Page 1

®

D

ENG

F

NL

Betriebs- und Montageanleitung

Präzisionskreissäge

Operating Instructions Precision Circular Saw

Notice de service et de montage Scie circulaire

de précision

Handleiding Bediening

Precisie-cirkelzaagmachine

PK 300 K

Le châssis n’est pas compris dans le programme de livraison (équipement optionnel)

Het onderstel wordt niet standaard meegeleverd (beschikbaar als optie).

D

Achtung! Lesen Sie diese Anleitung vor der Installation und Inbetriebnahme aufmerksam durch.

ENG

Attention! Carefully read through these instructions prior to installation and commissioning.

F

Attention! Prière de lire attentivement la présente notice avant l'installation et la mise en service.

NL

115 115 9270 / D/ENG/F/NL / 3100 - 3.1

Attentie! Lees deze instructies voor de installatie en ingebruikname aandachtig door.

Untergestell nicht im Lieferumfang enthalten (Sonderzubehör)

Base not included in Standard Delivery (Optional Accessoires)

Page 2

Page 3

ENG

Scope of Application

This Elektra Precision Circular Saw is designed to perform rip and crosscuts in wood or wooden materials having a square or

rectangular cross section.

- Crosscuts should be performed only with the help of a mitre fence or the Sliding Carriage PK, available as optional accessory.

- Do not crosscut round stock, for ripping use the Square and Round Stock Jig available as optional accessory.

- Maximum saw blade diameter is 300 mm, the minimum blade diameter must be 250 mm.

User Responsibility

This machine will perform in conformity with the description contained tin the instructions provided. This machine must be checked

periodically. Defective equipment (including power cable) should not be used. Parts that are broken, missing, plainly worn, distorted

or contaminated, should be replaced immediately. Should such repair or replacement become necessary, it is recommended that

such repairs are carried out be qualified persons approved by Elektra Beckum or its representative. This machine or any of its parts

should not be altered or changed from standard specifications. The user of this machine shall have the sole responsibility for any

malfunction which results from improper use or unauthorized modification from standard specification, faulty maintenance, damage

or improper repair by anyone other than qualified persons approved by Elektra Beckum or its representative.

Product Liability/Warranty

We explicitly draw your attention to the fact that, under the current product liability regulations, Elektra Beckum does not have to

assume liability for any damages causes by its products, if such damages result from improper repair, use of replacement parts other

than genuine Elektra parts, or repairs not having been carried out by customer service or authorized service centres.

The three-phase motor of this machine is equipped with an automatically engaging mechanical motor brake, designed for a long

service life. If the braking action fades, and the time to standstill exceeds 10 sec, the brake has to be replaced.

Consult your dealer or authorized service centre.

Table of Contents

1 Specifications

2 Standard Delivery

3 Installation

4 Connection to Power Mains

5 Controls/Settings

6 Saw Blades

7 Overview of Components/Terms

8 Jigs and Push Blocks

9 Safety Rules

10 Dust Collection

11 Operation

12 Adjusting the Saw Blade Position

13 Belt Tension

14 Care and Maintenance

15 Wiring Diagrams

16 Optional Accessories

17 Spare Parts Lists

1 Specifications PK 300 K/4200 DNB

Saw table size 710x900 mm

Table working height 940 mm

Dept of cut at 90°/45° 104/70 mm

Motor speed 2800 rpm

Arbor speed 3800 rpm

Main blade diameter 300 mm

Cutting speed with Ø 300 mm blade 60 mtr/sec

Motor capacity P

Motor voltage 3 ~ 400 V

1

Mains frequency 50/60 Hz

Mains fuse 3 x 16 A time-lag

Suction port diameter 100 mm

Weight 90 kg

Stock-no. 010 300 4209

Noise Emission

The noise emission levels shown below have been established by measuring methods according to:

The correction factor K3 has been established by DIN EN 31204.

1. PK 300 K operating under no load

A-sound pressure level L

A-sound power level L

pA

WA

2. PK 300 K operating under load

A-sound pressure level L

A-sound power level L

pA

WA

4200 W-

DIN EN 23 746;

DIN EN 31 202;

ISO 7960 appendix A.

74,3 dB(A)

87,8 dB(A)

84,7 dB(A)

98,2 dB(A)

