Page 1

METROLOGIC INSTRUMENTS, INC.

TECH 7™ Laser Bar Code

Projection Scanner

Installation and User’s Guide

MLPN 2159

Printed in USA

June 1998

Page 2

Locations:

USA Corporate Headquarters South America

Metrologic Instruments, Inc. Metrologic Instruments

90 Coles Road Centro Ciudad Comercial Tamanaco

Blackwood, NJ 08012 Torre B, piso 6, ofic. 603-B

Customer Service: 1-800-ID-METRO Chuao 1064

Tel: 609-228-8100 Caracas, Venezuela

Fax: 609-228-6673 Tel: 58-2-959-8911

EMAIL: info@metrologic.com Fax: 58-2-959-9328

INTERNET: http://www.metrologic.com EMAIL: info@sa.metrologic.com

Mailing Address:

P.O. Box 307

Bellmawr, NJ 08099-0307

Europe ASIA

Metrologic Instruments GmbH Metrologic Asia (PTE) Ltd.

Dornierstrasse 2 31, Kaki Bukit Road 3

82178 Puchheim b. #05-08,

Munich, Germany Techlink

Tel: 49-89-89019-0 Singapore 417818

Fax: 49-89-89019-200 Tel: 65-842-7155

EMAIL: metrologic@europe.metrologic.com Fax: 65-842-7166

EMAIL: ant888@cyberway.com.sg

Brasil

Metrologic do Brasil Ltda.

Rua Florida, 1821-5 andar

Brooklin-Sao Paulo-SP

04571-090 Brasil

Tel: (011) 5505-2396

Fax: (011) 5507-2301

EMAIL: metrolog@br.metrologic.com

Copyright

© 1999 by Metrologic Instruments, Inc. All rights reserved. No part of this work may

®

be reproduced, transmitted, or stored in any form or by any means without prior written

consent, except by reviewer, who may quote brief passages in a review, or provided for

in the Copyright Act of 1976.

Products and brand names mentioned in this document are trademarks of their

respective companies.

ii

Page 3

Table of Contents

Introduction .................................................. 1

Unpacking List ................................................ 1

Scanner Installation ............................................. 2

Configuration to the Host System .................................. 3

Stand Installation ............................................... 4

Back Plate Installation .......................................... 5

Parts of the Scanner ............................................. 6

Visual Indicators ............................................ 7-10

Labels ....................................................... 11

Depth of Scan Field for the MS770 Scanner ........................ 12

Depth of Scan Field for the MS775 Scanner ........................ 13

Applications and Protocols ...................................... 14

Maintenance .................................................. 14

Appendix A

Specifications ...................................... 15, 16

Appendix B

Pin Assignments .................................... 17, 18

Appendix C

Warranty and Disclaimer ............................. 19, 20

Appendix D

Notices ........................................... 21, 22

Appendix E

Patents ............................................... 23

Index .................................................... 24, 25

iii

Page 4

Introduction

Metrologic’s TECH 7 laser bar code projection scanner is encased in an

NEMA-12 steel case. The case construction enables the scanner to operate in

harsh surroundings, especially industrial environments. Water-resistant,

shock-resistant, and rugged, the TECH 7 is also fast, aggressive and reliable. It

can register bar codes at a range of 76mm - 254mm (3" - 10") and can

autodiscriminate among all common codes.

To suit particular applications, two different scan patterns are available: an

omnidirectional pattern of 20 interlocking lines (Model MS770); or a 12-line

raster pattern (Model MS775). The scanner has a VLD design, a scan speed of

up to 2000 lines per second, and uses less than 8 watts of power.

Other features include an Application Specific Integrated Circuit (ASIC) and

MECCA (Metrologic Enhanced Code Correcting Algorithm). An Application

Specific Integrated Circuit (ASIC) is in the decoding system and virtually

eliminates misreads. MECCA (Metrologic Enhanced Code Correcting

©

©

Algorithm) enables the TECH 7 scanner to read poorly printed, wrinkled or

even torn bar codes on the first pass.

Unpacking List

The shipping carton, should contain the following:

! Installation and User’s Guide (MLPN: 2159)

! ScanSelect Scanner Programming Guide (MLPN: 2186)

! TECH 7 Model MS770 with omnidirectional scan pattern or

TECH 7 Model MS775 with raster scan pattern

! Communication Cable with Power Supply (optional) or

Communication Cable (optional)

! Back Plate (optional) or Stand (optional)

If any item is missing or to order additional items, contact the dealer, distributor or call Metrologic’s Customer Service Department at 1-800-IDMETRO or 1-800-436-3876.

1

Page 5

Scanner Installation

To maintain compliance with applicable standards, all circuits connected to the

scanner must meet the requirements for SELV (Safety Extra Low Voltage)

according to EN 60950. To avoid potential problems, do not power up the

scanner until the communication cable is secured to the host.

1. "Power off" the host system.

2. Locate the 19-pin female end of the scanner link cable and find the

widest key located above pins L and A. Align this key with the

corresponding key on the scanner box’s Mil spec connector. While

pushing in on the connector, rotate the ring clockwise until it locks into

place with a click.

3. Connect the other end of the communication cable to the host device. (If

the scanner is powered by the host, skip to Step 5.)

4. Check the AC input requirements of the transformer/power supply to

make sure the voltage matches an available AC outlet. Plug the

transformer into the AC outlet to supply power to the scanner. (A

socket-outlet shall be installed near the equipment and shall be easily

accessible.)

5. "Power up" the host system.

Note: When the scanner first receives power, the LEDs will flash and

then the scanner will beep once. After the scanner performs this

startup sequence, the green LED will remain on for a specified

time indicating that the laser is on.

2

Page 6

Configuration to the Host System

The scanner is shipped from the factory programmed to a set of default

conditions noted in the ScanSelect Scanner Programming Guide by an asterisk

that appears before the brief definition located next to the bar code.

In order for the scanner to communicate with a host system properly, it may

need to be programmed. Since each host system is unique, configure the

scanner to match the host system requirements. Configure the scanner by

entering the program mode and scanning the appropriate bar codes that appear

in the ScanSelect Scanner Programming Guide. (To use ScanSet™, refer to

the ScanSet documentation for information on how to configure a scanner.)

1. Connect the scanner to the host system (Refer to the Scanner

Connections to the Host section in this guide).

