Page 1

English

Deutsch

Español

Français

Operating Instructions Automatic Feeder LV12

Bedienungsanleitung Automatikförderer LV12

Instrucciones de manejo Alimentador automático LV12

Mode d'emploi Vibreur automatique LV12

中文

日本語

产品说明书 自动进料机 LV12

取扱説明書 自動フィーダ LV12

Page 2

Page 3

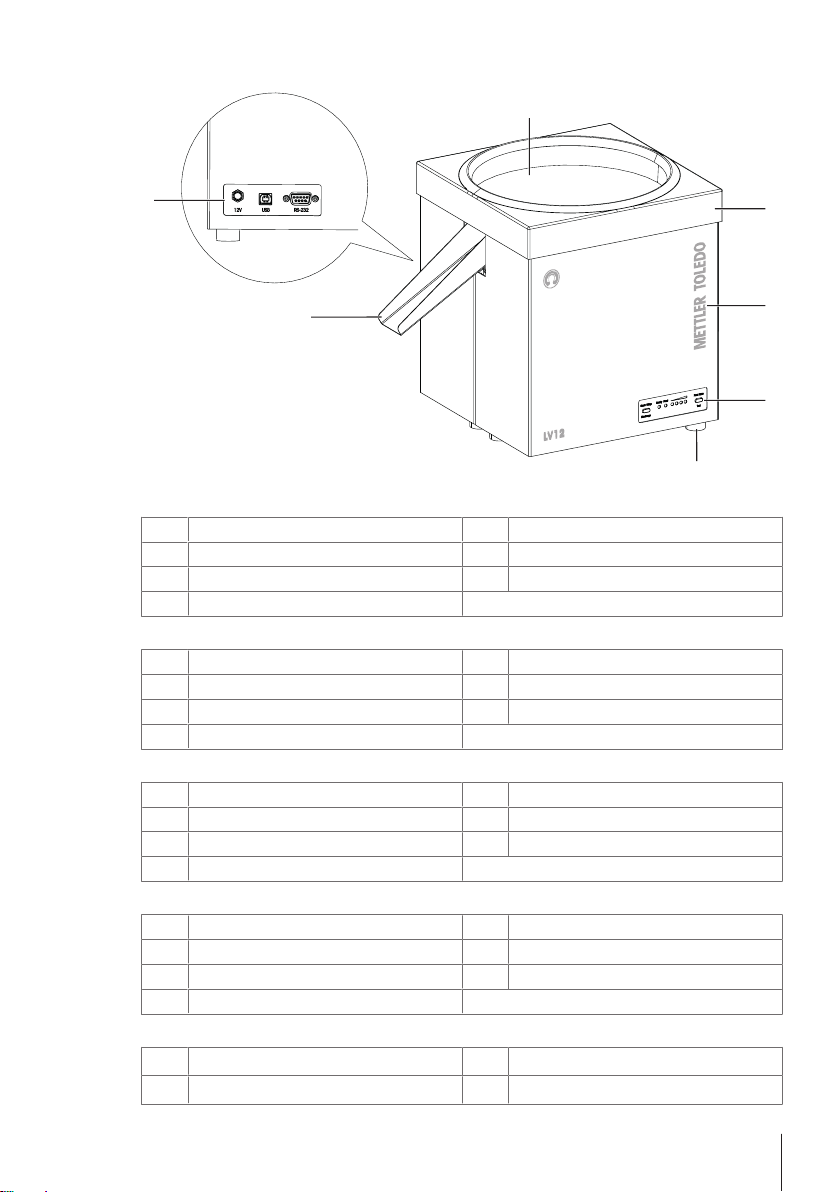

Overview

1

5

4

2

7

6

3

Legend device overview

Feeder plate

1

Housing

3

Rubber feet

5

Connection sockets

7

Legende Geräteübersicht

Förderteller

1

Gehäuse

3

Gummifüsse

5

Anschlussbuchsen

7

Leyenda de la visión general del dispositivo

Placa del alimentador

1

Carcasa

3

Patas de goma

5

Tomas de conexión

7

Légende – Présentation du dispositif

Plateau du vibreur

1

Boîtier

3

Pieds en caoutchouc

5

Prises de branchement

7

图例 设备概览

输料机板

1

外壳

3

Cover

2

Controls and indicators

4

Outlet chute

6

Abdeckung

2

Bedien- und Anzeigeelemente

4

Auslassrutsche

6

Cubierta

2

Controles e indicadores

4

Deslizadera de salida

6

Couvercle

2

Commandes et indicateurs

4

Glissière de sortie

6

保护罩

2

控件与指示灯

4

1

Page 4

橡胶支脚

5

连接插座

7

各部の名称

フィーダ プレート

1

ハウジング

3

ゴム足

5

接続ソケット

7

出口滑道

6

カバー

2

コントロールとインジケータ

4

排出シュート

6

2

Page 5

Operating Instructions Automatic Feeder

English

Bedienungsanleitung Automatikförderer

Instrucciones de manejo Alimentador automático

Mode d'emploi Vibreur automatique

产品说明书 自动进料机

取扱説明書 自動フィーダ

Deutsch

Español

Français

中文

日本語

Page 6

Page 7

1 Safety Information

• Read and understand the instructions in this manual before you use the device.

• Keep this manual for future reference.

• Include this manual if you pass on the device to other parties.

If the device is not used according to the instructions in this manual or if it is modified, the safety of

the user may be impaired and Mettler-Toledo GmbH assumes no liability.

1.1 Definition of signal words and warning symbols

Safety notes are marked with signal words and warning symbols. These show safety issues and

warnings. Ignoring the safety notes may lead to personal injury, damage to the instrument,

malfunctions and false results.

WARNING

CAUTION

NOTICE

Note

1.2 Product specific safety note

The device has been tested for the experiments and intended purposes documented in the appropriate

manual. However, this does not absolve you from the responsibility of performing your own tests of

the products supplied by us regarding their suitability for the methods and purposes you intend to use

them for.

Intended use

This device is designed to be used in quality testing laboratories by qualified staff. The LV12 is

intended to be used as automatic feeder for small parts (ø max. 20 mm) such as capsules, tablets

or small electronic and mechanical components.

Any other type of use and operation beyond the limits of technical specifications without written

consent from Mettler-Toledo GmbH, is considered as not intended.

Site requirements

The device has been developed for indoor operation. Avoid the following environmental influences:

• Conditions outside of the ambient conditions specified in the technical data

• Powerful vibrations

• Direct sunlight

• Corrosive gas atmosphere

• Explosive atmosphere of gases, steam, fog, dust and flammable dust

• Powerful electric or magnetic fields

for a hazardous situation with medium risk, possibly resulting in death or severe

injury if not avoided.

for a hazardous situation with low risk, resulting in minor or moderate injury if not

avoided.

for a hazardous situation with low risk, resulting in damage to the device, other

material damage, malfunctions and erroneous results, or loss of data.

(no symbol)

for useful information about the product.

General hazard Electrical shock

en

Safety Information 3Automatic Feeder

Page 8

Staff qualification

Incorrect use of the device or the chemicals used in the analysis can lead to death or injury. The

following experience is needed for operating the device.

• Knowledge and experience in working with toxic and caustic substances.

• Knowledge and experience in working with standard laboratory equipment.

• Knowledge and experience in working in accordance with general lab safety rules.

Responsibilities of the device owner

The device owner is the person that uses the device for commercial use or places the device at the

disposal of his staff. The device owner is responsible for product safety and the safety of staff, user(s)

and third party.

The operator has the following responsibilities:

• Know the rules for safety at the workplace that are in effect and enforce them.

• Ensure that only qualified staff uses the device.

• Define the responsibilities for installation, operation, cleaning, troubleshooting and maintenance

and ensure that the tasks are done.

• Train the staff in regular intervals and inform them about dangers.

• Provide the necessary protective gear for the staff.

Safety notes

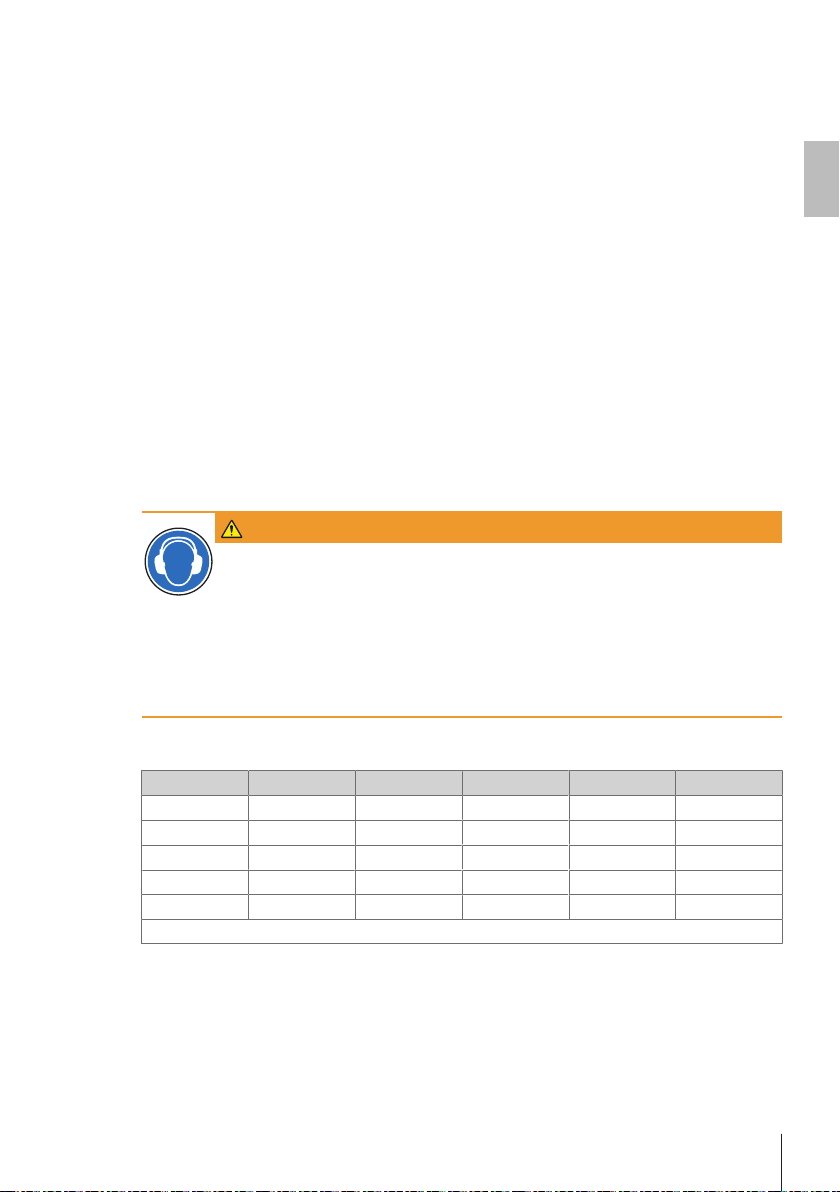

WARNING

Risk of hearing impairment due to high noise level!

Depending on the used samples (material and weight), potentially hazardous noise

levels may occur when samples fall down on the outlet chute. A noise level above

80db(A) may result in serious damage to hearing.

1 If you feed parts where you expect the noise level to be above 80 db(A), perform a

noise measurement. Take the examples below as references.

2 Wear ear protection if the noise level exceeds 80 db(A).

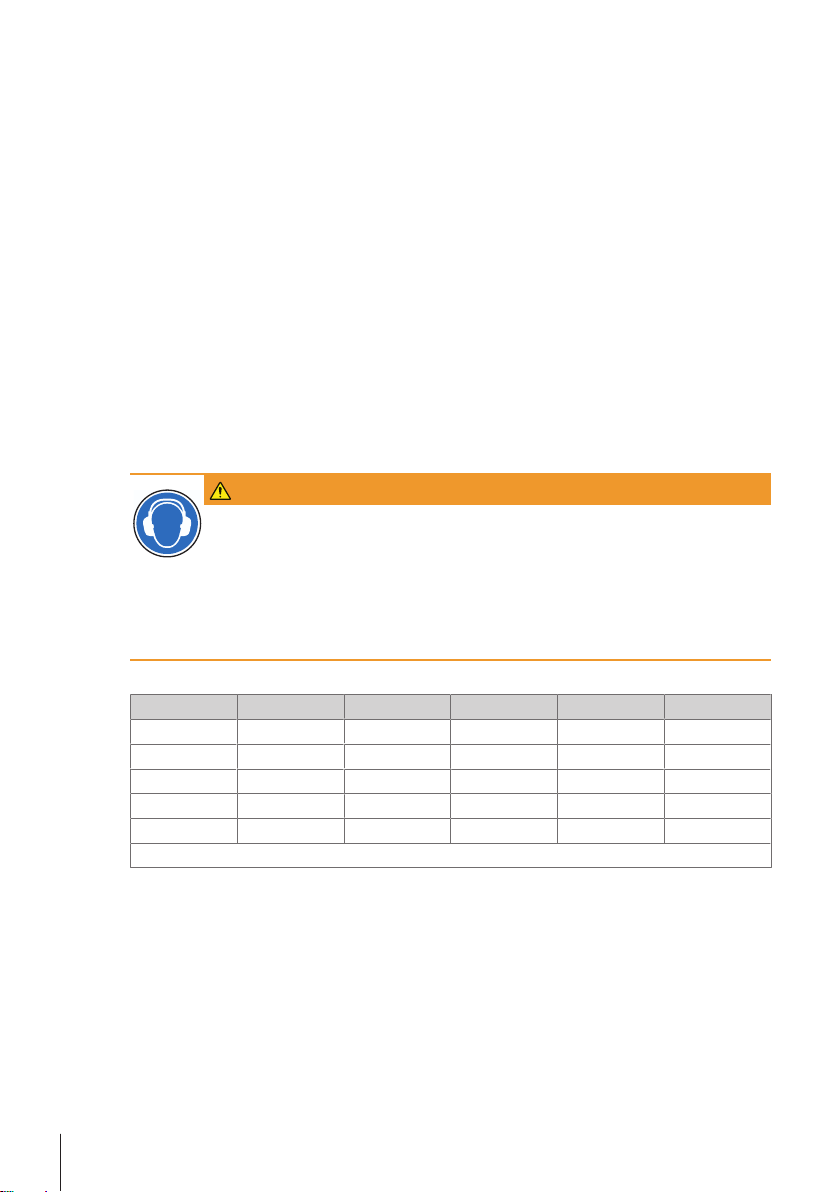

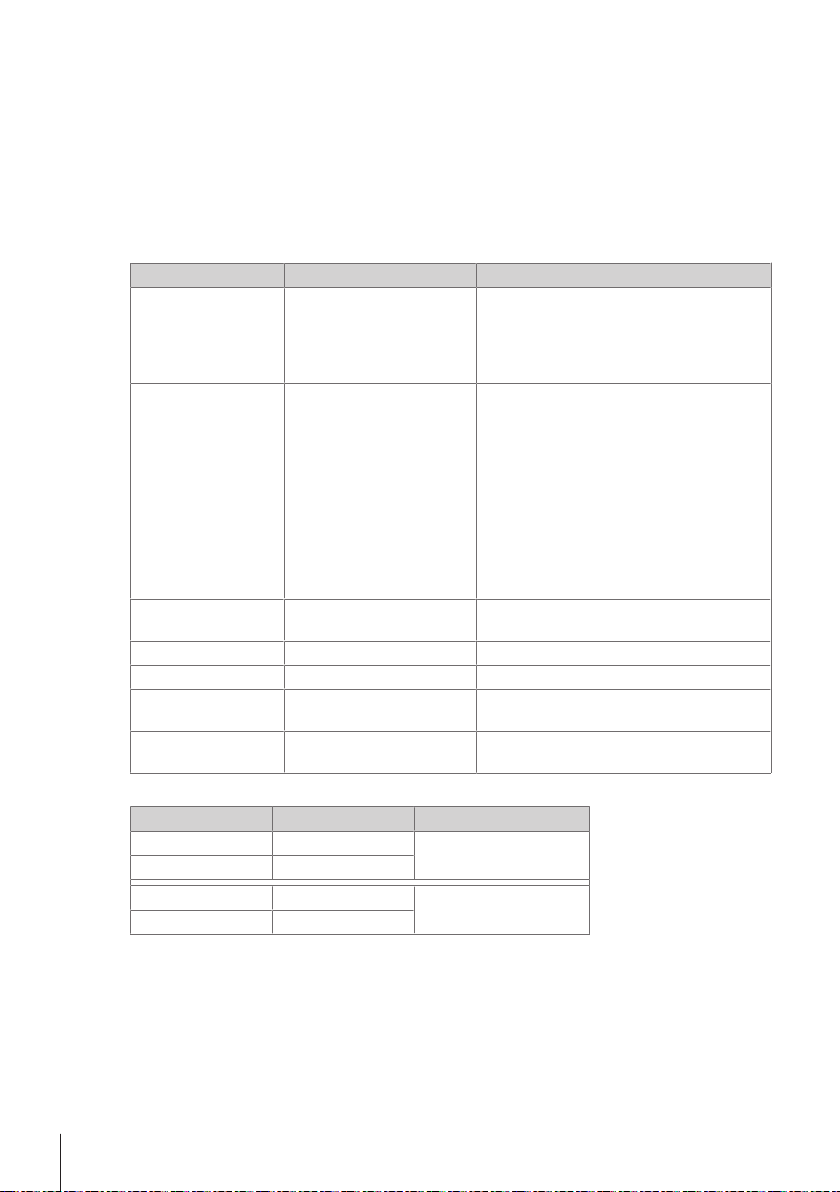

The following list provides approximate values of noise emissions (discharge mode, 20 cm):

