Page 1

®

®

Item # ______________________________________________

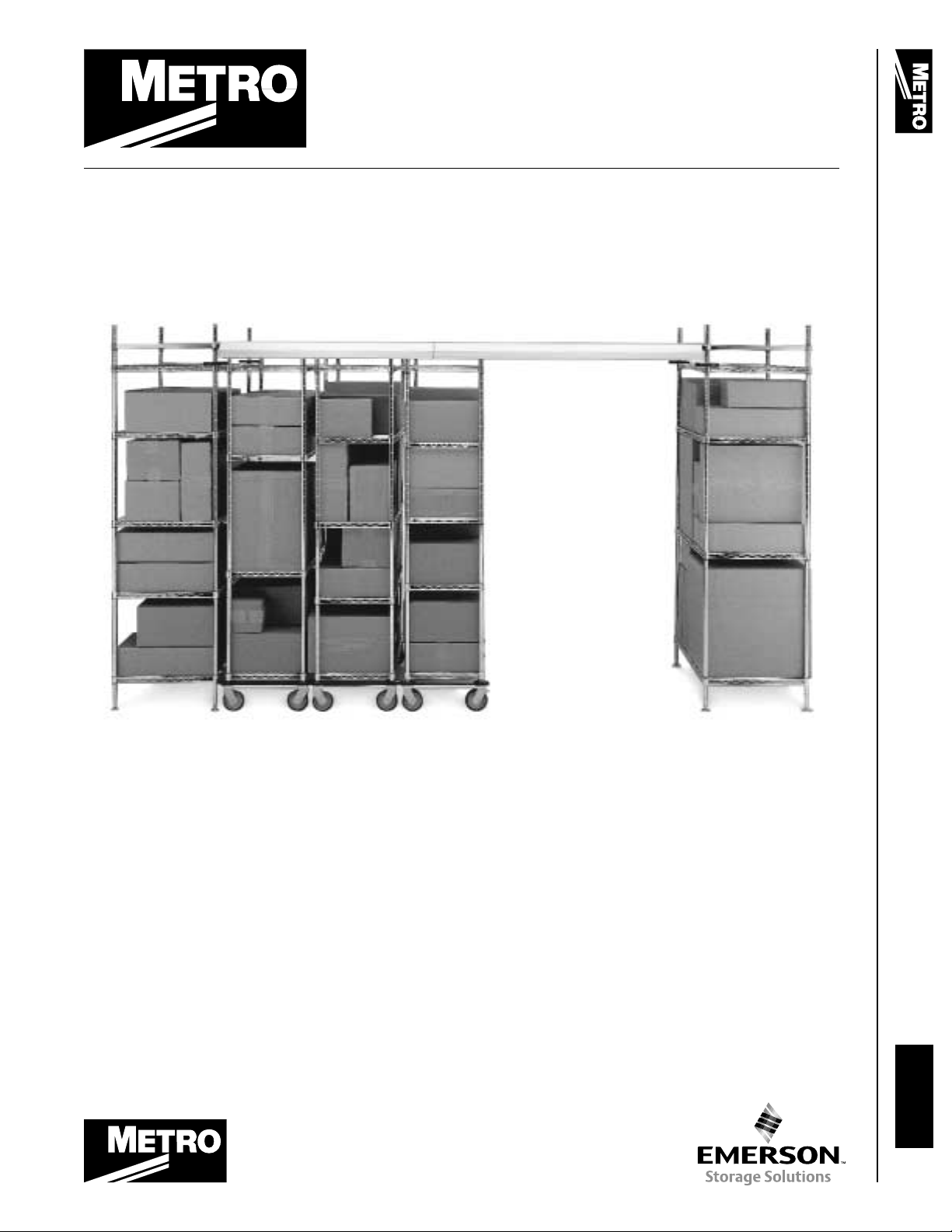

TOP-TRACK™ HIGH-DENSITY

STORAGE SYSTEMS

for Super Erecta® and

®

Super Adjustable Super Erecta

Systems

Job ________________________________________________

• Reduce Inventory Costs

• Increase Revenues

• Maximize Storage Capacity

• Increase Productivity

• Simplify Operations

• Cleaner Between Cleanings

Top-Track

™

High-Density Storage Systems

• Maximizes Storage Capacity: Top-Track can increase

the storage capacity of a given area by 30% to 40%.

Mobile units are used between stationary units. Only

one aisle, which can be opened between any two units

as needed, is required. The Top-Track Storage system

utilizes far less aisle space and maximizes the usable

storage area.