2. Enter program mode by scanning the ENTER/EXIT program mode bar

code. (The unit will beep three times)

3. Scan the appropriate bar code(s) that appear in the ScanSelect Scanner

Programming Guide. (Reveal only one bar code to the scanner each

time. With your hand, cover the bar code not to be scanned.)

4. Exit program mode by scanning the ENTER/EXIT program mode bar

code again. (The new options will be saved and the scanner is ready for

normal operation.)

3

Page 7

Stand Installation

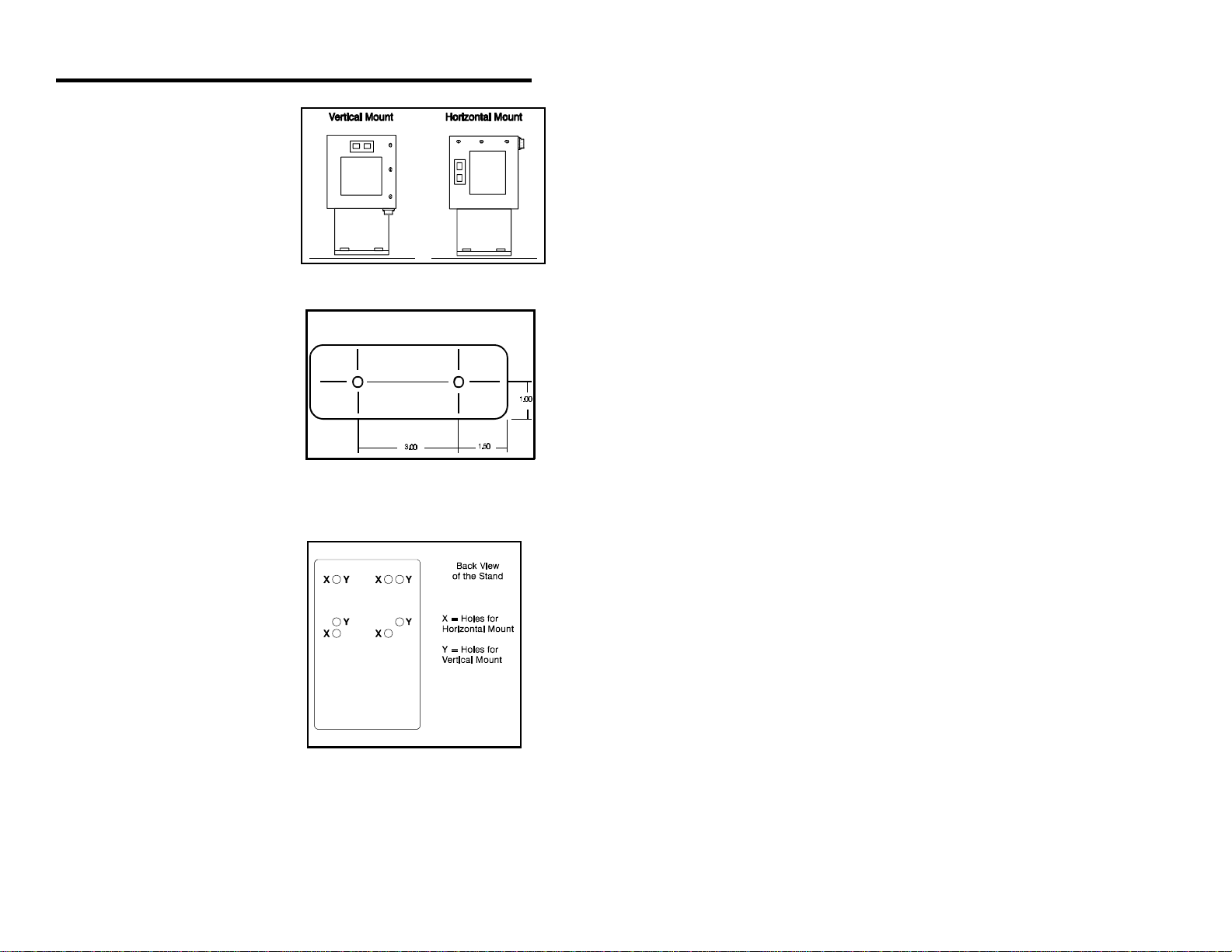

With the Metrologic stand (Part

#45475), the scanner can be

positioned in one of two directions.

The two orientation choices are

vertical or horizontal. (Refer to

Figure 1)

To install this stand, use the four 632 x ½ inch machine screws and two

#10 panhead wood screws.

Figure 1

1. Drill two holes into the work

surface that are the same size

and distance as the holes on

the stand base. (Refer to Figure

2)

2. Use the two #10 panhead

wood screws to attach the

stand to the work surface.

3. To fasten the scanner:

! For a horizontal mount,

align the four holes on the

back of the scanner with

the four clearance holes

located on the stand

marked with an X in

Figure 3.

! For a vertical mount, align

the four holes on the back

of the scanner with the

four clearance holes

located on the stand

marked with a Y in Figure

3.

Base of Stand

Figure 2

Figure 3

4. Fasten the scanner to the stand by inserting the four 6-32 x ½ inch

screws into the four holes in the scanner’s case.

