Page 1

SE 4000

SE 2800

Made in Germany

Operating Instructions ...........page

Mode d’emploi.......................page

Instrucciones de manejo..... página

Instruções de serviço.......... página

5

10

15

20

170 26 6890 - 1107

Page 2

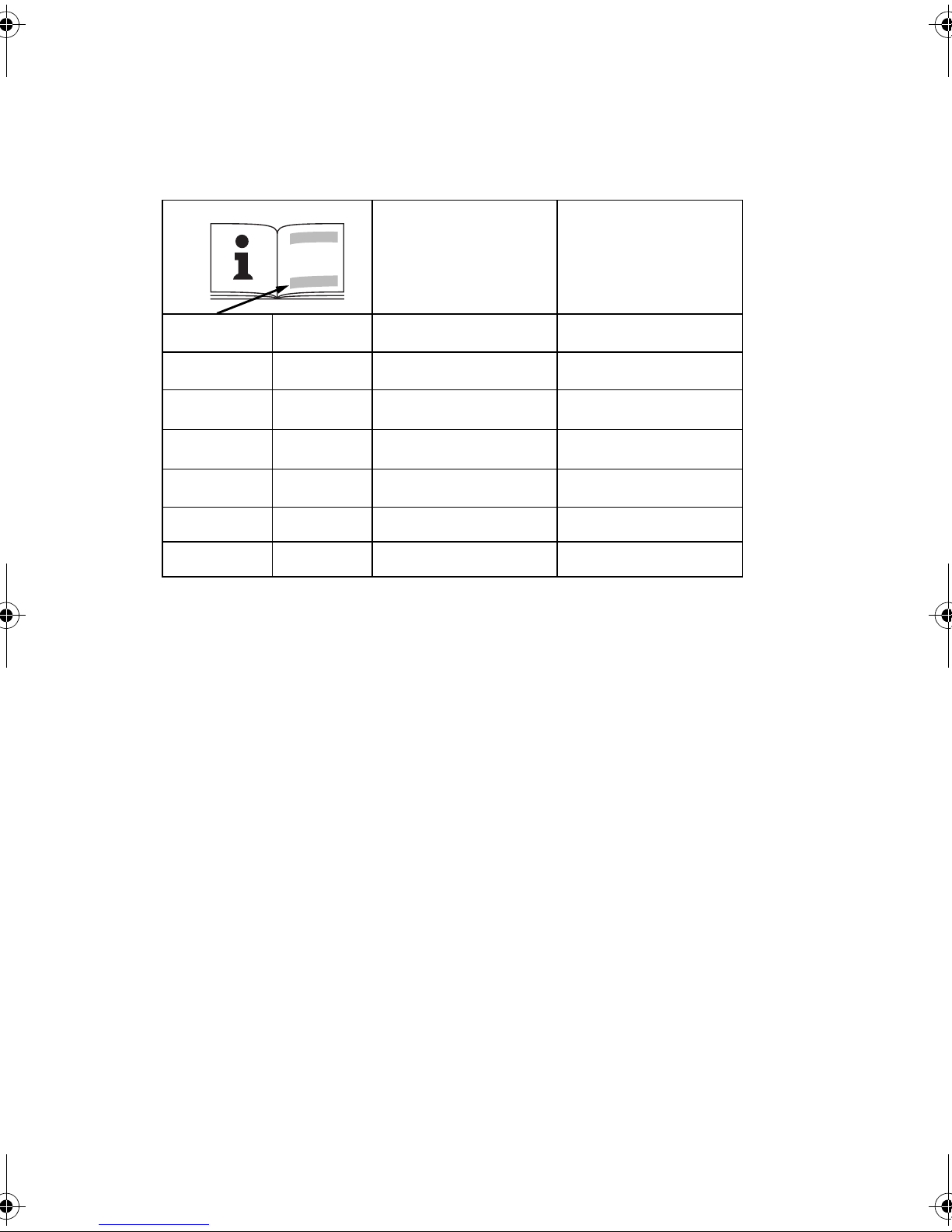

14

SE 4000 SE 2800

T

P

1

P

2

n

0

n

1

max.

W 400 400

W 220 220

min

min

-1

-1

(rpm)

(rpm)

0-4000 0-2850

2400 1800

Nm 6 8

H mm (in) 6,35 (1/4“) 6,35 (1/4“)

m kg (lbs) 1,2 (2.6) 1,2 (2.6)

© 2007

Metabowerke GmbH,

Postfach 1229

Metabo-Allee 1

D-72622 Nürtingen

Germany

2

Page 3

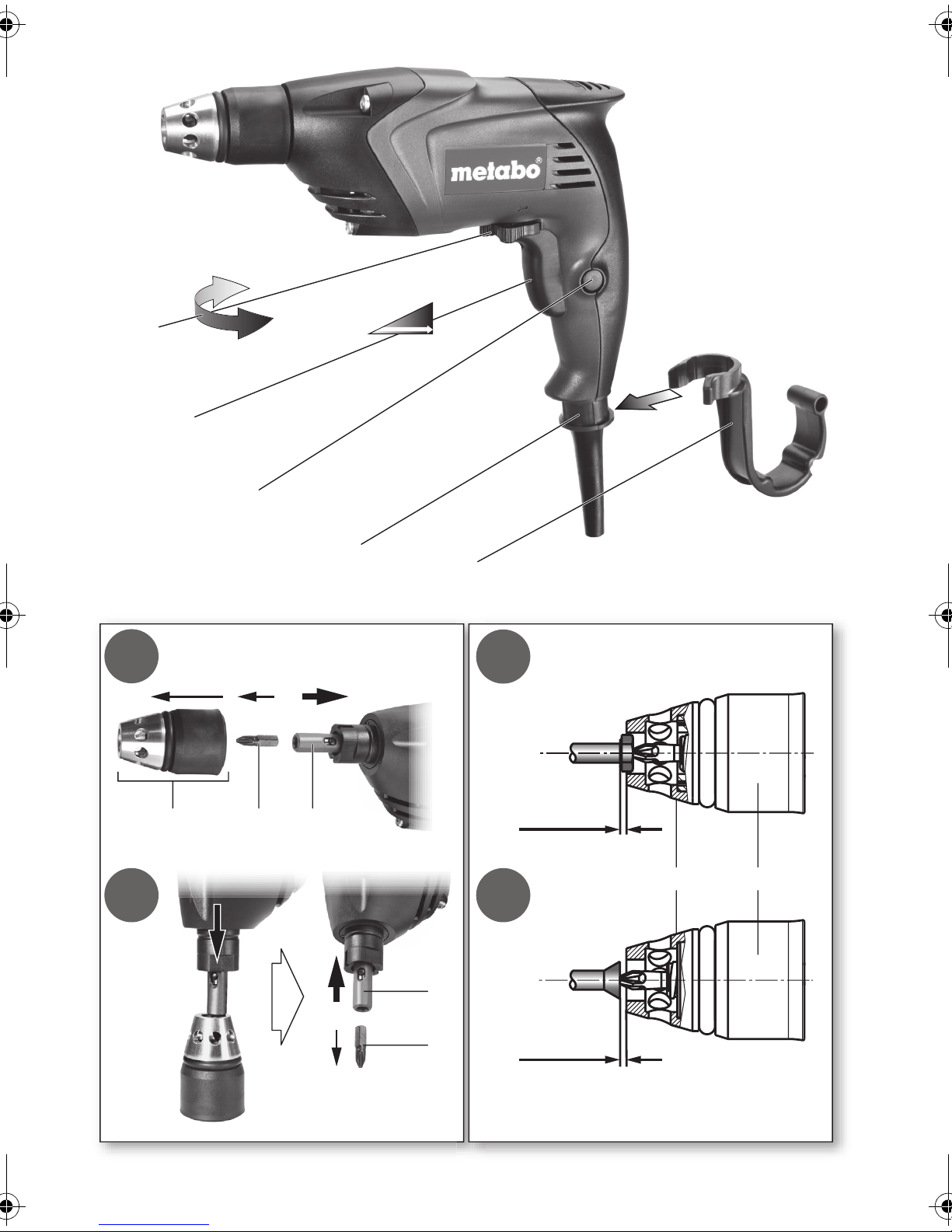

L

1

1a

1

R

2

3

0

4

5

2a

678

1b

3

2 mm, 1/16“

9

6

2b

8

7

2 mm, 1/16“

Page 4

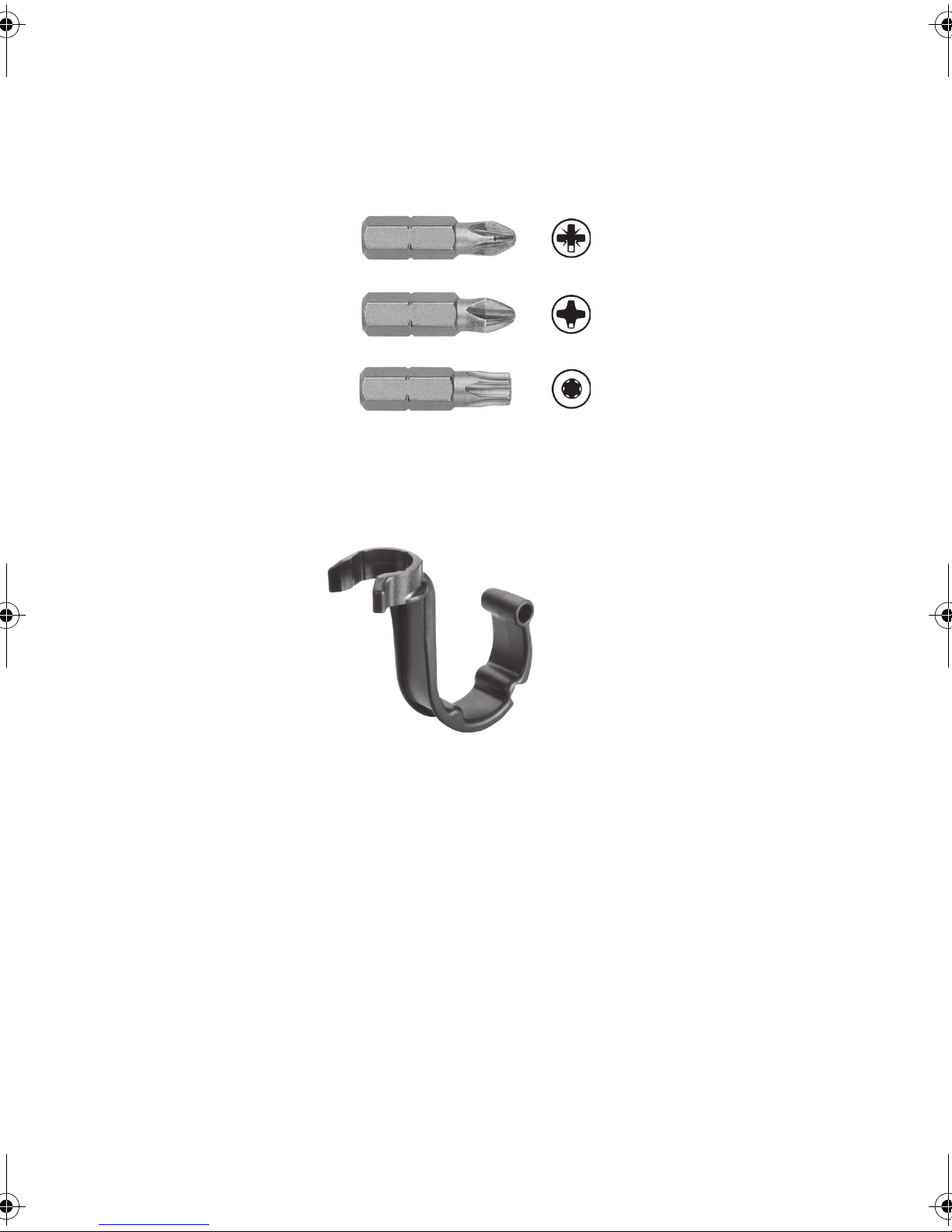

A

B

6.25070

4

Page 5

ENGLISH

ENG

Operating Instructions

Dear Customer,

Thank you for the trust you have placed in us by buying a Metabo power tool. Each Metabo power tool

is carefully tested and subject to strict quality controls by Metabo's quality assurance. Nevertheless, the

service life of a power tool depends to a great extent on you. Please observe the information contained

in these instructions and the enclosed documentation. The more carefully you treat your Metabo power

tool, the longer it will provide dependable service.

