Metabo BS 14.4 LTX Impuls, BS 18 LTX-X3 Quick, BS 18 LTX, SB 14.4 LTX Impuls, BS 18 LTX Impuls Operating Instructions Manual

...

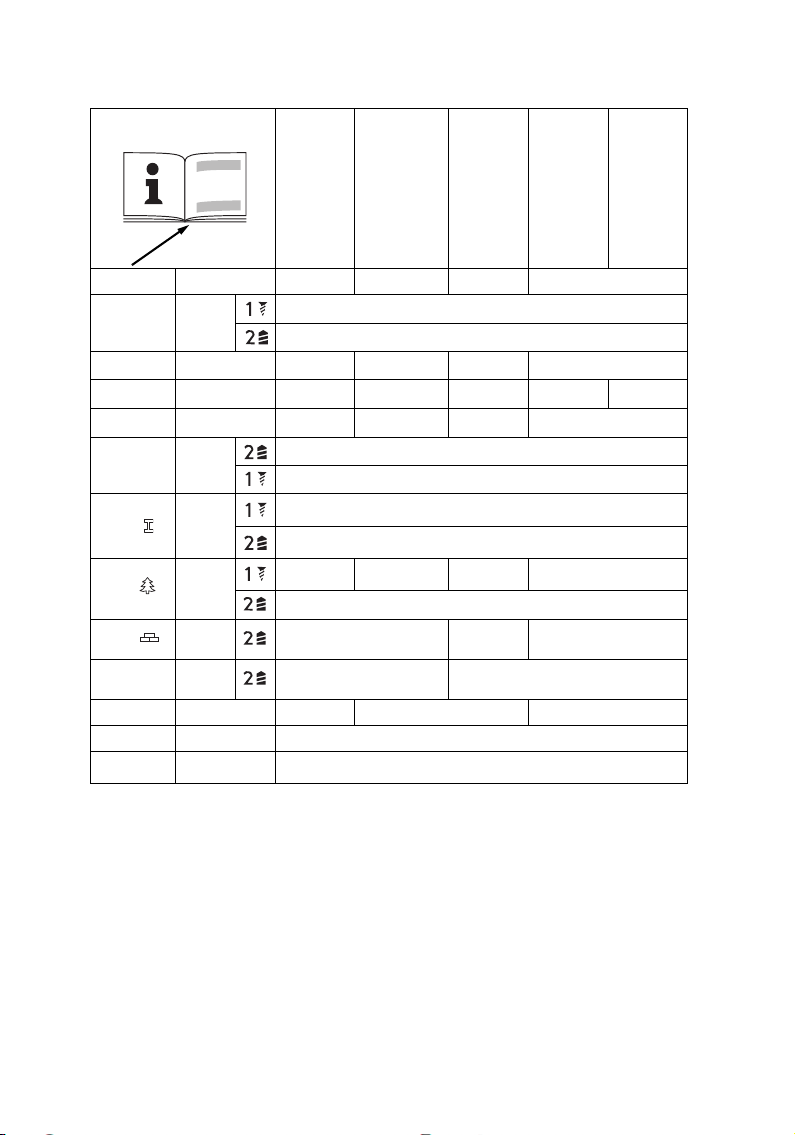

BS 14.4 LTX Impuls

BS 18 LTX

BS 18 LTX Quick

BS 18 LTX Impuls

BS 18 LTX-X3 Quick

SB 14.4 LTX Impuls

SB 18 LTX

SB 18 LTX Impuls

Operating Instructions........... page

Mode d’emploi ......................page

Instrucciones de manejo .... página

170 27 1000 - 0113

5

11

18

BS 18 LTX

13

BS 18 LTX Quick

BS 14.4 LTX Impuls

BS 18 LTX Impuls

SB 14.4 LTX Impuls

BS 18 LTX-X3 Quick

SB 18 LTX

UV 14,4 18 14,4 18

n

M

M

M

M

D

D

D

s

0

1

2

3

4

1 max

2 max

3 max

/min,

rpm

Nm (in-lbs)

Nm (in-lbs)

Nm (in-lbs)

Nm

(in-lbs)

mm

(in)

mm

(in)

mm

(in)