16

Page 4

2 Standard Delivery

Saw blade TCT 300x2.6/1.8x30 mm 28 alternate bevel teeth

Riving knife 2.5 mm

Saw blade guard

Rip fence

Mitre fence

Dust extraction port with hoses

Push stick

Tool set

Operating instructions

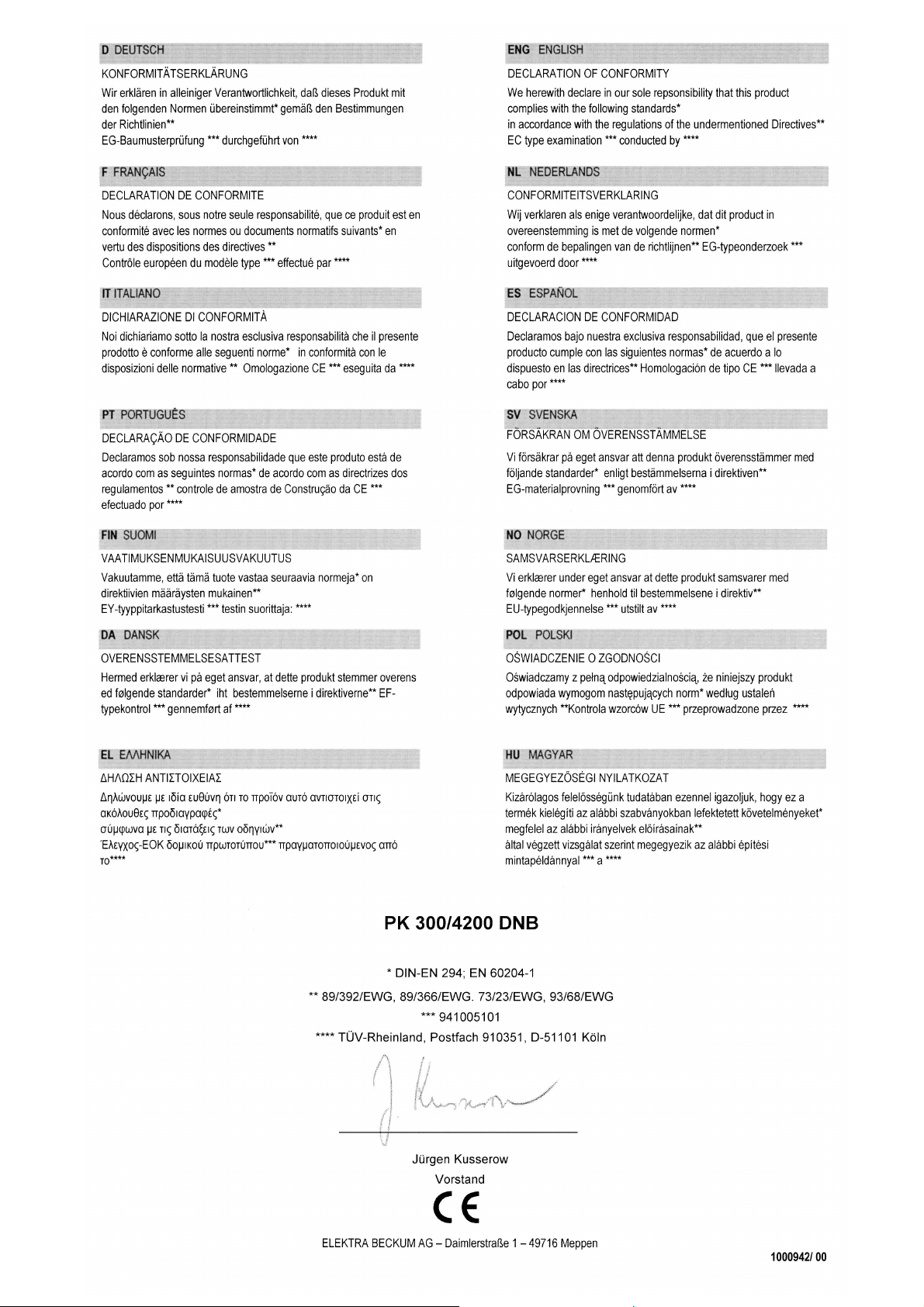

3 Installation

Place machine upside down on two battens to install the workstand. Do not tighten screws fully before all parts have been

installed.

Install suction port to chip case.

Use 3 each

hex. head screw M 6x16

serrated lock washer Ø 6.4

hex. nut M 6

Install dust collection port into hole of the

rear panel with 3 each

hex. head screw M 6x16

serrated lock washer Ø 6.4

hex. nut M 6

Place spiral hose Ø 100 mm onto suction

port and secure with hose clamp Ø 100

mm. Install both side panels, using 4 each

hex. head screw M 6x16

serrated lock washer Ø 6.4

hex. nut M 6

Place the spiral hose on the dust collection port and secure in place with the

second hose clamp Ø 100 mm.

Install rear panel (with hole) between the

side panels.

Use 6 each

hex. head screw M 6x16

serrated lock washer Ø 6.4

hex. nut M 6

Install the workstand's front panel.

Use 6 each

hex. head screw M 6x16

serrated lock washer Ø 6.4

hex. nut M 6

Put a hex. nut M 10 on the threaded bolt

of all 4 adjustable feet.

Install feet into tapped bushes M 10 located on each corner.

17

Now tighten all screw joints fully, then

stand machine on its feet. Place side

panels lids into the panel openings.

Page 5

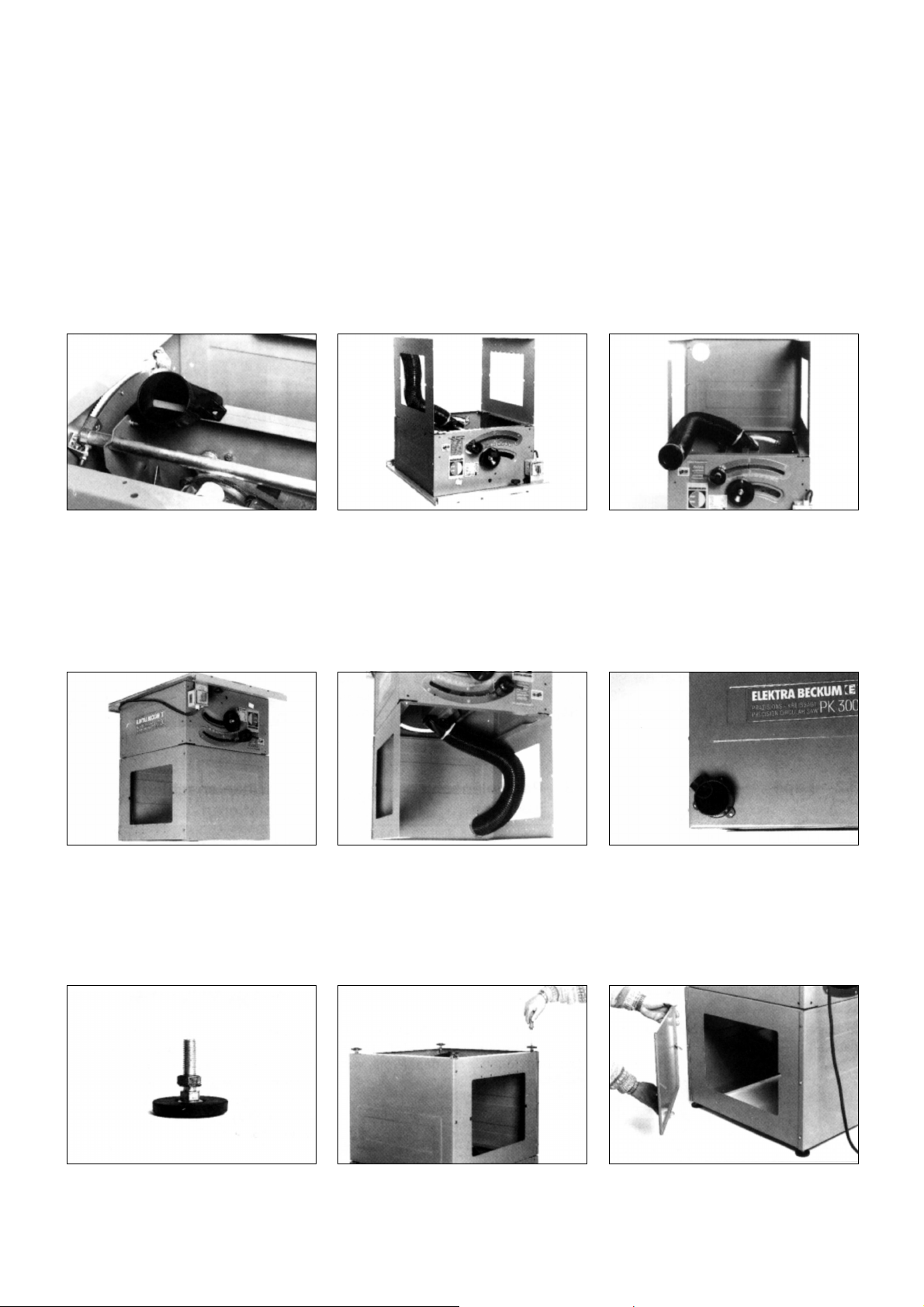

Loosely attach 2 carriage bolts M 6x16 to hose carrier, then slide hose carrier into the

rear T-groove of the table.

Install spiral hose between saw blade guard and dust collection port.

Raise saw blade (see paragraph 5) and

attach saw blade guard to riving knife.

3.1 Rip Fence Scale Adjustment

The rip fence scale is adjustable to accommodate saw blades of different widths.

Set rip fence against the blade. Loosen scale fixing screw and set scale until zero

mark matches the hairline of the fence bracket's magnifying glass. Tighten fixing

screw and verify setting by making a trial cut on a piece of scrap.

Note: The scale's zero mark and the hairline of the magnifying glass can only

line up with the fence extrusion installed in the upright position (wide edge facing

the blade).

