Page 1

SBE 601

en Operating Instructions 5

fr Mode d'emploi 9

es Instrucciones de manejo 14

www.metabo.com

Page 2

1

2

3

4

5

6

7

GRIP, ZU

AUF, RELEASE

8

9

10

b a

3 x

b a

L

R

2

Page 3

11.

P

1

P

2

W 600

W 340

SBE 601

Serial Number: 00601...

n

0

n

1

/min 0-2800

/min 1700

ø max. in (mm) 1/2“ (12 )

s max.

/min.

bpm

50000

ø max. in (mm) 1“ (25)

ø max. in (mm) 3/8“ (10)

G

UNF

(in)

1/2“-20

H in (mm) 1/4“ (6,35)

m lbs (kg) 3.7 (1,7)

D in (mm) 1 11/16“ (43)

Metabowerke GmbH,

Postfach 1229

Metabo-Allee 1

D-72622 Nuertingen

Germany

3

Page 4

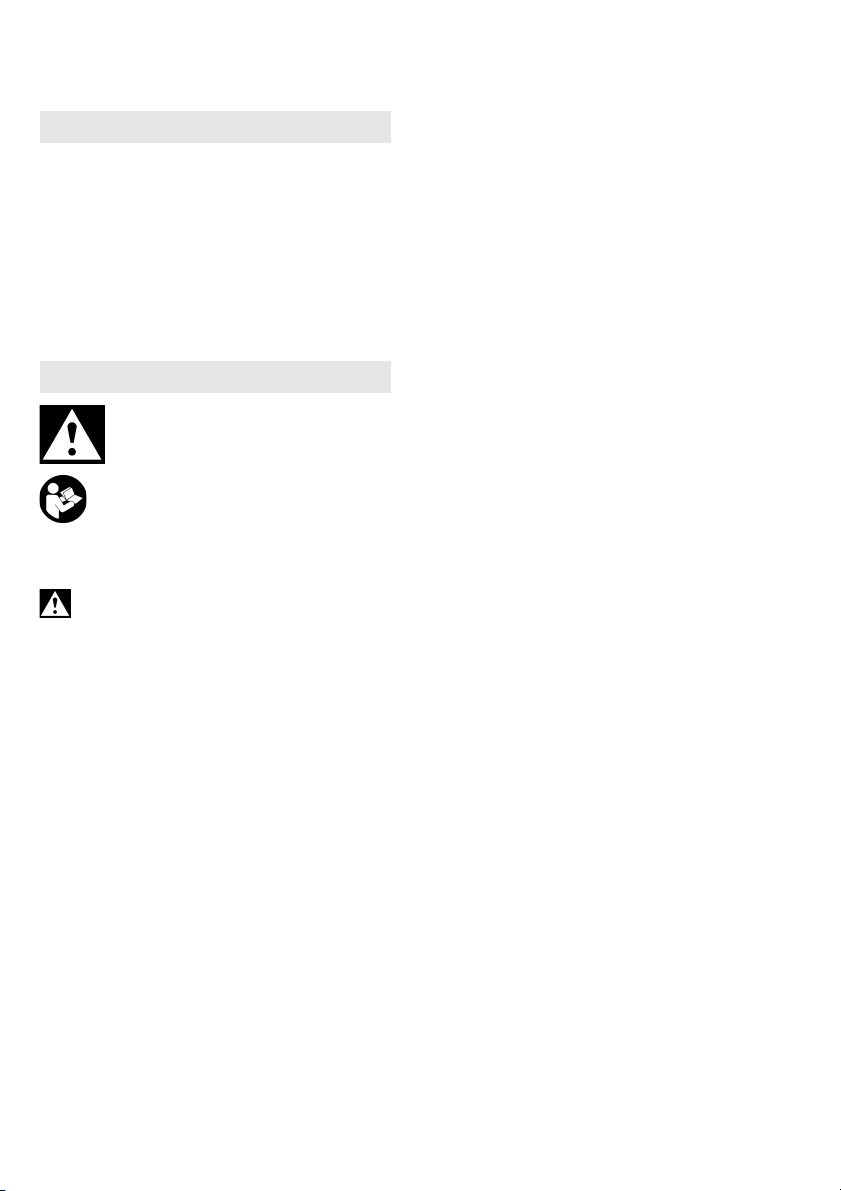

1 2 3 4 5 6

1300 1600 1900 2200 2500 2800 .../min

50 40 30 20 15 10 %

ALU

5

5

6

6 6 6

ø

mm

4

6

8

10

12

16

20

25

A

B

C

4

Page 5

Operating Instructions

1. Specified Use

The impact drill is suitable for non-impact drilling in

metal, wood, plastic and similar materials and

impact drilling in concrete, stone and similar

materials.

The impact drill is suitable for thread cutting and

screwdriving.

The user bears sole responsibility for any damage

caused by improper use.

Generally accepted accident prevention

regulations and the enclosed safety information

must be observed.

2. General Safety Instructions

For your own protection and for the

protection of your electrical tool, pay

attention to all parts of the text that are

marked with this symbol!

WARNING – Reading the operating instructions will reduce the risk of injury.

Pass on your electrical tool only together with these

documents.

General Power Tool Safety Warnings

WARNING – Read all safety warnings and

instructions. Failure to follow the warnings

and instructions may result in electric shock, fire

and/or serious injury.

Save all warnings and instructions for future

reference! The term "power tool" in the warnings

refers to your mains-operated (corded) power tool

or battery-operated (cordless) power tool.

2.1 Work area safety

a) Keep work area clean and well lit. Cluttered or

dark areas invite accidents.

b) Do not operate power tools in explosive

atmospheres, such as in the presence of

flammable liquids, gases or dust. Power tools

create sparks which may ignite the dust or fumes.

c) Keep children and bystanders away while

operating a power tool. Distractions can cause

you to lose control.

2.2 Electrical safety

a) Power tool plugs must match the outlet.

Never modify the plug in any way. Do not use

any adapter plugs with earthed (grounded)

power tools. Unmodified plugs and matching

outlets will reduce risk of electric shock.

b) Avoid body contact with earthed or

grounded surfaces, such as pipes, radiators,

ranges and refrigerators. There is an increased

risk of electric shock if your body is earthed or

grounded.

ENGLISH en

c) Do not expose power tools to rain or wet

conditions. Water entering a power tool will

increase the risk of electric shock.

d) Do not abuse the cord. Never use the cord

for carrying, pulling or unplugging the power

tool. Keep cord away from heat, oil, sharp

edges or moving parts. Damaged or entangled

cords increase the risk of electric shock.

e) When operating a power tool outdoors, use

an extension cord suitable for outdoor use.

Use of a cord suitable for outdoor use reduces the

risk of electric shock.

f) If operating a power tool in a damp location is

unavoidable, use a residual current device

(RCD) protected supply. Use of an RCD reduces

the risk of electric shock.

2.3 Personal safety

a) Stay alert, watch what you are doing and use

common sense when operating a power tool.

Do not use a power tool while you are tired or

under the influence of drugs, alcohol or

medication. A moment of inattention while

operating power tools may result in serious

personal injury.

b)

Use personal protective equipment. Always

wear eye protection. Protective equipment such

as dust mask, non-skid safety shoes, hard hat, or

hearing protection used for appropriate conditions

will reduce personal injuries.

c) Prevent unintentional starting. Ensure the

switch is in the off-position before connecting

to power source and/or battery pack, picking

up or carrying the tool. Carrying power tools with

your finger on the switch or energising power tools

that have the switch on invites accidents.

d) Remove any adjusting key or wrench before

turning the power tool on. A wrench or a key left

attached to a rotating part of the power tool may

result in personal injury.

e) Do not overreach. Keep proper footing and

balance at all times. This enables better control of

the power tool in unexpected situations.

f) Dress properly. Do not wear loose clothing or

jewellery. Keep your hair, clothing and gloves

away from moving parts. Loose clothes, jewellery

or long hair can be caught in moving parts.

g) If devices are provided for the connection of

dust extraction and collection facilities, ensure

these are connected and properly used. Use of

dust collection can reduce dust-related hazards.