your mains-operated (corded) power tool or

Contents

1 Specified Conditions of Use

2 General Safety Rules

3 Special Safety Rules

4 Functional Description

5 Special Product Features

6 Initial Operation

7Use

7.1 Switching On and Off

7.2 Selecting the direction of rotation

7.3 Tool change

7.4 Working with depth stop

7.5 Working without depth stop

8 Tips and Tricks

9 Troubleshooting

10 Maintenance

11 Accessories

12 Repairs

13 Environmental Protection

14 Technical Specifications

1 Specified Use

The machine is designed for inserting and

removing screws in/from wood, gypsum plasterboards on metal profile rails or timbers, plastics

and similar materials.

The machine is not suitable for inserting and

removing screws in metal materials.

The user bears sole responsibility for damage

caused by improper use.

Generally accepted accident prevention regulations and the enclosed safety information must be

observed.

2 General Safety Rules

WARNING!

all instructions listed below may result in electric

shock, fire and/or serious injury. The term „power

tool“ in all of the warnings listed below refers to

Read all instructions. Failure to follow

battery-operated (cordless) power tool.

SAVE THESE INSTRUCTIONS

1)

Work area safety

a)

Keep work area clean and well lit. Cluttered or

dark areas invite accidents.

b)

Do not operate power tools in explosive

atmospheres,such as in the presence of

flammable liquids, gases or dust.

create sparks which may ignite the dust or fumes.

c)

Keep children and bystanders away while

operating a power tool.

you to lose control.

2)

Electrical safety

a)

Power tool plugs must match the outlet.

Never modify the plug in any way. Do not use

any adapter plugs with earthed (grounded)

power tools.

outlets will reduce risk of electric shock.

b)

Avoid body contact with earthed or grounded

surfaces such as pipes, radiators, ranges and

refrigerators.

shock if your body is earthed or grounded.

c)

Do not expose power tools to rain or wet

conditions.

increase the risk of electric shock.

d)

Do not abuse the cord. Never use the cord for

carrying, pulling or unplugging the power tool.

Keep cord away from heat, oil, sharp edges or

moving parts.

increase the risk of electric shock.

e)

When operating a power tool outdoors, use

an extension cord suitable for outdoor use.

of a cord suitable for outdoor use reduces the risk

of electric shock.

3)

Personal safety

a)

Stay alert, watch what you are doing and use

common sense when operating a power tool.

Do not use a power tool while you are tired or

under the influence of drugs, alcohol or

medication.

operating power tools may result in serious

personal injury.

b)

Use safety equipment. Always wear eye

protection.

non-skid safety shoes, hard hat, or hearing

Unmodified plugs and matching

There is an increased risk of electric

Water entering a power tool will

Damaged or entangled cords

A moment of inattention while

Safety equipment such as dust mask,

Distractions can cause

Power tools

Use

5

Page 6

ENG

ENGLISH

protection used for appropriate conditions will

reduce personal injuries.

c)

Avoid accidental starting. Ensure the switch

is in the off-position before plugging in.

power tools with your finger on the switch or

plugging in power tools that have the switch on

invites accidents.

d)

Remove any adjusting key or wrench before

turning the power tool on.

attached to a rotating part of the power tool may

result in personal injury.

e)

Do not overreach. Keep proper footing and

balance at all times.

the power tool in unexpected situations.

f)

Dress properly. Do not wear loose clothing or

jewellery. Keep your hair, clothing and gloves

away from moving parts.

or long hair can be caught in moving parts.

g)

If devices are provided for the connection of

dust extraction and collection facilities, ensure

these are connected and properly used.

these devices can reduce dust-related hazards.

4)

Power tool use and care

a)

Do not force the power tool. Use the correct

power tool for your application.

power tool will do the job better and safer at the

rate for which it was designed.

b)

Do not use the power tool if the switch does

not turn it on and off.

be controlled with the switch is dangerous and

must be repaired.

c)

Disconnect the plug from the power source

and/or the battery pack from the power tool

before making any adjustments, changing

accessories, or storing power tools.

preventive safety measures reduce the risk of

starting the power tool accidentally.

d)

Store idle power tools out of the reach of

children and do not allow persons unfamiliar

with the power tool or these instructions to

operate the power tool.

dangerous in the hands of untrained users.

e)

Maintain power tools. Check for

misalignment or binding of moving parts,

breakage of parts and any other condition that

may affect the power tools operation. If

damaged, have the power tool repaired before

use.

Many accidents are caused by poorly

maintained power tools.

f)

Keep cutting tools sharp and clean. Properly

maintained cutting tools with sharp cutting edges

are less likely to bind and are easier to control.

g)

Use the power tool, accessories and tool bits

etc., in accordance with these instructions and

in the manner intended for the particular type of

power tool, taking into account the working

conditions and the work to be performed.

of the power tool for operations different from

those intended could result in a hazardous

situation.

A wrench or a key left

This enables better control of

Loose clothes, jewellery

The correct

Any power tool that cannot

Power tools are

Carrying

Such

Use of

Use

5)

Service

a)

Have your power tool serviced by a qualified

repair person using only identical replacement

parts.

This will ensure that the safety of the power

tool is maintained.

3 Specific Safety Rules

Hold powertools by insulated gripping surfaces

when performing an operation where the

cutting tool may contact hidden wiring or its

own cord.

exposed metal parts of the tool „live“ and shock

the operator.

Wear ear protectors.

cause hearingloss.

Before using this power tool, carefully read

through and familiarise yourself with all the

enclosed safety information (red booklet) and the

instructions. Keep all enclosed documentation for

future reference, and pass on your power tool only

together with this documentation.

Pull the plug out of the plug socket before any

adjustments or servicing are performed.

Take care to avoid gas, electricity, and water

supplies!

Note that high counter-torques are possible during

work. Always hold the tool firmly, ensure you have

good footing and concentrate when working.

Do not keep the ventilation slots closed.

SYMBOLS ON THE TOOL:

....... Class II Construction

V ........... volts

A........... amperes

Hz......... hertz

~

........... alternating current

n

.......... no load speed

0

../min ... revolutions per minute

Contact with a „live“ wire will make

Exposure to noise can

For your own protection and for

the protection of your power tool

pay attention to all parts of the text

that are marked with this symbol!

4 Functional Description

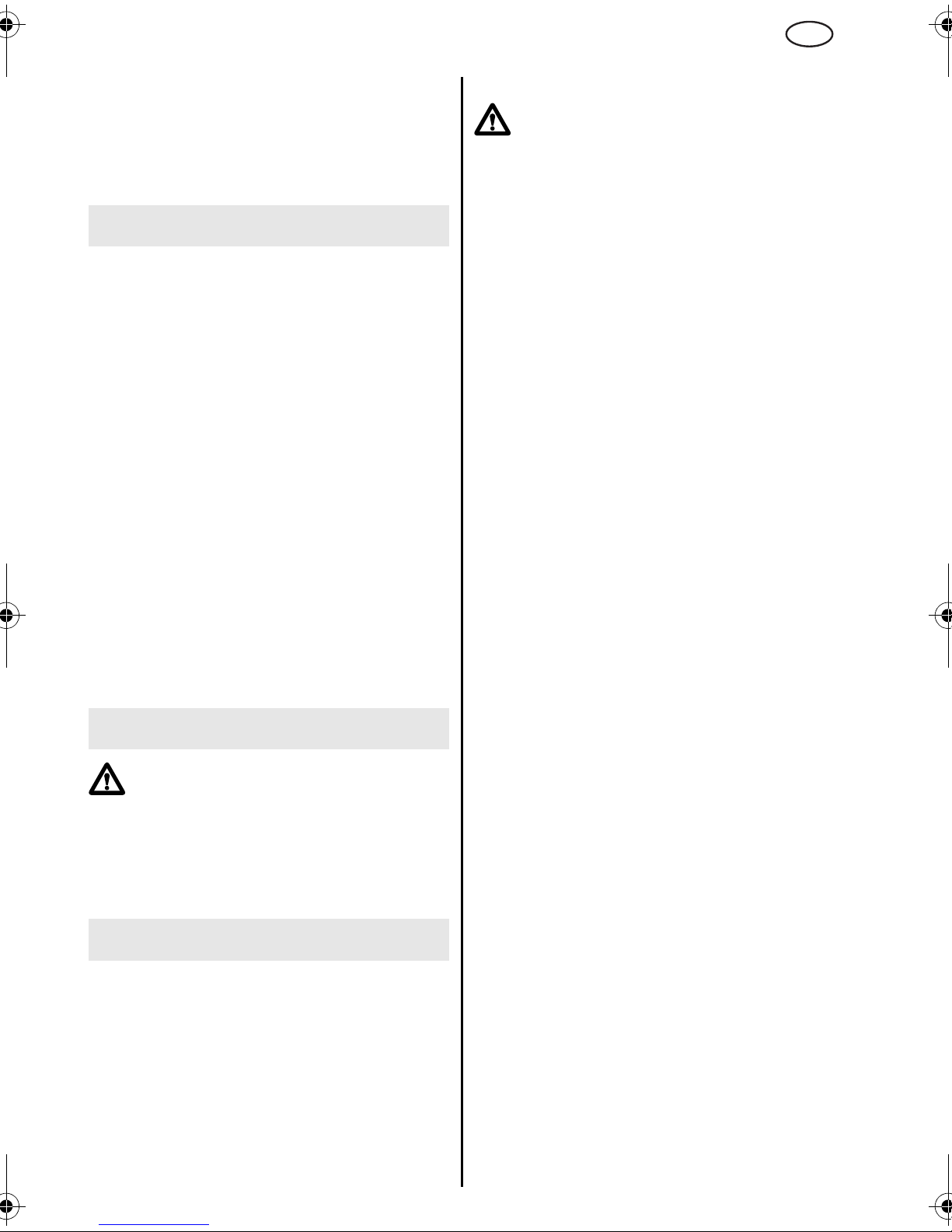

See page 3 (please unfold).