Settings Item Material Weight Size Value

General Spacer Synthetical 0.12 g 10 × 5 mm

Small Screw Metal 0.14 g M2 × 3 mm

Medium Screw Metal 0.2 g M2.5 × 5 mm

Large Distance holder Metal 1.5 g M3 × 10 mm

Large Distance holder Metal 5.1 g M4 × 20 mm

Empty: < 70 db(A)

78 dB(A)

75 dB(A)

79 dB(A)

89 dB(A)

93 dB(A)

Safety Information4 Automatic Feeder

Page 9

NOTICE

Danger of damage due to inappropriate use!

Inappropriate use of the instrument may lead to significant material damage.

1 Install and operate the instrument only in dry interior rooms.

2 Always operate and use the device only in accordance with the instructions

contained in this manual.

3 Do not open the device.

4 Never make any modifications to the device.

5 Use only instrument accessories and peripheral devices from METTLER TOLEDO;

they are optimally adapted to your instrument.

en

Safety Information 5Automatic Feeder

Page 10

2 Design and Function

The LV12 is an automatic feeder for capsules, tablets or small electronic and mechanical

components. Large weighing series are radically simplified. The LV12 is therefore especially suitable

for statistical quality control (SQC). Usually the LV12 is remotely controlled by commands over a

serial interface (RS232 or USB), but the system can also be controlled manually using push buttons.

The LV12 delivers a single part to the balance and then stops automatically. After receiving the appropriate command from the weighing instrument, the device delivers the next part. This process can be

stopped at any time by a command. At the end of a sample, the feeder plate can be emptied or the

feeder waits for the command for a further sample.

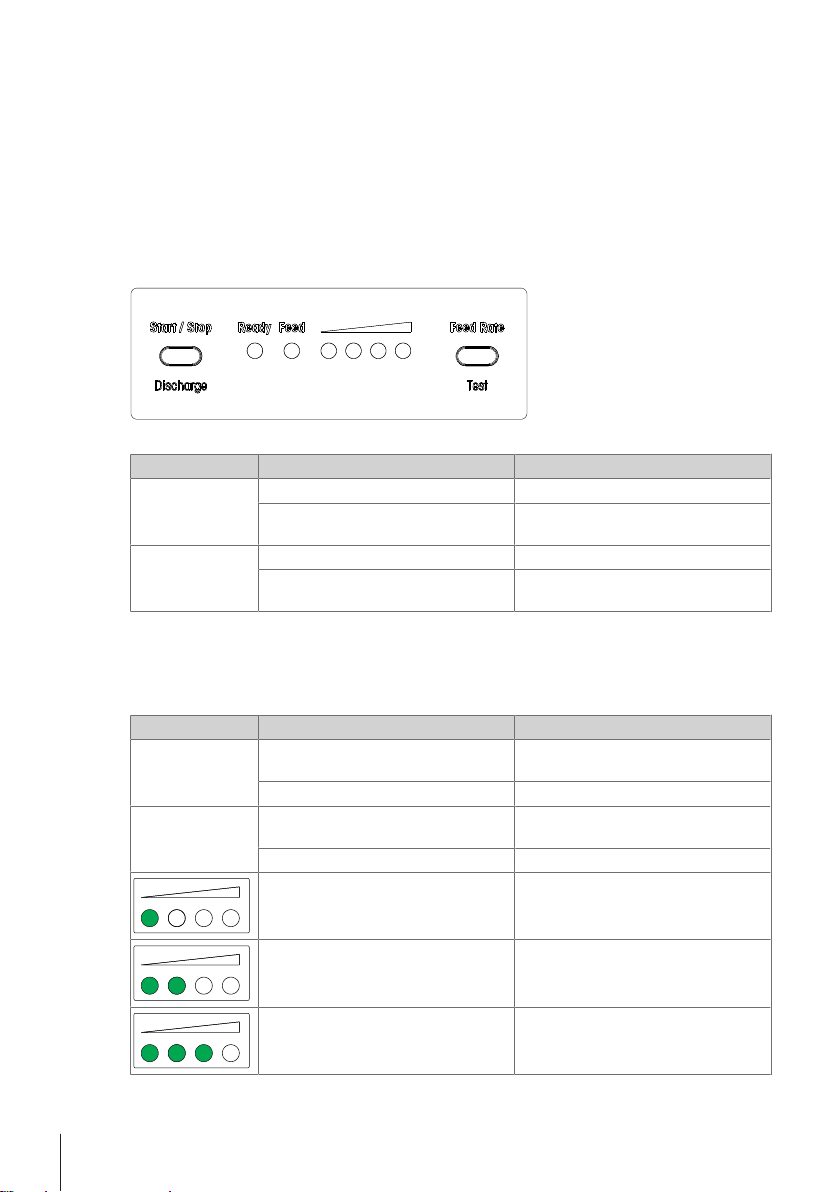

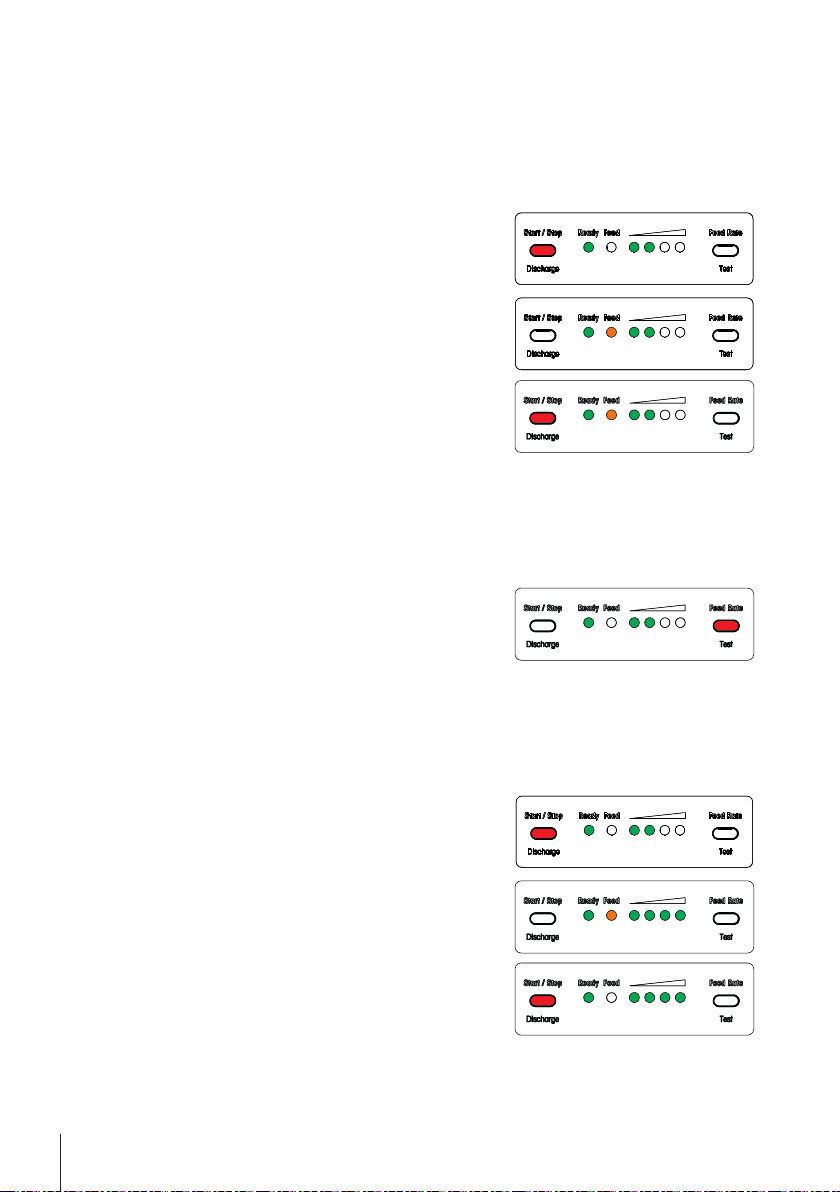

2.1 Controls and indicators

Controls

Button Action Objective

Start/Stop/

Discharge

Feed Rate/Test

Note

By pressing both buttons at the same time, the part size setting can be changed, see [Configure

feeding rate sets}Page17].

Indicators

LED indicator State Meaning

Ready

Feed

Press once To switch feeding action on/off

Press and hold until the level indicating

LEDs flash

Press once Change feed rate by one step

Press and hold until the LED Ready

flashes

Green LED lit up Instrument is switched on and ready for

Green LED flashes Instrument is in test mode

Orange LED lit up Feeding action is switched on and the

Orange LED flashes Light barrier is interrupted, dirty or faulty

One LED lit up Lowest feed rate

To switch on discharge

Activate the test mode to find the optimal

feed rate

operation

feeder plate vibrates

Two LEDs lit up Lower intermediate feed rate, default after

Three LEDs lit up Upper intermediate feed rate

switching on

Design and Function6 Automatic Feeder

Page 11

LED indicator State Meaning

1 2

3

All four LEDs lit up Highest feed rate

en

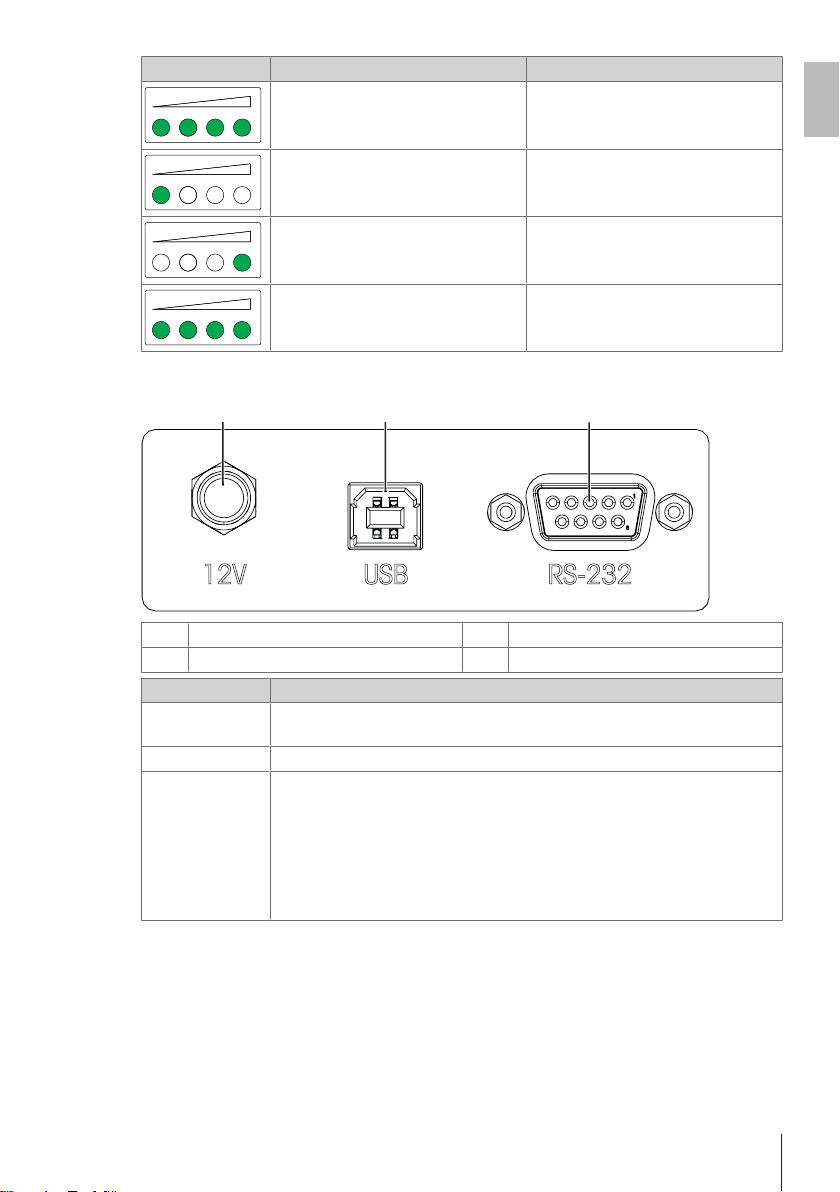

2.2 Connections

Socket for 12VDC power supply

1

RS232 interface

3

Connector Function

Socket for AC/DC

adapter

USB port (type B)

RS232 interface

Note

For the SICS command set of the LV12, see [MT-SICS interface commands and

functions}Page20].

First LED flashes

Fourth LED flashes

All Four LEDs flashes Instrument is in discharging mode

2

To connect the power supply. Use only the +12VDC standard AC/DC adapter which

is delivered with the device.

To connect a balance, a personal computer or a hub provided with an USB port.

The connection for RS232 is a 9-pin D-sub miniature connector, pin assignment as

for PCs. For the attachment of a computer, a so-called laplink or null modem cable

is needed.

