Page 1

METROLOGIC INSTRUMENTS, INC.

MS2xxx Stratos® Series

Configuration Addendum

Page 2

Copyright

© 2008 by Metrologic Instruments, Inc. All rights reserved. No part of this

work may be reproduced, transmitted, or stored in any form or by any means

without prior written consent, except by reviewer, who may quote brief

passages in a review, or provided for in the Copyright Act of 1976.

Trademarks

Metrologic is a registered trademark of Metrologic Instruments, Inc.

Products identified in this document are hereby acknowledged as

trademarks, registered or otherwise, of Metrologic Instruments, Inc. or their

respective companies.

Page 3

TABLE OF CONTENTS

Important Notes - Before You Start ...................................................................... 1

Scale Program Mode............................................................................................ 2

Scale/Load Cell Configuration Bar Codes

Single or Dual Cable Scale Configuration Bar Codes

Unit Configuration (Pounds or Kilograms).............................................. 5

Pole Display Configuration..................................................................... 6

Scale Settling Filter Configuration .......................................................... 7

Scroll Weight Configuration.................................................................... 9

Dual Cable Scale Configuration Bar Codes

Price Computing Configuration ............................................................ 10

Scale Protocols .................................................................................... 11

Scale COM Port Settings (Baud Rate) ................................................. 14

Scale COM Port Settings (Data Bits & Parity)...................................... 16

Single Cable Scale Configuration Bar Codes

Set Scale for Single Cable Communication ......................................... 19

Scanner Configuration Bar Codes

Dual Cable Scanner Configuration Bar Codes

Dual Cable Scanner Mode ................................................................... 20

Dual Cable Scanner OPOS Mode........................................................ 20

Various Dual Cable Scanner Mode ...................................................... 21

IBM 3rd Generation 46xx ...................................................................... 22

IBM OEM Full Speed USB ................................................................... 22

Single Cable Scanner Protocols for P.O.S. Compatibility

MSS Global.......................................................................................... 23

ISS45 ................................................................................................... 24

OPOS................................................................................................... 25

Retailix / NCR....................................................................................... 26

Retailix / OPOS.................................................................................... 27

IT Retail................................................................................................ 28

ii

Page 4

TABLE OF CONTENTS

IBM Self Checkout System .................................................................. 29

Various RS232 Single Cable Codes .................................................... 30

IBM 3rd Generation 46xx ...................................................................... 31

IBM OEM Full Speed USB ................................................................... 32

Additional POS Data Formatting

Full Speed USB Table Top/Handheld .................................................. 33

Special Function ACK .......................................................................... 35

Prefix/Suffix.......................................................................................... 36

3x-30 Acknowledge Responses ........................................................... 37

Special Function Command Responses .............................................. 38

BCC in POS communications .............................................................. 42

3 Scale Status Bytes ............................................................................ 43

Scale Options....................................................................................... 44

Remote Display.................................................................................... 45

StratosSTATS ...................................................................................... 46

Additional POS Related Functions

Scanner Beep on Weight Sent............................................................. 49

Restrict In-Store Codes........................................................................ 50

Scale Shadow Mode ............................................................................ 51

Scanner Razz on Not-On-File .............................................................. 52

Additional Scanner Configuration Bar Codes

Horizontal Depth of Field...................................................................... 53

Vertical Depth of Field.......................................................................... 55

Auxiliary Port

Stratos School...................................................................................... 57

Quick Start for a Secondary Metrologic Scanner ................................. 58

EAS Bar Codes

EAS Device Types ............................................................................... 60

EAS Timeout ........................................................................................ 63

EAS Connection................................................................................... 68

iii

Page 5

TABLE OF CONTENTS

Continuous Mode ................................................................................. 71

EAS Deactivation ................................................................................. 72

Sensormatic ScanMax Pro................................................................... 75

Scanner Test Bar Codes

Supplemental Tests..................................................................................... 77

Display Software Numbers................................................................... 77

Contact Information and Office Locations........................................................... 78

iv

Page 6

IMPORTANT NOTES - BEFORE YOU START

It is important to carefully read the notes marked with a

contained in this manual. Not all configuration codes are designed to be used for

both a single and dual cable scanner/scale system. Many of the configuration

bar codes require additional steps before the unit can be configured and placed

into service. Most of the bar codes in this addendum were designed to be used

with a Stratos model that includes a scale. The text marked with a

provide important additional information about the restrictions and uses of the bar

codes shown.

All of the bar codes in this manual require:

• The scanner/scale to have a firmware number of 14996 or higher

• All configuration bar codes must be scanned with the vertical window

The bar codes (starting with 996) located on pages 5 - 19 also

require the scanner/scale to:

• Be in scale program mode (see page 2)

• Be calibrated, sealed and certified by local Weights and Measures

authorities after the scale configuration process has been completed.

The scanner/scale can not be placed in service until it is sealed and

certified by the proper authorities.

For further details on calibration procedures for Weights and Measures

certification, refer to the Scale Operation: Calibration section of the

Stratos Installation and User’s Guide.

The certification of the weighing mechanism of the scale version of

this scanner is subject to federal, state and local Weights and

Measures statutes and regulations and can only be performed by

authorized government agencies and/or their duly registered

agents. Each time the scale or weighing mechanism is calibrated,

it should be properly sealed with a paper seal or a wire seal prior to

being placed into service in commerce.

It is the responsibility of the owner of the scale to confirm

compliance with the relevant Weights and Measures statutes and

regulations applicable in your area by checking with the appropriate

government agency before placing a newly calibrated unit into

service or removing any official seals.

symbol on the pages

symbol will

1

Page 7

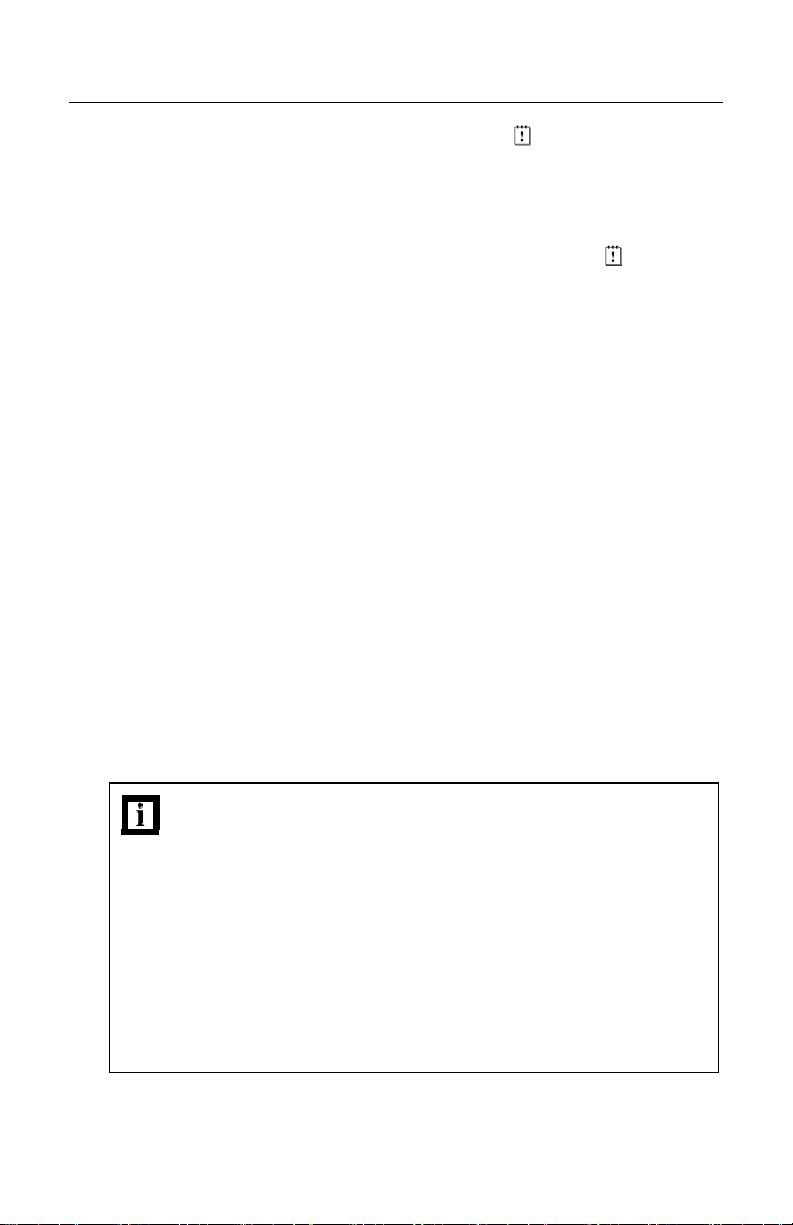

SCALE PROGRAM MODE

The following steps are only required for the scale configuration bar

codes located on pages 5 - 19 (bar codes beginning with 996.)