4

Page 8

Back Plate Installation

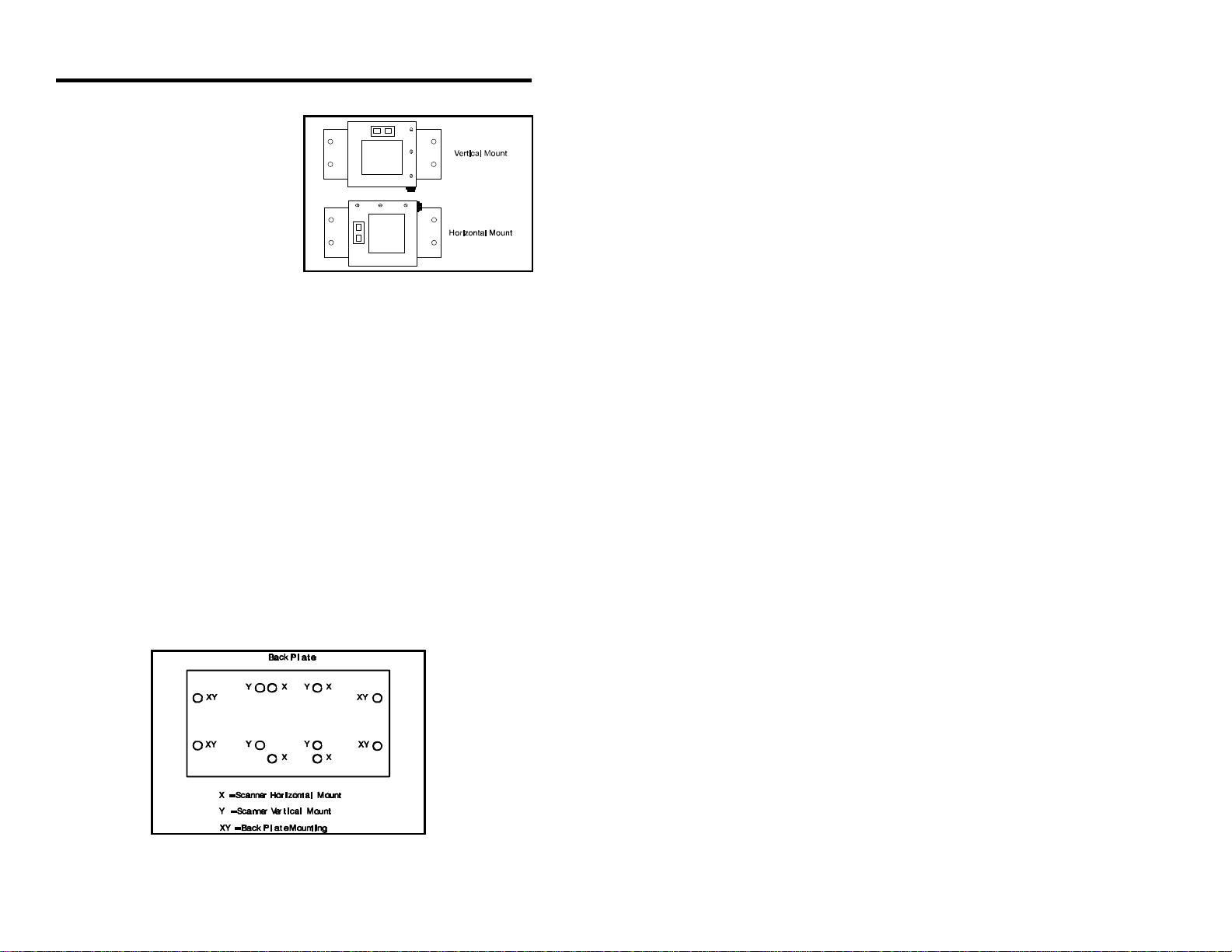

With the Metrologic back plate

(Part #45473), position the scanner

in one of two directions. The two

orientation choices are vertical or

horizontal. (Refer to Figure 4). To

use this stand, use the four 6-32 x ½

inch machine screws and four wood

screws to attach the unit to the back

plate and work surface. The maximum distance the screws should go

into the scanner is a ½ inch.

1. Drill four holes into the work surface that correspond with the holes

indicated by an XY in Figure 5.

2. To fasten the scanner to the back plate:

! For a horizontal mount, align the four holes on the back of the

scanner with the four clearance holes located on the back plate

marked with an X in Figure 5.

! For a vertical mount, align the four holes on the back of the

scanner with the four clearance holes located on the back plate

marked with a Y in Figure 5.

Figure 4

3. Fasten the scanner to the back plate by inserting the four 6-32 x ½ inch

screws into the four holes in the scanner’s case. Fasten the scanner and

back plate to the work surface.

Figure 5

5

Page 9

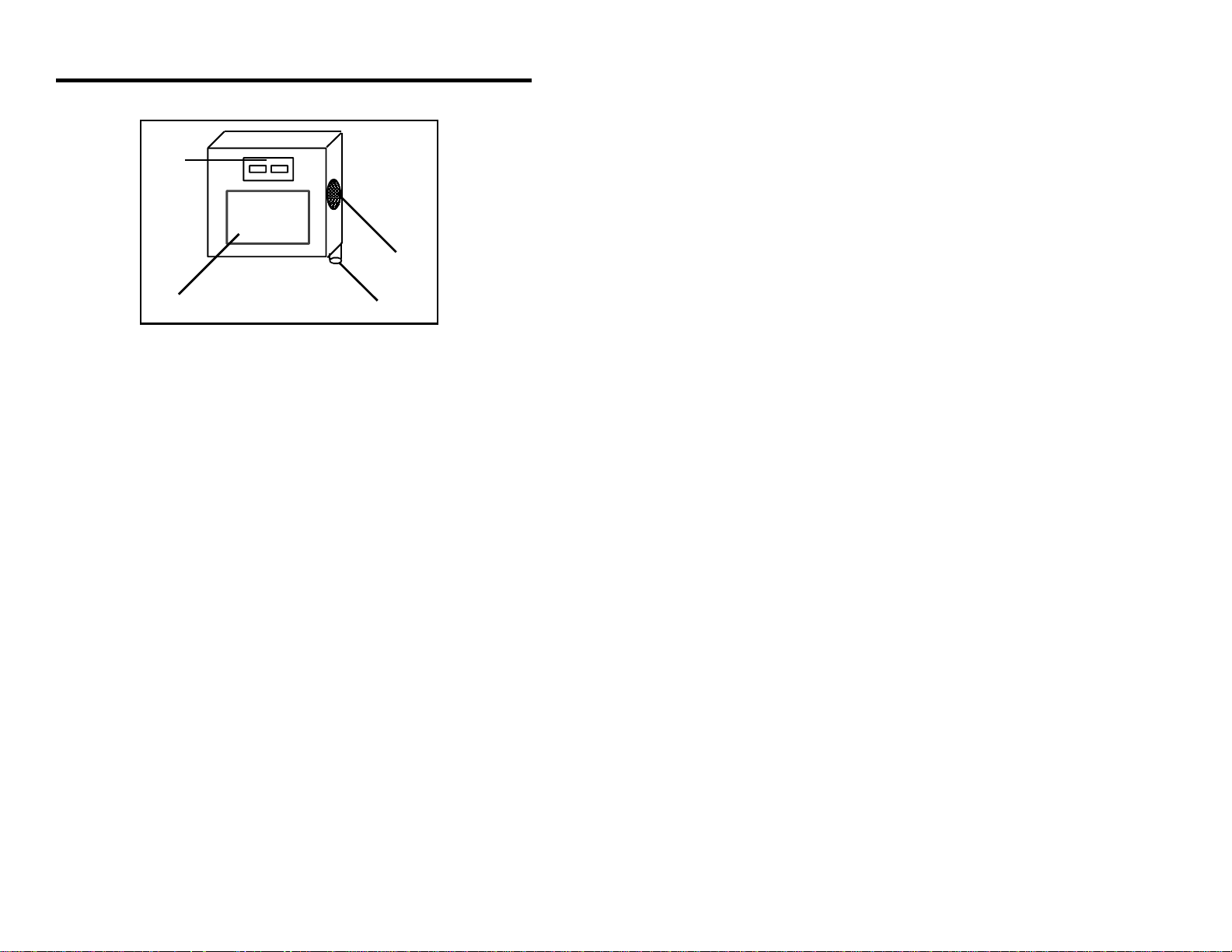

Parts of the Scanner

1

Green and

Red LEDs

2

Speaker

3

Laser Output Window

Figure 6

1 Green and Red LEDs When the green LED is on, this

indicates that the unit is receiving

power and the laser is on. When the

red LED flashes on, the scanner has

read a bar code successfully. When the

red light turns off, communica-tion to

the host is complete.

