Page 1

METROLOGIC INSTRUMENTS, INC.

MX001 Industrial Control Interface

Installation and User’s Guide

Page 2

Copyright

© 2007 by Metrologic Instruments, Inc. All rights reserved. No part of this work may be

reproduced, transmitted, or stored in any form or by any means without prior written

consent, except by reviewer, who may quote brief passages in a review, or provided

for in the Copyright Act of 1976.

Trademarks

Metrologic is a registered trademark of Metrologic Instruments, Inc. Products

identified in this document are hereby acknowledged as trademarks, registered or

otherwise, of Metrologic Instruments, Inc. or their respective companies.

Page 3

T

ABLE OF CONTENTS

Introduction................................................................................................1

Opening the MX001 Industrial Control Box...............................................2

Internal Components.................................................................................3

LED Status Indicators ...............................................................................4

Configuring the MX001 for 115 or 230 Volt Operation

USA: 115V Operation ............................................................................5

USA: 230V Operation ............................................................................6

Europe/Asia:230V Operation.................................................................7

Europe/Asia: 115V Operation................................................................8

Locating the Three Strain Reliefs and the Signal Connector....................9

Connecting External Wiring to the MX001 ................................................9

Power Requirements for the MX001.........................................................9

Connecting the AC Power Input Cable ................................................... 10

Connecting the TRIAC Controlled Power Output Cable .........................11

Temporarily Disabling the TRIAC Output................................................12

Sensor Support .......................................................................................13

Connecting the Sensor ........................................................................ 14

Temporarily Disabling the Sensor and/or Sensor Alarm .....................14

Sensors Powered Independently that Provide

either 12V, 5V or a 10mA DC Output Signal.......................................15

Sensors that Provide Switch Closures or Relay Type Output.............17

Low Voltage Self-Contained DC Sensors with

a Current Sinking Output .....................................................................18

Low Voltage Self-Contained DC Sensors with

a Current Sourcing Output..................................................................19

Universal Self-Contained Sensors that Provide

a Single Pole/Double Throw (SPDT) Relay Output.............................20

ii

Page 4

T

ABLE OF CONTENTS

Sensors Powered Independently that Provide Either

12V, or a 10mA DC Output Signal with a Sensor Alarm .....................22

Sensors that Provide Switch Closures or Relay Type

Output with a Sensor Alarm.................................................................24

Low Voltage Self-Contained DC Sensors with Current

Sinking Outputs and Sensor Alarm ..................................................... 25

Universal Self-contained Sensors That Provide Single

Pole/Double Throw (SPDT) Relay Outputs for Both

Object Sensing and Sensor Alarm ...................................................... 27

Closing the MX001 Industrial Control Box ..............................................29

Connecting the MX001 to the Scanner ...................................................29

Cable Pin Outs for the 8-Pin and 19-Pin Connectors ............................. 30

Specifications ..........................................................................................31

Troubleshooting ......................................................................................32

Limited Warranty .....................................................................................40

Notices ....................................................................................................41

iii

Page 5

I

NTRODUCTION

Metrologic’s MX001 Industrial Control Interface enhances Metrologic’s line of

industrial laser scanners. It does this by providing a way to connect an external

object sensor to the scanner and a way for the scanner to control an external

device through an electronic switch (a TRIAC). This enables the scanner to

sense the presence of objects to be scanned and then provide a line voltage

output signal if the scanned object meets preprogrammed conditions.

The MX001 can be configured to support any object sensor that can supply a

12V, 5V or 10mA output signal. It will also support switch closure (relay) type

sensor output. Additionally, the MX001 can provide 12V DC power (at 200mA

maximum) to a low voltage, DC type sensor unit making external sensor power

supplies unnecessary.

The MX001’s electronic switch or TRIAC, allows the scanner to control an

external device directly by switching a line voltage output signal off or on and can

handle device loads of up to a maximum of 6 amps US and Canada, 5 amps

Europe. The switching can take place in response to a good scan, a no read

scan, or a mismatch between scanned label data and expected label data

preprogrammed into the scanner for comparison purposes. The scanner can also

activate the TRIAC switch in response to a host system command sent through

the RS-232 scanner-host communications link.

This manual shows how to wire and configure the MX001 Industrial Control Box

so that it will work properly when connected to its associated sensor, output

device and TECH series scanner. Programming the associated TECH series

scanner is necessary to define how the object sensor and TRIAC switch will

operate. Tech series industrial scanners are programmed by using Metrologic’s

HoloSet® configuration software which operates through an RS-232 port of an

IBM XT, AT or compatible PC. In order to program the scanner a HoloSet kit

containing the necessary communications cable, software and manual will be

needed. Please refer to that manual for further details on how to configure the

scanner for use with the MX001 box.

1

Page 6

O

PENING THE

MX001 I

NDUSTRIAL CONTROL BOX

To open the MX001 box for wiring and configuration, proceed as follows:

1. Loosen the lid clamp screw with a flat blade screwdriver.

2. Disengage the clamp by pushing the lid down, then move the clamp to

the left, and rotate it outward in a counterclockwise direction.

3. Once the clamp is disengaged, open the lid.

2

Page 7

115V

I

NTERNAL COMPONENTS

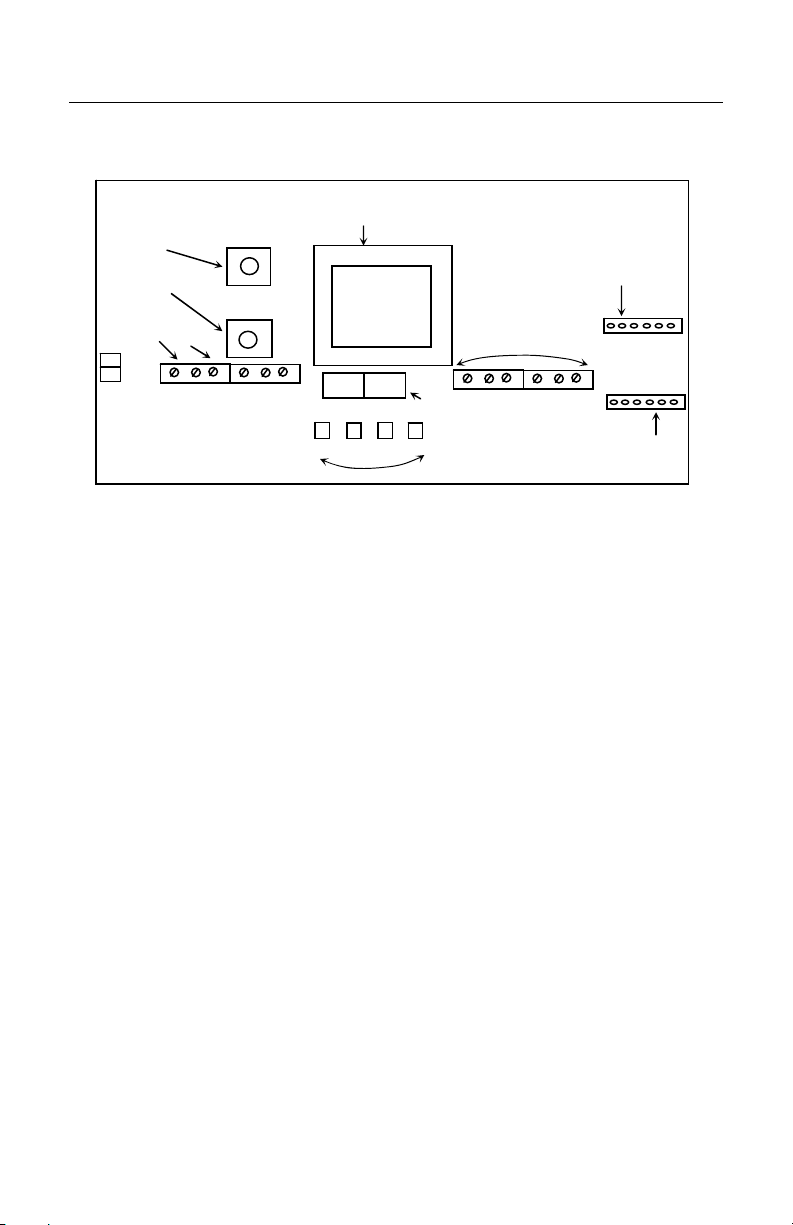

The following illustration and list explain the parts that pertain to the installation

and operation of the MX001.

F2

2

4

11

Control

3

5

Neutral

F1

TRIAC

Line in

Neutral

Triac out

1

230V

D2

D1

C

12V Triac S IN A IN

D3C D4

C

6

C

9

J2

10

7

A In-

S IN-

A In+

S in+

Common

+12V Out

J1

8

Figure 1

1. Power Transformer Supplies a stepped down and isolated voltage that

2. F2 Control Fuse Holder Contains the fuse that controls the 12V DC power

3. F1 TRIAC Fuse Holder Contains the fuse that controls the power for the

4. Power Terminal Block Provides the input connection point for the AC line

(Line Power Input) power to the industrial control box.

5. TRIAC Terminal Block Provides the output connection point

for the scanner controlled.

(Controlled Power Output) power output (switched by the TRIAC).

6. LED Status Indicators These light up when the +12V power

7. Voltage Selector Switch Used to configure the industrial control

box to match the incoming line voltage.

8. J1 Jumper Configures sensor input.

9. J2 Jumper Configures the sensor alarm input.

10. Sensor Terminal Block Provides the connection points for the sensor.

11. Protective Earthing Connectors To connect line cord protective earthing conductors to

produces the 12V DC power for the industrial

control box and external sensor.

in the industrial control box.

TRIAC output.

that supplies

supply, TRIAC, sensor, or sensor alarm circuits are

active.

industrial control box enclosure.

3

Page 8

LED S

TATUS INDICATORS

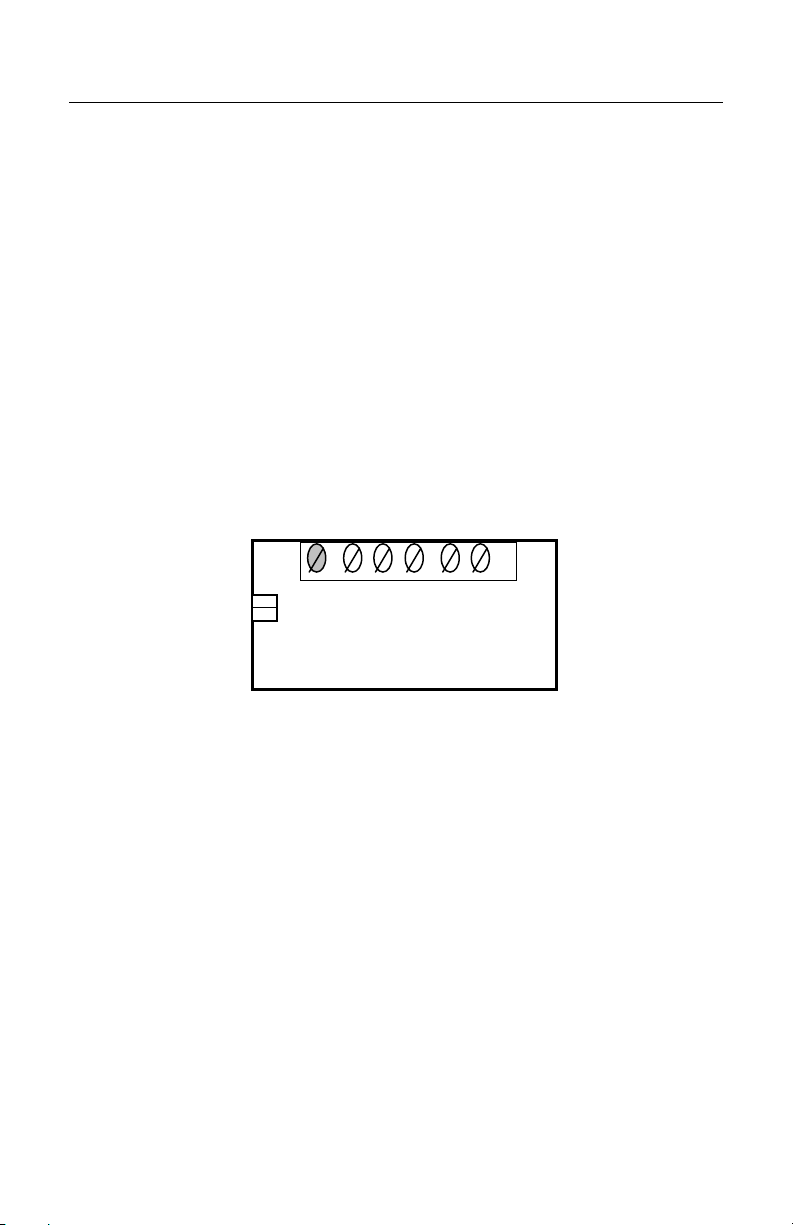

The LED, (light emitting diode) status indicators are found just below the voltage

selector switch. They indicate the operating state of the 12V power supply, the

TRIAC and the status of the sensor and sensor alarm inputs. An LED will glow

when a circuit is active. From these visual indications, it can be determined if the

