Page 1

Betriebsanleitung

Schweißgeräte mit stufenloser Regelung

Operating Instructions

Welding Transformers and Rectifiers

with Stepless Current Control

Instructions d'utilisation

Appareil de soudure avec réglage en continu

Handleiding

Lasapparaten met traploze instelling

SB 160 C / SB 200 CT

Achtung! Lesen Sie diese Anleitung vor der Installation und Inbetriebnahme aufmerksam durch.

Attention! Carefully read through these instructions prior to installation and commissioning.

Attention ! Prière de lire attentivement la présente notice avant l'installation et la mise en service.

Oppassen! Lees deze instructies voor de installatie en ingebruikname aandachtig door.

115 117 9491 / 2402 - 3.2 / de, en, fr, nl

Page 2

D DEUTSCH ENG ENGLISH

T

KONFORMITÄTSERKLÄRUNG DECLARATION OF CONFORMITY

Wir erklären in alleiniger Verantwortlichkeit, daß dieses Produkt mit

den folgenden Normen übereinstimmt* gemäß den Bestimmungen

der Richtlinien**.

F FRANÇAIS NL NEDERLANDS

DECLARATION DE CONFORMITE CONFORMITEITSVERKLARING

Nous déclarons, sous notre seule responsabilité, que ce produit est en

conformité avec les normes ou documents normatifs suivants* en

vertu des dispositions des directives **

IT ITALIANO ES ESPAÑOL

DICHIARAZIONE DI CONFORMITÀ DECLARACION DE CONFORMIDAD

Noi dichiariamo sotto la nostra esclusiva responsabilità che il presente

prodotto è conforme alle seguenti norme*. in conformità con le

disposizioni delle normative **

PT PORTUGUÊS SV SVENSKA

DECLARAÇÃO DE CONFORMIDADE

Declaramos sob nossa responsabilidade que este produto está de

acordo com as seguintes normas*.de acordo com as directrizes dos

regulamentos **

FIN SUOMI NO NORGE

VAATIMUKSENMUKAISUUSVAKUUTUS SAMSVARSERKLÆRING

Vakuutamme, että tämä tuote vastaa seuraavia normeja*.on

direktiivien määräysten mukainen**

We herewith declare in our sole responsibility that this product

complies with the following standards*

in accordance with the regulations of the undermentioned Directives**

Wij verklaren als enige verantwoordelijke, dat dit product in

overeenstemming is met de volgende normen*

conform de bepalingen van de richtlijnen**

Declaramos bajo nuestra exclusiva responsabilidad, que el presente

producto cumple con las siguientes normas*.de acuerdo a lo

dispuesto en las directrices**

FÖRSÄKRAN OM ÖVERENSSTÄMMELSE

Vi försäkrar på eget ansvar att denna produkt överensstämmer med

följande standarder*. Enligt bestämmelserna i direktiven**

Vi erklærer under eget ansvar at dette produkt samsvarer med

følgende normer*. henhold til bestemmelsene i direktiv**

DA DANSK POL POLSKI

OVERENSSTEMMELSESATTEST OŚWIADCZENIE O ZGODNOŚCI

Hermed erklærer vi på eget ansvar, at dette produkt stemmer overens

ed følgende standarder*. iht. bestemmelserne i direktiverne**

EL ΕΛΛHNIKA HU MAGYAR

∆ΗΛΩΣΗ ΑΝΤΙΣΤΟΙΧΕΙΑΣ MEGEGYEZŐSÉGI NYILATKOZAT

∆ηλώνουµε µε ιδία ευθύνη ότι το προϊόν αυτό αντιστοιχεί στις

ακόλουθες προδιαγραφές*

σύµφωνα µε τις διατάξεις των οδηγιών**

Oświadczamy z pełną odpowiedzialnością, że niniejszy produkt

odpowiada wymogom następujących norm*.według ustaleń

wytycznych **

Kizárólagos felelősségünk tudatában ezennel igazoljuk, hogy ez a

termék kielégíti az alábbi szabványokban lefektetett

követelményeket*.megfelel az alábbi irányelvek előírásainak**

SB 160 C - SB 200 C

* EN 50060; EN 55014 (1993); DIN EN 61000-4-1 (1993), EN 60974-1

** 89/336/EWG, 73/23/EWG

Dipl. Ing. Jürgen Kusserow

Vorstand

ELEKTRA BECKUM AG – Daimlerstraße 1 – 49716 Meppen

Tel.: +49 59 33 80 20

1000965/ 00

Page 3

ENG

Contents

1 Specifications

2 Taking a Single-Phase Machine Into Operation

2.1 Taking a Combination 1-Ph/2-Ph Machine into Operation

3 General Information for Welding Transformer/Rectifier Operators

3.1 Overview of Stick Electrodes and their correct Use

3.1.1 Care of Stick Electrodes

3.1.2 Function of the Stick Electrode Coating

3.1.3 Classification of Stick Electrodes according to DIN 1913

3.1.4 Selecting Suitable Electrodes for a Welding Task

3.1.5 Arc Starting and Arc Burning

3.1.6 Welding Positions According to DIN 1921

4 Welding Hints

4.1 Weld Types

4.2 Weld Flaws and possible Causes - Shown on Fillet Welds

5 Accessories and Accessory Maintenance

6 Wiring Diagrams

You have bought a high-quality electric arc welding machine, designed and built by specialists with many years of

experience. A machine built to last, giving a long service life.

All models have the correct size power supply cable fitted, the transformer‘s core is made from top-quality insulated

sheet steel, to keep eddy currents and cyclic magnetization losses to an absolute minimum.

Please read the instructions given in the manual in order to fully utilize the potential of your machine.

Know and adhere to all local safety codes and regulations governing the operation of electric arc welding machines.

User Responsibility

The operation of the welding divice in the data processing system environment is not allowed!

This product shall only be used as specified. Any other use requires the written consent of Elektra Beckum AG,

P.O.Box 1352, D-49703 Meppen, Germany

Please contact your dealer for any warranty claims.

Warranty work will essentially be carried out by service centres authorised by us. Repairs beyond the warranty

period may be carried out only by our authorised service centres.

Please preserve all repair invoices! We reserve the right to make technical changes!

We recommend attending a welding course at a recognised technical institute.

1 Specifications

Model SB 160 C SB 200 CT SB 200 CT

Main voltage 230/400 V 240 V 230/400 V

Mains frequency 50/60 Hz 50 Hz 50/60 Hz

Welding steps stepless stepless stepless

Stepless at 230 V 32 - 38 V 47 - 55 V 31 - 39 V

Stepless at 400 V 38 - 46 V 41 - 50 V

Max. OCV at 230 V 16 A time-lag 32 A time-lag 16 A time-lag

Max. OCV at 400 V 16 A time-lag 20 A time-lag

Insulation class H H H

Protection class IP 21 IP 21 IP 21

Setting range, stepless 230 V 30 - 110 A 70 - 180 A 20 - 110 A

Setting range, stepless 400 V 65 - 155 A 60 - 180 A

Cooling self fan fan

Weldable electrodes at 230 V Ø 1.6 - 2.5 mm Ø 2,0 - 4,0 mm Ø 1.6 - 2.5 mm

Weldable electrodes at 400 V Ø 2.0 - 3.25 mm Ø 2.0 - 4.0 mm

2 Taking a Single-Phase Machine into Operation

This machine is to be connected to the power mains via a Earth Fault Circuit Interrupter of 30 mA capacity. Worn

or damaged power cables should be replaced immediately by a qualified electrician.

