Page 1

METROLOGIC® INSTRUMENTS, INC.

TECH 8

®

Laser Bar Code

Projection Scanner

Installation and User’s Guide

MLPN 2168

Printed in USA

October 1999 Rev 01

Page 2

Locations

USA Corporate Headquarters

Metrologic Instruments, Inc. Customer Service: 1-800-ID-METRO

90 Coles Rd. Telephone: 856-228-8100

Blackwood, NJ 08012-4683

Fax: 856-228-6673

Email: info@metrologic.com

Internet: http://www.metrologic.com

South America

Rua Flórida 1.821, 5° Andar- Brooklin

CEP 04571-090, São Paulo-SP, Brasil

Outside Brazil

Metrologic South America Fax: 55-11-5505-1681

In Brazil Telephone: 55-11-5505-2396

Metrologic do Brasil Ltda

Outside Brazil

Telephone: 55-11-5505-6568

Email: info@sa.metrologic.com

In Brazil

Fax: 55-11-5507-2301

Email: metrolog@br.metrologic.com

Europe

Metrologic Instruments GmbH Telephone: 49-89-89019-0

Dornierstrasse 2

82178 Puchheim b. Fax: 49-89-89019-200

Munich, Germany

Email: metrologic@europe.metrologic.com

Asia

Metrologic Asia (PTE) Ltd. Telephone: 65-842-7155

31, Kaki Bukit Road 3

#05-08 Techlink Fax: 65-842-7166

Singapore 417818

Email: ahsu@sg.metrologic.com

Copyright

© 1999 by Metrologic

transmitted, or stored in any form or by any means without prior written consent, except by reviewer, who

may quote brief passages in a review, or provided for in the Copyright Act of 1976.

Products and brand names mentioned in this document are trademarks of their respective companies.

Instruments, Inc. All rights reserved. No part of this work may be reproduced,

ii

Page 3

Table of Contents

Unpacking List................................................................................................................................1

Introduction ....................................................................................................................................1

Labels............................................................................................................................................ 2

Applications and Protocols ........................................................................................................... 2

Maintenance.................................................................................................................................. 3

Configuration of the Scanner to the Host System ........................................................................ 3

Scanner Connections.................................................................................................................... 4

Attaching the Scanner to the Stand and Work Surface ............................................................... 5

Scanning Bar Codes..................................................................................................................... 6

Appendix A

Specifications................................................................................................................. 7, 8

Appendix B

Version A1 Pin Assignments for the Mil spec Connector................................................. 9

Version A15 Pin Assignments for the Mil spec Connector............................................. 10

Appendix C

Warranty and Disclaimer .................................................................................................11

Appendix D

Notices ...................................................................................................................... 12, 13

Appendix E

Patents ............................................................................................................................ 14

Index...................................................................................................................................... 15, 16

iii

Page 4

Unpacking List

The shipping carton, will contain the following:

®

• TECH 8

• Installation and User’s Guide

• ScanSelect™ Scanner Programming Guide

• Communication Cable (optional) or Communication Cable with Power Supply (optional)

Laser Bar Code Projection Scanner

• Stand (optional)

If any item is missing or to order additional items, contact the dealer, distributor or call

Metrologic’s Customer Service Department at 1-800-ID-METRO or 1-800-436-3876.

Introduction

Metrologic’s TECH 8® laser bar code projection scanner is encased in an NEMA-12 steel case.

The scanner’s construction enables the scanner to operate in harsh surroundings, especially

industrial environments. Water-resistant, shock-resistant, and rugged, the TECH 8 scanner is

also fast, aggressive and reliable. It can register bar codes at a range of 203mm - 457mm

(8" - 18") and can autodiscriminate among all common codes.

Among the scanner’s many features is an ASIC (Application Specific Integrated Circuit) in the

decoding system that virtually eliminates misreads and MECCA

Correcting Algorithm). MECCA

©

enables the scanner to read poorly printed, wrinkled or even

©

(Metrologic Enhanced Code

torn bar codes on the first pass.

The scanner has been configured at the time of manufacture based on information supplied at

the time of order.

