Page 1

STEB 70 Quick

STEB 80 Quick

en Original instructions 9

www.metabo.com

Page 2

1

2

3

4

5

6

7

8

9

11

10

12

13

14

15 17

30 mm

16

2

Page 3

STEB 70 Quick STEB 80 Quick

13.

M Nm (inlbs) 6 (53.1) 6 (53.1)

T

1

T

2

T

3

n

0

P

1

P

2

mm (in)

mm (in)

mm (in)

-1

min

(rpm)

W 570 590

W 335 350

3

70 (2

/4) 80 (3 5/32)

25

20 (

/32)

1

/4)8 (

6 (

3300 3300

m kg (lbs) 2,0 (4.4) 2,0 (4.4)

a

h,CM/Kh,CM

a

h,CW/Kh,CW

L

pA/KpA

L

WA/KWA

m/s

m/s

2

2

8,5 / 2 8,5 / 2

12 / 2 12 / 2

dB(A) 89 / 3 89 / 3

dB(A) 100 / 3 100 / 3

25 (1)

5

/16)

I - III

0 - III

0 - III

PVC

0 - II

PC

I - II

PS

0

ALU

0 - I

0 - I

0

EN 60745

2006/42/EG, 2004/108/EG, 2011/65/EU

-

-

2012-04-03

Volker Siegle

Director Product Engineering & Quality

Responsible Person for Documentation

Metabowerke GmbH, 72622 Nürtingen, Germany

PVC

PC

PS

ALU

3

Page 4

A

6.31340

a

b

5

d

c

e

4

Page 5

Original instructions

ENGLISH en

1. Conformity Declaration

We, being solely responsible, hereby declare that

these jigsaws conform to the standards and directives specified on page 3.

2. Specified Use

The machine is suitable for sawing non-ferrous

metals and sheet steel, wood and similar materials,

plastics and similar materials. Any other use is not

permitted.

The user bears sole responsibility for damage

caused by improper use.

Generally accepted accident prevention

regulations and the enclosed safety information

must be observed.

3. General Safety Instructions

For your own protection and for the

protection of your electrical tool, pay

attention to all parts of the text that are

marked with this symbol!

WARNING – Reading the operating instructions will reduce the risk of injury.

WARNING Read all safety warnings and

instructions. Failure to follow all safety warn-

ings and instructions may result in electric shock,

fire and/or serious injury.

Keep all safety instructions and information for

future reference.

Pass on your electrical tool only together with these

documents.

- To extract dust more efficiently, use the protective

cap (9) and a suitable Metabo vacuum cleaner

together with this tool.

- The work place must be well ventilated.

- The use of a dust mask of filter class P2 is

recommended.

Follow national requirements for the materials you

want to work with.

During work, the workpiece must lay flat and be

secured against moving, e.g. using clamps.

Do not try to saw extremely small workpieces.

When sawing, the footplate must make secure

contact with the workpiece.

When interrupting a cut for any reason, release the

trigger and hold the saw motionless in the material

until the saw blade comes to a complete stop. Never

attempt to remove the saw from the workpiece while

the saw blade is in motion or kickback may occur.

Do not switch the machine on while the saw blade is

touching the workpiece. Let the saw blade reach full

speed before making a cut.

When restarting a saw in the workpiece, centre the

saw blade in the kerf and check that saw teeth are

not engaged into the material. If the saw blade

seizes, it may kickback from the workpiece when

the saw is restarted.

Keep hands well away from the sawing area and the

saw blade. Do not reach underneath the workpiece.

Remove chips and similar material only with the

hine at standstill.

mac

Pull the plug out of the socket before making any

adjustments, converting or servicing the machine.

Danger of injury due to the sharp jigsaw blade. After

stopping work, the jigsaw blade may still be hot.

Wear protective gloves.

4. Special Safety Instructions

Hold power tool by insulated gripping

surfaces, when performing an operation where

the cutting accessory may contact hidden

wiring. Cutting accessory contacting a "live" wire

may make exposed metal parts of the power tool

"live" and could give the operator an electric shock.

Ensure that the spot where you wish to work is free

of power cables, gas lines or water pipes

(e.g. using a metal detector).