Do not operate this machine with a damaged power cable, danger of personal injury by electric shock.

Children are not permitted to operate this machine.

Connect to an earthed single-phase 230/240 V outlet, protected by a 16 A time-lag fuse. Operating other electric

machines or appliances on the same circuit while welding is only possible to a very limited extent and not

recommended.

Earth and welding cable are firmly attached to the machine.

Polarity does not matter with AC welding current.

13

Page 4

Attach earth clamp to the workpiece, close to the weld seam and on bare metal for good conduction.

Place stick electrode into the electrode holder.

With the handwheel select the desired welding current.

If there is not power outlet near the work area an extension cable is required. The cable's lead cross section must be

at least 2.5 mm2. Uncoil extension cable fully to prevent heatbuild-up by inductance. Inductance also conside-rably

reduces the welding current. Extension of the welding cables is also possible, but the cross section of the extension

cables must be larger than that of the cables supplied with the machine.

Every machine is protected against overloads by a thermo switch, which switches the power to the transformer off if it

becomes too hot. After a short cooling-down period the machine will switch back on automatically. Model SB 200 CT

is equipped with a fan for forced cooling, given better performance with a higher duty-cycle.

3 General Information for Welding Transformer/Rectifier Operators

Dust, dirt and metal chips will harm any welding machine. It is of particular importance that the air ventilation for

cooling is not obstructed.

A weld should join two work pieces as if they were made from a single piece. Prior to the welding the joints must

be cleaned and dirt, rust, grease and paint removed. Also slag from previous welds must be completely removed.

Attach earth clamp firmly to work piece, assuring good metal to metal contact. Check that all cables and

connectors are in proper operating condition to ensure proper current conduction.

Place electrode with the uncoated end into one of the electrode holder's notches. Each welding machine is

supplied complete with an accessory kit, comprising the welding cables, a welding visor and a slag hammer.

When removing slag it is recommended to protect the eyes by suitable means (goggles) from injury by sharp and

hot slag. The welding visor's dark glass plate protects the eye against ultra-violet and infrared rays. The clear

glass plate protects the dark plate against spatters and damage. The dark protective glass is available in different

shades for different types of electrodes and to suit different eye sensivity. Normally for electrodes from 1.5 mm

to 4 mm Ø protective glasses of shade DIN 9 are used, for electrode over 4 mm Ø shade DIN 10.

Select the correct welding current as shown below:

Current (A) Electrode Ø Material Thickness

25 - 50 1.0 - 2.0 mm 1.0 - 2.0 mm

50 - 100 2.0 - 2.5 mm 2.0 - 4.0 mm

100 - 140 2.5 - 3.25 mm 4.0 - 8.0 mm

140 - 220 3.25 - 5.0 mm 8.0 - 12.0 mm

220 - 300 5.0 - 6.0 mm 12.0 - 20.0 mm

In principle do not use too thick an electrode. As a general rule calculate 40 amps welding current per 1 mm of

electrode diameter. Depending on electrode type, material thickness and weld position this calculated value may

have to be adjusted to plus or minus. All machines work well with thin plate from 1.0 mm thickness.

3.1 Care of Stick Electrodes and their correct Use

In order to achieve a good weld the electrode has to be dry, thus storing in a dry place is essential- Should

electrodes have become moist, dry in an oven at between 200° C to 300° C for 30 minutes.

Basic coated low-hydrogen type electrodes always require pre-drying at 200° C to 300° C for 3 hours as atomic

hydrogen causes weld flaws.

The designation of welding electrodes is standardized by DIN 1913. The designation is stipulated by the

electrode manufacturers in accordance with the standard and checked by an inspection body. It is printed on

the electrode packet.

