Page 1

MS6720 Hand-Held Laser Scanner

Installation and User’s Guide

MLPN 2368

Printed in USA

October 1998

Page 2

Table of Contents

Introduction ................................................... 1

Scanner and Accessories ......................................... 2

Quick Start .................................................... 3

Operational Test ............................................... 4

Scanner Installation: Powered by External Power Supply ............... 5

Scanner Installation: Powered by the Host Device ..................... 6

Scanner Installation: to the PC for the Scanner with Built-In

PC Keyboard Wedge Interface .................................... 7

The MS6720 Stand ............................................. 8

Scanner Parts .................................................. 9

Audible Indicators ............................................ 10

Failure Modes ......................................... 11

Visual Indicators .............................................. 12

Label ....................................................... 13

Depth of Field Specifications .................................... 14

Normal Depth of Field .................................. 14

Short Depth of Field .................................... 15

Extended Depth of Field ................................. 16

Optional Depth of Field ................................. 17

Automatic Turn-On Specifications ................................ 18

Normal Depth of Field .................................. 18

Short Depth of Field .................................... 18

Scan Pattern Specifics .......................................... 19

Projection Axis ........................................ 19

Omnidirectional Scan Volume ............................ 19

Cross-Sectional Scan Pattern .................................... 20

Maintenance .................................................. 21

Troubleshooting Guide ..................................... 22 - 26

Application and Protocols ....................................... 27

iii

Page 3

Appendix A

Design Specifications 28, 29

Appendix B

Default Settings 30 - 33

Appendix C

Pin Assignments 34 - 36

Appendix D

Warranty and Disclaimer 37, 38

Appendix E

Notices 39, 40

Appendix F

Patents 41

Index 42 - 44

iv

Page 4

Introduction

The MS6720 is the first laser bar code scanner truly to bridge the gap between

omnidirectional fixed projection and hand-held scanners. It incorporates fixed

projection performance and our patented 20-line scan pattern into a

comfortable, ergonomic styling of our popular hand-helds. With this design,

Metrologic has engineered a scanner that transcends any other on the market

today.

The MS6720 utilizes a unique, patented infrared sensor and control scheme

for hands-free projection scanning and fatigue reduced hand-held operation.

Whether operators choose to present small items to the scanner or transport

the lightweight scanner to bulkier items, the compact size and comprehen-sive

scan pattern make the MS6720 the perfect choice for many applica-tions.

The superior performance and features the world has come to expect from

Metrologic were packaged into the comfortable case only after tests and

approvals by hands of all sizes. With 84 degrees rotation and 10 locking

positions through 45 degrees of tilt, the stand for the MS6720 is also ergonomically and application friendly. Mounting was designed to provide an

adequate distance for scanning between the scanner face and the counter top at

all times. When fully tilted, the face of the unit remains a full five inches from

the counter. In addition, the modular construction thoughtfully includes a

removable wall mount cap.

As with all Metrologic hand-held scanners, the MS6720 features both shortrange and long-range activation, user-friendly programming, reliability and

versatility. Operators are sure to appreciate the convenience and flexibility of

the MS6720, offered at an unbeatable price.

1

Page 5

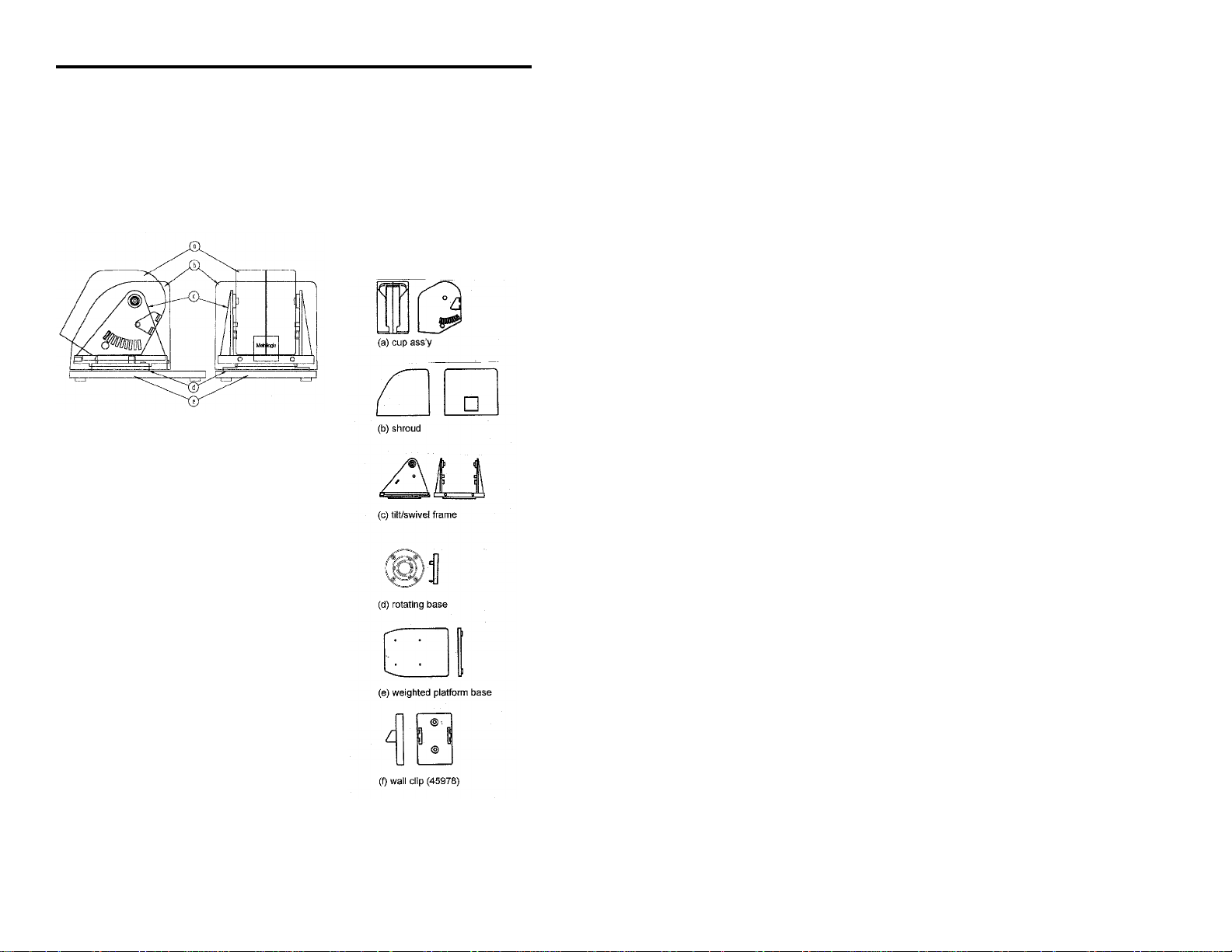

Scanner and Accessories

The following is a list of the parts included in the MS6720 kit.

! MS6720 Hand-Held Laser Scanner - Refer to page 27 for

available communication protocols

! Stand (MLPN 45967) - Refer to page 8 for available kits

! Optional Power Transformer 120V or 220V or 240V (AC in)

5V (DC out) @300mA regulated (MLPN 46010/46009/46008)

for applications where host power is not available

! Installation and User’s Guide (MLPN2368)

! ScanSelect™ Scanner Programming Guide

(MLPN 2186)

RS-232, Light Pen, some OCIA and some 46xx scanners:

! MCA (Metrologic Connector Adaptor) (MLPN MCA951)

! For direct connect application (No Power Transformer)

4 position MCA ground jumper (MLPN 51191)

Keyboard Wedge Scanners:

! Adaptor Cable with a 5-pin DIN male connector on one

end and a 6-pin mini DIN female connector on the other

(MLPN 19716)

! For direct connect application (No Power Transformer)

4 position direct power jumper (MLPN 52332)

for host powered applications

Other items may be ordered for the specific protocol being used. To order

additional items, contact the dealer, distributor or call Metrologic’s

Customer Service Department at 1-800-ID-METRO or 1-800-436-3876.

2

Page 6

Quick Start

1.) Plug in the scanner. Both LEDs come on

together along with the beep-the green LED

only flashes.

2.) The scanner is shipped from the factory

programmed with default settings.

To configure the MS6720 scanner to

meet the host system’s specific needs,

refer to the Programming Guide

(MLPN 2186) for instructions on how

to enter the program mode and to

select the appropriate bar codes.

Note: Any time the Load Defaults bar code is scanned the MS6720

is configured for an RS-232 interface. If a RS-232 is not being

used, scan at least one other bar code to enable Keyboard

Wedge, OCIA, Light Pen or 46xx. Refer to sections B and F

in the ScanSelect Programming Guide (MLPN 2186).

3

Page 7

Operational Test

If the scanner is to receive power from an external power supply, test the

scanner before it is connected to the host system.

Keyboard Wedge Scanners:

1. Plug one end of the coil cable into the keyboard connector on the PC.

Then plug the keyboard connector into the other end of the coil cable.

Plug in the external transformer.

2. Check the AC input requirements of the power supply to make sure the

voltage matches the AC outlet. Connect AC power to the transformer.

3. Both LEDs come on together along with the beep-the green LED

only flashes.

RS-232, Light Pen, OCIA and 46xx scanners:

1. Plug the scanner’s coil cable into the MCA (Metrologic Connector

Adaptor).

2. Check the AC input requirements of the power supply to make sure the

voltage matches the AC outlet. Plug the power supply into the MCA and

the appropriate AC outlet. (the socket-outlet shall be installed near the

equipment and shall be easily accessible.)

3. Both LEDs come on together along with the beep-the green LED

only flashes.

Note: Two methods that the scanner can be powered are as follows:

External Power Supply or Host Device ie the PC for the

MS6720 with a Built-in PC Keyboard Wedge interface.

4

Page 8

Scanner Installation: Powered by External Power Supply

To maintain compliance with applicable standards, all circuits connected to the

scanner must meet the requirements for SELV (Safety Extra Low Voltage)

according to EN 60950.

1. Turn off the host system.

2. If using a communication cable, connect the cable to the correct port on

the host device and the MCA (Metrologic Connector Adaptor). If the

host device is an IBM compatible PC with a male 9-pin serial port,

connect the MCA to the port.

3. Plug the scanner’s coil cable into the MCA.

4. Check the AC input requirements of the power supply to make sure the

voltage matches the AC outlet. (the socket-outlet shall be installed near

the equipment and shall be easily accessible.) Plug the power supply

into the MCA and the AC outlet.