1

Page 5

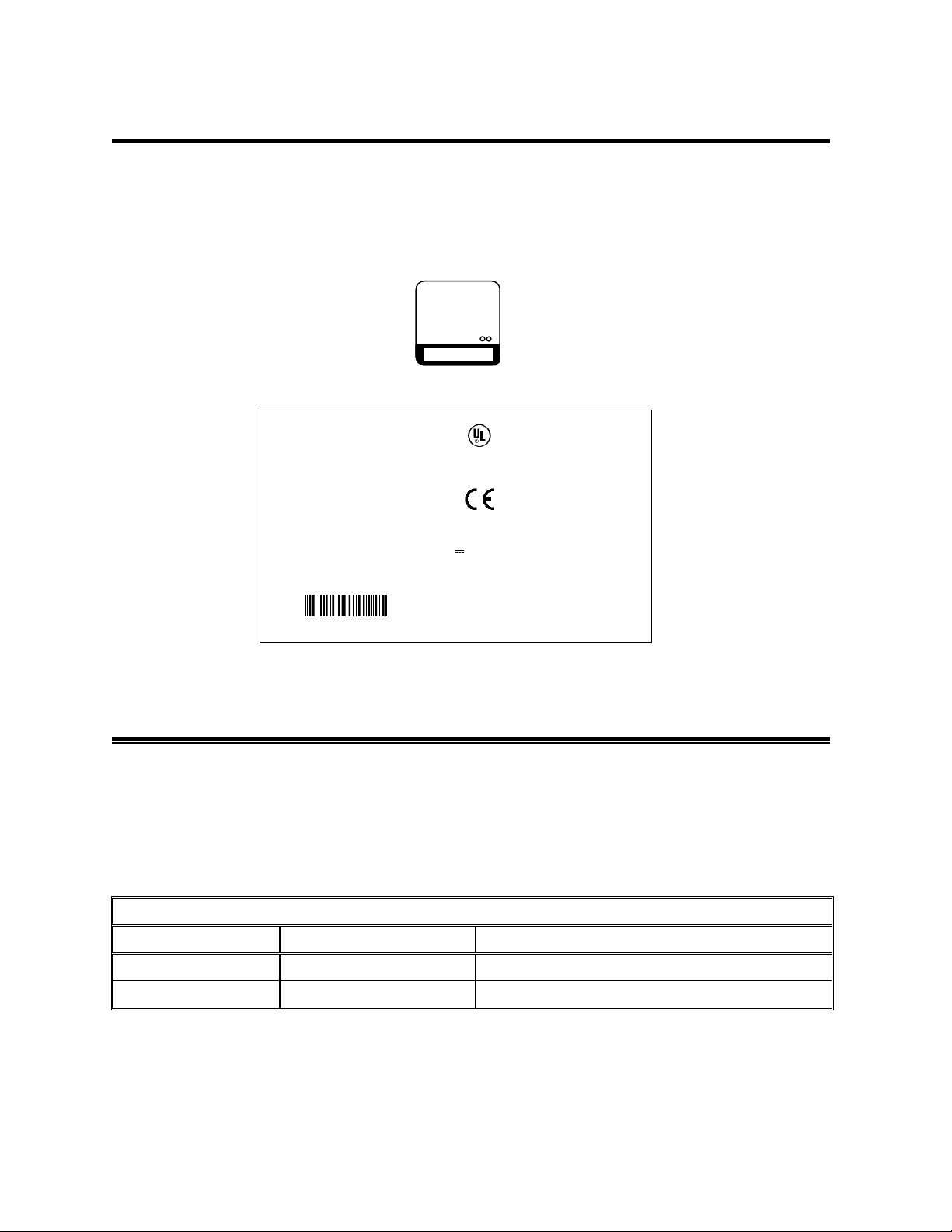

Labels

The first label is found inside the window of the scanner noting that this device is a CDRH Class

IIa laser product and EN 60825-1 LASERKLASSE 1. The second label is located on back of the

scanner. This label contains information such as the model number, the date of manufacture

and the serial number. The following are samples of the labels that are found on the unit.

Complies with 21 CFR

Chapter 1 subchapter

J. Class IIa laser

Product. Avoid longterm viewing of direct

laser light.

LASERKLASSE 1

Metrologic

Metrologic Instruments, Inc.

Blackwood, New Jersey, USA

Contains no user serviceable

components.

Warranty void if case is opened.

Complies with FCC and ICES-003 de la vue au rayonnement laser

Class A. See manual. direct. Apprareil laser Classe IIa

Manufactured Blackwood, NJ.

October 1999

Model :

Serial # :

®

IS872-E1

TECH 8™ Barcode Scanner

XXXXXXXXXX

C

11-30V

This product complies with US

DHHS Standard 21 CFR Chapter

US

1 Subchapter J. Class IIa Laser

LISTED

Product. Avoid long-term viewing

94J8

I.T.E.

of direct laser light.

Eviter toute exposition prolongee

CAUTION:

Laser light when opened.

DO NOT STARE INTO BEAM.

Applications and Protocols

The following chart lists the version identifiers for all the communication protocols. Listed on

each scanner is a model number. The model number includes the scanner number, revision

label, and denoted version identifier. For example, if the model number is MS870-B1, the

scanner is an MS870, B is the revision level, and 1 is the version identifier.

2

B UNITS

Scanner Version Identifier Communication Protocol(s)

MS870 1 RS-232, OCIA

MS870 15 Light Pen Emulation

Page 6

Maintenance

Smudges or dirt that appears on the scanner window can interfere with proper scanning.

Therefore, the window will need occasional cleaning.

1. Spray glass cleaner onto lint free, non-abrasive cleaning cloth.

2. Gently wipe the scanner window.

Configuration of the Scanner to the Host System

The scanner has been configured at the time of manufacture based on information supplied at

the time of order. If ScanSet

on how to configure your scanner.