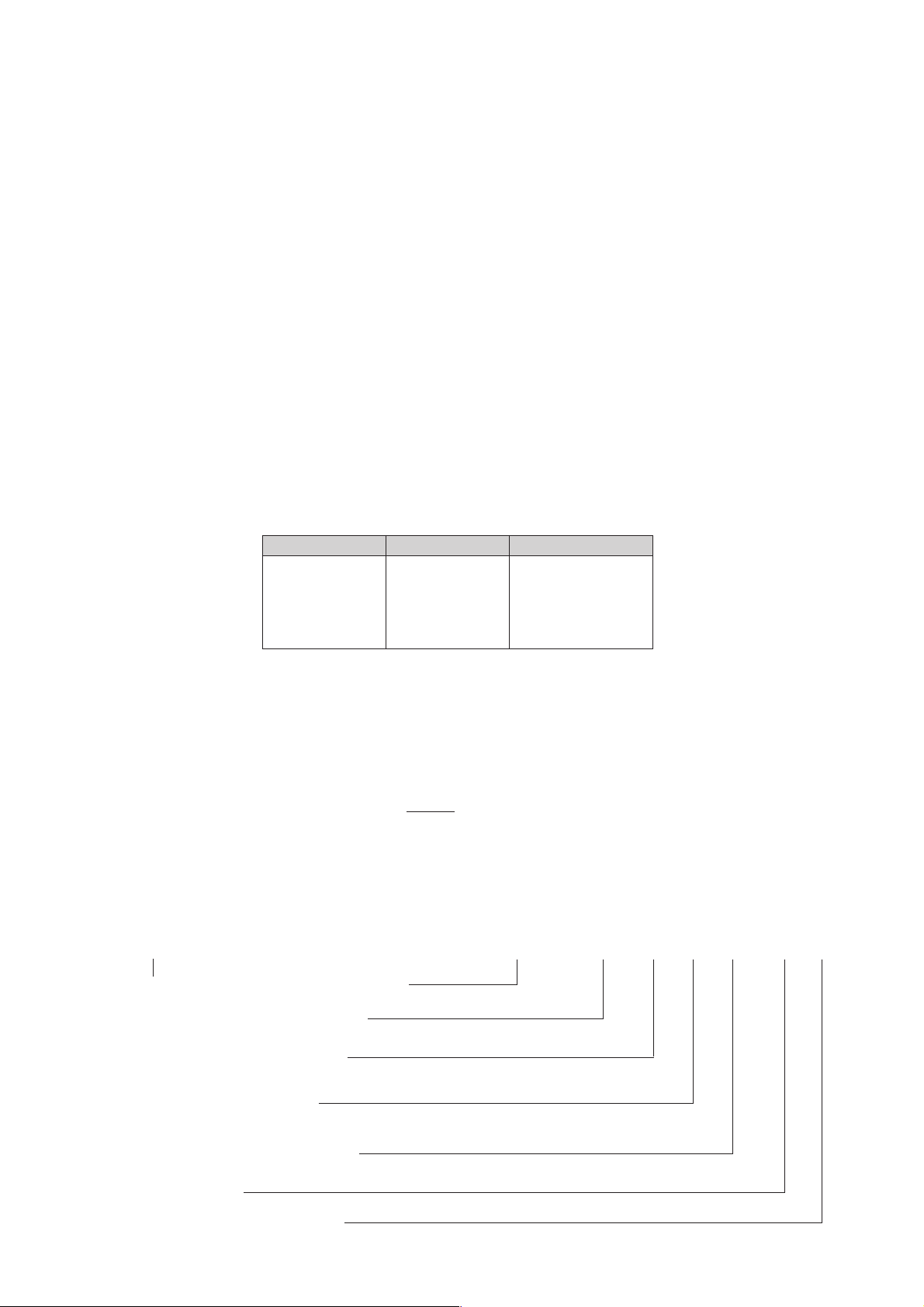

3.1.1Coding of Stick Electrodes according to DIN 1913

Example:

Stick electrode DIN 913 - E 43 3 2 AR 7

Type of electrode Number of DIN standard

Code for manual electric arc welding

Code number for tensile strength,

yield point and elongation

Code number for impact

engergy of 28 Joule minimum

Code number for increased impact

energy of 47 Joule minimum

Code for coating

Code number for electrode class

14

Page 5

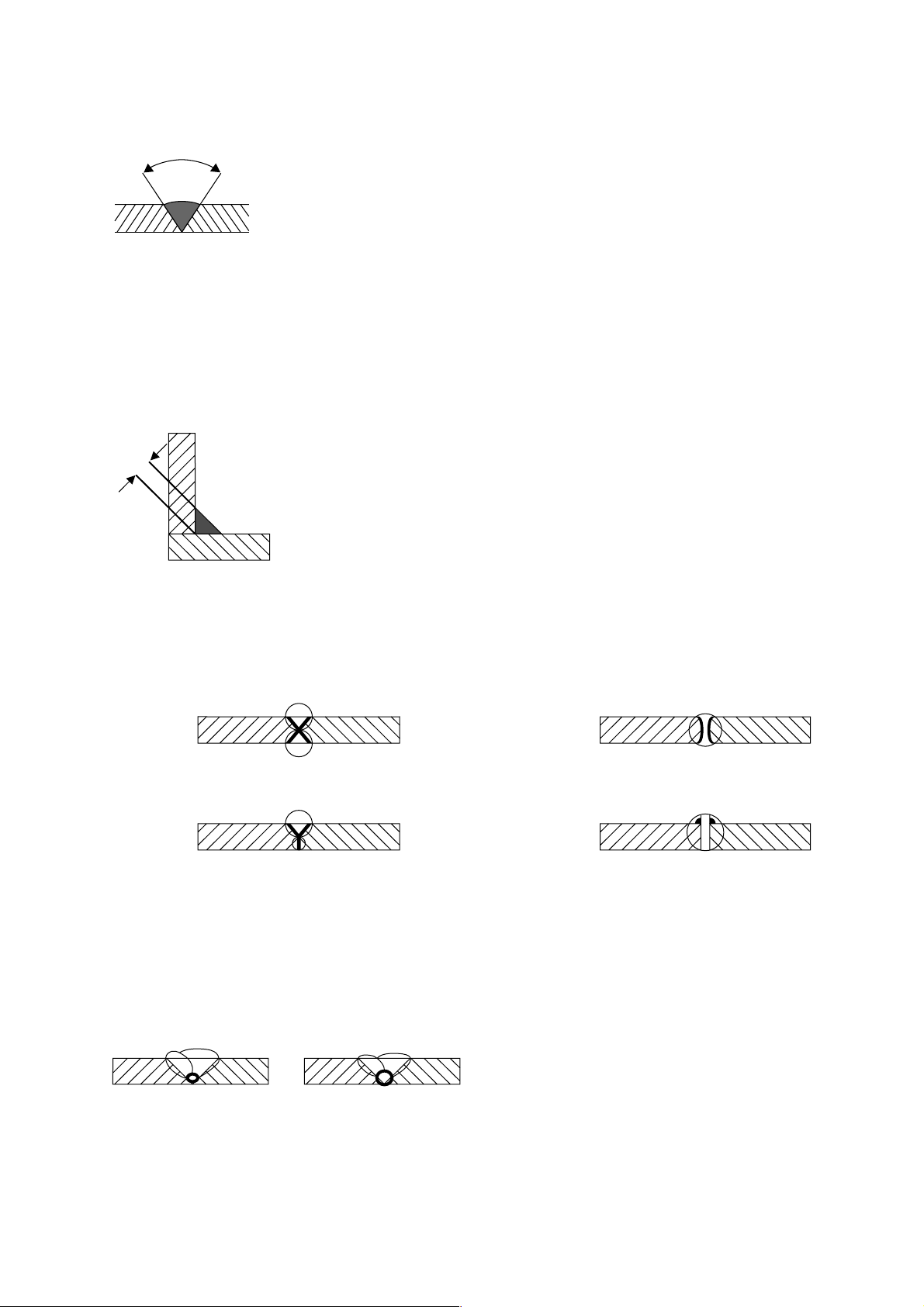

3.1.2Function of the Stick Electrode Coating

Stabilization of the

arc and lonization

of the arc space

bare

electrode

coated

electrode

unstable

arc

Protection of the weld

metal from atmospheric

oxygen and nitrogen

bare

electrode

This protection is achieved by the generation of shielding gases and slag during the

melting of the electrode.

Compensation of alloy burn-off.

Stick Electrodes According to DIN 1913

Coating thickness

D

d

stable

arc

coated

electrode

slag

DD

dd

shielding gas

Material transfer

Gap bridging ability

Weld seam appearance

Penetration depth

Types of Coating

A acid coated

R rutile light and medium coating

RR rutile heavy coating

AR rutile acid coating

C cellulose coating

light

D = 1.2 · d

medium

D > 1.2 · d

=

but < 1.55 · d

heavy

D > 1.55 · d

R(C) rutile cellulose medium coating

RR(C) rutile cellulose heavy coating

B basic coating

B(R) basic coating with non-basic proportions

RR(B) rutile basic heavy coating

15

Page 6

3.1.3Classification of Stick Electrodes

according to Table 3 of DIN 1913

Code for Welding Position

according to Table 4 of DIN 1913

Grade

2

3

4

5

6

7

8

9

10

11

12

Stick Electrode

Type

A 2

R 2

R 3

R(C) 3

C 4

RR 5

RR(C) 5

RR 6

RR(C) 6

A7

AR 7

RR(B) 7

RR 8

RR(B) 8

B 9

B(R) 9

B 10

R(R) 10

RR 11

AR 11

B 12

B(R) 12

Coating

Thickness

light

medium

heavy

(high-

performance

electrodes)