1. Power down the scanner/scale.

Then, temporarily remove the

scale platter and place it in a safe

location.

Figure 1.

2. Cut and remove the security seal over the program/calibration switch cover.

See Figure 2 below for seal location on the StratosE and the StratosH

models. See Figure 3 on page 3 for the seal location on the StratosS.

Once the security seal is cut the unit cannot be place in service until

it is calibrated, sealed and certified by local Weights and Measures

authority.

3. Remove the M3 screw securing the switch cover in place. Store the cover

and screw in a safe location. They will be needed again after the scale is

configured and calibrated.

Always follow all Electro-Static Discharge (ESD) procedures when

exposing the internal scanner/scale components.

4. Enter the scale program mode by sliding the switch to the program

position. See Figure 2 below for the switch location on the StratosE and

StratosH. See Figure 3 on page 3 for the switch location on the StratosS.

Figure 2. StratosE and StratosH Calibration Seal and Switch Location

2

Page 8

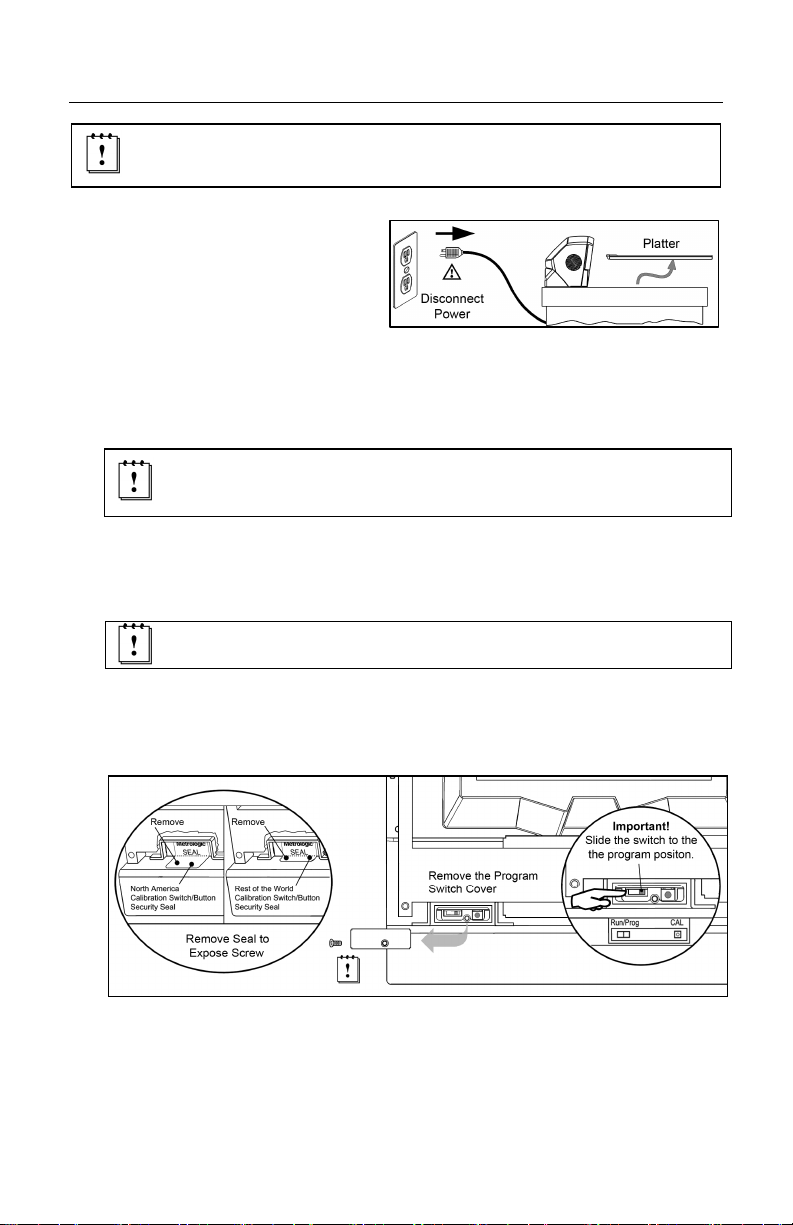

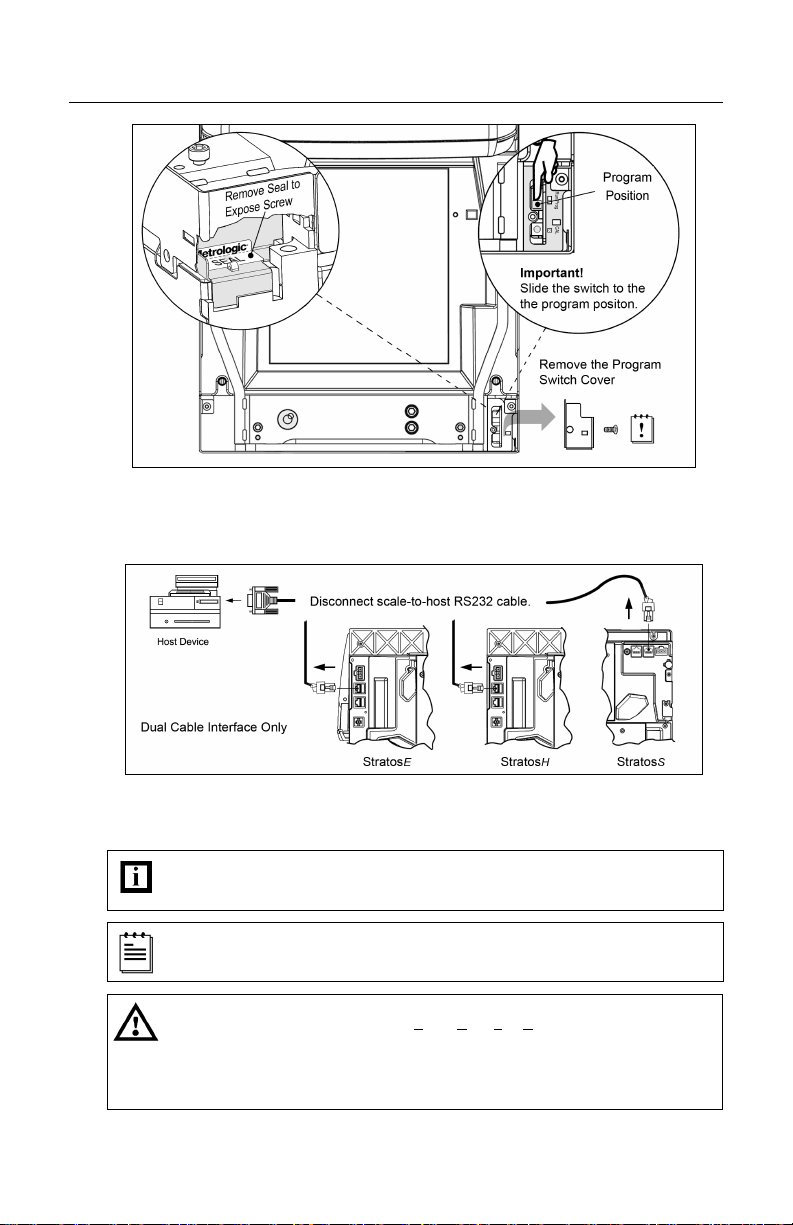

SCALE PROGRAM MODE

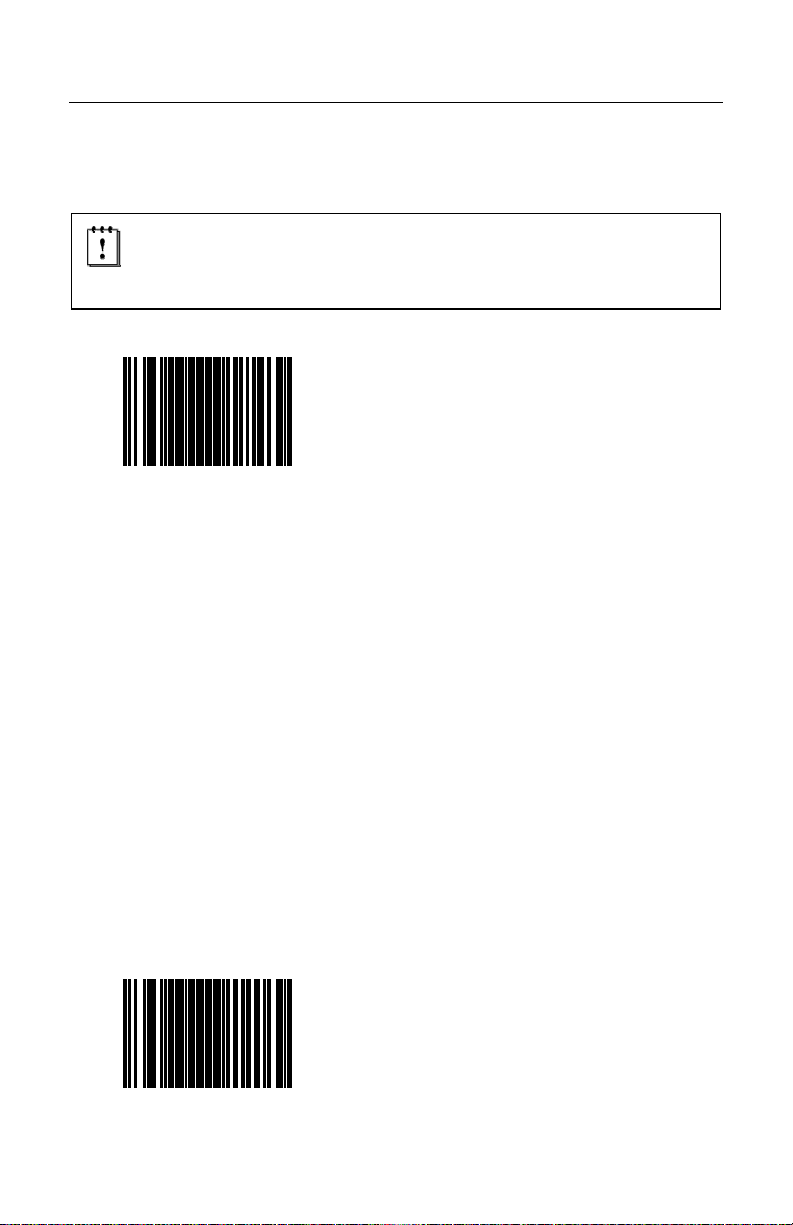

5. Disconnect the scale-to-host RS232 cable from the unit (dual cable

interface only.)

Figure 3. StratosS Calibration Seal and Switch Location

Figure 4. Disconnect scale-to-host RS232 Cable

6. Reinstall the platter and connect AC power to the scanner.

Check the AC input requirements of the power supply to make sure the voltage matches

the AC outlet. The outlet should be located near the equipment and be easily

accessible.

Metrologic recommends using a switched AC outlet. The switch should be located on

the operator’s side of the checkout counter in close proximity to the scanner/scale to

facilitate calibration and service of the unit.

To maintain compliance with applicable standards, all circuits connected to the scanner

must meet the requirements for SELV (Safety Extra Low Voltage) according to EN/IEC

To maintain compliance with standard CSA C22.2 No. 60950-1/UL 60950-1 and norm

60950-1.

EN/IEC 60950-1, the power source should meet applicable performance requirements

for a limited power source.

3

Page 9