• Cost-Saving Performance: This efficient utilization

of space addresses the storage needs of new or

growing operations. In a new facility, less square footage

would have to be dedicated to storage. In growing

operations, Top-Track can eliminate the need to expand

the facility to handle increasing storage requirements,

greatly reducing the costs associated with a growing

business’s needs.

• Improved Organization and Inventory Control:

Top-Track allows better organization of stored goods

and permits improved inventory control with one-stop

delivery and pick-up.

*MICROBAN® and the MICROBAN® symbol are registered trademarks of the Microban Products Company, Huntersville, NC.

InterMetro Industries Corporation

®

• Increased Productivity: With reduced square footage

dedicated to storage, Top-Track maximizes the amount

of productive “front of the house” space available,

increasing daily revenues.

• Accessible: The overhead track system guides the

mobile units and opens an access aisle between any

two units, whenever it is needed. The open access

promotes cleanliness and easy access for walking or

for utility carts, simplifying the material handling task.

• Super Erecta

Erecta and Super Adjustable shelves are available in a

variety of widths and lengths. Each system features

ease of assembly, promotes air circulation, promotes

light penetration and shelf level adjustability. Super

Adjustable features shelf corners with a quick release

lever. Shelves can be rapidly adjusted, without the use

of tools, to meet changing storage needs. Shelves are

available in Brite,

built-in product protection and stainless steel.