MX001 box is active and what action the scanner and sensor are performing in

your system. The following list explains the function of each indicator. They

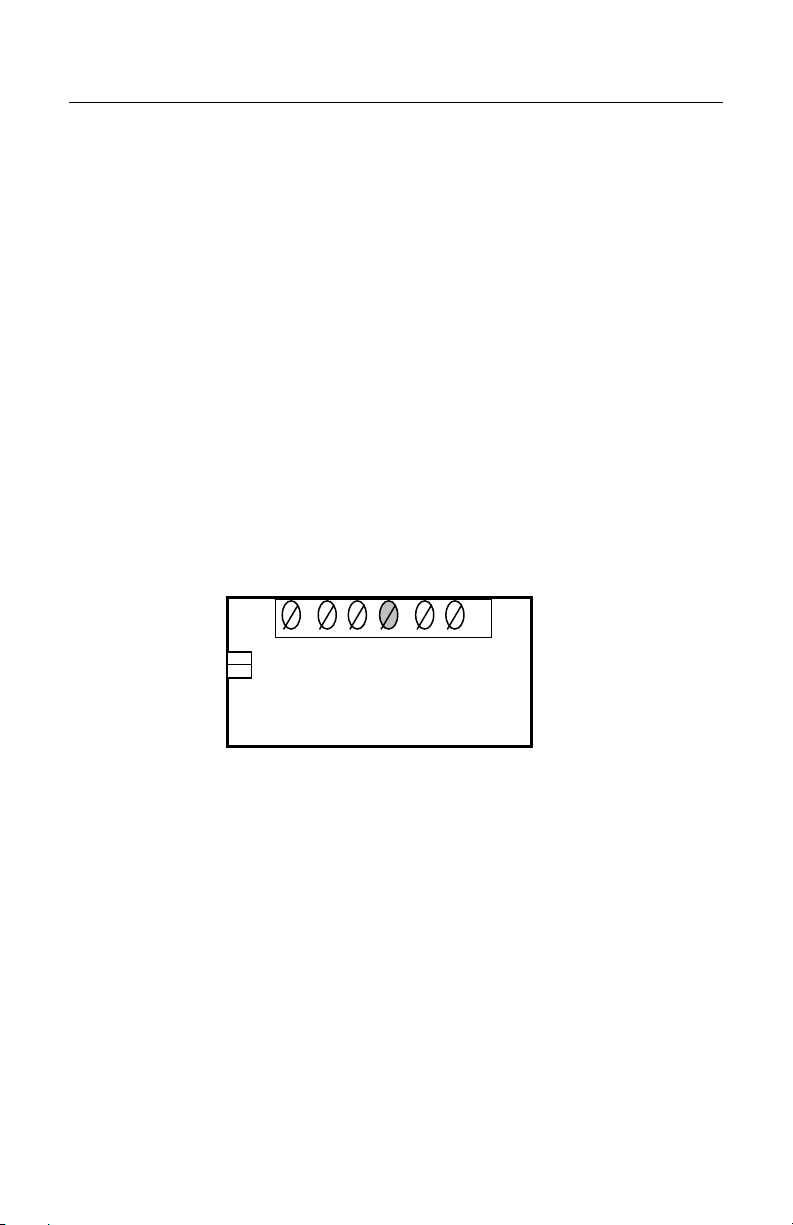

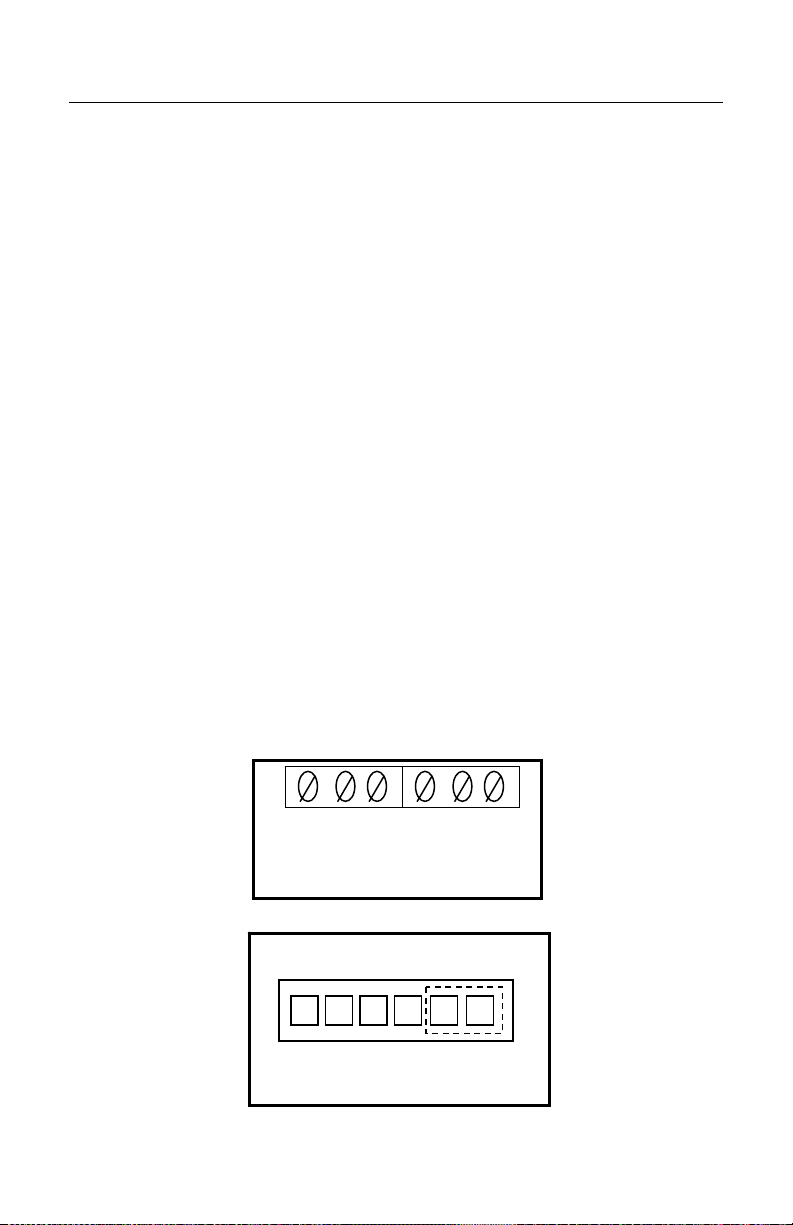

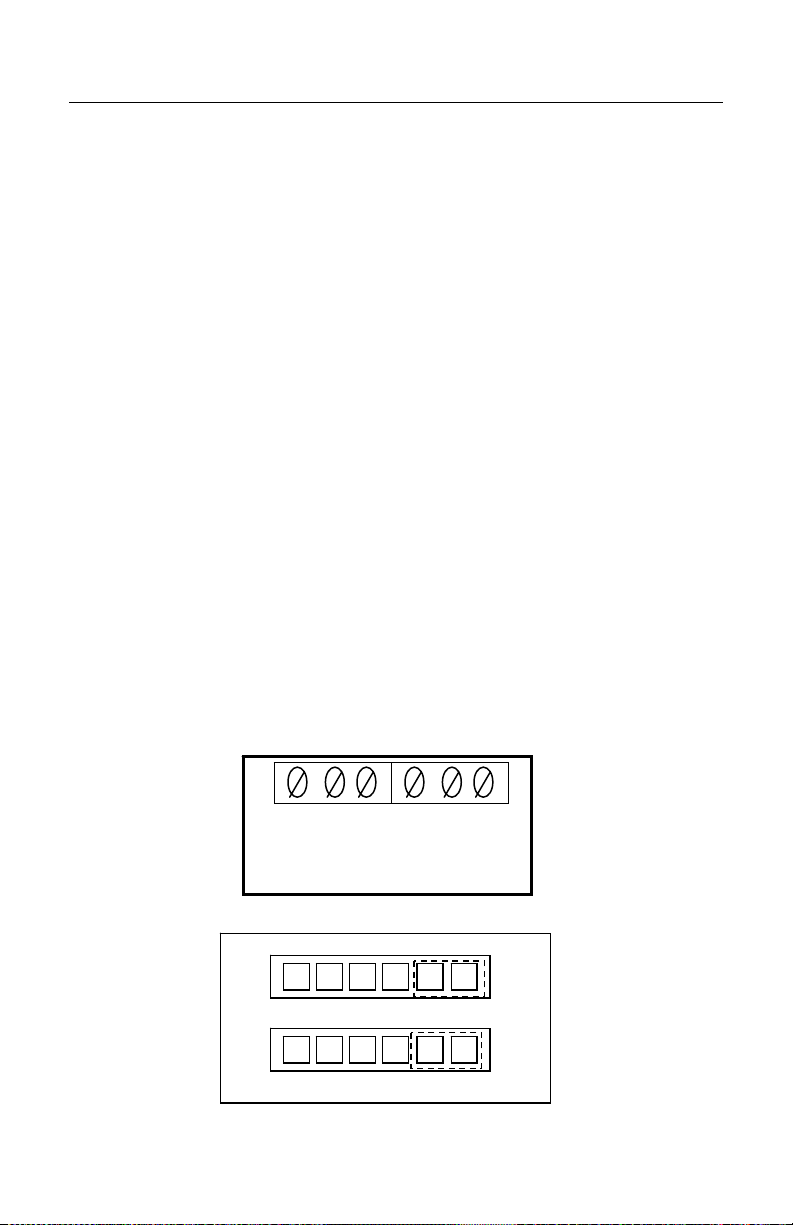

appear inside the box in the order illustrated in Figure 2.

D1

C

12V TRIAC S IN A IN

Green +12V (D1)

Indicates that the +12V control and sensor power supply is active

Red TRIAC (D2)

Indicates that the TRIAC switched power output circuit is active.

Red S IN (D3)

Indicates that the sensor circuit is active because an object is being sensed.

Red A IN (D4)

Indicates that the sensor alarm circuit is active because the sensing conditions

are marginal.

Note: The red TRIAC, S IN and A IN LED’s perform two functions.

Besides circuit activity (status), these indicators also monitor the

connection between the MX001 box and the scanner and will not

light if that connection is broken. Thus, if lit, the indicators also

show the user that the inter-connecting signal (link) cable between

the scanner and the MX001 box is good.

D2

C

Figure 2

D3

D4

C

4

Page 9

C

ONFIGURING THE

Before applying power to the MX001, it must first be configured for either

115 or 230 volt operation as required. This is accomplished by using the

voltage selector switch and the installation of the proper fuses. Refer to one

of the procedures on the following pages that apply to your voltage requirement

to learn which fuses should be inserted into the F1 and F2 fuse holders. (Refer to

Figure 3)

If fuse replacement becomes necessary, replace with the same type of fuse

originally supplied. Damage to the unit may result if the same type of fuse is not

used.

USA: 115V Operation

1. Move the voltage selector to the right with a small screwdriver so that the

115V legend shows in the window.

2. Open the fuse kit and remove the following:

• (2) Gray Fuse Holder Caps

• (1) 10 Amp 250V Fast Acting ¼ x 1 ¼ Inch Fuse

• (1) 1/8 Amp 250V Slow Blow ¼ X 1 ¼ Inch Fuse

3. Press the end of the 10 Amp fuse into one of the gray fuse holder caps until

it seats.

4. Insert the fuse and cap into the F1 TRIAC fuse holder with the screwdriver

slot pointing toward the power transformer.

5. Using a small screw driver, press the cap down into the fuse holder body

and turn the cap ¼ turn clockwise to lock the cap in place. This results in the

cap slot pointing toward the top and bottom of the box.

MX001

FOR

F2

Control

F1

TRIAC

115

115V

Figure 3

OR

230V

230 V

OLT OPERATION

5

Page 10

C

ONFIGURING THE

USA: 115V Operation (continued)

6. Press the end of the 1/8 Amp fuse into the other gray fuse holder cap unitl it

seats.

7. Insert the fuse and cap into the F2 control fuse holder with the screwdriver

slot pointing toward the power transformer.