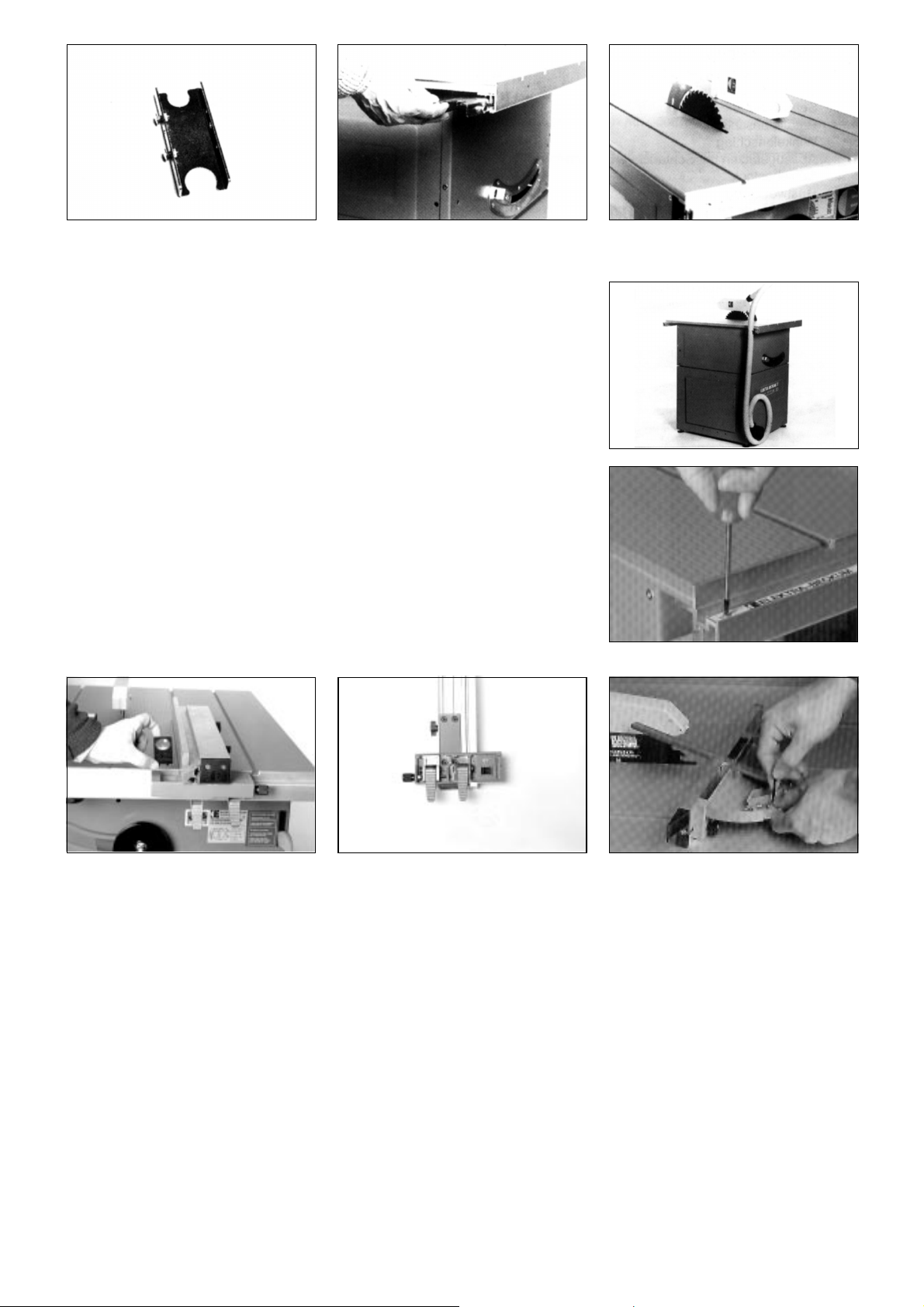

3.2 Magnifying Class 3.3 Rip Fence Adjustment 3.4 Mitre Fence Adjustments

The magnifying glass can be removed

from the rip fence for cleaning.

The rip fence is factory set parallel with the

saw blade. If adjustment is necessary

loosen the four screws holding the fence

extrusion to the carrier and set square

with the table.

Both left and right hand 45° end stops are

factory set. If required the positions can

be adjusted with the setting screws. The

angle scale is also adjustable.

4 Connection to Power Mains

- This machine must be operated on a residual current operated device of 30 mA capacity, having a fault current breaker.

- This machine must be safety earthed. The yellow/green lead is the earth conductor.

- Fit plug matching your local standard outlet to the power cable.

- The outlet this machine is connected to must be earthed and phase protected by a 16 A time-lag fuse or circuit breaker.

- Do not operate saw with a damaged power cable. Risk of electrical shock.

Worn or defective cables must be replaced immediately. Have replaced by a qualified electrician only.

Check if voltage of power mains matches with voltage stated on machine's type plate.

For mains connection a 5-lead power cable is required. The yellow/green lead is the earth conductor. Do not connect the

yellow/green earth lead to any of the current conducting terminals. If in doubt-consult a qualified electrician.

Extension cables should have a minimum lead cross section of 1.5 mm2 and a rubber outer jacket (HO7RNF/SJT or similar).

Use of extension cables with too small a lead cross section causes a voltage drop and possible damage to motor and/or switch.

Important! Always disconnect from power before servicing the saw.

Direction of rotation of the saw blade is clockwise, when looking at it from the left side of the saw. To check start saw briefly.

If the blade runs counter-clockwise on a three-phase machine, have a qualified electrician interchange two of the phases to

correct.

Note: Wrong direction of rotation of the saw blade is dangerous and may cause severe personal injury.

18

Page 6

4.1 Switch/Overload Protection

The switch is equipped with a no-volt release solenoid (magnetic switch), to

prevent start-up after a power failure. If the saw is not connected to the power

mains the switch does not engage. In the event of a power failure the machine

has to be restarted. In case of an overload of the main motor the build-in motor

protection relay trips and cuts the power to the motor. If the motor is shut off

repeatedly by the overload relay, check machine (motor brake action, dull blade,

low voltage etc.). A cooling down period of 30 min. is recommended.

A light humming from the solenoid inside the switch is normal and does not

indicate a fault.

- Block rotary switch knob with a padlock to prevent unauthorized use.