/min,

bpm

38 (336) 42 (372) 40 (354) 44 (389)

42 (372) - / 46 (407) 44 (389) - 48 (425)

88 (779) 96 (850) 92 (814) 100 (885)

45 (1

25

/32) 50 (1

31

-

- 28000

0 - 400

0 - 1400

1,5 - 3,5 (13 - 31)

3,5 - 13 (31 - 114)

1

13 (

/2)

5

/16)

8 (

/32) 45 (1

25

25 (1)

1

13 (

/2)16 (

/32)50 (1

31

5

/8)

m kg (lbs) 1,9 (4.2) 2,0 (4.4) 2,1 (4.6)

G UNF(in) 1/2“ - 20 UNF

D

max

mm (in)

13 (

1

/2)

SB 18 LTX Impuls

/32)

© 2011

Metabowerke GmbH,

Postfach 1229

Metabo-Allee 1

D-72622 Nürtingen

Germany

2

0

1

L

R

0

0

1

L

R

0

1234

5

6

7

8

9

10

11

12

13

24

5

6

7

8

9

10

11

12

13

SB...

BS...

1...

1...

3

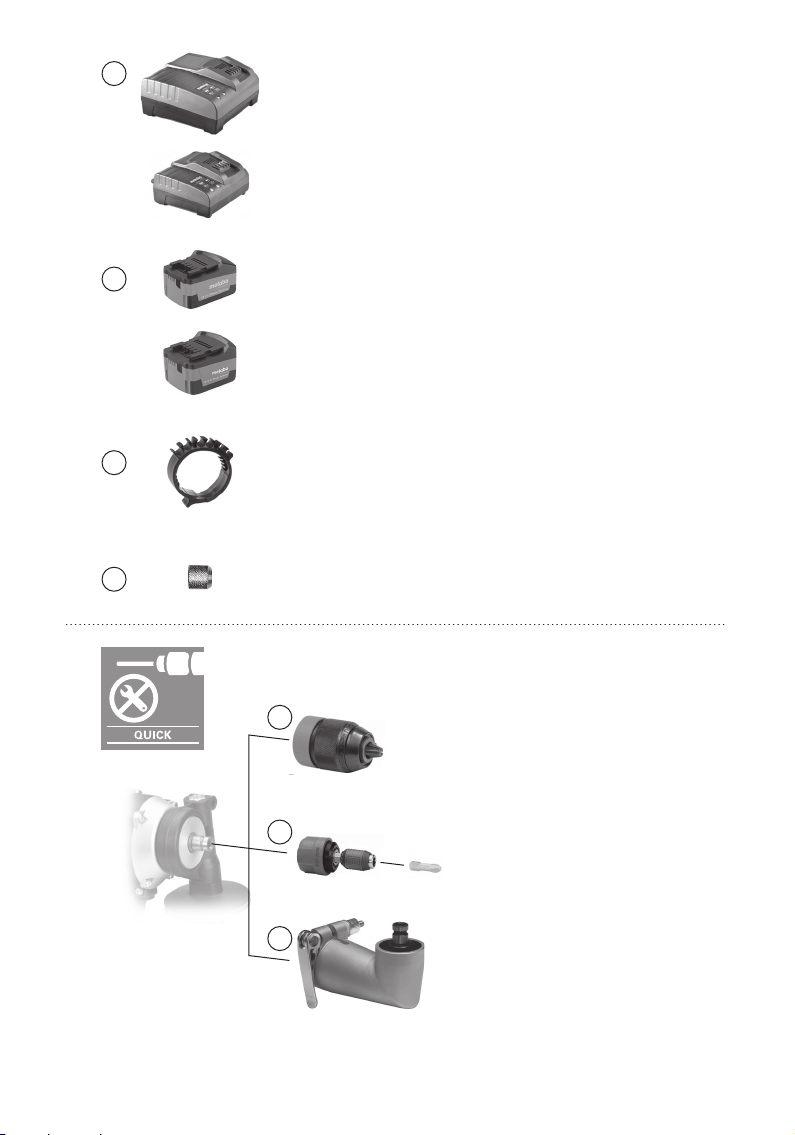

A

ASC 15

ASC 30

B

18 V 3,0 Ah 6.25455 Li-Power Extreme

18 V 4,0 Ah 6.25527 Li-Power Extreme

14,4 V 3,0 Ah 6.25454 Li-Power Extreme

14,4 V 4,0 Ah 6.25526 Li-Power Extreme

C

D

BS 18 LTX Quick:

343396590

6.31281

E

6.27240

F

6.27241

G

6.27242

4

ENGLISH

ENG

Operating Instructions

Dear Customer,

Thank you for the trust you have placed in us by buying a Metabo power tool. Each Metabo power tool

is carefully tested and subject to strict quality controls by Metabo's quality assurance. Nevertheless, the

service life of a power tool depends to a great extent on you. Please observe the information contained

in these instructions and the enclosed documentation. The more carefully you treat your Metabo power

tool, the longer it will provide dependable service.

Contents

1 Specified Conditions of Use

2 General Safety Instructions

3 Special Safety Instructions

4Overview

5 Special Product Features

6 Commissioning

7Use

8 Maintenance, cleaning

9 Tips and Tricks

10 Accessories

11 Repairs

12 Environmental Protection

13 Technical Specifications

1 Specified Use

The cordless drill/driver is suitable for drilling,

screwing and thread tapping as well as impact

drilling (depending on the model).

The user bears sole responsibility for damage

caused by improper use.

Generally accepted accident prevention regulations and the enclosed safety information must be

observed.

2 General Safety Instructions

WARNING

user must read instruction manual.

General Power Tool Safety Warnings

WARNING

all instructions.

ings and instructions may result in electric shock,

fire and/or serious injury.

instructions for future reference!

"power tool" in the warnings refers to your mainsoperated (corded) power tool or battery-operated

(cordless) power tool.

– To reduce the risk of injury,

For your own protection and for the

protection of your power tool pay attention to all parts of the text that are

marked with this symbol!

Read all safety warnings and

Failure to follow the warn-

Save all warnings and

The term

1) Work area safety

a)

Keep work area clean and well lit. Cluttered

or dark areas invite accidents.

b)

Do not operate power tools in explosive

atmospheres, such as in the presence of

flammable liquids, gases or dust.

tools create sparks which may ignite the dust

or fumes.

c)

Keep children and bystanders away while

operating a power tool.

cause you to lose control.

2) Electrical safety

a)

Power tool plugs must match the outlet.

Never modify the plug in any way. Do not

use any adapter plugs with earthed

(grounded) power tools.

and matching outlets will reduce risk of electric shock.

b)

Avoid body contact with earthed or

grounded surfaces, such as pipes, radiators, ranges and refrigerators.

increased risk of electric shock if your body is

earthed or grounded.

c)

Do not expose power tools to rain or wet

conditions.

increase the risk of electric shock.

d)

Do not abuse the cord. Never use the cord

for carrying, pulling or unplugging the

power tool. Keep cord away from heat, oil,

sharp edges or moving parts.

entangled cords increase the risk of electric

shock.

e)

When operating a power tool outdoors, use

an extension cord suitable for outdoor use.

Use of a cord suitable for outdoor use reduces

the risk of electric shock.

f)

If operating a power tool in a damp location

is unavoidable, use a residual current

device (RCD) protected supply.

RCD reduces the risk of electric shock.

3) Personal safety

a)

Stay alert, watch what you are doing and

use common sense when operating a

power tool. Do not use a power tool while

you are tired or under the influence of

drugs, alcohol or medication.

Water entering a power tool will

Distractions can

Unmodified plugs

There is an

Damaged or

Use of an

A moment of

Power

5

ENG

ENGLISH

inattention while operating power tools may

result in serious personal injury.

b)

Use personal protective equipment.

Always wear eye protection.

equipment such as dust mask, non-skid safety

shoes, hard hat, or hearing protection used for

appropriate conditions will reduce personal

injuries.

c)

Prevent unintentional starting. Ensure the

switch is in the off-position before

connecting to power source and/or battery

pack, picking up or carrying the tool.