8. Using a small screwdriver, press the cap down into the fuse holder body and

turn the cap ¼ turn clockwise to the lock the cap in place. This results in the

cap slot pointing toward the top and bottom of the box.

USA: 230V Operation

1. Move the voltage selector to the left with a small screwdriver so that the

230V legend shows in the window.

2. Open the fuse kit and remove the following:

• (2) Gray Fuse Holder Caps

• (1) 10 Amp 250V Fast Acting ¼ x 1 ¼ Inch Fuse

• (1) 1/16 Amp 250V Slow Blow ¼ x 1 ¼ Inch Fuse

3. Press the end of the 10 Amp fuse into one of the gray fuse holder caps until

seals.

4. Insert the fuse and cap into the F1 TRIAC fuse holder with the screwdriver

slot pointing toward the power transformer.

5. Using a small screwdriver, press the cap down into the fuse holder body and

turn the cap ¼ turn clockwise to lock the cap in place. This results in the cap

slot pointing toward the top and bottom of the box.

6. Press the end of the 1/16 Amp fuse into the other gray fuse holder cap until

it seats.

7. Insert the fuse and cap into the F2 control fuse holder with the screwdriver

slot pointing toward the power transformer.

8. Using a small screwdriver, press the cap down into the fuse holder body and

turn the cap ¼ turn clockwise to lock the cap in place. This results in the cap

slot pointing toward the top and bottom of the box.

MX001

FOR

115

OR

230 V

OLT OPERATION

6

Page 11

C

ONFIGURING THE

Europe/Asia: 230V Operation

1. Move the voltage selector to the left with a small screwdriver so that the

230V legend shows in the window.

2. Open the fuse kit and remove the following:

• (2) Black Fuse Holder Caps

• (1) 6.3 Amp 250V Fast Acting, High Interrupt 5 x 20 mm Fuse

• (1) 50ma 250V Time Delay 5 x 20 mm Fuse

3. Press the end of the 6.3 Amp fuse into one of the black fuse holder caps

until it seats.

4. Insert the fuse and cap into the F1 TRIAC fuse holder with the screwdriver

slot pointing toward the power transformer.

5. Using a small screwdriver, press the cap down into the fuse holder body and

turn the cap ¼ turn clockwise to lock the cap in place. This results in the cap

slot pointing toward the top and bottom of the box.

6. Press the end of the 50mA fuse into the other black fuse holder cap until it

seats.

7. Insert the fuse and cap into the F2 control fuse holder with the screwdriver

slot pointing toward the power transformer.

8. Using a small screwdriver, press the cap down into the fuse holder body and

turn the cap ¼ turn clockwise to lock the cap in place. This results in the cap

slot pointing toward the top and bottom of the box.

MX001

FOR

115

OR

230 V

OLT OPERATION

7

Page 12

C

ONFIGURING THE

Europe/Asia: 115V Operation

1. Move the voltage selector to the right with a small screwdriver so that the

115V legend shows in the window.

2. Open the fuse kit and remove the following:

• (2) Black Fuse Holder Caps

• (1) 6.3 Amp 250V Fast Acting, High Interrupt 5 x 20mm Fuse

• (1) 125mA 250V Time Delay 5 x 20mm Fuse

3. Press the end of the 6.3 Amp fuse into one of the black fuse holder caps

until it seats.

4. Insert the fuse and cap into the F1 TRIAC fuse holder with the screwdriver

slot pointing toward the power transformer.

5. Using a small screwdriver, press the cap down into the fuse holder body and

turn the cap ¼ turn clockwise to lock the cap in place. This results in the cap

slot pointing toward the top and bottom of the box.

6. Press the end of the 125mA fuse into the other black fuse holder cap until it

seats.

7. Insert the fuse and cap into the F2 control fuse holder with the screw driver

slot pointing toward the power transformer.

8. Using a small screwdriver, press the cap down into the fuse holder body and

turn the cap ¼ turn clockwise to lock the cap in place. This results in the cap

slot pointing toward the top and bottom of the box.

MX001

FOR

115

OR

230 V

OLT OPERATION

8

Page 13

L

OCATING THE THREE STRAIN RELIEFS AND THE SIGNAL CONNECTOR

There are three strain reliefs and one 8-pin signal connector located on the

bottom of the MX001 box. The two large strain reliefs on the left side allow the

use of flexible cordage for MX001 power input and controlled power (TRIAC)

output in that order. If your application requires the use of conduit for power

wiring, these two strain reliefs can be easily removed and standard conduit

fittings can be used in their place. The smaller strain relief is used to secure the

signal/ power cable from the object sensor that is a user supplied part. The 8-pin

signal connector is used to connect the MX001 box to the scanner through the

scanner link cable.

C

ONNECTING EXTERNAL WIRING TO THE

External wiring is connected to the MX001 by means of “lift clamp” terminal

blocks. These blocks have an opening in their base that will accept a wire with ¼

inch of insulation removed. Connections are made by first turning the terminal’s

binding screw counterclockwise with a small screwdriver which “opens” the

terminal allowing it to accept the wire. The stripped wire is then inserted into the

opening in the terminal and then clamped in place by turning the associated

terminal screw clockwise until tight.

There are two sets of terminal blocks inside the MX001. The larger set of 6

terminals on the left of the voltage selector switch handle the AC power wiring

while the smaller set of 6 terminals on the right handle the sensor wiring.

Two terminals mounted on the MX001 enclosure near the protective earthing

symbol are intended to be used for ground connection of the AC power input

cable and TRIAC controlled power output cable.

MX001

P

OWER REQUIREMENTS FOR THE

MX001

The MX001 control box neither supplies nor draws operating power from the

scanner to which it is connected. It contains an indepen-dent, regulated and

totally isolated 12 volt DC power supply that is used to drive the (optocoupled)

sensor and TRIAC signal circuit links to the scanner. Therefore, the MX001 must

be powered from the AC line at all times to allow it to communicate with the

scanner.

9

Page 14

C

ONNECTING THE AC POWER INPUT CABLE

1. Make sure power is not being applied to the power cable that is to be

connected to the unit.

2. Open the terminals in the power terminal block by turning each screw

counterclockwise until there is enough space to insert wires.

3. Strip off 1 ¾ inches of the power cable’s outer jacket.

4. Strip the insulation off each cable wire ¼ of an inch.

5. Feed the power cable through the first, large strain relief on the left.

6. Connect each wire to the appropriate locations noted in the table below and

secure the wires in the terminal block and protective earthing terminal by

turning each screw clockwise. (Refer to the MX001 box or to Figure 4 for the

order of the terminals for the power wires.)

7. Secure the cable by turning the strain relief’s domed sealing nut clockwise

until tight.

Protective

Earthing

Terminals

NOTE: Do not connect any wires to the first terminal.

Terminal Block Cable Color in USA Cable Color in

and Canada in Europe

Neutral White Blue

Line In Black Brown

Protective Cable Color in USA Cable Color in

Earthing and Canada in Europe

Terminals

Ground Green Yellow-Green

l

LINE IN

NEUTRA

Figure 4

l

NEUTRA

TRIAC OUT

10

Page 15

C

ONNECTING THE

The MX001 box contains a power line TRIAC that acts as an electronic power

output switch operated by the scanner and capable of controlling a current load

of 6 amps in the USA. In Europe, the maximum current load supported is 5

Amps. The TRIAC controlled output voltage equals the line input voltage when

the scanner activates the TRIAC. How the TRIAC will operate is defined by the

HoloSet Program.

1. Make sure power is not being applied to the unit.

2. Open the terminals in the TRIAC terminal block by turning each screw

counterclockwise until there is enough space to insert wires.

3. Strip off 1 ¾ inches of the power output cable’s outer jacket.

4. Strip the insulation off each cable wire ¼ of an inch.

5. Feed the power output cable through the second large strain relief.

6. Connect each wire to the appropriate locations noted in the table below and

secure the wires in the terminal block and protective earthing terminal by

turning each screw clockwise. (Refer to the MX001 box or to figure 5 for the

order of the terminals for the TRIAC wires.)

TRIAC C

ONTROLLED POWER OUTPUT CABLE

Protective

Earthing

Terminals

l

LINE IN

NEUTRA

Figure 5

l

NEUTRA

TRIAC OUT

Note: Do not connect any wires to the fourth terminal.

Terminal Block Cable Color in USA Cable Color in

and Canada in Europe

Neutral White Blue

Line In Black Brown

Protective Cable Color in USA Cable Color in

Earthing and Canada in Europe

Terminals

Ground Green Yellow-Green

Caution: Damage will occur to the unit if the TRIAC output is

shorted.

11

Page 16

T

EMPORARILY DISABLING THE

If, during set up or maintenance, there is a need to disable the TRIAC output of

the MX001, simply remove the F1 TRIAC fuse. This disconnects the AC line

voltage from the TRIAC circuitry and output terminal block, but leaves the TRIAC

LED indicator active allowing checks to be made for TRIAC circuit activity without

activating the TRIAC controlled device.

TRIAC O

UTPUT

12

Page 17

S

ENSOR SUPPORT

There are many different types of sensors available, which will work with the

MX001 control box.

Common types:

1. Sensors powered independently which provide 12V, 5V, or a 10mA DC

output signal (sourcing type output).

2. Sensors that provide switch closures or relay type outputs.

3. Low voltage, self-contained DC sensors that provide current sourcing

and/or sinking type outputs.

4. “Universal” self-contained sensors that provide a single pole, double throw

(SPDT) relay output.

In all cases, the sensor’s output signal or switch closure is expected to become

active when an object has been sensed.

The easiest sensor to use with the MX001 is a low voltage (a 10-30 volt) DC, self

contained, sensor. The industrial control box can power this type of sensor with

12V DC at 200 mA maximum and will interface to either a (PNP) current

sourcing, or (NPN) current sinking output. (Current sourced or sunk = 10 mA.) A

switch closure (relay) type output is also supported. All output types are expected

to become active when an object has been sensed.

Additionally, some sensors also provide an “alarm” output that warns the user

when sensing conditions are becoming marginal. This optional output is also

supported through the MX001. The option forces the scanner to emit a repetitive

warning tone when the sensor’s alarm output becomes active.

How the sensor interacts with the scanner depends upon which sensor options

were chosen in the HoloSet program. Refer to that manual for further details.

13

Page 18

S

ENSOR SUPPORT

Connecting the Sensor

Reference the documentation that came with your sensor to determine the

function of each sensor wire. Then, refer to one of the procedures on the

following pages that apply to your sensor for information on how to hook up the

appropriate wires and position the configuration jumper on the appropriate pins of

its header. If your sensor supports the alarm function, begin looking for the

procedure for your sensor on page 22.

Temporarily Disabling the Sensor and/or Sensor Alarm

If, during set up or maintenance, there is a need to disable the sensor and/or

sensor alarm inputs of the MX001, proceed as follows:

• To disable the sensor, position the J1 (S SET UP) jumper on

pins 2 and 3 of its header.

• To disable the sensor alarm, position the J2 (A SETUP) jumper on pins 2

and 3 of its header.

These procedures disconnect the sensor’s output signals from the MX001’s input

circuitry without physically disconnecting any sensor wiring.

14

Page 19

S

ENSOR SUPPORT

Sensors Powered Independently that Provide Either 12V, 5V or a 10mA DC Output Signal

1. Make sure power is not being applied to the unit.

2. Open the terminals in the sensor terminal block by turning each screw

counterclockwise until there is enough space to insert wires.

3. Strip off 2 ¼ inches of the sensor cable’s outer jacket.

4. Strip the insulation off each cable wire ¼ of an inch.

5. Feed the sensor cable through the small strain relief.

6. Insert the sensor’s DC common (or negative) output wire into the S IN-

terminal block and secure the wire by turning the terminal’s screw

clockwise.(Refer to the MX001 box or Figure 6 for the order of the terminals

for the sensor wires)

7. Insert and secure the sensor’s positive output wire to the

S IN+ terminal.

8. Secure the cable by turning the strain relief’s domed sealing nut clockwise

until tight.