1 Rotation selector switch

2Trigger

3 Locking button (continuous activation)

4 Scaffold hook mounting

5Scaffold hook *

6Depth stop

6

Page 7

ENGLISH

ENG

7Tool *

8 Quick-release lock

9 Stop sleeve

* depending on equipment/not in scope of delivery

5 Special Product Features

• Compact, light machine in barrel-type design

for continuous use

• Ergonomically designed housing for effortless

work

• Patented bit changing system

• Two-piece depth stop

• Fine adjustment of insertion depth

• Low-noise claw clutch

• Removable scaffold hook with integrated bit

depot (depending on equipment)

•

SE 4000:

Ideally suited for applications in dry construction, e.g. installation of gypsum plasterboards.

•

SE 2800:

Universal screwdriver for wood screws, drilling

screws and dry wall screws up to a diameter of

6.0 mm.

•

Depth stop:

Work with and without depth stop possible.

Removal of the depth stop does not alter the set

screw insertion depth. After refitting, work can

continue at the same insertion depth.

a

6 Commissioning

Before plugging in, check to see that the

rated mains voltage and mains frequency,

as stated on the rating label, match your

power supply.

Scaffold hook (5) assembly:

hood mounting (4)

desired position.

and turn until it engages in the

Clip into

scaffold

7Use

7.1 Switching On and Off

7.2 Selection of direction of rotation

Do not activate the rotation selector

switch (1) unless the motor has

completely stopped.

Select direction of rotation:

R = Clockwise

L = Counter-clockwise

7.3 Tool change

Inserting tool:

Hold the quick-change lock (8) firmly in position

and insert tool.

Check that the quick-change lock (8) is in its front

position. Pull on the tool. The tool must be held

securely in position by the quick-change lock (8).

Removing the tool:

(See page 3, illustration 1a)

- Remove depth stop (6).

- Pull the quick-change lock (8) to the rear as far as

the stop (which unlocks the tool) and hold in this

rear position.

- Remove the tool (7).

If the quick-change lock (8) cannot be pushed to

the rear by hand, the depth can be used to do this.

Proceed as follows (see page 3, illustration 1b):

Option 1 :

- Insert the tool in a lateral bore of the depth stop

(6).

- Use the depth stop (6) to push the quick-change

lock (8) to the stop at the rear (this locks the tool).

- Remove the tool (7).

Option 2 :

- Place the depth stop (6) on a table, for example.

- Mount the machine with the quick-change lock

(8) on the upper edge of the depth stop (6).

- Position the quick-change lock (8) on the upper

edge so that the quick-change lock (8) is pushed

to the rear when the machine is pressed down.

- Press the machine down.

- Hold the quick-change lock (8) firmly in this in

position by hand.

- Remove the tool (7).

Fit the depth stop (6) again:

turn and engage in position when mounting.

To start the machine, press the trigger switch (2).

The speed can be changed at the trigger switch by

pressing.

For continuous operation the trigger switch can be

locked using the lock button (3). To stop the

machine, press the trigger switch again.

7.4 Working with depth stop

See page 3, illustration 2 a and 2 b.

To preset screw insertion depth, one of the screws

to be inserted is fitted on the tool. Set the depth

stop (6) by turning as follows:

a) Screws whose heads are to sit on the material

(socket-head screws, oval head screws, hex

7

Page 8

ENG

ENGLISH

screws): the surface area of the screw head is 2

mm outside the stop sleeve (9).

b) Flat head screws: The surface area of the screw

head is 2 mm outside the stop sleeve (9).

Insert a screw as a test. Correct the insertion depth

if necessary: When the depth stop (6) is inserted,

the insertion depth changes by 0.25 mm per notch.

If screw insertion has to be deeper: Insert stop

sleeve If the screw insertion is too deep: Unscrew

stop sleeve.

Removal of the depth stop (6) does not alter the set

screw insertion depth. After refitting, work can

continue at the same insertion depth.

When screwing in crosshead screws, press

the machine with the screwdriver bit firmly

against the screw until the screw is fully

inserted; otherwise the bit could slip out of the

cross recess and damage the material.

If the machine is not held exactly vertical in relation

to the tool, the depth stop counterbalances this (to

a certain extent).

7.5 Working without depth stop

Adapt the speed of the screwing process by carefully pressing in the trigger switch.

When the screwing process is complete, switch off

the machine by releasing the trigger switch (2).

If the long hole in the quick-change lock (8) is

contaminated, clean it and blow out with

compressed air. Pour some oil into the long hole if

necessary.

Remove the depth stop (6) regularly and clean it

f

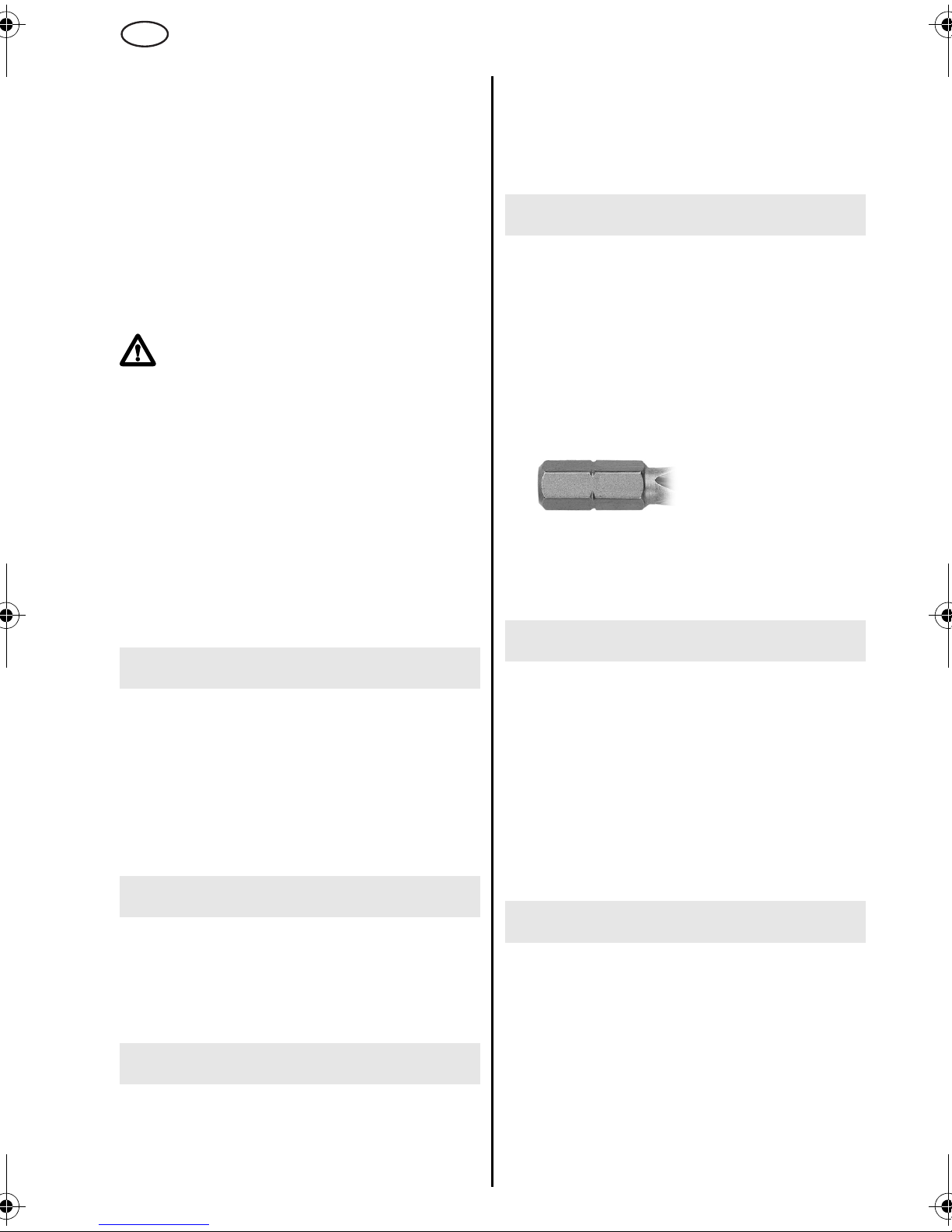

11 Accessories

Use only genuine Metabo accessories.

If you need any accessories, check with your

dealer.

For dealers to select the correct accessory, they

need to know the exact model designation of your

power tool.

See page 4.

A Screwdriver bits (length: 25 mm)

Recommendation: only use screwdriving bits

with insertions like this:

B Scaffold hook with integrated bit depot

For complete range of accessories, see

www.metabo.com or the main catalogue.

8 Tips and Tricks

Press the machine firmly against the screw until

the screwing process is complete.

This is particularly important when inserting dry

wall screws (with coarse threads) in gypsum plasterboards because the large thread pitch of the

screws means that they are very quickly inserted.

If the stop sleeve (9) is stiff, it can be removed to

clean the thread.

.

9 Troubleshooting

If the screwdriver bit is too tightly fitted in the toolholder, pull the screwdriver bit out with pliers or

push the quick-change lock (8) to the rear with the

help of the depth stop. See the chapter on Tool

change

ENG

10 Maintenance

12 Repairs

Repairs to electrical tools must be carried out by

qualified electricians ONLY!

The connection cable must only be replaced by

Metabo or an authorised customer service workshop.

Any Metabo power tool in need of repair can be

sent to one of the addresses listed in the spare

parts list.

Please enclose a description of the fault with the

power tool.

13 Environmental Protection

Metabo's packaging can be 100% recycled.

Scrap power tools and accessories contain large

amounts of valuable resources and plastics that

can be recycled.

These instructions are printed on chlorine-free

bleached paper.

Disconnect the mains plug before starting any

maintenance work.

Motor cleaning: blow out the machine regularly

through the rear air slots with compressed air.

8

Page 9

14 Technical Specifications

Explanatory notes on the specifications on page 2.

Changes due to technological progress reserved.

ENGLISH

ENG

P

1

= Nominal power input

P2 = Power output

n

n

T

0

1

max.

= No load speed

= On-load speed

= Max. tightening torque

H = Machine toolholder

m = Weight without mains cable

During operation the noise level can exceed

85 dB(A).

Wear ear protectors!

The technical specifications quoted are subject to

tolerances (in compliance with the relevant valid

standards).