5 Controls/Settings

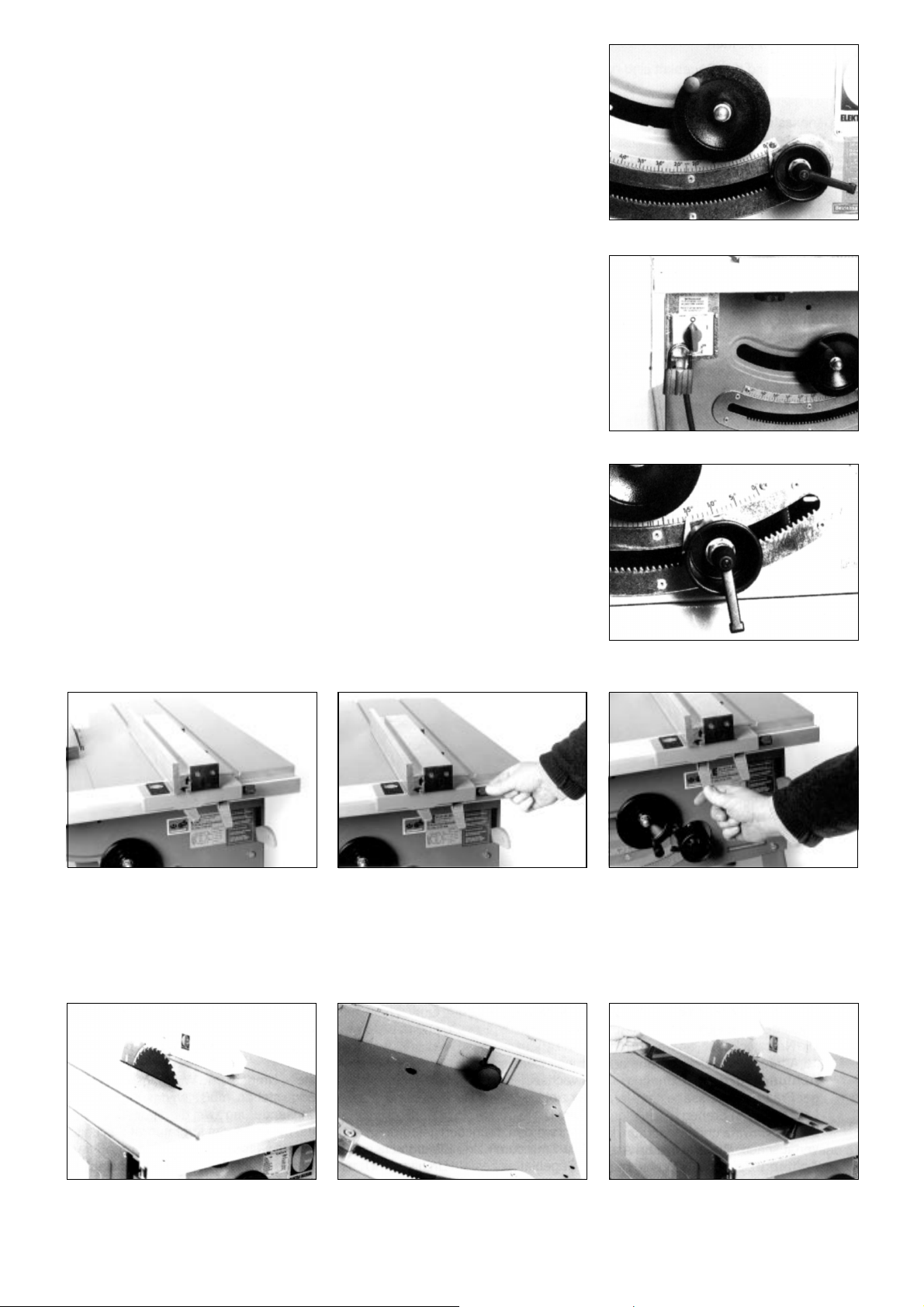

5.1 Sawblade Vertical Setting

The depth of cut of the main blade is set by turning the cranked handwheel.

Turn clockwise to raise blade

Turn counter-clockwise to lower blade

To compensate for possible play always raise blade into desired position.

5.2 Blade Tilt

After release of the ratchet lock lever inside the handwheel the blade can be tilted

steplessly to any position between 90° and 45° by turning the handwheel.

Reference point is the graduation mark to the right of the pointer.

- Tighten ratched lock lever after setting.

Caution! Carry out setting only with the blade at complete standstill.

5.3 Rip Fence Setting

Place rip tence onto the saw table. Set to

required width of cut, then push the right

hand side lock lever down.

Turn micro-adjuster screw to set fence to

exact dimension.

5.4 Opening the Chipcase

Disconnect from power before servicing!

After micro-adjustment is made push down

the left hand side lock lever to lock the rip

fence in position.

Loosen wingnut of saw blade guard a few

turns. Pull forward and up to remove blade

guard from riving knife.

Loosen starknobs located below the table

at front and rear of removable table section and push against the workstand panel.

19

Remove the removable table section.

Page 7

Lift chip case cover on both ends, pull forward by approx. 50 mm, then lower.

Riving knife and saw blade are now accessible for maintenance and servicing

5.5 Setting of Riving Knife

Disconnect from power before servicing!

The riving knife prevents the work

from closing behind the blade, thus

stalling it and causing kickback.

Except for set-in work (see paragraph 11.3) never perform any

cutting operation without the riving knife in place and correctly

set.

Set riving knife to a distance of 3 8 mm against the saw blade.

Set the height so that the top of the riving knife is not less then 2 mm below the crown of the saw blade.

Important! Check mounting screw regularly for stripped threads.

5.6 Changing the Main Blade

Disconnect from power before servicing!

Insert lock bar from tool set through the hole in the table into the hole of the blade

flange below. Turn blade by hand to line up holes. Use 30 mm spanner from tool

set to loosen arbor nut.

Note: Left-hand thread, turn clockwise to loosen!

Take off arbor nut and blade. Before fitting another blade be sure that blade seat

and arbor thread are clean. Wipe of with rag any chips or saw dust which may

have deposited there, so blade can fit snug against flanges to ensure safe

operation. Fit blade so that teeth on top point towards the operator in front of saw.

Replace arbor nut and tighten. Do not overtighten.

Remove lock bar, close chip case and put removable table section back in place.

Install saw blade guard before starting the saw.

6 Saw Blades

Never use HSS blades, as these are not flexible enough and will crack or break easily.

Saw blades must be marked with the name or trade mark of the manufacturer. On this saw the following blades can be used

with the standard riving knife: min. Ø 250 mm, max. Ø 300 mm, arbor bore 30 mm, blade thickness/tooth width 1.8 - 2.5 mm.

Use of thinner or thicker blades requires a different riving knife.

The riving knife must not be wider than the width of the kerf and not narrower than the blade body.

TCT blade T = 28 W

Ø 300x2,6/1.8x30 mm

Alternating teeth.

General purpose blade

for rip and cross cuts,

timber and particle

board.

Standard delivery.

Stock-no.

091 001 4099

TCT blade T = 60 DH

Ø 300x3.2/2.2x30mm

Pointed-hollow teeth.

For cutting plastic

laminated boards.

Makes scribing/scoring

blade obsolete.

Stock-no.

091 001 4102

TCT blade T = 48 UW

Ø 300x3.2/2.2x30 mm

Universal alternating

teeth.

For cutting cabinet

boards, veneered and

laminated boards as

well as solid timber.

Stock-no.

091 001 4110

TCT blade T = 72 KW

Ø 300x3.2/2.2x30 mm

Combination alternating teeth.

Cuts Melamin boards,

extrusions, all kinds of

plastics.

Stock-no.

091 001 4129

20

TCT blade T = 96 VW

Ø 300x3.2/2.2x30 mm

Multiple alternating

teeth. For the ultimate

performance in cabinet

making. Cuts solid

timber as well as all

plywoods and boards.

Stock-no.

091 001 4137

TCT blade T = 96 TF

Ø 300x3.2/2.6x30 mm

Trapezium-flat teeth.

For solid timber, ply,

plastic and aluminium

extrusions, fine

furniture boards.

Stock-no.