Weld

Position

1

2 (1)

1

2

1

2

1

2

1

2

4 (3)

Code Weld Position Code Letter For

Welding Position

1 all w, h, hü, s, f, q, ü

2 all except vertical-down w, h, hü, s, q, ü

3 gravity position w

fillet weld

gravity position w

horizontal h

4 gravity position w

3.1.4Selecting suitable Electrodes for a Welding Task

Component

Welding Task

out-of position

welding of butt and

fillet welds on thinwalled extrusion

horizontal or gravity

position fillet welds

on long beams with

"a" = 5 mm

gravity position

double-V welds on

thick plate tow bars

out-of-position fillet

welds on bracket of

10 mm thick plate

Stick Electrode Type

RR 6

RR 8

RR 11

AR 11

B 10

RR(B) 7

RR(B) 8

out-of-position butt

welds on pipelines

16

weld 1:

C 4

Page 7

Stick electrodes can be classified according to their coating as under:

Type Code

Type

Coating

Characteristics

O

Bare Electrode

finely distributed arc

stabilizers in the

electrode material

OO

Flux-Core Electrode

arc stabilizers rolled

into the electrode's

core

N

Titania Oxide Type

high contens of

titanium oxide

Acid-Coated Type

high contents of

heavy metal oxides

Type of Slag

Slag Removal Ability

minimal slag shallow

minimal slag average to deep

porous, even slag

blanket

easily removed

porous, even slag

blanket

Penetration Depth

Gap Bridging Ability

excellent

excellent

average

good to excellent,

depending on

coating thickness

deep

average

tion

more difficult to weld

than any other stick

electrode

slightly easier to

weld than bare

electrodes

weldability of fillet

welds improves with

increasing coating

thickness

weldability of fillet

welds improves with

increasing coating

thickness

very high deposition

rate, minimal heat

stress, little heat

distortion

good deposition

rate, minimal heat

stress, little weld

distorition,

especially for root

welds

general purpose

electrodes, for

steels sensitive to

welding conditions,

for thin plate

for steels sensitive

to welding

conditions, requires

good weld

preparation

Weld AppearanceCharacteristicsElectrode Manipula-

convex, coarsely

rippled

convex

coarsely rippled

slightly convex to

flat, finely to

medium-coarsely

rippled

flat, finely rippledEs

Ox

Iron Oxide Type

high contents of iron

oxides

Kb

Basic LowHydrogen Type

high contents of

calcium or other

alkaline carbonates

Ze

Cellulose Type

high contents of

organic components

tight slag blanket of

evenly distributed

thickness

very easily

thick slag blanket

fair

minimal, often

quickly solidifying

thin slag blanket

easy

shallow

very poor

medium

good

deep

very good

good weldability,

fillet welds in gravity

position only

handling requires

some practice, in

particular when

setting electrode to

and removing from

weld

good handling as

only minimal slag,

heavy fume

generation

for unalloyed lowcarbon steels,

requires good weld

preparation

particularly suitable

for thick plate and

rigid assemblies, for

high-carbon steels,

for thermo steels

for out-of-position

welding

concave, very finely

rippled

slightly convex,

medium-coarsely

rippled

slightly convex,

rippled

In addition to the electrodes types shown in the above table there are several special types available coded SO. Cast

iron electrodes, for example, fall into this class.

When buying Kb and So type electrodes make sure they are suitable for AC current. As far as the quality grades are

concerned, a higher number indicates a better grade quality. For common low-carbon steels grades 7 - 9 are best

suitable.

The last letter of the code shown on the stick electrode indicates the coating thickness.

d = light coating

m = medium coating

s = heavy coating

17

Page 8

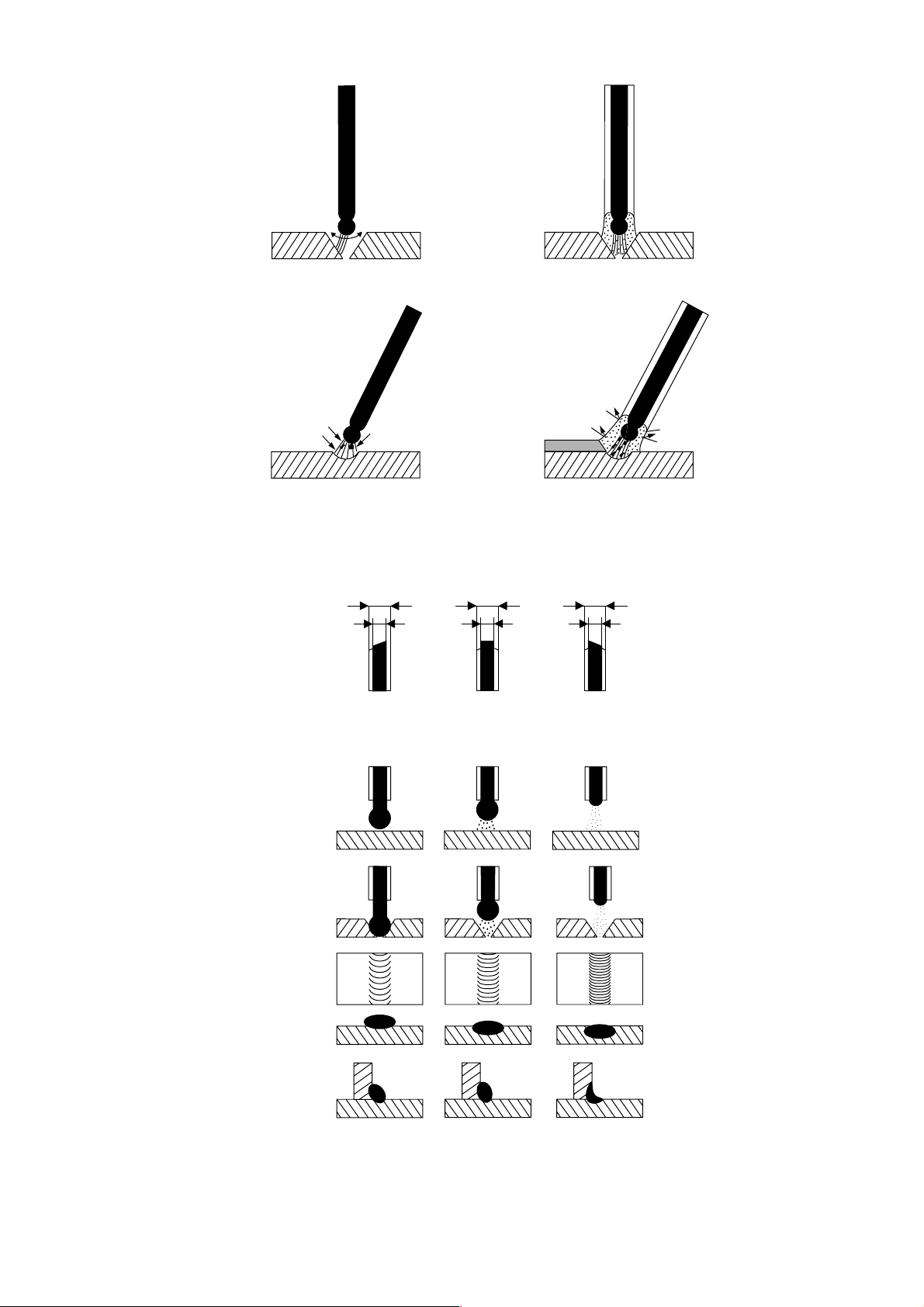

3.1.5Arc Starting and Arc Burning

Arc Strike

Always start the arc in the welding groove.