9

Page 10

F

FRANÇAIS

Mode d'emploi

Cher client,

merci de la confiance que vous nous avez témoignée en achetant un outil électrique Metabo. Tous les

outils électriques Metabo sont testés avec soin et font l'objet de contrôles qualité très stricts effectués

par le Service Qualité Metabo. Mais c'est vous qui avez la plus grande influence sur la durée de vie de

votre outil électrique. Veuillez respecter les informations contenues dans ces instructions d'utilisation et

dans les documents ci-joints. En prenant grand soin de votre outil électrique Metabo, vous en

augmenterez la durée de vie et en garantirez le bon fonctionnement.

Sommaire

1 Utilisation conforme à la destination

2 Consignes générales de sécurité

3 Consignes de sécurité particulières

4Vue d'ensemble

5 Particularités du produit

6Mise en service

7 Utilisation

7.1 Marche/arrêt

7.2 Sélection du sens de rotation

7.3 Changement d'embout

7.4 Travaux avec la butée de profondeur

7.5 Travaux sans la butée de profondeur

8 Conseils et astuces

9 Dépannage

10 Maintenance

11 Accessoires

12 Réparations

13 Protection de l'environnement

14 Caractéristiques techniques

2 Consignes générales de

sécurité

AVERTISSEMENT !

instructions. Le non-respect des instructions

consignées ci-dessous peut être la cause de

chocs électriques, d'incendie et/ou de blessures

graves. Le terme „outil électrique“ utilisé dans tous

les avertissements répertoriés ci-après fait

référence à votre outil électrique alimenté sur

secteur (à fil) ou sur batterie (sans fil).

CONSERVEZ CES INSTRUCTIONS

1)

Sécurité de l'espace de travail

a)

Veillez au nettoyage et au bon éclairage de

l'espace de travail.

propices aux accidents.

b)

N'utilisez pas d'outils électriques dans des

atmosphères explosives, comme en présence

de liquides inflammables, de gaz ou de

poussière.

étincelles susceptibles d'enflammer les poussières

ou vapeurs.

c)

Éloignez les enfants et les tiers pendant le

fonctionnement d'un outil électrique.

pouvez perdre le contrôle en étant distrait.

Les outils électriques créent des

Lisez attentivement les

Les espaces encombrés sont

Vous

1 Utilisation conforme à la

destination

Cet outil convient pour visser et dévisser des vis

sur bois, panneaux de placoplâtre posés sur rails

métalliques ou ossature bois, plastiques et

matériaux assimilés.

L'outil n'est pas destiné au vissage et dévissage

de vis d'assemblage de métaux.

L'utilisateur sera entièrement responsable de tous

dommages résultant d'une utilisation non

conforme à la destination de la machine.

Il est impératif de respecter les consignes

générales de protection contre les accidents ainsi

que les consignes de sécurité ci-jointes.

10

2)

Sécurité électrique

a)

Les fiches d'alimentation des outils

électriques doivent correspondre à la prise de

courant. Ne modifiez jamais la fiche en aucune

manière. N'utilisez pas de fiches d'adaptation

avec les outils électriques à la masse.

modification des fiches et la conformité des prises

de courant permettront de réduire le risque de

choc électrique.

b)

Évitez le contact avec les surfaces mises à la

terre ou la masse comme les tuyaux, les

radiateurs, les cuisinières et les réfrigérateurs.

Le risque de choc électrique est accru en cas de

corps mis à la terre ou à la masse.

c)

N'exposez pas les outils électriques à la pluie

ni à l'humidité.

électrique accroît le risque de choc électrique.

d)

Ménagez le cordon d'alimentation. Ne

portez, tirez ni débranchez l'outil électrique par

le cordon. Éloignez le cordon d'alimentation de

toute source de chaleur, de surfaces

graisseuses, d'arêtes vives et de pièces

La pénétration d'eau dans un outil

La non

Page 11

FRANÇAIS

F

mobiles. Des cordons endommagés ou

enchevêtrés augmentent le risque de choc

électrique.

e)

Si vous utilisez un outil électrique à

l'extérieur, prévoyez une rallonge adaptée aux

conditions extérieures.

adapté aux conditions extérieures réduit le risque

de choc électrique.

3)

Sécurité personnelle

a)

Restez vigilant et attentif à ce que vous faites

et faites preuve de bon sens lorsque vous vous

servez d'un outil électrique. N'utilisez pas

d'outil électrique si vous êtes fatigué ou sous

l'influence de l'alcool, d'un médicament ou

d'une drogue.

le maniement d'outils électriques peut entraîner

des blessures graves.

b)

Utilisez des dispositifs de protection. Portez

toujours des lunettes de sécurité.

dans les bonnes conditions, de dispositifs de

protection comme les masques anti-poussière,

chaussures de sécurité antidérapantes ou

protections auditives réduit les blessures

corporelles.

c)

Évitez les démarrages intempestifs. Vérifiez

que la gâchette est déverrouillée avant le

branchement.

doigt sur la gâchette ou leur branchement avec la

gâchette verrouillée est propice aux accidents.

d)

Retirez toute clavette de calage ou clé de

réglage avant de mettre l'outil électrique en

marche.

en mouvement de l'outil électrique risque de

provoquer des blessures corporelles.

e)

N'adoptez pas une posture instable. Restez

bien ancré au sol et gardez l'équilibre à tout

instant.

électrique dans des situations inattendues.

f)

pas de vêtements amples ni de bijoux. Prenez

soin de garder vos cheveux, vêtements et gants

à l'écart des pièces en mouvement.

vêtements amples, les bijoux ou les cheveux longs

risquent d'être pris dans les pièces en mouvement.

g)

branchement de dépoussiéreurs ou de

collecteurs de déchets, vérifiez que ceux-ci

sont correctement branchés et utilisés.

L'utilisation de ces dispositifs peut réduire les

dangers associés à la poussière.

4)

a)

électrique correspondant à votre application.

L'utilisation du bon outil électrique permet

d'obtenir de meilleurs résultats avec une plus

grande sécurité et avec un rendement pour lequel

il a été conçu.

b)

ne fonctionne pas.

Portez des vêtements appropriés. Ne portez

En cas de dispositifs prévus pour le

Utilisation et entretien des outils électriques

Ne forcez pas l'outil électrique. Utilisez l'outil

N'utilisez pas l'outil électrique si la gâchette

Un moment d'inattention pendant

Le port d'outils électriques avec le

Une clé ou une clavette fixée à une pièce

Ceci permet un meilleur contrôle de l'outil

L'utilisation d'un cordon

L'utilisation,

Les

Tout outil électrique dont la

gâchette est défectueuse représente un danger et

doit faire l'objet d'une réparation.

c)

Débranchez la fiche de la source électrique

et/ou la batterie de l'outil électrique avant de

procéder à des réglages, changer

d'accessoires ou de ranger les outils

électriques.

réduisent le risque de démarrage intempestif des

outils électriques.

d)

Rangez les outils électriques hors de la

portée des enfants et ne laissez pas les

personnes non familiarisées avec un outil

électrique ou avec ces instructions, utiliser

l'outil concerné.

non formées, les outils électriques constituent un

danger.

e)

Assurez la maintenance des outils

électriques. Recherchez le défaut d'alignement

ou grippage des pièces en mouvement, la

rupture de pièces ou tout autre état susceptible

d'affecter la bonne marche des outils

électriques. En cas de dommage constaté,

faites réparer l'outil électrique avant de

l'utiliser.

maintenance défectueuse des outils électriques.

f)

Veillez à la propreté et l'affûtage des outils de

coupe.

arêtes tranchantes sont moins sujets au grippage

et plus faciles à contrôler.

g)

Utilisez l'outil électrique, les accessoires, les

outils rapportés, etc. conformément à ces

instructions et de la manière prévue pour ce

type particulier d'outil, en tenant compte des

conditions d'exécution et du travail à réaliser.

L'utilisation d'un outil électrique à des fins autres

que celles prévues peut constituer une situation

dangereuse.

5)

Entretien

a)

Faites effectuer l'entretien de votre outil

électrique par une personne qualifiée qui utilise

uniquement des pièces de rechange

identiques.

de l'outil électrique.

Ces mesures préventives de sécurité

Dans les mains de personnes

De nombreux accidents sont dus à une

Les outils de coupe bien entretenus et aux

Ceci assure le maintien de la sécurité

3 Consignes de sécurité

particulières

Tenez les outils électriques par les surfaces de

prise isolantes lorsque vous exécutez une

opération au cours de laquelle l'outil de coupe

risque d'être en contact avec un câble caché

ou avec son propre cordon.

câble nu met les pièces métalliques exposées

sous tension et soumet l'opérateur à un choc

électrique.

Portez une protection auditive.

bruit peut engendrer une perte de capacité

auditive.

Avant d'utiliser l'outil électrique, lisez attentivement et entièrement les instructions de sécurité ci-

Le contact avec un

L'exposition au

11

Page 12

F

FRANÇAIS

jointes (carnet rouge) ainsi que le mode d'emploi.

Conservez les documents ci-joints et veillez à les

remettre obligatoirement avec l'appareil à tout

utilisateur concerné.

Dans l'intérêt de votre propre

sécurité et afin de protéger votre

outil électrique, respectez les

passages de texte marqués de ce

symbole !

Débrancher le cordon d'alimentation de la prise de

courant avant toute opération de réglage ou de

maintenance.

Attention aux fils électriques, aux conduites de gaz

et d'eau !

Des couples de réaction importants sont susceptibles de se produire pendant l'opération. Il convient

donc de toujours maintenir l'outil avec fermeté, de

prendre une posture stable et de se concentrer sur

son travail.

Ne pas fermer les fentes d'aération.

SYMBOLES SUR L’OUTIL:

...........Construction de classe II

V...............volts

A...............ampères

Hz.............hertz

~...............courant alternatif

n

.............vitesse à vide

0

../min .......révolutions par minute

• Butée de profondeur en deux parties

• Réglage fin de la profondeur de vissage

• Embrayage à griffes silencieux

• Crochet pour échafaudage amovible avec

rangement pour embouts (suivant version)

•

SE 4000 :

L'outil idéal en installation intérieure, par ex.

pour la fixation de panneaux de placoplâtre.

•

SE 2800 :

La visseuse pour une utilisation universelle avec

des vis à bois, vis autoperçantes et vis pour

pose rapide, diamètres jusqu'à 6,0 mm.

•

Butée de profondeur :

Les travaux sont possibles avec et sans butée

de profondeur. Le fait d'enlever la butée de

profondeur ne modifie aucunement la profondeur de vissage choisie. On peut donc continuer

à travailler avec la même profondeur de vissage

après avoir remis la butée en place.

a

6 Mise en service

Avant la mise en service, comparez si

tension secteur et la fréquence secteur indiquées sur la plaque signalétique correspondent aux caractéristiques de votre réseau

de courant.