2.4 Power tool use and care

a) Do not force the power tool. Use the correct

power tool for your application. The correct

power tool will do the job better and safer at the rate

for which it was designed.

b) Do not use the power tool if the switch does

not turn it on and off. Any power tool that cannot

5

Page 6

ENGLISHen

be controlled with the switch is dangerous and must

be repaired.

c) Disconnect the plug from the power source

and/or the battery pack from the power tool

before making any adjustments, changing

accessories, or storing power tools. Such

preventive safety measures reduce the risk of

starting the power tool accidentally.

d) Store idle power tools out of the reach of

children and do not allow persons unfamiliar

with the power tool or these instructions to

operate the power tool. Power tools are

dangerous in the hands of untrained users.

e) Maintain power tools. Check for

misalignment or binding of moving parts,

breakage of parts and any other condition that

may affect the power tool's operation. If

damaged, have the power tool repaired before

use. Many accidents are caused by poorly

maintained power tools.

f) Keep cutting tools sharp and clean. Properly

maintained cutting tools with sharp cutting edges

are less likely to bind and are easier to control.

g) Use the power tool, accessories and tool bits

etc. in accordance with these instructions,

taking into account the working conditions and

the work to be performed. Use of the power tool

for operations different from those intended could

result in a hazardous situation.

2.5 Service

a) Have your power tool serviced by a qualified

repair person using only identical replacement

parts. This will ensure that the safety of the power

tool is maintained.

3. Special Safety Instructions

Wear ear protectors when impact drilling.

Exposure to noise can cause hearing loss.

Use auxiliary handle(s), if supplied with the

tool. Loss of control can cause personal injury.

Hold power tool by insulated gripping

surfaces, when performing an operation where

the cutting accessory may contact hidden

wiring or its own cord. Cutting accessory

contacting a "live" wire may make exposed metal

parts of the power tool "live" and could give the

operator an electric shock.

Pull the plug out of the plug socket before any

adjustments or servicing are performed.

Beware of gas/water pipes and electric cables!

Avoid inadvertent starts by always unlocking the

switch when the plug is removed from the mains

socket or in case of a power cut.

Keep hands away from the rotating tool!

Remove chips and similar material only with the

machine at standstill.

Caution must be exercised when driving screws into

hard materials (driving screws with metric or

imperial threads into steel)! The screw head may

break or a high reverse torque may build up.

6

The machine produces powerful forces when

seizing or catching the workpiece. Always hold the

machine firmly, adopt a steady stance and focus on

your work.

Secure small workpieces. For example, clamp in a

vice.

Dust from material such as paint containing lead,

some wood species, minerals and metal may be

harmful. Contact with or inhalation of the dust may

cause allergic reactions and/or respiratory diseases

to the operator or bystanders.

Certain kinds of dust are classified as carcinogenic

such as oak and beech dust especially in

conjunction with additives for wood conditioning

(chromate, wood preservative). Material containing

asbestos must only be treated by specialists.

- Where the use of a dust extraction device is

possible it shall be used.

- The work place must be well ventilated.

- The use of a dust mask of filter class P2 is

recommended.

Follow national requirements for the materials you

want to work with.

SYMBOLS ON THE TOOL:

...... Class II Construction

V .......... volts

A .......... amperes

Hz ........ hertz

W ......... watts

~

.......... alternating current

n0......... no-load speed

rpm ......revolutions per minute

.../min... revolutions per minute

4. Overview

See page 2.

1 Chuck key (for geared chuck) *

2Geared chuck *

3 Futuro Plus keyless chuck *

4Depth stop

5 Additional handle

6 Direction switch

7 Sliding switch for normal drilling/impact drilling

8 Lock button (continuous operation)

9Trigger

10 Speed preselection wheel

* depending on the features / model

5. Commissioning

Before plugging in, check to see that the

rated mains voltage and mains frequency,

as stated on the rating label, match with your

power supply.

Make sure the chuck clamps securely:

After drilling for the first time (clockwise), firmly

tighten the safety screw inside the chuck using

a screwdriver. Caution: left-handed thread!

(see Section 6.8)

Page 7

5.1 Attaching the Additional Handle

For safety reasons, always use the

additional handle supplied.

Open the clamping ring by turning the additional

handle (5) anticlockwise. Push the additional

handle onto the collar of the machine. Insert the

depth stop (4). Securely tighten the additional

handle at the angle required for the application.

6. Use

6.1 Adjusting the Depth Stop

Loosen the additional handle (5). Set depth stop (4)

to the desired drilling depth and retighten additional

handle.

6.2 Switching On and Off

To start the machine, press the trigger switch (9).

Press in the trigger switch to change the speed.

For continuous operation the trigger switch can be

locked using the lock button (8). To stop the

machine, press the trigger switch again.

In continuous operation, the machine

continues running if it is forced out of your

hands. Therefore, always hold the machine

with both hands using the handles provided,

stand in a safe position and concentrate.

6.3 Speed Preselection

Select the (10) maximum speed using the

preselection wheel. See page 4 for recommended

drilling speeds.

6.4 Switching Between Normal Drilling/

Impact Drilling

Select the desired operating mode by pushing the

sliding switch (7).

Drilling

Impact drilling

Work with high speed settings when impact drilling.

Impact drilling and normal drilling only in

a clockwise direction.

6.5 Selecting the Direction of Rotation

Do not activate the direction switch (6)

unless the motor has completely stopped.

Select direction of rotation:

R=Clockwise

L=Anticlockwise

Screw the chuck firmly to the spindle and

tighten the safety screw inside the chuck

using a screwdriver. (Caution: left-handed

thread!)

Otherwise it may come loose during

anticlockwise operation (e.g. when

screwdriving).