SCALE PROGRAM MODE

7. If the system is equipped with a remote scale display, it will read H - - -.

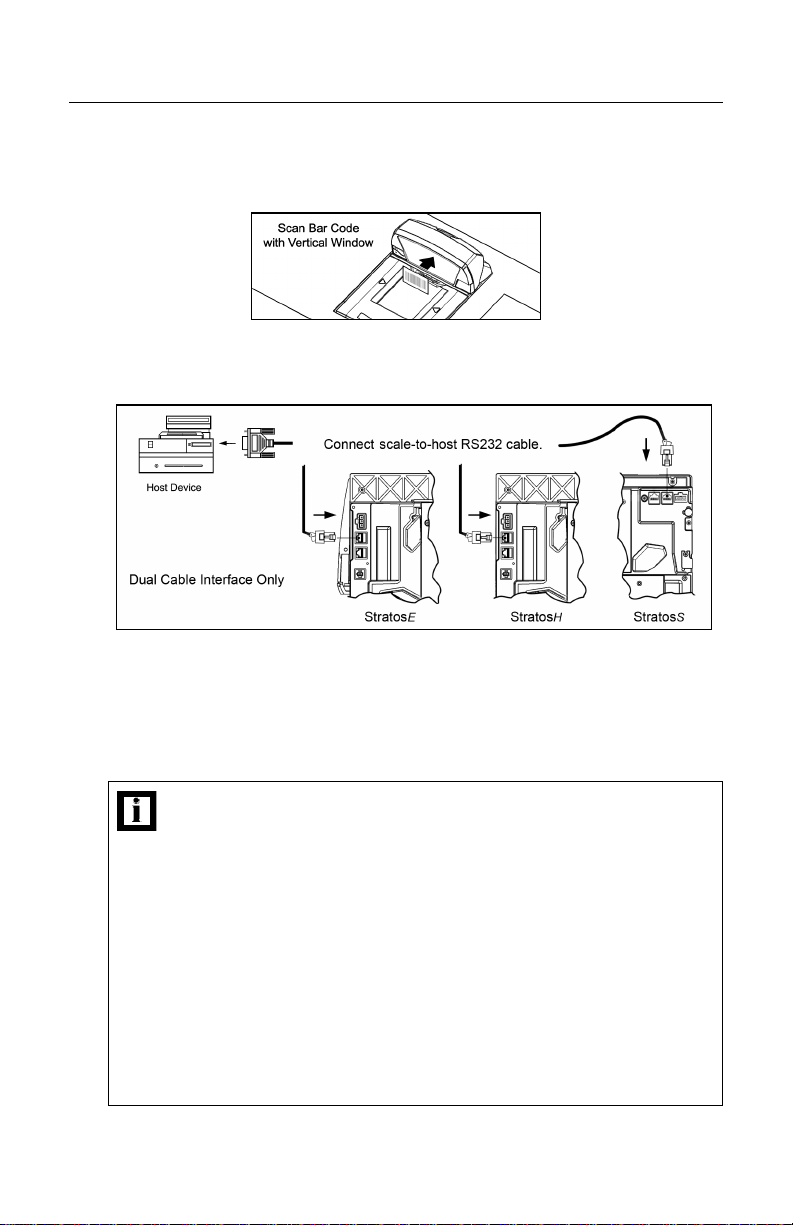

8. Use the vertical window to scan the desired scale configuration bar

codes, located on pages 5 - 19.

Figure 5.

9. Reconnect the scale-to-host RS232 cable to the scanner (dual cable

interface only.)

Figure 6.

10. The scale must now be calibrated, tested and certified by local Weights

and Measures authorities before it can be placed in service.

For further details on calibration procedures for Weights and Measures

certification, refer to the Scale Operation: Calibration section of the Stratos

Installation and User’s Guide.

The certification of the weighing mechanism of the scale version of

this scanner is subject to federal, state and local Weights and

Measures statutes and regulations and can only be performed by

authorized government agencies and/or their duly registered agents.

Each time the scale or weighing mechanism is calibrated, it should

be properly sealed with a paper seal or a wire seal prior to being

placed into service in commerce.

It is the responsibility of the owner of the scale to confirm compliance

with the relevant Weights and Measures statutes and regulations

applicable in your area by checking with the appropriate government

agency before placing a newly calibrated unit into service or

removing any official seals.

Type of seal to be used will depend on the guidelines specified by

the local Weights and Measures authorities.

4

Page 10

SCALE/LOAD CELL CONFIGURATION BAR CODES

Single or Dual Cable Scale Configuration Bar Codes

Unit Configuration (Pounds or Kilograms)

The following bar codes can be used to configure a Single or

Dual Cable MS2xx0.

The MS2xx0 must be in scale program mode to use these bar codes.

Scale = Pounds

Set the scale measuring range from

0.00 to 30.00 pounds.

³996001

Scale

= Kilograms

Set the scale measuring range from

0.000 to 15.000 kilograms.

³996002

5

Page 11

SCALE/LOAD CELL CONFIGURATION BAR CODES

Single or Dual Cable Scale Configuration Bar Codes

Pole Display Configuration

The following bar codes can be used to configure a Single or

Dual Cable MS2xx0.

The MS2xx0 must be in scale program mode to use these bar codes.