Interface parameters:

• 9600 baud, no parity, 8 data bits, 1 stop bit

• Software handshake Xon/Xoff

• Line ending <CR><LF>

Short circuit at Start/Stop/Discharge

button

Short circuit at Feed Rate/Test button

USB port (type B)

Design and Function 7Automatic Feeder

Page 12

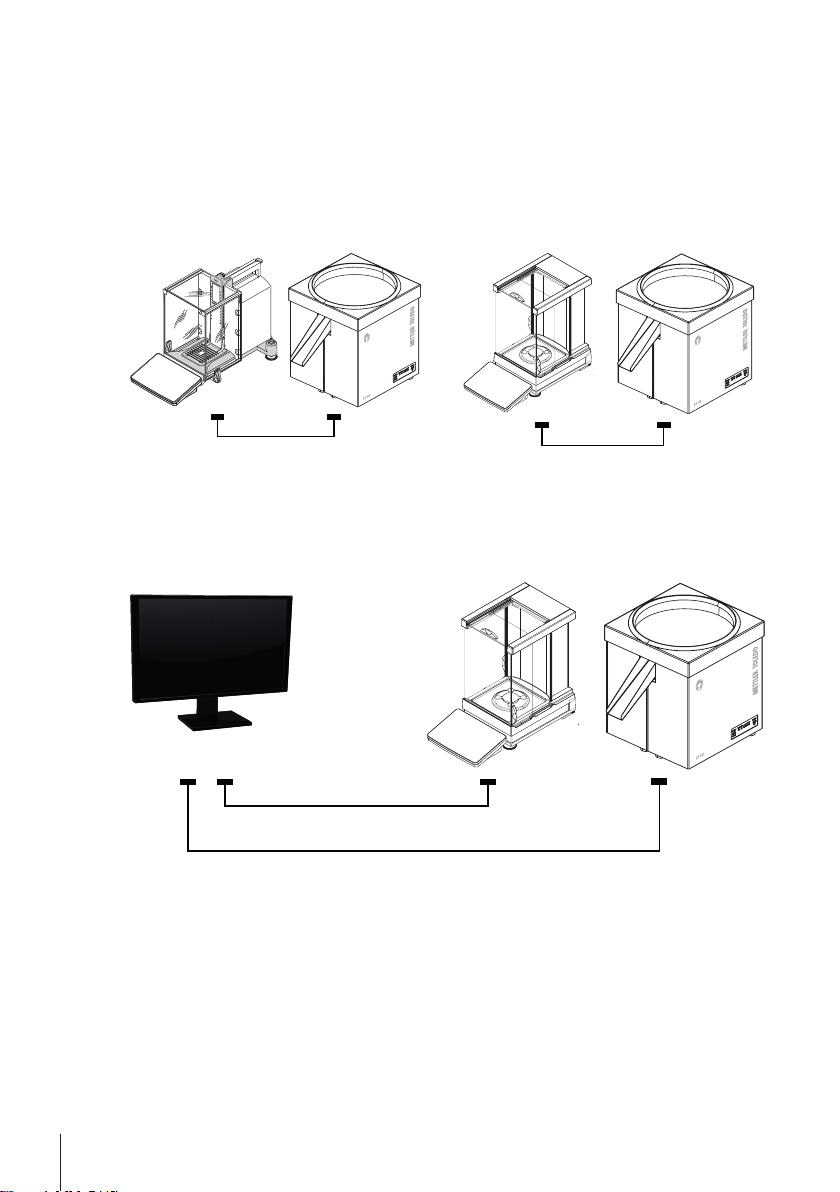

2.3 Operating modes

RS232

www.mt.co

m

X

PE204

F

F

METTLER TOLEDO

S

tatic

D

ete

c

t

USB (A/B)

USB

A

USB B

IND

890SQC

RS232

USB (A/B)

USB

A

USB B

Following system setups are supported by the LV12:

XP/XPE balances with RS232 connection XPR balances with USB connection

LV12 can be controlled by a METTLER TOLEDO

XP/XPE balance with RS232 interface. The

program for the control must be available in the

weighing instrument (e. g. SQC or statistics

application in Excellence balance).

IND890SQC direct connection

LV12 and balance are directly connected to an IND890SQC system (LV12 by RS232, balance by

USB).

LV12 can be controlled by a METTLER TOLEDO

XPR balance with USB interface.

Design and Function8 Automatic Feeder

Page 13

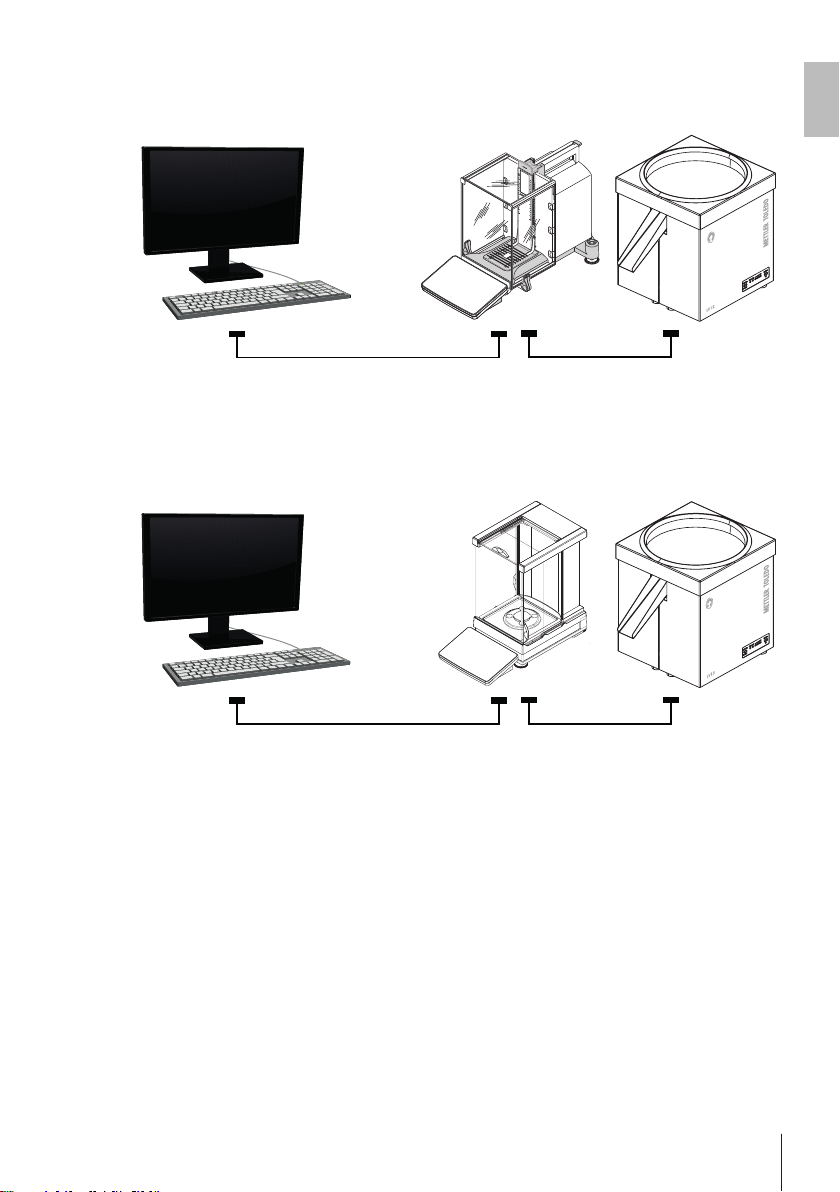

LabX or Freeweigh.net with XP, XPE balances

RS232

Ethernet or RS232

LabX

Freeweigh

.net

www.mt.co

m

X

PE204

F

F

METTLER TOLEDO

S

tatic

D

ete

c

t

USB (A/B)

Ethernet or USB (A/B)

La

bX

• XP/XPE balance connected to PC by Ethernet or with RS232 cable.

• LV12 connected to XP/XPE balance with RS232 interface.

LabX with XPR balances

• XPR balance connected to PC by Ethernet or with USB cable.

• LV12 connected to XPR balance with USB interface.

en

Design and Function 9Automatic Feeder

Page 14

3 Installation and Putting into Operation

This section describes how to set the new instrument into operation.

3.1 Unpacking the device

Delivery

The device is delivered by a local logistics company. All the components included in the scope of

delivery are delivered together in a single package.

Transport damages or missing parts

On receipt of the delivery, check it without delay to ensure that it is complete and undamaged.

If there is any visible external transport damage, proceed as follows:

• Do not accept the delivery.

• Make a note of the scope of damage on the carrier's delivery note.

• Inform a METTLER TOLEDO representative.

Note

Lodge a complaint for each defect as soon as it is identified. Claims for damages can only be made

within the applicable claim periods.

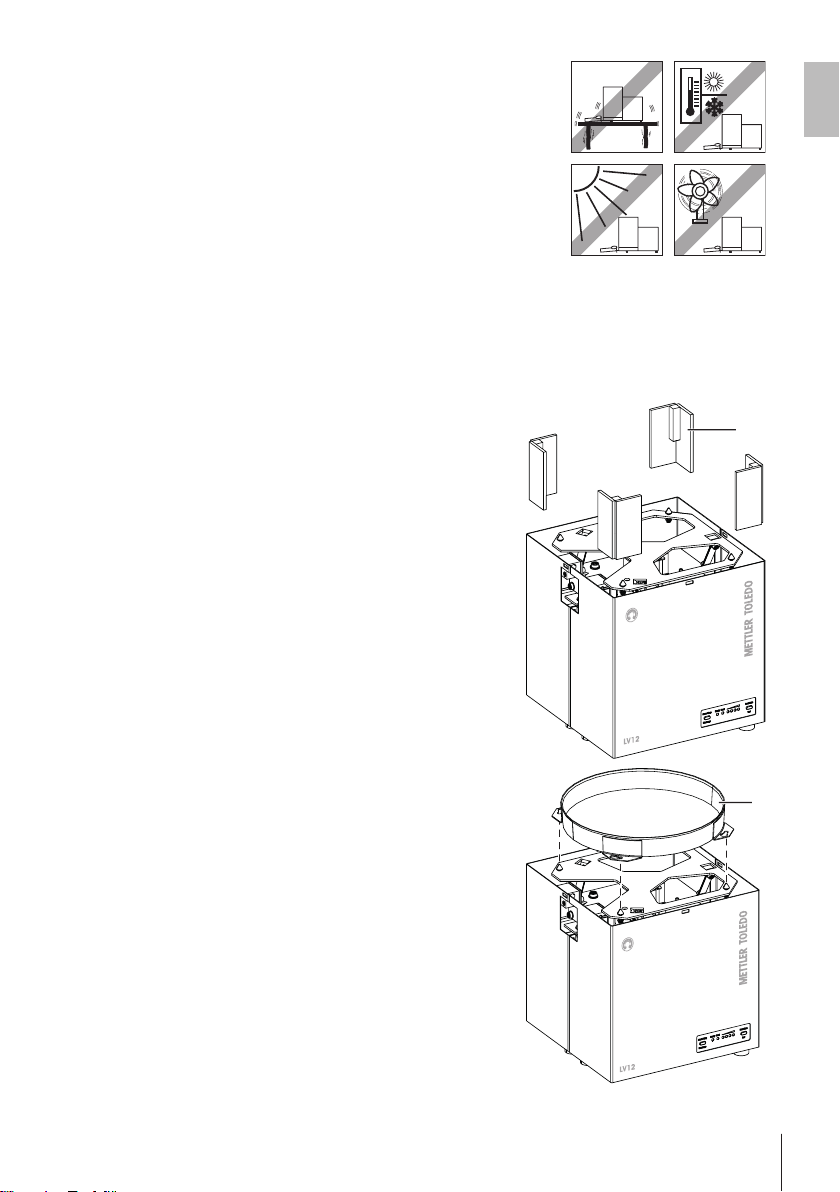

Unpacking device

Proceed as follows to unpack the device:

1 Open the packaging box.

2 Remove the package lifting it on the belt strap.

3 Remove the belt strap around the foam elements.

4 Remove the polystyrene element on the top of the device.

5 Unpack the feeder plate and the plastic cover.

6 Remove the upper foam element.

7 Lift and remove the device from the lower foam element.

8 Remove the belt strap fixing the device.

9 Check the device for transportation damages or missing parts.

10 To assemble the device, proceed as described in [Assembling the device}Page11].

Note

We recommend retaining all parts of the packaging. The packaging offers the best protection for

transporting the device over long distances.

3.2 Scope of delivery

• LV12 including chute

• Power supply 60 W/12 VDC with country-specific power cable

• RS232 cable (m/f, 1.0 m) to connect a balance

• USB cable (A/B, 1.0 m) to connect a PC or balance

• Operating instructions printed

• CD-ROM containing USB drivers and operating instructions

• EC declaration of conformity

3.3 Selecting the location

An optimal location will ensure accurate and reliable operation of the device. The following local

conditions must be observed:

Installation and Putting into Operation10 Automatic Feeder

Page 15

Observe the ambient conditions:

1

2

• The instrument must only be used indoors and up to a

maximum altitude of 5000 m above sea level.

• Temperature range: 10–30 °C

• Humidity: max. 80% noncondensing

Pay attention the following:

• The power plug must be accessible at all times.

• Firm, horizontal and vibration-free location.

• Avoid excessive temperature fluctuations.

• Avoid direct sunlight.

• No powerful drafts (e. g. from fans or air conditioners).

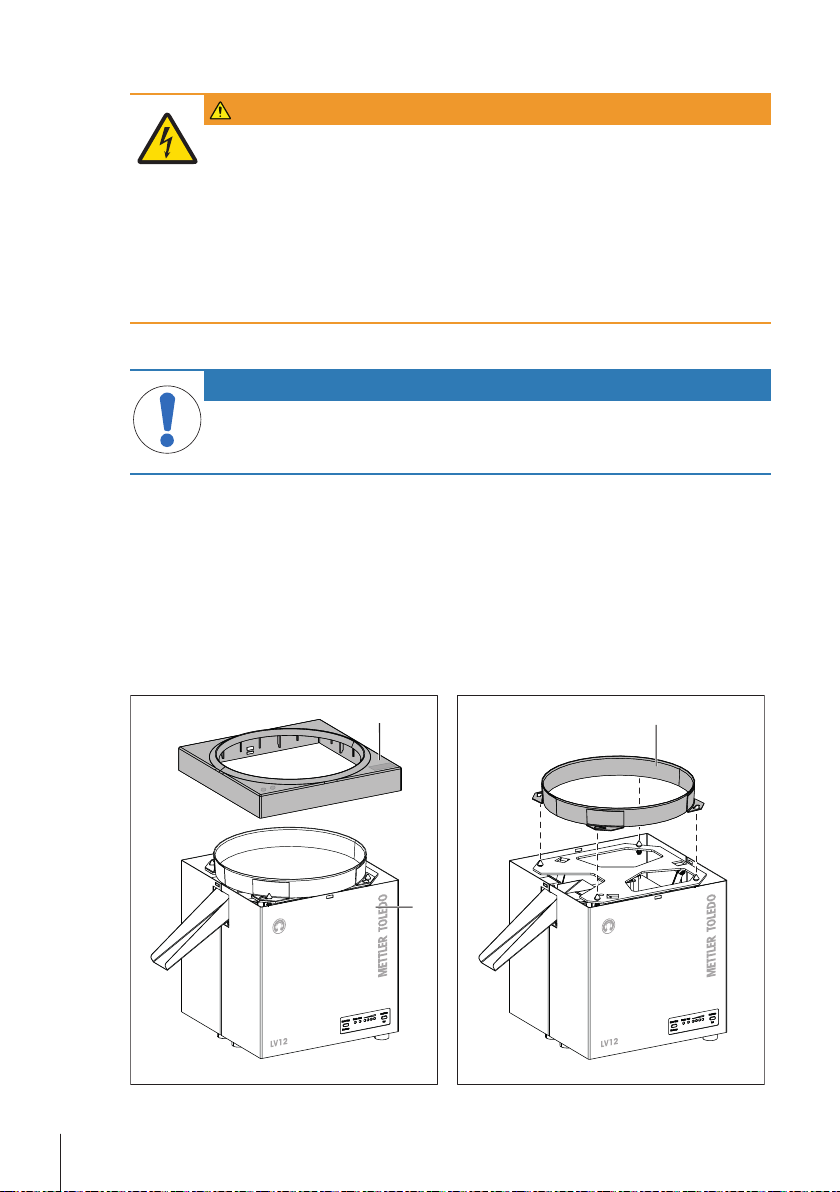

3.4 Assembling the device

After checking the scope of delivery, unpacking the device and after finding a proper location, the

device must be assembled.

1 Remove the four transportation locks (1) (one in each

corner).

en

2 Put the feeder plate (2) on the device and fix it by turning it

clockwise along the slotted holes.