5. Turn on the host system.

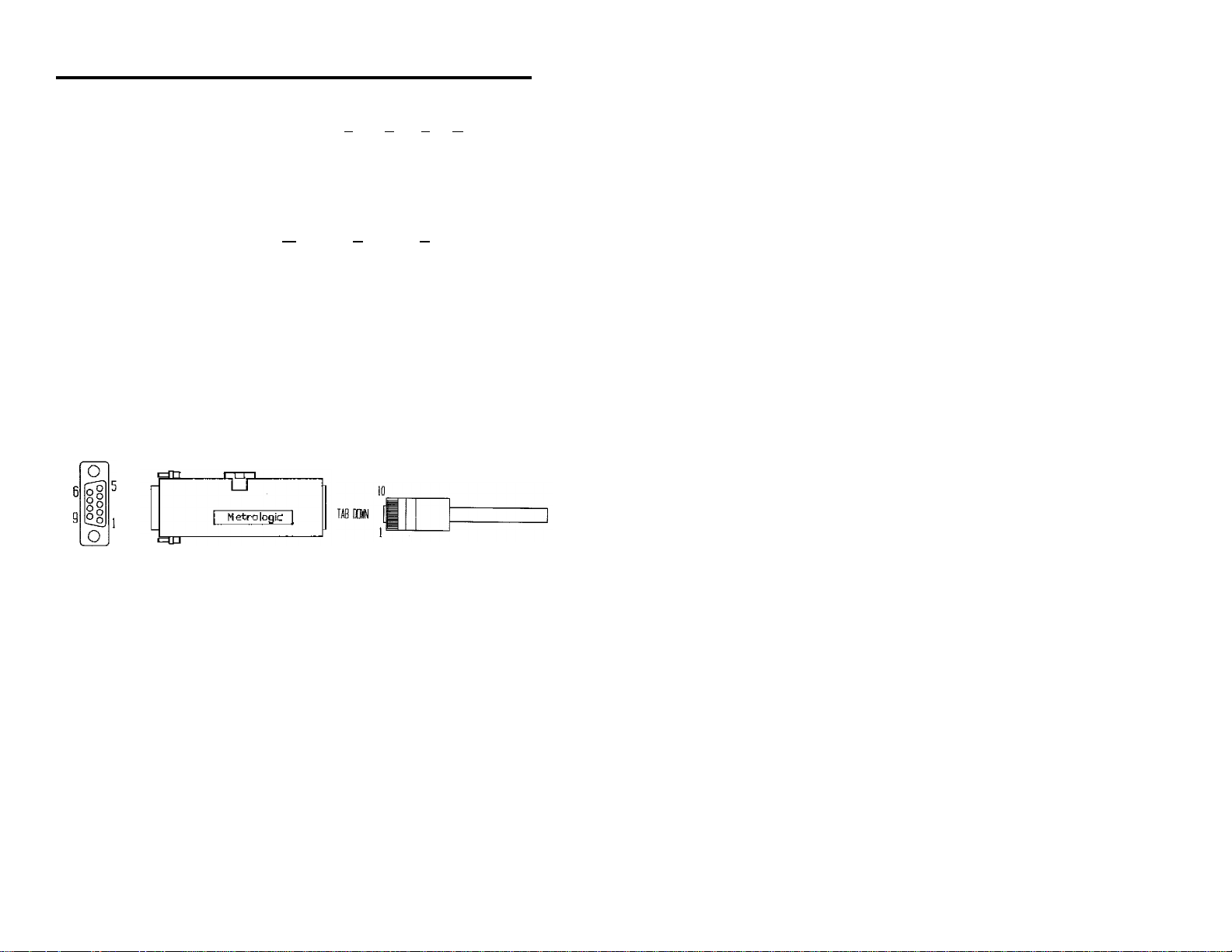

Female

9-pin D

MCA

10 Position Modular Connector

at the end of the Coil Cable

Note: a. When the scanner first receives power, both LEDs come on

together along with the beep-the green LED only flashes.

b. Plugging the scanner into the serial port of the PC does not

guarantee that scanned information will appear at the PC. A

software driver and correct configuration setting are also

required for proper communication to occur.

5

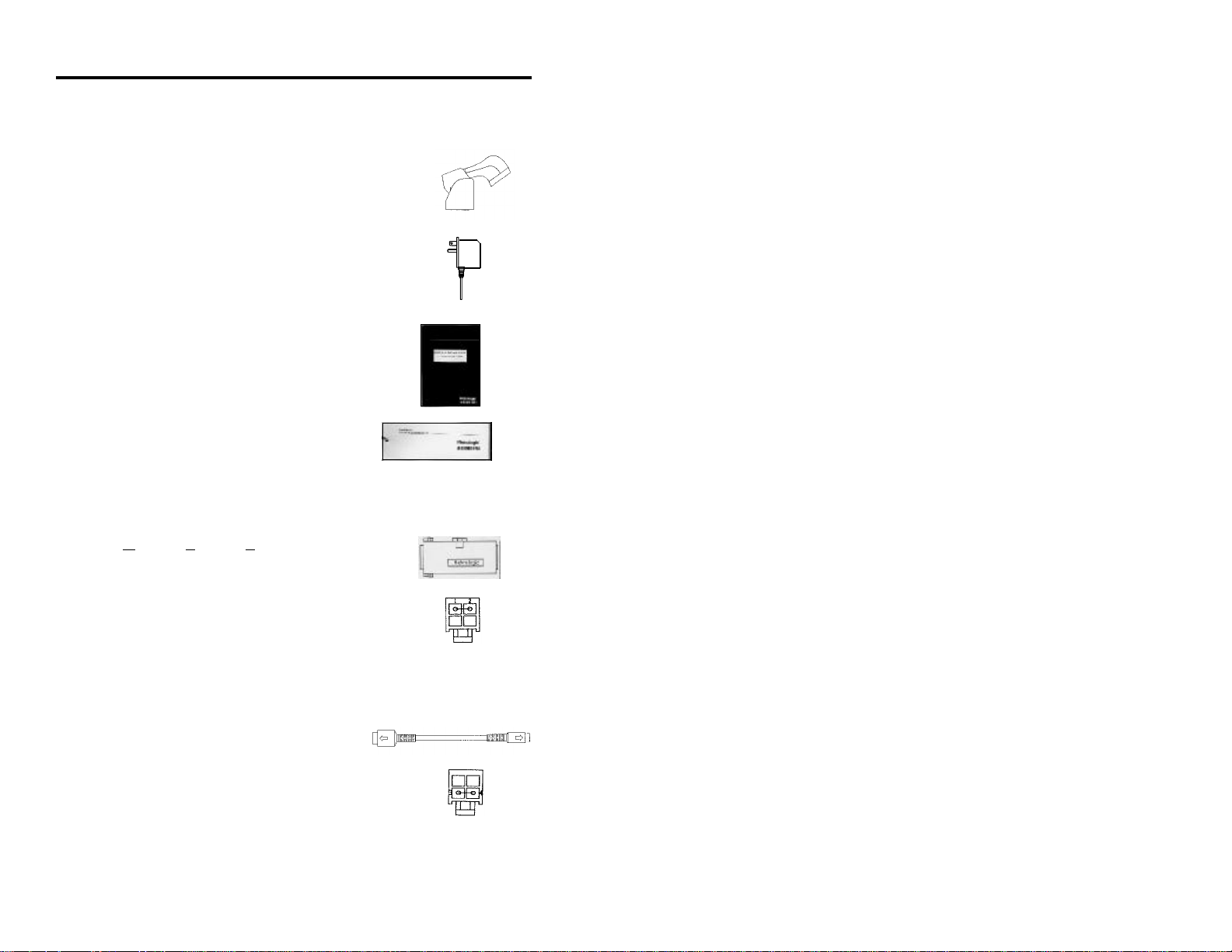

Page 9

Scanner Installation: Powered by Host Device

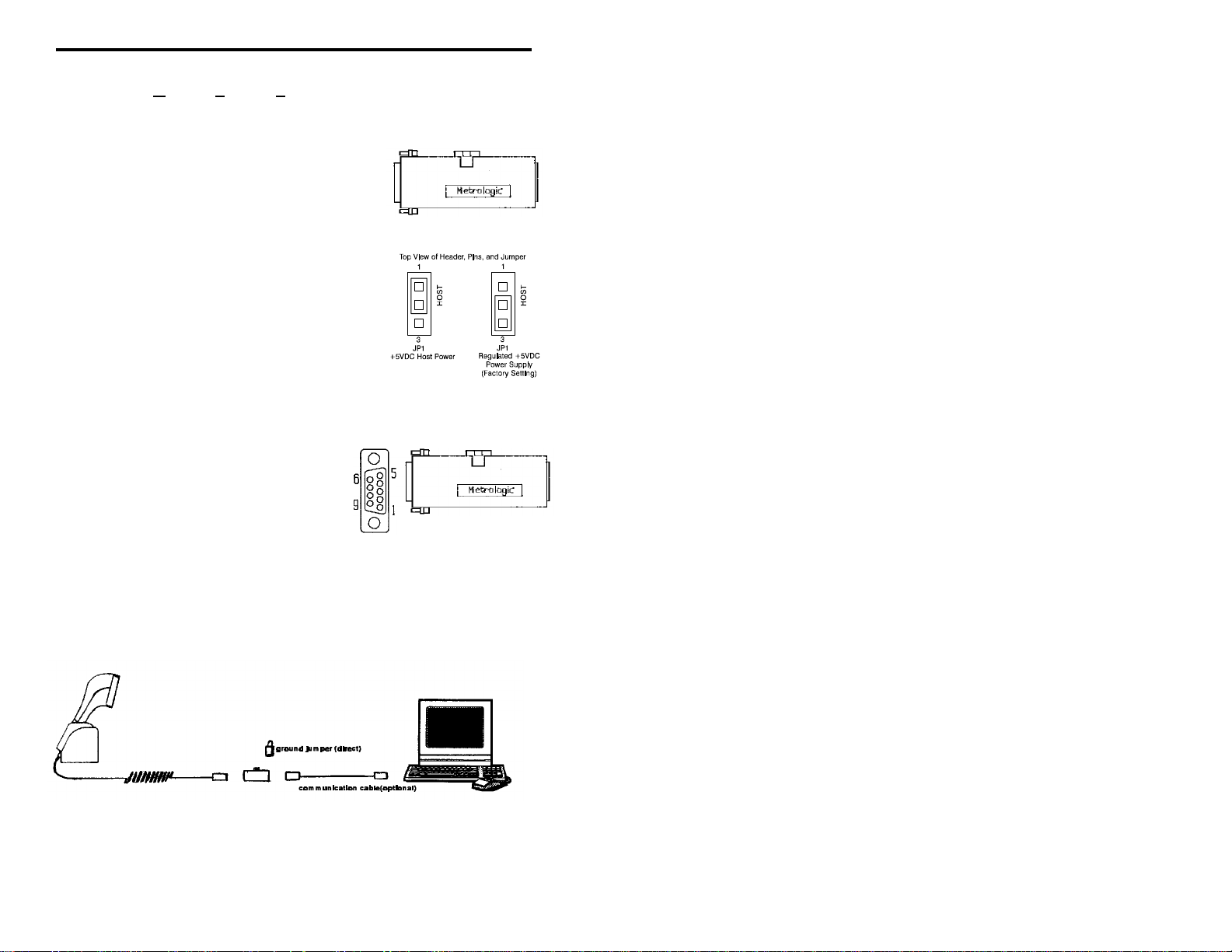

If the host system supplies +5VDC power to the scanner, reposition the internal jumper

within the MCA (Metrologic Connector Adaptor) before connecting the scanner to the

host device. In addition, plug the 4 position ground jumper into the power supply

connector located on the side of the MCA.