®

is being used, refer to the ScanSet documentation for information

3

Page 7

Scanner Connections

In order for the scanner to maintain compliance with applicable standards, all circuits connected

to the scanner must meet the requirements for SELV (Safety Extra Low Voltage) according to

EN 60950.

To avoid potential problems, do not power up the scanner until the communication

cable is secured to the host.

1. Turn off the host system.

2. Find the 19-pin female end of the scanner link cable and the widest key located above

pins L and A. Align this key with the corresponding key on the scanner box’s Mil spec

connector. While pushing in on the connector, rotate the ring clockwise until it locks

into place with a click.

3. Connect the other end of the communication cable to the host device.

The following statement is applicable if the optional power adapter available through

Metrologic does not power the bar code scanner, and the scanner receives power from

a host device such as a computer system.

Caution: To maintain compliance with standards CSA C22.2 No. 950/UL 1950 and

If the scanner will not receive power from a transformer, skip to Step 6.

4. If the scanner will receive power from an external power source, check the AC input

requirements of the transformer to make sure the voltage matches the AC outlet.

(A socket-outlet should be installed near the equipment and must be easily accessible.)

norm EN 60950, the power source must meet applicable performance

requirements for a limited power source.

5. Plug the transformer into the AC outlet to supply power to the scanner.

6. Power up the host system.

7. Scan a few items to verify that data is being properly transmitted between the scanner

and the host device.

4

Page 8

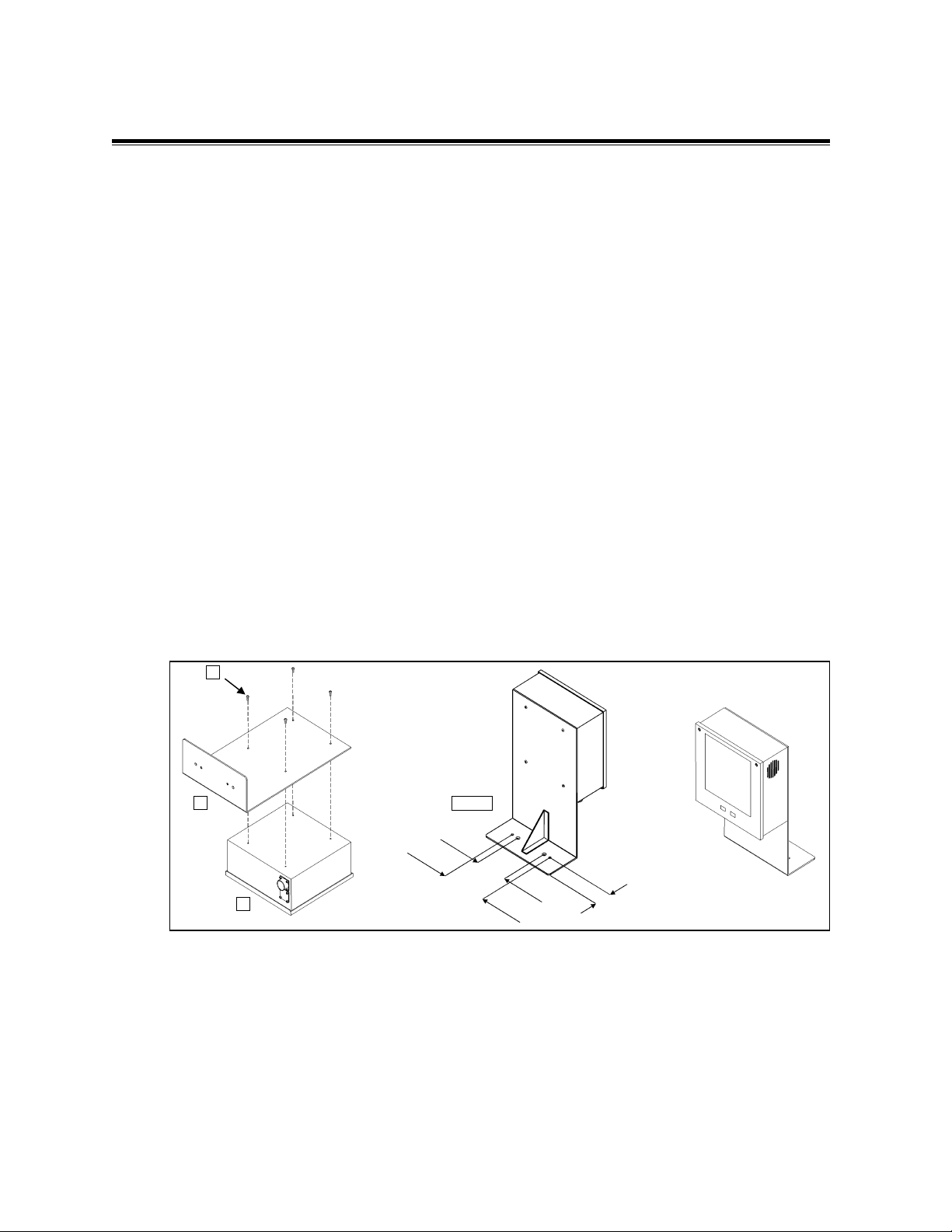

Attaching the Scanner to the Stand and Work Surface

The scanner can be positioned in a vertical orientation with the Metrologic stand (Part #45478).