When the arc is stable weld over the arc strike and melt for good fusion, otherwise there is a risk of cracking.

Arc starting

sequence

d

wrong

arc strike

correct

arc strike

open-circuit voltage

Short-circuit voltage

3 to 5 V

working voltage

20 to 30 V

Arc Length

The arc length "a", that is the distance between the stick electrode and the work, should be:

with stick electrodes of coating type R, RR, A, C = 1.0xd,

with stick electrodes of coating type B = 0.5xd,

Too long an arc reduces the penetration, increases the arc blow effect and, particularly with basic coated stick

electrodes, causes a porous weld seam.

3.1.6Welding Positions According to DIN 1921

ww

a

w = gravity position

f

s

s = vertical-up position

f = vertical-down position

q

q = horizontal-vertical position

h

h = horizontal position

ü

ü = overhead position

18

Page 9

4 Welding Hints

Because of the multitude of and great differences in the important points for welding only the very basic

operations for the most common electrodes for low-carbon steels, the Ti-type electrode, are introduced here.

In the case that other electrodes have to be used, the electrode manufacturers supply upon request all relevant

information for the type of special electrode to be used.

Always make some trial welds on scrap material. Select electrode diameter and welding current as per Table 1.

Attach earth clamp to work piece and place electrode into electrode holder as described earlier. Now hold the

electrode tip approx. 2 cm / 1 inch above the starting point of your welding seam. Hold the welding shield in front

of your face and draw the electrode with a short stroke along the groove. Through the welding shield you watch

the arc, keeping it to a length of 1 to 1.5 times the electrode diameter.

wrong

arc too long

(Pic. 3)

correct

approx. 1 - 1.5 the electrode-Ø

(Pic. 4)

The correct arc length is important for a good weld, because with too short or too long an arc both welding current

and working voltage change. A low working voltage causes insufficient penetration. Too high or too low welding

current gives a poor welding seam. Too long an arc does not sufficiently melt the parent material, resulting in

high spatter losses. Also the air, with its detrimental substances like hydrogen and nitrogen, may get access to

the weld pool.

For a good weld the work angle of the electrode (or electrode inclination angle) is of substantial importance. The

inclination should be 70° - 80° to the welding direction. With the work angle too steep slag will run under the weld

pool, too flat an work angle causes the arc to spatter, in both cases the result is a porous, weak welding seam

(see pictures 5 - 7).

wrong

welding direction

> 80°

wrong correct

welding direction

welding direction

< 70°

70-80°

(Pic. 5)

(Pic. 6)

(Pic. 7)

The welder has to keep the arc at the same length, that is the electrode burn-off is compensated by feeding the

electrode into the weld. At the same time the welder has to watch the weld pool for even penetration and width.

Welding is always done from left to right (backhand welding).

At the end of the welding seam the electrode can not simply be lifted or pulled from the weld, this creates porous

end craters, which weaken the weld. To correctly terminate a weld the electrode is held for a short moment at

the end of the weld seam, then lifted in an arc over the just laid weld.

wrong

(Pic. 8)

correct

(Pic. 9)

Remove slag only after it has cooled down and is no longer glowing.

If an interrupted weld is to be continued, the slag at the end of the already finished weld must be removed. Then

the arc can be started either in the groove or on the weld, as described earlier, and then moved to the end of

the weld, which has to be thoroughly melted for good fusion. Welding is then continued normally.