Mise en place du crochet pour échafaudage (5):

Clipser le crochet sur la

tourner jusqu'au blocage sur le cran voulu.

fixation du crochet (4)

puis

4Vue d'ensemble

Voir page 3 (à déplier).

1 Commutateur du sens de rotation

2 Gâchette

3 Bouton de marche continue

4 Fixation pour crochet d'échafaudage

5 Crochet pour échafaudage *

6 Butée de profondeur

7Embout *

8 Fermeture autoserrante

9 Douille de butée

* suivant version/non compris dans la fourniture

5 Particularités du produit

• Machine compacte et légère en conception

monobloc pour l'utilisation en continu

• Corps de forme ergonomique permettant de

travailler sans fatigue

• Système breveté pour le changement

d'embouts

7 Utilisation

7.1 Marche/arrêt

Pour mettre l'outil en route, appuyer sur la

gâchette (2).

La vitesse peut être modifiée en pressant la

gâchette.

Pour un fonctionnement en continu, il est possible

de bloquer la gâchette à l'aide du bouton de

blocage (3). Pour arrêter la machine, appuyer à

nouveau sur la gâchette.

7.2 Sélection du sens de rotation

S'assurer que le moteur est à l'arrêt

avant d'actionner le commutateur du

sens de rotation (1).

Sélectionner le sens de rotation:

R = Rotation à droite

L = Rotation à gauche

12

Page 13

FRANÇAIS

F

7.3 Changement d'embout

Mise en place de l'embout :

Maintenir la fermeture autoserrante (8) et mettre

l'embout en place.

Vérifier que la fermeture autoserrante (8) se trouve

dans sa position avant. Tirer l'embout. L'embout

doit maintenir la fermeture autoserrante (8) de

manière sûre.

Dépose de l'embout :

(voir page 3, figure 1a)

- Retirer la butée de profondeur (6).

- Tirer la fermeture autoserrante (8) vers l'arrière

jusqu'à la butée (ce qui verrouille l'embout) et la

maintenir dans cette position arrière.

- Déposer l'embout (7).

Si la fermeture autoserrante (8) résiste lorsque l'on

la tire vers l'arrière à la main, on peut s'aider en

poussant sur la butée de profondeur. Voici la

procédure à suivre (voir page 3, figure 1b) :

Possibilité 1 :

- Placer l'embout dans l'alésage latéral de la butée

de profondeur (6).

- Pousser la fermeture autoserrante (8) avec la

butée de profondeur (6) jusqu'à la butée vers

l'arrière ce qui permet de déverrouiller l'embout.

- Déposer l'embout (7).

Possibilité 2 :

- Poser la butée de profondeur (6), par ex. sur une

table.

- Poser la machine, en appliquant la fermeture

autoserrante (8) sur le bord supérieur de la butée

de profondeur (6).

- Positionner la fermeture autoserrante (8) sur le

bord supérieur de manière qu'en poussant la

machine vers le bas, la fermeture autoserrante (8)

sera poussée en arrière.

- Pousser la machine vers le bas.

- Maintenir la fermeture autoserrante (8) à la main

dans cette position arrière.

- Déposer l'embout (7).

Remettre en place la butée de profondeur (6) :

Tourner en la positionnant et la bloquer sur son

cran.

7.4 Travaux avec la butée de profondeur

Voir page 3, figures 2 a et 2 b.

Pour le préréglage de la profondeur de vissage,

placer l'une des vis à insérer sur l'embout. Régler

la butée de profondeur (6) par rotation comme

suit :

a) Pour les vis dont la tête devra se poser sur le

support (vis à tête cylindrique, vis à tête goutte-desuif, vis à tête six pans) :

La face d'appui de la tête de vis dépasse la douille

de butée (9) de 2 mm.

b) Vis à tête fraisée :

La face de la tête de vis dépasse la douille de

butée (9) de 2 mm.

Visser une vis pour faire un essai. Si nécessaire,

corriger la profondeur de vissage comme suit :

Lors de la rotation de la butée de profondeur (6), la

profondeur de vissage est modifiée de 0,25 mm

par cran. Pour un vissage plus profond de la vis,

serrer davantage la douille de butée. Si la vis est

déjà vissée trop profond : desserrer la douille de

butée.

Le fait d'enlever la butée de profondeur (6) ne

modifie aucunement la profondeur de vissage

choisie. On peut donc continuer à travailler avec la

même profondeur de vissage après avoir remis la

butée en place.

Lors du vissage de vis à empreinte cruciforme, fermement appliquer l'embout de la

visseuse sur la vis jusqu'à la fin de l'opération. En effet, avec une force insuffisante, l'embout

risquerait de sortir de l'empreinte cruciforme et

d'endommager le support.

Si la machine n'est pas maintenue exactement à la

verticale de la pièce, la butée de profondeur

compense ce défaut de verticalité jusqu'à un

certain degré.

7.5 Travaux sans la butée de profondeur

Adapter la vitesse de vissage à l'opération en

cours en modulant la pression exercée sur la

gâchette.

Après avoir terminé le vissage, la machine est

arrêtée en relâchant la gâchette (2).

8 Conseils et astuces

La machine doit être fermement appliquée sur la

vis jusqu'à la fin de l'opération de vissage.

Ce point est particulièrement important pour le

vissage de vis pour pose rapide (munies d'un

filetage à pas gros) sur des panneaux de placoplâtre. En effet, le pas important de ces vis fait que

leur vissage est très rapide.

Lorsque la douille de butée (9) n'est pas suffisamment mobile, on peut la dévisser afin d'en nettoyer

le filetage.

.

9 Dépannage

Lorsqu'un embout de vissage est serré trop fermement dans le porte-embouts : sortir l'embout de

vissage à l'aide d'une pince ou pousser la fermeture autoserrante (8) en arrière à l'aide de la butée

13

Page 14

F

de profondeur. Voir chapitre Changement

d'embout.

F

FRANÇAIS

13 Protection de

l'environnement

10 Maintenance

Avant toute intervention de maintenance, retirer la

prise du cordon du secteur !

Nettoyage du moteur : nettoyer la machine régulièrement en soufflant de l'air comprimé à travers

les fentes d'aération à l'arrière.

S'il est encrassé, le trou oblong sur la fermeture

autoserrante (8) devra être nettoyé et soufflé à l'air

comprimé. Si nécessaire introduire un peu d'huile

dans le trou oblong.

Régulièrement déposer et nettoyer la butée de

profondeur (6).

f

11 Accessoires

Utilisez uniquement du matériel Metabo.

S'il vous faut des accessoires, veuillez vous

adresser à votre revendeur.

Pour pouvoir sélectionner les accessoires appro-

priés, veuillez indiquer le type exact de votre outil

électrique au distributeur.

Voir page 4.

A Embouts de visseuse (longueur : 25 mm)

Recommandation : n'utiliser que des embouts

de vissage munis d'extrémités de montage de

ce type :

B Crochet pour échafaudage avec rangement

d'embouts incorporé

Les emballages Metabo sont recyclables à 100 %.

Les outils et accessoires électriques qui ne sont

plus utilisés contiennent de grandes quantités de

matières premières et de matières plastiques de

grande qualité pouvant être également recyclées.

Ce mode d'emploi est imprimé sur du papier

blanchi sans chlore.

14 Caractéristiques

techniques

Commentaires sur les indications de la page 2.

Sous réserve de modifications allant dans le sens

du progrès technique.

P

1

P

2

n

0

n

1

T

max.

H = Porte-embouts de la machine

m = Poids sans cordon d'alimentation

Pendant le fonctionnement, il se peut que le niveau

sonore dépasse les 85 db(A).

Les caractéristiques indiquées sont soumises à

tolérance (selon les normes en vigueur correspondantes).

= Puissance absorbée

= Puissance débitée

= Vitesse à vide

= Vitesse en charge

= Couple de serrage maxi

Porter un casque antibruit !

Voir programme complet des accessoires sur

www.metabo.com ou dans le catalogue principal.

12 Réparations

Les travaux de réparation sur les outils électriques

ne peuvent être effectués que par un spécialiste !

Seul Metabo ou un atelier de service autorisé est

habilité à effectuer le remplacement du câble de

raccordement.

Les outils Metabo qui sont à réparer peuvent être

expédiés à l'une des adresses indiquées sur la

liste des pièces de rechange.

Prière de joindre à l'outil expédié une description

du défaut constaté.

14

Page 15

ESPAÑOL

ES

Instrucciones de manejo

Estimado cliente,

le agradecemos la confianza depositada en nosotros al comprar una herramienta eléctrica Metabo. Cada

herramienta Metabo ha sido probada cuidadosamente y ha superado los estrictos controles de calidad

de Metabo. Sin embargo, la vida útil de una herramienta eléctrica depende en gran medida de usted. Le

rogamos que tenga en cuenta la información contenida en estas instrucciones y en los documentos

adjuntos. Una mejor conservación de su herramienta eléctrica de Metabo, repercute en un servicio eficaz

durante más tiempo.

Contenido

1 Aplicación de acuerdo a la finalidad

2 Instrucciones generales de seguridad

3 Instrucciones especiales de seguridad

4 Descripción general

5 Características especiales del producto

6 Puesta en marcha

7Manejo

7.1 Conexión/desconexión

7.2 Selección del sentido de giro

7.3 Cambio de herramienta

7.4 Trabajar con tope de profundidad

7.5 Trabajar sin tope de profundidad

8 Consejos y trucos

9 Localización de averías

10 Mantenimiento

11 Accesorios

12 Reparación

13 Protección ecológica

14 Especificaciones técnicas

1 Aplicación de acuerdo a la

finalidad

La herramienta se ha diseñado para apretar y

aflojar tornillos en madera, en placas de cartón de

yeso, en barras de perfil de metal o construcciones de madera, en plásticos y materiales similares.

La herramienta no es apta para apretar y aflojar

tornillos de máquinas en materiales de metal.

Los posibles daños derivados de un uso inadecuado son responsabilidad exclusiva del usuario.

Deben observarse los reglamentos para la prevención de accidentes y las instrucciones de seguridad incluidas.

2 Instrucciones generales de

seguridad

ATENCIÓN

de manejo. Si no se siguen todas las instrucciones

que se describen a continuación se corre el riesgo

de sufrir una descarga eléctrica, lesiones graves o

causar un incendio. El término "herramienta

eléctrica" que se utiliza en las siguientes

advertencias se refiere tanto a las herramientas

eléctricas de alimentación por red (con cable)

como a las herramientas eléctricas de

alimentación por batería (sin cable).

GUARDE ESTAS INSTRUCCIONES

1)

Seguridad en el lugar de trabajo

a)

Mantenga el lugar de trabajo limpio y bien

iluminado.

pueden dar lugar a accidentes.

b)

No trabaje con herramientas eléctricas en

lugares con peligro de explosión, como p. ej.

lugares donde se almacenan líquidos

inflamables, gases o polvo.

eléctricas producen chispas que pueden encender

el polvo o el humo.

c)

Mantenga alejados a los niños y a otras

personas mientras trabaje con la herramienta

eléctrica.

pérdida del control.