091 001 4145

Page 8

7 Overview of Components/Terms

1 Riving knife

2 Saw blade guard

3 Rip fence

3a Auxiliary fence

4 Mitre fence

5 Push stick

4

2

8

3

3a

1

7.1 Optional Accessories

6 Sliding Carriage

7 Table Rear Extension

8 Table Side extension

Optional accessories not shown:

- Edge Trimming Attachment

- Wheel Set

- Cam-lock Clamp

- Square & Round Stock Jig

8 Jigs and Push Blocks

7

5

6

Make a deflector board when crosscutting small work pieces (see paragraph 11.5

below). Do not use chipboard for making the deflector board.

Always use push stick when cutting strips

of less than 120 mm width (see para. 11.4

below).

Always use wedge cutting jig for cutting wedges or tapers (see para. 11.8 below). The

wedge cutting jig should be at least 300 mm long and 170 mm wide.

Make a push block for cutting tenons (see

para. 11.7 below). The recess must correspond to the thickness of the workpiece

that is to be worked.

9 Safety Rules

As with all power tools there is a certain amount of hazard involved with the operator and his use of the machine. Using the

machine with the respect and caution demanded as far as safety precautions are concerned will considerably lessen the

possibility of personal injury. If, however, normal safety precautions are overlooked or completely ignored, personal injury to

the operator can develop.

21

Page 9

General Safety Precautions

- FOR YOUR OWN SAFETY; READ AND UNDERSTAND INSTRUCTION MANUAL BEFORE OPERATING

- THE SAW: Learn the saw’s applications as well as the specific hazards peculiar to it.

- KEEP GUARDS IN PLACE and in working order.

- REMOVE ALL ADJUSTING KEYS AND WRENCHES: Form habit of checking to see that all keys and adjusting wrenches

are removed from tool before switching it “ON”.

- ALWAYS USE SAW BLADE GUARD AND RIVING KNIFE for every operation for which they can be used, including through

sawing. Through sawing operations are those when the blade cuts completely through the work piece as in ripping or cross

cutting.

- ALWAYS HOLD WORK FIRMLY AGAINST RIP FENCE OR MITRE FENCE.

- USE PUSH-STICK if distance between blade and rip fence is less than 120 mm / 5 in.

- NEVER PERFORM ANY OPERATION “FREE-HAND”.

- NEVER REACH BEHIND, OVER OR UNDER THE CUTTING TOOL WITH EITHER HAND FOR ANY

- REASON. Keep hands away from saw blade; do not reach into area 120 mm / 5 in. left and right of saw blade.

- DIRECTION OF FEED: Feed work into saw blade against direction of rotation only.

- AVOID KICKBACKS (work thrown back at you) by keeping the rip fence parallel to the blade, keeping riving knife and guards

in place and operating, by not releasing work before it is pushed all the way past the saw blade, and by not ripping stock

that is twisted or warped or does not have a straight edge to guide along the fence.

Safety Precautions particularly for this Saw Model PK 300 K

- Before operating the saw check if saw blade is mounted correctly and arbor bolt tightened. Check if blade turns freely.

- Large or long stock, which may tilt the saw by its weight, must be supported at both infeed and outfeed side of the table

by suitable means, e.g. the Roller Table Extensions available as optional accessory, saw horses or other supports of

suitable height.

- Never cut round stock without using suitable jigs.

- Do not use High Speed Steel (HSS) saw blade on this saw.

- Perform crosscuts only with the crosscut/mitre fence, or with a Sliding Carriage (optional accessory).

- Replace dull or cracked saw blades at once.

- Replace kerf plate if worn.

- Set guards as required for the job on hand.

- If operated indoors use a dust collector with a minimum air flow rate of 20 mtr/sec at the suction port.

9.1 Problems

- If the saw blade is stalled by waste, switch machine off and let blade come to a complete standstill before removing

obstruction.

- Switch motor off at once if blade is stalled. A dull blade is likely to be the cause, which may cause motor overloads.

- A dull blade may be the reason for what appears to be a loss of power.

- An extremely dull blade leaves burn marks in the kerf. The heat generated by friction may temper the blade body. Replace

at once to prevent overloading the motor.

- After a power failure the motor has to be restarted by switching ON again.

- Resin residue on the blade affects performance. Clean regularly.

- If the saw blade needs more than 10 sec. to come to a complete standstill the motor brake is worn. Have repaired by a

qualified electrician.

10 Dust Collection

The Precision Circulars Saws models PK 300 K must be connected to a dust

collector (e.g. Elektra Beckum model SPA 2000). The standard dust collection

port has a nominal diameter of 100 mm.

Adhere to all local codes and directives regarding dust collection on woodworking machines.

11 Operation

11.1 Through Sawing

If not in place install riving knife and saw blade guard, set as per paragraph 5.6

of this manual. Set depth of cut to approx. 10 -15 mm more than the workpiece

thickness and rip fence to desired width of cut. Start saw only after all setting

have been made. Place workpiece against the fence and feed into the blade

in a steady motion. Do not force work, as this may overload the motor.

- When ripping strips less then 120 mm wide always use pushstick supplied with

machine for feeding the work to prevent personal injury.

22

Page 10

11.2 Rabetting and Grooving

First cut Second cut

11.3 Set-In Work

Remove blade guard and set riving knife

as decribed in paragraph 5.6 of this

manual. Check depth of cut directly on the

blade with tape or stick measure. Set rip

fence to required width and make first cut.

The sequence of cuts is important: when

making the second cut the waste must be

on the left side of the blade. If on to the

right of the blade, the waste may jam

between fence and blade and kicked back

against you (danger of personal injury).

Remove the riving knife and tighten the

gusset plate.

With set-in work the cut starts somewhere

within the board. To do this work safely

(danger of kickback) backstops are required. These can simply be wooden

blocks clamped to the saw table or, for

longer workpieces, a complete jig or antikickback fence may be required, which is

firmly attached to the saw table.

11.4 Ripping with the Auxiliary Fence

Have riving knife and blade guard installed as described in paragraph 5.5.

The auxiliary fence is used for

ripping stock that tends to open or

close behind the blade.

Loosen both wing nuts holding the

rip fence extrusion, remove the rip

fence extrusion and install it with

the small edge facing the blade. In

this position it serves as an auxiliary

fence. The wide edge must rest on

the table. Position the fence extrusion to that its front end reaches

to approx. the centre of the saw

blade.

Set rip fence as required. Place workpiece with yout right hand against the

stop, the left hands holds the workpiece

against the fence and pushes it down into

the blade.

Note: Mark area where blade will cut

through on top of workpiece. Keep hands

at at least 150 mm distance from blade.

Always use the auxiliary fence when

ripping 45° bevels, guiding the work along

the small edge of the fence extrusion.

See also paragraph 5.3.

11.5 Crosscuts

Perform all crosscutting operations with the mitre fence supplied with this

machine or with a sliding carriage available as optional accessory.

Install fence extrusion with the small edge facing the blade and position so that

its front end just reaches the saw blade. With very small cutoffs use a deflector

board as described in paragraph 8 to keep the cutoffs from being picked up by

the rising teeth of the saw blade.

23

Page 11

11.6 Tenons and Slots

- To cut tenons and slots a push block is required as shown in paragraph 8. The recess in the push block has to match the

workpiece.