Dust from material such as paint containing lead,

some wood species, minerals and metal may be

harmful. Contact with or inhalation of the dust may

cause allergic reactions and/or respiratory diseases

to the operator or bystanders.

Certain kinds of dust are classified as carcinogenic

such as oak and beech dust especially in

conjunction with additives for wood conditioning

(chromate, wood preservative). Material containing

asbestos must only be treated by specialists.

- Where the use of a dust extraction device is

possible it shall be used.

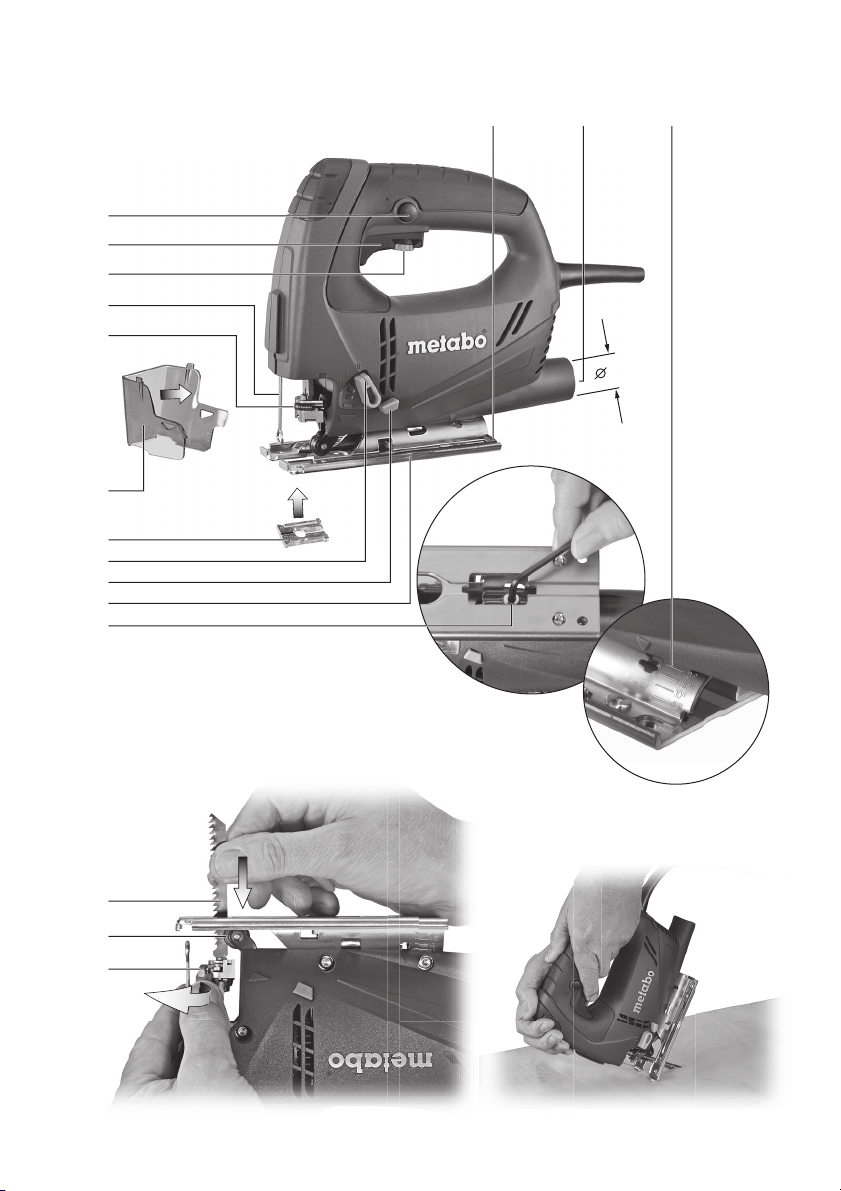

5. Overview

See page 2.