1. Make sure the MCA is not connected to the scanner,

communication cable or host and unfasten the case.

MCA

2. Reposition the shunt on JP1 to pins 1 and 2 and

close the case.

Note: The factory setting of jumper 1 (JP1) is on pins 2

and 3. To direct power for the scanner from the

host device, position the jumper on pins 1 and 2.

3. Plug the 4 position ground jumper into the power

supply connector.

4. Turn off the host system.

5. If using a communication cable, connect the

cable to the correct port on the host device

and the MCA. If the host device is an IBM

compatible with a male 9-pin serial port,

connect the MCA to the port. There is an

optional cable (MLPN 51236) that is available for IBM PC applications where the

MCA will not fit at the back of the computer.

Female

9-pin D

MCA

6. Plug the scanner’s coil cable into the MCA.

7. Turn on the host system.

MS6720 coil cable MCA host

6

Page 10

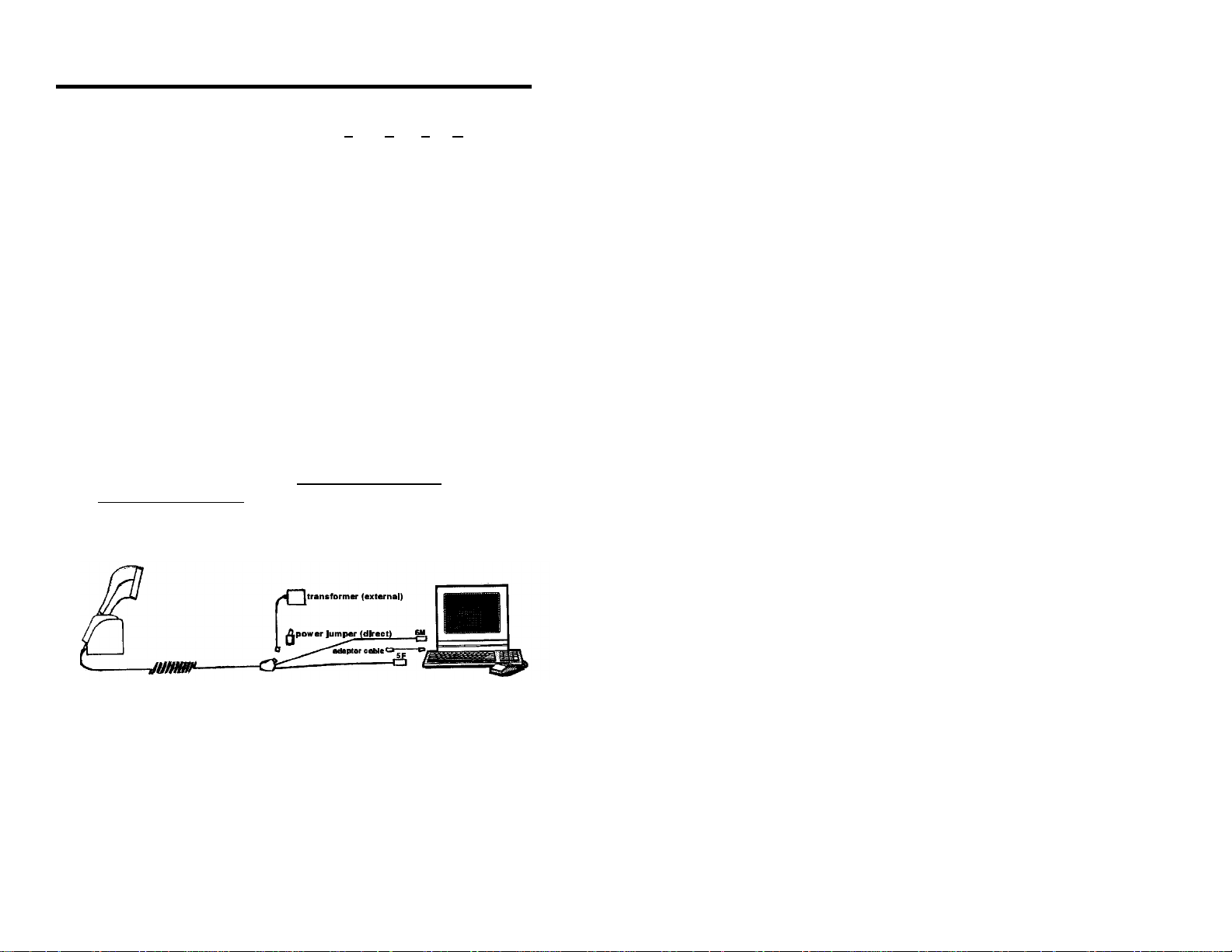

Scanner Installation to the PC for the Scanner with Built-in

PC Keyboard Wedge Interface

To maintain compliance with applicable standards, all circuits connected to the

scanner must meet the requirements for SELV (Safety Extra Low Voltage)

according to EN 60950.

1. The “Y” coil cable is terminated with a 5-pin DIN female connector

on one end, and a 6-pin mini DIN male on the other. Also included

with the MS6720 is an adaptor cable with a 5-pin male DIN on one

end and a 6-pin female mini DIN on the other to mate to a specific

keyboard. According to the termination required, connect the appropriate end of the adaptor cable to the coil cable, leaving the necessary termination exposed for connecting to the keyboard and the

keyboard port on the PC. Refer to Appendix C page 36 for pin

assignments.

2. If the PC is on, exit the application and turn the PC off.

3. Disconnect the keyboard from the PC.

4. Plug one end of the coil cable into the keyboard connector on the PC.

Then plug the keyboard connector into the other end of the coil cable.

Plug in the external transformer. Refer to Manufacturer’s

Recommendation below. Connect AC power to the transformer.

5. Power up the PC.

MS6720 »» “Y” coil cable ºº PC

Manufacturer’s Recommendation:

Metrologic recommends the use of an external power supply with MS6720-47 Keyboard Wedge applications. Powering the MS6720-47 directly from the computer

keyboard connector could interfere with the operation of the scanner or the computer.

Not all computers supply the same current through the keyboard port, this explains why

a scanner would work on one computer and not another.

7

Page 11

The MS6720 Stand

The stand for the MS6720 is ergonomic and application friendly. The mounting was

designed to provide an adequate distance for scanning between the scanner face and the

counter top at all times. When fully tilted, the face of the scanner remains a full five

inches from the counter. The stand comes preassembled so it can be attached to the

work surface with minimum effort (also included is the wall mount clip). The instructions for use of the wall mount clip are included with the general assembly instructions

for the stand. Listed below are the component parts of the MS6720 stand kits.

1) Complete Stand Kit:

MLPN 45967

Kit includes:

MLPN 45965 (counter top stand)

MLPN 45969 (weighted base)

MLPN 45978 (wall clip)

10-32 x 3/8" flat head screws

#10 x 1" flat head wood screws

2) Counter top Stand Kit:

(for securing directly to a counter top ONLY)

MLPN 45965

Kit includes:

each: parts a, b, c, d as shown

#10 x 1" flat head wood screws

3) Wall Mount Kit:

(for directly to a wall ONLY)

MLPN 45966

Kit includes:

part (a) as shown

45978 (wall clip)

#10 x 1" flat head wood screws

8

Page 12

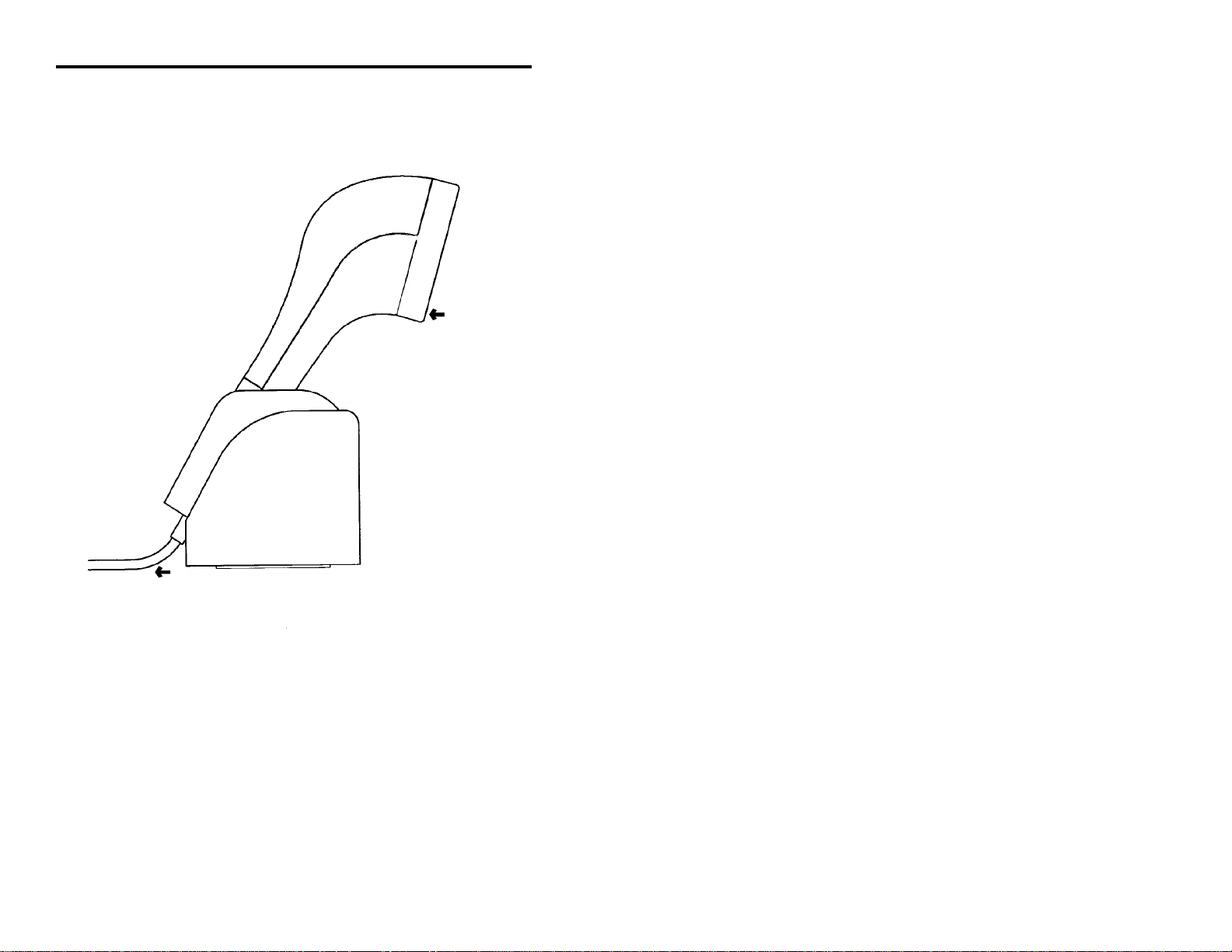

Scanner Parts

Green and Red LED

When the red LED is on, this indicates that the

laser is on. When the green LED flashes on,

the scanner has read a bar code successfully.