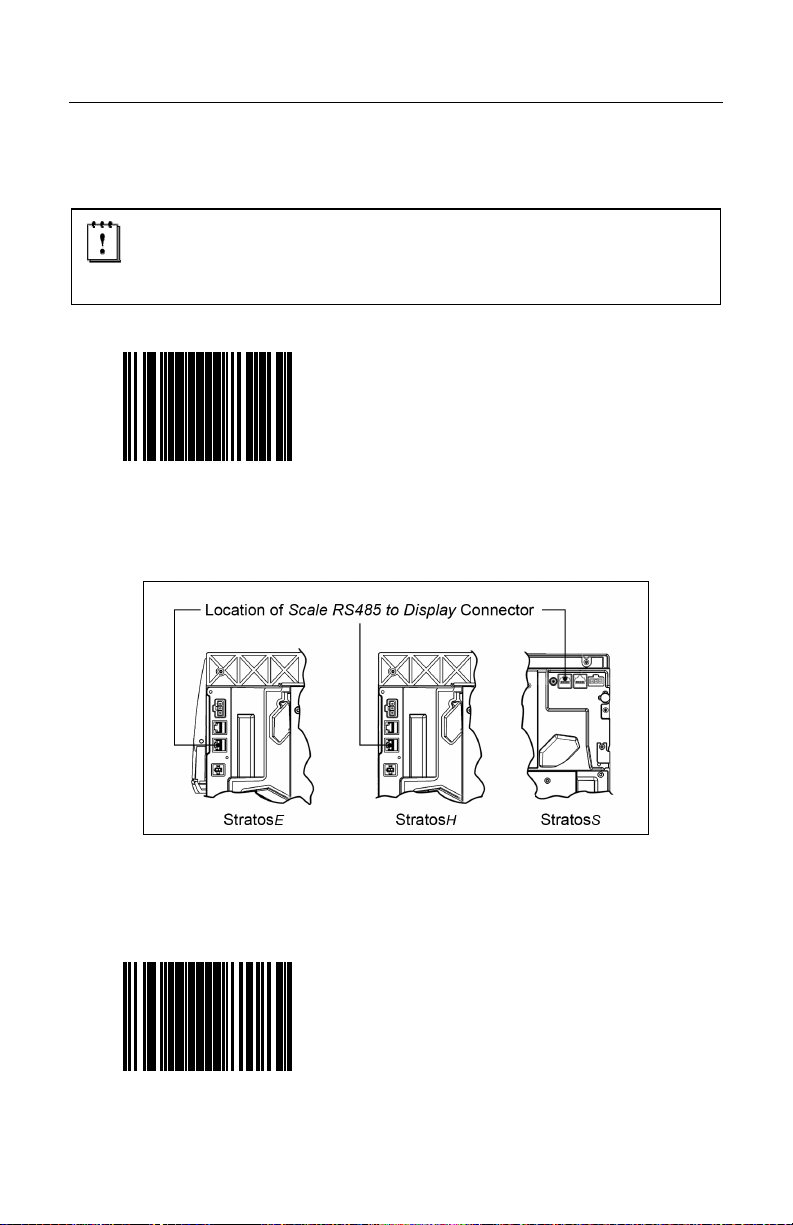

Scale Has Display

³996003

Set the scale to use a remote display to

show all scale activity.

A remote display must be plugged into the

Scale RS485 to Display connector on the

MS2xx0 (see Figure 7) for this feature to

function properly.

Figure 7. Location of Scale RS485 to Display Connector

Scale Has No Display

Set the scale to not use a remote display.

All weights are expected on a POS terminal

display.

A remote display can not be plugged into

the Scale RS485 to Display connector on

³996004

the scanner/scale (see Figure 7) or this

feature will not function properly.

6

Page 12

SCALE/LOAD CELL CONFIGURATION BAR CODES

Single or Dual Cable Scale Configuration Bar Codes

Scale Settling Filter Configuration

The following bar codes can be used to configure a Single or

Dual Cable MS2xx0.

The MS2xx0 must be in scale program mode to use these bar codes.

The scale’s filter setting allows the unit to withstand a certain amount of vibration

from the checkout counter. A stronger filter allows for more vibration to be

absorbed but the weight may take a little longer to settle. Scales are normally

shipped with a loose filter.

* Scale = Loose Filter

³996005

Loose filter setting for low vibration

environments.

* Factory Default Setting

7

Page 13

SCALE/LOAD CELL CONFIGURATION BAR CODES

Single or Dual Cable Scale Configuration Bar Codes

Scale Settling Filter Configuration

The following bar codes can be used to configure a Single or

Dual Cable MS2xx0.

The MS2xx0 must be in scale program mode to use these bar codes.

Scale = Medium Filter

Medium filter setting for moderate vibration

environments.

³996006

Scale = Strong Filter

Strong filter setting for high vibration

environments.

³996007

8

Page 14

SCALE/LOAD CELL CONFIGURATION BAR CODES

Single or Dual Cable Scale Configuration Bar Codes

Scroll Weight Configuration

The following bar codes can be used to configure a Single or

Dual Cable MS2xx0.

The MS2xx0 must be in scale program mode to use these bar codes.

These bar codes only affect the pole display.

Scale = Scroll Settling Weight

Scroll the weight on the display showing the

weight as it changes.

³996010

Scale = Blank Non-Steady

Blank the display weight as it changes.

Display stable weights only.

³996011

9

Page 15

SCALE/LOAD CELL CONFIGURATION BAR CODES

Dual Cable Scale Configuration Bar Codes

Price Computing Configuration

The following bar codes are only used when the scale is in Dual Cable

mode.

The MS2xx0 must be in scale program mode to use these bar codes.

* Scale = No Price Computing

³996008

Scale is not the price computing type.

* Factory Default Setting

Scale = Price Computing

³996009

Scale is the price computing type.

10

Page 16

SCALE/LOAD CELL CONFIGURATION BAR CODES

Dual Cable Scale Configuration Bar Codes

Scale Protocols

The following bar codes will change scale parameters intended for a

Dual Cable environment. To place the scanner in Dual Cable mode,

please refer to page 20.

The MS2xx0 must be in scale program mode to use these bar codes.

Scale = EPOS Protocol

³996013

Set the scale RS232 protocol to

Serial EPOS.

Communication Port Settings:

• 2400 Baud

• 7 Data Bits

• 1 Stop Bit

• Even Parity

Scale = EPOS2 Protocol

³996014

11

Set the scale RS232 protocol to

Modified Serial EPOS.

This Protocol does not require the POS

terminal to send the weight back to the scale

for validation.

Communication Port Settings:

• 2400 Baud

• 7 Data Bits

• 1 Stop Bit

• Even Parity

Page 17

SCALE/LOAD CELL CONFIGURATION BAR CODES

Dual Cable Scale Configuration Bar Codes

Scale Protocols

The following bar codes will change scale parameters intended for a

Dual Cable environment. To place the scanner in Dual Cable mode,

please refer to page 20.

The MS2xx0 must be in scale program mode to use these bar codes.

Scale = NCI-ECR Protocol

³996015

Set the scale RS232 protocol to NCI-ECR.

Communication Port Settings:

• 9600 Baud

• 8 Data Bits

• 1 Stop Bit

• No Parity

Scale = NCI Protocol

³996016

Reserved for Future NCI Protocol Variation

12

Page 18

SCALE/LOAD CELL CONFIGURATION BAR CODES

Dual Cable Scale Configuration Bar Codes

Scale Protocols

The following bar codes will change scale parameters intended for a

Dual Cable environment. To place the scanner in Dual Cable mode,

please refer to page 20.

The MS2xx0 must be in scale program mode to use these bar codes.

Scale = EMEA

Special Configuration

³996041

Set the scale to Avery EPOS protocol,

kilograms, with a remote display, loose filter,

no price computing, and scroll weight.

Communication Port Settings:

• 2400 Baud

• 7 Data Bits

• 1 Stop Bit

• Even Parity

13

Page 19

SCALE/LOAD CELL CONFIGURATION BAR CODES

Dual Cable Scale Configuration Bar Codes

COM Port Settings (Baud Rate)

The following bar codes will change scale parameters intended for a

Dual Cable environment.

If a Scale Protocol bar code from page 11 or 13 is used, the bar codes

below must be scanned after the Scale Protocol bar code in order to be

effective.

The MS2xx0 must be in scale program mode to use these bar codes.

Scale = 2400 Baud Rate

Set the scale baud rate for dual cable

applications to 2400 baud.

³996017

Scale = 9600 Baud Rate

Set the scale baud rate for dual cable

applications to 9600 baud.

³996018

14

Page 20

SCALE/LOAD CELL CONFIGURATION BAR CODES

Dual Cable Scale Configuration Bar Codes

COM Port Settings (Baud Rate)

The following bar codes will change scale parameters intended for a

Dual Cable environment.

If a Scale Protocol bar code from page 11 or 13 is used, the bar codes

below must be scanned after the Scale Protocol bar code in order to be

effective.

The MS2xx0 must be in scale program mode to use these bar codes.

Scale = 19200 Baud Rate

Set the scale baud rate for dual cable

applications to 19200 baud.

³996019

Scale = 38400 Baud Rate

³996020

15

Set the scale baud rate for dual cable

applications to 38400 baud.

Page 21

SCALE/LOAD CELL CONFIGURATION BAR CODES

Dual Cable Scale Configuration Bar Codes

COM Port Settings (Data Bits & Parity)

The following bar codes will change scale parameters intended for a

Dual Cable environment.

If a Scale Protocol bar code from page 11 or 13 is used, the bar codes

below must be scanned after the Scale Protocol bar code in order to be

effective.

The MS2xx0 must be in scale program mode to use these bar codes.

Scale = 7 Data Bits,

Odd Parity

Set the scale communication parameters to

7 data bits, odd parity.

³996021

Scale = 7 Data Bits,

Even Parity

³996022

Set the scale communication parameters to

7 data bits, even parity.