1 Clamping lever for securing the saw blade

2 Saw blade support roller

3 Saw blade

4 Screw for adjusting the footplate

5Footplate

Switch button

6

7 Adjustment lever for pendulum motion

8 Anti-splintering footplate insert

9Protective cap

10 Saw blade clamping fixture

11 Protective rod for preventing unintentional

contact with the saw blade

12 Setting wheel for speed adjustment

13 Trigger

14 Lock button for continuous activation

15 Hexagon spanner

16 Extractor connection piece

17 Curved support plate indicating preset cutting

angle

on the

chip blower

9

Page 6

ENGLISHen

6. Commissioning

Before plugging in, check to see that the rated

mains voltage and mains frequency, as stated

on the rating label, match your power supply.

Never operate the machine without a saw

blade.

6.1 Fitting the anti-splintering footplate

insert

Danger of injury due to the sharp jigsaw blade.

Remove the saw blade

splintering footplate insert.

Turn the machine over so that the footplate faces

upwards. Insert the anti-splintering footplate from

the front,

•

•

cable).

If you wish to work with the protective plate attached

(see chapter Accessories 10.), fit the anti-splintering

footplate insert in the protective plate.

6.2 Inserting the saw blade

be hot. Wear protective gloves.

Use a saw blade that is suitable for the material

being sawn.

-Push the clamping lever (1) forwards up to the

- Insert the saw blade (3) up to the stop. Ensure that

- Push back the clamping lever (1) to its original

6.3 Attaching / Removing the protective cap

Attachment: Push on the protective cap (9) from

the front until it engages

Removal: Grip both sides of the protective cap (9),

lift slightly, then pull forwards and remove.

6.4 Sawing with dust extraction

- Connect a suitable extraction device to the

- Attach the protective cap (9) for maximum

- Switch off the chip blower (see chapter 7.1).

6.5 Sawing without dust extraction

- Work with the protective cap (9) removed

6.6 Diagonal cuts

Remove the protective cap (9), anti-splintering

footplate insert (8) and extraction hose. These parts

cannot be used for diagonal cuts.

10

ensuring the following:

The smooth side of the footplate faces upwards.

The slot is facing to the rear (towards the mains

Danger of injury due to the sharp jigsaw blade.

After stopping work, the jigsaw blade may still

stop and release (the clamping lever remains

open).

the saw teeth are facing forwards and the blade is

seated correctly in the groove on the saw blade

support roller (2).

position (the saw blade is now clamped securely

in position).

extractor connection piece (16). Use a suction

hose with a 30 mm connector diameter.

extraction efficiency.

(see Removal chapter 6.3).

before fitting (8) the anti-

- Slacken the screw (4).

- Slid the footplate (5) forwards slightly and turn.

- Then slide the footplate (5) forwards or backwards

and engage in one of the detents (the detents can

be viewed through the semicircular opening at the

rear of the footplate (5).) The preset angle is

indicated on the curved support plate (17) on the

footplate. Adjust to different angles using an angle

gage.

- Tighten the screw (4) again.

6.7 Sawing close to the wall

Remove the protective cap (9), anti-splintering

footplate insert (8), circular-cutting and parallel

guide. These parts cannot be used when sawing

close to the wall.

- Slacken the screw (4) until the footplate (5) can be

raised slightly.

- Raise the footplate (5) slightly and slide

backwards up to the stop.

- Tighten the screw (4) again.

7. Use

7.1 Chip blower

Optional blower for a clear view of the cutting line.

On: press in the switch button (6) on the right side

of the machine. (look for the symbol).

Off: press in the switch button (6) on the left side of

the machine. (look for the symbol).