ENGLISH en

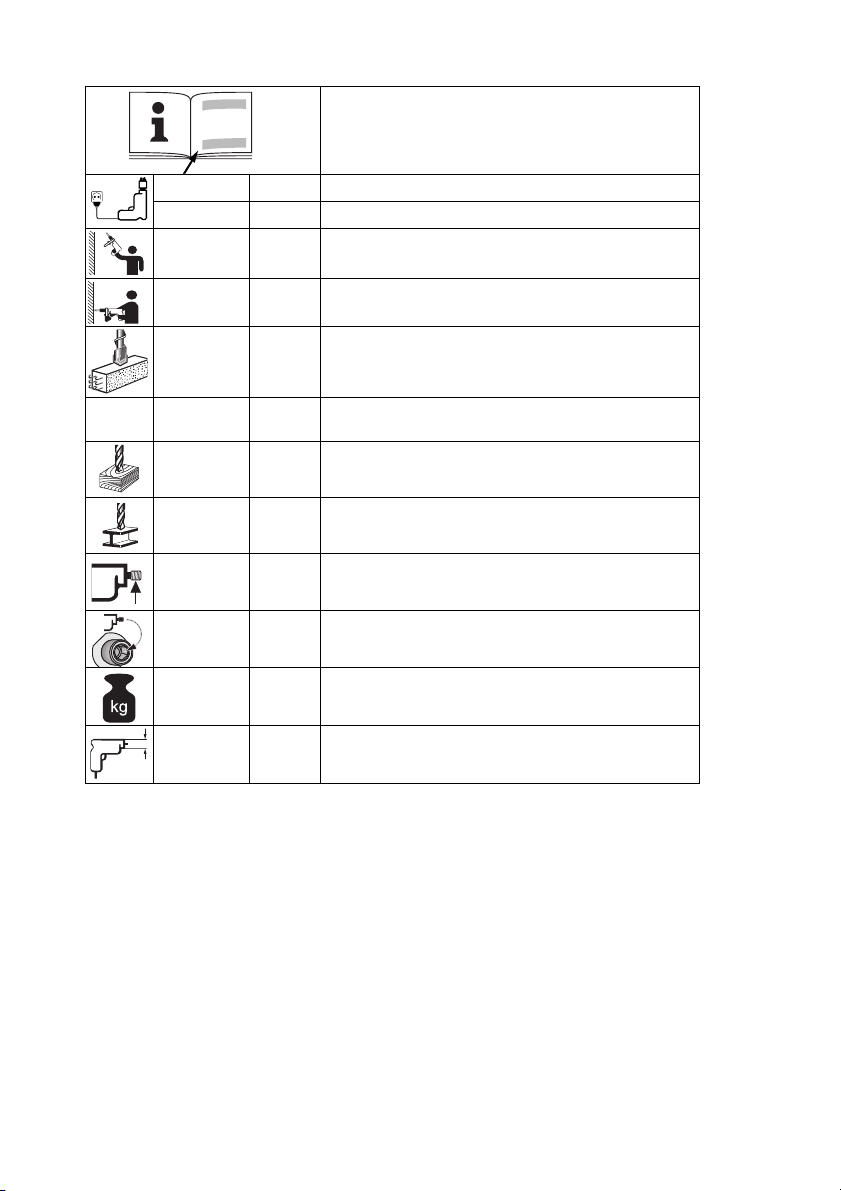

6.6 Tool Change With

Futuro Plus Keyless Chuck (3)

See illustrations on page 2.

Insert the tool. Hold the retaining ring (a) firmly and

turn the collet (b) towards "GRIP, ZU" with the other

hand until the mechanical resistance which can be

felt is overcome.

Caution! The tool is not yet clamped! Keep

turning the sleeve (it must "click" when turning)

until it cannot be turned any further - only now is the

tool securely clamped.

With a soft tool shank, retightening may be required

after a short drilling period.

Open the chuck:

Hold the retaining ring (a) firmly and turn the collet

(b) towards "AUF, RELEASE" with the other hand.

Note: The grating sound which may be heard after

opening the drill chuck is functional and is stopped

by turning the sleeve in the opposite direction.

If the chuck is very securely tightened: Unplug.

Hold the drill chuck using an open-end spanner at

the flats on its head, and turn the sleeve (b)

vigourously in the direction of "AUF, RELEASE".

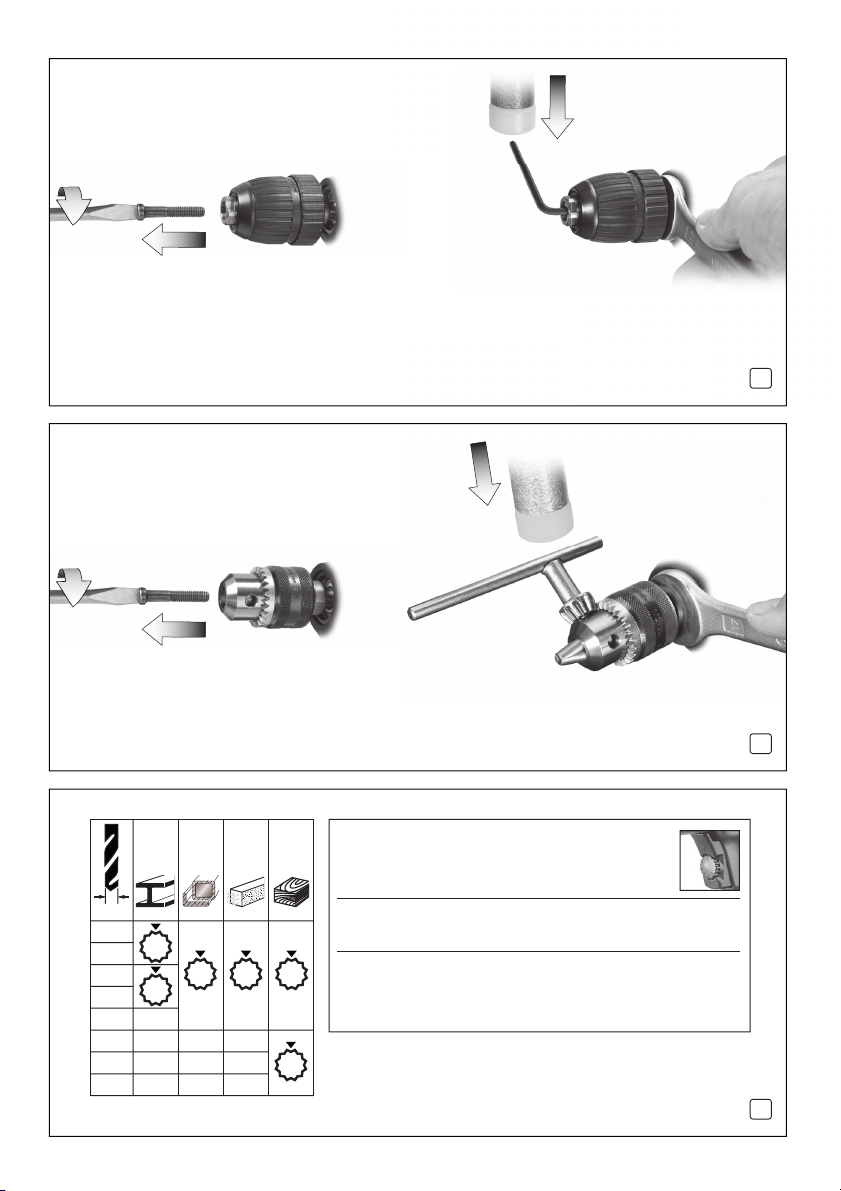

6.7 Tool Change With Geared Chuck (2)

See illustrations on page 2.

Clamping tools:

Insert the tool and clamp evenly in all 3 holes using

the chuck key (1).

Removing tools:

Open the geared chuck (2) using the chuck key (1)

and remove the tool.

6.8 Removing the Chuck

The chuck can be removed to insert a screwdriver

bit. Insert the bit directly in the hexagon socket on

the spindle.

The screwdriver bit is retained if a bit clamping bush

(as an accessory: order no. 6.31281)

Futuro Plus keyless chuck

See page 4, illustration A.

Unscrew the safety screw - if available. Caution:

left-handed thread!

Hold the drill spindle securely using an open-end

wrench. Clamp an Allen key in the chuck and strike

lightly with a rubber hammer to loosen, then

unscrew.

Geared chuck

See page 4, illustration B.

Unscrew the safety screw - if available. Caution:

left-handed thread!

Hold the drill spindle securely using an open-end

wrench. Insert the key in the chuck and strike lightly

with a rubber hammer to loosen, then unscrew.

is fitted.

7. Maintenance

Keyless chuck cleaning:

After prolonged use hold the chuck vertically, with

the opening facing down, and fully open and close it

several times. The dust collected falls from the

7

Page 8

ENGLISHen

opening. Regular use of cleaning spray on the jaws

and jaw openings is recommended.

f

8. Accessories

Use only genuine Metabo accessories.

Use only accessories which fulfil the requirements

and specifications listed in these operating instructions.

Fit accessories securely. Secure the machine if it is

operated in a bracket. Loss of control can cause

personal injury.

For a complete range of accessories, see

www.metabo.com or the main catalogue.

9. Repairs

Repairs to electrical tools must be carried out by

qualified electricians ONLY!

Contact your local Metabo representative if you

have Metabo power tools requiring repairs. For

addresses see www.metabo.com.