When the green light turns off, communication to the host is complete. The green LED

blinks while the scanner is waking up from an

IR sensor timeout. The LED’s are also used

as diagnostic indicators and mode indicators.

Refer to pages 10-12 for details.

Coil Cable

This cable is terminated with a 10-pin modular connector, which attaches to

the MCA951. The Keyboard Wedge unit has a “Y” coil cable terminated with

a 5-pin female on one end, a 6-pin male and a 4-pin locking connector for

power input (power jumper). An adaptor is included with a 5-pin male DIN

on one end and a 6-pin female mini DIN on the other to mate to a specific

keyboard. Refer to Appendix C page 36 for pin assignments.

º

Output Window

Laser light emits from this aperture.

Adjustable Stand

»

Designed to provide an adequate

distance for scanning between the

scanner face and counter at all

times. When fully tilted, the face

of the scanner remains a full five

inches from the counter. Refer to

page 8 for available kits.

9

Page 13

Audible Indicators

When the MS6720 scanner is in operation, it provides audible feedback.

These sounds indicate the status of the scan and scanner. Four settings are

available for the tone of the beep. To change the tone, refer to the Programming Guide section: Beeper Tones.

One Beep

*

When the scanner first receives power, both LEDs come on

together along with the beep-the green LED only flashes.

After the scanner performs this startup sequence, the

scanner is ready to scan.

When the scanner successfully reads a bar code, the green light

will flash and beep once (if programmed to do so). If the scanner

does not beep once and the green light does not flash, then the

bar code has not been successfully read.

Razzberry Tone

This tone is a failure indicator. Refer to failure modes page 11.

Three Beeps - after power up

***

When entering the program mode, the green LED will flash

while the scanner simultaneously beeps three times. The green

LED will continue to flash until the unit exits program mode.

Upon exiting program mode, the scanner will beep three times

and the green LED will stop flashing. When configured, 3 beeps

can also indicate a communications timeout during normal

scanning mode.

10

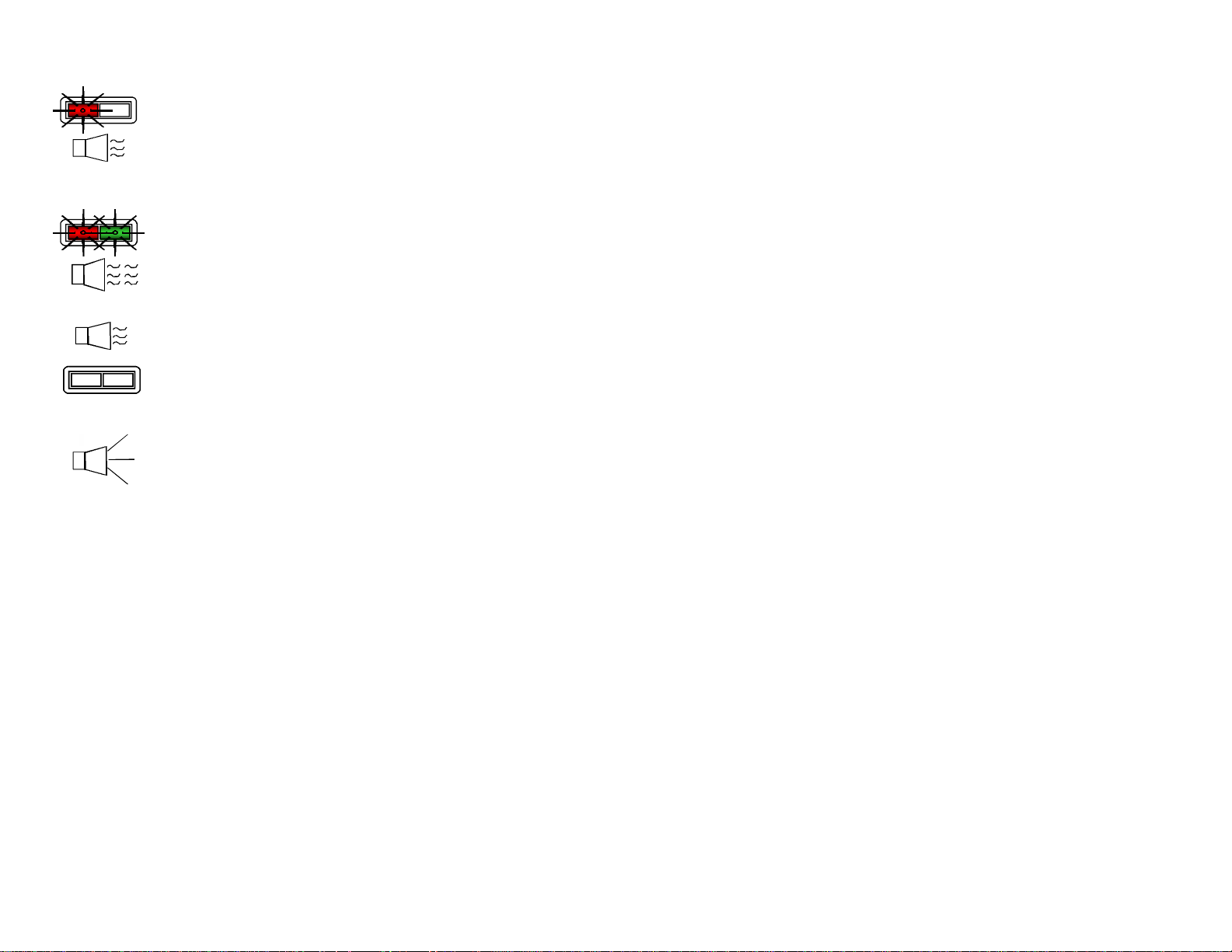

Page 14

Failure Modes

Flashing Red and One Razzberry Tone

Flashing Red and Green and Two Razzberry Tones

Continuous Razzberry Tone with both LEDs off

***

center.

This indicates the scanner has experienced a laser

subsystem failure. Return the unit for repair at an

authorized service center.

This indicates the scanner has experienced a motor failure.

Return the unit for repair at an authorized service center.

If, upon power up, the scanner emits a continuous razzberry tone, then the scanner has an electronic failure.

Return the unit for repair at an authorized service center.

Three Beeps - on power up

If the scanner beeps 3 times on power up then, the non

volatile memory which holds the scanner configuration has

failed. Return the unit for repair at an authorized service

11

Page 15

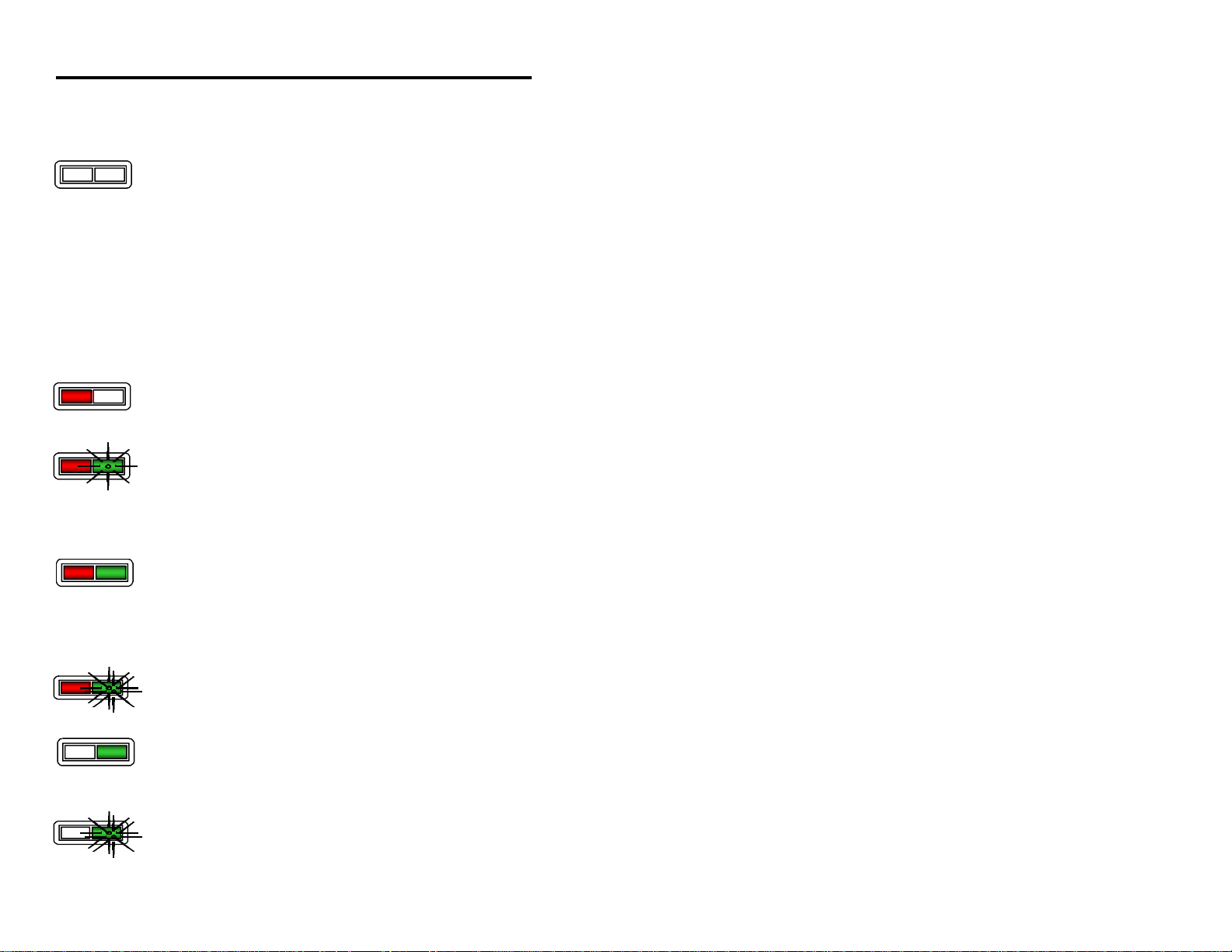

Visual Indicators

There are a red LED and a green LED on the scanner. When the scanner is on, the

flashing or stationary activity of the LEDs indicates the status of the scan and scan-ner.