- The riving knife must be installed.

Cutting:

Guide workpiece along the rip fence with your right hand. The left hand, holding the push block, feeds the work into the blade,

keeping it from tilting and twisting. When the cut is completed pull back both workpiece and push block clear of the blade.

11.7 Cutting the Tenon Shoulder

To cut the shoulder of the tenon always use the mitre fence or the sliding carriage, available as optional accessory.

- The riving knife must be installed.

- Have auxiliary fence installed on rip fence and positioned for crosscuts.

11.8 Cutting Wedges

Cut wedges only with a wedge cutting jig made for the wedge dimensions as described in paragraph 8.

- Have riving knife and saw blade guard installed.

With the right hand guide the wedge cutting jig along the rip fence until the wedge is clear of the riving knife. The left hand

keeps the waste clear of the blade (use push stick if waste is small to keep hand clear of blade).

11.9 Dimensioning with the Optional Accessory Sliding Carriage

- For dimensioning have the riving knife and blade guard installed.

Hang roller carriage extrusion into

crosshead plates.

Use tape or stick measure to set flipstop to

desired width.

When dimensioning large panels, which are not adequately supported by the saw table,

install the table rear and/or table side extension, available as optional extras, for

additional support.

Place table onto traversing saddle and

secure with locking levers.

Swing flipstop up and place workpiece on

table.

Start saw and square workpiece.

Set fence extrusion closely against the

blade, tighten starknobs.

Pull sliding carriage back.

Turn work around by 180°, swing flipstop

down again and place squared edge

against the stop.

Make second cut.

24

Page 12

12 Adjusting the Saw Blade Position

The saw blade is factory set to a centre position in the table slot. Use of saw blades with wider teeth may require a resetting

of the blade position

Tilt machine to the rear and rest on rear

housing panel to have access to the chip

case.

Loosen the two bolts size M 12, holding

the chip case, by 1/2 turn.

13 Belt Tension

Disconnect from power before servicing!

To set belt tension loosen the 4 motor

mounting screws one full turn.

Remove table insert and chip case lid.

Loosen counter nuts M6 on the swivel

trunnions and adjust saw blade position by

turning the nuts as required, until blade

runs clear of the table's edge.

Turn motor to tighten belt. The belt tension

can be checked through the opening in the

transmission housing. Slack should be

approx. 5 mm.

Important!

Make sure that all screws and nuts are

retightened after setting.

14 Care and Maintenance

- Always disconnect from power before servicing.

This machine is designed to require only minimal maintenance. It is recommended to protect it from high humidity, rain and

agressive agents, such as acid vapors or solvents. All bearings and threaded rods, as well as the extrusions supporting the

rip fence, should regularly given a light coating with gun oil.

To ensure smooth operation clean the threaded rod (218) of the main blade's rise and fall mechanism regularly with kerosene,

then give a light coat of oil to the spindle and bearing. Keep saw blades from rust.

Regularly clean the motor's cooling fins from dust to ensure sufficient cooling.

Note

Both single-phase and 3-phase motors supplied with this saw are equipped with a mechanical motor brake designed for a

long service life. However, friction causes the brake pad to wear. If the blade needs more than 10 sec. to come to a complete

standstill the motor brake has to be replaced. Contact your dealer or a authorized service centre for help.

14.1 Tool Maintenance

Residue resin built-up on the saw blades should be removed regularly. Immerse blade(s) in a sodium carbonate solution, or

in a parafin/kerosene solution or mineral turpentine for 24 hours. The residue resin can then be easily wiped off with a rag.

Clean blades improve performance and cut quality.

25

Page 13

15 Wiring Diagram

Circuit diagram PK 300 K 4.2 DNB

16 Optional Accessories

Sliding Carriage PKS 1500 Stock-no. 0910003291

Sliding Carriage PKS 2300 Stock-no. 0910003321

Table Rear Extension PK Stock-no. 0910003330

Table Side Extension PK Stock-no. 0910003305

Square and Round Stock Jig Stock-no. 0910004018

Cam-Lock Clamp Stock-no. 0910009680

Wheel Set BKH/PK Stock-no. 0910007262

Saw Blades Stock-nos. see paragraph 6

26

Page 14

17 Spare Parts List PK 300 K

Pos. Description Dimension DIN Stock-no.