16

Page 22

SCALE/LOAD CELL CONFIGURATION BAR CODES

Dual Cable Scale Configuration Bar Codes

COM Port Settings (Data Bits & Parity)

The following bar codes will change scale parameters intended for a

Dual Cable environment.

If a Scale Protocol bar code from page 11 or 13 is used, the bar codes

below must be scanned after the Scale Protocol bar code in order to be

effective.

The MS2xx0 must be in scale program mode to use these bar codes.

Scale = 8 Data Bits, No Parity

Set the scale communication parameters to

8 data bit, no parity.

³996023

Scale = Odd Parity

³996024

Set the scale communication to odd parity.

17

Page 23

SCALE/LOAD CELL CONFIGURATION BAR CODES

Dual Cable Scale Configuration Bar Codes

COM Port Settings (Data Bits & Parity)

The following bar codes will change scale parameters intended for a

Dual Cable environment.

If a Scale Protocol bar code from page 11 or 13 is used, the bar codes

below must be scanned after the Scale Protocol bar code in order to be

effective.

The MS2xx0 must be in scale program mode to use these bar codes.

Scale = Even Parity

Set the scale communication to even parity.

³996025

Scale = No Parity

³996026

Set the scale communication to no parity.

18

Page 24

SCALE/LOAD CELL CONFIGURATION BAR CODES

Single Cable Scale Configuration Bar Codes

Set Scale for Single Cable Communication

The MS2xx0 must be in scale program mode to use this bar code.

If your application requires single cable communication, scan the following bar

code to set the scale configuration to the single cable defaults as required by the

scanner.

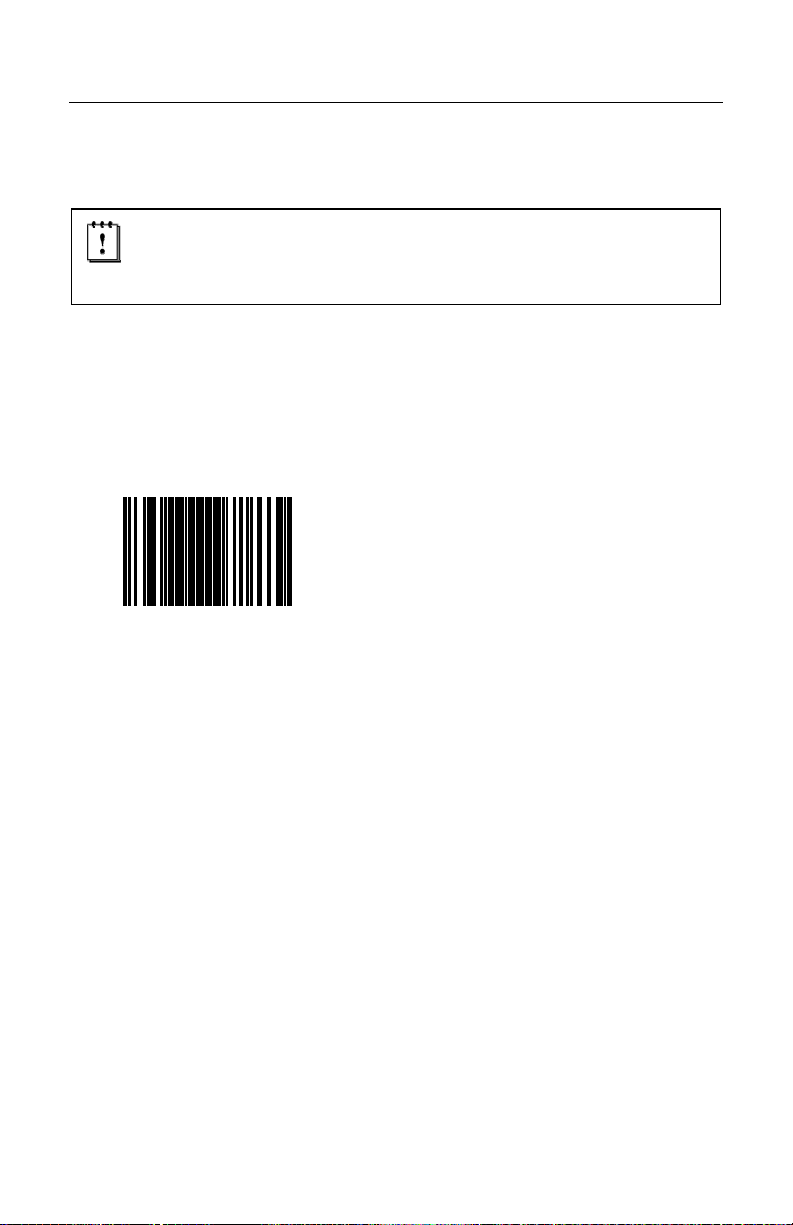

Scale = Single Cable Interface

Set the scale to communicate via the

single-cable interface.

³996012

19

Page 25

SCANNER CONFIGURATION BAR CODES

Dual Cable Scanner Configuration Bar Codes

Dual Cable Scanner Mode

The following bar codes can be used to place, as well as configure, the

scanner in Dual Cable mode.

The MS2xx0 does not need to be in scale program mode to use the

following bar codes.

Places the scanner in Dual Cable mode.

Scanner = Dual Cable Mode

³999953

Communication Port Settings:

• 9600 Baud, 8 Data Bits, 1 Stop Bit, No Parity

In a dual cable environment, the scanner

and scale work independently. In this mode

the host must have a dedicated RS232 port

to receive the scale data and the bar code

data is sent via its own cable to a separate

communication port.

There are two methods of configuring the scanner to a stand-alone protocol:

• Scan the Dual Cable Mode bar code on this page (if a scale is used)

or

• If no scale is required, scan one of the single cable protocols on

pages 23 - 32 and then scan the No Scale bar code on page 44.

Dual Cable Scanner OPOS Mode

Scanner Only

Dual Cable OPOS Defaults

³999911

20

Use this bar code when the scanner is to be

setup using the OPOS drivers in the dual

cable mode.

Communication Port Settings:

• 9600 Baud

• 8 Data Bits

• 1 Stop Bit

• No Parity

Page 26

SCANNER CONFIGURATION BAR CODES

Dual Cable Scanner Configuration Bar Codes

Various Dual Cable Scanner Mode

The following bar codes can be used to configure a Dual Cable

MS2xx0.

The following codes do not require that the MS2xx0 to be in scale

program mode.

REWE

³997010

Dual Cable RS232 - REWE

Communication Port Settings:

• 9600 Baud

• 7 Data Bits

• 2 Stop Bit

• Space Parity

TESCO UK

³997013

21

Dual Cable RS232 – TESCO UK

Communication Port Settings:

• 9600 Baud

• 8 Data Bits

• 1 Stop Bit

• Odd Parity

Page 27

SCANNER CONFIGURATION BAR CODES

Dual Cable Scanner Configuration Bar Codes

IBM 3rd Generation 46xx and IBM OEM Full Speed USB

The following bar codes can be used to configure a Dual Cable

MS2xx0.

The following codes do not require that the MS2xx0 to be in scale

program mode.

rd

Generation

IBM 3

Communication

³999952

When scanned the Stratos will operate

as a table top scanner only.

Terminal configuration, IBM 4690.OS

terminal device group configuration

screen select:

#1 scanner or

#3 scanner.

IBM OEM Full Speed USB

Communication Defaults

³999970

When scanned the Stratos will operate

as a table top scanner only.

22

Page 28

SCANNER CONFIGURATION BAR CODES

Single Cable Protocols for POS Compatibility

MSS Global

The following bar codes can be used to configure a Single Cable

MS2xx0.

The following codes do not require that the MS2xx0 to be in scale

program mode.

MSS Global, English

³999951

Scanner/Scale, Single Cable RS232

MSS Global Retail, English Units

Communication Port Settings:

• 9600 Baud

• 7 Data Bits

• 1 Stop Bit

• Odd Parity

MSS Global, Metric

³999950

23

Scanner/Scale, Single Cable RS232 MSS

Global Retail, Metric Units

Communication Port Settings:

• 9600 Baud

• 7 Data Bits

• 1 Stop Bit

• Odd Parity

Page 29

SCANNER CONFIGURATION BAR CODES

Single Cable Protocols for POS Compatibility

ISS45

The following bar codes can be used to configure a Single Cable

MS2xx0.

The following codes do not require that the MS2xx0 to be in scale

program mode.

ISS45, English

³999949

Scanner/Scale, Single Cable RS232

ISS45, English Units

Communication Port Settings:

• 9600 Baud

• 7 Data Bits

• 1 Stop Bit

• Even Parity

Scanner/Scale, Single Cable RS232

ISS45, Metric

ISS45, Metric Units

Communication Port Settings:

• 9600 Baud

• 7 Data Bits

³999948

• 1 Stop Bit

• Even Parity

24

Page 30

SCANNER CONFIGURATION BAR CODES

Single Cable Protocols for POS Compatibility

OPOS

The following bar codes can be used to configure a Single Cable

MS2xx0.

