Page 1

daeg SPO2 Simulator

User Manual

Version 1.15_2

Updated 22/01/2007

Page 2

Warranty and Product Support

Fluke Biomedical warrants this instrument against defects in materials and

workmanship for one full year from the date of original purchase. During the

warranty period, we will repair or, at our option, replace at no charge a product

that proves to be defective, provided you return the product, shipping prepaid, to

Fluke Biomedical. This warranty does not apply if the product has been damaged

by accident or misuse or as the result of service or modification by other than

Fluke Biomedical. IN NO EVENT SHALL FLUKE BIOMEDICAL BE

LIABLE FOR CONSEQUENTIAL DAMAGES.

Only serialized products and their accessory items (those products and items

bearing a distinct serial number tag) are covered under this one–year warranty.

PHYSICAL DAMAGE CAUSED BY MISUSE OR PHYSICAL ABUSE IS

NOT COVERED UNDER THE WARRANTY. Items such as cables and

nonserialized modules are not covered under this warranty.

Recalibration of instruments is not covered under the warranty.

This warranty gives you specific legal rights, and you may also have other rights

which vary from state to state, province to province, or country to country. This

warranty is limited to repairing the instrument to Fluke Biomedical’s

specifications.

Warranty Disclaimer

Should you elect to have your instrument serviced and/or calibrated by someone

other than Fluke Biomedical, please be advised that the original warranty

covering your product becomes void when the tamper-resistant Quality Seal is

removed or broken without proper factory authorization. We strongly

recommend, therefore, that you send your instrument to Fluke Biomedical for

factory service and calibration, especially during the original warranty period.

Page 3

Notices

All Rights Reserved

Copyright 2006, Fluke Biomedical. No part of this publication may be reproduced, transmitted, transcribed, stored in a retrieval

system, or translated into any language without the written permission of Fluke Biomedical.

Copyright Release

Fluke Biomedical agrees to a limited copyright release that allows you to reproduce manuals and other printed materials for use in

service training programs and other technical publications. If you would like other reproductions or distributions, submit a written

request to Fluke Biomedical.

Unpacking and Inspection

Follow standard receiving practices upon receipt of the instrument. Check the shipping carton for damage. If damage is found, stop

unpacking the instrument. Notify the carrier and ask for an agent to be present while the instrument is unpacked. There are no

special unpacking instructions, but be careful not to damage the instrument when unpacking it. Inspect the instrument for physical

damage such as bent or broken parts, dents, or scratches.

Technical Support

For application support or answers to technical questions, either email techservices@flukebiomedical.com or call 1-800- 648-7942

or 1-425-446-6945.

Claims

Our routine method of shipment is via common carrier, FOB origin. Upon delivery, if physical damage is found, retain all packing

materials in their original condition and contact the carrier immediately to file a claim. If the instrument is delivered in good

physical condition but does not operate within specifications, or if there are any other problems not caused by shipping damage,

please contact Fluke Biomedical or your local sales representative.

Standard Terms and Conditions

Refunds and Credits

Please note that only serialized products and their accessory items (i.e., products and items bearing a distinct serial

number tag) are eligible for partial refund and/or credit. Nonserialized parts and accessory items (e.g., cables, carrying

cases, auxiliary modules, etc.) are not eligible for return or refund. Only products returned within 90 days from the date of

original purchase are eligible for refund/credit. In order to receive a partial refund/credit of a product purchase price on a serialized

product, the product must not have been damaged by the customer or by the carrier chosen by the customer to return the goods, and

the product must be returned complete (meaning with all manuals, cables, accessories, etc.) and in “as new” and resalable

condition. Products not returned within 90 days of purchase, or products which are not in “as new” and resalable condition, are not

eligible for credit return and will be returned to the customer. The Return Procedure (see below) must be followed to assure prompt

refund/credit.

Restocking Charges

Products returned within 30 days of original purchase are subject to a minimum restocking fee of 15 %. Products

returned in excess of 30 days after purchase, but prior to 90 days, are subject to a minimum restocking fee of 20 %.

Additional charges for damage and/or missing parts and accessories will be applied to all returns.

Return Procedure

All items being returned (including all warranty-claim shipments) must be sent freight-prepaid to our factory location. When you

return an instrument to Fluke Biomedical, we recommend using United Parcel Service, Federal Express, or Air Parcel Post. We

also recommend that you insure your shipment for its actual replacement cost. Fluke Biomedical will not be responsible for lost

shipments or instruments that are received in damaged condition due to improper packaging or handling.

