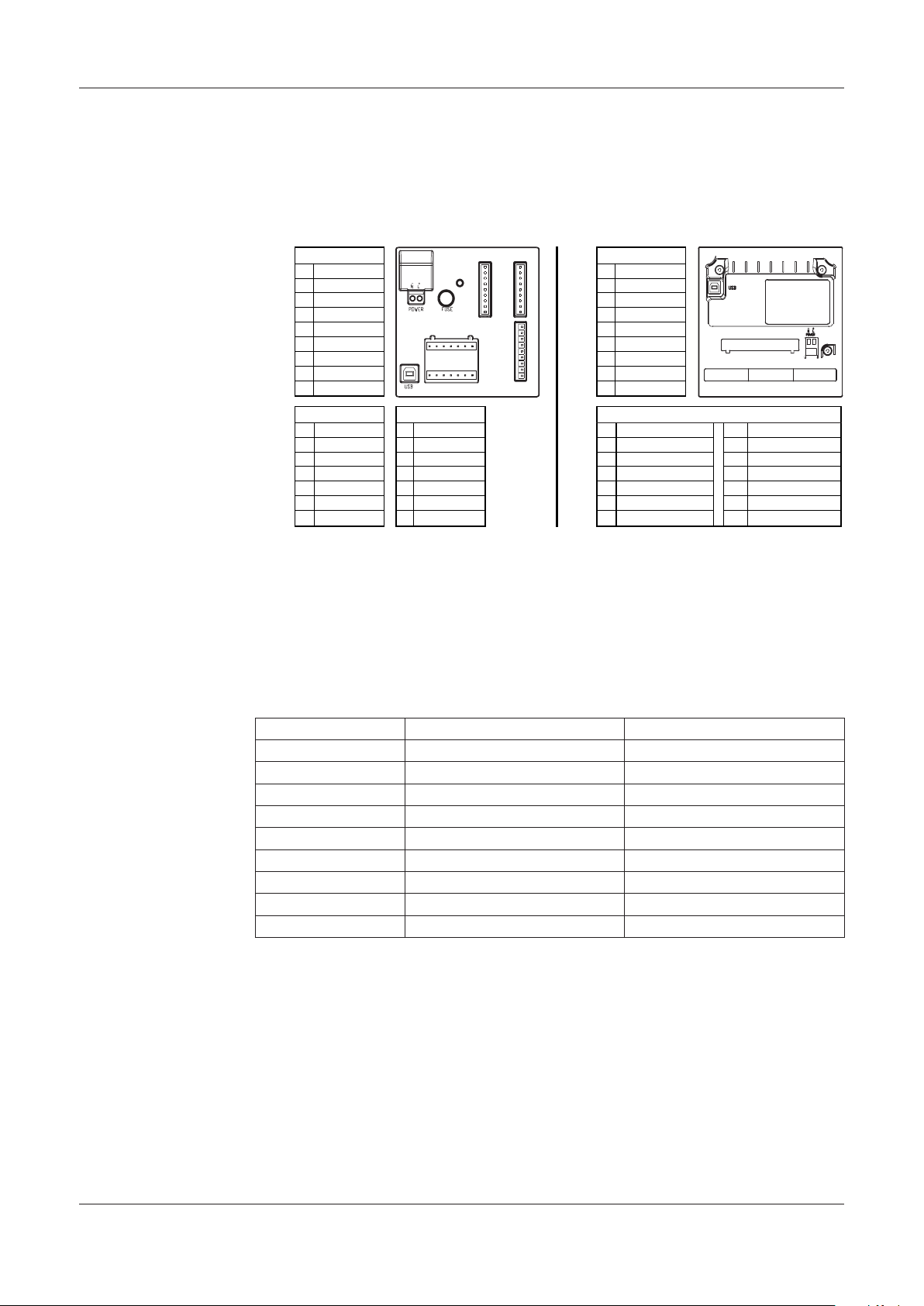

Power connections are labeled –N for Neutral and +L for Line, for 100 to 240 VAC or 20 – 30 VDC.

1

⁄4DIN

1

⁄2DIN

* Dual-Channel only

TB1A for 1⁄4DIN

1 NO2

2 COM2

3 NC2

4 NO6*

5 COM6*

6 NO4

7 COM4

TB1B for 1⁄4DIN

1 NO1

2 COM1

3 NC1

4 NC5*

5 COM5*

6 NO3

7 COM3

TB2 for 1⁄4DIN

1 AO1+

2 AO1–/AO2–

3 AO2+

4 AO3+*

5 AO3–/AO4–*

6 AO4+*

7 DI1+

8 DI1–/DI2–*

9 DI2+*

TB2 for 1⁄2DIN

1 AO1+

2 AO1–/AO2–

3 AO2+

4 AO3+*

5 AO3–/AO4–*

6 AO4+*

7 DI1+

8 DI1–/DI2–*

9 DI2+*

1 NO1

2 COM1

3 NC1

4 NO2

5 COM2

6 NC2

7 COM5*

8 NC5*

9 COM6*

10 NO6*

11 NO3

12 COM3

13 NO4

14 COM4

TB4

TB2

TB3

TB1A

TB1B

1 7

1 7

9

1

9

1

9

1

TB2 TB3

TB4

TB1

1 14

1 9 1 9 1 9

TB1 for 1⁄2 DIN

NO= normally

open (contact

is open if

unactuated).

NC= normally

closed

(contact is

closed if unactuated)

4.3 Connector PIN definition

4.3.1 TB1 and TB2 for 1/2DIN and 1/4DIN versions

NO = normally open (contact open if un-actuated).

NC = normally closed (contact closed if un-actuated).

4.3.2 TB3/TB4* – ISM (digital) Sensors, pH and Dissolved Oxygen

The wiring of the digital 9 terminal connectors is:

Pin no. Sensor wire Color Function

1 – 24 VDC

2 – GND (24 VDC)

3 Cable core 1-Wire

4 Shield GND (5 VDC)

5 – No connection

6 – GND (5 VDC)

7 – RS485–

8 – RS485+

9 – 5 VDC

* only on dual channel unit.