2)

Seguridad eléctrica

a)

Los enchufes de la herramienta eléctrica

tienen que ser compatibles con la toma de

corriente En ningún caso se debe modificar el

enchufe. No utilice ningún adaptador de

enchufe con herramientas eléctricas con

conexión a masa (toma de tierra).

que no han sido manipulados y las tomas de

corriente compatibles reducen el riesgo de

descarga eléctrica.

b)

Evite el contacto corporal con superficies

con toma a masa o tierra, como tubos,

radiadores, cocinas y refrigeradores.

mayor riesgo de descarga eléctrica si su cuerpo se

halla en contacto con el suelo.

c)

No exponga las herramientas eléctricas a la

lluvia o la humedad.

herramienta eléctrica, aumenta el riesgo de

descarga eléctrica.

Lea completamente las instrucciones

Los lugares desordenados y oscuros

Las herramientas

Las distracciones pueden provocar la

Los enchufes

Existe un

Si entra agua en una

15

Page 16

ES

d)

No fuerce el cable. Nunca utilice el cable

para transportar la herramienta, tirar de ella o

desenchufarla. Mantenga el cable alejado de

fuentes de calor, aceite, bordes cortantes y

piezas móviles.

hacen que aumente el riesgo de descarga

eléctrica.

e)

Cuando trabaje con herramientas eléctricas

al aire libre, utilice un alargo apto para uso

exterior.

exteriores reduce el riesgo de descarga eléctrica.

3)

Seguridad personal

a)

Preste atención a lo que está haciendo y use

el sentido común al trabajar con una

herramienta eléctrica. No utilice una

herramienta si está cansado o se encuentra

bajo la influencia de las drogas, el alcohol o

medicación.

herramientas eléctricas puede causar un grave

accidente.

b)

Utilice accesorios de seguridad. Utilice

siempre protección ocular.

seguridad, como la mascarilla antipolvo, el calzado

especial antideslizante, el casco o los protectores

para los oídos, reducen el riesgo de lesiones si se

utilizan en las condiciones apropiadas .

c)

Evite el accionamiento accidental de la

herramienta. Compruebe que el interruptor

está en la posición off antes de enchufarla.

evitar accidentes, evite transportar las

herramientas eléctricas con el dedo situado en el

interruptor o enchufar las herramientas eléctricas

con el interruptor en la posición on.

d)

Retire cualquier llave de ajuste o llave de

tuercas antes de encender la herramienta

eléctrica.

fijada en alguna pieza giratoria de la herramienta

eléctrica, ya que podría causarle lesiones.

e)

No se extralimite. Mantenga la estabilidad y

el equilibrio en todo momento.

mejor control de la herramienta eléctrica en

situaciones inesperadas.

f)

Vístase adecuadamente. Evite llevar puestas

ropa ancha o joyas. Mantenga el pelo, la ropa y

los guantes alejados de las piezas móviles.

ropa ancha, las joyas o el pelo largo se pueden

enganchar en las piezas móviles.

g)

Si se suministran dispositivos para la

conexión de herramientas de aspiración y

captación de polvo, asegúrese de que están

bien conectados y se usan correctamente.

utilización de estos dispositivos puede reducir los

riesgos provocados por el polvo.

ESPAÑOL

Los cables dañados o enredados

La utilización de un cable apto para

Un pequeño descuido al trabajar con

Los accesorios de

Evite dejar cualquiera de estas llaves

Ello permite un

Para

La

La

b)

No utilice la herramienta eléctrica si el

interruptor no funciona correctamente.

Cualquier herramienta eléctrica que no se pueda

controlar con el interruptor es peligrosa y debe

repararse.

c)

Desconecte el enchufe de la fuente de

alimentación y extraiga la batería de la

herramienta antes de hacer cualquier

reparación, cambiar accesorios o almacenar

las herramientas eléctricas.

seguridad preventivas reducen el riesgo de que la

herramienta eléctrica se encienda

accidentalmente.

d)

Mantenga las herramientas eléctricas fuera

del alcance de los niños y no permita que la

utilicen personas ajenas a la herramienta

eléctrica o a estas instrucciones.

herramientas eléctricas son peligrosas en manos

de usuarios inexpertos.

e)

Mantenimiento de las herramientas

eléctricas. Compruebe la alineación y los

puntos de unión de las piezas móviles, la rotura

de piezas o cualquier otro aspecto que pueda

afectar al funcionamiento de las herramientas

eléctricas. Si se avería, repare la herramienta

eléctrica antes de usarla.

deben al mantenimiento inadecuado de las

herramientas eléctricas.

f)

Mantenga las herramientas cortadoras

limpias y afiladas.

las herramientas cortadoras y el afilado periódico

de los cantos de corte reduce el riesgo de

agarrotamiento de las herramientas y facilita el

control de las mismas.

g)

Utilice la herramienta eléctrica, los

accesorios, las puntas y láminas de atornillar,

etc. siguiendo estas instrucciones de la

manera prevista para cada tipo de herramienta

eléctrica, teniendo en cuenta las condiciones

de trabajo y el trabajo que hay que llevar a

cabo.

Un uso indebido de la herramienta eléctrica

podría originar situaciones peligrosas.

5)

Servicios

a)

El servicio y reparación de la herramienta

eléctrica debe llevarlo a cabo una persona

cualificada y utilizando sólo piezas de

recambio originales.

que se mantenga la seguridad de la herramienta

eléctrica.

El adecuado mantenimiento de

De este modo se asegura

Estas medidas de

Muchos accidentes se

Las

3 Instrucciones especiales

de seguridad

4)

Cuidado y uso de las herramientas eléctricas

a)

No fuerce la herramienta eléctrica. Utilice la

herramienta eléctrica apropiada para cada

aplicación.

trabajo mejor y de forma más segura a la velocidad

para la cual fue diseñada.

La herramienta apropiada hará el

16

Sujete las herramientas eléctricas por las

superficies de agarre con aislamiento cuando

realice un trabajo en el que la herramienta

cortadora pueda entrar en contacto con

cableado oculto o con su propio cable.

contacto con un cable "cargado" hará que las

piezas de metal expuestas de la herramienta se

El

Page 17

"carguen" y le transmitan una descarga eléctrica al

trabajador.

Lleve orejeras.

causar pérdida de audición.

Antes de utilizar esta herramienta, lea y entienda

completamente las instrucciones y la información

de seguridad (folleto rojo) incluidos. Guarde todos

los documentos para referencia en el futuro, y

solamente entregue su herramienta junto con

estos documentos.

Desenchufe el equipo antes de llevar a cabo cualquier ajuste o mantenimiento.

Tenga cuidado con las tuberías de gas y agua y los

cables eléctricos.

Al trabajar pueden aparecer momentos de retrogiro elevados. Sujete la máquina con fuerza,

adopte una postura segura y trabaje concentrado.

No tapar la ranura de ventilación.

SÍMBOLOS SOBRE LA HERRAMIENTA:

.................. Classe II de construcción

V......................voltios

A......................amperios

Hz....................hertzios

~

.....................corriente alterna

n0....................velocidad sin carga

../min ..............revoluciones por minuto

La exposición a ruidos puede

Para su propia protección y la de

su herramienta eléctrica, observe

las partes marcadas con este

símbolo.

ESPAÑOL

ES

5 Características especiales

del producto

• Máquina compacta, ligera y de construcción

tubular para una aplicación continua

• Carcasa con diseño ergonómico para trabajar

sin esfuerzo.

• Sistema patentado de cambio de puntas de

destornillador

• Tope de profundidad de dos piezas

• Ajuste preciso de la profundidad de atornillado

• Acoplamiento de garra silencioso

• Gancho de soporte desmontable con compartimiento de puntas de destornillador integrado

(según la versión)

•

SE 4000:

Es apropiada para su aplicación en construcciones en seco como p.ej. el montaje de placas

de cartón de yeso.

•

SE 2800:

Destornillador multiuso para tornillos para

madera, tornillos perforadores y tornillos de

sujeción rápida de hasta 6 mm de diámetro.

•

Tope de profundidad:

posibilidad de trabajar con o sin tope de

profundidad. Si se retira el tope de profundidad,

la profundidad de atornillado ajustada no varía.

Tras la colocación se puede seguir trabajando

con la misma profundidad de atornillado.

a

6 Puesta en marcha

4 Descripción general

Véase la página 3 (desplegarla).

1 Conmutador de giro

2Interruptor

3Botón de retención

(funcionamiento continuado)

4 Sujeción de gancho de soporte

5 Gancho de soporte *

6 Tope de profundidad

7 Herramientas *

8 Cierre de cambio rápido

9 Manguito de tope

* según la versión/no incluido en el volumen de

suministro

Antes de enchufar la herramienta,

compruebe que la tensión y la frecuencia

de red que se indican en la placa de identificación se corresponden con las características de la red eléctrica.

Montaje del gancho de soporte (5) :

sujeción de gancho de soporte (4)

que encaje en la posición deseada.

fíjelo

a la

y gírelo hasta

7Manejo

7.1 Conexión y desconexión

Pulse el interruptor (2) de la herramienta para

ponerla en marcha.

El número de revoluciones puede modificarse

presionando el interruptor.

Para un funcionamiento continuado puede

bloquearse el interruptor con el botón de retención

(3). Para parar la herramienta, pulse de nuevo el

interruptor.

17

Page 18

ES

ESPAÑOL

7.2 Selección del sentido de giro

Pulse el conmutador de giro (1) sola-

mente durante el estado de parada del

motor.

Selección del sentido de giro

R = giro a la derecha

L = giro a la izquierda

7.3 Cambio de herramienta

Insertar la herramienta:

Sujete el cierre de cambio rápido (8) e inserte la

herramienta.

Compruebe que el cierre de cambio rápido (8) se

halle en la posición delantera. Tire de la herramienta. La herramienta debe quedar bien sujeta

por el cierre de cambio rápido (8).

Extraer la herramienta:

(Véase la página 3, figura 1a)

- Cómo extraer el tope de profundidad (6).

- Tirar hacia atrás del cierre de cambio rápido (8)

hasta el tope (la herramienta se desbloquea) y

mantener en esta posición.

- Cómo retirar la herramienta (7).

Si el cierre de cambio rápido (8) no se puede

empujar manualmente hacia atrás, es posible

empujarlo hacia atrás con ayuda del tope de

profundidad. Procedimiento (véase la página 3,

imagen 1b):

Posibilidad 1 :

- Introducir la herramienta en un orificio lateral del

tope de profundidad (6).

- Con el tope de profundidad (6), empujar el cierre

de cambio rápido (8) hacia atrás hasta el tope (la

herramienta se desbloquea).

- Cómo retirar la herramienta (7).

Posibilidad 2 :

- Colocar el tope de profundidad, (6) p.ej. encima

de una mesa.