Carrying power tools with your finger on the

switch or energising power tools that have the

switch on invites accidents.

d)

Remove any adjusting key or wrench

before turning the power tool on.

or a key left attached to a rotating part of the

power tool may result in personal injury.

e)

Do not overreach. Keep proper footing and

balance at all times.

control of the power tool in unexpected

situations.

f)

Dress properly. Do not wear loose clothing

or jewellery. Keep your hair, clothing and

gloves away from moving parts.

clothes, jewellery or long hair can be caught in

moving parts.

g)

If devices are provided for the connection

of dust extraction and collection facilities,

ensure these are connected and properly

Use of dust collection can reduce

used.

dust-related hazards

4) Power tool use and care

a)

Do not force the power tool. Use the

correct power tool for your application.

correct power tool will do the job better and

safer at the rate for which it was designed.

b)

Do not use the power tool if the switch

does not turn it on and off.

that cannot be controlled with the switch is

dangerous and must be repaired.

c)

Disconnect the plug from the power

source and/or the battery pack from the

power tool before making any adjustments,

changing accessories, or storing power

Such preventive safety mea ures reduce

tools.

the risk of starting the power tool accidentally.

d)

Store idle power tools out of the reach

of children and do not allow persons

unfamiliar with the power tool or these

instructions to operate the power tool.

Power tools are dangerous in the hands of

untrained users.

e)

Maintain power tools. Check for misalignment or binding of moving parts, breakage

of parts and any other condition that may

affect the power tool's operation. If

Protective

A wrench

This enables better

Loose

Any power tool

damaged, have the power tool repaired

before use.

poorly maintained power tools.

f)

Keep cutting tools sharp and clean.

Properly maintained cutting tools with sharp

cutting edges are less likely to bind and are

easier to control.

g)

Use the power tool, accessories and tool

bits etc. in accordance with these instructions, taking into account the working

conditions and the work to be performed.

Use of the power tool for operations different

from those intended could result in a

hazardous situation.

5) Battery tool use and care

a)

Ensure the switch is in the off position

before inserting battery pack.

battery pack into power tools that have the

switch on invites accidents.

b)

Recharge only with the charger specified

by the manufacturer.

able for one type of battery pack may create

a risk of fire when used with another battery

pack.

c)

Use power tools only with specifically

designated battery packs.

battery packs may create a risk of injury and

fire.

d)

When battery pack is not in use, keep it

away from other metal objects like paperclips, coins, keys, nails, screws, or other

small metal objects that can make a

connection from one terminal to another.

Shorting the battery terminals together may

The

cause burns or a fire.

e)

Under abusive conditions, liquid may be

ejected from the battery; avoid contact. If

contact accidentally occurs, flush with

water. If liquid contacts eyes, additionally

seek medical help.

battery may cause irritation or burns.

6

) Service

a)

Have your power tool serviced by a

qualified repair person using only identical

replacement parts.

safety of the power tool is maintained.

Many accidents are caused by

A charger that is suit-

Liquid ejected from the

This will ensure that the

3 Special Safety Instructions

Wear ear protectors with impact drills.

sure to noise can cause hearing loss.

Use auxiliary handles supplied with the tool

(depending on the model).

cause personal injury.

Hold power tools by insulated gripping

surfaces when performing an operation where

Loss of control can

Inserting the

Use of any other

Expo-

6

ENGLISH

ENG

the cutting tool may contact hidden wiring or its

own cord

exposed metal parts of the tool „live“ and shock

the operator.

Ensure that the spot where you wish to work is

free of

(e.g. using a metal detector).

Do not use faulty or deformed battery packs!

Do not open battery packs!

Do not touch or short-circuit battery packs!

out and comes into contact with your eyes, wash

them with clean water and seek medical treatment

immediately.

Dust from material such as paint containing lead,

some wood species, minerals and metal may be

harmful. Contact with or inhalation of the dust may

cause allergic reactions and/or respiratory

diseases to the operator or bystanders.

Certain kinds of dust are classified as carcinogenic

such as oak and beech dust especially in conjunction with additives for wood conditioning (chromate, wood preservative). Material containing

asbestos must only be treated by specialists.

- Where the use of a dust extraction device is

- The work place must be well ventilated.

- The use of a dust mask of filter class P2 is

Follow national requirements for the materials you

want to work with.

Secure the workpiece against slipping, e.g. with

the help of clamping devices.