Installation and Putting into Operation 11Automatic Feeder

Page 16

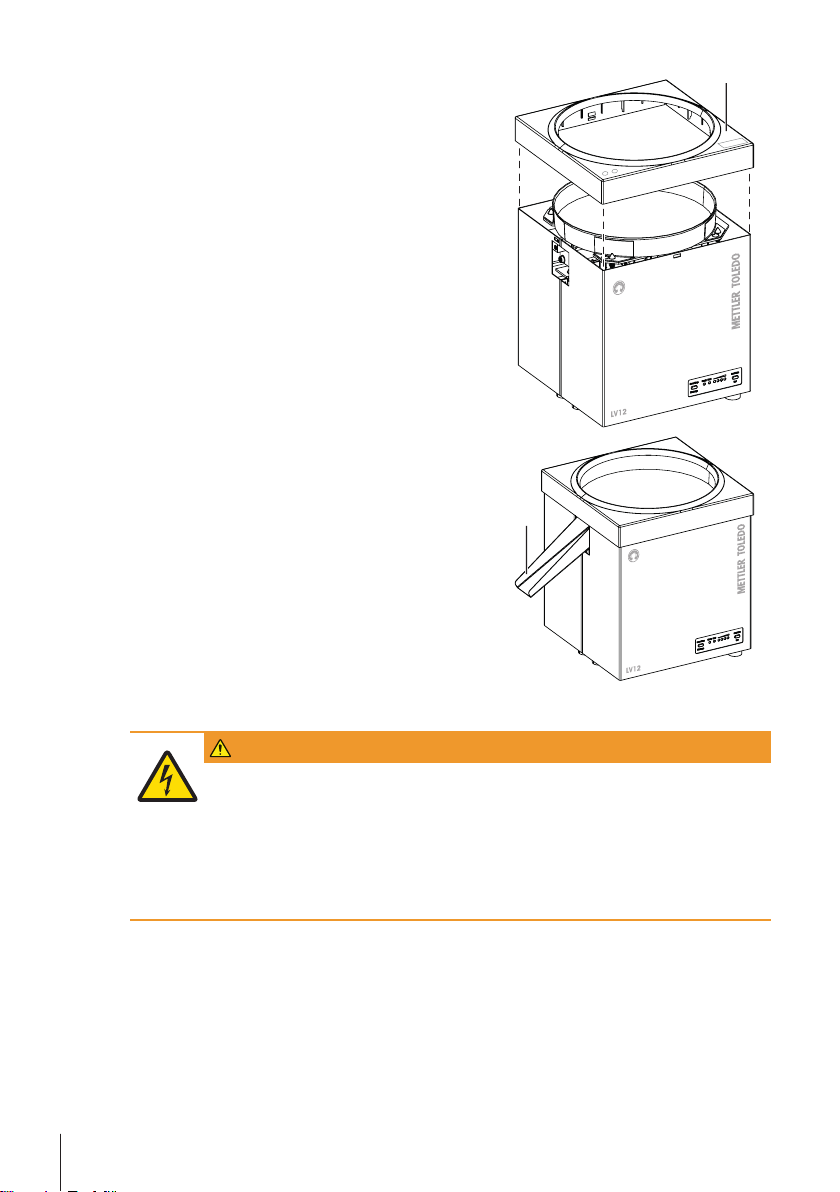

3 Put the cover (3) on the device. Take the marks on the top

3

4

of cover as reference for the correct orientation (the marks

have to point to the front as indicated in the image). Push

the cover down until it snaps into place.

4 Fit the chute (4) to the two clamping blots at the lateral

opening and push it in as far as it will go.

5 Connect the device to the balance using the delivered

cables (either by USB or RS232 according to the used

balance).

6 Set up the device as described in [Connecting the

device}Page12].

3.5 Connecting the device

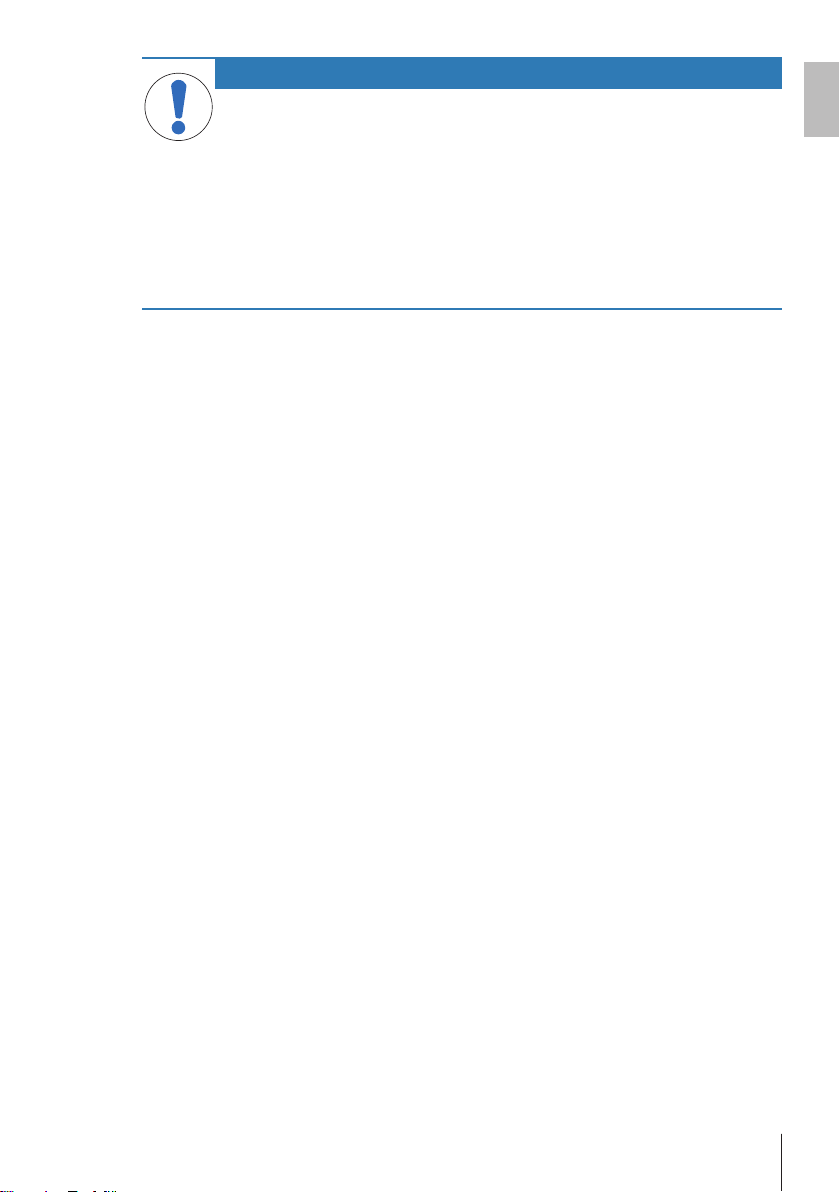

WARNING

Risk of electric shock

1 To connect the device, only use the supplied three-core power cable with equipment

grounding conductor.

2 Only connect the device to a three-pin power socket with earthing contact.

3 Only standardized extension cable with equipment grounding conductor must be

used for operation of the device.

4 Intentional disconnection of the equipment grounding conductor is forbidden.

Installation and Putting into Operation12 Automatic Feeder

Page 17

NOTICE

Property damage due to short circuit!

Damage to the insulation on the AC/DC adapter or the cable can result in a short-circuit

and damage the device.

1 Only use the original AC/DC adapter which was supplied with your device.

Otherwise, the device may get damaged.

2 If the AC/DC adapter or the cable is damaged, pull out the power plug and have the

AC/DC adapter replaced.

3 Route the cable so that it cannot be damaged by external influences.

4 The power plug must always be accessible.

5 Keep moisture away from live parts. Moisture can result in short-circuit.

Note

When the device is connected to the mains, it starts automatically. To switch off the device and to

disconnect it from the power supply, the mains plug has to be plugged out.

The device is supplied with an AC/DC adapter and a country-specific power cable. The AC/DC adapter

is suitable for use with the following voltage range:

100 – 240 VAC, 50/60Hz.

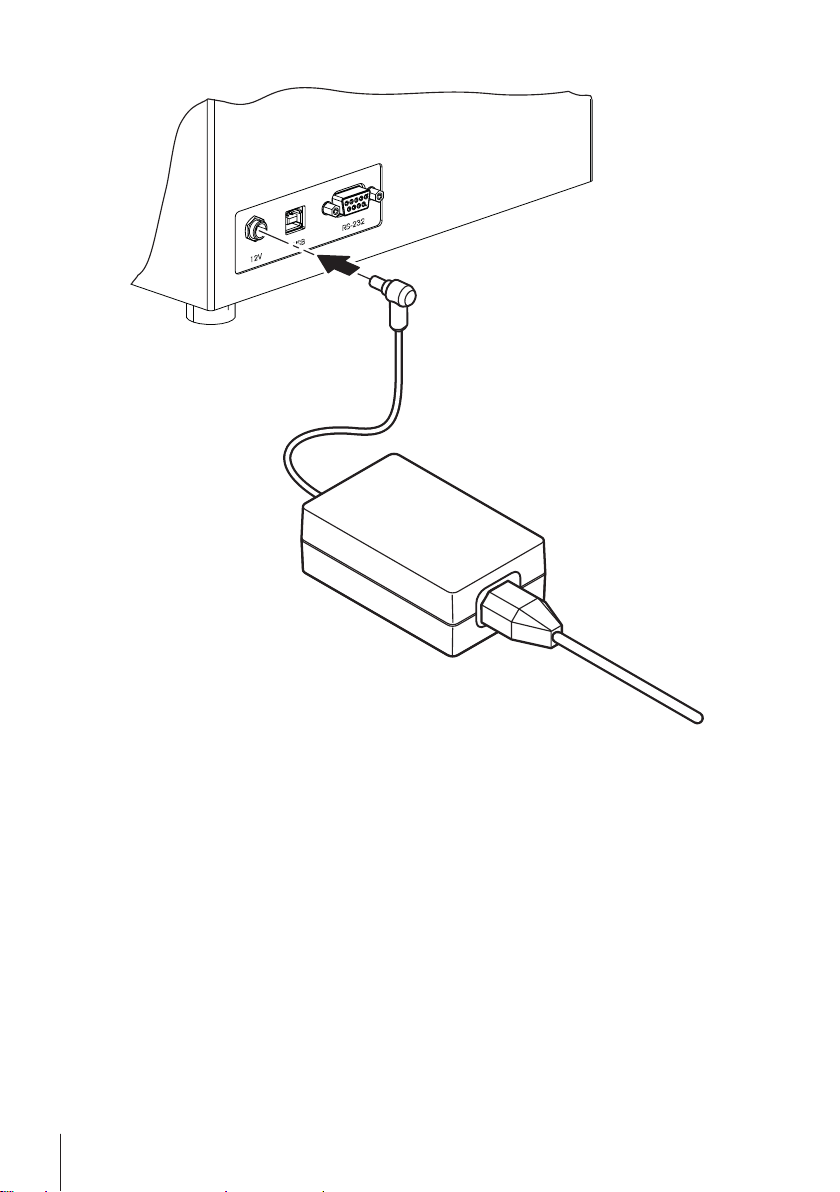

Proceed as follows to connect and set up the device:

1 Position the device on a firm surface. Pay attention to the required ambient conditions, see

[Selecting the location}Page10].

2 Check the AC/DC adapter and the cable for damage.

3 Check whether your local power supply falls within the range of the delivered AC/DC adapter. If

this is not the case, under no circumstances connect the AC/DC adapter to the power supply, but

contact a METTLER TOLEDO representative.

en

Installation and Putting into Operation 13Automatic Feeder

Page 18

4 Connect the AC/DC adapter to the connection socket at the rear of the device.

5 Connect the AC/DC adapter to a grounded electrical outlet.

ð When the LV12 is connected to the mains supply, an initialization (reset) runs for approx. 2

seconds. During this time, all LEDs light up. The instrument is then in the normal mode with preselected intensity level2.

Note

• The basic setting of the vibration is selected so that most parts can be delivered without any

problems. For very small or large parts, this setting can be adjusted, see [Configure feeding rate

sets}Page17].

Installation and Putting into Operation14 Automatic Feeder

Page 19

3.6 Transporting the device

NOTICE

Risk of property damage due to improper transport!

In the event of improper transport, the device may fall. This can cause major property

damage.

1 Only transport the device when it is disconnected from the mains supply.

2 If you would like to transport or ship your device over long distances, use the

complete original packaging.

3 Always transport packages upright and never throw them.

Remove the power cable and any interface cable from the device. Refer to the notes in section

[Selecting the location}Page10] regarding the choice of an optimal location.

en

Installation and Putting into Operation 15Automatic Feeder

Page 20

4 Operation

4.1 Starting/stopping feeding

Usually the LV12 is remotely controlled by commands over a serial interface (RS232 or USB), but the

device can also be controlled manually. To start or stop the feeding action manually, proceed as

follows:

The device is in state "ready" (LED Ready is lit up).

§

1 Press once the button Start/Stop/Discharge.

ð Feeding action starts. The orange LED Feed lights up.

2 Press the button Start/Stop/Discharge anew to stop

feeding action. If feeding is not stopped manually, the

system feeds until an object interrupts the light barrier and

then stops automatically.

4.2 Adjusting feeding rate

The feeding rate can be adjusted before starting or during the feeding process. Changing the feeding

rate during the feeding process takes effect immediately. Proceed as follows to change the feeding

rate:

The device is in state "ready" (LED Ready is lit up).

§

− By briefly pressing the button Feed Rate/Test, you can

adjust the feeding rate so that only one part at a time falls

onto the balance.

4.3 Discharging device

Discharge is used to empty the system of all objects. The system feeds at the configured discharge

feed rate and stops 90 seconds after the last object has passed the light barrier. Proceed as follows

to activate discharge:

The device is in state "ready" (LED Ready is lit up).

§

1 Press and hold the button Start/Stop/Discharge for at least

2 seconds.

ð Discharge action starts. The orange LED Feed lights up

and all four level indicating LEDs flash.

2 To stop discharging manually, press once the button Start/

Stop/Discharge. Otherwise, discharging will stop automatically.

Operation16 Automatic Feeder

Page 21

4.4 Find optimal feeding rate

The test mode allows you to find the optimal feeding rate and therefore to ensure, that only one part at

a time is fed to the balance. Proceed as follows to adjust the feeding rate using the test mode:

The device is in state "ready" (LED Ready is lit up).

§

1 To enter the test mode, press and hold the button Feed

Rate/Test for at least 5 seconds.

ð The LV12 starts delivery until a part passes through the

light barrier. It then stops for 2.5 seconds and then

continues delivery until the next passage through the

light barrier.

2 By briefly pressing the button Feed Rate/Test, you can now

select the rate so that only one part at a time falls onto the

balance.

3 To quit the test mode, press the button Start/Stop/

Discharge.