You can download a list of spare parts from

www.metabo.com.

10. Environmental Protection

Observe national regulations on environmentally

compatible disposal and on the recycling of disused

machines, packaging and accessories.

11. Technical Specifications

Explanatory notes on the specifications on page 3.

Changes due to technological progress reserved.

P

=Nominal power input

1

P

=Power output

2

n

=No load speed

0

n

=Speed at rated load

1

ø max = Max. solid drill diameter

s max =Max. impact rate

G =Drill spindle thread

H = Drill spindle with hexagon socket

m =Weight without mains cable

D = Collar diameter

The technical specifications quoted are subject to

tolerances (in compliance with the relevant valid

standards).

Wear ear protectors!

8

Page 9

Mode d'emploi

1. Utilisation conforme à la

destination

Cette perceuse à percussion convient pour le

perçage sans percussion sur métal, bois, matières

plastiques et assimilées, ainsi que pour le perçage

avec percussion sur béton, pierre et matériaux similaires.

Cette perceuse à percussion convient pour les

travaux de taraudage et de vissage.

L'utilisateur sera entièrement responsable de tous

dommages résultant d'une utilisation non conforme

à la destination de l'appareil.

Les règles générales relatives à la prévention des

accidents et les consignes de sécurité ci-jointes

doivent être respectées.

2. Consignes générales de

sécurité

Pour des raisons de sécurité et afin de

protéger l'outil électrique, respecter les

passages de texte marqués de ce

symbole !

AVERTISSEMENT – Lire la notice d'utilisation afin d'éviter tout risque de blessure.

Remettre l'outil électrique uniquement accompagné

de ces documents.

Avertissements de sécurité généraux pour

l'outil

AVERTISSEMENT – Lire tous les

avertissements de sécurité et toutes les

instructions. Ne pas suivre les avertissements et

instructions peut donner lieu à un choc électrique,

un incendie et/ou une blessure sérieuse.

Conserver tous les avertissements et toutes

les instructions pour pouvoir s'y reporter

ultérieurement! Le terme «outil» dans les

avertissements fait référence à votre outil électrique

alimenté par le secteur (avec cordon d'alimentation)

ou votre outil fonctionnant sur batterie (sans cordon

d'alimentation).

2.1 Sécurité de la zone de travail

a) Conserver la zone de travail propre et bien

éclairée. Les zones en désordre ou sombres sont

propices aux accidents.

b) Ne pas faire fonctionner les outils électriques en atmosphère explosive, par exemple en

présence de liquides inflammables, de gaz ou

de poussières. Les outils électriques produisent

des étincelles qui peuvent enflammer les poussières ou les fumées.

c) Maintenir les enfants et les personnes

présentes à l'écart pendant l'utilisation de

l'outil. Les distractions peuvent vous faire perdre le

contrôle de l'outil.

FRANÇAIS fr

2.2 Sécurité électrique

a) Il faut que les fiches de l'outil électrique

soient adaptées au socle. Ne jamais modifier la

fiche de quelque façon que ce soit. Ne pas

utiliser d'adaptateurs avec des outils à

branchement de terre. Des fiches non modifiées

et des socles adaptés réduiront le risque de choc

électrique.

b) Eviter tout contact du corps avec des

surfaces reliées à la terre telles que les tuyaux,

les radiateurs, les cuisinières et les

réfrigérateurs. Il existe un risque accru de choc

électrique si votre corps est relié à la terre.

c) Ne pas exposer les outils à la pluie ou à des

conditions humides. La pénétration d'eau à

l'intérieur d'un outil augmentera le risque de choc

électrique.

d) Ne pas maltraiter le cordon. Ne jamais

utiliser le cordon pour porter, tirer ou

débrancher l'outil. Maintenir le cordon à l'écart

de la chaleur, du lubrifiant, des arêtes ou des

parties en mouvement. Des cordons endom-

magés ou emmêlés augmentent le risque de choc

électrique.

e)

Lorsqu'on utilise un outil à l'extérieur,

utiliser un prolongateur adapté à l'utilisation

extérieure. L'utilisation d'un cordon adapté à

l'utilisation extérieure réduit le risque de choc

électrique.

f) Si l'usage d'un outil dans un emplacement

humide est inévitable, utiliser une alimentation

protégée par un dispositif à courant différentiel

résiduel (RCD). L'usage d'un RCD réduit le risque

de choc électrique.

2.3 Sécurité des personnes

a) Rester vigilant, regarder ce que vous êtes en

train de faire et faire preuve de bon sens dans

votre utilisation de l'outil. Ne pas utiliser un

outil lorsque vous êtes fatigué ou sous

l'emprise de drogues, d'alcool ou de médicaments. Un moment d'inattention en cours

d'utilisation d'un outil peut entraîner des blessures

graves des personnes.

b) Utiliser un équipement de sécurité. Toujours

porter une protection pour les yeux. Les

équipements de sécurité tels que les masques

contre les poussières, les chaussures de sécurité

antidérapantes, les casques ou les protections

acoustiques utilisés pour les conditions

appropriées réduiront les blessures de personnes.

c) Eviter tout démarrage intempestif. S'assurer

que l'interrupteur est en position arrêt avant de

brancher l'outil au secteur et/ou au bloc de

batteries, de le ramasser ou de le porter. Porter

les outils en ayant le doigt sur l'interrupteur ou

brancher des outils dont l'interrupteur est en

position marche est source d'accidents.

d) Retirer toute clé de réglage avant de mettre

l'outil en marche. Une clé laissée fixée sur une

9

Page 10

FRANÇAISfr

partie tournante de l'outil peut donner lieu à des

blessures de personnes.

e) Ne pas se précipiter. Garder une position et

un équilibre adaptés à tout moment. Cela

permet un meilleur contrôle de l'outil dans des

situations inattendues.

f) S'habiller de manière adaptée. Ne pas porter

de vêtements amples ou de bijoux. Garder les

cheveux, les vêtements et les gants à distance

des parties en mouvement. Des vêtements

amples, des bijoux ou les cheveux longs peuvent

être pris dans des parties en mouvement.

g) Si des dispositifs sont fournis pour le

raccordement d'équipements pour l'extraction

et la récupération des poussières, s'assurer

qu'ils sont connectés et correctement utilisés.

Utiliser des collecteurs de poussière peut réduire

les risques dus aux poussières.

2.4 Utilisation et entretien de l'outil

a) Ne pas forcer l'outil. Utiliser l'outil adapté à

votre application. L'outil adapté réalisera mieux le

travail et de manière plus sûre au régime pour

lequel il a été construit.

b) Ne pas utiliser l'outil si l'interrupteur ne

permet pas de passer de l'état de marche à

arrêt et vice versa. Tout outil qui ne peut pas être

commandé par l'interrupteur est dangereux et il faut

le réparer.

c) Débrancher la fiche de la source

d'alimentation en courant et/ou le bloc de

batteries de l'outil avant tout réglage,

changement d'accessoires ou avant de ranger

l'outil. De telles mesures de sécurité préventives

réduisent le risque de démarrage accidentel de

l'outil.

d) Conserver les outils à l'arrêt hors de la

portée des enfants et ne pas permettre à des

personnes ne connaissant pas l'outil ou les

présentes instructions de le faire fonctionner.

Les outils sont dangereux entre les mains

d'utilisateurs novices.

e) Observer la maintenance de l'outil. Vérifier

qu'il n'y a pas de mauvais alignement ou de

blocage des parties mobiles, des pièces

cassées ou toute autre condition pouvant

affecter le fonctionnement de l'outil. En cas de

dommages, faire réparer l'outil avant de

l'utiliser. De nombreux accidents sont dus à des

outils mal entretenus.

f) Garder affûtés et propres les outils

permettant de couper. Des outils destinés à

couper correctement entretenus avec des pièces

coupantes tranchantes sont moins susceptibles de

bloquer et sont plus faciles à contrôler.

g) Utiliser l'outil, les accessoires et les lames

etc., conformément à ces instructions, en

tenant compte des conditions de travail et du

travail à réaliser. L'utilisation de l'outil pour des

opérations différentes de celles prévues pourrait

donner lieu à des situations dangereuses.