LED (12): Do not view LEDs directly through optical

instruments, LED class 1M, classified as per DIN

EN 60825-1: 2003, wavelength: 400-700 nm;

300 µs.

SYMBOLS

V ............ volts

n

../min ...... revolutions per minute

rpm ........ revolutions per minute

. Contact with a "live" wire will make

power cables, gas lines or water pipes

Protect battery packs from water and

moisture!

Do not expose battery packs to naked

flame!

Slightly acidic, flammable fluid may leak

from defective Li-ion battery packs!

If battery fluid leaks out and comes into

contact with your skin, rinse immediately

with plenty of water. If battery fluid leaks

possible it shall be used.

recommended.

....... direct current

0...............

rated speed

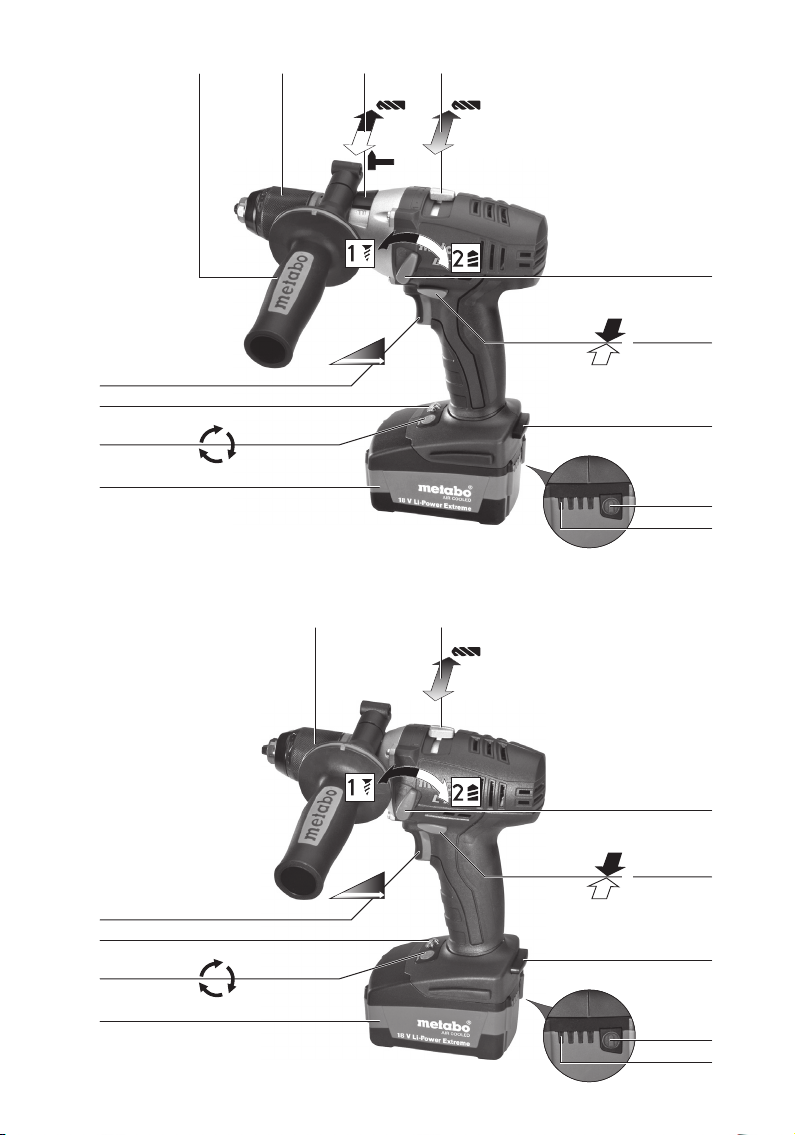

4Overview

See page 3.

1

Additional handle

2

Keyless chuck

3

Slide switch (drilling/impact drilling) *

4

Slide switch (torque control, drilling)

5 Switch

6R

7B

8 Capacity indicator button

9 Capacity and signal indicator

10

11 Button

12 LED lights

13 T

* depending on model

(1st/2nd gear) - both sides of the

machine

otation selector switch (rotation setting,

transport lock) - both sides of the machine

attery pack release button

Battery pack

for pulse function *

rigger

5 Special Product Features

•Metabo "Quick" (depending on features): rapid

replacement of the tool attachment and the tool

- e.g. allowing you to switch from drilling to

driving screws in a matter of seconds.