Use the original carton and packaging material for shipment. If they are not available, we recommend the following guide for

repackaging:

Use a double–walled carton of sufficient strength for the weight being shipped.

Use heavy paper or cardboard to protect all instrument surfaces. Use nonabrasive material around all projecting parts.

Use at least four inches of tightly packed industry-approved, shock-absorbent material around the instrument.

Returns for partial refund/credit:

Page 4

Every product returned for refund/credit must be accompanied by a Return Material Authorization (RMA) number, obtained from

our Order Entry Group at 1-800-648-7952 or 1-425-446-6945.

Repair and calibration:

To find the nearest service center, go to www.flukebiomedical.com/service or

In the U.S.A.:

Cleveland Calibration Lab

Tel: 1-800-850-4606

Email: globalcal@flukebiomedical.com

Everett Calibration Lab

Tel: 1-800-850-4606

Email: service.status@fluke.com

In Europe, Middle East, and Africa:

Eindhoven Calibration Lab

Tel: +31-402-675300

Email: ServiceDesk@fluke.com

In Asia:

Everett Calibration Lab

Tel: +425-446-6945

Email: service.international@fluke.com

Certification

This instrument was thoroughly tested and inspected. It was found to meet Fluke Biomedical’s manufacturing specifications when

it was shipped from the factory. Calibration measurements are traceable to the National Institute of Standards and Technology

(NIST). Devices for which there are no NIST calibration standards are measured against in-house performance standards using

accepted test procedures.

WARNING

Unauthorized user modifications or application beyond the published specifications may result in electrical shock hazards or

improper operation. Fluke Biomedical will not be responsible for any injuries sustained due to unauthorized equipment

modifications.

Restrictions and Liabilities

Information in this document is subject to change and does not represent a commitment by Fluke Biomedical. Changes

made to the information in this document will be incorporated in new editions of the publication. No responsibility is

assumed by Fluke Biomedical for the use or reliability of software or equipment that is not supplied by Fluke

Biomedical, or by its affiliated dealers.

Manufacturing Location

The daeg is manufactured in Norway for Fluke Biomedical, Everett, WA, U.S.A.

Page 5

Table of Contents

daeg Specifications ......................................................................................................................... 7

daeg Quick Start .............................................................................................................................. 9

Unit Setup ..................................................................................................................................... 11

Operation....................................................................................................................................... 13

Troubleshooting ............................................................................................................................ 19

Page 6

6

This page was intentionally left blank.

www.metron-biomed.com

Page 7

7

daeg Specifications

SPO2 SIMULATION

GENERAL

Factory installed, downloadable and user

programmable R-curves, patient conditions

and templates.

Probe signal and LED test

ACTIVE PROBE SPO2 SIMULATION

O2 saturation range: 35 – 100 %

Simulation resolution: 1% SpO2%

Simulation accuracy:

± 0.5 SpO2% 65-100% SpO2%

± 1 SpO2% 30-64% SpO2%

Simulation repeatability: ± 0.2 SpO2%

Simulation rate: 30 – 300 bpm

Rate resolution: 5 bpm (sync. to ECG

for

“C-lock” testing)

Rate accuracy: ± 0.1%

Pulse amplitude 0 – 100% of nominal

pleth amplitude.

Amplitude resolution: 0-10 range, 1%

10-100 range, 5%

Amplitude accuracy: ≥30% amplitude ±1%.

1-29% amplitude ±5%.

Pigmentation: Low, medium and high

Light repeater bandwidth:

DC – 1MHz

Optical slew rate: 50 mcd/ s

Light repeater dynamic range:

1mcd + 13 dB – 60 dB

Receiver optical 3 dB bandwidth:

600 – 1050 nm.

INSTALLED R-CURVES

BCI Oxipuls

Criticare

Nellcor

HP

Ohmeda

ADDITIONAL R-CURVES

These are R-Curves that are available and

can be uploaded using the PRO-Soft daeg

software.