19

Page 10

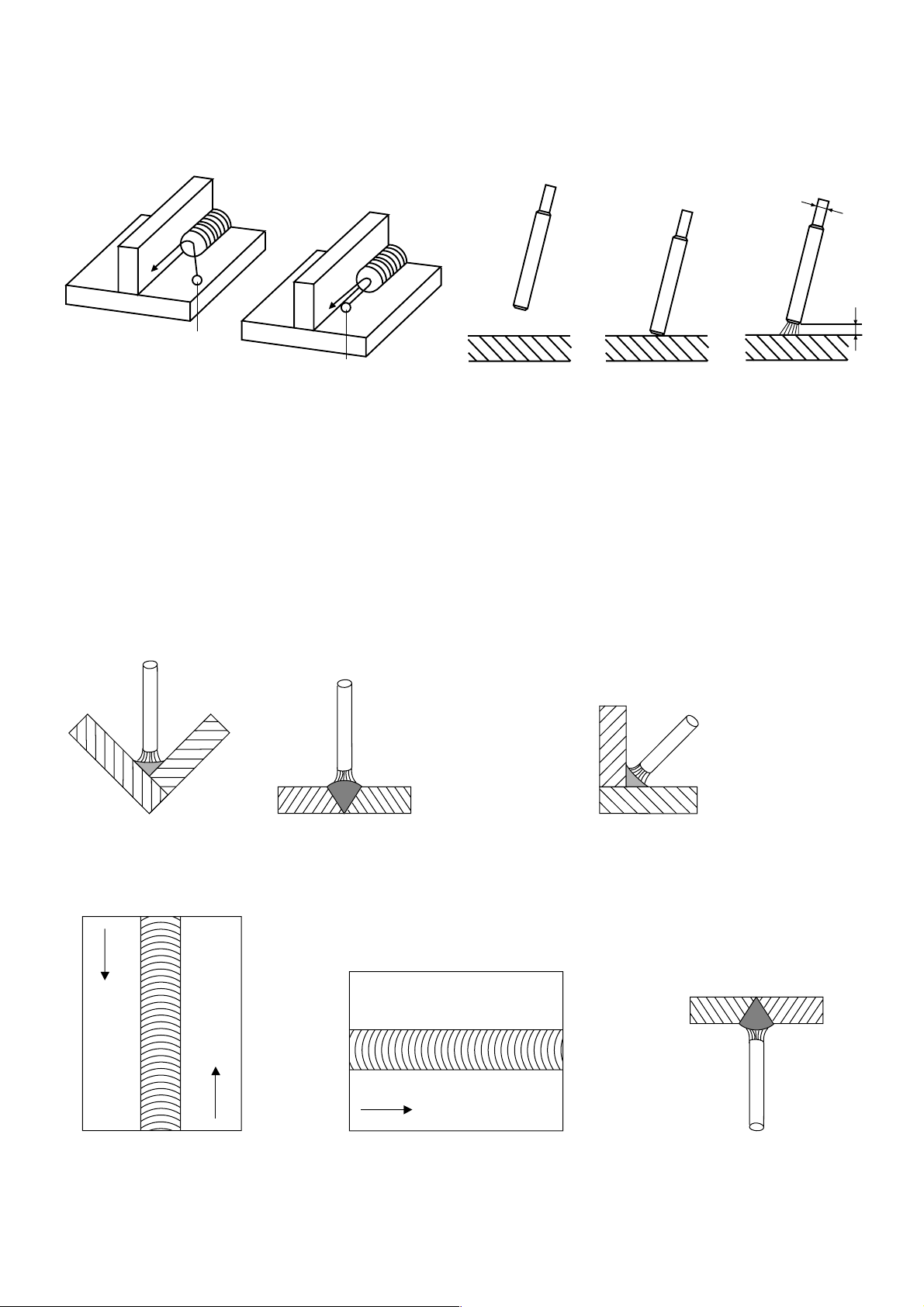

4.1 Weld Types

For Butt Welds the work piece edges should be bevelled to approx. 30°, which gives a groove angle of 60°

(Pic. 10).

The root opening between the two work pieces should be 2 - 3 mm.

60°

(Pic. 10)

For Fillet Welds "a" is the throat width size. The throat width should be at least x 0.7 the plate thickness of the

thinner plate.

a

(Pic. 11)

Other weld types:

x-weld

y-weld Flange weld

A joint weld must always have a good fusion at the root.

wrong

correct

J-weld

(Pic. 12)

Let weld cool down in the ambient air, do not quench.

(Pic. 13)

20

Page 11

4.2 Weld Flaws and possible Causes - Shown on Fillet Welds

Weld Undercut

Welding current to high

Electrode work angle too steep

Arc too long

End Crater

Electrode removed too quickly

from the weld pool, particularly

with high welding currents risk

of shrinkage cracking

Slag Inclusion

Welding current too low

Welding speed to high

Welding over slag on multilayer welds

Gas Inclusion

Work surface not clean

(rust, grease, paint)

Arc to long

Basic coated electrodes not

sufficiently dried

5 Accessories and Accessory Maintenance

Connecting Welding Cables to the Welding

Power Source

Weld Toe Cracks

Material sensitive to welding

conditions

Weld cooled down too fast after

welding

Root Flaw

Slag entering root area

because distance too great

Connecting (Extending) Welding Cables

Ring tongue terminal soldered, crimped, clamped

Fully Insulated Electrode Holder Connection of Welding Cables to the Work Piece

spring

handle

Replace broken insulating parts at once!

Attach earth clamp as close as possible to the weld. Structural components, beams, pipes or rails should not be used

for earth conducting if they are not the actual work piece.

hand lever

insulated jaws

Insulate screw joint terminal with rubber bush or heatshrinkable sleeve

Clean work piece surface for good conduction

21

Page 12

6 Wiring Diagrams

6 Schaltpläne

6 Schémas électriques

6 Schakelschema's

III

400 V

230 V

N

L1

L2

PE

CEE Plug

3P+N+PE

400 V

Contacts

N - N

L1 - L1

L2 - L2

N

L1

L2

Red Light

CEE Adapter

3P+N+PE

Schwitch Positions

400 V

On

OFF

OFF

0

ON

ON

ON

Plug

230 V

230 V

OFF

OFF

ON

SB 160 C (230/400 V)

Transformer

240V

Fan

Thermo

switch

Control

light

N

L1

PE

240V 0

Voltage selector switch

42

SB 200 CT (240 V)

Page 13

III

400 V

230 V

N

L1

L2

PE

CEE Plug

3P+N+PE

400 V

Contacts

N - N

L1 - L1

L2 - L2

N

L1

L2

Red Light

CEE Adapter

3P+N+PE

Schwitch Positions

400 V

On

OFF

OFF

0

ON

ON

ON

Plug

230 V

230 V

OFF

OFF

ON

SB 200 CT (230/400 V)

43

Page 14

Szczecinski; (+48) 91 - 5 78 11 95; (+48) 91 - 5 78 07 76;

serwis@metabo.pl

10-12; Apartado 53; 7000-171 Evora Codex; (+351) 266 - 74 93 00;

(+351) 266 - 74 93 09; bolas@mail.telepac.pt

65; ganesh@gulfincon.com

Apartado 342, Zona 9-A; Panam· ; (+507) 2 23 77 05; (+507) 2 69 18 66;

germante@cableonda.net

BIJL STREET; MEADOWDALE - Germiston; Johannesburg; (+27) 11 -

372 - 96 00; (+27) 11 - 453-41 63; ebotha@metabo.co.za

Santo Domingo; (+1) 809 - 531 50 80; (+1) 809 - 531 53 38;

jgarcia@agroindustrialferretera.com

(+40) 1 - 3 20 31 41; (+40) 1 - 3 20 31 42; agent@dial.kappa.ro

198 43 14/198 17 13; (+7) 095 - 198 43 14; metabo_service@mail.ru

) 52 - 3 54 34 44; (+41) 52 - 3 54 34 45; service@metabo.ch

Number One Building; Singapore 408563; (+65) 7 48 28 66; (+65) 7 45 38

72; sales@homely.com.sg

20; (+386) 61 - 1 68 16 16; metabo@dilex.si

263-1 Ipchung-Dong, Chung-Gu; Seoul; (+82) 2 - 22 76 09 14/5; (+82) 2 -

2 78 62 62; kwlee@metabokorea.co.kr

West Indies; Santa Lucia; (+1)758 - 452-99 14; (+1)758 - 452-99 15;

eurotools@candw.Lc

3566; Postal Code 112; Ruwi; (+968)70 31 70; (+968)70 83 05;

sjuma@email.com

10 06 60; (+46) 36 - 16 07 54; mwidell@metabo.dk

Halmstad; (+46) 35 - 154400; (+46) 35 - 104835; bo.rosenbaum@hdf.se

Pomprab Bangkok 10100; (+66) 2 - 3 28 11 89; (+66) 2 - 3 28 13 04;

vinai@ssm.co.th

1 - 25 83 92; (+216) 1 - 35 18 45; equipement-moderne@planet.tn

212 - 2 56 49 50; (+90) 212 - 2 38 98 26; elalet@burla.com

Opolcheniaya; 03 151 Kiev; (+380) 44 - 2 45 94 34; (+380) 44 - 2 45 93

65; comserv@ukrnet.net

6 - 533 05 51 ; (+971) 6 - 533 73 68; sedana@emirates.net.ae

Principal II, Piso 4; Caracas 1071; (+58) 212 - 2 37 30 22; (+58) 212 - 2 39

23 65; masmuss@olycopia.com

Ward 12; Tan Binh District; Ho Chi Minh City; (+84) 8 - 811 74 54; (+84) 8

- 811 63 38; TVTLinh@hcm.fpt.vn

Polska; Metabo Polska Sp. z o.o.; Gdynska 28; ; 73-110 Stargard

Portugal; BOLAS-Maq. e Ferramentas de Qualidade, S.A.; Rua B, Lotes 8-

Qatar; Gulf Incon; P.O.Box 4076; ; Doha; (+974) 4 68 35 11; (+974) 4 68 40

Rep. de Panam·; G erman-Tec (Panam·) S.A.; Via Argentina 46-70;