• Torque clutch with precise electronic cut-off

system ensures that the machine has an

extremely long service life.

• Metabo pulse function (depending on the

model)

Optional pulse mode for precise fastening and

convenient drilling.

• Electronic single-cell monitor that extends the

service life of the battery pack.

• Electronic overload protector with integral

temperature monitor protects the machine and

the battery pack.

• Torque coupling for a broader range of applica-

tions.

• Hexagon socket holder in the spindle for a

shorter, more lightweight machine.

• Spanner flat for easy chuck changes, even if the

chuck is overtightened.

6 Commissioning

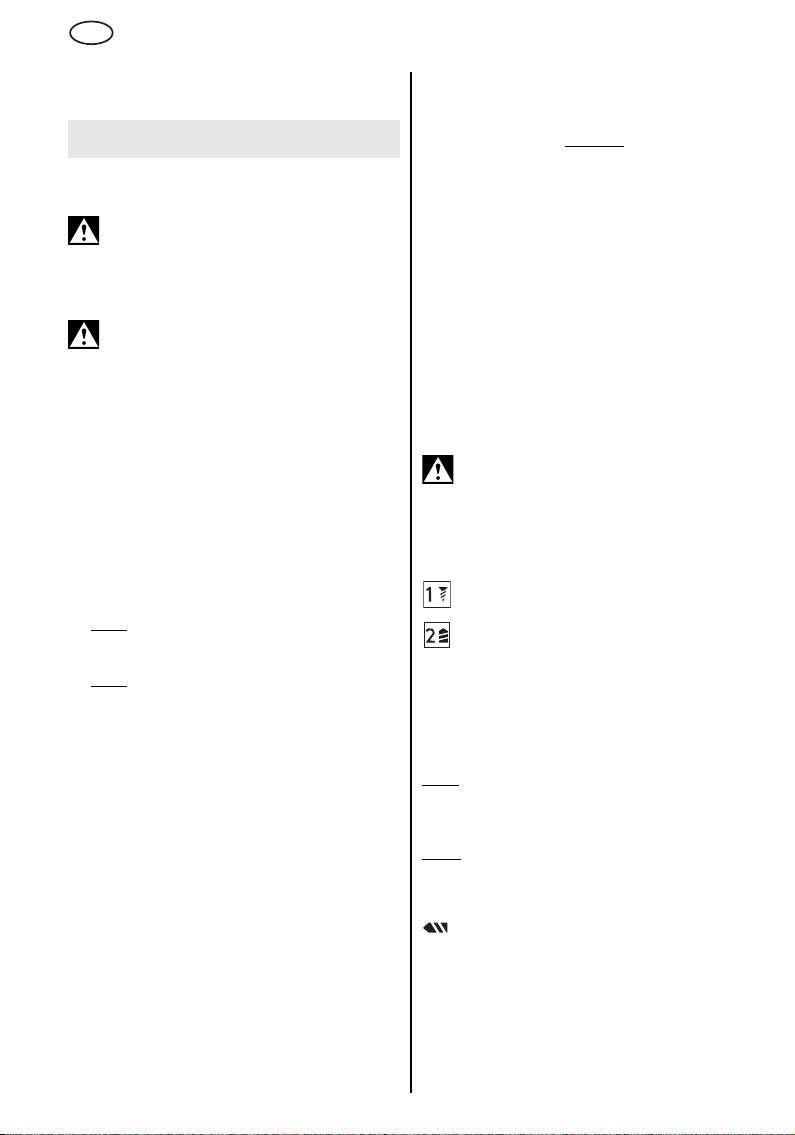

6.1 Assembly of additional handle (1)

(depending on the model)

For safety reasons, always use the additional

handle supplied.

Open the clamping ring by turning the additional

handle (1) anticlockwise. Push the additional

handle onto the collar of the machine. Securely

7

ENG

ENGLISH

tighten the additional handle at the angle required

for the application.

7Use

7.1 Automatic protection mode

If the machine switches off automatically, the

machine electronics have activated automatic protection mode. A warning signal sounds

(continuous beeping). The beeping stops after a

maximum of 30 seconds or when the trigger is

released (13).