BCI Oxipulse 3301

Criticare 504

Dolphin 2100

HP/Philips

Massimo

Nellcor N-20, N-180, N-200, NBP-40,

Symphony

Nonin 8500 & Marquette Apex

Novametrix Oxypleth

Ohmeda 3700, 3740

Welch Allen Propaq

INSTALLED PATIENT CONDITIONS

Normal patient

Geriatric patient

Obese patient

Patient with weak pulse

Bradycardia

Tachycardia

ARTIFACTS (ACTIVE PROBE ONLY)

Motion: 0 - 4Hz

Ambient sunlight: Ambient, Sun

Interfering light: 50Hz, 60Hz

PROBE LED OPTICAL FREQUENCY

Frequency range: 550 – 1050 nm

Resolution: 1nm

Accuracy: ±2% of range

PROBE TEST

Available with PTA-1 Probe Test Adapter Box Tests cable, photo sensors, Red LED and IR

LED.

Interface for Nellcor and Ohmeda type sensors

as standard.

Adapters for most major manufacturers

available.

LED current continuity tests.

Photodiode response test with numerical

display of light transfer function, 0-100%

Advance cable test by detecting response

glitches when flexing the cable.

ECG SIMULATION -

GENERAL

The data below is related both to factory installed

and downloadable waveforms.

Lead configuration:

5 lead RL, RA, LA, LL, V1-6

Low level output amplitude:

0.2-2mV, resolution 100 V

Low level output impedance:

1000 ohm to RL

High level output amplitude:

0.5V/mV of low level.

High level output impedance: 50 ohm

System amplitude accuracy: ±2% @1mV

System rate accuracy: ± 0.1%

System time resolution: 10 s

(100 kHz maximum update rate)

ECG OUTPUT

The data below is related to factory installed

waveform types.

NORMAL ECG SINUS

30 – 300 BPM, resolution 5 BPM

(synchronized with pleth wave)

ACCESSORIES

Battery Eliminator 240V or 115V

Batteries

User/Service Manual

OPTIONS

PTA-1 Probe Test Adapter Box

SpO2 Probe Adapters (check availability)

Carrying case

Universal Snap-to-Banana Adapters

GENERAL INFORMATION

POWER SUPPLY

Power sources: 4 standard AA/LR6/MN-1500

cells.

230VAC/115VAC to 9vDC battery

eliminator.

Power consumption:

200 mA w/o display backlight.

400 mA w/full backlight.

Battery lifetime:

12 h for alkaline cells without

backlight.

HOUSING

High impact plastic case.

DIMENSIONS

Height: 237 mm/9.2”

Width: 122 mm/4.8”

Depth: 42 mm/1.6”

www.metron-biomed.com

WEIGHT

With battery: 0.6 kg/1.3 lb

TEMPERATURE

Storage temperature:

0/32 to +50/122 C/F

Operating temperature:

+ 15/59 to +35/95 C/F

HUMIDITY

Operating humidity:

10% - 80% (non-condensing)

DISPLAY

Graphical LCD, with backlighting.

CONNECTORS

9V DC power inlet (standard 2.1 mm power

jack.

RS-232/C for PC or printer communication (9-

pin D-sub male)

1 probe connector (Redel 8-pin).

5 low level ECG outputs RA, RL, LA, LL and

V1 (AHA color coded safety connector)

1 high level ECG output (standard phono jack).

RECOMMENDED PRINTERS

HP DeskJet, Canon Bubble Jet or compatible.

daeg SpO2 Analyzer

Ordering Information

Order no:

12700: daeg SpO2 Analyzer

Accessories:

12715: Finger Probe AFP-1

17030: Battery Eliminator daeg, 240V

or

17027R: Regulated Battery Eliminator 115V

17031: Battery package, 4-cells

12710: User and Service Manual (CD)

Options:

11150: Carrying case

12711: Probe Test Adapter Box

12712: PRO-Soft daeg

12713: PRO-Soft daeg, demo

12714: User Manual PRO-Soft daeg

17024: Universal Banana Adapter

SpO2 Probe Adapters

12761: BCI Compatible Direct SpO2

12761N: BCI Compatible 9-Pin SpO2

12762: Criticare Compatible Direct SpO2

12762N: Criticare Compatible 9-Pin SpO2

12764: Datascope Compatible Direct SpO2

12764N: Datascope Compatible 9-Pin SpO2

12765: Datex Compatible Direct SpO2

12765N: Datex Compatible 9-Pin SpO2

12766: Philips Compatible Direct SpO2

12767: Invivo Compatible Direct SpO2

12768: Nihon Kohden Compatible Direct SpO2

12769: Nonin Compatible Direct SpO2

12770: Novametrix Compatible Direct SpO2

12773: Simed Compatible Direct SpO2

12774: Spacelabs Compatible Direct SpO2

12775: Sensormedics Compatible Direct SpO2

12776: Masimo Compatible Direct SpO2

Page 8

8

This page was intentionally left blank.