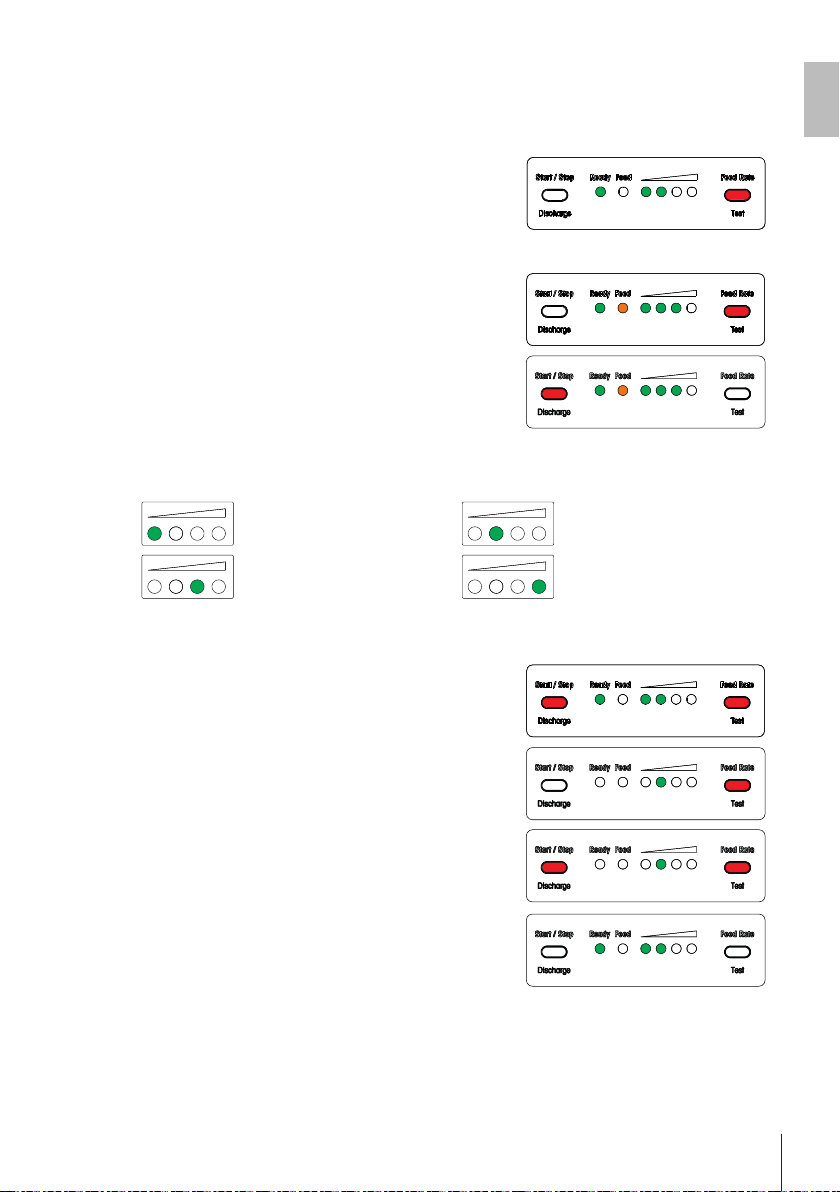

4.5 Configure feeding rate sets

During the configuration, the intensity level is indicated by the four green LEDs as follows:

General (for most parts, factory

settings)

Midsize parts Large parts

To configure the feeding rate set, proceed as follows:

The device is in state "ready" (LED Ready is lit up).

§

1 Press and hold the two buttons for at least 5 seconds.

ð The LED Ready goes out.

Small parts

en

2 Change the feeding rate set by toggling using the button

Feed Rate/Test.

3 To quit the setting mode, press anew the two buttons.

ð The LED Ready is lit up.

Operation 17Automatic Feeder

Page 22

5 Maintenance

2

3

1

WARNING

Danger of death or serious injury due to electric shock!

Contact with parts that contain a live current can lead to injury and death. If the device

cannot be shut down in an emergency situations, people can be injured or the device

can be damaged.

1 Disconnect the device from the power supply prior to cleaning and maintenance.

2 Only use METTLER TOLEDO power cable, if these need to be replaced.

3 Make sure that no liquid enters into the device or AC/DC adapter.

4 Do not open the device or AC/DC adapter.

These contain no user-serviceable parts.

5.1 Cleaning

NOTICE

Damage of the device due to the use of inappropriate cleaning agents!

− On no account use cleaning agents which contain solvents or abrasive ingredients,

as this can result in damage to the device.

Clean the housing regularly with a damp, soft cloth. The feeder plate is made of stainless chrome

steel and can be removed for cleaning as follows:

1 Disconnect power plug.

2 Press slightly together the side walls of the housing (1) and simultaneously lift off the plastic

cover (2).

3 Detach the feeder plate (3) by turning it counter clockwise along the slotted holes.

4 Clean all contaminated parts using a mild cleaning agent.

5 After cleaning, put the feeder plate and the plastic cover back on the device. Pay attention to the

correct orientation of the cover (the marks on top of the cover have to point to the front).

Maintenance18 Automatic Feeder

Page 23

5.2 Disposal

In conformance with the European Directive 2012/19/EU on Waste Electrical and

Electronic Equipment (WEEE) this device may not be disposed of in domestic waste. This

also applies to countries outside the EU, per their specific requirements.

Please dispose of this product in accordance with local regulations at the collecting point

specified for electrical and electronic equipment. If you have any questions, please

contact the responsible authority or the distributor from which you purchased this device.

Should this device be passed on to other parties (for private or professional use), the

content of this regulation must also be related.

Thank you for your contribution to environmental protection.

en

Maintenance 19Automatic Feeder

Page 24

6 MT-SICS interface commands and functions

The device is capable of integration in a complex computer or data acquisition system.

To enable you to integrate the device in your system in a simple manner and utilize its capabilities to

the full, most functions are also available as appropriate commands via the data interface. Therefore,

the device supports the standardized command set "METTLER TOLEDO Standard Interface Command

Set" (MT-SICS).

The following table gives a short overview about the commands available for LV12. For further information please contact your METTLER TOLEDO representative.

MT-SICS commands

MT-SICS command MT-SICS command header Description

LV01 Software Restart The software is restarted just as it was in the

LV02 >Level< Feed Rate Sets the actual feed rate intensity to a specific

LV03 Vibrate until Light Barrier

Signal

LV04 Vibrate until Stop or Reset Vibrate until stop or reset.

LV05 Discharge Discharge device.

LV06 Stop Stops the current action and brings the device

LV99 Light Barrier Signal Status changes of the light barrier results in this

Light barrier signal

Action Syntax Description

Query LV99 Light barrier is free

Response LV99 A

Query LV99 Light barrier is blocked

Response LV99 B

case of power on. This command brings the

device back to the power-up state. Power-up

state means, that the device is ready and feed

rate is set to level 2. Feeding rate set remains.

level.

Feed rate level.

{Data type: unsigned 8 bits. Range see below}

• Value: '1' → Feed rate level 1

• Value: '2' → Feed rate level 2

• Value: '3' → Feed rate level 3

• Value: '4' → Feed rate level 4

The initial value is given by the software of the

device (initial value is feed rate level 2).

Vibrate until light barrier signal.

back to the ready state.

command. For details see the table below.

Pay attention to the following:

• All commands must be closed with <CR> and <LF>.

• The system responds to an unknown command with "ES".

• The device may response unsolicited (e. g. by manual operation and startup)

MT-SICS interface commands and functions20 Automatic Feeder

Page 25

7 Technical Data

7.1 General data

WARNING

Danger of death or serious injury due to electric shock!

Contact with parts that contain a live current can lead to injury and death.

1 Only use an approved AC/DC adapter with a current-limited SELV output.

2 Ensure correct polarity

Power supply

AC/DC adapter: Primary: 100 – 240VAC, 50/60 Hz

Secondary: 12VDC ±5%, 5A max (with electronic overload

protection)

Device power supply: 12 VDC ±5%, 0.9 A

Protection and standards

Overvoltage category: II

Degree of pollution: 2

Protection: Only use indoors in dry locations

Standards for safety and EMC: See Declaration of Conformity

Range of application: For use only in closed interior rooms

Environmental conditions

Height above mean sea level: Up to 5000m

Ambient temperature: 10–30°C

Relative air humidity: Max. 80% noncondensing

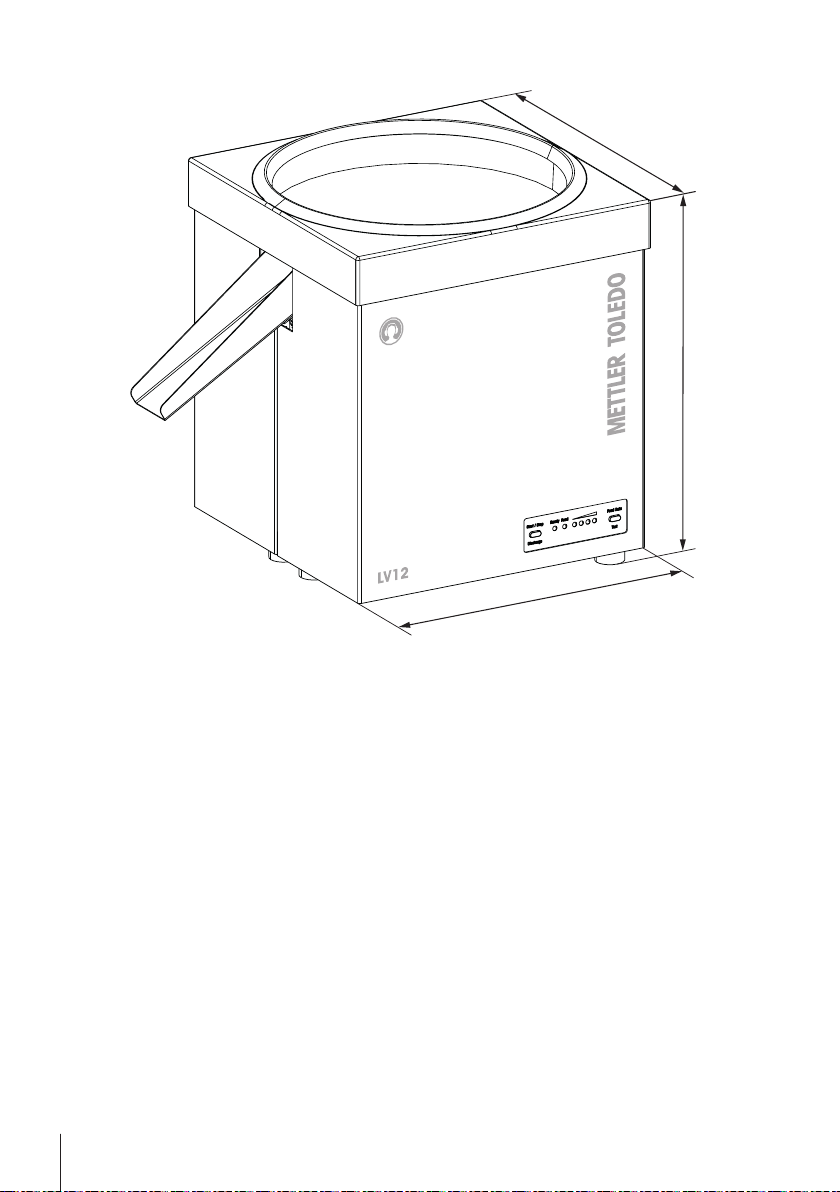

Weight and Dimensions

W x H x D 225 x 260 x 225 mm

Net weight 10.9 kg

Admissible part size ø 1 mm up to ø 20 mm

en

Technical Data 21Automatic Feeder

Page 26

7.2 Dimensions

225 mm

225 mm

260 mm

Technical Data22 Automatic Feeder

Page 27

8 Accessories and Spare Parts

Country-specific 3-Pin power cable with grounding

conductor.

Power cable AU 00088751

Power cable BR 30015268

Power cable CH 00087920

Power cable CN 30047293

Power cable DK 00087452

Power cable EU 00087925

Power cable GB 00089405

Power cable IL 00225297

Power cable IN 11600569

Power cable IT 00087457

Power cable JP 11107881

Power cable TH, PE 11107880

Power cable US 00088668

Power cable ZA 00089728

USB (A/B): connection cable for PC/balance, 1.0 m

(included in the standard equipment)

en

30388322

RS232 (m/f, 1:1): connection cable for balance, 1.0 m

(included in the standard equipment)

RS232 (f/f, Nullmodem): connection cable for PC, 1.8 m 21900576

Chute (included in the standard equipment) 30388039

Power supply 60 W/12VDC (included in the standard

equipment)

11101051

30388323

Available on request:

Door with opening, for Excellence analytical balances 11106715

Door with opening, for Excellence precision balances with high draft shield 11132711

Accessories and Spare Parts 23Automatic Feeder

Page 28

1 Sicherheitshinweise

• Bitte machen Sie sich mit den Anweisungen in dieser Bedienungsanleitung vertraut, ehe Sie das

Gerät verwenden.

• Heben Sie diese Anleitung zur späteren Verwendung auf.

• Bitte legen Sie auch dieses Handbuch bei, wenn Sie das Gerät anderen zur Verfügung stellen.

Wenn das Gerät modifiziert oder nicht gemäss den Anweisungen in dieser Anleitung verwendet wird,

können Gefahren für den Benutzer entstehen. Mettler-Toledo GmbH keinerlei Haftung.

1.1 Definition von Signalwörtern und Warnsymbolen

Sicherheitshinweise sind mit Signalwörtern und Warnbildsymbolen gekennzeichnet. Sie kennzeichnen

Sicherheitsrisiken und Warnungen. Die Missachtung der Sicherheitshinweise kann zu persönlicher

Gefährdung, Beschädigung des Geräts, Fehlfunktionen und falschen Ergebnissen führen.

WARNUNG

VORSICHT

HINWEIS

Hinweis

1.2 Produktspezifischer Sicherheitshinweis

Das Gerät wurde für die in der jeweiligen Anleitung dokumentierten Anwendungen und vorgesehenen

Verwendungszwecke getestet. Dennoch liegt es in Ihrer Verantwortung, mittels eigener Tests zu überprüfen, ob sich die von uns gelieferten Produkte wirklich für die Verfahren und Zwecke eignen, für die

Sie sie verwenden wollen.

Bestimmungsgemässe Verwendung

Dieses Gerät wurde dafür entwickelt, von qualifiziertem Personal in Prüflaboren verwendet zu werden.

Der LV12 ist vorgesehen als Automatikförderer für Kleinteile (ø max. 20 mm), wie beispielsweise

Kapseln, Tabletten oder kleine elektronische oder mechanische Komponenten, benutzt zu werden.

Jegliche anderweitige Verwendung, die über die Grenzen der technischen Spezifikationen hinausgeht,

gilt ohne schriftliche Absprache mit der Mettler-Toledo GmbHals nicht bestimmungsgemäss.

Anforderungen vor Ort

Das Gerät wurde für die Verwendung in Innenbereichen entwickelt. Schliessen Sie folgende Umwelteinflüsse aus:

• Bedingungen, die nicht den in den technischen Daten genannten Umgebungsbedingungen ent-

sprechen

• Starke Vibrationen

• Direkte Sonneneinstrahlung

• Korrosive Gasatmosphären

• Explosionsgefährdete Gas-, Dampf-, Nebel- und Staubatmosphären bzw. entflammbare Staubat-

mosphären

• Starke elektrische oder magnetische Felder

Eine Gefährdung mit mittlerem Risiko, die möglicherweise zum Tod oder zu schweren Körperverletzungen führen kann, wenn sie nicht vermieden wird.

Eine gefährliche Situation mit niedrigem Risiko, die leichte oder mittelschwere Verletzungen zur Folge haben kann, wenn sie nicht vermieden wird.

Eine gefährliche Situation mit niedrigem Risiko, die eine Beschädigung des Geräts,

Materialschäden, Fehlfunktionen und falsche Resultate oder Datenverlust zur Folge

haben kann.

(kein Symbol)

allgemeine Informationen zum Produkt.

Allgemeine Gefahr Stromschlag

Sicherheitshinweise24 Automatikförderer

Page 29

Mitarbeiterqualifikation

Eine unsachgemässe Verwendung des Geräts oder der im Rahmen der Analyse verwendeten Chemikalien kann zum Tod oder zu Verletzungen führen. Für die Bedienung des Geräts sind die folgenden

Qualifikationen erforderlich:

• Kenntnisse und Erfahrung im Umgang mit toxischen und ätzenden Substanzen.