- Colocar la herramienta con el cierre de cambio

rápido (8) en el borde superior del tope de

profundidad (6).

- Colocar el cierre de cambio rápido (8) en el borde

superior de manera que cuando la máquina se

presione hacia abajo, el cierre de cambio rápido

(8) se desplace hacia atrás.

- Presionar hacia abajo la herramienta.

- Sujetar el cierre de cambio rápido (8) con la mano

en esta posición (hacia atrás).

- Cómo retirar la herramienta (7).

Volver a montar el tope de profundidad (6) :

Al colocarlo girarlo y encajarlo.

7.4 Trabajos con el tope de profundidad

Véase la página 3, imagen 2 a y 2 b.

Para preajustar la profundidad de atornillado debe

colocarse en la herramienta uno de los tornillos

que se van a apretar. Ajuste el tope de

profundidad (6) girándolo como se explica a continuación:

a) Tornillos que deban introducirse hasta que su

cabeza esté asentada sobre el material (tornillos

cilíndricos, tornillos de cabeza alomada, tornillos

de cabeza hexagonal):

La superficie de apoyo de la cabeza del tornillo se

encuentra a una distancia de 2 mm fuera del

manguito de tope. (9)

b) Tornillos avellanados:

La superficie de la cabeza de tornillo se encuentra

a una distancia de 2 mm fuera del manguito de

tope. (9)

Realice un atornillado de prueba. Si fuera necesario, corrija la profundidad de atornillado:

Al girar el tope de profundidad (6), la profundidad

de atornillado varía en 0,25 mm por trama. Para

atornillar a mayor profundidad, apriete el manguito

de tope. Para atornillar a menor profundidad, afloje

el manguito de tope.

Si se retira el tope de profundidad (6), la

profundidad de atornillado ajustada no varía. Tras

la colocación se puede seguir trabajando con la

misma profundidad de atornillado.

Al atornillar tornillos de estrella, presionar

con fuerza la herramienta con la lámina de

destornillador hasta finalizar el proceso de

atornillado, ya que en caso contrario la punta del

destornillador podría salirse de la ranura en cruz y

dañar el material.

Si la herramienta no se sujeta perpendicularmente

a la pieza de trabajo, el tope de profundidad lo

regula (hasta cierto punto).

7.5 Trabajar sin tope de profundidad

Ajustar el número de revoluciones al proceso de

atornillado apretando el interruptor.

Al finalizar el proceso de atornillado, apagar la

máquina desconectando el interruptor. (2) .

8 Consejos y trucos

Presionar la herramienta con fuerza contra el

tornillo hasta finalizar el proceso de atornillado.

Esto es importante especialmente al atornillar

tornillos de sujeción rápida (con rosca gruesa) en

placas de cartón de yeso, ya que estos tornillos se

atornillan muy rápido gracias a su paso de rosca

grande.

18

Page 19

ESPAÑOL

ES

Si el manguito de tope (9) se mueve con dificultad,

puede desatornillarse para limpiar la rosca.

.

9 Localización de averías

Si la lámina de destornillador en el portaherramientas de la máquina está muy apretada: extraer

la lámina de destornillador con unas tenazas o

empujar hacia atrás el cierre de cambio rápido (8)

con ayuda del tope de profundidad. Véase el

capítulo cambio de herramienta.

ES

10 Mantenimiento

Antes de llevar a cabo cualquier trabajo de

mantenimiento recuerde extraer el enchufe de la

toma de corriente.

Limpieza del motor: limpie periódicamente la

herramienta con aire comprimido por las ranuras

de ventilación traseras.

En caso de suciedad, limpiar con aire a presión la

ranura en el cierre de cambio rápido (8). En caso

necesario, aplicar un poco de aceite en la ranura.

Retirar y limpiar el tope de profundidad (6) con

regularidad

f

11 Accesorios

Use solamente accesorios originales Metabo.

Si necesita accesorios, consulte a su proveedor.

Para que el proveedor pueda seleccionar el acce-

sorio correcto, necesita saber la designación

exacta del modelo de su herramienta.

Véase la página 4.

A Láminas de destornillador (longitud: 25 mm)

Recomendación: utilizar sólo inserciones con

estos gorrones empotrables:

B Ganchos de soporte con compartimiento

integrado de puntas de destornillador

La sustitución del cable de conexión sólo puede

ser realizada por Metabo o un taller autorizado.

Cualquier herramienta Metabo, que requiera reparación, se puede enviar a una de las direcciones

indicadas en la lista de piezas de repuesto.

Sírvase incluir a la herramienta eléctrica enviada

para su reparación una descripción de la anomalía

determinada.

13 Protección ecológica

Los envases Metabo son 100% reciclables.

Las herramientas eléctricas y sus accesorios fuera

de uso contienen grandes cantidades de materia

prima y plásticos que también pueden ser reciclados.

Estas instrucciones están impresas en papel blanqueado sin cloro.

14 Especificaciones técnicas

Notas explicativas sobre la información de la

página 2.

Nos reservamos el derecho a efectuar modificaciones conforme al avance técnico.

P

1

P

2

n

0

n

1

T

máx.

H = Portaherramientas de la máquina

m = Peso sin cable a la red

Al trabajar, el nivel de ruido puede superar los

85 dB(A).

Las especificaciones técnicas aquí indicadas se

entienden dentro de determinadas tolerancias

(conformes a las normas que rigen actualmente).

= Potencia de entrada nominal

= Potencia suministrada

= Número de revoluciones en marcha

en vacío

= Revoluciones bajo carga

= Par de apriete máx.

¡Utilice cascos protectores para los

oídos!

Programa completo de accesorios disponible en

www.metabo.com o en el catálogo principal.

12 Reparación

Las reparaciones de herramientas eléctricas

SOLAMENTE deben ser efectuadas por técnicos

electricistas especializados!

19

Page 20

PT

PORTUGUÊS

Instruções de serviço

Caro Cliente,

agradecemos-lhe a confiança que deposita em nós ao comprar-nos esta ferramenta eléctrica Metabo.

Cada ferramenta Metabo é cuidadosamente testada e sujeita a controlos de qualidade exaustivos antes

de ser entregue. No entanto a vida útil de um equipamento deste tipo depende em grande parte do uso

e dos cuidados que lhe dão. Cumpra pois todas as indicações incluídas neste manual. Quanto mais

cuidadosamente tratar a sua ferramenta Metabo, maior será a longevidade que poderá esperar dela.

Índice

1 Utilização autorizada

2 Recomendações gerais de segurança

3 Notas de segurança especiais

4Vista geral

5 Características especiais do produto

6 Colocação em operação

7 Utilização

7.1 Ligar/desligar

7.2 Seleccionar o sentido de rotação

7.3 Troca de ferramentas

7.4 Trabalhar com limitador de

profundidade

7.5 Trabalhar sem limitador de

profundidade

8Conselhos úteis

9 Detecção de avarias

10 Manutenção

11 Acessórios

12 Reparações

13 Protecção ao meio-ambiente

14 Dados técnicos

1 Utilização autorizada

A ferramenta é adequada para aparafusar e desaparafusar parafusos em madeiras, em placas de

gesso prensado com cartão sobre barras de perfil

de metal, em plásticos e materiais similares.

A ferramenta não é adequada para aparafusar e

desaparafusar parafusos de maquinarias em

materiais de metal.

O utilizador é inteiramente responsável por qualquer dano que seja fruto de um uso indevido.

Deve sempre cumprir-se toda a regulamentação

aplicável à prevenção de acidentes, assim como a

informação sobre segurança que aqui se incluí.

2 Recomendações gerais de

segurança

AVISO!

cumprimento das instruções seguintes pode

resultar em choque eléctrico, incêndio e/ou

acidentes graves. O termo „ferramenta eléctrica“

em todos os avisos seguintes refere-se às

ferramentas eléctricas de ligação à rede eléctrica

(com fio) ou às ferramentas eléctricas alimentadas

por bateria (sem fio).

GUARDE ESTAS INSTRUÇÕES

1)

a)

iluminada.

um convite aos acidentes.

b)

atmosferas explosivas, tal como na presença

de líquidos, gases ou pó inflamáveis.

ferramentas eléctricas geram faíscas que podem

inflamar o pó ou fumos.

c)

afastados enquanto está a utilizar uma

ferramenta eléctrica.

com que perca o controlo.

2)

a)

ser adequadas às tomadas. Nunca altere a

ficha seja de que forma for. Não use fichas com

adaptador em ferramentas eléctricas ligadas à

terra (à massa).

correspondentes reduzem o risco de choque

eléctrico.

b)

com ligação à terra e à massa, tal como tubos,

radiadores e refrigeradores.

risco de choque eléctrico se o seu corpo ficar

ligado à terra ou à massa .

c)

chuva ou condições húmidas.

na ferramenta eléctrica aumenta o risco de choque

eléctrico.

d)

eléctrico. Nunca use o cabo eléctrico para

transportar, puxar ou desligar a ferramenta

eléctrica. Mantenha o cabo afastado do calor,

óleo, esquinas afiadas ou partes móveis.

Leia todas as instruções. O não

Segurança na área de trabalho

Mantenha a área de trabalho limpa e bem

As áreas desarrumadas e escuras são

Não utilize as ferramentas eléctricas em

As

Mantenha as crianças e os observadores

As distracções podem fazer

Segurança eléctrica

As fichas das ferramentas eléctricas têm de

Fichas não alteradas e tomadas

Evite o contacto do corpo com superfícies

Existe um maior

Não exponha as ferramentas eléctricas à

A entrada de água

Não faça uma má utilização do cabo

Os

20

Page 21

PORTUGUÊS

PT

cabos eléctricos danificados ou emaranhados

aumentam o risco de choque eléctrico.

e)

Ao usar uma ferramenta eléctrica no exterior,

utilize uma extensão do cabo eléctrico

adequada para uso exterior.

eléctrico adequado para uso exterior reduz o risco

de choque eléctrico.

3)

Segurança pessoal

a)

Esteja sempre atento, observe o que está a

fazer e use o senso comum ao trabalhar com

uma ferramenta eléctrica. Não utilize uma

ferramenta eléctrica quando estiver cansado

ou sob a influência de drogas, álcool ou

medicamentos.

enquanto trabalha com uma ferramenta eléctrica

pode resultar em acidentes pessoais graves.

b)

Utilize equipamento de segurança. Use

sempre uma protecção para os olhos.

equipamento de segurança, tal como máscara

anti-poeira, calçado de segurança anti-derrapante,

capacete de segurança ou protecção auditiva,

usado nas condições adequadas reduz o risco de

acidentes pessoais graves.

c)

Evite o arranque acidental. Assegure-se que

o interruptor está na posição de desligado (off)

antes de ligar a ficha da ferramenta.

transporte de ferramentas eléctricas com o seu

dedo no interruptor ou a ligação de ferramentas

eléctricas com o interruptor ligado (on) é um

convite aos acidentes.

d)

Remova qualquer chave de ajuste ou chave

de fendas antes de ligar a ferramenta eléctrica.