To attach the unit to the stand and work surface purchase the following: four 6-32 x ½"

(maximum length) machine screws and two (2) #10 pan head or two (2) #8 countersunk wood

screws. (Refer to figure 1)

1. Lay the scanner face down on a clean cloth to prevent any scratches from occurring

on the output window. Position the scanner so the red and green LEDs are pointed

toward you.

2. Lay the stand on the scanner with the angled bracket pointing up and toward you.

3. Align the four clearance holes to the four holes in the scanner’s case. Fasten the

scanner to the stand by inserting the four 6-32 x ½" screws into the four holes in the

scanner’s case.

4. Drill two holes into the work surface that correspond with the holes in the

216mm - 96mm (8.5" x 3.80") base of the stand.

5. Use two pan head or countersunk wood screws to attach the scanner and stand to the

work surface.

3

4 & 5 2

3.50 in.

5.00 in.

1

Figure 1: Stand Installation

1.90 in.

5

Page 9

Scanning Bar Codes

The depth of field for the scanner is 203mm to 457mm (8" to 18") from the scanner window.

The symbol must be passed through the scan area in order for the scanner to recognize the bar

code. (Refer to Figure 2)

6

Figure 2

Page 10

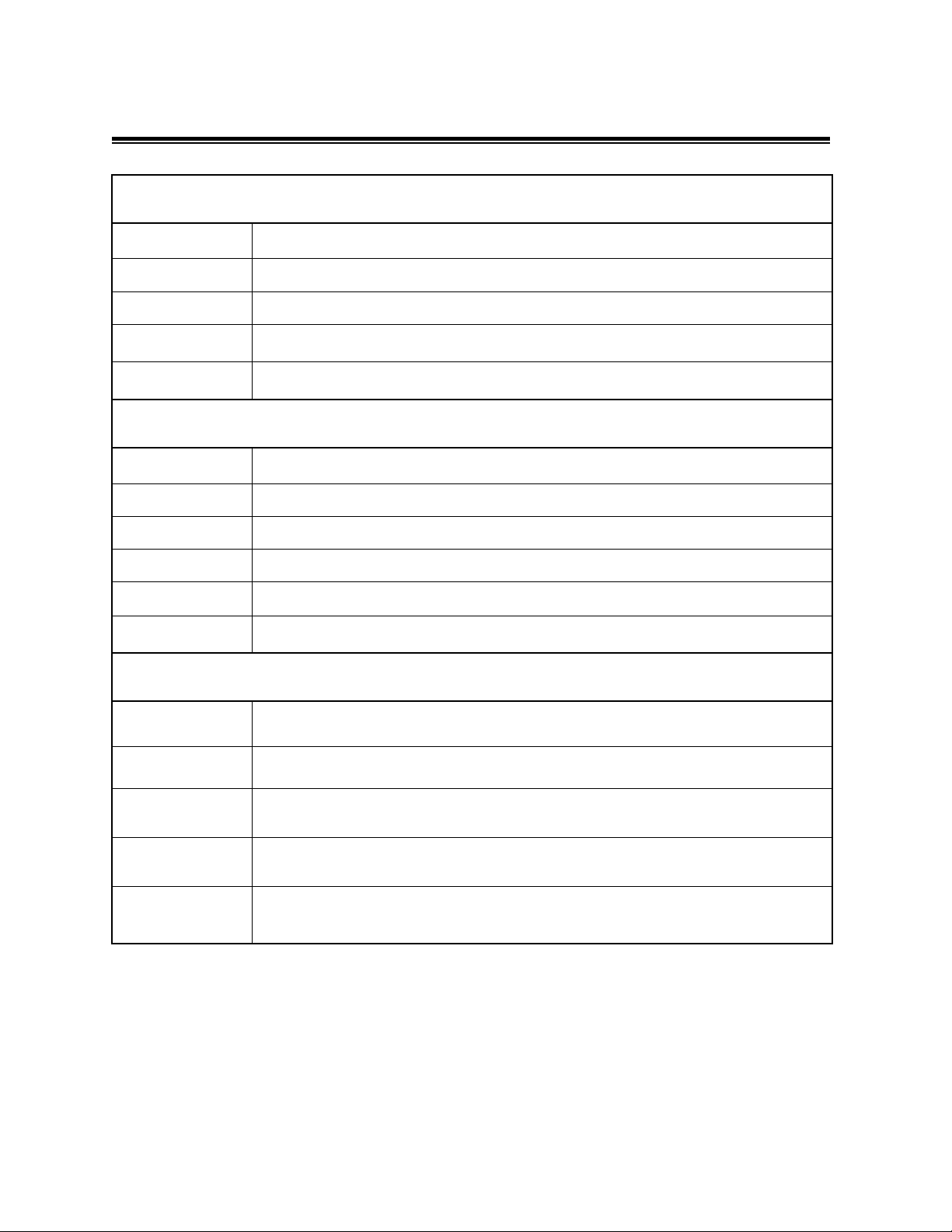

Appendix A

Application

Light Source

Laser Class

EMC

EMI

Dimensions

Weight

Orientation

Mounting

Top Cover

Cable Length

TECH 8

®

Laser Bar Code Scanner Specifications

Industrial Scanner

Visible Laser Diode 670 ± 5nm

CDRH: Class IIa; EN 60825: Class 1

CE, UL listed for US and Canada

FCC, ICES-003 & EN 55022 Class A

Mechanical

203mm x 216mm x 96mm (8"L x 8.5"W x 3.8"D)