• Kenntnisse und Erfahrung im Umgang mit standardmässiger Laborausrüstung.

• Kenntnisse und Erfahrung im Hinblick auf die Einhaltung allgemeiner Laborsicherheitsbestimmun-

gen.

Verantwortlichkeiten des Gerätebesitzers

Der Gerätebesitzer ist diejenige Person, welche das Gerät für kommerzielle Zwecke nutzt oder es ihren

Mitarbeitern zur Verfügung stellt. Der Gerätebesitzer ist für die Produktsicherheit sowie für die Sicherheit von Mitarbeitern, Benutzern und Dritten verantwortlich.

Der Gerätebesitzer hat folgende Verantwortlichkeiten:

• Die geltenden Regeln für die Sicherheit am Arbeitsplatz kennen und diese durchsetzen.

• Sicherstellen, dass das Gerät nur von qualifizierten Mitarbeitern verwendet wird.

• Die Zuständigkeiten im Hinblick auf Installation, Bedienung, Reinigung, Fehlerbehebung und War-

tung festlegen und sicherstellen, dass diese Aufgaben ausgeführt werden.

• Die Mitarbeiter regelmässig schulen und sie über Gefahren informieren.

• Den Mitarbeitern die erforderliche Schutzausrüstung zur Verfügung stellen.

Sicherheitshinweise

WARNUNG

Risiko von Gehörschädigungen durch hohen Lärmpegel!

Je nach verwendeten Proben (Material und Gewicht) kann ein hoher Lärmpegel entstehen, wenn die Proben aus der Auslassrutsche fallen. Ein Lärmpegel von über 80db(A)

kann zu einer schweren Gehörschädigung führen.

1 Wenn Sie Teile zuführen, bei denen ein Lärmpegel von über 80 db(A) zu erwarten

ist, sollten Sie eine Lärmmessung vornehmen. Die nachstehenden Beispiele dienen

als Referenzwerte.

2 Tragen Sie einen Gehörschutz, wenn der Lärmpegel 80 db(A) überschreitet.

de

In der folgenden Liste werden ungefähre Werte für Lärmemissionen (Entleerungsmodus, 20cm) aufgeführt:

Einstellungen Artikel Material Gewicht Grösse Wert

Allgemein Distanzhalter Kunststoff 0,12 g 10 × 5 mm

Klein Schraube Metall 0,14 g M2 × 3 mm

Mittel Schraube Metall 0,2 g M2,5 × 5 mm

Gross Abstandhalter Metall 1,5 g M3 × 10 mm

Gross Abstandhalter Metall 5,1 g M4 × 20 mm

Leer: < 70 db(A)

78 dB(A)

75 dB(A)

79 dB(A)

89 dB(A)

93 dB(A)

Sicherheitshinweise 25Automatikförderer

Page 30

HINWEIS

Es besteht die Gefahr einer Beschädigung durch unsachgemässe Verwendung!

Eine unsachgemässe Verwendung des Instruments kann zu erheblichen Materialschäden führen.

1 Installieren und betreiben Sie das Instrument nur in trockenen Innenräumen.

2 Bedienen und verwenden Sie das Gerät nur unter Berücksichtigung der Anweisun-

gen in diesem Handbuch.

3 Öffnen Sie das Gerät nicht.

4 Nehmen Sie keine Veränderungen am Gerät vor.

5 Verwenden Sie mit Ihrem Instrument ausschliesslich Zubehör und Peripheriegeräte

von METTLER TOLEDO, diese sind optimal auf Ihr Instrument abgestimmt.

Sicherheitshinweise26 Automatikförderer

Page 31

2 Aufbau und Funktion

Der LV12 ist ein Automatikförderer für Kapseln, Tabletten oder kleine elektronische bzw. mechanische

Komponenten. Grosse Wägeserien werden radikal vereinfacht. Der LV12 ist deshalb insbesondere für

die statistische Qualitätskontrolle (SQC) geeignet. In der Regel wird der LV12 mittels Befehlen über

eine serielle Schnittstelle (RS232 oder USB) ferngesteuert; das System kann aber auch manuell über

Drucktasten gesteuert werden.

Der LV12 fördert ein Einzelteil zur Waage und stoppt dann automatisch. Nach Erhalt eines entsprechenden Befehls von der Waage liefert das Gerät das nächste Einzelteil. Dieser Vorgang kann durch

einen Befehl jederzeit gestoppt werden. Am Ende einer Probe kann der Förderteller geleert werden oder

der Förderer wartet auf den Befehl für eine weitere Probe.

2.1 Bedien- und Anzeigeelemente

Bedienelemente

Taste Arbeitsschritt Zielsetzung

Start/Std.Adj./Ent-

leeren

Fördergeschwindigkeit/Test

Hinweis

Durch gleichzeitiges Drücken beider Tasten kann die Einstellung für die Grösse der Teile geändert

werden, siehe [Einstellungen für die Zuführrate konfigurieren}Seite38].

Anzeigen

LED-Anzeige Zustand Bedeutung

Bereit

Zuführen

Einmal drücken Zuführen einschalten/ausschalten

Gedrückt halten, bis zustandsanzeigende

LEDs aufleuchten

Einmal drücken Zuführrate um eine Stufe ändern

Gedrückt halten, bis LED Bereit auf-

leuchtet

Grüne LED leuchtet Gerät ist eingeschaltet und betriebsbereit

Grüne LED blinkt Gerät ist im Testmodus

Orange LED leuchtet Zuführen ist eingeschaltet und der Förder-

Orange LED blinkt Lichtschranke ist unterbrochen, ver-

Eine LED leuchtet Niedrigste Zuführrate

Entleeren einschalten

Testmodus aktivieren, um die optimale

Zuführrate zu bestimmen

teller vibriert

schmutzt oder defekt

de

Zwei LEDs leuchten Untere mittlere Zuführrate, Standardein-

Drei LEDs leuchten Obere mittlere Zuführrate

stellung nach dem Einschalten

Aufbau und Funktion 27Automatikförderer

Page 32

LED-Anzeige Zustand Bedeutung

1 2

3

Alle vier LEDs leuchten Höchste Zuführrate

Erste LED leuchtet

Vierte LED blinkt

Alle vier LEDs blinken Instrument ist im Entleeren-Modus

Kurzschluss bei Start/Std.Adj./Entlee-

ren-Taste

Kurzschluss bei Fördergeschwindigkeit/

Test-Taste

2.2 Anschlüsse

Anschluss für Stromversorgung (12VDC)

1

RS232-Schnittstelle

3

Anschluss Funktion

Anschluss für

Netzadapter

USB-Port (Typ B)

RS232-Schnitt-

stelle

An die Stromversorgung anschliessen. Nur mit Standard-Netzadapter (+12VDC)

betreiben, der im Lieferumfang enthalten ist.

An eine Waage, einen PC oder einen Hub (mit USB-Port) anschliessen.

Der RS232-Anschluss ist eine 9-polige D-Sub-Buchse mit Pinbelegung wie ein PC.

Für den Anschluss an einen Computer wird ein sogenanntes Laplink- oder Nullmodemkabel benötigt.

Schnittstellenparameter:

• 9600 Baud, keine Parität, 8 Datenbits, 1 Stoppbit

• Software-Handshake (Xon/Xoff)

• Zeilenende <CR><LF>

Hinweis

Zum SICS-Befehlssatz für den LV12, siehe [Schnittstellenbefehle und -funktionen MTSICS}Seite41].

2

USB-Port (Typ B)

Aufbau und Funktion28 Automatikförderer

Page 33

2.3 Betriebsarten

RS232

www.mt.co

m

X

PE204

F

F

METTLER TOLEDO

S

tatic

D

ete

c

t

USB (A/B)

USB

A

USB B

IND

890SQC

RS232

USB (A/B)

USB

A

USB B

Folgende System-Setups werden vom LV12 unterstützt:

XP/XPE-Waagen mit RS232-Anschluss XPR-Waagen mit USB-Anschluss

Der LV12 kann von einer XP/XPE-Waage von

METTLER TOLEDO mit RS232-Schnittstelle

gesteuert werden. Das Programm zur Steuerung

muss in der Waage vorhanden sein (z. B. SQC

oder Statistik-Anwendung in Excellence-Waage).

Direktanschluss IND890SQC

Der LV12 und die Waage sind direkt an ein IND890SQC-System angeschlossen (LV12 über RS232,

Waage über USB).

Der LV12 kann von einer XPR-Waage von

METTLER TOLEDO mit USB-Schnittstelle gesteuert

werden.

de

Aufbau und Funktion 29Automatikförderer

Page 34

LabX oder Freeweigh.net mit XP/XPE-Waagen

RS232

Ethernet or RS232

LabX

Freeweigh

.net

www.mt.co

m

X

PE204

F

F

METTLER TOLEDO

S

tatic

D

ete

c

t

USB (A/B)

Ethernet or USB (A/B)

La

bX

• Die XP/XPE-Waage wird über Ethernet oder mittels eines RS232-Kabels mit dem PC verbunden.

• Der LV12 wird über die RS232-Schnittstelle an die XP/XPE-Waage angeschlossen.

LabX mit XPR-Waagen

• Die XPR-Waage wird über Ethernet oder mittels eines USB-Kabels an den PC angeschlossen.

• Der LV12 wird über die USB-Schnittstelle an die XPR-Waage angeschlossen.

Aufbau und Funktion30 Automatikförderer

Page 35

3 Installation und Inbetriebnahme

In diesem Kapitel finden Sie Informationen zur Inbetriebnahme Ihres neuen Geräts.

3.1 Auspacken des Geräts

Lieferung

Das Gerät wird von einem lokalen Logistikunternehmen geliefert. Alle im Lieferumfang enthaltenen

Komponenten werden in einem einzigen Paket geliefert.

Transportschäden und fehlende Teile

Überprüfen Sie bei Erhalt unverzüglich die Lieferung, um sicherzustellen, dass sie vollständig und

unbeschädigt ist.

Verhalten Sie sich bei sichtbaren Anzeichen von Transportbeschädigungen wie folgt:

• Nehmen Sie die Lieferung nicht an.

• Geben Sie Art und Umfang der Beschädigung auf dem Lieferschein des Auslieferers an.

• Wenden Sie sich an einen METTLER-TOLEDO-Vertreter.

Hinweis

Reklamieren Sie jeden Defekt, sobald er erkannt wurde. Schadensersatzansprüche können nur innerhalb der gültigen Schadensmeldefristen geltend gemacht werden.

Auspacken des Geräts

Gehen Sie beim Auspacken des Geräts wie folgt vor:

1 Öffnen Sie die Verpackungsschachtel.

2 Holen Sie das Gerät aus der Schachtel, indem Sie es am Gurtband anheben.

3 Entfernen Sie das Gurtband um die Schaumelemente.

4 Entfernen Sie das Styropor-Element oben auf dem Gerät.

5 Packen Sie den Förderteller und den Kunststoffdeckel aus.

6 Entfernen Sie das obere Schaumelement.

7 Heben Sie das Gerät hoch und entfernen Sie das untere Schaumelement.

8 Entfernen Sie das Gurtband, mit dem das Gerät fixiert ist.

9 Überprüfen Sie das Gerät auf Transportschäden oder fehlende Teile.

10 Der Aufbau des Geräts erfolgt wie im Abschnitt [Aufbauen des Geräts}Seite32] beschrieben.

Hinweis

Bewahren Sie alle Teile der Verpackung auf. Die Verpackung garantiert bestmöglichen Schutz für den

Transport Ihres Geräts über weite Entfernungen.

3.2 Lieferumfang

• LV12 einschliesslich Rutsche

• Stromversorgung (60 W/12 VDC) mit länderspezifischem Netzkabel

• RS232-Kabel (m/f, 1,0 m) zum Anschliessen einer Waage

• USB-Kabel (A/B, 1,0 m) zum Anschliessen von PC oder Waage

• Gedruckte Bedienungsanleitung

• CD-ROM (mit USB-Treibern und Bedienungsanleitungen)

• EG-Konformitätsbescheinigung

3.3 Wahl des Standortes

Die Wahl eines geeigneten Standortes ist wichtig für die Genauigkeit und Zuverlässigkeit des Geräts.

Stellen Sie sicher, dass folgende Umgebungsbedingungen eingehalten werden:

de

Installation und Inbetriebnahme 31Automatikförderer

Page 36

Beachten Sie die Umgebungsbedingungen:

1

• Das Instrument darf nur in Innenräumen und in einer Höhe von

maximal 5000 Metern über dem Meeresspiegel verwendet werden.

• Temperaturbereich: 10 – 30 °C

• Luftfeuchtigkeit: Max. 80%, nicht kondensierend

Achten Sie auf Folgendes:

• Der Netzstecker muss jederzeit zugänglich sein.

• Das Gerät benötigt eine stabile, ebene und erschütterungsfreie

Unterlage.

• Vermeiden Sie starke Temperaturschwankungen.

• Vermeiden Sie direkte Sonneneinstrahlung.

• Vermeiden Sie starken Luftzug (z. B. von Ventilatoren oder Kli-

maanlagen).

3.4 Aufbauen des Geräts

Nach der Überprüfung des Lieferumfangs, dem Auspacken des Geräts und der Auswahl eines geeigneten Aufstellorts kann das Gerät zusammengebaut werden.

1 Entfernen Sie die vier Transportsicherungen (1) (eine pro

Ecke).

Installation und Inbetriebnahme32 Automatikförderer

Page 37

2 Setzen Sie den Förderteller (2) auf das Gerät und befesti-

2

3

4

gen Sie ihn, indem Sie ihn im Uhrzeigersinn entlang der

eingekerbten Löcher drehen.

3 Setzen Sie den Deckel (3) auf das Gerät. Richten Sie den

Deckel anhand der Markierungen auf dem Deckel aus (die

Markierungen müssen, wie abgebildet, nach vorne zeigen). Drücken Sie den Deckel nach unten, bis er in seine

Position einrastet.

de

4 Setzen Sie die Rutsche (4) an der seitlichen Öffnung auf

die beiden Klemmschrauben und schieben Sie sie bis zum

Anschlag hinein.

5 Schliessen Sie das Gerät mit den mitgelieferten Kabeln an

6 Richten Sie das Gerät ein, wie in [Anschliessen des

die Waage an (entweder über USB oder RS232, je nach

Waagentyp).

Geräts}Seite34] beschrieben.

Installation und Inbetriebnahme 33Automatikförderer

Page 38

3.5 Anschliessen des Geräts

WARNUNG

Gefahr eines elektrischen Schlags

1 Zum Anschliessen des Geräts darf nur das im Lieferumfang enthaltene 3-adrige

Netzkabel mit Schutzleiter verwendet werden.

2 Schliessen Sie das Gerät nur an 3-polige Netzsteckdosen mit Schutzkontakt an.

3 Zum Betrieb des Geräts dürfen ausschliesslich genormte Verlängerungskabel mit

Schutzleiter verwendet werden.

4 Die absichtliche Trennung der Ausrüstung vom Schutzleiter ist verboten.

HINWEIS

Sachschaden durch Kurzschluss!

Beschädigungen der Isolierung des Netzadapters oder des Kabels können zu einem

Kurzschluss führen und das Gerät beschädigen.

1 Verwenden Sie ausschliesslich den mit Ihrem Gerät gelieferten Originalnetzadapter.

Andernfalls kann es zu einem Defekt des Geräts kommen.

2 Wenn Netzadapter oder Kabel beschädigt sind, muss der Netzstecker herausgezo-

gen und der Netzadapter ausgetauscht werden.

3 Verlegen Sie das Kabel so, dass es nicht durch äussere Einflüsse beschädigt wer-

den kann.