4

Mil spec Connector

2 Speaker The speaker emits a beep when a bar

code has been decoded.

3 Laser Output Window This aperture emits the laser light.

4 Mil spec Connector The 19-pin male Mil spec connector

was designed to connect a communi

cation cable from the scanner to a host

device. The communication cable may

include a power supply or it may be de

signed to draw power directly from the

host device. The standard TECH 7 has

one connector. (When atrium option is

installed, a second connector is

installed on the unit to connect the

MX001 Industrial Control Interface

box.)

6

Page 10

Visual Indicators

There is a red and green LED at the top of the scanner. When the scanner is

on, the flashing or stationary activity of the LEDs indicates the status of the

scan and scanner.

Steady Green

When the laser is on, the green LED is also on. This occurs when an object is

in the scan field.

Steady Green; Red Flash

When the scanner successfully reads a bar code, the red LED will flash then

beep once. If the red LED does not flash or the scanner does not beep once,

then the bar code has not been successfully read.

Steady Red and Green

After a successful scan, the scanner transmits the data to the host device. When

the host is not ready to accept the information, the scanner’s red LED will

remain on until the data can be transmitted.

Alternating Red and Green

This indicates the scanner is in program mode.

Steady Red

This indicates the scanner is in ScanSet mode.

No Red or Green LED

There are two reasons why the LEDs will not be illuminated. First, if the

scanner is receiving power and the LEDs are not on, then the scanner has

remained dormant for a specified time and the laser has turned off. To

reactivate the unit, touch the touch plate. Secondly, if the scanner is not

receiving power from the host or transformer, then the LEDs will not turn on.

Flashing Red

This indicates the scanner has experienced a laser subsystem failure. Return

the unit for repair at an authorized service center.

7

Page 11

Signaux optiques

Sur la partie supérieure du scanner se trouvent une diode LED rouge et une diode LED

verte. Quand le scanner est sous tension, les diodes rouge et verte clignotantes ou

allumées vous informent sur l'état du scanner.

Ni la diode rouge, ni la diode verte n'est allumée

Il existe deux raisons possibles pour que les diodes ne s'allument pas. Premièrement: si

le scanner reçoit de l'énergie sans que les diodes ne s'allument, le scanner est resté sans

servir pendant une certaine période et le laser est désactivé. Pour le réactiver, passer un

objet devant le palpeur infrarouge. Deuxièmement: quand le scanner ne reçoit de

l'énergie ni de l'ordinateur central, ni du transformateur, les diodes restent éteintes.

La diode verte reste allumée

Quand le laser est en service, la diode verte s'allume également. C'est le cas quand un

objet se trouve devant le palpeur. La diode verte reste allumée tant que la temporisation

de l'infrarouge dure ou jusqu'à ce que le scanner soit désactivé.

La diode verte reste allumée; la diode rouge clignote

Après lecture avec succès d'un code à barres par le scanner, la diode rouge se met à

clignoter, suivie d'un bip sonore unique. Si la diode rouge ne clignote pas ou quand

aucun bip sonore n'est émis, cela signifie que le code à barres n'a pas pu être lu avec

succès.

Les diodes rouges et vertes restent allumées

Une fois la lecture effectuée avec succès, le scanner transmet les données à l'ordinateur

central. Si ce dernier n'est pas prêt à recevoir les données, la diode rouge du scanner

reste allumée jusqu'à ce que les données puissent être transmises.

Les diodes rouges et vertes clignotent en alternance

Indique que le scanner se trouve en mode de programmation.

La diode rouge reste allumée

Indique que le scanner se trouve en mode ScanSet.

Diode rouge clignotante

Indique une panne de laser pendant la lecture. Veuillez envoyer votre appareil chez

unconcessionnaire pour réparation.

8

Page 12

Optische Anzeigen

Auf dem Scanner befinden sich eine rote und eine grüne Leuchtdiode. Bei

eingeschaltetem Scanner geben Ihnen die blinkenden bzw. feststehenden

Leuchtdiodenanzeigen Aufschluß über den Abtast- und Scannerstatus.

Weder rote noch grüne Leuchtdiodenanzeige

Es gibt zwei mögliche Gründe, weshalb die Leuchtdiodenanzeigen nicht aufleuchten.

Erstens: Wenn der Scanner mit Energie versorgt wird und die Leuchtdiodenanzeigen

nicht aufleuchten, so ist der Scanner für einen bestimmten Zeitraum untätig geblieben,

und der Laser ist abgeschaltet. Zur Reaktivierung der Einheit sollten Sie ein Objekt vor

dem Infrarot-Sensor hin- und herbewegen. Zweitens: Wenn der Scanner weder vom

Hostrechner noch vom Transformator Energie erhält, so leuchten die

Leuchtdiodenanzeigen nicht auf.

Feststehende grüne Anzeige

Wenn der Laser in Betrieb ist, leuchtet die grüne Leuchtdiodenanzeige ebenfalls auf.

Dies ist dann der Fall, wenn sich ein Objekt im Abtastfeld befindet. Die grüne

Leuchtdiodenanzeige leuchtet solange auf, bis das Infrarot-Timeout abgelaufen ist, oder

bis der Scanner abgeschaltet wird.

Feststehende grüne Leuchtanzeige; rote Blinkanzeige

Nach erfolgreichem Lesen eines Barcodes durch den Scanner blinkt die rote

Leuchtdiodenanzeige auf, gefolgt von einem einmaligen Piep-Signal. Blinkt die rote

Leuchtdiodenanzeige nicht auf oder sendet der Scanner kein Piep-Signal aus, so konnte

der Barcode nicht erfolgreich gelesen werden.