9. Depending upon your sensor’s output, perform one of the following steps.

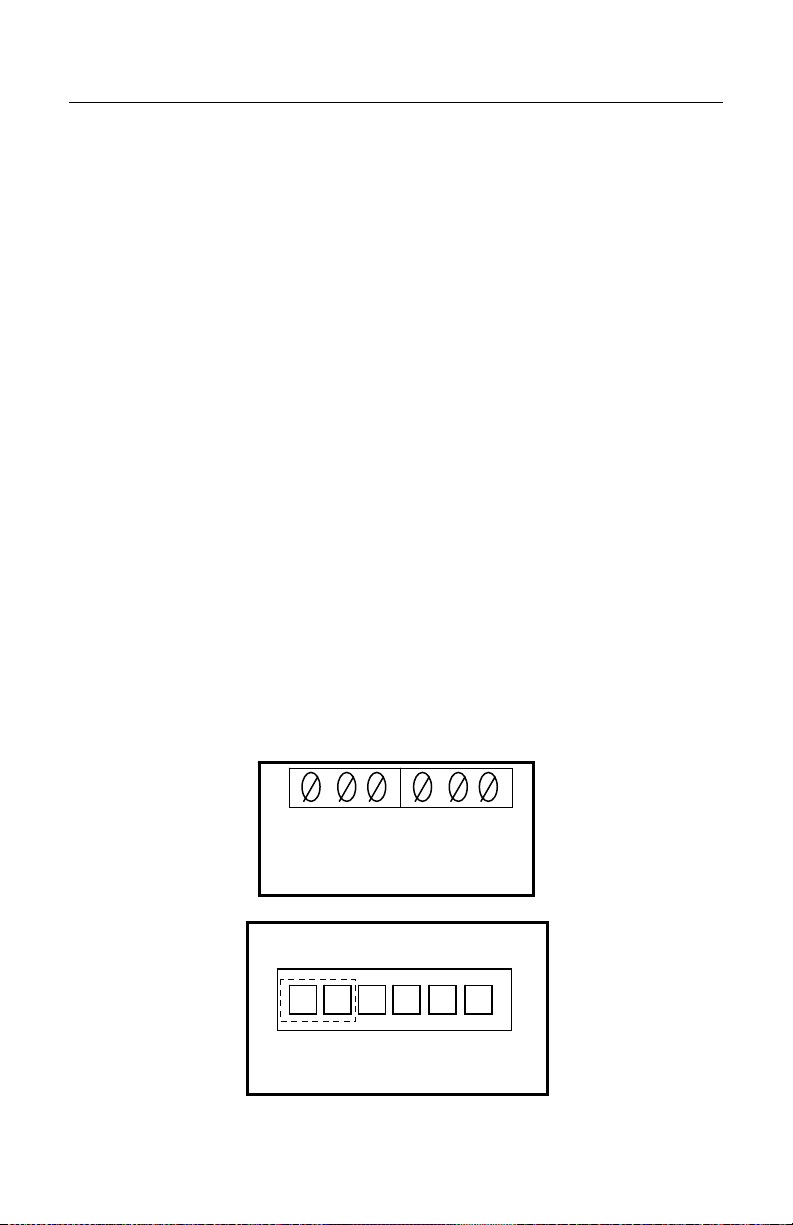

• For a 12V DC output signal, position the jumper on pins 1 and 2 of the

J1 (S SET UP) header. (Refer to Figure 7)

• For a 5V DC output signal, position the jumper on pins 3 and 4 of the

J1 (S SET UP) header. (Refer to Figure 7)

• For a 10mA DC output signal, position the jumper on pins 4 and 5 of

the J1 (S SET UP) header. (Refer to Figure 7)

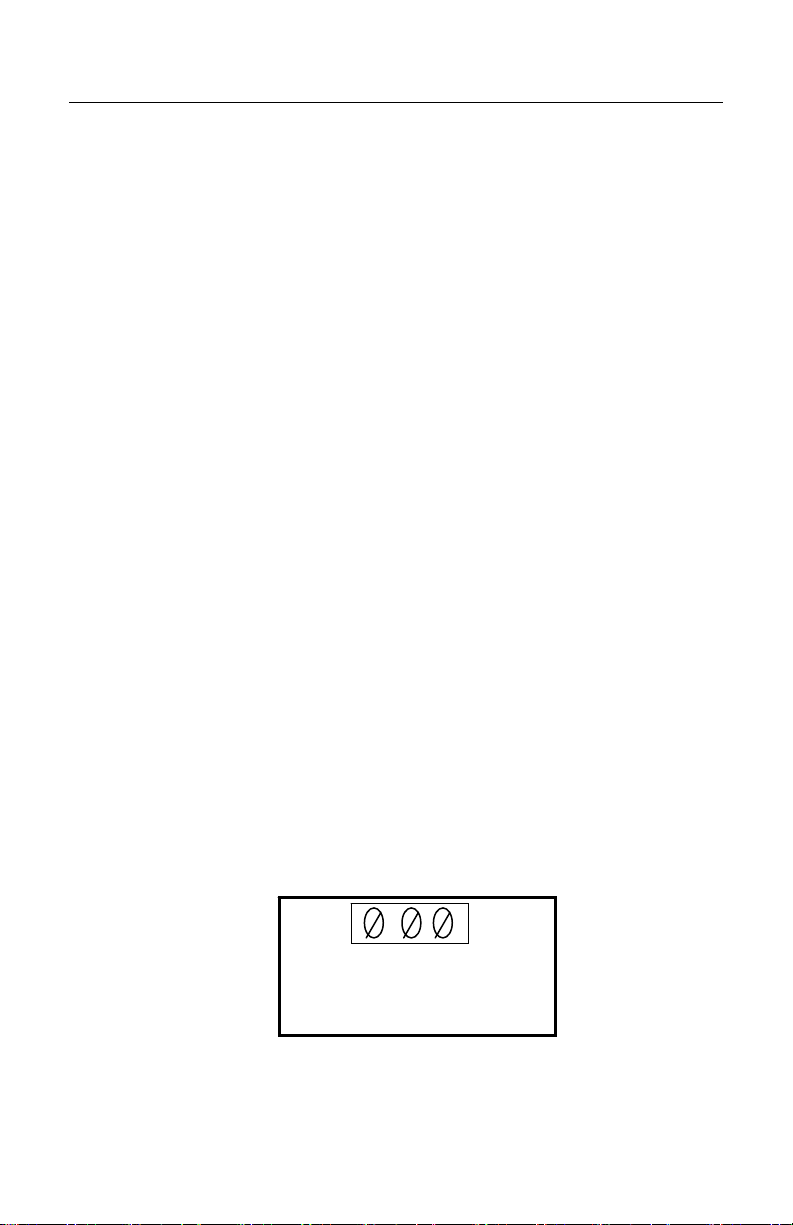

S IN-

S IN+

+12V OUT

Figure 6

15

Page 20

S

ENSOR SUPPORT

Sensors Powered Independently that Provide Either 12V, 5V or a

10mA DC Output Signal

Caution: When configured for a 10mA DC source input, the

MX001 box expects a current limited 10 mA DC signal to be

supplied by the sensor. Failure to limit this current to 10mA can

damage the sensor input circuitry of the system.

Current limiting can be accomplished by using an external limiting resistor of the

appropriate value (which is dependent upon the sensor’s DC signal output

voltage level). This resistor is connected between the S IN+ input of the MX001

box and the sensor.

Sensor Output Voltage – 3V

Approximate Resistance = 10mA

If the source is a 12V DC signal:

If the source is a 5V DC signal:

If the source is a 10mA DC signal:

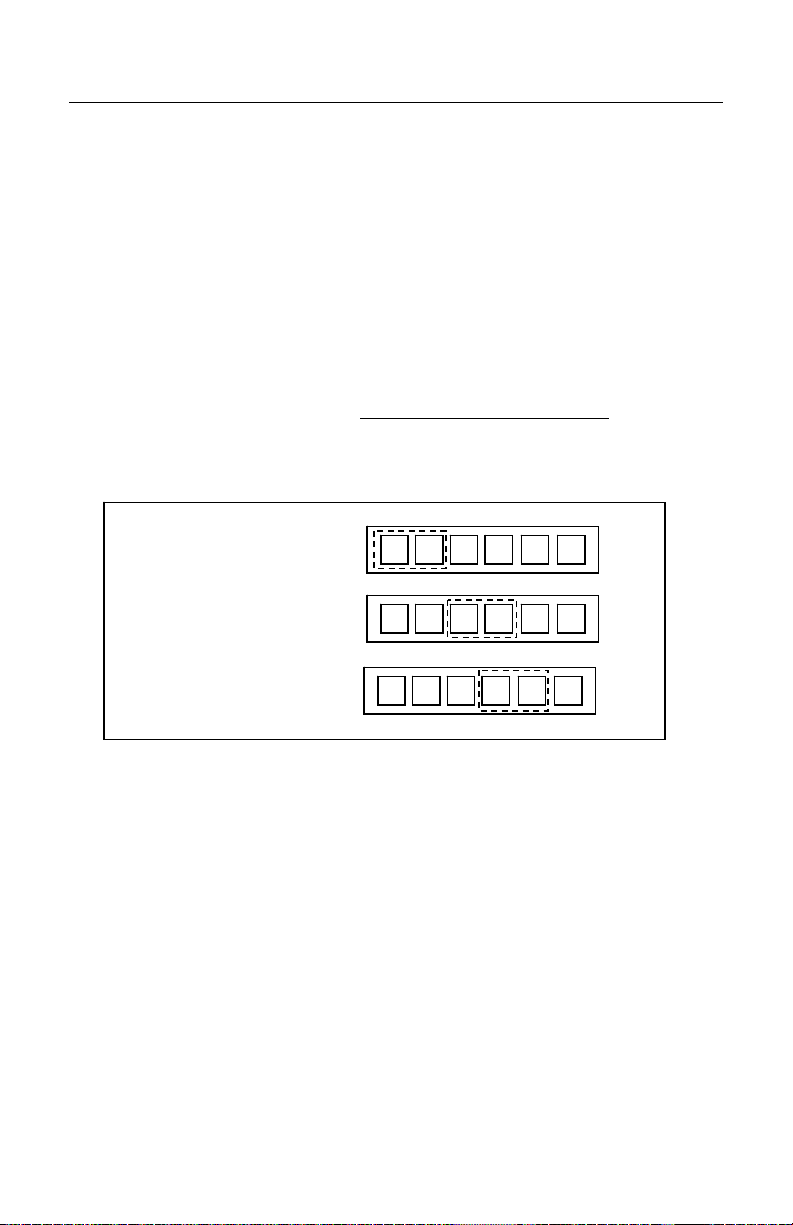

J1

1

2 3 4 5

1 6

1 6

1 6

S SET UP

1

2 3 4 5

S SET UP

1

2 3 4 5

6

J1

6

J1

6

Figure 7

16

Page 21

S

ENSOR SUPPORT

Sensors that Provide Switch Closures or Relay Type Output

1. Make sure power is not being applied to the unit.

2. Open the terminals in the sensor terminal block by turning each screw

counterclockwise until there is enough space to insert wires.

3. Strip off 2 ¼ inches of the sensor cable’s outer jacket

4. Strip the insulation off each cable wire ¼ of an inch.

5. Feed the sensor cable through the small strain relief.

6. Insert one of the sensors signal output wires into the COMMON terminal

and secure the wire by turning the terminal’s screw clockwise. (Refer to the

MX001 box or to Figure 8 for the order of the terminals for the sensor

wires.)

7. Insert and secure the sensor’s other signal output wire into the S IN-

terminal.

8. Secure the cable by turning the strain relief’s domed sealing nut clockwise

until tight.

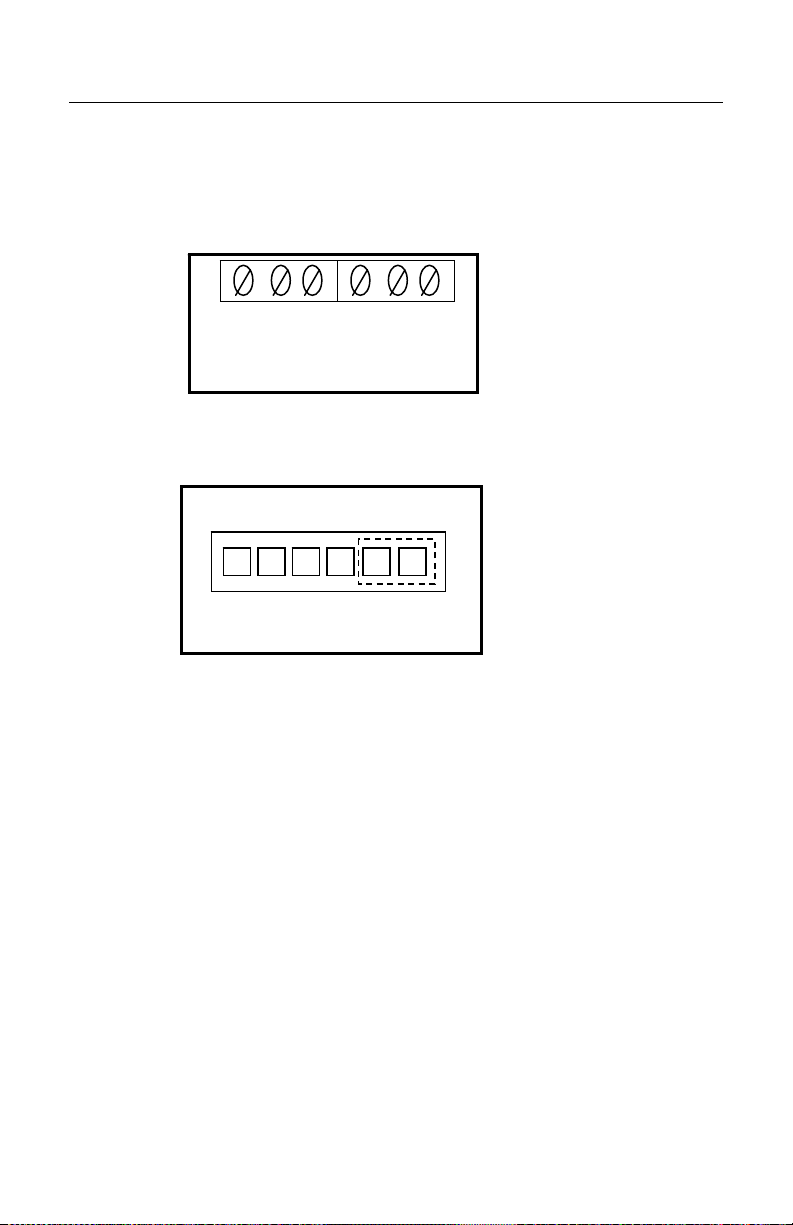

9. Position the jumper on pins 5 and 6 of the J1 (S SET UP) header. (Refer to

Figure 9).