4 Der Netzstecker muss jederzeit zugänglich sein.

5 Spannungsführende Teile dürfen keiner Feuchtigkeit ausgesetzt sein. Feuchtigkeit

kann zu einem Kurzschluss führen.

Hinweis

Wenn das Gerät ans Netz angeschlossen wird, schaltet es sich automatisch ein. Um das Gerät auszuschalten und von der Stromversorgung trennen zu können, muss der Netzstecker herausgezogen

werden.

Das Gerät wird mit einem Netzadapter und einem länderspezifischen Netzkabel geliefert. Der Netzadapter eignet sich für alle Netzspannungen im Bereich von:

100 – 240 VAC, 50/60Hz.

Gehen Sie wie folgt vor, um das Gerät anzuschliessen und einzurichten:

1 Stellen Sie das Gerät auf eine feste Oberfläche. Beachten Sie die erforderlichen Umgebungsbedin-

gungen, siehe[Wahl des Standortes}Seite31].

2 Überprüfen Sie den Netzadapter und das Kabel auf Beschädigungen.

3 Prüfen Sie, ob die lokale Stromversorgung dem Bereich des mitgelieferten Netzadapters entspricht.

Sollte dies nicht der Fall sein, schliessen Sie den Netzadapter auf keinen Fall an die Stromversorgung an und wenden Sie sich an einen METTLER-TOLEDO-Vertreter.

Installation und Inbetriebnahme34 Automatikförderer

Page 39

4 Schliessen Sie den Netzadapter an die Anschlussbuchse auf der Rückseite des Geräts an.

de

5 Stecken Sie anschliessend den Netzadapter in eine geerdete Netzsteckdose.

ð Beim Einschalten des LV12 wird das Gerät dann für ca. zwei Sekunden initialisiert (Reset).

Während dieser Zeit leuchten alle LEDs. Anschliessend befindet sich das Gerät im Normalmodus

mit vorgewählter Intensitätsstärke 2.

Hinweis

• Die Grundeinstellung der Vibration ist so gewählt, dass die meisten Teile problemlos gefördert

werden. Für sehr kleine oder grosse Teile kann diese Einstellung angepasst werden, siehe[Einstellungen für die Zuführrate konfigurieren}Seite38].

Installation und Inbetriebnahme 35Automatikförderer

Page 40

3.6 Gerätetransport

HINWEIS

Durch unsachgemässen Transport kann das Gerät beschädigt werden!

Bei unsachgemässem Transport kann das Gerät herunterfallen. Dadurch kann es stark

beschädigt werden.

1 Transportieren Sie das Gerät nur, wenn es vom Netz genommen wurde.

2 Wenn Sie Ihr Gerät über weite Strecken transportieren oder verschicken wollen, ver-

wenden Sie die komplette Originalverpackung.

3 Verpackte Geräte müssen immer aufrecht transportiert und dürfen nie geworfen wer-

den.

Entfernen Sie das Netzkabel und alle Schnittstellenkabel vom Gerät. Beachten Sie die Hinweise im

Kapitel [Wahl des Standortes}Seite31] zur Wahl eines optimalen Standorts.

Installation und Inbetriebnahme36 Automatikförderer

Page 41

4 Betrieb

4.1 Zuführen starten/stoppen

In der Regel wird der LV12 durch Befehle über eine serielle Schnittstelle (RS232 oder USB) ferngesteuert; das Gerät kann aber auch manuell gesteuert werden. Um das Zuführen manuell zu starten

oder zu stoppen, muss Folgendes beachtet werden:

Das Gerät befindet sich im Zustand "bereit" (LED Bereit

§

leuchtet).

1 Drücken Sie die Taste Start/Std.Adj./Entleeren.

ð Das Gerät beginnt mit dem Zuführen. Die orange LED

Fördern leuchtet.

2 Drücken Sie erneut die Taste Start/Std.Adj./Entleeren, um

das Zuführen zu stoppen. Wird das Zuführen nicht manuell

gestoppt, führt das System so lange zu, bis ein Objekt die

Lichtschranke unterbricht und es dadurch gestoppt wird.

4.2 Einstellen der Zuführrate

Die Zuführrate kann vor dem Start oder während des Zuführprozesses eingestellt werden. Änderungen

der Zuführrate während des Zuführens werden sofort umgesetzt. Gehen Sie wie folgt vor, um die

Zuführrate zu ändern:

Das Gerät befindet sich im Zustand "bereit" (LED Bereit

§

leuchtet).

− Durch kurzes Drücken der Taste Fördergeschwindigkeit/

Test können Sie die Zuführrate so einstellen, dass immer

nur jeweils ein Stück auf die Waage fällt.

de

4.3 Entleeren des Geräts

Die Entleeren-Funktion wird verwendet, um alle Objekte aus dem System zu entfernen. Das System

führt mit der konfigurierten Zuführrate zu und stoppt 90Sekunden nachdem das letzte Objekt die

Lichtschranke passiert hat. Gehen Sie wie folgt vor, um die Entleeren-Funktion zu aktivieren:

Das Gerät befindet sich im Zustand "bereit" (LED Bereit

§

leuchtet).

1 Halten Sie die Taste Start/Std.Adj./Entleeren mindestens

zwei Sekunden lang gedrückt.

ð Die Entleerung wird gestartet. Die orange LED Zufuhr

leuchtet auf und alle vier LEDs für die Vibrationsstärke

blinken.

2 Drücken Sie einmal die Taste Start/Std.Adj./Entleeren, um

die manuelle Entleerung zu stoppen. Andernfalls wird die

Entleerung automatisch gestoppt.

Betrieb 37Automatikförderer

Page 42

4.4 Optimale Zuführrate finden

Mit dem Testmodus können Sie die optimale Zuführrate finden und damit sicherstellen, dass immer

nur jeweils ein Stück der Waage zugeführt wird. Gehen Sie wie folgt vor, um die Zuführrate mithilfe

des Testmodus einzustellen:

Das Gerät befindet sich im Zustand "bereit" (LED Bereit

§

leuchtet).

1 Drücken Sie die Taste Fördergeschwindigkeit/Test min-

destens fünf Sekunden lang, um den Testmodus aufzurufen.

ð Der LV12 beginnt mit dem Förderbetrieb, bis ein Stück

die Lichtschranke passiert. Dann stoppt der LV12 für

2,5 Sekunden, um anschliessend bis zum nächsten

Passieren der Lichtschranke weiter zu fördern.

2 Durch kurzes Drücken der Taste Fördergeschwindigkeit/

Test können Sie die Zuführrate so einstellen, dass immer

nur jeweils ein Stück auf die Waage fällt.

3 Durch Drücken der Taste Start/Std.Adj./Entleeren können

Sie den Testmodus verlassen.

4.5 Einstellungen für die Zuführrate konfigurieren

Bei der Konfiguration wird die Vibrationsstärke durch vier grüne LEDs wie folgt angezeigt:

Allgemein (für die meisten

Teile, Werkseinstellung)

Mittelgrosse Teile Grosse Teile

Kleine Teile

Gehen Sie wie folgt vor, um die Zuführrate einzustellen:

Das Gerät befindet sich im Zustand "bereit" (LED Bereit

§

leuchtet).

1 Halten Sie beide Tasten mindestens fünf Sekunden lang

gedrückt.

ð Die LED Bereit erlischt.

2 Ändern Sie die Zuführrate durch Umschalten mit der Taste

Fördergeschwindigkeit/Test.

3 Drücken Sie erneut beide Tasten, um den Einstellungsmo-

dus zu beenden.

ð Die LED Bereit leuchtet.

Betrieb38 Automatikförderer

Page 43

5 Wartung

WARNUNG

Es besteht Lebensgefahr bzw. die Gefahr schwerer Verletzungen durch Stromschlag!

Der Kontakt mit spannungsführenden Teilen kann zum Tod oder zu Verletzungen führen.

Falls das Gerät in Notfallsituationen nicht ausgeschaltet werden kann, besteht die Gefahr

von Personen- oder Geräteschäden.

1 Trennen Sie das Gerät von der Stromversorgung, bevor Sie mit Reinigungs- oder

Wartungsarbeiten beginnen.

2 Verwenden Sie nur Netzkabel von METTLER TOLEDO, falls diese ersetzt werden

müssen.

3 Achten Sie darauf, dass keine Flüssigkeit in das Gerät oder den Netzadapter

gelangt.

4 Öffnen Sie niemals das Gerät oder den Netzadapter.

Diese enthalten keine Bestandteile, die vom Anwender gereinigt, repariert oder ausgetauscht werden können.

5.1 Reinigung

HINWEIS

Das Gerät kann durch ungeeignete Reinigungsmittel beschädigt werden!

− Verwenden Sie auf keinen Fall Reinigungsmittel, die Lösungsmittel oder scheuernde

Bestandteile enthalten. Dies kann zu einer Beschädigung des Geräts führen.

Reinigen Sie das Gehäuse regelmässig mit einem feuchten, weichen Lappen. Der Förderteller ist aus

rostfreiem Chromstahl und kann zum Reinigen wie folgt herausgenommen werden:

1 Ziehen Sie den Netzstecker heraus.

2 Drücken Sie die Seitenwände des Gehäuses (1) leicht zusammen und heben Sie gleichzeitig den

Kunststoffdeckel (2) ab.

3 Entfernen Sie den Förderteller (3), indem Sie ihn gegen den Uhrzeigersinn entlang der eingekerb-

ten Löcher drehen.

4 Reinigen Sie alle verschmutzten Teile mit einem milden Haushaltsreinigungsmittel.

5 Montieren Sie den Förderteller und den Kunststoffdeckel nach dem Reinigen wieder auf das Gerät.

Achten Sie auf die richtige Ausrichtung des Deckels (die Markierungen müssen, wie abgebildet,

nach vorne zeigen).

de

Wartung 39Automatikförderer

Page 44

2

3

1

5.2 Entsorgung

In Übereinstimmung mit den Anforderungen der Europäischen Richtlinie 2012/19/EU

über Elektro- und Elektronik-Altgeräte (WEEE) darf dieses Gerät nicht mit dem Hausmüll

entsorgt werden. Sinngemäss gilt dies auch für Länder ausserhalb der EU entsprechend

den geltenden nationalen Regelungen.

Bitte entsorgen Sie dieses Produkt gemäss den örtlichen Bestimmungen in einer getrennten Sammlung für Elektro- und Elektronikgeräte. Bei allfälligen Fragen wenden Sie sich

bitte an die zuständige Behörde oder den Händler, bei dem Sie dieses Gerät erworben

haben. Bei Weitergabe dieses Gerätes (z. B. für private oder gewerbliche/industrielle Weiternutzung) ist diese Bestimmung sinngemäss weiterzugeben.

Vielen Dank für Ihren Beitrag zum Schutz der Umwelt.

Wartung40 Automatikförderer

Page 45

6 Schnittstellenbefehle und -funktionen MT-SICS

Das Gerät kann in komplexe Rechner- oder Datenerfassungssysteme integriert werden.

Um das Gerät auf einfache Art und Weise in Ihr System integrieren und seine Funktionen optimal nut-

zen zu können, stehen die meisten dieser Gerätefunktionen auch als entsprechende Befehle über die

Datenschnittstelle zur Verfügung. Deshalb unterstützt das Gerät den standardisierten Befehlssatz

"METTLER TOLEDO Standard Interface Command Set" (MT-SICS).

Die folgende Tabelle bietet einen kurzen Überblick über die für den LV12 verfügbaren Befehle. Für weiterführende Informationen setzen Sie sich bitte mit Ihrem METTLER TOLEDO-Vertreter in Verbindung.

MT-SICS-Befehle

MT-SICS-Befehl MT-SICS-Befehlskopfzeile Beschreibung

LV01 Software-Neustart Die Software wird, so wie beim Einschalten,

LV02 >Level< Zuführrate Stellt die aktuelle Zuführratenintensität auf einen

LV03 Vibration bis Lichtschranken-

signal

LV04 Vibration bis Stopp oder Reset Vibration bis Stopp oder Reset.

LV05 Entleeren Gerät entleeren.

LV06 Stopp Stoppt den aktuellen Vorgang und versetzt das

LV99 Lichtschrankensignal Statusänderungen der Lichtschranke lösen die-

Lichtschrankensignal

Arbeitsschritt Syntax Beschreibung

Abfrage LV99 Lichtschranke ist frei

Antwort LV99 A

Abfrage LV99 Lichtschranke ist blockiert

Antwort LV99 B

Achten Sie auf Folgendes:

• Alle Befehle müssen mit <CR> und <LF> beendet werden.

• Das System reagiert auf einen unbekannten Befehl mit "ES".

• Das Gerät reagiert möglicherweise unaufgefordert (z. B. bei Handbetrieb oder Startup)

neu gestartet. Durch diesen Befehl wird das

Gerät zurück in den Einschaltzustand versetzt.

Im Einschaltzustand ist das Gerät betriebsbereit

und die Zuführrate ist auf Stärke 2 eingestellt.

Die eingestellte Zuführrate wird beibehalten.

bestimmten Wert ein.

Zuführratenstärke.

{Datentyp: Vorzeichenlose 8 Bits. Bereich siehe

unten}

• Wert: '1' → Zuführratenstärke 1

• Wert: '2' → Zuführratenstärke 2

• Wert: '3' → Zuführratenstärke 3

• Wert: '4' → Zuführratenstärke 4

Der Ausgangswert wird durch die Geräte-Software vorgegeben (Ausgangswert ist Zuführratenstärke 2).

Vibration bis Lichtschrankensignal.

Gerät wieder in Betriebsbereitschaft.

sen Befehl aus. Weitere Informationen dazu finden Sie in folgender Tabelle:

de

Schnittstellenbefehle und -funktionen MT-SICS 41Automatikförderer

Page 46

7 Technische Daten

7.1 Allgemeine Daten

WARNUNG

Es besteht Lebensgefahr bzw. die Gefahr schwerer Verletzungen durch Stromschlag!

Der Kontakt mit spannungsführenden Teilen kann zum Tod oder zu Verletzungen führen.

1 Nur mit geprüftem Netzadapter betreiben, dessen SELV-Ausgang strombegrenzt ist.

2 Sorgen Sie für die richtige Polarität

Stromversorgung

Netzadapter: Primär: 100 – 240VAC, 50/60 Hz

Stromversorgung Gerät: 12 VDC ±5%, 0,9 A

Schutz und Normen

Überspannungskategorie: II

Verschmutzungsgrad: 2

Schutzart: Nur in trockenen Innenräumen verwenden

Normen für Sicherheit und EMV: Siehe Konformitätsbescheinigung

Verwendungsbereich: Nur in geschlossenen Innenräumen verwenden

Umgebungsbedingungen

Höhe über NN: Bis zu 5000m

Umgebungstemperatur: 10 – 30 °C

Relative Luftfeuchtigkeit: Max. 80%, nicht kondensierend

Gewicht und Abmessungen

B x H x T 225 x 260 x 225 mm

Nettogewicht 10,9 kg

Zulässige Stückgrösse ø 1 mm bis ø 20 mm

Sekundär: 12 V DC ±5%, max. 5 A (mit elektronischem Überlastschutz)

Technische Daten42 Automatikförderer

Page 47

7.2 Abmessungen

225 mm

225 mm

260 mm

de

Technische Daten 43Automatikförderer

Page 48

8 Zubehör und Ersatzteile

Länderspezifisches 3-adriges Netzkabel mit Schutzleiter.