Republic of South Africa; Metabo Power Tools SA (Pty.) Ltd.; 165 Van DER

Republica Dominicana; Agroindustrial Ferretera S.A.; Av. Luperon No. 42; ;

Rumania; Agent Trade S.R.L.; Splaiul Unlrii 235-237; ; 74299 Bucuresti 3;

Russia; OOO ITA-Strojinkom; Uliza Alabjana 3; ; 125057 Moskau; (+7) 095 -

Schweiz; Metabo (Schweiz) AG; Lindauerstr. 17; ; 8317 Tagelswangen; (+41

Singapore; HOMELY HARDWARE PTE LTD; No. 1 Ubi Crescent #01-01;

Slovenia; Dilex d.o.o.; Ogrinceva 17; ; 1000 Ljubljana; (+386) 61 - 1 68 16

South Corea; Metabo-Korea Co. Ltd.; Room No. 101, Daesung Building;

St. Lucia; Eurotools Int`l Ltd; P.O.Box RB 2484; Rodney Bay, Gros Islet,

Sultanate of Oman; AHMED RAMADHAN JUMA & CO.L.L.C.; P.O. Box

Sverige; Metabo Sverige AB; Skifferv‰gen 6; ; 553 03 Jˆ nkˆ ping; (+46) 36 -

Sverige; HDF - Bolagen AB ; Svarvaregatan 5; P.O.Box 525; 30180

Thailand; SSM - Sri Siam Mongkol Co., Ltd; 1570-1576 Krung Kasem RD.; ;

Tunesia; L¥Equipment Moderne; 86, Ave. de Carthage; ; 1000 Tunis; (+216)

Turkey; Burla A.S.; Voyvoda Cad. 61-65; ; 80003 Karakˆ y-Istanbul; (+90)

Ukraine; Comservice; Ukraian-Russian Joint Venture 2; Narodnogo

United Arab Emirates; Sedana Trading Co; P.O. Box 1919; ; Sharjah; (+971)

Venezuela; OLY-COPIA C.A.; 3 ra Transversal Los Ruices ; Edificio

Vietnam; HUU HONG MACHINERY CO., LTD.; 157-159 Xuan Hong Street,

Estate; Southampton / SO 16 OYT; (+44) 2380 - 73 20 00; (+44) 2380 -

74 75 00; info@metabo.co.uk

Ciudad, 01009; (+502) 3 32 47 24; (+502) 3 32 47 81;

almpalma@amigo.net.gt

Cheung Sha Wan Road; Kowloon / Hong Kong; (+852) 29 26 22 00;

(+852) 28 82 19 78; rileytam@mail.jebsen.com.hk

(+354) 5 641135; asborg@centrum.is

Complex; Ambethan Road, Kharabwadi; Chakan, Tal.: Khed, Dist.-

Pune(Pin410 501); (+91) 213 - 55 22 03; (+91) 213 - 55 21 61;

Kencana No. 1; Meruya - Kembangan; Jakarta 11610; (+62) 21 - 5 82 82

82; (+62) 21 - 5 82 55 88; kawanlama@kawanlama.com

Road; 33033 Haifa; (+972) 4 - 8 64 04 69; (+972) 4 - 8 67 18 03;

dubovsky@matav.net.il

Milanese (MI); (+39) 02 - 52 77 71; (+39) 02 - 55 60 03 22;

cstechel@stechel.it

0063; (+81) 4 - 28 77 05 06; (+81) 4 - 28 77 05 07;

Center; Amman 111 18; (+962) 6 - 465 56 80; (+962) 6 - 464 54 39;

jsakkab@nta.com.jo

Road, Kilo 9; P.O.Box 11429; Jeddah 21453; (+96) 62 - 6 82 04 58; (+96)

62 - 6 91 12 67; sitaco@sitaco.com.sa

663 SAFAT; 13007 State of Kuwait; (+965) 47 47 137; (+965) 47 47 945;

Alsayer_electro@hotmail.com

56100 Kuala Lumpur; (+60) 3 - 92002966 / 92003966; (+60) 3 - 92007599;

finetools@pd.jaring.my

Sentul; ; 51700 Kuala Lumpur; (+60)3 - 6 18 88 88; (+60)3 - 6 17 66 16;

11; (+356) 43 54 24; (+356) 41 73 58; gtimports@mail.global.net.mt

525 14 09; STAF@toptechnology.mr

2 12 64 05; (+230) 2 10 74 57; dema@intnet.mu

(+212) 2 31 25 06; (+212) 2 - 31 24 62;

(+31) 3462 - 6 42 44; (+31) 3462 - 6 35 54; verkoop@metabo.nl

668; 98845 NoumÈa; (+687) 27 20 02; (+687) 27 30 94;

szemmelveisz@canl.nc

Christchurch; (+64) 3 - 36 55 931; (+64) 3 - 36 55 932;

hamish@metabo.co.nz

Great Britain; Metabo (UK) Ltd.; 25 Majestic Road ; Nursling Industrial

Guatemala; Almacen la Palma S.A.; 2a Calle 4-38, Zona 9; ; Guatemala

Hong Kong; Jebsen & Co. Ltd. ; 9/F, Jebsen Motor Group Building; 924-926

Iceland; ASBORG S.F.; Smidjuvegi 11; ; 200 Kopavogi; (+354) 5 641212;

India; Metabo Power Tools PVT Ltd.; Plot No. 40, WMDC Industrial

Indonesia; P.T. Kawan Lama Sejahtera pt; Gedung Kawan Lama Jl. Puri

Israel; Proter + Cohn Ltd; Technical Supply P.O.Box 33215 / 3; Haatzmaut

Italia; Carlo Stechel & Figli S.rl; Via Buozzi, 22; ; 20 097 San Donato

Japan; Metabo Japan Co., Ltd.; 5-1024-3, Baigou, Ohme-city; ; Tokyo 198-

Jordan; Newport Trading Agency; P.O.Box 6166 / 151 Hashimi Str.; City

Kingdom of Saudi Arabia; Saudi Industrial Tools Corporation; Madinah

Kuwait; Naser Moh. Al-Sayer ; Gen. Trading & Contracting Co.; P.O. Box

Malaysia; Finetools SDN BHD; No. 7 Jalan 1/92C; Batu 3 1/4 Jalan Cheras;