© 03/08 Mettler-Toledo AG, CH-8606 Greifensee, Switzerland Transmitter Multiparameter M300 ISM

Printed in Switzerland 52 121 365

Page 20

Transmitter Multiparameter M300 ISM 20

A

B

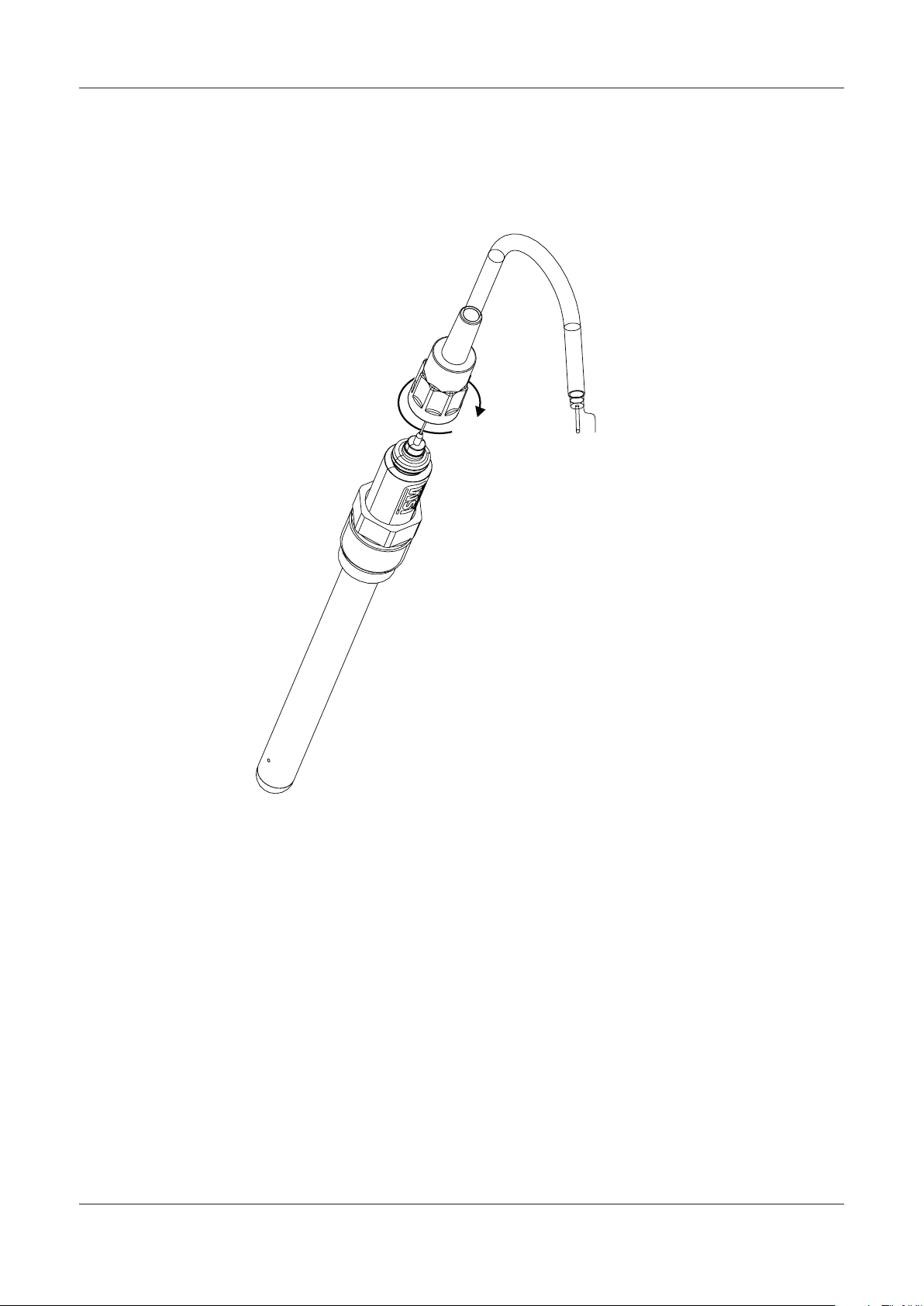

4.4 Connection of Sensor

4.4.1 Connection of ISM Sensor, pH and Dissolved Oxygen

NOTE: Connect the Sensor and screw the plug head clockwise (hand tight).

C

4.4.2 AK9 Cable Assignment

A: 1-wire data

B: Ground

© 03/08 Mettler-Toledo AG, CH-8606 Greifensee, Switzerland Transmitter Multiparameter M300 ISM

Printed in Switzerland 52 121 365

Page 21

Transmitter Multiparameter M300 ISM 21

5 Placing transmitter in, or out, of service

5.1 Placing transmitter in service

After connecting the transmitter to power supply circuit, it will be active as soon as the circuit is

powered.

5.2 Placing transmitter out of service

First disconnect the unit from the main power source, then disconnect all remaining electrical

connections. Remove the unit from the wall/panel. Use the installation instruction in this manual

as reference for dis-assembling mounting hardware.

© 03/08 Mettler-Toledo AG, CH-8606 Greifensee, Switzerland Transmitter Multiparameter M300 ISM

Printed in Switzerland 52 121 365

Page 22

Transmitter Multiparameter M300 ISM 22

6 Quick Setup

(PATH: Menu/Quick Setup)

Select Quick Setup and press the [ENTER] key. Enter the security code if necessary

(see section 9.3)

Note: Please find the complete description of the Quick Setup routine described in the separate

C

Note: Refer to section 3.3 for information on menu navigation.

booklet ”Quick Setup Guide for Transmitter M300” enclosed in the box.

C

© 03/08 Mettler-Toledo AG, CH-8606 Greifensee, Switzerland Transmitter Multiparameter M300 ISM

Printed in Switzerland 52 121 365

Page 23

Transmitter Multiparameter M300 ISM 23

7 Sensor Calibration

(PATH: Cal)

The calibration key allows the user one-touch access to Sensor calibration and verification

features.