No Red or Green LED

There are two reasons why the LEDs will not be illuminated:

1.) If the scanner is receiving power and the LEDs are not on, then

the scanner has been dormant for a specified time and the laser

has turned off. To reactivate the unit, pass an object through

the scan field.

2.) If the scanner is not receiving power from the host or transformer, then the LEDs will not be on.

Steady Red

When the laser is on, the red LED is also on. The red LED will

remain on until the scanning period has expired.

Steady Red and Single Green Flash

When the scanner successfully reads a bar code, the green LED

will flash then beep once. If the green LED does not flash or the

scanner does not beep once, then the bar code has not been successfully read.

12

Steady Red and Steady Green

After a successful scan, the scanner transmits the data to the host

device. If the host is not ready to accept the information, the scanner’s green LED will remain on until the data can be transmitted.

The red LED will turn off when the scanning period expires.

Steady Red and Flashing Green

This indicates the scanner is in program mode. A razzberry tone

indicates that an invalid bar code has been scanned in this mode.

Steady Green

This indicates the scanner may be waiting for communication from

the host.

Flashing Green

This indicates the scanner is waking up from a dormant state in

response to an IR sensor activation. Refer to page 18.

Page 16

Label

Each scanner has a label located on the bottom of the unit. This label contains

information such as the model number, date of manufacture,

serial number, and approvals. This label also notes that the device is a CDRH

Class IIa laser product. The following is an example of this label:

13

Page 17

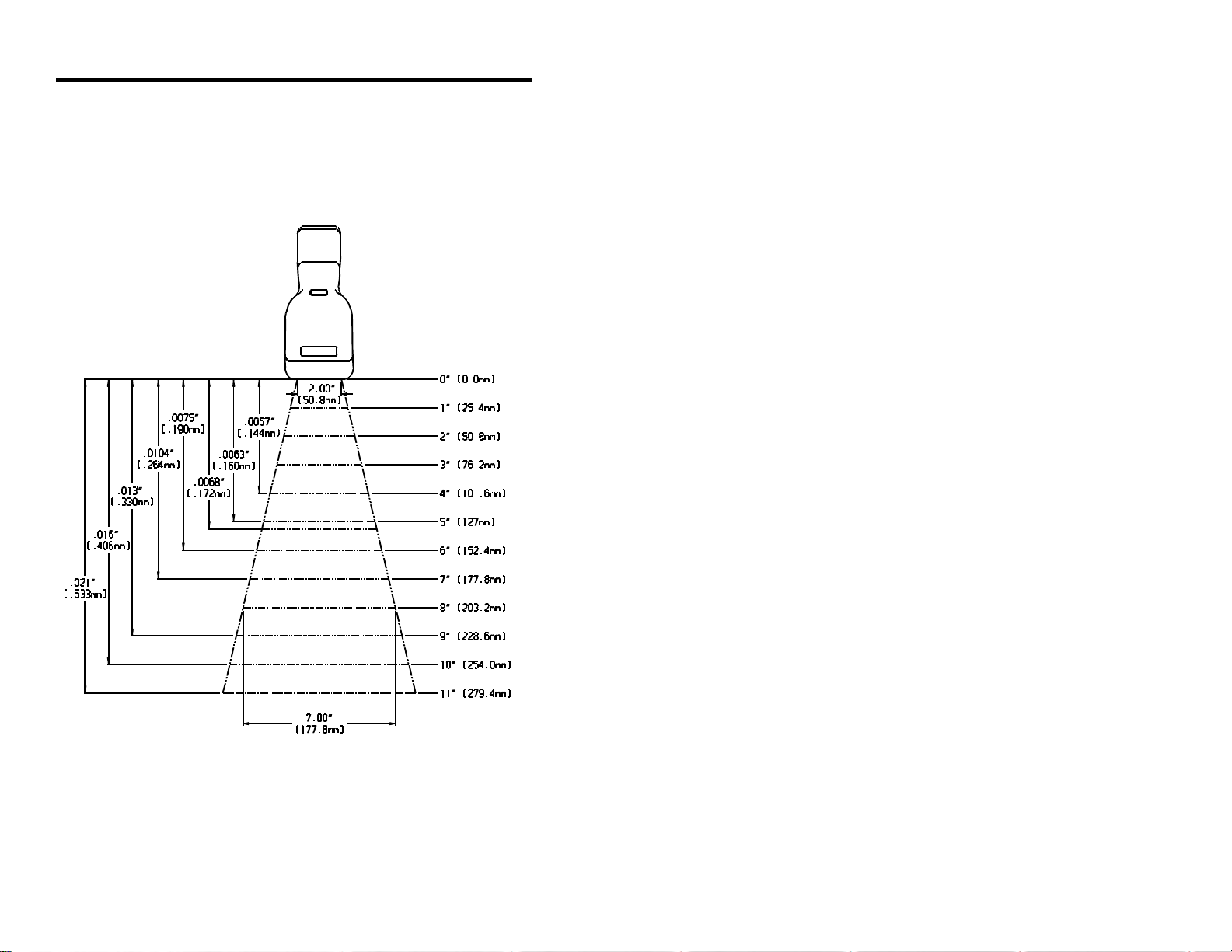

Depth of Field Specifications

Normal Depth of Field

14

Page 18

Short Depth of Field

15

Page 19

Extended Depth of Field

16

Page 20

Optional Depth of Field

17

Page 21

Automatic Turn-On Specifications (IR Sensor)

Normal Depth of Field

Short Depth of Field

Note: Depth of Field based on 13mil (.013") minimum element width,

Turn On Range is nominal; small variances do NOT indicate a

malfunction.

18

Page 22

Scan Pattern Specifics

Projection Axis

The scan pattern of the MS6720 exits straight out of the scanner. This feature

was purposefully designed to provide pointing efficiency in the

hand held mode and instinctive positioning in the fixed presentation mode.

Omnidirectional Scan Volume

Note: The above scan volume shows omnidirectional volume. This volume does not reflect

the entire length of all the laser lines. (Please refer to the Cross-Sectional Pattern in

this section, page 20).

19

Page 23

Cross-Sectional Scan Pattern

20

Page 24

Maintenance

Smudges and dirt can interfere with the proper scanning of a bar code.

Therefore, the output window will need occasional cleaning.

1. Spray glass cleaner onto lint free, non-abrasive cleaning cloth.

2. Gently wipe the scanner window.

21

Page 25

The following guide is for reference purposes only. Contact a Metrologic

representative at 1-800-ID-METRO or 1-800-436-3876 to preserve the

limited warranty terms. Pg. 37.

All Interfaces

MS6720 Troubleshooting Guide

SYMPTOMS POSSIBLE CAUSE(S) SOLUTION

No LEDS, beep No power at power up Check transformer, outlet and power

or motor spin strip

NOTE: If it’s a direct connect scanner, the problem could be inadequate power being supplied to

the scanner. It may be necessary to use a Metrologic transformer for power. Check the

fuse in the MCA.

3 beeps on Non-volatile RAM failure Contact a Metrologic Rep, if the unit

power up will not hold the programmed

configuration

Continuous razz RAM or ROM failure Contact a Metrologic Rep, if the unit

tone on power will not function

up

Razz tone and VLD failure Contact a Metrologic Rep

red LED flash at

power up

Razz tone and Scanner motor failure Contact a Metrologic Rep

both LEDs flash

at power up

Unit scans, Same symbol timeout set Adjust same symbol timeout for a

Communicates too short longer time

and beeps twice

22

Page 26

All Interfaces continued

SYMPTOMS POSSIBLE CAUSE(S) SOLUTION

Unit goes to IR sensor used to wake up Adjust scanner positioning so that the

sleep and does the scanner is always IR senses an object when a bar code

not wake up sensing an object is presented. For example; point to

the ceiling and then back to the

object.

Disable IR sleep mode

Unit scans bar wake up requires full Disable IR sleep mode

code too slowly motor spin up for operation

upon waking up

NOTE: Disabling the IR sleep mode allows the scanner to respond to bar codes quicker

23

Page 27

SYMPTOMS

The unit powers up properly, lasers come on, but the unit does not scan and does not

beep when a bar code is presented

POSSIBLE CAUSE(S)/SOLUTION(S)

Improper settings can be the cause for a scanner not to scan. The following would be

typical examples:

1. Scanning a particular symbology that is not enabled. (UPC/EAN, Code 39,

Interleaved 2 of 5, Code 93, Code 128 and Codabar are enabled by default.)

Verify that the type of bar code being read has been selected.

2. The scanner has been programmed for a character length lock, or a

minimum length and the bar code being scanned does not satisfy the

programmed criteria. Verify that the bar code that is being scanned falls

into the criteria. (Typical of Non-UPC/EAN codes.)

3. The scanner scans a bar code but the scanner locks up (green LED comes

on and stays on) after the first scan. The scanner is configured to support

some form of host handshaking but is not receiving the signal. If the scanner

is setup to support ACK/NAK, RTS/CTS, XON/XOFF or D/E, verify that the

host cable and host are supporting the handshaking properly.

4. The scanner scans and transmits but the data is not correct at the host.

Verify that the scanner’s data format matches that required by the host.

Make sure that the scanner is connected to the proper host port.

SYMPTOMS

Scanner beeps at some bar codes and NOT for others of the same bar code symbology

POSSIBLE CAUSE(S)/SOLUTION(S)

1. The print quality of the bar code is suspect.

2. The aspect ratio of the bar code is out of tolerance.

3. The bar code may have been printed incorrectly.

(check digit/character/or border problem.)

24

Page 28

Keyboard Wedge Only

SYMPTOMS POSSIBLE CAUSE(S) SOLUTION

Unit scans the Configuration is not correct Make sure the scanner is configured

bar code but for keyboard wedge mode - Section

there is no data F of the ScanSelect Guide (MLPN

2186)

Unit scans but Configuration is not correct Make sure that the proper PC type

data is not AT, PS2, XT is selected

correct

verify correct country code and data

formatting are selected

Adjust inter character delay

Unit is Configuration is not correct Increase the inter scan code delay

transmitting setting

each character

twice Adjust whether the F0 break is

transmitted. It may be necessary to

try this in both settings.