10

2.5 Maintenance et entretien

a) Faire entretenir l'outil par un réparateur

qualifié utilisant uniquement des pièces de

rechange identiques. Cela assurera que la

sécurité de l'outil est maintenue.

3. Consignes de sécurité

particulières

Porter une protection auditive lors de

l'utilisation d'une perceuse à percussion. Le

bruit est susceptible de provoquer une perte de

capacité auditive.

Utiliser la poignée complémentaire fournie

avec l'outil. En cas de perte de contrôle, il y a un

risque de blessures.

Lors d'opérations où l'accessoire risque de

rencontrer des conducteurs électriques non

apparents, voire son câble d'alimentation, tenir

l'outil exclusivement par les côtés isolés des

poignées. Le contact avec un conducteur

électrique sous tension peut également mettre les

parties métalliques de l'outil sous tension et

provoquer un choc électrique.

Débrancher le cordon d'alimentation de la prise de

courant avant toute opération de réglage ou de

maintenance.

Veillez à ne toucher aucune conduite de gaz,

électricité ou eau !

Eviter les démarrages intempestifs : la gâchette doit

toujours être déverrouillée lorsque l'on retire le

connecteur de la prise ou après une coupure de

courant.

Ne pas toucher l'outil lorsque la machine est en

marche !

Eliminer sciures de bois et autres uniquement

lorsque la machine est à l'arrêt.

Attention pour les vissages en force (avec des vis à

pas métrique ou en pouces sur de l'acier) ! Risque

d'arrachement de la tête de vis ou d'apparition de

couples de réaction élevés.

Si l'outil inséré dans le mandrin reste coincé ou

accroché, des forces importantes apparaîtront.

Maintenez donc toujours fermement la machine,

positionnez-vous dans une posture stable et restez

concentré en travaillant.

Fixer les pièces de petite taille, par ex. en les serrant

dans un étau.

Les poussières de matériaux tels que les peintures

au plomb, certains types de bois, de minéraux et de

métaux peuvent s'avérer nocives pour la santé.

Toucher ou inhaler ces poussières peut entraîner

des réactions allergiques et/ou des maladies

respiratoires chez l'utilisateur ou les personnes

se trouvant à proximité.

Certaines poussières provenant par exemple du

chêne ou du hêtre sont considérées comme

cancérigènes, particulièrement lorsqu'elle sont

associées à des adjuvants de traitement du bois

(chromate, produit de protection du bois). Seuls des

spécialistes sont habilités à traiter les matériaux

contenant de l'amiante.

Page 11

- Utiliser le plus possible un système d'aspiration

des poussières.

- Veiller à une bonne aération du site de travail.

- Il est recommandé de porter un masque

antipoussières avec filtre à particules de classe 2.

Respecter les directives nationales en vigueur

relatives aux matériaux à traiter.

SYMBOLES SUR L’OUTIL:

........Construction de classe II

V............volts

A ...........ampères

Hz .........hertz

W ..........watts

~............courant alternatif

n

..........vitesse à vide

0

rpm........révolutions par minute

.../min....révolutions par minute

4. Vue d'ensemble

Voir page 2.

1 Clé de mandrin (pour mandrins à clé) *

2 Mandrin à couronne dentée *

3 Mandrin autoserrant Futuro Plus *

4 Butée de profondeur de perçage

5 Poignée supplémentaire

6 Commutateur du sens de rotation

7 Interrupteur coulissant perçage avec/sans

percussion

8 Bouton de blocage (marche continue)

9 Gâchette

10 Molette de présélection de la vitesse

* en fonction de l'équipement / du modèle choisis

5. Mise en service

Avant la mise en service, comparez si

tension secteur et la fréquence secteur

indiquées sur la plaque signalétique

correspondent aux caractéristiques de votre

réseau de courant.

Afin de garantir la bonne tenue en place

du mandrin : dès la fin du premier perçage

(en rotation à droite), resserrer vigoureusement la

vis de freinage à l'intérieur du mandrin à l'aide d'un

tournevis. Attention, il s'agit d'un pas à gauche !

(voir chapitre 6.8)

5.1 Montage de la poignée supplémentaire

Pour des raisons de sécurité, utilisez

toujours la poignée supplémentaire qui

est comprise dans la livraison.

Ouvrir l'anneau de serrage en tournant la poignée

(5) vers la gauche. Faire coulisser la poignée sur le

collier de la machine. Introduire la butée de

profondeur (4). Selon l'utilisation souhaitée, serrer

la poignée dans l'angle désiré.

FRANÇAIS fr

6. Utilisation

6.1 Réglage de la butée de profondeur de

perçage

Desserrer la poignée supplémentaire (5). Régler la

butée de profondeur (4) à la profondeur de perçage

voulue et resserrer la poignée supplémentaire.

6.2 Marche/arrêt

Pour mettre l'outil en route, appuyer sur la

gâchette (9).

La vitesse peut être modifiée en pressant la

gâchette.

Pour un fonctionnement en continu, il est possible

de bloquer la gâchette à l'aide du bouton de

blocage (8). Pour arrêter la machine, appuyer

à nouveau sur la gâchette.

Lorsque l'outil est en position de marche

continue, il continue de tourner s'il vous

échappe des mains. Afin d'éviter tout

comportement inattendu de l'outil, le tenir avec

les deux mains au niveau des poignées, veiller

à un bon équilibre et travailler de manière

concentrée.

6.3 Présélection de la vitesse

Présélectionner la vitesse maximale sur la molette

(10). Voir les vitesses de perçage recommandées

page 4.

6.4 Sélection perçage avec/

sans percussion

Le mode de fonctionnement voulu est sélectionné

en déplaçant l'interrupteur coulissant (7).

Perçage sans percussion

Perçage avec percussion

Pour le perçage avec percussion, utiliser une

vitesse élevée.

Pour tous perçages avec ou sans

percussion, la rotation à droite est

obligatoire.

6.5 Sélection du sens de rotation

S'assurer que le moteur est à l'arrêt avant

d'actionner le commutateur du sens de

rotation (6).

Sélectionner le sens de rotation:

R = Rotation à droite

L = Rotation à gauche

Le mandrin doit être fermement vissé sur

la broche et la vis de freinage à l'intérieur

du mandrin doit être vigoureusement serrée à

l'aide d'un tournevis. (Attention, il s'agit d'un

pas à gauche !)

En effet, il risquerait de se desserrer dans

le cas contraire lors d'une rotation à gauche

(par ex. au vissage).

11

Page 12

FRANÇAISfr

6.6 Changement d'accessoire

Mandrin autoserrant Futuro Plus (3)

Voir les illustrations page 2.

Insérer l'outil. Maintenir l'anneau de maintien (a) et

de l'autre main, tourner la douille (b) dans le sens

indiqué "GRIP, ZU" jusqu'à ce que la résistance

mécanique perceptible soit dépassée.

Attention ! L'outil n'est alors pas encore serré !

Continuer à tourner avec force (on doit entendre

un "clic") jusqu'à ce que l'on ne puisse plus tourner

du tout - ce n'est que maintenant que l'outil est

véritablement serré.

En cas d'outils souples, il faudra éventuellement

resserrer peu de temps après le début du travail

de perçage.

Pour ouvrir le mandrin :

Maintenir l'anneau de maintien (a) et de l'autre

main, tourner la douille (b) dans le sens marqué

"AUF, RELEASE".