Uma chave de fendas ou qualquer chave que fique

agarrada a uma parte rotativa da ferramenta

eléctrica pode resultar em acidentes pessoais.

e)

Não tente esticar-se. Mantenha-se sempre

com os pés bem assentes e equilibrado.

permite um melhor controlo da ferramenta

eléctrica em situações inesperadas.

f)

Vista-se de forma adequada. Não use roupa

larga ou bijuterias. Mantenha o seu cabelo,

roupa e luvas afastados das partes móveis.

roupas largas, bijuteria ou cabelo comprido podem

ser apanhados pelas partes móveis.

g)

Se forem providenciados dispositivos para a

ligação de facilidades de extracção e recolha

de poeiras, garanta que estes são devidamente

ligados e utilizados.

dispositivos pode diminuir os perigos relacionados

com as poeiras.

4)

Utilização e manutenção da ferramenta

eléctrica

a)

Não force a ferramenta eléctrica. Utilize a

ferramenta eléctrica correcta para a cada

aplicação.

executa melhor o trabalho e de forma mais segura,

ao nível para o qual foi concebida.

b)

Não utilize a ferramenta eléctrica se não a

consegue ligar ou desligar através do

interruptor.

Um momento de distracção

O uso deste tipo de

Uma ferramenta eléctrica correcta

Qualquer ferramenta eléctrica que

O uso de um cabo

O

O

Isto

As

não pode ser controlada através do interruptor é

perigosa e tem de ser reparada.

c)

Retire a ficha da tomada eléctrica e/ou a

bateria da ferramenta eléctrica antes de fazer

qualquer ajuste ou mudança de acessórios, ou

antes de armazenar as ferramentas.

medidas preventivas de segurança reduzem o

risco de arrancar a ferramenta eléctrica

acidentalmente.

d)

Armazene as ferramentas eléctricas

inactivas longe do alcance das crianças e não

permita que pessoas não familiarizadas com a

ferramenta ou com estas instruções trabalhem

com a ferramenta eléctrica.

eléctricas são perigosas não mãos de utilizadores

sem formação.

e)

Manutenção das ferramentas eléctricas.

Verifique se as partes móveis estão

desalinhadas ou unidas, com roturas ou

qualquer outra condição que influencie o

funcionamento das ferramentas eléctricas. Se

a ferramenta estiver danificada, mande-a

reparar antes de a utilizar.

causados pela má manutenção das ferramentas

eléctricas.

f)

Mantenha as ferramentas de corte afiadas e

limpas.

conservadas, com as extremidades de corte

afiadas, são menos prováveis de dobrar e mais

fáceis de controlar.

g)

pontas da ferramenta, etc. de acordo com

estas instruções e da forma prevista para o tipo

de ferramenta específica, tendo em

consideração as condições de trabalho e o

trabalho a ser executado.

ferramentas eléctricas para operações diferentes

daquelas para que estão indicadas pode resultar

em situações perigosas.

5)

a)

reparada por uma pessoa qualificada, usando

apenas peças sobresselentes iguais.

garante que a segurança da ferramenta eléctrica

se mantenha.

As ferramentas de corte devidamente

Utilize a ferramenta eléctrica, acessórios,

Assistência

A sua ferramenta eléctrica só deve ser

As ferramentas

Muitos acidentes são

A utilização das

Estas

Isto

3 Notas de segurança

especiais

Segure as ferramentas eléctricas pelas pegas

isolantes sempre que haja alguma

possibilidade de, com a sua operação, a

ferramenta de corte atingir cabos eléctricos

ocultos ou o seu próprio cabo eléctrico.

contacto com um cabo condutor coloca as partes

metálicas expostas sob tensão e provoca o

choque no operador.

Use protectores auditivos.

pode causar a perda de audição.

A exposição ao ruído

O

21

Page 22

PT

PORTUGUÊS

Antes de utilizar a sua ferramenta eléctrica, leia

atentamente toda a informação de segurança que

se incluí (panfleto vermelho) assim como as

instruções de serviço. Mantenha todos os

manuais e folhetos para futura consulta e, se

emprestar ou vender a ferramenta, faça-a sempre

acompanhar dessa documentação.

Para sua própria protecção, e para

proteger a sua ferramenta,

cumpra muito em especial todas

as referências marcadas com o

símbolo!

Antes de iniciar qualquer manutenção ou ajuste,

puxe a ficha da tomada da rede.

Dar atenção a tubulações de gás, de corrente e de

água!

Durante os trabalhos podem surgir altos torques

de reversão. Segurar firmemente a ferramenta,

posicionar-se de forma segura e trabalhar concentrado.

Não manter fechadas as aberturas de ventilação.

SÍMBOLOS NA FERRMENTA:

...........Constru

V...............volts

A...............amperes

Hz.............hertz

~

..............corrente alternada

n0............ rotaçoes por minuto

../min ..... velocidade sem carga

ção da Classe II

4Vista geral

Ver página 3 (desdobrar a página).

1 Comutador para sentido de rotação

2 Gatilho

3 Botão de bloqueio (ligamento contínuo)

4 Fixação do gancho para andaime

5 Gancho para andaime *

6 Limitador de profundidade

7 Ferramenta*

8 Sistema de fixação para troca rápida

9 Casquilho limitador

* conforme equipamento/não incluído no volume

de fornecimento

• Caixa com formato ergonómico para um

trabalho menos cansativo

• Sistema de troca de pontas aparafusadoras

patenteado

• Limitador de profundidade de duas peças

• Profundidade ajustável com precisão

• Embraiagem dentada silenciosa

• Gancho para andaime removível com depósito

integrado para pontas (conforme equipamento)

SE 4000:

•

Adequado especialmente na construção seca

como p.ex. na fixação de placas de gesso

prensado com cartão.

•

SE 2800:

Aparafusadora para utilização universal para

parafusos de madeira, parafusos autoroscantes e parafusos de montagem rápida até

diâmetro 6,0 mm.

•

Limitador de profundidade:

Possibilidade de trabalhar com ou sem limitador

de profundidade. A profundidade ajustada não

se altera ao remover o limitador de profundidade. Depois de remontar o limitador, é

possível continuar a trabalhar com a mesma

profundidade.

a

6 Colocação em operação

Antes de ligar o cabo de alimentação, verifique se a voltagem e a frequência da rede

de alimentação se adequam aos valores

inscritos na placa técnica da ferramenta.

Montar o gancho para andaime (5):

fixação do gancho para andaime (4)

engatar na posição desejada.

Içar na

e girar para

7 Utilização

7.1 Ligar/desligar

Para ligar a ferramenta, prima o gatilho do interruptor (2).

É possível mudar a rotação pressionando no

gatilho do interruptor.

Em operação contínua pode-se prender o gatilho

com o botão de fixação (3). Para desligar, primese novamente o gatilho .

7.2 Seleccionar o sentido de rotação

5 Características especiais

do produto

• Ferramenta leve e compacta do tipo tacho para

utilização contínua

22

Accionar o comutador do sentido de

rotação (1) somente com o motor

parado.

Seleccionar o sentido de rotação:

R = rotação direita

L = rotação esquerda

Page 23

PORTUGUÊS

PT

7.3 Troca de ferramentas

Montar a ferramenta:

Segure o sistema de fixação para troca rápida (8) e

monte a ferramenta.

Certifique-se de que o sistema de fixação para

troca rápida (8) está na sua posição dianteira.

Puxe na ferramenta. Mantenha a ferramenta seguramente no sistema de fixação para troca rápida (8).

Retirar a ferramenta:

(Ver página 3, figura 1a)

- Remova o limitador de profundidade (6).

- Puxe o sistema de fixação para troca rápida (8)

para trás até parar (a fim de destravar a ferramenta) e mantenha-o nesta posição.

- Retire a ferramenta (7).

Aquando não for possível puxar para trás o

sistema de fixação para troca rápida (8), ele pode

ser deslocado para trás com a ajuda do limitador

de profundidade. Proceda conforme se segue (ver

página 3, figura 1b):

Possibilidade 1 :

- Insira a ferramenta numa perfuração lateral do

limitador de profundidade (6).

- Servindo-se do limitador de profundidade (6),

pressione o sistema de fixação para troca rápida

(8) para trás até ao batente (nisso é destravada a

ferramenta).

- Retire a ferramenta (7).

Possibilidade 2 :

- Deposite o limitador de profundidade (6) p.ex.

sobre uma mesa.

- Coloque a máquina com o sistema de fixação

para troca rápida (8) sobre o canto superior do

limitador de profundidade (6).

- Posicione o sistema de fixação para troca rápida

(8) sobre o canto superior de modo que ao pressionar a ferramenta para baixo, o sistema (8) é

deslocado para trás.

- Pressione a máquina para baixo.

- Mantenha o sistema de fixação para troca rápida

(8) com a mão nesta posição posterior.

- Retire a ferramenta (7).

Volte a montar o limitador de profundidade (6):

Na montagem, rode-o e engate-o.

7.4 Trabalhar com batente de profundidade

Ver página 3, figura 2 a e 2 b.

Para o pré-ajuste da profundidade de aparafusa-

mento deve inserir um parafuso a aparafusar

sobre a ferramenta. Ajustar o batente de profundidade (6) rodando conforme se segue:

a) Parafusos que devem assentar com a cabeça

sobre o material (parafusos cilíndricos, parafusos

com cabeça lenticular, parafusos sextavados):

A superfície de apoio da cabeça do parafuso

encontra-se a 2 mm por fora do casquilho

limitador (9).

b) Parafusos de embutir:

A superfície da cabeça do parafuso encontra-se a

2 mm por fora do casquilho limitador (9).

Aparafusar um parafuso como ensaio. Se necessário, corrigir a profundidade:

Rodando no batente de profundidade (6) altera-se

a profundidade por 0,25 mm por engate. Para

aumentar a profundidade: Rodar o casquilho

limitador para dentro. Quando o parafuso foi aparafusado demasiado profundo: Rodar o casquilho

limitador para fora.

A profundidade ajustada não se altera ao remover

o limitador de profundidade (6). Depois de

remontar o limitador, é possível continuar a

trabalhar com a mesma profundidade.

Para enroscar parafusos Phillips, premir a

máquina com a ponta aparafusadora

usando toda força contra o parafuso, até

finalizado o processo de aparafusamento, de

contrário a ponta desliza da fenda em cruz

podendo danificar o material.

Aquando a máquina não é mantida exactamente

na vertical à peça a trabalhar, o desvio será

compensado pelo limitador de profundidade (até

um determinado grau).

7.5 Trabalhar sem limitador de

profundidade

Ajustar as rotações do processo de aparafusamento através da pressão sensível do interruptor

integrado no punho.

Após finalizado o processo de aparafusamento,

desligar a máquina soltando o interruptor integrado no punho (2).

8 Conselhos úteis