The following codes do not require that the MS2xx0 to be in scale

program mode.

OPOS, English

³999958

Scanner/Scale Single Cable RS232 OPOS,

English Scale Defaults

Communication Port Settings:

• 9600 Baud

• 8 Data Bits

• 1 Stop Bit

• No Parity

Scanner/Scale Single Cable RS232 OPOS,

OPOS, Metric

Metric Scale Defaults

Communication Port Settings:

• 9600 Baud

• 8 Data Bits

³999957

• 1 Stop Bit

• No Parity

25

Page 31

SCANNER CONFIGURATION BAR CODES

Single Cable Protocols for POS Compatibility

Retailix/NCR

The following bar codes can be used to configure a Single Cable

MS2xx0.

The following codes do not require that the MS2xx0 to be in scale

program mode.

Retailix/NCR English

³999956

Scanner/Scale Single Cable RS232

Retailix/NCR Communication, English

Communication Port Settings:

• 9600 Baud

• 8 Data Bits

• 1 Stop Bit

• No Parity

Scanner/Scale Single Cable RS232

Retailix/NCR Metric

Retailix/NCR Comm, Metric

Communication Port Settings:

• 9600 Baud

• 8 Data Bits

³999955

• 1 Stop Bit

• No Parity

26

Page 32

SCANNER CONFIGURATION BAR CODES

Single Cable Protocols for POS Compatibility

Retailix/OPOS

The following bar codes can be used to configure a Single Cable

MS2xx0.

The following codes do not require that the MS2xx0 to be in scale

program mode.

Scanner/Scale Single Cable RS232

Retailix / OPOS Metric

³997019

Retailix / OPOS Communication, Metric

Communication Port Settings:

• 9600 Baud

• 8 Data Bits

• 1 Stop Bit

• No Parity

27

Page 33

SCANNER CONFIGURATION BAR CODES

Single Cable Protocols for POS Compatibility

IT Retail

The following bar codes can be used to configure a Single Cable

MS2xx0.

The following codes do not require that the MS2xx0 to be in scale

program mode.

Retail, English

IT

³997008

Scanner/Scale Single Cable RS232

IT Retail, English

Communication Port Settings:

• 9600 Baud

• 7 Data Bits

• 1 Stop Bit

• Odd Parity

Scanner/Scale Single Cable RS232

IT Retail, Metric

IT Retail, Metric

Communication Port Settings:

• 9600 Baud

• 7 Data Bits

³997009

• 1 Stop Bit

• Odd Parity

28

Page 34

SCANNER CONFIGURATION BAR CODES

Single Cable Protocols for POS Compatibility

IBM Self Checkout System

The following bar codes can be used to configure a Single Cable

MS2xx0.

The following codes do not require that the MS2xx0 to be in scale

program mode.

Scanner/Scale Single Cable RS232 -

IBM Self Checkout System,

English

³997020

IBM Self Checkout System, English

Communication Port Settings:

• 19200 Baud

• 7 Data Bits

• 1 Stop Bit

• Odd Parity

IBM Self Checkout System,

Metric

³997021

29

Scanner/Scale Single Cable RS232 -

IBM Self Checkout System, Metric

Communication Port Settings:

• 19200 Baud

• 7 Data Bits

• 1 Stop Bit

• Odd Parity

Page 35

SCANNER CONFIGURATION BAR CODES

Single Cable Protocols for POS Compatibility

Various RS232 Single Cable Codes

The following bar codes can be used to configure a Single Cable

MS2xx0.

The following codes do not require that the MS2xx0 to be in scale

program mode.

Morrison’s Tec Metric

³997023

Scanner/Scale Single Cable RS232 –

Morrison’s with Tec Display, Metric

Communication Port Settings:

• 9600 Baud

• 7 Data Bits

• 1 Stop Bit

• Odd Parity

Reliance India Metric

Scanner/Scale Single Cable RS232 -

Reliance India, Metric

Communication Port Settings:

• 9600 Baud

³997019

• 8 Data Bits

• 1 Stop Bit

• No Parity

30

Page 36

SCANNER CONFIGURATION BAR CODES

Single Cable Protocols for POS Compatibility

IBM 3rd Generation 46xx

The following bar codes can be used to configure a Single Cable

MS2xx0.

The following codes do not require that the MS2xx0 to be in scale

program mode.

rd

Generation 46xx,

IBM 3

English

†

Scanner/Scale Single Cable

IBM 46xx†, RS485,

English (lbs.)

³999960

† Terminal Configuration, IBM 4690.OS Terminal Device Group

Configuration screen select:

#2 Scanner with integrated scale

or

#4 4696 scanner/scale

rd

Generation 46xx,

IBM 3

Metric

†

Scanner/Scale Single Cable

IBM 46xx

†

, RS485

Metric (kg)

³999959

31

Page 37

SCANNER CONFIGURATION BAR CODES

Single Cable Protocols for POS Compatibility

IBM OEM Full Speed USB

The following bar codes can be used to configure a Single Cable

MS2xx0.

The following codes do not require that the MS2xx0 to be in scale

program mode.

IBM OEM

Full Speed USB, English

Table Top Scanner/Scale Single Cable,

IBM OEM Full Speed USB,

4-Digit Weight Mode, English (lbs.)

³999962

IBM OEM

Full Speed USB, Metric

Table Top Scanner/Scale Single Cable,

IBM OEM Full Speed USB,

5-Digit Weight Mode, Metric (kg)

³999961

32

Page 38

SCANNER CONFIGURATION BAR CODES

Additional POS Data Formatting

Full Speed USB Table Top/Handheld

The following codes do not require that the MS2xx0 to be in scale

program mode.

Scanner 4B Handheld

Full Speed USB interface to 4B00h

handheld usage.

³316430

Scanner 4A Flatbed

Full Speed USB interface to 4A00h

table top usage.

³316410

33

Page 39

SCANNER CONFIGURATION BAR CODES

Additional POS Data Formatting

Full Speed USB Table Top/Handheld

The following codes do not require that the MS2xx0 to be in scale

program mode.

Scanner/Scale 4A/6E

Table Top

Full Speed USB interface to the

4A00h/6E00h table top scanner/scale

usage.

This option is only compatible with Stratos

models that have a scale.

³316440

34

Page 40

SCANNER CONFIGURATION BAR CODES

Additional POS Data Formatting

Special Function ACK

The following codes do not require that the MS2xx0 to be in scale

program mode.

Enable Special

Function ACK Answer

Answer simple special functions with ACK.

³141714

* Disable Special

Function ACK

³141704

* Factory Default Setting

35

Page 41

SCANNER CONFIGURATION BAR CODES

Additional POS Data Formatting

Prefix/Suffix

The following codes do not require that the MS2xx0 to be in scale

program mode.

Use Protocol Prefix/Suffix

Add protocol prefixes and suffixes to the

bar code.

³141715

* Program the

Prefix/Suffix Separate

³141705

* Factory Default Setting

36

Page 42

SCANNER CONFIGURATION BAR CODES

Additional POS Data Formatting

3x-30 Acknowledge Responses

The following codes do not require that the MS2xx0 to be in scale

program mode.

No 3x-30 Answer

This bar code will inhibit all ‘simple

acknowledge’ (3x-30) answers to POS or

OPOS commands.

³141710

*3x-30 Answer

³141700

The scanner will answer all NCR and OPOS

commands that require a 3x-30

acknowledgement.

* Factory Default Setting

37

Page 43

SCANNER CONFIGURATION BAR CODES

Additional POS Data Formatting

Special Function Command Responses

The following codes do not require that the MS2xx0 to be in scale

program mode.

Spec Func Ans 3x30

Answer Special Function commands in the

3x-30 format as opposed to the Ack / Nak

which is the norm.

³141914

*Spec Func Ans Ack

³141904

Answer Special Function commands in the

Ack / Nak format.

* Factory Default Setting

38

Page 44

SCANNER CONFIGURATION BAR CODES

Additional POS Data Formatting

Special Function Command Responses

The following codes do not require that the MS2xx0 to be in scale

program mode.

Spec Func 30-30 Status

³142215

Returns Special Function commands in the

30-30 status as opposed to the 33-30 status.

Note: Requires ‘Spec Func Ans 3x-30’ on

page 38 to be set.

*No Spec Func 30-30 Status

³142205

Disables redirection of Special Function

3x-30 status to 30-30 status.

* Factory Default Setting

39

Page 45

SCANNER CONFIGURATION BAR CODES

Additional POS Data Formatting

Special Function Command Responses

The following codes do not require that the MS2xx0 to be in scale

program mode.

No Command Reject Answer

This bar code will ignore sending a

command reject answer to the POS mode.

³142117

*Send Command Reject

Answer

³142107

This bar code will send command reject

answer to the POS if the command is

rejected by the scanner.