A IN-

A IN+

Figure 8

1

2 3 4 5

1

S SET UP 6

Figure 9

S IN-

COMMON

S IN+

+12V OUT

J1

6

17

Page 22

S

ENSOR SUPPORT

Low Voltage Self-Contained DC Sensors with a Current Sinking Output

1. Make sure power is not being applied to the unit.

2. Open the terminals in the sensor terminal block by turning each screw

counterclockwise until there is enough space to insert wires.

3. Strip off 2 ¼ inches of the sensor cable’s outer jacket.

4. Strip the insulation off each cable wire ¼ of an inch.

5. Feed the sensor cable through the small strain relief.

6. Inserts the sensor’s DC common wire into the COMMON terminal and

secure the wire by turning the terminals’s screw clockwise. (Refer to the

MX001 box or to Figure 10 for the order of the terminals for the sensor

wires.)

7. Insert and secure the sensor’s +DC power input wire into the +12V OUT

terminal.

8. Insert and secure the sensor’s signal output wire into the S IN- terminal.

9. Secure the cable by turning the strain relief’s domed sealing nut clockwise

until tight.

10. Position the jumper on pins 5 and 6 of the J1 (S SET UP) header. (Refer to

Figure 11).

-

A IN-

A IN+

Figure 10

S IN

COMMON

S IN+

+12V OUT

J1

1

2 3 4 5

1

S SET UP 6

Figure 11

6

18

Page 23

S

S

ENSOR SUPPORT

Low Voltage Self-Contained DC sensors with a Current Sourcing

Output

1. Make sure power is not being applied to the unit.

2. Open the terminals in the sensor terminal block by turning each screw

counterclockwise until there is enough space to insert wires.

3. Strip off 2 ¼ inches of the sensor cable’s outer jacket.

4. Strip insulation off each cable wire ¼ of an inch.

5. Feed the sensor cable through the small strain relief.

6. Connect a small jumper wire between the COMMON and the S IN-

terminals. Secure the jumper wire in the S IN- terminal by turning the

terminal’s screw clockwise. (Refer to the MX001 box or to Figure 12 for the

order of the terminals for the sensor wires.

7. Connect the sensor’s DC common wire to the COMMON terminal and

secure the sensor and jumper wire by turning the terminal’s screw

clockwise.

8. Insert and secure the sensor’s +DC power input wire into the +12V OUT

terminal.

9. Insert and secure the sensor’s sourcing output wire into the

S IN+ terminal.

10. Secure the cable by turning the strain relief’s domed sealing nut clockwise

until tight.

11. Position the jumper on pins 1 and 2 of the J1 (S SET UP) header. (Refer to

Figure 13).

-

IN+

A IN-

A IN+

Figure 12

S IN

COMMON

+12V OUT

J1

1

2 3 4 5

1

S SET UP 6

6

Figure 13

19

Page 24

S

ENSOR SUPPORT

“Universal” Self-Contained Sensors that Provide a Single

Pole/Double Throw (SPDT) Relay Output

1. Make sure the “universal” sensor can operate on +12 volts DC at 200mA or

less. If so, then the MX001 box can supply the +12 volts necessary to

power the “universal” sensor.

2. Make sure power is not being applied to the unit.

3. Open the terminals in the sensor terminal block by turning each screw

counterclockwise until there is enough space to insert wires.

4. Strip 2 ¼ inches of the sensor cable’s outer jacket

5. Strip the insulation off each cable wire ¼ of an inch.

6. Feed the sensor cable through the small strain relief.

7. Insert the sensor’s +DC power input wire into the +12V OUT terminal and

secure the wire by turning the terminal’s screw clockwise. (Refer to the

MX001 box or to Figure 14 for the order of the terminals for the sensor

wires.)

8. Insert the sensor’s –DC or common power input wire and the relay output

common signal wire into the COMMON terminal and secure both wires.

9. Determine from the literature supplied with your sensor which sensor relay

output makes contact with its common terminal when an object is sensed. If

the output cannot be determined, go on to Step 10. Otherwise, skip to Step

11.

10. Temporarily apply power to the MX001 box to activate the sensor and then

determine with a continuity tester or ohm meter which relay output (the

normally closed [NC] or the normally open [NO] output) make contact with

the COMMON terminal when the sensor “sees” the object to be scanned.

11. Remove any power applied to the MX001 (in Step 10) and connect and

secure the relay output wire previously determined to the S IN- terminal.

(The other relay output wire may be cut off or connected to the MX001

COMMON terminal if desired).

12. Secure the cable by turning the strain relief's domed sealing nut clockwise

until tight.

20

Page 25

S

ENSOR SUPPORT

“Universal” Self-Contained Sensors that Provide a Single

Pole/Double Throw (SPDT) Relay Output

13. Position the jumper on pins 5 and 6 of the J1 (S SET UP) header. (Refer to

Figure 15).

-

A IN-

A IN+

Figure 14

1

2 3 4 5

1

S SET UP 6

S IN

COMMON

S IN+

+12V OUT

J1

6

Figure 15

21

Page 26

S

ENSOR SUPPORT

Sensors Powered Independently that Provide Either 12V, 5V or a

10mA DC Output Signal with a Sensor Alarm

1. Make sure power is not being applied to the unit.

2. Open the terminals in the sensor terminal block by turning each screw

counterclockwise until there is enough space to insert wires.

3. Strip off 2 ¼ inches of the sensors cable’s outer jacket.

4. Strip the insulation off each cable wire ¼ of an inch.

5. Feed the sensor cable through the small strain relief.

6. Insert the sensor’s DC common (or negative) output wire into the

S IN- terminal block and secure the wire by turning the terminal’s screw

clockwise. (Refer to the MX001 box or to Figure 16 for the order of the

terminals for the sensor wires.)

7. Insert and secure the sensor’s positive output wire into the S IN+ terminal.

8. Insert and secure the sensor’s alarm DC common (or negative) output wire

into the A IN- terminal and the sensor’s alarm positive output wire into the

A IN+ terminal.

9. Secure the cable by turning the strain relief’s domed sealing nut clockwise

until tight.

10. Depending upon your sensor’s output, perform one of the of the following

steps:

A IN+

A IN-

Figure 16

S IN-

COMMON

S IN+

+12V OUT

22

Page 27

S

ENSOR SUPPORT

Sensors Powered Independently that Provide Either 12V, 5V or a

10mA DC Output Signal with a Sensor Alarm

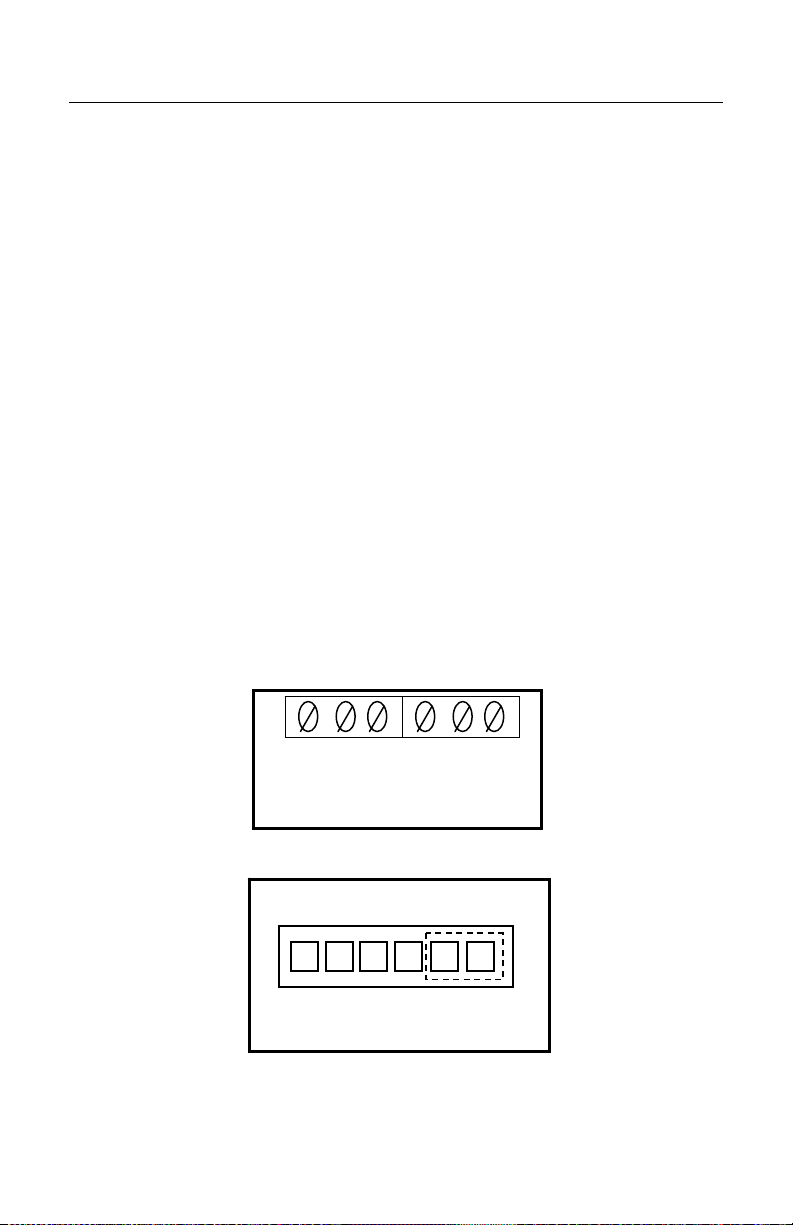

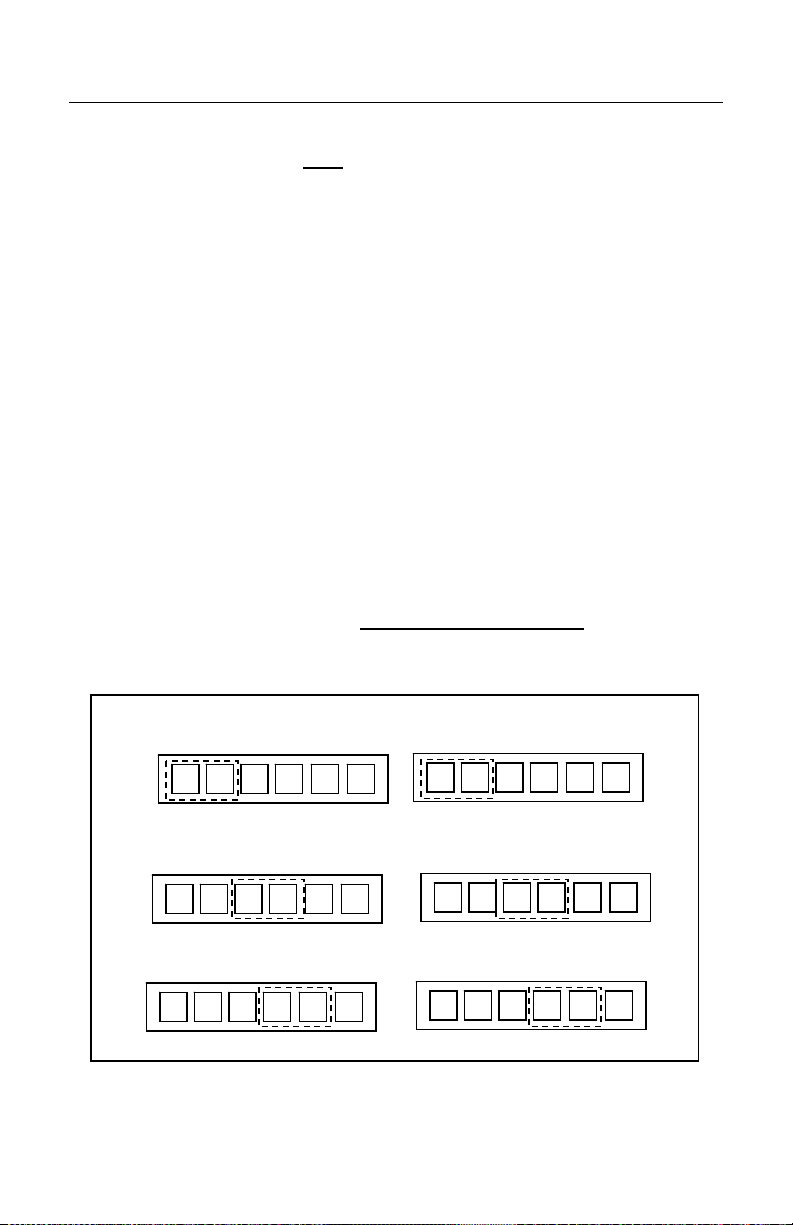

• For 12V DC output signals, position the jumpers on pins 1 and 2 of the

J1 (S SET UP) and J2 (A SET UP) headers. (Refer to Figure 17)