100 Removable table section 863 mm 138 321 3769

101 Saw table assembly PK 101 021 3823

102 Hex. socket head cap screw M 8x35 912 612 100 0812

103 Disk spring Ø16 Ø8.2x0.6 2093 705 301 6795

104 Hexagon lock nut M 8 985 620 200 2305

105 Clamping piece A 55x20x31 138 020 7482

106 Hex. head drilling screw w. collar 4.8x16 614 406 3978

107 Blind rivet 6x16 F 662 101 0423

108 Toothed plate 149 220 0723

109 Blind rivet 6x8 F 662 100 9530

110 Rear panel, motor housing 139 220 0246

111 Side panel, motor housing 139 220 0211

112 Hexagon head screw M 8 934 620 000 2235

113 Stop plate 139 220 0319

114 Hexagon head screw M 8x35 933 610 300 1208

115 Clamping piece B 55x26x33 138 020 7474

116 Toothed rack 724 mm 139 320 0746

117 Clamping rod Ø7.1 (M8) x 753 149 520 7516

118 Washer A 21 125 630 008 7696

119 Setting knob Ø 72x52 139 120 0390

120 Washer A 17 630 001 6713

121 Hexagon thin nut, shape B M 17 936/439 620 503 2396

122 Washer A 8.4 125 630 001 6322

123 Ratchet lever M 8 female 700 602 8653

124 Blind rivet 6x12 F 662 101 0407

129 Cross rec. pan head tapping screw 4.8x9.5 7981 617 201 6683

130 Arbor tilt scale 114 120 0468

135 Hexagon head screw M 8x16 933 610 300 1178

136 Cross rec. pan head tapping screw 2.9x9.5 7981 617 203 9632

137 Rip fence scale 0.23x13x707 114 220 0623

138 Spring plate 0.3x22x60 139 220 4918

139 Carriage bolt M 8x40 603 611 001 5990

140 Spacer bushing 8.2/15x25 mm 139 108 7560

141 Starknob M 8 female 700 002 8937

142 Switch ass'y PK 4.2 DNB 101 001 4499

143 Cord clamp 0.9x15x40 705 207 8118

144 Front panel, machine housing 139 220 0238

145 Hexagon lock nut M6 985 620 200 2291

146 Carriage bolt M 6x16 603 611 000 0594

147 Disk spring 5x6.5 mm 6888 672 000 8538

148 Spacer bushing DH 14x55 644 220 0309

149 Washer A 15 125 630 001 9984

150 Handwheel Ø 125 700 308 7322

151 Washer A 13 125 630 001 6705

152 Cap nut M 12x1.5 1587 620 107 4264

153 Crank handle M 6 700 407 6740

154 Hexagon nut M 6 934 620 000 2219

158 Pointer 148 221 4718

159 Pointer support 148 221 4700

160 Push stick pocket 138 221 4699

200 Hexagon thin nut, L.H. thread M 20x1.5 L 936/439 620 500 8460

201 Counter flange PK 300 148 521 3682

202 Saw blade, TCT 300x2.6/1.8x30 T=28 091 001 4099

203 Bearing bolt M 8 10h7 139 520 0611

204 Circlip ring 58x2 471 640 008 7588

205 Pilot link plate 139 220 0343

206 Shim for ball bearing 58x67.0x0.5 714 000 6941

207 Riving knife carrier plate Bl 2.5x347x152 139 220 7151

208 Washer A 6.4 125 630 001 6365

209 Swivel segment pair L + R 239 020 0199

210 Hexagon head screw M 10x20 933 610 300 5270

211 Serrated lock washer A 6.4 6798 630 408 4047

212 Hex. head screw, thread rolling M 8x35 614 310 1264

213 Swivel trunnion PK 239 020 0202

214 Bearing plate 139 220 0289

215 Grooved roller bearing 6202-2Z/QE6LHT23 710 013 6915

216 Setting tube Ø24.6x675.5 139 320 7503

217 Hexagon head screw M 6x45 933 610 300 0430

218 Threaded rod 149 502 4381

219 Adapter sleeve 6x16 1481 650 300 1711

220 Saw blade spindle, 30mm arbor PK 300 Rd 57x137 138 521 3669

221 Transmission housing 139 020 0753

222 Grooved ball bearing 6005 2RS 25x47x12 710 001 6812

223 Hex. thin nut, shape B M 20x1.5 936/439 620 505 2753

224 Grooved belt pulley 14J x 46.5PK 300 46.5x50/M 24x1.5 138 521 3693

225 Poly-V-belt 14 PJ 457 723 308 7313

226 Circlip for bores 42x1.75 472 640 112 1364

227 Grooved ball bearing 6004 2RS 20x42x12 710 001 6995

228 Hex. head bolt with washer Ø25 M 8x16 933 610 310 2632

229 Eccentric plate standard motor D = 80 139 220 0360

231 Motor pulley standard motor PK 300 54.0x57/20 PN 6 138 521 3707

27

Page 15

Pos. Description Dimension DIN Stock-no.

232 Hex. socket head cap screw M 6x16 912 612 102 3081

233 Feather key A 6x4x30 6885 672 105 9322

234 Motor 4.2 DNB w/o switch PK 300 101 017 9145

235 Hexagon nut M 12 934 620 001 7992

236 Bolt Ø 25x35 139 520 0271

237 Hexagon lock nut M 12 985 620 202 4139

238 Hexagon lock nut M 10 985 620 200 2313

239 Carriage bolt M 6x35 603 611 002 9436

240 Chip case PK 300 101 021 3793

241 Pressure spring Ø 9.9x2x22.5 705 120 7240

242 Guide bracket PK 300 Fl 16x5x215 148 221 3754

243 Disk spring 23x8.2x0.9 705 307 5104

244 Cover plate, transmission housing 139 220 0084

245 Carriage bolt M 12x30 603 611 000 0691

246 Saw blade guard w/suction port PK 300 Ø 37.4 138 115 8612

247 Riving knife carrier 60x80x16 238 021 3730

248 Riving knife, std. Gr. 25x2.5 138 221 3722

249 Gusset plate PK 300 Bl 2.99x80x60 138 221 3749

250 Hexagon nut, Keps type M 12 620 900 2432

251 Chip case cover w/o hooks PK 300 138 221 3803

252 Hook, chip case cover Bl 2x20x146 139 220 0386

253 Hexagon head screw M 6x16 958/933 610 301 5675

254 Suction port 139 120 0501

255 Washer B 6.4 9021 630 500 2087

256 Carriage bolt M 6x45 603 611 000 0624

257 Wing nut M 6 700 512 5213

285 Pan head tapping screw St 3.9x13 7981 617 200 1805

286 Motor brake ass'y 805 504 6132

287 Motor fan 120/13 133 140 8839

288 Fan cover 120/13 133 140 8847

289 Hexagon head bolt M12x1.5x25 L.H. 961 610 300 1267

290 Brake pad 133 218 5329

294 Terminal box. workstand 133 140 9657

295 Cross rec. pan head screw M4x12 7985 612 300 2022

296 Rectifier 101 000 1141

297 Lid, terminal box 133 140 9665

298 Pan head screw 5x20 618 901 1421

308 Push stick 10x70x410 139 420 1630

317 Carriage bolt M6x25 603 611 003 1325

326 Guide rail 149 202 7223

327 Stop block 139 120 0439

328 Cross recessed countersunk head screw M 6x12 965 613 105 9530

329 Vernier scale, mitre fence 114 120 0450

330 Hexagon socket head cap screw M 4x20 912 612 110 2640

331 Hexagon nut M 4 934 620 000 2197

332 Serrated lock washer A 4.3 6798 630 408 4020

333 Mitre fence body 139 020 0419

334 Ratchet lever M 6x25 700 600 3847

335 Cross recessed countersunk head screw St 4.2x13 7982 617 400 1942

336 Mitre fence extrusion end plate, std. 239 109 1725

337 Mitre fence extrusion 300 mm 139 300 5315

338 Mitre fence scale 0-2x45° 114 120 0441

339 Cross recessed pan head tapping screw St. 3.5x9.5 7981 617 202 8215

340 Washer A 4.3 125 630 001 6330

341 Slotted headless screw w/chamfered end M 6x25 427 616 000 0340

342 Knurled nut M 6 624 112 5058

343 Extrusion end plate, extented 139 120 0145

350 Rip fence carrier extrusion S8x48x450 138 321 4420

351 Thumb screw M6xLB=68 615 019 0299

352 Washer B6.6 verz. 9021 630 500 2087

353 Square nut M8 verz. 557 621 800 5126

354 Hex. socket head cap screw M8x16 912 612 100 0790

355 Rip fence carrier 138 021 4497

356 Set screw Ø6/M8/Ø20x110 148 521 4379

357 Dish spring 16x8.2x0.6 2093 705 301 6795

358 Clamping fork 138 021 4349

360 Hexagon nut, self-locking M8 985 620 200 2305

361 Bolt Ø10/Ø11/Ø17x47 148 521 4360

362 Eccentric clamp 239 020 5484

363 Circlip for shafts 10x1 471 640 004 7349

364 Cross rec. pan head tapping screw M5x6 galv. 7985 612 314 9287

365 Leaf spring 0.8x25 705 221 4356

366 Thread cutting screw AM 5x12-St-Lt galv. 7516 617 517 4166

367 Extrusion end plug 57x49x7 138 121 4458

368 Cross rec. counters. head tapping screw Stz 4.8x19-C-Lt galv. 7982 617 415 5800

369 Slide rail 16x5x200 148 221 4548

370 Holder, magnifying glass 63x36x30 138 121 4393

371 Magnifying glass Ø 30 138 121 4407

372 Auxiliary fence extrusion 60x35x700 138 321 4447

7000 Mitre-/Crosscut fence 201 020 0108

7002 Spiral hose Ø 100x1000 785 412 6290

7003 Shoulder plate 139 220 1595

7004 Extension ring 148 521 3674

28

Page 16

U.K Supplement to Operating Instructions for Elektra Beckum

PK 300 K Precision Circular Saw

Please note the following supplementary information associated with this machine:

1974 Woodworking Machinery Regulations

When in industrial use, this machine falls under the scope of these regulations. In the interest of health & safety of

the machine user we recommend you study and follow these regulations.