3.5kg. (7.75 lbs.) without cable

May be used in any orientation

Vertical stand

NEMA-12 steel case

1.83m (6') cable with mil spec connector

Electrical

Power 9 watts, host system or wall transformer

Input Voltage 11-30 VDC

Operating

Current

Standby

Current

DC

Transformers

Specifications subject to change without notice.

6061/6113-220V (AC in) 6062/6114-120V (AC in) 6115-240V (AC in)

450mA typical @ 20V

210mA typical @ 20V

output 24/20VDC @ 750mA

7

Page 11

Appendix A (Continued)

Operational

Depth of Scan Field 203mm to 457mm (8" to 18")

Scan Speed

Scan Pattern

Indicators LED: green=on ready to scan; red=good read

Beeper Operation Selection of 3 tones for “Good Read”

Maintenance Required Clean window periodically

Decode Capability Autodiscriminates

System Interfaces RS-232C; Light Pen Emulation; OCIA

Optional Interfaces

Print Contrast 35% minimum reflectance difference

Roll, Pitch, Yaw 360°, 60°, 60°

Opto coupled 6 amp US and Canada, 5 amps EEA countries

Model 870 1250 scan lines per second

Model 875: 450 scan lines per second

Model 870: Omnidirectional (20 interlocking lines)

Model 875: 6-line raster

TRIAC output; object sensor input

Environmental

Storage Temperature -40°C to 60°C (-40°F to 140°F)

Operating Temperature 0°C to 35°C (32°F to 95°F)

Humidity 5% to 95% relative humidity, non-condensing

Light Levels Up to 3200 foot candles - works in direct sun

Ventilation None required

Shock 100g for 1ms

ESD 8kV IEC 801-2

Contaminants

Specifications subject to change without notice

8

Protects against dust, falling dirt, and dripping

non-corrosive liquid

.