Super Erecta Super Adjustable: Super

/

™

North Washington Street

Wilkes-Barre, PA 18705

www.metro.com

chrome, Metroseal 3 with *Microban

®

11.12

Page 2

®

TOP-TRACK™ HIGH-DENSITY STORAGE SYSTEMS

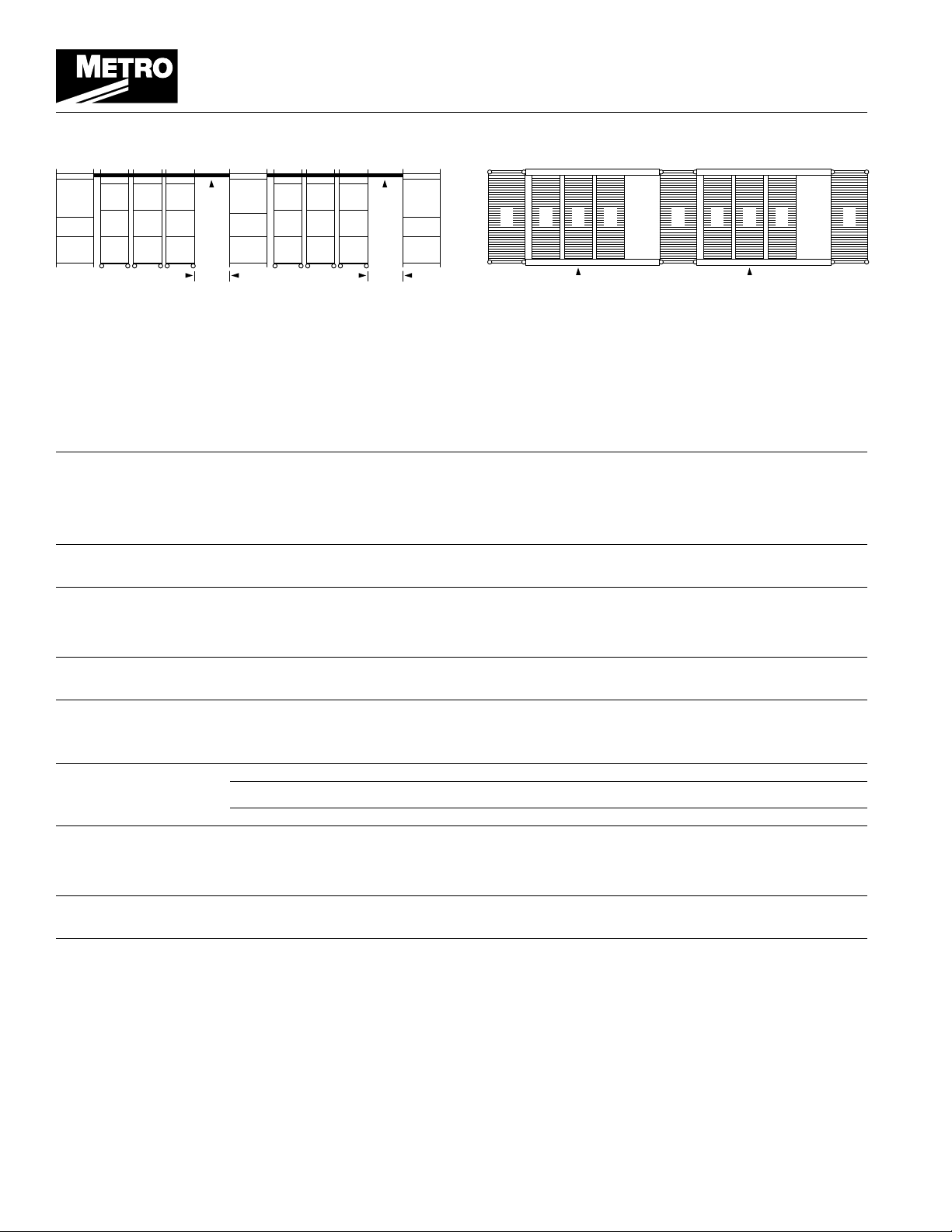

OVERHEAD VIEWFRONT VIEW

C

D D DA B

E

D D D A

C

BA D D D E

E

C

C

System Components

A = Stationary End Units

B = Stationary Intermediate Unit (Optional)

C = Track Set

D = Mobile Units

E = Open Aisle

Dimensions

Stationary End Unit Kits Chrome-Plated Metroseal 3 Stainless Steel (in.) (mm)

Includes hardware necessary for connecting stationary end units to TTE18C TTE18K3 TTE18S 18 457

track. ONE KIT IS REQUIRED PER SINGLE SYSTEM. SHELVES SOLD TTE21C TTE21K3 TTE21S 21 530

SEPARATELY. 86" (2185mm) posts included. Just add shelves. TTE24C TTE24K3 TTE24S 24 610

Stationary Intermediate Unit Kits Chrome-Plated Metroseal 3 Stainless Steel (in.) (mm)

Includes hardware necessary for connecting intermediate unit to track TTA18C TTA18K3 TTA18S 18 457

on both sides. ONE KIT IS REQUIRED PER SINGLE SYSTEM. SHELVES TTA21C TTA21K3 TTA21S 21 530

SOLD SEPARATELY. 86" (2185mm) posts included. Just add shelves. TTA24C TTA24K3 TTA24S 24 610

Cat. No. Cat. No. Cat. No. Shelf Width

Cat. No. Cat. No. Cat. No. Shelf Width

AD D D E

Track Sets (1830mm) (2135mm) (2440mm) (2745mm) (3050mm) (3355mm) (3660mm) (3965mm)

6' 7' 8' 9' 10' 11' 12' 13'

Includes necessary sections TTS6NA TTS7NA TTS8NA TTS9NA TTS10NA TTS11NA TTS12NA TTS13NA

of track for assembling

track runs of 6'–21'

(1830mm–6405mm).

Mobile Unit Kits Chrome-Plated Metroseal 3 Stainless Steel (in.) (mm)

14' 15' 16' 17' 18' 19' 20' 21'

(4270mm) (4575mm) (4880mm) (5185mm) (5490mm) (5795mm) (6100mm) (6405mm)

TTS14NA TTS15NA TTS16NA TTS17NA TTS18NA TTS19NA TTS20NA TTS21NA

Cat. No. Cat. No. Cat. No. Shelf Width

One kit required per mobile unit. Kit includes posts, casters/caster TTM18C TTM18K3 TTM18S 18 457

channels, donut bumpers, roller bearing assemblies, hardware, and TTM21C TTM21K3 TTM21S 21 530

split sleeves. SHELVES SOLD SEPARATELY. Just add shelves. TTM24C TTM24K3 TTM24S 24 610

NOTES:

1. The stationary end and intermediate units must have a minimum of four shelves.

2. The standard Top-Track™ system requires the use of 86" (2185mm) posts (i.e., 86PK3 or 86PS) on the stationary end and intermediate units. Shelves for the stationary end and

intermediate units are sold separately.

3. The mobile unit kits includes special 74" (1880mm) posts with casters. Shelves for mobile units are sold separately.

4. Recommended maximum load rating for a mobile unit is 900 lbs. (400kg). Floor should be level, smooth, and free from large cracks and raised obstacles.

5. Under normal conditions, an aisle width of 30"-36" (762-914mm) is recommended. The storage of very large objects within the system, however, may require an aisle width larger

than 36" (914mm).

6. A stationary intermediate unit is required when track length exceeds 21 feet (6401mm). A stationary intermediate unit may be used at the discretion of the user when track lengths are less

than 21 feet (6401mm).