NOTE: During Calibration, a flashing ‘H’ in the upper left corner of the display indicates a calib-

C

ration is in process with a Hold condition active. (The hold output function need to be activated)

7.1 Enter Calibration Mode

While in Measurement mode press the key.

Press the or key to select the type of calibration desired.

After selecting ‘Sensor’, use the key to move to the next line. Select the channel ‘A’ or ‘B’ to

be calibrated. Select the desired Sensor Calibration task. The choices for each sensor type are:

Conductivity = Conductivity, Resistivity, Temperature, Edit, Verify

Oxygen = Oxygen, Temperature, Edit, Verify

pH = pH, mV, Temperature, Edit pH, Edit mV, Verify

Press [ENTER].

7.2 Conductivity Calibration

This feature provides the ability to perform a one-point or two-point Conductivity ‘Sensor’

calibration. The procedure described below works for both types of calibrations. There

is no reason to perform a two-point calibration on a two-electrode conductivity sensor. Four

electrode sensors do require a two-point calibration.

NOTE: When performing calibration on a conductivity sensor, results will vary depending on the

C

methods, calibration apparatus and/or quality of reference standards used to perform the

calibration.

Enter Conductivity Sensor Calibration mode as described in section 7.1.

All other models operate in the Standard Compensation mode.

Press [ENTER].

© 03/08 Mettler-Toledo AG, CH-8606 Greifensee, Switzerland Transmitter Multiparameter M300 ISM

Printed in Switzerland 52 121 365

Page 24

Transmitter Multiparameter M300 ISM 24

7.2.1 One-point Sensor Calibration

(Display reflects typical Conductivity Sensor calibration)

Select 1 point Calibration and press [ENTER].

Enter the Value of calibration Point 1 and then press the [ENTER] key to start calibration. The

value in the 2nd text line is the actual measured value from the sensor prior to calibration.

After the calibration the Multiplier or slope calibration factor ‘M’ and the Adder or offset

calibration factor ‘A’ are displayed.

7.2.2 Two-point Sensor Calibration (4-electrode sensors only)

Enter Conductivity Sensor Calibration mode as described in section 7.1.

Select 2 point Calibration and press [ENTER].

CAUTION: Rinse sensors with a high-purity water solution between calibration points to prevent

contamination of the reference solutions.

Enter the Value of Point 1 and press the [ENTER] key. Place the sensor into the second reference

solution.

Enter the Value of Point 2 and press the [ENTER] key to start the calibration.

After the calibration the Multiplier or slope calibration factor ‘M’ and the Adder or offset calibration

factor ‘A’ are displayed.

7.3 Oxygen Calibration

Dissolved Oxygen calibration is performed as either a one-point or process calibration.

7.3.1 One-Point Sensor Calibration

Before air calibration, for highest accuracy, enter the barometric pressure as in section 8.2.1.6.

Enter Oxygen Calibration mode as described in section 7.1.

A DO sensor calibration is always either a one point Air (Slope) or a Zero (Offset) calibration. A

one point slope calibration is done in air and a one point offset calibration is done at 0 ppb DO.

A one-point zero dissolved oxygen calibration is available but not normally recommended since

zero DO is very hard to achieve

© 03/08 Mettler-Toledo AG, CH-8606 Greifensee, Switzerland Transmitter Multiparameter M300 ISM

Printed in Switzerland 52 121 365

Page 25

Transmitter Multiparameter M300 ISM 25

Select 1 point followed by either Slope or ZeroPt as the calibration type. Press [ENTER].

Enter the value for Point 1 including a decimal point and units. The value in the second text line

is the value being measured by the transmitter and sensor in the units selected by the user.

Press [ENTER] when this value is stable to perform the calibration.

After the calibration the slope calibration factor S and the offset calibration factor Z are displayed.

7.3.2 Process Calibration

Enter Oxygen Calibration mode as described in section 7.1.

Select Process followed by either Slope or ZeroPt as the calibration type. Press [ENTER]

Take a sample and press the [ENTER] key again to store the current measuring Value. To show

the ongoing Calibration Process an H is displayed in the top left hand corner.

After determining the O2 Value of the Sample press the key again to proceed with the

calibration. Enter the O2 value of the sample then press the [ENTER] key to start calibration.

After a successful calibration, the calibration values are taken over and stored in the cal history

(Adjust), only stored in the cal history (Calibrate) or aborted.

7.4 pH Calibration

For pH sensors, the M300 transmitter features one-point, two-point (Auto or Manual mode)

or process calibration with

8 preset buffer sets or manual buffer entry. Buffer values refer to 25 °C. To calibrate the

instrument with automatic buffer recognition, you need a standard pH buffer solution that

matches one of these values. (See section 8.2.2.2 for configuring modes and selecting

buffer sets)

Enter pH Calibration mode as described in section 7.1.

© 03/08 Mettler-Toledo AG, CH-8606 Greifensee, Switzerland Transmitter Multiparameter M300 ISM

Printed in Switzerland 52 121 365

Page 26

Transmitter Multiparameter M300 ISM 26

7.4.1 One point calibration

Select 1 point Calibration.

Place the electrode in the buffer solution and press the [ENTER] key to start the calibration.

Auto mode: The display shows the buffer that the transmitter has recognized (Point 1) and the

measured value.

Manual mode: Enter the buffer value and press [ENTER] to proceed.

As soon as the drift conditions have stabilized (or [ENTER] pressed in manual mode) the

display changes to show the slope calibration factor S and the offset calibration factor Z.

Select Yes to save the calibration values and the successful Calibration is confirmed on the

display.

7.4.2 Two point calibration

Select 2 point Calibration.

Place the electrode in the first buffer solution and then press the [ENTER] key.

Auto mode: The display shows the buffer that the transmitter has recognized (Point 1) and

the measured value.