Feststehende rote und grüne Leuchtanzeige

Nach erfolgreichem Abtasten überträgt der Scanner die Daten an das Hostgerät. Falls

das Hostgerät zur Datenannahme nicht bereit ist, leuchtet die rote Leuchtdiodenanzeige

des Scanners solange auf, bis die Daten übertragen werden können.

Alternierende rote und grüne Leuchtanzeige

Zeigt an, daß sich der Scanner im Programmiermodus befindet.

Feststehende rote Leuchtanzeige

Zeigt an, daß sich der Scanner im ScanSet-Modus befindet.

Aufblinkende rote Leuchtanzeige

Zeigt an, daß beim Scanner ein Laserausfall vorliegt. Bringen Sie das Gerät zur

Reparatur in ein Vertragsservicecenter.

9

Page 13

Segnali ottici

Sullo scanner si trovano due diodi luminosi: uno rosso e uno verde. Quando lo scanner

è inserito, i diodi luminosi, che possono o essere accesi in continuazione o lampeggiare,

Vi informano sullo stato della scansione e dell’apparecchio.

Né il diodo luminoso rosso né quello verde sono accesi

Vi sono due possibili cause se i diodi luminosi non sono accesi. Prima causa: se lo

scanner viene alimentato e i diodi luminosi non sono accesi, lo scanner è rimasto

disattivato per un determinato periodo e il laser è spento. Per riattivare l’unità dovreste

muovere un oggetto davanti al sensore a infrarossi. Seconda causa: se lo scanner non

viene alimentato né dal calcolatore host né dal trasformatore, i due diodi luminosi non

sono accesi.

Il diodo luminoso verde è acceso

Quando il laser è inserito, è acceso anche il diodo luminoso verde. Questo si ha quando

un oggetto si trova nella zona di scansione. Il diodo luminoso verde è acceso fino al

raggiungimento del timeout infrarossi oppure fino allo spegnimento dello scanner.

Il diodo luminoso verde è acceso; quello rosso lampeggia

Dopo la lettura riuscita di un codice a barre da parte dello scanner il diodo luminoso

rosso lampeggia e quindi viene emesso un unico segnale beep. Se il diodo luminoso

rosso non lampeggia oppure lo scanner non emette un segnale beep, ciò significa che la

lettura del codice a barre non è riuscita.

Sono accesi sia il diodo luminoso rosso che quello verde

Dopo la scansione riuscita lo scanner trasmette i dati all’host. Se l’host non è pronto per

accettare i dati, il diodo luminoso rosso dello scanner è acceso fino a che i dati possono

essere trasmessi.

Il diodo luminoso rosso e quello verde sono accesi in alternanza

Ciò indica che lo scanner si trova nella modalità di programmazione.

Il diodo luminoso rosso è acceso

Ciò indica che lo scanner si trova nella modalità ScanSet.

Il diodo luminoso rosso lampeggia

Ciò indica che lo scanner ha un guasto a livello del laser. Fate riparare l’apparecchio da

un centro di assistenza autorizzato.

10

Page 14

Labels

There is one label located inside the window of the scanner noting that this

device is a CDRH Class IIa laser product and IEC 825 LASERKLASSE 1.

Also, on the scanner is a label located on the back of the unit. This label

contains information such as the model number, date of manufacture, serial

number, and approvals. The following are samples of the labels located on the

unit.

11

Page 15

Depth of Scan Field for the MS770 Scanner

The depth of field for the scanner is 76mm to 254mm (3" - 10") from the laser

output window. Pass the symbol through the scan area in order for the scanner

to recognize the bar code. (Refer to Figure 7)

12

Figure 7

Page 16

Depth of Scan Field for the MS775 Scanner

The depth of field for the scanner is 76mm to 254mm (3" - 10") from the laser

output window. Pass the symbol through the scan area in order for the scanner

to recognize the bar code. (Refer to Figure 8)

Figure 8

13

Page 17

Maintenance

Smudges and dirt can interfere with the proper scanning of a bar code.

Therefore, the output window will need occasional cleaning.

1. Spray glass cleaner onto lint free, nonabrasive cleaning cloth.

2. Gently wipe the output window.

Applications and Protocols

The model number on each scanner includes the scanner number and

communications protocol.

Version Identifier Communication Protocol(s)

1 RS-232, OCIA, Bidirectional RS-232

15 Light Pen Emulation

14

Page 18

Appendix A

Specifications

Application: Industrial Projection Scanner

Light Source: Visible Laser Diode 670 ± 5nm,

Laser Class: CDRH: CLASS IIa; EN 60825 Class 1

Certifications: CE, UL listed for US and Canada

EMC: FCC Class A, CISPR Class A

Mechanical

Dimensions: 184mmL x 186mmW x 78mmD

(7.25"L x 7.3"W x 3.06"D)

Weight: 2.35 kg. (5.19 lbs.) without cable

Orientation: May be used in any orientation

Mounting: Back plate mount or Vertical stand

Top Cover: NEMA-12 steel case

Host Cable Length: 1.83m (6') cable with mil spec connector

Electrical

Power Consumption: 8 watts, host system or wall transformer

Input Voltage: 11-30 VDC

Operating Current: 420mA typical @ 20V

Standby Current: 210mA typical @ 20V

DC Transformers: 120V (AC in), 230V (AC in), 240V ( AC in);

output 20V @ 750mA

Patents Pending

Specifications subject to change without notice.

15

Page 19

Operational

Depth of Scan Field: 76mm to 254mm (3" to 10")

Scan Speed: Model 770: 2000 scan lines per second

Model 775: 1200 scan lines per second

Scan Pattern: Model 770: Omnidirectional

(20 interlocking lines)

Model 775: 12-line raster

Indicators: LED: green = laser on; red = good read

Beeper Operation: Selection of 3 tones for “Good Read”

Maintenance Required: Clean window periodically

Decode Capability: Autodiscriminates

System Interfaces: RS232C; Light Pen Emulation; OCIA

Optional: Opto coupled 6 amps US and Canada, 5 amps

EEA countries TRIAC output; object sensor input

Print Contrast: 35% minimum reflectance difference

Roll, Pitch, Yaw: 360E, 60E, 60E

Environmental

Storage Temperature: -40EC to 60EC (-40EF to 140EF)

Operating Temperature: 0EC to 35EC (32EF to 95EF)

Humidity: 5% to 95% relative humidity, non-condensing

Light Levels: Up to 3200 foot candles - works in direct sun

Ventilation: None required

Shock: 100g for 1ms

ESD: 8 kV IEC 801-2

Contaminants: Protects against dust, falling dirt, and dripping

non-corrosive liquid

Specifications subject to change without notice.