Page 12

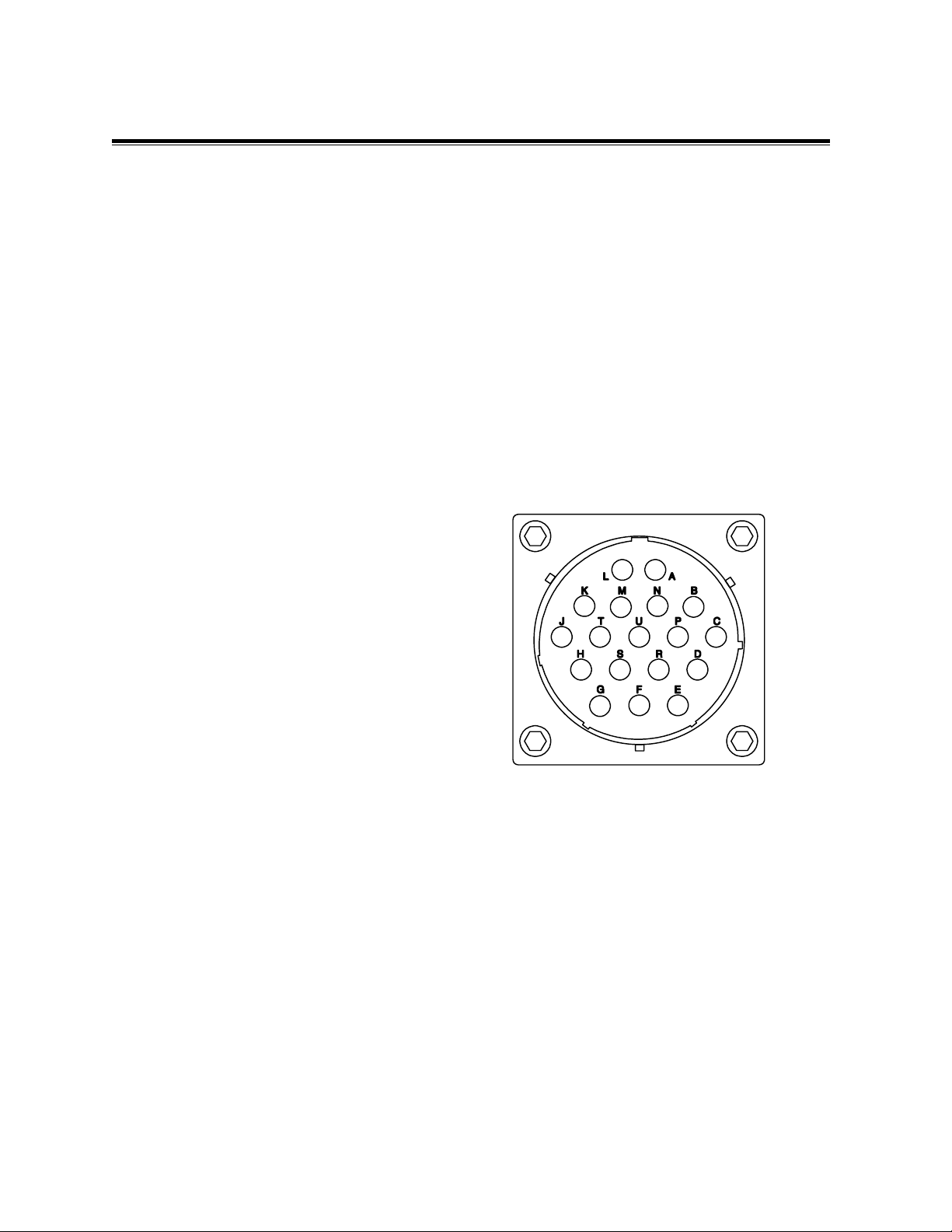

Appendix B

Version A1 Pin Assignments for the Mil spec Connector

Each TECH 8 scanner has a 19-pin male Mil spec connector that is found on the side of the unit.

To connect the scanner to the host device, use a communication cable with a female Mil spec

connector. The communication cable may include a power transformer or it may be designed to

draw power directly from the host device. This item can be ordered when the scanner is

purchased.

The following is a list of pin assignments for Version A1 scanners. The communication

protocols for Version A1 are RS-232 and OCIA. The pin numbers are impressed on the male

Mil spec connector. For easier reference, refer to Figure 3 for pin locations.

PIN FUNCTION

A R Data

B RTS Output

C Signal Ground

D CTS Input

E R Data Return

F RS-232 Output

G Clock In

H Clock In Return

J Clock Out

K Shield Ground

L DTR Input

M Clock Out Return

N Power to Scanner + 24 VDC

P Earth Ground

R Power Ground

S RS-232 Input

Figure 3

9

Page 13

Appendix B (Continued)

Version A15 Pin Assignments for the Mil spec Connector

Each TECH 8 scanner has a 19-pin male Mil spec connector that is found on the side of the unit.

To connect the scanner to the host device, use a communication cable with a female Mil spec

connector. The communication cable may include a power transformer or it may be designed to

draw power directly from the host device. This item can be ordered when the scanner is

purchased.

The following is a list of pin assignments for Version A15 scanners. The communication

protocol for Version A15 is light pen emulation. The pin numbers are impressed on the male Mil

spec connector. For easier reference, refer to Figure 4 for pin locations.

PIN FUNCTION

A R Data

B

C

D

E

F

G

H Clock In Return

J Clock Out

K Shield Ground

L

M

N Power to Scanner + 24 VDC

P Earth Ground

R Power Ground

S RS-232 Input

Light Pen Data Output

Signal Ground

Light Pen Source + 5 VDC

R Data Return

RS-232 Output

Clock In

DTR Input

Clock Out Return

Figure 4

10

Page 14

Appendix C

Warranty and Disclaimer

Limited Warranty

The Tech 8® Series of scanners are manufactured by Metrologic at its Blackwood, New Jersey, U.S.A.

facility. The Tech 8 Series scanners have a two (2) year limited warranty from the date of manufacture.

Metrologic warrants and represents that all Tech 8 Series scanners are free of all defects in material,

workmanship and design, and have been produced and labeled in compliance with all applicable U.S.

Federal, state and local laws, regulations and ordinances pertaining to their production and labeling.

This warranty is limited to repair, replacement of Product or refund of Product price at the sole discretion

of Metrologic. Faulty equipment must be returned to the Metrologic facility in Blackwood, New Jersey,

U.S.A. or Puchheim, Germany. To do this, contact a Metrologic’s Customer Service/Repair Department to

obtain a Returned Material Authorization (RMA) number.

In the event that it is determined the equipment failure is covered under this warranty, Metrologic shall,

at its sole option, repair the Product or replace the Product with a functionally equivalent unit and return

such repaired or replaced Product without charge for service or return freight, whether distributor,

dealer/reseller, or retail consumer, or refund an amount equal to the original purchase price.