• For 5V DC output signals, position the jumpers on pins 3 and 4 of the

J1 (S SET UP) and J2 (A SET UP) headers. Refer to Figure 17)

• For 10mA DC output signals, position the jumpers on pins 4 and 5 of

the J1 (S SET UP) and J2 (A SET UP) headers. (Refer to Figure 17)

Caution: When configured for a 10mA DC source input, the MX001 box

expects a current limited 10 mA DC signal to be supplied by the

sensor. Failure to limit this current to 10 mA can damage the sensor

input circuitry of the system.

Current limiting can be accomplished by using external limiting resistors of

an appropriate value (which are dependent upon the sensor’s DC signal

output voltage level). One resistor is connected between the S IN+ input of

the MX001 box and the sensor. The other resistor is connected between the

A IN+ input of the MX001 box and the sensor (for the sensor alarm circuit).

Approximate Resistance = 10 mA

Sensor Output Voltage – 3V

If the source is a 12 V DC Signal:

1 A SET UP 6

1

2 3 4 5

1 A SET UP 6

1

2 3 4 5

1 A SET UP 6

1

2 3 4 5

6

6

J2

6

J2

1

1 S SET UP 6

J2

1

1 S SET UP 6

1

1 S SET UP 6

2

2

2

3 4

3 4

3 4

J1

5

6

J1

5

6

J1

5

6

Figure 17

23

Page 28

S

ENSOR SUPPORT

Sensors that Provide Switch Closures or Relay Type Output with a Sensor Alarm

1. Make sure power is not being applied to the unit.

2. Open the terminals in the sensor terminal block by turning each screw

counterclockwise until there is enough space to insert wires.

3. Strip off 2 ¼ inches of the sensor cable’s outer jacket.

4. Strip the insulation off each cable wire ¼ of an inch.

5. Feed the sensor cable through the small strain relief.

6. Insert one of the sensor’s signal output wires and one of the sensor’s alarm

output wires into the COMMON terminal and secure the wires by turning the

terminal’s screw clockwise. (Refer to the MX001 box or to Figure 18 for the

order of the terminals for the sensor wires.)

7. Insert and secure the sensor’s remaining signal output wire into the S IN-

terminal.

8. Insert and secure the sensor’s remaining alarm output wire into the A IN-

terminal.

9. Secure the cable by turning the strain relief’s domed sealing nut clockwise

until tight.

10. Position the jumpers on pins 5 and 6 of the J1 (S SET UP) and J2 (A SET

UP) headers. (Refer to Figure 19)

-

A IN-

A IN+

Figure 18

1 A SET UP 6

1

2 3 4 5

1

2 3 4 5

1 S SET UP 6

S IN

COMMON

S IN+

6

J1

J2

6

+12V OUT

Figure 19

24

Page 29

S

ENSOR SUPPORT

Low Voltage Self-Contained DC Sensors with Current Sinking Outputs and Sensor Alarm

1. Make sure power is not being applied to the unit.

2. Open the terminals in the sensor terminal block by turning each screw

counterclockwise until there is enough space to insert wires.

3. Strip off 2 ¼ inches of the sensor cable’s outer jacket.

4. Strip the insulation off each cable wire ¼ of an inch.

5. Feed the sensor cable through the small strain relief.

6. Insert the sensor’s DC common wire into the COMMON terminal and

secure the wire by turning the terminal’s screw clockwise. (Refer to the

MX001 box or to Figure 20 for the order of the terminals for the sensor

wires.)

7. Insert and secure the sensor’s +DC power input wire into the +12V OUT

terminal.

8. Insert and secure the sensor’s signal output wire into the S IN- terminal.

9. Insert and secure the sensor’s alarm signal output wire into the A IN-

terminal.

10. Secure the cable by turning the strain relief’s domed sealing nut clockwise

until tight.

11. Position the jumpers on pins 5 and 6 of the J1 (S SET UP) and J2 (A SET

UP) headers. (Refer to figure 21).

A IN+

A IN-

COMMON

Figure 20

-

S IN

S IN+

+12V OUT

1 A SET UP 6

1

2 3 4 5

1

2 3 4 5

1 S SET UP 6

6

J2

J1

6

Figure 21

25

Page 30

S

ENSOR SUPPORT

Low Voltage Self-Contained DC Sensors with Current Sourcing

Output and Sensor alarm

1. Make sure power is not being applied to the unit.

2. Open the terminals in the sensor terminal block by turning each screw

counterclockwise until there is enough space to insert wires.

3. Strip off 2 ¼ inches of the sensor cable’s outer jacket.

4. Strip the insulation off each cable wire ¼ of an inch.

5. Feed the sensor cable through the small strain relief.

6. Connect a small jumper wire between the COMMON and the S IN-

terminals and secure the jumper in the S IN- terminal by turning the

terminal’s screw clockwise. (Refer to the MX001 box or to Figure 22 for the

order of the terminals for the sensor wires.)

7. Connect a small jumper wire between the COMMON and the A IN- terminal

and secure the jumper in the A IN- terminal.

8. Connect the sensor’s DC common wire to the COMMON terminal and

secure the jumpers and wire by turning the terminal’s screw clockwise.

9. Insert and secure the sensor’s +DC power input wire into the +12V OUT

terminal.

10. Insert and secure the sensor’s signal output wire into the S IN+ terminal.

11. Insert and secure the sensor’s alarm output wire into the A IN+ terminal.

Secure the cable and turn the strain relief’s domed sealing nut clockwise

until tight.

12. Position the jumpers on pins 1 and 2 of the J1 (S SET UP) and J2 (A SET

UP) headers. (Refer to Figure 23)

A IN+

A IN-

Figure 22

-

S IN

COMMON

S IN+

+12V OUT

1 A SET UP 6

2 3 4 5

1

1

2 3 4 5

1 S SET UP 6

6

J2

J1

6

Figure 23

26

Page 31

S

ENSOR SUPPORT

“Universal” Self-contained Sensors That Provide Single

Pole/Double Throw (SPDT) Relay Outputs for Both Object Sensing

and Sensor Alarm

1. Make sure the “universal” sensor can operate on +12 volts DC at 200ma or

less. If so, then the MX001 box can supply the +12 volts necessary to

power the “universal” sensor.

2. Make sure power is not being applied to the unit.

3. Open the terminals in the sensor terminal block by turning each screw

counterclockwise until there is enough space to insert wires.

4. Strip off 2 ¼ inches of the sensor cable’s outer jacket.

5. Strip the insulation off each cable wire ¼ of an inch.

6. Feed the sensor cable through the small strain relief.

7. Insert the sensor’s +DC power input wire into the +12V OUT terminal and

secure the wire by turning the terminal’s screw clockwise. (Refer to the

MX001 box or to figure 24 for the order of the terminals for the sensor

wires.)

8. Insert the sensor’s -DC or common power input wire and both the object

sense and alarm relay output common signal wires into the COMMON

terminal and secure all three wires.

9. Determine from the literature supplied with your sensor which sensor relay

output makes contact with its common terminal when an object is sensed. If

the output cannot be determined, go on to Step 10. Otherwise, skip to Step

11.

10. Temporarily apply power to the MX001 box to activate the sensor and then

determine with a continuity tester or ohm meter which relay output (the

normally closed [NC] or the normally open {NO] output) makes contact with

the COMMON terminal when the sensor “sees" the object to be scanned.

11. Remove any power applied to the MX001 (in Step 100 and connect and

secure the “sense” relay output wire previously determined to the S INterminal. (The other sense relay output wire may be cut off or connected to

the MX001 COMMON terminal if desired).

27

Page 32

S

ENSOR SUPPORT

“Universal” Self-contained Sensors That Provide Single

Pole/Double Throw (SPDT) Relay Outputs for Both Object Sensing

and Sensor Alarm

12. Determine from the literature supplied with your sensor which sensor alarm

relay output makes contact with its common terminal when sensing

conditions become marginal. If the output cannot be deter-mined, go on to

Step 13. Otherwise, skip to Step 14.

13. Temporarily apply power to the MX001 box again to activate the sensor

and try to make sensing conditions marginal by placing the object to be

sensed at a greater than normal distance from the sensor or misalign the

sensor to activate the sensor’s alarm output. (Most sensors have a small

indicator that shows when the alarm output is active by being either on or

off depending upon the type of sensor.) Determine with a continuity tester

or ohm meter which relay output (the normally closed [NC or the normally

open {NO] output) makes contact with the COMMON terminal when the

sensor indicates that its alarm output is active.

14. Remove any power applied to the MX001 box (in Step 13) and connect and

secure the “alarm” relay output wire previously determined to the A IN-

terminal. (The other alarm relay output wire may be cut off or connected to

the MX001 COMMON terminal if desired.)

15. Secure the cable by turning the strain relief’s domed sealing nut clockwise

until tight.

16. Position the jumpers on pins 5 and 6 of the J1 (S SET UP) and J2 (A SET

UP) headers (Refer to Figure 25).

-

A IN-

A IN+

Figure 24

1 A SET UP 6

2 3 4 5

1

1

2 3 4 5

1 S SET UP 6

Figure 25

S IN

COMMON

S IN+

6

J2

J1

6

+12V OUT

28

Page 33

C

LOSING THE

MX001 I

NDUSTRIAL CONTROL BOX

1. Close the lid of the MX001 box.

2. Rotate the clamp clockwise while pushing down on the lid. Then move the

clamp to the right, positioning it over the ledge on the lid.

3. Fasten the clamp in place by tightening its screw with a flat blade

screwdriver.