16

Page 20

Appendix B

Pin Assignments

Version “1” Pin Assignments for RS-232, OCIA, and Bidirectional

RS-232

Each TECH 7 scanner has a 19-pin male Mil spec connector that is located on

the side of the unit. To connect the scanner to the host device, use a

communication cable with a female Mil spec connector. The communication

cable may include a power supply or it may be designed to draw power

directly from the host device. This item can be ordered when the scanner is

purchased.

The Version “1” scanner is designed to be used for RS-232, OCIA, and

RS-232 with limited receiving capabilities.

The following is a list of pin assignments. The pin numbers are impressed on

the male Mil spec connector. For easier reference, refer to Figure 9 for pin

locations.

Pin Function

A R Data

B RTS Output

C Signal Ground

D CTS Input

E R Data Return

F RS-232 Output

G Clock in

H Clock in Return

J Clock Out

K Shield Ground

L DTR Input

M Clock Out Return

N Power to Scanner & 24 VDC

P Earth Ground

R Power Ground

S RS-232 Input

Figure 9

17

Page 21

Version “15” Pin Assignments for Light Pen Emulation

Each TECH 7 scanner has a 19-pin male Mil spec connector that is located on

the side of the unit. To connect the scanner to the host device, use a

communication cable with a female Mil spec connector. The communication

cable may include a power supply or it may be designed to draw power

directly from the host device. This item can be ordered when the scanner is

purchased.

The Version “15” scanner is designed to be used for Light Pen Emulation

communication.

The following is a list of pin assignments. The pin numbers are impressed on

the male Mil spec connector. For easier reference, refer to Figure 10 for pin

locations.

Pin Function

A R Data

B Light Pen Data Output

C Signal Ground

D Light Pen Source & 5

VDC

E R Data Return

F RS-232 Output

G Clock in

H Clock in Return

J Clock Out

K Shield Ground

L DTR Input

Figure 10

M Clock Out Return

N Power to Scanner & 24 VDC

P Earth Ground

R Power Ground

S RS-232 Input

18

Page 22

Appendix C

Warranty and Disclaimer

Limited Warranty

Products manufactured by Metrologic have a 2-year limited warranty from

date of manufacture.

This warranty is limited to repair, replacement or refund at Metrologic’s

discretion. Faulty equipment must be returned to the Metrologic facility in

Blackwood, New Jersey or Puchheim, Germany. To do this, contact

Metrologic Customer Service/Repair for a Returned Material Authorization

(RMA) number.

In the event that it is determined that the equipment failure is covered under the

warranty, Metrologic shall, as its sole option, repair, replace with a functionally

equivalent unit, or refund an amount equal to the purchase price to the original

purchaser, whether distributor, dealer/reseller, or retail consumer, and return the

equipment to the customer without charge for service or return freight.

This limited warranty does not extend to any Product which, in the sole judge-ment

of Metrologic, has been subjected to misuse, neglect, improper installation or

accident, nor does it extend to any Product which has been repaired or altered by

anyone who is not a Metrologic authorized representative.

THIS LIMITED WARRANTY, EXCEPT AS TO TITLE, IS IN LIEU OF ALL

OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING

MERCHANTABILITY OR FITNESS FOR ANY PARTICULAR PURPOSE,

ARISING BY LAW, CUSTOM OR CONDUCT. THE RIGHTS AND

REMEDIES PROVIDED HEREIN ARE EXCLUSIVE AND IN LIEU OF ANY

OTHER RIGHTS OR REMEDIES. IN NO EVENT SHALL METROLOGIC BE

LIABLE FOR INDIRECT, INCIDENTAL, OR CONSEQUENTIAL DAMAGES,

INCLUDING, WITHOUT LIMITATION, ANY INJURY TO PROPERTY OR

PERSON OR EFFECT ON BUSINESS OR PROFIT, AND IN NO EVENT

SHALL ANY LIABILITY OF METROLOGIC EXCEED THE ACTUAL

AMOUNT PAID TO METROLOGIC FOR THE PRODUCT.

Metrologic Instruments, Inc. Customer Service Department

90 Coles Road 1-800-ID-METRO (1-800-436-3876)

Blackwood, NJ 08012 TEL: 609-228-8100

FAX: 609-228-6673

Metrologic Instruments GmbH

Dornierstrasse 2

82178 Puchheim b.

Munich, Germany

TEL: 49-89-89019-0

FAX: 49-89-89019-200

19

Page 23

Disclaimer

Metrologic Instruments, Inc. and the author or authors make no claims or warranties with respect

to the contents or accuracy of this publication, or the product it describes, including any warranties

of fitness or merchantability for a particular purpose. Any stated or expressed warranties are in

lieu of all obligations or liability for any damages, whether special, indirect, or consequential,

arising out of or in connection with the use of this publication or the product it describes.

Furthermore, the right is reserved to make any changes to this publication without obligation to

notify any person of such changes. Metrologic also reserves the right to make any changes to the

product described herein.

Exclusion des responsabilités

Metrologic Instruments, Inc. et le/les auteur(s) ne sont ni garants, ni responsables pour l'exhaustivité et la correction des informations contenues dans cette brochure - que ce soit relativement à leur teneur et à l' exactitude - ou pour le produit qui y est décrit. Ils ne sont en outre

responsables d'aucune garantie de propriété ou de qualité pour un usage particulier. Toutes les

assurances nommées ou exprimées excluent toute garantie ou responsabilité pour les dommages

spéciaux, indirects ou des suites de l'utilisation de cette brochure ou du produit qui y est décrit

respectivement. en rapport avec l'emploi de cette brochure et du produit qui y est décrit. Il leur est

également réservé le droit de procéder à des modifications de cette brochure sans avoir à en avertir

qui que ce soit. Metrologic se réserve en outre le droit de procéder à des modifications du produit

qui y est décrit.