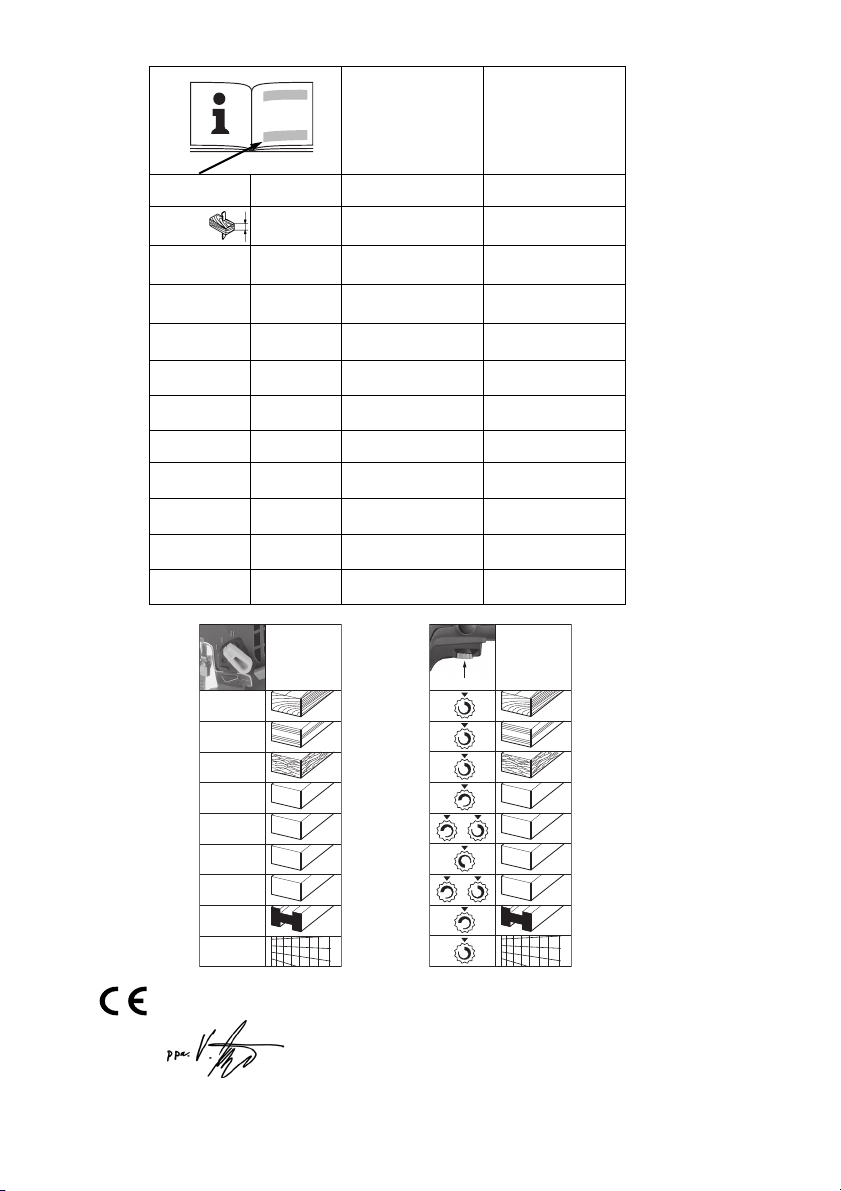

7.2 Adjusting the pendulum motion

Set the required pendulum motion using the

adjustment lever (7).

Position "0" = pendulum motion is switched off

. . .

Position "III" = maximum pendulum motion

See page 3 for recommend setting values.

The best way to determine the ideal setting is

through a practical trial.

7.3 Setting maximum speed

Set the machine to maximum speed using the

setting wheel (12). This is also possible during

operation.

See page 3 for recommend setting values.

The best way to determine the ideal setting is

through a practical trial.

7.4 Switching on and off, adjusting the

speed, continuous operation

On: press the trigger (13). Press the trigger more

to increase the speed (up to preset maximum

speed, see chapter 7.3).

Off: release the trigger (13).

Continuous operation: For continuous operation,

the pressed trigger (13) can be locked using the

lock button (14). To stop the machine, press the

gger (13) again.

tri

In continuous operation, the machine

continues running if it is forced out of your

Page 7

hands. Therefore always hold the machine with

both hands using the handle provided, stand

securely and concentrate.

8. Cleaning, Maintenance

Clean the machine regularly. This includes

vacuum cleaning the ventilation louvres on the

motor.

Clean the saw blade clamping fixture regularly and

thoroughly by blowing with compressed air.

If necessary, clean the openings behind the saw

blade support roller (2).

Apply a drop of oil to the saw blade support roller (2)

from time to time.

9. Tips and Tricks

Plunging

The jigsaw blade can plunge into workpieces made

from thin, soft materials without the necessity of

drilling a hole beforehand. Only use short saw

blades. Only at 0° angle setting.