Malaysia; LINTREX (Malaysia) SON: BHD.; 68100 BATU Caves, Box S 24

Malta; G + T Imports Limited; Metabo Shop, Birkirkara By-Pass; ; Iklin BZN

Mauritanie; S.T.A.F; B.P.: 40246; ; Nouakchott; (+222) 525 33 85; (+222)

Mauritius; Dema - Supplies Ltd.; 2A Deschartres Street; ; Port Louis; (+230)

Morocco; StÈ Yyes Rouger; 20 Bd. Ibn Tachfine; ; 20300 Casablanca;

Nederland; Metabo Nederland b.v.; Postbus 180; ; 3620 AD Breukelen;

New Caledonia; Ets. Szemmelveisz; 3, Rue Fernand Forest; Boite Postale

New Zealand; Tooline Limited; 50 Disraeli Street; P.O. Box 798;

55 55; (+47) 33 - 44 55 50; psteingrimsen@metabo.no

Norway; Metabo Norge AS; Postboks 1296; ; 3205 Sandefjord; (+47) 33 - 44

Sad; (+38) 12 15 28 56; (+38) 12 15 24 57; woby@Eunet.yu

Yugoslavia; WHM WOBY HAUS MARKT; Brace Ribnikara 55; ; 21000 Novi

AD/AC (EB)

(+595) 981 - 43 15 13; (+595) 21 - 33 36 77; taguato@conexion.com.py

Quezon City; (+63) 2 - 3 63 01 59; (+63) 2 - 3 61 48 41;

Paraguai; Taguato S.A.; Avda.Gra.Santos No. 1948/Tte. Garay; ; Asuncion;

nancytanyu@speedsurf.pacific.net.ph

Philippines; Mach Tools Inc.; 185 A & B del Monte Avenue; ; Manresa,

62; (+355) 42 - 3 30 62; abeqiri@t-online.de

Rouiba; (+213) 21 - 85 49 05; (+213) 21 - 85 57 72;

Ciudadela - Buenos Aires; (+54) 11 - 44 88 - 9180; (+54) 11 - 44 88 - 39

89; info@metabo.com.ar

3179; (+61) 3 - 97 65 01 99; (+61) 3 - 97 65 01 89; sales@metabo.com.au

(+973)40 43 23; almahros@batelco.com.bh

(+880) 2 - 9 56 94 77 / 9 55 04 00;

- 4 67 32 10; (+32) 2 - 4 66 75 28; general@metabo.be

51 - 302 718; (+387) 51 - 785 708; agrokombinat@blic.net

Diadema - Sao Paulo - Cep 09911-630; (+55) 11 - 40 51 - 25 11; (+55) 11

- 4056 - 4152; metabo@metabo.com.br

Labem; (+420) 202 - 80 44 55; (+420) 202 - 80 44 56;

mlanda@metabo.cz

11; (+56) 2 - 6 99 04 85; empresa@nordchil.cl

2400; San JosÈ; (+506) 2 32 91 11; (+506) 2 32 93 53;

webmaster@capris.co.cr

Ave; 1641 Lefkosia, Cyprus; (+357) 2 - 34 95 77; (+357) 2 - 34 93 94;

condam@spidernet.com.cy

- 31 34 00; (+45) 43 - 31 34 01; scarstensen@metabo.dk

33 34 56; 0180 -3 33 34 57; Ersatzteilverkauf@elektra-beckum.de

(+372) 620 11 12; mecro@mecro.ee

; Cairo; (+20)2 -25 91 32 77; (+20)2 -25 90 02 23; eea@eea.co.eg

Cuscatancingo; San Salvador; (+503) 2 - 38 47 65; (+503) 2 86 52 36;

metabo1@telesal.net

C/Forjadores, 12; 28660 Boadilla del Monte (Madrid); (+34) 91 - 6 32 47

40; (+34) 91 - 6 32 41 47; wbuhrle@metabo.es

27 58; (+251) 1-51 50 82; sutco@telecom.net.et

804861; (+358) 9 - 803 9485; reijo.helenius@nofa.fi

33 37 57 19; (+33)2 33 37 72 25;

Country; Company; Address 1; Address 2; City; Phone; Fax; E-mail

Albania; Extra Industrial Goods; Rl. Fadil Rada 88; ; Tirana; (+355) 42 - 3 30

Algerie; Haddad Equipement Professione; 98 A, Site du LycÈe; ; 16012

Argentina; Metabo Argentia S.A.; Teniente Gral. Richieri 4773; ; 1702 -

Australia; Metabo Pty. Ltd; 10 Dalmore Drive; ; Scoresby, Melbourne, Vic.

Bahrain; AL-MAHROOS; P.O. Box 65, Manama; ; Bahrain; (+973)40 06 96;

Bangladesh; East Bengal Impex; 175, Nawabpur Road (4th floor); ; Dhaka; ;

Belgique; Metabo Belgium; ¥t Hofveld 3 - 5; ; 1702 Groot Bijgaarden; (+32) 2

Bosnia and Herzegovina; Agrarkombinat; Majevicka 1; ; Banja Luka; (+387)

Brazil; Metabo do Brasil Ltda.; Rua Guicurus 306 - Vila Conceicao; ;

Ceska Republica; Metabo s.r.o; Kralovicka 544; ; 250 01 Brandys nad

Chile; Nordchil S.A.; San Diego 895; ; Santiago de Chile; (+56) 2 - 6 72 29

Costa Rica; Capris S.A.; Frente la Imprenta Nacional, La Uruca; P.O. Box 7-

Cyprus; Med Marketing Ltd. (eurotools); P.O. Box 27017; 17, Digenis Akritas

Danmark; Metabo Danmark A/S; Helgeshoj AllÈ 12; ; 2630 Tastrup; (+45) 43

Deutschland; Elektra-Beckum AG; Daimlerstr. 2; ; 49716 Meppen; 0180 - 3

Eestlane; A/S MECRO; Peterburi tee 44; ; 11415 Tallinn; (+372) 620 11 11;

Egypt; EGYPTIAN ENGINEERING AGENCIES; 16 Naguib El-Rihani Street;

El Salvador; Metabo S.A. de C.V.; Colonia Santa Clara, Pasaje C No. 20;

Espana; Herramientas Metabo S.A.; PolÌgono Ind. Prado del Espino;

Ethiopia; SUTCO Pvt. Ltd. Co.; P.O. Box 17924; ; Addis Ababa; (+251) 1-51

Finland; NOFA O.Y.; Hannuksentie 1; O.O. Box 28 ; 02270 Espoo; (+358) 9-

House; P.O. Box 1783; Accra; (+233) 21 - 66 39 94; (+233) 21 - 78 02 90;

France; LUREM MACHINES A BOIS S.A.; BP 1 ; ; 61700 Domfront; (+33)2

Ghana; Emmnock Tradingcompany Ltd.; Knutsford. Avenue opp. Morocco

Loading...

Loading...