We would also draw your attention to the booklet "Woodworking Machines Regulations 1974 - Guidance on

Regulations" ref L4 (ISBN 0118855921) published by HMSO.

Rabetting, Grooving etc.

This manual is prepared for world-wide distribution. Some of the operations depicted here are prohibited by the 1974

Regulations without the use of special guards. These operations include rabetting, grooving, tenoning etc. Always

follow the 1974 Regulations.

Paragraph 4 Connection to Power Mains

230 V motor. Although the motors supplied with this machine will run safely on a 13A domestic ring main, on starting

the machine a high current of very short duration is drawn, which could cause your 13A fuse to blow. If this persists

we recommend to have the machine connected to a 16A separate radial circuit. Ensure a suitably sized fuse

matching the motor is used.

This work should be undertaken only by a qualified electrician!

Paragraphs 11.2, 11.3, 11.6, 11.7

See note above "Rabetting; Grooving etc."

Wiring Instructions

Warning: This appliance must be earthed!

If the plug, fitted to the power cable supplied with the machine, has to be changed or replaced, connect the mains lead

conductors in accordance with the following colour code.

Single-phase motors (110/115/220/230/240 volts):

Yellow/green - Earth

Blue - Neutral

Brown - Live

Three-phase motors (220/380/400/415 volts):

Machines with a 3-phase motor are connected to power mains using a 5-pin industrial appliance-inlet/connector

according to VDE 0623/BS 4343/IEC 309.

4-wire mains lead Yellow/green - Earth

Brown - Phase (L1)

Black - Phase (L2)

Black - Phase (L3)

5-wire mains lead Yellow/green - Earth

Brown - Phase (L1)

Black - Phase (L2)

Black - Phase (L3)

Blue - Neutral

IF IN DOUBT - CONSULT A QUALIFIED ELECTRICIAN!

29

Page 17

56

Page 18

57

Page 19

13-217 445, Fax: +40-13-214 505

-

Dilex d.o.o.,

Orginceva ut. 17, SLO-51113 Ljublijana

Remtech Spol. S.R.O.,

Vinice 293, SK-90021 Svaty Jur

Tel.: +42-1-744 971 981, Fax: +42-1-744 971 291

Agent Trade, S. C., S.R.L.,

Aleea Bran Nr. 2, BL. 92, P., Ap. 47,

RO- 751552 Bucuresli 4

Metabo s.r.o.,

Kralovicka 544, CZ-25001 Brandys nad Labem

Tel.: +42-202-804 458, Fax: +42-202-804 456,

e-mail: Miranda@metabo.cz,

Internet: http://www.metabo.cz

Tel.: +40

Tel.: +386-61-168 16 20, Fax: +386-61-168 16 16

EB_Adr1B.fm

c

Bolas - Máquinas e Ferramentas de Qualidade, S.A.,

Rua 8, Lotes 8, 10, 12, P.O. Box 53,

P-7001 Évora-Codex

P

s

Metabo Danmark A/S,

Tel.: +351-66-74 93 00, Fax: +351-66-74 93 09,

e-mail: bolas@mail.telepac.pt

K

R

Marielundvej 48 C, DK-2730 Herlev

Tel.: +44-84-13 55, Fax: +44-84-86 04,

e-mail: brasmus@post10.tele.dk

Profilma-Import A/S,

N

O

HDF-Paulsson AB,

Box 525, Svaravaregatan 5, S-30180 Halmstad

Tel.: +46-35-154 400, Fax: +46-35-121 780

Nofa OY, P.O.Box 28,

Hannuksentie 1, FIN-02270 Espoo

Postboks 536 Nanset, Sophus Buggesvei 48,

N-3252 Larvik

Tlf.: +47-33-114 777, Fax: +47-33-114 108

S

Tel.: +358-9-804 851, Fax: +358-9-809 485

J

91-578 47 72

-

28,

GdyĖska

SzczeciĖski

z o.o.J.V., ul.

EB Nefro KFT,

EB- Polska,

Spółka

PL-73110 Stargard

p

Futo U. 70, HU-3508 Miskolc

Tel.: +48-91-578 47 72, Fax: +48

h

Extra Industrial Goods,

Tel.: +36-46-362 264; +36-46-366 363,

+36-30-450 618, Fax: +36-46-362 761

a

ITA Ltd.,

Balakirevskij Pereulok 19, str. 1, RUS-Moscow

Tel.: +7-95-737 93 11; +7-95-737 93 12,

+7-95-737 93 13, Fax: +7-95-737 93 14,

Rr. Fadil Rada 88, AL-Tirana

Tel.: +355-42-330 62, Fax: +355-42-330 63

AS Mecro,

Peterburi tee 44, EST-11415 Tallinn

Tel.: +372-6-201 101, Fax: +372-6-201 112

e

r

e-mail: ita1@online.ru

Elektra Beckum AG,

D

Metabo UK Ltd., 25 Majestic Road, GB-SO 16 OYT

Tel.: +44-2380-732 000, Fax: +44-2380-747 500

Daimlerstraße 1, D-49716 Meppen

Tel.: +49-1803-333 456, Fax: +49-1803-333 457

A

Lurem MACHINES à BOIS,

G

F

S.A. Ferunion N.V., 19-23, Rue de L‘Escaut /

Scheldestraat 19-23, B-1080 Bruxelles/Brussel

Tél.: +32-2-427 71 10, Fax: +32-2-425 37 21,

e-meil: general@ferunion.be

Metabo Nederland b. v.,

Keulschevaart 8, NL-3621 MX Breukelen,

Zone Industriell/BP 1, F-617000 Domfront

Tel.: +33-2-333 757 00, Fax: +33-2-333 720 70

B

Postbus 180, NL-3620 AD Breukelen,

H

Metabo Kistool AG,

Badener Str. 816, CH-8010 Zürich

Tel.: +41-1-437 82 80, Fax: +41-1-437 82 77,

e-mail: metkis@swissonline.ch

Fischknecht, Markus Schweisstechnik,

Marktgasse 6, 9050 Appenzell

Tel.: +41-71-787 14 05, +41-79-696 36 44,

Fax: +41-78-782 07

Carlo Stechel & Figli S.R.L.,

Tel.: +31-3462-642 44, Fax: +31-3462-635 54,

e-mail: marianne@metabo.nl

C

Via Buozzi 22, I-20097 San Donato Milanese (MI)

I

Herramientas Metabo, S.A.,

Polígono Ind. N°6, Parcela 16,

E-28935 Móstoles (Madrid)

Tel.: +34-91-616 57 67, Fax: +34-91-616 43 55,

e-mail: metabo-madrid@accesosis.es

Kestra S.A. Soldadura,

Polg. Ind. La Ferreria, C.Del Treball, No. 19,

E- 08110 Montcada I Reixac,

Tel.: +39-02-556 001 11, Fax: +39-02-556 003 22,

e-mail: a.casano@stechel.it

Tel.: +34-935-750 030, Fax: +34-935-753 394

E

Loading...

Loading...