www.metron-biomed.com

Page 9

9

daeg Quick Start

daeg Startup

Release

------------------STATUS --------

--------Preset : Manual

SpO2 : 96 %

Rate : 60 BPM

P.ampl : 100 %

F1

F3

----------------- STATUS ---------------Preset : Manual

SpO2 : 96 %

Rate : 60 BPM

P.ampl : 100 %

FUNC. displ-1

METR N

SpO2 Analyzer

LED-test

Red

IR

F1

F2

F3

daeg

no

clear

yes

enter

1

. , # $

7

template

esc

2

3

4

9

8

0 _-

6

5

on

off

Battery Compartment

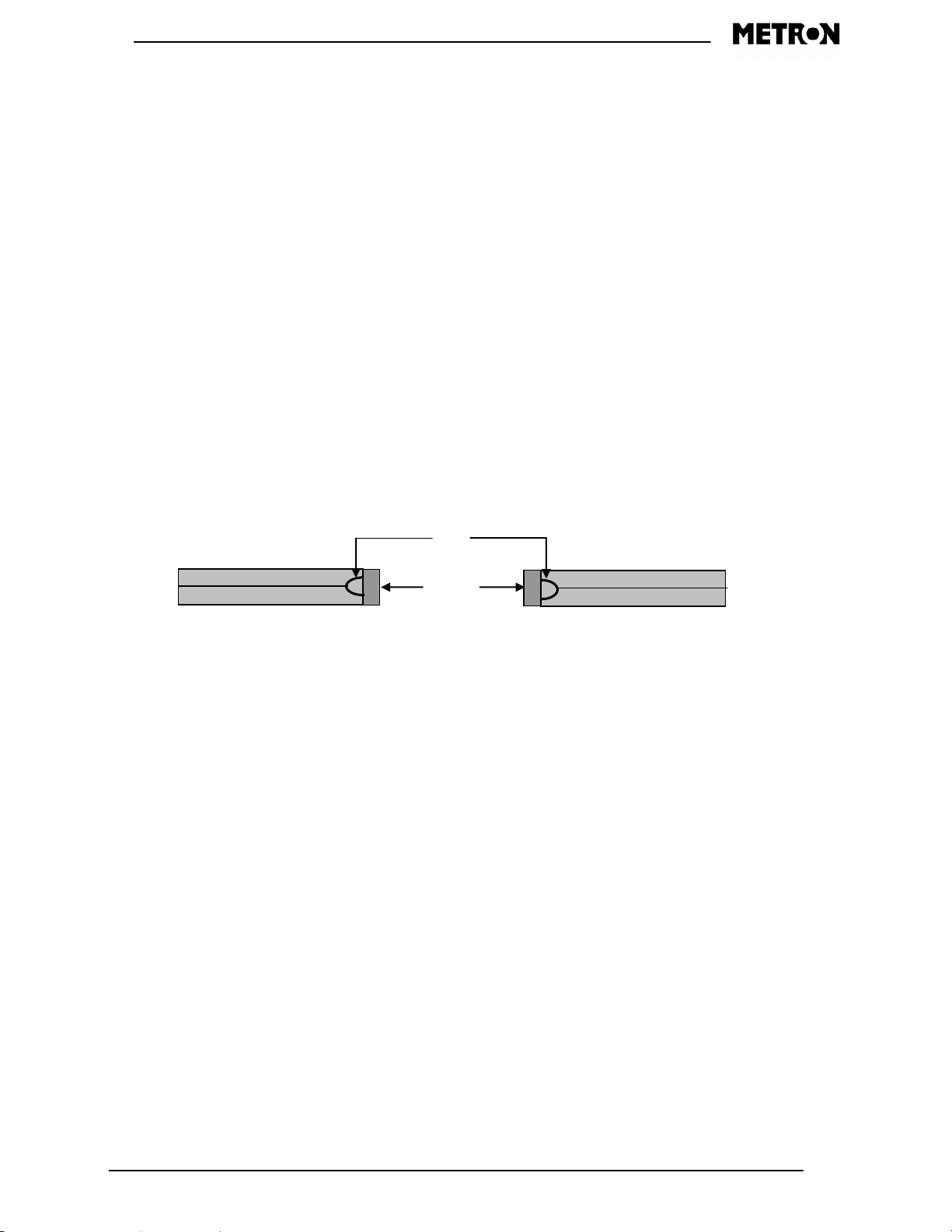

daeg finger probe

Label side to bottom.