C

ONNECTING THE

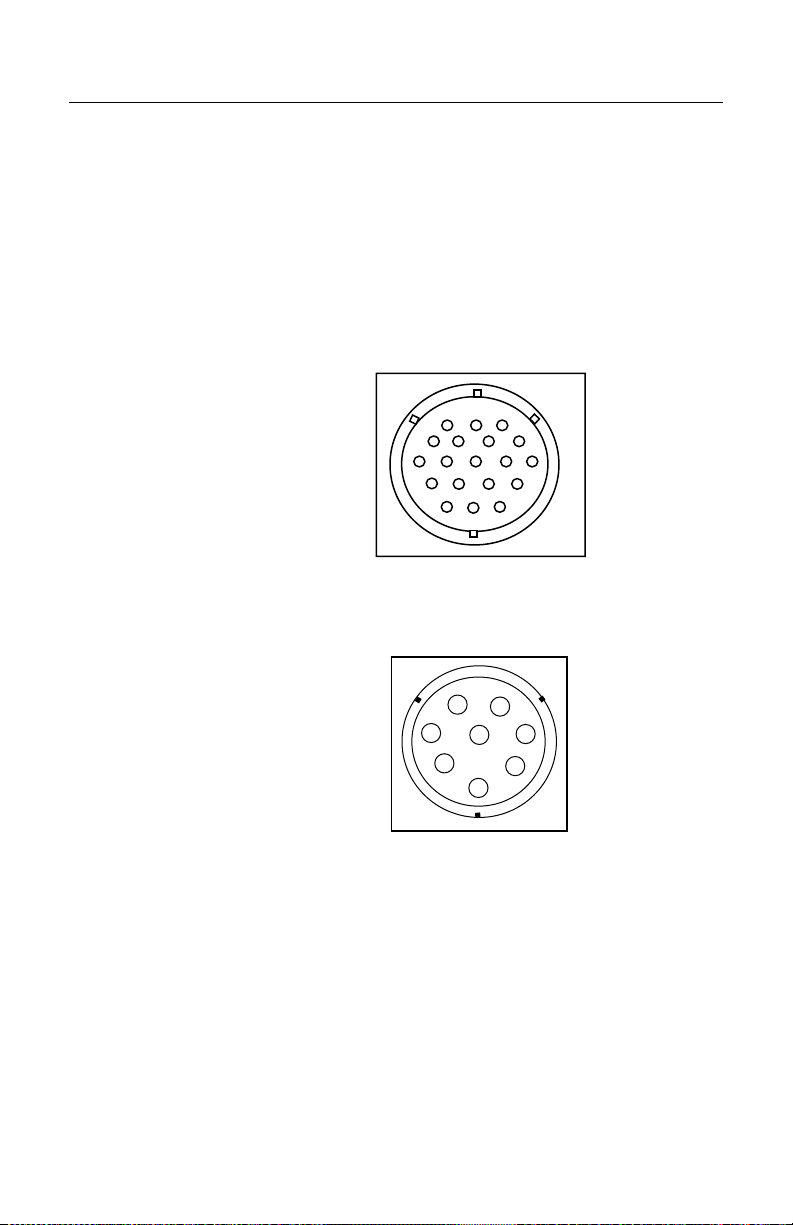

The supplied, scanner link cable is used to connect the MX001 box to a TECH

series scanner. This one meter cable carries the MX001’s control signals and is

terminated with an 8 and a 19 pin connector. (Other cable lengths are available,

contact Metrologic for details.)

1. Find the 8-pin male end of the scanner link cable and locate the wide

connector key found above pins A and G. Align this key with the

corresponding key on the MX001’s signal connector. Push in on the cable

connector slightly and rotate its ring clockwise until the connector locks in

place with a click.

2. Likewise, the 19-pin female connector found on the other end of this cable

is connected to the 19-pin male connector on the scanner case. This

connector is the one closest to the scanner window.

MX001

TO THE SCANNER

29

Page 34

g

A

C

ABLE PIN OUTS FOR THE

The standard scanner link cable length is 3 feet – 1 meter. Other scanner link

cable lengths are available upon request. Contact Metrologic Customer Service

for additional details.

If there is a need to lengthen the scanner link cable, use a cable with #26 wire.

The scanner link cable can be easily extended to 100 feet without signal

difficulty. The following are listings of the cable pin outs for the 19-pin female and

the 8-pin male ends of the link cable. (Refer to Figures 26 and 27)

19-Pin Female Mil Spec Connector

Pin Function

A TRIAC1+

B TRIAC1C-L RESERVED

M SENSOR+

N SENSORP SENSE ALARM+

R SENSE ALARMS-V RESERVED

8-Pin Male Mil Spec Connector

Pin Function

A TRIAC+

B TRIACC SENSOR+

D SENSORE SENSE ALARM/AUX+

F SENSE ALARM/AUXG RESERVED

H RESERVED

8-P

IN AND

D

19-P

B

P

C

R

S

E

F

Fi

F

E

Figure 27

IN CONNECTORS

A

M

L

N

V

K

U

J

T

H

G

ure 26

G

B

H

C

D

30

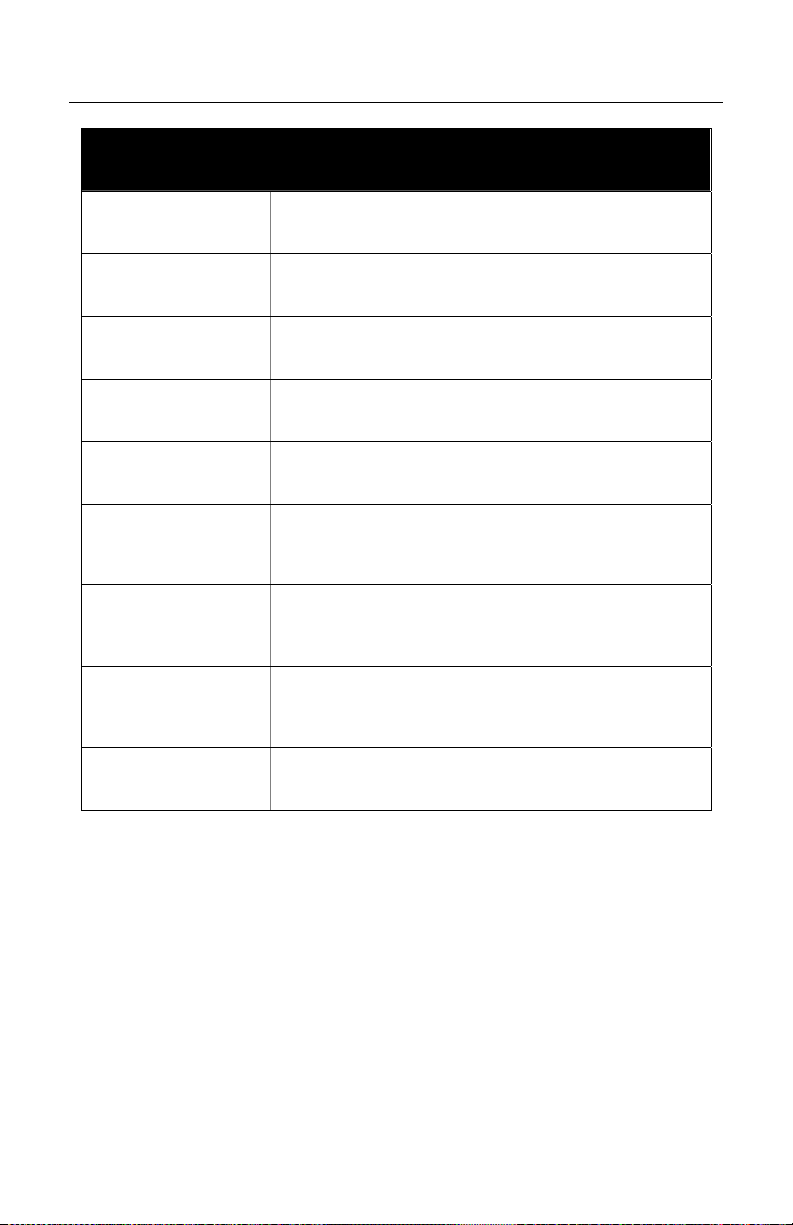

Page 35

S

PECIFICATIONS

Application: Industrial Control Interface

MX001 Specifications

Orientation:

Dimensions: 152mm L x 102mm W x 76mm D (6” x 4” x 3”)

Weight: 1.36 Kg (93 lbs.)

Case Material: Oil Tight J1C box

Electrical:

System Interfaces:

Status Indicators:

UL, CSA and IEC: UL and CUL listed, CE

L-bracket with TECH scanner or independently

mounted

12 V at 200mA for low voltage

DC type object sensor

6 Amp TRIAC output (5 Amp in Europe) 12V, 5V,

10mA or switch closure object sensor input

Four LED’s for: 12V Power supply, TRIAC, sensor

and sensor alarm

Specifications are subject to change without notice.

31

Page 36

T

ROUBLESHOOTING

No Operation – Green LED off:

1. Check power input wiring for correct connection and security at power

terminal block. (Wires must be stripped before insertion into the terminal

block and terminal block screws must be tight, clamping the stripped

wire firmly in the block.)

2. Check for AC power input between LINE IN and NEUTRAL terminals of

the power terminal block.

3. Check F2 Control fuse.

F2 Control Fuse Open:

1. Review the MX001 manual detailing the fuse installation procedure and

check the F2 Control fuse for correct rating. (Depends upon line

voltage in use.)

2. If a low voltage DC type sensor is connected to the MX001 and is using

the MX001 as its power source (+12V OUT in use), make sure this

sensor does not draw more than 200mA of current from the MX001 or

that the sensor is incorrectly connected or shorted.

No Operation Sensor & TRIAC with Green LED on

(other LED’s do not light):

1. Check that the scanner link cable is connected to the MX001 and

scanner.

2. Check the connection of the MX001 internal link cable to the printed

circuit board at J3 (Lower right corner).

3. Check for proper connection of the sensor (if used) plus proper

positioning of the S and A set up jumpers at J1 and J2. (Depends upon

sensor type.)

4. Check for proper HoloSet programming of the TRIAC. (To check TRIAC

output, temporarily program the scanner via HoloSet to support only the

TRIAC with TRIAC Normally On. This will activate the red TRIAC LED

and the TRIAC output continuously.)

32

Page 37

T

ROUBLESHOOTING

No TRIAC Output with Red TRIAC LED On:

1. Check that the TRIAC load is properly connected to the TRIAC

terminal block. (Wires must be stripped before insertion into the

terminal block and terminal block screws must be tight, clamping the

stripped wire firmly in the block.)

2. Check for AC power output between the TRIAC OUT and NEUTRAL

terminals of the TRIAC terminal block when the TRIAC LED is on.

3. Check the fuse in the F1 TRIAC fuse holder.

F1 TRIAC Fuse Open:

1. Review the section detailing the fuse installation procedure and

check the F1 TRIAC fuse for correct rating (10 or 6.3 Amps). Make

sure one of the F2 CONTROL fuses have not been installed in place

of the correct TRIAC fuse.

2. Check that the TRIAC load has been properly connected to the

TRIAC terminal block and does not draw current greater than the

rating of the F1 TRIAC fuse installed (10 Amp in USA or 6.3 Amp in

Europe/Asia).

3. Check that the TRIAC load does not draw an excessively large

surge or start up current that is beyond the capabilities of the MX001

fuse rating.

4. Check to make sure the TRIAC load is not or has not been

accidentally shorted. If a short is found, remove the short and check

for proper TRIAC operation after installing a new F1 TRIAC fuse.

(See item 5.)

5. Disconnect the normal TRIAC load and temporarily connect a 60W

light bulb in a wired test socket to the TRIAC output. If the bulb does

not light when the red LED TRIAC indicator is on after a new fuse

has been installed or if the bulb lights continuously with the red LED

TRIAC indicator off, then MX001 TRIAC circuit damage is indicated.

The Mx001 can be damaged if the TRIAC output is accidentally

shorted.

NOTE: TRIAC load refers to the device that is connected by the MX001 TRIAC.

33

Page 38

T

ROUBLESHOOTING

TRIAC Output Active with Red TRIAC LED off:

Tests for AC power output from the TRIAC should only be made when a device

or load is connected between the TRIAC OUT and NEUTRAL terminals of the

TRIAC terminal block. Attempting to measure output voltage with nothing

connected to the TRIAC terminal block will result in a false output reading which

may show partial or full line voltage present at all times. This is due to the TRIAC

snubber circuit in the MX001 that protects the TRIAC from surge damage due to

inductive loads. This circuit produces a small amount of AC output (5mA) at the

TRIAC terminal block that can be measured when no load is connected there

but is of no consequence otherwise.

To test properly for AC power output from the TRIAC, temporarily connect a 60W

light bulb in a wired test socket to the TRIAC output. This lamp will provide a

proper load for the TRIAC. If the bulb lights when the red LED TRIAC indicator is

OFF, then MX001 circuit damage is indicated as the problem. The unit can be

damaged if the TRIAC output is accidentally shorted.

No Sensor Input Indication (Red S in LED does not light):

1. Review the documentation that came with your sensor to learn the type

of output the sensor provides. Review the MX001 manual and find the

set up procedure that applies to your sensor. Check for proper

connection of the sensor to the MX001 sensor terminal block plus

proper positioning of the S set up jumper J1. (Depends upon sensor

type in use.)

2. Check your sensor for output indication. Most sensors have a small

indicator on them or their controller that lights when the sensor output is

active. Make sure the sensor is active when expected.

3. Check the positioning of the sensor making sure it is oriented correctly.

4. Check sensor gain/sensitivity adjustment for correctness. Most sensors

provide this adjustment to adapt to various sensing conditions. Check to

see if the gain/sensitivity is not set too low in diffuse proximity type

sensors or not set too high in beam break type sensors. Review the

documentation that came with your sensor to learn how to make this

adjustment correctly.

5. Make sure the MX001 scanner link cable is connected to both the

scanner and the MX001.