Manual mode: Enter the buffer value and press [ENTER] to proceed.

As soon as the drift conditions have stabilized (or [ENTER] pressed in manual mode) the

display changes and prompts you to place the electrode in the second buffer solution.

As soon as the drift conditions have stabilized (or [ENTER] pressed in manual mode) the

display changes to show the slope calibration factor S and the offset calibration factor Z.

Select Yes to save the calibration values and the successful Calibration is confirmed on the

display.

© 03/08 Mettler-Toledo AG, CH-8606 Greifensee, Switzerland Transmitter Multiparameter M300 ISM

Printed in Switzerland 52 121 365

Page 27

Transmitter Multiparameter M300 ISM 27

7.4.3 Process calibration

Select Process Calibration.

Take a sample and press the [ENTER] key again to store the current measuring Value. To show

the ongoing Calibration Process, A or B (depending on the channel) is blinking in the display.

After determining the pH Value of the Sample, press the key again to proceed with the

calibration.

Enter the pH value of the sample then press the [ENTER] key to start calibration.

After the calibration the slope calibration factor S and the offset calibration factor Z are displayed.

Select Yes to save the new calibration values and the successful Calibration is confirmed on the

display.

7.4.4 mV calibration

Enter mV Calibration mode as described in section 7.1.

The user can now enter Point 1. The offset calibration factor is calculated as:

Point1 + mV (measured value) and displayed on the next screen.

Z is the newly calculated offset calibration factor. The slope calibration factor S is always 1

and does not enter the calculation.

After a successful calibration, the calibration values are taken over and stored in the cal history

(Adjust), only stored in the cal history (Calibrate) or aborted.

7.5 Sensor Temperature Calibration

Enter Sensor Calibration mode as described in section 7.1 and select Temperature.

© 03/08 Mettler-Toledo AG, CH-8606 Greifensee, Switzerland Transmitter Multiparameter M300 ISM

Printed in Switzerland 52 121 365

Page 28

Transmitter Multiparameter M300 ISM 28

7.5.1 One-Point Sensor Temperature Calibration

Select 1 point calibration. Slope or Offset can be selected with the 1 point calibration. Select

Slope to recalculate the Slope factor M (Multiplier) or Offset to recalculate the offset calibration

factor A (Adder).

Enter the value for Point 1 and press [ENTER].

The newly calculated value – either M or A – is displayed. Select Yes to save the new calibration

values and the successful Calibration is confirmed on the display.

7.5.2 Two – Point Sensor Temperature Calibration

Select 2 point as calibration Type.

Enter the value for Point 1 and press [ENTER].

Enter the value for Point 2 and press [ENTER].

The newly calculated values M and A are displayed. Select Yes and press [ENTER] to save the

new calibration values and the successful Calibration is confirmed on the display.

© 03/08 Mettler-Toledo AG, CH-8606 Greifensee, Switzerland Transmitter Multiparameter M300 ISM

Printed in Switzerland 52 121 365

Page 29

Transmitter Multiparameter M300 ISM 29

7.6 Edit Sensor Calibration Constants

Enter Calibration mode as described in section 7.1 and select Edit, Edit pH or Edit mV.

All calibration constants for the selected sensor channel are displayed. Primary measurement

constants (p) are displayed on Line 3. Secondary measurement (temperature) constants (s)

for the sensor are displayed on Line 4.

The calibration constants can be changed in this menu.

Select Yes to save the new calibration values and the successful Calibration is confirmed on

the display.

NOTE: Each time a new conductivity sensor is connected to the M300 transmitter, it is

C

necessary to enter the unique calibration constant located on the sensor label.

7.7 Sensor Verification

Enter Calibration mode as described in section 7.1. and select Verify.

The measured signal of the primary and the secondary measurement in electrical units

are shown. The meter calibration factors are used when calculating these values.

Use the or key to toggle between Channel A and B

© 03/08 Mettler-Toledo AG, CH-8606 Greifensee, Switzerland Transmitter Multiparameter M300 ISM

Printed in Switzerland 52 121 365

Page 30

Transmitter Multiparameter M300 ISM 30

Configure

Measurement Analog Outputs Set Points Alarm/Clean Display Hold Outputs

8 Configuration

(PATH: Menu/Configure)

8.1 Enter Configuration Mode

While in Measurement mode, press the key. Press the or key to navigate to the

Configure – Menu and press [ENTER].

8.2 Measurement

(PATH: Menu/Configure/Measurement)

Enter configuration mode as described in Section 8.1.

Press the [ENTER] key to select this Menu. The following sub menus can now be selected:

Channel Setup, Temperature Source, Comp/pH/O2 and Set Averaging.

8.2.1 Channel Setup

Press the [ENTER] key to select the ‘Channel Setup’ Menu.

Select Sensor Type and press [ENTER].

Available Sensor Types are:

pH/ORP = pH or ORP

O2 hi = Dissolved oxygen (ppm)

Cond (2) = 2 electrode conductivity*

Cond (4) = 4 electrode conductivity*

Auto: = The transmitter automatically recognizes the connected sensor

* Q4/2008

If you select a specific parameter instead of auto, the transmitter only accepts the selected

parameter type.

© 03/08 Mettler-Toledo AG, CH-8606 Greifensee, Switzerland Transmitter Multiparameter M300 ISM

Printed in Switzerland 52 121 365

Page 31

Transmitter Multiparameter M300 ISM 31

The 4 lines of the display can now be configured with sensor channel ‘A’ (if conventional Sensor

is chosen) or ‘B’ (if ISM Sensor is chosen) for each line of the display as well as measurements

and unit multipliers. Pressing the [ENTER] key will display the selection for lines a, b, c and d.

Pressing the [ENTER] key again will bring up the Save Changes dialog. Selecting No will

discard the entered values and return to the measurement display screen, selecting Yes will

save changes made.

8.2.2 pH/O2 Parameter related settings

Press [ENTER] to select this Menu. Additional measurement and calibration parameters can be

set for each parameter; conductivity, pH and O2.