Alpha characters Computer is in Caps Lock Enable Caps Lock detect setting of

show as lower mode the scanner to detect whether PC is

case operating in Caps Lock

Everything These characters may not be Try operating the scanner in Alt

works except for supported by that country’s mode

a couple of key look up table

characters

25

Page 29

RS-232 only

SYMPTOMS POSSIBLE CAUSE(S) SOLUTION

Power-up OK Com port at the host not Check to make sure the baud rate

working or not configured and parity of the scanner and the

Scans OK properly communication port match and the

program is looking for “RS-232"

Does not Cable not connected to the data.

communicate proper com port

properly to the

host Com port not operating

properly

NOTE: Metrologic’s default of 7 data bits, space parity is usually what is expected when an IBM

compatible type PC is configured for 8 data bits, no parity.

SYMPTOMS SOLUTION

Host receiving data but data does not Check that the scanner and host are

look correct configured for the same interface format

Characters are being dropped Add some intercharacter delay to the

transmitted output. This can be programmed

into the scanner through ScanSelect

RS-232 Demonstration Program

If an RS-232 scanner is not communicating with your IBM compatible PC, key in the

following BASIC program to test that the communication port and scanner are working.

This program is for demonstration purposes only. It is only intended to prove that cabling

is correct, the comx port is working, and the scanner is working. If the bar code data

displays on the screen while using this program, it only demon-strates that the hardware

interface and scanner are working. At this point, investigate whether the application

software and the scanner configuration match. If the applica-tion does not support RS232 scanners, a software wedge program that will take RS-232 data and place it into a

keyboard buffer may be needed. This program tells the PC to ignore RTS-CTS, Data Set

Ready (DSR) and Data Carrier Detect (DCD) signals. If the demostration program works

and yours still does not, jumper RTS to CTS and Data Terminal Reading (DTR) to DCD

and DSR on the back of your PC.

10 CLS

20 ON ERROR GOTO 100

30 OPEN “COM1:9600,S,7,1,CS0,DS0,CD0,LF” AS #1

35 PRINT “SCAN A FEW BAR CODES”

40 LINE INPUT #1, BARCODE$

50 PRINT BARCODE$

60 K$ = INKEY$: IF K$ = CHR$(27) THEN GOTO 32766

70 GOTO 40

100 PRINT “ERROR NO.”; ERR; “ PRESS ANY KEY TO TERMINATE.”

110 K$ = INKEY$: IF K$ = “” THAN GOTO 110

32766 CLOSE: SYSTEM

32767 END

26

Page 30

Applications and Protocols

The model number on each scanner includes the scanner number and

communications protocol.

Scanner Version Identifier Communication Protocol(s)

6720 9 OCIA (OCIA)

6720 11 IBM (46XX)

6720 14 RS-232 (232)

6720 15 Light Pen Emulation (LTPN)

6720 47 Keyboard Wedge (KBW)

The MS6720 Hand-Held Laser Scanner with Built-in PC Keyboard

Wedge Interface is designed to be used for keyboard emulation only. However,

many RS-232 programmable functions that are available

in other Metrologic scanners are also available as keyboard wedge functions.

The most important selectable options specific to the keyboard wedge are the following:

Keyboard Type

! ** AT (includes IBM PS2 models 50, 55, 60, 80)

®

! XT

! IBM PS2 (includes models 30, 70, 8556)

Keyboard Country Type

! ** USA ! United Kingdom

! French ! German

! Italian ! Spanish

! Belgium ! Swiss

**Default setting. Refer to Appendix B pages 30 - 33 for default settings.

Refer to ScanSelect Scanner Programming Guide (MLPN 2186) for

information on how to change the default settings.

27

Page 31

Appendix A

Design Specifications

Application: Fixed Projection/Hand-Held Laser Bar Code

Scanner

Max. Radiant Power: 0.681 Milliwatts (PEAK)

Light Source: VLD 675 ± 5nm

CDRH: Class IIa laser product

CE: EN 60950: 1993, EN 60825-1:1994/A11:1996,

Laser Class 1, EN 55022:1987 Class A, EN

55082-1:1992, IEC 801-2:1991 8kVAD, IEC

100-4-3:1995 3V/m IEC 801-4:1988 1kV Power

Lines

EMI: FCC Class A

Mechanical

Dimensions: 110mm L x 75mm W x 160mm H

Weight: 450 grams

Termination: ~ 1 meter retracted coil cable

Electrical

Input Voltage: 5VDC ± .25V

Power : 1.1 watt

Operating Current : 225 mA typical @5VDC (468x - 300mA)

Standby Current: 74 mils (468x - 165mils)

DC Transformers: Class 2; 5VDC @300mA

28

Page 32

Operational

Depth of Field: 0" - 4"; 0"- 8" (programmable)

0 - 101.6mm; 0 - 203.2mm

Scan Speed: 1000 scan lines per second

Scan Pattern: 5 fields of 4 parallel lines

Scan Lines: 20

Min Bar Width: 5.2 mil

Indicators (LED): red = laser on, ready to scan

green = good read, decoding

Beeper Operation: 3 tones or no beep

Maintenance: Clean output window periodically

Decode Capability: Autodiscriminates all standard bar codes;

for other symbologies call Metrologic

System Interfaces: Keyboard Wedge, RS-232, OCIA, Light Pen, IBM

46xx

Print Contrast: 35% minimum reflectance difference

Roll, Pitch, Yaw: 360E, 60E, 60E

Environmental

Storage Temperature: -40EC to 60EC (-40EF to 140EF)

Operating Temperature: 0EC to 35EC (32EF to 95EF)

Humidity: 5% to 95% relative humidity, non-condensing

Light Levels: Up to 300 LUX

Ventilation: None required

Shock: 1m. (40") drop

Contaminants: Sealed to resist airborne particulate contaminants

This Metrologic product may be covered by one or more of the following U.S.

patents:

5, 073,702, 5,115,333, 5, 216,232, 5,484,992, 5,525,789, 5,557,093,

5,591,953, 5,616,908.

Specifications subject to change without notice.

29

Page 33

Appendix B

Default Settings

Many functions of the scanner can be "programmed" - that is, enabled or

disabled. The scanner is shipped from the factory programmed to a set of

default conditions. The default parameter of the scanner has an asterisk ( * ) in

the charts on the following pages. If an asterisk is not in the default column

then the default setting is Off or Disabled. Every communication does not

support every parameter. If the communication supports a para-meter listed in

the charts on the following pages, a check mark will appear.

Parameter Default OCIA RS-232* Ligh IBM KBW

UPC/EAN * T T T T T

Code 128 * T T T T T

Code 93 * T T T T T

Codabar * T T T T T

Interleaved 2 of 5 (ITF) * T T T T T

MOD 10 Check on ITF T T T T T

Code 11 T T T T T

Code 39 * T T T T T

Full ASCII Code 39 T T T T T

MOD 43 Check on Code 39 T T T T T

MSI-Plessey T T T T T

MSI-Plessey 10/10 Check Digit T T T T T

MSI-Plessey MOD 10 Check * T T T T T

Digit

MECCA T T T T T

Paraf Support T T T T T

ITF Symbol Lengths Variable T T T T T

Minimum Symbol Length 04 T T T T T

Symbol Length Lock None T T T T T

Bars High as Code 39 * T

Spaces High as Code 39 T

t Pen 46XX

Bars High as Scanned T

Spaces High as Scanned T

DTS/SIEMENS T

30

Page 34

Parameter Default OCIA RS-232* Ligh IBM KBW

DTS/NIXDORF * T

NCR F T

NCR S T

Poll Light Pen Source T

Beeper Tone Normal T T T T T

Beep/Transmit Sequence Before T T T T T

Communication Timeout None T T T T T

Razzberry Tone on Timeout T T T T T

Three Beeps on Timeout T T T T T

No Beeps on Timeout * T T T T T

IR Timeout 10 Min. T T T T T

Same Symbol Rescan T T T T T

Timeout: 200 msecs

Same Symbol Rescan * T T T T T

Timeout: 500 msecs

Same Symbol Rescan T T T T T

Timeout: 1250 msecs

Same Symbol Rescan T T T T T

Timeout: 2000 msecs

Intercharacter Delay 1 msecs T T T T

Scan Buffer 1 of 2 1 T T T T T

Transmit UPC-A Check Digit * T T T T T

Transmit UPC-E Check Digit T T T T T

Expand UPC-E T T T T T

Convert UPC-A to T T T T

EAN-13

Transmit Lead Zero on UPC-E T T T T T

Convert EAN-8 to EAN-13 T T T T

Transmit UPC-A Number * T T T T T

System

Transmit Codabar T T T T

Start/Stop Characters

CLSI Editing (Enable) T T T T

Transmit

t Pen 46XX

Transmit Mod 43 Check Digit T T T T

on Code 39

Transmit Code 39 T T T T

Stop/Start Characters

31

Page 35

Parameter Default OCIA RS-232* Ligh IBM KBW

Transmit Mod 10/ITF T T T T

Transmit MSI-Plessey Check T T T T

Characters

Parity Space T

Baud Rate 9600 T

8 Data Bits T

7 Data Bits * T

Transmit Sanyo ID Characters T T

Nixdorf ID T T

Shell Schulmberger T T

Formatting

UPC Prefix T T

UPC Suffix T T

Transmit AIM ID Characters T T

STX Prefix T T

ETX Suffix T T

Carriage Return * T T

Line Feed * T T

Tab Prefix T T

Tab Suffix T T

"DE" Disable Command T

t Pen 46XX

"FL" Laser Enable Command T

DTR Handshaking Support T

RTS/CTS Handshaking T

Character RTS/CTS * T

Message RTS/CTS T

XON/XOFF Handshaking T

ACK/NAK T

Two Digit Supplements T T as T T

Five Digit Supplements T T as T T

Bookland T T as T T

code

39

code

39

code

39

32

Page 36

Parameter Default OCIA RS-232* Ligh IBM KBW

977 (2 digit) Supplemental T T T T T

Requirement

Supplements are not Required * T T T T T

Two Digit Redundancy * T T T T T

Five Digit Redundancy T T T T T

200 msec to Find Supplement T T T T T

100 msec to Find Supplement * T T T T T

t Pen 46XX

Coupon Code 128 T T as T T

code

39

33

Page 37

Appendix C

Pin Assignments

Cable Pin Assignments for the Coil Cable

The MS6720 scanners are terminated to a 10 position shielded modular

connector. All of the coil cables (MLPN 44530) for the MS6720 scanner are

terminated the same. The difference between versions is the end of the cable

going into the scanner. This connector plugs into different “J” positions on

various computer/interface boards. Since each computer/interface board is

different, the output signals are different.