SpO2 sensor

Red, IR light source

introduced on unlabeled

side of daeg finger.

Daeg Operation / Simulation

1. Connect daeg’s Finger Probe to the main daeg unit,

and switch the daeg unit on.

The daeg must be powered by the 9VDC 400mA

power supply or by 4 AA alkaline batteries loaded

into the unit’s battery compartment.

2. The version number of the firmware will be briefly

displayed, followed by the first display screen

(below). The unit is immediately outputting the

simulation as displayed.

3. Apply the oximeter’s sensor to the daeg finger

probe. The sensor’s transmitter must be on the

bottom (unlabeled) side of the daeg finger.

1. To adjust the simulation settings, use the F2

function key to select the “active” parameter. The

active parameter is marked with an asterisk (*).

Note: Menu items at the bottom of the display are

activated/accessed using the F1, F2, and F3 function

keys.

2. Adjust the active parameter using the yellow Up

and Down arrow keys on the keypad, then press

enter to confirm the change.

3. To change the simulation setting for oximeter

model (Make), Ambient Light, Pigmentation, or to

select an automated simulation sequence, select the

F3 function key to go to the second display screen.

4. To access additional test and auxiliary functions,

press the F1 function key while in the first or

second screen display.

Additional / Auxiliary functions include:

Alarm Tests, Print functions, Remote Control Operation,

Probe Tests, and Simulation Setup.

www.metron-biomed.com

Page 10

10

This page was intentionally left blank.

www.metron-biomed.com

Page 11

11

Unit Setup

Bottom

Tabs

Right

Left

Unpacking

Unpack the unit and confirm the presence of the following components:

1 - daeg main unit

1 - daeg artificial finger

4 - AA batteries

1 – battery eliminator

If any of these items are missing or damaged, please contact your local Metron office.

Battery Installation

Refer to the diagram below when installing the batteries. You will need to depress the tabs

shown in the diagram below and remove the bottom dark gray piece of the chassis. This will

then expose the battery connector and battery tray. Disconnect the battery clip and remove the

battery tray. When inserting the batteries into the tray, be sure to observe the polarity of the

batteries. When the tray is loaded back into the unit, reconnect the clip, and then replace the

chassis piece.

www.metron-biomed.com

Page 12

12

This page was intentionally left blank.

www.metron-biomed.com

Page 13

13

Operation

---- METRON daeg ---

SpO2 Meter Analyzer

Revision X.XX

loading sim data...

------ STATUS -----Preset:*Manual

SpO2 : 96 %

Rate : 60 BPM

P.ampl: 100 %

FUNC. * displ-1

------ SETUP ------Make :*Nellcor

Oper. : Manual

Amb.L.: Manual

Pigm. : Manual

FUNC. * displ-2

Power up Screen

Main Simulation Screens

This screen is the first one that is visible when the unit is

turned on. It indicates which version of the firmware is

installed.

These are the two screens that are used when performing

SPO2 simulations. You can change between the screens by

pressing the (F3) button. The (F2) button will move the

cursor, (*), to the next parameter. Using the Up and Down

arrows will let you change the value of the selected

parameter. You will then need to press the (yes/enter)

button to accept the change. Pressing the (F1) button will

take you the Function Selection Menu.

www.metron-biomed.com

Page 14

14

-----FUNCTIONS----- Alarm limits

Print header

Print Status

Remote Contr

ENTER EXIT

-----FUNCTIONS----- Print Status

Remote Contr

Probe Analyz

Sim. Setup

ENTER EXIT

AL_LIMIT t= 0.0 sec

Pulse :*On

SpO2 : 96 %

Rate : 60 BPM

P.ampl: 100 %

STOPt * PRINT

Function Selection Menu

This screen will let you select which testing function of

the daeg that you wish to perform. Using the Up and

Down arrows will let you move the cursor (->) next to the

function that you wish to use. Once the cursor is placed

press the (F2) button or the (yes/enter) button to enter

that function. Pressing the (F3) or (esc) buttons will take

you back to the Main Simulation Screen.