For more details, please see the following explanations depending on the selected parameter.

8.2.2.1 Conductivity Temperature Compensation

The temperature compensation mode for any of the four measurement lines can be selected.

Temperature compensation should be matched to the characteristics of the application.

Choices are ‘Standard’ and ‘Linear’. Press [ENTER] and save changes.

Standard compensation includes compensation for non-linear high purity effects as well as

conventional neutral salt impurities and conforms to ASTM standards D1125 and D5391.

Linear compensation adjusts the reading by a factor expressed as a “% per °C” (deviation

from 25 °C). Use only if the sample has a well-characterized linear temperature coefficient.

The factory default setting is 2.0 %/°C.

8.2.2.2 pH Parameters

Select pH and press [ENTER].

Select the Drift control for calibration as Auto (drift and time criteria have to be fulfilled) or

Manual (The user can decide when a signal is stable enough to complete calibration)

followed by the relevant buffer table for the automatic buffer recognition. If the drift rate is less

than 0.4 mV over a 20 second interval then the reading is stable and the calibration is done

using the last reading. If the drift criteria is not met within 300 seconds then the calibration

times out and the message “Calibration Unsuccessful Press Enter to Continue” is displayed.

© 03/08 Mettler-Toledo AG, CH-8606 Greifensee, Switzerland Transmitter Multiparameter M300 ISM

Printed in Switzerland 52 121 365

Page 32

Transmitter Multiparameter M300 ISM 32

For automatic buffer recognition during calibration, select the buffer solution set that will be

used: Mettler-9, Mettler-10, NIST Tech, NIST Std, HACH, CIBA, MERCK, WTW or None. See

Section 20 for buffer values. If the auto buffer feature will not be used or if the available buffers

are different from those above, select None.

STC is the solution temperature coefficient in units of pH/°C referenced to 25 °C (Default =

0.000 for most applications). For pure waters, a setting of 0.016 pH/°C should be used. For

low conductivity power plant samples near 9 pH, a setting of 0.033 pH/°C should be used.

These positive coefficients compensate for the negative temperature influence on the pH of these

samples.

IP is the isothermal point value (Default = 7.000 for most applications). For specific

compensation requirements or non standard inner buffer value, this value can be changed.

The option to enter a fixed Calibration Temperature is given. ‘Fixed’ allows a specific

temperature value to be entered. Selecting ‘No’ means the Temperature configured under 8.2.2

will be used for the Calibration.

Pressing [ENTER] again will bring up the Save Changes dialog. Selecting No will discard the

entered values and return to the measurement display screen, selecting Yes will save changes

made.

© 03/08 Mettler-Toledo AG, CH-8606 Greifensee, Switzerland Transmitter Multiparameter M300 ISM

Printed in Switzerland 52 121 365

Page 33

Transmitter Multiparameter M300 ISM 33

8.2.2.3 Dissolved Oxygen Parameters

Select O2 and press [ENTER]

Enter the Atmospheric pressure. The default value for AtmPres is 760.0 and the default unit is

mmHg.

Enter the Process Pressure. The units for ProcPres and AtmPres do not have to be the same.

The salinity of the measured solution and the relative humidity of the calibration gas can also be

entered. The allowed values for Relative Humidity are in the range 0.00 to 100%.

Pressing the [ENTER] key again will bring up the Save Changes dialog. Selecting No will discard

the entered values and return to the measurement display screen, selecting Yes will save

changes made.

8.2.4 Set Averaging

Press the [ENTER] key to select this Menu. The averaging method (noise filter) for each

measurement line can now be selected. The options are Special (Default), None, Low, Medium

and High:

None = no averaging or filtering

Low = equivalent to a 3 point moving average

Medium = equivalent to a 6 point moving average

High = equivalent to a 10 point moving average

Special = averaging depending on signal change (normally High averaging but Low averaging

for large changes in input signal)

Pressing the [ENTER] key again will bring up the Save Changes dialog. Selecting No will discard

the entered values and return to the measurement display screen, selecting Yes will save

changes made.

© 03/08 Mettler-Toledo AG, CH-8606 Greifensee, Switzerland Transmitter Multiparameter M300 ISM

Printed in Switzerland 52 121 365

Page 34

Transmitter Multiparameter M300 ISM 34

8.3 Analog Outputs

(PATH: Menu/Configure/Analog Outputs)

Enter configuration mode as described in Section 8.2.

Press the [ENTER] key to select this Menu, which lets you configure the 4 Analog Outputs.

Once analog outputs have been selected, use the and buttons to navigate between

configurable parameters. Once a parameter is selected, its setting can be selected per the

following table:

When an Alarm Value is selected, the analog output will go to this value if any alarm condition

occurs.

Parameter Selectable Values

Aout: 1, 2, 3 or 4 (default is 1)

Measurement: a, b, c, d or blank (none) (default is blank)

Alarm Value: 3.6 mA, 22.0 mA or Off (default is off)

The Aout type can be Normal, Bi-Linear, Auto-Range or Logarithmic. The range can be 4–20mA

or 0–20mA. Normal provides linear scaling between the minimum and maximum scaling l

imits and is the default setting. Bi-Linear will also prompt for a scaling value for the mid-point

of the signal and allows two different linear segments between the minimum and maximum

scaling limits.

Enter the minimum and maximum Value of Aout.

If Auto-Range was selected then Aout max1 can be configured. Aout max1 is the maximum

value for the first range on Auto-Range. The maximum value for the second range on AutoRange was set in the previous menu. If Logarithmic Range was selected, it will also prompt

for the number of decades as ‘Aout1 # of Decades =2’.

The value for the Hold mode can be configured to hold the Last value or can be set to a Fixed

value.

Pressing the [ENTER] key again will bring up the Save Changes dialog. Selecting No will

discard the entered values and return to the measurement display screen, selecting Yes will

save changes made.