In spite of this protective function, over-

loading is still possible with certain applications and can result in damage to the

machine.

Causes and remedies:

1.

Battery pack almost flat

prevent the battery pack from discharging

totally and avoid irreparable damage).

If one LED is flashing (9), the battery pack is

almost flat. If necessary, press the (8) button

and check the LEDs (9) to see the charge level.

If the battery pack is almost flat, it must be

recharged.

2. Long continuous overloading of the machine

will activate the

Leave the machine or battery pack to cool.

Note: If the battery pack feels very warm, the

pack will cool more quickly in your "AIR

COOLED" charger.

The machine will cool more quickly if you

Note:

operate it at idling speed.

current is too high

3. If the

machine seizes continuously for long periods),

the machine switches off.

Switch off the machine at the trigger (13). Then

continue working as normal. Try to prevent the

machine from seizing.

7.2 Battery pack

Charge the battery pack before use (10).

If performance diminishes, recharge the

battery pack.

"Li-Power" li-ion battery packs have a

capacity and signal indicator: (9)

- Press the (8) button, the LEDs indicate the

charge level.

- If one LED is flashing, the battery pack is almost

flat and must be recharged.

temperature cut-out

(the electronics

.

(for example, if the

7.3 Removing and inserting the battery pack

Removal:

Press the battery pack release (7) button and pull

the battery pack

Inserting:

Slide in the battery pack

7.4 Setting the direction of rotation,

engaging the transporting safety device

(switch-on lock)

Set the rotation selector switch (6).

See page 3 (please unfold).

R = Clockwise setting

L = Counter-clockwise setting

0 = Central position: transport lock setting

(switch-on lock)

7.5 Selecting gear stage

Do not actuate the switch

motor has stopped completely!

If the switch

however, press the trigger (13) slightly so that the

motor rotates slowly. It will then be possible to turn

the switch

Press the switch (5) (left or right of the machine).

1st gear setting (low speed), very high torque

2nd gear setting (high speed)

7.6 Setting the torque limit

Press the slide switch (4).

1... = Torque setting (for working with torque

Note: the torque can be adjusted to different

Note: Once the set torque has been reached,

= Drill setting - no torque control

7.7 Drilling and impact drilling

(depending on the model)

Press the slide switch (3).

(10)

forwards.

(10)

until it engages.

(5)

unless the

(5)

cannot be turned up to the stop,

(5)

all the way up to the stop.

control)

settings depending on the gear selected!

In 2nd gear from 1.5 to 3.5 Nm and in 1st

gear from 3.5 to 12.5 Nm.

the screwdriver clutch emits a rattling

noise and the machine is automatically

switched off.

(for max. torque)

8

ENGLISH

AUF, RELEASE

2

GRIP, ZU

b

a

2

c b

a

ENG

= Impact drilling

Note:

Always work at high speeds

when impact drilling.

= Normal drilling without impact

7.8 Activating the pulse function

(depending on the model)

Do not work for long periods with pulse function switched on! (The motor can overheat.)

Press the button (11) to activate or deactivate

the pulse function.

The button (11) flashes when the pulse function is

active.

If the machine is not used for approx.

Note:

5 minutes, the pulse function switches off automatically and the flashing button (11) goes out.

7.9 On/Off switch, setting the speed

Switching on, speed:

rotational speed can be changed at the

trigger switch by pressing.

Switching off:

noise that the machine makes when it

switches off is due to the design (quick stop)

and has no influence on the function or the

service life of the machine.

7.10 LED lights

For working on dimly lit areas. The LED lights (12)

light up when the machine is switched on.