34

Page 39

T

ROUBLESHOOTING

Reversed Sensor Input Indication

(Red S in LED goes off when object is

1. Some sensors provide the option of output activation when they sense

or do not sense an object. Having the sensor set up to produce an

output when it does not sense an object will result in reversed sensing

conditions. The MX001 expects to receive an active output signal from

the sensor (source voltage/current or switch closure) when the object to

be scanned is being sensed. Review the documentation that came with

your sensor to learn what type of output it provides and how to configure

it.

2. Some sensors that provide switch closure type output provide both

normally open (NO) and normally closed (NC) switched outputs. If the

sensor as connected is providing a reversed sensing condition (switch

closure when no object is being sensed), disconnect the switched

output used and connect the other switched output in its place.

3. If the sensor in use provides an output only when an object is not being

sensed and cannot be configured otherwise, contact Metrologic for

special instructions on how to adapt to this type of sensor.

Erratic Sensor Operation:

1. Check the sensor wiring for correct connection and security at the

sensor terminal block. (wires must be stripped before insertion into the

terminal block and terminal block screws must be tight, clamping the

stripped wire firmly in the block.)

2. Check the positioning of the sensor making sure it is oriented correctly

and not dirty.

3. Check sensor gain/sensitivity adjustments for correctness. Most sensors

provide this adjustment to adapt to various sensing conditions. Review

the documentation that came with your sensor to learn how to make this

adjustment correctly. If this adjustment is made incorrectly, the sensor

will act erratically.

sensed):

35

Page 40

T

ROUBLESHOOTING

Continuous Sensor Input Indication

(Red S IN LED continuously on):

1. Review the documentation that came with your sensor to learn the type

of output the sensor provides. Review the MX001 manual and find the

set up procedure that applies to your sensor. Check for proper

connection of the sensor to the MX001 sensor terminal block plus

proper positioning of the S set up jumper at J1. (Depends upon sensor

type in use.)

2. Check your sensor for output indication. Most sensors have a small

indicator on them or their controller that lights when the sensor output is

active. Make sure the sensor is not providing a continuous output.

3. Some sensors provide the option of output activation when they sense

or do not sense an object. Having the sensor set up to produce an

output when it does NOT sense an object will result in continuous

sensor output when the sensor is idle. Review the documentation that

came with your sensor to learn what type of output it provides and how

to configure it. The MX001 box expects to receive an active output

signal from the sensor (source voltage/current or switch closure) when

an object to be scanned is being sensed.

4. Check sensor gain/sensitivity adjustment for correctness. Most sensors

provide this adjustment to adapt to various sensing conditions. Check to

see if the gain/sensitivity is not set too low in beam break type sensors

or not set to high in diffuse proximity type sensors. Review the

documentation that came with your sensor to learn how to make this

adjustment correctly.

Continuous Sensor Alarm Indication

(Red A IN LED continuously on):

1. Review the documentation that came with your sensor to learn the type

of alarm output the sensor provides. Review the MX001 manual and

find the set up procedure that applies to your sensor. Check for proper

connection of the sensor alarm output to the MX001 sensor terminal

block plus proper positioning of the A Set Up jumper at J2. The MX001

expects to receive an active alarm output signal from the sensor (source

voltage/current or switch closure) when sensing conditions have

become marginal.

2. If the sensor in use provides an alarm output only when sensor

conditions are not marginal and cannot be configured otherwise,

contact Metrologic for special instructions on how to adapt to this type of

sensor.

36

Page 41

T

ROUBLESHOOTING

Erratic Sensor Alarm Indication (Red A IN LED blinks):

1. Check the positioning of the sensor to make sure it is oriented correctly.

2. Check to see if the sensor is dirty and clean it if necessary.

Check sensor gain/sensitivity adjustment for correctness. Most sensors

3.

provide this adjustment to adapt to various sensing conditions. Review

the documentation that came with your sensor to learn how to make this

adjustment correctly. If this adjustment is made incorrectly, the sensor

may produce an erratic alarm output.

Scanner cannot be placed in program mode using HoloSet label:

1. Disconnect then reconnect power to the scanner. Enter scanner

program mode by choosing Enter Program Mode from the HoloSet

Main Menu.

2. If the scanner has been programmed for sensor support, the scanner

will not scan any label including the HoloSet label unless a sensor is

connected to the MX001 box and activated.

3. If the scanner has been programmed to support DTR, the scanner will

not scan any label including the HoloSet label unless the DTR input is

active.

Scanner cannot be placed in program mode using HoloSet menu:

1. Disconnect then reconnect power to the scanner. Retry entering

program mode by choosing Enter Program Mode from the HoloSet

Main Menu.

2. Check to see if the HoloSet communication cable is plugged into your

PC correctly.

3. Make sure the correct COM option (COM 1 or 2 as required) is being

used.

37

Page 42

T

ROUBLESHOOTING

Operational Check Out Procedure for the MX001 Box:

The following procedure provides a basic test of the MX001 hardware and

confirms effective communication with the HoloSet program. This quick test

should be preformed before the MX001 box has been configured by the HoloSet

program for its final application. These steps are not required for proper

installation and application programming of the MX001 box.

1. Do not connect a sensor to the MX001 at this time. Tighten each sensor

terminal block screw by turning each screw clockwise.

2. Temporarily place both S and A SET UP jumpers (J1 and J2) at

positions 5 and 6.

3. Connect a standard 60W light bulb in a wired test socket to the TRIAC

terminal block at the TRIAC OUT and NEUTRAL terminals. This lamp

will act as a load for the TRIAC. (Do Not try to monitor TRIAC output

without a load connected.)

4. Connect the MX001 box to the scanner with the scanner link cable.

5. Apply power to both the MX001 and the scanner. The green LED inside

the MX001 should light.

6. If a volt meter is available, measure the DC output voltage between the

+12V OUT and COMMON terminals on the sensor terminal block. This

voltage should be between 11.5 and 12.5 volts DC.

7. Temporarily program the TECH options of the scanner using HoloSet

for the following:

• Support Line Sensor

• Support Line Sensor Alarm

• Support TRIAC

• TRIAC Normally On

• Activate on No Read

8. After programming, the MX001’s red TRIAC LED should light and the

test light bulb should be on.

9. Short the S IN- terminal screw to the COMMON terminal screw with a

short piece of wire. The red S IN LED should light and the test light bulb

connected to the TRIAC output should flash off then back on.

38

Page 43

T

ROUBLESHOOTING

10. Short the A IN- terminal screw to the COMMON terminal screw with a

short piece of wire. The red A IN LED should light and the scanner

should emit a repetitive warning tone as long as this connection is

maintained.

11. Disconnect then reconnect power to the scanner. Enter scanner

program mode by choosing Enter Program Mode from the HoloSet

Main Menu. (Do not try to use the HoloSet bar code label at this time)

DISABLE all TECH options then re-program the scanner. This

neutralizes the test program disabling the unconnected sensor inputs

and turns the TRIAC output off.

12. If needed, the scanner can now be programmed for your particular

application.

39

Page 44

L

IMITED WARRANTY

The MX001 interface is manufactured by Metrologic at its Blackwood, New Jersey, USA

facility. The MX001 interface has a two (2) year limited warranty from the date of

manufacture. Metrologic warrants and represents that all MX001 interface is free of all

defects in material, workmanship and design, and have been produced and labeled in

compliance with all applicable US Federal, state and local laws, regulations and ordinances

pertaining to their production and labeling.

This warranty is limited to repair, replacement of Product or refund of Product price at the

sole discretion of Metrologic. Faulty equipment must be returned to the Metrologic facility in

Blackwood, New Jersey, USA or Puchheim, Germany. To do this, contact Metrologic’s

Customer Service/Repair Department to obtain a Returned Material Authorization (RMA)

number.

In the event that it is determined that the equipment failure is covered under the warranty,

Metrologic shall, as its sole option, repair the Product or replace the Product with a

functionally equivalent unit and return such repaired or replaced Product without charge

for service or return freight, whether distributor, dealer/reseller, or retail consumer, or

refund an amount equal to the original purchase price.

This limited warranty does not extend to any Product which, in the sole judgement of

Metrologic, has been subjected to abuse, misuse, neglect improper installation, or

accident, nor any damage due to use or misuse produced from integration of the Product

into any mechanical, electrical or computer system. The warranty is void if the case of

Product is opened by anyone other than Metrologic’s repair department or authorized

repair centers.

THIS LIMITED WARRANTY, EXCEPT AS TO TITLE, IS IN LIEU OF ALL OTHER WARRANTIES OR

GUARANTEES, EITHER EXPRESS OR IMPLIED, AND SPECIFICALLY EXCLUDES, WITHOUT

LIMITATION, WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR

PURPOSE UNDER THE UNIFORM COMMERCIAL CODE, OR ARISING OUT OF CUSTOM OR

CONDUCT. THE RIGHTS AND REMEDIES PROVIDED HEREIN ARE EXCLUSIVE AND IN LIEU OF

ANY OTHER RIGHTS OR REMEDIES. IN NO EVENT SHALL METROLOGIC BE LIABLE FOR ANY

INDIRECT OR CONSEQUENTIAL DAMAGES, INCIDENTAL DAMAGE, DAMAGES TO PERSON OR

PROPERTY, OR EFFECT ON BUSINESS OR PROPERTY, OR OTHER DAMAGES OR EXPENSES

DUE DIRECTLY OR INDIRECTLY TO THE PRODUCT, EXCEPT AS STATED IN THIS WARRANTY.

IN NO EVENT SHALL ANY LIABILITY OF METROLOGIC EXCEED THE ACTUAL AMOUNT PAID TO

METROLOGIC FOR THE PRODUCT. METROLOGIC RESERVES THE RIGHT TO MAKE ANY

CHANGES TO THE PRODUCT DESCRIBED HEREIN.

C

ORPORATE HEADQUARTERS

N

ORTH AMERICA

Metrologic Instruments, Inc. Metrologic Eria Ibérica, SL

90 Coles Rd. C/Alfonso Gomez, 38-40, 1D

Blackwood, NJ 08012-4683 28037 Madrid

Customer Service Department Tel: +34 913 751 249

Tel: 1-800-ID-METRO Fax: +34 913 270 437

Fax: 856-228-6673

Email: info@metrologic.com

AUTO ID INSTRUMENTS (SHANGHAI) CO., LTD

MTLG

Suzhou Sales Office

BLK A, Room# 03/03-04

No.5 Xinghan Street, Xinsu Industrial Square

China-Singapore Suahou Industrial Park, Suzhou, PRC

Tel: 86-512-67622550

Fax: 86-512-67622560

Email: info@cn.metrologic.com

40

,

M

ETROLOGIC EUROPEAN REPAIR CENTER

(MERC)

Page 45

N

OTICES

Changes or modifications not expressly approved by the party responsible for

compliance could void the user’s authority to operate the equipment.

Class A Devices

This equipment has been tested and found to comply with limits for a Class A digital

device, pursuant to part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference when the equipment is operated in

a commercial environment. This equipment generates, uses and can radiate radio

frequency energy and, if not installed and used in accordance with the instruction

manual, may cause harmful interference to radio communications. Operation of this

equipment in a residential area is likely to cause harmful interference, in which case

the user will be required to correct the interference at their own expense. Any

unauthorized changes or modifications to this equipment could void the user’s

authority to operate this device.

This device complies with part 15 of the FCC Rules. Operation is subject to the

following two conditions: (1) This device may not cause harmful interference, and (2)

this device must accept any interference received, including interference that may

cause undesired operation.

Notice

This Class A digital apparatus complies with Canadian ICES-003.

Remarque

Cet appareil numérique de classe A est conforme à la norme canadienne NMB-003.

European Standard

Warning

This is a class A product. In a domestic environment this product may cause radio

interference in which case the user may be required to take adequate measures.

Funkstöreigenschaften nach EN55022:1998

Warnung!

Dies ist eine Einrichtung der Klasse A. Diese Einrichtung kann im Wohnbereich

Funkstörungen verursachen. In diesem Fall kann vom Betreiber verlangt werden,

angemessene Massnahmen durchzuführen.

Standard Europeo

Attenzione

Questo e’ un prodotto di classe A. Se usato in vicinanza di residenze private

potrebbe causare interferenze radio che potrebbero richiedere all’utilizzatore

opportune misure.

Attention

Ce produit est de classe “A”. Dans un environnement domestique, ce produit peut

être la cause d’interférences radio. Dans ce cas l’utiliseteur peut être amené à

predre les mesures adéquates.

41

Page 46

42

Page 47

Page 48

March 2004, Version 01

Printed in the USA

00- 02173

Loading...

Loading...