USB (A/B): Verbindungskabel für PC/Waage, 1,0m (gehört

zur Standardausstattung)

Netzkabel AU 00088751

Netzkabel BR 30015268

Netzkabel CH 00087920

Netzkabel CN 30047293

Netzkabel DK 00087452

Netzkabel EU 00087925

Netzkabel GB 00089405

Netzkabel IL 00225297

Netzkabel IN 11600569

Netzkabel IT 00087457

Netzkabel JP 11107881

Netzkabel TH, PE 11107880

Netzkabel US 00088668

Netzkabel ZA 00089728

30388322

RS232 (m/f, 1:1): Verbindungskabel für Waage, 1,0m

(gehört zur Standardausstattung)

RS232 (f/f, Nullmodem): Verbindungskabel für PC, 1,8 m 21900576

Rutsche (gehört zur Standardausstattung) 30388039

Stromversorgung, 60 W/12VDC (gehört zur Standardausstattung)

11101051

30388323

Auf Anfrage erhältlich:

Tür mit Aussparung, für Excellence-Analysenwaagen 11106715

Tür mit Aussparung, für Excellence-Präzisionswaagen mit hohem Windschutz 11132711

Zubehör und Ersatzteile44 Automatikförderer

Page 49

1 Información de seguridad

• Lea las instrucciones de este manual y asegúrese de que las entiende perfectamente antes de uti-

lizar el dispositivo.

• Guarde este manual para futuras consultas.

• Incluya este manual si el dispositivo se transfiere a algún otro tercero.

Si el dispositivo no se utiliza conforme a las instrucciones de este manual o si este se modifica, la

seguridad del usuario puede verse afectada y Mettler-Toledo GmbH no asumirá ninguna responsabilidad.

1.1 Definición del texto y los símbolos de advertencia

Las indicaciones de seguridad se marcan con texto y símbolos de advertencia. Hacen referencia a

cuestiones de seguridad y advertencias. Si se hace caso omiso de las indicaciones de seguridad

pueden producirse daños personales o materiales, funcionamientos anómalos y resultados incorrectos.

ADVERTENCIA

ATENCIÓN

AVISO

Aviso

situación de peligro con un nivel de riesgo medio que puede provocar lesiones graves o incluso la muerte en caso de que no se impida.

situación de peligro de bajo riesgo que puede provocar lesiones de carácter leve o

medio, en caso de que no se impida.

situación de peligro de bajo riesgo que puede provocar daños en el dispositivo,

otros daños materiales, errores de funcionamiento y resultados erróneos o pérdida

de datos.

(sin símbolo)

información útil sobre el producto.

Peligro general Descarga eléctrica

es

1.2 Indicaciones de seguridad específicas del producto

El dispositivo se ha probado para los experimentos y los usos previstos que se indican en el manual

pertinente. No obstante, esto no le exime de la responsabilidad de realizar sus propias comprobaciones de los productos suministrados a fin de garantizar su idoneidad para los métodos y los propósitos para los que tiene previsto utilizarlos.

Uso previsto

Este dispositivo está diseñado para su uso por personal cualificado en laboratorios de ensayos de

calidad. El LV12 se ha previsto para su uso como alimentador automático para piezas pequeñas

(Ømáx. 20mm) como, por ejemplo, pastillas y cápsulas, aunque también para pequeños componentes electrónicos y mecánicos.

Cualquier otro tipo de uso y manejo que difiera de los límites establecidos en las especificaciones

técnicas sin consentimiento escrito por parte de Mettler-Toledo GmbHse considera no previsto.

Requisitos de ubicación

El dispositivo se ha diseñado para su uso en interiores. Evite las siguientes influencias ambientales:

• Situaciones que incumplan las condiciones ambientales que se especifican en las características

técnicas.

• Vibraciones fuertes.

• Luz solar directa.

• Atmósferas de gases corrosivos.

• Atmósferas explosivas de gases, vapor, niebla, polvo y polvo inflamable.

Información de seguridad 45Alimentador automático

Page 50

• Campos eléctricos o magnéticos de gran intensidad.

Cualificación del personal

El uso incorrecto del dispositivo o de los productos químicos empleados en el análisis puede producir lesiones o la muerte. Es imprescindible contar con la cualificación siguiente para el manejo del

dispositivo:

• Conocimientos y experiencia de trabajo con sustancias tóxicas y cáusticas.

• Conocimientos y experiencia de trabajo con equipos convencionales de laboratorio.

• Conocimientos y experiencia de trabajo en el cumplimiento de las normas generales de seguri-

dad en laboratorios.

Responsabilidades del propietario del dispositivo

El propietario del dispositivo es la persona que lo usa con fines comerciales o que lo pone a disposición de su personal. El propietario del dispositivo es el responsable de velar por la seguridad del

producto y del personal, los usuarios y cualquier tercero.

Las responsabilidades del operario son las siguientes:

• Conocer las normas de seguridad en el puesto de trabajo y velar por su cumplimiento.

• Asegurarse de que el dispositivo solo sea utilizado por personal cualificado.

• Definir las responsabilidades relacionadas con la instalación, el funcionamiento, la limpieza, la

resolución de problemas y el mantenimiento, además de asegurarse de que las tareas se realicen.

• Formar al personal de forma periódica e informarle sobre los peligros.

• Proporcionar al personal el equipo de protección necesario.

Notas acerca de la seguridad

ADVERTENCIA

Riesgo de discapacidad auditiva debido a un nivel de ruido alto.

En función de las muestras utilizadas (material y peso), es posible que se produzcan

niveles de ruido potencialmente peligrosos cuando las muestras caen por la deslizadera de salida. Los niveles de ruido por encima de 80dB(A) pueden provocar lesiones

auditivas graves.

1 En el caso de una alimentación de piezas para la que se espere un nivel de ruido

por encima de 80dB(A), realice una medición del ruido. Utilice los ejemplos siguientes a modo de referencia.

2 Use protección auditiva si el nivel de ruido supera los 80dB(A).

La lista siguiente ofrece los valores aproximados de emisiones de ruido (modo de descarga a

20cm):

Configuración Elemento Material Peso Tamaño Valor

General Espaciador Sintético 0,12g 10×5mm

Pequeña Tornillo Metal 0,14g M2×3mm

Media Tornillo Metal 0,2g M2,5×5mm

Grande Soporte separa-

dor

Grande Soporte separa-

dor

Vacía: <70dB(A)

Metal 1,5g M3×10mm

Metal 5,1g M4×20mm

78dB(A)

75dB(A)

79dB(A)

89dB(A)

93dB(A)

Información de seguridad46 Alimentador automático

Page 51

AVISO

Peligro de daño debido a un uso indebido.

El uso indebido del instrumento puede ocasionar daños materiales importantes.

1 Instale y maneje el instrumento únicamente en espacios interiores secos.

2 Maneje y utilice siempre el dispositivo de acuerdo con las instrucciones incluidas

en este manual.

3 No abra el dispositivo.

4 No realice nunca modificaciones en el dispositivo.

5 Utilice solamente dispositivos periféricos y accesorios de METTLER TOLEDO, ya que

se adaptan de manera óptima al instrumento.

es

Información de seguridad 47Alimentador automático

Page 52

2 Diseño y función

El LV12 es un alimentador automático para pastillas y cápsulas, aunque también para pequeños

componentes electrónicos y mecánicos. Las series de pesaje prolongadas se simplifican drásticamente. Por ello, el LV12 está especialmente recomendado para un control estadístico de la calidad

(SQC). Normalmente, el LV12 se controla a distancia mediante comandos ejecutados en una interfaz

serie (RS232 o USB), si bien el sistema también se puede controlar manualmente con ayuda de botones.

El LV12 alimenta la balanza con una única pieza y, a continuación, se detiene automáticamente.

Tras recibir el comando oportuno del instrumento de pesaje, el dispositivo alimenta la balanza con la

siguiente pieza. Este proceso puede iniciarse o detenerse en cualquier momento mediante un comando. Al final de una muestra, la placa del alimentador puede vaciarse o el alimentador espera

hasta obtener el comando para otra muestra.

2.1 Controles e indicadores

Controles

Botón Acción Objetivo

Comienzo/

Std.Adj./Discharge

Intensidad vibrac./

Comprobación

Aviso

Al pulsar los dos botones a la vez, es posible modificar la configuración de tamaño de las piezas;

consulte [Configuración de los niveles de velocidad de alimentación}página60].

Indicadores

Indicador LED Estado Significado

Está lista

Feed

Pulse una vez Para activar o desactivar la acción de

Mantenga pulsado hasta que los LED indicadores de nivel parpadeen

Pulse una vez Para cambiar la velocidad de alimenta-

Mantenga pulsado hasta que el LED Está

lista parpadee

El LED verde está encendido El instrumento está activado y listo para

El LED verde parpadea El instrumento está en modo de prueba

El LED naranja está encendido La acción de alimentación está activada

El LED naranja parpadea La barrera luminosa está obstruida, su-

Un LED encendido Velocidad de alimentación más baja

alimentación

Para activar la descarga

ción en un paso

Para activar el modo de prueba y encon-

trar la velocidad de alimentación óptima

utilizarse

y la placa del alimentador vibra

cia o defectuosa

Diseño y función48 Alimentador automático

Page 53

Indicador LED Estado Significado

1 2

3

Dos LED encendidos Velocidad de alimentación intermedia

Tres LED encendidos Velocidad de alimentación intermedia

Cuatro LED encendidos Velocidad de alimentación más alta

El primer LED parpadea

más baja; valor predeterminado al encender

más alta

Cortocircuito en el botón Comienzo/

Std.Adj./Discharge

es

2.2 Conexiones

Toma para fuente de alimentación de

1

12VCC

Interfaz RS232

3

Conector Función

Toma para el

adaptador de CA/

CC

Puerto USB (tipo

B)

El cuarto LED parpadea

Los cuatro LED parpadean El instrumento está en modo de descar-

2

Para la conexión de la fuente de alimentación. Utilice únicamente el adaptador de

CA/CC de +12VCC de serie que se suministra junto con el dispositivo.

Para la conexión de una balanza, un ordenador personal o un concentrador equipado con un puerto USB.

Cortocircuito en el botón Intensidad vi-

brac./Comprobación

ga

Puerto USB (tipo B)

Diseño y función 49Alimentador automático

Page 54

Conector Función

Interfaz RS232

La conexión para RS232 es un conector en miniatura D-sub de nueve clavijas con

una asignación idéntica a la de los PC. Para la conexión de un ordenador, se necesita un cable de módem nulo o laplink.

Parámetros de la interfaz:

• 9600baudios, sin paridad, 8bits de datos, 1bit de parada

• Software de circuito de inicio de conmutación Xon/Xoff

• Final de línea <CR><LF>

Aviso

Para conocer el conjunto de comandos SICS del LV12, consulte [Comandos y funciones de la interfaz MT-SICS}página63].

Diseño y función50 Alimentador automático

Page 55

2.3 Modos de funcionamiento

RS232

www.mt.co

m

X

PE204

F

F

METTLER TOLEDO

S

tatic

D

ete

c

t

USB (A/B)

USB

A

USB B

IND

890SQC

RS232

USB (A/B)

USB

A

USB B

El LV12 es compatible con las configuraciones de sistema siguientes:

Balanzas XP/XPE con conexión RS232 Balanzas XPR con conexión USB

El LV12 puede controlarse mediante una balanza XP/XPE de METTLER TOLEDO con interfaz

RS232. El programa para el control debe estar

disponible en el instrumento de pesaje (por

ejemplo, la aplicación de SQC o de estadísticas

en las balanzas Excellence).

Conexión directa IND890SQC

El LV12 y la balanza se conectan directamente a un sistema IND890SQC (el LV12 mediante RS232,

la balanza mediante USB).

El LV12 puede controlarse mediante una balanza XPR de METTLER TOLEDO con interfaz USB.

es

Diseño y función 51Alimentador automático

Page 56

LabX o Freeweigh.net con balanzas XP/XPE

RS232

Ethernet or RS232

LabX

Freeweigh

.net

www.mt.co

m

X

PE204

F

F

METTLER TOLEDO

S

tatic

D

ete

c

t

USB (A/B)

Ethernet or USB (A/B)

La

bX

• Balanza XP/XPE conectada al PC por Ethernet o con un cable RS232.

• LV12 conectado a la balanza XP/XPE con una interfaz RS232.

LabX con balanzas XPR

• Balanza XPR conectada al PC por Ethernet o con un cable USB.

• LV12 conectado a la balanza XPR con una interfaz USB.

Diseño y función52 Alimentador automático

Page 57

3 Instalación y puesta en marcha

Este apartado describe cómo poner el nuevo equipo en funcionamiento.

3.1 Desembalaje del dispositivo

Entrega

El dispositivo se entrega por medio de una empresa de logística local. Todos los componentes incluidos en el suministro estándar se entregan juntos en un único embalaje.

Daños durante el transporte o falta de piezas

Inmediatamente después de la entrega, compruebe su contenido para garantizar que esté completo y

que no presente daños.

Si existe algún desperfecto externo visible causado durante el transporte, siga este procedimiento:

• No acepte la entrega.

• Anote el alcance de los daños en el albarán de entrega del transportista.

• Informe a un representante de METTLER TOLEDO.

Aviso

Presente una reclamación por cada uno de los defectos tan pronto como los identifique. Las reclamaciones por daños solo se pueden efectuar dentro de los plazos de reclamación aplicables.

Desembalaje del dispositivo

Realice el procedimiento siguiente para desembalar el dispositivo:

1 Abra la caja de embalaje.

2 Retire el embalaje levantándolo por la correa de fijación.

3 Retire la correa de fijación que rodea los elementos de espuma.

4 Retire el elemento de poliestireno de la parte superior del dispositivo.

5 Desembale la placa del alimentador y la cubierta de plástico.

6 Retire el elemento de espuma superior.

7 Levante y extraiga el dispositivo del elemento de espuma inferior.

8 Retire la correa de fijación del dispositivo.

9 Revise el dispositivo en busca de daños durante el transporte o falta de piezas.

10 Para el montaje del dispositivo, realice el procedimiento que se describe en [Montaje del disposi-

tivo}página54].

Aviso

Se recomienda conservar el embalaje de todas las piezas. El embalaje ofrece la mejor protección posible para el transporte a larga distancia del dispositivo.

3.2 Suministro estándar

• LV12 con deslizadera

• Fuente de alimentación de 60W/12VCC con cable de alimentación específico del país

• Cable RS232 (m/h, 1,0m) para conectar una balanza

• Cable USB (A/B, 1,0m) para conectar un PC o una balanza

• Instrucciones de manejo impresas

• CD-ROM con los controladores USB y las instrucciones de manejo

• Declaración de conformidad CE

3.3 Selección de la ubicación

Escoja un lugar óptimo para que el dispositivo funcione de forma precisa y fiable. Deben respetarse

las siguientes condiciones del local:

es

Instalación y puesta en marcha 53Alimentador automático

Page 58

Observe las condiciones del entorno:

1

• Utilice el instrumento únicamente en recintos cerrados y a una

altitud máxima de 5000m sobre el nivel del mar.

• Zona de temperatura: 10-30°C

• Humedad: máx. 80% sin condensación

Preste atención a lo siguiente:

• El enchufe debe estar accesible en todo momento.

• Coloque el dispositivo en un emplazamiento firme, horizontal y

sin vibraciones.

• Evite los cambios bruscos de temperatura.

• Evite la exposición solar directa.

• Evite las corrientes de aire fuertes (por ejemplo, de ventiladores

o aires acondicionados).

3.4 Montaje del dispositivo

Después de comprobar el suministro estándar, desembalar el dispositivo y encontrar una ubicación

adecuada para él, ha llegado el momento de montar el dispositivo.

1 Retire los cuatro seguros para transporte (1) (uno en cada

esquina).

Instalación y puesta en marcha54 Alimentador automático

Page 59

2 Coloque la placa del alimentador (2) en el dispositivo y fí-

2

3

4

jela girándola hacia la derecha por los orificios ranurados.

3 Coloque la cubierta (3) en el dispositivo. Tome las marcas

de la parte superior de la cubierta como referencia para

una orientación correcta (las marcas deben situarse hacia

delante tal y como se muestra en la imagen). Presione la