Page 1

MX8020-001 Cable Connector Kit Manual

Manual for Trimming the Cable and Connecng the

Connector to an MX8031 Extension Cable

The Metrix MX8020-001 Cable Trimming and

Connector Kit provides an easy way to reduce

the length of an extension cable and maintain

the electrical integrity of the MX8030/8031 or

MX2030/2031 Proximity Probe System. This

kit coupled with the Metrix Digital Proxim-

ity System soware provides the means for

plants, OEM’s and packagers to clean up their

cabinets and enclosures from the usual coils

of cable associated with Proximity Probe

Systems.

Part# 100951 • REV A (January 2018)

Page 2

MX8020-001 Cable Connector Kit Manual

Parts Included

Quanty Descripon

1 Hand Crimping Tool

1 Crimping Tool Die for Cable Connectors

1 Triaxial Cable Cuer (Black Cartridge)

1 Wire Cuer

1 Wire Stripper

10 MX8031 Cable Connectors

10 Shrink Tubing Segments

Parts not Included, but recommended for procedure

• Needle Nose Pliers

• Heat Gun (for the Shrink Tubing)

• Safety Glasses

Accessories not included

MX8020-002 Cable Connector Rell Kit

Quanty Descripon

1 Cable Cuer Cartridge (Black)

20 MX8031 Cable Connectors

20 Shrink Tubing Segments

Part# 100951 • REV A (January 2018) Page 2 of 5

Page 3

Procedure:

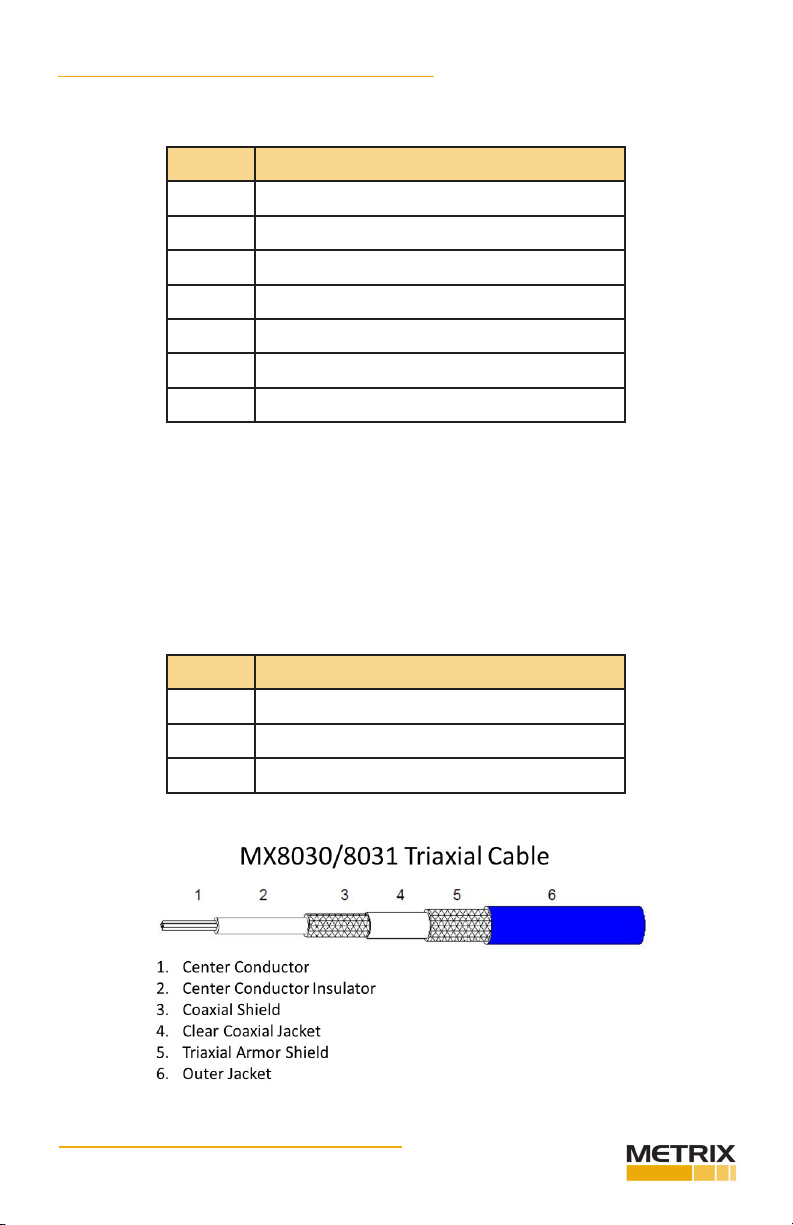

1. Cut the MX8031 Triaxial Cable to the desired length using an appropriate wire cung

tool.