See illustration on page 2. Set the adjustment lever

(7) to position "0" (pendulum motion is switched off).

Position the jigsaw with the front edge of the

footplate (5) on the workpiece. Hold the operating

jigsaw firmly and guide slowly downwards. Once

the saw blade has penetrated the workpiece, the

pendulum motion can be activated.

In thicker workpieces, a hole for inserting the saw

blade must be drilled first.

10. Accessories

Use only genuine Metabo accessories.

Use only accessories which fulfil the requirements

and specifications listed in these operating instructions.

Fit accessories securely. Secure the machine if it is

operated in a bracket. Loss of control can cause

personal injury.

See page 4.

A Circular-cutting and parallel guide

For complete range of accessories, visit

www.metabo.com or refer to the main catalogue.

10.1 Attaching the circular-cutting and

parallel guide

For sawing circles (dia. 100 - 360 mm) and making

cuts parallel with edges (max. 210 mm).

Attaching clamping elements (page 4, Fig. I)

Place the clamping elements (a) on the footplate (5)

with the opening facing forwards and the threaded

hole facing up. Insert the screws (b) from

underneath.

Remove the clamping elements after use

otherwise the saw blade clamping fixture (10)

may be damaged when diagonal cuts are made.

ENGLISH en

At a 45° diagonal cut angle, tilting the jigsaw to

the right will damage the saw blade clamping

fixture (10).

Attaching the circular-cutting guide

(page 4, Fig. II)

- Slide the rod on the circular-cutting and parallel

guide sideways into the clamping elements (a)

(centre point (c) faces downwards).

- Set the desired radius (d).

- Tighten the screws (b).

Attaching the parallel guide (page 4, Fig. III)

- Slide the rod on the circular-cutting and parallel

guide sideways into the clamping elements (a)

(centre point (c) faces upwards).

- Unscrew the centre point (c).

- Set the dimension (e)

- Tighten the screws (b).

11. Repairs

Repairs to electrical tools must be carried out

by qualified electricians ONLY!

If you have Metabo electrical tools that require

repairs, please contact your Metabo service centre.

For addresses see www.metabo.com.

You can download spare parts lists from

www.metabo.com.

12. Environmental Protection

Observe national regulations on environmentally

compatible disposal and on the recycling of disused

machines, packaging and accessories.

Only for EU countries: Never dispose of

power tools in your household waste! In

accordance with European Guideline 2002/

96/EC on used electronic

and its implementation in national legal systems,

used power tools must be collected separately and

handed in for environmentally compatible recycling.

and electric equipment

13. Technical Specifications

Explanatory notes on the specifications on page 3.

Changes due to technological progress reserved.

M=Torque

=Maximum material thickness in wood

T

1

T

=Maximum material thickness in non-

2

ferrous metals

=Maximum material thickness in sheet

T

3

n

P

P

m =Weight without mains cable

Measured values determined in conformity with

EN 60745.

steel

=Stroke rate at idle speed

0

=Nominal power input

1

=Power output

2

Machine in protection class II

~ Alternating current

The technical specifications quoted are subject to

tolerances (in compliance with the relevant valid

standards).

11

Page 8

ENGLISHen

Emission values

These values make it possible to assess the

emissions from the power tool and to compare

different power tools. Depending on the operating

conditions, the condition of the power tool or the

accessories, the actual load may be higher or lower.

For assessment purposes, please allow for breaks

and periods when the load is lower. Based on the

adjusted estimates, arrange protective measures

for the user e.g. organisational measures.

Vibration total value

determined in accordance with EN 60745:

=Vibration emission value

a

h,CM

a

K

(sawing sheet metal)

=Vibration emission value

h,CW

(sawing wood)

h,...

= Uncertainty (vibration)

Typical A-effective perceived sound levels

=Sound pressure level

L

pA

L

=Acoustic power level

WA

KpA, KWA= Uncertainty

Wear ear protectors!

(vector sum of three directions)

:

12

Page 9

Metabowerke GmbH,

72622 Nürtingen, Germany

www.metabo.com

170 26 9190 - 0412

Loading...

Loading...