* Factory Default Setting

40

Page 46

SCANNER CONFIGURATION BAR CODES

Additional POS Data Formatting

Special Function Command Responses

The following codes do not require that the MS2xx0 to be in scale

program mode.

No Spec Func Answer

This bar code will ignore sending a special

function response answer in POS mode.

³142116

*Spec Func Answer

³142106

This bar code will send a special function

response answer to the POS.

* Factory Default Setting

41

Page 47

SCANNER CONFIGURATION BAR CODES

Additional POS Data Formatting

BCC in POS communications

The following codes do not require that the MS2xx0 to be in scale

program mode.

Skip BCC in messages

This bar code will tell the scanner to NOT

expect or transmit the Block Check

Character in all message transmissions.

³141410

*Add BCC in messages

³141400

The scanner will expect and answer all

messages with the Block Check Character

included.

* Factory Default Setting

42

Page 48

SCANNER CONFIGURATION BAR CODES

Additional POS Data Formatting

3 Scale Status Bytes

The following codes do not require that the MS2xx0 to be in scale

program mode.

Enable

3 Scale Status Bytes

Required for applications where the host

system display is the primary scale display

and there is no remote pole display

connected directly to the scanner/scale unit.

³124813

Disable

3 Scale Status Bytes

³124803

43

Page 49

SCANNER CONFIGURATION BAR CODES

Additional POS Data Formatting

Scale Options

The following codes do not require that the MS2xx0 to be in scale

program mode.

5-Digit Weight

³141010

Sets the English Mode weight to 5-digits, as

in xx.yyy pounds.

In order to work properly, this bar code must

be scanned AFTER scanning one of the

English configuration bar codes found on

pages 23 - 32.

Scan the No Scale bar code:

No Scale

1. If no scale is installed and one of the

single cable protocol bar codes found

on pages 23 - 32 has already been

scanned.

2. If the scale is in a dual cable

environment and one of the single cable

protocol bar codes found on

pages 23 - 32 has already been

³141407

scanned.

44

Page 50

SCANNER CONFIGURATION BAR CODES

Additional POS Data Formatting

Remote Display

The following codes do not require that the MS2xx0 to be in scale

program mode.

No Remote Display

When no remote display is installed, scan

the No Remote Display bar code AFTER

scanning one of the configuration bar codes

found on pages 23 - 32 to remove the

scale’s display from the scanner memory.

³140902

Remote Display

³140912

Add remote display to the scanner’s

memory.

45

Page 51

SCANNER CONFIGURATION BAR CODES

Additional POS Data Formatting

StratosSTATS

The following codes do not require that the MS2xx0 to be in scale

program mode.

Activate StratosSTATS

³997017

This bar code sets:

• StratosSTATS bar code data

formatting active.

• Bar code Attempt Interval to

0.5 seconds.

• Time to find supplements (code 128)

to 0.3 seconds.

Use StratosSTATS monitor to test this

output format. When used with a POS, it

must have the capability to parse and

recognize the additional data.

*StratosSTATS Off

Remove StratosSTATS data formatting from

the bar code output transmission.

³997018

* Factory Default Setting

46

Page 52

SCANNER CONFIGURATION BAR CODES

Additional POS Data Formatting

StratosSTATS

The following codes do not require that the MS2xx0 to be in scale

program mode.

Do not scan these bar codes unless instructed by a Metrologic

Representative.

Dual Stats Xmit

³138511

Allows non-RS232 interfaces transmit

normally without StratosSTATS and

concurrently RS232 interfaces transmit with

StratosSTATS.

Recommended RS232 Settings:

• 38400 Baud

• 8 Data Bits

• 1 Stop Bit

• No Parity

• No Inter-character Delay

*No Dual Stats Xmit

³138501

47

* Factory Default Setting

Page 53

SCANNER CONFIGURATION BAR CODES

Additional POS Data Formatting

StratosSTATS

The following codes do not require that the MS2xx0 to be in scale

program mode.

Do not scan these bar codes unless instructed by a Metrologic

Representative.

Dual Xmit Carriage Return

This bar code enables a secondary carriage

return suffix to be used only for the dual

StratosSTATS RS232 transmission.

³138512

*No Dual Xmit Carriage Return

³138502

Resets StratsSTATS RS232 dual

transmission suffix.

* Factory Default Setting

48

Page 54

SCANNER CONFIGURATION BAR CODES

Additional POS Related Functions

Scanner Beep on Weight Sent

The following codes do not require that the MS2xx0 to be in scale

program mode.

Beep on Weight

³141917

Request scanner beep when a successful

weight is sent. This code should only be

used for ‘weight on demand’ applications. If

used with periodic weight request

applications, the beeper will be continuously

active (ON).

*Disable

Beep on Weight

³141907

When no beep on weight is desired.

* Factory Default Setting

49

Page 55

SCANNER CONFIGURATION BAR CODES

Additional POS Related Functions

Restrict In-Store Codes

The following codes do not require that the MS2xx0 to be in scale

program mode.

Restrict In-Store Codes

This bar code places tighter restrictions on

in-store codes. These codes are:

EAN13 Sys2

UPCA Sys2 and Sys4

³125810

*No Restrict In-Store Codes

³125800

Disable restrictions on in-store codes.

* Factory Default Setting

50

Page 56

SCANNER CONFIGURATION BAR CODES

Additional POS Related Functions

Scale Shadow Mode

The following codes do not require that the MS2xx0 to be in scale

program mode.

Scale Shadow Mode

³142217

This bar code sets the scale to the highest

priority to allow for frequent scale - POS

commands.

This bar code is only to be used in single

cable scale mode.

*No Scale Shadow Mode

³142207

Disables the Scale Shadow Mode.

* Factory Default Setting

51

Page 57

SCANNER CONFIGURATION BAR CODES

Additional POS Related Functions

Scanner Razz on Not-On-File

The following codes do not require that the MS2xx0 to be in scale

program mode.

Razz on Not-On-File

This bar code changes the audible to a razz

signal when a Not-On-File command is

received.

³142115

*Beep on Not-On-File

³142105

This bar code restores the beep as the NotOn-File audible.

* Factory Default Setting

52

Page 58

SCANNER CONFIGURATION BAR CODES

Additional Scanner Configuration Bar Codes

Horizontal Depth of Field

The following codes do not require that the MS2xx0 to be in scale

program mode.

Do not scan these bar codes unless instructed by a Metrologic

Representative.

*Horizontal High DOF

³218702

This bar code sets the DOF for all horizontal

laser channels to High DOF, which allows

the farthest scanning.

* Factory Default Setting

Horizontal Medium DOF

³218712

53

This bar code sets the DOF for all horizontal

laser channels to Medium DOF.

Page 59

SCANNER CONFIGURATION BAR CODES

Additional Scanner Configuration Bar Codes

Horizontal Depth of Field

The following codes do not require that the MS2xx0 to be in scale

program mode.

Do not scan these bar codes unless instructed by a Metrologic

Representative.

Horizontal Close DOF

This bar code sets the DOF for all horizontal

laser channels to Close DOF.

³218722

Horizontal Ultra Close DOF

³218732

This bar code sets the DOF for all horizontal

laser channels to Ultra Close DOF.

54

Page 60

SCANNER CONFIGURATION BAR CODES

Additional Scanner Configuration Bar Codes

Vertical Depth of Field

The following codes do not require that the MS2xx0 to be in scale

program mode.

Do not scan these bar codes unless instructed by a Metrologic

Representative.

*Vertical High DOF

³218700

This bar code sets the DOF for the vertical

laser channels to High DOF, which allows

the farthest scanning.

* Factory Default Setting

Vertical Medium DOF

³218710

55

This bar code sets the DOF for vertical laser

channels to Medium DOF.

Page 61

SCANNER CONFIGURATION BAR CODES

Additional Scanner Configuration Bar Codes

Vertical Depth of Field

The following codes do not require that the MS2xx0 to be in scale

program mode.

Do not scan these bar codes unless instructed by a Metrologic

Representative.

Vertical Close DOF

³218720

This bar code sets the DOF for the vertical

laser channels to Close DOF.

Vertical Ultra Close DOF

This bar code sets the DOF for vertical laser

channels to Ultra Close DOF.

³218730

56

Page 62

SCANNER CONFIGURATION BAR CODES

Auxiliary Port

StratosSCHOOL™

The following codes do not require that the MS2xx0 to be in scale

program mode.

Auxiliary History Report

³997011

The Auxiliary port may be used to download

or clear data to StratosSCHOOL™.

The two commands that can be used are

Upload Scanner Data and Clear Scanner

Data within the Serial Program Interface box

on the StratosSCHOOL™ screen.

Auxiliary Program Cable

MLPN 57-57008x-N-3) is required

(

for this feature.