© 03/08 Mettler-Toledo AG, CH-8606 Greifensee, Switzerland Transmitter Multiparameter M300 ISM

Printed in Switzerland 52 121 365

Page 35

Transmitter Multiparameter M300 ISM 35

8.4 Setpoints

(PATH: Menu/Configure/Setpoints)

Enter configuration mode as described in Section 8.2.

Press the [ENTER] key to select this Menu.

Up to 6 Setpoints can be configured on any of the measurements (a thru d). The possible

Setpoint types are Off, High, Low, Outside and Between.

An ‘Outside’ Setpoint will cause an alarm condition whenever the measurement goes above its

high limit or below its low limit. A ‘Between’ Setpoint will cause an alarm condition to occur

whenever the measurement is between its high and low limits.

Enter the desired value(s) for the Setpoint and press [ENTER]

This screen provides the option to configure a setpoint to be active on an over range condition.

Select the setpoint and ‘Yes’ or ‘No’. Select the desired relay that will activate when the setpoint

alarm condition is reached.

Over Range

Once configured, the selected relay will be activated if a sensor over-range condition is detected

on the assigned input channel.

Delay

Enter the delay time in seconds. A time delay requires the setpoint to be exceeded continuously

for the specified length of time before activating the relay. If the condition disappears before the

delay period is over, the relay will not be activated.

Hysteresis

Enter the hysteresis as a percentage-value. A hysteresis value requires the measurement to

return within the setpoint value by a specified percentage before the relay is deactivated.

For a high setpoint, the measurement must decrease more than the indicated percentage

below the setpoint value before the relay is deactivated. With a low setpoint, the measurement

must rise at least this percentage above the setpoint value before the relay is deactivated. For

example, with a high setpoint of 100, when this value is exceeded, the measurement must fall

below 90 before the relay is deactivated.

Hold

Enter the Relay Hold Status of ‘Last’ or ‘Off’. This is the state the Relay will go to during a Hold

status.

State

Relay contacts are in normal state until the associated setpoint is exceeded, then the relay is

activated and the contact states change.

Select ‘Inverted’ to reverse the normal operating state of the relay (i.e. Normally open contacts

are in a closed state, and normally closed contacts are in an open state, until the setpoint is

exceeded). ‘Inverted’ relay operation is functional when power is applied to the M300

transmitter.

Pressing the [ENTER] key again will bring up the Save Changes dialog. Selecting No will

discard the entered values and return to the measurement display screen, selecting Yes will

save changes made.

© 03/08 Mettler-Toledo AG, CH-8606 Greifensee, Switzerland Transmitter Multiparameter M300 ISM

Printed in Switzerland 52 121 365

Page 36

Transmitter Multiparameter M300 ISM 36

8.5 Alarm/Clean

(PATH: Menu/Configure/Alarm/Clean)

Enter configuration mode as described in Section 8.1.

This Menu allows the configuration of Alarm and Clean functionality.

8.5.1 Alarm

To select ‘Setup Alarm’, press the or key so that ‘Alarm’ is flashing.

Using the and buttons, navigate to “Use Relay #”. Using the or keys, select a relay

to be used for the Alarm and press [ENTER].

One of the following events may be alarmed:

1. Power Failure

2. Software Failure

3. Rg Diagnostics – pH glass membrane resistance (only for pH sensors)

4. Rr Diagnostics – pH reference resistance (only for pH sensors)

If any of these are set to Yes, an alarm signal will be initiated, the selected relay will be

activated, and an alarm message will be recorded if:

1. there is a power failure or power cycling

2. the software watchdog performs a reset

3. Rg is out of tolerance – for example, broken measuring electrode (only for pH sensors)

4. Rr is out of tolerance – for example, coated or depleted reference electrode (only for pH

sensors)

For 1 and 2 the alarm indicator will be turned off when the alarm message is cleared. It will

reappear if the power is constantly cycling or if the watchdog is repeatedly resetting the system.

Only for pH sensors

For 3 and 4 the alarm indicator will go off if the message is cleared and the sensor has been

replaced or repaired so that the Rg and Rr values are within specification. If the Rg or Rr

message is cleared and Rg or Rr is still out of tolerance then the alarm will stay on and the

message will reappear. The Rg and Rr alarm can be turned off by going into this menu and

setting Rg Diagnostics and/or Rr Diagnostics to No. The message can then be cleared and

the alarm indicator will be off even though Rg or Rr is out of tolerance.

Each Alarm Relay can be configured in either a Normal or Inverted state. In addition, a Delay

for the activation can be set. For more information, refer to Section 8.4.

If power failure is turned on, only inverted state is possible and cannot be changed.

Pressing the [ENTER] key again will bring up the Save Changes dialog. Selecting No will

discard the entered values, selecting Yes will make the entered values the current ones.

© 03/08 Mettler-Toledo AG, CH-8606 Greifensee, Switzerland Transmitter Multiparameter M300 ISM

Printed in Switzerland 52 121 365

Page 37

Transmitter Multiparameter M300 ISM 37

8.5.2 Clean

Configure the Relay to be used for the cleaning cycle.

The Default value is Relay 1.

The Cleaning Interval can be set from 0.000 to 999.9 hours. Setting it to 0 turns the clean

cycle off. The cleaning time can be 0 to 9999 seconds and must be smaller than the Cleaning

Interval.

Select the desired Relay state: Normal or Inverted.

Pressing the [ENTER] key again will bring up the Save Changes dialog. Selecting No will

discard the entered values and return to the measurement display screen, selecting Yes will

save changes made.

8.6 Display

(PATH: Menu/Configure/Display)

Enter configuration mode as described in Section 8.2.

This Menu allows for the configuration of the values to be displayed and also the configuration

of the Display itself.

8.6.1 Measurement

The Display has 4 lines. Line 1 on top and Line 4 on the bottom.

Select the values (Measurement a, b, c or d) to be displayed on each line of the display.

The selection of the values for a, b, c, d needs to be done under Configuration/Measurement/

Channel Setup.