Page 3

TOP-TRACK™ HIGH-DENSITY STORAGE SYSTEMS

®

OVERHEAD VIEWFRONT VIEW

C

AD D D E

C

D D DA B

E

C

C

BA D D D E AD D D E

D D D A

E

BA D D D E

System Components

A = Stationary End Units

B = Stationary

Intermediate Unit

(Optional)

C = Track Set

D = Mobile Units

E = Open Aisle

C

Close-up showing shelving units connected end-to-end

in two Top-Track™ systems

C

Dimensions

Stationary End Unit Kits Chrome-Plated (in.) (mm)

Includes hardware necessary for connecting stationary end units in Double Deep systems and LTTE18C 18 457

connecting to an overhead track set. ONE KIT IS REQUIRED FOR ENTIRE DOUBLE DEEP LTTE21C 21 530

CONFIGURATION. SHELVES SOLD SEPARATELY. 86" (2185mm) posts included. Just add shelves. LTTE24C 24 610

Cat. No. Shelf Width

Stationary Intermediate Unit Kits Chrome-Plated (in.) (mm)

Cat. No. Shelf Width

Includes hardware necessary for connecting intermediate stationary end units in Double Deep systems and LTTA18C 18 457

connecting to an overhead track set on each side. ONE KIT IS REQUIRED FOR ENTIRE DOUBLE DEEP LTTA21C 21 530

CONFIGURATION. SHELVES SOLD SEPARATELY. 86" (2185mm) posts included. Just add shelves. LTTA24C 24 610

Track Sets (1830mm) (2135mm) (2440mm) (2745mm) (3050mm) (3355mm) (3660mm) (3965mm)

Includes necessary sections of

track for assembling track runs of 6'

to 21' (763-6405mm). ONLY ONE

TRACK SET IS REQUIRED

BETWEEN STATIONARY UNITS.

Mobile Unit Kits Chrome-Plated (in.) (mm)

6' 7' 8' 9' 10' 11' 12' 13'

TTS6NA TTS7NA TTS8NA TTS9NA TTS10NA TTS11NA TTS12NA TTS13NA

14' 15' 16' 17' 18' 19' 20' 21'

(4270mm) (4575mm) (4880mm) (5185mm) (5490mm) (5795mm) (6100mm) (6405mm)

TTS14NA TTS15NA TTS16NA TTS17NA TTS18NA TTS19NA TTS20NA TTS21NA

Cat. No. Shelf Width

Includes the necessary posts, casters, caster channels, donut bumpers, roller bearing LTTM18C 18 457

assemblies, and tie-together hardware to connect two mobile units together (i.e., one in LTTM21C 21 530

each system). SHELVES SOLD SEPARATELY. Just add shelves. LTTM24C 24 610

NOTES:

1. The stationary end and intermediate units must have a minimum of four shelves. For all Super Adjustable applications, the top and bottom shelves are to be non “quick adjust”

Super Erecta shelves.

2. The standard Double Deep Top-Track™ system requires the use of 86" (2185mm) posts (i.e., 86P) on the stationary end and intermediate units. Shelves for the stationary end and

intermediate units are sold separately.

3. The mobile unit kit includes special 74" (1880mm) posts with casters. Shelves for mobile units are sold separately. For all Super Adjustable applications, the top and bottom shelves are to

be non “quick adjust” Super Erecta shelves.

4. Under normal conditions, an aisle width of 30"-36" (762mm-914mm) is recommended. The storage of very large objects within the system, however, may require an aisle width larger

than 36" (914mm).

5. Two intermediate shelving units connected end-to-end are required when the track length exceeds 21 feet (6401mm). Stationary intermediate shelving units may be used at the discretion of

the user when track lengths are less than 21 feet (6401mm).

6. The maximum Double Deep system configuration is 10'7" (3202mm) (e.g., two systems, each having 60" (1525mm) for long shelves plus 6" (152mm) for Top-Track components.)

7. Ease of rollability for the mobile unit is an important consideration in evaluating Top-Track as a possible storage alternative. The floor should be level, smooth, and free from large cracks and

raised obstacles. Two mobile shelving units connected end-to-end and loaded with between 800 to 1,200 lbs. (365-550kg) will require a human effort range (in lbs. of human force) of

between 18-24 lbs. (8-11kg) to move the unit from a complete stop. An average person will perceive this as acceptable effort levels.