Remarque : Le cliquètement que l'on entend

éventuellement après avoir ouvert le mandrin de

perçage (bruit dû au fonctionnement) disparaîtra

si l'on tourne la douille dans le sens contraire.

Au cas où le mandrin est complètement bloqué

: Débrancher le cordon d'alimentation. Maintenir le

mandrin au niveau de la tête avec une clé à fourche

et tourner la douille (b) avec force dans le sens

marqué "AUF, RELEASE".

6.7 Changement d'accessoire

Mandrin à clé (2)

Voir les illustrations page 2.

Pour insérer l'outil :

Insérer l'outil et le serrer à l'aide d'une clé de

mandrin (1) en veillant à bien répartir l'effort sur les

3 perçages.

Pour sortir l'outil :

Ouvrir le mandrin à clé (2) à l'aide de la clé de

mandrin (1) et sortir l'outil.

6.8 Dépose du mandrin

Le mandrin peut être dévissé pour les travaux de

vissage. On insère alors l'embout de vissage

directement dans le six pans creux de la broche.

Si une douille de serrage d'embouts

comme accessoire : réf. de cde 6.31281)

installée, l'embout de vissage sera maintenu en

place.

Mandrin autoserrant Futuro Plus

Voir page 4, figure A.

Dévisser la vis de freinage (s'il y en a une).

Attention, il s'agit d'un pas à gauche !

Maintenir la broche à l'aide d'une clé à fourche.

Dé co ller le mand ri n en ta po tan t l ég ère me nt a ve c u n

maillet en plastique sur une clé six pans insérée

dans le mandrin, puis dévisser.

Mandrin à clé

Voir page 4, figure A.

Dévisser la vis de freinage (s'il y en a une).

Attention, il s'agit d'un pas à gauche !

12

(disponible

a été

Maintenir la broche à l'aide d'une clé à fourche.

Décoller le mandrin en tapotant légèrement avec un

maillet en plastique sur la clé de mandrin insérée

dans le mandrin, puis dévisser.

7. Maintenance

Nettoyage du mandrin autoserrant :

Après une utilisation prolongée du mandrin, tenir

celui-ci en position verticale, ouverture vers le bas,

l'ouvrir entièrement et le refermer, puis

recommencer plusieurs fois de suite. La poussière

qui s'était accumulée tombera alors par l'ouverture.

Il est conseillé d'utiliser régulièrement un spray de

nettoyage pour les mâchoires de serrage.

f

8. Accessoires

Utiliser uniquement des accessoires Metabo.

Utiliser exclusivement des accessoires, qui sont

conformes aux exigences et données caractéristiques indiquées dans la présente notice d'utilisation.

Monter correctement les access oires. Si la machine

est utilisée dans un support : fixer correctement la

machine. En cas de perte de contrôle, il y a un

risque de blessures.

Voir programme complet des accessoires sur

www.metabo.com ou dans le catalogue principal.

9. Réparations

Les travaux de réparation sur les outils électriques

ne peuvent être effectués que par un spécialiste !

Pour toute réparation sur un outil Metabo, contacter

le représentant Metabo. Voir les adresses sur

www.metabo.com.

Les listes des pièces détachées peuvent être

téléchargées sur www.metabo.com.

10. Protection de l'environnement

Suivre les réglementations nationales concernant

l'élimination dans le respect de l'environnement et

le recyclage des machines, emballages et accessoires.

11. Caractéristiques techniques

Commentaires sur les indications de la page 3.

Sous réserve de modifications allant dans le sens

du progrès technique.

P

=Puissance absorbée

1

P

=Puissance débitée

2

n

=Vitesse à vide

0

n

=Vitesse en charge nominale

1

ø

=Capacité de perçage maxi

max

s

=Cadence de frappe maxi

max

G =Filet de la broche de perçage

H = Broche de perçage à six pans creux

m =Poids sans cordon d'alimentation

D = Diamètre du collet

Page 13

Les caractéristiques indiquées sont soumises à

tolérance (selon les normes en vigueur

correspondantes).

Porter un casque antibruit !

FRANÇAIS fr

13

Page 14

ESPAÑOLes

Instrucciones de manejo

1. Aplicación de acuerdo a la

finalidad

La taladradora con percutor es adecuada para el

taladrado sin percusión en metal, madera, plástico

y materiales similares y para el taladrado con

percusión en hormigón, piedra y materiales semejantes.

La taladradora es adecuada para tallar roscas y

para atornillar.

Los posibles daños derivados de un uso inadecuado son responsabilidad exclusiva del usuario.

Deben observarse los reglamentos generales para

la prevención de accidentes y la información sobre

seguridad incluida.

2. Instrucciones generales de

seguridad

Para su propia protección y la de su

herramienta eléctrica, observe las partes

marcadas con este símbolo.

ADVERTENCIA: Lea el manual de instrucciones para reducir el riesgo de accidentes.

Si entrega su herramienta eléctrica a otra persona,

es imprescindible acompañarla de este documento.

Instrucciones generales de seguridad para

herramientas eléctricas

¡ATENCIÓN! Lea íntegramente estas

instrucciones de seguridad. La no

observación de las instrucciones de seguridad

siguientes puede dar lugar a descargas eléctricas,

incendios y/o lesiones graves.

¡Guarde estas instrucciones en un lugar

seguro! El término "herramienta eléctrica"

empleado en las siguientes instrucciones se refiere

a su aparato eléctrico portátil, ya sea con cable de

red, o sin cable, en caso de ser accionado por

acumulador.

2.1 Puesto de trabajo

a) Mantenga limipo y bien iluminado su puesto

de trabajo. El desorden y una iluminación

deficiente en las áreas de trabajo pueden provocar

accidentes.

b) No utilice la herramienta eléctrica en un

entorno con peligro de explosión, en el que se

encuentren combustibles líquidos, gases o

material en polvo. Las herramientas eléctricas

producen chispas que pueden llegar a inflamar los

materiales en polvo o vapores.

c) Mantenga alejados a los niños y otras

personas de su puesto de trabajo al emplear la

herramienta eléctrica. Una distracción le puede

hacer perder el control sobre el aparato.

14

2.2 Seguridad eléctrica

a) El enchufe de la herramienta eléctrica debe

corresponder a la toma de corriente utilizada.

No es admisible modificar el enchufe en forma

alguna. No emplee adaptadores con

herramientas eléctricas dotadas de una toma

de tierra. Los enchufes sin modificar adecuados a

las respectivas tomas de corriente reducen el

riesgo de una descarga eléctrica.

b) Evite que su cuerpo toque partes

conectadas a tierra como tuberías, radiadores,

cocinas y refrigeradores. El riesgo a quedar

expuesto a una sacudida eléctrica es mayor si su

cuerpo tiene contacto con tierra.

c) No exponga las herramientas eléctricas a la

lluvia y evite que penetren líquidos en su

interior. Existe el peligro de recibir una descarga

eléctrica si penetran ciertos líquidos en la

herramienta eléctrica.

d) No utilice el cable de red para transportar o

colgar la herramienta eléctrica, ni tire de él

para sacar el enchufe de la toma de corriente.

Mantenga el cable de red alejado del calor,

aceite, esquinas cortantes o piezas móviles.

Los cables de red dañados o enredados pueden

provocar una descarga eléctrica.

e) Al trabajar con la herramienta eléctrica a la

intemperie utilice solamente cables de

prolongación homologados para su uso en

exteriores. La utilización de un cable de

prolongación adecuado para su uso en exteriores

reduce el riesgo de una descarga eléctrica.

f)

Si fuera necesario utilizar la herramienta

eléctrica en un entorno húmedo, utilice un

interruptor de protección diferencial. La

utilización de un cable de prolongación adecuado

para su uso en exteriores reduce el riesgo de una

descarga eléctrica.