Select the ‘Error Display’ mode. If this is set to ‘On’ when an alarm has occurred, the message

“Failure – Press Enter” will be displayed on Line 4 when an alarm occurs in the normal

Measurement mode.

Pressing the [ENTER] key again will bring up the Save Changes dialog. Selecting No will

discard the entered values, selecting Yes will make the entered values the current ones.

© 03/08 Mettler-Toledo AG, CH-8606 Greifensee, Switzerland Transmitter Multiparameter M300 ISM

Printed in Switzerland 52 121 365

Page 38

Transmitter Multiparameter M300 ISM 38

8.6.2 Resolution

This menu allows the setting of the resolution of each displayed value.

Possible settings are 1, 0.1, 0.01, 0.001 or Auto.

Pressing the [ENTER] key will bring up the Save Changes dialog.

8.6.3 Backlight

This Menu allows the setting of the back light options of the display.

Possible settings are On, On 50% or Auto Off 50%. If Auto Off 50% is selected then the

backlight will go to 50% after 4 minutes with no keypad activity. The backlight will automatically

come back on if a key is pressed.

Pressing the [ENTER] key Will bring up the Save Changes dialog.

8.6.4 Name

This menu allows for the configuration of an alpha-numeric name which is displayed in the first

9 characters on Lines 3 and 4 of the Display. The default is nothing (blank).

If a name is entered on line 3 and/or 4 a measurement can be still displayed on the same line.

Use the and keys to navigate between digits to be altered. Using the and keys to

change the character to be displayed. Once all digits of both display channels have been

entered, press [ENTER] to bring up the Save Changes dialog.

The resulting display in the measurement mode appears on Lines 3 and 4 ahead of the

measurements.

© 03/08 Mettler-Toledo AG, CH-8606 Greifensee, Switzerland Transmitter Multiparameter M300 ISM

Printed in Switzerland 52 121 365

Page 39

Transmitter Multiparameter M300 ISM 39

8.7 Hold Analog Outputs

(PATH: Menu/Configure/Hold Outputs)

Enter configuration mode as described in Section 8.1.

The ‘Hold outputs’ function applies during the calibration process. If set ‘Hold outputs’ to Yes,

during calibration process the analog output, the output relay and USB ouptut will be at hold

state. The hold state depends on the setting. For the possible hold settings, see the list below.

The following options are possible:

Hold Outputs? Yes/No

The ‘DigitalIn’ function applies all the time. As soon as a signal is active on the digital input the

transmitter goes to hold mode and the values on the analog output, the output relays and the

USB output will be at hold state.

DigitalIn1/2 State = On/Low/High

NOTE: DigitalIn1 is to hold channel A (conventional sensor)

C

DigitalIn2 is to hold channel B (ISM sensor)

Possible Hold states:

Output relays: On/Off (Configuration/Set point)

Analog Output: Last/Fixed (Configuration/Analog output)

USB: Last/Off (System/USB)

© 03/08 Mettler-Toledo AG, CH-8606 Greifensee, Switzerland Transmitter Multiparameter M300 ISM

Printed in Switzerland 52 121 365

Page 40

Transmitter Multiparameter M300 ISM 40

System

Set Language USB Passwords

Set/Clear

Lockout

Reset

9 System

(PATH: Menu/System)

While in Measurement mode press the key. Press the or key to navigate to ‘System’ –

Menu and press [ENTER].

9.1 Set Language

(PATH: Menu/System/Set Language)

This Menu allows the configuration of the Display language.

The following selections are possible:

English, French, German, Italian, Spanish, Portuguese*, Russian* or Japanese*(Katakana).

* Q3/2008

Pressing the [ENTER] key will bring up the Save Changes dialog.

9.2 USB

(PATH: Menu/System/USB)

This menu allows configuration of the USB hold function.

USB Hold may be set to either Off or Last Values. An external host device may poll the M300

for data. If the USB Hold is set to Off, current values are returned. If the USB Hold is set to Last

Values, the values present at the time the hold condition was established are returned.

Details of USB functions and communication protocols are covered in separate documentation.

Press [ENTER] to bring up the Save Changes dialog.

© 03/08 Mettler-Toledo AG, CH-8606 Greifensee, Switzerland Transmitter Multiparameter M300 ISM

Printed in Switzerland 52 121 365

Page 41

Transmitter Multiparameter M300 ISM 41

9.3 Passwords

(PATH: Menu/System/Passwords)

This Menu allows for the configuration of Operator and Administrator Passwords, as well as

setting up a List of allowed Menus for the Operator. The Administrator has rights to access all

Menus. All default passwords for new transmitters are ‘00000’.

The Passwords Menu is protected: Enter the Administrator Password to enter the Menu.

9.3.1 Changing Passwords

See Section 9.3 on how to enter the Passwords Menu. Select Change Administrator or Change

Operator and set the new Password.

Press the [ENTER] key and confirm the new password. Press [ENTER] again to bring up the

Save Changed dialog.

9.3.2 Configuring Menu Access for Operator

See 9.3 on how to enter the Passwords Menu. Select Configure Operator to configure the

Access list for the Operator. It is possible to assign/deny rights to the following Menus: Cal Key,

Quick Setup, Configuration, System, PID Setup and Service.

Choose either Yes or No to give/deny access to the above Menus and press [ENTER] to advance

to the next items. Pressing the [ENTER] key after configuring all menus will bring up the Save

Changes dialog. Selecting No will discard the entered values, selecting Yes will make the entered

values the current ones.

© 03/08 Mettler-Toledo AG, CH-8606 Greifensee, Switzerland Transmitter Multiparameter M300 ISM

Printed in Switzerland 52 121 365

Page 42

Transmitter Multiparameter M300 ISM 42

9.4 Set/Clear Lockout

(PATH: Menu/System/Set/Clear Lockout)

This menu enables/disables the Lockout functionality of the transmitter. The user will be asked

for a password before being allowed into any menus if the Lockout functionality is enabled.