Version “9” (OCIA) Version “11” (46XX)

Pin Function Pin Function

1 Power/Signal Ground 1 Power/Signal Ground

2 RDATA 2 RS-232 Transmit Output

3 RDATA Return 3 RS-232 Receive Input

4 Clock In 4 RTS Output

5 Clock In Return 5 CTS Input

6 Clock Out 6 IBM 46XX Transmit

7 Clock Out Return 7 IBM 46XX Receive

8 No Connection 8 No Connection

9 +5 VDC Power to Scanner 9 +5 VDC Power to Scanner

10 OCIA Shield Ground 10 Shield Ground

Version “14” (232) Version “15” (LTPN)

PinFunction Pin Function

1 Power/Signal Ground 1 Power/Signal Ground

2 RS-232 Transmit Output 2 RS-232 Transmit Output

3 RS-232 Receive Input 3 RS-232 Receive Input

4 RTS Output 4 RTS Output

5 CTS Input 5 CTS Input

6 DTR Input 6 Light Pen Source +5V

7 DSR Output 7 Light Pen Data

8 No Connection 8 No Connection

9 +5 VDC Power to Scanner 9 +5 VDC Power to Scanner

10 Shield Ground 10 Shield Ground

34

Page 38

Pin Assignments for the MCA951 (DEC9S)

Located on the MCA is a 9-pin female D-type connector used to connect the

MCA to the host device. The output signals on the 9-pin host end of the MCA

are dependent upon which version of the scanner that is being used. The

following is a list of the pin assignments for the different versions:

Version “9” (OCIA) Version “11” (46XX)

Pin Function Pin Function

1 OCIA Shield Ground 1 Shield Ground

2 RDATA 2 RS-232 Transmit Output

3 RDATA Return 3 RS-232 Receiver Input

4 Clock Out 4 IBM 4680 -B

5 Power/Signal Ground 5 Power/Signal Ground

6 Clock Out Return 6 IBM 4680 +A

7 Clock In Return 7 Clear to Send Input

8 Clock In 8 Request to Send Output

*9 +5VDC Power to Scanner *9 +5VDC Power to Scanner

Version “14” (232) Version “15” (LTPN)

Pin Function PinFunction

1 Shield Ground 1 Shield Ground

2 RS-232 Transmit Output 2 RS-232 Transmit Output

3 RS-232 Receiver Input 3 RS-232 Receive Input

4 Data Terminal Ready Input 4 Light Pen Source (+5V Input)

5 Power/Signal Ground 5 Power/Signal Ground

6 Data Set Ready Output 6 Light Pen Data (Output)

7 Clear to Send Input 7 Clear to Send (Input)

8 Request to Send Output 8 Request to Send (Output)

9 +5VDC Power to Scanner *9 +5VDC Power to Scanner

*When the host supplies power to the scanner, this is the pin assignment for

the +5VDC for the scanner. If, in the application, the host device will supply

the power necessary for the scanner, reposition an internal jumper within the

MCA and plug the 4 position ground jumper to the power supply connector for

FCC and ESD purposes. (Refer to Scanner Installation: Powered by

External Power Supply page 5).

35

Page 39

Pin Assignments for the 5-pin DIN and 6-pin mini-DIN MS6720 HandHeld Laser Scanner with Built-in PC Keyboard Wedge Interface

The coil cable is terminated with a 5-pin DIN female connector on one end,

and a 6-pin mini DIN male on the other. Metrologic will supply an adaptor

cable with a 5-pin DIN male connector on one end and a 6-pin mini DIN

female connector on the other.

Coil Cable Connectors

5-pin Female 6-pin Male

Adaptor Cable Connectors

6-pin Female 5-pin Male

According to the termination required, connect the appropriate end of the

adaptor cable to the coil cable, leaving the necessary termination exposed for

connecting to the keyboard and the keyboard port on the PC. The pin

assignments are as follows:

5-pin Female DIN 6-pin Female mini-DIN

Pin Function Pin Function

1 Keyboard Clock 1 Keyboard Data

2 Keyboard Data 2 No Connect

3 No Connect 3 Power Ground

4 Power Ground 4 +5 Volts DC

5 +5 Volts DC 5 Keyboard Clock

6 No Connect

5-pin Male DIN 6-pin Male mini-DIN

Pin Function Pin Function

1 PC Clock 1 PC Data

2 PC Data 2 No Connect

3 No Connect 3 Power Ground

4 Power Ground 4 +5 Volts DC

5 +5 Volts DC 5 PC Clock

6 No Connect

36

Page 40

Appendix D

Warranty and Disclaimer

Limited Warranty

Products manufactured by Metrologic have a 2-year limited warranty from

date of manufacture.

In the event that it is determined that the equipment failure is covered under the

warranty, Metrologic shall, as its sole option, repair, replace with a functionally

equivalent unit, or refund an amount equal to the purchase price to the original

purchaser, whether distributor, dealer/reseller, or retail consumer, and return the

equipment to the customer without charge for service or return freight.

This limited warranty does not extend to any Product which, in the sole judge-ment

of Metrologic, has been subjected to misuse, neglect, improper installation or

accident, nor does it extend to any Product which has been repaired or altered by

anyone who is not a Metrologic authorized representative.

THIS LIMITED WARRANTY, EXCEPT AS TO TITLE, IS IN LIEU OF ALL OTHER

WARRANTIES, EXPRESS OR IMPLIED, INCLUDING MERCHANTABILITY OR

FITNESS FOR ANY PARTICULAR PURPOSE, ARISING BY LAW, CUSTOM OR

CONDUCT. THE RIGHTS AND REMEDIES PROVIDED HEREIN ARE EXCLUSIVE

AND IN LIEU OF ANY OTHER RIGHTS OR REMEDIES. IN NO EVENT SHALL

METROLOGIC BE LIABLE FOR INDIRECT, INCIDENTAL, OR CONSEQUENTIAL

DAMAGES, INCLUDING, WITHOUT LIMITATION, ANY INJURY TO PROPERTY

OR PERSON OR EFFECT ON BUSINESS OR PROFIT, AND IN NO EVENT SHALL

ANY LIABILITY OF METROLOGIC EXCEED THE ACTUAL AMOUNT PAID TO

METROLOGIC FOR THE PRODUCT.

37

Page 41

Disclaimer

Metrologic Instruments, Inc. and the author or authors make no claims or warranties with respect

to the contents or accuracy of this publication, or the product it describes, including any warranties

of fitness or merchantability for a particular purpose. Any stated or expressed warranties are in

lieu of all obligations or liability for any damages, whether special, indirect, or consequential,

arising out of or in connection with the use of this publication or the product it describes.

Furthermore, the right is reserved to make any changes to this publication without obligation to

notify any person of such changes. Metrologic also reserves the right to make any changes to the

product described herein.

Exclusion des responsabilités

Metrologic Instruments, Inc. et le/les auteur(s) ne sont ni garants, ni responsables pour l'exhaustivité et la correction des informations contenues dans cette brochure - que ce soit relativement à leur teneur et à l' exactitude - ou pour le produit qui y est décrit. Ils ne sont en outre

responsables d'aucune garantie de propriété ou de qualité pour un usage particulier. Toutes les

assurances nommées ou exprimées excluent toute garantie ou responsabilité pour les dommages

spéciaux, indirects ou des suites de l'utilisation de cette brochure ou du produit qui y est décrit

respectivement. en rapport avec l'emploi de cette brochure et du produit qui y est décrit. Il leur est

également réservé le droit de procéder à des modifications de cette brochure sans avoir à en avertir

qui que ce soit. Metrologic se réserve en outre le droit de procéder à des modifications du produit

qui y est décrit.

Haftungsausschluß

Metrologic Instruments, Inc. und der/die Autor(en) übernehmen keinerlei Gewähr und haften nicht

für die Richtigkeit im Hinblick auf Inhalt oder Genauigkeit der Angaben dieser Veröffentlichung

oder des hierin beschriebenen Produkts. Sie übernehmen ebenso keinerlei Eignungsgarantie oder

Gewährleistung durchschnittlicher Qualität für einen bestimmten Zweck. Alle benannten oder

ausdrücklichen Zusicherungen schließen sämtliche Verpflichtungen oder Haftungen aus jeglichem

Schaden aus, ganz gleich ob speziell, indirekt oder als Folge der Verwendung dieser

Veröffentlichung oder des hierin beschriebenen Produkts bzw. in Zusammenhang mit der

Verwendung dieser Veröffentlichung oder des hierin beschriebenen Produkts. Darüber hinaus wird

das Recht vorbehalten, Änderungen an dieser Veröffentlichung vorzunehmen ohne die

Verpflichtung, irgend jemanden über solche Änderungen zu unterrichten. Metrologic behält sich

ferner das Recht vor, Änderungen an dem hierin beschriebenen Produkt vorzunehmen.

Esclusione della responsabilità

La Metrologic Instruments, Inc. e l’autore/gli autori non assumono nessuna garanzia e non

rispondono della correttezza per quanto riguarda il contenuto o la precisione di quanto indicato nel

presente Manuale o del prodotto in esso descritto. Neppure essi assumono una garanzia per

l’idoneità o una garanzia della qualità media per un determinato scopo. Tutte le garanzie citate o

fatte espressamente escludono qualsiasi obbligo o responsabilità derivanti da qualsiasi danno,

indipendentemente dal fatto che questo obbligo/questa responsabilità risulti in particolare, indirettamente o come conseguenza dall’uso del presente Manuale o del prodotto in esso descritto

oppure se è legato/a all’uso del presente Manuale o del prodotto in esso descritto. Inoltre ci si

riserva il diritto di modificare il presente Manuale senza essere obbligati ad informare persona

alcuna circa dette modifiche. Metrologic si riserva il diritto di apportare modifiche al prodotto

descritto nel presente Manuale.

38

Page 42

Appendix E

Notices

Notice

This equipment has been tested and found to comply with limits for a Class A digital device,

pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection

against harmful interference when the equipment is operated in a commercial environment. This

equipment generates, uses and can radiate radio frequency energy and, if not installed and used in

accordance with the instruction manual, may cause harmful interference to radio communications.

Operation of this equipment in a residential area is likely to cause harmful interference, in which

case the user will be required to correct the interference at his own expense. Any unauthorized

changes or modifications to this equipment could void the users authority to operate this device.

Notice

This digital apparatus does not exceed the Class A limits for radio noise emissions from digital

apparatus set out in the Radio Interference Regulations of the Industry and Canada.

Caution

Use of controls or adjustments or performance of procedures other than those specified herein may

result in hazardous laser light. Under no circumstances should the customer attempt to service the

laser scanner. Never attempt to look at the laser beam, even if the scanner appears to be

nonfunctional. Never open the scanner in an attempt to look into the device. Doing so could result

in hazardous laser light exposure. The use of optical instruments with the laser equipment will

increase eye hazard.