Haftungsausschluß

Metrologic Instruments, Inc. und der/die Autor(en) übernehmen keinerlei Gewähr und haften nicht

für die Richtigkeit im Hinblick auf Inhalt oder Genauigkeit der Angaben dieser Veröffentlichung

oder des hierin beschriebenen Produkts. Sie übernehmen ebenso keinerlei Eignungsgarantie oder

Gewährleistung durchschnittlicher Qualität für einen bestimmten Zweck. Alle benannten oder

ausdrücklichen Zusicherungen schließen sämtliche Verpflichtungen oder Haftungen aus jeglichem

Schaden aus, ganz gleich ob speziell, indirekt oder als Folge der Verwendung dieser

Veröffentlichung oder des hierin beschriebenen Produkts bzw. in Zusammenhang mit der

Verwendung dieser Veröffentlichung oder des hierin beschriebenen Produkts. Darüber hinaus wird

das Recht vorbehalten, Änderungen an dieser Veröffentlichung vorzunehmen ohne die

Verpflichtung, irgend jemanden über solche Änderungen zu unterrichten. Metrologic behält sich

ferner das Recht vor, Änderungen an dem hierin beschriebenen Produkt vorzunehmen.

Esclusione della responsabilità

La Metrologic Instruments, Inc. e l’autore/gli autori non assumono nessuna garanzia e non

rispondono della correttezza per quanto riguarda il contenuto o la precisione di quanto indicato nel

presente Manuale o del prodotto in esso descritto. Neppure essi assumono una garanzia per

l’idoneità o una garanzia della qualità media per un determinato scopo. Tutte le garanzie citate o

fatte espressamente escludono qualsiasi obbligo o responsabilità derivanti da qualsiasi danno,

indipendentemente dal fatto che questo obbligo/questa responsabilità risulti in particolare, indirettamente o come conseguenza dall’uso del presente Manuale o del prodotto in esso descritto

oppure se è legato/a all’uso del presente Manuale o del prodotto in esso descritto. Inoltre ci si

riserva il diritto di modificare il presente Manuale senza essere obbligati ad informare persona

alcuna circa dette modifiche. Metrologic si riserva il diritto di apportare modifiche al prodotto

descritto nel presente Manuale.

20

Page 24

Appendix D

Notices

Notice

This equipment has been tested and found to comply with limits for a Class A digital device,

pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection

against harmful interference when the equipment is operated in a commercial environment. This

equipment generates, uses and can radiate radio frequency energy and, if not installed and used in

accordance with the instruction manual, may cause harmful interference to radio communications.

Operation of this equipment in a residential area is likely to cause harmful interference, in which

case the user will be required to correct the interference at his own expense. Any unauthorized

changes or modifications to this equipment could void the users authority to operate this device.

Notice

This digital apparatus does not exceed the Class A limits for radio noise emissions from digital

apparatus set out in the Radio Interference Regulations of the Industry and Canada.

Caution

Use of controls or adjustments or performance of procedures other than those specified herein may

result in hazardous laser light. Under no circumstances should the customer attempt to service the

laser scanner. Never attempt to look at the laser beam, even if the scanner appears to be

nonfunctional. Never open the scanner in an attempt to look into the device. Doing so could result

in hazardous laser light exposure. The use of optical instruments with the laser equipment will

increase eye hazard.

Remarque

Après contrôle de cet appareil, on a noté qu'il répondait aux valeurs limites de la classe A, conformément à la partie 15 des directives de l'administration fédérale américaine pour les télécommunications. Ces valeurs limites ont été prévues pour garantir une protection suffisante

contre les effets nocifs dus à l'emploi de l'appareil dans un magasin. L'appareil génère et utilise une

énergie haute fréquence et peut, s'il n'est pas installé et utilisé conformément aux instructions

mentionnées dans le guide d'utilisation, entraîner des perturbations dans la radiocommunications.

L'utilisation de cet appareil dans une zone d'habitation entraînera très vraisemblablement des

perturbations. Dans ce cas, l'utilisateur est tenu de remédier à ces perturbations à ses propres frais.

Toute modification ou remplacement non autorisé sur cet appareil peut entraîner l'invalidité de

l'autorisation d'utilisation de l'appareil.

Remarque

Cet appareil numérique ne va pas contre les valeurs limites pour émissions de bruits radios des

appareils numérique de la classe A, conformément aux directives relatives aux perturbations des

radiocommunications du ministère canadien pour l'industrie.

Attention

L'emploi de commandes, réglages ou procédés autres que ceux décrits ici peut entraîner de graves

irradiations. Le client ne doit en aucun cas essayer d'entretenir lui-même le scanner ou le laser. Ne

regardez jamais directement le rayon laser, même si vous croyez que le scanner est inactif.

N'ouvrez jamais le scanner pour regarder dans l'appareil. Ce faisant, vous vous exposez à une

rayonnement laser mortel. L'emploi d'appareils optiques avec cet équipement laser augmente le

risque d'endommagement de la vision.

21

Page 25

Anmerkung

Nach Überprüfung dieses Geräts wurde festgestellt, daß es den Grenzwerten für Digitalgeräte der

Klasse A gemäß Teil 15 der Richtlinien der US-amerikanischen Bundesbehörde für das

Fernmeldewesen entspricht. Diese Grenzwerte wurden festgelegt, um einen angemessenen Schutz

gegen schädliche Auswirkungen bei Einsatz des Geräts in einer Ladenumgebung zu gewähren.

Das Gerät erzeugt und verwendet Hochfrequenzenergie und kann diese ausstrahlen, und kann,

falls es nicht gemäß den im Bedienerhandbuch enthaltenen Anweisungen installiert und verwendet

wird, zu einer Störung des Funkverkehrs führen. Der Betrieb dieses Geräts in einem Wohngebiet

führt höchstwahrscheinlich zu Störungen. In diesem Fall ist der Bediener verpflichtet, die Störung

auf eigene Kosten zu beseitigen. Durch jegliche unerlaubte Auswechselung oder Änderung an

diesem Gerät könnte die Genehmigung des Bedieners zur Verwendung dieses Geräts ungültig

werden.

Anmerkung

Dieses Digitalgerät verstößt nicht gegen die Grenzwerte für Funkrauschemissionen von

Digitalgeräten der Klasse A gemäß den Richtlinien für Funkstörungen des kanadischen

Ministeriums für Industrie.

Achtung

Die Verwendung anderer als der hierin beschriebenen Steuerungen, Einstellungen oder Verfahren

kann eine lebensgefährliche Laserstrahlung hervorrufen. Der Kunde sollte unter keinen

Umständen versuchen, den Laser-Scanner selbst zu warten. Sehen Sie niemals in den Laserstrahl,

selbst wenn Sie glauben, daß der Scanner nicht aktiv ist. Öffnen Sie niemals den Scanner, um in

das Gerät hineinzusehen. Wenn Sie dies tun, können Sie sich einer lebensgefährlichen

Laserstrahlung aussetzen. Der Einsatz optischer Geräte mit dieser Laserausrüstung erhöht das

Risiko einer Sehschädigung.