2. Use the Triaxial Cable Cuer with the Black Cartridge (1 acve blade) to remove

approximately 25mm (1.0”) of the outer shield of the triaxial cable. This is the most

dicult step of this process. The armor shield is very tough and rugged. Be careful with

sharp edges and bare wires. With proper blade adjustment, rotate the cuer at least

ten mes for a clean cut. Use the wire strippers to remove the triaxial shield (10 AWG,

2.6mm). A proper cut may leave the clear coaxial jacket of the coaxial cable (clear plas-

c covering) intact. Adjust the blade and tension to obtain the desired depth of cut,

you don’t want to cut through the coaxial shield so you may have to remove the clear

coaxial jacket with the wire stripping tool (14 AWG, 1.6mm).

3. Remove the clear coaxial jacket without cung into the coaxial shield using the wire

stripping tool if necessary. Put the shield ferrule over the coaxial cable shield, with the

thicker edge away from the cut (or trimmed) end. Move the ferrule down the coaxial

cable so it meets the blue triaxial cable. Slide on the blue heat shrink tubing.

Part# 100951 • REV A (January 2018) Page 3 of 5

Page 4

4. Pull back, and fan out, the wire coaxial shield to the ferrule to expose the center conductor insulator and conductor. Use the wire strippers to expose approximately 6mm

(0.25”) of the center conductor (22 AMG, 0.80mm). Gently twist the center conductor

wire, then slide the center core pin onto the center conductor wire and insulator.

6mm

12mm

6mm

5. Push the shield onto the shield side of the center core pin. Slide the ferrule onto the

center core pin to cover 30% of the back end of the center core pin. Trim o the

shield to 30% engagement on the pin. This will allow the ferrule to slide up easier and

sll maintain shield engagement. Put the wire strippers in the locked positon and use

the strippers as a dri (stop) for the pin body. This will help you with counter force to

slide the ferrule on. Do not let the center core pin slip while sliding on the ferrule. Do

not let shield wire extrude beyond the ferrule, or it will make installing the connector

dicult. Remove excess coaxial shield that will not t under the ferrule. Note: The

shield takes the cable load not the center pin conductor.

6. Crimp the center core pin, using the .041 hole, next to the connector insulaon. Use

the kit supplied die and crimping tool. Note: The crush is very light on the center pin

conductor.

Shrink Wrap

Part# 100951 • REV A (January 2018) Page 4 of 5

Page 5

7. Slide the connector onto the center core pin and ferrule. Be careful to ensure the

center core pin comes through the connector. Crimp the connector, using the .178

hexagon hole, at the ridge line. Test the connecon by pulling on the connector with

approximately 8kg (20lbs) of force. Use the hot air gun to shrink the tubing onto the

connecon.

8. Test the modied MX8031 extension cable. Ensure you have an open circuit between

the center pin and the connector case. Ensure you have connuity between the

cases at both ends of the cable. Ensure you have connuity between the pin at one

end and center conductor at the other end. If any of these checks are not true you

must do the connecon over again.

9. Ensure you program the Metrix DPS unit (MX2033 or MX2034) for the closest meter

electrical length that you now have. Verify the system is linear. Perform calibraon if

necessary. For instrucons on how to modify the Metrix DPS conguraon, from the

Factory Purchased conguraon go to the below link.

hp://www.metrixvibraon.com/tenants/metrix/documents/100545.pdf

info@metrixvibraon.com

8824 Fallbrook Dr. Houston, TX 77064, USA

Tel: 1.281.940.1802 • Fax: 1.713.559.9421

Aer Hours (CST) Technical Assistance: 1.713.452.9703

Part# 100951 • REV A (January 2018) Page 5 of 5

www.metrixvibraon.com

Loading...

Loading...