2.3 Seguridad de personas

a) Esté atento a lo que hace y emplee la

herramienta eléctrica con prudencia. No utilice

la herramienta eléctrica si estuviese cansado,

ni tampoco después de haber consumido

alcohol, drogas o medicamentos. El no estar

atento durante el uso de una herramienta eléctrica

puede provocarle serias lesiones.

b) Utilice un equipo de protección y en todo

caso unas gafas de protección. El riesgo de

lesionarse se reduce considerablemente si,

dependiendo del tipo y la aplicación de la

herramienta eléctrica empleada, se utiliza un

equipo de protección adecuado como una

mascarilla antipolvo, zapatos de seguridad con

suela antideslizante, casco, o protectores

auditivos.

c) Evite una puesta en marcha fortuita del

aparato. Asegúrese de que la herramienta

eléctrica está apagada antes de conectarla a la

toma de corriente y/o la batería, de

desconectarla o de transportarla. Si transporta

la herramienta eléctrica sujetándola por el

Page 15

interruptor de conexión/desconexión, o si introduce

el enchufe en la toma de corriente con el aparato

conectado, puede dar lugar a un accidente.

d) Retire las herramientas de ajuste o llaves

fijas antes de conectar la herramienta eléctrica.

Una herramienta o llave colocada en una pieza

rotante puede producir lesiones al ponerse a

funcionar.

e) Evite trabajar con posturas forzadas. Trabaje

sobre una base firme y mantenga el equilibrio

en todo momento. Ello le permitirá controlar mejor

la herramienta eléctrica en caso de presentarse una

situación inesperada.

f) Lleve puesta una vestimenta de trabajo

adecuada. No utilice vestimenta amplia ni

joyas. Mantenga su pelo, vestimenta y guantes

alejados de las piezas móviles. La vestimenta

suelta, las joyas y el pelo largo se pueden

enganchar con las piezas en movimiento.

g) Siempre que sea posible utilizar equipos de

aspiración o captación de polvo, asegúrese

que éstos estén montados y que sean

utilizados correctamente. La utilización de un

equipo de aspiración de polvo puede reducir los

riesgos de aspirar polvo nocivo para la salud.

2.4 Trato y uso cuidadoso de herramientas

eléctricas

a) No sobrecargue el aparato. Use la herramienta prevista para el trabajo a realizar. Con la

herramienta adecuada podrá trabajar mejor y más

seguro dentro del margen de potencia indicado.

b) No utilice herramientas con un interruptor

defectuoso. Las herramientas que no se puedan

conectar o desconectar son peligrosas y deben

hacerse reparar.

c) Saque el enchufe de la red y/o retire la

batería antes de realizar un ajuste en la

herramienta, cambiar de accesorio o guardar

el aparato. Esta medida preventiva reduce el

riesgo de conectar accidentalmente el aparato.

d) Guarde las herramientas eléctricas fuera del

alcance de los niños. No permita que las

utilcen personas que no estén familiarizadas

con ellas o que no hayan leído estas

instrucciones. Las herramientas utilizadas por

personas inexpertas son peligrosas.

e) Cuide sus herramientas eléctricas con

esmero. Controle si funcionan correctamente,

sin atascarse, las partes móviles de la herramienta y si existen partes rotas o deterioradas

que pudieran afectar a su funcionamiento. Si la

herramienta eléctrica estuviese defectuosa,

hágala reparar antes de volver a utilizarla.

Muchos de los accidentes se deben a aparatos con

un mantenimiento deficiente.

f) Mantenga los útiles limpios y afilados. Los

útiles mantenidos correctamente se dejan guiar y

controlar mejor.

g) Utilice las herramientas eléctricas, los

accesorios, las herramientas de inserción, etc.

de acuerdo con estas instrucciones. Considere

en ello las condiciones de trabajo y la tarea a

ESPAÑOL es

realizar. El uso de herramientas eléctricas para

trabajos diferentes de aquellos para los que han

sido concebidas puede resultar peligroso.

2.5 Servicio

a) Únicamente haga reparar su herramienta

eléctrica por un profesional, empleando

exclusivamente piezas de repuesto originales.

Solamente así se mantiene la seguridad de la

herramienta eléctrica.

3. Instrucciones especiales de

seguridad

Póngase cascos protectores cuando maneje

taladradoras con percutor. El efecto del ruido

puede provocar pérdida auditiva.

Utilice la empuñadura complementaria

suministrada con la herramienta. El usuario

puede resultar herido por la pérdida del control de

la herramienta.

Sujete la herramienta por las superficies de la

empuñadura aisladas cuando realice trabajos

en los que la herramienta de inserción pudiera

entrar en contacto con cables eléctricos

ocultos o con el propio cable de alimentación.

El contacto con un cable conductor de corriente

puede electrizar también las partes metálicas de la

herramienta y causar una descarga eléctrica.

Desenchufe el equipo antes de llevar a cabo

cualquier ajuste o mantenimiento.

Tenga cuidado con las tuberías de gas y agua

y los cables eléctricos.

Evite que la máquina se ponga en funcionamiento

por error: desconecte la máquina siempre al extraer

el enchufe de la toma de corriente o cuando se haya

producido un corte de corriente.

¡No toque la herramienta en rotación!

La máquina debe estar siempre en reposo para

eliminar virutas y otros residuos similares.

Preste atención en caso de un roscado duro

(atornillado de tornillos con roscad o métrico o rosca

inglesa en acero). La cabeza del tornillo puede

desprenderse o pueden producirse momentos de

retroceso.

Si la herramienta de inserción se atasca o se

engancha, aparecerán fuerzas elevadas. Sujete la

herramienta con fuerza, adopte una postura segura

y trabaje concentrado.

Fije las piezas de trabajo pequeñas. Por ejemplo,

sujételas en un tornillo de banco.

El polvo procedente de algunos materiales, como la

pintura con plomo o algunos tipos de madera,

minerales y metales, puede ser perjudicial para la

salud. Tocar o respirar el polvo puede causar

reacciones alérgicas y/o enfermedades

respiratorias al usuario o a las personas próximas a

él.

Algunas maderas, como la madera de roble o de

haya, producen un polvo que podría ser

cancerígeno, especialmente en combinación con

otros aditivos para el tratamiento de madera

(cromato, conservante para madera). Sólo

15

Page 16

ESPAÑOLes

personal especializado debe trabajar el material

con contenido de asbesto.

- Si fuera posible, utilice un aspirador de polvo.

- Ventile su lugar de trabajo.

- Se recomienda utilizar una máscara de

protección contra el polvo con clase de filtro P2.

Preste atención a la normativa vigente en su país

respecto al material que se va a trabajar.

SÍMBOLOS SOBRE LA HERRAMIENTA:

.......Classe II de construcción

V...........voltios

A...........amperios

Hz.........hertzios

W..........vatios

~

..........corriente alterna

n0.........velocidad sin carga

rpm.......revoluciones por minuto

.../min ...revoluciones por minuto

4. Descripción general

Véase la página 2.

1 Llave para portabrocas

(para los portabrocas de corona dentada) *

2 Portabrocas de corona dentada *

3 Portabrocas de sujeción rápida

Futuro Plus *

4 Tope de profundidad de taladrado

5 Empuñadura complementaria

6 Conmutador de inversión

7 Relé neumático de taladro/taladrado

con percusión

8 Botón de retención

(funcionamiento continuado)

9Interruptor

10 Ruedecilla de ajuste para preselección

del número de revoluciones

* según el equipamiento/según el modelo

5. Puesta en marcha

Antes de enchufar la herramienta,

compruebe que la tensión y la frecuencia

de red, indicadas en la placa de identificación,

se corresponden con las de la red eléctrica.