57

Page 63

SCANNER CONFIGURATION BAR CODES

Auxiliary Port

Quick Start for a Secondary Metrologic Scanner

The following codes do not require that the MS2xx0 to be in scale

program mode.

STEP 1

Use the Stratos to scan the following bar code. This bar code will configure

the Stratos’ auxiliary port to accept a Metrologic scanner as the secondary

scanner.

Enable Stratos Auxiliary Port

³437320

The auxiliary input port’s data format must match the main output format

of the secondary scanner

STEP 2

Configure the secondary scanner to match the auxiliary port’s data format.

Use the Secondary Scanner to scan the following bar codes in the order

shown.

Enter Configuration Mode

³999999

Enable Auxiliary Output

³124817

58

Page 64

SCANNER CONFIGURATION BAR CODES

Auxiliary Port

Quick Start for a Secondary Metrologic Scanner

Configuration sequence continued from previous page.

Set Stratos Format

³437520

Disable Secondary

Scanner Beeper

³318505

Enable Communication

Time Out

³118412

Disable CR Suffix

³116603

Disable LF Suffix

³116602

Exit Configuration Mode

³999999

59

Page 65

SCANNER CONFIGURATION BAR CODES

EAS Bar Codes

EAS Device Types

The following codes do not require that the MS2xx0 to be in scale

program mode.

*No EAS Device

³337200

No EAS device is connected.

* Factory Default Setting

EAS Device Type 1

³337210

60

Page 66

SCANNER CONFIGURATION BAR CODES

EAS Bar Codes

EAS Device Types

The following codes do not require that the MS2xx0 to be in scale

program mode.

EAS Device Type 2

³337220

EAS Device Type 3

³337230

61

Page 67

SCANNER CONFIGURATION BAR CODES

EAS Bar Codes

EAS Device Types

The following codes do not require that the MS2xx0 to be in scale

program mode.

EAS Device Type 4

³337240

62

Page 68

SCANNER CONFIGURATION BAR CODES

EAS Bar Codes

EAS Timeout

The following codes do not require that the MS2xx0 to be in scale

program mode.

*EAS = 0 seconds

³846000

* Factory Default Setting

EAS = 1 second

³84600100

63

Page 69

SCANNER CONFIGURATION BAR CODES

EAS Bar Codes

EAS Timeout

The following codes do not require that the MS2xx0 to be in scale

program mode.

EAS = 2 seconds

³84600200

EAS = 3 seconds

³84600300

64

Page 70

SCANNER CONFIGURATION BAR CODES

EAS Bar Codes

EAS Timeout

The following codes do not require that the MS2xx0 to be in scale

program mode.

EAS = 4 seconds

³84600400

EAS = 5 seconds

³84600500

65

Page 71

SCANNER CONFIGURATION BAR CODES

EAS Bar Codes

EAS Timeout

The following codes do not require that the MS2xx0 to be in scale

program mode.

EAS = 7 seconds

³84600700

EAS = 10 seconds

³84601000

66

Page 72

SCANNER CONFIGURATION BAR CODES

EAS Bar Codes

EAS Timeout

The following codes do not require that the MS2xx0 to be in scale

program mode.

EAS = 15 seconds

³84601500

EAS = 20 seconds

³84602000

67

Page 73

SCANNER CONFIGURATION BAR CODES

EAS Bar Codes

EAS Connection

The following codes do not require that the MS2xx0 to be in scale

program mode.

*EAS Digital Aux Port

³146100

The EAS signals use the RTS and CTS line

of the Auxiliary RS232 In connector.

* Factory Default Setting

EAS Digital Host Port

The EAS signals use the RTS and CTS lines

of the scanner RS232 to Host connector.

³146110

68

Page 74

SCANNER CONFIGURATION BAR CODES

EAS Bar Codes

EAS Connection

The following codes do not require that the MS2xx0 to be in scale

program mode.

EAS RS232 on Aux Port

³146111

This bar code allows the EAS RS232 signal

to use the Tx Out and Rx In lines of the

scanner to Aux RS232 In connector.

*No EAS RS232 on Aux Port

³146101

There is no EAS RS232 signal (Tx Out and

Rx In) used on the scanner Aux RS232 In

connector.

* Factory Default Setting

69

Page 75

SCANNER CONFIGURATION BAR CODES

EAS Bar Codes

EAS Connection

The following codes do not require that the MS2xx0 to be in scale

program mode.

EAS RS232 on Host Port

³146112

This bar code allows the EAS RS232 signal

to use the Tx Out and Rx In lines of the

scanner to Host RS232 In connector.

*No EAS RS232 on Host Port

³146102

There is no EAS RS232 signal (Tx Out and

Rx In) used on the scanner to Host RS232

In connector.

* Factory Default Setting

70

Page 76

SCANNER CONFIGURATION BAR CODES

EAS Bar Codes

Continuous Mode

The following codes do not require that the MS2xx0 to be in scale

program mode.

EAS Continuous Mode

³146115

When in continuous mode and the scanner

is enabled, the EAS will always be online to

deactivate an EAS tag.

*EAS Interlock Mode

³146105

This bar code establishes EAS is used in the

Interlocked mode.

* Factory Default Setting

71

Page 77

SCANNER CONFIGURATION BAR CODES

EAS Bar Codes

EAS Deactivation

The following codes do not require that the MS2xx0 to be in scale

program mode.

Blink Scan LED on

Deactivation

The scanner will blink the scan LED upon

receipt of an EAS deactivate acknowledge

signal.

³146113

*No Blink LED on Deactivation

³146103

Do not blink the scan LED upon receipt of

an EAS deactivate acknowledge signal.

* Factory Default Setting

72

Page 78

SCANNER CONFIGURATION BAR CODES

EAS Bar Codes

EAS Deactivation

The following codes do not require that the MS2xx0 to be in scale

program mode.

Fast Beep on Deactivation

Fast beep the scanner’s beeper receipt of

an EAS deactivate acknowledge signal.

³146114

*No Beep on Deactivation

³146104

Do not fast beep the scanner’s beeper

receipt of an EAS deactivate acknowledge

signal.

* Factory Default Setting

73

Page 79

SCANNER CONFIGURATION BAR CODES

EAS Bar Codes

EAS Deactivation

The following codes do not require that the MS2xx0 to be in scale

program mode.

Volume Switch = Manual

The volume switch is used for manual EAS

deactivation.

³146116

*Volume Switch = Normal

³146106

Volume switch is used for normal volume

function.

* Factory Default Setting

74

Page 80

SCANNER CONFIGURATION BAR CODES

EAS Bar Codes

Sensormatic ScanMax Pro

The following codes do not require that the MS2xx0 to be in scale

program mode.

The RS232 EAS cable must be connected to one of the RS232 scanner

ports.

EAS Function #3

³998067

For Sensormatic ScanMax Pro, get EAS’s

hardware version, software version, and

serial number and transmit the information

over the current scanner interface.

EAS Function #2

³998066

75

For Sensormatic ScanMax Pro, get EAS’s

device type and transmits the information

over the current scanner interface.

Page 81

SCANNER CONFIGURATION BAR CODES

EAS Bar Codes

Sensormatic ScanMax Pro

The following codes do not require that the MS2xx0 to be in scale

program mode.

The RS232 EAS cable must be connected to one of the RS232 scanner

ports.

EAS Function #1

³998065

For Sensormatic ScanMax Pro, get EAS’s

deactivation count and transmit the

information over the current scanner

interface.

ScanMax RS232 Defaults

For Sensormatic ScanMax Pro, RS232

default setup.

• AUX port connect

• 5 second timeout

• blink LED on deactivate

³999909

76

Page 82

SCANNER TEST BAR CODES

Supplemental Tests

Display Software Numbers

The following codes do not require that the MS2xx0 to be in scale

program mode.

These codes are for test purposes only.

The following code will display software #’s on the 2-digit diagnostic display. The

lasers will be turned off while the numbers are being displayed. The first number

is the main decode processor software number. The second number is the I/O

processor’s software number. Since only 2 digits can be displayed at a time, the

following sequence is used as an example of what may be observed:

2-Digit

Display

Description of each sequentially displayed sets of digits.

(Example shown will represent: ‘ 15269’ ‘ 15138’)

x 1 =

5 2 = The second and third digits.

6 9 = The forth and fifth digits.

x x = Pause before next set of numbers.

x 1 =

5 1 = The second and third digits.

3 8 = The forth and fifth digits.

x = Blank / No Digit Displayed

The first digit of the five main decode processor software number

appears right justified.

The first digit of the five digit I/O processor software number

appears right justified.

After the last sets of digits are displayed, the scanner resumes scanning

operation. If the current interface does not use an I/O processor, the software

number may appear ‘ 0 00 00’. This capability exists in software 15269 and

later.

Display Software Number

³998062

77

Page 83

78

Page 84

NOTES

Page 85

NOTES

Page 86

Page 87

Page 88

May 2008

Printed in the USA

00 - 02034E

Loading...

Loading...