This limited warranty does not extend to any Product which, in the sole judgement of Metrologic, has

been subjected to abuse, misuse, neglect, improper installation, or accident, nor any damage due to

use or misuse produced from integration of the Product into any mechanical, electrical or computer

system. The warranty is void if the case of Product is opened by anyone other than Metrologic’s repair

department or authorized repair centers.

THIS LIMITED WARRANTY, EXCEPT AS TO TITLE, IS IN LIEU OF ALL OTHER WARRANTIES OR

GUARANTEES, EITHER EXPRESS OR IMPLIED, AND SPECIFICALLY EXCLUDES, WITHOUT

LIMITATION, WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR

PURPOSE UNDER THE UNIFORM COMMERCIAL CODE, OR ARISING OUT OF CUSTOM OR

CONDUCT. THE RIGHTS AND REMEDIES PROVIDED HEREIN ARE EXCLUSIVE AND IN LIEU OF

ANY OTHER RIGHTS OR REMEDIES. IN NO EVENT SHALL METROLOGIC BE LIABLE FOR ANY

INDIRECT OR CONSEQUENTIAL DAMAGES, INCIDENTAL DAMAGES, DAMAGES TO PERSON

OR PROPERTY, OR EFFECT ON BUSINESS OR PROPERTY, OR OTHER DAMAGES OR

EXPENSES DUE DIRECTLY OR INDIRECTLY TO THE PRODUCT, EXCEPT AS STATED IN THIS

WARRANTY. IN NO EVENT SHALL ANY LIABILITY OF METROLOGIC EXCEED THE ACTUAL

AMOUNT PAID TO METROLOGIC FOR THE PRODUCT.

METROLOGIC ALSO RESERVES THE RIGHT TO MAKE ANY CHANGES TO THE PRODUCT

DESCRIBED HEREIN.

Metrologic Instruments, Inc. Metrologic Instruments GmbH

90 Coles Road Dornierstrasse 2

Blackwood, NJ 08012-4683 82178 Puchheim b

Customer Service Department Munich, Germany

1-800-ID-METRO (1-800-436-3876) TEL: 49-89-89019-0

TEL: 856-228-8100 FAX: 49-89-89019-200

FAX: 856-228-6673

11

Page 15

Appendix D

Notices

Notice

This equipment has been tested and found to comply with limits for a Class A digital device, pursuant to Part 15 of

the FCC Rules. These limits are designed to provide reasonable protection against harmful interference when the

equipment is operated in a commercial environment. This equipment generates, uses and can radiate radio

frequency energy and, if not installed and used in accordance with the instruction manual, may cause harmful

interference to radio communications. Operation of this equipment in a residential area is likely to cause harmful

interference, in which case the user will be required to correct the interference at his own expense. Any

unauthorized changes or modifications to this equipment could void the users authority to operate this device.

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two conditions: (1) This

device may not cause harmful interference, and (2) this device must accept any interference received, including

interference that may cause undesired operation.

Notice

This Class A digital apparatus complies with Canadian ICES-003.

Remarque

Cet appareil numérique de la classe A est conforme à la norme NMB-003 du Canada.

Caution

Use of controls or adjustments or performance of procedures other than those specified herein may result in

hazardous laser light exposure. Under no circumstances should the customer attempt to service the laser scanner.

Never attempt to look at the laser beam, even if the scanner appears to be nonfunctional. Never open the scanner in

an attempt to look into the device. Doing so could result in hazardous laser light exposure. The use of optical

instruments with the laser equipment will increase eye hazard.

Atención

La modificación de los procedimientos, o la utilización de controles o ajustes distintos de los especificados aquí,

pueden provocar una luz de láser peligrosa. Bajo ninguna circunstancia el usuario deberá realizar el mantenimiento

del láser del escáner. Ni intentar mirar al haz del láser incluso cuando este no esté operativo. Tampoco deberá abrir

el escáner para examinar el aparato. El hacerlo puede conllevar una exposición peligrosa a la luz de láser. El uso de

instrumentos ópticos con el equipo láser puede incrementar el riesgo para la vista.

Attention

L'emploi de commandes, réglages ou procédés autres que ceux décrits ici peut entraîner de graves irradiations. Le

client ne doit en aucun cas essayer d'entretenir lui-même le scanner ou le laser. Ne regardez jamais directement le

rayon laser, même si vous croyez que le scanner est inactif. N'ouvrez jamais le scanner pour regarder dans

l'appareil. Ce faisant, vous vous exposez à une rayonnement laser qú êst hazardous. L'emploi d'appareils optiques

avec cet équipement laser augmente le risque d'endommagement de la vision.

Achtung

Die Verwendung anderer als der hier beschriebenen Steuerungen, Einstellungen oder Verfahren kann eine

gefährliche Laserstrahlung hervorrufen. Der Kunde sollte unter keinen Umständen versuchen, den Laser-Scanner

selbst zu warten. Sehen Sie niemals in den Laserstrahl, selbst wenn Sie glauben, daß der Scanner nicht aktiv ist.