Remarque

Après contrôle de cet appareil, on a noté qu'il répondait aux valeurs limites de la classe A, conformément à la partie 15 des directives de l'administration fédérale américaine pour les télécommunications. Ces valeurs limites ont été prévues pour garantir une protection suffisante

contre les effets nocifs dus à l'emploi de l'appareil dans un magasin. L'appareil génère et utilise une

énergie haute fréquence et peut, s'il n'est pas installé et utilisé conformément aux instructions

mentionnées dans le guide d'utilisation, entraîner des perturbations dans la radiocommunications.

L'utilisation de cet appareil dans une zone d'habitation entraînera très vraisemblablement des

perturbations. Dans ce cas, l'utilisateur est tenu de remédier à ces perturbations à ses propres frais.

Toute modification ou remplacement non autorisé sur cet appareil peut entraîner l'invalidité de

l'autorisation d'utilisation de l'appareil.

Remarque

Cet appareil numérique ne va pas contre les valeurs limites pour émissions de bruits radios des

appareils numérique de la classe A, conformément aux directives relatives aux perturbations des

radiocommunications du ministère canadien pour l'industrie.

Attention

L'emploi de commandes, réglages ou procédés autres que ceux décrits ici peut entraîner de graves

irradiations. Le client ne doit en aucun cas essayer d'entretenir lui-même le scanner ou le laser. Ne

regardez jamais directement le rayon laser, même si vous croyez que le scanner est inactif.

N'ouvrez jamais le scanner pour regarder dans l'appareil. Ce faisant, vous vous exposez à une

rayonnement laser mortel. L'emploi d'appareils optiques avec cet équipement laser augmente le

risque d'endommagement de la vision.

39

Page 43

Anmerkung

Nach Überprüfung dieses Geräts wurde festgestellt, daß es den Grenzwerten für Digitalgeräte der

Klasse A gemäß Teil 15 der Richtlinien der US-amerikanischen Bundesbehörde für das

Fernmeldewesen entspricht. Diese Grenzwerte wurden festgelegt, um einen angemessenen Schutz

gegen schädliche Auswirkungen bei Einsatz des Geräts in einer Ladenumgebung zu gewähren.

Das Gerät erzeugt und verwendet Hochfrequenzenergie und kann diese ausstrahlen, und kann,

falls es nicht gemäß den im Bedienerhandbuch enthaltenen Anweisungen installiert und verwendet

wird, zu einer Störung des Funkverkehrs führen. Der Betrieb dieses Geräts in einem Wohngebiet

führt höchstwahrscheinlich zu Störungen. In diesem Fall ist der Bediener verpflichtet, die Störung

auf eigene Kosten zu beseitigen. Durch jegliche unerlaubte Auswechselung oder Änderung an

diesem Gerät könnte die Genehmigung des Bedieners zur Verwendung dieses Geräts ungültig

werden.

Anmerkung

Dieses Digitalgerät verstößt nicht gegen die Grenzwerte für Funkrauschemissionen von

Digitalgeräten der Klasse A gemäß den Richtlinien für Funkstörungen des kanadischen

Ministeriums für Industrie.

Achtung

Die Verwendung anderer als der hierin beschriebenen Steuerungen, Einstellungen oder Verfahren

kann eine lebensgefährliche Laserstrahlung hervorrufen. Der Kunde sollte unter keinen

Umständen versuchen, den Laser-Scanner selbst zu warten. Sehen Sie niemals in den Laserstrahl,

selbst wenn Sie glauben, daß der Scanner nicht aktiv ist. Öffnen Sie niemals den Scanner, um in

das Gerät hineinzusehen. Wenn Sie dies tun, können Sie sich einer lebensgefährlichen

Laserstrahlung aussetzen. Der Einsatz optischer Geräte mit dieser Laserausrüstung erhöht das

Risiko einer Sehschädigung.

N.B.

Dal controllo di questo apparecchio risulta che esso risponde ai valori limite per apparecchi

digitali della classe A conf. parte 15 delle direttive sulle telecomunicazioni dell’Autorità federale

statunitense. Questi valori limite sono stati fissati per garantire una protezione adeguata contro gli

effetti nocivi se questo apparecchio viene usato all’intero di un negozio. L’apparecchio genera,

utilizza e può emettere energia ad alta frequenza e, se non viene installato ed utilizzato

conformemente alle indicazioni fornite nel Manuale utente, può provocare disturbi al servizio

radiofonico. L’uso di questo apparecchio in zone residenziali causa molto probabilmente dei

disturbi. In questo caso l’utente è obbligato ad eliminare questi disturbi a sue spese. Qualsiasi

sostituzione o modifica non autorizzata all’apparecchio potrebbe rendere invalida l’autorizzazione

dell’utente all’uso dell’apparecchio.

N.B.

Questo apparecchio digitale non supera I valori limite per l’emissione di radiorumori da parte di

apparecchi digitali della classe A conformemente alle direttive per radiodisturbi del Ministero

canadese per l’Industria.

Attenzione

L’utilizzo di sistemi di controllo, di regolazioni o di procedimenti diversi da quelli decritti nel

presente Manuale può provocare dei raggi laser pericolosi per la vita. Il cliente non deve

assolutamente tentare di riparare egli stesso lo scanner laser. Non guardate mai nel raggio laser,

anche se credete che lo scanner non sia attivo. Non aprite mai lo scanner per guardare dentro

l’apparecchio. Se tuttavia lo fate, potete esporVi a dei raggi laser pericolosi per la vita. L’uso di

apparecchi ottici con questo equipaggiamento laser aumenta il rischio di danni alla vista.

40

Page 44

Appendix F

Patents

“Patent Information

This METROLOGIC product may be covered by one or more of the following

U.S. Patents:

U.S. Patent No. 4,360,798; 4,369,361; 4,387,297; 4,460,120; 4,496,831;

4,593,186; 4,607,156; 4,673,805; 4,736,095; 4,758,717; 4,816,660;

4,845,350; 4,896,026; 4,923,281; 4,933,538; 4,992,717; 5,015,833;

5,017,765; 5,059,779; 5,117,098; 5,124,539; 5,130,520; 5,132,525;

5,140,144; 5,149,950; 5,180,904; 5,200,599; 5,229,591; 5,247,162;

5,250,790; 5,250,791; 5,250,792; 5,262,628; 5,280,162; 5,280,164;

5,304,788; 5,321,246; 5,324,924; 5,396,053; 5,396,055; 5,408,081;

5,410,139; 5,436,440; 5,449,891; 5,468,949; 5,479,000; 5,532,469;

5,545,889, 5,216,232; 1,268,257; 5,484,992; 5,468,951; 5,340,971;

5,424,525; 4,960,985

No license right or sublicense is granted, either expressly or by implication,

estoppel, or otherwise, under any METROLOGIC or third party intellectual

property rights (whether or not such third party rights are licensed to

METROLOGIC), including any third party patent listed above, except for an

implied license only for the normal intended use of the specific equipment,

circuits, and devices represented by or contained in the METROLOGIC

products that are physically transferred to the user, and only to the extent of

METROLOGIC’s license rights and subject to any conditions, covenants and

restrictions therein.”

41

Page 45

Index

A

Accessories 2

AC input/outlet 2, 4, 5, 7

Adaptor

cable 2, 7, 36

5M 6F 7

MCA 2, 4-6

Application 2, 27, 28, 35 DC transformer 28

Approvals 13 Decode capability 29

Assignments Default Settings 30-33

pin 34-36 Depth of field 14-18, 29

Audible indicators 10 Design specifications 28, 29

Authorized service center 37 Dimensions 28

Autodiscriminates 29 Disclaimer 38

Automatic turn-on specifications

Normal DOF 18

Short DOF 18

Axis

projection 19

B

Bar code 3, 10, 12, 21,

23-26, 29

Bar width 29

Beep(s) 3-5, 10-12, 22, 24, 29,

31

Beeper operation 29

Built-in PC keyboard wedge

interface 4, 7, 27, 36

C

Cable

adaptor 2, 4, 7, 36

coil 4-7, 28, 34, 36

communication 5, 6

pin assignments 34-36

Caution 39

CDRH 28

CE 28

Characteristics 9-13

Compliance 5, 7

Configuration procedures 5-7

Connector(s) 2, 4-7, 34-36

Cross sectional scan pattern

20

Current 7, 28

Customer service 37

D

E

Electrical 28

EMI 28

Extended DOF 16

External power supply 4, 5,

7, 35

F

Failure indicator(s) 10, 11

Failure modes 10, 11

Female connector 2, 7, 36

Function(s) 27, 30-36

G

Green LED 2, 5, 10-12, 24,

29

Ground 34-36

Ground jumper 2, 6, 35

H

Host 2-6, 12, 24, 26, 35

I

Indicators

Audible 10

Visual 12

LED 3-5, 10-12, 22, 24, 29

Input voltage 28

42

Page 46

Installation 5-7 P

Interfaces 22, 24, 29

Parts 9

Patents 41

J PC 4-7, 27, 36

J positions 34

JP1 6

Jumper 2, 6, 35

Pin assignments 34-36

Port 5-7, 24, 26, 36

Powered by 5, 6

Power supply 4-7, 35

K

Keyboard Type(s) 27

Keyboard Wedge (KBW) 2-4, 7,

25-27, 29, 36

Programming guide 2, 3,

27

Projection axis 19

Protocols 27

L

Label 13

LEDs 3-5, 10-12, 22, 24, 29

Light levels 29

Light source 28

List 2

LTPN 27, 34, 35

M

Maintenance 21, 29

Manufacturer’s recommendation

7

MCA 2, 4-6, 22, 35

Mechanical 28

Min bar width 29

N

Normal depth of field 14, 18

Notices 39, 40

O

OCIA 2-4, 27, 29-35

Omindirectional scan volume

19

Operating current 28

Operating temperature 29

Operation 4-7

Operational 29

Operational test 4

Optional depth of field 17

Output 34, 35

Output window 21, 29

Q

Quick start 3

R

Razzberry tone 10-12, 31

RDATA 34, 35

Recommendation 7

Red led 3-5, 10, 12, 22

Repair 22, 37

Rights

property 41

warranty 37

RMA 37

Roll, pitch, yaw 29

RS-232 2-4, 26, 27, 29-35

S

Scan lines 29

Scan pattern(s) 19, 20, 29

Scan speed 29

Scan volume 19

Scanner installation 5-7

ScanSelect manual 2, 3,

25-27

SELV 5, 7

Service 37

Shock 29

Specifications 14-20, 28, 29

Stand 2, 8

Storage temperature 29

43

Page 47

System interfaces 29

T

Termination 34-36

Test 4

Transformers 28

Troubleshooting 22-26

Tones 10-12, 29

Turn-on specifications 18

V

Ventilation 29

Version 27, 34, 35

Visual indicators 12

Voltage 4, 5, 7, 28

W

Warranty 22, 37

Watt 28

Weight 28

Window 21

44

Loading...

Loading...