Para garantizar una sujeción segura del

portabrocas: después de la primera

perforación (giro a la derecha), apriete de nuevo

con fuerza el tornillo de seguridad que hay en el

interior del portabrocas con ayuda de un

destornillador. Atención, rosca a la izquierda.

(véase el capítulo 6.8)

5.1 Montaje de la empuñadura

complementaria

Por razones de seguridad, utilice

siempre la empuñadura complementaria

suministrada.

Abrir el anillo elástico girando hacia la izquierda la

empuñadura complementaria (5) Deslizar la

empuñadura complementaria en el cuello de

sujeción de la máquina Insertar el tope de

profundidad de perforación (4) Apretar con firmeza

16

la empuñadura complementaria en el ángulo

deseado después de cada uso.

6. Manejo

6.1 Ajuste del tope de profundidad de

taladrado

Soltar la empuñadura complementaria (5) Ajustar el

tope de profundidad de perforación (4)a la

profundidad deseada y apretar de nuevo la

empuñadura complementaria

6.2 Conexión y desconexión

Pulsar el interruptor (9)de la herramienta para

ponerla en marcha.

El número de revoluciones puede modificarse

presionando el interruptor.

Para un funcionamiento continuado puede

bloquearse el interruptor con el botón de retención

(8). Para parar la herramienta, pulsar el interruptor

de nuevo.

En la posición de funcionamiento

continuado, la máquina seguirá

funcionando en caso de pérdida del control de

la herramienta debido a un tirón. Por este

motivo se deben sujetar las empuñaduras

siempre con ambas manos, adoptar una buena

postura y trabajar sin distraerse.

6.3 Preselección del número de

revoluciones

Preajustar el número de revoluciones en la

ruedecilla de ajuste (10). Véase la página 4 para

obtener información sobre los números de

revoluciones para taladrar.

6.4 Conmutación entre taladrado/taladrado

con percusión

Seleccionar el modo de funcionamiento deseado

desplazando el relé neumático (7).

Taladrado

Taladrado con percusión

Al taladrar con percusión, trabajar con números de

revoluciones elevados.

Taladrado y taladrado con percusión sólo

con giro a la derecha.

6.5 Selección del sentido de giro

Pulsar el conmutador de giro (6)

solamente durante el estado de parada

del motor.

Selección del sentido de giro

R = giro a la derecha

L = giro a la izquierda

El portabrocas debe atornillarse con

fuerza sobre el husillo, y el tornillo de

seguridad que hay en el interior del

portabrocas debe apretarse con firmeza con

ayuda de un destornillador. (Atención, rosca a

la izquierda).

Page 17

De lo contrario podría soltarse al rotar a la

izquierda (por ejemplo, al atornillar).

6.6 Cambio de herramienta

Portabrocas de sujeción rápida

Futuro Plus (3)

Véanse las imágenes, página 2.

Colocación de la herramienta. Sujetar el anillo de

retención (a) y con la otra mano girar el casquillo (b)

en dirección "GRIP, ZU" hasta notar que se ha

superado el mecanismo de resistencia.

¡Atención! La herramienta no está todavía

tensada Seguir girando con fuerza (debe hacer

"clic"), hasta el tope. Ahora sí está tensada la

herramienta de forma segura.

Con un vástago blando de la herramienta debe

tensarse si fuera necesario tras un periodo de

perforación.

Abrir el portabrocas:

Sujete el anillo de retención (a) y con la otra mano

girar el casquillo (b) en la dirección "AUF,

RELEASE".

Advertencia: el sonido de carraca que

posiblemente se oiga después de abrir el

portabrocas (según la función) se elimina girando el

manguito en sentido inverso.

Si el portabrocas está demasiado apretado: extraer

el cable del enchufe. Sujetar el portabrocas con una

llave de boca en la cabeza del portabrocas y girar

con fuerza el casquillo (b) en la dirección "AUF,

RELEASE".

6.7 Cambio de herramienta

portabrocas de corona dentada (2)

Véanse las imágenes, página 2.

Sujetar la herramienta:

Insertar la herramienta y fijarla con la llave para

portabrocas (1) ejerciendo la misma presión en los

3 agujeros.

Retirar la herramienta:

Abrir el portabrocas de corona dentada (2) con una

llave para portabrocas (1) y retirar la herramienta.

6.8 Cómo retirar el portabrocas

Para atornillar puede desatornillarse el

portabrocas. Colocar la punta de destornillador

directamente en el hexágono interior del husillo.

Si el manguito de sujeción de puntas de

destornillador está montado

pedido 6.31281),

mantiene.

la punta de destornillador se

(como accesorio: n.º de

Portabrocas de sujeción rápida Futuro Plus

Ver página 4, imagen A.

Desenroscar el tornillo de seguridad (en caso de

que haya uno). Atención, rosca a la izquierda.

Sujetar el husillo de taladrar con una llave de boca.

Aflojar y desatornillar el portabrocas aplicando un

ligero golpe con un martillo de goma en una llave

hexagonal tensada.

Portabrocas de corona dentada

Ver página 4, imagen B.

ESPAÑOL es

Desenroscar el tornillo de seguridad (en caso de

que haya uno). Atención, rosca a la izquierda.

Sujetar el husillo de taladrar con una llave de boca.

Aflojar y desatornillar el portabrocas aplicando un

ligero golpe con un martillo de goma en una llave

para portabrocas insertada.

7. Mantenimiento

Limpieza del portabrocas de sujeción rápida:

Después de un uso prolongado mantenga el

portabrocas con la abertura perpendicular hacia

abajo y ábralo y ciérrelo completamente varias

veces. El polvo acumulado sale por el orificio: Se

recomienda el uso regular de s pra ys de l impie za e n

las mordazas de sujeción y los orificios de que

constan.

f

8. Accesorios

Utilice únicamente accesorios Metabo originales.

Utilice únicamente accesorios que cumplan con los

requerimientos y los datos indicados en estas indicaciones de funcionamiento.

Montar accesorios de manera segura. En caso de

usar la máquina en un soporte: montar la máquina

de manera fija. El usuario puede resultar herido por

la pérdida del control de la herramienta.

Programa completo de accesorios disponible en

www.metabo.com o en el catálogo principal.

9. Reparación

Las reparaciones de herramientas eléctricas

SOLAMENTE deben ser efectuadas por

electricistas especializados

En caso de tener herramientas eléctricas que

necesiten ser reparadas, diríjase, por favor, a su

representante de Metabo. En la página

www.metabo.com encontrará las direcciones

necesarias.

En la página web www.metabo.com puede

descargar listas de repuestos.

10. Protección ecológica

Cumpla lo estipulado por las normativas nacionales

relativas a la gestión ecológica de los residuos y al

reciclaje de herramientas, embalaje y accesorios

usados.

11. Especificaciones técnicas

Notas explicativas sobre la información de la

página 3.

Nos reservamos el derecho a efectuar

modificaciones conforme al avance técnico.

P

=Potencia de entrada nominal

1

P

=Potencia suministrada

2

n

=Número de revoluciones en marcha en

0

vacío

17

Page 18

ESPAÑOLes

n

=Número de revoluciones con carga

1

ø max = Diámetro máximo de perforación

s max =Número máximo de percusiones

G =Rosca del husillo de taladrar

H = Husillo de taladrar con hexágono interior

m=Peso sin cable a la red

D = Diámetro cuello de sujeción

Las especificaciones técnicas aquí indicadas se

entienden dentro de determinadas tolerancias

(conformes a las normas que rigen actualmente).

nominal

¡Use auriculares protectores!

18

Page 19

Page 20

170 27 2330 - 0715

Metabowerke GmbH

Metabo-Allee 1

72622 Nuertingen

Germany

www.metabo.com

Loading...

Loading...