N.B.

Dal controllo di questo apparecchio risulta che esso risponde ai valori limite per apparecchi

digitali della classe A conf. parte 15 delle direttive sulle telecomunicazioni dell’Autorità federale

statunitense. Questi valori limite sono stati fissati per garantire una protezione adeguata contro gli

effetti nocivi se questo apparecchio viene usato all’intero di un negozio. L’apparecchio genera,

utilizza e può emettere energia ad alta frequenza e, se non viene installato ed utilizzato

conformemente alle indicazioni fornite nel Manuale utente, può provocare disturbi al servizio

radiofonico. L’uso di questo apparecchio in zone residenziali causa molto probabilmente dei

disturbi. In questo caso l’utente è obbligato ad eliminare questi disturbi a sue spese. Qualsiasi

sostituzione o modifica non autorizzata all’apparecchio potrebbe rendere invalida l’autorizzazione

dell’utente all’uso dell’apparecchio.

N.B.

Questo apparecchio digitale non supera I valori limite per l’emissione di radiorumori da parte di

apparecchi digitali della classe A conformemente alle direttive per radiodisturbi del Ministero

canadese per l’Industria.

Attenzione

L’utilizzo di sistemi di controllo, di regolazioni o di procedimenti diversi da quelli decritti nel

presente Manuale può provocare dei raggi laser pericolosi per la vita. Il cliente non deve

assolutamente tentare di riparare egli stesso lo scanner laser. Non guardate mai nel raggio laser,

anche se credete che lo scanner non sia attivo. Non aprite mai lo scanner per guardare dentro

l’apparecchio. Se tuttavia lo fate, potete esporVi a dei raggi laser pericolosi per la vita. L’uso di

apparecchi ottici con questo equipaggiamento laser aumenta il rischio di danni alla vista.

22

Page 26

Appendix E

Patents

“Patent Information

This METROLOGIC product may be covered by one or more of the following

U.S. Patents:

U.S. Patent No. 4,360,798; 4,369,361; 4,387,297; 4,460,120; 4,496,831;

4,593,186; 4,607,156; 4,673,805; 4,736,095; 4,758,717; 4,816,660;

4,845,350; 4,896,026; 4,923,281; 4,933,538; 4,992,717; 5,015,833;

5,017,765; 5,059,779; 5,117,098; 5,124,539; 5,130,520; 5,132,525;

5,140,144; 5,149,950; 5,180,904; 5,200,599; 5,229,591; 5,247,162;

5,250,790; 5,250,791; 5,250,792; 5,262,628; 5,280,162; 5,280,164;

5,304,788; 5,321,246; 5,324,924; 5,396,053; 5,396,055; 5,408,081;

5,410,139; 5,436,440; 5,449,891; 5,468,949; 5,479,000; 5,532,469;

5,545,889

No license right or sublicense is granted, either expressly or by implication,

estoppel, or otherwise, under any METROLOGIC or third party intellectual

property rights (whether or not such third party rights are licensed to

METROLOGIC), including any third party patent listed above, except for an

implied license only for the normal intended use of the specific equipment,

circuits, and devices represented by or contained in the METROLOGIC

products that are physically transferred to the user, and only to the extent of

METROLOGIC’s license rights and subject to any conditions, covenants and

restrictions therein.”

23

Page 27

Index

A

AC 2, 15

Application 15

Application and protocols 14

Asia ii

ASIC 1

B

Back plate

hortizontal mount 5

vertical mount 5

Bar code(s) 1, 3, 6, 7, 12-14

Beep 2, 3, 6, 7, 10, 16

Beeper operation 16

C

Cable

communication 1, 2, 6,

17, 18

length 15

CDRH class IIa 11

Clean 14, 16

Communication protocol 14

Compliance 2

Configuration 3

Contrast 16

Copyright ii

Current 15

Customer Service ii, 19

D

Depth of field 12, 13

Dimensions 15

Disclaimer 20

E

Electrical 15

EMI 15

Email ii

Environmental 16

ESD 16

Europe ii

F

Faulty equipment 19

Fax ii

G

Germany (GmbH) ii, 19

Good read 16

Green LED 2, 6, 7

H

Headquarters ii

Host 2, 3, 6, 7, 9, 10, 15, 17,

18

Humidity 16

I

IEC 825 LASERKLASSE 1 11

Indicators

LED 2, 6, 7, 16

Visual 4-10

Interfaces 14, 16

Installation

Back plate 5

Scanner 2

Stand 4

Internet ii

Introduction 1

L

Labels 11

LEDs 2, 6, 7, 16

Light levels 16

Light pen emulation 14,

16, 18

Light source 15

Limited warranty 19

List 1

Locations ii

24

Page 28

M Scan field 12, 13, 16

Maintenance 14, 16

MECCA 1

Mechanical 15

Mil spec connector 2, 6,

15, 17, 18

Model number 11, 14

Mounting 4, 5, 15

MS770 1, 12

MS775 1, 13

Scan lines 16

Scan pattern 1, 16

Scan speed 1, 16

ScanSelect 1, 3

ScanSet 3, 7-9

Service 19

Shipping carton 1

Shock 16

South America ii

Speaker 6

N

NEMA-12 steel case 1, 15

Notices 21, 22

Specifications 15, 16

Stand 1, 4, 5, 15

hortizontal mount 4

vertical mount 4

O

OCIA 14, 16, 17

Storage temperature 16

System interfaces 16

Operating current 15

Operating temperature 16

Operation 3, 16

Operational 16

Output window 6, 12-14, 16

T

Temperature 16

Tones 16

Transformer 2, 7, 15

P

Parts 6

Patents 23

Print contrast 16

Programming guide 1, 3

Protocols 14

R

Red LED 6, 7

Repair 19

Rights

property 23

warranty 19

RMA 19

Roll, pitch, yaw 16

RS-232 14, 16-18

S

U

UL/CSA/TUV/CE 15

USA corporate headquarters

ii

V

Ventilation 16

Version “1" 17

Version “15" 18

Version identifiers 14

Voltage 2, 15

W

Warranty 19

Watts 1, 15

Weight 15

Window 6, 12-14, 16

25

Loading...

Loading...