Alarm Limits

This test is designed to test your alarm system on your

monitor. The (F2) button will move the cursor, (*), to the

next parameter. Using the Up and Down arrows will let

you change the value of the selected parameter. You will

then need to press the (yes/enter) button to accept the

change and start the timer. Press the (F1) button to stop

the clock when you hear the alarm from your monitor.

The (F3) button will generate a line of printout via the

parallel port. Pressing the (esc) button will take you back

to the Main Simulation Screen.

www.metron-biomed.com

Page 15

15

------ STATUS -----Preset:*Manual

SpO2 : 96 %

Rate : 60 BPM

P.ampl: 100 %

LOCAL

CONTR. *

-- PROBE ANALYZER –-

Choose a test to

perform on the

SpO2 probe.

DIODE CONTI SENSI

-- PROBE ANALYZER –-

Probe OK!

DIODE CONTI SENSI

Remote Control

Probe Analyzer

This is the screen that is shown when the daeg is in

remote control mode. All currently active parameters are

displayed on the screen. Pressing (F1) will cancel the

remote control mode and take you back to the local Main

Simulation Screen.

This screen will let you select which test you wish to

perform on the finger probe when you have the probe

tester adaptor box attached.

Diode Test

Pressing (DIODE) runs the test.

This test gives a descriptive message as to the condition

of the probe’s LEDs and sensing elements. It tests the

probe for electrical shorts and open circuits.

www.metron-biomed.com

Page 16

16

Continuity Test

-- PROBE ANALYZER --

- ---Dio:----------- = ---Phd:----- ----

- --DIODE CONTI SENSI

-- PROBE ANALYZER –-

IR : XX %

Red: XX %

DIODE CONTI SENSI

IR :--------------- =

Red:--------------- =

Phd:----------------

DIODE CONTI SENSI

Pressing (CONTI) starts the continuity test. This test

constantly monitors the LED’s and the photocell.

Depending on the nature of the probe you will either

have “Dio” and “Phd” or “IR”, “RED”, and “Phd”

status lines. This is a continuous test and will display

changes in the status in real time. If the status changes

this will be reflected on the graph. A “High” line

indicates a short in that element. A “Middle” line is

normal operation. A “Low” indicates an open circuit.

Since this is a continuously running test it lets you flex

you cable to check for intermittent failures.

Sensitivity Test

Press (SENSI) to start the sensitivity test. This test gives

a value for the Red and IR light being seen by the sensor.

The scale is from 0 – 100. For repeatability purposes, do

not hold your probe open or squeeze it shut. Just let it

rest in its normal position.

www.metron-biomed.com

Page 17

17

Simulation Setup

SIM SETUP:

To change values,

use 'Yes' –button

for up, and

'No' –button for

down!

Make :Nellcor

RedDC:2048

IRDC :1024

Lcode: 101

Rval :0.48@SpO2:100

SAVE &

SpO2- SpO2+ QUIT

This function lets you manually alter the R-Curves within

the daeg unit.

Be cautious when using this mode as you are altering the

simulator output. If you make any changes that you do

not wish to keep you must turn off the daeg for 5 seconds

then turn it back on.

When in this mode the controls will be as follows:

Up and Down arrows control the cursor position.

(yes/enter) increases the indicated value.

(no/clear) decreases the selected value.

(F1) decreases the selected SPO2 value.

(F2) increases the selected SPO2 value.

(F3) Saves the changes and takes you back to the Main

Simulation Screen.

The saving procedure may take up to 5 minutes. Do not

turn off the power during this time.

www.metron-biomed.com

Page 18

18

This page was intentionally left blank.

www.metron-biomed.com

Page 19

19

Troubleshooting

Q: SPO2 values do not match.

A: Confirm that the “Make” is properly selected. Confirm your selection by pressing the

(ENTER) key after changing the value.

Q: The monitor is not reading any values.

A: Check all connections and verify if the “Red” and “IR” lights on the daeg are illuminated.

www.metron-biomed.com

Page 20

20

This page was intentionally left blank

www.metron-biomed.com

Loading...

Loading...