The Lockout – Menu is protected: Enter the Administrator Password and select YES to enable or

NO to disable the Lockout functionality. Pressing the [ENTER] key after the selection will bring up

the Save Changes dialog. Selecting No will discard the entered value, selecting Yes will make

the entered value the current one.

9.5 Reset

(PATH: Menu/System/Reset)

This Menu allows access to the following options:

Reset System, Reset Meter Cal, Reset Analog Cal.

9.5.1 Reset System

This Menu allows the reset of the meter to the factory default settings (Setpoints off, analog

outputs off, etc.). The meter calibration and the analog output calibration are not affected.

Pressing the [ENTER] key after the selection will bring up a confirmation screen. Selecting No

will return the user to the Measurement mode with no changes. Selecting Yes will reset the meter.

9.5.2 Reset Meter Calibration

This Menu allows the reset of the meter’s calibration factors to the last factory calibration values.

Pressing the [ENTER] key after the selection will bring up a confirmation screen. Selecting No

will return the user to the Measurement mode with no changes. Selecting Yes will reset the meter

calibration factors.

© 03/08 Mettler-Toledo AG, CH-8606 Greifensee, Switzerland Transmitter Multiparameter M300 ISM

Printed in Switzerland 52 121 365

Page 43

Transmitter Multiparameter M300 ISM 43

9.5.3 Reset Analog Calibration

This Menu allows reset of the Analog Output calibration factors to the last factory calibration

values.

Pressing the [ENTER] key after the selection will bring up a confirmation screen. Selecting No

will return the user to the Measurement mode with no changes. Selecting Yes will reset the

Analog Output calibration.

© 03/08 Mettler-Toledo AG, CH-8606 Greifensee, Switzerland Transmitter Multiparameter M300 ISM

Printed in Switzerland 52 121 365

Page 44

Transmitter Multiparameter M300 ISM 44

PID Setup

Tune

Parameters

ModePID A/M PID Display

10 PID Setup

(PATH: Menu/PID Setup)

PID control is proportional, integral and derivative control action that can provide smooth

regulation of a process. Before configuring the transmitter, the following process characteristics

must be identified.

Identify the control direction of the process

– Conductivity:

Dilution – direct acting where increasing measurement produces increasing control output

such as controlling the feed of low conductivity diluting water to rinse tanks, cooling towers

or boilers

Concentrating – reverse acting where increasing measurement produces decreasing control

output, such as controlling chemical feed to attain a desired concentration

– Dissolved Oxygen:

Deaeration – direct acting where increasing DO concentration produces increasing control

output such as controlling the feed of a reducing agent to remove oxygen from boiler

feedwater

Aeration – reverse acting where increasing DO concentration produces decreasing control

output, such as controlling an aerator blower speed to maintain a desired DO concentration

in fermentation or wastewater treatment

– pH/ORP:

Acid feed only – direct acting where increasing pH produces increasing control output, also

for ORP reducing reagent feed

Base feed only – reverse acting where increasing pH produces decreasing control output,

also for ORP oxidizing reagent feed

Both acid and base feed – direct and reverse acting

Identify the control output type based on the control device to be used:

Pulse Frequency – used with pulse input metering pump

Pulse Length – used with solenoid valve

Analog – used with current input device such as electric drive unit, analog input metering

pump or current-to-pneumatic (I/P) converter for pneumatic control valve

Default control settings provide linear control, which is appropriate for conductivity, dissolved

oxygen. Therefore, when configuring PID for these parameters (or simple pH control) ignore

settings of deadband and corner points in the Tuning Parameter section below. The non-linear

control settings are used for more difficult pH/ORP control situations.

If desired, identify the non-linearity of the pH/ORP process. Improved control can be obtained

if the non-linearity is accommodated with an opposing non-linearity in the controller. A titration

curve (graph of pH or ORP vs. reagent volume) made on a process sample provides the

best information. There is often a very high process gain or sensitivity near the setpoint and

decreasing gain further away from the setpoint. To counteract this, the instrument allows for

adjustable non-linear control with settings of a deadband around the setpoint, corner points

© 03/08 Mettler-Toledo AG, CH-8606 Greifensee, Switzerland Transmitter Multiparameter M300 ISM

Printed in Switzerland 52 121 365

Page 45

Transmitter Multiparameter M300 ISM 45

further out and proportional limits at the ends of control as shown in the figure below.

Determine the appropriate settings for each of these control parameters based on the shape

of the pH process titration curve.

10.1 Enter PID Setup

While in Measurement mode press the key. Press the or key to navigate to the PID

Setup – Menu and press [ENTER].

10.2 PID Auto/Manual

(PATH: MENU/PID Setup/PID A/M)

This menu allows selection of Automatic or Manual operation. Select Auto or Manual operation.

Pressing the [ENTER] key will bring up the Save Changes dialog.

© 03/08 Mettler-Toledo AG, CH-8606 Greifensee, Switzerland Transmitter Multiparameter M300 ISM

Printed in Switzerland 52 121 365

Page 46

Transmitter Multiparameter M300 ISM 46

10.3 Mode

(PATH: MENU/PID Setup/Mode)

This menu contains the selection of control modes using relays or analog outputs. Press

[ENTER].

10.3.1 PID Mode

This menu assigns a relay or analog output for PID control action as well as details of their

operation. Based on the control device being used, select one of the following three paragraphs

for use with solenoid valve, pulse input metering pump or analog control.

Pulse Length – If using a solenoid valve, select “Relays” and “PL”, Pulse Length.

Choose the first relay position as #3 (recommended) and/or the second relay position

as #4 (recommended) as well as the Pulse Length (PL) according to the table below. A longer

pulse length will reduce wear on the solenoid valve. The % “on” time in the cycle is proportional

to the control output.

NOTE: All relays from #1 to #6 can be used for the controlling function.

C

1st Relay Position

(#3)

Controlling

Conductivity

pH/ORP Feeding base Feeding acid

Dissolved

Oxygen

concentrating reagent

feed

Reverse control action