press the trigger (13). The

Release the trigger (13). Note: The

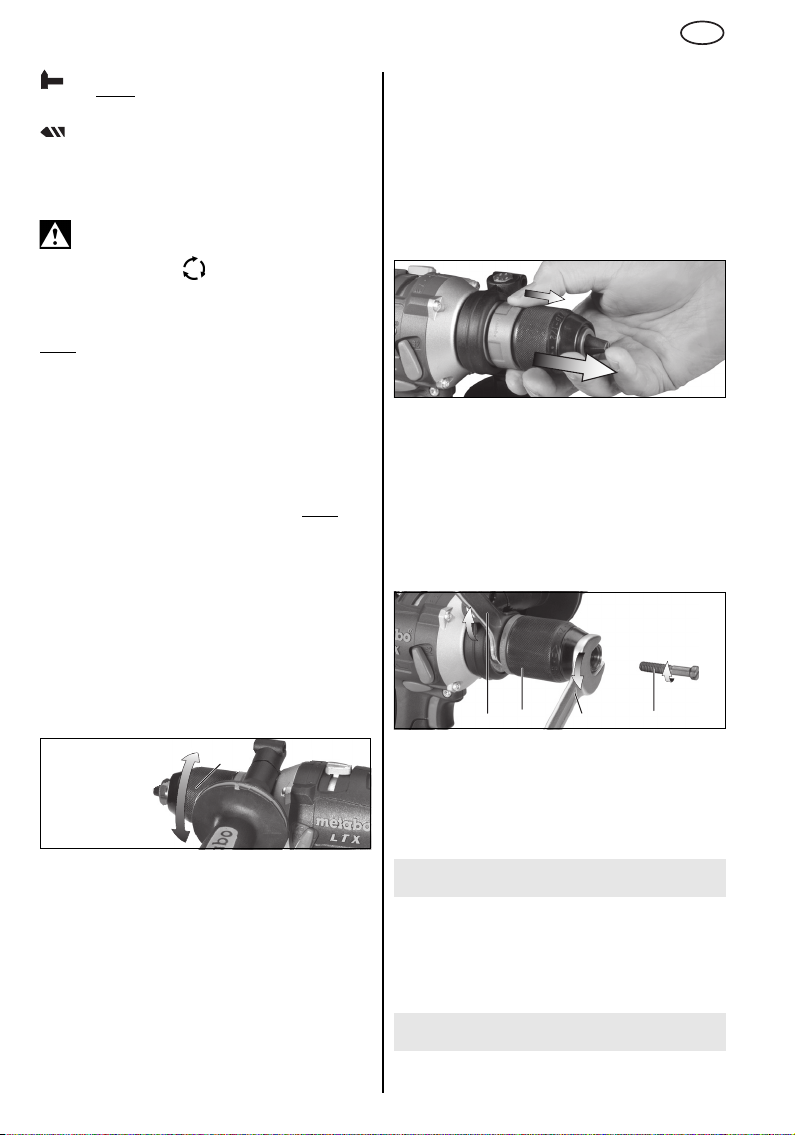

- Turn sleeve

noticeable mechanical resistance has been overcome.

-

Caution! The tool is not yet clamped!

turning the sleeve (

until it cannot be turned any further the tool

7.12 Chuck with Quick replacement

To remove:

advance and pull off the chuck (b).

To mount:

the chuck as far as the limit stop on the drill spindle.

7.13 Unscrewing the chuck

(2)

in direction "GRIP, ZU" until the

it must "click" when turning

securely

clamped.

system

(for BS 18 LTX Quick)

Push the interlock ring forward (a),

Push the interlock ring forward and move

(for BS 14.4 LTX Impuls, BS 18 LTX,

BS 18 LTX Impuls, SB14.4LTXImpuls,

SB 18 LTX, SB18LTX Impuls)

Keep

only now

is

)

7.11 Opening, tensioning the keyless chuck

Opening the chuck

Turn sleeve (2) in the direction "AUF,

RELEASE".

The grating sound which may be heard after

opening the drill chuck is functional and is

stopped by turning the sleeve (2) in the opposite direction.

Clamping the tool

- Open the keyless chuck and insert the tool as far

as possible.

- Open the keyless chuck.

- Slacken the screw (a) (note: left-handed thread!).

- Lock the spindle using a spanner (c) and

unscrew the keyless chuck

Employ the same procedure when attaching the

chuck, except in reverse order.

(2)

using spanner (b).

8 Maintenance, cleaning

From time to time, hold the machine vertically with

the chuck facing downwards and turn the sleeve

fully in the direction "GRIP, ZU" and then turn fully

in the direction "AUF, RELEASE". The dust

collected falls from the keyless chuck.

9

Tips and Tricks

Drilling

9

Loading...

Loading...