8. Mobile units should have the top shelf positioned as close as possible to the track.

Page 4

®

®

Job ________________________________________________

11.12

TOP-TRACK™ HIGH-DENSITY

STORAGE SYSTEMS

Specifications

• Track: Aluminum extrusion 6063-T6.

• Joining Channel: 16 gauge galvanized steel.

• Roller Assembly: Zinc-plated steel hardware with

nylon roller.

• Casters:

For applications where Brite™ or chrome finishes are

acceptable: 5" (127mm) wheel with offset rigid horn,

ball bearings in axle, nickel-plated, pre-lubricated.

Workable Configurations of Mobile Units Base on Various Track Lengths and Desired Aisle Sizes

Nominal Aisle Size = 30" (760mm) Nominal Aisle Size = 33" (838mm) Nominal Aisle Size = 36" (914mm)

Length 18" 21" 24" Aisle Size 18" 21" 24" Aisle Size 18" 21" 24" Aisle Size

of Track (457mm) (530mm) (610mm) (in.) (mm) (457mm) (530mm) (610mm) (in.) (mm) (457mm) (530mm) (610mm) (in.) (mm)

10 2 1 1 30 762 3 1 33 838 3 1 36 914

11 1 3 30 762 2 2 33 838 3 1 36 914

12 1 4 303/4 781 2 3 343/4 857 3 2 361/4 933

13 2 3 303/4 781 3 2 343/4 857 4 1 361/4 933

14 4 3 311/2 800 2 4 321/4 819 6 1 351/4 895

15 4 3 291/4 749 5 2 321/4 819 6 1 351/4 895

16 8 30 762 1 6 321/4 819 2 5 351/4 895

17 4 4 30 762 5 3 33 838 7 1 36 914

18 8 30 762 1 7 33 838 2 6 36 914

19 2 6 30 762 2 1 5 33 838 3 5 36 914

20 8 30 762 1 7 33 838 2 6 36 914

21 5 5 341/2 876 6 4 371/2 952

NOTE 1: Actual overall width of nominal 18" (457mm), 21" (530mm), and 24" (610mm) wide mobile units is 201/4" (667mm). The number of mobile units here applies to individual

NOTE 2: In confined spaces, usable space for the Top-Track installation should be determined by deducting 4" (102mm) from the overall measured space. This allows for

No. Mobile Units (Note 1) Actual No. Mobile Units (Note 1) Actual No. Mobile Units (Note 1) Actual

62 31

7231

81 2 29

9329

units in a single system, and sets of units (two mobile units tied back-to-back) in a double deep system.

variables such as building tolerances.

1

/2 800 2 311/2 800

1

/2 800 2 311/2 800 2 371/2 952

1

/4 749 2 1 321/4 819 3 351/4 895

1

/4 749 1 2 321/4 819 1 2 351/4 895

• For applications where Metroseal 3 and stainless steel

are acceptable: 5" (127mm) wheel with offset stainless

steel rigid horn, stainless steel ball bearings in axle, prelubricated.

Example

High-Density Storage Systems

™

Top-Track

Selection Criteria: Actual track length required: 17'3" (5228mm). Aisle width must be in 30"-36" (762-914mm) range.

Nominal 30" (762mm) Aisle Nominal 33" (838mm) Aisle

Selection of Mobile Units (457mm) (530mm) (610mm) (457mm) (530mm) (610mm)

17' (5185mm) 4 4 5 3

Other selections would produce a movable aisle outside the 30"-36" (762-914mm) range.

18" 21" 24" 18" 21" 24"

Beyond the standard configurations mentioned above, custom Top-Track capabilities include:

• Attaching one end of the track to a wall in a single or double deep installation.

• Tying together a cluster of two mobile units (i.e., side-to-side) in a single system, or four mobile units in a double deep system.

• A taller installation up to a maximum height of 8' (2438mm) (i.e., 86" (2185mm) high posts in the stationary end units).

• Metroseal 3 and stainless steel Top-Track components for the double deep application.

• Track assemblies 6.5', 7.5' (1956, 2261mm) in length.

Contact factory for details.

All Metro Catalog Sheets are available on our Web Site:

InterMetro Industries Corporation

®

North Washington Street, Wilkes-Barre, PA 18705

Phone: 570-825-2741 • Fax: 570-825-2852

For Product Information Call: 1-800-433-2232

www.metro.com

Printed in U.S.A. 8/03

Information and specifications are subject to change

without notice. Please confirm at time of order.

Copyright © 2003 InterMetro Industries Corp.

L02-039

Loading...

Loading...