Öffnen Sie niemals den Scanner, um in das Gerät hineinzusehen. Wenn Sie dies tun, können Sie sich einer

gefährlichen Laserstrahlung aussetzen. Der Einsatz optischer Geräte mit dieser Laserausrüstung erhöht das Risiko

einer Sehschädigung.

Attenzione

L’utilizzo di sistemi di controllo, di regolazioni o di procedimenti diversi da quelli descritti nel presente Manuale può

provocare delle esposizioni a raggi laser rischiose. Il cliente non deve assolutamente tentare di riparare egli stesso

lo scanner laser. Non guardate mai il raggio laser, anche se credete che lo scanner non sia attivo. Non aprite mai

lo scanner per guardare dentro l’apparecchio. Facendolo potete esporVi ad una esposizione laser rischiosa. L’uso

di apparecchi ottici, equipaggiati con raggi laser, aumenta il rischio di danni alla vista.

12

Page 16

Appendix D (Continued)

European Standard

Warning

This is a class A product. In a domestic environment this product may cause radio

interference in which case the user may be required to take adequate measures.

Funkstöreigenschaften nach EN 55022:1998

Warnung!

Dies ist eine Einrichtung der Klasse A. Diese Einrichtung kann im Wohnbereich

Funkstörungen verursachen; in diesem fall kann vom Betrieber verlangt werden,

angemessene Maßnahmen durchführen.

Standard Europeo

Attenzione

Questo e’ un prodotto di classe A. Se usato in vicinanza di residenze private potrebbe

causare interferenze radio che potrebbero richiedere all’utilizzatore opportune misure.

Attention

Ce produit est de classe “A”. Dans un environnement domestique, ce produit peut être la

cause d’interférences radio. Dans ce cas l’utiliseteur peut être amené à predre les mesures

adéquates.

13

Page 17

Appendix E

Patents

For patent information, please refer to www.honeywellaidc.com/patents.

14

Page 18

Index

A

AC outlet 4

Application 7

Application and protocols 2

Asia ii

ASIC 1

Attaching stand 5

A1 pin assignments 9

A15 pin assignments 10

B

B units 2

Bar codes 6

Base 5

Beeper operation 8

Bracket 5

C

Case 1, 5, 7

CDRH class IIa 2, 7

CDRH/IEC 7

CE Mark 7

Class 1 7

Clean 3, 8

Communication cable 1,4, 9, 10

Communication protocol 2

Compliance 4

Configuration 3

Connectors 4, 7, 9, 10

Connections 4

Construction 1

Containments 8

Contrast 8

Copyright ii

Current 7

Customer Service ii, 11

D

DC transformer 7

Decode capability 8

Depth of field 6, 8

Dimensions 7

Disclaimer 11

E

Electrical 7

Email ii

EN 60825-1 2, 4

Environmental 8

ESD 8

EU 7

Europe

Exit angle

F

Faulty equipment

Fax

Functions 9, 10

G

Germany (GmbH)

Good read

Guides 1

H

Headquarters

Host

Humidity 8

I

Input voltage

Internet

Introduction 1

K

Key 4

L

Labels 2

LASERKLASSE 1 2

LEDs 5

Light levels 8

Light pen emulation 2, 8

Light source 7

Limited warranty 11

Link cable 4

Locations ii

M

Maintenance 3, 8

MECCA 1

Mechanical 7

Mil spec connector 4, 7, 9, 10

Model number 2

Mounting options 7

3, 4, 9, 10

8

11

11

8

7

ii

ii

ii

ii

15

Page 19

Index

N

NEMA-12 steel case

Notices

O

OCIA

Operating current

Operating temperature

Operational

Optional interfaces

Orientation

P

Patents

Pin assignments

Power consumption

Print contrast

Programming guide

Protocols

R

RMA

Roll, pitch, yaw

RS-232

S

Scan field

Scanning bar codes

Scan pattern

Scanner connections

ScanSet

ScanSelect manual

Scan speed

Service

1, 7

12, 13

2, 9

7

8

8

8

7

15

9, 10

7

8

1

2

11

8

2, 8, 9

6, 8

6

8

4

3

1

8

1, 11

Shipping carton 1

Socket-outlet 4

South America ii

Specifications 7, 8

Stand 1, 5, 7

Storage temperature 8

System interfaces 8

T

Temperature 8

Top cover 7

Transformer 4, 7, 9, 10

U

UL/CSA 7

Units 2

USA corporate headquarters ii

V

Ventilation 8

Version A1 9

Version A15 10

Version identifiers 2

Vertical stand 1, 5, 7

Visible laser diode 7

Voltage 4, 7

W

Warranty 11

Weight 7

Window 2, 3, 5, 6, 8

16

Loading...

Loading...